Page 1

Operating and Installation Instructions

Ventilation System

To prevent accidents and damage to the appliance, you must read

these instructions before installing the appliance and using it for the first

time.

en-US M.-Nr. 10 770 050

Page 2

Contents

IMPORTANT SAFETY INSTRUCTIONS ................................................................ 4

Caring for the environment ................................................................................12

Description of functions .....................................................................................13

Guide to the appliance........................................................................................14

Operation.............................................................................................................. 16

Turning on the blower............................................................................................ 16

Selecting the power level ...................................................................................... 16

Delayed shut-off.................................................................................................... 16

Turning off the blower............................................................................................ 16

Turning the overhead lighting on/off...................................................................... 16

Power management .............................................................................................. 16

Turning power management on/off .................................................................. 17

Safety shut-off....................................................................................................... 17

Energy-saving tips............................................................................................... 18

Service and warranty .......................................................................................... 19

Location of the data plate ..................................................................................... 19

MieleCare .............................................................................................................. 19

Cleaning and care ...............................................................................................20

Stainless steel housing.......................................................................................... 20

Grease filters ......................................................................................................... 21

OdorFree Charcoal Filter ....................................................................................... 22

Disposing of charcoal filters............................................................................. 23

Changing a light bulb ............................................................................................ 24

Installation............................................................................................................ 25

Before installation.................................................................................................. 25

Installation parts .................................................................................................... 25

Appliance dimensions ........................................................................................... 26

Distance between cooktop and ventilation hood (S)............................................. 27

Installation recommendations ............................................................................... 28

Structural support ................................................................................................. 28

Removing the protective film................................................................................. 28

Air venting ............................................................................................................ 40

Condensate trap.................................................................................................... 41

Electrical connection ..........................................................................................42

Grounding Instructions.......................................................................................... 42

2

Page 3

Contents

Technical data..................................................................................................... 43

3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

This appliance complies with current safety requirements.

Improper use of the appliance can lead to personal injury and

material damage.

Read all instructions before installing or using the appliance for the

first time. Only use the appliance for its intended purpose.

Keep these operating instructions in a safe place and pass them

on to any future user.

Appropriate use

CAUTION: For General Ventilating Use Only. Do Not Use To

Exhaust Hazardous Or Explosive Materials And Vapors.

This appliance is intended for residential use only. Use only as

described in these operating instructions.

This ventilation hood is not intended for outdoor use.

It must only be used to extract and clean vapors produced during

cooking. Any other use occurs at the owner's own risk.

This appliance is suitable for installation above gas or electric

cooking surfaces.

Persons who lack physical, sensory or mental abilities, or

experience with the appliance should not use it without supervision

or instruction by a responsible person.

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

Safety with children

As with any appliance, close supervision is necessary when used

by children.

Please supervise children in the vicinity of the hood and do not let

them play with it.

The LED ClearView lighting is very intense.

Ensure that especially babies/small children don't look into the light.

Danger of suffocation! Ensure that any plastic wrappings, bags,

etc. are disposed of safely and kept out of the reach of children.

Technical safety

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

– Use this appliance only in the manner intended by the

manufacturer. If you have questions, contact Miele.

– Before servicing or cleaning the appliance, switch power off at the

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. If the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

Unauthorized installation, maintenance, and repairs can cause

considerable danger for the user. Installation, maintenance, and

repairs must only be carried out by a Miele authorized technician.

A damaged ventilation hood can be dangerous. Always check for

visible signs of damage. Never use a damaged ventilation hood.

Be certain your appliance is properly installed and grounded by a

qualified technician. To guarantee the electrical safety of this

appliance, continuity must exist between the appliance and an

effective grounding system. It is imperative that this basic safety

requirement be met. If there is any doubt, have the electrical system

of the house checked by a qualified electrician.

5

Page 6

IMPORTANT SAFETY INSTRUCTIONS

Reliable and safe operation of this hood can only be guaranteed if

it has been connected to the electrical supply.

To avoid damaging the ventilation hood, make sure that the

connection data (voltage and frequency) on the data plate

correspond to the building's power supply before connecting the

appliance.

If in doubt, consult a qualified electrician.

Do not use a power bar or extension cord to connect the

ventilation hood to electricity. These are a fire hazard and do not

guarantee the required level of appliance safety.

To ensure safe operation, only use the ventilation hood after it has

been properly installed.

This ventilation hood may not be used in non-stationary locations

(e.g. on a ship).

Adequate ventilation must be provided when the hood is operated

simultaneously with devices that burn gas or other fuels.

Only open the housing as described in the enclosed “Installation

diagram” and in the “Cleaning and care” section of this manual.

Under no circumstances should any other parts of the housing be

opened.

Tampering with electrical connections or components and

mechanical parts is highly dangerous to the user and can cause

operation faults.

Defective components should be replaced by Miele original parts

only. Only with these parts can the manufacturer guarantee the

safety of the appliance.

If the power cord is damaged, it must only be replaced by a

qualified service technician.

6

Page 7

IMPORTANT SAFETY INSTRUCTIONS

During installation, maintenance, and repair work, the ventilation

hood must be disconnected from the electrical supply. It is only

completely isolated from the electricity supply if one of the following

applies:

– The circuit breakers on the electrical service panel are tripped.

– The screw-type fuses on the electrical service panel have been

removed.

– The power cord (if present) has been unplugged from the socket

(pull the plug not the cord).

Correct use

WARNING: TO REDUCE THE RISK OF A COOKTOP GREASE

FIRE:

– a) Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers may ignite. Heat oils slowly

on low or medium settings.

