Page 1

Installation plan

Washing machine

PW 5064 MOPSTAR 60

To avoid the risk of accidents or damage to the machine, it is essential to read

operating and installation instructions before installation and commissioning

This will prevent both personal injury and damage to the machine.

en - AU, NZ

10 291 490 / 02

Page 2

Legend:

Connection required

Connection optional or required,

depending on model

AV

Drain valve

KW

Cold water connection

AW

Drain connection

LP

Drain pump

B

Machine anchors

PA

Equipotential bonding

BW

Grey water connection

SLA

Peak-load connection

DOS

Dispenser connection

UG

Box plinth

EL

Electrical connection

UO

Open plinth

F

Machine feet, adjustable

WTV

Washer-dryer stacking kit

KG

Payment system

WW

Hot water connection

KGA

Payment system connection

XKM

Communication module

All rights reserved. 04/16/36

2 10 291 490 / 02

Page 3

PW 5064 en - AU, NZ

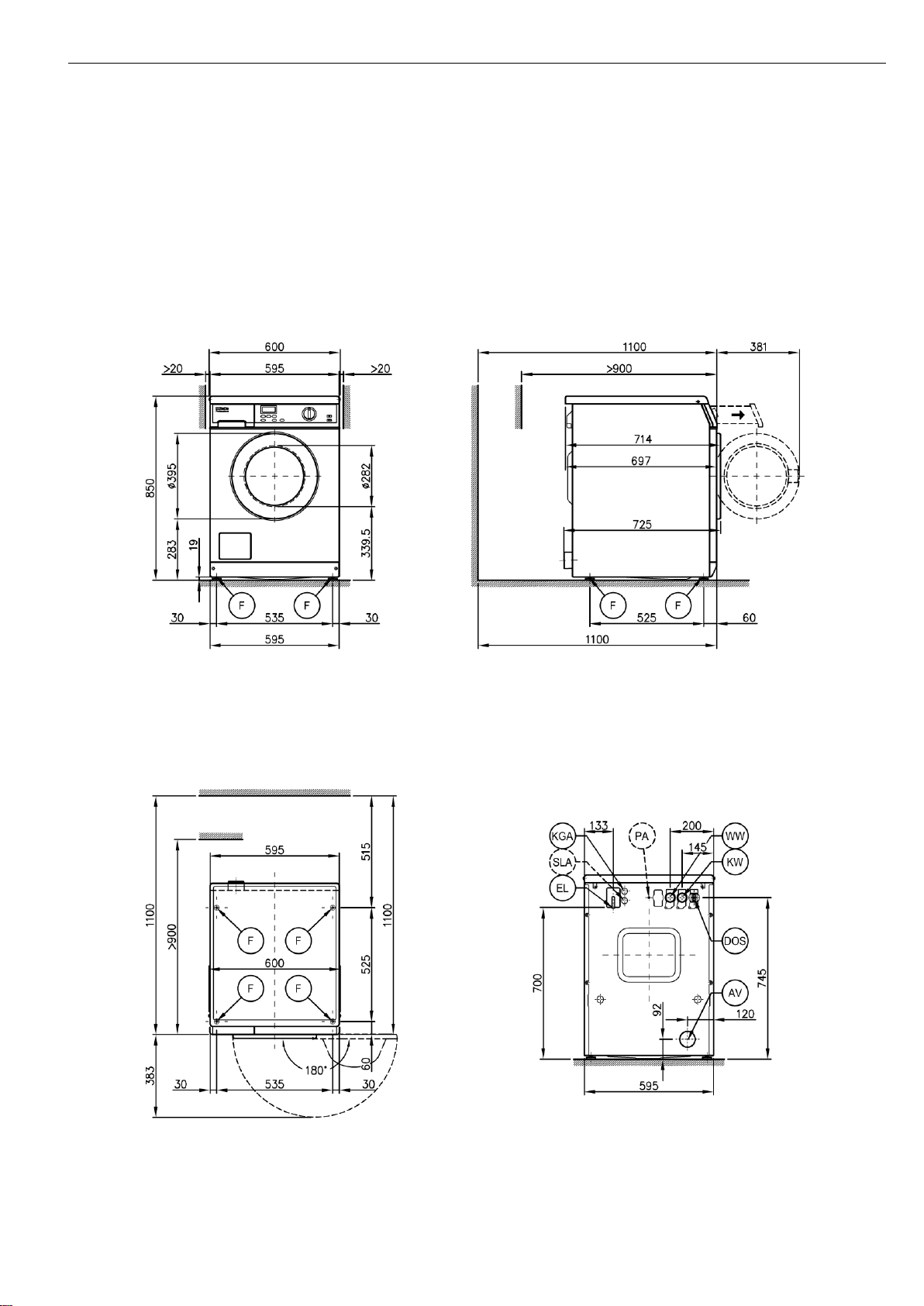

Machine dimensions

10 291 490 / 02 3

Page 4

en - AU, NZ PW 5064

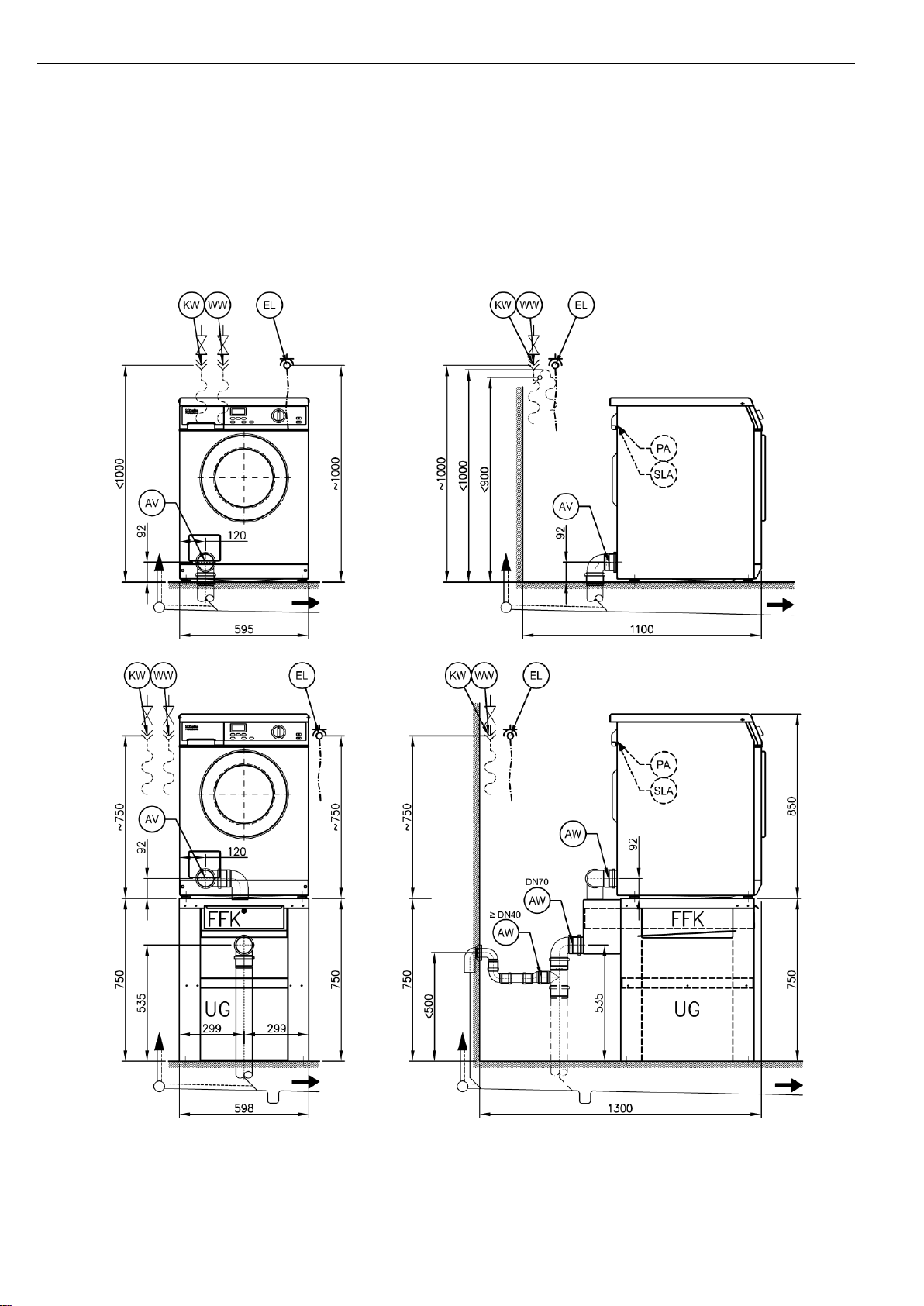

Installation

4 10 291 490 / 02

Page 5

PW 5064 en - AU, NZ

Installation with FFK 01

10 291 490 / 02 5

Page 6

en - AU, NZ PW 5064

Installation

6 10 291 490 / 02

Page 7

PW 5064 en - AU, NZ

Installation

10 291 490 / 02 7

Page 8

en - AU, NZ PW 5064

Technical data

PW 5064 AV

Drum volume

l

59

Load capacity

kg

6.5 Door opening diameter

mm

282 Max. spin speed

rpm

1400 g factor

526 Residual moisture (standard load per DIN 60456)

%

<25

