Page 1

Mira P

Product Manual

8.0924.8001EN / 2019-03-29

Page 2

Page 3

Metrohm AG

Ionenstrasse

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

Mira P

Product Manual

8.0924.8001EN /

2019-03-29

Page 4

Technical Communication

Metrohm AG

CH-9100 Herisau

techcom@metrohm.com

This documentation is protected by copyright. All rights reserved.

This documentation has been prepared with great care. However, errors

can never be entirely ruled out. Please send comments regarding possible

errors to the address above.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

■■■■■■■■

III

Table of contents

1 Overview 1

1.1 Instrument description ......................................................... 1

1.2 Model versions ...................................................................... 1

1.3 Mira Cal Software ................................................................. 2

1.4 About the documentation ................................................... 2

1.5 Additional information - Software tutorials ....................... 4

1.5.1 Accessories .............................................................................. 4

2 Safety 5

2.1 Product safety ....................................................................... 5

2.2 Hazard levels ......................................................................... 5

2.3 Intended use ......................................................................... 6

2.4 Residual risks ........................................................................ 7

2.4.1 General dangers at the workplace ........................................... 7

2.4.2 Danger from electrical potential ............................................... 8

2.4.3 Laser safety ............................................................................. 8

2.4.4 Warning stickers on the instrument ........................................ 10

2.5 Responsibility of the operator ........................................... 11

2.6 Personnel requirement ....................................................... 12

3 Overview of the instrument 13

4 Transport and storage 17

4.1 Checking the delivery ......................................................... 17

4.2 Storing the packaging ........................................................ 17

4.3 Storage ................................................................................ 17

5 Installation 18

5.1 Power supply with batteries .............................................. 18

5.2 USB connection ................................................................... 21

6 Initial configuration 23

7 Operation and control 24

7.1 Smart tips – Overview ........................................................ 24

7.2 Attaching smart tips ........................................................... 27

7.3 Data acquisition .................................................................. 35

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

IV

■■■■■■■■

7.4 Calibrate an instrument ..................................................... 38

7.5 Configuration ...................................................................... 39

8 Maintenance 41

8.1 Maintenance agreement .................................................... 41

8.2 Checking and replacing product parts .............................. 41

8.3 Cleaning the product .......................................................... 42

9 Disposal 44

10 Technical specifications 45

10.1 Ambient conditions ............................................................ 45

10.2 Interfaces ............................................................................. 45

10.3 Power Supply ...................................................................... 45

10.4 Dimensions and materials .................................................. 46

10.5 Operating specifications .................................................... 47

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Overview

■■■■■■■■

1

1 Overview

1.1 Instrument description

Metrohm Instant Raman Analyzers (Mira) are handheld, high-power

Raman spectrometers designed for the rapid, nondestructive identification

and verification of chemical and pharmaceutical samples, both liquid and

solid. Barely larger than a smartphone, the Mira spectrometers are the

only handheld Raman spectrometers currently on the market with Orbital

Raster Scan (ORS) technology.

1.2 Model versions

Mira P instruments are available in the following versions:

Table 1

Model versions

2.927.0010 Mira P Basic (1.927.0010)

■ With Calibrate/Verify Attachment

(CVA)

■ With Vial Holder

Laser class 1

2.927.0020 Mira P Advanced (1.927.0020)

■ With Calibrate/Verify Attachment

(CVA)

■ With Vial Holder

■ Short Working Distance Attach-

ment Lens (SWD)

■ Long Working Distance Attach-

ment Lens (LWD)

Laser class 3B

NOTICE

You can find the accessories for your product version on the Internet

at http://partslists.metrohm.com. There you can download the list of

accessories as a PDF file.

Page 8

Mira Cal Software

■■■■■■■■■■■■■■■■■■■■■■

2

■■■■■■■■

1.3 Mira Cal Software

In order to configure a Mira P instrument, the following software is needed:

Table 2 Model versions

606071010 Mira Cal P

1.4 About the documentation

NOTICE

Please read through this documentation carefully before putting the

product into operation.

The document contains important safety information and warnings

which you must follow in order to ensure safe operation of the instrument. Metrohm is not responsible for damages and safety hazards

that occur from using the instrument in a manner that is not specified

in the user manual.

Symbols and conventions

The following icons and formatting may appear in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the second to the product part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Method Designations for names of parameters, menu items,

tabs and dialog windows in the software.

File ▶ New Menu or menu item

Work area /

Properties

Menu paths in order to arrive at a particular position

in the software.

[Next] Button or key

Proprietary information statement

This manual contains the valuable proprietary information of Metrohm

Raman, Inc. and its affiliates, including all designs and related material,

and such information is disclosed in confidence. It is intended solely for

Page 9

■■■■■■■■■■■■■■■■■■■■■■

Overview

■■■■■■■■

3

the information and use of the persons operating and maintaining the

equipment described herein. No part of this manual may be reproduced,

copied, translated, incorporated in any other material, disclosed or transmitted in any form or by any means, whether electronic, mechanical, photocopying, recording, or otherwise to any other persons for any other purpose without the express written permission of Metrohm Raman, Inc. To

obtain such permission, or to obtain additional copies of this manual,

please contact Metrohm Raman, Inc.

