Miele DG 408, DG 4082, DG 4080 Technical Information

TECHNICAL INFORMATION

DG 408x Steam Ovens

© 2012 Miele USA

DG 408x Steam Ovens

Technical Information

Table of Contents

A Warning and Safety Instructions ............................................................................. 5

B Modification History ................................................................................................. 5

C Technical Data .......................................................................................................... 5

D Component Layouts ................................................................................................. 7

1 Appliance Overviews .................................................................................................. 7

2 Electrical Components ................................................................................................ 9

010 Casing ...................................................................................................................... 11

1 Technical Data .......................................................................................................... 12

2 Function .................................................................................................................... 12

2.1 Air and Vapor Ducting ............................................................................................ 12

2.2 Fan Coastdown ...................................................................................................... 13

2.3 Door Contact Switch (S24) .................................................................................... 13

2.4 Release Element (Y56) for Steam Reduction ....................................................... 13

3 Fault Repair .............................................................................................................. 14

3.1 Fan Coastdown Too Long ..................................................................................... 14

3.2 Top Clearance Too Small When Combined with Warming Drawer (DG 4080) .... 14

4 Service ...................................................................................................................... 15

4.1 Removing the Appliance from its Niche ................................................................. 15

4.2 Removing the Side Panels .................................................................................... 15

4.3 Rear Panel Removal .............................................................................................. 16

4.4 Fan (M2/1) Removal .............................................................................................. 17

4.5 Removing the Door Contact Switch (S24) ............................................................. 18

4.6 Upper Air Duct Removal ........................................................................................ 18

4.7 Fan Wheel Removal .............................................................................................. 20

020 Door ......................................................................................................................... 21

3 Fault Repair .............................................................................................................. 22

3.1 Whistling Sound When Closing the Door .............................................................. 22

4 Service ...................................................................................................................... 22

4.1 Door Removal ........................................................................................................ 22

4.2 Installing the Door .................................................................................................. 23

4.3 Door Disassembly .................................................................................................. 23

030 Oven Cavity ............................................................................................................. 24

1 Technical Data .......................................................................................................... 25

2 Function .................................................................................................................... 25

2.1 Floor Heater Element ............................................................................................. 25

2.2 PT 1000 Temperature Sensor (R30 or R30/10) .................................................... 25

4 Service ...................................................................................................................... 25

4.1 PT 1000 Temperature Sensor (R30 or R30/10) Removal ..................................... 25

4.2 Removing the Floor Heater Element (R28) ........................................................... 26

4.3 Floor Heater Temperature Regulator (2F1) and Temperature Limiter (2F8)

Removal ................................................................................................................. 28

040 Water Tank .............................................................................................................. 29

1 Technical Data .......................................................................................................... 30

2 Function .................................................................................................................... 30

2.1 Steam Generation .................................................................................................. 30

3 Fault Repair .............................................................................................................. 31

3.1 Appliance Does Not Heat ...................................................................................... 31

3.2 Appliance Heats Too Slowly .................................................................................. 31

2

DG 408x Steam Ovens

Technical Information

3.3 Appliance Generates Strong Steam at First Use, or After a Power Outage/Reset 32

3.4 Appliance Appears to be Incorrectly Installed ....................................................... 32

3.5 Steam Generator is Discolored ............................................................................. 32

4 Service ...................................................................................................................... 33

4.1 Checking the Resistance of the Steam Generator Heater (1R25, 2R25) ............. 33

4.2 Removing the Steam Generator Heater (1R25, 2R25) ......................................... 34

4.3 Removing the Steam Generator Temperature Regulator (1F1) and Temperature

Limiter (1F8) .......................................................................................................... 34

4.4 Removing the Steam Duct and Seal ..................................................................... 35

4.5 Accessing the Tank Float/Float Switch Actuating Magnet (DG 4080 Only) .......... 36

4.6 Removing the Reed Contact Float (PCB) (S12) .................................................... 36

4.7 Removing the Steam Generator Present Switch (S84) ......................................... 37

4.8 Removing the Steam Generator Socket ................................................................ 37

060 Fascia, Electronics ................................................................................................. 38

2 Function .................................................................................................................... 39

2.1 Optical Interface ..................................................................................................... 39

2.2 Electronics Overview ............................................................................................. 40

2.3 Warming Function .................................................................................................. 41

2.4 Power Management ............................................................................................... 41

2.5 Descaling ............................................................................................................... 41

3 Fault Repair .............................................................................................................. 42

3.1 Fault Code Summary ............................................................................................. 42

3.2 F05 - Short Circuit in PT 1000 Temperature Sensor ............................................. 42

3.3 F06 - Open Circuit in PT 1000 Temperature Sensor ............................................. 42

3.4 F20 - Heating Fault ................................................................................................ 42

3.5 F44 - Control Electronic/Power Electronic Interface is Faulty ............................... 44

3.6 Displays Look Different .......................................................................................... 44

3.7 Wrong Language Setting ....................................................................................... 44

3.8 Display Dims .......................................................................................................... 44

3.9 Time of Day Shown in 12-Hour Format/24-Hour Format ...................................... 44

3.10 Cooking Program Does Not Start .......................................................................... 45

3.11 Excessive Steam in the Oven Cavity ..................................................................... 45

3.12 Cooked Food Is Not Kept Warm ............................................................................ 45

3.13 Recommended Temperatures Are Changed ........................................................ 45

3.14 Display Is Hard To Read........................................................................................ 45

3.15 Buzzer at the End of a Cooking Cycle is Too Loud/Soft/Short .............................. 45

3.16 When Touching a Keypad, Tone is Too Loud or Too Soft .................................... 46

3.17 System Lock Is Possible/Not Possible .................................................................. 46

3.18 Temperature in °C / °F ........................................................................................... 46

4 Service ...................................................................................................................... 46

4.1 Programming Mode ............................................................................................... 46

4.2 Service Mode ......................................................................................................... 49

