ServiceManual

EngineControlModule(ECM),DiagnosticTroubleCode

(DTC),Guide

2010Emissions

CHU,CXU,GU,TD

Trucks

Group28

PV776-88961816

Foreword

Thedescriptionsandserviceprocedurescontainedinthismanualarebasedondesignsand

methodsstudiescarriedoutuptoMarch2010.

Theproductsareundercontinuousdevelopment.Vehiclesandcomponentsproducedafterthe

abovedatemaythereforehavedifferentspecicationsandrepairmethods.Whenthisisbelieved

tohaveasignicantbearingonthismanual,supplementaryservicebulletinswillbeissuedtocover

thechanges.

Theneweditionofthismanualwillupdatethechanges.

Inserviceprocedureswherethetitleincorporatesanoperationnumber ,thisisareferencetoa

LaborCode(StandardTime).

Serviceprocedureswhichdonotincludeanoperationnumberinthetitleareforgeneralinformation

andnoreferenceismadetoaLaborCode(StandardTime).

Eachsectionofthismanualcontainsspecicsafetyinformationandwarningswhichmustbe

reviewedbeforeperforminganyprocedure.Ifaprintedcopyofaprocedureismade,besureto

alsomakeaprintedcopyofthesafetyinformationandwarningsthatrelatetothatprocedure.The

followinglevelsofobservations,cautionsandwarningsareusedinthisServiceDocumentation:

Note:Indicatesaprocedure,practice,orconditionthatmustbefollowedinordertohavethe

vehicleorcomponentfunctioninthemannerintended.

Caution:Indicatesanunsafepracticewheredamagetotheproductcouldoccur.

Warning:Indicatesanunsafepracticewherepersonalinjuryorseveredamagetotheproduct

couldoccur.

Danger:Indicatesanunsafepracticewhereseriouspersonalinjuryordeathcouldoccur.

MackTrucks,Inc.

Greensboro,NCUSA

Ordernumber:PV776-88961816

Repl:

©2010MackTrucks,Inc.,Greensboro,NCUSA

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinretrievalsystem,

ortransmittedinanyformsbyanymeans,electronic,mechanical,photocopying,recordingor

otherwise,withoutthepriorwrittenpermissionofMackTrucks,Inc.

USA40713

Contents

DesignandFunction....................................................................................................................3

EngineControlModule(ECM)......................................................................................................3

OnBoardDiagnostic(OBD)Monitors............................................................................................4

Troubleshooting..........................................................................................................................22

EngineControlModule(ECM)DiagnosticTroubleCodes(DTCs).....................................................22

1

2

Group28

EngineControlModule(ECM)

EngineControlModule(ECM)

DesignandFunction

Themanufacturerscantoolisthepreferredtoolfor

performingdiagnosticwork.Contactyourlocaldealerfor

moreinformationorvisit“www.premiumtechtool.com”.

SystemOverview

Sixelectroniccontrolunits(ECUs)areused;theenginecontrol

module(ECM),instrumentcontrolmodule(ICM),Vehicle

ElectronicControlUnit(VECU),transmissioncontrolmodule

(TCM),thegearselectorcontrolmodule(GSCM)andthe

aftertreatmentcontrolmodule(ACM).T ogether ,thesemodules

operateandcommunicatethroughtheSAEJ1939(CAN

1)datalinktocontrolavarietyofengineandvehiclecab

functions.TheECMcontrolssuchthingsasfueltimingand

delivery,fanoperation,engineprotectionfunctions,engine

brakeoperation,theexhaustgasrecirculation(EGR)valve

andtheturbochargernozzle.TheVECUcontrolscruise

controlfunctions,accessoryrelaycontrolsandidleshutdown

functions.TheICMprimarilydisplaysoperationalparameters

andcommunicatesthesetotheotherECUs.Allhavethe

capabilitytocommunicateovertheSAEJ1587datalink

primarilyforprogramming,diagnosticsanddatareporting.