Continuous improvements

To remain the leader of the industry, Metrohm Raman, Inc. has a policy of

continuous improvement of its products. As such, all products, product

specifications, data and operating instructions are subject to change without notice.

Liability disclaimer

Metrohm Raman, Inc. and its affiliates take steps to assure that their published specifications and manuals are correct. Nevertheless, errors do

occur. Metrohm Raman, Inc. and its affiliates reserve the right to correct

any such errors and disclaim all liability resulting therefrom. The equipment described in this manual is warranted in accordance with the terms

of Metrohm Raman, Inc.’s warranty. However, actual performance of such

equipment is dependent upon factors such as system configuration, customer data and operator control. Since implementation by customers of

the equipment may vary, the suitability of specific equipment configurations and applications must be determined by the customer and is not

warranted by Metrohm Raman, Inc. or its affiliates.

Export control statement

These items are controlled by the U.S. Government and authorized for

export only to the country of ultimate destination for use by the ultimate

consignee or end-user(s) identified on the invoice. They may not be resold,

transferred, or otherwise disposed of, to any other country or to any person other than the authorized ultimate consignee or end-user(s), either in

their original form or after being incorporated into other items, without

first obtaining approval from the U.S. Government or as otherwise authorized by U.S. law and regulations.

No liability for certain damages

Metrohm Raman, Inc., its affiliates, and anyone else involved in the

design, manufacture, or delivery of the accompanying product (including

hardware and software) shall not be liable, under any circumstances, for

any loss of profits or any special, incidental, consequential, exemplary, or

punitive damages whatsoever (including, without limitation, damages

resulting from cost of replacement, loss of use, loss of data, loss of royalties, loss of profits, loss of revenue, loss of business, loss of prospective

economic advantage, or failure or delay in performance) arising out of the

Page 10

Additional information - Software tutorials

■■■■■■■■■■■■■■■■■■■■■■

4

■■■■■■■■

use of or inability to use such product, even if Metrohm Raman, Inc. or its

affiliates have been notified of the possibility of such damages.

1.5 Additional information - Software tutorials

Refer to following software tutorials for more information:

■ Mira Cal P tutorial: 8.0105.8004EN

1.5.1 Accessories

Up-to-date information on the scope of delivery and optional accessories

for your product can be found on the Internet. You can download this

information using the article number as follows:

Downloading the accessories list

1

Enter https://www.metrohm.com/ into your Internet browser.

2

Enter the article number of the product (e.g. 2.1001.0010) into the

search field.

The search result is displayed.

3

Click on the product.

Detailed information regarding the product is shown on various tabs.

4

On the Included parts tab, click Download the PDF.

The PDF file with the accessories data is created.

NOTICE

When you receive your new product, we recommend downloading

the accessories list from the Internet, printing it out and keeping it for

reference purposes.

Page 11

■■■■■■■■■■■■■■■■■■■■■■

Safety

■■■■■■■■

5

2 Safety

2.1 Product safety

This product exhibited no flaws in terms of technical safety at the time it

left the factory. To preserve this status and ensure non-hazardous operation of the product, the following instructions must be observed carefully.

2.2 Hazard levels

The following warning messages indicate the severity of the danger and

its possible effects.

DANGER

Immediate danger of life

Irreversible injuries that will result in death.

Warns of dangerous situations or unsafe actions that will most certainly cause severe injuries or death.

Lists measures to avoid hazard.

WARNING

Severe health hazards

Serious injuries that could result in death.

Warns of dangerous situations or unsafe actions that could result in

serious injuries or death.

Lists measures to avoid hazard.

Page 12

Intended use

■■■■■■■■■■■■■■■■■■■■■■

6

■■■■■■■■

CAUTION

Health hazards or severe property damage

Warns of dangerous situations or unsafe actions that could result in

moderate injuries or considerable property damage.

Lists measures to avoid hazard.

2.3 Intended use

Metrohm products are used for the analysis and handling of chemicals

and other materials.

Usage therefore requires the user to have basic knowledge and experience

in handling chemicals. Knowledge with respect to the application of the

fire prevention measures prescribed for laboratories is also mandatory. Be

sure to take proper safety precautions when working with chemicals

Adherence to this technical documentation and compliance with the

maintenance specifications make up an important part of intended use.

Any utilization in excess of or deviating from the intended use is regarded

as misuse.

Specifications regarding the operating values and limit values of individual

products are contained in the "Technical specifications" section, if relevant.

Exceeding and/or not observing the mentioned limit values puts people

and components at risk. The manufacturer assumes no liability for damage

due to non-observance of these limit values.

The EU declaration of conformity loses its validity if modifications are carried out on the instruments and/or the components.

Page 13

■■■■■■■■■■■■■■■■■■■■■■

Safety

■■■■■■■■

7

2.4 Residual risks

2.4.1 General dangers at the workplace

Generally, the regulations and provisions of the regulatory institutions and

authorities in the field of work apply.