4.3 Removing the Fascia Panel Assembly .................................................................. 51

4.4 Removing the Control Electronic (DG 4082) ......................................................... 53

4.5 Removing the Selection Electronic ........................................................................ 53

070 Technical Service Bulletins ................................................................................... 54

1 DG 4080 Steam Oven Displays F20 in a New Installation ........................................ 54

List of Figures

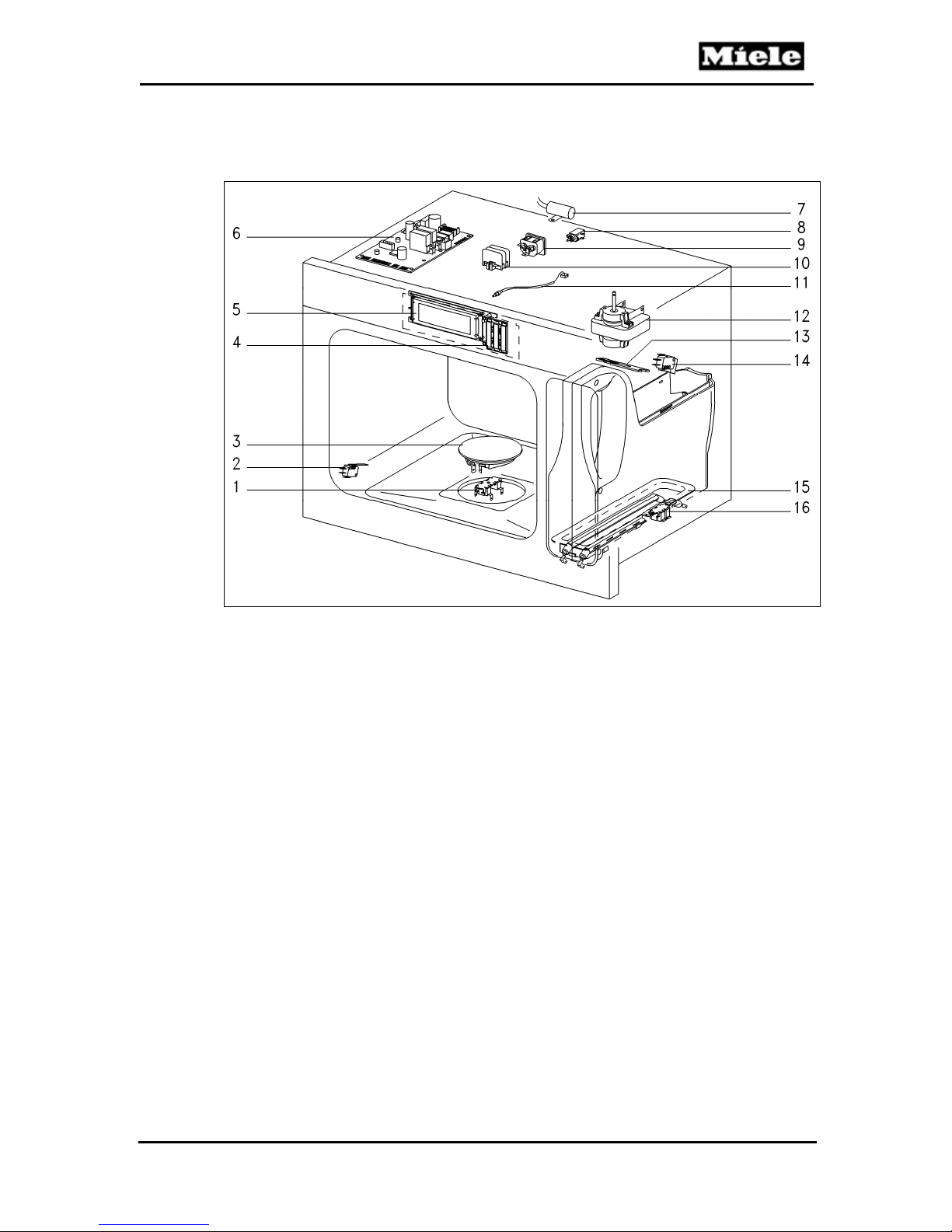

Figure D-1: Overview of DG 4080 (Front View) ...................................................................... 7

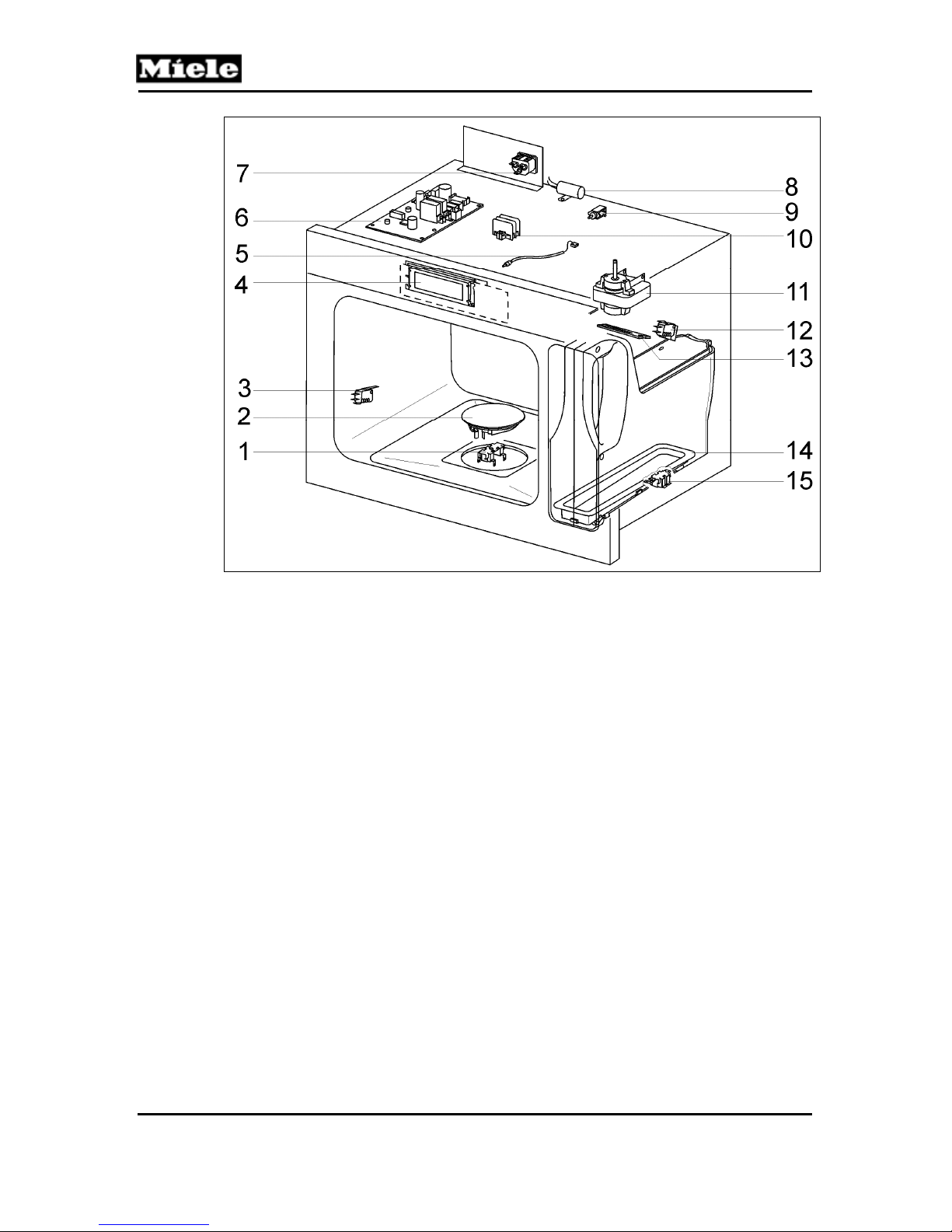

Figure D-2: Overview of DG 4082 (Front View) ...................................................................... 8

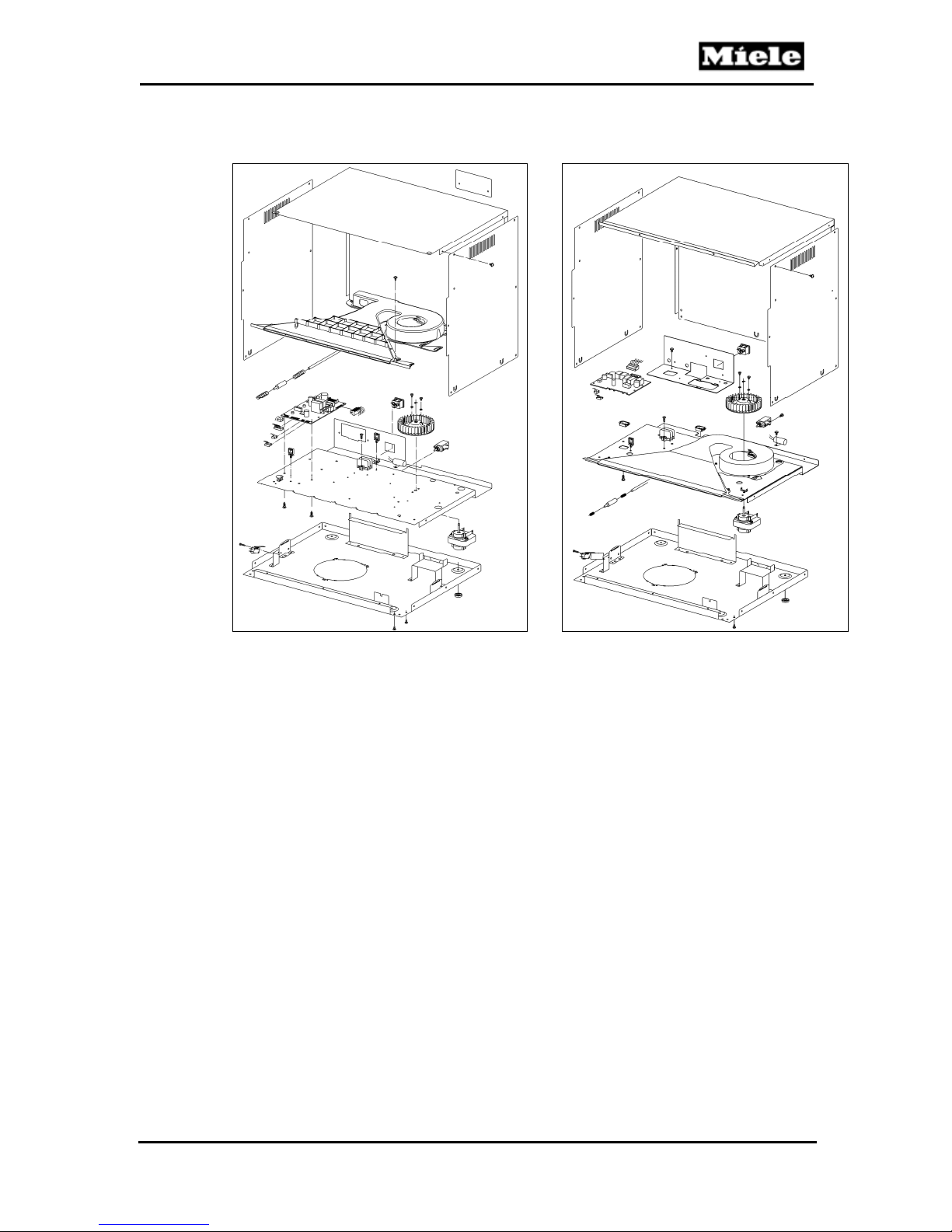

Figure D-3: DG 4080 Electrical Components .......................................................................... 9