Electrical connection (EL)

Standard voltage

2N AC 400 V

Frequency

Hz

50 Total rated load

kW

4.8 Fuse rating (B trip rating according to EN 60898)

A

2 x 16

Supply lead min. cross-section

mm²

4 x 1.5

Supply lead without plug for hard-wired connection

Length of supply lead

mm

1800

Alternative voltage (convertible by Service)

1N AC 230 V

Total rated load

kW

2.5 Fuse rating (B trip rating according to EN 60898)

A

1 x 16

Supply lead min. cross-section

mm²

3 x 1.5 mm²

Variations in the following countries:

Standard voltage 13A (GB only)

1N AC 230 V

Frequency

Hz

50 Total rated load

kW

2.5 Fuse rating (B trip rating according to EN 60898)

A

1 x 13

Supply lead min. cross-section

mm²

3 x 1.5

Supply lead without plug for hard-wired connection

Length of supply lead

mm

2000

Alternative voltage (convertible)

2N AC 400 V

Total rated load

kW

4.8 Fuse rating (B trip rating according to EN 60898)

A

2 x 13

Supply lead min. cross-section

mm²

4 x 1.5

Standard voltage 25A (GB only)

1N AC 220-240 V

Frequency

Hz

50 Total rated load

kW

4.4 - 5.2

Fuse rating (B trip rating according to EN 60898)

A

1 x 25

Supply lead min. cross-section

mm²

3 x 2.5

Supply lead without plug for hard-wired connection

Length of supply lead

mm

2000

Standard voltage (DK, S only)

3N AC 400 V

Frequency

Hz

50 Total rated load

kW

4.8 Fuse rating (B trip rating according to EN 60898)

A

3 x 10

Supply lead min. cross-section

mm²

5 x 1.5

Supply lead without plug for hard-wired connection

Length of supply lead