– b) Always turn the hood on when cooking at a high heat.

– c) Clean the ventilation hood frequently. Grease should not be

allowed to accumulate on the fan or filter.

– d) Use the proper pan size. Always use cookware appropriate for

the size of the cooking area.

Never use an open flame beneath the ventilation hood.

To avoid the risk of fire, do not flambé or grill over an open flame.

When turned on, the ventilation hood will draw any flames into the

filter. Fat deposits may ignite.

WARNING: TO REDUCE THE RISK OF INJURY TO PERSONS IN

THE EVENT OF A COOKTOP GREASE FIRE, OBSERVE THE

FOLLOWING*:

– a) SMOTHER FLAMES with a close fitting lid, cookie sheet, or

metal tray then turn off the burner. BE CAREFUL TO PREVENT

BURNS. If the flames do not go out immediately, EVACUATE AND

CALL THE FIRE DEPARTMENT.

7

Page 8

IMPORTANT SAFETY INSTRUCTIONS

– b) NEVER PICK UP A FLAMING PAN - You may be burned.

– c) DO NOT USE WATER, including wet dishcloths or towels - a

violent steam explosion will result.

– d) Use a fire extinguisher ONLY if:

– 1) You have a class ABC extinguisher, and you know how to operate it.

– 2) The fire is small and contained in the area where it started.

– 3) The fire department is being called.

– 4) You can fight the fire with your back to an exit.

*Based on “Kitchen Fire Safety Tips” published by NFPA.

The ventilation hood may become damaged if exposed to

excessive heat from a gas cooktop.

– When using the ventilation hood over a gas cooktop, ensure that

any burners in use are always covered by cookware. Turn burners

off when removing the cookware, even if doing so for just a short

time.

– Select cookware that is suitable for the size of the burner.

– Adjust the flame so that it never extends up the sides of the

cookware.

– Avoid overheating the cookware (e.g., when cooking with a wok).

Always turn the ventilation hood on whenever a burner is in use to

prevent damage from condensation.

Overheated oil and fat can ignite, causing fire damage to the

ventilation system.

Do not leave cookware, pans, and deep fryers unattended when

cooking with oil or fat. Similarly, never leave an open grill unattended

when grilling.

Fat and debris deposits impair the proper functioning of the

ventilation hood.

To ensure that cooking vapors are properly cleaned, never use the

ventilation hood without the grease filters in place.

8

Page 9

IMPORTANT SAFETY INSTRUCTIONS

There is a risk of fire if cleaning is not completed according to the

instructions in this manual.

Please note that the heat rising from the stovetop during cooking

can cause the ventilation hood to become very hot.

Do not touch the housing or the grease filters until the ventilation

hood has cooled down.

9

Page 10

IMPORTANT SAFETY INSTRUCTIONS

Proper installation

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

– a) Installation work and electrical wiring must be done by qualified

person(s) in accordance with all applicable codes and standards,

including fire-rated construction.

– b) Sufficient air is needed for combustion and exhausting of gases

through the flue (chimney of fuel burning equipment to prevent

back drafting. Follow the heating equipment manufacturer’s

guideline and safety standards such as those published by the

National Fire Protection Association (NFPA) and the American

Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

– c) When cutting or drilling into the wall or ceiling, do not damage

electrical wiring and other hidden utilities.

– d) Ducted hoods must always be vented to the outdoors.

– e) Do not use this hood with any solid-state speed control device.

To determine whether a ventilation hood may be operated above

your cooking appliance, please refer to the information provided by

the appliance's manufacturer.

Safety regulations prohibit the installation of a ventilation hood

over solid fuel stoves.

An insufficient safety distance between the cooktop and the

ventilation hood can result in damage to the ventilation hood.

The minimum safety distances between the top of the cooktop and

the bottom of the ventilation hood given in the “Installation” section

of this booklet must be observed, unless the cooktop manufacturer

states that a greater safety distance is required.

If more than one cooking appliance is installed beneath the

ventilation hood, and they have different minimum safety distances

to the ventilation hood, select the greater distance.

10

Page 11

IMPORTANT SAFETY INSTRUCTIONS

Be sure to observe the information contained in the “Installation”

section when mounting the ventilation hood.

Metal parts can have sharp edges which may cause injury.

Wear gloves to protect your hands from being cut.

When installing the exhaust duct, only use pipes or tubes made of

non-flammable material. These can be obtained from your Miele

dealer or from Miele Technical Service.

Exhaust air should not be vented into a chimney or vent flue which

is otherwise in use and should not be channeled into ducting which

ventilates rooms with fuel-burning installations.

If exhaust air is to be extracted into a chimney or ventilation duct

no longer used for other purposes, seek professional advice.

WARNING: TO REDUCE THE RISK OF FIRE USE ONLY METAL

DUCTWORK.

Cleaning and maintenance

Never use a steam cleaner to clean the ventilation hood.

The steam can reach the electrical components and cause a short

circuit.

Accessories

Use only genuine original Miele parts. If parts or accessories from

other manufacturers are used, the warranty will become void.

11

Page 12

Caring for the environment

Disposal of the packing material

The cardboard box and packing

materials protect the appliance during

shipping. They have been designed to

be biodegradable and recyclable.

Ensure that any plastic wrappings,

bags, etc. are disposed of safely and

kept out of the reach of children.

Danger of suffocation!

