E-TECH™ ENGINE

SERVICE MANUAL

(Includes Left-Side Redesign)

OCTOBER 2000

(REVISED)

5-106

front.fm Page -ii Friday, August 4, 2000 11:16 AM

-ii

newknow.fm Page 1 Thursday, May 21, 1998 2:23 PM

Manual: _______________________________ Publication Number: _______

Vehicle Model: _________________________ Model Year: ______________

Do you find procedures properly organized and easy to follow? m Yes m No

If not, please explain: ____________________________________ __________

___________________________________ ____________________________

PLEASE LET US KNOW!

Your comments and suggestions will help

us improve this manual!

Please complete and mail this form or FAX

your comments to: (610) 709-3800.

___________________________________ ____________________________

Manual page numbers: _____________________________________________

Are there any important procedures or other information presently not in this

manual that you would like to see included? m Yes m No

If yes, please describe: _____________________________ ________________

___________________________________ ____________________________

___________________________________ ____________________________

Did you find any errors in the procedures or illustrations? m Yes m No

If yes, what pages? _______________________________ ________________

Please explain: ___________________________________________________

_______________________________________________________________

Please include a copy of each page in question and mark your comments and

suggestions.

Name: ________________________________ Phone: (_____) _____-_______

Company: _______________________________________________________

Address: ________________________________________________________

City: _________________________________ State: _______ Zip: _______

Position Title: ____________________________________ ________________

Thank You For Your Assistance

Mack Trucks, Inc.

(ATTENTION: RTS STAFF, 6S3)

DO NOT STAPLE — USE TRANSPARENT T A PE

Busreply.fm Page 1 Thursday, May 21, 1998 2:24 PM

FOLD ALONG THIS LINE • DO NOT STAPLE • USE TRANSPARENT TAPE

BUSINESS REPLY MAIL

FIRST CLASS MAIL PERMIT NO. 1602 ALLENTOWN, PA

POSTAGE WILL BE PAID BY ADDRE SS EE

SERVICE PUBLICATIONS (RTS), 6S3

MACK TRUCKS INC

WORLD HEADQUARTERS

PO BOX M

ALLENTOWN PA 18105-9972

FOLD ALONG THIS LINE

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

10_125erb.fm Page 2 Tuesday, April 18, 2006 11:43 AM

ERRATA SHEET — ENGINE

Crankshaft Center Main Bearing

Effective January 2006, Mack Powertrain Engineering has

widened the crankshaft center main bearing runout

specification. The maximum allowable crankshaft runout

specification was changed from 0.005 in. (0.127 mm) to

0.007 in. (0.178 mm). The manuals listed below are affected

by this change.

Specification Update

Reference: Engine Manuals

5-101 E7

5-106 E-Tech™

5-107 E7G

5-110 ASET™ AI/AMI

5-111 ASET™ AC

JANUARY 2006 © MACK TRUCKS, INC. 2006

(NEW ISSUE) MACK ENGINE SERIES

SERVICE BULLETIN

NUMBER: SB-210-034

DATE: 5/14/02

MODEL: E-Tech™

(Also applies to Mack Trucks Australia)

MISCELLANEOUS FASTENER CHANGES — E-TECH™ ENGINES

The following fastener changes were made on E-Tech™ engines:

Injection Nozzle Hold-Down Screws — Beginning 3/00, the injection nozzle holddown screws having the 15 mm external hex head have been changed to a new screw

(part No. 421GC2116M) that has a 16 mm internal hex head.

Rocker Shaft Mounting Bracket Bolts — Beginning 4/00, the bolts and washers

used to secure the rocker shaft mounting brackets to the cylinder head have been

changed to a flange-head bolt (part No. 65AM5010). Tightening torque value for this

new fastener remains the same at 40 lb-ft (50 N•m).

Air Com pressor Mounting Screw — Beginning 8/00, the original hex-head screw has

been changed to a flange-head screw (part No. 27AM16). This change was made so

that the mounting screw clamp load is distributed over a wider area of the flat washer.

Camshaft Thrust Washer — Beginning 10/00, the two screws and washers used to

secure the camshaft thrust washer to the block were changed to a flange-head screw

(part No. 66AM44). Tightening torque value for this fastener remains the same at 15 lbft (20 N•m).

Cylinder Head Capscrews — Beginning 6/01, the cylinder head capscrews and the

separate hardened flat washer were replaced in production with capscrews having

captured washers (part number series 400GC317M). This change was implemented to

prevent the possibility of omitting or installing more than one washer during assembly.

Additionally, the outside diameter of the captured washer was reduced slightly

(approximately 0.030″) to accommodate the redesigned cylinder head cover that was

phased into production 7/01. Cylinder head capscrew torque remains the same at 205

lb-ft (278 N•m).

Flywheel-to-crankshaft m ounting bolts — Beginning 9/01, bolts having captured

washers (part Nos. 419GC31M and 419GC31M2) were released into production to

replace the previously used bolts and separate hardened flat washer used to secure

the flywheel to the crankshaft. Flywheel-to-crankshaft mounting bolt torque remains the

same at 185 lb-ft (250 N•m).

Electronic Unit Pump (EUP) hold-down screws — Beginning 11/01, new hold-down

screws (part No. 421GC2123M) were released into production for the electronic unit

pumps. These screws are dimensionally the same as the previously used screws, but

conform to a more stringent specification that controls minor surface forming defects to

a greater degree than for common fasteners.Torque of the EUP hold-down bolts has

been changed from 42 lb-ft (57 N·m) to 60 lb-ft (81 N·m).

Turbocharger Mounting Nuts — Beginning 5/02, new turbocharger mounting nuts

were released into production. These nuts (part No. 142GC247M) are composed of

silver-plated stainless steel to provide greater resistance to heat than the previous nuts.

Additionally, these nuts have the Spiralock™ self-locking thread feature to prevent

loosening in service.

SB-210-034 — Page 1of 1

2002.CNI,SKCURTKCAM©50181AP,NWOTNELLA,SNOITACILBUPECIVRES

E-TECH™ ENGINE

SERVICE MANUAL

(Includes Left-Side Redesign)

MAY 2006 REPRINTED 2.5M

SEPTEMBER 2004 REPRINTED 2.5M

APRIL 2003 REPRINTED 2.5M

JUNE 2002 REPRINTED 2.5M

OCTOBER 2001 REPRINTED 2.5M

OCTOBER 2000

(REVISED – SUPERSEDED ISSUE JULY 1999)

© MACK TRUCKS, INC. 2000

5-106

front.fm Page ii Friday, August 4, 2000 11:16 AM

ATTENTION

The information in this manual is not all inclusive and

cannot take into account all unique situations. Note that

some illustrations are typical and may not reflect the

exact arrangement of every component installed on a

specific chassis.

The information, specifications, and illustrations in this

publication are based on information that was current at

the time of publication.

No part of this publication may be reproduced, stored in a

retrieval system, or be transmitted in any form by any

means including electronic, mechanical, photocopying,

recording, or otherwise without prior written permission

of Mack Trucks, Inc.

ii

front.fm Page iii Friday, August 4, 2000 11:16 AM

TABLE OF CONTENTS

TABLE OF CONTENTS

iii

front.fm Page iv Friday, August 4, 2000 11:16 AM

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Advisory Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Service Procedures and Tool Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

EXPLANATION OF NUMERICAL CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ABOUT THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Changes from the Existing E-Tech™ Service Procedur es Manual . . . . . . . . . . . . . . . . . . . . . . .6

ABOUT THE E-TECH™ ENGINE AND ITS SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

ENGINE MODEL IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Engine Information Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 0

Engine Serial Number Identificati on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

DESCRIPTION & OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

E-TECH™ ENGINE DESIGN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electronic Unit Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

V-MAC III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Belt Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

J-Tech™ Engine Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Valve Train . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Low-Pressure Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Fuel Filtration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

High-Pressure Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

High-Pressure Fuel Injection Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Fuel Injector Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Cylinder Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Block Heater for Front (Water Pump) Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Cylinder Head Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Gear Train . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Air Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Power Steering Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Vibration Damper Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Centri-Max® Oil Filter Breather Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Lubrication System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