The instructions regarding the following areas have to be followed when

using the products:

■ Work safety

■ Handling mechanical installations

■ Handling electricity

■ Handling hazardous and environmentally damaging substances

■ Handling hazardous and environmentally damaging liquids

■ Disposing hazardous and environmentally damaging substances

If they are not followed, this may result in:

■ Disturbing, injuring and/or killing of people

■ Malfunction and/or damage to instruments and infrastructure

■ Damage and/or contamination of the environment

WARNING

General dangers at workplace

If the safety measures are not followed, working in a laboratory bears

a high risk of injury, which can endanger your life and health.

■ Only professionally trained and qualified specialist personnel may

operate the products.

■ Follow the applicable provisions concerning work safety and all

regulations on wearing protective clothing.

■ Use suitable tools to perform your work.

■ Check the fill level of waste bottles or waste canisters and analysis

vessels, and make sure they do not overflow.

■ Use protective grounding when working with highly flammable

substances and gases.

Page 14

Residual risks

■■■■■■■■■■■■■■■■■■■■■■

8

■■■■■■■■

2.4.2 Danger from electrical potential

WARNING

Electric shock from electrical potential

Risk of injury by touching live components or through moisture on

live parts.

■ Never open the housing of the instrument.

■ Protect live parts (e.g. power supply unit, power cord, connection

sockets) against moisture.

■ If you suspect that moisture has gotten into the instrument, dis-

connect the instrument from the energy supply. Then notify Metrohm Service.

■ Only personnel who have been issued Metrohm qualification may

perform service and repair work on electrical and electronic components.

2.4.3 Laser safety

NOTICE

NOHD

The following information refers to NOHD for Mira P instruments in

accordance with the international standard IEC 60825-1, "Safety of

laser products".

The nominal ocular hazard distance (NOHD) is listed in technical specifications page 47.

Page 15

■■■■■■■■■■■■■■■■■■■■■■

Safety

■■■■■■■■

9

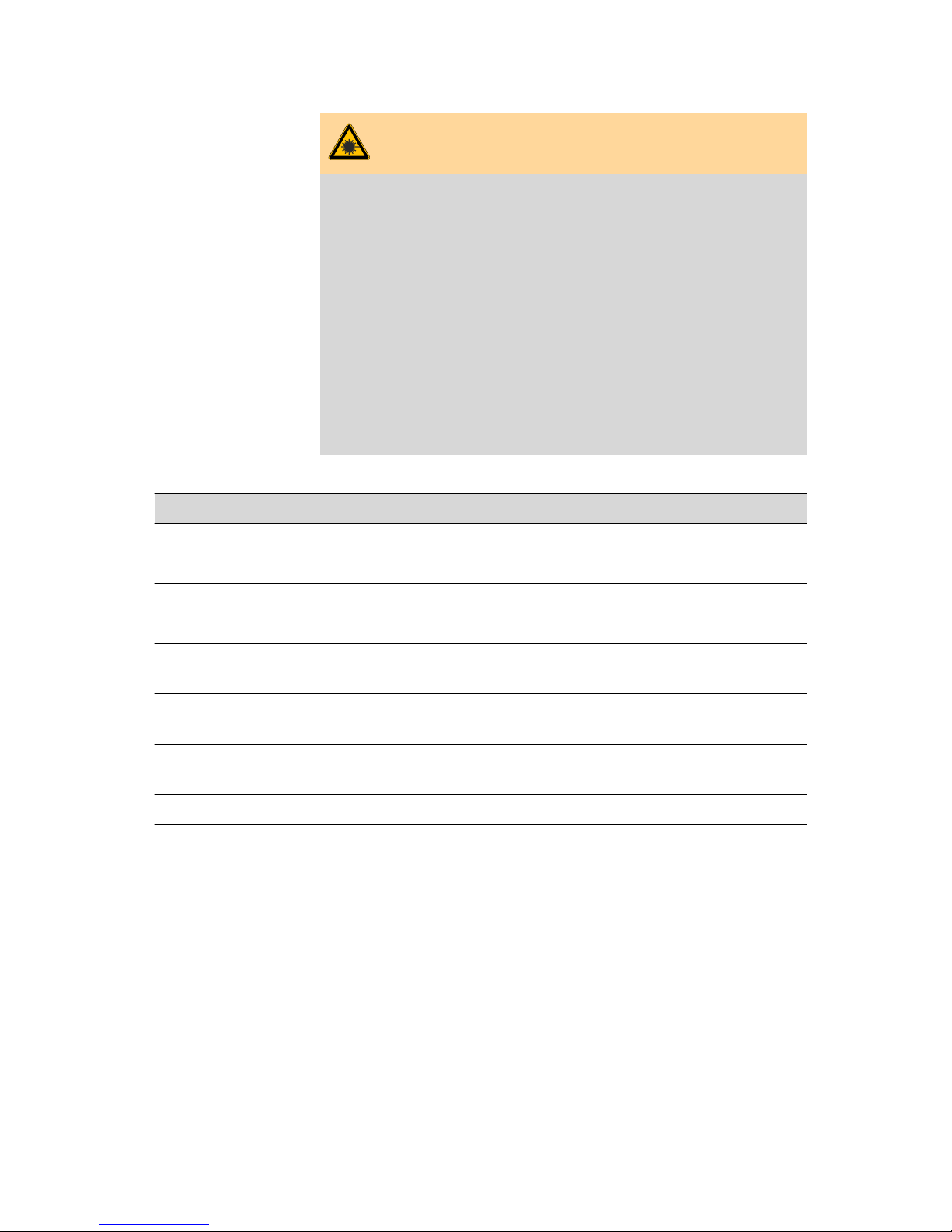

WARNING

Risk of injury by laser radiation

Serious eye injuries by laser radiation.

