MCCULLOCH LST42C-669 User Manual

™

owners manual MANUAL DEL USUARIO

MANUEL DU PROPRIÉTAIRE BEDIENUNGSANLEITUNG

MANUALE DEL PROPRIETARIO

Model No.

Modelo nº

Modèle nº

Modell-Nr.

Modello nº

LST42C-669

CAUTION:

Read Rules for Safe Operation and Instructions Carefully

PRECAUCIÓN:

Lea cuidadosamente las instrucciones y las reglas para una operación segura

AVERTISSEMENT :

Lire et suivre attentivement les instructions et consignes de sécurité

AACHTUNG:

Lesen Sie bitte sowohl die Hinweise zum sicheren Betrieb sowie auch die Anweisungen sorgfältig durch

ATTENZIONE:

Leggere attentamente le norme di sicurezza e le istruzioni

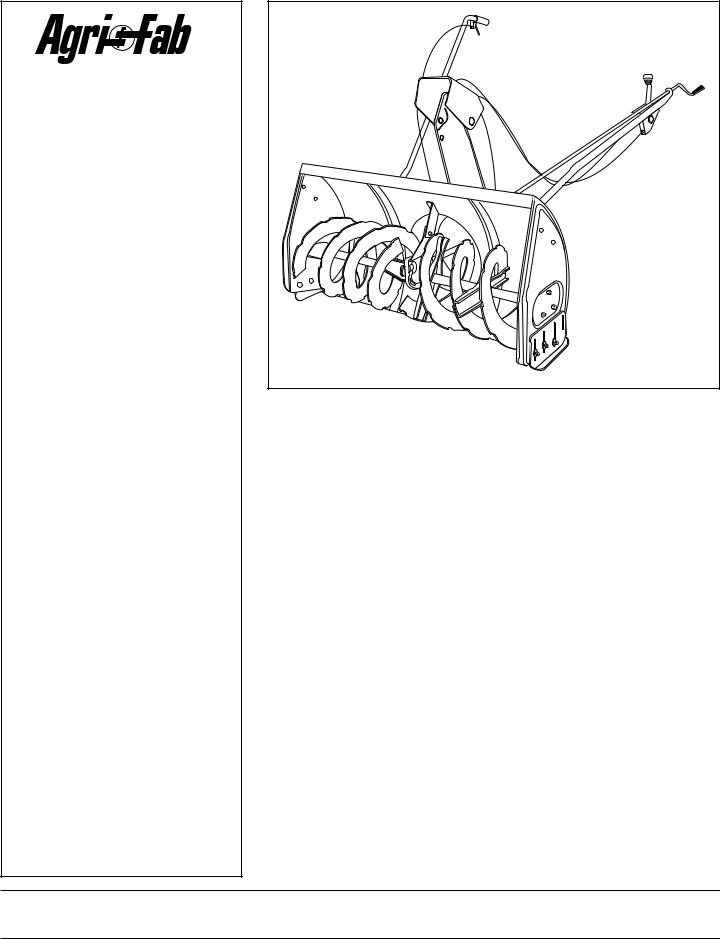

42" SNOW THROWER SOPLADOR DE NIEVE DE 42" (106 cm) SOUFFLEUSE À NEIGE 42 PO. (106 cm)

SCHNEEFRÄSE 42" (106 cm) SPARTINEVE A TURBINA 42" (106 cm)