GLOSSARY OF TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ENGINE SYMPTOM DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

V-MAC III Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

CAMSHAFT TIMING AND LOBE LIFT CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Camshaft Timing Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Camshaft Lobe Lift Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

CHASSIS-MOUNTED CHARGE AIR COOLING TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Special Tool Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

CMCAC Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

CMCAC Pressure Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Restriction Pressure Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

iv

front.fm Page v Friday, August 4, 2000 11:16 AM

Core Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

CMCAC Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

CYLINDER HEAD AND CYLINDER BLOCK LEAK TEST PROCEDURE . . . . . . . . . . . . . . . . . . .71

Cylinder Head and Head Gasket Check — In Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Cylinder Head Fuel Passages Leak Check — In Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Cylinder Block/Cylinder Head Coolant Passages Leak Check — In Chassis . . . . . . . . . . . . . .72

Cylinder Head Oil Passage Leak Check — Out of Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Cylinder Head Coolant Passage Leak Check — Out of Chassis . . . . . . . . . . . . . . . . . . . . . . . .75

Cylinder Block Coolant Passage Leak Check — Out of Chassis . . . . . . . . . . . . . . . . . . . . . . . .76

ENGINE BRAKE TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Operational Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Electrical Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Hydraulic/Mechanical Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Final Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

TABLE OF CONTENTS

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

BELT DRIVE SYSTEM TENSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Manually Tensioned System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Automatically Tensioned System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

FILTER ELEMENT REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Crankcase Breather Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Oil Filter Element Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Fuel Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Coolant Conditioner Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

REPAIR INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

ENGINE REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Removal from Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

ENGINE DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Filter Element Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Oil Cooler and Oil Filter Mounting Bracket Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . .101

Mounting Engine in Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Alternator Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Engine Electronic Control Unit (EECU) Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Fuel Filter Adapter Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Coolant Conditioner Element Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Oil Cooler-to-Water Pump Inlet Line Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Thermostat Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Coolant Manifold Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Air Inlet Manifold Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Water Pump Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Turbocharger Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Fuel Nozzle Inlet Tube Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Exhaust Manifold Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Engine Wiring Harness Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Engine Electronic Control Unit (EECU) and Cooling Plate Removal . . . . . . . . . . . . . . . . . . . .115

Electronic Unit Pump (EUP) Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Oil Fill Tube Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

v

front.fm Page vi Friday, August 4, 2000 11:16 AM

Air Compressor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Valve Cover and Spacer Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Rocker Arm, Valve Yoke and Push Rod Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Nozzle Holder Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Cylinder Head Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Vibration Damper and Crankshaft Hub Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Oil Pan Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2 3

Oil Pump Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Front Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Auxiliary Shaft Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Camshaft Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Piston and Connecting Rod Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Flywheel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Flywheel Housing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Main Bearing Cap Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Crankshaft Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

CYLINDER BLOCK RECONDITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Special Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Piston Cooling Spray Nozzle Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Cylinder Sleeve Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

Cylinder Sleeve Counterbore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Cup Plug Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Pipe Plug Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

H-Ring Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

Camshaft Bushing Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Auxiliary Shaft Bushing Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Cylinder Sleeve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Piston Cooling Spray Nozzle Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Cylinder Block Dowel Pin Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

CRANKSHAFT AND FLYWHEEL BENCH PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

Crankshaft Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Crankshaft Dowel Pin Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Crankshaft Gear Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Crankshaft Wear Ring Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Flywheel Inspection and Resurfacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

AUXILIARY SHAFT AND CAMSHAFT BENCH PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . .168

Auxiliary Shaft Inspecti on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Camshaft Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

CONNECTING ROD AND PISTON BENCH PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Connecting Rod Inspection and Reconditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Piston Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Piston Ring Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Assembling Connecting Rod to Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

CYLINDER HEAD OVERHAUL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Special Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Inlet and Exhaust Valve Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Cylinder Head Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Fire Ring Groove Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Valve Guide Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

TABLE OF CONTENTS

vi

front.fm Page vii Friday, August 4, 2000 11:16 AM

Valve Seat Insert Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Valve Spring Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .196

Injection Nozzle Holder Insert Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

Valve Yoke Guide Pin Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

Cylinder Head Cup Plug Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Cylinder Head Pipe Plug Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

VALVE ROCKER ARM SHAFT BENCH PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

Rocker Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

Valve Rocker Arm Shaft Disassembly (without/with Engine Brake) . . . . . . . . . . . . . . . . . . . . . 206

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Valve Rocker Arm Shaft Reassembly (without Engine Brake) . . . . . . . . . . . . . . . . . . . . . . . . . 207

Valve Rocker Arm Shaft Reassembly (with J-Tech™ Engine Brake) . . . . . . . . . . . . . . . . . . .209

LUBRICATION SYSTEM BENCH PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

Oil Cooler Assembly Reconditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

Oil Pump Reconditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

COOLING SYSTEM COMPONENTS BENCH PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . .215

Oil Cooler Reconditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

Water Pump Reconditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .218

FUEL SYSTEM COMPONENTS BENCH PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

Electronic Unit Pump (EUP) Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Installation of Electronic Unit Pump Plunger Spring and Seat . . . . . . . . . . . . . . . . . . . . . . . . .219

Fuel Injector Nozzle Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

ENGINE REASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

Crankshaft Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

Main Bearing Cap Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

Piston and Connecting Rod Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Flywheel Housing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234

Crankshaft Rear Oil Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .238

Flywheel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .240

Valve Lifter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

Camshaft Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

Camshaft Core Plug Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .243

Camshaft Idler Gear Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244

Auxiliary Shaft Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .245

Oil Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .246

Front Cover Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .247

Crankshaft Front Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .248

Crankshaft Hub Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .249

Vibration Damper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .249

Oil Pan Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250

Cylinder Head Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

Exhaust Manifold Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Nozzle Holder Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .257

Push Rod Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

Valve Yoke Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

Rocker Arm and Engine Brake Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

Valve Cover and Spacer Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .264

Oil Fill Tube Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

Engine ECU/Cooling Plate Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

TABLE OF CONTENTS

vii

front.fm Page viii Friday, August 4, 2000 11:16 AM

Air Compressor Install a tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

Electronic Unit Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Engine Wiring Harness Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .269

Fuel Nozzle Inlet Tube Assembly Installa tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Turbocharger Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Water Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .271

Oil Cooler and Oil Filter Mounting Bracket Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Coolant Manifold Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Air Inlet Manifold Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Thermostat, Housing and Seal Installat ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Coolant Conditioner Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .278

Fuel Filter Adapter Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Engine ECU Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

Oil Cooler-to-Water Pump Inlet Line Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Alternator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Removing Engine from Engine Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

Plate-Type Oil Cooler and Oil Filter Mounting Bracket Assembly Installation . . . . . . . . . . . . .282

ENGINE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .284

Engine Installation into Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .284

IN-CHASSIS PART/COMPONENT PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .286

Electronic Unit Pump (EUP) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Camshaft Replacement (Engine in Chassis) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Engine Brake Control Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Valve Lifter H-Ring Installation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

ENGINE SETUP AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .297

Fuel Injection Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .297

Valve Yoke, Valve Lash and Engine Brake Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . .297

Engine Speed and Position Sensors Installation and Adjustment . . . . . . . . . . . . . . . . . . . . . . 304

Electronic Unit Pump (EUP) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

ENGINE FINAL PREPARATION AND OPERATIONAL CHECK . . . . . . . . . . . . . . . . . . . . . . . . .306

Filter Element Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 06

Engine Lubrication System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .306

Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .306

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Engine Operational Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .307

REBUILT ENGINE RUN-IN PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .308

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .308

Run-In Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .308

TABLE OF CONTENTS

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .309

E-TECH™ ENGINE MECHANICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Material and Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .311

E-Tech™ Component Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .319

SPECIFICATION FOOTNOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .328

E-TECH™ ENGINE LUBRICANT AND SEALANT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . 329

FASTENER TORQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .330

Fastener Selection and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .330

Fastener Sizes and Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .331

viii

front.fm Page ix Friday, August 4, 2000 11:16 AM

SCHEMATICS & DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

ENGINE SYSTEM SCHEMATICS (FLUIDS FLOW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .334

Cooling System Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .334

Lubrication System Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .335

Fuel System Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .336

SPECIAL TOOLS & EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .337

E-TECH™ ENGINE SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .338

Special Tools for Engine Overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .338

V-MAC III Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .341

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

TABLE OF CONTENTS

ix

front.fm Page x Friday, August 4, 2000 11:16 AM

NOTES

x

5_106_00.bk Page 1 Friday, August 4, 2000 11:17 AM

INTRODUCTION

INTRODUCTION

Page 1

5_106_00.bk Page 2 Friday, August 4, 2000 11:17 AM

SAFETY INFORMATION

Advisory Labels

INTRODUCTION

Cautionary

manual. Information accented by one of these signal words must be observed to minimize the risk of

personal injury to service personnel, or the possibility of improper service methods which may damage

the vehicle or cause it to be unsafe. Additional Notes and Service Hin ts are used to emphasize areas of

procedural importance and provide suggest ions for ease of repair. The following definitions indicate the

use of these advisory labels as they appear through out the manual:

signal words

Activities associated with

injury may result from failing to heed the advisory. Serious personal injury

may be equated to career-ending inj ury.

