Makita 4328 User Manual [ru]

Jig Saw

Instruction Manual

Stichsäge

Betriebsanleitung

Piła włośnica

Instrukcja obsługi

Лобзик

Инструкция по эксплуатации

4326

4327

4328

4329

1

1

4

4

3

6

8 9

9

5

8 9 11

7

7

6

6

12

2 |

3 |

2

5

6

7

4

10

10

7

7

6

13

7 |

8 |

2

14

12

12

9

7

6

12

12

11

7

6

12

12

13

10 |

15 |

16 |

12 |

17 |

14 |

15 |

16 |

3

19

13 |

18 |

20 |

17

21

20

20

19

21

6

7 23

7 23

20

21

21

24

23 |

25 |

|

|

|

20 |

23

18

19

7

22

6

20

20

19

24

22

20

25

22

19

20

24

4

21

20

25

28

28

26

26

27

26

27

27

26

29

29

28

28

28

5

Symbols

The followings show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt mit ihrer Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед использованием, что Вы понимаете их значение.

Read instruction manual.

Bitte Bedienungsanleitung lesen.

Przeczytaj instrukcję obsługi.

Прочитайте инструкцию по эксплуатации.

DOUBLE INSULATION

DOPPELT SCHUTZISOLIERT

PODWÓJNA IZOLACJA

ДВОЙНАЯ ИЗОЛЯЦИЯ

Only for EU countries

Do not dispose of electric equipment together with household waste material!

In observance of European Directive 2002/96/EC on waste electrical and electronic equipment and its implementation in accordance with national law, electric equipment that have reached the end of their life must be collected separately and returned to an environmentally compatible recycling facility.

Nur für EU-Länder

Werfen Sie Elektrowerkzeuge nicht in den Hausmüll!

Gemäß Europäischer Richtlinie 2002/96/EG über Elektround Elektronik-Altgeräte und Umsetzung in nationales Recht müssen verbrauchte Elektrowerkzeuge getrennt gesammelt und einer umweltgerechten Wiederverwertung zugeführt werden.

Dotyczy tylko państw UE

Nie wyrzucaj urządzeń elektrycznych wraz z odpadami z gospodarstwa domowego!

Zgodnie z Europejską Dyrektywą 2002/96/WE w sprawie zużytego sprzętu elektrotechnicznego i elektronicznego oraz dostosowaniem jej do prawa krajowego, zużyte urządzenia elektryczne należy posegregować i zutylizować w sposób przyjazny dla środowiska.

Только для стран ЕС Не выкидывайте электрическое оборудование вместе с бытовым мусором!

В соответствии с европейской директивой 2002/96/EC об утилизацияи старого электрического и электронного оборудования и её применения в соответствии с местными законами электрическое оборудование, бывшее в эксплуатации, должно утилизовываться отдельно безопасным для окружающей среды способом.

6

ENGLISH

Explanation of general view

1 |

Cutting action changing lever |

11 |

Retainer |

|

|

21 |

Aluminum base type |

||||||

2 |

Switch trigger |

12 |

Base |

|

|

22 |

Guide facing |

|

|||||

3 |

Lock button |

|

|

13 |

Dust cover |

|

|

23 |

Fence guide |

|

|||

4 |

Speed adjusting dial |

14 |

Cutting line |

|

24 |

Threaded knob |

|

||||||

5 |

Blade holder |

15 |

Edge |

|

|

25 |

Pin |

|

|||||

6 |

Bolt |

|

|

16 |

Graduation |

|

|

26 |

Anti-splintering device |

||||

7 |

Hex wrench |

|

|

17 |

Starting hole |

|

27 |

Protrusions |

|

||||

8 |

Blade |

|

|

18 |

Hose |

|

|

28 |

Aluminum base |

|

|||

9 |

Roller |

|

|

19 |

Steel base type |

29 |

Cover plate |

|

|||||

10 |

Hook |

|

|

20 |

Rip fence (Guide rule) |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

SPECIFICATION |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

|

4326 |

|

|

|

4327 |

|

4328 |

|

4329 |

||

|

|

|

|

|

|

|

|

|

|

||||

Length of stroke |

|

18 mm |

|

|

18 mm |

|

18 mm |

|

18 mm |

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

Blade type |

|

|

|

|

|

|

B type |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. cutting |

|

Wood |

|

65 mm |

|

|

65 mm |

|

65 mm |

|

65 mm |

||

|

|

|

|

|

|

|

|

|

|

|

|

||

capacities |

|

Mild steel |

|

6 mm |

|

|

|

6 mm |

|

6 mm |

|

6 mm |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||

Strokes per minute (min–1) |

|

3,100 |

|

|

|

500 – 3,100 |

|

500 – 3,100 |

|

500 – 3,100 |

|||

|

|

|

|

|

217 mm |

|

|

217 mm |

|

|

|

|

|

Overall length |

|

(Steel base type) |

|

|

(Steel base type) |

|

217 mm |

|

223 mm |

||||

|

|

|

|

|

|

|

|

|

|||||

|

|

223 mm |

|

|

223 mm |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

(Aluminum base type) |

|

(Aluminum base type) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1,8 kg |

