ELECTRICAL

TROUBLESHOOTING

SERVICE MANUAL

OCTOBER 1999

(NEW ISSUE)

8-212

Front.fm Page -ii Tuesday, June 29, 1999 3:11 PM

-ii

newknow.fm Page 1 Thursday, May 21, 1998 2:23 PM

Manual: _______________________________ Publication Number: _______

Vehicle Model: _________________________ Model Year: ______________

Do you find procedures properly organized and easy to follow? m Yes m No

If not, please explain: ____________________________________ __________

___________________________________ ____________________________

PLEASE LET US KNOW!

Your comments and suggestions will help

us improve this manual!

Please complete and mail this form or FAX

your comments to: (610) 709-3800.

___________________________________ ____________________________

Manual page numbers: _____________________________________________

Are there any important procedures or other information presently not in this

manual that you would like to see included? m Yes m No

If yes, please describe: _____________________________ ________________

___________________________________ ____________________________

___________________________________ ____________________________

Did you find any errors in the procedures or illustrations? m Yes m No

If yes, what pages? _______________________________ ________________

Please explain: ___________________________________________________

_______________________________________________________________

Please include a copy of each page in question and mark your comments and

suggestions.

Name: ________________________________ Phone: (_____) _____-_______

Company: _______________________________________________________

Address: ________________________________________________________

City: _________________________________ State: _______ Zip: _______

Position Title: ____________________________________ ________________

Thank You For Your Assistance

Mack Trucks, Inc.

(ATTENTION: RTS STAFF, 6S3)

DO NOT STAPLE — USE TRANSPARENT T A PE

Busreply.fm Page 1 Thursday, May 21, 1998 2:24 PM

FOLD ALONG THIS LINE • DO NOT STAPLE • USE TRANSPARENT TAPE

BUSINESS REPLY MAIL

FIRST CLASS MAIL PERMIT NO. 1602 ALLENTOWN, PA

POSTAGE WILL BE PAID BY ADDRE SS EE

SERVICE PUBLICATIONS (RTS), 6S3

MACK TRUCKS INC

WORLD HEADQUARTERS

PO BOX M

ALLENTOWN PA 18105-9972

FOLD ALONG THIS LINE

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

ELECTRICAL

TROUBLESHOOTING

SERVICE MANUAL

OCTOBER 1999

NEW ISSUE

© MACK TRUCKS, INC. 1999

8-212

Front.fm Page ii Tuesday, June 29, 1999 3:11 PM

ATTENTION

The information in this manual is not all inclusive and

cannot take into account all unique situations. Note that

some illustrations are typical and may not reflect the

exact arrangement of every component installed on a

specific chassis.

The information, specifications, and illustrations in this

publication are based on information that was current at

the time of publication.

No part of this publication may be reproduced, stored in a

retrieval system, or be transmitted in any form by any

means including electronic, mechanical, photocopying,

recording, or otherwise without prior written permission

of Mack Trucks, Inc.

ii

Front.fm Page iii Tuesday, June 29, 1999 3:11 PM

SAFETY INFORMATION

SAFETY INFORMATION

iii

Front.fm Page iv Tuesday, June 29, 1999 3:11 PM

Advisory Labels

SAFETY INFORMATION

Cautionary

manual. Information accented by one of these signal words must be observed to minimize the risk of

personal injury to service personnel, or the possibility of improper service methods which may damage

the vehicle or render it unsafe. Additional Notes and Service Hints are utilized to emphasize areas of

procedural importance and provide suggestions for ease of repair. The following definitions indicate the

use of these advisory labels as they appear through out the manual:

signal words

(Danger-Warning-Caution) may appear in various locations throughout this

Directs attention to unsafe practices which could result in damage to equipment and

possible subsequent personal injury or death if proper precautions are not taken.

Directs attention to unsafe practices which could result in personal injury or

death if proper precautions are not taken.

Directs attention to unsafe practices and/or existing hazards which will result

in personal injury or death if proper precautions are not taken.

An operating procedure, practice, condition, etc., which is essential to emphasize.

A helpful suggestion which will make it quicker and/or easier to perform a certain

procedure, while possibly reducing overhaul cost.

000001a

iv

Front.fm Page v Tuesday, June 29, 1999 3:11 PM

Service Procedures and Tool Usage

Anyone using a service procedure or tool not recommended in this manual must first satisfy himself

thoroughly that neither hi s safet y nor vehi cle saf ety will b e jeo pardized b y the s erv ice method he s ele cts .

Individuals deviating in any manner from the instructions provided assume all risks of consequential

personal injury or damage to equipment involved.

Also note that particular service procedures may require the use of a special tool(s) designed for a

specific purpose. These special tools must be used in the manner described, whenever specified in the

instructions .

1. Before starting a vehicle, always be seated in the driver’s seat, place the

transmission in neutral, be sure that parki ng brakes are se t, and disengage

the clutch (if equipped).

SAFETY INFORMATION

2. Before working on a vehicle, place the transmission in neutral, set the

parking brakes, and block the wheels.

3. Before towing the vehicle, place the transmiss ion in neutral and li ft the rear

wheels off the ground, or disconnect the driveline to avoid damage to the

transmission during towing.

Engine driven components such as Power Take-Off (PTO) units, fans and fan

belts, driveshafts and other related rotating assemblies, can be very

dangerous. Do not work on or service engine driven components unless the

engine is shut down. Always keep body parts and loose clothing out of range

of these powerful components to prevent serious personal injury. Be aware of

PTO engagement or nonengagement status. Always disengage the PTO when

not in use.

REMEMBER,

SAFETY . . . IS NO ACCIDENT!

v

Front.fm Page vi Tuesday, June 29, 1999 3:11 PM

NOTES

vi

Front.fm Page vii Tuesday, June 29, 1999 3:11 PM

TABLE OF CONTENTS

TABLE OF CONTENTS

vii

Front.fm Page viii Tuesday, June 29, 1999 3:11 PM

TABLE OF CONTENTS

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

ADVISORY LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

SERVICE PROCEDURES AND TOOL USAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

DESCRIPTION AND OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ELECTRICAL CONCEPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Understanding Electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Sources of Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CURRENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Actual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Conventional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Types of Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

RESISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Resistance, Heat and Current Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CIRCUIT TYPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Series Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Parallel Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Series-Parallel Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

OHM’S LAW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EXPRESSING ELECTRICAL VALUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

DIAGNOSTIC TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 6

Jumper Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Multimeter (Volt-Ohm Meter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Multimeter (Volt-Ohm Meter) Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TROUBLESHOOTING METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Diagnostic Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Diagnostic Application s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Locating Shorts or Grounded Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Circuit Continuity Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Checking Circuit Grounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

POWER DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Battery-Powered Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Key-Powered Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Ground Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

TYPICAL ELECTRIC EQUIPMENT PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

CIRCUIT BREAKERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

SAE Type 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SAE Type 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SAE Type 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Testing Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

WIRE SIZES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

WIRE IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

BATTERIES — GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Types of Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Battery Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

viii

Front.fm Page ix Tuesday, June 29, 1999 3:11 PM

STARTING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

CHARGING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Charging System Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

MISCELLANEOUS CIRCUITS — DESCRIPTION/FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Sending Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

TROUBLESHOOTING OF INSTRUMENT CLUSTER, GAUGES, SENDING UNITS,

SENSORS AND HORN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Gauge Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Specific Gauge and Sending Unit Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Speed Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

TABLE OF CONTENTS

REPAIR PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

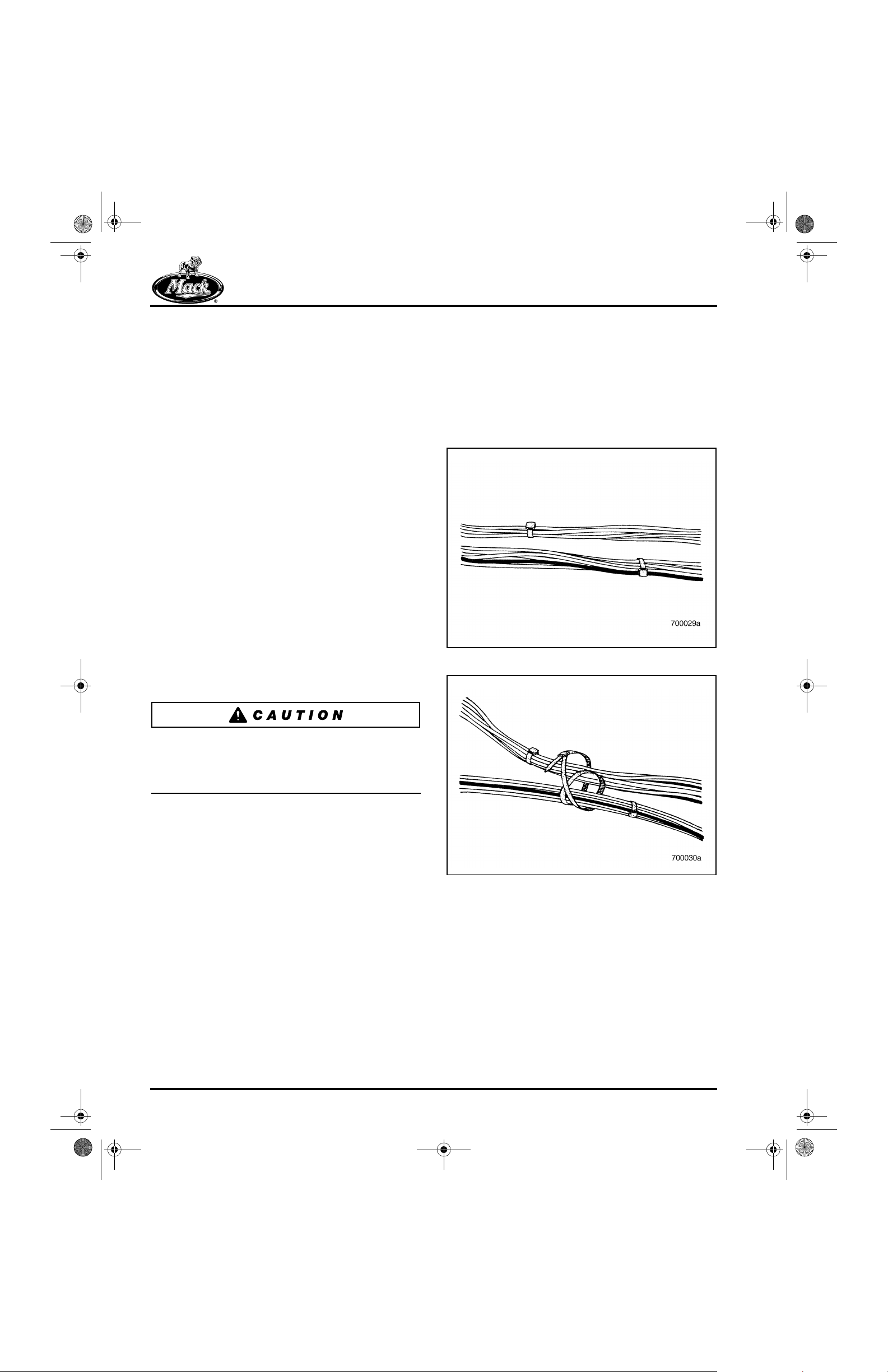

COMMON ELECTRICAL PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Correct Use of Tie Wraps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Typical Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Chassis Electrical Sealant Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

SPECIAL TOOLS & EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

RECOMMENDED ELECTRICAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

ix

Front.fm Page x Tuesday, June 29, 1999 3:11 PM

NOTES

x

8_212desc.fm Page 1 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

DESCRIPTION AND OPERATION

Page 1

8_212desc.fm Page 2 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

INTRODUCTION

Electricity provides the power necessary for

starting the engine and operating the various

lights and other auxi liary sy stems in stal led on t he

chassis. Diagnosing problems t hat can occu r in a

truck electrical system involves a basic

understanding of electrical concept s, and testing

and measurement procedures. The purpose of

this manual is to familiarize the technician with

basic electrical concepts and diagnostic

procedures. It is not intended to be vehicle

specific.

ELECTRICAL CONCEPTS

Understanding Electricity

Electricity is the movement of electrons through a

conductor. An electrical circuit can easily be

compared to a hydraulic (or pneumatic) circuit,

where hydraulic fluid (or compressed air) is

pushed through a conductor to an actuator that

performs a function.