Activities associated with

from failing to heed the advisory. In this case, personal injury is not equated to

career-ending injury, but results in possible change in quality of life.

(Danger-Warning-Caution) may appear in various locations throughout this

Danger

Warning

indicate that death or serious personal

indicate that personal injury may result

Activities associated with Caution indicate that product damage may resul t fr om

failing to heed the advisory. Caution is not used for personal injury.

A procedure, practice, or condition that is essential to emphasize.

A helpful suggestion that will make it quicker and/or easi e r to perform a procedure,

while possibly reducing service cost.

Page 2

5_106_00.bk Page 3 Friday, August 4, 2000 11:17 AM

Service Procedures and Tool Usage

Anyone using a service procedure or tool not recommended in this manual must fi rst satisfy himself

thoroughly that neither h is saf ety nor veh icle saf ety will be je opardized by the ser vice method he selects.

Individuals deviating in any manner from the ins tr u ctions provided assume all risks of consequential

personal injury or damage to equipment involved.

Also note that particular service proce dures may require the use of a special tool(s) designed for a

specific purpose. These special tools must be used in the manner described, whenever specified in the

instructions.

1. Before starting a vehicle, always be seated in the driver’s seat, place the

transmission in neutral, be sure that parking brakes are set, and

disengage the clutch.

2. Before working on a vehicle, place the transmission in neutral, set the

parking brakes, and block the wheels.

INTRODUCTION

3. Before towing the vehicle, place the transmission in neutral and li ft the

rear wheels off the ground, or disconnect the dr iveline to avoid damage to

the transmission during towing.

Engine-driven components such as Power Take-Off (PTO) units, fans and fan

belts, driveshafts and other related rotating assemblies, can be very

dangerous. Do not work on or service engine-driven components unless the

engine is shut down. Always keep body parts and loose clothing out of range

of these powerful components to prevent serious personal injury. Be aware of

PTO engagement or nonengagement status. Always disengage the PTO when

not in use.

REMEMBER,

SAFETY . . . IS NO ACCIDENT!

Page 3

5_106_00.bk Page 4 Friday, August 4, 2000 11:17 AM

INTRODUCTION

Mack Trucks, In c. cannot anticipate every

possible occurrence that may involve a potential

hazard. Accidents can be avoided by recogniz ing

potentially hazardous situations and taking

necessary precautions. Performing se rvice

procedures correctly is cr itical to technician saf ety

and safe, reliable vehicle operation.

The following list of general shop safe ty practi ces

can help technicians avoid potentially hazardous

situations and reduce the risk of personal injury.

DO NOT perform any services, maintenance

procedures or lubrications until this manual has

been read and understood.

r Perform all service work on a flat, level

surface. Block wheels to prevent vehicle

from rolling.

r DO NOT wear loose-fitting or torn clothing.

Remove any jewelry before servicing

vehicle.

r AL W AYS wear safety glasses and protective

shoes. Avoid injury by being aware of sharp

corners and jagged edges.

r Use hoists or jacks to lift or move heavy

objects.

r NEVER run engine indoors unless exhaust

fumes are adequately vented to the outside.

r Be aware of hot surfaces. Allow engine to

cool sufficiently befor e performing any

service or tests in the vicinity of the engine.

r Keep work area clean and orderly. Clean up

any spilled oil, grease, fuel, hydraulic fluid,

etc.

r Only use tools that are in good condition,

and always use accurately calibrated to rque

wrenches to tighten all f asteners to specified

torques. In instances where procedures

require the use of special tools which are

designed for a specific purpose, use only in

the manner described in the instruct ions.

r Do not store natural gas powered vehicles

indoors for an extended period of time

(overnight) without first removing the fuel.

r Never smoke around a natural gas powered

vehicle.

Page 4

5_106_00.bk Page 5 Friday, August 4, 2000 11:17 AM

INTRODUCTION

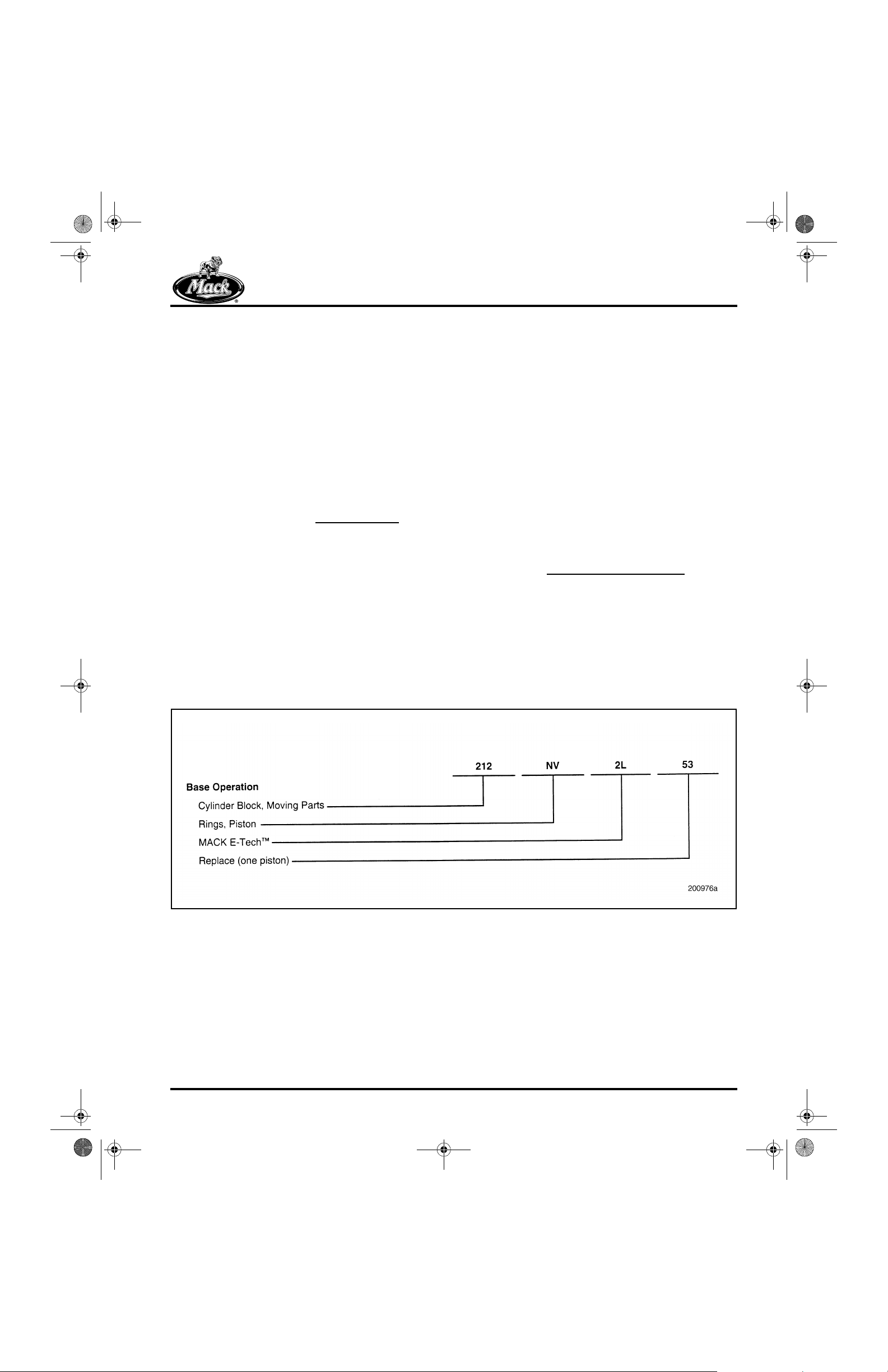

EXPLANA TION OF NUMERICAL

CODE

The organization of MACK service manuals has

been upgraded to standardize manual content

according to a reference system based on

component identification. The new reference

system will help link the information contained in

this publication with related information included

in other MACK service/warranty publications,

such as associated service bulletins, warranty

manuals, and MACK Service Labor Time

Standards.