Disposal of your old appliance

Electrical and electronic appliances

contain valuable materials. They also

contain certain substances, compounds

and components which were essential

for the proper functioning and safe use

of the equipment. Handling these

materials improperly by disposing of

them in your household waste can be

harmful to your health and the

environment. Therefore, please do not

dispose of your old appliance with

regular household waste and follow

local regulations on proper disposal.

Consult with local authorities, dealers or

Miele in order to dispose of and recycle

electrical and electronic appliances.

Miele assumes no responsibility for

deleting any personal data left on the

appliance being disposed. Please

ensure that your old appliance is kept

away from children until removal.

Observe safety requirements for

appliances that may tip over or pose an

entrapment hazard.

12

Page 13

Description of functions

The following functions are available on

your ventilation hood, depending on the

model:

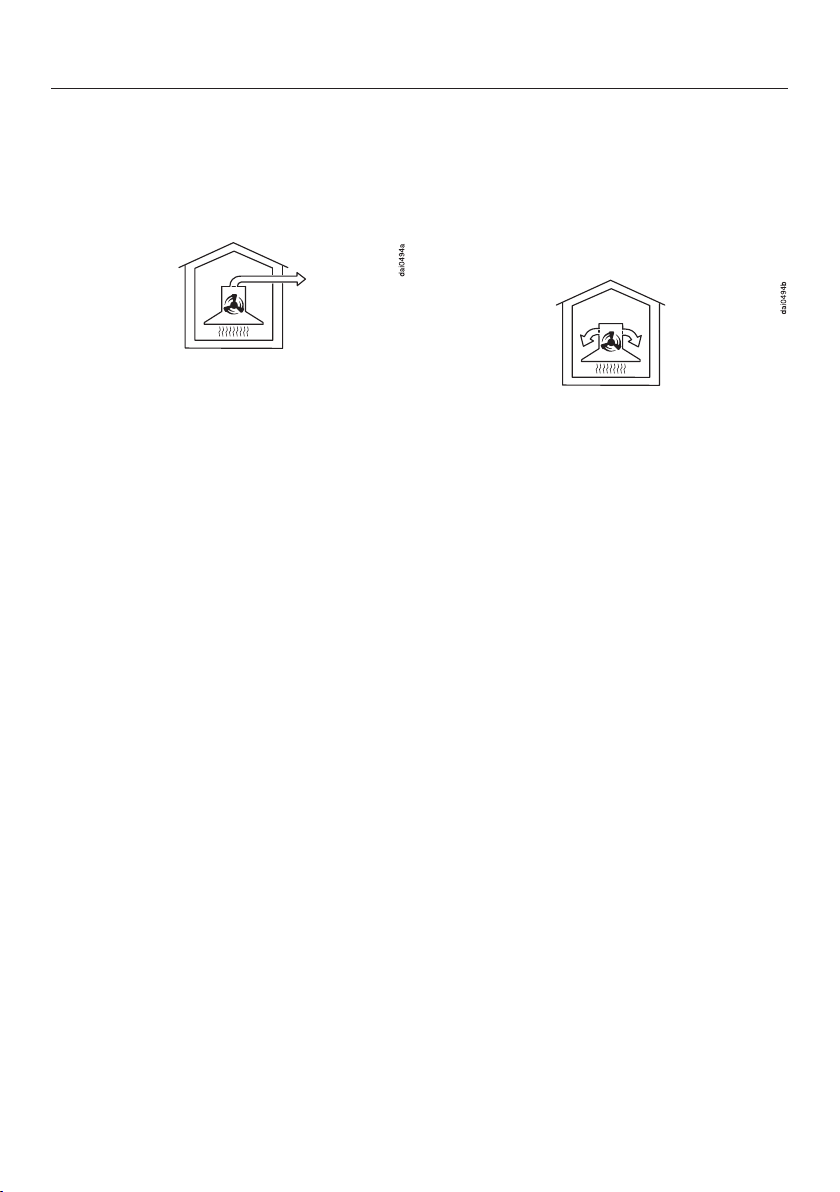

Vented mode

The air is drawn in and cleaned by the

grease filters and directed outside.

Non-return flap

A non-return flap in the ducting

prevents the exchange of inside and

outside air from occurring when the

ventilation hood is not in use.

The flap is closed when the ventilation

hood is turned off.

When the ventilation hood is turned on,

the non-return flap opens so that the

exhaust air can be transported outside

without any obstruction.

Recirculation mode

The recirculation mode requires a

recirculation kit and OdorFree Charcoal

Filter (available as optional accessories,

see “Technical Data” for more

information)

The air is drawn in and first cleaned by

the grease filters and then by an

OdorFree Charcoal Filter. The cleaned

air is then recirculated back into the

kitchen.

A non-return flap has been provided

with the hood in case your ducting does

not have one. It is inserted into the

outlet duct collar of the fan.

