Page 1

CH-9101 Herisau/Switzerland

Tel. ++41 71 353 85 85

Fax ++41 71 353 89 01

Internet www.metrohm.ch

E-Mail info@metrohm.ch

754 Dialysis Unit

Dialysis Unit754

POWER

REMOTE PUMP

ON ON

OFFOFF

MetrohmMetrohm

8.754.1003 Instructions for Use

19.01.98 / dö

Page 2

Table of contents

Table of contents

1 Introduction............................................................................................1

1.1 Instrument description.............................................................................1

1.2 Parts and controls..................................................................................... 2

1.3 Information about the Instructions for Use..........................................4

1.3.1 Organization ..................................................................................4

1.3.2 Notation and pictograms............................................................... 4

1.4 Support documentation...........................................................................5

1.5 Safety notes ...............................................................................................6

1.5.1 Electrical safety..............................................................................6

1.5.2 General precautionary rules.......................................................... 6

2 Installation..............................................................................................7

2.1 Setting up the instrument........................................................................ 7

2.1.1 Packaging......................................................................................7

2.1.2 Check ............................................................................................7

2.1.3 Location......................................................................................... 7

2.1.4 Arrangement of the instruments....................................................7

2.2 Mains connection......................................................................................8

2.2.1 Setting the mains voltage..............................................................8

2.2.2 Fuses.............................................................................................9

2.2.3 Mains cable and mains connection ..............................................9

2.2.4 Switching the instrument on/off..................................................... 9

2.3 Attaching the accessories.....................................................................10

2.3.1 Electrical connection to the 732 IC Detector............................... 10

2.3.2 Attaching the accessories to the

733.0020 IC Separation Center................................................... 10

2.3.3 Attaching the accessories to the 754 Dialysis Unit.....................13

2.3.4 Assembling the dialysis cell ........................................................15

2.3.5 Connecting the dialysis cell ........................................................17

2.3.6 Attaching the accessories to the waste bottle ............................19

2.3.7 Conditioning the dialysis system ................................................20

754 Dialysis Unit

3 Operation................................................................................................21

3.1 Manual operation.....................................................................................21

3.2 Operation via 732 IC Detector...............................................................22

3.3 The dialysis procedure...........................................................................23

3.3.1 Dialysis flow chart........................................................................ 23

3.3.2 Programming with the 732 IC Detector.......................................24

3.3.3 Setting the rinsing time................................................................ 25

3.3.4 Setting the transfer time ..............................................................25

3.3.5 Setting the dialysis time...............................................................26

3.3.6 Setting the program time............................................................. 27

3.3.7 Dialysis procedure....................................................................... 27

I

Page 3

Table of contents

4 Malfunctions – Maintenance..........................................29

5 Appendix .................................................................................................35

4.1 Malfunctions and their rectification.....................................................29

4.2 Maintenance and servicing ................................................................... 30

4.2.1 Handling dialysis membranes .................................................... 30

4.2.2 Care of the unit............................................................................ 30

4.2.3 Maintenance by Metrohm service............................................... 30

4.2.4 Shutdown ....................................................................................31

4.2.5 Replacing the pump tubing ........................................................ 31

4.2.6 Replacing the dialysis membrane .............................................. 32

5.1 Technical data ......................................................................................... 35

5.2 Standard equipment............................................................................... 37

5.3 Optional accessories.............................................................................. 39

5.4 Warranty and conformity....................................................................... 40

5.4.1 Warranty ...................................................................................... 40

5.4.2 EU Declaration of conformity ...................................................... 41

5.4.3 Certificate of conformity and system validation.......................... 42

5.5 Index.......................................................................................................... 43

List of figures

Fig. 1: Front of the 754 Dialysis Unit ............................................................................ 2

Fig. 2: Rear of the 754 Dialysis Unit ............................................................................. 3

Fig. 3: Setting the mains voltage.................................................................................. 9

Fig. 4: Connection of 754 Dialysis Unit to 732 IC Detector........................................ 10

Fig. 5: Interior of the 733.0020 IC Separation Center................................................. 12

Fig. 6: Installing pump tubings................................................................................... 14

Fig. 7: Assembling the dialysis cell ............................................................................ 16

Fig. 8: Diagram of tubing connections ...................................................................... 18

II

754 Dialysis Unit

Page 4

1 Introduction

1.1 Instrument description

The 754 Dialysis Unit is a unit for on-line sample preparation in ion

chromatography permitting the use of automatic sample dialysis directly before sample injection. It consists of a dual-channel peristaltic

pump for conveying the sample and acceptor solutions, and the actual

dialysis cell in which the ions from the flowing sample solution are enriched in the resting acceptor solution and then injected directly into the

IC system. This special Stopped-Flow Method (for which Metrohm

has applied for a patent) means that 100% of the sample concentration

can be achieved in the acceptor solution, allowing easy calibration with

external standards.

1.1 Instrument description

The 754 Dialysis Unit can be operated manually, via the ON/OFF

switch, or by remote control, via the remote interface.

Valve B, which is built into the 733.0020 IC Separation Center and

controlled by the 732 IC Detector, is required to operate the 754 Dialysis Unit. For this variant, which is described in these Instructions for

Use, the following units are required:

Operation without suppressor

2.732.0010 IC Detector

2.733.0020 IC Separation Center

2.709.0010 IC Pump

2.754.0010 Dialysis Unit

As an alternative to valve B, which is built into the IC Separation Center,

an external valve controlled via the remote output of the 732 IC De-

tector can also be used. This allows the 754 Dialysis Unit to be operated in combination with the following units:

Operation with suppressor

2.732.0010 IC Detector

2.733.0030 IC Separation Center

2.709.0010 IC Pump

2.752.0010 Pump Unit

2.754.0010 Dialysis Unit

Operation with suppressor

2.732.0010 IC Detector

2.733.0020 IC Separation Center

2.709.0010 IC Pump

2.754.0010 Dialysis Unit

2.753.0010 Suppressor Module

External valve

754 Dialysis Unit

More information about this variant is available from Metrohm on request.

1

Page 5

1 Introduction

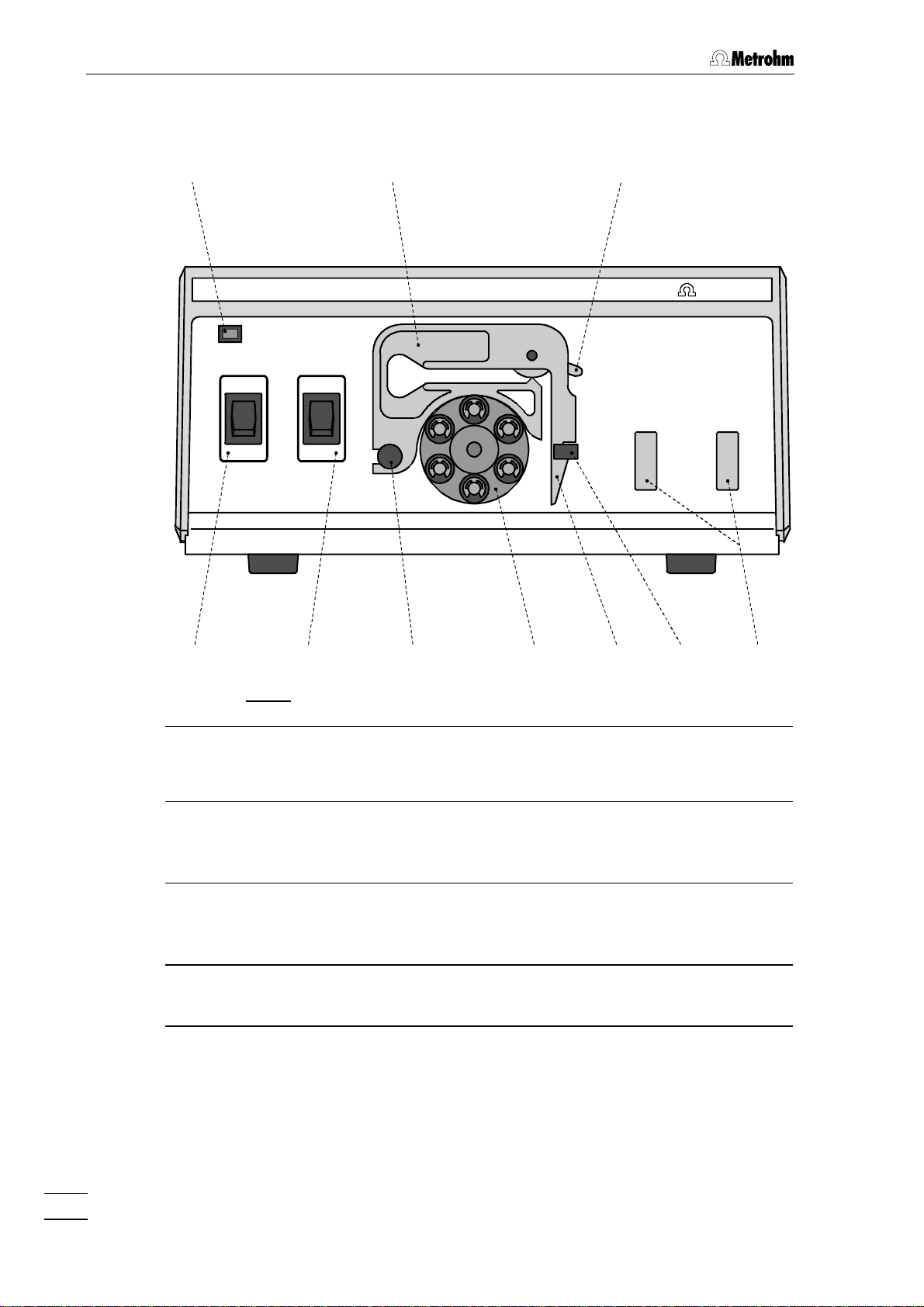

1.2 Parts and controls

33 44 55

Dialysis Unit754

POWER

REMOTE PUMP

ON ON

OFFOFF

MetrohmMetrohm

22 11 77991010 88 66

Fig. 1: Front of the 754 Dialysis Unit (without dialysis cell)

11 Pump ON/OFF

On/Off switch for the pump

(manual operation mode)