The system is based on a numerical code

first digit of which identifies the general

component grouping as listed here:

GROUP 000 — GENERAL DATA

GROUP 100 — CHASSIS

GROUP 200 — ENGINE

GROUP 300 — CLUTCH, TRANSMISSION,

TRANSFER CASE AND PTO

, the

GROUP 400 — STEERING, AXLES, WHEELS

AND TIRES, DRIVELINE

GROUP 500 — BRAKES, AUXILIARY

SYSTEMS

GROUP 600 — CAB, TRUCK BODY

GROUP 700 — ELECTRICAL

The second two digits of the three-digit code are

used to identify the system, assembly or

subassembly, as appropriate, within each of the

groupings. The codes applicable to this

publication are shown at the beginning of each

procedure, as necessary, to guide you to specific

component information.

Additionally, a two-character alpha code

[NV] RINGS, PISTON) may be referenced with

each procedure. This alpha code, in combination

with the three-digit Group number, identifies the

specific assembly, sub-assembly or part, and

directly relates to the fir st five positions of the

operation code listed in MACK Service Labor

Time Standards.

(i.e.,

Examples:

Numerical Code

Page 5

5_106_00.bk Page 6 Friday, August 4, 2000 11:17 AM

INTRODUCTION

ABOUT THIS MANUAL

Changes from the Existing E-T ech™

Service Procedures Manual

Mack Trucks, In c. has made many major

improvements to this E-Tech™ Service

Procedures Manual, with changes to both content

and organization. This is a complete manual,

describing engine features and the operation of

major systems as well as providing

comprehensive overhaul procedures,

specifications and adjustments.

All specifications and torque values are given i n

English and metric measurements. Critic al torque

values are also included in the text, eliminating

the need to refer to SPECIFICATIONS section

each time a specified torque value is required.

The Special Tools list has been revised to include

all special tools requi red f or a c omplet e overhau l.

Warnings, cautions, notes and service hints help

the technician service the engine safely and

efficiently.

The engine disassembly procedures show how to

remove components in an order t hat requires the

least amount of handling. Where appropriate , it

includes general information needed to properly

service that component.

The engine reassembly procedure includes stepby-step instructions for reassembli ng the engine.

This helps to ensure proper installation and

longer service life.

Under Engine Setup and Adjustments, the latest

setup information is provided for adjust ing all

E-Tech™ engine models. Engines perform best

and conserve fuel most efficientl y when ad justed

properly.

Two addi tional procedures are included as guides

for removing and reinstalling the engine. Both

sections are generic in nature since E-Tech™

engine installation procedures vary from one

vehicle style to another. As such, the procedures

are intended as a checklist to remind the

technician of all necessary tasks.

While troubleshooting procedures are similar for

most diesel engines, this manual includes only

those that pertain to the E-Tech™ engine. The

TROUBLESHOOTING section contains

symptom-related questions as well as tests to

help the technician consider all possible problem

sources.

This service manual also includes applicable

information from active service bulletins and

service letters since publication of the E-Tech™

Service Procedures Manual dated July 1999.

Various component bench procedures guide the

technician in disassembly, cleaning, inspection

and assembly of each component. Each bench

procedure helps in determining if the part is

serviceable or should be replaced.

Page 6

5_106_00.bk Page 7 Friday, August 4, 2000 11:17 AM

INTRODUCTION

ABOUT THE E-TECH™ ENGINE

AND ITS SERVICE

This publication is intended to provide technician s

with a working knowledge of the E-Tech™

engine, including both early-production and

current-production ver sions.

The E-Tech™ engine has undergone a left-side

redesign. Changes include a new plate-type oil

cooler and a new oil filter mounting arr angement.

This new oil filter arrangement includes a new

centrifugal oil filter assembly, where the

centrifugal filter assembly is now mounted upside

down, and the external oil drain is eliminated.

This new centrifugal oil filter is call ed Centri-Max

PLUS.

The engine electronic control unit (EECU) has

been relocated to the left side of the engine and

is mounted on a new one-piece inlet manifold.

Relocating the EECU has eliminated the need fo r

the EECU cooling plate, and has also brought

about a design change to the unit pump front

outboard heat shield. Additionally, with the

change to the one-piece inlet manifold, the fuel

filter mounting adapter is new and is located

slightly forward of the previous location.

Descriptions of these design changes and the

other features are provided in the DESCRIP TION

& OPERATION section. Additionally, the service

effects of these changes on removal, installation,

disassembly, assembly, setup and adjustment

procedures, etc., are included in the respective

sections of this publication.

®

Development of the E-Tech™ engine has been

driven by three basic requirements. It was

designed to:

r Meet projected exhaust and noise emissions

regulations.

r Meet customer demands for improved fuel

economy, driveability and engin e braki ng.

r Compete in a world market.

Although the drive to reduce emissions and noise

levels is primarily the result of gove rnment

mandates, the E-Tech™ engine is designed to

provide customers with an improved engine over

the existing E7 engine it replaces. Specific

improvements include:

r Improved fuel economy.

r Increased throttle response (time to

90 percent torque is faster with the

E-Tec h ™).

r More retarding horsepower through a newly

designed J-Tech™ Engine Brake from

Jacobs.

Mack Trucks, Inc . is looking beyond the borders

of North America to increas e its mar ket and br ing

the quality, toughness and technology associated

with the MACK name to a worldwide audience.

The current environment of global regulati ons

concerning exhaust emissions, noise and other

factors has leveled the playing field on an

international basis. This means that the

improvements made to meet the North American

environmental regulations can now be applied

worldwide.

The E-Tech™ engine is used in MACK trucks and

European Renault VI trucks.