|

|

1,8 kg |

|

|

|

|

|

Net weight |

|

(Steel base type) |

|

|

(Steel base type) |

|

1,8 kg |

|

1,9 kg |

||||

|

|

|

|

|

|

|

|

|

|||||

|

|

1,9 kg |

|

|

1,9 kg |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

(Aluminum base type) |

|

(Aluminum base type) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

Safety class |

|

|

|

|

|

|

/II |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•Due to our continuing programme of research and development, the specifications herein are subject to change without notice.

•Note: Specifications may differ from country to country.

Intended use

The tool is intended for the sawing of wood, plastic and metal materials. As a result of the extensive accessory and saw blade program, the tool can be used for many purposes and is very well suited for curved or circular cuts.

Power supply

The tool should be connected only to a power supply of the same voltage as indicated on the nameplate, and can only be operated on single-phase AC supply.

They are double-insulated in accordance with European Standard and can, therefore, also be used from sockets without earth wire.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

Work area safety

1.Keep work area clean and well lit. Cluttered and dark areas invite accidents.

2.Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

3.Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

4.Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

5.Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

6.Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

7.Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

7

8.When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

9.If operating a power tool in a damp location is unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of an GFCI reduces the risk of electric shock.

Personal safety

10.Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

11.Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

12.Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

13.Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

14.Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

15.Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

16.If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

Power tool use and care

17.Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

18.Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

19.Disconnect the plug from the power source and/ or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

20.Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

21.Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

22.Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

23.Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

SERVICE

24.Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

25.Follow instruction for lubricating and changing accessories.

26.Keep handles dry, clean and free from oil and grease.

SPECIFIC SAFETY RULES

GEB016-1

DO NOT let comfort or familiarity with product (gained from repeated use) replace strict adherence to jig saw safety rules. If you use this tool unsafely or incorrectly, you can suffer serious personal injury.

1.Hold power tools by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will make exposed metal parts of the tool "live" and shock the operator.

2.Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body leaves it unstable and may lead to loss of control.

3.Always use safety glasses or goggles. Ordinary eye or sun glasses are NOT safety glasses.

4.Avoid cutting nails. Inspect workpiece for any nails and remove them before operation.

5.Do not cut oversize workpiece.

6.Check for the proper clearance beyond the workpiece before cutting so that the blade will not strike the floor, workbench, etc.

7.Hold the tool firmly.

8.Make sure the blade is not contacting the workpiece before the switch is turned on.

9.Keep hands away from moving parts.

10.Do not leave the tool running. Operate the tool only when hand-held.

11.Always switch off and wait for the blade to come to a complete stop before removing the blade from the workpiece.

12.Do not touch the blade or the workpiece immediately after operation; they may be extremely hot and could burn your skin.

13.Do not operate the tool at no-load unnecessarily.

8

14.Some material contains chemicals which may be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier safety data.

15.Always use the correct dust mask/respirator for the material and application you are working with.

WARNING:

MISUSE or failure to follow the safety rules stated in this instruction manual may cause serious personal injury.

SAVE THESE INSTRUCTIONS.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and unplugged before adjusting or checking function on the tool.

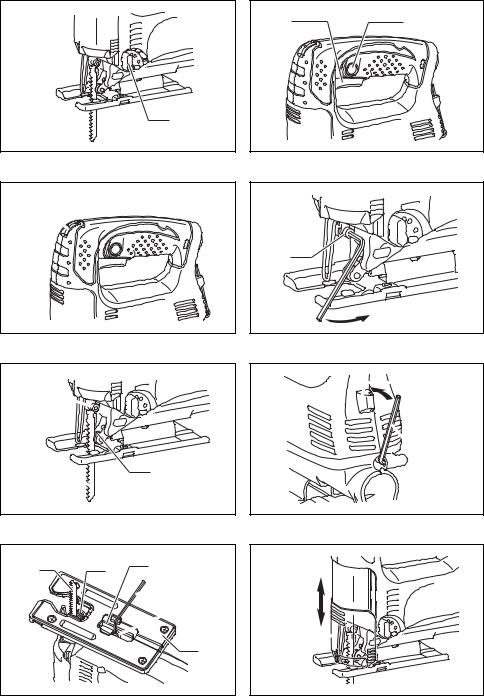

Selecting the cutting action (For models 4328/4329) (Fig. 1)

This tool can be operated with an orbital or a straight line (up and down) cutting action. The orbital cutting action thrusts the blade forward on the cutting stroke and greatly increases cutting speed.