13

Page 14

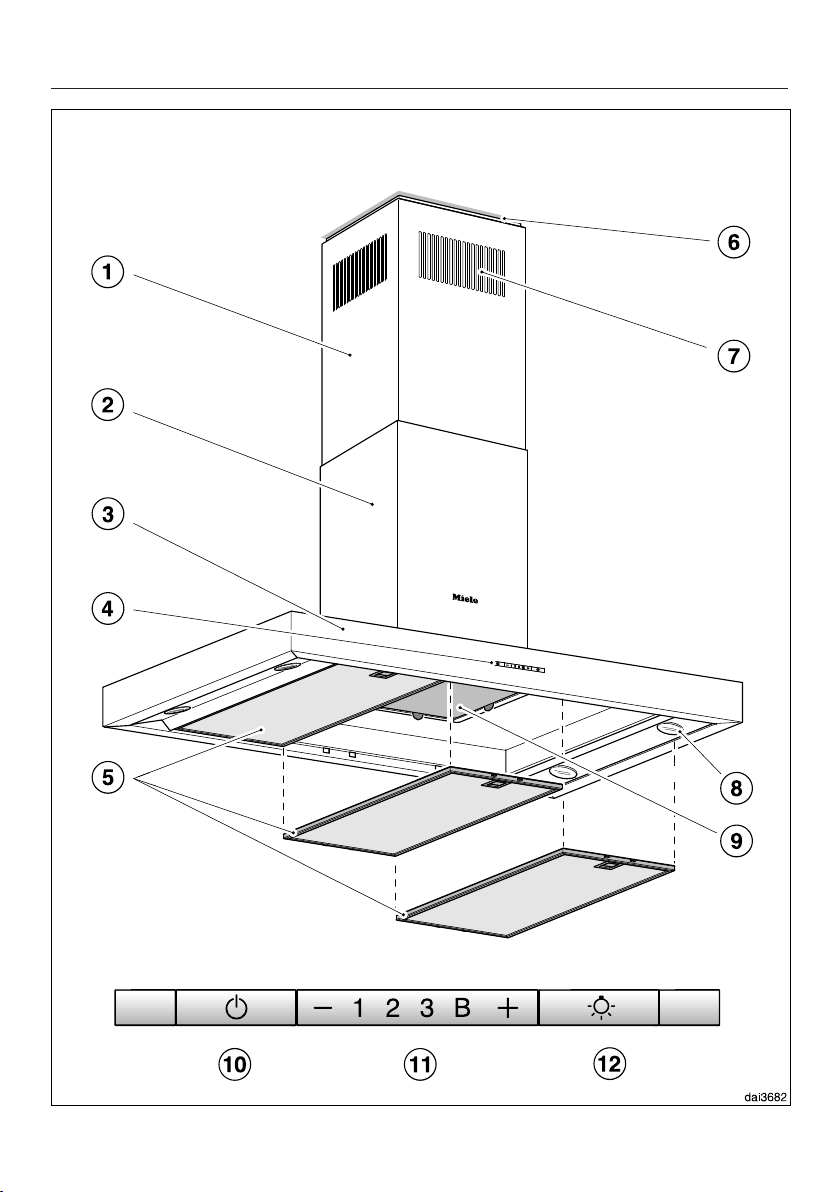

Guide to the appliance

14

Page 15

Guide to the appliance

a

Telescopic chimney

b

Chimney

c

Canopy

d

Control panel

e

Grease filter

f

Spacer frame

The spacer frame creates a shadow gap between the chimney and the ceiling.

The ventilation hood can be installed with or without the spacer frame.

g

Recirculation vent

(only for recirculation mode)

h

Cooktop lighting

i

OdorFree Charcoal Filter

Optional accessory for recirculation mode

j

On/Off button for fan

k

Buttons for setting the fan power

l

Button for cooktop lighting

15

Page 16

Operation

Turning on the blower

Switch the blower on as soon as you

start cooking. This is to ensure that

vapors are captured right from the start.

Press the On/Off control.

The blower turns on at level 2. The

symbol and 2 will light up in the blower

level display.

Selecting the power level

Power levels 1 to 3 are available for light

to heavy cooking vapors and odors.

For strong vapors and odors that are

temporarily produced when cooking,

e.g., during searing, select the B

Booster setting.

Select the power level you want by

pressing the or control.

Reducing power down from the Booster setting

If power management is activated

(default setting), the blower

automatically switches back to level 3

after 5minutes.

Delayed shut-off

It is advisable to run the blower for a

few minutes after cooking has

finished to neutralize any lingering

vapors and odors in the air.

Turning the overhead lighting on/off

The overhead lighting can be turned on

and off separately from the blower.

To do this, press the lighting

control.

The symbol will light up when the

overhead lighting is turned on.

Power management

The ventilation hood features a power

management system to help save

energy. The blower power level is

reduced and the lighting is turned off

automatically.

– If the booster level is selected, the

blower automatically switches to

level 3 after 5 minutes.

– If the blower is set to level 3, 2 or 1, it

switches back one blower setting

after 2 hours and then in 30-minute

intervals until the blower eventually

switches off.

– If the overhead lighting is on, it will

switch off automatically after 12

hours.

You can deactivate power

management.

This can, however, result in increased

energy consumption.

Turning off the blower

Press the On/Off control to turn

the blower off.

The symbol will go out.

16

Page 17

Operation

Turning power management on/off

You can deactivate power

management.

Keep in mind that this may increase

energy consumption.

To set this option, turn off the fan and

the overhead lighting first.

Press theandbuttons at the

same time for approx. 10 seconds,

until 1 lights up.

Then, press the following buttons in

succession:

– the lighting button,

– followed by thebutton and then

– the lighting button.

If power management is turned on, the

1 and B indicators will be continuously

lit.

If it is turned off, the 1 and B indicators

will flash.

Press the button to turn power

management off.

Safety shut-off

If power management has been

deactivated, the ventilation hood will

switch itself off automatically after

12hours if it has been left on (blower

and overhead lighting).

To switch it back on, press the On/

Off control or the lighting

control.

The 1 and B indicators will flash.

To turn it on, press the button.

The 1 and B indicators will be

continuously lit.

Confirm your choice with the On/Off

button .

All the indicator lights will go out.

If the new setting is not confirmed

within 4minutes, the ventilation system

reverts to the previous setting.