Figure D-4: DG 4082 Electrical Components ........................................................................ 10

3

DG 408x Steam Ovens

Technical Information

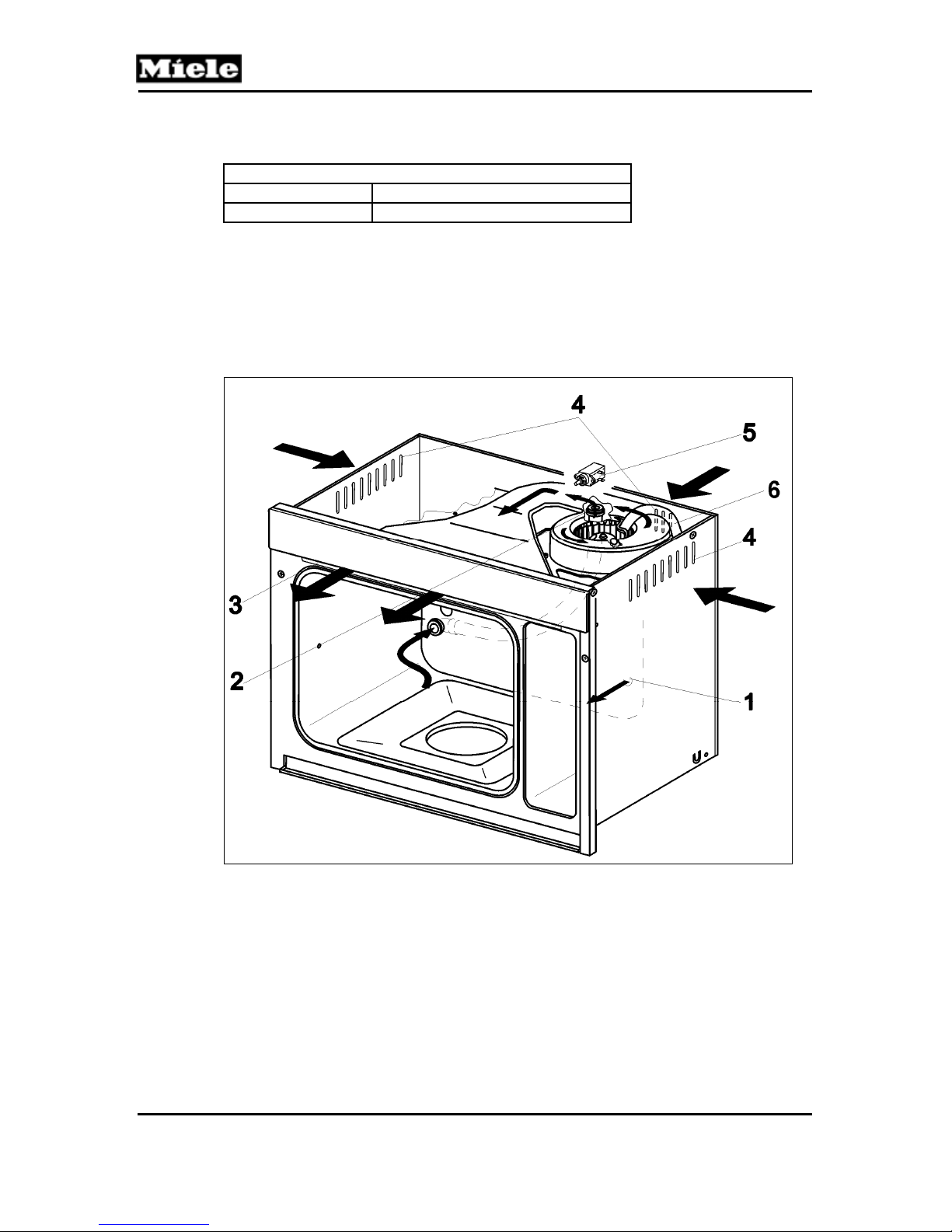

Figure 010-1: Ducting ............................................................................................................ 12

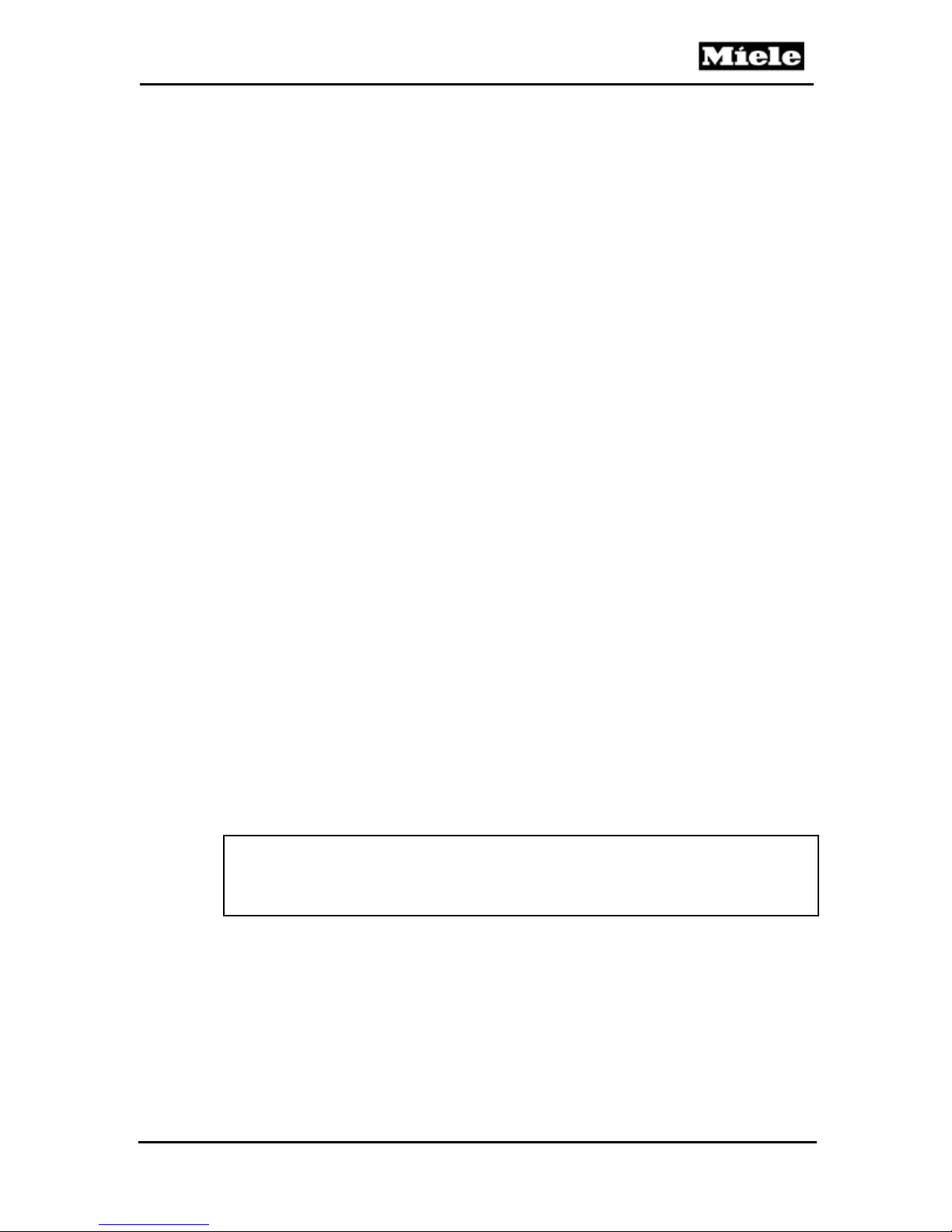

Figure 010-2: Screws on the Bottom of the Appliance (DG 4080) ........................................ 15