To change the cutting action, just turn the cutting action changing lever to the desired cutting action position. Refer to the table to select the appropriate cutting action.

Position |

Cutting action |

Applications |

|

|

|

|

|

|

|

For cutting mild steel, stainless steel and plastics. |

|

0 |

Straight line cutting action |

|

|

For clean cuts in wood and plywood. |

|||

|

|

||

|

|

|

|

I |

Small orbit cutting action |

For cutting mild steel, aluminum and hard wood. |

|

|

|

|

|

|

|

For cutting wood and plywood. |

|

II |

Medium orbit cutting action |

|

|

For fast cutting in aluminum and mild steel. |

|||

|

|

||

|

|

|

|

III |

Large orbit cutting action |

For fast cutting in wood and plywood. |

|

|

|

|

Switch action (Fig. 2)

CAUTION:

•Before plugging in the tool, always check to see that the switch trigger actuates properly and returns to the “OFF” position when released.

To start the tool, simply pull the switch trigger. Release the switch trigger to stop.

For continuous operation, pull the switch trigger and then push in the lock button.

To stop the tool from the locked position, pull the switch trigger fully, then release it.

Speed adjusting dial (For models 4327/4328/4329) (Fig. 3)

The tool speed can be infinitely adjusted between 500 and 3,100 strokes per minute by turning the adjusting dial. Higher speed is obtained when the dial is turned in the direction of number 6; lower speed is obtained when it is turned in the direction of number 1.

Refer to the table to select the proper speed for the workpiece to be cut. However, the appropriate speed may differ with the type or thickness of the workpiece. In general, higher speeds will allow you to cut workpieces faster but the service life of the blade will be reduced.

Workpiece to be cut |

Number on adjusting dial |

|

|

Wood |

5 – 6 |

|

|

Mild steel |

3 – 6 |

|

|

Stainless steel |

3 – 4 |

|

|

Aluminum |

3 – 6 |

|

|

Plastics |

1 – 4 |

|

|

CAUTION:

•If the tool is operated continuously at low speeds for a long time, the motor will get overloaded and heated up.

•The speed adjusting dial can be turned only as far as 6 and back to 1. Do not force it past 6 or 1, or the speed adjusting function may no longer work.

ASSEMBLY

CAUTION:

•Always be sure that the tool is switched off and unplugged before carrying out any work on the tool.

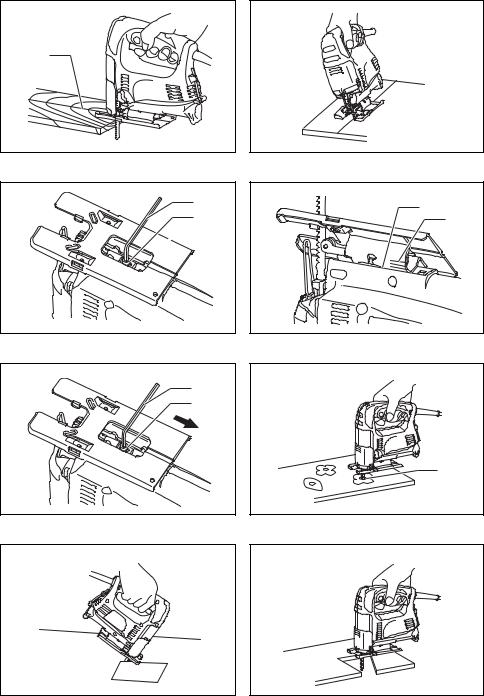

Installing or removing saw blade (Fig. 4 & 5)

CAUTION:

•Always clean out all chips or foreign matter adhering to the blade and/or blade holder. Failure to do so may cause insufficient tightening of the blade, resulting in a serious personal injury.

9

•Do not touch the blade or the workpiece immediately after operation; they may be extremely hot and could burn your skin.

•Always secure the blade firmly. Insufficient tightening of the blade may cause blade breakage or serious personal injury.

•Use only B type blades. Using blades other than B type blades causes insufficient tightening of the blade, resulting in a serious personal injury.

To install the blade, loosen the bolt counterclockwise on the blade holder with the hex wrench.

With the blade teeth facing forward, insert the blade into the blade holder as far as it will go. Make sure that the back edge of the blade fits into the roller. Then tighten the bolt clockwise to secure the blade.

To remove the blade, follow the installation procedure in reverse.

NOTE:

• Occasionally lubricate the roller.

Hex wrench storage (Fig. 6)

When not in use, store the hex wrench as shown in the figure to keep it from being lost.