Inadditiontotheircontrolfunctions,themoduleshaveon

boarddiagnostic(OBD)capabilities.TheOBDisdesignedto

detectfaultsorabnormalconditionsthatarenotwithinnormal

operatingparameters.Whenthesystemdetectsafaultor

abnormalcondition,thefaultwillbeloggedinoneorbothof

themodules’memory ,thevehicleoperatorwillbeadvisedthat

afaulthasoccurredbyilluminationamalfunctionindicator

lamp(MIL)andamessageinthedriverinformationdisplay ,

ifequipped.Themodulemayinitiatetheengineshutdown

procedureifthesystemdeterminesthatthefaultcoulddamage

theengine.

Note:Theuseofascantoolisnecessarytoperformdiagnostic

workaswellasclearingofanydiagnostictroublecodes

(DTCs).DTC(s)cannolongerbeclearedusingthevehicles

instrumentclusterdigitaldisplayandstalkswitchcontrol.

Theuseofascantoolisnecessarytoperformdiagnosticwork

aswellasclearingofanydiagnostictroublecodes(DTCs).

DTC(s)cannolongerbeclearedusingthevehiclesinstrument

clusterdigitaldisplayandstalkswitchcontrol.Additional

dataanddiagnostictestsareavailablewhenascantoolis

connectedtotheSerialCommunicationPort.

Fordiagnosticsoftware,contactyourlocaldealer.

TheECMisamicroprocessorbasedcontrollerprogrammed

toperformfuelinjectionquantityandtimingcontrol,diagnostic

faultlogging,andtobroadcastdatatootherECUs.Thefuel

quantityandinjectiontimingtoeachcylinderisprecisely

controlledtoobtainoptimalfueleconomyandreducedexhaust

emissionsinalldrivingsituations.

TheECMcontrolstheoperationoftheinjectors,enginebrake

solenoid,EGRvalve,turbochargernozzleposition,andcooling

fanclutchbasedoninputsfrommanysensorsandinformation

receivedoverthedatalinksfromotherECUs.

TheVECUandECMaredependentoneachothertoperform

theirspeciccontrolfunctions.Inadditiontoswitchandsensor

data,thebroadcastofdatabetweenmodulesalsoincludes

variouscalculationsandconclusionsthateachmodulehas

developed,basedontheinputinformationithasreceived.

Insomesituationswhenafaultisdetected,thesystemwill

entera"derate"mode.Thederatemodeallowscontinued

vehicleoperationbutthesystemmaysubstituteasensor

orsignalvaluethatmayresultinreducedperformance.In

someinstances,thesystemwillcontinuetofunctionbut

enginepowermaybelimitedtoprotecttheengineandvehicle.

Diagnostictroublecodes(DTCs)loggedinthesystemmemory

canlaterberead,toaidindiagnosingtheproblemusinga

diagnosticcomputerorthroughtheinstrumentclusterdisplay ,

ifequipped.WhendiagnosinganintermittentDTCorcondition,

itmaybenecessarytouseascantoolconnectedtotheSerial

CommunicationPort.

3

Group28

OnBoardDiagnostic(OBD)Monitors

SystemElectronicControlUnit(ECU)Overview

OnBoardDiagnostic(OBD)Monitors

Theenginecontrolmodule(ECM)monitorsandmodels(using

physicalprinciples)engineparameterstomonitortheengine

system’sperformanceinrealtime.Thisisperformedtoaidthe

ECMwithitsselfdiagnosticcapabilities.Manysensorsare

usedforinputtotheemissioncontrolsystem.

Thesystemcontainsthefollowing“emissioncritical”ECUs

thataremonitored;

•EngineControlModule(ECM)

•VehicleElectronicControlUnit(VECU)

•AftertreatmentControlModule(ACM)

•AftertreatmentNitrogenOxides(NOx)Sensors

•EngineV ariableGeometryTurbocharger(VGT)Smart

RemoteActuator(SRA)

MalfunctionIndicatorLamp(MIL),DescriptionandLocation

AMILlocatedintheinstrumentcluster.Thisambercolored

lampisusedtoinformthedriverthata“emissioncritical”

malfunctionsignalhasoccurred.