■ Follow the safety measures and instructions.

■ Instruments must be used by trained personnel only.

■ Instruments of the laser class 3B must be used in protected and

labeled rooms only.

■ The protective glasses provided must be used when working with

open laser beams (e.g. attachment lens).

■ Observe the nominal ocular hazard distance (NOHD).

■ Follow the provisions of the IEC 60825-1 standard "Safety of laser

products" and the regulations for the use of laser systems in your

country.

Laser classification depending on smart tips

Attached smart tip

Laser Class 1 Laser Class 3B

Right Angle Attachment X

Contact Ball-Probe X

Calibrate/Verify Attachment (CVA) X

Vial Holder X

Short Working Distance Attachment Lens

(SWD)

X

Long Working Distance Attachment Lens

(LWD)

X

Extra Long Working Distance Attachment Lens

(XLWD)

X

Tablet Holder X

Vial Holder, Tablet Holder and CVA have an interlock mechanism for measurement. This mechanism prevents laser radiation from emerging.

Laser stops immediately if:

■ The lid of the smart tip is opened.

■ Attached smart tip is disconnected from the instrument.

Page 16

Residual risks

■■■■■■■■■■■■■■■■■■■■■■

10

■■■■■■■■

2.4.4 Warning stickers on the instrument

The instrument is equipped with stickers that warn of potential hazards.

These warning stickers are listed and explained below.

1

Laser aperture

2

Laser aperture sticker

3

Laser specification / serial number (bottom of instrument)

4

Laser class

5

Type plate

6

Bluetooth label

Laser aperture

Figure 1

Sticker - Emergence of laser

Page 17

■■■■■■■■■■■■■■■■■■■■■■

Safety

■■■■■■■■

11

Laser specification / serial number

Figure 2 Sticker - laser data / serial number / standards

Laser class

The following laser classification is used for all Mira instruments.

Figure 3

Sticker - Mira instrument with attachment lenses

2.5 Responsibility of the operator

■ Eliminate defects or damage which impair operating safety without

delay.

■ Eliminate malfunctions which could impair safety without delay.

■ The rules, regulations and instructions listed in the present document

are not the only valid ones. Comply with the applicable statutory rules,

government agency directives and regulations.

■ Unauthorized modification of the products excludes any and all liability

on the part of the manufacturer for any damage resulting from this as

well as for any consequential damage. No modifications, attachments

or conversions which could impair safety may be carried out on the

products without the approval of the manufacturer.

■ Spare parts must meet the technical requirements established by the

manufacturer. Original spare parts always meet these requirements.

■ Personnel must be familiar with this safety-relevant information and it

must be available for consultation at all times.

Page 18

Personnel requirement

■■■■■■■■■■■■■■■■■■■■■■

12

■■■■■■■■

2.6 Personnel requirement

Only qualified personnel may operate the present product.

Qualified personnel are people authorized by the safety responsible to

carry out the necessary operations. They are capable of recognizing and

avoiding possible dangers. These people are qualified due to their professional training, experience and/or instruction. They know the relevant

standards, laws, provisions, accident prevention regulations and the company conditions.

Page 19

■■■■■■■■■■■■■■■■■■■■■■

Overview of the instrument

■■■■■■■■

13

3 Overview of the instrument

Front

Figure 4 Mira P - Front

1

Magnetic smart tip fixture/ laser aperture

2

Touch screen

3

Battery compartment

4

Type B mini USB connector

5

On/off switch

Page 20

■■■■■■■■■■■■■■■■■■■■■■

14

■■■■■■■■

Rear

Figure 5 Mira P - Rear

1

Barcode reader

2

Accessories covering

3

Long Working Distance Attachment

Lens (LWD) Storage

4

Short Working Distance Attachment

Lens (SWD) Storage

Case

The instrument and attachments are delivered in a case.

Page 21

■■■■■■■■■■■■■■■■■■■■■■

Overview of the instrument

■■■■■■■■

15

Figure 6 Mira P - Case

1

Vials

2

Right Angle Attachment

3

Universal Attachment

4

Extra Long Working Distance Attachment (XLWD)

5

Extra Long Working Distance Attachment (XLWD)

6

Calibrate/Verify Attachment (CVA)

7

Contact Ball-Probe

8

Calibration Standard

9

Mira P

10

Stick with Mira Cal P

11

Batteries

12

Tablet Holder

13

Vial Holder

14

Manual

Page 22

■■■■■■■■■■■■■■■■■■■■■■

16

■■■■■■■■

NOTICE

The following attachments are optional:

■ Contact Ball-Probe

■ Right Angle Attachment

■ Tablet Holder

■ XLWD

Page 23

■■■■■■■■■■■■■■■■■■■■■■

Transport and storage

■■■■■■■■

17

4 Transport and storage

4.1 Checking the delivery

Immediately upon arrival of the merchandise, check the shipment against

the delivery note to ensure completeness and absence of damage.