• Safety |

• Sécurité |

• Sicurezza |

• Assembly |

• Assemblage |

• Montaggio |

• Operation |

• Utilisation |

• Funzionamento |

• Maintenance |

• Entretien |

• Manutenzione |

• Seguridad |

• Sicherheit |

• Montaje |

• Zusammenbau |

• Funcionamiento |

• Betrieb |

• Mantenimiento |

• Wartung |

the fastest way to purchase parts www.speedepart.com

the fastest way to purchase parts www.speedepart.com

PRINTED IN U.S.A. |

FORM NO. 40429 (REV. 1/7/08) |

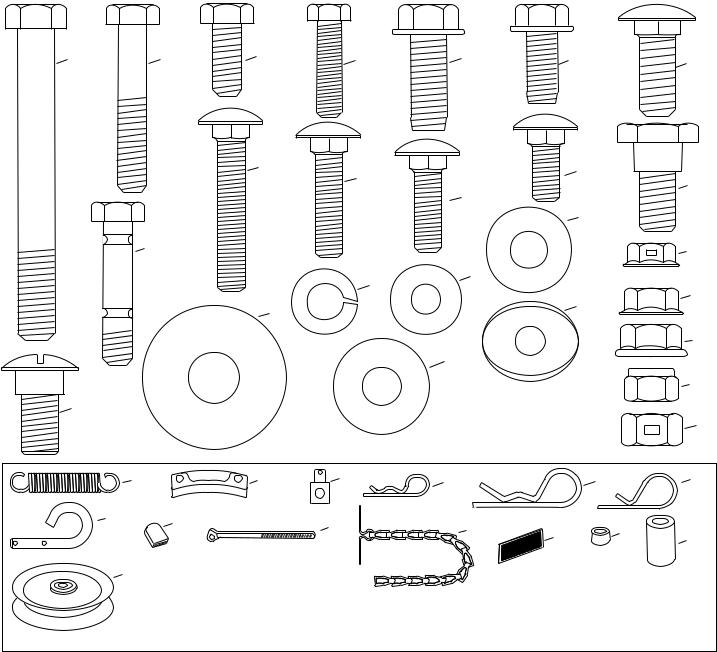

A |

B |

|

N |

M

C |

D |

E |

F |

G |

|

|

|

|

H |

|

I |

|

K |

|

|

|

||

|

|

|

L |

|

|

|

|

|

|

|

|

|

|

J |

|

|

|

|

Q |

|

|

|

|

V |

|

|

|

O |

P |

|

|

|

W |

|

|

|

|

|

|

|

R |

|

|

U |

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

S,T |

|

|

|

|

Y |

|

|

|

|

Z |

AA |

BB |

CC |

DD |

|

EE |

|

FF |

GG |

HH |

II |

JJ |

|

|

LL |

|

|

|

|

|

||||

|

|

KK |

|

MM |

|||

|

|

|

|

|

|

||

NN |

|

|

|

|

|

|

|

REF. |

QTY |

DESCRIPTION |

REF. |

QTY |

DESCRIPTION |

REF. |

QTY |

DESCRIPTION |

|

A |

1 |

Hex Bolt, 3/8" x 3-1/4" |

L |

4 |

Shoulder Bolt |

Z |

2 |

Hex Lock Nut, 3/8" |

|

B |

2 |

Hex Bolt, 5/16" x 1-3/4" |

M |

2 |

Shoulder Bolt |

AA |

1 |

Spring |

|

C |

4 |

Hex Bolt, 5/16" x 3/4" |

N |

2 |

Shear Bolt (spare parts) |

BB |

3 |

Chute Keeper |

|

D |

6 |

Hex Bolt, 1/4" x 1" |

O |

7 |

Lock Washer, 3/8" |

CC |

1 |

Trunnion |

|

E |

6 |

Hex Bolt, 3/8" x 1" (Thread |

P |

7 |

Washer, 1/4" |

DD |

2 |

Hairpin Cotter, 5/64" |

|

|

|

Forming) |

Q |

6 |

Washer, 5/16" |

EE |

4 |

Hairpin Cotter, 1/8" |

|

F |

2 |

Hex Bolt, 5/16" x 3/4" |

R |

8 |

Washer, 1/2" |

FF |

1 |

Hairpin Cotter, 3/32" |

|

|

|

(Thread Forming) |

S |

1 |

Washer, 3/8" (Thin) |

GG |

2 |

Lock Pin |

|

G |

6 |

Carriage Bolt, 3/8" x 1" |

T |

3 |

Washer, 3/8" |

HH |

1 |

Plastic Cap |

|

H |

2 |

Carriage Bolt, 5/16" x |

U |

2 |

Bowed Washer |

II |

2 |

Nylon Tie |

|

|

|

1-3/4" |

V |

6 |

Flanged Nut, 1/4" |

JJ |

2 |

Chain, Tensioning |

|

I |

2 |

Carriage Bolt , 5/16" x |

W |

1 |

Flanged Nut, 5/16" |

KK |

2 |

Tail Reflector |

|

|

|

1-1/4" |

X |

10 |

Flanged Nut, 3/8" |

LL |

1 |

Small Spacer |

|

|

|

Y |

17 |

Nylock Nut, 5/16" (2 spare |

MM |

1 |

Large Spacer |

||

J |

4 |

Carriage Bolt, 5/16" x 1" |

|||||||

|

|

parts) |

NN |

1 |

Pulley |

||||

K |

2 |

Carriage Bolt, 5/16" x 3/4" |

|

|

|||||

|

|

|

|

|

|

|

|

|

2

REF. |

CANT. |

DESCRIPCIÓN |

REF. |

CANT. |

DESCRIPCIÓN |

REF. |

CANT. |

DESCRIPCIÓN |

|

A |

1 |

Tuerca hexagonal de 3/8” |

J |

4 |

Perno de cabeza de |

Y |

17 |

Tuerca Nylock de 5/16" (2 |

|

|

|

x 3-1/4" |

|

|

hongo y cuello cuadrado |

|

|

piezas de repuesto) |

|

B |

2 |

Tuerca hexagonal de |

|

|

de 5/16” x 1" |

Z |

2 |

Tuerca hexagonal de |

|

|

|

5/16” x 1-3/4" |

K |

2 |

Perno de cabeza de |

|

|

cierre de 3/8 |

|

C |

4 |

Tuerca hexagonal de |

|

|

hongo y cuello cuadrado |

AA |

1 |

1 resorte |

|

|

|

5/16" x 3/4" |

|

|

de 5/16 x 3/4" |

BB |

3 |

Sujetador del conducto |

|

D |

6 |

Perno de cabeza |

L |

4 |

Perno de tope |

CC |

1 |

Muñón de sujeción |

|

|

|

hexagonal de 1/4” x 1" |

M |

2 |

Perno de tope |

DD |

2 |

Pasador de horquilla de |

|

E |

6 |

Perno de cabeza |

N |

2 |

Perno de seguridad |

||||

|

|

5/64" |

|||||||

|

|

hexagonal de 3/8” x 1" |

|

|

(piezas de repuesto) |

EE |

4 |

Pasador de horquilla de |

|

|

|

(auto-roscante) |

O |

7 |

Arandela de presión de |

||||

|

|

|

|

1/8" |

|||||

F |

2 |

Perno de cabeza |

|

|

3/8" |

FF |

1 |

Pasador de horquilla de |

|

|

|

hexagonal de 5/16” x 3/4" |

P |

7 |

Arandela de 1/4" |

||||

|

|

|

|

3/32" |

|||||

|

|

(auto-roscante) |

Q |

6 |

Arandela de 5/16" |

GG |

2 |

Pasador de traba |

|

G |

6 |

Perno de cabeza de |

|||||||

R |

8 |

Arandela de 1/2" |

HH |

1 |

Tapa plástica |

||||

|

|

hongo y cuello cuadrado |

|||||||

|

|

S |

1 |

Arandela de 3/8" |

II |

2 |

Tirante de Nylon |

||

|

|

de 3/8" x 1" |

|||||||

|

|

|

|

(delgada) |

JJ |

2 |

Cadena, tensora |

||

H |

2 |

Perno de cabeza de |

|

|

|||||

T |

3 |

Arandela de 3/8" |

|||||||

KK |

2 |

Reflector de cola |

|||||||

|

|

hongo y cuello cuadrado |

|||||||

|

|

U |

2 |

Arandela curvada |

|||||

|

|

LL |

1 |

Espaciador pequeño |

|||||

|

|

de 5/16 x 1-3/4" |

|||||||

|

|

V |

6 |

Tuerca con brida de 1/4" |

|||||

I |

2 |

Perno de cabeza de |

MM |

1 |

Espaciador grande |

||||

W |

1 |

Tuerca con brida de 5/16" |

|||||||

|

|

hongo y cuello cuadrado |

NN |

1 |

Polea |

||||

|

|

X |

10 |

Tuerca con brida de 3/8" |

|||||

|

|

de 5/16 x 1-1/4" |

|

|

|

||||

|

|

|

|

|

|

|

|

|

RÉF. |

QTÉ |

DESCRIPTION |

RÉF. |

QTÉ |

DESCRIPTION |

RÉF. |

QTÉ |

DESCRIPTION |

|

A |

1 |

Boulon hex., 3/8 x 3-1/4 po. |

M |

2 |

Boulon à épaulement |

AA |

1 |

1 Ressort |

|

B |

2 |

Boulon hex., 5/16 x 1-3/4 po. |

N |

2 |

Boulon de cisaillement |

BB |

3 |

Gâches de la goulotte |

|

C |

4 |

Boulon hex., 5/16 x 3/4 po. |

|

|

(pièces de rechange) |

|

|

d’éjection |

|

D |

6 |

Boulon hex., 1/4 x 1 po. |

O |

7 |

Rondelle de blocage, 3/8 po. |

CC |

1 |

Tourillon |

|

E |

6 |

Boulon hex., 3/8 x 1 po. |

P |

7 |

Rondelle, 1/4 po. |

DD |

2 |

Goupille fendue, 5/64 po. |

|

|

|

(auto-taraudeur) |

Q |

6 |

Rondelle, 5/16 po. |

EE |

4 |

Goupille fendue, 1/8 po. |

|

F |

2 |

Boulon hex., 5/16 x 3/4 po. |

R |

8 |

Rondelle, 1/2 po. |

FF |

1 |

Goupille fendue, 3/32 po. |

|

|

|

(auto-taraudeur) |

S |

1 |

Rondelle, 3/8 po. (fine) |

GG |

2 |

Axe de blocage |

|

G |

6 |

Boulon de carrosserie, 3/8 |

T |

3 |

Rondelle, 3/8 po. |

HH |

1 |

Capuchon en plastique |

|

|

|

x 1 po. |

U |

2 |

Rondelle frein |

II |

2 |

Attache en nylon |

|

H |

2 |

Boulon de carrosserie, 5/16 |

|||||||

V |

6 |

Écrou à embase, 1/4 po. |

JJ |

2 |

Chaîne de tension |

||||

|

|

x 1-3/4 po. |

|||||||

|

|

W |

1 |

Écrou à embase, 5/16 po. |

KK |

2 |

Catadioptre arrière |

||

I |

2 |

Boulon de carrosserie , 5/16 |

|||||||

X |

10 |

Écrou à embase, 3/8 po. |

LL |

1 |

Petite rondelle d’espacement |

||||

|

|

x 1-1/4 po. |

|||||||

|

|

Y |

17 |

Écrou mécanique de |

MM |

1 |

Grande rondelle |

||

J |

4 |

Boulon de carrosserie, 5/16 |

|||||||

|

|

sécurité, 5/16 po. (2 pièces |

|

|

d’espacement |

||||

|

|

x 1 po. |

|

|

|

|

|||

|

|

|

|

de rechange) |

NN |

1 |

Poulie |

||

K |

2 |

Boulon de carrosserie, 5/16 |

|

|

|||||

Z |

2 |

Écrou de blocage hex. 3/8 |

|

|

|

||||

|

|

x 3/4 po. |

|

|

|

||||

|

|

|

|

po. |

|

|

|

||

L |

4 |

Boulon à épaulement |

|

|

|

|

|

||

|

|

|

|

|

|

3

BEZ. |

ANZ. |

BESCHREIBUNG |

BEZ. |

ANZ. |

BESCHREIBUNG |

BEZ. |

ANZ. |

BESCHREIBUNG |

|

A |

1 |

Sechskantschraube, 3/8" |

K |

2 |

Schlossschraube, 5/16" |

Z |

2 |

Sechskantsicherungsmut |

|

|

|

x 3-1/4" |

|

|

x 3/4" |

|

|

ter, 3/8" |

|

B |

2 |

Sechskantschraube, 5/16" |

L |

4 |

Gelenkschraube |

AA |

1 |

1 Feder |

|

|

|

x 1-3/4" |

M |

2 |

Gelenkschraube |

BB |

3 |

Leitblechhalterung |

|

C |

4 |

Sechskantschraube, 5/16" |

N |

2 |

Scherschraube |

CC |

1 |

Zapfen |

|

|

|

x 3/4" |

|

|

(Ersatzteile) |

DD |

2 |

Haarnadelsplint, 5/64" |

|

D |

6 |

Sechskantschraube, 1/4" |

O |

7 |

Sicherungsscheibe, 3/8" |

EE |

4 |

Haarnadelsplint, 1/8" |

|

|

|

x 1" |

P |

7 |

Unterlegscheibe, 1/4" |

FF |

1 |

Haarnadelsplint, 3/32" |

|

E |

6 |

Sechskantschraube, 3/8" x |

|||||||

Q |

6 |

Unterlegscheibe, 5/16" |

GG |

2 |

Steckbolzen |

||||

|

|

1" (gewindeschneidend) |

|||||||

|

|

R |

8 |

Unterlegscheibe, 1/2" |

HH |

1 |

Plastikkappe |

||

F |

2 |

Sechskantschraube, |

|||||||

S |

1 |

Unterlegscheibe, 3/8" |

II |

2 |

Kabelbinder |

||||

|

|

5/16" x 3/4" |

|||||||

|

|

|

|

(dünn) |

JJ |

2 |

Spannkette |

||

|

|

(gewindeschneidend) |

|

|

|||||

|

|

T |

3 |

Unterlegscheibe, 3/8" |

|||||

|

|

KK |

2 |

Rückwärtiger Reflektor |

|||||

G |

6 |

Schlossschraube, 3/8" x 1" |

|||||||

U |

2 |

Gewölbte Unterlegscheibe |

|||||||

LL |

1 |

Kleines Distanzstück |

|||||||

H |

2 |

Schlossschraube, 5/16" x |

|||||||

V |

6 |

Flanschmutter, 1/4" |

|||||||

MM |

1 |

Großes Distanzstück |

|||||||

|

|

1-3/4" |

|||||||

|

|

W |

1 |

Flanschmutter, 5/16" |

|||||

I |

2 |

Schlossschraube, 5/16" x |

NN |

1 |

Riemenscheibe |

||||

X |

10 |

Flanschmutter, 3/8" |

|||||||

|

|

1-1/4" |

|

|

|

||||

|

|

Y |

17 |

Sechskantmutter mit |

|

|

|

||

J |

4 |

Schlossschraube, 5/16" |

|

|

|

||||

|

|

Klemmteil, 5/16" (2 |

|

|

|

||||

|

|

x 1" |

|

|

|

|

|

||

|

|

|

|

Ersatzteile) |

|

|

|

||

|

|

|

|

|

|

|

|

RIF. |

QTÀ. |

DESCRIZIONE |

RIF. |

QTÀ. |

DESCRIZIONE |

RIF. |

QTÀ. |

DESCRIZIONE |

|

A |

1 |

Bullone esagonale da 3/8" |

K |

2 |

Chiavarda a testa rotonda |

Y |

17 |

Dado Nylock da 5/16" (2 |

|

|

|

x 3-1/4" |

|

|

da 5/16" x 3/4" |

|

|

parti di ricambio) |

|

B |

2 |

Bullone esagonale da 5/16" |

L |

4 |

Vite con gambo |

Z |

2 |

Controdado esagonale da |

|

|

|

x 1-3/4" |

|

|

parzialmente filettato |

|

|

3/8" |

|

C |

4 |

Bullone esagonale da 5/16" |

M |

2 |

Vite con gambo |

AA |

1 |

1 molla |

|

|

|

x 3/4" |

|

|

parzialmente filettato |

BB |

3 |

Fissatore dello scivolo |

|

D |

6 |

Bullone esagonale da 1/4" |

N |

2 |

Perno di sicurezza (pezzi di |

CC |

1 |

Perno di articolazione |

|

|

|

x 1" |

|

|

ricambio) |

DD |

2 |

Chiavetta a forcella da 5/64" |

|

E |

6 |

Bullone esagonale da 3/8" x |

O |

7 |

Rondella elastica da 3/8" |

||||

EE |

3 |

Chiavetta a forcella da 1/8" |

|||||||

|

|

1" (autofilettante) |

P |

7 |

Rondella da 1/4" |

||||

|

|

FF |

1 |

Chiavetta a forcella da 3/32" |

|||||

F |

2 |

Bullone esagonale da 5/16" |

Q |

6 |

Rondella da 5/16" |

||||

GG |

2 |

Spinotto di bloccaggio |

|||||||

|

|

x 3/4" (autofilettante) |

R |

8 |

Rondella da 1/2" |

||||

|

|

HH |

1 |

Tappo di plastica |

|||||

G |

6 |

Chiavarda a testa rotonda |

|||||||

S |

1 |

Rondella da 3/8" (Thin) |

|||||||

II |

2 |

Tirante di plastica |

|||||||

|

|

da 3/8" x 1" |

|||||||

|

|

T |

3 |

Rondella da 3/8" |

|||||

|

|

JJ |

2 |

Catena, Messa in tensione |