22 Remote ON/OFF

On/Off switch for remote control

of the pump

33 Power on lamp

Lights up when instrument is

switched on

44 Tubing cartridge

For 6.1826.0X0 pump tubing

55 Contact pressure lever

For adjusting the contact pressure

66 Cell holder

For holding the dialysis cell

77 Holding clamp

For locking the tubing cartridge into

place

88 Snap-action lever

For releasing the tubing cartridge

99 Pump drive

Roller head with contact rollers

1010 Mounting pin

For attaching the tubing cartridge

2

754 Dialysis Unit

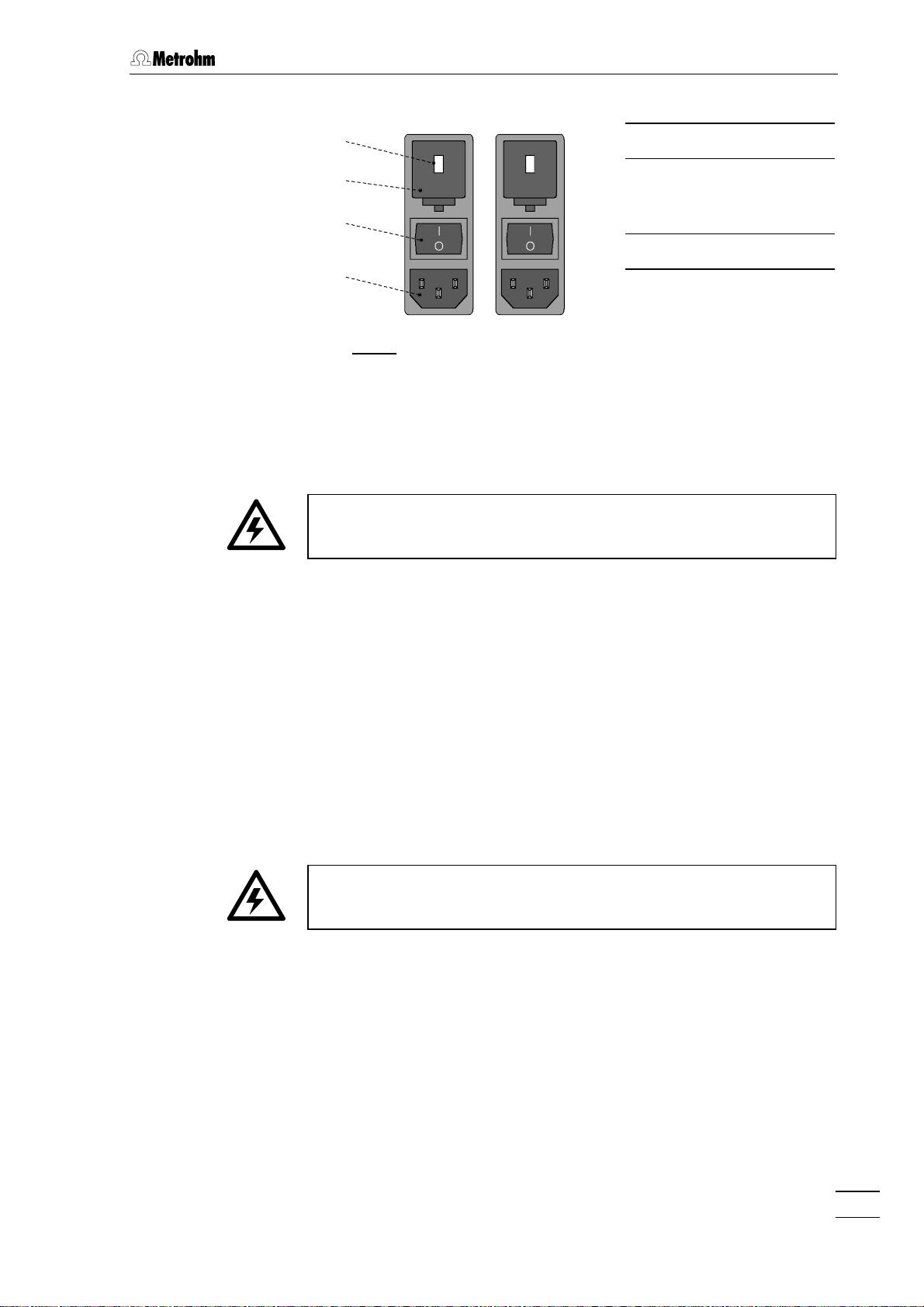

Page 6

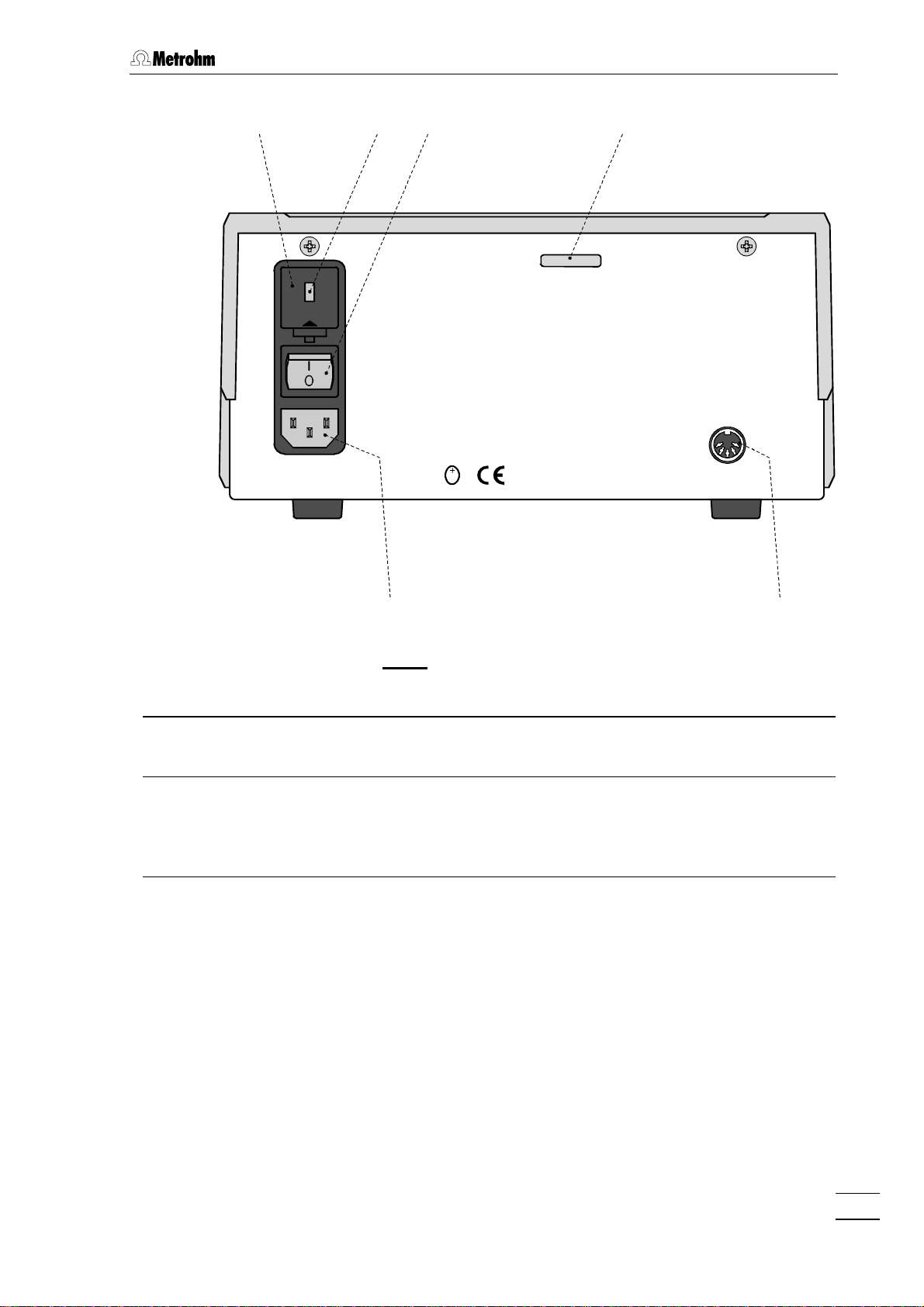

1.2 Parts and controls

1111

WARNING - Fire Hazard -

For continued protection replace only

with the same type and rating of fuse

f=50-60 Hz

S=12 VA

115V: 110-120V:

230V: 220-240V:

Type 1.754.0010 Nr.

Fuse

0,2A(T)

0,1A(T)

S

141413131212

Remote

Pump

Made by Metrohm Herisau Switzerland

1616 1515

Fig. 2: Rear of the 754 Dialysis Unit

1111 Fuse holder

Changing the fuses, see section 2.2

1212 Voltage selection insert with

display of voltage

1313 Mains switch

For switching the instrument on/off:

I = ON 0 = OFF

1414 Serial number

1515 Remote interface

Remote I/O lines for connecting

external devices (e.g. 732 IC Detector)

1616 Mains connection plug

Mains connection, see section 2.2

754 Dialysis Unit

3

Page 7

1 Introduction

1.3 Information about the Instructions for Use

Please read through these Instructions for Use carefully before operating the 754 Dialysis Unit. The Instructions for Use contain information and warnings to which the user must pay attention in order to

assure safe operation of the instrument.

1.3.1 Organization

These 8.754.1003 Instructions for Use for the 754 Dialysis Unit provide a comprehensive overview of the installation, startup procedure,

operation, fault rectification and technical specifications of this instrument. The Instructions for Use are organized as follows:

Section 1 Introduction

Description of the instrument, parts and controls,

safety notes

Section 2 Installation

Setting up, mains connection, attachment of

accessories, connection to IC system

Section 3 Operation

Manual operation, operation via 732 IC Detector,

dialysis procedure

Section 4 Faults – Maintenance

Fault rectification, maintenance

Section 5 Appendix

Technical data, standard equipment, options, warranty,

declarations of conformity, index

To find the information you require about the instruments please use

either the Table of contents or the Index at the back.

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

<PUMP> Switch or key

1515 Part or control of 754

8989 Part or control of 732/733

Range Parameter or entry value

at 732 IC Detector

4

754 Dialysis Unit

Page 8

1.4 Support documentation

Hazard

This symbol draws attention to a

possible danger to life or injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important information. Read these directions

before continuing.

1.4 Support documentation

Application Bulletins

The «Application Bulletin» is a collection of analytical methods, application examples and literature references. Of Metrohm's approximately

200 Application Bulletins, 34 currently refer to ion chromatography. All

these Application Bulletins are available on request free of charge from

your Metrohm supplier.

You will find an updated list of the Application Bulletins at any time under «http://www.metrohm.ch».

Application Notes

The «Application Notes» present application information in concentrated form, i.e. on maximum 2 pages. There are currently 88 Application Notes (in English) in the field of ion chromatography. You can order

these free of charge from your Metrohm supplier or view them in the

Internet under «http://www.metrohm.ch» and copy them from there.

Comment

This symbol marks additional information and tips.

754 Dialysis Unit

5

Page 9

1 Introduction

1.5 Safety notes

1.5.1 Electrical safety

While electrical safety in the handling of the 754 Dialysis Unit is assured

in the context of the specifications IEC 1010-1 (protection class I, degree of protection IP40), the following points should be noted:

• Mains connection

Set the mains voltage and check the mains fuse and mains

connection in accordance with the instructions in section 2.2.

• Opening the 754 Dialysis Unit

To avoid all danger of coming into contact with live components do

not open the instrument or remove any parts when the 754 Dialysis

Unit is connected to the power supply. Always disconnect the instrument from all voltage sources before you open it and ensure that the

mains cable is disconnected from mains connection 1616 !

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 754 Dialysis Unit, you should earth yourself and any tools

you are using by touching an earthed object (e.g. housing of the

instrument or a radiator) to eliminate any static charges which exist.

1.5.2 General precautionary rules

• Handling of solvents

Check all pump tubings and all input and output leads periodically for

possible leaks. Follow the relevant instructions regarding the handling

of flammable and/or toxic solvents and their disposal.

• Regular exchange of pump tubings

Pump tubings constitute consumable material and must be replaced

from time to time (see section 4.4). Suitable measures must be taken

so that any leak which might occur in the pump tubing or connections

during unattended operation will cause no damage (placing the

instrument at the bottom, collection device for any liquid which may

leak out).

6

754 Dialysis Unit

Page 10

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 754 Dialysis Unit is supplied together with the separately packed

accessories in special packagings containing shock-absorbing foam

linings designed to provide excellent protection. The actual instrument

is packed in an evacuated polyethylene bag to prevent the ingress of

dust. Please store all these special packagings as only they can assure

damage-free transport of the instrument.

2.1.2 Check

2.1 Setting up the instrument

After receipt, immediately check whether the shipment is complete and

undamaged (compare with delivery note and list of accessories in

section 5.2). In the case of transport damage, see instructions in

section 5.4.1 "Warranty".

