Operating instructions

Water recycling unit WRG 02

It is essential to read these

operating instructions before

installing or using the machine,

to avoid the risk of accident

or damage to the machine.

Q

M.-Nr. 04 809 250

M.-Nr. 04809250 2

Contents

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Guide to the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Use

- Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cleaning and care

- Cleaning programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

- Cleaning fluff filter and filter unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

- Cleaning tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Programme sequences

WRG-Emptying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

WRG-Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Notes for the installer

- Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

- Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Page

The water recycling unit “WRG” must only be installed by an

approved Service technician or authorized Service Dealer.

Disposal of the packing material

The transport and protective packing has been selected from materials which are environmentally friendly for

disposal and can normally be recycled.

Disposal of old machines or appliances

Old machines or appliances contain materials which can be re-cycled. Please contact your local authorities or

scrap merchant about potential recycling schemes, before disposing of the machine or appliance. See also the

section under “Warning and Safety instructions”.

3 M.-Nr. 04809250

Warning and Safety instructions

To avoid danger of cross infection no

water must be recycled from programmes

treating laundry which may be infectious.

Water being recycled must never be

used as drinking water.

This water recycling unit must only be

used for water which has not come in con-

tact with dangerous or inflammable materials.

On no account use high pressure

cleaners or hose down the machine.

Disinfecting and cleaning agents often

contain chlorides (salts). If these substances dry on steel surfaces the residual

chlorides attack the steel and can cause rusting.

To protect your machine from rust damage

we recommend only using chloride free disinfecting and cleaning agents for washing and

disinfecting, and for cleaning the machine. If

you are not sure about a particular agent, contact the manufacturer for advice.

If you accidentally spill an agent containing

chloride on the machine it should be rinsed

off with water and dried using a soft cloth.

Accessories

Accessory parts may only be fitted when

expressly approved by Miele. If other

parts are used, guarantee, performance and

product liability claims may be invalidated.

It is also essential to read the operating in-

structions for the washer extractor.

Keep these instructions in a safe place.

The electrical safety of this appliance can

only be guaranteed when continuity is

complete between the appliance and an effective earthing system which complies with local

and national regulations.

It is most important that this basic safety requirement is regularly tested by a qualified

electrician. The manufacturer cannot be held

responsible for the consequences of an inadequate earthing system.

Do not use a machine with damaged con-

trols or damaged cables. These must be

repaired before it is used again.

During the cleaning programme the tank

is rinsed out with hot water. Ensure that

no personnel touch the tank and the filter unit

while it is still hot. They could burn themselves.