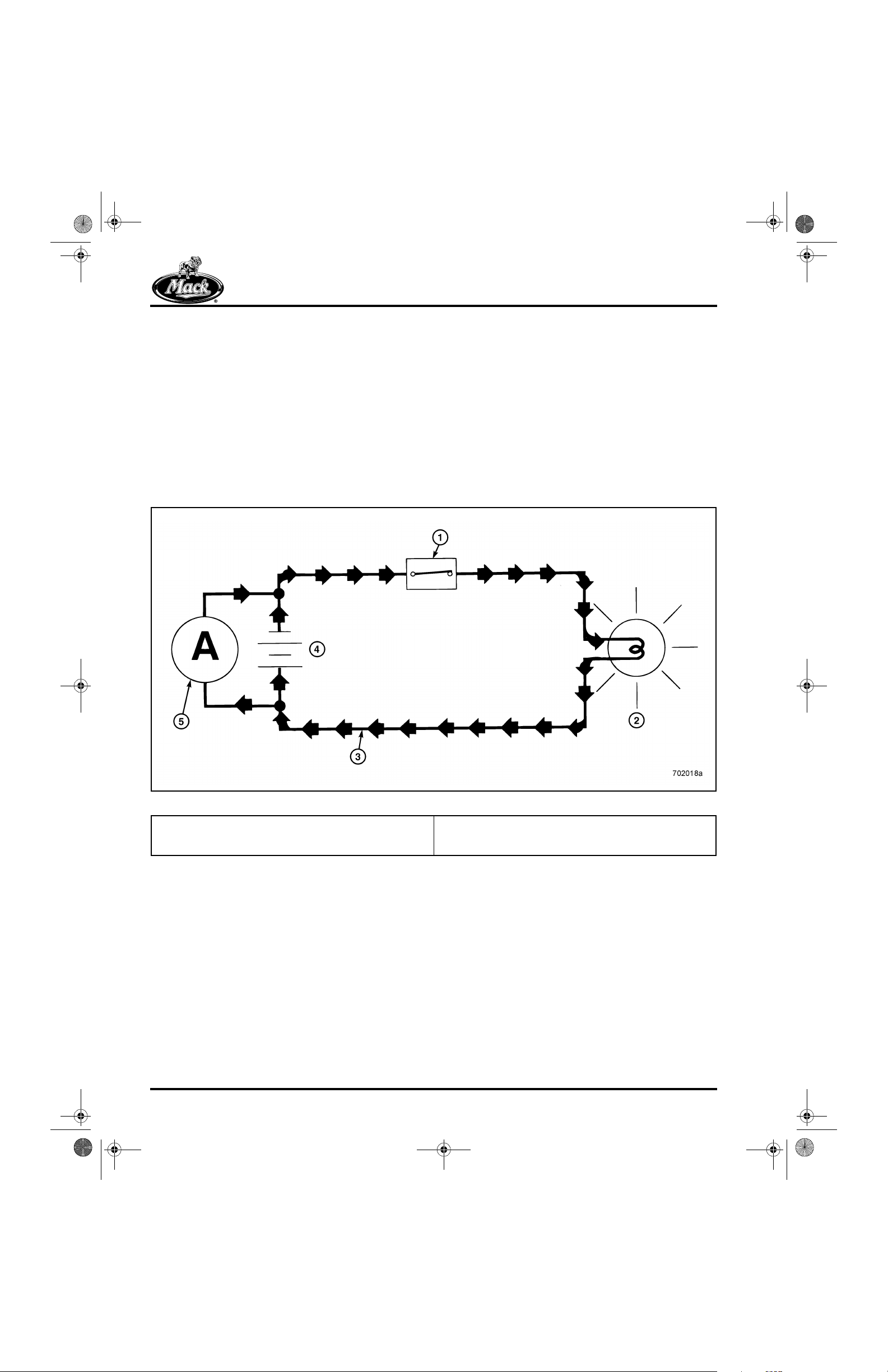

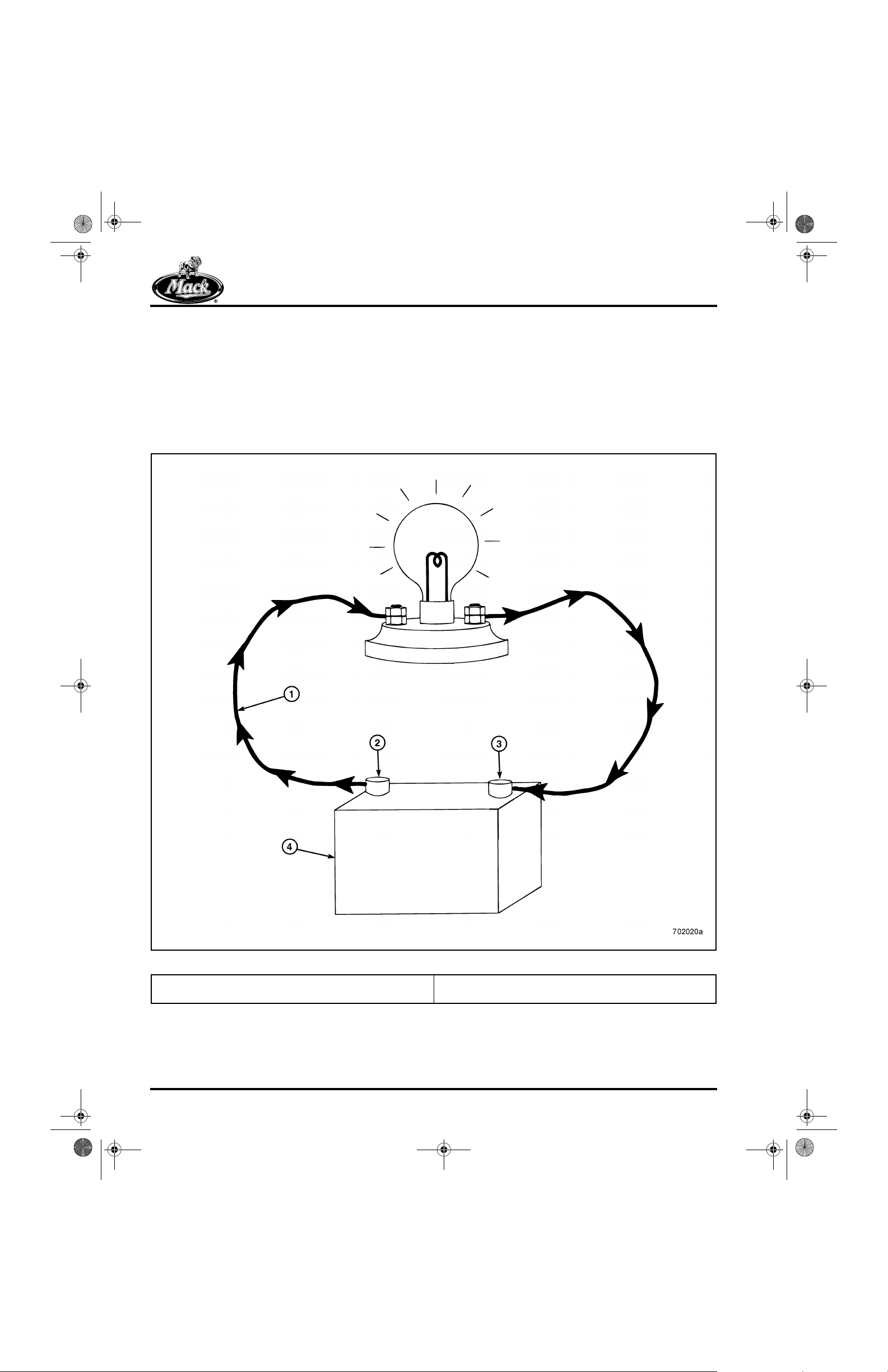

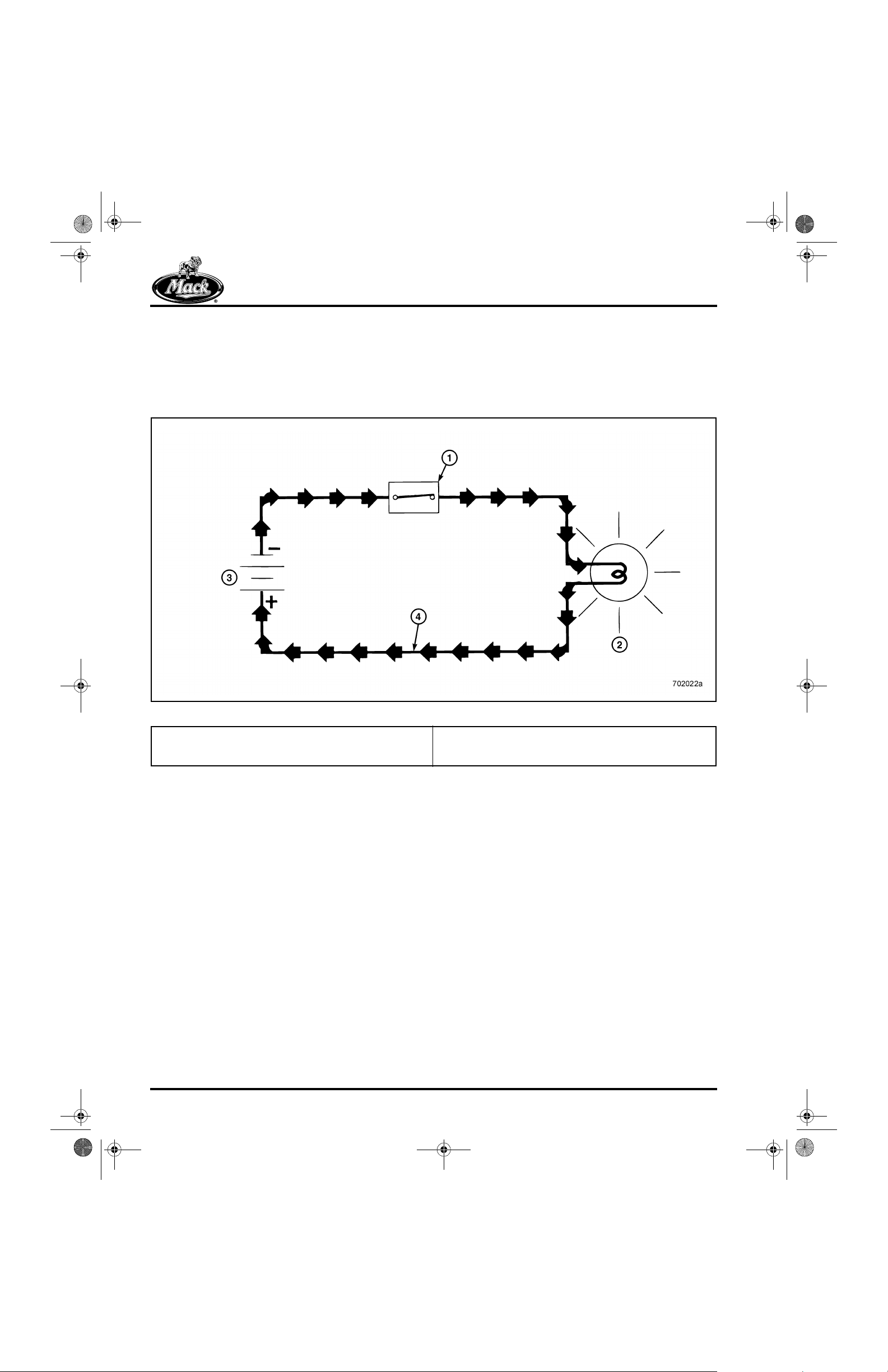

1

1. Switch (Control)

2. Light Bulb (Load)

3. Electron Flow

Page 2

Figure 1 — Electrical Circuit

4. Battery (Voltage Storage & Source)

5. Alternator (Voltage Source — Electron Pump)

8_212desc.fm Page 3 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

2

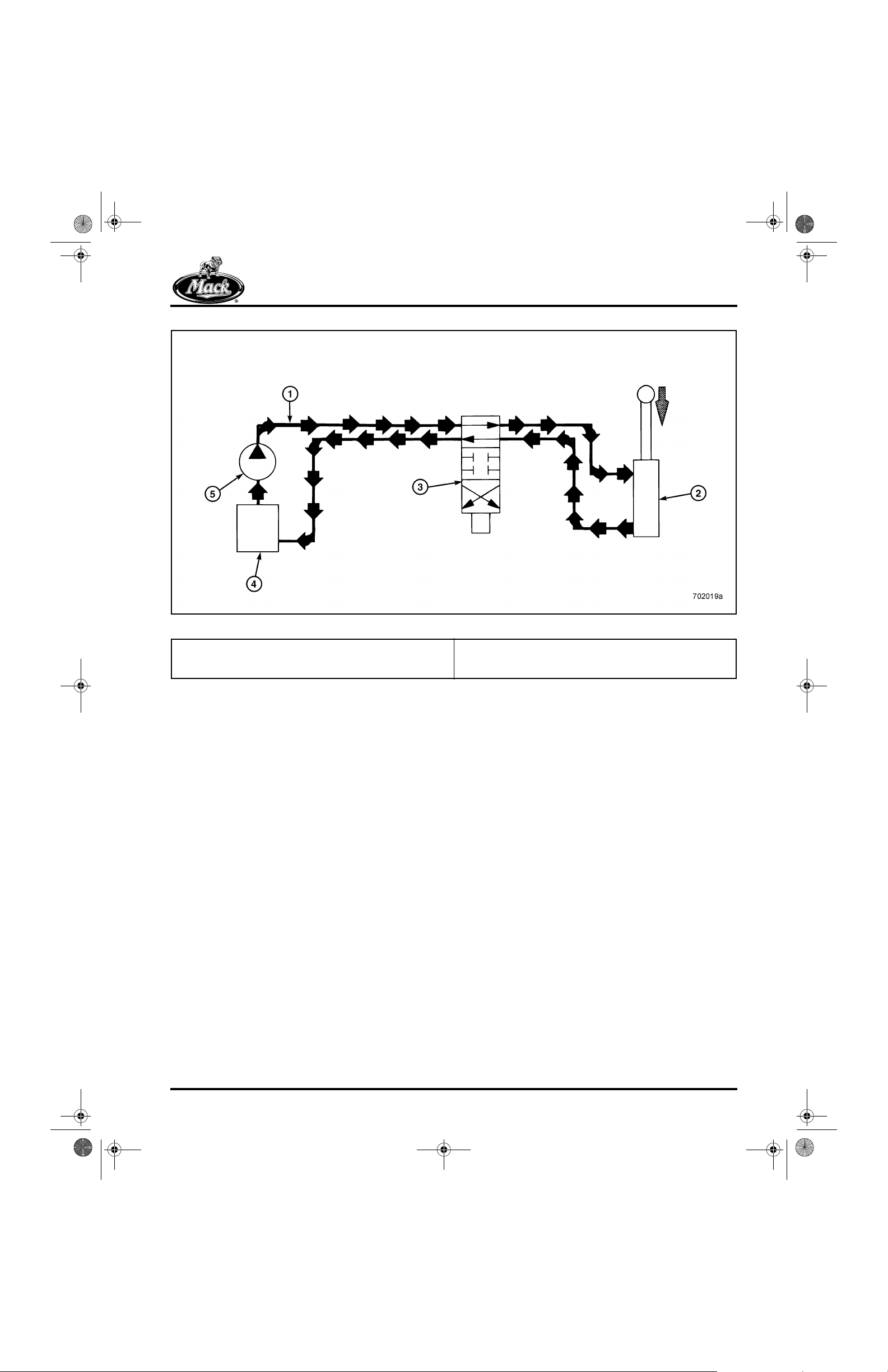

Figure 2 — Hydraulic Circuit

1. Fluid Flow

2. Cylinder (Load)

3. Valve (Control)

A basic understanding of electricity begins with

an understanding of a few basic electrical terms

and concepts. They are:

r Voltage

r Current

r Resistance

r Circuit Types

r Ohm’s Law

4. Reservoir (Fluid Storage)

5. Fluid Pump

Page 3

8_212desc.fm Page 4 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

VOLTAGE

The force that causes the electrons to move is

called “electromotive force.” Electromotive force

is more commonly known as voltage. Voltage is

the potential difference in electron pressure

between two points. The potential dif ference is an

excess of electrons on the negative side and a

lack of electrons on the positive side.

The movement of electrons requires:

r An excess of electrons on one side.

r A lack of electrons on the other side.

r A path between the two.

r A force capable of moving the electrons.

3

Figure 3 — Voltage (Electromotive Force)

1. Path for Electron Flow (Wire and Bulb Filament)

2. Negative Battery Terminal — Excess of Electrons

Page 4

3. Positive Battery Terminal — Lack of Electrons

4. Battery (Force That Moves Electrons)

8_212desc.fm Page 5 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Sources of Voltage

Voltage can be generated by:

r Heat

r Friction

r Light

r Pressure

r Chemical Reaction

r Magnetism

The two sources of voltage available in a truck

electrical system are chemical reaction and

magnetism.

CHEMICAL REACTION

4

Voltage is created in a storage battery by

chemical reaction. The reaction that takes place

between the sulfuric acid/water (elect rolyte) and

lead plates inside the battery, produces a

potential difference in electron pressure between

the positive and negative terminals. As the free

electrons are drawn from the battery, the reaction

continues until the chemicals inside the battery

are exhausted.

The battery provides and stores the voltage

necessary for the starting system to crank the

engine. The battery also provides the additional

voltage needed when electrical demands exceed

the electron flow supplied by the charging

system.

MAGNETISM

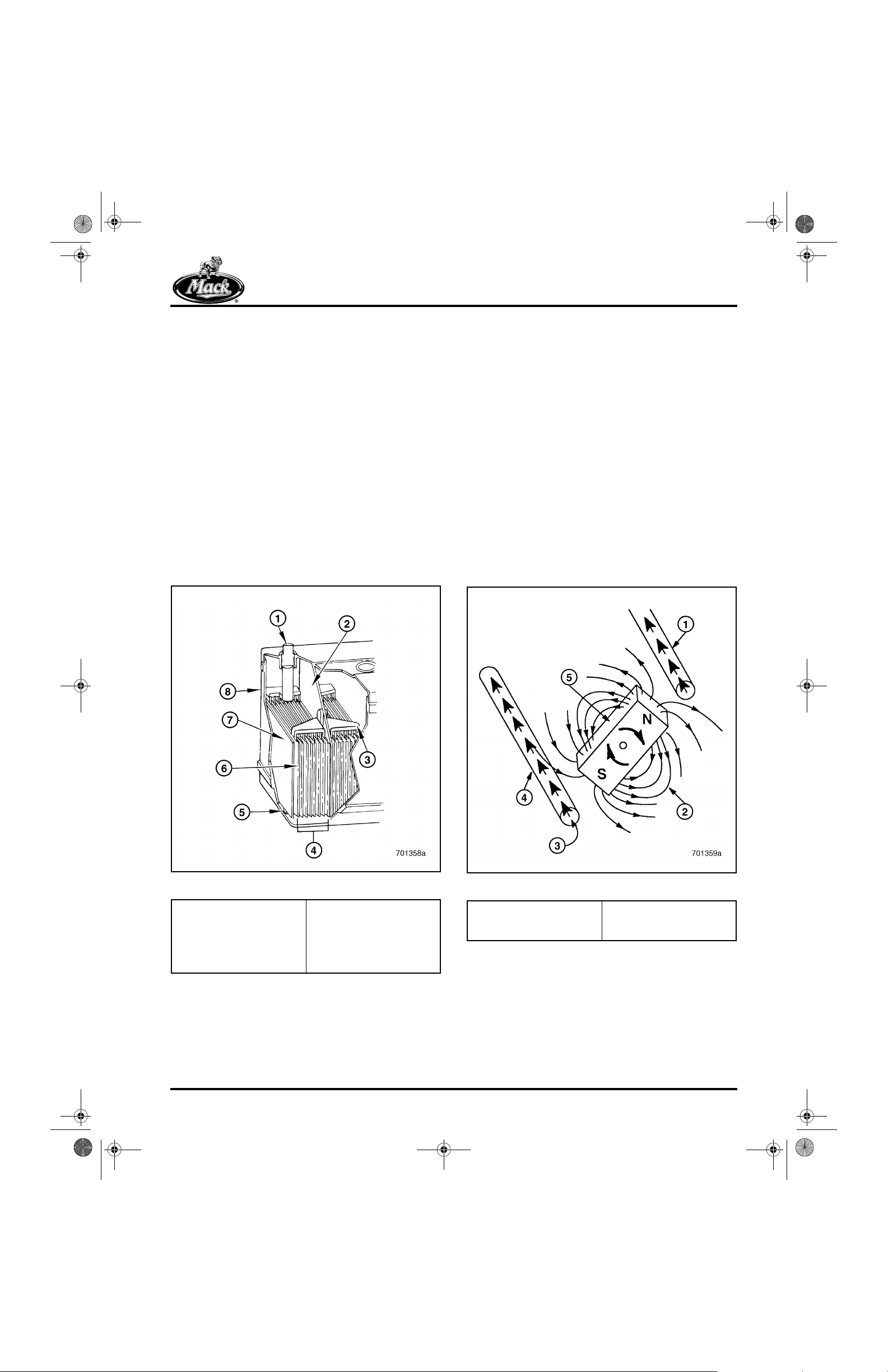

5

Figure 4 — Chemical Reaction (Battery)

1. Terminal Post

2. Cell Partition

3. Intercell Connections

4. Plates and Separators

5. Element Rest

6. Positive Plate (Lead

Peroxide)

7. Negative Plate (Sponge

Lead)

8. Case

Figure 5 — Magnetism (Magnet and Conductor)

1. Conductor

2. Magnetic Field

3. Electron Flow

4. Conductor

5. Permanent Magnet

Page 5

8_212desc.fm Page 6 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Voltage is also generated when a wire is

physically passed through a magnetic field. This

process is called “induction.” As an example, an

alternator generates electricity when a magnetic

field (rotor) is passed over a coil of wire (stator).