mm

2000

Standard voltage (DK only)

1N AC 220-240 V

Frequency

Hz

50 Total rated load

kW

2.1 - 2.4

Fuse rating (B trip rating according to EN 60898)

A

1 x 10

Supply lead min. cross-section

mm²

3 x 1.5

Supply lead without plug for hard-wired connection

Length of supply lead

mm

2000

Standard voltage (B only)

3 AC 230 V

= standard, = optional, + = only on request, - not available

8 10 291 490 / 02

Page 9

PW 5064 en - AU, NZ

Technical data

PW 5064 AV

Frequency

Hz

50

Total rated load

kW

4.8 Fuse rating (B trip rating according to EN 60898)

A

3 x 20

Supply lead min. cross-section

mm²

4 x 2.5

Supply lead without plug for hard-wired connection

Length of supply lead

mm

1800

Alternative voltage (convertible)

2N AC 400 V

Total rated load

kW

4.8 Fuse rating (B trip rating according to EN 60898)

A

2 x 16

Supply lead min. cross-section

mm²

4 x 1.5

Alternative voltage (convertible)

1N AC 230 V

Total rated load

kW

2.5 Fuse rating (B trip rating according to EN 60898)

A

1 x 16

Supply lead min. cross-section

mm²

3 x 1.5

Standard voltage (N only)

1N AC 220-240 V

Frequency

Hz

50 Total rated load

kW

2.95 - 3.45

Fuse rating (B trip rating according to EN 60898)

A

1 x 16

Supply lead min. cross-section

mm²

3 x 1.5

Supply lead with plug

Length of supply lead

mm

2000

Alternative voltage (convertible)

2N AC 400 V

Total rated load

kW

4.8 Fuse rating (B trip rating according to EN 60898)

A

2 x 16

Supply lead min. cross-section

mm²

4 x 1.5

Standard voltage (USA only)