M.-Nr. 04809250 4

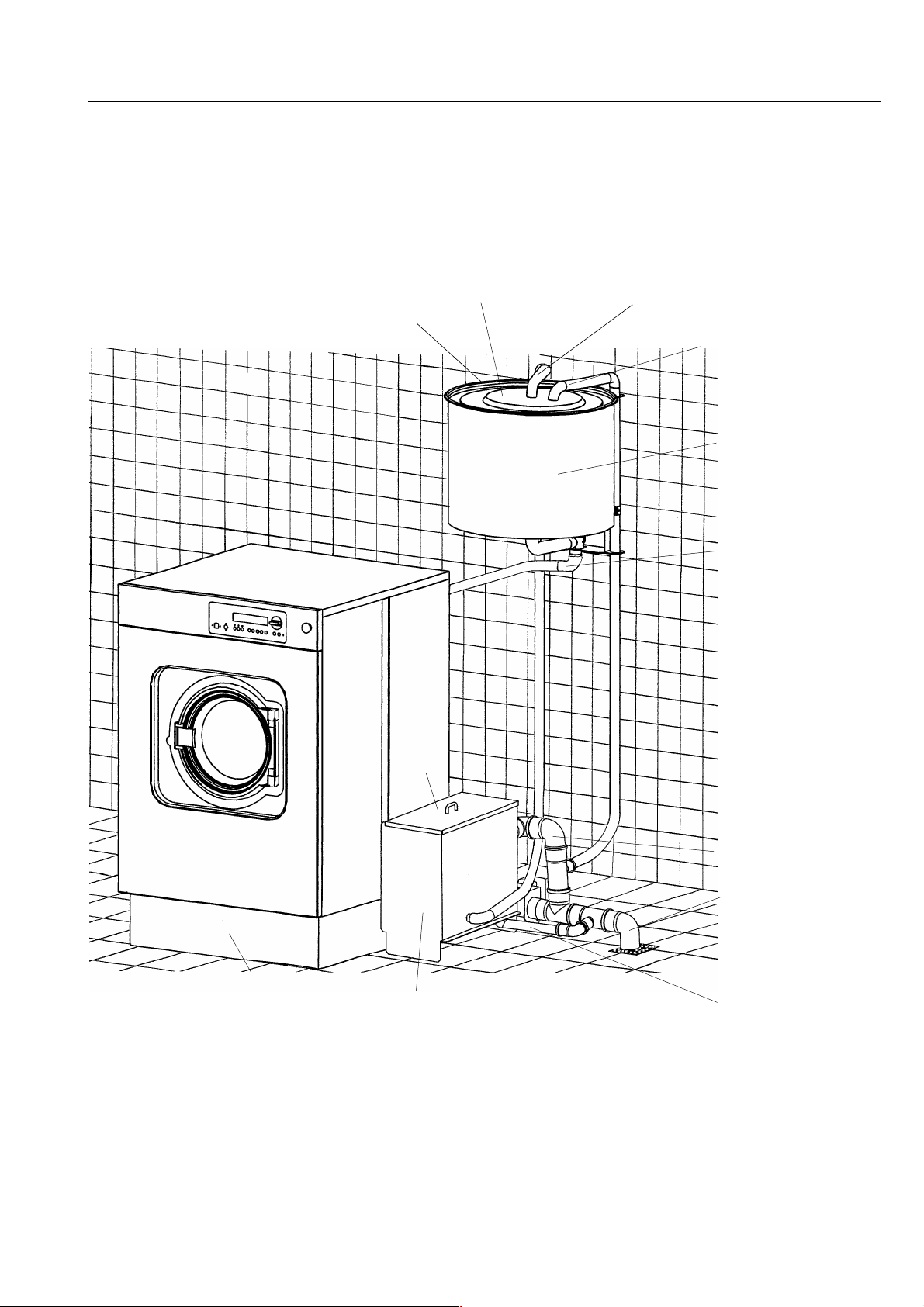

Guide to the machine

Tension band

Tank lid Tank inlet

Water overflow

Tank

Plinth

Machine inlet

Lid

Water overflow

Water drain

Filter unit Filter unit drain

WRG 02

5 M.-Nr. 04809250

Use

COMMISSIONING

If this procedure is not adhered to the wash

and rinse effect can be spoilt by dirt residues.

The washer-extractor must be installed and

commissioned by an approved Customer Service technician or authorised Service Dealer.

It is also essential to read the operating in-

Water for recycling should not be taken from

laundry which is heavily soiled or not colour-

fast.

structions for the washer extractor.

The standard programmes for the washer extractor envisage water recycling in the last

two rinses.

Area Pre-wash Area Main wash Area Rinse

Block Pre-wash 1 Block main wash 1 Block Rinse 1 Block Rinse 2 Block Rinse 3

Drain valves: WS & WRG WS & WRG WS & WRG

Drain with drum movement: yes yes yes yes yes

Drain level: 0 mm 0 mm 0 mm 0 mm 0 mm

Wash time 5: 0 Minutes 0 Minutes 0 Minutes 0 Minutes 0 Minutes

Drain valves: WS & WRG WS & WRG WS & WRG

WS WS

WS WS

Programming of the drain valve must be in

Block Rinse 2 and Block Rinse 3 “outflow”

(to holding tank).

The rinse water flows from the machine

through the filter into the filter box and from

there is pumped into the tank.

This rinse water can be used in the pre-wash,

main wash, and first rinse of the following programme.

Area Pre-wash Area Main wash Area Rinse

Block Pre-wash 1 Block Main wash 1 Block Rinse 1 Block Rinse 2 Block Rinse 3

Water inlet 1:

Dispensing 1: automatic automatic automatic automatic automatic

Dispensing delay 1: automatic automatic automatic automatic automatic

Movement from level: automatic automatic automatic automatic automatic

Revolutions: normal normal normal normal normal

Rhythm: normal normal normal normal normal

Wash time 1: 1 Minute 4 Minutes 6 Minutes 5 Minutes 4 Minutes

Thermostop: yes yes no no no

Level 2: 110 mm wtr clm 110 mm wtr clm 120 mm wtr clm 100 mm wtr clm 80 mm wtr clm

Water inlet 2

automatic automatic automatic automatic automatic

automatic automatic automatic automatic automatic

In Block Pre-wash 1, Block Main wash 1,

and Block Rinse 1, programming of water

inlet 1 and water inlet 2 must be “automatic”

or via valves selected with K6 by the user.