|||||

H |

2 |

Chiavarda a testa rotonda |

|||||||

U |

2 |

Rondella arcuata |

|||||||

KK |

2 |

Riflettore di coda |

|||||||

|

|

da 5/16" x 1-3/4" |

|||||||

|

|

V |

6 |

Dado a colletto da 1/4" |

|||||

|

|

LL |

1 |

Piccolo distanziale |

|||||

I |

2 |

Chiavarda a testa rotonda |

|||||||

W |

1 |

Dado a colletto da 5/16" |

|||||||

MM |

1 |

Grande distanziale |

|||||||

|

|

da 5/16" x 1-1/4" |

|||||||

|

|

X |

10 |

Dado a colletto da 3/8" |

|||||

J |

4 |

Chiavarda a testa rotonda |

NN |

1 |

Puleggia |

||||

|

|

|

|||||||

|

|

da 5/16" x 1" |

|

|

|

|

|

|

4

2 |

3 |

4 |

5 |

|

|||

1 |

|

|

|

|

|

|

6 |

7 |

|

11 |

|

8 |

|

12 |

|

|

|

||

|

|

|

|

9 |

|

|

18 |

|

10 |

|

|

13 |

|

|

|

17 |

|

|

|

14 |

|

|

|

15 |

|

|

|

16 |

|

|

|

|

|

19 |

20 |

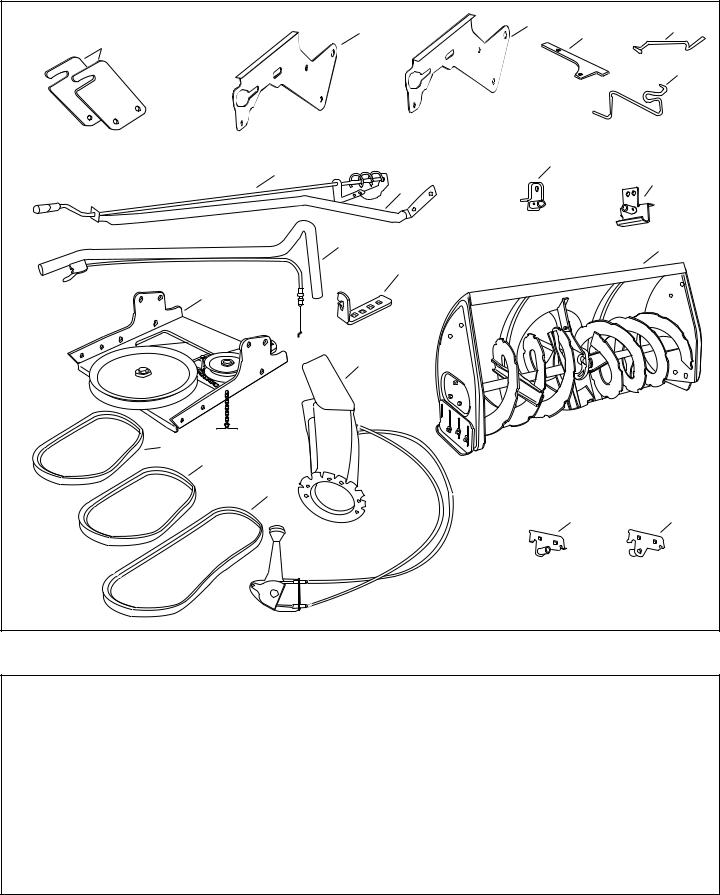

CARTON CONTENTS

1. |

Suspension Arms (2) |

11. |

L.H. Hanger Bracket (Outside Mounting) |

2. |

Left Hand Side Plate |

12. |

R.H. Hanger Bracket (Outside Mounting) |

3. |

Right Hand Side Plate |

13. |

Clutch Idler Assembly |

4. |

Anti-rotation Bracket |

14. |

V-Belt, Drive (Short) #46989 |

5. |

Engagement Rod (Not used on some models) |

15 |

V-Belt, Drive (Long) #48138 |

6. |

Engine Pulley Keeper (Not used on some models) |

16. |

V-Belt, Auger (Attached to Housing Assembly) |

7. |

Chute Crank Rod Assembly |

17. |

Chute and Control Cable Assembly |

8. |

Support Tube, Crank Rod |

18. |

Housing Assembly |

9. |

Lift Handle and Cable |

19. |

L.H. Hanger Bracket (Inside Mounting) |

10. |

Cable Bracket |

20. |

R.H. Hanger Bracket (Inside Mounting) |

|

|

|

Hardware Package (Stored inside Plastic Keg) |

5

CONTENIDO DE LA CAJA |

12. Soporte de suspensión lado derecho (Se monta en el |

|

1. Brazos de suspensión (2) |

exterior) |

|

13. Conjunto de embrague/polea libre |

||

2. Placa lateral izquierda |

14. Correa trapezoidal, transmisión (corta) #46989 |

|

3. Placa lateral derecha |

15. Correa trapezoidal, transmisión (larga) #48138 |

|

4. Soporte antirrotación |

16. Correa trapezoidal, barrena (enganchada al conjunto de la |

|

5.Varilla de enganche (No se utiliza en algunos modelos) |

carcasa) |

|

6. Sujetador de la polea motor (No se utiliza en algunos |

17. Conjunto de cable de control y de conducto. |

|

modelos) |

18. Carcasa |

|

7. Conjunto varilla manivela del conducto |

19. Soporte de suspensión lado izquierdo (Se monta en el |

|

8.Tubo soporte, varilla de la manivela |

interior) |

|

9. Manivela de elevación y cable |

20. Soporte de suspensión lado derecho (Se monta en el |

|

10. Soporte para el cable |

interior) |

|

11. Soporte de suspensión lado izquierdo (Se monta en el |

Paquete de accesorios (se guarda en el interior de una bolsa |

|

exterior) |

de plástico) |

|

|

|

|

|

|

|

CONTENU DU CARTON |

11. Support suspendu gauche (montage extérieur) |

|

1. Bras de suspension (2) |

12. Support suspendu droit (montage extérieur) |

|

13. Ensemble embrayage et galet tendeur |

||

2. Plaque latérale gauche |

14. Petite courroie en V du mécanisme d’entraînement no. |

|

3. Plaque latérale droite |

46989 |

|

4. Patte anti-rotation |

15. Longue courroie en V du mécanisme d’entraînement no. |

|

5. Biellette de mise en prise (n'est pas utilisée sur certains |

48138 |

|

modèles) |

16. Courroie en V de la tarière (fixée au carter de protection) |

|

6. Gâche de la poulie du moteur (n'est pas utilisée sur certains |

17. Ensemble de la goulotte d’éjection et du câble de |

|

modèles) |

commande |

|

7. Bielle de la goulotte d’éjection |

18. Carter de protection |

|

8.Tube de support de la bielle de la goulotte |

19. Support suspendu gauche (montage intérieur) |

|

9. Poignée d’élévation et câble |

20. Support suspendu droit (montage intérieur) |

|

10. Support de fixation du câble |

Sac de pièces de quincaillerie (située à l’intérieur d’un baril en |

|

|

plastique) |

|

|

|

|

|

|

|

INHALT DES KARTONS |

10. Kabelkonsole |

|

1. Aufhängungsarme (2) |

11. linke Hängerhalterung (Außenmontage) |

|

12. rechte Hängerhalterung (Außenmontage) |

||

2. Linke Seitenplatte |

||

13. Kupplungs-/Umlenkrollenbaugruppe |

||

3. Rechte Seitenplatte |

||

14. Keilriemen, Antrieb (kurz) Nr. 46989 |

||

4.Verdrehschutzhalterung |

||

15 Keilriemen, Antrieb (lang) Nr. 48138 |

||

5. Einrückstange (kommt nicht bei allen Modellen zum |

||

16. Keilriemen, Schnecke (Mit der Gehäusebaugruppe |

||

Einsatz) |

||

verbunden) |

||

6. Keilriemenhalter (kommt nicht bei allen Modellen zum |

||

17. Leitblechund Steuerkabelbaugruppe |

||

Einsatz) |

||

18. Gehäusebaugruppe |

||

7. Leitblechverstellstangenbaugruppe |

||

19. linke Hängerhalterung (Innenmontage) |

||

8. Stützrohr, Verstellstange |

||

20. rechte Hängerhalterung (Innenmontage) |

||

9. Hebergriff und Kabel |

||

Kleinteilepackung (im Plastikfass untergebracht) |

||

|

||

|

|

|

|

|

|

CONTENUTO DEI CARTONI |

11. Staffa del gancio sinistro (montaggio esterno) |

|

1. Bracci di sospensione (2) |

12. Staffa del gancio destro (montaggio esterno) |

|

13. Gruppo innesto ingranaggio folle |

||

2. Piastra laterale sinistra |

||

14. Cinghia a V, motrice (corta) no.46989 |

||

3. Piastra laterale destra |

||

15 Cinghia a V, motrice (lunga) no. 48138 |

||

4. Staffa antirotazione |

||

16. Cinghia a V, Coclea (Attaccata al gruppo |

||

5. Asta di inserimento (Non usato in alcuni modelli) |

||

alloggiamento) |

||

6. Fissatore della puleggia motrice (Non usato in alcuni |

||

17. Gruppo scivolo e cavo di comando |

||

modelli) |

||

18. Gruppo alloggiamento |

||

7. Gruppo asta manovella dello scivolo |

||

19. Staffa del gancio sinistro (montaggio interno) |

||

8.Tubo di supporto, Asta manovella |

||

20. Staffa del gancio destro (montaggio interno) |

||

9. Maniglia e cavo di sollevamento |

||

Pacchetto bulloneria (conservato all’interno del barilotto |

||

10. Staffa del cavo |

||

di plastica) |

||

|

||

|

|

6

SAFETY

Anypowerequipmentcancauseinjuryifoperatedimproperlyoriftheuserdoesnotunderstandhowtooperatetheequipment. Exercise caution at all times, when using power equipment.

•Read this owner's manual carefully and know how to operate your snow thrower and how to stop the unit and disengage the controls quickly.

•Never allow children to operate the equipment.

•Never allow adults to operate the equipment without proper instruction.

•Keeptheareaofoperationclearofallpersons,especially small children, and pets.

•Thoroughly inspect the area where the equipment is to be used and remove all door mats, sleds, boards, wires and other foreign objects.

•Disengage all clutches and shift into neutral before starting engine.

•Do not operate equipment without wearing adequate winter outer garments.

•Wear substantial footwear which will protect feet and improve footing on slippery surfaces.

•Checkfuelbeforestartingtheengine.Donotremovethe fuel cap or fill the fuel tank while the engine is running or hot. Do not fill the fuel tank indoors. Gasoline is an extremely flammable fuel.

•Make sure the snow thrower height is adjusted to clear the type surface it will be used on.

•Do not use the snow thrower without the rear weight attached to the tractor.

•Never make any adjustments while the engine is running.

•Alwayswearsafetyglassesoreyeshieldduringoperation or while performing adjustment or repair.

•Do not place hands or feet near rotating parts. Keep clear of the discharge opening at all times.

•Use extreme caution when operating on or crossing gravel surfaces.

•Do not carry passengers.

•After striking a foreign object, stop the engine, remove the wire from the spark plug and then thoroughly inspect thesnowthrowerfordamage.Repairanydamagebefore restarting and operating the snow thrower.

•If the snow thrower starts to vibrate abnormally, stop the engine immediately and check for the cause. Vibration is generally a warning of trouble.

•Stop the engine whenever you leave the operating position, before unclogging the snow thrower or making any adjustments or inspections.

•Take all possible precautions when leaving the unit unattended. Disengage the attachment clutch lever or switch, lower the snow thrower, shift into neutral, set the parking brake, stop the engine and remove the key.

•When cleaning, repairing or inspecting, make certain all moving parts have stopped. Disconnect the spark plug wireandkeepitawayfromtheplugtopreventaccidental starting.

•Do not run engine indoors except when transporting the snow thrower in or out of the building. Open the outside doors. Exhaust fumes are dangerous.

•Do not clear snow across the face of slopes. Exercise extreme caution when changing direction on slopes. Do not attempt to clear steep slopes. Refer to the slope guide on page 79 of this manual.

•Never operate the snow thrower without guards, plates or other safety protection devices in place.

•Never operate the snow thrower near glass enclosures, automobiles, window wells, drop offs etc.without proper adjustment of the snow thrower discharge angle.

•Never direct discharge at bystanders or allow anyone in front of the snow thrower.

•Never run the snow thrower into material at high speeds.

•Do not overload the machine capacity by attempting to clear snow at too fast a rate.

•Never operate the machine at high transport speed on slippery surfaces. Look behind and use care when backing up.

•Watchfortrafficandstayalertwhencrossingoroperating near roadways.

•Disengagepowertothesnowthrowerwhentransporting or when not in use.

•Use only attachments and accessories approved by the manufacturer of the snow thrower (such as wheel weights, counter weights, cabs etc.)

•Never operate the snow thrower without good visibility or light.

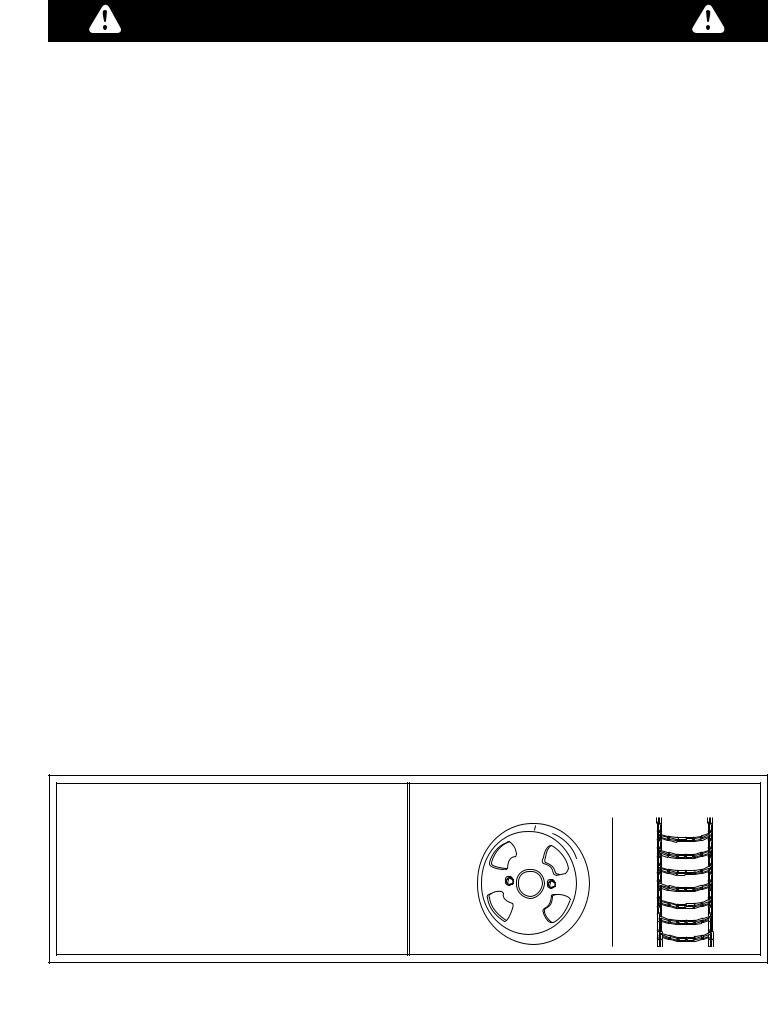

IMPORTANT: |

WHEEL WEIGHTS |

TIRE CHAINS |

Rear wheel weights and tire chains are required to provide extra traction and stability when using this snow thrower attachment. These items are available where you purchased your tractor.

7

TOOLS REQUIRED FOR ASSEMBLY

(2) 7/16" Wrenches

(2) 1/2" Wrenches

(2) 9/16" Wrenches

(2) 3/4" Wrenches

(1) Screw Driver

(1) Knife

ADDITIONAL ITEMS REQUIRED

General Purpose Grease

ASSEMBLY

IDENTIFYYOU TRACTOR

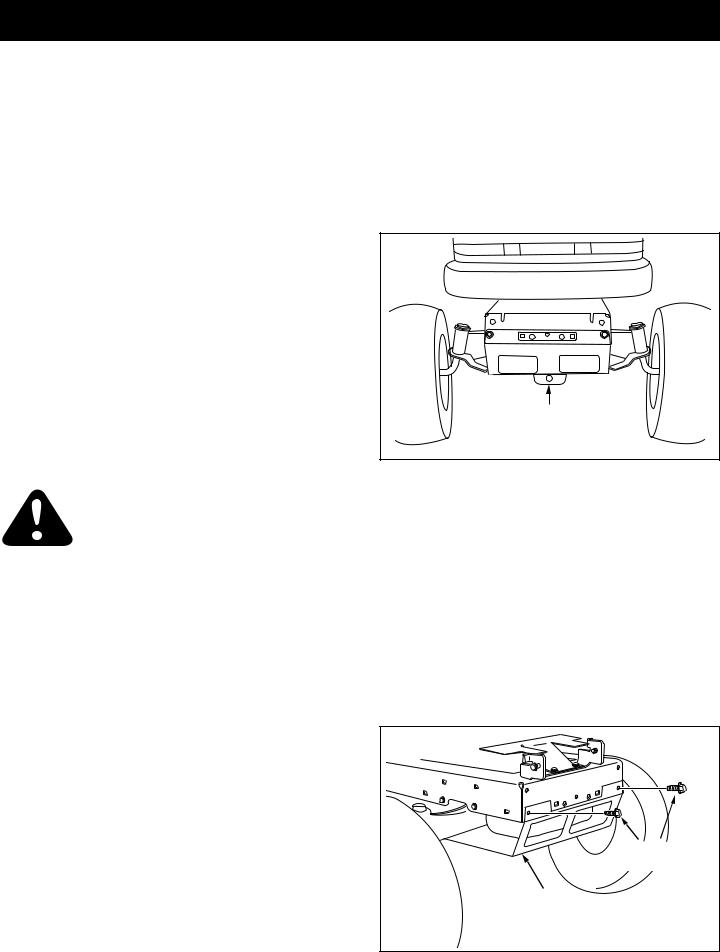

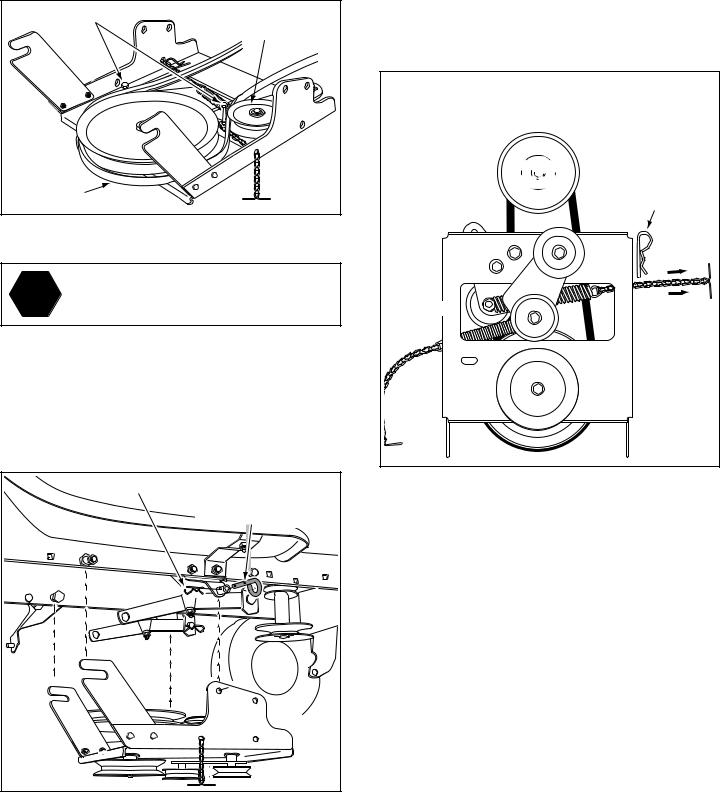

STEP 1: (SEE FIGURE 1)

•Look under the front of your tractor. If there is a single mower deck suspension bracket located underneath the middle of the front axle, continue on to step 2.