2.1.3 Location

Position the instrument in the laboratory at a location convenient for

operation, free from vibrations and protected against a corrosive

atmosphere and contamination by chemicals.

2.1.4 Arrangement of the instruments

To make the connections with the tubing supplied, position the 754 Dialysis Unit immediately under the 733 IC Separation Center. The other

units (732 IC Detector, 709 IC Pump, 753 Suppressor Module) can be

arranged as required.

Take precautions to ensure that any leaks from pump tubings or

connections cannot cause more damage.

754 Dialysis Unit

7

Page 11

2 Installation

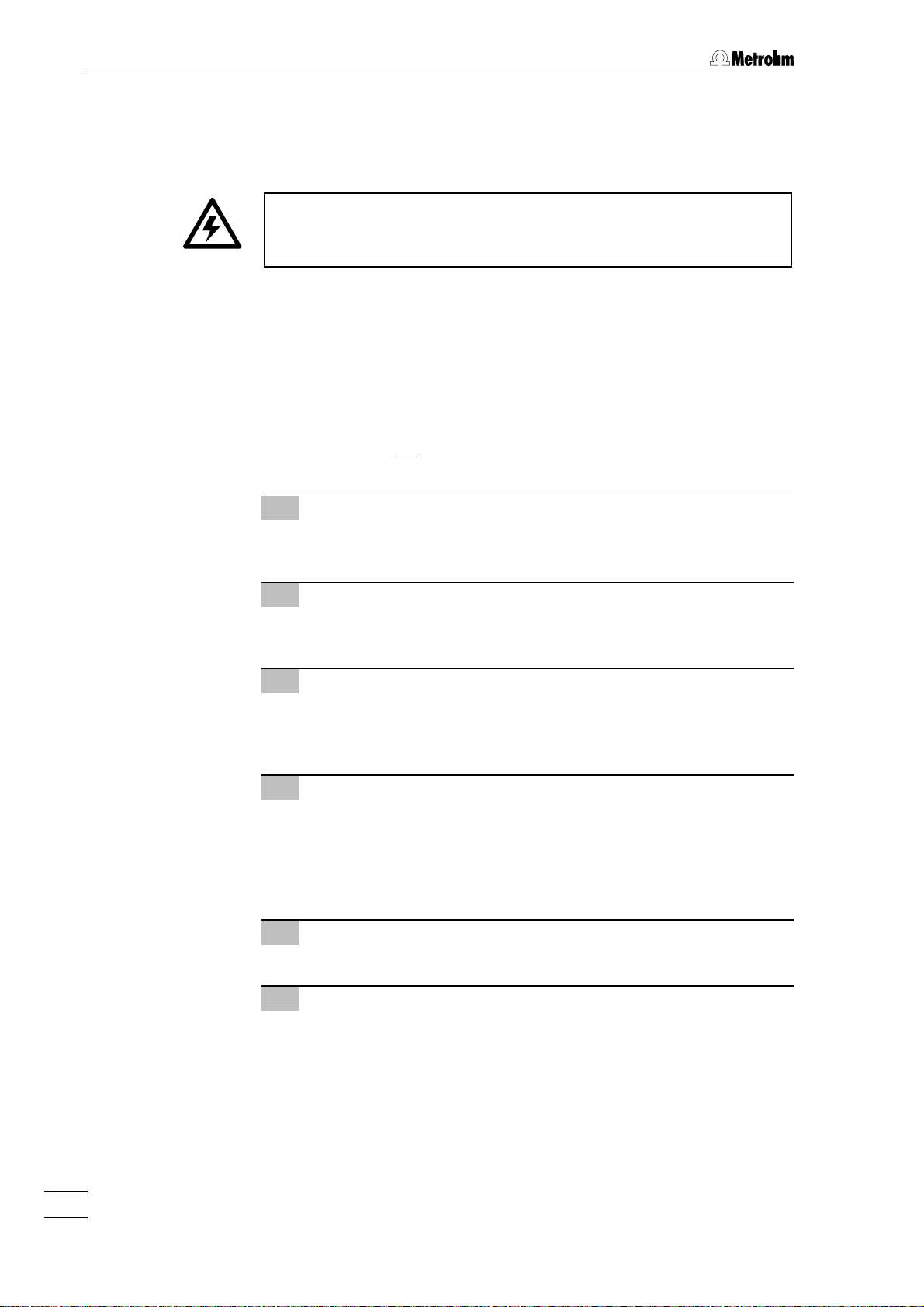

2.2 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with the mains voltage set wrongly and/or

wrong mains fuse there is a danger of fire!

2.2.1 Setting the mains voltage

Before switching on the 754 Dialysis Unit for the first time, check that

the mains voltage set on the instrument (see Fig. 3) matches the local

mains voltage. If not, reset the mains voltage on the instrument as follows:

Disconnect mains cable

1

Disconnect mains cable from mains connection plug 1616 of the

754 Dialysis Unit.

Remove fuse holder

2

Using a screwdriver, loosen fuse holder 1111 and remove com-

pletely.

Change mains voltage

3

Completely remove voltage selector insert 1212 by hand, rotate it

through 180° and reinsert it. The required mains voltage (115 or

230 V) should now be visible from the front.

Check fuses

4

Carefully take both fuses out of fuse holder 1111 and check their

specifications:

100……120 V 0.2 A (slow-blow) Metrohm-No. U.600.0009

220……240 V 0.1 A (slow-blow) Metrohm-No. U.600.0006

Insert fuses

5

Change both fuses if necessary and reinsert in fuse holder 1111.

Install fuse holder

6

Push fuse holder 1111 back into the opening of the 754 Dialysis

Unit by hand until it clicks into place properly.

8

754 Dialysis Unit

Page 12

2.2.2 Fuses

2.2 Mains connection

100 – 120 V220 – 240 V

1212

1111

230

115

1111 Fuse holder

1212 Voltage selection

insert with display

1313

of voltage

1313 Mains switch

1616

1616 Mains connection

plug

Fig. 3: Setting the mains voltage

Two fuses 0.2 A/slow-blow for 100…120 V or 0.1 A/slow-blow for

220…240 V are installed in the fuse holder 1111 of the 754 Dialysis Unit

as standard.

To eliminate any danger of fire, ensure that the instrument is never

operated with any other type of fuses!

To check or change fuses, proceed as described in section 2.2.1.

2.2.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a

different plug has to be fitted, the yellow/green lead (IEC standard)

must be connected to protective earth (protection class I).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug 1616 of the 754 Dialysis

Unit (see Fig. 3).

2.2.4 Switching the instrument on/off

The 754 Dialysis Unit is switched on and off using mains switch 1313.

When the instrument is switched on, lamp 33 lights up.

754 Dialysis Unit

9

Page 13

2 Installation

2.3 Attaching the accessories

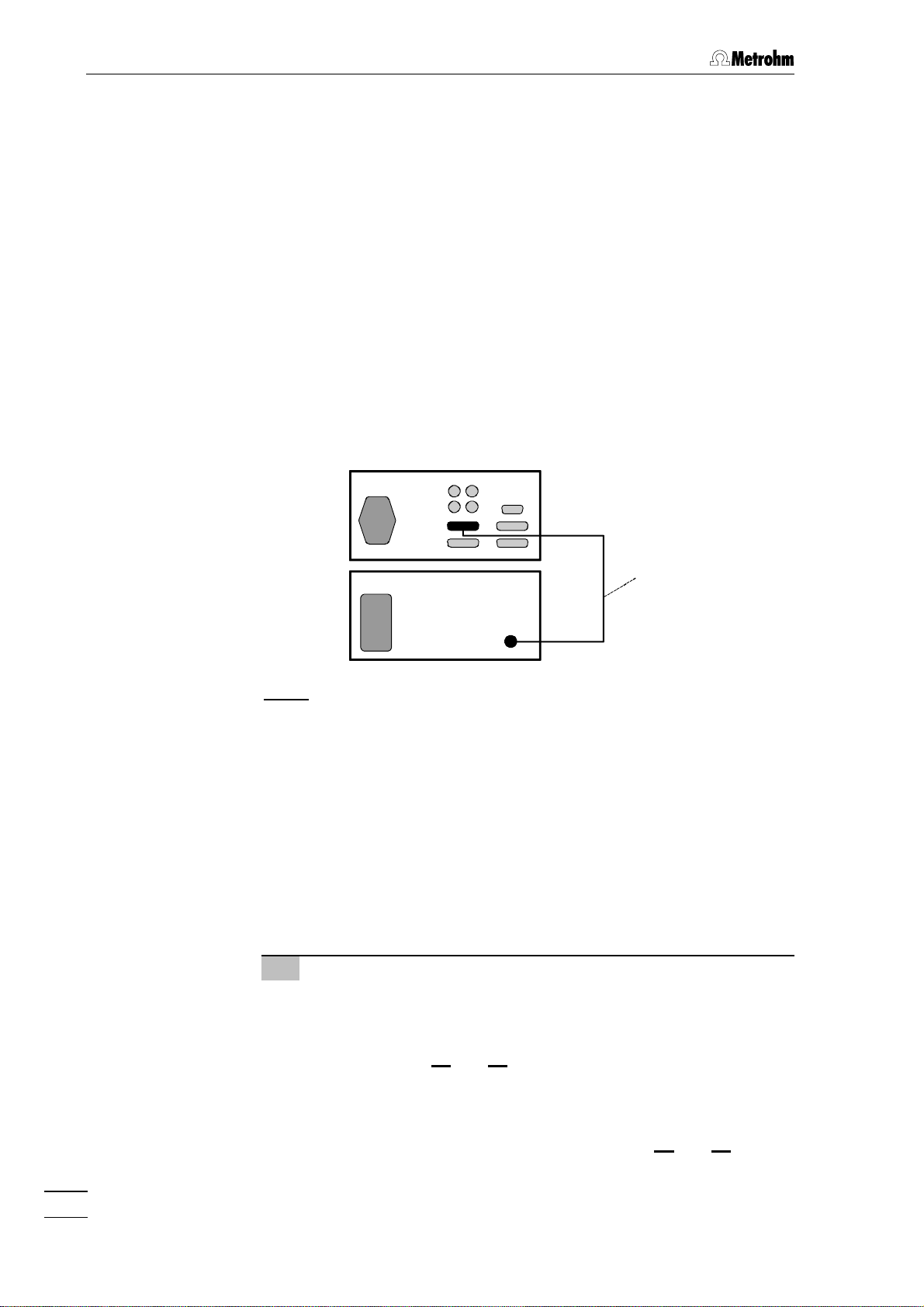

2.3.1 Electrical connection to the 732 IC Detector

In order to allow remote operation of the pump via the 732 IC Detector,

connection 1515 of the 754 Dialysis Unit must be connected to the

"Remote" connection of the 732 IC Detector by means of the

6.2143.200 cable as per Fig. 4. The switch 22 <REMOTE> on the front

of the 754 Dialysis Unit must additionally be set to "ON" to permit remote operation.

If you wish to connect a second, additional unit (e.g. 752, 753, 754) to

the remote interface of the 732 IC Detector, connect the Dialysis Unit

754 using the optionally available 6.2143.220 cable instead of the

6.2143.200 cable.

732

754

6.2143.200

Fig. 4: Connection of 754 Dialysis Unit to 732 IC Detector

2.3.2 Attaching the accessories to the 733.0020 IC Separation

Center

The 2.733.0020 IC Separation Center comes ready to operate with two

IC columns. To operate it with the 754 Dialysis Unit, reassemble it as

follows (see Fig. 5 and Fig. 8):

Dismantle accessories

1

• Unscrew the two sample loops mounted on valve A 1818 and

valve B 2222.