See programming instructions.

M.-Nr. 04809250 6

Cleaning and Care

Carry out cleaning and care of the unit as

soon as possible after use. Cleaning must

not be carried out during a wash programme.

Do not use a high pressure cleaner.

Before each wash cycle check the fluff filter

for fluff build-up and clean if necessary.

Cleaning programme

If use of the unit is to be or has just been discontinued for some time, there is a cleaning

programme available for this circumstance.

Before starting the cleaning programme,

clean the fluff filter and filter unit as described

below.

Remove any fluff and dirt from the filter

unit, the filter and the pump and rinse out

with water.

➧

For cleaning the water must first be let out

of the filter unit. To do this pull out the

stopper in the filter unit.

Refit the stopper.

Start the WRG cleaning programme.

At the end of the programme pull out the

stopper again to let the water out of the filter unit, and if necessary clean the fluff filter once again.

7 M.-Nr. 04809250

Cleaning and care

Cleaning the tank

From time to time the tank must be opened

and checked for dirt.

Start the WRG emptying programme.

At the end of the emptying programme

loosen the tension band at the top edge of

the tank with an SW 13 screwdriver.

Repairs to machines should only be under-

taken by a suitably qualified service engineer

to ensure safety. Unauthorized repairs could

be dangerous. Please contact the Service

Department in cases of malfunction.

Service Department needs model, machine

number (N°) and part number (TN).

This data is on the data plate.

Components should only be exchanged

for Miele original spare parts. In this case

Spare Parts Department also needs the

model, machine number (N°) and part num-

ber (TN).

Lift the lid.

Use a brush to remove any stubborn dirt.

Refit the lid and then start the cleaning programme.

The tank and the filter unit are made of stainless steel. However water with an iron content or foreign bodies in the water can lead to

rust deposits especially if the unit is out of use

for some time. In this case clean the tank

and filter unit with a gentle domestic scouring

agent.

Rinse thoroughly with water afterwards.

M.-Nr. 04809250 8

Programme sequences

Name: WRG-Emptying

If a washer extractor is being operated together with a water recycling unit (WRG) then two

extra programmes must be entered. One programme to empty the (WRG) recycled water container, and a programme for cleaning out the WRG unit.