If your tractor does not have a mower deck suspension bracket underneath the middle of the front axle, skip to step 21 on page 14 for tractors with dual suspension brackets.

REMOVAL OF PARTS FROM CARTON

•Remove all parts and hardware packages from the carton. Lay out parts and hardware and identify using the illustrations on pages 2 and 5.

NOTE: Not all of the supplied parts and hardware will be needed for your particular tractor. Unneeded items may be discarded after you have completed assembly and checked operation of unit. DO NOT DISCARD the two spare shear bolts (N) and 5/16" nylock nuts (Y). Refer to the Service and Adjustments section on page 28.

CAUTION: Beforestartingto assemblethe snowthrower,removethesparkplugwire(s), set the parking brake and remove the key from the tractor ignition.

TRACTOR PREPARATION

Before performing these instructions, refer to the Service and Adjustments section of your tractor owner's manual for specific safety instructions.

•Allow engine, muffler and exhaust deflector to cool before beginning.

•Remove any front or rear attachment which is mounted to your tractor.

•Remove the mower deck. Refer to your tractor owner's manual for removal instructions. Mark all loose parts and save for reassembly.

•Remove the tractor hood. Refer to your tractor owner's manual for removal instructions.

IMPORTANT: Right hand (R.H.) and left hand (L.H.) side of the tractor are determined from the operators position while seated on the tractor.

MOWER DECK

SUSPENSION

BRACKET

FIGURE 1

INSTRUCTIONS FOR TRACTORS WITH SINGLE FRONT DECK SUSPENSION BRACKET

STEP 2: (SEE FIGURE 2)

•Remove the browning shield from the front of the tractor as shown. Hold onto the shield as you remove the second screw to prevent it from falling.

•Be sure to reinstall the browning shield when so instructed in step 3.

|

REMOVE |

|

FRONT SCREWS |

|

REMOVE |

|

BROWNING SHIELD |

FIGURE 2 |

RIGHT SIDE VIEW |

8

INSTALL SIDE PLATES

STEP 3: (SEE FIGURE 3)

•Fasten the R.H. Side Plate (bend facing out) to the front three holes in the tractor frame using three 3/8" x 1" carriage bolts (G), three 1/2" washers (R) (see note) and three 3/8" flange nuts (X). For the rear hole, use a 5/16" x 1" carriage bolt (J), a 1/2" washer (R) and a 5/16" nylock nut (Y). Place the 1/2" washers (R) between the tractor frame and the side plate. Repeat for L.H. side plate.

•Reinstall the browning shield onto the tractor frame using the original screws.

NOTE: If there is an engine mounting plate (shown with dotted lines) leave the 1/2 washer off the bolt that goes through the plate.

5/16" x 1" |

|

ENGINE MOUNTING |

|

CARRIAGE BOLT (J) |

|||

PLATE |

|||

|

|

||

|

SEE NOTE |

||

5/16" |

|

|

|

NYLOCK |

|

|

|

NUT (Y) |

|

|

|

|

|

(3) 3/8" x 1" |

|

|

|

CARRIAGE |

|

|

|

BOLTS (G) |

|

|

|

(4) 1/2" WASHERS (R) |

|

|

(3) 3/8" FLANGE NUTS (X) |

||

FIGURE 3 |

|

RIGHT SIDE VIEW |

|

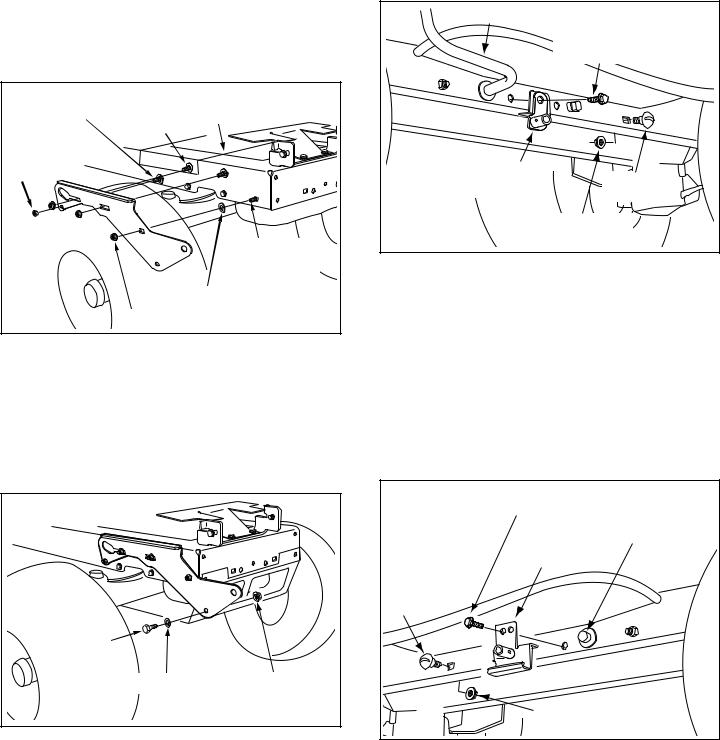

STEP 4: (SEE FIGURE 4)

•Assemble a shoulder bolt (L) and a 3/8" washer (T) to the outside of R.H. side plate, securing it with a 3/8" flanged nut (X). Repeat for L.H. side plate.

INSTALL HANGER BRACKETS AND SHOULDER BOLTS TO OUTSIDE OF FRAME

STEP 5: (SEE FIGURE 5)

•Remove the bolt, if present, in the hole directly behind the brake rod on the left side of the tractor frame.

•Attach the L.H. Hanger Bracket (tube facing out) to the hole using a 5/16" x 3/4" self threading bolt (F).

•Install a round head shoulder bolt (M) into the hole that is 9-1/2" to the rear of the bolt you just installed. Secure it with a 3/8" flange nut (X) on the inside of the frame.

|

BRAKE ROD |

|

|

|

5/16" x 3/4" SELF |

|

|

THREADING BOLT (F) |

|

L.H. HANGER |

SHOULDER |

|

BRACKET |

|

|

BOLT (M) |

|

|

|

|

|

|

3/8" FLANGED |

|

|

NUT (X) |

FIGURE 5 |

|

LEFT SIDE VIEW |

STEP 6: (SEE FIGURE 6)

•Remove the bracket, if present, from the hole directly behind the end of the brake rod on the right side of the tractor frame. Store the bracket and bolt.

•Attach the R.H. Hanger Bracket to the hole using a 5/16" x 3/4" self threading bolt (F).

•Install a round head shoulder bolt (M) into the hole that is 9-1/2" to the rear of the bolt you just installed. Secure it with a 3/8" flange nut (X) on the inside of the frame.

|

|

5/16" x 3/4" SELF |

|

|

|

THREADING BOLT (F) |

RIGHT END OF |

|

|

|

|

|

|

R.H. HANGER |

BRAKE ROD |

|

|

|

|

|

|

BRACKET |

|

|

SHOULDER |

|

|

|

BOLT (M) |

|

|

SHOULDER |

|

|

|

BOLT (L) |

|

|

|

3/8" WASHER (T) |

3/8" FLANGED |

|

|

|

NUT (X) |

|

|

|

|

3/8" FLANGED |

|

FIGURE 4 |

RIGHT SIDE VIEW |

NUT (X) |

|

|

|

||

|

FIGURE 6 |

|

RIGHT SIDE VIEW |

|

9 |

|

|

THIS SECTION IS FOR TRACTORS WITH A MANUAL ATTACHMENT CLUTCH

If your tractor has an electric attachment clutch go to step 14 on page 12.

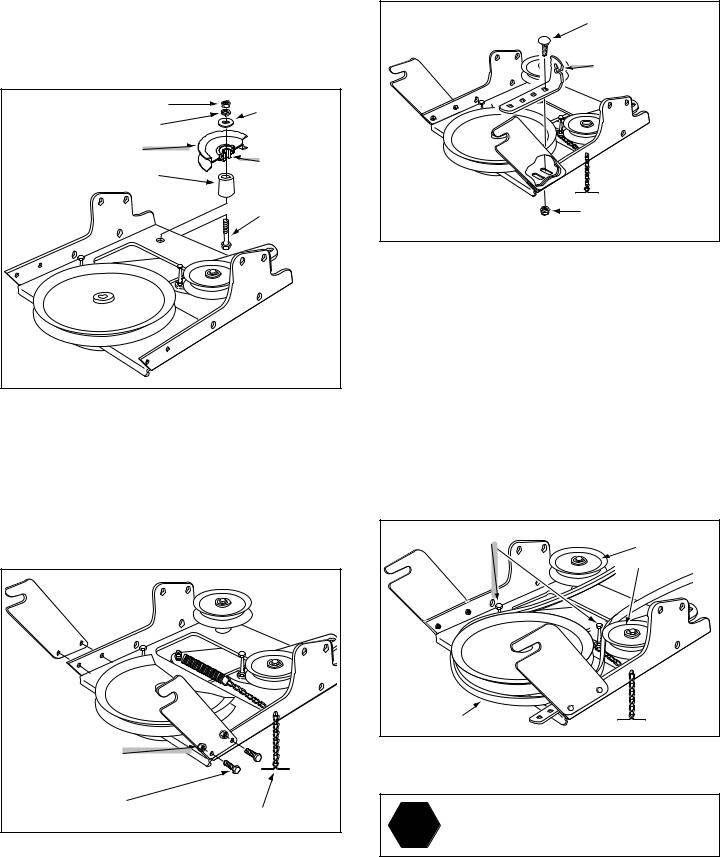

STEP 7: (SEE FIGURE 7)

•Attach the pulley (long end of hub facing down) and the large spacer (MM) to the hole shown in the clutch/ idler assembly. Use a 3/8" x 3-1/4" hex bolt (A), a 3/8" washer (T), a 3/8" lock washer (O) and a 3/8" hex lock nut (Z).

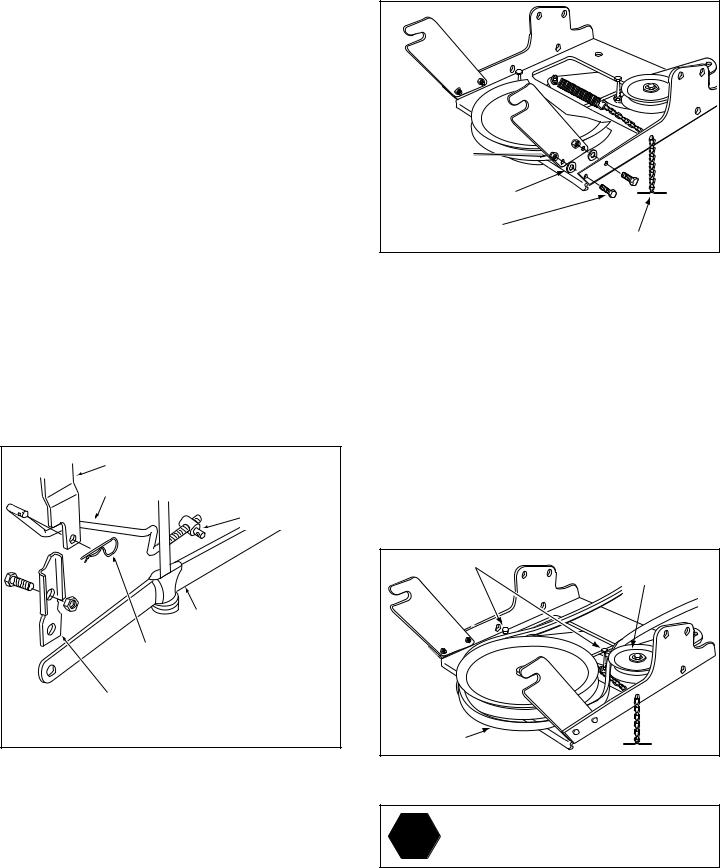

3/8" HEX LOCK NUT (Z) |

3/8" |

3/8" LOCKWASHER (O) |

WASHER (T) |

|

|

PULLEY (NN) |

LONG END |

|

|

LARGE SPACER (MM) |

OF HUB |

|

3/8" X 3-1/4" |

|

HEX BOLT |

|

(A) |

FIGURE 7

STEP 8: (SEE FIGURE 8)

•Attach the two suspension arms to the rear of the clutch/idler assembly using two 5/16" x 3/4" hex bolts

(C) and 5/16" nylock nuts (Y) for each arm. Place the arms on the outside of the frame with the notches to the rear.

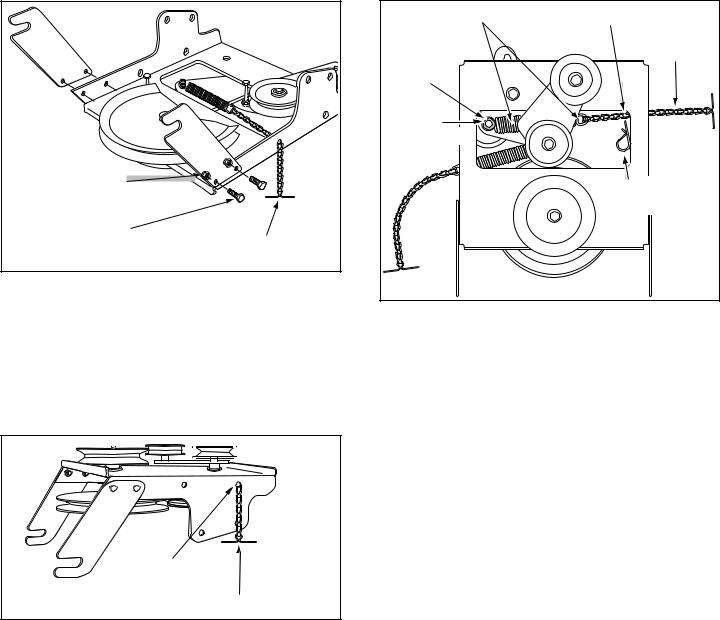

•Insert a tensioning chain through the hole shown and attach the end link to the spring on the lower idler arm.