2 AC 208-240 V

Frequency

Hz

60 Total rated load

kW

4.0 - 5.2

Fuse rating

A

2 x 30

Supply lead min. cross-section

mm²

3 x AWG 10

Supply lead with plug

Length of supply lead

mm

2000

Cold water (KW)

Permissible water flow pressure

kPa

100 - 1000

Required flow rate (cold water connection only)

l/min

11 Required flow rate (with additional hot water connection)

l/min

10 Average water consumption (60°C standard programme)

l/h

36 Connection to be provided on site, external thread according to DIN 44991

Inch

¾“

Connection hose ½“ with ¾“ threaded union

Connection hose length

mm

1550

Hot water (WW)

Max. water intake temperature

°C

70 Permissible water flow pressure

kPa

100 - 1000

Min. flow rate

l/min

11

Average water consumption (60°C standard programme)

l/h

13 Connection to be provided on site, external thread according to DIN 44991

Inch

¾“

Connection hose ½“ with ¾“ threaded union

Connection hose length

mm

1550

Drain valve (AV)

Connection (ext. diameter)

mm

75 (DN70)

Drainage temperature, max.

°C

90 Max. transient flow rate

l/min

62

Equipotential bonding (PA)

= standard, = optional, + = only on request, - not available

10 291 490 / 02 9

Page 10

en - AU, NZ PW 5064

Technical data

PW 5064 AV

Machine connection (with installation kit)

Peak load / Energy management (SLA)

Machine connection (with installation kit)

Control signal voltage

AC 230 V

Communication module (XKM)

RS 232 serial interface (XKM module retrofitting kit)

Liquid dispensing (DOS)

Connection for liquid detergents

No. of dispenser pumps, max.

6

Installation on machine feet (F)

No. of machine feet

No. 4

Machine foot, height-adjustable with thread

mm

±4 Machine foot diameter

mm

40

Anchoring (B)

Standard anchoring

Floor anchor kit (for 2 machine feet)

Wood screws according to DIN 571

mm

6 x 50

Rawl plugs (diameter x length)

mm

8 x 40

Anchoring of Miele plinths

Accessory: Miele plinth (fasteners included)

Required anchor points

No. 4

Wood screws according to DIN 571

mm

8 x 65

Rawl plugs (diameter x length)

mm

12 x 60

Plinth floor anchoring (to be provided on site)

Machine installation on permanent plinth (concrete or masonry)

Plinth installation footprint (W/D)

mm

600/650

Wood screws according to DIN 571

mm

6 x 50

Rawl plugs (diameter x length)

mm

8 x 40

Machine data

Overall machine dimensions (H/W/D)

mm

850/600/725

Casing dimensions (H/W/D)

mm

850/595/665

Site-access dimensions (H/W)

Min. site-access (excl. packaging)

mm

900/600

Installation dimensions

Min. side gap

mm

20

Recommended side gap - washer-dryer stack

mm

>300 Min. distance to opposite wall from front of machine

mm

900 Recommended distance to opposite wall from front of machine

mm

1100

Weights and floor loads

Machine weight (net weight)

kg

105

Max. floor load in operation

N

2820

Max. floor load, static

N

1380 Max. floor load, dynamic

N

1365 Max. drum rotation frequency

Hz

22

Emissions

Emission sound pressure level in accordance with EN ISO 11203/11204

dB(A)

<70 Heat dissipation rate to installation site

W

250

= standard, = optional, + = only on request, - not available

10 10 291 490 / 02

Page 11

PW 5064 en - AU, NZ

Options / Accessories

Features

Box plinth (UG)

Box plinth, H 300 mm (UG 5005)

Galvanised plinth, stainless-steel sides

Box plinth, H 470 mm (UG 5005-47)

Galvanised plinth, octoblue stove-finished side panels

Box plinth, H 750mm (UG 5005-75)

Galvanised plinth, octoblue stove-finished side panels

Open plinth (UO)

Open plinth, H 300 mm (UO 5005)

Galvanised plinth, octoblue stove finish

Open plinth, H 470 mm (UO 5005-47)

Galvanised plinth, octoblue stove finish

Washer-dryer stacking kit (WTV)

Stainless-steel kit (WTV 5062)

Washer-dryer stacking kit

Lotus white kit (WTV 5061)