Page 7

5_106_00.bk Page 8 Friday, August 4, 2000 11:17 AM

NOTES

Page 8

5_106_00.bk Page 9 Friday, August 4, 2000 11:17 AM

IDENTIFICATION

IDENTIFICATION

Page 9

5_106_00.bk Page 10 Friday, August 4, 2000 11:17 AM

IDENTIFICATION

ENGINE MODEL

IDENTIFICATION

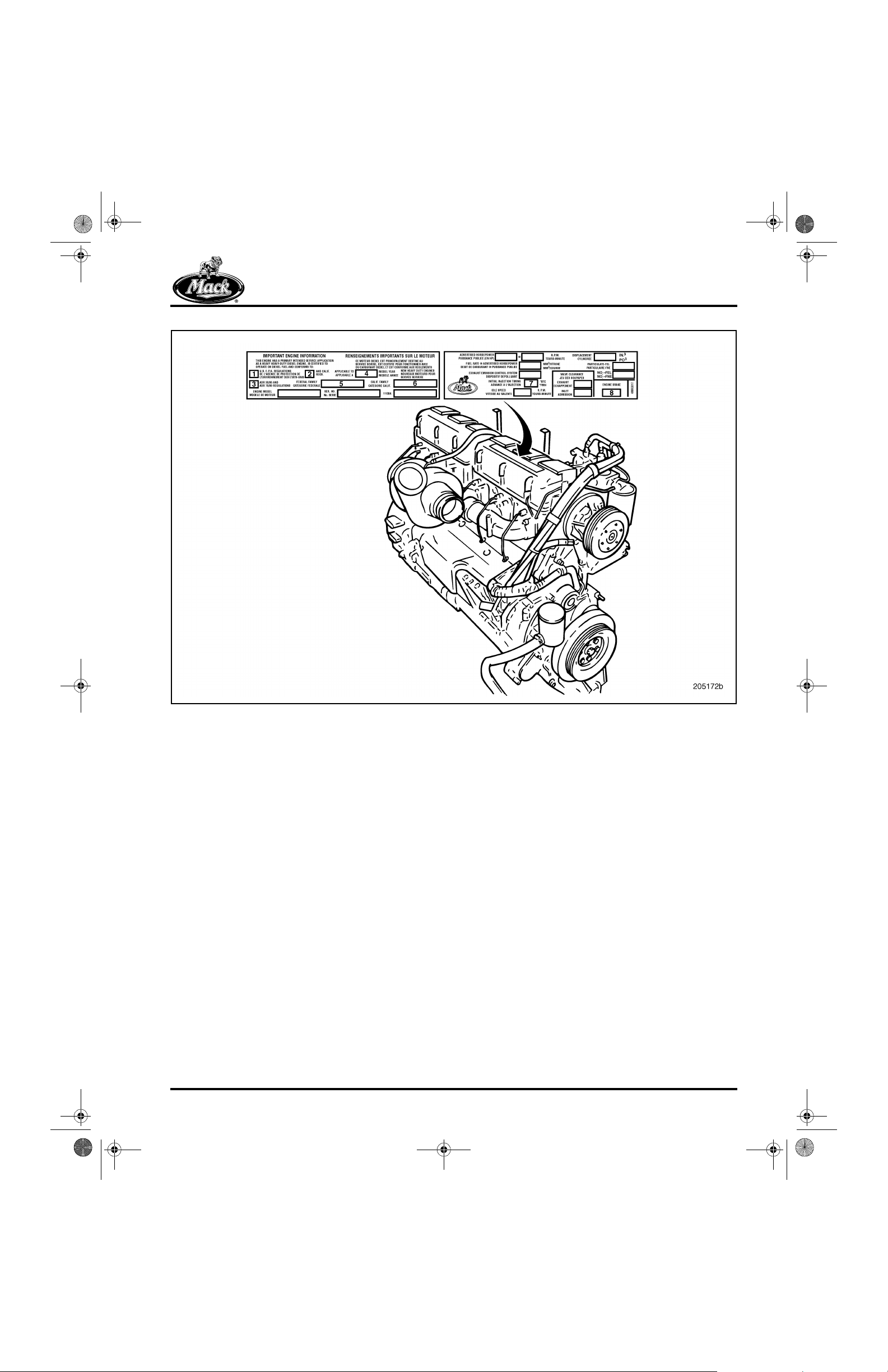

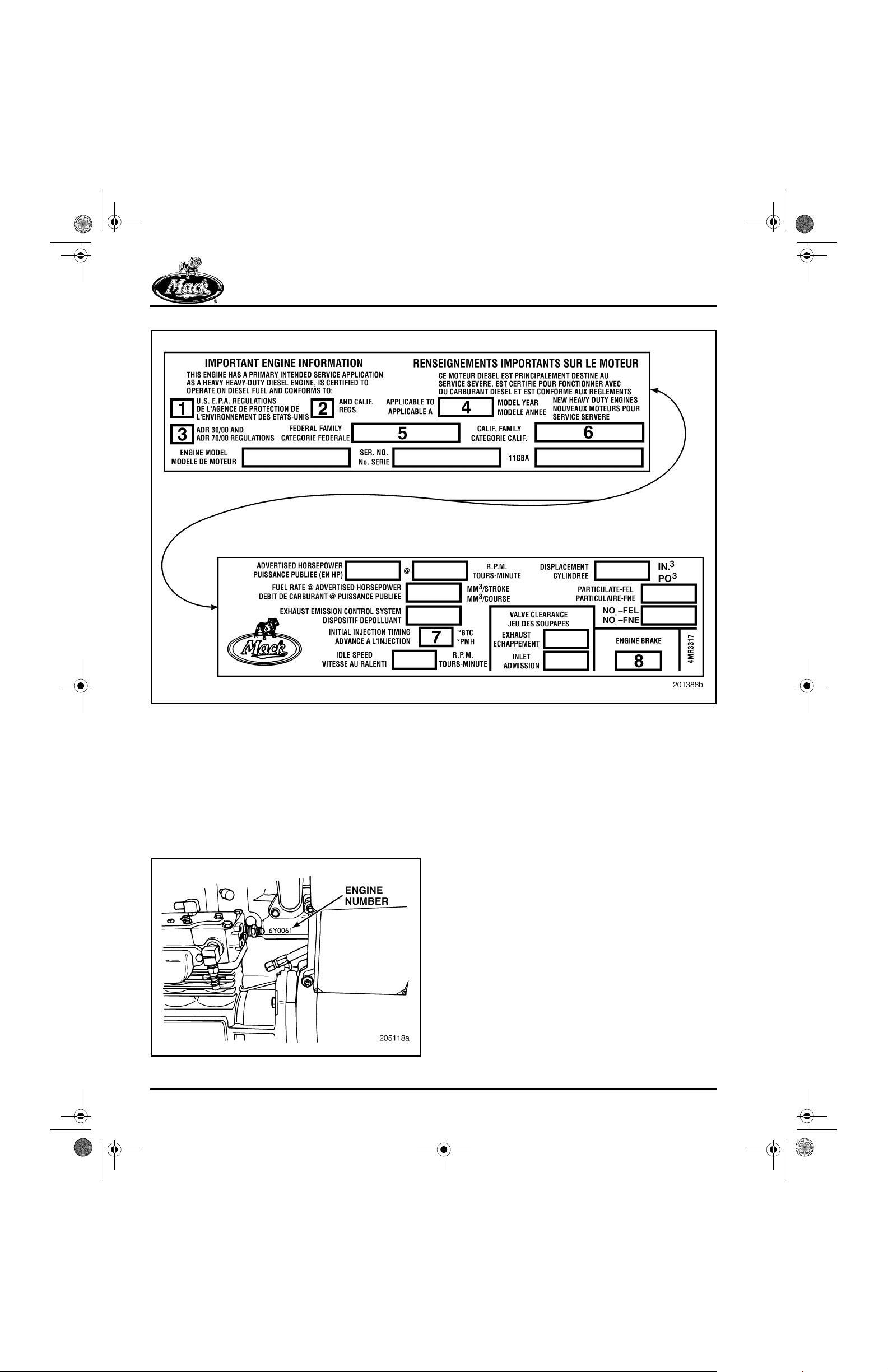

Engine Information Plate

The E-Tech™ engine information plate is located

on the top of the front cylinder head cover (back

cover for LE and MR chassis). This plate includes

information concerning:

r Engine model, serial number and 11GBA

part number.

r Advertised horsepower at rated speed rpm.

r Emissions regulations to which the engine

conforms and other pertinent information

required by emissions regulations.

r Inlet and exhaust valve lash settings and

engine brake slave piston lash setting.

The following explanations are provided to aid in

interpreting some of the key information found on

the engine information plate.

Block 1 — U.S. EPA Regulations

r An “X” in block one means the eng ine meets

United States EPA regulations for the year

stamped in block four.

Block 3 — ADR Regulations

r An “X” in block three means the engine has

been certified to meet Australian emissions

regulations.

r Two dashes in block three mean the engine

does not meet Australian emissions

regulations.

Block 4 — Model Year

r The four-digit number stamped in block four

represents the year in which the engi ne was

certified.

Block 5 — Federal Family

r A 12-digit number stamped in block five

denotes the Federal Family to which the

engine belongs for emissions certification

purposes.

r All domestic engines will have a 12-digit

Federal Family number in block five.

Block 6 — California Family

r If the engine meets California emissions

regulations, the same 12-digit number

stamped in the Federal Family block is

stamped in block six.

r Two dashes in bl ock one indicate the engine

does not meet United States EPA

regulations for the year stamped in block

four. This is only permissible with certain

export engines. All domestic engines will

have an “X” in block one.