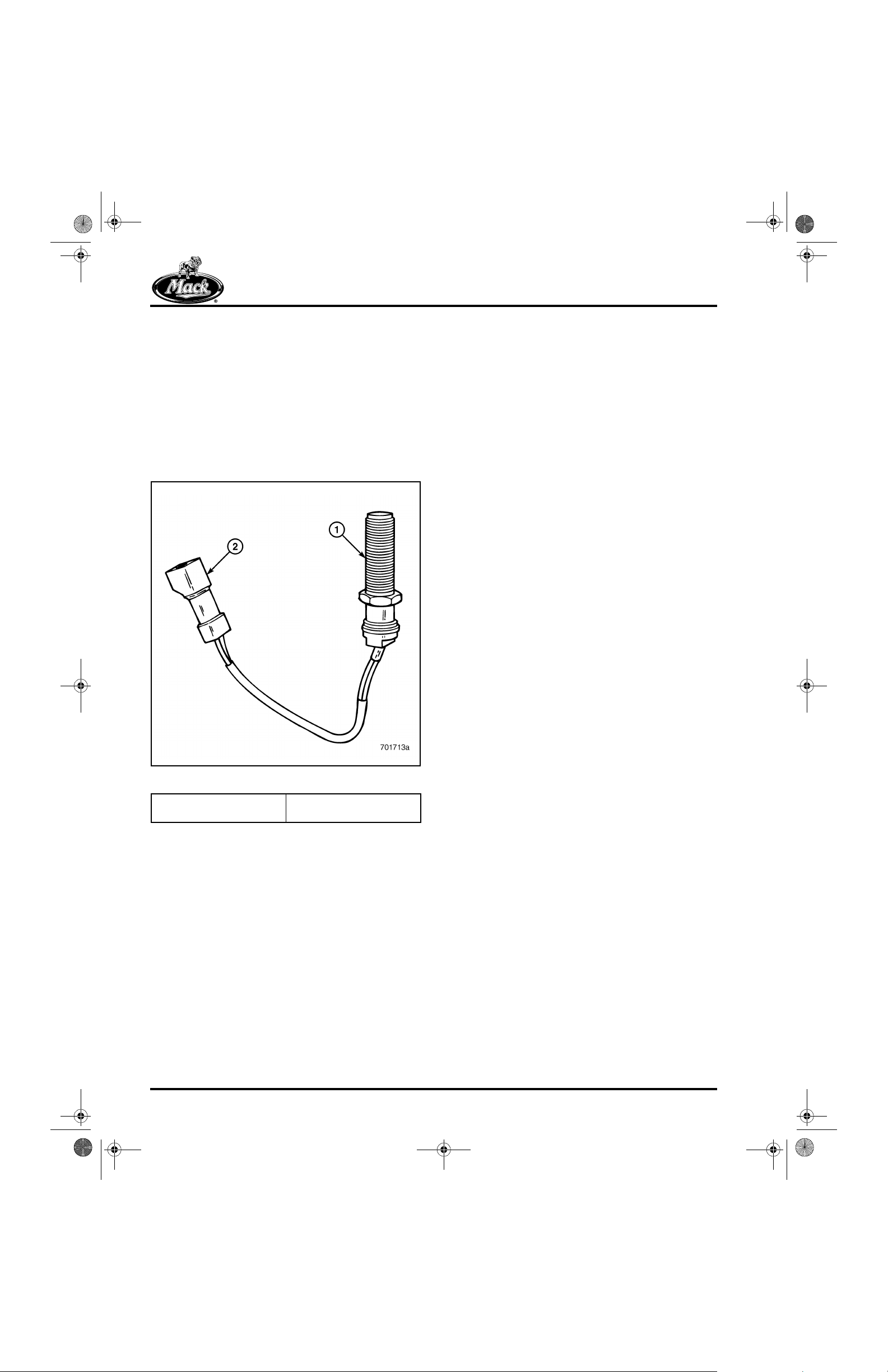

Another example of voltage generated by the

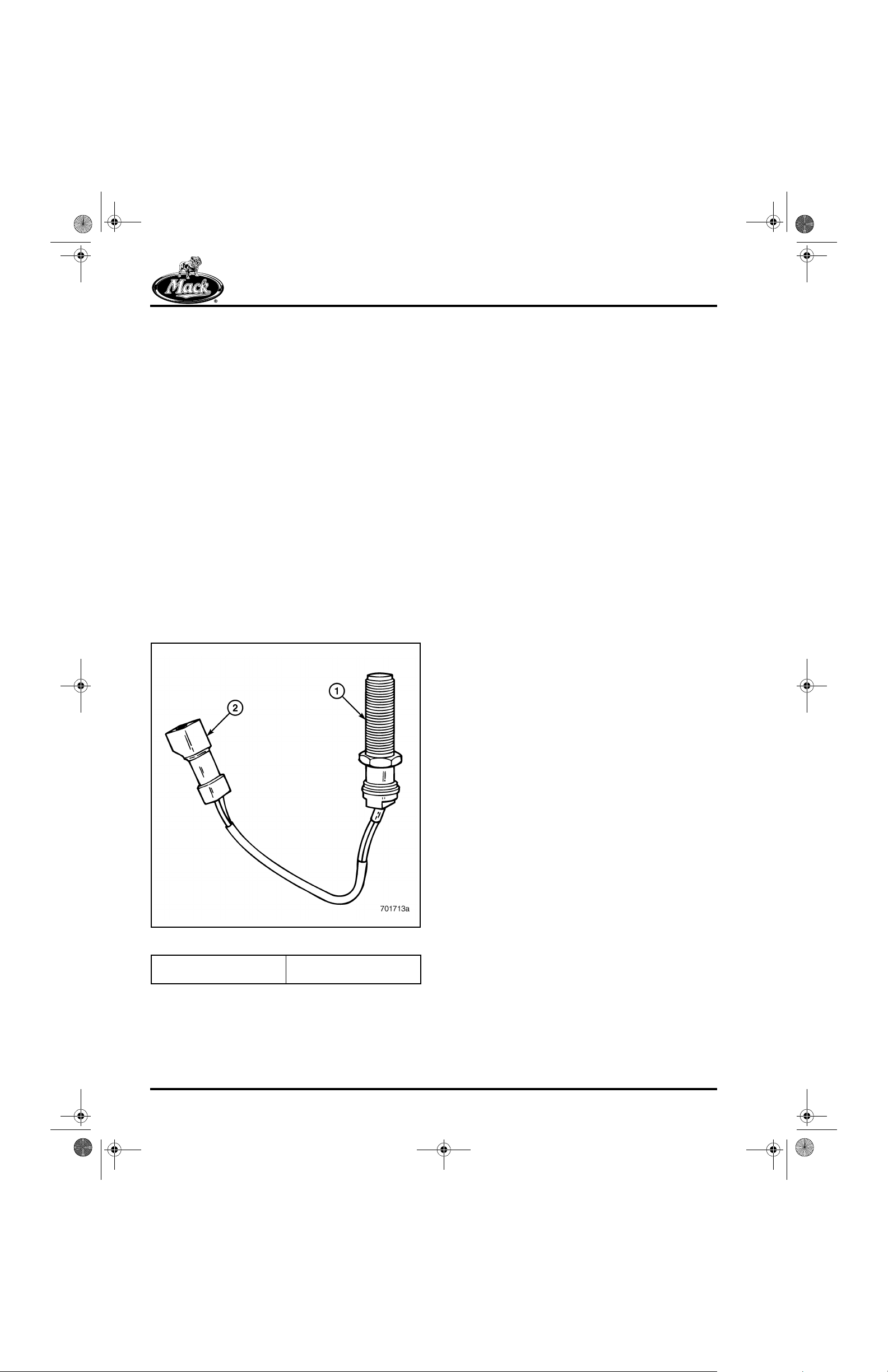

principle of induction is the speed sensor used to

determine engine speed or vehicle speed. When

a toothed gear passes in front of a magnetic pickup, the magnetic field is broken and an electrical

pulse is generated.

6

Figure 6 — Speed Sensor

1. Speed Sensor 2. Speed Sensor

Connector (Integral)

Page 6

8_212desc.fm Page 7 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

CURRENT

Electrical current is the movement of electrons

through a conductor. Just as flow in a hydraulic

system is measured as the amount of fluid

flowing past a given point in a certain amount of

time (expressed as gallons per minute), electr ical

current is measured as the amount of electrons

moving past a certain point in a given amount of

time. Electron flow is expressed in amperes or

amps.

One AMP equals 6.25 trillion electrons flowing

past a given point in one second.

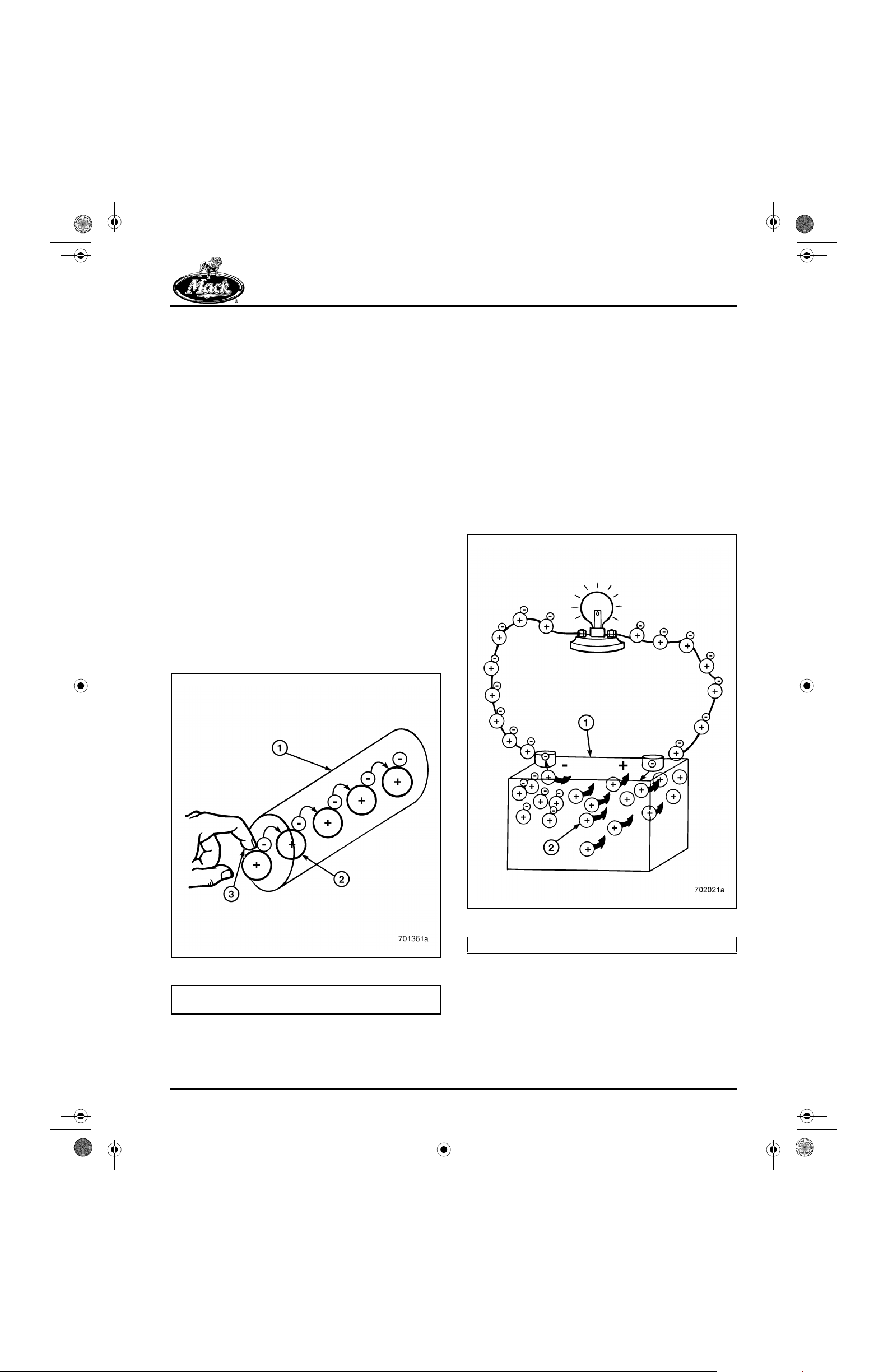

Actual

Actual current flow is the flow of free electrons

through a conductor. Current flow is the

movement of negatively charged electrons from

one atom to the next atom. The positi ve side of a

voltage source (which has a lack of electrons)

attracts the free electrons from the negati ve side

(which is giving up electr ons). Electr ons flow from

negative to positive.

7

Conventional

Conventional current flow describes a circui t

inside a battery. Atoms that gain or lose electrons

are called ions. Excess electrons do not move

through a battery, but are carried by ions. The

movement of ions inside a battery is from the

positive plates (or battery post) where free

electrons are given up, to the negative plates (or

battery post) where electrons are received. This

makes it appear as though current flow is from

positive to negative.

Conventional current flow is considered to be

from positive to negative.

8

Figure 7 — Electron Current Flow Through a Conductor

1. Copper Wire

2. Copper Atom

3. Voltage (Electron Push)

Figure 8 — Conventional Current Flow Through a Circuit

1. Battery 2. Migrating Positive Ions

Page 7

8_212desc.fm Page 8 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Types of Current

There are two types of current flow: Direct

Current (DC) and Alternating Current (AC).

DIRECT CURRENT (DC)

In a direct current circuit, electrons flow in one

direction only, from the negative terminal to the

positive terminal. Direct current, supplied by the

storage battery, is the type of current flow in a

truck electrical system.

9

1. Closed Switch

2. Lamp

3. Battery (Force to Move Current)

Figure 9 — Direct Current

4. Electrons flow in one direction only, from negative to

positive.

Page 8

8_212desc.fm Page 9 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

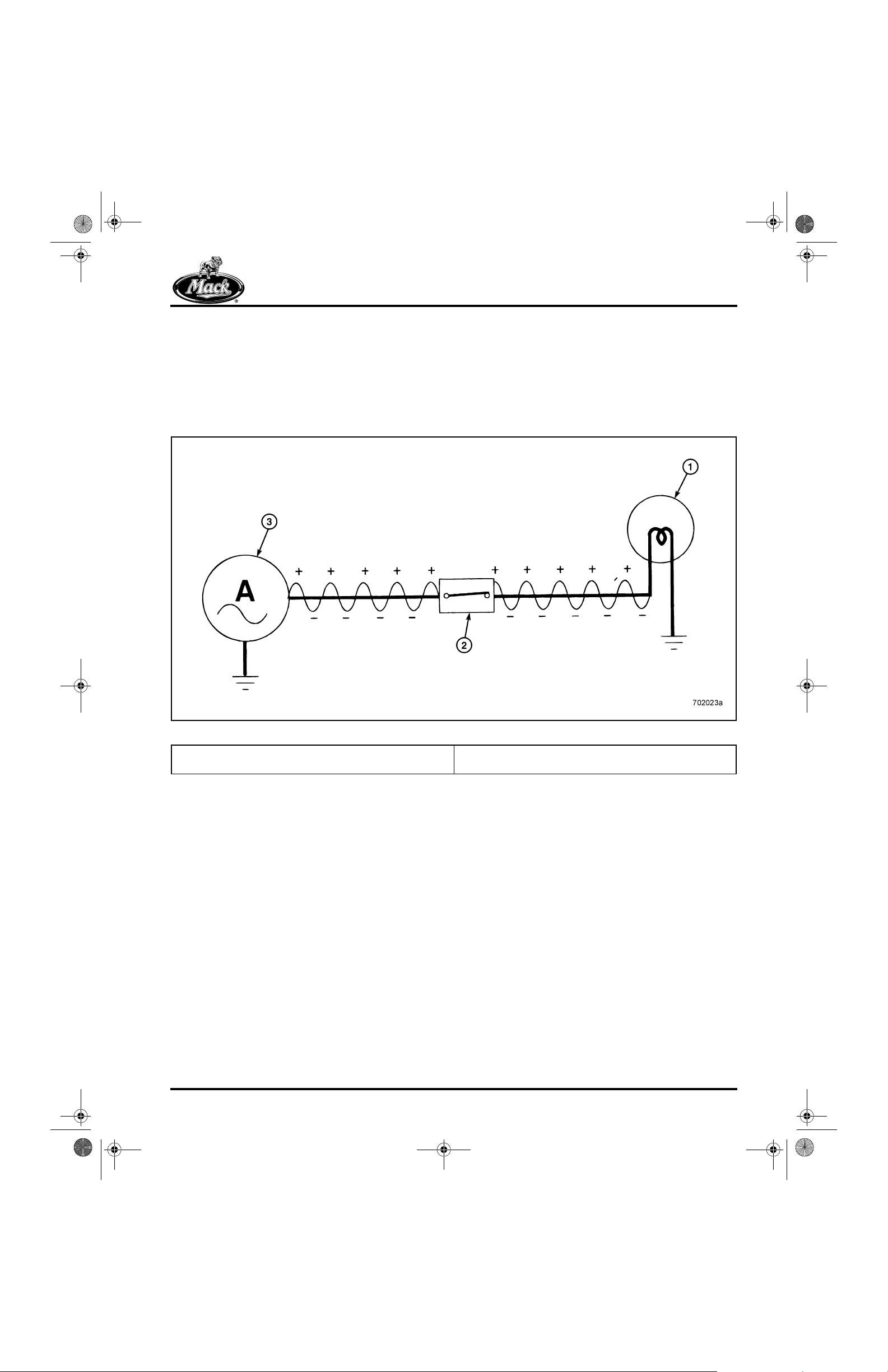

ALTERNATING CURRENT (AC)

In an alternating current circuit, electron flow

changes direction at a fixed rate or cycle.

Alternating current is the t ype of current produced

by the charging system alternator. This type of

current however, is not compatible with a vehicle

electrical system. To be usable, it must be

converted (or rectified) into direct current. To

accomplish this, diodes are added to the circuit.

Diodes are used in an electrical system much li ke

check valves in a hydraulic or pneumatic syst em.

They allow current flow in one direction, and

block current flow when the c ycle rever ses (in t he

opposite direction).

10

1. Lamp (Uses DC Current)

2. Closed Switch

Figure 10 — Alternating Current

3. Alternator (Produces AC Current)

Page 9

8_212desc.fm Page 10 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

RESISTANCE

Electrical current is the movement of electrons

from one atom to the next. Electrons, however,

resist being moved out of their shells. The atoms

of some substances (such as copper), give up

their electrons more readily than the atoms of

other substances (such as nickel). Atoms of

substances like rubber do not give up electron s

easily. Substances that readily give up electrons

are called “conductors.” Substances that resist

giving up electrons are called “resistors.”

Substances that do not give up electrons easily

are called “insulators.”

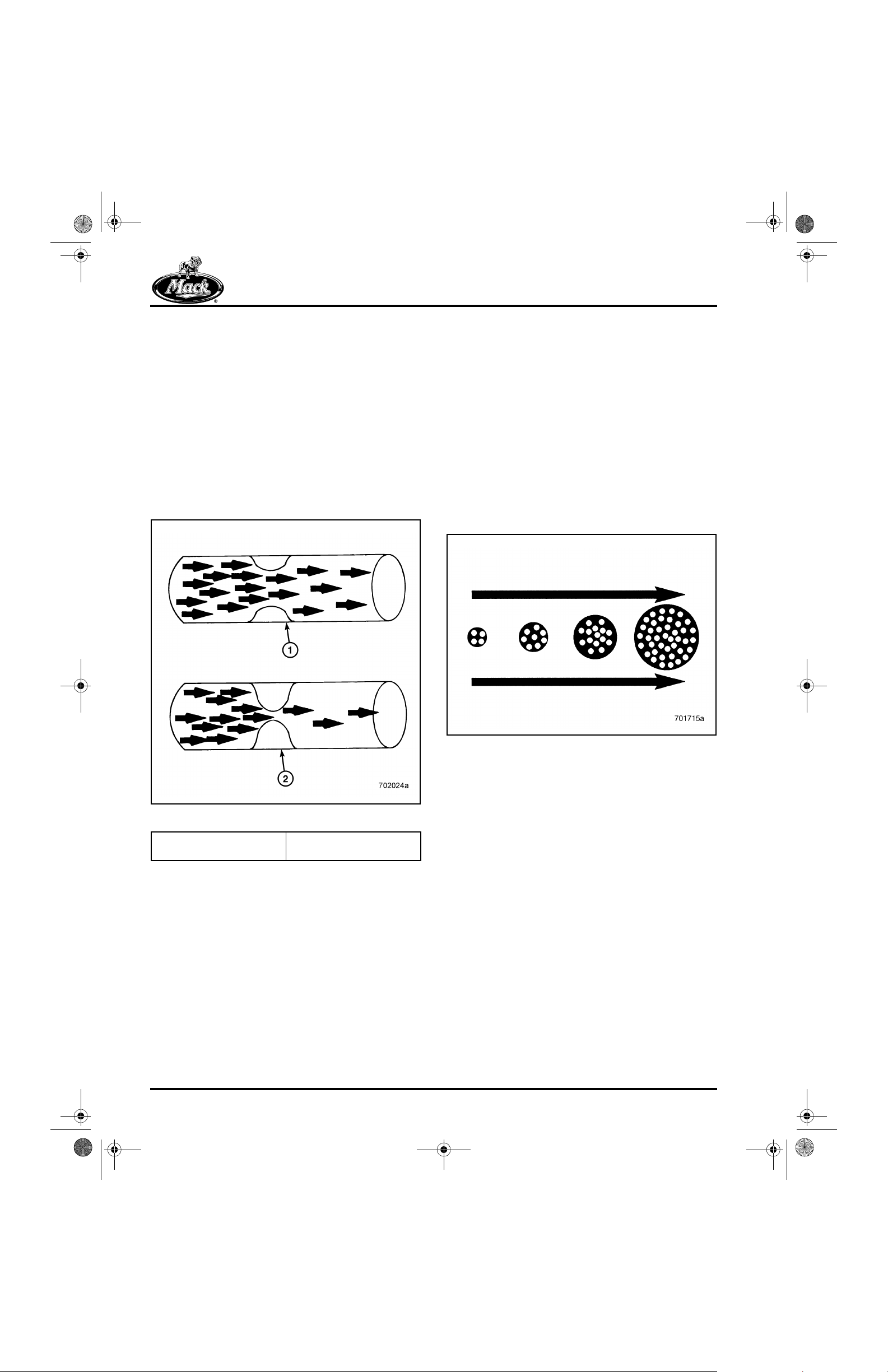

11

Resistance, Heat and Current Flow

Electron flow through a conductor or component

generates a certain amount of heat. A light bulb

illuminates when electrons flow through the

filament of the bulb. The thin filament inside the

light bulb offers such a great resistance to

electron flow that the filament heats up and

glows.