5/16" NYLOCK |

|

NUT (Y) |

|

5/16" x 3/4" |

|

HEX BOLT (C) |

TENSIONING CHAIN (JJ) |

FIGURE 8

STEP 9: (SEE FIGURE 9)

•Attach the cable bracket to the slot shown in the clutch/idler assembly using a 5/16" x 3/4" carriage bolt (K) and a 5/16" nylock nut (Y). Place the bolt in the front hole of the bracket and in the end of the slot closest to the pulley. Do not tighten yet.

5/16" x 3/4" |

CARRIAGE BOLT (K) |

CABLE |

BRACKET |

5/16" NYLOCK |

NUT (Y) |

FIGURE 9

STEP 10: (SEE FIGURE 10)

•Two different length drive belts are included with your snow thrower.Tractors with manual attachment

clutches and single front deck suspension brackets use the 56" drive belt with #48138 printed on the outside of the belt. DO NOT USE the other belt.

•Slightly loosen the hex bolt next to the flat idler pulley. Install the drive belt down between the hex bolt and the flat idler pulley with the flat side of the belt against the pulley. Retighten the hex bolt.

•Loop the belt around the large v-pulley, placing it between the v-pulley and the hex bolt next to the pulley. Place the belt to the inside of the other flat idler pulley.

HEX BOLTS |

FLAT IDLER |

|

|

|

PULLEYS |

(#48138) |

|

DRIVE BELT |

|

FIGURE 10

Did you select the correct drive belt for your STOP tractor? Using the wrong length belt may

cause premature bearing or belt failure.

10

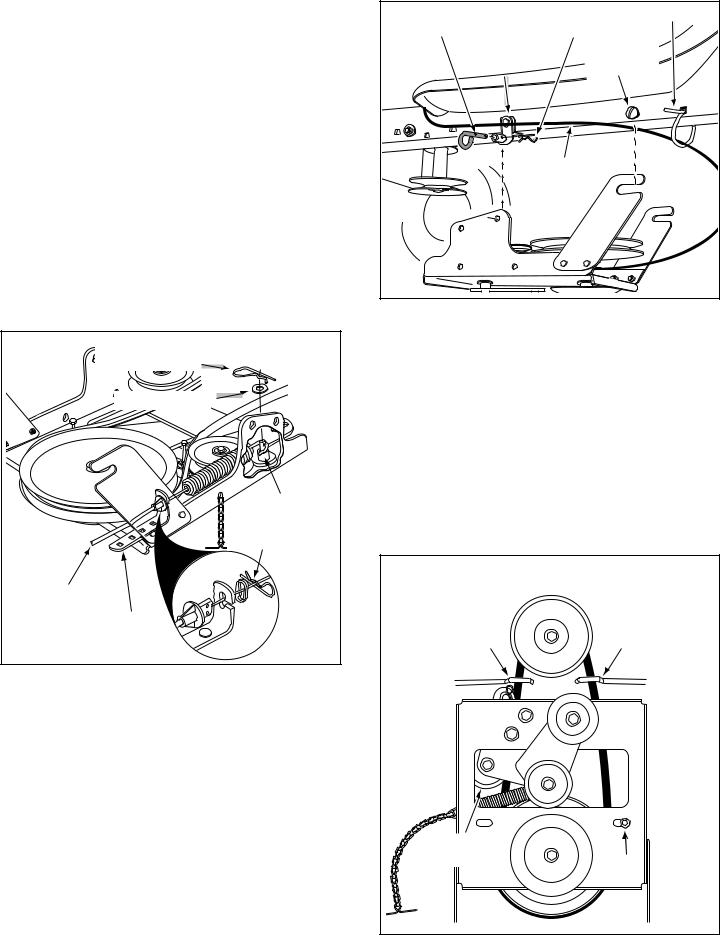

STEP 11: (SEE FIGURE 11)

•Find the cable clip that is attached to the left side of the tractor frame underneath the footrest. Open the clip and remove the mower clutch cable. Do not remove the clip from the tractor frame.The cable reattaches to the clip when using the mower deck.

•Move the attachment clutch lever on the dash panel to the disengaged position.

•Place the clutch/idler assembly on the floor on the left side of the tractor.

•Attach the tractor's mower clutch cable to the cable bracket on the clutch/idler assembly. Secure the cable housing guide (groove down) to the cable bracket using the original collar and a 5/64" hair cotter pin (DD).

•Place a spacer (LL) on the welded pin on the idler arm. Hook the end of the clutch cable spring over the pin and secure it with a 1/4" washer (P) and a 5/64" hair cotter pin (DD).

•Align cable bracket with welded pin and tighten the nut assembled in step 9.

5/64" HAIR |

COTTER PIN (DD) |

1/4" WASHER (P) |

SPACER (LL) |

5/64" HAIR |

COTTER PIN (DD) |

TRACTOR'S |

CLUTCH CABLE |

CABLE |

BRACKET |

FIGURE 11

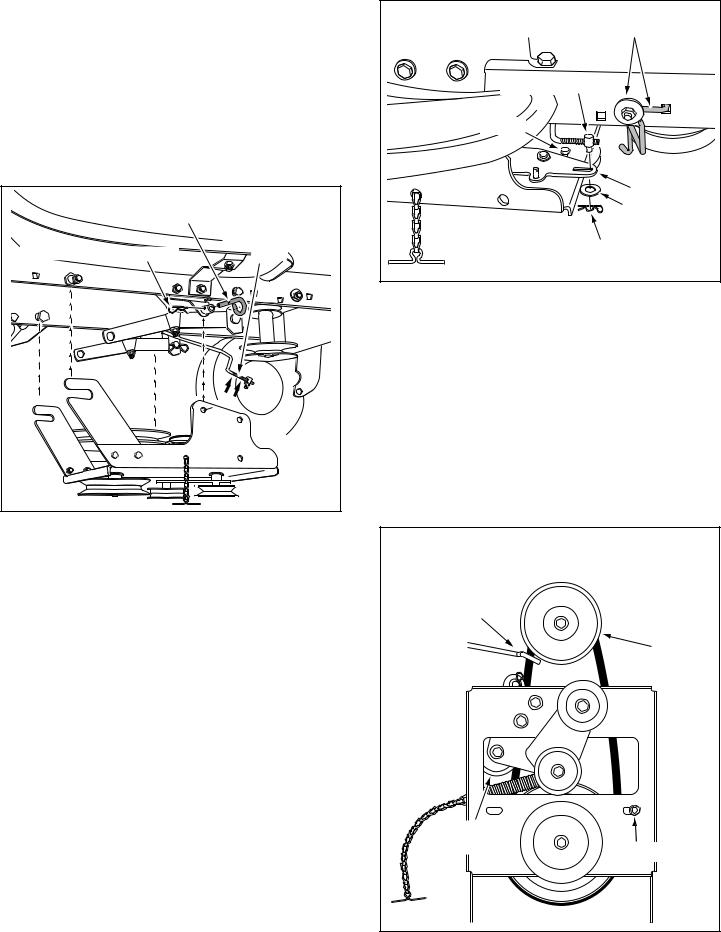

ATTACH CLUTCH IDLER ASSEMBLY TO TRACTOR

STEP 12: (SEE FIGURE 12)

•Attach the clutch/idler assembly to the tractor frame. Hook the notched suspension arms onto the two shoulder bolts (M) assembled to the outside of the tractor frame. Lift the front of the assembly and attach it to the R.H. and L.H. hanger brackets using two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

•Loosely attach the mower clutch cable to the left side of the tractor frame with a nylon tie (II). Do not pull the nylon tie completely tight.The cable may need to be removed from the nylon tie when using the mower deck.

PIVOT LOCK PIN (GG) |

1/8" HAIRPIN |

NYLON TIE (II) |

|

(use this hole) |

COTTER (EE) |

|

|

L.H. HANGER |

SHOULDER |

||

BRACKET |

BOLT (M) |

||

|

MOWER |

|

|

|

CLUTCH |

|

|

|

CABLE |

|

|

FIGURE 12 |

VIEWED FROM LEFT SIDE |

||

STEP 13: (SEE FIGURE 13)

•Assemble the drive belt onto the engine pulley first and then onto the large pulley on top of the clutch/ idler assembly.The belt must be placed inside the engine pulley belt keeper(s) and between the large pulley and the keeper bolt next to it.

IMPORTANT: Do Not assemble the "V" belt outside of the engine pulley keepers or outside of the keeper bolt next to the large pulley.

•Go to step 48 on page 21.

CLUTCH/IDLER ASSEMBLY |

|

ENGINE |

ENGINE |

PULLEY |

PULLEY |

KEEPER |

KEEPER |

|

Left Side |

|

of Tractor |

IDLER |

|

PULLEY |

KEEPER BOLT |

|

|

FIGURE 13 |

VIEWED FROM UNDERNEATH |

11

THIS SECTION IS FOR TRACTORS WITH AN ELECTRIC ATTACHMENT CLUTCH

STEP 14: (SEE FIGURE 14)

•Attach the two suspension arms to the rear of the clutch/idler assembly using two 5/16" x 3/4" hex bolts

(C) and 5/16" nylock nuts (Y) for each arm. Place the arms on the outside of the frame with the notches to the rear.

•Insert a tensioning chain through the hole shown and attach the end link to the spring on the lower idler arm.

5/16" NYLOCK |

|

NUT (Y) |

|

5/16" x 3/4" |

|

HEX BOLT (C) |

TENSIONING CHAIN (JJ) |

FIGURE 14

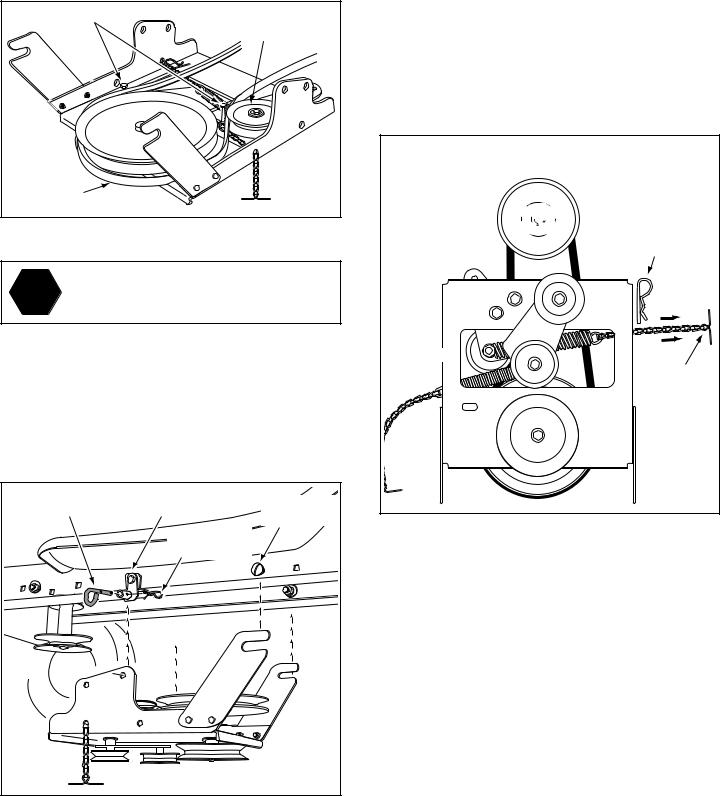

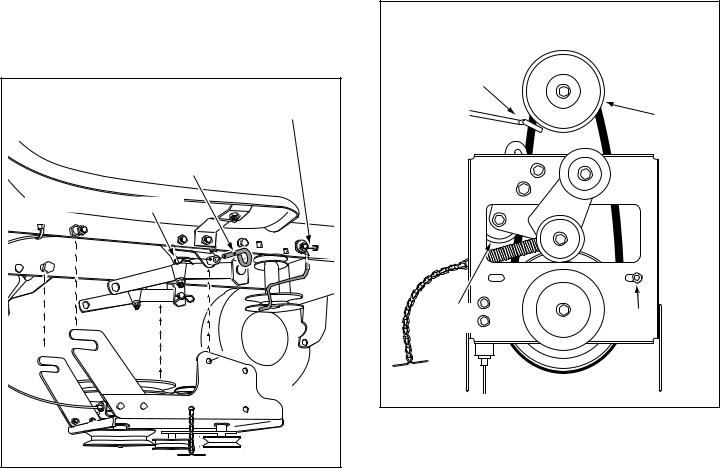

STEP 16: (SEE FIGURE 16)

•Hook one end of the spring supplied in the parts bag through the end link of the tensioning chain.

•With the clutch/idler assembly turned upside down, hook the other end of the spring onto the end of the bolt and nut which secure the idler pulley to the upper idler arm. Assemble a 3/8" hex lock nut (Z) onto the bolt and nut, leaving enough gap between the nuts for the spring to pivot freely.

•Attach a 3/32" hairpin cotter (FF) to the chain, placing it in the fifth link from the spring.