17

Page 18

Energy-saving tips

This hood operates in a very efficient

and energy-saving manner. The

following will help you to save even

more energy when using it:

– Ensure that there is sufficient

ventilation in the kitchen when

cooking. If there is insufficient air flow

during vented mode, the hood

cannot operate efficiently, causing

increased operating noise levels.

– Always cook with the lowest possible

setting. This produces fewer cooking

vapors so that you can use a lower

hood power level and therefore

benefit from reduced energy

consumption.

– Check the power level selected on

the hood. A lower power level is

generally sufficient for the majority of

cooking. Only use the booster level

when necessary.

– When a large volume of cooking

vapors are being produced, switch to

a high power level in good time. This

is more efficient than operating the

hood for longer to try to capture

cooking vapors that have already

been distributed throughout the

kitchen.

– Make sure that you switch off the

hood after use.

– Clean or change the filters at regular

intervals. Heavily soiled filters reduce

performance, increase the risk of fire

and are unhygienic.

18

Page 19

Service and warranty

For faults that you cannot resolve on

your own, please contact your Miele

dealer or Miele Technical Service.

The telephone number for Miele is listed

at the back of these instructions.

When contacting Miele, please state the

model and serial number of your

ventilation hood.

These can be found on the data plate.

Location of the data plate

The data plate is visible once you have

removed the grease filters.

Warranty

For further information, please refer to

your warranty booklet.

MieleCare

This service is available in USA only.

MieleCare, our Extended Service

Contract program, gives you the

assurance of knowing that your

appliance investment is covered by

5years of worry free ownership.

MieleCare is the only Extended Service

Contract in the industry that guarantees

repairs by a Miele Authorized Service

Provider using genuine Miele parts.

Only genuine Miele parts installed by

factory trained professionals can

guarantee the safety, reliability, and

longevity of your Miele appliance.

Please note that unless expressly

approved in writing by Miele’s Service

department, Extended Service

Contracts offered by other providers for

Miele products will not be recognized

by Miele. Our goal is to prevent

unauthorized (and untrained) service

personnel from working on your Miele

products, possibly doing further

damage to them, you and/or your

home.

To learn more about MieleCare

Extended Service Contracts, please

contact your appliance dealer or visit us

online at:

www.mieleusa.com

19

Page 20

Cleaning and care

WARNING: TO REDUCE THE

RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Before cleaning or servicing the

hood, disconnect it from the power

supply, see “IMPORTANT SAFETY

INSTRUCTIONS”.

Stainless steel housing

General information

The surfaces and control buttons

are susceptible to scratching and

chipping.

Observe the following cleaning

instructions.

Clean all surfaces and control buttons

using warm water and liquid dish

soap. Apply with a sponge cloth.

Make sure that no water gets

into the interior of the hood.

Only use a damp cloth to clean the

hood, especially in the control panel

area.

Special instructions for stainless steel surfaces

(does not apply to control buttons)

Stainless steel surfaces can also be

cleaned using a non-abrasive

stainless steel cleaner, available from

Miele.

To prevent the surfaces from quickly

becoming dirty again, we recommend

treating them with a stainless steel

care conditioner.

Apply sparingly over the entire area

using a soft cloth.

Important for the controls

Do not leave dirt and debris on the

buttons for any length of time.

Otherwise they may become

discolored or damaged.

Remove any dirt or debris

immediately.

Observe the general cleaning

instructions contained in this chapter.

Do not use a stainless steel cleaner

to clean the control buttons.

After cleaning, dry the surfaces with a

soft cloth.

Avoid the following:

– Cleaners containing soda, acid or

chloride, or cleaners containing

solvents

– Abrasive sponges, e.g. pot scourers

or sponges which have been

previously used with abrasive

cleaning agents.

20

Page 21

Grease filters

The reusable metal grease filters in the

appliance remove the solid particles

contained in kitchen vapors (grease,

dust, etc.), thereby preventing the

ventilation hood from becoming dirty.

The grease filters must be cleaned at

regular intervals.

Cleaning and care

Heavily soiled grease filters hinder air

extraction and will lead to increased

levels of soiling in the ventilation hood

and in the kitchen.

Risk of fire!

Oversaturated grease filters are a fire

hazard.

Clean the grease filters at regular

intervals.

Cleaning intervals

Accumulated grease solidifies over a

longer period of time and makes

cleaning more difficult. The grease

filters should therefore be cleaned every

3 to 4 weeks.

Removing the grease filters

When handling the grease filter,

be careful not to drop it.

This can result in damage to the filter

and the cooktop below.

Make sure you hold the filter securely

at all times when handling it.

To remove a grease filter, release the

locking clip. Then, open the filter to a

45° angle, unhook it, and remove it

from the hood.

Cleaning the grease filters by hand

Clean the filters with a soft nylon

brush in a mild solution of hot water

and dish soap. Do not use undiluted

dish soap.

Unsuitable cleaning agents

Unsuitable cleaners can cause damage

to the filter surfaces if used regularly.

Do not use any of the following:

– Lime removers

– Abrasive powders or abrasive liquids

– Aggressive all-purpose cleaners and

degreaser sprays

– Oven sprays

Cleaning the grease filters in a dishwasher

Place the grease filters upright or

slightly inclined in the lower basket.

Ensure the spray arm is not

obstructed.

Use a commonly available household

dishwashing detergent.

21

Page 22

Cleaning and care

In a Miele dishwasher use the

“Normal” program.