Washer-dryer stacking kit

Fluff filter box (FFK)

Fluff filter box (FFK 5005)

Fluff filter box for retrofitting on UG 5005-75 or UO 5005

Fluff filter box, incl. UG 5005-75 plinth (FFK 5005)

Fluff filter box integrated into plinth

Fluff filter box, stand-alone (FFK 01)

Fluff filter box, stainless steel

Payment systems (KG)

Single unit (C 4060)

Payment system (programme operation only)

Single unit (C 4065)

Payment system (time and programme operation)

Single unit (C 4070)

Payment system for tokens and euro coins, time and programme operation

Multi-machine unit (C 5200 BT)

Base unit for GeldKarte transactions (for max. 8 machines)

Remote bundle (ABT 5220)

Machine monitoring with Bluetooth communication (one each per machine)

Accessories

Connection of peak-load/energy management (BSS)

Connection for peak-load and energy management functionalities

Equipotential bonding kit

Kit (Mat. no 09439350) available from Miele

Communication module XKM (XKM RS 232-10)

Retrofitting kit XKM module with RS 232, including building-in kit

Connection box for dispenser pumps (ASK)

Connection box for dispenser pumps and 'Container empty' signal

= standard, = optional, + = only on request, - not available

10 291 490 / 02 11

Page 12

en - AU, NZ PW 5064

Installation and planning notes

Installation requirements

Electrical connection should only be made to a power supply provided

in accordance with all appropriate local and national legislation and

regulations.

In addition, all regulations issued by the appropriate utilities as well as

standards relating to occupational safety, and all applicable valid

regulations and technical standards must be observed.

Transportation and site access

The machine must not be moved without the transit bars in place.

Keep the transit bars in a safe place. They must be refitted if the

machine is to be moved again (e.g. when relocating machine).

General operating conditions

Ambient temperature in installation room: +2°C to +35°C.

Depending on the nature of the installation site, sound emissions and

vibration may occur. Miele recommends consulting a specialist if

particular requirements apply at the installation site with respect to

sound emissions.

Electrical connection

Depending on the model, the machine is delivered with a supply lead

with/without a plug.

The washer may only be connected to an electrical system that

conforms to the national and local codes and regulations. The

installation must be performed by a qualified electrician.

The machine data plate indicates the nominal power consumption and

the appropriate fuse capacity. Compare the specifications on the data

plate with those of the electrical power supply.

The machine can be hard-wired or connected using a switched

connection in accordance with IEC 60309-1 or AS/NZS 3000. It is

always recommended to make electrical connection via a plug and

socket so that electrical safety checks, e.g. during repair or service

work, can be carried out easily.

If the machine is hard wired, a dual circuit breaker must be provided

on-site. When switched off, there must be an all-pole contact gap of 3

mm in the isolator switch (including switch, fuses and relays according

to IEC/EN 60947 or AS/NZS 3000)

The plug connectors or isolator switch should be easily accessible for

servicing work. If the machine is disconnected from the electricity

supply, ensure adequate measures are taken to ensure that the

machine cannot be reconnected to the electricity supply until all work

has been carried out.

New connections, modifications to the system or servicing of the

ground conductor, including determining the correct fuse amperage,

must be carried out by a qualified electrician, as they are familiar with

the pertinent regulations and the specific requirements of the

electricity supplier.

If converting the machine to an alternative voltage, observe the

instructions in the wiring diagram. Conversion must be performed

by an authorised agent or a Miele service technician. The heater

rating must also be properly set.

Add drawing and instructions as per below for installing the non-return

valve.

• Disconnect the mains (switch off or unplug the power).

• Turn off the water tap.

• Place the seals on both sides of the non-return valve.

• Connect the female of the non-return valve to the tap (G3/4” thread).

• Connect the hose to the male end of the non-return valve (G3/4”

thread).

• Turn on the tap gradually to test for leaks. If there is a leak, the

connection might not be on securely, or it may have been screwed

on at an angle. Unscrew and reconnect the water correctly before

tightening it.

Connection to the water supply should be carried out by a qualified

plumber using a tap with a threaded union. If a tap is not available, a

qualified plumber should connect the machine to the water supply.

A suitable connection hose with a threaded union is provided with the

machine.

Longer hoses (2.5 or 4.0 m in length) are available from Miele as

separate items. These hoses must be connected after the non-return

valve.