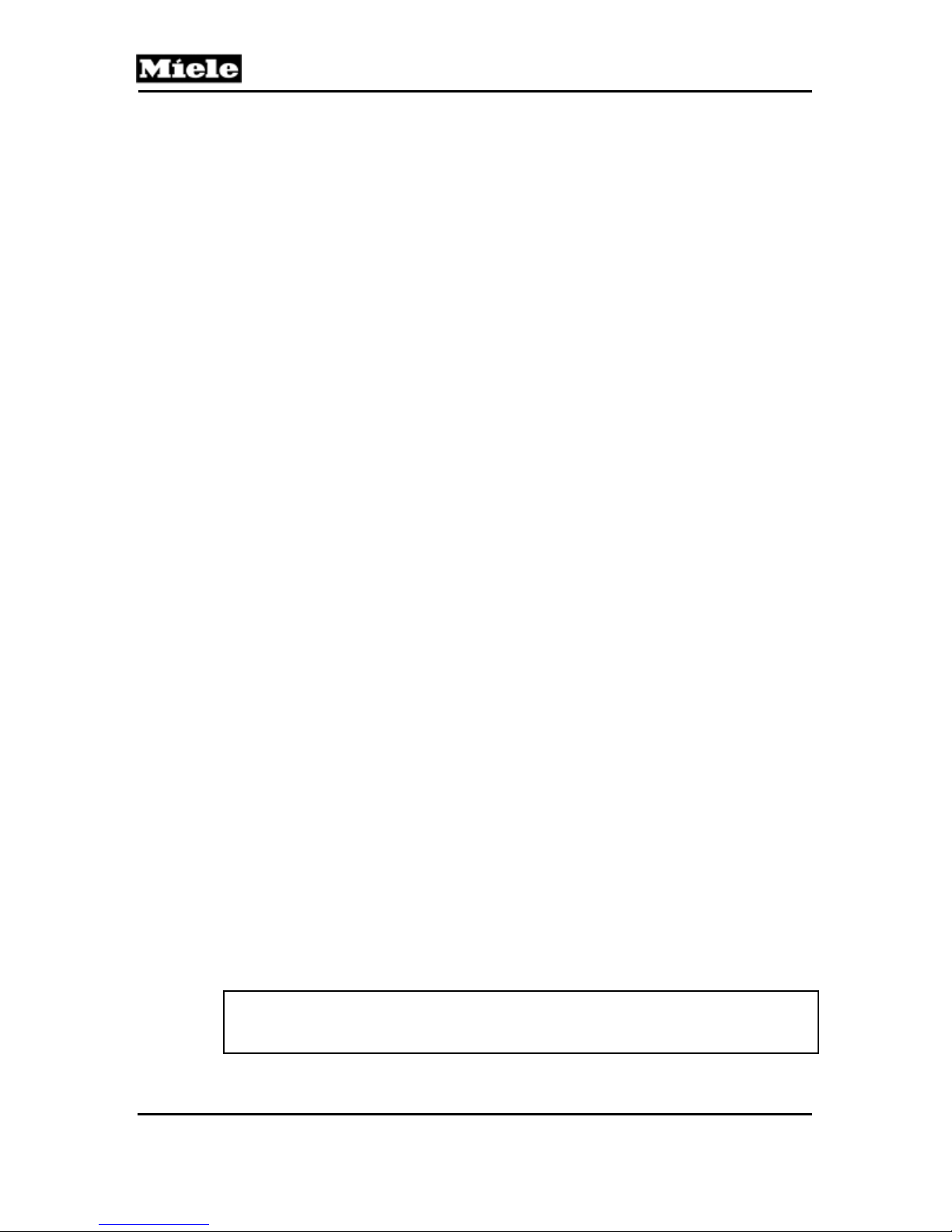

Figure 010-3: Appliance Retaining Screws ........................................................................... 15

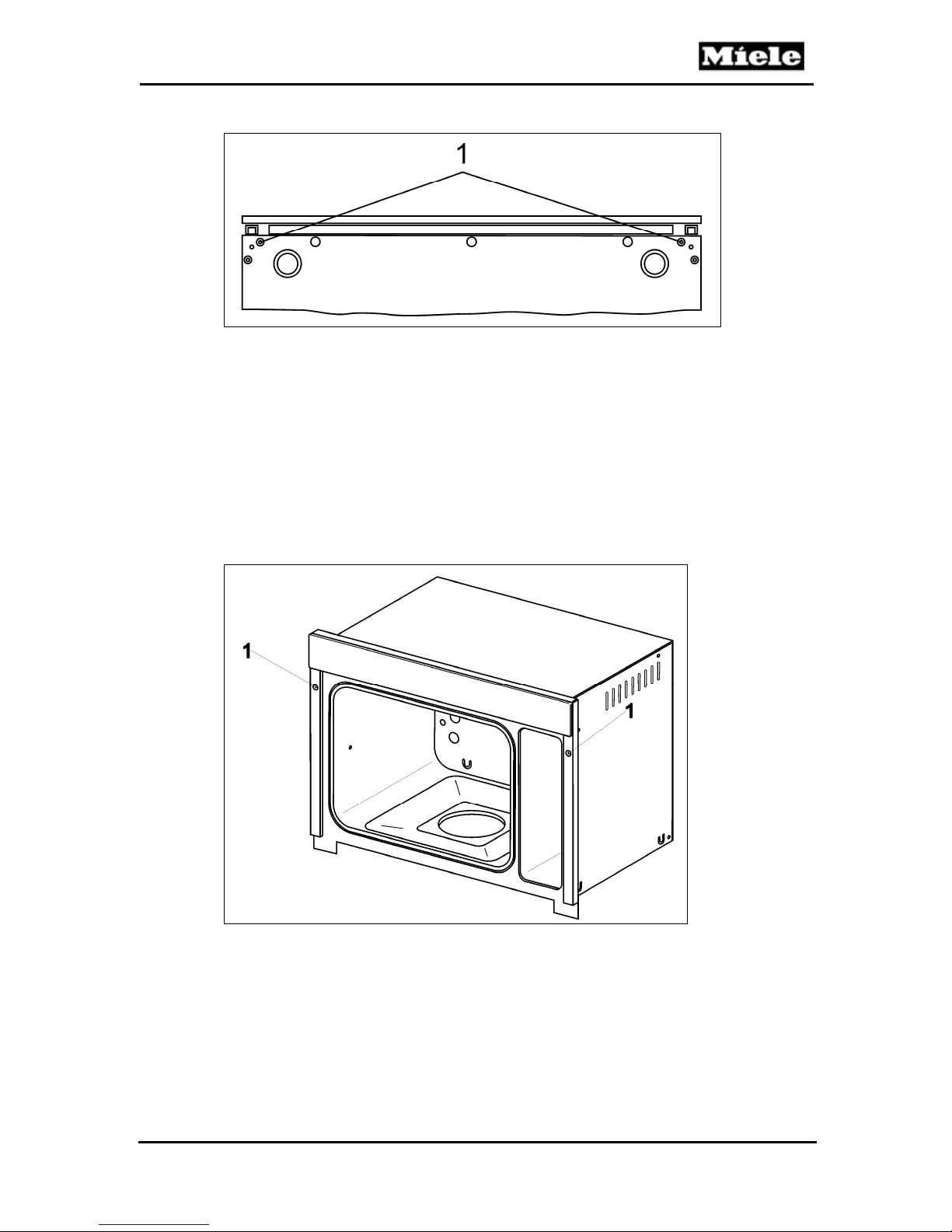

Figure 010-4: Side Panel Screws (DG 4082 Shown) ............................................................ 16