Adjusting roller (For models 4326/4327) (Fig. 7)

Loosen the bolt on the back of the tool base with the hex wrench. Move the retainer so that the roller contacts the blade lightly. Then tighten the bolt to secure the tool base and the retainer.

NOTE:

• Occasionally lubricate the roller.

Dust cover (Fig. 8)

CAUTION:

•Always wear safety goggles even when operating the tool with the dust cover lowered.

Lower the dust cover to prevent chips from flying. However, when making bevel cuts, raise it all the way.

OPERATION

CAUTION:

•Always hold the base flush with the workpiece. Failure to do so may cause blade breakage, resulting in a serious injury.

•Advance the tool very slowly when cutting curves or scrolling. Forcing the tool may cause a slanted cutting surface and blade breakage.

Turn the tool on without the blade making any contact and wait until the blade attains full speed. Then rest the tool base flat on the workpiece and gently move the tool forward along the previously marked cutting line. (Fig. 9)

Bevel cutting

CAUTION:

•Always be sure that the tool is switched off and unplugged before tilting the tool base.

•Raise the dust cover all the way before making bevel cuts.

With the base tilted, you can make bevel cuts at any angle between 0° and 45° (left or right).(Fig. 10) Loosen the bolt on the back of the base with the hex wrench. Move the tool base so that the bolt is positioned in the center of the cross-shaped slot in the base.

(Fig. 11)

Tilt the base until the desired bevel angle is obtained. The edge of the motor housing indicates the bevel angle by graduations. Then tighten the bolt to secure the base.

(Fig. 12)

Front flush cuts (Fig. 13)

Loosen the bolt on the back of the tool base with the hex wrench, and slide the base all the way back. Then tighten the bolt to secure the tool base.

Cutouts

Cutouts can be made with either of two methods A or B.

A)Boring a starting hole

For internal cutouts without a lead-in cut from an edge, pre-drill a starting hole 12 mm or more in diameter. Insert the blade into this hole to start your cut.

(Fig. 14)

B)Plunge cutting

You need not bore a starting hole or make a lead-in cut if you carefully do as follows.

1.Tilt the tool up on the front edge of the base with the blade point positioned just above the workpiece surface. (Fig. 15)

2.Apply pressure to the tool so that the front edge of the base will not move when you switch on the tool and gently lower the back end of the tool slowly.

3.As the blade pierces the workpiece, slowly lower the base of the tool down onto the workpiece surface.

4.Complete the cut in the normal manner.

Finishing edges (Fig. 16)

To trim edges or make dimensional adjustments, run the blade lightly along the cut edges.

Metal cutting

Always use a suitable coolant (cutting oil) when cutting metal. Failure to do so will cause significant blade wear. The underside of the workpiece can be greased instead of using a coolant.

Dust extraction (Fig. 17)

Clean cutting operations can be performed by connecting this tool to a Makita vacuum cleaner. Insert the hose of the vacuum cleaner into the hole at the rear of the tool. Lower the dust cover before operation.

NOTE:

•Dust extraction cannot be performed when making bevel cuts.

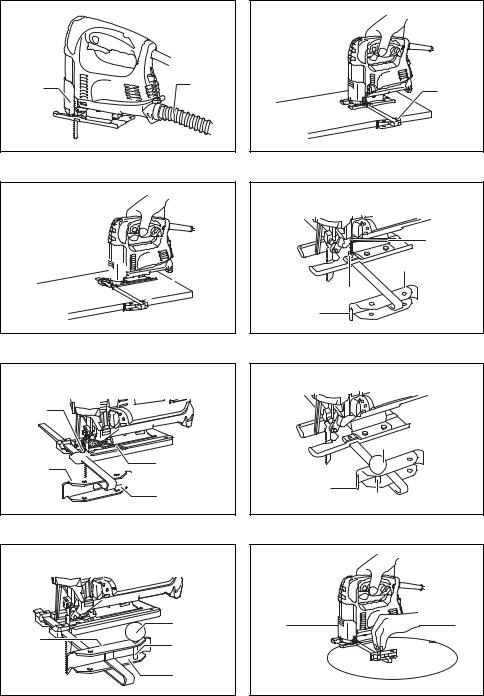

Rip fence (optional accessory)

CAUTION:

•Always be sure that the tool is switched off and unplugged before installing or removing accessories.

1) Straight cuts (Fig. 18, 19, 20 & 21)

When repeatedly cutting widths of 160 mm or less, use of the rip fence will assure fast, clean, straight cuts.

To install, insert the rip fence into the rectangular hole on the side of the tool base with the fence guide facing down. Slide the rip fence to the desired cutting width position, then tighten the bolt to secure it.

10

Loading...

Loading...