TheseECUsallcommunicatewiththeECMviadatalinks.The

VECUcommunicatesacrosstheSAEJ1939(CAN1)datalink

whiletheothersusetheSAEJ1939-7(CAN2)datalink.

TheOBDsystemsuseSAEJ1939datalinkprotocolfor

communicationwithscantoolsbut,MACKtrucksstillare

capableofcommunicatingviatheSAEJ1587datalinkfor

diagnostics.Theuseofascantoolisnecessarytoperform

diagnosticworkaswellasclearingofanydiagnostictrouble

codes(DTCs).DTC(s)cannolongerbeclearedusingthe

vehiclesinstrumentclusterdigitaldisplayandstalkswitch

control.

ThereareotherECUssuchastheInstrumentControlModule

(ICM),TransmissionControlModule(TCM)andAnti-lock

BrakeSystem(ABS)Modulethatprovidedatatotheemission

controlsystemorthediagnosticsystembutarenot“emission

critical”.

W2036007

4

Group28

SystemsMonitoringInformation

SectionContent

OnBoardDiagnostic(OBD)Monitors

•“AcceleratorPedalPosition(APP)Sensor,Overview”,page

6

•“Active/intrusiveInjection(AftertreatmentHydrocarbon

DoserClogging)”,page6

•“AftertreatmentDieselExhaustFluid(DEF)Feedback

Control”,page6

•“AftertreatmentDieselExhaustFluid(DEF)Quality”,page

6

•“AftertreatmentDieselParticulateFilter(DPF)”,page6

•“AftertreatmentDieselParticulateFilter(DPF)Regeneration

Frequency”,page6

•“AftertreatmentDieselParticulateFilter(DPF)Incomplete

Regeneration”,page6

•“AftertreatmentDieselParticulateFilter(DPF)Regeneration

FeedbackControl”,page6

•“AftertreatmentFuelSystem,RationalityMonitors”,page7

•“AftertreatmentNon-MethaneHydroCarbons(NMHC)

Catalyst”,page7

•“AftertreatmentNitrogenOxides(NOx)Sensor(s)

Overview”,page7

•“AftertreatmentSelectiveCatalyticReduction(SCR)”,page

7

•“AftertreatmentSelectiveCatalyticReduction(SCR)