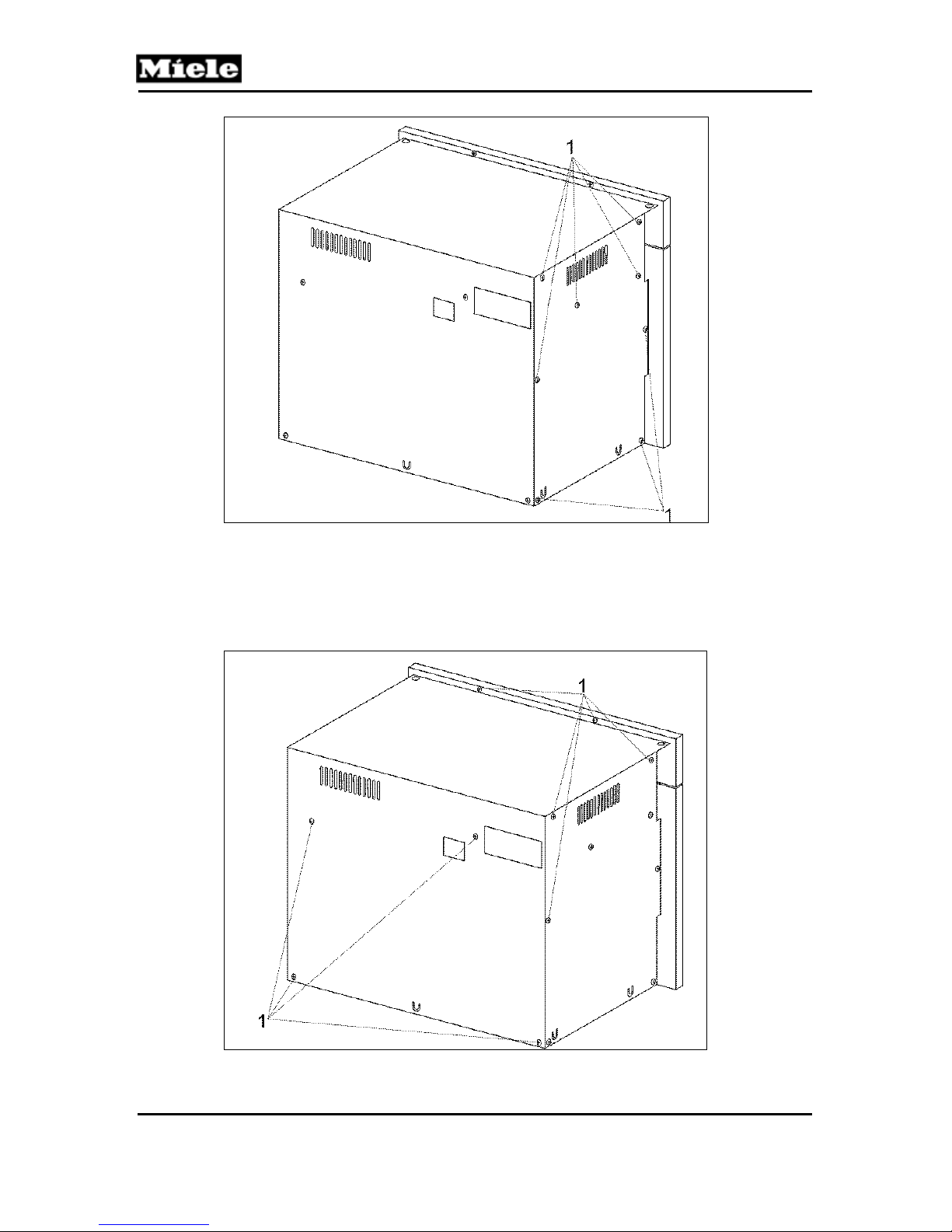

Figure 010-5: Rear Panel Screws ......................................................................................... 16

Figure 010-6: Fan Screws and C-Clip ................................................................................... 17

Figure 010-7: Fan Connections ............................................................................................. 17

Figure 010-8: Door Contact Switch Removal ........................................................................ 18

Figure 010-9 Fascia Fastening Screws ................................................................................. 19

Figure 010-10: Upper Air Duct Retaining Screws and Hose ................................................. 19

Figure 010-11: Silicone Seal ................................................................................................. 20

Figure 010-12: Front Lugs ..................................................................................................... 20

Figure 020-1: Hinge Clamps ................................................................................................. 22

Figure 020-2: Door Removal ................................................................................................. 22

Figure 020-3: Door Handle Removal ..................................................................................... 23

Figure 030-1: Temperature Sensor R30 Removal (DG 4080) ............................................... 26

Figure 030-2: Temperature Sensor R30/10 Removal (DG 4082) .......................................... 26

Figure 030-3: Floor Heater Cover ......................................................................................... 27

Figure 030-4: Floor Heater Removal (DG 4080) ................................................................... 27

Figure 030-5: Floor Heater Removal (DG 4082) ................................................................... 28

Figure 040-1: Steam Generator ............................................................................................ 30

Figure 040-2: Hose Clamp .................................................................................................... 32

Figure 040-3: Steam Generator Heater Contacts ................................................................. 33

Figure 040-4: Housing Base ................................................................................................. 34

Figure 040-5: Steam Generator Temperature Regulator and Temperature Limiter .............. 35

Figure 040-6: Steam Duct Retaining Screws ........................................................................ 35

Figure 040-7: Removing the Top Cover from the Steam Duct Assembly .............................. 36

Figure 040-8: Reed Contact Float ......................................................................................... 37

Figure 040-9: Steam Generator Present Switch ................................................................... 37

Figure 060-1 Optical Interface ............................................................................................... 39

Figure 060-2: EPL700 Electronic – Overview (DG 4080 Shown) .......................................... 40

Figure 060-3: AC Power Electrical Circuit (DG 4080) ........................................................... 41

Figure 060-4: Fascia Panel Assembly (DG 4080) ................................................................. 51

Figure 060-5: Control Electronic Screws (DG 4080) ............................................................. 52

Figure 060-6: Fascia Panel (DG 4082) ................................................................................. 52

Figure 060-7: Removing the Control Electronic (DG 4082) ................................................... 53

List of Tables

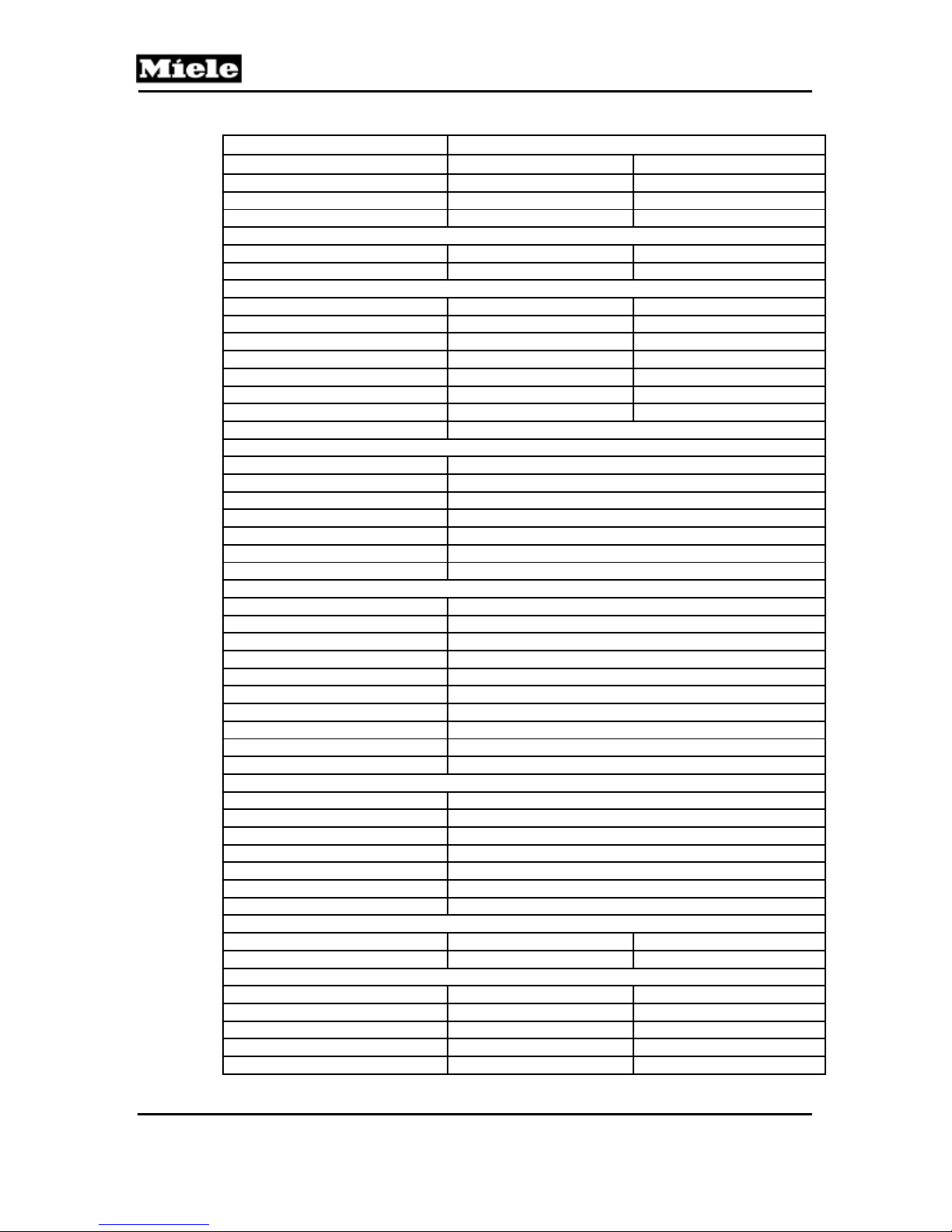

Table C-1: US Data Sheet ...................................................................................................... 6