4.2 Storing the packaging

The product is supplied in extremely protective packaging together with

the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the product.

4.3 Storage

NOTICE

Always remove batteries if the instrument is not in use.

Page 24

Power supply with batteries

■■■■■■■■■■■■■■■■■■■■■■

18

■■■■■■■■

5 Installation

5.1 Power supply with batteries

Changing batteries

The instrument uses exchangeable or rechargeable batteries of type AA/

LR6.

NOTICE

Battery type

We recommend to use AA Energizer® Ultimate Lithium™ batteries.

We also support rechargeable NiMH Panasonic eneloop pro™ batteries.

NOTICE

Power save mode

If you use the Mira P with batteries, you can configure a shutdown

delay to save power (see "Shutdown Delay", page 39).

Open the battery compartment

Pull the lever.

Page 25

■■■■■■■■■■■■■■■■■■■■■■

Installation

■■■■■■■■

19

Push the lateral cover upwards.

Open the lateral cover.

Open the top cover.

The battery compartment is now open.

Page 26

Power supply with batteries

■■■■■■■■■■■■■■■■■■■■■■

20

■■■■■■■■

Close the battery compartment

Rotate the lateral cover.

Push the lateral cover down to the limit.

Page 27

■■■■■■■■■■■■■■■■■■■■■■

Installation

■■■■■■■■

21

The battery compartment is now closed.

5.2 USB connection

NOTICE

We do not recommend to use third party USB cables, only use the

provided Metrohm USB Mini-B cable (order number 6.215.1110).

Power supply

For stationary use in the laboratory, you can operate the instrument with

the USB interface which is connected to a powered USB hub. The USB

hub also allows data transfer.

NOTICE

Battery charging function

The instrument has no charging function for rechargeable batteries.

You must replace drained batteries.

Synchronization

Connect the instrument to the computer that uses the USB Mini-B cable.

If the instrument is off, connecting the USB cable to a computer initiates

an instrument start-up.

Page 28

USB connection

■■■■■■■■■■■■■■■■■■■■■■

22

■■■■■■■■

Refer to the Mira Cal P software tutorial for further steps Additional information - Software tutorials (see chapter 1.5, page 4).

Page 29

■■■■■■■■■■■■■■■■■■■■■■

Initial configuration

■■■■■■■■

23

6 Initial configuration

NOTICE

Configuration

Use Mira Cal P software to change instrument settings or to install

spectral libraries.

Refer to Mira Cal P software tutorial for detailed information Addi-

tional information - Software tutorials (see chapter 1.5, page 4).

Page 30

Smart tips – Overview

■■■■■■■■■■■■■■■■■■■■■■

24

■■■■■■■■

7 Operation and control

7.1 Smart tips – Overview

The following smart tips are available.

Smart tips are attached to the instrument with magnetic connectors. The

smart tips contain a memory chip so that the instrument can identify

them. Due to design, smart tips will not allow operation of Mira P when

seated in an incorrect position.

The following attachments are within scope of delivery of Mira P

Advanced:

■ Calibrate/Verify Attachment (CVA)

■ Short Working Distance Attachment Lens (SWD)

■ Long Working Distance Attachment Lens (LWD)

■ Vial holder

You can purchase other attachments separately from Metrohm AG Accessories (see chapter 1.5.1, page 4).

Page 31

■■■■■■■■■■■■■■■■■■■■■■

Operation and control

■■■■■■■■

25

1

Contact Ball-Probe (6.07506.030)

The Contact Ball-Probe Attachment is an

optional attachment.

The Contact Ball-Probe Attachment allows

to collect data from a substance with no

concern of proper focus. Simply contact the

substance with the probe to acquire the

data.

The 6” (15.3 cm) stainless steel construction

allows for easy cleaning.

The focal point on the probe is 400 microns

from the tip of the lens. This means the

probe will not perform well on substances

through a bag. The probe is designed for

direct contact of liquids and solids.

Sleeves are available to prevent contamination of the Contact Ball-Probe.

Class 3B laser operation.

2

Tablet Holder (6.07504.000)

The Tablet Holder is an optional attachment.

The Tablet Holder is used for different tablet

or capsule shapes. A spring-loaded holder

helps to mount and position the sample.

Interlock mechanism allows measurement

with class 1 laser operation. The laser stops

if the housing is opened.

Page 32

Smart tips – Overview

■■■■■■■■■■■■■■■■■■■■■■

26

■■■■■■■■

3

Right Angle Attachment (6.07506.000)

The Right Angle Attachment is an optional

attachment.

The Right Angle Attachment allows to collect data by placing the substance on a surface and laying the Mira P down next to the

substance with the right angle tip covering

the substance.

Ideal for a baggie on the hood of a squad

car.

Class 3B laser operation.

4

Short Working Distance Attachment

Lens (SWD) (6.07505.010)

A short distance lens for point and shoot

measurement with class 3B laser operation.