• Loosen the rotary nipples screwed onto the interior side of

feedthrough 2222 and 2828, pull the two PTFE suction tubings

right out of the connections and unscrew from connection "1"

of valve A 1818 and valve B 2222.

• Remove the PEEK capillaries running from connection "2" of

valve A 1818 and valve B 2222 to feedthroughs 2121 and 2727.

10

754 Dialysis Unit

Page 14

2.3 Attaching the accessories

Connect new feedthrough

2

• Using a wrench or a spanner, unscrew the nut on the interior

side of feedthrough 2727 and remove the feedthrough.

• Insert new 6.2756.000 tubing feedthrough in the hole and

retighten the nut.

Attach tubing to valve A

3

• Screw 6.1825.210 PEEK sample loop (20 µL) to connections

"3" and "6" of valve A 1818 using the enclosed 6.2744.010 PEEK

compression fittings.

• Screw PEEK capillary 1919 (6.1831.060; L =1 m) to connection

"2" of valve A 1818 using a 6.2744.010 PEEK compression fit-

ting. Pull the other end of the tubing to the back through the

rear panel opening 4141.

• Screw PEEK capillary 2020 (6.1831.040; L =15 cm) to connec-

tion "1" of valve A 18 18 using a 6.2744.010 PEEK compression

fitting.

Attach tubing to valve B

4

• Screw the PEEK capillary 2020 (6.1831.040; L =15 cm) at-

tached to connection "1" of valve A 1818 to connection "3" of

valve B 22 22 using a 6.2744.010 PEEK compression fitting.

• Screw PEEK capillary 2121 (6.1831.040; L =15 cm) to connec-

tions "1" and "2" of valve B 2222 using two 6.2744.010 PEEK

compression fittings.

• Screw PEEK capillary 2525 (6.1831.050; L =40 cm) to connec-

tion "4" of valve B 2222 using a 6.2744.010 PEEK compression

fitting and pull the other end to the front through feedthrough

2727.

• Screw PEEK capillary 2424 (6.1831.050; L =40 cm) to connec-

tion "5" of valve B 2222 using a 6.2744.010 PEEK compression

fitting and pull the other end to the front through feedthrough

2727.

• Screw PEEK capillary 2323 (6.1831.050; L =40 cm) to connec-

tion "6" of valve B 2222 using a 6.2744.010 PEEK compression

fitting and pull the other end to the front through feedthrough

2828.

Connecting to the 753 Suppressor Module (Option)

5

• Insert the suppressor block in the 733 IC Separation Center

as per the 753 Instructions for Use.

• Connect tubing to the IC column, the detector block and the

waste in the 733 IC Separation Center as per the 753 Instructions for Use.

• Pull the two inlet capillaries for H2SO4 and H2O to the front

through feedthrough 2727 and connect to the 753 Suppressor

Module pump tubings.

754 Dialysis Unit

11

Page 15

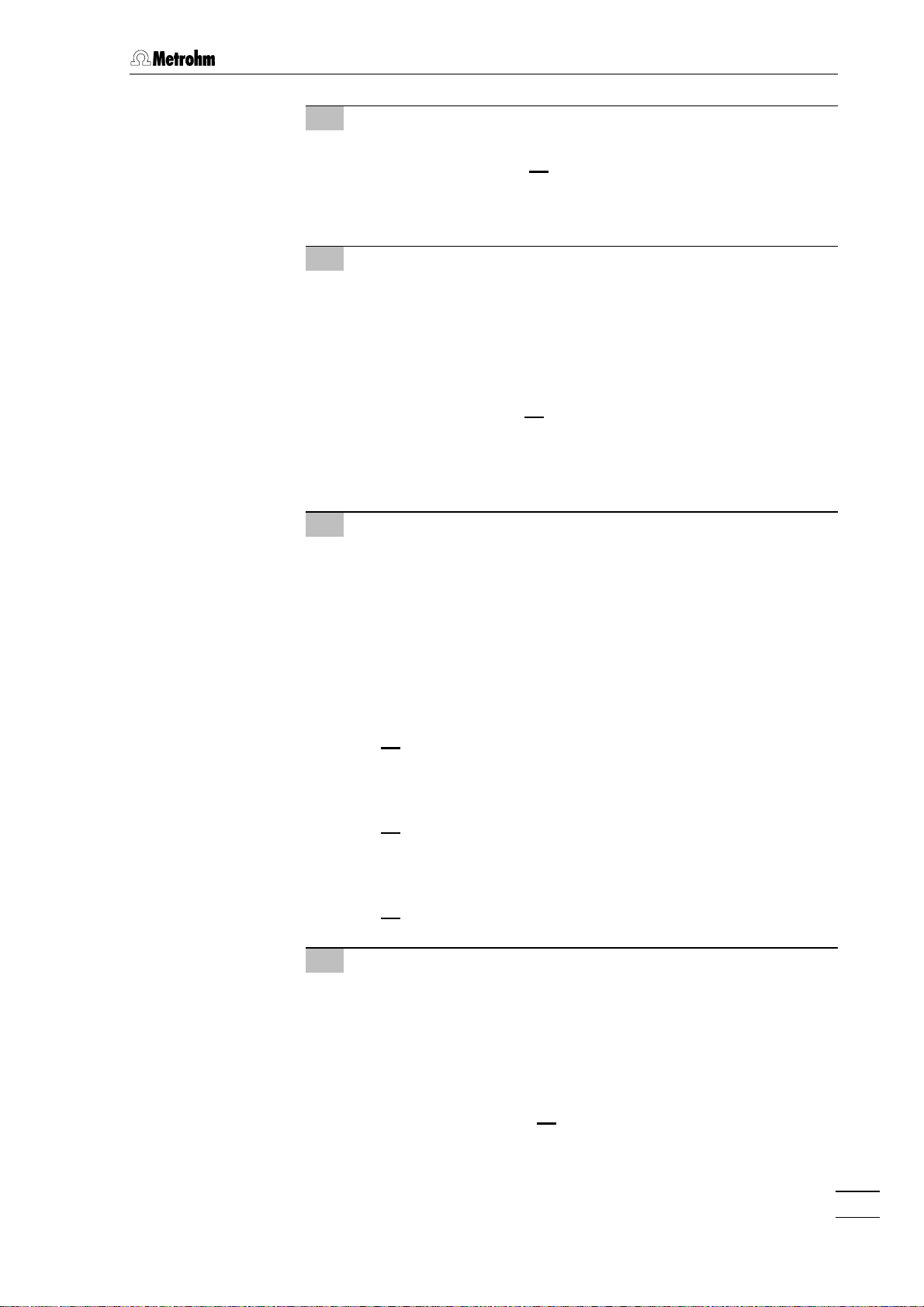

2 Installation

1919

1818

20

21

22

23

24

1717

FILL INJECT

A B

STEP

FILL INJECT

4141

Fig. 5: Interior of the 733.0020 IC Separation Center

1717 PEEK sample loop

(6.1825.210; 20 µµL )

1818 Injection valve A 2525 PEEK capillary

1919 PEEK capillary

(6.1831.060; 1 m)

2424 PEEK capillary

(6.1831.050; 40 cm)

(6.1831.050; 40 cm)

2121 Connection for syringe

2727

25

28282121 2222

12

2020 PEEK capillary

2222 Feedthrough

(6.1831.040; 15 cm)

2121 PEEK capillary

2727 Feedthrough

(6.1831.040; 15 cm)

2222 Injection valve B 2828 Feedthrough

2323 PEEK capillary

4141 Rear panel opening

(6.1831.040; 15 cm)

754 Dialysis Unit

Page 16

2.3 Attaching the accessories

2.3.3 Attaching the accessories to the 754 Dialysis Unit

Attach the tubing cartridges with the pump tubings to the 754 Dialysis

Unit. Proceed as follows (see Fig. 5 and Fig. 8):

Attach pump tubings

9

• Loosen both tubing cartridges 44 from the holding clamp 77 by

pressing down snap-action lever 88 and remove from mount-

ing pin 1010 on 754 Dialysis Unit (see Fig. 1).

• Press contact pressure lever 55 on both tubing cartridges

down as far as it will go.

• Insert a length of pump tubing 3131 (6.1826.030) for feeding the

acceptor solution into the first tubing cartridge as shown in

Fig. 6. The orange-yellow stopper 3232 must click into the cor-

responding holder on the left-hand side of the tubing cartridge.

• Insert a length of pump tubing 3030 (6.1826.040) for feeding the

sample into the second tubing cartridge. The black-black

stopper 3232 must click into the corresponding holder on the

left-hand side of the tubing cartridge.

• Place the tubing cartridge for the acceptor solution and then

the tubing cartridge for the sample on mounting pin 1010 and

press down on the right-hand side until snap-action lever 88

clicks into position on holding clamp 77. Take care that no

kinks are formed in the pump tubing.

Tubing connections for acceptor solution

2

• Mount a PEEK compression fitting 2828 (6.2744.010) on the

end of the PEEK capillary 23 23 projecting from feedthrough 2828

(see Fig. 5) and screw it on to coupling 2929 (6.2744.030) (see

Fig. 6).

• Push coupling 2929 on to the outlet end of the pump tubing 3131

(see Fig. 6 and Fig. 8).

• Cut a piece of PTFE tubing (6.1803.030) to the desired length

for the suction tubing 2626.

• Mount a PEEK compression fitting 2828 (6.2744.010) on one

end of suction tubing 2626 and screw this on to coupling 2929

(see Fig. 6).

• Push coupling 2929 on to the inlet end of the pump tubing 3131

(see Fig. 6 and Fig. 8).

• Immerse the other end of the suction tubing 2626 in a vessel

containing acceptor solution and fix in place. The acceptor

solution is usually ultrapure water that has previously been

degassed (with N2, He or a vacuum).

754 Dialysis Unit

13

Page 17

2 Installation

26/2726/27

2929 30/3130/31 3232 44 55 3232 2929 23/3323/3388 28282828

Fig. 6: Installing pump tubings

44 Tubing cartridge 2828 PEEK compression fitting

(6.2744.010)

55 Contact pressure lever 2929 Coupling (6.2744.030)

88 Snap-action lever 3030 Pump tubing (6.1826.040)

for conveying the sample

2323 PEEK capillary (6.1831.050)

for conveying the acceptor

solution to valve B

2626 PTFE capillary (6.1803.030)

for feeding the sample in

2727 PTFE capillary (6.1803.030)

for feeding the acceptor solution

in

Tubing connections for sample

3

• Mount a PEEK compression fitting 2828 (6.2744.010) on the

end of PTFE capillary tubing 3333 (6.1803.050, L = 20 cm) and

screw this on to coupling 2929 (6.2744.030) (see Fig. 6).

• Push coupling 2929 on to the outlet end of the pump tubing 3030

(see Fig. 6 and Fig. 8).

• Cut a piece of PTFE tubing (6.1803.030) to the desired length

for the suction tubing 2727.

• Mount a PEEK compression fitting 2828 (6.2744.010) on one

end of suction tubing 2727 and screw this on to coupling 2929

(see Fig. 6).

• Push coupling 2929 on to the inlet end of the pump tubing 3030

(see Fig. 6 and Fig. 8).

• Immerse the other end of suction tubing 2727 in the sample

vessel and fix in place.

3131 Pump tubing (6.1826.030)

for conveying the acceptor solution

3232 Stopper on pump tubing

3333 PTFE capillary (6.1803.050)

for conveying sample to dialysis cell

14

754 Dialysis Unit

Page 18

Pump tubings are consumable material with a lifetime which depends

on the contact pressure. This is why the tubing cartridges should be

raised completely by loosening snap-action lever 88 on the right-hand

side if the pump is to remain switched off for a considerable length of

time (the set contact pressure remains unchanged).