SPRING |

5TH LINK |

ATTACH |

CHAIN |

(L.H. SIDE) |

|

SPRING |

|

HERE |

|

3/8" HEX |

|

LOCK NUT (Z) |

|

|

3/32" HAIR |

|

COTTER PIN (FF) |

RIGHT |

LEFT |

SIDE |

SIDE |

FIGURE 16 |

VIEW OF BOTTOM |

STEP 15: (SEE FIGURE 15)

•Turn the clutch/idler assembly upside down and insert the second tensioning chain (JJ) through the left front hole.

LEFT FRONT HOLE

TENSIONING CHAIN (JJ)

FIGURE 15

SELECT THE CORRECT DRIVE BELT

(Electric clutch tractors with a single front deck suspension bracket)

STEP 17: (SEE TABLE 1)

•Two different length drive belts are included with your snow thrower. Use the table below to select the correct drive belt for your type tractor.The part number is printed on the outside of the belt .

•Set aside the belt that is not for your tractor to avoid accidentally using it.

55" BELT (PART #46989) |

||

TRACTOR TYPE |

DECK SIZE |

CLUTCH TYPE |

|

|

|

(LT) Lawn Tractor |

38", 42" |

Electric |

|

||

56" BELT (PART #48138) |

||

TRACTOR TYPE |

DECK SIZE |

CLUTCH TYPE |

|

|

|

(LT) Lawn Tractor |

48" |

Electric |

(GT) Garden Tractor |

48", 54" |

Electric |

TABLE 1

12

STEP 18: (SEE FIGURE 17)

•Turn the clutch/idler assembly right side up.

•Slightly loosen the hex bolt next to the flat idler pulley. Install the drive belt down between the hex bolt and the flat idler pulley with the flat side of the belt against the pulley. Retighten the hex bolt.

•Loop the belt around the large v-pulley, placing it between the v-pulley and the hex bolt next to the pulley.

HEX BOLTS |

FLAT IDLER |

|

PULLEY |

DRIVE BELT |

|

FIGURE 17

Did you choose the correct drive belt for STOP your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

STEP 19: (SEE FIGURE 18)

•Attach the clutch/idler assembly to the tractor frame. Hook the notched suspension arms onto the two shoulder bolts (M) assembled to the outside of the tractor frame. Lift the front of the assembly and attach it to the R.H. and L.H. hanger brackets using two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

PIVOT LOCK PIN (GG) |

L.H. HANGER |

SHOULDER |

|

(use second hole) |

BRACKET |

||

BOLT (M) |

|||

|

|

||

|

1/8" HAIRPIN |

|

|

|

COTTER (EE) |

|

|

FIGURE 18 |

VIEWED FROM LEFT SIDE |

||

STEP 20: (SEE FIGURE 19)

•Assemble the drive belt onto the engine pulley first and then onto the large pulley on top of the clutch/ idler assembly. Place the belt to the inside of the idler pulley and the belt keeper bolt located beside the large pulley.

•Place tension on the belt by pulling the left side tensioning chain (JJ) out as far as the 3/32" hairpin cotter in the chain will allow. Secure the chain in this position by inserting a 1/8" hairpin cotter (EE) through the chain.

IMPORTANT: Do Not assemble the drive belt around the outside of the keeper bolt beside the large pulley.

•Go to step 48 on page 22.

CLUTCH/IDLER ASSEMBLY

ENGINE |

|

PULLEY |

1/8" HAIRPIN |

|

|

|

COTTER (EE) |

IDLER PULLEY

CHAIN (JJ)

(L.H. SIDE)

KEEPER BOLT

KEEPER BOLT

FIGURE 19 |

VIEWED FROM UNDERNEATH |

13

INSTRUCTIONS FOR TRACTORS WITH DUAL FRONT DECK SUSPENSION BRACKETS

FASTEN SIDE PLATES TO TRACTOR

If your tractor resembles figure 20, go to step 21. If your tractor resembles figure 22, go to step 23.

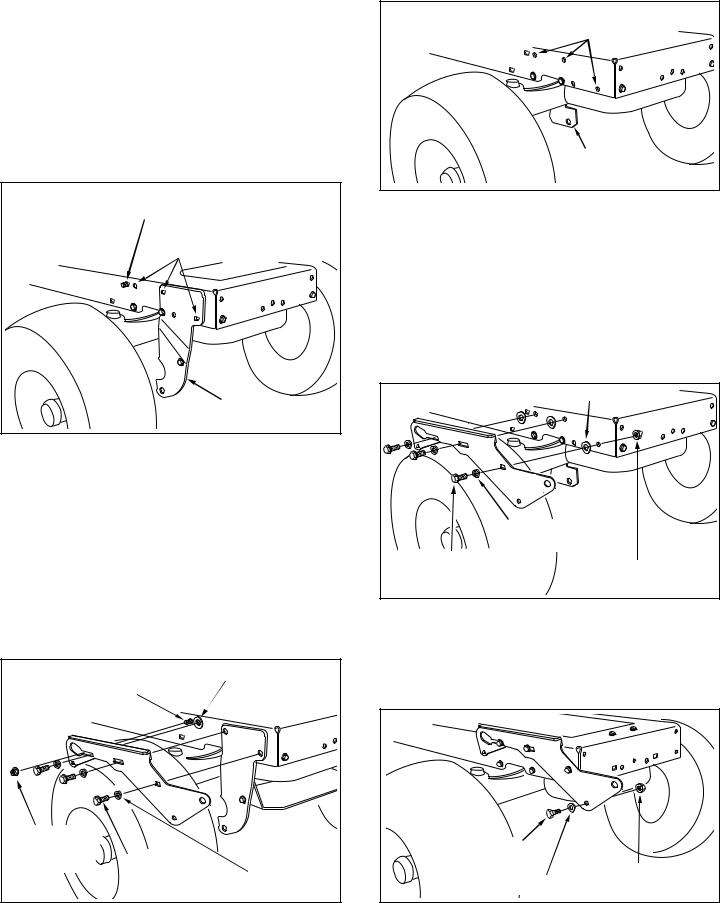

STEP 21: (SEE FIGURE 20)

•Remove bolts from front three holes shown.

•If a bolt is present in the fourth hole, replace it with a 5/16" x 1" carriage bolt (J) without a nut.The bracket fastened to inside of frame must remain in place.

|

REPLACE BOLT |

|

(IF PRESENT) |

|

REMOVE BOLTS |

|

(IF PRESENT) |

|

FRONT |

|

SUSPENSION |

|

BRACKET |

FIGURE 20 |

RIGHT SIDE VIEW |

STEP 22: (SEE FIGURE 21)

•Fasten the R.H. Side Plate (bend facing out) to the front three holes shown in the tractor frame using three 3/8" x 1" thread forming bolts (E), three 3/8" lock washers (O) and one 1/2" washer (R) placed on the third bolt as a shim between the side plate and the frame.Tighten all bolts. Repeat for the L.H. side.

NOTE: If you installed a bolt in the fourth hole in step 21, assemble a 5/16" flange nut (W) onto the bolt after the side plate is installed.

•Go to step 25 on this page.

5/16" x 1" |

|

1/2" WASHER (R) |

|

CARRIAGE BOLT (J) |

|

|

|

(SEE NOTE) |

|

|

|

5/16" FLANGED |

|

|

|

NUT (W) |

|

|

|

(SEE NOTE) |

|

|

(3) 3/8" LOCK |

|

THREAD FORMING |

||

|

WASHERS (O) |

||

|

BOLTS (E) |

|

|

|

|

|

|

FIGURE 21 |

|

RIGHT SIDE VIEW |

|

STEP 23: (SEE FIGURE 22)

•Remove any bolts found in the holes shown.

|

REMOVE BOLTS |

|

IF PRESENT |

|

SUSPENSION |

|

BRACKET |

FIGURE 22 |

RIGHT SIDE VIEW |

STEP 24: (SEE FIGURE 23)

•Fasten the R.H. Side Plate (bend facing out) to the three holes shown in the tractor frame. Use three 3/8" x 1" thread forming bolts (E), 3/8" lock washers (O)

and 1/2" washers (R). Use the 1/2" washers as shims between the Side Plate and the tractor frame.Tighten all bolts and repeat for the L.H. side.

NOTE: If the bolt inserts freely into the front hole, assemble a 3/8" flanged nut (X) onto the bolt.

|

|

(3) 1/2" WASHERS (R) |

|

|

(3) 3/8" LOCK |

||

|

WASHERS (O) |

||

(3) 3/8" x 1" |

|

3/8" FLANGED NUT (X) |

|

THREAD FORMING |

|||

(SEE NOTE) |

|||

BOLTS (E) |

|

||

|

|

||

FIGURE 23 |

|

RIGHT SIDE VIEW |

|

STEP 25: (SEE FIGURE 24)

•Assemble a shoulder bolt (L) and a 3/8" washer (T) to the outside of each side plate, securing them with a 3/8" flanged nut (X).

|

SHOULDER |

|

|

BOLT (L) |

3/8" FLANGED |

|

3/8" WASHER (T) |

|

|

NUT (X) |

|

|

|

|

FIGURE 24 |

|

RIGHT SIDE VIEW |

14

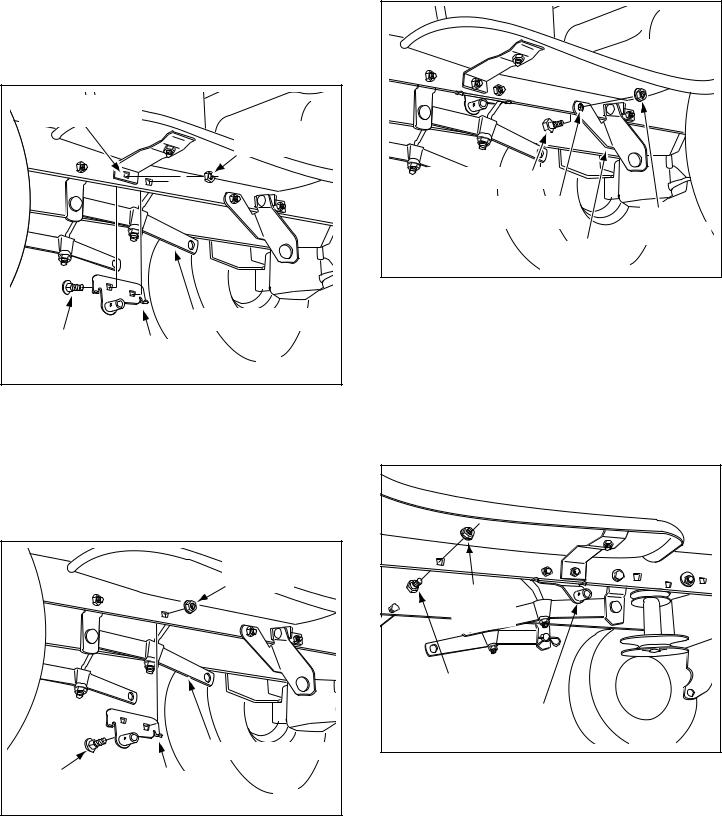

INSTALLING HANGER BRACKETS

For better clearance, lower the tractor's suspension arms using the attachment lift lever.

STEP 26: (SEE FIGURE 25 or 26)

On Tractors With Foot Rest Brackets

•Remove the bolt and nut that fasten the L.H. and R.H. foot rest brackets to the frame.

•Attach the L.H. Hanger Bracket (marked "L") to the inside of the tractor frame using two 3/8" x 1" carriage bolts (G) and 3/8" flanged nuts (X). Bolt heads go on inside of tractor frame. Repeat for the R.H. side.

BOLT REMOVED |

|

|

FROM THIS HOLE |

3/8" FLANGED |

|

|

||

|

NUT (X) |

|

|

SUSPENSION ARM |

|

3/8" x 1" |

L.H. HANGER |

|

CARRIAGE |

||

BRACKET |

||

BOLT (K) |

||

|

||

FIGURE 25 |

LEFT SIDE VIEW |

On Tractors Without Foot Rest Brackets

•Find the empty hole beneath the foot rest. Attach the L.H. Hanger Bracket (marked "L") to the inside of the frame using a 3/8" x 1" carriage bolt (G) and a 3/8" flanged nut (X). Bolt head goes on inside of tractor frame. Repeat for the R.H. side.

|

3/8" FLANGED |

|

|

NUT (X) |

|

|

SUSPENSION ARM |

|

3/8" x 1" |

L.H. HANGER |

|

CARRIAGE |

||

BRACKET |

||

BOLT (G) |

||

|

||

FIGURE 26 |

LEFT SIDE VIEW |

INSTALLING SHOULDER BOLTS

STEP 27: (SEE FIGURE 27)

•Remove the bolt, washer and nut which fasten the sway bar bracket to the L.H. side of the tractor frame. Replace with a shoulder bolt (L) and a 3/8" flanged nut (X). Bolt goes on inside of frame.

SHOULDER BOLT (L) |

|

|

BOLT REMOVED |

3/8" |

|

FROM THIS HOLE |

||

FLANGED |

||

|

||

SWAY BAR |

NUT (X) |

|

|

||

BRACKET |

|

|

FIGURE 27 |

LEFT SIDE VIEW |

STEP 28: (SEE FIGURE 28)

•Assemble a shoulder bolt (L) and 3/8" flanged nut (X) to the R.H. side of the tractor frame, using the first empty hole to the rear of the R.H. hanger bracket. Bolt goes on inside of frame.

3/8" |

|

FLANGED |

|

NUT (X) |

|

SHOULDER BOLT (L) |

|

R.H. HANGER BRACKET |

|

FIGURE 28 |

RIGHT SIDE VIEW |

15

INSTALLING CLUTCH/IDLER ASSEMBLY

This section covers the installation of the Clutch/Idler assembly to tractors with attachment clutches that are either rod operated (p. 16), cable operated (p. 19) or electric (p. 20). Use the appropriate instructions for your tractor.