ConversionEfciency”,page7

•“AmbientAirT emperature(AAT)Sensor,Overview”,page

7

•“ChargeAirCooler(CAC)”,page8

•“CombinedMonitoring”,page8

•“CrankcaseVentilation”,page8

•“CrankcaseVentilationDiagnosticFunction”,page8

•“EngineControlModule(ECM),RationalityMonitors”,page

8

•“EngineCoolantT emperature(ECT)SensorOverview”,

page8

•“ExhaustGasRecirculation(EGR)”,page8

•“ExhaustGasRecirculation(EGR)LowFlow”,page8

•“ExhaustGasRecirculation(EGR)HighFlow”,page8

•“ExhaustGasRecirculation(EGR)SlowResponse”,page

9

•“ExhaustGasRecirculation(EGR)FeedbackControl”,

page9

•“ExhaustGasRecirculation(EGR)CoolerPerformance”,

page9

•“Exotherm”,page9

•“FilteringPerformance”,page9

•“FuelSystem”,page9

•“IdleSpeed,RationalityMonitors”,page9

•“IntakeManifoldPressure(IMP)ControlSystem”,page9

•“Misre”,page10

•“MissingSubstrate”,page10

•“Over-boost”,page10

•“ParkingBrakeSwitch,Overview”,page10

•“PowerTake-off(PTO)EnableSwitch,Overview”,page10

•“SAEJ1939(CAN1)DataLink,Overview”,page10

•“ThermostatMonitor”,page10

•“Time/DateOverview”,page10

•“VariableGeometryTurbocharger(VGT)Feedback

Control”,page10

•“VehicleSpeedSensor(VSS),Overview”,page11

•“Under-boost”,page11

•“VariableGeometryTurbocharger(VGT)SlowResponse”,

page11

5

Group28

AcceleratorPedalPosition(APP)Sensor,Overview

OnBoardDiagnostic(OBD)Monitors

TheAPPsensorinputisananalogvoltagesignalproportional

tothepedalpositionthatisreadbythevehicleelectronic

controlunit(VECU).Theangularpositionofthepedalis

dividedinthreedifferentareasusedforfaultdetection

and/orrecovery.Thevaluethatistransmittedundernormal

Active/intrusiveInjection(AftertreatmentHydrocarbonDoserClogging)

Thisdiagnosticisbasedonthecheckingtheaftertreatment

dieselparticulatelter(DPF)intaketemperatureduring

aftertreatmentDPFactiveparkedregenerationcycles.If

theaftertreatmentDPFintaketemperaturedoesnotreacha

AftertreatmentDieselExhaustFluid(DEF)FeedbackControl

TheaftertreatmentDEFcontrolconsistsofafeedforward

controltogetherwithafeedbackcontrol.Thefeedforward

controlvalueishowmuchureathatmustbeinjectedinorder

AftertreatmentDieselExhaustFluid(DEF)Quality

AftertreatmentDEFqualityisevaluatedanddetermined

throughconversionefciency .IftheaftertreatmentSCR

systemefciencyisbelowthespeciedlimit,afaultisreported.

AftertreatmentDieselParticulateFilter(DPF)

conditions(valueof0-100%),isdirectlyproportionaltothe

pedal’sangularposition.Thephysicalacceleratorassembly

alsosupportsadigitalDCvoltage(On/Off)generatedbyan

idlevalidation(IV)switchthatisalsopoweredbythesame

regulatedreferencevoltagesource.

minimumregenerationtemperaturewithinaspeciedtime

thentheaftertreatmenthydrocarbondoserisconsideredto

beclogged.

toobtainthedemandednitrogenoxides(NOx)conversion

efciency.Thefeedbackcontrolstheammonia(NH3)bufferin

theaftertreatmentselectivecatalyticreduction(SCR).

TheaftertreatmentDPFcollectsparticulateandsootin

aceramicwall-owsubstrate.Thestrategytomanage

theaccumulationofsootistotakeadvantageofnatural

aftertreatmentDPFpassiveregenerationwheneverpossible,

andtoinvokeanoperatingmodethatenhancesaftertreatment

DPFpassiveregenerationwhennecessary.Aftertreatment

DPFactiveregenerationisperformedusinganaftertreatment

hydrocarbondoser.

AftertreatmentDieselParticulateFilter(DPF)RegenerationFrequency

ThisfunctiondetectsiftheaftertreatmentDPFregeneration

frequencyincreasestoalevelthatitwouldcausethe

non-methanehydrocarbon(NMHC)emissionstoexceed

thelegallimitationorifthefrequencyexceedsthedesign

requirements.IfthenumberofaftertreatmentDPF

regenerationsareabovethethresholdattheendofthetime

periodafaultisreported.

AftertreatmentDieselParticulateFilter(DPF)IncompleteRegeneration

TheaftertreatmentDPFregenerationstrategyistoreducethe

sootlevelintheDPFusingpassiveregeneration.However,

ifthedrivingconditionsdonotenableenoughexhaustheat

forpassiveregenerationtokeepupwiththesootloadingan

activeparkedaftertreatmentDPFregenerationwillberequired.

AninterruptedparkedaftertreatementDPFregeneration

isdetectedbythisfunction.Thisisnotafaultmodebut

handledbytheaftertreatmentsystem.Iftheratiobetween

theuncompletedandcompletedregenerationsisabovethe

speciedlimit,afaultisreported.