Table 010-1: Cooling Fan Data ............................................................................................. 12

Table 030-1: Floor Heater Data ............................................................................................ 25

Table 030-2: PT 1000 Temperature Sensor Resistance Values ........................................... 25

Table 030-3: Threshold Temperatures .................................................................................. 25

Table 040-1: Steam Generator Data ..................................................................................... 30

Table 060-1: Fault Codes ...................................................................................................... 42

Table 060-2: Programming Mode ......................................................................................... 49

Table 060-3: Service Mode ................................................................................................... 50

4

DG 408x Steam Ovens

A Warning and Safety Instructions

Service may only be carried out by qualified electricians and in keeping

with the appropriate safety regulations.

All applicable guidelines, accident prevention rules and laws must be

observed.

Before service or repair work can be started, all cables carrying power

must be safely disconnected.

Even when the appliance is disconnected from power, elements may

carry voltage.

A general visual check must be performed at all times.

A touch current measurement must be conducted on all conductive parts

that are not connected to ground.

Wear protective gloves and use the edge protection (mat. no. 5057680) to

prevent cuts by sharp edges.

B Modification History

When? Who? What?

2/2/2012 Jessica Naples Tech service bulletins added

5/27/2010 Jessica Naples Compilation for Website

Technical Information

C Technical Data

Figure C-1: DG 408x

5

DG 408x Steam Ovens

Technical Information

Model

Design

Construction

Door stop

Dimensions

Appliance dimensions H x W x D 18.0” x 23.4” x 18.2” 17.9” x 23.6” x 16.7”

Depth with door open 30.8“ 30.8“

Niche dimensions

Height 17.6” – 17.8” 17.7”

Width 22.0” – 22.4” 22.0” – 22.4”

Depth min. 19.7” min. 19.7”

Weight

Capacity

Cavity height

Cavity base dimensions W x D

Levels in cavity (for racks)

Equipment

Vapor cooling system X

Water supply hookup —

System lock during operation X

Oven cavity floor heater X

Automatic steam reduction X

Recipe book X

Water tank capacity 1.3L

Operational features

Standard text display X

Recessed controls X

Temperature control 104 – 212°F

Automatic shutoff X

Fault indication X

Door contact switch X

Programmable cooking time X

Use of residual energy X

Steady water level indicator X

Warming function X

Operating modes

Cooking levels 4

Heat X

Defrost X

Descale X

Automatic programs X

Own favorites X

Interference suppressed X

Heaters

Floor heater 300W 350W

Steam generator 2200W 2200W

Power connection

Voltage (208) 240 VAC 240VAC

Frequency 60Hz 60Hz

Electrical connection NEMA 6-15 NEMA 6-15

Connected load 2500W 2700W

Fuse (circuit breaker) rating 15A 15A

DG 4080 DG 4082

Steam oven Steam oven

Built-in Built-in

Bottom Bottom

59.4 lbs 61.8 lbs

0.88 cu. ft. 0.88 cu. ft.

9.4” 9.5”

13.2” x 14.4” 13.2” x 14.4”

4 (incl. 1 for condensate tray)

Table C-1: US Data Sheet

6

DG 408x Steam Ovens

D Component Layouts

1 Appliance Overviews

Technical Information

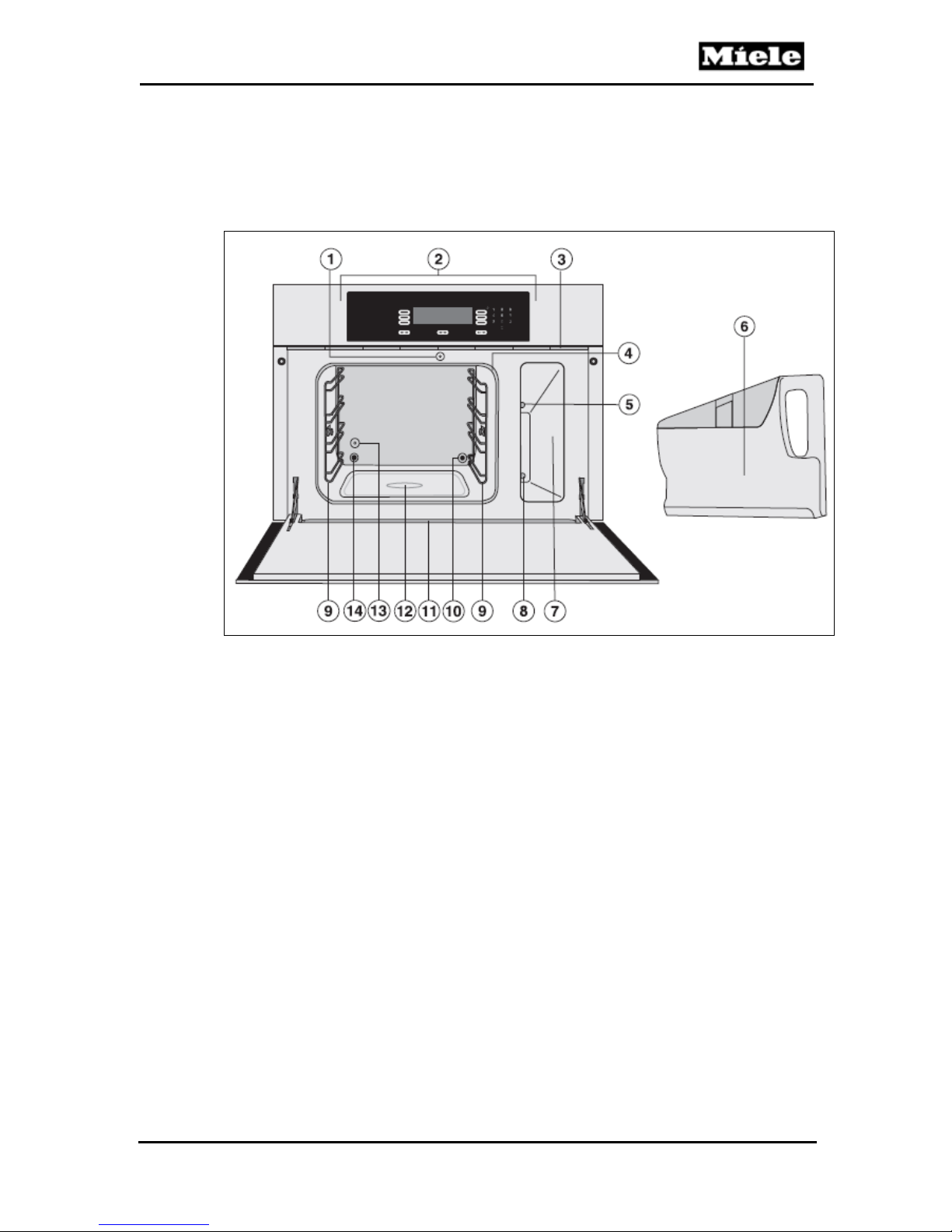

Figure D-1: Overview of DG 4080 (Front View)

1

Door release

2

Control panel

3

Air vent

4

Door seal

5

Steam channel

6

Steam generator (with insert)

7

Steam generator compartment

8

Steam generator electrical connection

9

Runners (4)