Hot water connection

The same connection requirements as for cold water also apply to hot

water (max. 70°C).

A suitable connection hose with a threaded union is provided with the

machine.

The machine can be connected to a hot water supply of 70°C to max.

85°C. This requires the use of a separate heat-resistant inlet hose.

This additional hose must be obtained from Miele. In addition, the

appliance must be programmed accordingly by a Miele service

technician or an authorised agent.

Connection to hot water only is not possible for functional reasons.

In the event that hot water is not available on site, connection of the

second hose must be made to a cold water supply.

Alternatively, the hot water connection should be blocked using the

enclosed blind stopper and the machine controls set to cold water

intake.

The required amount of hot water should be added to the cold water

volume.

Drain valve

The washing machine is drained using a motorised drain valve. The

machine can be connected directly to the on-site drainage system

(without an odour trap) or via a floor drain (floor drain with odour trap).

A vented drainage system is vital for unimpeded drainage. If on-site

venting is insufficient, a vent kit (Mat. no. 05239540) is available from

Miele.

If several machines are connected to a single drain pipe, this should

be sufficiently large to allow all machines to drain simultaneously.

The machine must be permanently connected to the electricity supply

so that the door can be opened. For this reason, it must not be

connected to devices such as timers which would switch it off

automatically.

References to cable cross-sections in the technical data refer only to

the required supply lead. Please consult relevant local and national

regulations when calculating any other wire gauges.

Cold water connection

The machine should be connected to a mains water supply in

accordance with current local and national regulations on water

safety.

IMPORTANT: Australia and New Zealand

This appliance must be installed according to AS/NZS 3500.1. This

appliance has been supplied with a separate backflow prevention

device.

Equipotential bonding

If necessary, equipotential bonding with good galvanic contact must

be guaranteed in compliance with all applicable local and national

installation specifications.

Connection material for equipotential bonding must be provided on

site or using a kit available from Miele.

12 10 291 490 / 02

Page 13

PW 5064 en - AU, NZ

Peak load / Energy management

The machine can be connected to a peak-load or energy

management system using an optional kit.

Three signals are issued by the machine via a terminal strip. The

terminal strip is labelled a, b, c, and d.

a - Output signal, Start of machine operation

b - Output signal, Machine heating request

c - Peak-load input signal, Machine heating deactivated

d - Neutral conductor

When a peak-load signal is received, the heating is deactivated and

the programme stopped. An appropriate message appears in the

display.

The programme is resumed automatically when the peak-load system

reactivates the heating.

Liquid dispensing connection

External liquid dispenser pumps with a 'container empty' indicator can

be used to dispense liquid detergents.

Only liquid dispenser pumps with their own controls or

programming facilities can be used.

It is particularly important to observe manufacturer's instructions when

using a combination of detergents, additives and special-purpose

products.

Serial interface

The serial interface is provided by an additional XKM RS323 module.

The led through data interface from the XKM RS232 module conforms

with SELV (safety extra-low voltage) according to EN 60950. External

connection units must also comply with SELV.

The plug-in module is provided with a connection cable and a D-Sub

plug for connection.

Installation and anchoring

The machine must be installed on a perfectly smooth, level and firm

surface which is able to withstand the quoted loads.

The floor load created by the machine is concentrated and transferred

to the installation footprint via the machine feet.

The machine must be secured to its installation location.

The machine should be levelled in both directions with the aid of the

adjustable feet.

The anchors provided can be used to bolt the machine to the floor by

both front feet. The material provided is intended for use in bolting the

machine to a concrete floor.

Bolts and fasteners for all other floor types must be provided on site.

Plinth installation

The machine can be installed on a machine plinth (open or box plinth,

available as an optional Miele accessory) or on a concrete platform to

be provided on site.

The quality of the concrete and its strength must be assessed

according to the machine load. Ensure that any raised concrete plinth

is adequately bonded to the concrete floor below.

If the machine is installed on a concrete or masonry plinth, it must be

secured using the anchors supplied with the machine. Otherwise there

is the danger of the machine moving and falling off the plinth during

spinning.

Washer-dryer stack

This washing machine can be installed with a Miele tumble dryer on

top of it. A WTV stacking kit (optional accessory) is required for this.

Installation of the stacking kit must be performed by a Miele service

technician or an authorised agent.

10 291 490 / 02 13

Loading...

Loading...