Block 2 — California Regulations

r An “X” in block two indicates the engine

meets California emissions regulations for

the year stamped in block four. This engine

is referred to as a “50-state” engine and can

be sold in any state throughout the U.S.

r Two dashes stamped in block two mean the

engine does not meet California emissions

regulations. If an engine has an “X” in block

one and two dashes in block two, it is

referred to as a “49-sta te” engine, meaning it

is not certified for sale in California.

r If the engine does not meet California

emissions regulations, there will be two

dashes in block six.

Block 7 — Initial Injection Timing

r E-Tech™ engines do not have an initial

injection timing, as this is controlled

electronically.

r E-Tech™ engines will have “NA” stamped in

block seven.

Block 8 — Engine Brake

r This block is only used when the engine is

equipped with an engine brake. The

stamping in this block indicates the engine

brake slave-piston lash setting.

Figure 1 illustrates the location of the information

plate and Figure 2 illustrates its content.

Page 10

5_106_00.bk Page 11 Friday, August 4, 2000 11:17 AM

1

IDENTIFICATION

Figure 1 — Engine Information Plate Location

Page 11

5_106_00.bk Page 12 Friday, August 4, 2000 11:17 AM

2

IDENTIFICATION

Figure 2 — Engine Information Plate

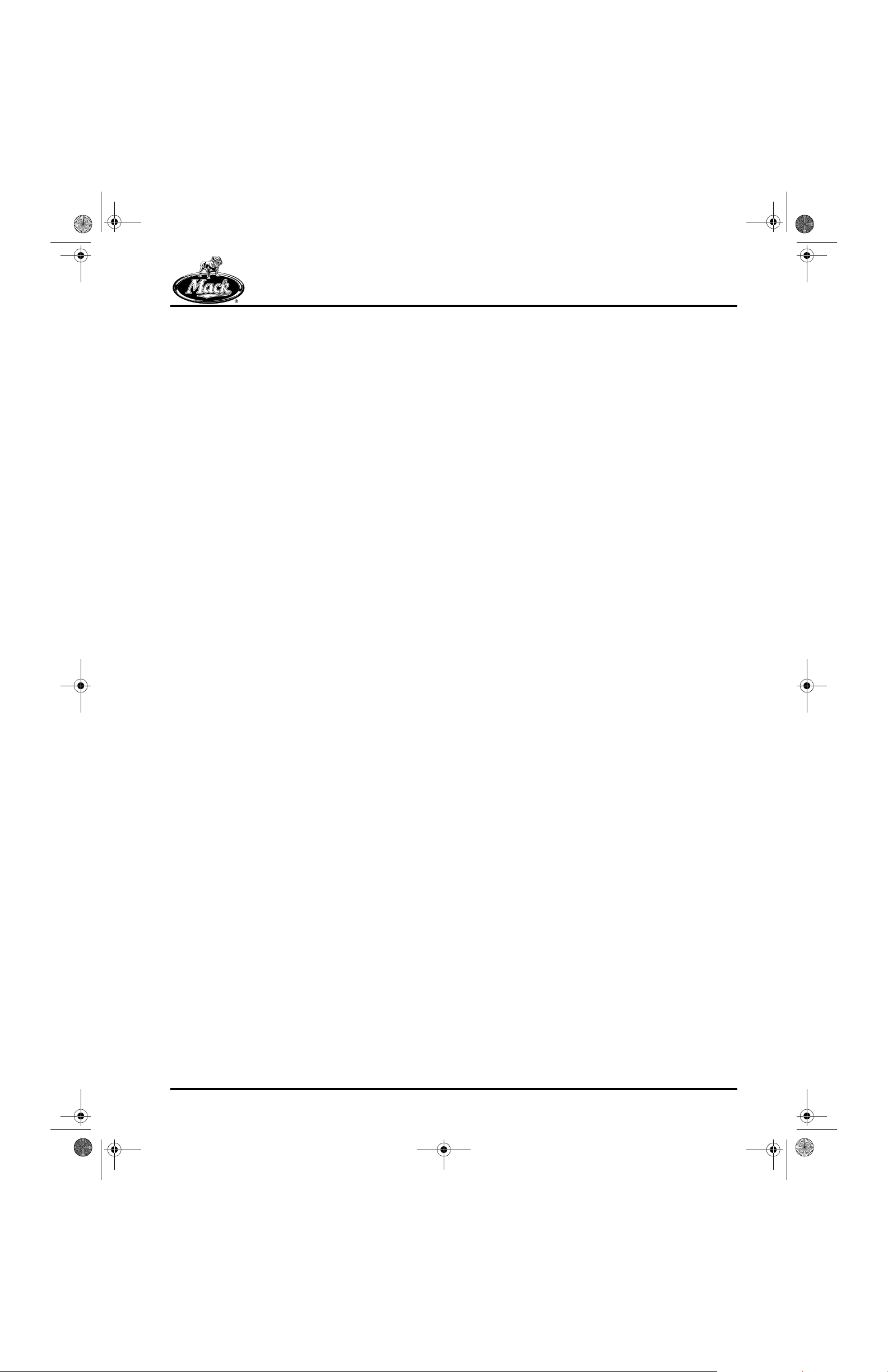

Engine Serial Number Identification

In addition to the engine information plate on the

front cylinder head cover, the engine is also

identified by the engine serial number stamped

into the cylinder block. This serial number is

located on the block right side just below the

turbo oil drain tube flange as shown in Figure 3.

3

Page 12

Figure 3 — Engine Serial Number

5_106_00.bk Page 13 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

DESCRIPTION & OPERATION

Page 13

5_106_00.bk Page 14 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

E-TECH™ ENGINE DESIGN

FEATURES

The E-Tech™ engine evolved from the E7 PLN

(commonly referred to as the E7). The four

primary design features that differentiate the

E-Tech™ engine from the E7 engine are as

follows:

r Electronic Unit Pump (EUP) fuel injection

system

®

r V-MAC

r Poly-v belt drive system

r J-Tech™ engine brake system from Jacobs

These major changes resulted in subsequent

improvements and redesign of related

components within the engine.