The 6.1826.0X0 pump tubing is made of PVC and must not be used

for rinsing with solutions which contain acetone. In such cases, rinse

with different pump tubing or a different pump.

2.3.4 Assembling the dialysis cell

A dialysis membrane has to be inserted before the dialysis cell can be

placed inside the 754 Dialysis Unit. Proceed as follows (see Fig. 7):

Prepare dialysis cell

1

• Extract dialysis cell 3434 (6.2729.100) from its packaging and

remove the four 6.2744.060 dummy stoppers.

• Using the 6.2621.070 Allen key, completely loosen the 5

screws 3939, separate top part 3838 from bottom part 3535 and re-

move sealing ring 3636.

• Thoroughly rinse the sealing ring 3636, bottom part 3535 and top

part 3838 of the dialysis cell with ultrapure water and dry with N

or a lint-free cloth.

2.3 Attaching the accessories

2

Use only ultrapure water or ethanol to clean the dialysis cell;

organic solvents (e.g. acetone) will cause damage to the plexiglas

cell !

Prepare dialysis membrane

2

• Use the 6.2831.010 pincette to extract a new dialysis mem-

brane 3838 (e.g. 6.2714.010) from its packaging and immerse

in a Petri dish containing ultrapure water for approx. 2 min

until the membrane is completely saturated with water.

Insert dialysis membrane

3

• Lay bottom part 3535 on a paper wipe with its inside facing

upwards.

• Insert sealing ring 3636 in the appropriate recess in bottom part

3535.

• Using the 6.2831.010 pincette, place the wet dialysis mem-

brane 3838 (e.g. 6.2714.010) inside the sealing ring 3636 on the

bottom part 3535.

Once saturated, take care that the dialysis membrane is not allowed to

dry out, otherwise it cannot be used any more !

754 Dialysis Unit

15

Page 19

2 Installation

Close dialysis cell

4

• Place top part 3838 on bottom part 3535 so that both parts lie

flush.

• Using the 6.2621.070 Allen key, screw the 5 screws 39 39 right

in and tighten up.

Attach dialysis cell

5

• Insert the assembled dialysis cell 3434 in the cell holder 66 of the

754 Dialysis Unit.

3434 3535 3636 3838 39393737

16

4040

4141 4242 4343 4444 4040

Fig. 7: Assembling the dialysis cell

3434 Dialysis cell (6.2729.100) 4040 Slot for positioning the dialysis

cell in cell holder 66

3535 Bottom part of the dialysis

cell

3636 Sealing ring (E.301.0111) 4242 Inlet for acceptor solution

3737 Dialysis membrane

(e.g. 6.2714.010)

3838 Top part of the dialysis cell 4444 Outlet for sample solution

3939 Screws V.022.6030 incl.

washer 4.754.4090

4141 Outlet for acceptor solution

4343 Inlet for sample solution

754 Dialysis Unit

Page 20

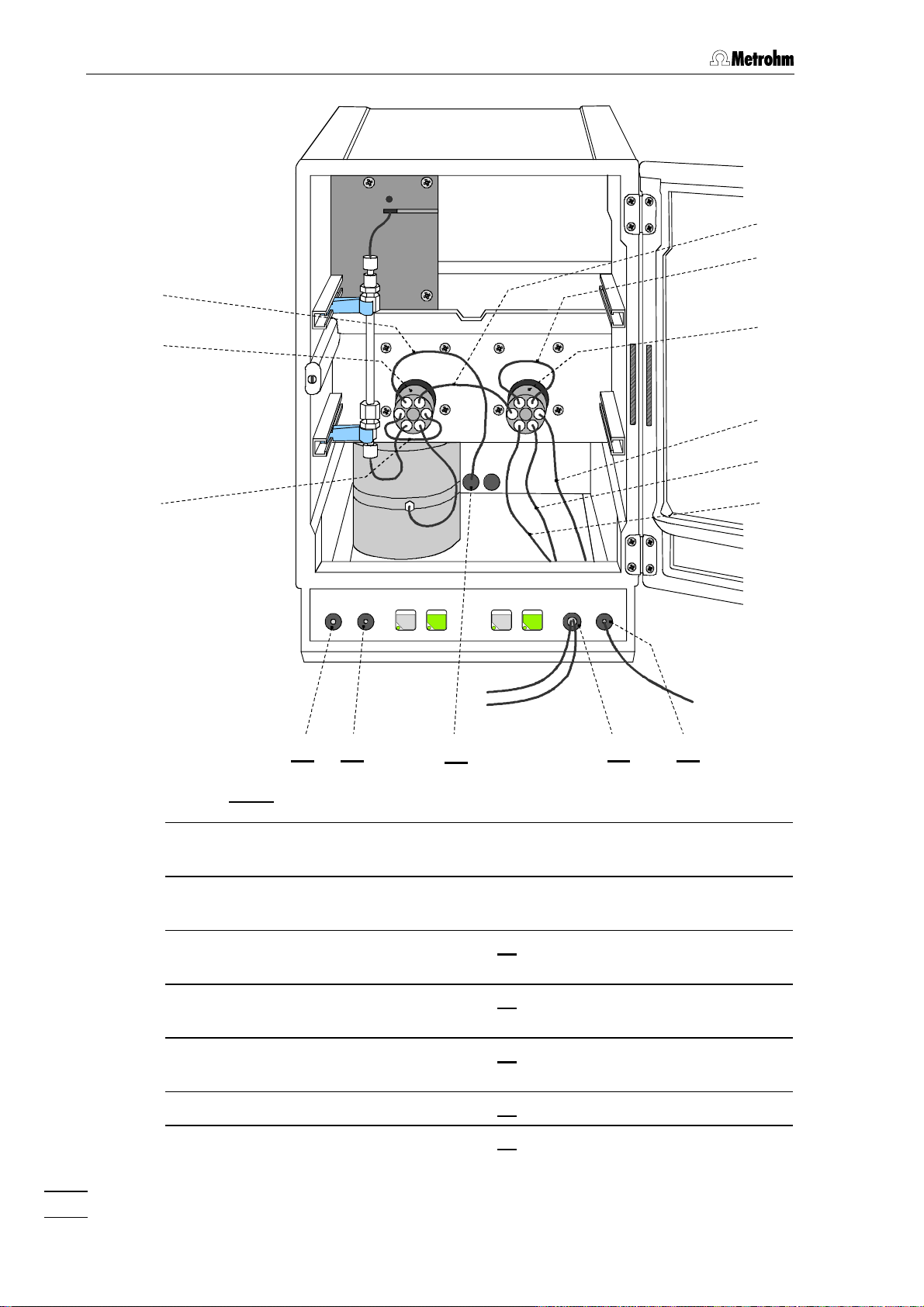

2.3.5 Connecting the dialysis cell

To connect the dialysis cell to the IC system proceed as follows (see

Fig. 8):

Tubing connections for acceptor solution

1

• Mount a PVDF compression fitting 5050 (6.2744.000) on the

end of PEEK capillary 24 24 projecting from feedthrough 2727 (see

Fig. 5).

• Screw PEEK capillary 2424 to inlet opening 4242 of the bottom

part 3535 of the cell (see Fig. 7).

• Mount a PVDF compression fitting 5050 (6.2744.000) to the end

of PEEK capillary 25 25 projecting from feedthrough 2727 (see Fig.

5).

• Screw PEEK capillary 2525 to outlet opening 4141 of the bottom

part 3535 of the cell (see Fig. 7).

Tubing connections for sample

2

• Mount a PVDF compression fitting 5050 (6.2744.000) on the

end of the PTFE capillary 33 33 connected to pump tubing 3030.

• Screw PTFE capillary 3333 to inlet opening 4343 of the top part 3838

of the cell (see Fig. 7).

• Mount a PVDF compression fitting 5050 (6.2744.000) to one

end of the PTFE capillary 4545 (6.1803.040; L = 1 m).

• Screw PTFE capillary 4545 to outlet opening 4444 of the top part

3838 of the cell (see Fig. 7).

2.3 Attaching the accessories

Do not connect the dialysis cell with anything other than the

6.2744.000 PVDF compression fittings supplied. If 6.2744.010

PEEK compression fittings are used, stress cracks may appear in the

dialysis cell !

754 Dialysis Unit

17

Page 21

2 Installation

27 26

20

17

733

A B

Column

Eluent

754

21

23

24

25

19

45

46

47

48

49

Acceptor Waste

Sample

1717 PEEK sample loop

(6.1825.210; 20 µµL)

1919 PEEK capillary (6.1831.060; 1 m)

Connection Valve A – Waste

2020 PEEK capillary (6.1831.040; 15 cm)

Connection Valve A – Valve B

2121 PEEK capillary (6.1831.040; 15 cm)

Connection at Valve B

2323 PEEK capillary (6.1831.050; 40 cm)

Connection Pump tubing – Valve B

2424 PEEK capillary (6.1831.050; 40 cm)

Connection Valve B – Dialysis cell

30 28 33 34

Fig. 8: Diagram of tubing connections

50 502931

3030 Pump tubing (6.1826.040)

for conveying the sample

3131 Pump tubing (6.1826.030)

for conveying the acceptor solution

3333 PTFE capillary (6.1803.050; 20 cm)

Connection Pump tubing – Dialysis cell

3434 Dialysis cell (6.2729.100)

4545 PTFE capillary (6.1803.040; 1 m)

Connection Dialysis cell – Waste

4646 PVDF compression fitting

(6.2744.000)

2525 PEEK capillary (6.1831.050; 40 cm)

Connection Valve B – Dialysis cell

2626 PTFE capillary (6.1803.030)

for feeding the sample in

2727 PTFE capillary (6.1803.030)

for feeding in the acceptor solution in

2828 PEEK compr. fitting (6.2744.010) 5050 PVDF compr. fitting (6.2744.000)

2929 Coupling (6.2744.030)

4747 PEEK compression fitting

(6.2744.010)

4848 Bottle attachment (6.1602.150)

4949 Waste bottle (6.1608.070)

18

754 Dialysis Unit

Page 22

2.3 Attaching the accessories

2.3.6 Attaching the accessories to the waste bottle

The waste bottle which receives the sample and acceptor solutions is

connected to the IC system as follows (see Fig. 8):

Attach bottle attachment

1

• Screw bottle attachment 4848 (6.1602.150) on to waste bottle

4949 (6.1608.070).

Connect tubing to the dialysis cell

2

• Pull one end of the PTFE capillary 45 45 connected to the dialy-

sis cell through a PVDF compression fitting 4646 (6.2744.000),

allowing 5 cm of tubing to project.

• Screw the PVDF compression fitting 4646 with tubing into an

opening in the bottle attachment 4848 and tighten so that the

tubing is held secure.

Connect tubing to valve A

3

• Pull the free end of the PEEK capillary 19 19 screwed to connec-

tion "2" of valve A through a PEEK compression fitting 4747

(6.2744.010), allowing 5 cm of tubing to project.

• Screw the PEEK compression fitting 4747 with tubing into an

opening in the bottle attachment 4848 and tighten so that the

tubing is held secure.

The end of the two tubings 1919 and 4545 inserted in the waste bottle

must be at the same height !

754 Dialysis Unit

19

Page 23

2 Installation

2.3.7 Conditioning the dialysis system

Before effecting the first analysis, rinse the dialysis cell, the inserted dialysis membrane and all tubing connections with ultrapure water. Proceed as follows:

Settings on the 733 IC Separation Center

1

• Press the <FILL> key for injection valve A on the 733 IC

Separation Center. This switches injection valve A to the

"FILL" position.