The focal point is approximately 0.85 mm

from the top of the lens.

The SWD attachment lens is used for samples with direct contact or in thin plastic

bags.

5

Long Working Distance Attachment

Lens (LWD) (6.07505.000)

A long distance lens for point and shoot

measurement with class 3B laser operation.

The focal point is approximately 8 mm from

the top of the lens.

The LWD attachment lens is used for samples in moderately thick-walled bottles.

6

Extra Long Working Distance Attachment Lens (XLWD) (6.07505.020)

An extra long distance lens for point and

shoot measurement with class 3B laser operation.

The focal point is approximately 18 mm

from the top of the lens.

The XLWD attachment lens is used for samples in very thick containers as for example

glass bottles.

7

Calibrate/Verify Attachment (CVA)

(6.06071.040)

The CVA contains a toluene-acetonitrile calibration standard and a polystyrene verification sample.

The CVA is needed for the calibration of the

instrument.

8

Vial Holder (6.07502.000)

The Vial Holder is used for samples in glass

vials.

Interlock mechanism allows measurement

with class 1 laser operation. The laser stops

if the housing is opened.

NOTICE

The following attachments are optional:

■ Contact Ball-Probe

■ Right Angle Attachment

■ Tablet Holder

■ XLWD

Page 33

■■■■■■■■■■■■■■■■■■■■■■

Operation and control

■■■■■■■■

27

7.2 Attaching smart tips

Using Calibrate/Verify Attachment

WARNING

Risk of injury by laser radiation

Serious eye injuries by laser radiation.

■ Follow the safety measures and instructions.

■ Instruments must be used by trained personnel only.

■ Instruments of the laser class 3B must be used in protected and

labeled rooms only.

■ The protective glasses provided must be used when working with

open laser beams (e.g. attachment lens).

■ Observe the nominal ocular hazard distance (NOHD).

■ Follow the provisions of the IEC 60825-1 standard "Safety of laser

products" and the regulations for the use of laser systems in your

country.

NOTICE

The CVA has 2 positions. Attaching the smart tip works the same way

for both positions.

Attach the smart tip by engaging the bottom

left corner of the tip into the left edge of the

mounting point. Rotate the tip into position.

Page 34

Attaching smart tips

■■■■■■■■■■■■■■■■■■■■■■

28

■■■■■■■■

Side 1 of the CVA contains a toluene-acetonitrile standard for calibration.

Side 2 of the CVA contains a polystyrene sample for verification.

Page 35

■■■■■■■■■■■■■■■■■■■■■■

Operation and control

■■■■■■■■

29

Using attachment lenses

WARNING

Risk of injury by laser radiation

Serious eye injuries by laser radiation.

■ Follow the safety measures and instructions.

■ Instruments must be used by trained personnel only.

■ Instruments of the laser class 3B must be used in protected and

labeled rooms only.

■ The protective glasses provided must be used when working with

open laser beams (e.g. attachment lens).

■ Observe the nominal ocular hazard distance (NOHD).

■ Follow the provisions of the IEC 60825-1 standard "Safety of laser

products" and the regulations for the use of laser systems in your

country.

Attach the smart tip by engaging the bottom

left corner of the tip into the left edge of the

mounting point. Rotate the tip into position.

Page 36

Attaching smart tips

■■■■■■■■■■■■■■■■■■■■■■

30

■■■■■■■■

Using Vial Holder

Closing the lid prevents laser radiation from emerging.

The lid contains a safety feature which cancels the measurement and

stops the laser if you open the lid.

Attach the smart tip by engaging the bottom

left corner of the tip into the left edge of the

mounting point. Rotate the tip into position.

Page 37

■■■■■■■■■■■■■■■■■■■■■■

Operation and control

■■■■■■■■

31

Open the Vial Holder and insert a vial to measure its contents.

Using Right Angle Attachment

WARNING

Risk of injury by laser radiation

Serious eye injuries by laser radiation.

■ Follow the safety measures and instructions.

■ Instruments must be used by trained personnel only.

■ Instruments of the laser class 3B must be used in protected and

labeled rooms only.

■ The protective glasses provided must be used when working with

open laser beams (e.g. attachment lens).

■ Observe the nominal ocular hazard distance (NOHD).

■ Follow the provisions of the IEC 60825-1 standard "Safety of laser

products" and the regulations for the use of laser systems in your

country.

Page 38

Attaching smart tips

■■■■■■■■■■■■■■■■■■■■■■

32

■■■■■■■■

Attach the smart tip by engaging the bottom

left corner of the tip into the left edge of the

mounting point. Rotate the tip into position.

Page 39

■■■■■■■■■■■■■■■■■■■■■■

Operation and control

■■■■■■■■

33

Using Contact Ball-Probe

WARNING

Risk of injury by laser radiation

Serious eye injuries by laser radiation.

■ Follow the safety measures and instructions.

■ Instruments must be used by trained personnel only.

■ Instruments of the laser class 3B must be used in protected and

labeled rooms only.

■ The protective glasses provided must be used when working with

open laser beams (e.g. attachment lens).

■ Observe the nominal ocular hazard distance (NOHD).