AftertreatmentDieselParticulateFilter(DPF)RegenerationFeedbackControl

Thisfunctionmonitorstheparticulatematterregeneration

feedbackcontrolanddetects:

notbereachedoriftheactuatorissaturatedmorethanagiven

percentageofthetime.

•Ifthesystemfailstobeginfeedbackcontrol

•Ifafailureordeteriorationcausesopenloop

•Ifthefeedbackcontrolhasusedupalloftheallowed

adjustment

Whentheaftertreatmenthydrocarbondoserisused,the

feedbackcontrolismonitoredforasaturatedcontrollerora

saturatedactuator.Asaturatedcontrolleroractuatormeans

thatallallowedadjustmenthasbeenusedup.Themonitors

detectamalfunctionifthecontrollerissaturatedmorethana

givenpercentageofthetimeandthetargettemperaturecan

6

Group28

AftertreatmentFuelSystem,RationalityMonitors

OnBoardDiagnostic(OBD)Monitors

Theaftertreatmentfuelsystemconsistsofaaftertreatmentfuel

shutoffvalve,aseparateaftertreatmenthydrocarbondoser

(injector),andanaftertreatmentfuelpressuresensor.The

aftertreatmentfuelshutoffvalvediagnosticfunctionlookatthe

aftertreatmentfuelpressurewhenthevalveisopenedand

closed.Whenconditionsareproperforthediagnostic,the

functionrequestsanopeningoftheaftertreatmentfuelshutoff

valveinordertopressurizetheaftertreatmentfuelsystem.

AftertreatmentNon-MethaneHydroCarbons(NMHC)Catalyst

Todetectwhenthehydrocarbonconversionfailsinthe

aftertreatmentdieseloxidationcatalyst(DOC),thetemperature

reactionattheaftertreatmentDOCoutletismonitoredwhen

fuelisinjectedintheexhaust.Theamountofhydrocarbon

suppliedbytheaftertreatmenthydrocarbondoserwill

determinetheexpectedincreaseintemperatureafterthe

aftertreatmentDOC.Theaftertreatmenthydrocarbondoser

AftertreatmentNitrogenOxides(NOx)Sensor(s)Overview

TheNOxsensorsconsistof:

•Housingholdingthesensingelement.

•Anelectroniccontrolunit(ECU),interfacingthesensorand

theenginecontrolmodule(ECM).

•Awire,electricallyconnectingthesensingelementwith

theECU.

TherearetwoaftertreatmentNOxsensors,onebeforeand

oneaftertheaftertreatmentselectivecatalyticreduction(SCR)

catalyst.TheaftertreatmentNOxsensorbeforeandafterSCR

catalysthaveuniqueCANidenticationnumbershencecan

notbeswapped.ThesensorbeforetheSCRcatalystmonitors

theengineoutNOxlevel.ThesensorafterSCRmonitors

systemoutNOxlevel.

Thisactionshouldincreasesystempressure.Whenthe

aftertreatmentfuelshutoffvalveisclosedthesystempressure

shoulddecreasesincethevalvehasaninternaldrainpipethat

constantlydepressurizesthesystem.Formoreinformation

aboutthesecomponentsreferto

Sensor,CircuitMonitors”,page16,“AftertreatmentFuel

ShutoffValve,CircuitMonitors”,page16or

HydrocarbonDoser,CircuitMonitors”,page16.

injectionrate(dutycycle)ismonitoredandusedtocalculate

whetherthereshouldbeacorrespondingheatreaction.

Onceithasreachedanacceptableaccumulateddutycycle

theexpectedtemperaturedifferencecanbecalculated.

Thisdifferenceshouldthenbeaboveacertainlimitifthe

hydrocarbonconversionwasachieved.