ROD OPERATED MANUAL ATTACHMENT CLUTCH

STEP 29: (SEE FIGURE 29)

•Move the attachment clutch lever on the dash panel to the disengaged (down) position.

•Screw the trunnion (CC) onto the end of the snow thrower engagement rod.

•Locate the clutch arm (where the mower clutch rod was connected) underneath the right hand side the tractor, just to the inside of the suspension arm. If there is an extension attached to the clutch lever, the extension, bolt and nut must be removed and stored with the mower deck.

IMPORTANT: Re-attach the extension to the clutch lever before reinstalling the mower deck.

•Position the engagement rod to the inside of the clutch arm and insert the drilled end of the rod through the arm. Secure with a 5/64" hairpin cotter

(DD).

|

TRACTOR'S CLUTCH ARM |

|

ENGAGEMENT ROD |

|

TRUNNION (CC) |

|

SUSPENSION ARM |

|

5/64" HAIRPIN |

|

COTTER (DD) |

|

REMOVE EXTENSION, |

|

BOLT AND NUT |

|

(IF PRESENT) |

FIGURE 29 |

RIGHT SIDE VIEW |

5/16" NYLOCK |

|

NUT (Y) |

|

5/16" WASHER (Q) |

|

5/16" x 3/4" |

|

HEX BOLT (C) |

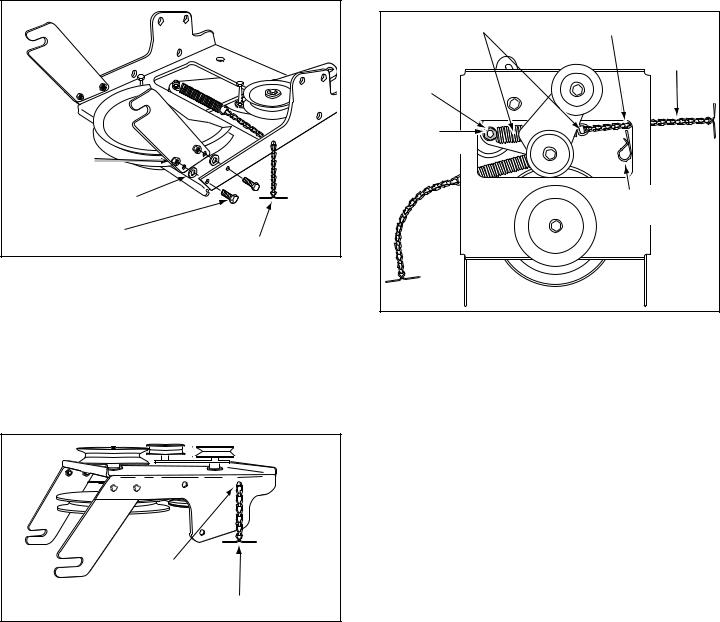

TENSIONING CHAIN (JJ) |

FIGURE 30

STEP 31: (SEE FIGURE 31)

•Two different length drive belts are included with your snow thrower.Tractors with manual attachment clutches and dual front deck suspension brackets use the 55" drive belt with #46989 printed on the outside of the belt. DO NOT USE the other belt.

•Slightly loosen the hex bolt next to the flat idler pulley. Install the drive belt down between the hex bolt and the flat idler pulley with the flat side of the belt against the pulley. Retighten the hex bolt.

•Loop the belt around the large v-pulley, placing it between the v-pulley and the hex bolt next to the pulley.

HEX BOLTS |

FLAT IDLER |

|

PULLEY |

(#46989) |

|

DRIVE BELT |

|

FIGURE 31

STEP 30: (SEE FIGURE 30)

•Attach the two suspension arms to the inside of the clutch/idler assembly using two 5/16" x 3/4" hex bolts (C), 5/16" washers (Q) and 5/16" nylock nuts (Y) for each arm. Place the washers between the arms and the assembly frame.

•Insert a tensioning chain through the hole shown and attach the end link to the spring on the lower idler arm.

Did you choose the correct drive belt for STOP your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

16

STEP 32: (SEE FIGURE 32)

•Be sure to lift up the front end of the engagement rod as shown when performing the next operation.You can temporarily support the rod using a rubber band tied to the engine pulley keeper.

•Attach the clutch/idler assembly to the tractor frame as follows. Hook the assembly's notched arms onto the two shoulder bolts you assembled to the inside of the tractor frame. Lift the front of the assembly and attach it to the R.H. and L.H. hanger brackets using two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

PIVOT LOCK PIN (GG) |

|

(use second hole) |

|

|

ENGAGEMENT |

1/8" HAIRPIN COTTER (EE) |

ROD |

FIGURE 32 |

RIGHT SIDE VIEW |

STEP 33: (SEE FIGURE 33)

•Make sure the attachment clutch lever on the dash panel is in the disengaged (down) position.

•Pivot the upper idler arm so that it rests against the stop bolt and is pointing toward the front as shown. Screw the trunnion (CC) along the threads of the engagement rod until it is aligned at the front end of the idler arm slot. Attach the trunnion (CC) to the slot using the 3/8" thin washer (S) and a 5/64" hairpin cotter (DD).

•Remove the engine pulley keeper from the side of the tractor frame by removing the washer and nut that secure the keeper. Attach the new pulley keeper supplied with the snow thrower, reusing the original bolt, washer and nut.

NOTE: Some tractors may already be equipped with a pulley keeper that is identical to the new one supplied.

NEW ENGINE PULLEY KEEPER WITH

ORIGINAL BOLT, NUT AND WASHER

TRUNNION (CC)

STOP BOLT

IDLER ARM

3/8" THIN

WASHER (S)

5/64" HAIRPIN

COTTER (DD)

FIGURE 33 |

RIGHT SIDE VIEW |

STEP 34: (SEE FIGURE 34)

•Assemble the short "V" belt onto the engine pulley and then onto the large pulley on top of the clutch/ idler assembly.The belt must be placed to the inside of the engine pulley keeper, the idler pulley and the keeper bolt located beside the large pulley.

IMPORTANT: Do Not assemble the "V" belt around the outside of the engine pulley keeper or the keeper bolt.

•Go to step 48 on page 22.

CLUTCH/IDLER ASSEMBLY |

|

ENGINE |

Left Side |

PULLEY |

of Tractor |

KEEPER |

|

|

ENGINE |

|

PULLEY |

IDLER |

|

PULLEY |

KEEPER BOLT |

|

|

FIGURE 34 |

VIEWED FROM UNDERNEATH |

17

CABLE OPERATED MANUAL ATTACHMENT CLUTCH

STEP 35: (SEE FIGURE 35)

•Attach the two suspension arms to the rear of the clutch/idler assembly using two 5/16" x 3/4" hex bolts (C), 5/16" washer (Q) and 5/16" nylock nuts (Y) for each arm. Place the arms on the outside of the frame with the notches to the rear.

•Insert a tensioning chain through the hole shown and attach the end link to the spring on the lower idler arm.

5/16" NYLOCK |

|

NUT (Y) |

|

5/16" WASHER (Q) |

|

5/16" x 3/4" |

|

HEX BOLT (C) |

TENSIONING CHAIN (JJ) |

FIGURE 35

STEP 36: (SEE FIGURE 36)

•Assemble the cable bracket to the clutch/idler assembly using two 5/16" x 3/4" carriage bolts (K) and 5/16" nylock nuts (Y). Use the two front holes in the cable bracket if your tractor has a 42" mower deck. Use the two rear holes if your tractor has a 46" mower deck.

|

5/16" x 3/4" |

|

CARRIAGE BOLT (K) |

|

CABLE |

|

BRACKET |

46" |

42" |

DECKS |

DECKS |

|

5/16" NYLOCK |

|

NUT (Y) |

FIGURE 36

STEP 37: (SEE FIGURE 37)

•Two different length drive belts are included with your snow thrower.Tractors with manual attachment clutches and dual front deck suspension brackets use the 55" drive belt with #46989 printed on the outside of the belt. DO NOT USE the other belt.

•Slightly loosen the hex bolt next to the flat idler pulley. Install the drive belt down between the hex bolt and the flat idler pulley with the flat side of the belt against the pulley. Retighten the hex bolt.

•Loop the belt around the large v-pulley, placing it between the v-pulley and the hex bolt next to the pulley.

HEX BOLTS |

FLAT IDLER |

|

PULLEY |

(#46989) |

|

DRIVE BELT |

|

FIGURE 37

Did you choose the correct drive belt for STOP your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

STEP 38: (SEE FIGURE 38)

•Move the attachment clutch lever on the dash panel to the disengaged (down) position.

•Place the clutch/idler assembly on the floor on the right side of the tractor.

•Attach the tractor's clutch cable to the cable bracket. Secure the cable housing guide (groove down) to the cable bracket using the original collar and a 5/64" hair cotter pin (DD).

•Place a spacer (LL) on the welded pin on the idler arm. Hook the end of the clutch spring over the pin and secure it with a 1/4" washer (P) and a 5/64" hair cotter pin (DD).

5/64" HAIR |

COTTER PIN (DD) |

1/4" WASHER (P) |

SPACER (LL) |

TRACTOR'S |

CLUTCH CABLE |

5/64" HAIR |

COTTER PIN (DD) |

FIGURE 38

18

STEP 39: (SEE FIGURE 39)

•Remove the engine pulley keeper from the side of the tractor frame by removing the washer and nut that secure the keeper. Attach the new pulley keeper supplied with the snow thrower, reusing the original bolt, washer and nut.

NOTE: Some tractors may already be equipped with a pulley keeper that is identical to the new one supplied.

•Attach the clutch/idler assembly to the tractor frame as follows. Hook the assembly's notched arms onto the two shoulder bolts you assembled to the inside of the tractor frame. Lift the front of the assembly and attach it to the R.H. and L.H. hanger brackets using two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

NEW ENGINE PULLEY KEEPER WITH

ORIGINAL BOLT, NUT AND WASHER

PIVOT LOCK PIN (GG) (use second hole)

1/8" HAIRPIN COTTER (EE)

FIGURE 39

STEP 40: (SEE FIGURE 40)

•Assemble the short "V" belt onto the engine pulley and then onto the large pulley on top of the clutch/idler assembly.The belt must be placed to the inside of the engine pulley keeper, the idler pulley and the keeper bolt located beside the large pulley.

IMPORTANT: Do Not assemble the "V" belt around the outside of the engine pulley keeper or the keeper bolt.

•Go to step 48 on page 22.

CLUTCH/IDLER ASSEMBLY |

||

ENGINE |

Left Side |

|

PULLEY |

of Tractor |

|

KEEPER |

|

|

|

ENGINE |

|

|

PULLEY |

|

IDLER |

KEEPER BOLT |

|

PULLEY |

||

|

||

FIGURE 40 |

VIEWED FROM UNDERNEATH |

|

19

ELECTRIC ATTACHMENT CLUTCHES

STEP 41: (SEE FIGURE 41)

•Attach the two suspension arms to the rear of the clutch/idler assembly using two 5/16" x 3/4" hex bolts (C), 5/16" washer (Q) and 5/16" nylock nuts (Y) for each arm. Place the arms on the outside of the frame with the notches to the rear.

•Insert a tensioning chain through the hole shown and attach the end link to the spring on the lower idler arm.

5/16" NYLOCK |

|

NUT (Y) |

|

5/16" WASHER (Q) |

|

5/16" x 3/4" |

|

HEX BOLT (C) |

TENSIONING CHAIN (JJ) |

FIGURE 41

STEP 43: (SEE FIGURE 43)

•Hook the spring from the parts bag through the end of the tensioning chain.

•Hook the other end of the spring onto the bottom of the bolt and nut which secure the idler pulley to the upper idler arm. Hold the bolt head and assemble a 3/8" hex lock nut (Z) onto the bolt, leaving enough space for the spring to pivot freely between the two nuts.

•Attach a 3/32" hairpin cotter (FF) to the chain, placing it in the fifth link from the spring.

SPRING |

5TH LINK |

ATTACH |

CHAIN |

(L.H. SIDE) |

|

SPRING |

|

HERE |

|

3/8" HEX |

|

LOCK NUT (Z) |

|

|

3/32" HAIR |

|

COTTER PIN (FF) |

RIGHT |

LEFT |

SIDE |

SIDE |

FIGURE 43 |

VIEW OF BOTTOM |

STEP 42: (SEE FIGURE 42)

•Pace the extra tensioning chain (JJ) through the left front hole in the clutch/idler assembly and then turn the assembly upside down.

LEFT FRONT HOLE

TENSIONING CHAIN (JJ)

FIGURE 42

STEP 44: (SEE TABLE 2)

•Two different length drive belts are included with your snow thrower. Use the table below to select the correct drive belt for your type tractor.The part number is printed on the outside of the belt .

•Set aside the belt that is not for your tractor to avoid accidentally using it.

55" BELT (PART #46989) |

||

TRACTOR TYPE |

DECK SIZE |

CLUTCH TYPE |

|

|

|

(LT) Lawn Tractor |

38", 42", 46" |

Electric |

|

||

56" BELT (PART #48138) |

||

TRACTOR TYPE |

DECK SIZE |

CLUTCH TYPE |

|

|

|

(LT) Lawn Tractor |

48" |

Electric |

TABLE 2

20

STEP 45: (SEE FIGURE 44)

•Turn the clutch/idler assembly right side up.

•Slightly loosen the hex bolt next to the flat idler pulley. Install the drive belt down between the hex bolt and the flat idler pulley with the flat side of the belt against the pulley. Retighten the hex bolt.