■ Follow the provisions of the IEC 60825-1 standard "Safety of laser

products" and the regulations for the use of laser systems in your

country.

Attach the smart tip.

Seat the brass knob into the recess on the left

side of the Mira P.

Page 40

Attaching smart tips

■■■■■■■■■■■■■■■■■■■■■■

34

■■■■■■■■

Tighten using the adjustment knob on the

attachment. Do not over tighten.

Using Tablet Holder

Closing the lid prevents laser radiation from emerging.

The lid contains a safety feature which cancels the measurement and

stops the laser if you open the lid.

Attach the smart tip by engaging the bottom

left corner of the tip into the left edge of the

mounting point. Rotate the tip into position.

Page 41

■■■■■■■■■■■■■■■■■■■■■■

Operation and control

■■■■■■■■

35

Open the Tablet Holder. Push the levers and

position the sample in the middle.

Release the levers to fix the sample.

7.3 Data acquisition

The following steps show how samples can be acquired with the instrument.

NOTICE

Operating procedures and users have to be defined and synchronized

beforehand in Mira Cal P. Refer to Mira Cal P software tutorial for

more information Additional information - Software tutorials (see

chapter 1.5, page 4)

Make sure the instrument is connected to the power supply or has battery

power.

1

Switching on the instrument

Switch on the instrument using the on/off switch.

Page 42

Data acquisition

■■■■■■■■■■■■■■■■■■■■■■

36

■■■■■■■■

2

Login

Select your user name from the dropdown list, enter your password

and click on [Login].

3

Attach smart tip

If not already done, attach the correct smart tip to the instrument

Attaching smart tips (see chapter 7.2, page 27)

Within an operating procedure a certain smart tip type may be

required. A data acquisition will only be possible when the instrument recognizes the correct smart tip.

Page 43

■■■■■■■■■■■■■■■■■■■■■■

Operation and control

■■■■■■■■

37

4

Selecting an operating procedure

Select an operating procedure from the dropdown list.

5

Read a barcode

Click on to use the barcode reader instead of typing

in by hand.

Barcode functionality and behavior is defined in the operating procedure.

Click on [Next].

6

Enter Batch ID, Lot ID, Container

Enter the Batch ID, Lot ID and Container by hand or use the barcode

reader.

Click on [Next].

7

Arm laser

Click on [Arm laser].

Laser armed display is displayed.

Page 44

Calibrate an instrument

■■■■■■■■■■■■■■■■■■■■■■

38

■■■■■■■■

8

Measuring the sample

■ Click on [Acquire] to start the measurement.

When the measurement is finished, a spectrum is displayed with

information according to definitions within the operating procedure.

9

Measuring the next sample

Click on [Next] to start the next measurement.

7.4 Calibrate an instrument

Calibration

1

Attach the CVA.

2

Click on the instrument settings icon .

3

Click on [Calibrate Instrument].

4

Click on [Calibrate].

NOTICE

Instrument calibration can also be done in Mira Cal P with a connected instrument.

System suitability test (SST)

1

Attach the CVA.

2

Click on the instrument settings icon .

3

Click on System Suitability Test.

4

Click on Run SST.

Page 45

■■■■■■■■■■■■■■■■■■■■■■

Operation and control

■■■■■■■■

39

7.5 Configuration

Open Settings

1

Click on to go to the settings section.

Speaker

Enable or disable the internal speaker. This will activate an acoustic signal

when the barcode reader is used.

Calibrate Instrument

Calibrate the instrument (see "Calibration", page 38).

System Suitability Test

Conduct a system suitability test (see "System suitability test (SST)", page

38).

Shutdown Delay

NOTICE

The shutdown delay will only affect battery-powered instruments.

For an instrument connected with a power supply, the shutdown

delay is disabled.

By default, no shutdown delay is configured.

Define a shutdown time to conserve battery charge.

For example if you enter value "3": A battery-powered instrument will

automatically shutdown after 3 minutes not in use.

Battery Chemistry

There are many different types of AA batteries. For an accurate battery life

indicator, it is important to choose the battery chemistry that is being used

in the device. The two chemistries that are supported are Li and NiMH.

Set the battery chemistry:

1

In the Settings section, click on [Battery Chemistry].

2

Select the battery type:

Page 46

Configuration

■■■■■■■■■■■■■■■■■■■■■■

40

■■■■■■■■

■ Lithium

■ NiMH

The change will be reflected by the text in the battery indicator. This

setting is persistent.

NOTICE

We recommend to change the batteries when the battery indicator

changes color from white to yellow, orange or red.

Page 47

■■■■■■■■■■■■■■■■■■■■■■

Maintenance

■■■■■■■■

41

8 Maintenance

8.1 Maintenance agreement

Maintenance of the product is best carried out as part of an annual service

performed by specialist personnel from Metrohm. Shorter maintenance

intervals may be necessary if you frequently work with caustic and corrosive chemicals. Metrohm Service personnel are properly trained in procedures for safely repairing the instrument.

Routine cleaning of the instrument can be done using non-corrosive

cleansers such as water, ethanol, or acetone.