Wires used in an electric circuit are selected

according to the amount of current they must

carry. Thick wires have less resistance to current

than thin wires, and so are used to carry greater

amounts of current.

12

Figure 11 — Resistance in a Conductor

1. Less Resistance, Mo re

Current Flow

2. More Resistance, Less

Current Flow

The capacity of a substance to resist electron

flow is called “resistance.” Resistance is

expressed in ohms. All components in an

electrical circuit (light bulbs, motors, solenoids,

sensors, horns) add to the total resistance in a

circuit.

Figure 12 — Wire Size, Current Capacity and Resistance

Properly selected wires in a circuit have a low

resistance. If the resistance of a wire is too high,

circuit operation will be faulty in some way.

Examples of high-resistance conditions incl ude

partially cut wires and loose or corroded

connections. These types of faults can be

compared to a faulty hydraulic circuit where oil

flow is restricted by a kinked or leaking hydraulic

hose. With less oil flow, the hydraulic circuit will

not operate at full potential.

Page 10

8_212desc.fm Page 11 Tuesday, June 29, 1999 3:13 PM

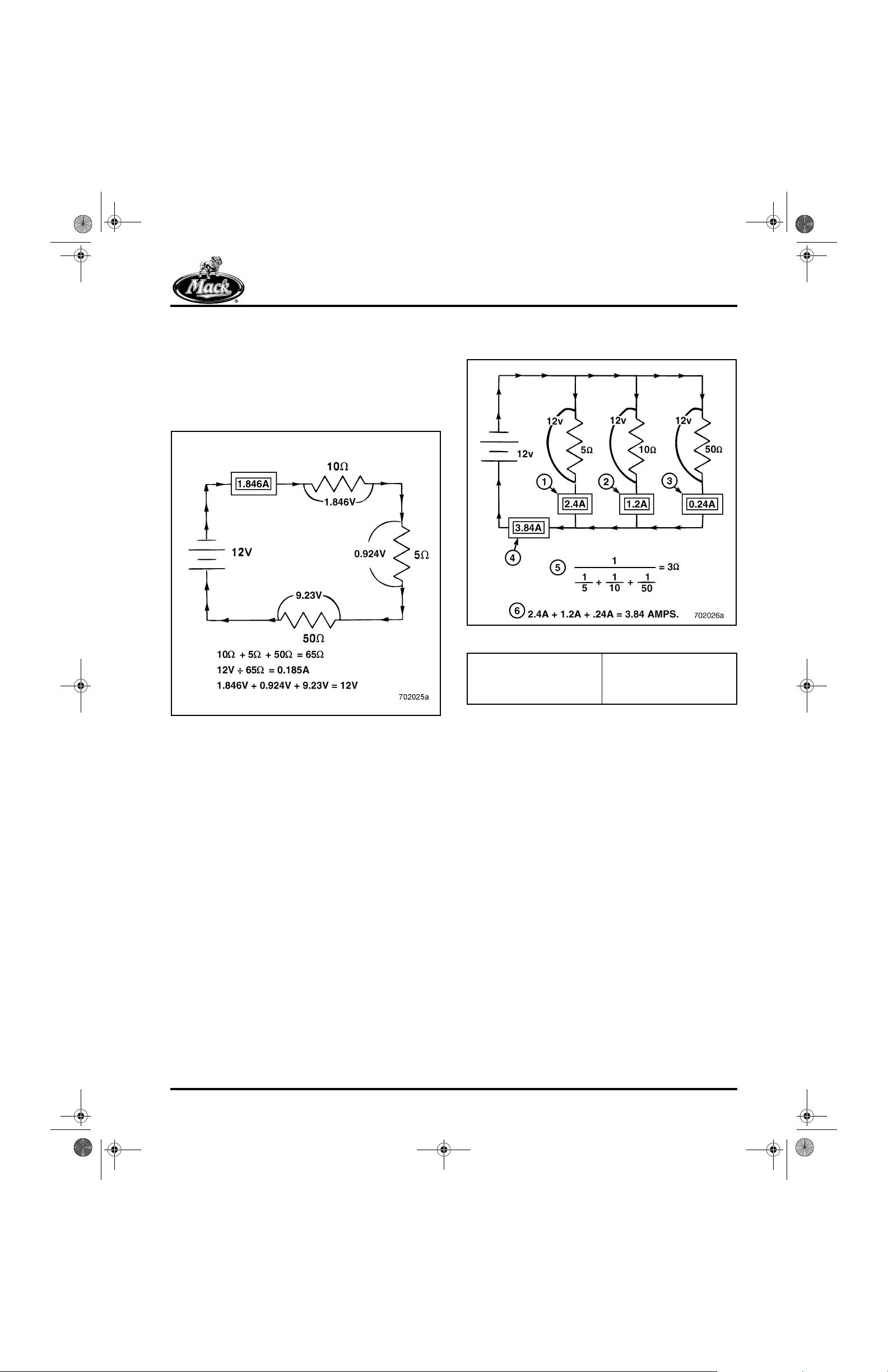

DESCRIPTION AND OPERATION

CIRCUIT TYPES

The three basic types of circuits are series,

parallel and series-parallel.

Series Circuits

13

Parallel Circuits

14

Figure 14 — Parallel Circuit

Figure 13 — Series Circuit

Series circuits are the simplest of circuits. In a

series circuit, all the resistors are connected

together (end to end), to one voltage source.

There is only one path for electron flow. Series

circuits have the following characteri stics:

r The total resistance of the circuit is equal to

the sum of each resistor.

r Current flow (amperage) through each

resistor in the circuit is the same, and is

equal to the total amperage through the

circuit.

r The voltage drop across each resistor

equals resistance multiplied by the

amperage.

r The source voltage is equal to the sum of

the voltage drops across eac h resis tor in t he

circuit.

1. Branch 1 Amperage

2. Branch 2 Amperage

3. Branch 3 Amperage

4. 3.84 Amps (Total Amps)

5. Total Resistance

Calculation

6. Total Amperage

Calculation

A parallel circuit is one in which the resistors are

connected side by side, and there are several

paths for current flow. Parallel circuits, which are

the most commonly used circuits in truck

electrical systems are parallel circuits. The

following principles apply.

r Total resistance of the circuit is always less

than the value of the lowest resistor.

r Current flow (amperage) through each

resistor is different and depends on the

value of the resistor.

r The voltage drop across each resistor is the

same, and is equal to the source voltage.

r Total circuit amperage is equal to the sum of

the amperage through each branch.

r If one resistor in a parallel circuit is

disconnected, the remaining circuit still

operates.

If one resistor in a series circuit is disconnected,

the path for electron flow i s broken, and the entir e

circuit will not operate.

Page 11

8_212desc.fm Page 12 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

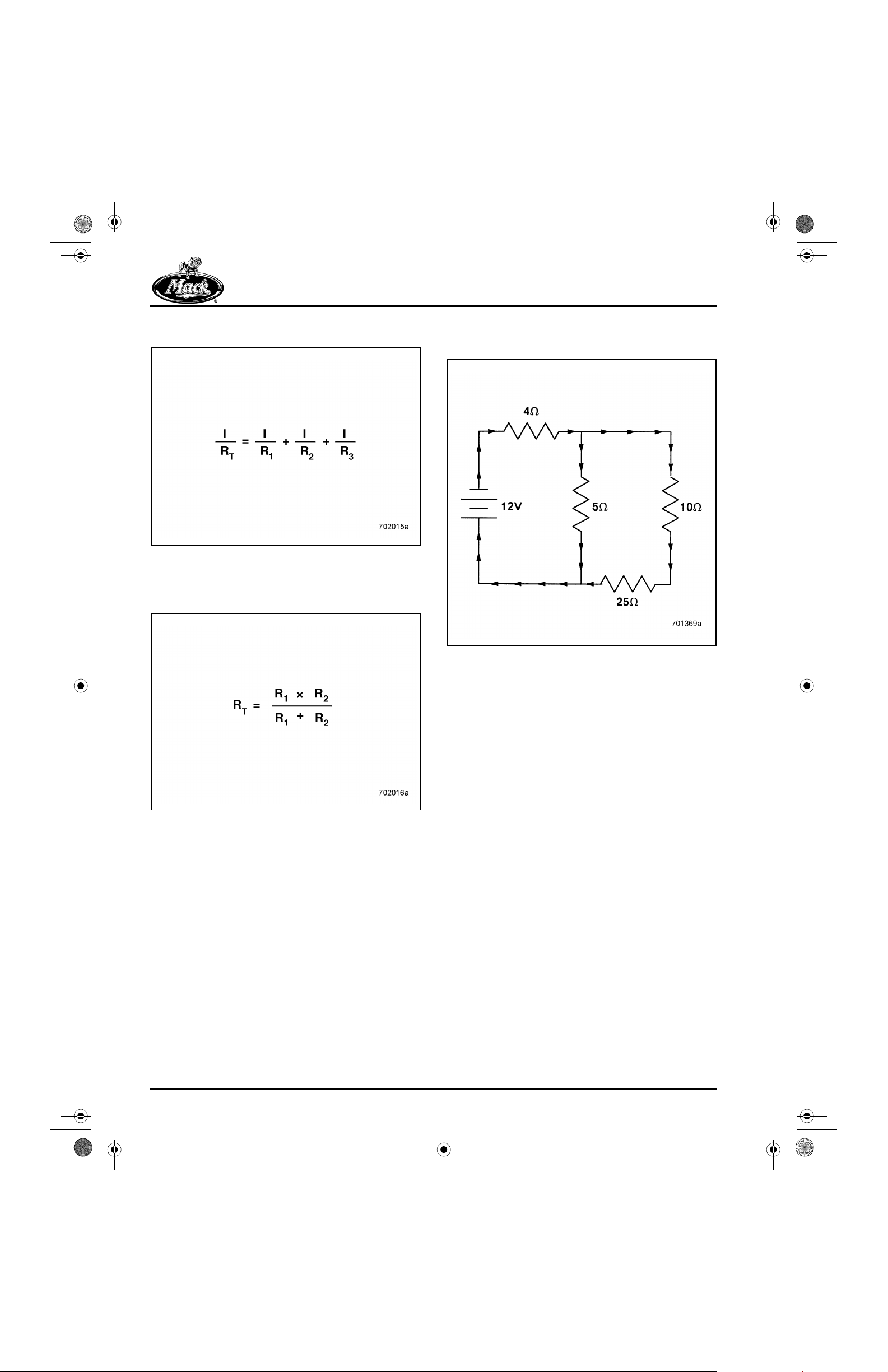

To calculate total resistance in a parallel circuit:

15

Figure 15 — Calculating Resistance

To calculate total resistance in a parallel circuit

with only two branches:

16

Series-Parallel Circuits

17

Figure 16 — Calculating Resistance

Figure 17 — Series-Parallel Circuit

When series and parallel connections are used in

the same circuit, it is called a “series-parallel

circuit.” Calculating total resistance in a seriesparallel circuit involves simplifying the circuit into

a basic series circuit. To do this first calculate the

total resistance of the parallel branches. Then

add the result to the resist ance value of the seri es

part of the circuit. Once the circuit is brok en down

into a simple series circuit, amperage, total

resistance and voltage drops can be determined.

Series-parallel circuits are not used in truc k

electrical systems very often.

Page 12

8_212desc.fm Page 13 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

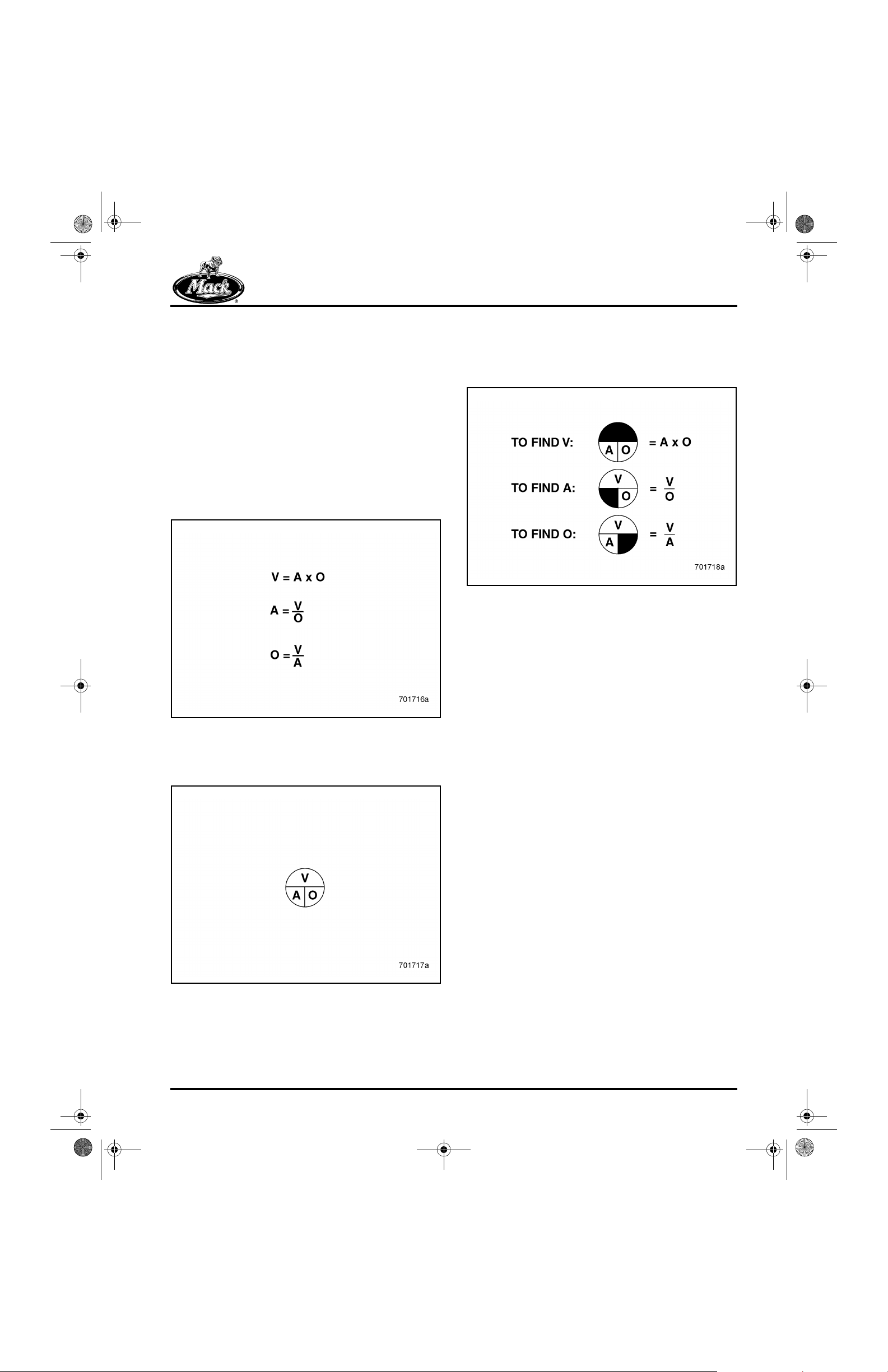

OHM’S LAW

Ohm’s Law describes the relationshi p between

voltage, resistance and amperage. When any two

variables (voltage, amperage or resistance) are

known, the third variable can be determined

mathematically. Ohm’s Law states that voltage

(V) and amperage (I or A) are directly

proportional to any one value of resistance (R or

O), and amperage is inversely proportional to

voltage when voltage remains constant and

resistance changes.

The mathematical formula for Ohm’s Law is:

18

To use the Ohm’s Law circle, simply cover the

unknown variable, then perform the mathematic al

operation (either multiplication or division), using

the two remaining variables.

20

Figure 20 — Using the Ohm's Law Circle

To make it simple, the relationship between

voltage, resistance and amperage can be

described as follows:

Figure 18 — Mathematical Formulas for Ohm's Law

An easy way to remember Ohm’s Law is to use

the following Ohm’s Law circle:

19

r As voltage increases and resistance

remains constant, current increases.

r As voltage decreases and resistance

remains constant, current decreases.

r As resistance increases and voltage

remains constant, current decreases.

r As resistance decreases and voltage

remains constant, current increases.

It is not usually necessary to use Ohm’s Law

when troubleshooting an electrical problem, but

understanding the relationship between voltage,

resistance and amperage makes the job much

easier.