Depending on the detergent used,

cleaning the filters in a dishwasher

may cause the inside filter surfaces to

become discolored. However, this will

not affect the functioning of the grease

filters in any way.

After cleaning

After cleaning, leave the filters on an

absorbent surface to dry.

When removing the filters for

cleaning, also clean off any

accessible oil or fat buildup from the

housing. Doing so will prevent a fire

hazard.

Reinstall the grease filters. When

inserting the filters, make sure that

the locking clip is facing down.

OdorFree Charcoal Filter

If the hood is equipped for recirculation,

an OdorFree Charcoal Filter must be

installed in addition to the grease filters.

This filter is designed to absorb odorcausing agents and is mounted in the

canopy above the grease filters.

Charcoal filters are available to order via

the Miele Webstore, Miele Service (see

end of this booklet for contact details)

or directly from Miele.

How to install/replace a charcoal filter

Remove the grease filters before

fitting or replacing a charcoal filter.

Take the charcoal filter out of its

packaging.

If the filters have been installed

incorrectly, you can insert a small

screwdriver into the slit to disengage

the locking clip.

22

Press the charcoal filter into the

frame.

Reinsert the grease filters.

Page 23

When to change the OdorFree Charcoal Filter

Replace the charcoal filter when it no

longer absorbs kitchen odors

effectively.

It should be replaced at least every 6

months.

Disposing of charcoal filters

The used charcoal filter can be

disposed of with the normal

household waste.

Cleaning and care

23

Page 24

Cleaning and care

Changing a light bulb

Only use the specified light bulbs.

Other bulbs, for example halogen

bulbs, may become damaged due to

the high generation of heat.

The light bulbs should be replaced with

the following:

Bulb type .............................. LED, GU10

Power ............................................... 3W

Light bulbs are available from Miele or

specialist dealers.

Turn off the blower and the lighting.

The light bulbs can get very hot

when in use.

Allow the bulbs to cool down for a

few minutes before changing them.

Disconnect the hood from the

electrical supply before replacing the

light bulbs (see “IMPORTANT

SAFETY INSTRUCTIONS”).

Insert the lever supplied into the gap

between the bulb and the bulb

holder..

The bulb will then drop downwards.

Grip the light bulb, turn it

counterclockwise and take it out.

24

Screw the new bulb into the socket

and push it upwards. Please follow

the manufacturer's safety

instructions.

Page 25

Before installation

Installation

Before installing the appliance,

read all of the information contained

in this chapter and also in the

“IMPORTANT SAFETY

INSTRUCTIONS” section.

Information is subject to change. Please

refer to our website to obtain the most

current product specification, technical

& warranty information.

Installation parts

41/4x45/16" (7x110mm) screws

and

43/8 x31/8" (10x80mm) plugs

for securing the ventilation system to

the ceiling (not for use in USA / CDN).

The screws and plugs are designed

for use in solid ceilings only.

Use different fasteners for other

construction types. Make sure that

the ceiling can support the load.

4 M4x8.5mm screws

for securing the telescopic extension

piece holders.

14M4x8mm screws

for securing the spacer frame and

securing the ventilation system to the

installation frame.

1M4x16mm screw

for securing the chimney.

DUI 32 conversion kit for

recirculation mode

(not supplied, available as an optional

accessory). The kit contains a

directional unit socket and flexible

aluminum hose with hose clips.

Keep the following in a safe place:

4telescopic extension piece holders

for aligning and securing the telescopic

extension piece

1 lever

for replacing the bulbs.

25

Page 26

Installation

Appliance dimensions

a

Mounting area for the exhaust ducting and power cable. In recirculation mode,

only the power cord is required.

b

Possible height range for appliance in vented mode

c

Possible height range for appliance in recirculation mode

d

Alternative installation with spacer frame

e

Air vent positioned at the top for recirculation

26

Page 27

Installation

f

A power cord is required to connect the hood to the socket in the ceiling. With

extraction mode flexible ducting is also required.

Exhaust connection 6" (150mm)

Distance between cooktop and ventilation hood (S)

Provided a larger distance is not given by the manufacturer of the cooktop,

follow the minimum safety distances between a cooktop and the bottom of the

hood.

Please also observe the information contained in the “IMPORTANT SAFETY

INSTRUCTIONS” section.

Minimum distance S

Cooking appliance Miele

appliance

Electric Cooktops 24" (610 mm)

Electric Barbeques and Fryers 26" (660 mm)

Multiburner Gas Cooktops

≤ 43,000 BTU/hr (12.6kW),

no burner > 15,000 BTU/hr (4.5 kW).

Multiburner Gas Cooktops

≤ 73,800 BTU/hr (21.6kW),

no burner > 16,500 BTU/hr (4.8 kW)

Multiburner Gas Cooktops

> 73,800 BTU/hr (21.6kW),

or one of the burners > 16,500 BTU/hr (4.8 kW)

Single Burner Gas Cooktops

≤ 20,500 BTU/hr (6 kW)

Single Burner Gas Cooktops

> 20,500 BTU/hr (6 kW)

≤ 27,600 BTU/hr (8.1 kW)

Single Burner Gas Cooktops

> 27,600 BTU/hr (8.1 kW)

26" (660 mm) 30" (760 mm)

30" (760 mm)

Not possible

26" (660 mm) 30" (760 mm)

30" (760 mm)

Not possible

Non-Miele

appliance

27

Page 28

Installation

Installation recommendations

– A distance of at least 26" (660mm) is

recommended above electric

cooktops to provide more workspace

and easier cooking under the hood.