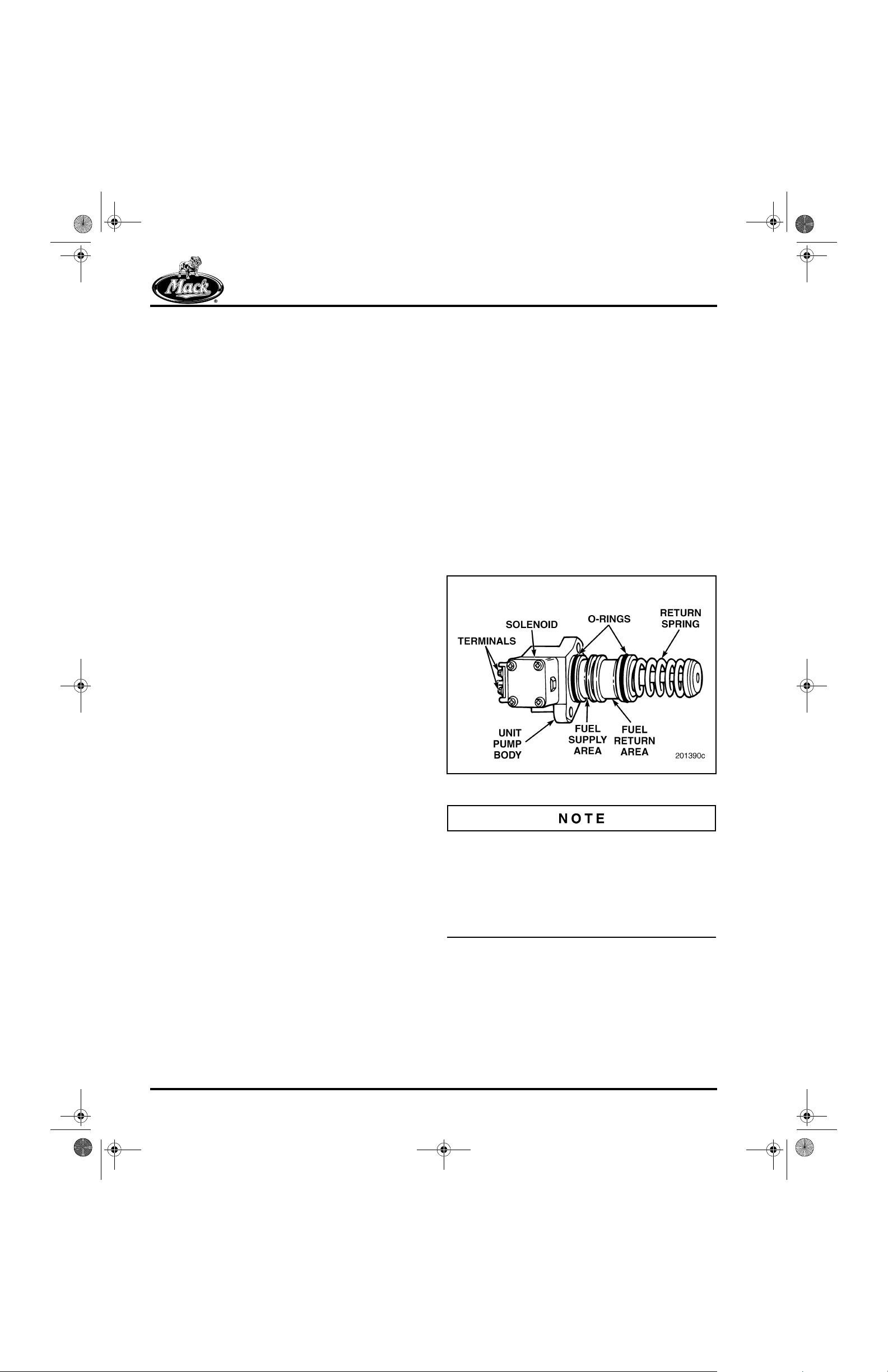

Electronic Unit Pumps

Electronic Unit Pump (EUP) technology, which

has been utilized in the heavy-duty industry for

many years, has been adapted for the E-Tech™

engine to achieve:

III electronic control system

The EUP is very similar to a unit injector. The

primary difference is that the EUP delivers fuel

through a fuel injection line to a convent ionalstyle nozzle-holder assembly, whereas a unit

injector has a nozzle mounted directly on it.

The EUP is capable of providing very high fuelinjection pressures. The pump is controlled b y a

high-speed solenoid valve (see Figure 4)

responding to electronic signals from the

V-MAC III engine control module. This electronic

control provides a greater timing range. The

combination of higher pressures and greater

timing control improves the combustion process

and optimizes engine performance. This enables

the E-Tech™ engine to conform to more stringent

emissions regulations while providing

performance and fuel economy improvements.

4

r Optimum performance

r Lower emissions

r Simplified service

r More effective pump/engine diagnostics

(individual cylinders can be isolated)

An EUP is a single-plunger fuel-injection pump,

one per cylinder, driven by a third lobe on the

engine camshaft. The pump roller follower

(tappet) is in contact with the engine cam lobe.

Figure 4 — EUP Components

Electronic unit pumps for engines produced

through approximately late 3r d quarter 2000 were

fitted with three O-rings on the pump housings.

Pumps on engines produced later than 3rd

quarter 2000 are fitted with two O-rings in the top

and bottom grooves. The O-ring in the center

groove has been eliminated.

Page 14

5_106_00.bk Page 15 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

The EUP design does not include a helix on the

pump plunger. Fuel delivery is controlled entirely

by the solenoid valve. To start fuel delivery, the

V- MAC III c ontrol syst em allows current to fl ow to

the solenoid, closing the solenoid valve and

trapping fuel in the pump. As the plunger moves

upward, fuel is delivered through the highpressure line to the fuel-inj ector nozzle assembly.

When current flow to the solenoid is stopped, the

solenoid valve opens and fuel in the pump then

flows to the cylinder block fuel return gallery.

Refer to Figure 5.

5

The EUP system, using proven industry

technology, is well adapted to troubleshooting.

When required, an individual EUP can be

replaced with a minimum of downtime.

Because the unit pumps are located in close

proximity to the exhaust manifold, heat shiel d s

have been added to prevent excessive heat from

reaching the EUP components.

The right-side heat shields on an E-Tech™

engine are a mandatory part of the engine

(Figure 6). The heat shields must

be reinstalled if

they are removed for mainten ance or repair .

Failure to do so will result in damage to the

sensitive electr onic components.

6

Figure 5 — Electronic Unit Pump

Current production E-Tech™ engines contain

EUPs with three O-rings. On future production

engines the center O-ring will be eliminated.

Present EUP service kits available through

MACK service parts do not contain the center

(brown) O-ring.

Figure 6 — Heat Shields (with Right-Side Mounted

EECU)

1. Heat Shield Attachment Points

Page 15

5_106_00.bk Page 16 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

7

Figure 7 — Heat Shields (with Left-Side Mounted EECU)

1. Fuel Temperature Sensor 2. Redesigned Heat Shield

V-MAC III

The V-MAC II I engine control system has been

developed specifically for the E-Tech™ engine.

Features include electronic drivers and

diagnostics for unit pumps, separate engine and

vehicle control units, and a revised wiring

harness. These features make V-MAC III

applicable only to the E-Tech™ engine.

V-MAC III ELECTRONIC CONTROL UNITS

The Engine Electronic Control Unit (EECU) is

located on the right side of the engine (Figure 8)

in early-production engine s. Characteristics of the

engine design, such as heat shields, vibration

isolation, and running low-pressure fuel through

the EECU mounting plate (to cool it), permit the

EECU to be mounted directly on the engine in the

right-side location.

8

Page 16

Figure 8 — V-MAC III Engine EECU (Righ t-Side Mounte d)

5_106_00.bk Page 17 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

For current-production engines, the EECU is

relocated to the left side of the engine (Figure 9)

and mounted on a new one-piece air inlet

manifold (Figure 13). With this relocation, the

fuel-cooled backing plate is no longer necessary

and has been eliminated. The new harness is

routed around the rear of the engine, and the

module and harness connections are mounted

vertically at the forward end of the module . This

provides an improved environment and less

chance for water infiltration at the harness

connectors.

9

With the two-module design, a more efficient and

reliable electronic communication network,

known as multiplexing, can be used. Mul ti plexing

essentially means that inputs and outputs to and

from one control unit are “batched” and sent as a

package to the other control unit via a single,

high-speed communication line. Inherent to this

system is a significant reducti on in the length and

number of wires, specifically those which must

pass through the bulkhead, as well as the rel ated

connections.

V- MAC III SYSTEM SENSORS

There are a total of eight engine-mounted

sensors and one vehicle-mounted sensor. Seven

of the sensors provide input for the operation of

the V- MAC III engine cont rol system, while the

remaining two sensors provide input for the dash

gauges. The dash gauge oil temperature sensor

is optional.

The following list and Figure 10 through Fi gure 19

identify the nine sensors and the features and

location of each. Three of the V-MAC III sensors

will be described in detail. These are the fuel

temperature sensor and the engine speed and

engine position sensors. The engine speed and

engine position sensors are functionally simila r to

the E7 RPM/TDC and TEM sensors, but are later

designs, quite different from the E7 sensors.

Figure 9 — EECU (Left-Side Mounted)

1. Engine ECU 2. Air Inlet Manifold

The cab-mounted V ehicle Electronic Control Unit

(VECU) provides a base for future development,

such as “total vehicle” systems and wireless

communication.

For enhanced quality, an engine-mounted EECU

allows the complete engine system (EECU,

harness and sensors) to be assembled at the

engine manufacturing/assembly plant, then

tested and verified on site. The entire engine

electronic package can be left undisturb ed during

the vehicle assembly process.

r Engine Speed Sensor

r Fuel Temperature Sensor

r Oil Pressure Sensor

r Ambient Air Temperature Sensor (see Note)

r Boost Air Temperature Sensor

r Dash Gauge Coolant Temperature Sensor

r V-MAC III Coolant Temperature Sensor

r Engine Position Sensor

r Dash Gauge Oil Temperature Sensor

(optional)

Page 17

5_106_00.bk Page 18 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

The chassis-mounted ambient air temperature

sensor was not available with early-production

engines. It was phased into produc tion begi nning

approximately mid-July 1999 for CX model

chassis, mid-September 1999 for CH, CL, RD8,

MR, DM and DMM model chassis and early

November 1999 for RD6, RB and LE model

chassis. The sensor is mounted off-engine and

supplies temperature input to the engine

electronic control unit (EECU), so t hat the V -MAC

system can determine a mor e accurate i ndicati on

of inlet air temperature.