Figure 19 — Ohm's Law Circle

Page 13

8_212desc.fm Page 14 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

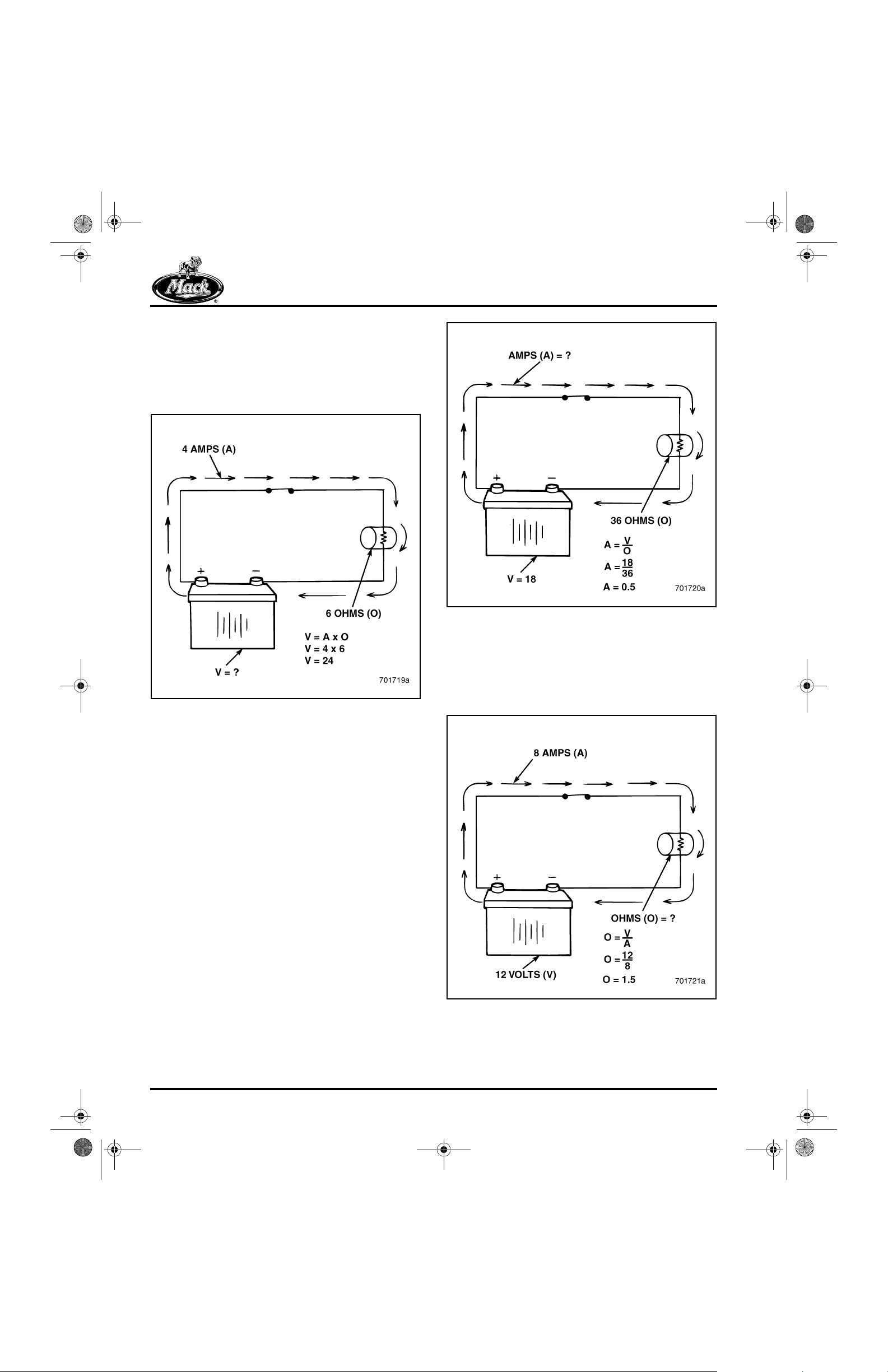

Given the values for current (amps) and

resistance (ohms) shown in Figure 21, use Ohm’s

Law to determine the value for voltage (volts).

Multiply 4 amps of current by 6 ohms of

resistance. What is the total voltage (volt s) in the

series circuit?

21

Figure 21 — Finding Voltage (Series Circuit)

22

Figure 22 — Finding Amperage (Series Circuit)

Given the values for current (amps) and voltage

(volts) shown in Figure 23, use Ohm’s Law to

determine the value for res istance (ohms). Di vide

12 volts by 8 amps of current. What is the total

resistance (ohms) in the series cir cuit?

23

Given the values for voltage (volts) and

resistance (ohms) shown in Figure 22, use Ohm’s

Law to determine the value for current

(amperage). Divide 18 volts by 36 ohms of

resistance. What is the total current flow

(amperage) in the series circui t?

Figure 23 — Finding Resistance (Series Circuit)

Page 14

8_212desc.fm Page 15 Tuesday, June 29, 1999 3:13 PM

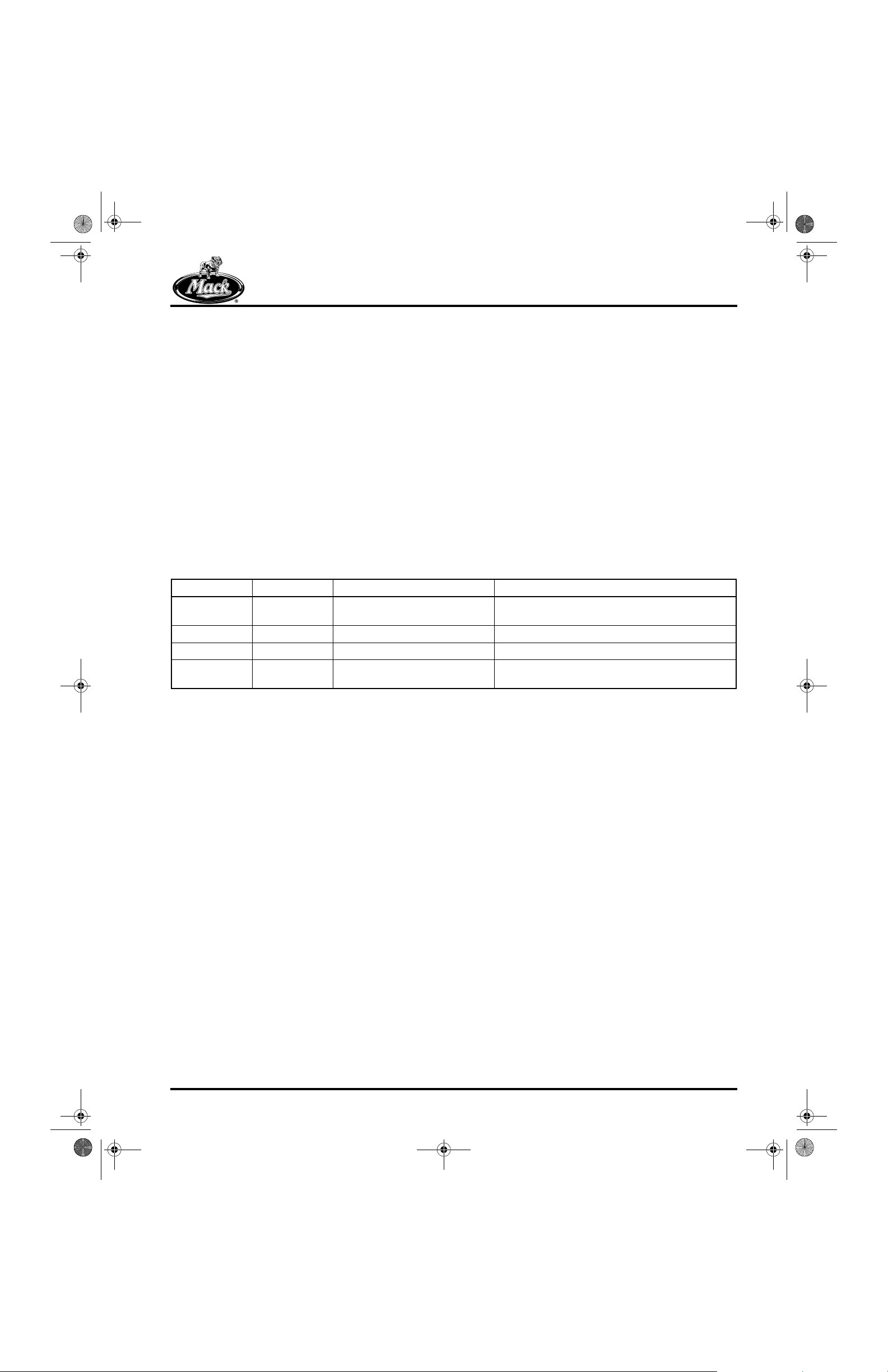

DESCRIPTION AND OPERATION

EXPRESSING ELECTRICAL

VALUES

In many instances, the numerical values used to

express amperage, voltage and resistance, are

either very large or very small. For example,

resistance in a circuit may be millions of ohms, or

current (amperage) may be in the milliampere

range (a few thousandths or millionths of an

ampere).

In these cases, it is more practical to express

values as multiples or submultiples of the basic

values. The values are based on the decimal

system of tens, hundreds, thousands and so on,

with a prefix to designate the value. For small

units (submultiples), “milli” and “micro” are used.

For large units (multiples), “kilo” and “mega” are

used. As an example, 5,000,000 ohms is written

as 5M ohms. When measuring the resistance of

an unknown resistor and the multimeter is

displaying 12.30K, the value of the resistor is

It is not practical to express these large or small

actually 12,300 ohms, not 12.30 ohms.

electrical values in pure numeric form, and it is

not possible for a meter to display these values.

It is important to know and understand these

prefixes. The following table lists the most

common prefixes used to express large or small

electrical values.

ELECTRICAL VALUES

Prefix Symbol Relation to Basic Unit Examples

mega M 1,000,000 (or 1 x 10

kilo k 1,000 (or 1 x 103)12.30 kΩ (kilo-ohms) = 12,300 ohms or 12.3 x 10

milli m 0.001 (or 1 x 10-3) 48 mA (milliamperes) = 0.048 ampere or 48 x 10

micro µ 0.000,0001 (or 1 x 10-6)15 µA (microamperes) = 0.000,015 ampere or

6

)5 MΩ (megaohms) = 5,000,000 ohms or 5 x

6

ohms

10

15 x 10

-6

3

-3

Page 15

8_212desc.fm Page 16 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

DIAGNOSTIC TOOLS

Most electrical test procedures require taking

measurements of voltage, current flow

(amperage), resistance and continuity. Some

important diagnostic tools t hat wil l be needed ar e:

Jumper Wire

A jumper wire is used to bypass an open circuit

by providing an alternate path for current flow. It

is a short length of wire with either alligator clips

or probes on each end, and provides a quick

means of bypassing switches, suspected opens,

and other components. Adding a 5-amp fuse to

the jumper wire is recommended to protect the

circuit being tested.

Never connect a jumper across a load, such as a

motor that is wired between hot and ground.

Doing so would introduce a direct short that could

result in a fire a n d c a us e se rious inju ry.

Multimeters are available with a variety of

functions. All multimeters measure voltage,

current and resistance. Some meters can perform

additional functions such as quick conti nuity

checks, capacitance checks and diode tests.

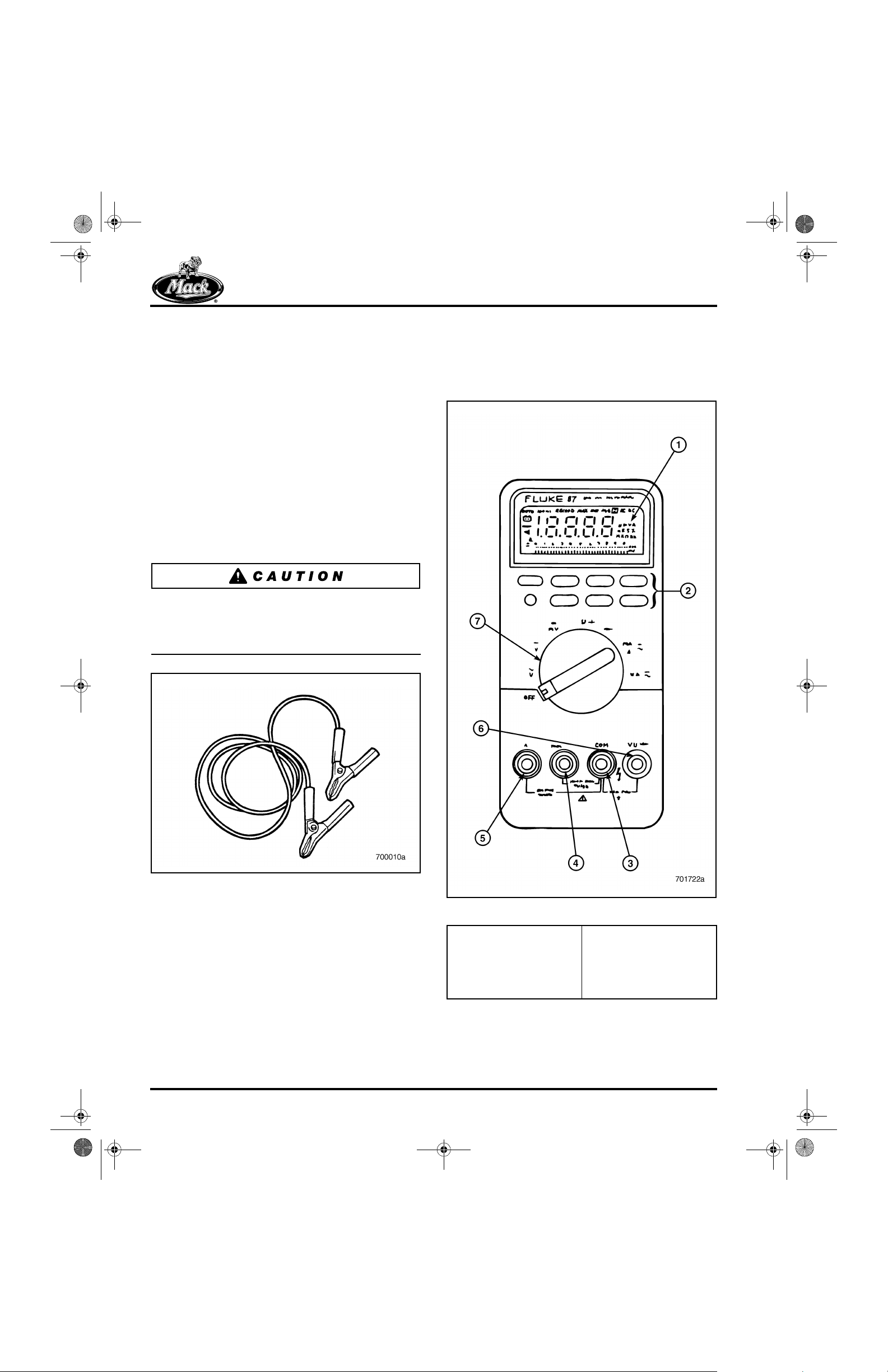

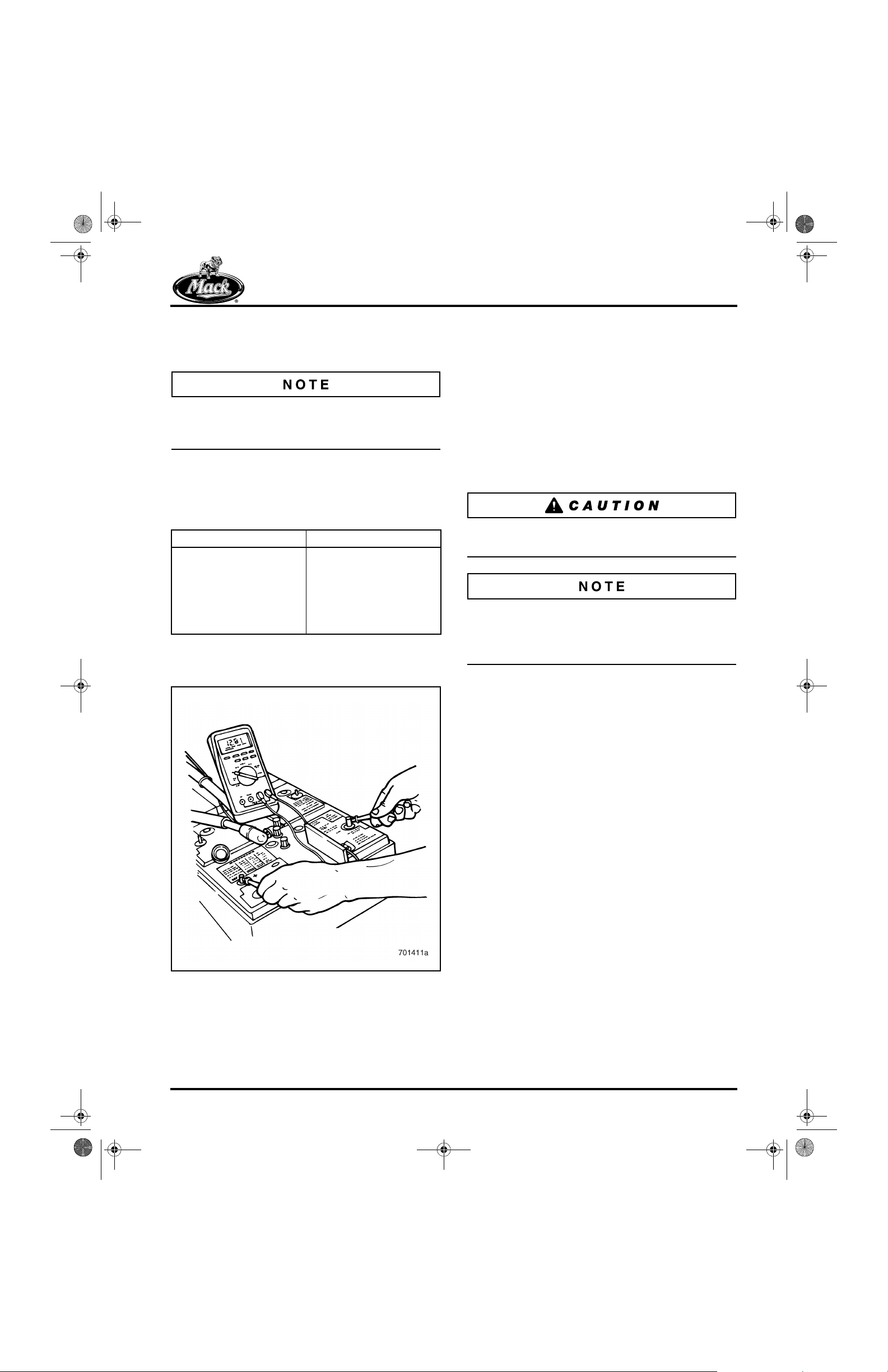

25

24

Figure 24 — Jumper Wire

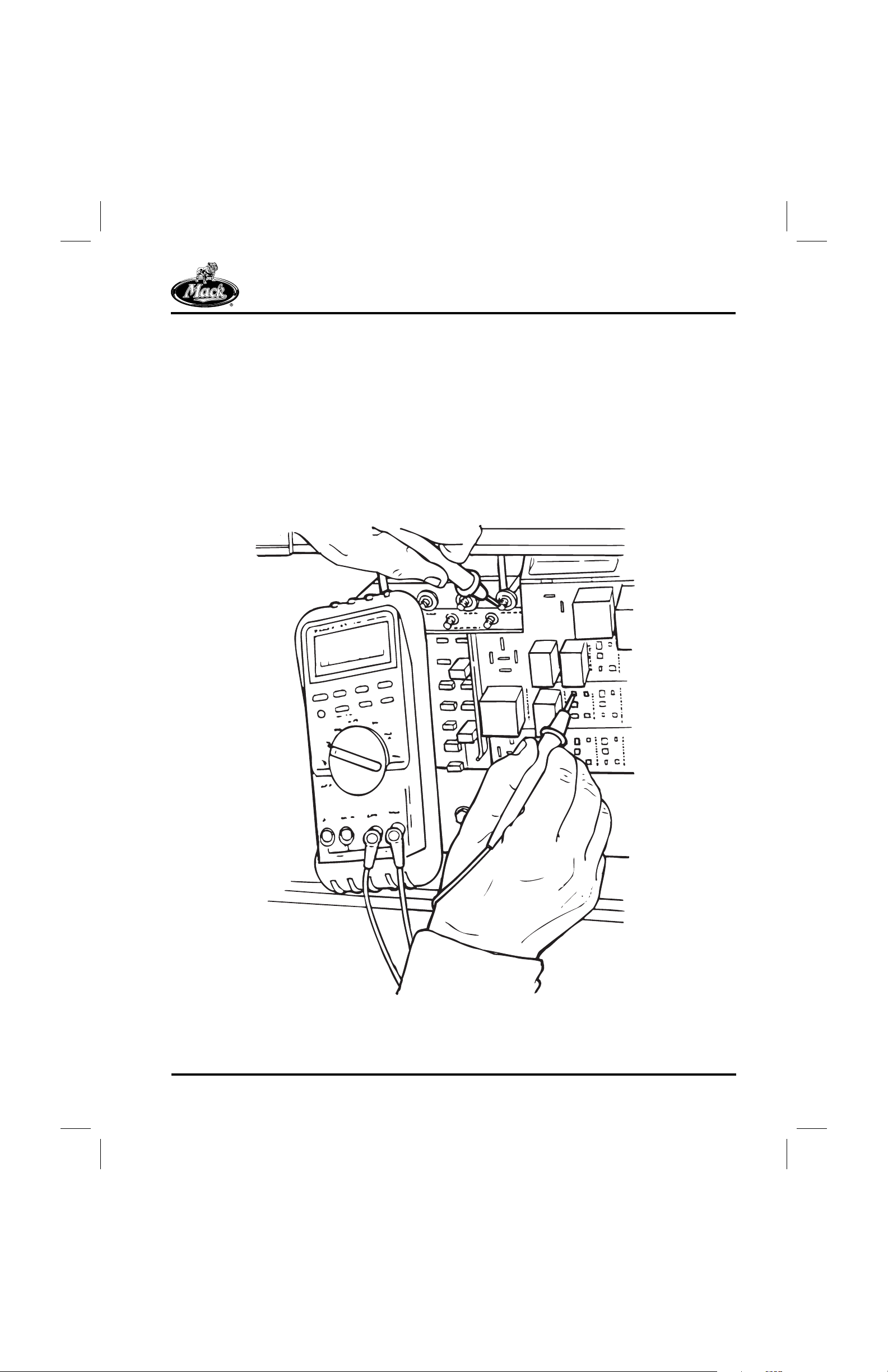

Multimeter (Volt-Ohm Meter)