• Press the <FILL> key for injection valve B on the 733 IC

Separation Center. This switches injection valve B to the

"FILL" position.

Starting up the 754 Dialysis Unit

2

• Immerse the two suction tubings 2626 and 2727 in the acceptor

solution (ultrapure degassed water).

• Set the <REMOTE> switch 22 on the 754 Dialysis Unit to

"OFF".

• Switch on the 754 Dialysis Unit with mains switch 1313 and set

the <PUMP> switch 33 to "ON".

• Adjust the contact pressure for both tubing cartridges: Press

contact pressure lever 55 upwards until the solutions just start

to be drawn in. Then push the contact pressure lever upwards until it clicks again to achieve the optimum contact

pressure.

• Rinse the dialysis system with ultrapure water for approx.

10 min and check that the solutions flow steadily through the

two tubings into the waste bottle.

20

Conditioning the dialysis membrane

3

• Press the <INJECT> key for injection valve B on the 733 IC

Separation Center. This switches injection valve B to the

"INJECT" position.

• Rinse the dialysis system with ultrapure water for approx.

20 min. Check that the solutions flow steadily through the two

tubings into the waste bottle.

• Check all tubing from the storage vessels through the tubing

cartridges and the dialysis cell up to the waste containers for

any leaks. If liquid escapes anywhere, tighten or replace the

corresponding connection.

• If air bubbles remain in the dialysis cell, unscrew PEEK tubing

2525 (Acceptor solution) and PTFE tubing 4545 (sample) from

outlets 4141 and 4444 of the dialysis cell and wait until the air

bubbles disappear. Reconnect the tubings to the dialysis cell.

754 Dialysis Unit

Page 24

3 Operation

The 754 Dialysis Unit cannot be manually operated unless the installation has been carried out properly as described in section 2 (mains

connection, attaching pump tubing and dialysis cell, connection to

the IC system).

3.1 Manual operation

Switch instrument on/off

The 754 Dialysis Unit is switched on and off using mains switch

1313 on the rear of the instrument (see Fig. 2):

I Instrument switched on

0 Instrument switched off

3.1 Manual operation

REMOTE

ON

OFF

PUMP

ON

OFF

POWER

After the instrument has been switched on the power lamp 33

lights up to show that the instrument is ready for use.

Switch off remote control of the pump

In order to allow manual operation the remote control of the pump

must be switched off with switch 22.

ON Remote control switched on

OFF Remote control switched off

Switch pump on/off

The drive of the pump is switched on and off with the switch 11

<PUMP>:

ON Pump switched on

OFF Pump switched off

754 Dialysis Unit

21

Page 25

3 Operation

3.2 Operation via 732 IC Detector

Switch instrument on/off

The 754 Dialysis Unit is switched on and off using mains switch

1313 on the rear of the instrument (see Fig. 2):

I Instrument switched on

0 Instrument switched off

POWER

REMOTE

ON

OFF

Switch on:

After the instrument has been switched on the power lamp 33

lights up to show that the instrument is ready for use.

Switch on remote control of the pump

In order to allow remote operation via 732 IC Detector, the remote

control must be switched on with switch 22.

ON Remote control switched on

OFF Remote control switched off

Switch pump on/off in a program

In the 732 IC Detector the <PROGRAM> key can be used to

create time programs with a maximum of 20 program steps (see

section 4.7.1 of 732/733 Manual). The pump can be switched on

or off at any program step by setting the remote output lead (lead

1 or 4 depending on the cable) to 1 (on, active, 0 V) or 0 (off,

inactive, open) respectively:

with 6.2143.200 cable with 6.2143.220 cable

>PROGRAM/edit XXX.X min

remote 1TTTTTTT

>PROGRAM/edit XXX.X min

remote TTT1TTTT

22

Switch off:

Switch on:

Switch off:

>PROGRAM/edit XXX.X min

remote 0TTTTTTT

>PROGRAM/edit XXX.X min

remote TTT0TTTT

Switch pump on/off at an event

In the 732 IC Detector the <EVENT> key can be used to

program a maximum of 4 different events (see section 4.7.3 of

732/733 Manual). The pump can be switched on or off at any

event by setting the remote output lead (lead 1 or 4 depending on

the cable) to 1 (on, active, 0 V) or 0 (off, inactive, open) respectively:

with 6.2143.200 cable with 6.2143.220 cable

EVENT YY-MM-DD HH:MM:SS

remote 1TTTTTTT

EVENT YY-MM-DD HH:MM:SS

remote 0TTTTTTT

EVENT YY-MM-DD HH:MM:SS

remote TTT1TTTT

EVENT YY-MM-DD HH:MM:SS

remote TTT0TTTT

754 Dialysis Unit

Page 26

3.3 The dialysis procedure

3.3.1 Dialysis flow chart

Every sample dialysed with the 754 Dialysis Unit comprises the following four steps:

Rinsing

1

Valve A: FILL

Valve B: INJECT

Sample channel, acceptor channel and

sample loop are rinsed

(rinsing time: approx. 2

min).

Dialysis with «Stopped Flow»

2

Valve A: FILL

Valve B: FILL

The sample is dialysed

with resting acceptor

solution (dialysis time:

approx. 10 min).

3.3 The dialysis procedure

Fill Inject

A B

Column

Eluent

Acceptor

Sample

Fill Fill

A B

Column

Eluent

Acceptor

Sample

Waste

Waste

Transfer to sample loop

3

Valve A: FILL

Valve B: INJECT

The acceptor solution

enriched with ions from

the sample is transferred to the sample

loop (transfer time:

approx. 0.4 to 0.6 min).

Injection

4

Valve A: INJECT

Valve B: INJECT

The acceptor solution

enriched with ions from

the sample is injected

into the IC system.

Fill Inject

A B

Column

Eluent

Acceptor

Sample

Inject Inject

A B

Column

Eluent

Acceptor

Sample

Waste

Waste

754 Dialysis Unit

23

Page 27

3 Operation

3.3.2 Programming with the 732 IC Detector

Program without suppression

To dialyse in an IC system without suppression a program has to be

created for controlling the valves in the 733 IC Separation Center and

the 754 Dialysis Unit connected with cable 6.2143.200. The following

example program contains the necessary program steps.

PROGRAM

progr.type: cycle

number of cycles 1

Rinsing time

Dialysis time

Transfer time

Programming

time

0.0 valve A: fill

valve B: inject

remote: 1*******

2.0 valve B: fill

12.0 zero: on

valve B: inject

12.5 valve A: inject

remote 0*******

15.0 flag: end

Rinsing of sample loop

Rinsing of dialysis cell

Start of 754 Pump

Stop of acceptor solution

Trigger the auto-zero function

Transfer to sample loop

Injection (Õ Start evaluation)

Stop of 754 Pump

End of program

Rinsing time

Dialysis time

Transfer time

Programming

time

Program with suppression

To dialyze in an IC system with suppression a program has to be created for controlling the valves in the 733 IC Separation Center and the

754 Dialysis Unit and 753 Suppressor Module connected with cable

6.2143.220. The following example program contains the necessary

program steps.

PROGRAM

progr.type: cycle

number of cycle 1

0.0 valve A: fill

valve B: inject

remote: *0*1****

2.0 valve B: fill

12.0 zero: on

valve B: inject

remote: *1******

12.5 valve A: inject

remote ***0****

15.0 flag: end

Rinsing of sample loop

Rinsing of dialysis cell

Resetting of the remote line for the

suppressor and start of 754 Pump

Stop of acceptor solution

Trigger the auto-zero function

Transfer to sample loop

Switch suppressor to next position

Injection (Õ Start evaluation)

Stop of 754 Pump

Program end

24

754 Dialysis Unit

Page 28

3.3.3 Setting the rinsing time

A rinsing time of 2 min is normally sufficient to ensure thorough rinsing

of the sample and acceptor channels. This time can be increased if required.

3.3.4 Setting the transfer time

The time allowed for transferring the enriched acceptor solution to the

sample loop must be set to ensure that the part of the acceptor solution

with the highest concentration of ions is transferred to the sample loop.

With standard accessories the optimum transfer time depends on the

rate of operation of the pump; the following values can be used as a

guideline:

Mains frequency Optimum transfer time

50 Hz 0.5 min

60 Hz 0.4 min

3.3 The dialysis procedure

For each analysis problem, determine the optimum transfer time by

taking measurements of the individual ion concentrations in relation to

the transfer time itself and verify your measurements from time to time.

Proceed as follows:

First measurement

1

• Set the transfer time in the program to 0.2 min and the dialysis time to 10 min (see section 3.3.2).

• Immerse sample suction tubing 2626 in the standard with 10

mg/L of the required anion or cation.

• Start the program on the 732 IC Detector with the <PROG

R/S> key. Wait until the LED in the <PROG R/S> key stops

flashing, signalling the end of the measuring process.

Additional measurements

2

• Increase the transfer time in the program (see section 3.3.2)

by increments of 0.1 min until the concentration measured

falls again.

• Take measurements as in point 1.

Determining the optimum transfer time

3

• Record the measured peak area resp. concentration in relation to the transfer time and determine the optimum transfer

time.

754 Dialysis Unit

The Figure below shows an example of this determination process for

anions using the 6.2714.010 dialysis membrane (cellulose acetate;

thickness = 115 µm; pore size = 0.2 µm) available from Metrohm. The

sample was a standard solution containing 10 mg/L of each of the individual anions, which was dialysed for 10 min (mains frequency 50 Hz).

25

Page 29

3 Operation

12.0

10.0

8.0

6.0

4.0

Concentration [mg/L]

2.0

0.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

3.3.5 Setting the dialysis time

After calculating the optimum transfer time, determine the optimum dialysis time. This value will depend on the total ion concentration. The

dialysis time with a stopped acceptor flow should be selected so that

100% of the sample concentration is achieved in the acceptor solution.

For the 6.2714.010 dialysis membrane (cellulose acetate; thickness = 115 µm; pore size = 0.2 µm) available from Metrohm, the optimum dialysis time for a total ion concentration of ≥ 5 mg/L is 10 min.

Fluoride

Chloride

Nitrite

Bromide

Nitrate

Phosphate

Sulphate

Transfer time [min]

If a different dialysis membrane is used, or measurements are taken

with a total ion concentration of < 5 mg/L, then the optimum dialysis

time will have to be redetermined by measuring the recovery rate in relation to time. Proceed as follows:

Measure the standard directly

1

• Switch off remote control of the 754 Dialysis Unit with the

<REMOTE> key 22 (see section 3.1).

• Set the two valves A and B on the 733 IC Separation Center

to "FILL" with keys 2323 and 2525.

• Immerse suction tubing 2727 in the required ion standard,

which has approximately the same total ion concentration as

the samples.

• Switch on the pump on the 754 Dialysis Unit with the

<PUMP> key 11.

• After approx. 2 min, switch valve A on the 733 IC Separation

Center to "INJECT" with key 2424 and simultaneously start the

data evaluation system. In operation with the 753 Suppressor

Module, the suppressor has to be rotated with the <STEP>

key.

• Immerse suction tubing 2727 in the acceptor solution and rinse

the acceptor channel for approx. 2 min.

• Switch off the pump on the 754 Dialysis Unit with the

<PUMP> key 11.

• Switch the remote control of the 754 Dialysis Unit back on

with the <REMOTE> key 22.

26

754 Dialysis Unit

Page 30

3.3 The dialysis procedure

Measure the standard with dialysis

2

• Set the dialysis time in the program to 5 min (see section

3.3.2).