Location of the sensor depends upon chassis

model, but in general, it is located at the front of

the chassis mounted either on the front

crossmember behind the bumper, on a hood

hinge, hood hinge bracket, body, spring bracket,

or grille guard assembly.

10

Figure 10 — V-MAC III Engine-Mounted Sensor Locations (Pre-Left-Side Redesign)

1. Fuel Temperature Sensor (Behind Fittings)

2. Dash Gauge Coolant Temperature Sensor

3. V-MAC III Coolant Temperature Sensor

4. Boost Air Temperature Sensor

5. Engine Speed Sensor (on Left Side of Flywheel Housing)

Page 18

6. Dash Gauge Oil Temperature Sensor (on Left Side of Oil

Pan)

7. Oil Pressure Sensor

8. Engine Position Sensor (on Engine Front Cover)

5_106_00.bk Page 19 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

11

Figure 11 — V-MAC III Engine-Mounted Sensor Locations (with Left-Side Mounted EECU)

1. Fuel Temperature Sensor (Behind Fittings)

2. Dash Gauge Coolant Temperature Sensor (on Side of

Coolant Manifold)

3. V-MAC III Co olant Temperature Sensor (on End of Coolant

Manifold)

4. Boost Temperature Sensor (on Top of Air Inlet Manifold)

On current-production engines with the left-side

mounted EECU, there are three harness

connectors adjacent to the oil pressure sensor.

One connector, the oil pressure sensor

connector, is always used. The other two

connectors are for an optional oil temperatur e

sensor. One connector (color-coded black) is for

the oil temperature sensor used with the standard

dashboard, and the other connect or (co lor-c oded

gray) is for the oil temperature sensor used with

the electronic dash. Oil temperature sensor part

No. 64MT2116 is used with the standard

dashboard and sensor part No. 64MT2103 is

used with the electronic dashboard.

5. Oil Temperature Sensor (on Filter Mounting Bracket)

6. Oil Pressure Sensor (on Filter Mounting Bracket)

7. Engine Speed Sensor

8. Dash Gauge Oil Temperature Sensor

9. Engine Position Sensor (on Engine Front Cover)

12

Figure 12 — V-MAC III Sensor Locations at Filter

Mounting Bracket (with Left-Side Mounted EECU)

1. Oil Temperature Sensor

2. Oil Pressure Sensor

3. Filter Mounting Bracket

Page 19

5_106_00.bk Page 20 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

On current-production engines with the left-side

mounted EECU, the boost temperature sensor

port has been moved to the manifold inlet area

(depending upon chassis model, the manifold

inlet is at the front, or the center) . There is a large

boss at the rear of the manifold for boost air

supply to the air compressor and boost pressure

access ports.

13

Figure 13 — V-MAC III Sensor Locations with Front Air Inlet Manifold (Left-Side Mounted EECU)

1. Boost Temperature Sensor

2. Fuel Filter Mounting Bracket Boss

3. Port for Boost Pressure Test Gauge

4. Boost Pressure Port for Line-to-Dash Gauge or Boost

Pressure Sensor

5. Boost Air Supply to Air Compressor

6. Engine Electronic Con trol Unit Isolator Mounting Stud,

Threaded Bosses

Page 20

5_106_00.bk Page 21 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

14

Figure 14 — V-MAC Sensor Locations with Center Air Inlet Manifold (Left-Side Mounted EECU)

A. Side View

B. Top View

1. Fuel Filter Mounting Bracket Boss

2. Port for Boost Pressure Test Gauge

3. Boost Temperature Sensor

An interim version front manifold was used on

engines with the new oil cooler/filter arrangement,

but without the engine ECU relocation.

4. Boost Pressure Port for Line-to-Dash Gauge or Boost

Pressure Sensor

5. Boost Air Supply to Air Compressor

6. Engine Electronic Con trol Unit Isolator Mounting Stud,

Threaded Bosses

The V-MAC II I sensors have different mounting

methods, or mounting threads, compared to the

similar V-MAC

®

II sensors:

r V- MAC III engine speed a nd engine po sit ion

sensors are flange-mounted with a mounting

screw .

r V-MAC III oil pressure, boost temperature,

fuel temperature and coolant temperature

sensors have English pipe threads.

r Dash gauge sensors for coolant and oil

temperatures are threaded sensors with

English pipe threads, the same as the E7

with V-MAC II.

Page 21

5_106_00.bk Page 22 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

Fuel Temperature Sensor

On early-production engines with a right- side

mounted EECU, a fuel temperature sensor is

provided at the top of the secondary fuel filter

mounting adapter (Figure 15) installed in a boss

adjacent to the outlet fitting. The V-MAC III

system monitors fuel temperature at the

secondary fuel filter outlet, as fuel is being

supplied to the cylinder block fuel gallery inlet.

This fuel temperature data improves accuracy of

the mpg fuel consumption information shown on

®

the Co-Pilot

display.

The fuel temperature sensor is the same as the

coolant temperature sensor used at the rear of

the water manifold location. The illustration that

follows shows a CH/CL/DM engine-mounted, fu el

filter adapter. The RD/MR/LE chassis-mounted

secondary fuel filter mounting adapter has a

similar sensor mounting boss. In either case, if

the fuel temperature sensor is not used, the boss

should not be drilled and tapped.

15

On current-production engines with the left-side

mounted EECU, the fuel temperature sensor is

located at the fuel cylinder block fu el gallery inlet

(Figure 16). This location is standardized for all

fuel filter arrangements, simplifying and

improving the line routing.

16

Figure 15 — Fuel Temperature Sensor (Engine with

Right-Side Mounted EECU)

Figure 16 — Fuel Temperature Sensor (Engine with

Left-Side Mounted EECU)

1. Fuel Temperature Sensor 2. EUP Heat Shield

Page 22

5_106_00.bk Page 23 Friday, August 4, 2000 11:17 AM

DESCRIPTION & OPERATION

Engine Speed Sensor

This sensor is located at the left side of the

engine flywheel housing (Figure 17). It is flan gemounted and held in place by a retaining screw.

The engine speed sensor is the same part

number as the engine position sensor,

located on the engine front cover.

17

Figure 17 — Engine Speed Sensor

18

Figure 18 — Engine Position Sensor

Boost Temperature Sensor and Boost

Pressure Diagnostic Ports

A V-MAC III boost temperature sensor is located

on the top of the rear inlet manifold (Figure 19).

There is no boost pressure sensor because, as

with all V-MAC systems, V-MAC III uses ECU

programming for transient smoke control.

The E-Tech™ flywheel has 117 teeth (one less

tooth than the E7 engine flywheel) and has two

adjacent teeth with part of their width (1/4 inch)

machined off. These two teeth on the E-Tech™

flywheel allow the sensor to determine top dead

center (TDC) of cylinder Nos. 1 and 6, whereas

sensing notches are used on the front face of the

E7 flywheel. Because of this feature, ring gear-toflywheel indexing must be maintained.

Engine Position Sensor

The engine position sensor is located on the

engine front cover (Figure 18) and is retained in

the same manner as the engine speed sensor.

This sensor is designed to monitor the passage of

holes which are in the front face of the camshaft

timing gear . This sensor performs a function

similar to the TEM sensor in the Bosch Injection

Pump RE30 governor on the E7 engine.

There are two boost pressure gauge ports just

forward of the boost temperature sensor. The

forward port is used for the dash boost pressure

gauge when chassis is so equipped. The port

adjacent to the boost temperature sensor can be

used to install a boost pressure gauge for

diagnostic purposes if the need arises.

19

Figure 19 — Boost Temperature Sensor and Boost

Pressure Gauge Ports