Probably the most valuable tool needed for

diagnostics is the multimeter, which is used to

take accurate measurements of voltage,

amperage and resistance. Digital mult imeters are

recommended because of their accuracy, ease of

use, circuit protection capabilities, and are

required for troubleshooting cir cuits containing

solid state components or digital circuitry.

Figure 25 — Digital Multimeter (Volt-Ohm Meter)

1. Digital Display Screen

2. Function Selector

Switches (continuity

check, display hold,

range change, etc.)

3. Common Lead Input

4. Milli/Microampere Lea d

Input

5. Amperage Lead Input

6. Volt-Ohm Lead Input

7. Function Selector Dial

Page 16

8_212desc.fm Page 17 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

To get the most from the multimeter, it is

important to read the instructions supplied with

the instrument. Always follow the manufactur er’s

recommendations and safety precautions

regarding proper input limits and lead

connections. When working with electricity,

always adhere to all safety precautions

The following illustration provides an explanation

for the various symbols that may be found on

most meters.

26

Multimeter (Volt-Ohm Meter) Usage

MEASURING VOLTAGE

The easiest way to begin troubleshooting a circuit

is by checking for the presence of voltage. To

check for DC voltage, use a multi me ter set to the

VDC function. With the circuit powered, connect

the negative lead to a good ground. Then touch

the positive lead to various connections al ong the

suspect circuit.

27

Figure 26 — Rotary Dial Selector Function Symbols

Figure 27 — Measuring Voltage

1. Circuit Breaker

2. Switch

3. Motor

4. Battery

The meter should indicate the approximate

source voltage, but may vary slightly due to the

length of the wire runs and other factors. A

difference of one or more volts, however,

indicates that a high-resistance conditi on (loose

or corroded connection, damaged wi re, etc .) may

exist in the circuit.

r 11 or more Volts — Circuit is OK.

r Less than 11 Volts — Poor Connections.

r 0 Volts — Circuit is Open.

Page 17

8_212desc.fm Page 18 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

VOLTAGE DROP

A circuit that is operating properly uses a speci fic

amount of voltage. The amount of voltage used

by a component is indicated by the voltage drop.

As long as circuit resistance remains normal,

voltage drop across a component remains

normal. Voltage drop across a component in a

parallel circuit should be equal to, or close to,

battery voltage. If a component is dropping less

voltage than expected, an unwanted resistanc e

exists elsewhere in the circuit, and is in seri es

with the load (component).

Devices such as switches, solenoids, cables and

connectors should hav e no measurabl e, or only a

fractional voltage drop. Measuring voltage drop

across these types of components is useful in

determining if an unwanted high resistan ce exists

inside the components. V oltage dro p is measured

by placing the meter in parallel with the device.

28

AMPERAGE

Amperage is the amount of current that flows

through a circuit. Measure amperage with the

multimeter set to the AMPS function. Measuring

amperage requires placing the meter in series

with the circuit so that current p asses through the

meter.

29

Figure 28 — Measuring Voltage Drop

1. Circuit B reaker

2. Switch

3. Motor

4. Battery

Depending on the device being tested, voltage

drop should be:

r 0.1 Volt or less for a wire, switch, cable, or

connector.

r 0.3 Volt across solenoid contacts.

1. Switch

2. Motor

Figure 29 — Measure Amperage

3. Battery

r 0.5 Volt for an insulated or ground circuit.

Page 18

8_212desc.fm Page 19 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Measuring current involves “opening” the circuit

to connect the meter. This can disturb an existing

fault and prevent its discovery. To prevent this

from happening, clamp-on type current probes

are available that detect current thro ugh the

principle of induction.

30

RESISTANCE

Resistance is the opposition to current flow wit hin

a circuit. To measure resistance, set the

multimeter to the resistance (oh ms) fu nction, and

place it in parallel with the component.

31

Figure 30 — Clamp-on Current Probe

Figure 31 — Measuring Resistance

1. Resistance

(disconnected from

circuit)

2. Battery

Page 19

8_212desc.fm Page 20 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Since the multimeter measures resistance by

passing a small current through the component,

the power in the circuit must be turned OFF. For

an accurate resistance measurement, the

component should be disconnected from the

circuit. Otherwise, resistance fr om elsewhere in

the circuit may affect the measurement.

32

CONTINUITY

33

Figure 33 — Checking Continuity of a Toggle Switch

Figure 32 — Resistance Measurements

1. Relay

2. Around 70 Ohms

Continuity is a condition of very low or no

resistance which indicates that a complete path

for current flow exists. A multimeter set to the

OHMS or CONTINUITY function is used to check

continuity by placing the leads at each end of the

component, wire, switch or other component.

3. Sensor

4. Variable Resistance

Page 20

8_212desc.fm Page 21 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Continuity is indicated by the following meter

readings:

r Low to zero resistance reading

— A continuous path for current flow

exists. Circuit has continuity.

r High resistance reading

— Poor connections, unwanted high

resistance, defective component, etc.

r Infinity (indicated by OL on the digital

readout)

— Indicates an open circuit, or that the

path for current flow is broken.

The meter emits an audible beep when in the

continuity function and circuit continuity is

detected.

34

Figure 34 — Continuity Checks

1. Closed Switch (No

Resistance)

2. Light Bulb (Very Low

Resistance)

3. Open Switch (Infinite

Resistance)

Page 21

8_212desc.fm Page 22 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

TROUBLESHOOTING METHOD

Diagnostic Techniques

Troubleshooting an electrical problem is easy

when a logical method is used to isolate the

problem. Considerable time can be wasted with

“hit-or-miss” diag nostic procedures. The following

steps provide an orderly method for

troubleshooting electrical probl ems :

1. VERIFY THE PROBLEM

Operate the system and check all the symptoms

to verify the accuracy of the complaint. Try to

learn as much about the nature, location and

probable cause of the failure.

2. ISOLATE THE PROBLEM

Study the schematic diagrams to see how the

circuit operates and to determine which

components may share the same circuit.

Operate the faulty circuit in different modes to

determine the exact nature of the failure. Check

to see whether the failure is isolated to one

component or affects several components on the

same circuit. Also determine if the fault occurs

across a number of seemingly unrelated circuits.

Narrow the possible causes and locations of the

failure. Start with the obvious by first looking for

broken or frayed wires, loose, corroded or

disengaged connections, or poor ground

connections.

Diagnostic Applications

For a circuit to operate properly, voltage must:

r Originate at the positive (+) battery post.

r Flow uninterrupted through the conductors

(wires), and through any controls (switches,

relays, etc.) in the circuit.

r Flow through the component (light bulb,

motor, etc.) to perform its function.

r Flow back to the negative (−) battery post.

Keep these requirements in mind when beginning

the troubleshooting process . Always start with the

obvious. Begin by looking for loose, broken or

corroded connections or wir es, burne d-out bulbs,

blown circuit breakers, inoperative components,

misadjusted switches, and other problems.

If an obvious cause cannot be located, begin

troubleshooting by consulting the wiring diagra ms

and analyzing the circuits. If a problem exists

within an individual circuit only, correcting the

fault should be a matter of simply locating and

repairing or replacing the fault y item (component,

conductor, control, etc.).

Circuits within an electrical system may share

common connectors, grounds, power sources

and other elements. Faults are frequently seen

across several components within the same

circuit, or across seemingly unrelated circuits.

Begin troubleshooting these ty pes of problems by

first locating and isolating, and then testing the

areas that the circuits have in common.

3. TEST AND VERIFY THE CAUSE

Once a probable cause has been determined,

use standard electrical test procedures to verify.

4. MAKE THE REPAIRS

Repair or replace the faulty component,

connector or wire.

5. VERIFY THE REPAIR

Operate the system and check that the re pair has

eliminated the failure.

Page 22

Faults that can render a circuit inefficient or

inoperative are:

r Open circuits

r Short circuits

r Grounded circuits

r High-resistance circuits

8_212desc.fm Page 23 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

OPEN CIRCUIT

A circuit in which the path for current flow has

been broken is called an open circuit and will not

operate.

35

SHORT CIRCUIT

A short circuit is a circuit in which an alternate

path for current flow has occurred, allowing

current to bypass part of it s intended load . Shorts

can occur within a component (inside a starter

motor, relay, or other device) when the insulat ion

of overlaying wires rubs through, allowing

previously unconnected circuits to cont act each

other. This type of short is known as a “crosscircuit” short.

36

Figure 35 — Open Circuit

1. Path for current flow is

broken

2. Switch (Closed)

3. Connectors

4. Motor

5. Battery

6. Circuit Breaker

Figure 36 — Short Circuit

1. Short Across Circuits

2. Lamp

3. Motor

4. Switch

5. Circuit Breaker

6. Battery

7. Connectors

Page 23

8_212desc.fm Page 24 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

GROUNDED CIRCUIT

In a grounded circuit, all of the current has fo und

an alternate path of low resistance back to the

negative battery terminal before reaching its

intended load. A grounded circuit is evidence of

an inoperative circuit, a blown circuit breaker,

and/or excessive battery drain.

37

HIGH-RESISTANCE CIRCUIT

A high-resistance circuit is one in which an

unwanted high resistance condition such as a

loose, broken, or corroded wire or connector, is

causing a decrease in current flow. These types

of faults are usually evidenced as dim lights, slow

operation, or other performance problems.

38

Figure 37 — Grounded Circuit

1. Alternate Current Path to

Ground

2. Switch

3. Motor

4. Connector

5. Battery

6. Circuit B reaker

Figure 38 — High-Resistance Circuit

1. Connector

2. Switch

3. Unwanted High

Resistance Insi de

Connector

4. Motor

5. Battery

6. Circuit Breaker

Page 24

8_212desc.fm Page 25 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Locating Shorts or Grounded

Circuits

Circuit breakers that continuously trip or do not

reset, are usually indica tions of a shorted or

grounded circuit. The fo llowing procedure can be

used to locate the short:

39

Figure 39 — Locating Shorts and Grounds

1. Switch (Closed)

2. Connector 2 (Meter Goes to Zero Volts)

3. Short to Ground

4. Motor (Disconnected)

5. Connector 3 (Meter Stays at 12 Volts)

1. Turn OFF all components that are powered

through the circuit breaker.

2. Disconnect all loads powered through the

circuit breaker by:

r Disconnecting connectors from motors,

solenoids, and other devices.

r Removing light bulbs or other loads.

6. “AUX” Terminal

7. “BAT” Terminal

8. Battery

9. Circuit Breaker

10. Connector 1 (Meter Goes to Zero Volts)

3. Set the multimeter to the VDC function.

Then connect the black lead to a good

ground, and the red lead to the battery

terminal of the suspect circuit breaker.

r The multimeter should indicate battery

voltage. (If the circuit breaker is

powered through the key switch, the

key must be turned ON.)

4. Disconnect the multimeter lead from ground.

Then connect to the load side of the circuit

breaker.

Page 25

8_212desc.fm Page 26 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

5. Close or jumper any normally opened

switches found in the circuit.

r If the multimeter indicates no voltage,

the short is located in one of the

disconnected components.

r If the multimeter indicates battery

voltage, the short is located in the

wiring. To isolate the short, disconnect

and then reconnect each connector

found in the circuit one at a time,

beginning with the connector closest to

the circuit breaker.

Circuit Continuity Checks

Continuity checks can be used to locate a short,

ground or open in a circuit.

r If the multimeter drops to 0 voltage

when a connector is disengaged, the

wiring between the connector and the

circuit breaker is good.

r If the multimeter remains at battery

voltage when a connector is

disengaged, the short exists

somewhere between that connector

and the last connector disconnected.

Refer to the previous illustration.

40

1. Switch (Closed)

2. Connector 2

3. Short to Ground

4. Connector 3

5. Motor (Disconnected)

Page 26

Figure 40 — Continuity Check

6. Battery

7. Disconnect Power

8. Circuit Breaker

9. Connector 1

8_212desc.fm Page 27 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Power in the circuit must be turned OFF, and the

ground must be isolated before performing any

continuity checks.

1. Disconnect the load by:

If the approximate area of the problem is known:

1. Insert one meter lead into the connector of

the suspect harness, and connect the other

lead to a good ground.

2. Begin wiggling the wires, and continue every

couple of inches along the harness while

watching the meter.

r Disconnecting connectors from motors,

solenoids, and other devices.

r Removing light bulbs or other loads.

2. Set the meter to the OHMS or CONTINUITY

function.

3. Connect one lead to the “AUX” terminal of

the circuit breaker.

Close or jumper any normally opened switches

found in the circuit.

4. Probe the circuit by touching the other lead

at various connections along the circuit,

while watching the meter.

r Readings of zero ohms, fractions of

ohms, indicate a completed circuit.

r Infinite (OL on the digital meter)

indicate an opened circuit.

Use one of the following proced ures to isolate an

intermittent shorted, grounded o r opened ci rcuit.

3. When the resistance reading changes

(drops to zero ohms from an infinite [OL]

reading, or goes to infinity [OL] from a zero

ohms reading), the problem is located near

that point.

If the area of the problem is not known:

1. Connect the meter between a good ground

and the “AUX” terminal of the circuit breaker.

2. Starting at the circuit breaker, begin wiggling

the harnesses.

3. Continue with this procedure while watching

the meter. When th e readi ngs change, the

approximate area of the problem has been

located.

Page 27

8_212desc.fm Page 28 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Checking Circuit Grounds

For a circuit to ope rate properly, a completed path

for current flow must exist between the positive

battery terminal, thr ough the load, and back to

the negative battery terminal. It would not be

practical for circuits to ter minate at the negative

battery post, so the negative side of the batter y is

connected directly to the chassis frame, and all

circuits are then connected to the frame. Ground

straps provide a connection between the frame

and any component (such as the engine,

transmission, cab, etc.) that would be electr ically

insulated.

Faults such as dim lights or components that

operate too slowly can generally be attribut ed to

bad ground connections. The following checks

can be used to locate a bad ground connection:

VOLTAGE CHECKS

1. Set the multimeter to read VDC.

2. Power the circuit.

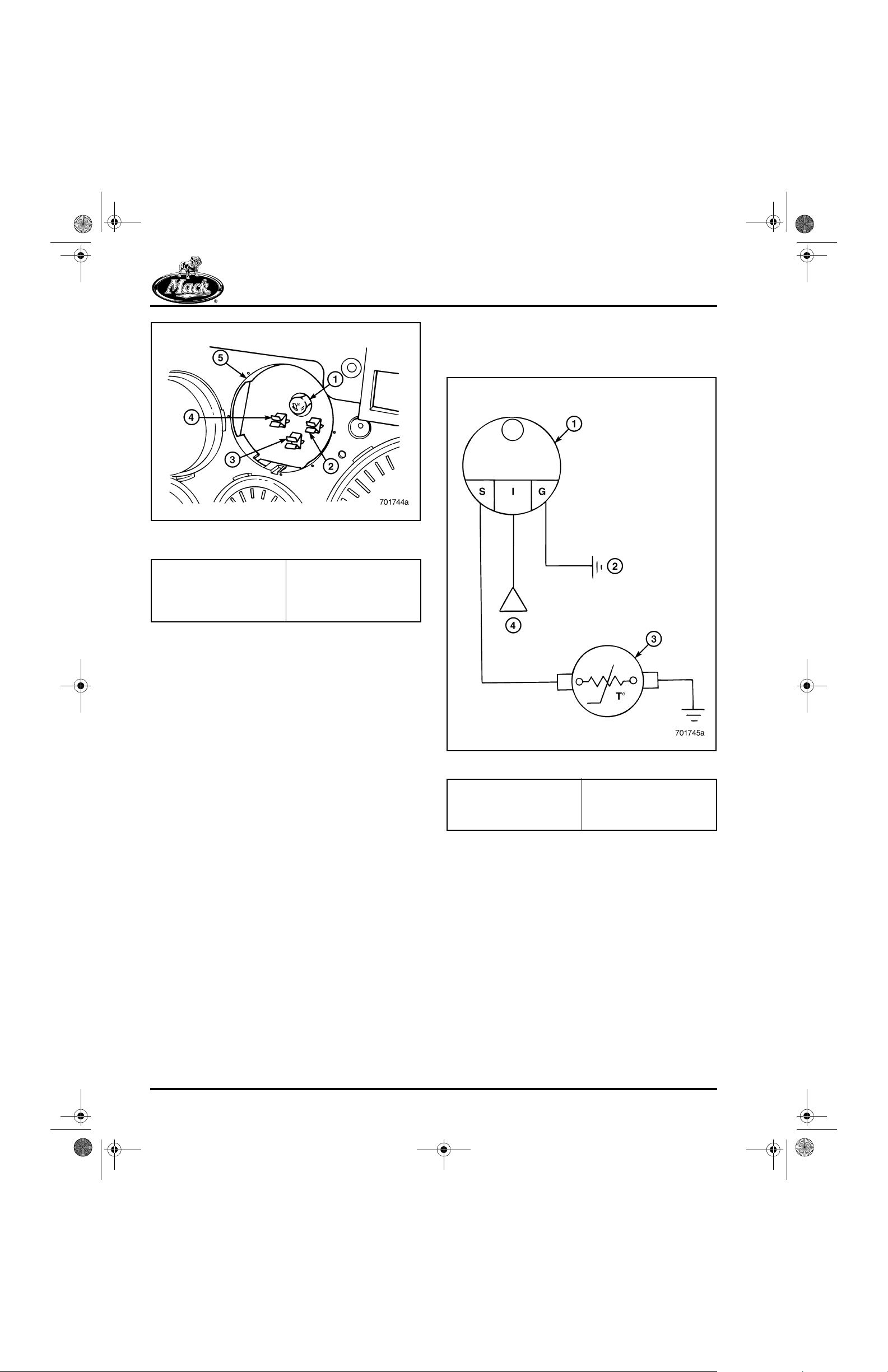

41

3. Connect the red lead to a good ground on

the frame.