• Immerse sample suction tubing 2626 in the standard used in

point 1.

• Start the program on the 732 IC Detector with the <PROG

R/S> key. Wait until the LED in the <PROG R/S> key stops

flashing, signalling the end of the evaluation.

Additional measurements

3

• Increase the dialysis time in the program (see section 3.3.2)

by 5 min increments until the measured values remain constant.

• Take measurements as per point 2.

Determine optimum dialysis time

4

• Record the ratio of the peak surfaces, i.e. concentrations

measured with and without dialysis in relation to the dialysis

time (i.e. the recovery rate) and determine the optimum dialysis time.

3.3.6 Setting the program time

Set the program time so that the chromatogram can be completely recorded and evaluated within this period.

3.3.7 Dialysis procedure

To analyse samples using dialysis you should preferably proceed as

follows:

Prepare acceptor solution

1

• To avoid malfunctions caused by air bubbles in the acceptor

channel, the ultrapure water used for the acceptor solution

should always be degassed for at least 10 min with vacuum,

N2 or He.

Prepare sample

2

• To prevent blockages in the sample channel, samples con-

taining a high volume of (suspended/solid particles) should

always be centrifuged using a table centrifuge at 10,000

rev./min for 5 min.

754 Dialysis Unit

27

Page 31

3 Operation

Starting up the IC System

3

• Switch on the 732 IC Detector, load method and set program

status to active (see the 732/733 Manual).

• Switch on 709 IC Pump and condition IC column (see the 709

Manual).

• If applicable, switch on the 753 Suppressor Module and the

remote control (see the 753 Manual).

• Switch on data evaluation system (e.g. «IC Metrodata for

Win95»).

Starting up the dialysis system

4

• Switch on the 754 Dialysis Unit and switch off the remote

control with the <REMOTE> key 22 (see section 3.1).

• Immerse suction tubings 2626 and 2727 in the acceptor solution,

switch on the pump with the <PUMP> key 1 1 and rinse the

dialysis system with acceptor solution for approx. 10 min.

• Switch off the pump with the <PUMP> key 11 and switch on

the remote control with the <REMOTE> key 22.

Calibration

5

• Immerse sample suction tubing 2626 in the standard solution.

• Start program on the 732 IC Detector with the <PROG R/S>

key. The LED in the key will start to flash.

• The next standard can be measured as soon as the LED in

the <PROG R/S> key stops flashing.

Measuring the sample

6

• Immerse sample suction tubing 2626 in the sample solution.

• Start program on the 732 IC Detector with the <PROG R/S>

key. The LED in the key will start to flash.

• The next sample can be measured as soon as the LED in the

<PROG R/S> key stops flashing.

Rinse the dialysis system

7

• After completing the measurements, switch off the remote

control on the 754 Dialysis Unit with the <REMOTE> key 22

(see section 3.1).

• Immerse sample suction tubing 2626 in the acceptor solution,

switch on the pump with the <PUMP> key 1 1 and rinse the

dialysis system with acceptor solution for approx. 10 min.

• Switch off the pump with the <PUMP> key 11.

28

Shutting down the dialysis system

8

• If the dialysis cell is to remain switched off for a long period of

time, remove the inlet and outlet leads connecting to the dialysis cell and block openings 4141, 4242, 4343 and 4444 (see Fig. 7)

with 6.2744.060 dummy stoppers.

754 Dialysis Unit

Page 32

4.1 Malfunctions and their rectification

4 Malfunctions – Maintenance

4.1 Malfunctions and their rectification

If difficulties appear with the IC system during analysis, their cause are

best investigated in the order separating column →→ pump →→ eluent

→→ IC system. An overview of possible malfunctions, their causes and

remedies can be found in the instruction manuals of the 732/733 IC

System (section 5.3.2). In addition to these general malfunctions the

table below contains others which might arise as a result of the operation of the 754 Dialysis Unit.

Malfunction Possible causes Rectification

Insufficient or nonexisting flow rate at

754 Dialysis Unit

Leakage • Leaking compression fittings • Tighten the compression fittings or replace

Air bubbles in pump

circuit

• Contact pressure too low

• Pump tubing faulty

• Inlets to dialysis cell blocked

• Sample tubing blocked by

particles that are too large

• Bacterial growth in the sample

channel and dialysis cell

• Overly narrow PTFE tubings due

to excessive tightening of the

compression fittings

• Suction tubing is not immersed

• Leaking compression fittings

• Acceptor solution insufficiently

degassed

• Standing air bubbles

• Set contact pressure correctly with contact

pressure lever (see section 2.3.3).

• Replace pump tubing

(see section 4.2.5).

• Replace the dialysis membrane and clean

the cell (see section 4.2.6).

• Replace blocked tubing; always centrifuge

samples (see section 3.3.7).

• Periodically replace tubings 2626, 3030, 3333 and

4545 for the sample channel; replace the

dialysis membrane

• Replace tubings.

if necessary.

• Ensure suction tubing is fully immersed in

the acceptor or sample solution.

• Tighten the compression fittings or replace

if necessary.

• Re-degas the acceptor solution.

• Small air bubbles are not a problem. If big

air bubbles occur, rinse the sample channel with degassed acceptor solution (open

outlet briefly if need be).

Insufficient yield from

dialysis

754 Dialysis Unit

• Transfer time incorrectly set

• Dialysis time too short (e.g.

when concentration is too low)

• Dried out or damaged dialysis

membrane

• Deposits on the dialysis mem-

brane, recognizable from discolouring at the sample inlet

• Unsuitable dialysis membrane

• Check optimum transfer time, especially

after each change of membrane or tubing

(see section 3.3.4).

• Check optimum dialysis time (see section

3.3.5).

• Replace dialysis membrane

(see section 4.2.6).

• Replace dialysis membrane

(see section 4.2.6).

• Use different dialysis membrane.

29

Page 33

4 Malfunctions – Maintenance

4.2 Maintenance and servicing

4.2.1 Handling dialysis membranes

Dialysis membranes are very sensitive to contact and drying out. Avoid

touching them by hand and ensure that the membrane in the cell never

dries out.

The service life of a dialysis membrane is approx. 1 week under frequent use. Do not hesitate to replace the membrane if signs of decreased yield or blockages become apparent.

Please ensure you follow the instructions on how to install the dialysis

cell (section 2.3.4), how to shut it down (section 4.2.4) and how to re-

place the dialysis membrane (section 4.2.6).

4.2.2 Care of the unit

The 754 Dialysis Unit requires proper care and attention. Excessive

contamination of the instrument could possibly lead to malfunctions

and a shorter service life of the inherently rugged mechanical and electronic parts.

Wipe up spilled chemicals and solvents immediately. It is especially

important to protect the plug connections at the rear of the instrument

(particularly the mains plug) against contamination.

The unit has been constructed in such a way as to virtually eliminate

the possibility of penetration of corrosive media into the interior of the

instruments. If such a situation does occur, disconnect the mains

plug of the 754 Dialysis Unit immediately to prevent extensive damage

to the instrument electronics. Inform Metrohm service if your instrument has been damaged in such a way.

The instrument must not be opened by untrained personnel. Please

comply with the safety notes in section 1.5.1.

4.2.3 Maintenance by Metrohm service

Maintenance of the 754 Dialysis Unit is best done as part of an annual

service performed by specialists from the Metrohm company. If work is

frequently performed with caustic and corrosive chemicals, it may be

necessary to shorten the interval between servicing.

The Metrohm service department is always willing to offer expert advice

on the maintenance and servicing of all Metrohm instruments.

30

754 Dialysis Unit

Page 34

4.2.4 Shutdown

If the dialysis cell is to be switched off a long period of time the acceptor and sample channels should be rinsed with ultrapure water for approx. 10 min. Then remove the inlet and outlet leads from the dialysis

cell and block each of the openings 4141, 4242, 4343 and 4444 (see Fig. 7) with

a 6.2744.060 dummy stopper.

4.2.5 Replacing the pump tubing

Pump tubings are consumable material with a limited lifetime and

should be replaced at regular intervals (approx. every 2 weeks under

continuous use).

The working life of pump tubing depends to a considerable extent on

the contact pressure. This is why the contact pressure must be correctly set as described in section 2.3.3. If the pump is to remain

switched off for a lengthy period of time the tubing cartridges should be

raised completely by loosening snap-action lever 88 on the right-hand

side (the pre-set contact pressure remains unchanged).

4.2 Maintenance and servicing

To replace a pump tubing proceed as follows:

Remove old pump tubing

1

• Press contact pressure lever 55 on the tubing cartridge down

as far as it will go.

• Release tubing cartridge 44 from holding clamp 77 by pressing

down snap-action lever 88 and remove from mounting pin 1010

on the 754 Dialysis Unit (see Fig. 1).

• Remove old pump tubing.

Insert new pump tubing

2

• Insert the new pump tubing 3030 (6.1826.040) or 3131

(6.1826.040) in the tubing cartridge as shown in Fig. 6. The

stopper 3232 must click into the corresponding holder on the

left-hand side of the tubing cartridge.

• Place the tubing cartridge on mounting pin 1010 and press

down on the right-hand side until snap-action lever 88 clicks

into position on holding clamp 77. Take care that no kinks are

formed in the pump tubing.

754 Dialysis Unit

Set contact pressure

3

• Press contact pressure lever 55 upwards until the solution just

starts to be drawn in. Then press contact pressure lever upwards until it clicks once more to obtain optimal contact pressure.

31

Page 35

4 Malfunctions – Maintenance

4.2.6 Replacing the dialysis membrane

The dialysis membrane may have to be replaced in the following cases

(see section 4.1 as well):

• Reduced yield from dialysis

• Membrane has dried out, or is damaged by depos-

its or bacterial growth

• Irremediable blockage of the sample channel (sample

can no longer be conveyed through the dialysis cell)

To replace the membrane, proceed as follows (see Fig. 7):

Dismantle the dialysis cell

1

• Unscrew the four inlet/outlet leads from the dialysis cell 3434

and remove cell from cell holder 66.

• Loosen the 5 screws 39 39 completely using the 6.2621.070

Allen key and separate the top part 3838 from the bottom part

3535.

• Remove old dialysis membrane 3737.

Use only ultrapure water or ethanol to clean the dialysis cell;

organic solvents (e.g. acetone) will cause damage to the plexiglas

cell !

Clean dialysis cell

2

• Rinse the sealing ring 3636, the bottom part 3535 and the top part

3838 of the dialysis cell thoroughly with ultrapure water and dry

with N2 or a lint-free cloth.

Prepare dialysis membrane

3

• Take a new dialysis membrane 3838 (e.g. 6.2714.010) out of its

packaging using the 6.2831.010 pincette and immerse in a

Petri dish containing ultrapure water for approx. 2 min until

the membrane is completely saturated with water.

Insert dialysis membrane

4

• Place bottom part 3535 on a paper wipe with the inside facing

upwards.

• Insert sealing ring 3636 in the appropriate recess in the bottom

part 3535.

• Using the 6.2831.010 pincette, insert the wet dialysis mem-

brane 3838 (e.g. 6.2714.010) inside the sealing ring 3636 on the

bottom part 3535.

32

754 Dialysis Unit

Page 36

4.2 Maintenance and servicing

Close dialysis cell

5

• Place top part 3838 on bottom part 3535 so that both parts lie

flush.

• Screw the 5 screws 3939 in all the way in and tighten using the

6.2621.070 Allen key.

Attach dialysis cell

6

• Place the assembled dialysis cell 3434 in cell holder 66 of the

754 Dialysis Unit.

Connect dialysis cell

7

• Screw PEEK capillary 2424 to inlet opening 4242 of the bottom

part 3535 of the cell.