– When selecting an installation height,

always take the user height into

consideration. Users should have

ample space to work comfortably on

the cooktop and reach the ventilation

hood controls with ease.

– Please note that the greater the

distance from the cooktop, the less

effective the hood is at drawing in the

cooking vapors.

– To achieve optimum vapor extraction,

the ventilation system must be

centered over the cooktop, not to the

side or behind.

Structural support

– The cooktop should be no wider than

the hood. Preferably, it should be

narrower for better extraction.

– The mounting area must be easily

accessible. The ventilation hood

should be easy to reach and

disassemble in case a service call is

necessary. This should be taken into

consideration when planning the

position of cabinetry, shelves,

ceilings or decorative elements in the

vicinity of the ventilation hood.

28

The hood must be attached to rigid

structural framing that is supported

in its entirety by the ceiling joists, or

to the ceiling joists directly. Do not

attach the plate directly to the ceiling

with anchors, toggle bolts, etc.

Removing the protective film

The housing components are covered

by a protective film to prevent them

from damage during transport.

Please remove this film before

installing the housing components. It

can be peeled off easily without any

additional tools.

Page 29

Draw two intersecting lines on the

ceiling.

Installation

For vented mode:

– Place a section of the exhaust

ducting in the ceiling and feed it

down through the cross-sectional

area as illustrated. Exhaust ducting of

approx. 27 ⁹/₁₆" (700 mm) length is

required between the ceiling and the

hood exhaust socket.

– Secure the exhaust ducting to the

exhaust socket, e.g. with a hose clip

(available as an optional accessory)

on flexible ducting.

Place the power cord and guide it

through the ceiling in the area shown.

A power cord approx. 27 ⁹/₁₆" (700

mm) in length is required between the

ceiling and the hood connectors.

29

Page 30

Installation

Use a knife to release the four

spacers and the two covers from the

spacer frame supplied.

Use the spacer frame as a drilling

template. Place it on the ceiling with

the arrows pointing forwards. Using

the notches, align the spacer frame

on the intersecting lines and make

pencil marks for the drill holes.

30

Drill four holes ³/₈“ (10mm),

approx. 4 ¹/₂” (115mm) deep for the

plugs supplied.

Place the four plugs in the holes and

screw in the four screws so that they

protrude by approx. 1 ³/₁₆" (30mm).

Page 31

The spacer frame can be installed

between the chimney and the ceiling.

This creates a shadow which gives the

illusion of a gap between the ceiling and

the chimney. This is useful if the ceiling

is not level or is uneven. The hood is

aligned vertically with the spacers

supplied. Visual irregularities between

the chimney and the ceiling are then

concealed by the shadow.

Installation

Mount the spacer frame onto the

installation frame.

If you wish to install the hood with the

spacer frame, remove the four inserts

from the fixing holes.

31

Page 32

Installation

Hang the installation frame on the

four screws. The front of the frame is

marked with a “V”.

If using the spacer frame, place the

two covers into the fixing holes.

32

Align the installation frame and

secure it with the screws.

The spacers, which were removed

from the spacer frame at the start,

can be used to align the hood

vertically.

Page 33

Holding the installation frame

securely, remove the two fixing

screws and extend the installation

frame to its maximum length.

Replace the screws.

The directional unit from recirculation kit

DUI 32 (optional accessory) is installed

for recirculation mode (RM):

Installation

Bend the four retaining tabs on the

installation frame outward.

Place the power cord inside the

installation frame.

Fit the directional unit as shown,

noting the marking on the front.

Bend the retaining tabs back and

approx. 45° inward to hold the

directional unit in place.

33

Page 34

Installation

Secure the exhaust socket to the

hose using a hose clip.

Secure the hose to the directional unit

socket using a hose clip.

Check that the hose is held securely.

34

Push the telescopic chimney over the

installation frame:

– with the recirculation grilles at the

bottom for vented mode (AE),

– with the recirculation grilles at the top

for recirculation mode (RM).

Bend the two retaining tabs outwards

to prevent the telescopic chimney

from slipping down again.

Page 35

Installation

Fit the four telescopic chimney

clamps. When the screws are

tightened, the clamps spread out and

push the telescopic expansion piece

upwards.

Tighten the screws only until the top

edge of the telescopic chimney is

evenly aligned with the ceiling or the

spacer frame.

Bend back the two retaining tabs.

Push the chimney over the telescopic

extension piece and bend the

retaining tabs outward again to

prevent the chimney from slipping

down again.

35

Page 36

Installation

A non-return flap is supplied with the

hood or is already fitted in the exhaust

socket of the motor unit (depending on

model).

With vented mode (AE) insert the

non-return flap in the exhaust socket

if your ducting system is not

equipped with one.

Recirculation mode (RM) does not

require the non-return flap to be

inserted. If there is one present, it

should be removed.

Hang the hood on the brackets,

making sure that the controls are at

the front.

36

Secure the hood with the screws

supplied.

Page 37

Connect the power cord. See

“Electrical connection.”

Place the exhaust ducting onto the

exhaust socket.

Installation

Unscrew both screws from the

installation frame again.

The canopy can now be adjusted to the

desired height, observing the

permissible height ranges:

– With vented mode: upwards as far as

it will go, downwards only to the “A”

marking.

– With recirculation mode: upwards as

far as the “U”, downwards as far as it

will go.

Follow the instructions in “Appliance

dimensions.” Safety distances

between the cooktop and ventilation

hood must be observed.

37

Page 38

Installation

Raise the canopy to the desired

height and secure it with the screws.