4. Probe the ground connections with the black

meter lead. Any voltage reading indi cates a

bad ground.

Figure 41 — Using Voltage to Check Grounds

1. Positive Lead to Frame

Ground

2. Negative Lead on

Sending Unit Ground

Terminal

Page 28

8_212desc.fm Page 29 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

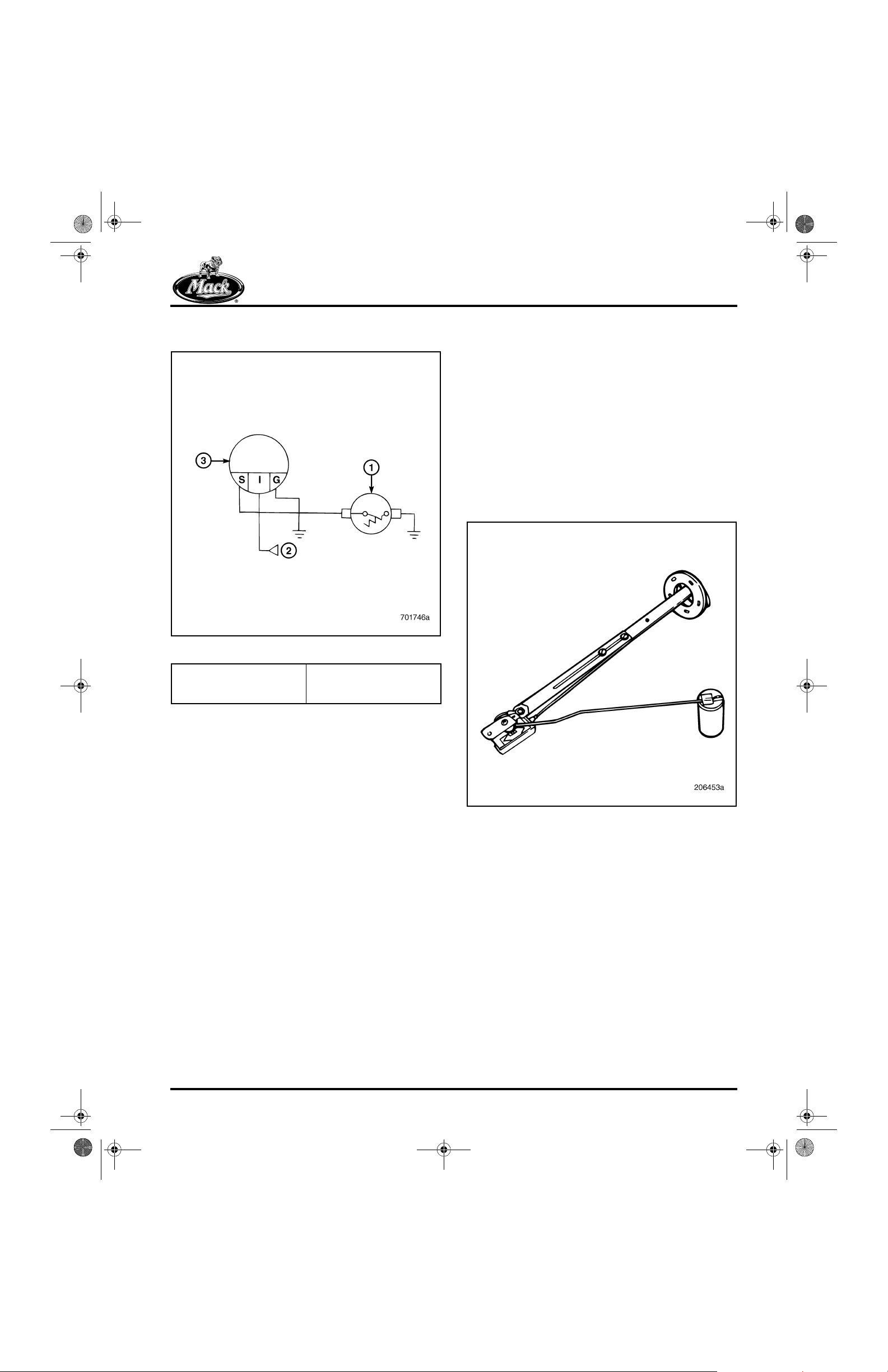

CONTINUITY CHECKS

1. Turn the power to the circuit OFF.

2. Set the meter to the resistance function.

3. Connect one meter lead to a good ground.

4. Probe the ground circuits and ground

connections with the other lead. Meter

readings of zero ohms or fractions of ohms

indicate the ground connections are good.

High-resistance readings or infinite (OL on

the digital meter) indicate that the ground

connection is bad.

42

Referring to the schematic diagrams is the

easiest way to pinpoint common areas in a circuit.

When looking for a problem that affects severa l

circuits, check the diagram and look for common

power or common ground connections. If only

part of the circuit fails, however, check for

connections between the part of the circuit that

functions properly and the part that does not.

Figure 42 — Using Resistance to Check Grounds

1. Ground Circuit Terminal 2. Dash Panel Ground

Page 29

8_212desc.fm Page 30 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

POWER DISTRIBUTION

Power distribution is broken down into battery

power and keyed power.

Distribution points include the batteries, circuit

breakers and key (ignition) switch.

Battery-Powered Circuits

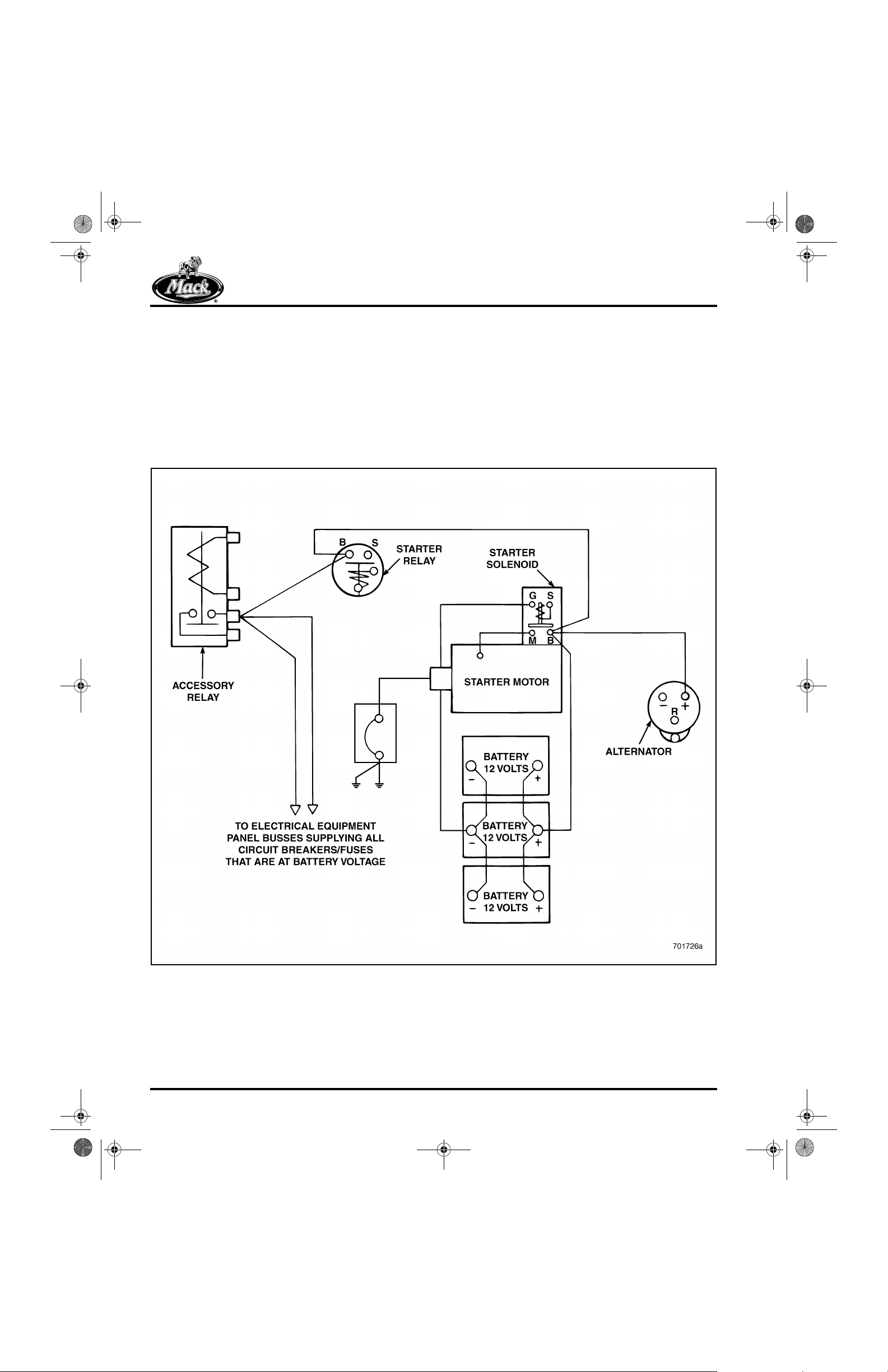

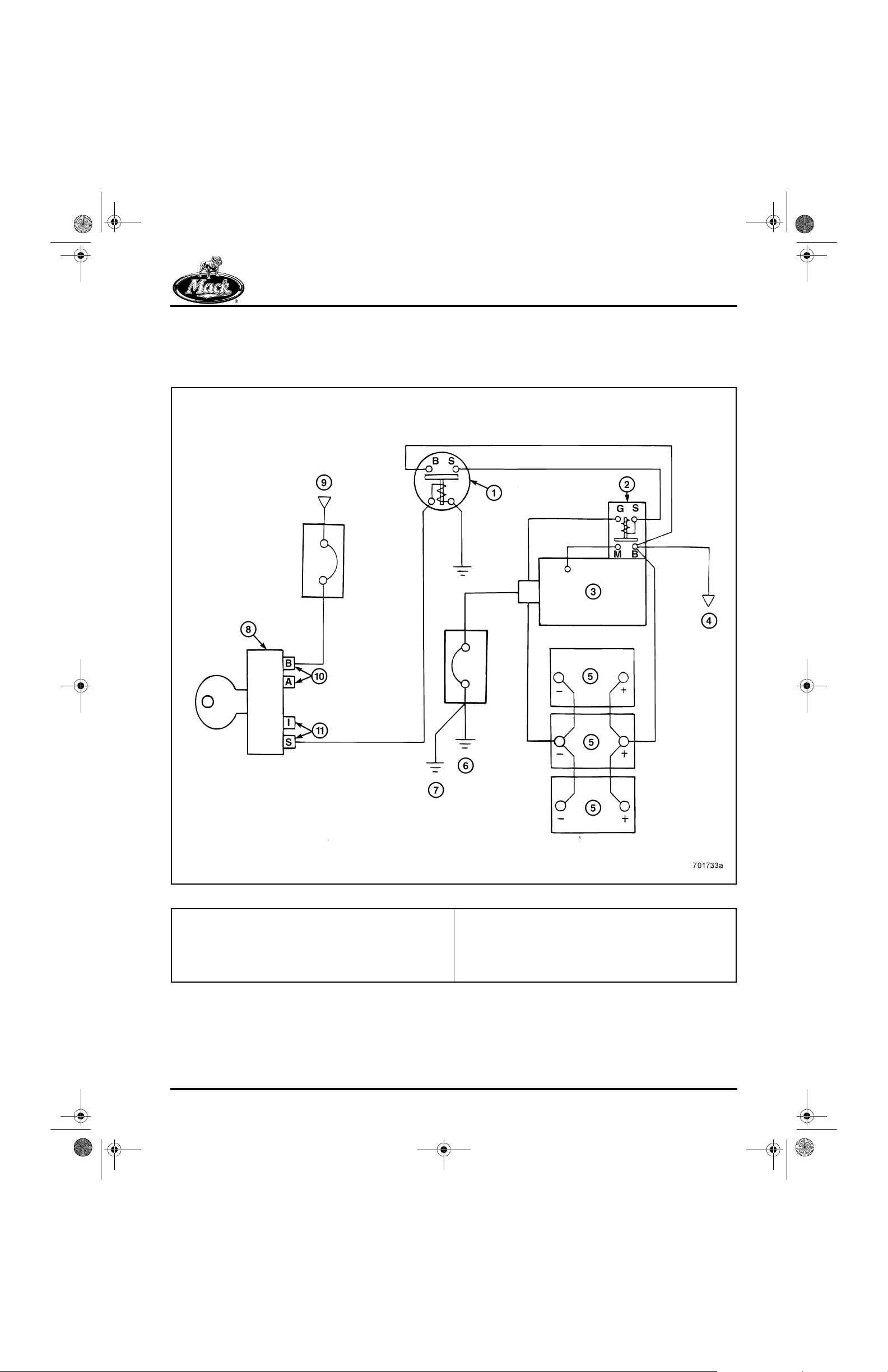

43

Figure 43 — Battery Power

The positive terminal of the battery is connected

directly to the battery terminal of the starter

solenoid. From the starter solenoid, vol tage is

distributed to the starter relay and the accessory

Page 30

relay . From the acces sory relay, battery voltage is

distributed to the electrical equipment panel (bus

bar) where voltage is suppled to those circuits

that are at battery voltage at all times.

8_212desc.fm Page 31 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Key-Powered Circuits

44

Figure 44 — Keyed Power

From one of the circuit breakers that are at

battery voltage, power is supplied to the battery

terminal of the ignition key switch. When the

ignition switch is turned to the RUN position,

current flows through the ignition switc h to ground

through the coil of the accessory relay. With

current flowing through the accessory rel ay coil,

the relay energizes, which closes the relay

contacts. Current then flows to the electrical

equipment panel bus to supply power to those

circuit breakers t hat are only power ed through the

key switch.

On V-MAC III vehicles, the accessory relay is

energized by a signal from the V -MAC III Vehi cle

Electronic Control Unit (VECU).

Page 31

8_212desc.fm Page 32 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Ground Circuits

45

Figure 45 — Ground Circuits

For an electrical circuit to operate, a path for

current flow must exist between the positive side

of the battery, through the load and back to the

negative side of the battery. Since it is not

possible to have all circuits terminate back at the

negative battery termin al, a common ground must

be provided. The negative battery terminal is

connected to the starter ground terminal. The

Page 32

ground circuit is protected by a high amperage

circuit breaker, in case of overload in the ground

side of the electrical system. The starter ground

terminal is connected to one side of the ground

circuit breaker, which is then connected to the

frame. The frame provides the common

connection point for all circuit grounds that

terminate at the negative battery terminal.

8_212desc.fm Page 33 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

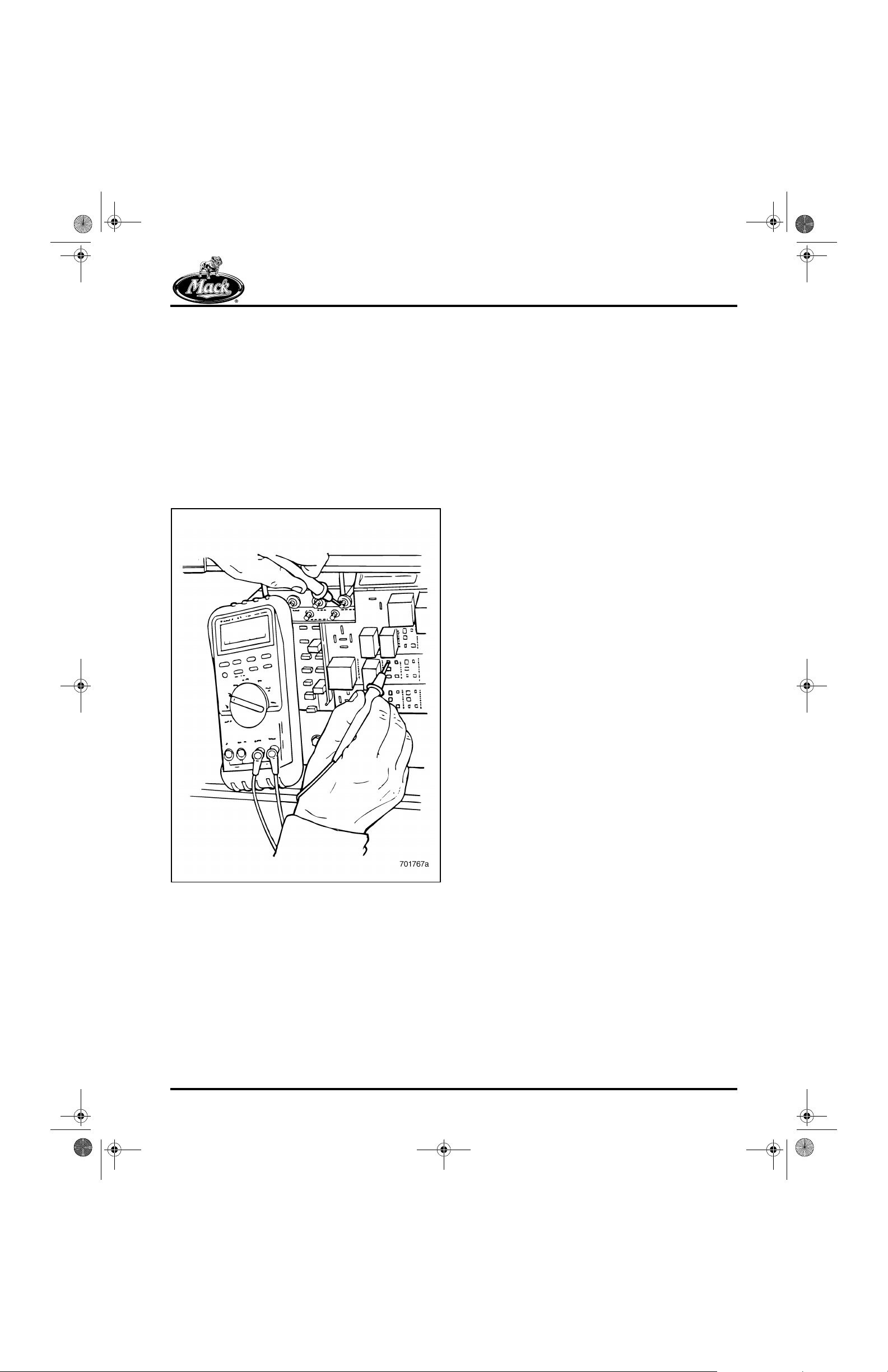

TYPICAL ELECTRIC

EQUIPMENT PANEL

Power is distributed to the various ci rcuits of the

electrical system by the electrical equipment

panel. This panel contains the fuses (or optional

circuit breakers) that protect the system from

overload, as well as some of the various relays

that provide electrical control. A typical electrical

equipment panel is shown below.