10

Steam port

11

Drip channel

12

Floor heater

13

Temperature sensor

14

Vent port

7

Technical Information

DG 408x Steam Ovens

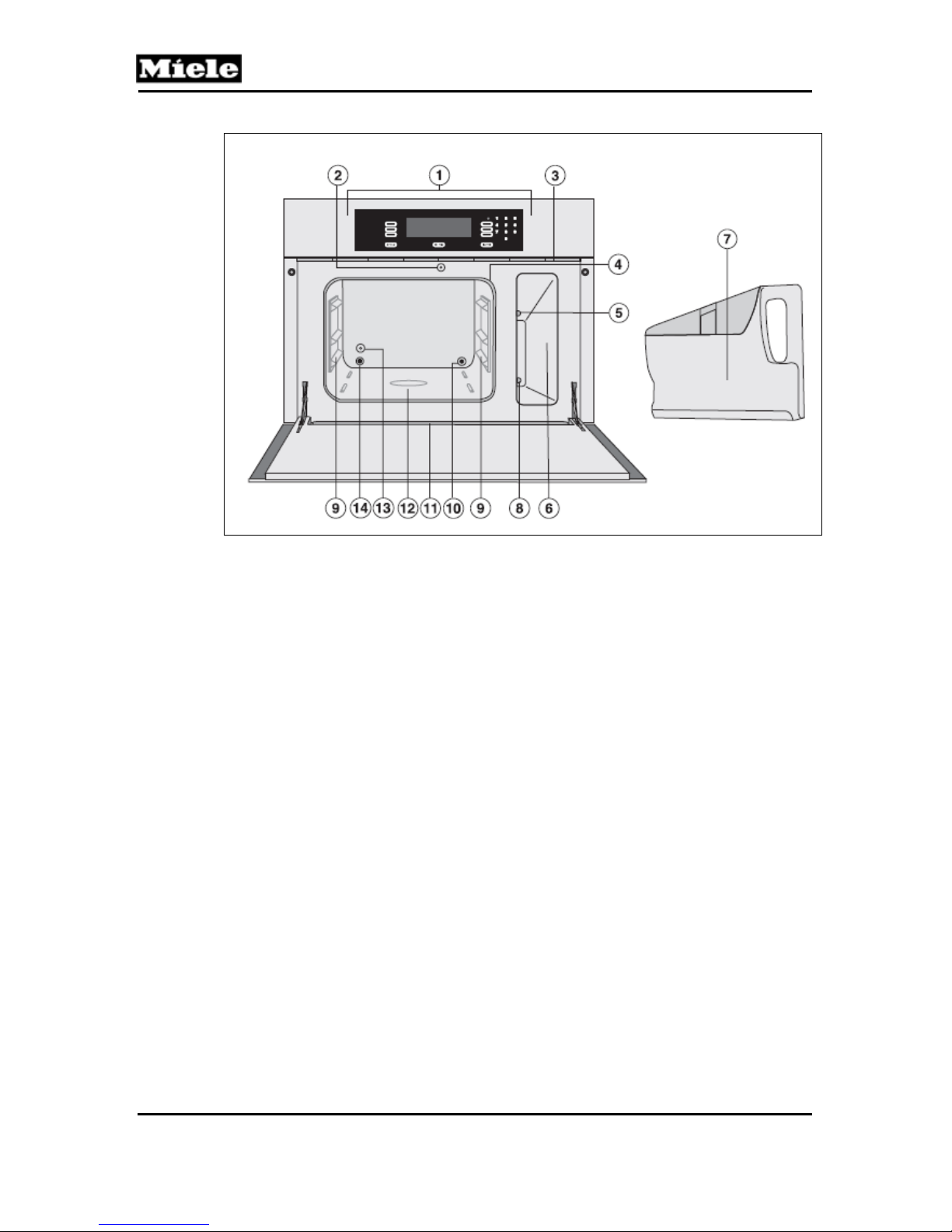

Figure D-2: Overview of DG 4082 (Front View)

1

Control panel

2

Door release

3

Air vent

4

Door seal

5

Steam channel

6

Steam generator compartment

7

Steam generator (with insert)

8

Steam generator electrical connection

9

Runners

10

Steam port

11

Drip channel

12

Floor heater

13

Temperature sensor

14

Air vent

8

DG 408x Steam Ovens

–

–

–

–

2 Electrical Components

Technical Information

Figure D-3: DG 4080 Electrical Components

1

(2F1, 2F8) Floor heater temperature regulator (239°F) and

temperature limiter (402°F)

2

(S4) Door contact switch

3

(R28) Floor heater

4

(1N1) Selection electronic EW

5

(2N1) Control electronic EPX

6

(3N1) Power electronic EPL

(1K1/1, 2K1/1) Steam generator relay (not shown)

(K1/3) Floor heater relay (not shown)

(K1/5) Fan relay (not shown)

(K1/61) Release element relay (not shown)

7

(Z2) Interference suppression capacitor

8

(Y56) Release element

9

(X2) Socket for power cable

10

(X7) Plug strip

11

(R30) PT1000 temperature sensor

12

(M2) Fan

13

(S12) Water level float switch (PCB)

14

(S84) Steam generator present switch

15

(1R25, 2R25) Steam generator heater elements

16

(1F1, 1F8) Steam generator temperature regulator (410°F)

and temperature limiter (568°F)

9

Technical Information

DG 408x Steam Ovens

Figure D-4: DG 4082 Electrical Components

1

(2F1, 2F8) Floor heater temperature regulator (239°F) and

temperature limiter (402°F)

2

(R28) Floor heater

3

(S4) Door contact switch

4

(2N1) Control/selection electronic EW

5

(R30/10) PT1000 temperature sensor

6

(1N1) Power electronic

7

(X2) Power socket

8

(Z2) Interference suppression capacitor

9

(Y56) Release element

10

(X7) Plug strip

11

(M2/1) Cooling fan

12

(S84) Steam generator switch

13

(S12) Water level float switch (PCB)

14

(1R25, 2R25) Steam generator heater

15

(1F1, 1F8) Steam generator temperature regulator (410°F)

and temperature limiter (568°F)

10

DG 408x Steam Ovens

010 Casing

Technical Information

DG 4080 DG 4082

11

Technical Information

1 Technical Data

Cooling fan M2 (DG 4080) or M2/1 (DG 4082)

Voltage 240VAC, 60Hz

Output 15W

Table 010-1: Cooling Fan Data

2 Function

2.1 Air and Vapor Ducting

DG 408x Steam Ovens

Figure 010-1: Ducting

1

Steam inlet

2

Oven vent hose

3

Cool air/vapor outlet

4

Cool air inlet

5

Release element for steam reduction (door opener)

6

Steam vent hose

During the cooking process, fresh steam is pumped into the oven cavity

(Figure 010-1, Item 1). The generated vapors are pushed out through the

vent opening. Through a hose at the rear of the oven cavity, the vapors move

12

DG 408x Steam Ovens

to the air duct (Figure 010-1, Item 2). The fan draws in cool air through the air

vents in the housing, and the cool air mixes with the vapors in the air duct

(Figure 010-1, Item 4). The cool air/vapor mix is expelled through the gap

between the fascia and the oven cavity (Figure 010-1, Item 3). Excess steam

from the steam generator is carried directly to the fan via the vent hose

(Figure 010-1, Item 6) and pushed out at the front of the appliance. Shortly

before cooking time is up, relay K1/61 activates the release element, which

causes a metal rod to slowly open the door a crack. This reduces the steam

in the oven cavity. See Figure 010-1, Item 5. Once the buzzer sounds to

indicate the end of cooking time, the door slowly closes.

2.2 Fan Coastdown

To reduce the vapors that are still in the oven cavity after cooking has ended,

the fan continues running after the appliance is switched off.

This prevents

steam from settling on the fascia of the cabinetry when opening the door

condensate from forming in the housing by residual steam.

Coastdown duration depends on whether or not the steam generator has

been removed from the appliance after the cooking process. Warm cooked

food in the appliance delays the cooling and leads to a longer coastdown

time. Coastdown time is not adjustable!

Technical Information

If steam generator was removed: Coastdown takes at least 8 minutes. If

after the first 8 minutes the interior temperature has not dropped below

113°F (45°C), then the coastdown time is extended for an additional 8

minutes until the interior temperature drops below 113°F (45°C).