• Screw PEEK capillary 2525 to outlet opening 4141 of the bottom

part 3535 of the cell.

• Screw PTFE capillary 3333 to inlet opening 4343 of the top part 3838

of the cell.

• Screw PTFE capillary 4545 to the outlet opening 4444 of the top

part 3838 of the cell.

Condition dialysis membrane

8

• Immerse suction tubings 2626 and 2727 in the acceptor solution,

switch on pump with the <PUMP> key 1 1 and rinse the di-

alysis system with acceptor solution for approx. 20 min.

Check that the solution flows steadily from the two lines into

the waste bottle.

• Check all tubings between the storage vessels, the tubing

cartridges, the dialysis cell and the waste bottles for leaks. If a

leak occurs anywhere, tighten or replace the connection in

question.

• Switch off pump with the <PUMP> key 11.

754 Dialysis Unit

33

Page 37

4 Malfunctions – Maintenance

34

754 Dialysis Unit

Page 38

5 Appendix

external

754

5.1 Technical data

Dialysis cell

Material Plexiglass (polymethyl methacrylate)

Solvent compatibility Water, ethanol

Cell volume 240 µL (from inlet to outlet opening)

Diameter of membrane 47 mm

Pump

Pump type 2-channel peristaltic pump with rotational speed

5.1 Technical data

(no organic sovents!)

of

20/min (50 Hz)

24/min (60 Hz)

Pump capacity

(with water,

without counterpressure)

with 6.1826.030 pump tubing:

typically 0.5…0.6 mL/min

with 6.1826.040 pump tubing:

typically 0.9…1.1 mL/min

Pressure max. 1.5 bar (0.15 MPa)

Pump tubing material PVC (Tygon)

Mains connection

Mains voltage 115 V: 100...120 V ± 10 %

230 V: 220...240 V ± 10 %

Switchable with voltage selector in fuse holder

(see section 2.2.1)

Mains frequency 50...60 Hz

Power consumption 12 VA

Fuse 5 mm Ø, 20 mm length

100…120 V: 0.2 A (slow-blow)

220…240 V: 0.1 A (slow-blow)

Remote interface

Purpose

Remote control of pump (switching on/off)

754 Dialysis Unit

Pin assignment

+5V

330

Pin

Current flows: on

Current does not flow: off

2

+

-

5

35

Page 39

5 Appendix

Safety specifications

Construction / Testing According to IEC 1010 / EN 61010 / UL 3101-1,

protection class I, degree of protection IP40

Safety directions The Instructions for Use include information and

warnings to which the user must pay attention in

order to assure safe operation of the instrument.

Electromagnetic compatibility (EMC)

Emitted interference Standards met:

EN55011 (class B), EN55022 (class B),

EN50081-1

Immunity to interference Standards met:

IEC801-2/IEC1000-4-2 (class 4), IEC801-3/

IEC1000-4-3 (class 3), IEC801-4/IEC1000-4-4

(class 4), IEC801-6/IEC1000-4-6 (class 3),

IEC1000-4-11, EN50082-2, EN60555-2

Ambient temperature

Nominal operating range +5…+45°C

(at 20…80 % atmospheric humidity)

Storage, transport –40…+70°C

Housing

Material of cover Polyurethane rigid foam (PUR) with fire protection

for fire class UL94VO, CFC-free

Material of base Steel, enamelled

Dimensions

Width 260 mm

Height 129 mm

Depth 366 mm (without dialysis cell)

Weight 5.6 kg (incl. accessories)

36

754 Dialysis Unit

Page 40

5.2 Standard equipment

GL45

262

1.59

1.59

1.59

136

0.5

0.5

0.5

Subject to changes!

All dimensions are given in mm.

The 2.754.0010 Dialysis Unit includes the following parts:

Quant. Order No. Description

1 6.1602.150 Bottle attachment GL45

for 6.1608.070 clear glass bottle

1 6.1608.070 Clear glass bottle 2 L

Waste bottle, with GL45 thread

5.2 Standard equipment

GL45

1 6.1803.030 PTFE Capillary tubing

Length = 5 m

5 6.1803.040 PTFE Capillary tubing

Length = 1 m

5 6.1803.050 PTFE Capillary tubing

Length = 20 cm

1 6.1825.210 PEEK Sample loop 20 µµL

For injection valve.

Incl. two 6.2744.010 PEEK

compression fittings

2 6.1826.030 Pump tubing

made of PVC (Tygon); with 2 firmly

attached orange-yellow stoppers;

i.d. = 0.51 mm, e.d. = 2.27 mm

2 6.1826.040 Pump tubing

made of PVC (Tygon); with 2 firmly

attached black-black stoppers;

i.d. = 0.76 mm, e.d. = 2.27 mm

150

400

150

400

754 Dialysis Unit

37

Page 41

5 Appendix

802821

Quant. Order No. Description

2 6.1831.040 PEEK Capillary tubing

Length = 15 cm

3 6.1831.050 PEEK Capillary tubing

Length = 40 cm

1 6.1831.060 PEEK Capillary tubing

Length = 1 m

1 6.2122.0X0 Mains cable

to customer's specifications:

Cable socket Cable connector

Type IEC 320/C 13 Type SEV 12 (CH…)............................... 6.2122.020

Type IEC 320/C 13 Type CEE (7), VII (D…)........................... 6.2122.040

Type CEE (22), V Type NEMA 5-15 (USA…) ......................6.2122.070

0.5

0.5

0.5

1.59

1.59

1.59

1 6.2621.070 Allen Key 5 mm

For the dialysis cell screws

1 6.2729.100 Dialysis cell (plexiglass)

incl. the following accessories:

1 × E.301.0111 NBR sealing ring

5 × V.022.6030 Steel screw

5 × 4.754.4090 POM washer for screw

4 × 6.2744.060 Dummy stopper for

blocking inlet and outlet

openings

1 6.2744.000 PVDF Compression fitting

For connecting 6.1803.0X0 PTFE

capillaries to the dialysis cell,

set of 5 pcs

1 6.2744.010 PEEK compression fitting

For connecting 6.1831.0X0 PEEK capillaries

and 6.1803.0X0 PTFE capillaries,

set of 5 pcs

SW5

26

1 6.2744.030 PEEK coupling

Connection between 6.2744.010 PEEK compression fitting and 6.1826.0X0 pump tubing ;

set of 4 pcs

38

25

754 Dialysis Unit

Page 42

Quant. Order No. Description

5.3 Optional accessories

1 6.2756.000 Feedthrough

For the 733 IC Separation Center, for feeding

through capillary tubings

1 6.2831.010 Pincette

For handling dialysis membranes

1 8.754.1003 Instructions for use (English)

for 754 Dialysis Unit

5.3 Optional accessories

Order No. Description

6.2143.200 Connecting cable

Connecting cable 732 IC Detector – 754 Dialysis Unit.

12

10

120

9

6.2143.220 Connecting cable

Connecting cable 732 IC Detector – 753 Suppressor Module – 754 Dialysis Unit.

6.2714.010 Dialysis membranes

Dialysis membranes in cellulose acetate;

diameter 47 mm; thickness 115 µm; nominal pore size 0.2 µm.

set of 50 pcs

754 Dialysis Unit

39

Page 43

5 Appendix

5.4 Warranty and conformity

5.4.1 Warranty

The warranty on our products is limited to defects that are traceable to

material, construction or manufacturing error which occur within 12

months from the day of delivery. In such cases the defects will be rectified in our workshops free of charge. Transport costs are to be paid by

the customer.

For day and night operation the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not covered

by the warranty. Checks which we are asked to carry out during the

warranty period for reasons other than material or manufacturing faults

will be invoiced. For parts manufactured by third parties, insofar as

these constitute an appreciable part of our instrument, the warranty

stipulations of the manufacturer in question apply.

With regard to the guarantee of accuracy, the technical specifications in

the instruction manual are authoritative.

With regard to defects in material, construction or design as well as the

absence of guaranteed features, the purchaser has no rights or claims

except those mentioned above.

If damage of the packaging is evident on receipt of a consignment or if

the goods show signs of transport damage after unpacking, the carrier

must be informed immediately and a written damage report for requested. Lack of an official damage report releases Metrohm from any

liability to pay compensation.

If any instruments and parts have to be returned, the original packaging

should be used if at all possible. This applies above all to instruments,

electrodes, burette cylinders and PTFE pistons. Before embedding

them in wood shavings or similar material, the parts must be packed in

a dustproof package (for instruments the use of a plastic bag is imperative). If open assemblies are enclosed in the scope of delivery that

are sensitive to electromagnetic voltages (e.g. data interfaces etc.)

these must be returned in the associated original protective packaging

(e.g. conductive protective bag). (Exception: assemblies with built-in

voltage source belong in a non-conductive protective packaging). No

warranty responsibility whatsoever will be accepted by Metrohm for

damage which arises as a result of non-compliance with these instructions.

40

754 Dialysis Unit

Page 44

5.4.2 EU Declaration of conformity

EU Declaration of Conformity

The METROHM AG company, Herisau, Switzerland hereby certifies that the instrument:

754 Dialysis Unit

meets the requirements of EC Directives 89/336/EWG and 73/23/EWG.

5.4 Warranty and conformity

Source of the specifications

EN 50081-1 Electromagnetic compatibility, basic specification

Emitted Interference

EN 50082-2 Electromagnetic compatibility, basic specification

Interference Immunity

EN 61010 Safety requirements for electrical laboratory measurement

and control equipment

Description of the instrument

Appliance for on-line dialysis sample preparation with 2-channel peristaltic

pump

Herisau, September 27, 1997

754 Dialysis Unit

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

41

Page 45

5 Appendix

5.4.3 Certificate of conformity and system validation

Certificate of Conformity and System Validation

This is to certify the conformity to the standard specifications for electrical appliances and accessories, as well as to the standard specifications for security and

to system validation issued by the manufacturing company.

Name of commodity: 754 Dialysis Unit

Name of manufacturer: Metrohm Ltd., Herisau, Switzerland

Principal technical information: Voltages: 100…120, 220…240 V

Frequency: 50…60 Hz

This Metrohm instrument has been built and has undergone final type testing

according to the standards:

IEC801-2/IEC1000-4-2 (class 4), IEC801-3/IEC1000-4-3 (class 3),

IEC801-4/IEC1000-4-4 (class 4), IEC801-6/IEC1000-4-6 (class 3),

IEC1000-4-11, EN55011 (class B), EN55022 (class B), EN50081-1,

EN50082-2, EN60555-2 — Electromagnetic compatibility

IEC1010, EN61010, UL3101-1 — Security specifications

The technical specifications are documented in the instruction manual.

Metrohm Ltd. is holder of the SQS-certificate of the quality system ISO 9001 for

quality assurance in design/development, production, installation and servicing.

Herisau, September 27, 1997

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

42

754 Dialysis Unit

Page 46

5.5 Index

5.5 Index

A

Acceptor solution ..................................13,17,19,26

Air bubbles ......................................................20,29

Allen key (6.2621.070)................................ 15,32,38

Ambient temperature............................................ 36

Appendix ..............................................................35

Application Bulletins............................................... 5

Application Notes................................................... 5

Arrangement of the instruments............................. 7

Assembling the dialysis cell ................................. 16

Attaching the accessories............................... 10,13

Attaching the dialysis cell..................................... 15

B

Bacterial growth............................................... 29,32

Blockage ......................................................... 29,32

Bottle attachment 4848

Figure .............................................................18