Area Pre-wash

Block Pre-wash 1

Name: Emptying

Block activation: permanent

Programme stop 1: no

Programme stop signal 1: no

Free Temperature selection 1: no

Temperature: cold

Hysteresis: normal

Level 1: 0 mm Water column

Water inlet 1: automatic

Dispensing 1: no

Dispensing delay 1: no

Movement from level: automatic

Spin time: normal

Rhythm: normal

Wash time 1 0 Minutes

Thermostop: no

Level 2: 0 mm Water column

Water inlet 2: automatic

Dispensing 2: no

Dispensing delay 2: no

Wash time 2: 0 Minutes

Wash time 3: 0 Minutes

Cool Down: no

Wash time 4: 0 Minutes

Programme stop 2: no

Programme stop signal: no

Drain valves: WS & K6 & WRG

Drain with drum movement: yes

Drain level: 0 mm

Wash time 5: 5 Minutes

Drain valves: WS & WRG

Spin time with drain: 0 Minutes

Free spin speed selection: no

Spin speed: 0 rpm

Block-/Prg. repeat: no

Block end signal: no

9 M.-Nr. 04809250

Programme sequences

Name: WRG-Cleaning

Area Pre-wash Area Main wash

Block Pre-wash 1 Block Pre-wash 2 Block Pre-wash 3 Block Main wash 1

Name: Emptying Rinse Emptying Cleaning

Block activation: permanent permanent permanent permanent

Programme stop 1: no no no no

Programme stop signal 1: no no no no

Free Temperature selection: no no no no

Temperature: cold cold cold 80°C

Hysteresis normal normal normal normal

Level 1: 0 mm Wtr clm 110 mm Wtr clm 0 mm Wtr clm 50 mm Wtr clm

Water inlet 1: automatic automatic automatic automatic

Dispensing 1: no no no no

Dispensing delay 1: no no no no

Movement from level: automatic automatic automatic automatic

Spin speed: normal normal normal normal

Rhythm: normal normal normal normal

Wash time 1: 0 Minutes 2 Minutes 0 Minutes 0 Minutes

Thermostop: no no no yes

Level 2: 0 mm Wtr clm 110 mm Wtr clm 0 mm Wtr clm 50 mm Wtr clm

Water inlet 2: automatic automatic automatic automatic

Dispensing 2: no no no no

Dispensing delay 2: no no no no

Wash time 2: 0 Minutes 0 Minutes 0 Minutes 0 Minutes

Wash time 3: 0 Minutes 0 Minutes 0 Minutes 2 Minutes

Cool Down: no no no no

Wash time 4: 0 Minutes 0 Minutes 0 Minutes 0 Minutes

Programme stop 2: no no no no

Programme stop signal: no no no no

Drain valves: WS & K6 & WRG WS & K6 WS & K6 & WRG WS & K6

Drain with drum movement: yes yes yes yes

Drain level: 0 mm 0 mm 0 mm 0 mm

Wash time 5: 5 Minutes 5 Minutes 2 Minutes 10 Minutes

Drain valves: WS & WRG WS & WRG WS & WRG WS & WRG

Spin time with drain: 0 Minutes 0 Minutes 0 Minutes 0 Minutes

Free spin speed selection: no no no no

Spin speed: 0 rpm 0 rpm 0 rpm 0 rpm

Block-/Prg.repeat: no no no no

Block end signal: no no no no

Programme continued on next page.

M.-Nr. 04809250 10

Programme sequences

Area Main wash Area Rinse

Block Main wash 2 Block Rinse 1 Block Rinse 2

Name: Emptying Rinse Emptying

Block activation: permanent permanent permanent

Programme stop 1: no no no

Programme stop signal 1: no no no

Free Temperature selection: no no no

Temperature: cold cold cold

Hysteresis: normal normal normal

Level 1: 0 mm Water column 110 mm Water column 0 mm Water column

Water inlet 1: automatic automatic automatic

Dispensing 1: no no no

Dispensing delay 1: no no no

Movement from level: automatic automatic automatic

Spin speed: normal normal normal

Rhythm: normal normal normal

Wash time 1 0 Minutes 2 Minutes 0 Minutes

Thermostop: no no no

Level 2: 0 mm Water column 110 mm Water column 0 mm Water column

Water inlet 2: automatic automatic automatic

Dispensing 2: no no no

Dispensing delay 2: no no no

Wash time 2: 0 Minutes 0 Minutes 0 Minutes

Wash time 3: 0 Minutes 0 Minutes 0 Minutes

Cool Down: no no no

Wash time 4: 0 Minutes 0 Minutes 0 Minutes

Programme stop 2: no no no

Programme stop signal: no no no

Drain valves: WS & K6 & WRG WS & K6 WS & K6 & WRG

Drain with drum movement: yes yes yes

Drain level: 0 mm 0 mm 0 mm

Wash time 5: 2 Minutes 5 Minutes 2 Minutes

Drain valves: WS & WRG WS & WRG WS & WRG

Spin time with drain: 0 Minutes 0 Minutes 0 Minutes

Free spin speed selection: no no no

Spin speed: 0 rpm 0 rpm 0 rpm

Block-/Prg. repeat: no no no

Block end signal: no no no

11 M.-Nr. 04809250

Notes for the installer

To avoid the possibility of frost damage on no

account install the machine in a room which is

exposed to frost.

It is essential that the machine is installed

level, and is secured (see installation diagram

supplied).

Plumbing

Connection must be made to the water supply

via an on-site stopcock, which conforms with

local and national regulations. This work

must be carried out by an authorized competent person.

See the installation diagram supplied for instructions on connection to the water supply

and drainage.

Electrical connection

All electrical work must be carried out by a

suitably competent person in compliance with

national and local regulations. The washer extractor and WRG water recycling unit must be

installed by an approved service engineer or

authorised service dealer.

Please take note of the Installation Diagram

and instructions supplied.

Any removable outer panels must be in

place, and all moving or electrical parts

shielded before the machine is operated.

M.-Nr. 04809250 12

13 M.-Nr. 04809250

United Kingdom

Miele Co. Ltd., Fairacres, Marcham Road, Abingdon OX14 1TW

tel. (01235) 554455 - fax (01235) 554477

Service Office, tel. (01235) 554466

Alteration rights reserved 18.97

This paper consists of cellulose which has been bleached without the use of chlorine.

Loading...

Loading...