•Loop the belt around the large v-pulley, placing it between the v-pulley and the hex bolt next to the pulley. Place the belt to the inside of the other flat idler pulley.

HEX BOLTS |

FLAT IDLER |

|

PULLEY |

DRIVE BELT |

|

FIGURE 44

Did you choose the correct drive belt for STOP your tractor? Using the wrong length belt

may cause premature bearing or belt failure.

STEP 46: (SEE FIGURE 45)

•Attach the clutch/idler assembly to the tractor frame as follows. Hook the assembly's notched arms onto the two shoulder bolts you assembled to the inside of the tractor frame. Lift the front of the assembly and attach it to the R.H. and L.H. hanger brackets using two pivot lock pins (GG) and 1/8" hairpin cotters (EE).

1/8" HAIRPIN COTTER (EE) |

|

|

PIVOT LOCK PIN (GG) |

|

(use second hole) |

FIGURE 45 |

RIGHT SIDE VIEW |

STEP 47: (SEE FIGURE 46)

•Assemble the drive belt onto the engine pulley and then onto the large pulley on top of the clutch/idler assembly.The belt must be placed to the inside of the idler pulley and the keeper bolt located beside the large pulley.

•Place tension on the belt by pulling the left side tensioning chain out as far as the 3/32" hairpin cotter

(FF)will allow. Secure the chain in this position by inserting a 1/8" hairpin cotter (EE) through the chain.

IMPORTANT: Do Not assemble the "V" belt around the outside of the engine pulley keeper or the keeper bolt.

CLUTCH/IDLER ASSEMBLY

|

Left Side |

ENGINE |

of Tractor |

|

|

PULLEY |

1/8" HAIRPIN |

|

|

|

COTTER (EE) |

IDLER

PULLEY

KEEPER

KEEPER

BOLT

FIGURE 46 |

VIEWED FROM UNDERNEATH |

21

ASSEMBLY OF THE SNOW THROWER

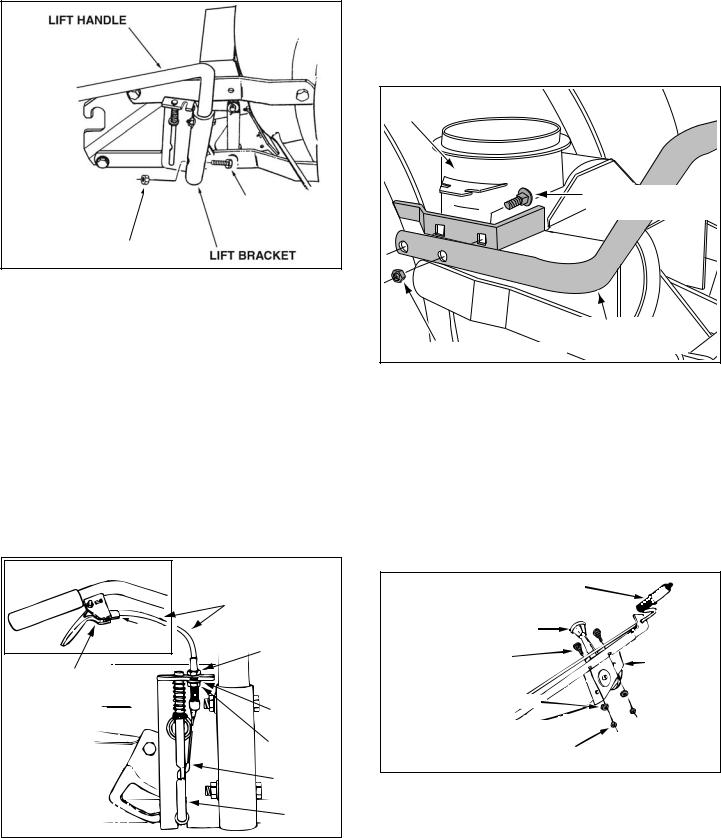

STEP 48: (SEE FIGURE 47)

•Place the lift handle into the lift bracket on the right side of the snow thrower. Fasten the handle to the bracket using two 5/16" x 1-3/4" hex bolts (B) and 5/16" Nylock nuts (Y).

5/16" x 1-3/4" HEX BOLT (B)

5/16" NYLOCK NUT (Y)

FIGURE 47 |

RIGHT SIDE VIEW |

NOTE: Be sure the lift release cable's plastic covering stays inserted into the trigger assembly for the next step.

STEP 49: (SEE FIGURE 48)

•Push the lift handle down into the locked position. Insert the end of the cable wire into the hole in the lift rod. Place the threaded fitting into the slot in the lift bracket, with one hex nut above and one hex nut and the lock washer below the slot.Tighten the nuts, adjusting them to eliminate slack in the cable wire.

Refer also to the Service and Adjustments section on page 28 in this manual.

HINT: For easier assembly of the lift release cable, tilt the snow thrower forward onto the spiral auger.

|

LIFT RELEASE |

|

CABLE |

|

HEX NUT |

TRIGGER |

|

ASSEMBLY |

LOCK |

|

|

|

WASHER |

|

HEX NUT |

|

CABLE |

|

WIRE |

|

LIFT |

|

ROD |

FIGURE 48 |

RIGHT SIDE VIEW |

STEP 50: (SEE FIGURE 49)

•Tilt the snow thrower back down to the ground.

•Remove the nylon tie which fastens the auger drive belt to the discharge housing, leaving the belt assembled around the pulleys.

•Remove the nylon tie which fastens the chute crank rod to the crank rod support tube.

•Assemble the crank rod support tube to the bracket on the left side of the discharge housing using two 5/16" x 1-1/4" carriage bolts (I), and 5/16" Nylock nuts

(Y).

DISCHARGE |

|

HOUSING |

|

|

5/16" x 1-1/4" |

|

CARRIAGE BOLT (I) |

|

CRANK ROD |

5/16" NYLOCK NUT (Y) |

SUPPORT TUBE |

|

|

FIGURE 49 |

LEFT SIDE VIEW |

STEP 51: (SEE FIGURE 50)

•Attach the chute tilt control assembly to the top side of the crank support tube using two 5/16" x 1-3/4" carriage bolts (H), bowed washers (U) and 5/16"

Nylock nuts (Y).

CHUTE CRANK ROD

CRANK SUPPORT TUBE

CRANK SUPPORT TUBE

TILT CONTROL HANDLE

5/16" x 1-3/4" |

TILT |

|

CONTROL |

||

CARRIAGE BOLT (H) |

||

ASSEMBLY |

||

|

||

BOWED WASHER (U) |

|

|

5/16" NYLOCK NUT (Y) |

|

FIGURE 50 LEFT SIDE VIEW

22

STEP 52: (SEE FIGURE 51)

•Attach the chute crank rod assembly brackets to the plastic bracket on the left side of the discharge housing. Align the chute crank bracket beneath the rod support bracket and assemble both to the plastic bracket using two 5/16" x 1" carriage bolts (J), 5/16" washers (Q) and 5/16" Nylock nuts (Y). Do not tighten yet.

CHUTE CRANK |

5/16" x 1" |

|

BRACKET |

CARRIAGE BOLT (J) |

|

|

CHUTE |

|

|

CRANK |

|

|

ROD |

|

|

ROD |

|

SPIRAL |

SUPPORT |

|

BRACKET |

||

|

||

|

5/16" WASHER (Q) |

|

|

5/16" NYLOCK NUT (Y) |

|

FIGURE 51 |

LEFT SIDE VIEW |

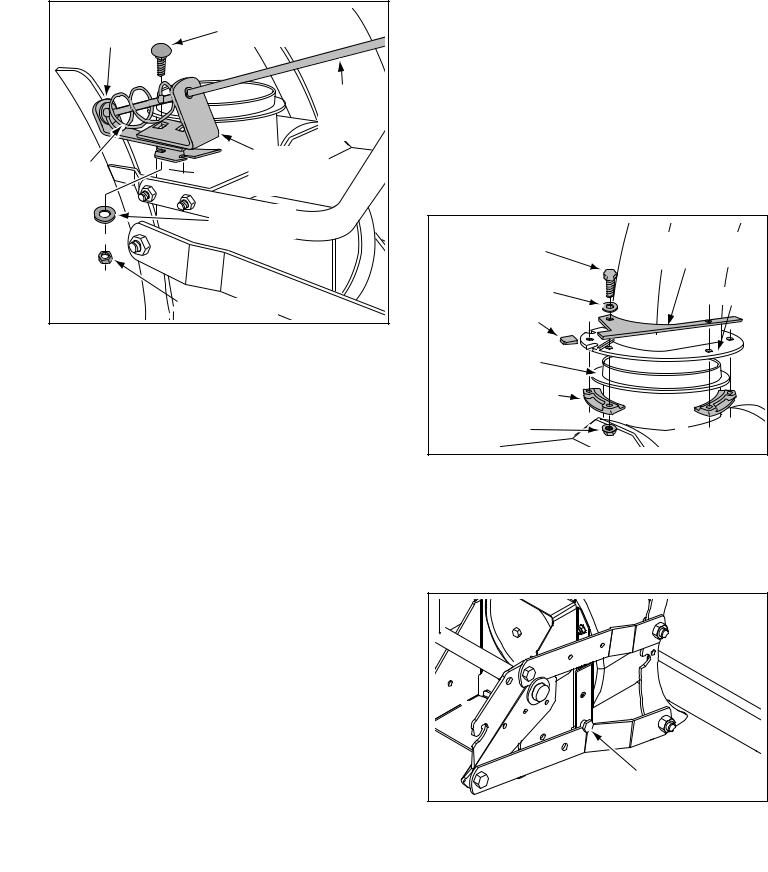

STEP 53: (SEE FIGURE 52)

•Coat the top of the ring around the discharge opening with general purpose grease.

•Place the discharge chute (facing forward) onto the ring. Place the anti-rotation bracket on top of the chute flange, aligning it with the holes on the right hand side of the flange. Attach the three chute keepers (BB) (right side up as shown) to the bottom of the flange using six 1/4" x 1" hex bolts (D), 1/4" flat washers (P) and 1/4" flanged lock nuts (V). Tighten carefully so that the nuts are snug but do not dig into the plastic chute keepers.

•Place the plastic cap (HH) onto the short end of the anti-rotation bracket.

•Position the crank rod spiral (see figure 51) so that it does not rub against the bottoms of the notches in the chute flange. Tighten the nuts.

•Check if the crank rod rotates the chute freely. If not, loosen by 1/4 turn each of the six hex bolts holding the chute keepers to the chute flange.

•Secure the control cables to the crank rod support tube using a nylon tie (II).

1/4" x 1" |

ANTI-ROTATION |

HEX BOLT (D) |

|

|

BRACKET |

1/4" FLAT |

|

WASHER (P) |

FLANGE |

|

|

PLASTIC CAP (HH) |

|

GREASED |

|

SURFACE |

|

CHUTE KEEPER (BB) |

|

1/4" FLANGED |

|

LOCK NUT (V) |

|

FIGURE 52 |

RIGHT SIDE VIEW |

STEP 54: (SEE FIGURE 53)

Skip this step if you have a lawn tractor.

This step is for garden tractors only.

•If you have a (GT) Garden Tractor, remove the stop bolts from each side of the snow thrower frame.

|

STOP BOLT |

FIGURE 53 |

RIGHT SIDE VIEW |

23

ATTACHING SNOW THROWER TO TRACTOR

NOTE: An additional person's help may be required to mount the snow thrower to the front of the tractor.

STEP 55: (SEE FIGURE 54)

•Place the tractor and snow thrower on a flat, level surface so that the tractor can be rolled forward to attach the snow thrower.

•Remove the Attachment Pin from the snow thrower.

•Extend the auger belt out behind the snow thrower, making sure the belt is still looped over the top of the large drive pulley and underneath the two idler pulleys.The "V" side of the belt must be seated in the grooves of all three pulleys.

•Roll the tractor up behind the snow thrower, centering it between the snow thrower's mounting plates.

•Raise the rear of the snow thrower by lifting up on the lift handle until the notches in the mounting plates align with the shoulder bolts in the tractor's side plates. Guide the bolts into the notches.

•To ease the assembly of the auger drive belt, delay the installation of the attachment pin until you have assembled the belt as instructed in steps 56 and 57.

|

ATTACHMENT PIN |

|

(After installing auger belt) |

1/8" HAIRPIN |

|

COTTER (EE) |

|

SHOULDER |

|

BOLT |

|

|

SIDE PLATE |

MOUNTING |

|

PLATE |

|

FIGURE 54 |

RIGHT SIDE VIEW |

BEFORE INSTALLING THE AUGER BELT

STEP 56: (SEE FIGURE 55)

•The auger belt comes preassembled to the pulleys on the snow thrower housing. Make sure the belt passes over the top of the auger pulley and then twists 1/4 turn to pass underneath each side idler pulley.The "V" side of the belt must mate with the grooves of the pulleys.

TWIST |

AUGER PULLEY |

TWIST |

|

||

1/4 TURN |

|

1/4 TURN |

IDLER |

|

IDLER |

PULLEY |

|

PULLEY |

FIGURE 55

INSTALLING THE AUGER BELT

STEP 57: (SEE FIGURE 56)

•Push the lift handle down to increase slack in the belt (attachment pin must first be removed).

•Swing the idler arm over to the left side.

•Place the auger belt around the rear pulley and between the two pulleys on the idler arm.The "V" side of the belt must be seated in the grooves of the v- pulleys.

CLUTCH/IDLER ASSEMBLY

IDLER

ARM

REAR |

LEFT SIDE |

PULLEY |

OF |

|

TRACTOR |

FIGURE 56 |

VIEWED FROM UNDERNEATH |

24

Loading...

Loading...