If steam generator was not removed: Coastdown takes at least 60

minutes. If after the first 60 minutes the interior temperature has not

dropped below 113°F (45°C), then the cooldown time is extended for an

additional 8 minutes until the interior temperature drops below 113°F

(45°C).

2.3 Door Contact Switch (S24)

If the door is opened during the cooking process, the door contact switch

signals the control electronic, which switches off the steam generator heater

(1R25, 2R25).

Note:

With the door open a crack, new cooking selections can be made.

However, the steam generator heater will not be switched on for

approximately one to two minutes.

2.4 Release Element (Y56) for Steam Reduction

Shortly before cooking time is up, relay K1/61 activates the release element,

which slowly opens the door a crack. This reduces the steam in the oven

cavity. After the buzzer sounds to signal the end of cooking time, the door

slowly closes again.

While the door is open a crack, new cooking selections can be made.

However, the steam generator heater will not be switched on for

approximately one to two minutes.

13

Technical Information

3 Fault Repair

3.1 Fan Coastdown Too Long

Symptom:

Coastdown is at least 8 minutes and can be more than 60 minutes.

Cause:

Steam generator remains in the appliance after cooking has ended.

Coastdown duration depends on whether or not the steam generator has

been removed from the appliance after the cooking process. Warm cooked

food in the appliance delays the cooling and leads to a longer coastdown.

Coastdown time is not adjustable!

Steam generator was removed: Coastdown takes at least 8 minutes. If

after the first 8 minutes the interior temperature has not reduced to below

113°F (45°C), then the coastdown is extended for an additional 8 minutes

until the interior temperature drops below 113°F (45°C).

Steam generator was not removed: Coastdown takes at least 60

minutes. If after 60 minutes the oven cavity temperature has not dropped

below 45°C, the coastdown duration is extended in increments of 8

minutes until the oven cavity temperature is below 45°C. In addition, if

food remains in the oven cavity, the cooling-off period is delayed and

causes a longer coastdown.

DG 408x Steam Ovens

Remedy:

1. Remove steam generator and cooked food after a cooking program.

2. Leave door open.

3. Empty steam generator before inserting it again.

3.2 Top Clearance Too Small When Combined with Warming Drawer (DG 4080)

Symptom:

When combining the appliance with the built-in EGW 4000 warming drawer,

the clearance on top to the cabinetry is too small. This becomes particularly

obvious if other Miele machines are built in next to it.

Cause:

Two screw heads at the bottom of the appliance meet exactly with rivets at

the top of the EGW 4000 warming drawer. This causes the appliance to be

positioned slightly higher, and the gap within the cabinetry to be insufficient to

allow proper installation.

Series modification:

The position of the rivets on the warming drawer has been changed so that

the screw caps will not meet the rivets.

Remedy:

Note:

Both screws can be permanently removed, since they are only used during

production and will not have any adverse effects if removed.

Remove both screws (Figure 010-2, Item 1).

14

DG 408x Steam Ovens

Technical Information

Figure 010-2: Screws on the Bottom of the Appliance (DG 4080)

4 Service

4.1 Removing the Appliance from its Niche

1. Open the door.

2. Take the steam generator and equipment out of the oven cavity.

3. Remove the appliance retaining screws (Figure 010-3, Item 1).

4. Slide the appliance out of its niche.

5. Disconnect the appliance from the power supply.

Figure 010-3: Appliance Retaining Screws

4.2 Removing the Side Panels

1. Uninstall the appliance. See Section 010-4.1.

2. Remove the side panel screws; see Figure 010-4, Item 1.

3. Take off the side panel(s).

15

Technical Information

DG 408x Steam Ovens

Figure 010-4: Side Panel Screws (DG 4082 Shown)

4.3 Rear Panel Removal

1. Uninstall the appliance. See Section 010-4.1.

2. Remove the T20 screws securing the rear panel (Figure 010-5, Item 1).

3. Remove the rear panel.

Figure 010-5: Rear Panel Screws

16

DG 408x Steam Ovens

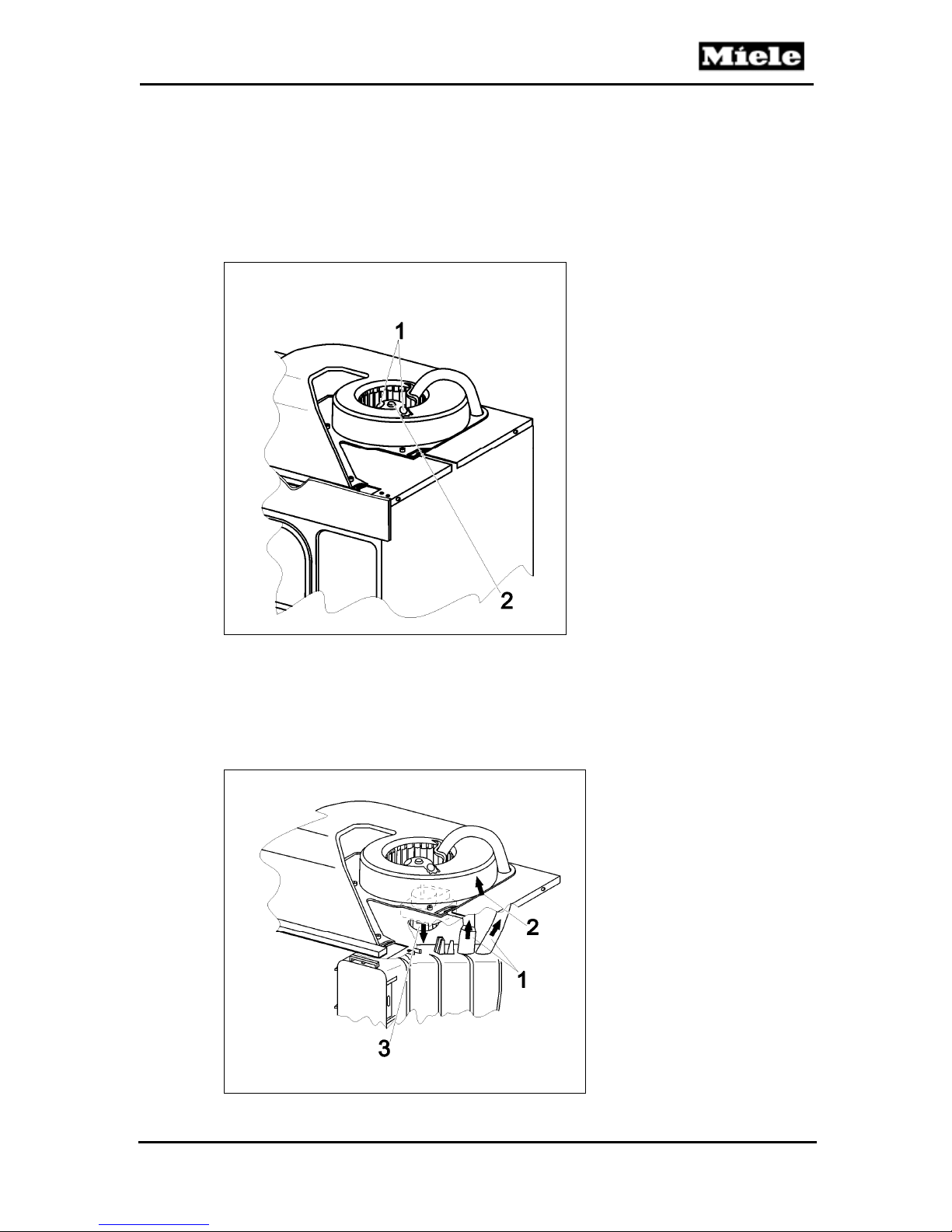

4.4 Fan (M2/1) Removal

1. Uninstall the appliance. See Section 010-4.1.

2. Remove the right side panel. See Section 010-4.2.

3. Remove the screws securing the fan (Figure 010-6, Item 1).

4. Remove the C-clip securing the blower wheel (Figure 010-6, Item 2).

5. Turn the blower wheel as necessary to permit access to the motor

mounting screws.

Technical Information

Figure 010-6: Fan Screws and C-Clip

6. Disconnect hoses (Figure 010-7, Item 1) as necessary to access the fan

motor from the underside of the air duct.

7. Raise the air duct slightly (Figure 010-7, Item 2) and take out the fan

motor (Figure 010-7, Item 3).

8. Disconnect all fan connections.

Figure 010-7: Fan Connections

17

Loading...

Loading...