Metrohm Service offers every form of technical advice for maintenance

and service of all Metrohm products.

8.2 Checking and replacing product parts

To guarantee the flawless functioning and operation of the products as

well as of their functional units, all parts must be regularly checked and

replaced if needed.

NOTICE

The following points must always be observed:

■ The product is switched off.

■ The product is disconnected from the power grid.

In the following paragraphs you will find an explanation of how the product parts can be checked individually and what has to be taken into

account. The procedure for replacing the parts is then described step-bystep where necessary.

Page 48

Cleaning the product

■■■■■■■■■■■■■■■■■■■■■■

42

■■■■■■■■

WARNING

Electric shock from electrical potential

Risk of injury by touching live components or through moisture on

live parts.

■ Never open the housing of the product.

■ Protect live parts (e.g. power supply unit, power cord, connection

sockets) against moisture.

■ If you suspect that moisture has gotten into the product, discon-

nect the product from the energy supply. Then notify Metrohm

Service.

■ Only personnel who have been issued Metrohm qualification may

perform service and repair work on electrical and electronic components.

8.3 Cleaning the product

WARNING

Danger of poisoning and chemical burns from chemical hazardous substances

Poisoning and/or chemical burns by contact with aggressive chemical

substances.

■ Use only detergents that do not cause any unwanted side reac-

tions with the materials to be cleaned.

■ Clean contaminated surfaces.

■ Wear protective equipment.

■ Use exhaust equipment when working with vaporizing hazardous

substances.

■ Dispose of chemically contaminated materials (e.g. cleaning mate-

rial) properly.

Page 49

■■■■■■■■■■■■■■■■■■■■■■

Maintenance

■■■■■■■■

43

WARNING

Electric shock from electrical potential

Risk of injury by touching live components or through moisture on

live parts.

■ Never open the housing of the product.

■ Protect live parts (e.g. power supply unit, power cord, connection

sockets) against moisture.

■ If you suspect that moisture has gotten into the product, discon-

nect the product from the energy supply. Then notify Metrohm

Service.

■ Only personnel who have been issued Metrohm qualification may

perform service and repair work on electrical and electronic components.

Cleaning the surfaces of the product

Prerequisites

■ The product is disconnected from the power grid.

1

Clean the surfaces with a damp cloth.

NOTICE

If the suspicion arises that liquids have found their way into the

product, disconnect the product from the power grid and contact your Metrohm Service.

NOTICE

Water or ethanol can be used as a cleaning medium.

NOTICE

The connectors at the rear of the product must only be cleaned

with a dry cloth.

Page 50

■■■■■■■■■■■■■■■■■■■■■■

44

■■■■■■■■

9 Disposal

This product is covered by European Directive, WEEE – Waste Electrical

and Electronic Equipment.

The correct disposal of your old product will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old product can be obtained from

your local authorities, from waste disposal companies or from your local

dealer.

Page 51

■■■■■■■■■■■■■■■■■■■■■■

Technical specifications

■■■■■■■■

45

10 Technical specifications

10.1 Ambient conditions

Nominal function range –20 - +50 °C (At a maximum of 93%

humidity)

Storage and Transport –20 - +70 °C (At a maximum of 93%

humidity)

10.2 Interfaces

USB connector

Type A/B mini USB connector

(USB 2.0) with the following

functions:

Power supply

Data transmission

with USB cable

(6.2151.110)

10.3 Power Supply

Battery

Battery specifications

2 x 1.5 V, size AA / LR6

Nominal input voltage 5 V DC

Power consumption 1,300 mA max.

Power supply unit

Power supply unit specifications

Instrument connected to a

powered USB hub.

Nominal input voltage 100 - 240 V AC

Page 52

Dimensions and materials

■■■■■■■■■■■■■■■■■■■■■■

46

■■■■■■■■

Frequency 50 - 60 Hz

Output voltage 5 V DC

Nominal output current 1,500 mA max.

10.4 Dimensions and materials

Dimensions

Width 88.4 mm

Depth 44.8 mm

Height 126 mm

Display 3.7'' TFT LCD Display, glove

compatible

Weight 705 g

Material

Housing Aluminum anodized

Accessories covering Thermoplastic elastomers

(TPE-E)

IP Rating (according to EN 60529) IP67

Samples for Vial Holder

Vial Holder Vials 15 mm x 26 mm

Page 53

■■■■■■■■■■■■■■■■■■■■■■

Technical specifications

■■■■■■■■

47

10.5 Operating specifications

Laser wavelength 785 nm ± 0.5 nm

Laser output power ≤ 100 mW

Wavenumber range 400 - 2,300 cm

-1

Spectral resolution 8 - 10 cm-1 (FWHM)

Collection optics NA = 0.50, 1 mm and

7.6 mm working distance;

0.042 - 2.5 mm measuring

spot size

Beam divergence 2 degrees

Detection technique Orbital Raster Scan (ORS) to

average over the sample

Laser class according to EN 60825-1 Class 3B

Protection Level of goggles (according to EN 207)

D LB5 775 - 795 nm

NOHD - Nominal Ocular Hazard Distance

Contact Ball-Probe Attachment: 34.5 cm

Loading...

Loading...