38

Hold the chimney securely, bend

back the retaining tabs and carefully

lower it.

The chimney will locate in the cut-out in

the canopy.

Page 39

Remove the grease filters from the

hood.

Installation

With recirculation mode (RM)

ventilation hoods, insert the OdorFree

Charcoal Filter.

Insert the safety screw on the inside.

Carefully remove the protective foil

from the grease filters.

Reinsert the grease filters.

39

Page 40

Air venting

WARNING: Danger of toxic fumes.

Gas cooking appliances release

carbon monoxide that can be

harmful or fatal if inhaled.

To reduce the risk of fire and to

properly exhaust air, the exhaust

gases extracted by the hood should

be vented outside of the building

only.

Do not vent exhaust air into spaces

within walls or ceilings or in attics,

crawl spaces or garages.

To reduce the risk of fire, only use

metal ductwork.

Please read and follow the

“IMPORTANT SAFETY

INSTRUCTIONS” to reduce the risk

of personal injury. Follow all local

building codes when installing the

hood.

Only use smooth pipes or flexible

duct hoses made from noncombustible materials for exhaust

ductwork.

To achieve the greatest possible air

extraction with the lowest noise levels,

please note the following:

– The diameter of the exhaust duct

should not be less than 6" (150mm).

– If flat exhaust ducts are used, the

cross section should not be smaller

than that of the exhaust connector.

– The exhaust duct should be as short

and straight as possible.

– Make sure that all connections are

secure and airtight.

Remember that any constriction of

the airflow will reduce extraction

performance and increase operating

noise.

If the exhaust duct is to be routed

through an outside wall, we

recommend installing a telescopic

wall vent or a rooftop vent (available

as an optional accessory).

If the exhaust air is conveyed into an

exhaust air chimney, the inlet

connector must face the flow

direction.

When installing the exhaust duct

horizontally, a minimum slope of ¹/₈

inch per foot must be maintained to

prevent condensate from flowing into

the ventilation hood.

If the exhaust duct is to be routed

through cool rooms, ceilings, etc., the

temperatures in these different areas

may differ greatly. Therefore water

condensation must be considered

and the exhaust duct will need to be

insulated.

– If elbows are needed, make sure they

have a large radius.

– The exhaust duct itself must not be

kinked or compressed.

40

Page 41

Condensate trap

In addition to insulating the exhaust

duct, we recommend installing a

condensate trap to collect and

evaporate any condensate which might

accumulate.

Condensate traps are available for

exhaust ducts with a diameter of

5" (125 mm) or 6" (150 mm).

Air venting

When installing a condensate trap,

make sure that it is positioned

vertically and, if possible, directly

above the hood outlet duct collar.

The arrow on the housing indicates

the direction of airflow.

41

Page 42

Electrical connection

WARNING: TO REDUCE THE RISK

OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

All electrical work should be

performed by a qualified electrician

in strict accordance with national

regulations (for USA: ANSI-NFPA 70)

and local safety regulations.

Installation, repairs and other work

by unqualified persons could be

dangerous.

Ensure that power to the appliance is

OFF while installation or repair work

is performed.

Verify that the voltage, load and

circuit rating information found on

the data plate (located behind the

baffle filters), match the household

electrical supply before installing the

hood.

Use only with ventilation hood cordconnection kits that have been

investigated and found acceptable

for use with this model hood.

If there is any question concerning

the electrical connection of this

appliance to your power supply,

please consult a licensed electrician

or call Miele’s Technical Service

Department.

Grounding Instructions

WARNING - Improper grounding can

result in a risk of electric shock.

This appliance must be grounded. In

the event of an electrical short

circuit, grounding reduces the risk of

electric shock by providing a path of

least resistance.plug.

If there is any doubt, have the

electrical system of the house

checked by a qualified electrician.

To increase security before the

machine is installed, it is

recommended to install a protective

switch (30 mA).

The hood must be hard wired

accordingly:

Black/Red wire: connect to L1 (live)

White wire: connect to N (neutral)

Green wire: connect to GND (ground)

If the unit will be hard wired to the

electricity supply, the wire gauge of the

individual leads must be between 18

AWG and 16 AWG.

WARNING: THIS APPLIANCE MUST

BE GROUNDED

42

The strain relief must be used to ensure

problem-free connection.

Page 43

Technical data

Blower motor 350W

Overhead lighting 4x3W

Total connected load 362W

Supply voltage, frequency 120VAC, 60Hz

Fuse 15A

Weight 74.8lbs (34kg)

Optional accessories for recirculation mode

DUI32 conversion kit to change from vented mode to recirculation mode and

DKF12-900 OdorFree Charcoal Filter.

43

Page 44

Page 45

Page 46

Page 47

9 Independence Way

Princeton, NJ 08540

Phone:

Fax:

www.mieleusa.com

U.S.A.

Miele, Inc.

National Headquarters

Please have the model and serial number

of your appliance available when

contacting Technical Service.

Canada

Importer

Miele Limited

Headquarters and Miele Centre

800-843-7231

609-419-4298

Technical Service & Support

Phone:

Fax:

TechnicalService@mieleusa.com

161 Four Valley Drive

Vaughan, ON L4K 4V8

www.miele.ca

800-999-1360

888-586-8056

Customer Care Centre

Phone:

customercare@miele.ca

800-565-6435

905-532-2272

International Headquarters

Miele & Cie. KG

Carl-Miele-Straße 29

33332 Gütersloh

Germany

Page 48

PUR 98 D

M.-Nr. 10 770 050 / 02en-US

Loading...

Loading...