AftertreatmentNOxsensordiagnosticsmonitorthesensors

signalqualityandperformance.Thepurposeofthisfunctionis

todetectthefollowing,

“AftertreatmentFuelPressure

“Aftertreatment

•Badsignalquality

•Removedsensor

•Missingsignal

CircuitintegrityoftheaftertreatmentNOxsensorischecked

bythesensoritselfandthestatusistransmittedtotheengine

controlmodule(ECM)overtheCANdatalink.Thefollowing

canbetransmitted,

•opencircuit

•highvoltage

•circuitloworhigh

AftertreatmentSelectiveCatalyticReduction(SCR)

TheaftertreatmentSCRsystemisacatalystsystemthatis

usedtoreduceexhaustNitrogenOxides(NOx)emissions.

Thisreductionisperformedbyinjectingdieselexhaustuid

(DEF)(aureasolution)intotheexhaustfumespriortothe

aftertreatmentSCRcatalyst.Achemicalprocessperformed

byaftertreatmentSCRcatalystandDEF ,convertsNOxto

AftertreatmentSelectiveCatalyticReduction(SCR)ConversionEfciency

TheaftertreatmentSCRcatalystdiagnosiscalculatesthelow

temperatureperformanceoftheaftertreatmentSCRsystem

andcomparesittotheperformancewhenthecatalystis

warmenoughtoreachhighnitrogenoxides(NOx)conversion.

AmbientAirTemperature(AAT)Sensor,Overview

TheAATsensorisananaloginputthatisreadbythe

instrumentclusterelectroniccontrolunit.Theinstrument

clusterprocessestherawsignalandtransmitstheAA Tvalue

ontheSAEJ1939datalink.Thevehicleelectroniccontrolunit

(VECU)receivestheAA Tvalueandbasedoncertainvehicle

conditionsthevalueisadjusted.TheVECUthentransmits

nitrogenoxide(NO)andwater(H2O).Theaftertreatment

controlmodule(ACM)isusedtocontroltheaftertreatment

SCRcomponentsandrelayssysteminformationtotheEngine

ControlModule(ECM).TheECMcontrolstheoverallsystem

function.

Thisisbasedonthepremisethatadeterioratedcatalystcan

beconsideredasacatalystwithlessvolume.Thevolume

iscriticaltoreachthelowtemperatureperformanceofthe

aftertreatmentSCRsystem.

theAATvaluebackontheSAEJ1939datalinkwhereitis

receivedbytheenginecontrolmodule(ECM).

7

Group28

ChargeAirCooler(CAC)

OnBoardDiagnostic(OBD)Monitors

ThenominalCACefciencyisamapbasedonmassairow

(MAF)andambientairtemperature(AAT).Themethodto

evaluatetheCACefciencyistocompareanominalCAC

CombinedMonitoring

Cylinderbalancingfunctionisusedtodetectfuelsystem

pressure,quantityandtimingfault.Byprocessingthetooth

timescylinderbalancingdetectsifthecombustionpower

contributionfromoneorseveralcylindersistooweekortoo

strongandneedtobecompensatedtogetevencombustion

CrankcaseVentilation

Thecrankcasepressure(CCP)dependsontheblow-byow

andtheunderpressuregeneratedbytheseparator.Blow-by

gasescomemainlyfromthecombustionwhenexhaustgas

passesthepistonrings.Amalfunctioningofthevalveguides,

CrankcaseVentilationDiagnosticFunction

Whenthehighspeedseparatorenablingconditionsexist,

theminimumvalueofthedifferencebetweencrankcaseand

barometricpressure(BARO)duringatimeperiodisstored.

EngineControlModule(ECM),RationalityMonitors

IfelectricalpowertotheECMislostorverylow,theECMwill

stoptofunctioningandtheenginewillstop.Otherelectronic

efciencywithonecalculatedbasedontheexhaustgas

recirculation(EGR)andtheintakeairtemperature(IA T)sensor

alongwiththeircorrespondingmassows.

powerfromallcylinders.Thecompensationiscalculatedat

thelowerenginespeed(RPM)andtorqueregionsduringwarm

enginewheretheimpactfromeachcombustionbecomesmost

visible.Ifthecompensationbecomestoohighortoolowfault

isdetected.

ortheturbochargercanalsocontribute.Theblow-bygases

consistofexhaustgasesmixedwithoil.Ahighspeedrotating

separatorisusedtoexpelengineoilfromthesegases.