46

Figure 46 — Typical Electric Equipment Panel

Location of the electrical panel varies by vehicle

model. Consult the specific vehicle operator’s

manual for the exact location of the panel on the

chassis.

Page 33

8_212desc.fm Page 34 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

CIRCUIT BREAKERS

Fuses are standard on a MACK chassis, but

circuit breakers are available as an option. There

are two different types of circuit breaker s: SAE

Type 1 and SAE Type 2.

SAE Type 1

Circuits that require quick restoration of power

(e.g., headlamp and windshield wiper circuits),

use SAE Type 1 breakers. These circuits

automatically reset without having to remove

power from the circuit. This prevents unsafe

situations from occurring, such as totally losing

headlamps while driving at night, or losing the

windshield wipers while driving in rain.

The T ype 1 circ uit breaker consists of a bimeta llic

strip that heats up and breaks the circuit, i f an

overload occurs. The circuit remains open until

the bimetallic strip cools, at which point , the

breaker contacts close and power in the circuit is

restored. This cycling contin ues until the overload

is repaired.

47

Whether or not the chassis is equipped with fuses

or optional circuit breakers, SAE Type 1 circuit

breakers are always used in the headlamp and

windshield wiper circuits.

SAE Type 2

Circuits that do not require quick restoration of

power use SAE T ype 2 circuit break ers. Th is type

of circuit breaker will not reset, but remains open

until power is removed from the circuit, either by

turning off th e power in t he circuit, or b y removin g

the circuit breaker. The type 2 circuit breaker

consists of a bimetallic strip that heats up and

breaks the circuit when an overload occurs. The

circuit breaker also contains a coi l that surrounds

the bimetallic strip. When a circuit overload

occurs, the circuit breaker contacts open the

circuit. Current, however, continues to flow

through the coil of wire which keeps the bimetall ic

strip heated. Because the bimetallic strip remains

heated, the circuit breaker contacts remain open

until power is removed from the circuit breaker or

the circuit breaker is removed.

48

Figure 47 — SAE Type 1 Circuit Breaker

1. Path of Current Flow (In)

2. Path of Current Flow

(Out)

3. “BAT” Terminal

4. Contacts

Page 34

5. Low-expansion Metal

6. Bi-metallic Strip

7. High-expansion Metal

8. “AUX” Terminal

Figure 48 — SAE Type 2 Circuit Breaker

1. Path of Current Flow

2. “BAT” Terminal

3. Contacts

4. Bi-metallic Strip

5. Coil

6. Low-expansion Metal

7. High-expansion Metal

8. “AUX” Terminal

8_212desc.fm Page 35 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

When using a continuity test, or measuring

resistance to test the functiona lity of an SAE T ype

2 breaker , remember that th e coil of wire acts lik e

a closed circuit. A good circuit breaker should

have very low resistance or none at all. If the

multimeter indicates approximately 50 ohms, the

circuit breaker contacts are open. This rea ding

indicates the resistance through the coil of wire

that surrounds the bimetallic strip.

SAE Type 3

An SAE Type 3 cir cuit breaker is similar to type 1

and type 2 circuit breakers. However, type 3

breakers are manually reset. A button must be

pushed to close the contacts of the breaker, to

restore continuity. It is not necessary to remove

power from the circuit of a SAE Type 3 circuit

breaker.

The type 3 breaker is an optional breaker with

only a small volume of customers specifying them

for use in their trucks.

r If the circuit breaker is good, the meter

indicates zero or very low resistance for type

1, type 2 and type 3 circuit breakers.

r If the circuit breaker is defective, the meter

indicates infinite resistance for type 1

breakers and approximately 50 ohms

resistance for type 2 breakers. Type 3

breakers will show very high to infinite

resistance after a manual reset has been

attempted.

Testing Circuit Breakers

Type 1 or type 2 circuit breakers can be tested

with a multimeter by setting the meter to the

resistance function and touching the leads to t he

terminal lugs of the breaker.

49

Figure 49 — Testing the Circuit Breaker

Page 35

8_212desc.fm Page 36 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

WIRE SIZES

Wires used in the MACK Truck chassis electrical

system are sized according to the thickness of

the wire core, not the insulation. The wires are

sized according to the metric wire gauge system

and used in the electrical system acco rding to the

amount of current they must carry and the circuit

they are in. Another method of gauging wire sizes

is the American Wire Gauge (AWG) numbering

system. To convert between the AWG and metric

wire sizes, refer to the table below:

AWG TO METRIC WIRE SIZE CONVERSION CHART

AWG Sizes Metric Sizes Ohms/1000 ft —

20 0.5 10.32

18 0.8 7.24

16 1.0 4.72

14 2.0 2.99

12 3.0 1.883

10 5.0 1.166

88.00.733

6 13.0 0.377

4 19.0 0.293

2 32.0 0.178

1 40.0 0.142

0 50.0 0.112

00 62.0 0.089

000 81.0 0.070

0000 103.0 0.055

Stranded

In the AWG numbering system, the higher

numbered wires (such as 20), are thin, and the

lower numbered wires (such as 2) are thick. The

opposite is true of metric wire gauges, the lower

numbered wires (such as 0.5) are thin, and the

higher numbered wires (such as 50.0) are thick.

Whenever wires must be replaced, i t is important

that wires of the same gauge be used. Replaci ng

a thick wire (metric gauge 13.0, or A WG 6), with a

thin wire (metric gauge 0.5 or AWG 20) poses a

fire hazard. If it cannot accommodate the amount

of current flow needed for a particular circuit, a

thinner wire may overheat and eventually burn.

Page 36

8_212desc.fm Page 37 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

WIRE IDENTIFICATION

Wires used on MACK chassis are identified by a

numbering system that designates the circui t and

circuit branch the wire is in, and the metric size of

the wire. On V-MAC II and V - MAC III chas sis, t he

connector pin number and module connector

number are identified instead. These numbers

are imprinted on each wire at int ervals no gr eater

than 30 mm. On larger wires, the numbers are

printed on two sides of the wire, 180-degrees

apart, continuously along the length of the wire.

The identification numbers on smaller gauge

wires are imprinted on one side of the wire only,

along the entire length of the wire. The electrical

wiring diagrams use the same wire identification

numbers that are imprinted on the wires.

Refer to the followin g illust rations fo r examples of

the wire identification numbering system.

50

Figure 50 — Chassis Electrical Wire Identification

Page 37

8_212desc.fm Page 38 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

51

Figure 51 — V-MAC System Wire Identification

In addition to the numeric identification system,

all wires used on MACK chassis are one of three

colors. Wire color use is as follows:

r White — Used on all circuits that are

protected by a circuit breaker.

r Red — Used on all unprotected battery

circuits.

r Black — Used on all ground circuits,

including the ground circuit containing t he

master ground circuit breaker.

Page 38

8_212desc.fm Page 39 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

BATTERIES — GENERAL

INFORMATION

Batteries provide the power needed to start the

engine. They also supply power for the electrical

system when electrical demand exceed s what the

charging system can deliver.

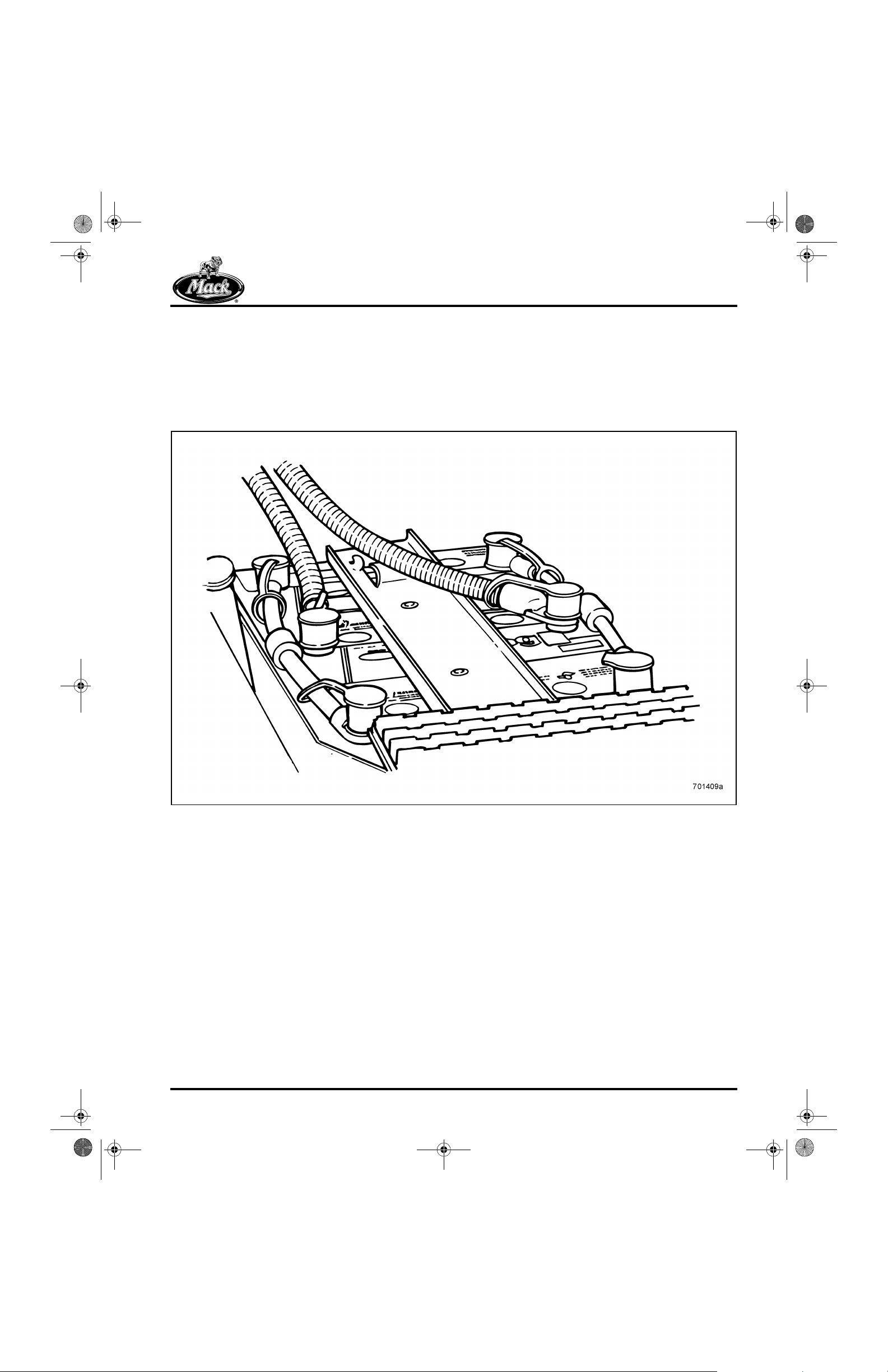

52

Figure 52 — Batteries

Description

Batteries produce and store electrical energy by

chemical reaction. The battery contains sets of

positive plates and negative plates, straps, and

separators that are suspended in an electrolyte

solution. The positive plates are made of lead

peroxide (PbO

made of sponge (porous) lead (Pb). The sponge

lead of the negative plates includes antimony, or

calcium, to increase battery performance and to

decrease acid fume gassing. The electrolyte

solution in the battery is a mixture of sulfuric acid

(H

) and water (approximately 35–40% acid

2SO4

and 60–65% water). The water optimizes v oltage

production and reduces the caustic effect of the

acid on the internal components of the battery.

), while the negative plates are

2

For each battery, there are a series of batter y

elements (cells) made from a number of positive

and negative plates with separators in between.

A single element or cell produces between

2–2.5 volts of electricity. A 12 volt battery would

then contain 6 cells, while a 6-volt battery

contains 3 cells.

Page 39

8_212desc.fm Page 40 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Operation

Inside the battery during the discharge cycle

(using the starter, running electrical equipment),

SO

molecules chemically separate from the

4

sulfuric acid (H

) and attach to the plates of

2SO4

the battery. Electrical energy is released during

this process. Also, oxygen atoms (O) bond with

hydrogen molecules (H

) to form water (H2O). As

2

the discharge cycle continues, the plates in the

battery become lead sulfate (PbSO

53

).

4

Figure 53 — Battery Chemical Action

During the charging cycle, the SO4 molecules

leave the lead plates and the oxygen atoms in the

water separate from the hydrogen atoms. The

SO

bonds with the hydrogen to form H2SO4. The

4

oxygen atoms reattach to the positive plates of

the battery.

The models described, represent totally charged

and totally discharged batteries. The electrolyte

of a totally charged battery is concentrated

sulfuric acid diluted with some water. In a totally

discharged state, the battery electrolyte would

contain a much higher concentration of water.

During normal operation, the battery would

generally be fully charged to somewhat

discharged.

Page 40

When the electrolyte level is low, the oxygen and

hydrogen in the battery has “gassed” off, leaving

behind only sulfate (SO

) molecules. Sulfate is

4

not gassed off like the oxygen and hydrogen

because the molecules are heavi er . T he only way

a battery can loose sulfate is if the electrolyte is

spilled. Never introduce premixed electrolyte into

an in-service battery as an over-concentration of

acid will result.

8_212desc.fm Page 41 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

The capacity of the battery to produce electricity

is directly related t o the a mount of lead remaining

on the plates. As batteries lose lead, they lose

capacity. Batteries lose lead as fol lows:

r Shedding (flaking) due to vibration

r Shedding due to “gassing” when “fast-

charging” the battery

r Sulfation during periods of battery no nuse —

The lead sulfate turns to permanent hard

crystals. When this occurs, the lead is no

longer suitable for chemical reaction.

All batteries are perishable, but reasonable care

and maintenance can substan tially extend battery

life.

Types of Batteries

Basically, three different types of automotive

batteries are available on the market:

r Maintenance Free — This type of battery

uses a lead-acid grid construction that

contains no Antimony. The battery case may

be sealed so there is no provisi on for adding

water during the service life of the battery.

Periodic Maintenance

Some periodic maintenance items include the

following:

1. Inspect the battery hold-down arrangement

for dirt and corrosion, and the mounting

hardware for tightness. Remove, clean,

repaint and reinstall the hold-down

arrangement as necessary.

2. Check the state of charge indicator (if so

equipped) on maintenance-free batteries.

On low-maintenance type batteries with

removable vent caps, check the specific

gravity. Recharge as necessary.

3. Check the battery terminals for corrosion

and tightness. Clean battery terminals wi th a

wire brush, and cable connections with a

solution of baking soda and water. Coat the

connections with a light film of non-metallic

grease.

4. Check battery cable routing and clamping.

Make sure that there is no possibility of

cables rubbing, chafing and/or shorting.

r Semi-Maintenance Free — This battery is

the lead-acid type with a reduced amount of

antimony. These batteries require periodic

addition of distilled water during battery

service life.

r Filler Cap Type — This battery is also the

lead-acid type, and contains a l arger amount

of antimony in its construction. These

batteries have vented filler caps that can be

removed to add distilled water. Distilled

water must be added to these batteries at

regular intervals to maintain service life.

Page 41

8_212desc.fm Page 42 Tuesday, June 29, 1999 3:13 PM

DESCRIPTION AND OPERATION

Battery Tests

VISUAL INSPECTION

Conduct a visual inspection of the batteries and

look for obvious signs of damage that could affect

their performance. Inspect each batt ery for the

following:

r Cracks or other damage to the battery case

that could allow electrolyte leakage.

r Dirt on the battery case that could allow

current flow to ground and drain the battery.

r Loose or damaged terminal posts which

could indicate a loose internal connec tion.

r Loose or corroded battery cable connec tions

that would add unwanted high resistance to

the circuit.

54

Do not check battery state-of-charge j u st after

distilled water has been added to the electrolyte

level. A false hydrometer reading or incorrect

voltage test will result. Recharge the batter y, then

check state-of-charge.

STATE OF CHARGE

State of charge can be determined by using a

hydrometer to check the specific gravity of the

electrolyte, or by performing an open-circuit

voltage test. Some maintenance-free batteries

have a built-in hydrometer (state-of-charge

indicator) allowing quick checks of batte ry

condition. If equipped with low-maintenance type

batteries, measure the specific gravity of each

cell, corrected to 80°F.

r If the specific gravity is below 1.230, or the

readings of each cell vary by more than .050

between the highest and lowest cell, replace

the battery.

r If the specific gravity readings of each cell

are less than .050 between the highest and

lowest cell, but the specific gravity is below

1.230, recharge the battery and retest. If

recharging does not bring the specific

gravity up to specification, replace the

battery.

Figure 54 — Battery Inspection

1. Check Terminals &

Connections

2. Check for Dirt

3. Check for Cracks

Replace the battery if any signs of damage are

evident. Then clean and tighten all the battery

cable connections. If t he vehicle is equipped with

a low-maintenance type battery having

removable vent caps, remove the caps and check

the electrolyte level inside the battery. If the level

is low, add enough distilled water to bring the

level above the tops of the plates.

Page 42

State of charge can also be tested with an opencircuit voltage test, using a voltmeter as follows:

If the battery has just been recharged or has

been in service, the surface charge must be

removed before performing the open-circuit

voltage test. T urn the lights o n and leav e them on

for approximately 2–3 minutes (per battery or

6–12 minutes for a four-battery system). Then