Thesystemperformshighspeedandlowspeedevaluationsof

theseparatortoconcludeifthesystemistight.

controlunits(ECUs)ontheSAEJ1939(CAN1)datalinkwill

indicatethatdatafromtheECUismissing.

EngineCoolantT emperature(ECT)SensorOverview

TheECTsensorismonitoredforrationalityatkeyONby

comparingtheECTwiththeotherenginetemperaturesensors

(engineoiltemperature(EOT)andengineturbocharger

compressoroutlettemperature).Usingthiscomparisonthe

followingconclusionsmaybemadewhenaproblemoccurs:

•UnabletoreachClosedloop/FeedbackenableT emperature

(coveredbythermostatwarmeduptemperature)

•TimetoreachClosedloop/FeedbackenableT emperature

(coveredbythermostatwarmeduptemperature)

ExhaustGasRecirculation(EGR)

US2010emissionlevelMACKenginesuseEGRtoenhance

engineoutNitrogenOxides(NOx)control.EGRowis

managedusinganEGRvalveandaV ariableGeometry

Turbocharger(VGT)nozzleposition.Theseactuatorsettings

arebasedonopenloopsettingsestablishedtoachieve

ExhaustGasRecirculation(EGR)LowFlow

ThisfunctionmonitorsthereductionofEGRowintheEGR

system,i.e.toolowEGRmassowcomparedwithdemand.It

isactivatedwhentheengineenterstheburnedfractionmode

•StuckinarangebelowthehighestminimumEnable

temperature

•StuckinaRangeAbovetheLowestmaximumEnable

temperature-RationalityCheck

Whentheengineisused,thethreetemperaturesarenot

thesameanddependingonhowfasttheengineisrestarted

normaldifferenceswillbefound.Whenthesedifferencesand

theambientairtemperature(AAT)exceedsalimit,thefault

limitsareadjustedinordertoallowthesedifferences.

desiredburnedfractionrates.Thesesettingscanbemodied

inaclosedloopburnedfractionmodebyfeedbackfroma

combustionpropertymodel.TheEGRsystemisdiagnosedby

monitoringtheburnedfractionwhenevertheengineenters

burnedfractionclosedloopmode.

withminimumdemandforBFandtheenginespeed/torqueis

inarangewhereEGRowmeasurementsandBFcalculations

havesufcientaccuracy.

ExhaustGasRecirculation(EGR)HighFlow

ThisfunctiondiagnosestoomuchEGRinthesystem,i.e.too

highEGRmassowcomparedwiththedemand.Thisfunction

handlespositivedeviationswhenEGRclosedloopcontrolis

active.WhenclosedloopEGRcontrolisentered,aninitial

differencebetweenmeasuredburnedfractionandburned

8

fractiondemandmightexist.Duetothefactthatsometime

isneededforadaptation,notallthedifferenceistakeninto

account.

Group28

ExhaustGasRecirculation(EGR)SlowResponse

OnBoardDiagnostic(OBD)Monitors

Asdescribedin“ExhaustGasRecirculation(EGR)LowFlow”,

page8and“ExhaustGasRecirculation(EGR)HighFlow”,

page8,thedeviationbetweenthedemandedandmeasured

ExhaustGasRecirculation(EGR)FeedbackControl

Thisfunctiondetects:

•Ifanyofthefeedbackcontrolloopsarenotachieved.

ExhaustGasRecirculation(EGR)CoolerPerformance

Thisfunctionusesanequationbasedoffofengine

turbochargerturbineintaketemperature,EGRtemperature

andtheenginecoolanttemperature(ECT),tocalculatecooler

Exotherm

Exotherm,exothermicorexothermalallrefertoachemical

changethatisaccompaniedbyagreatreleaseofheat.

Theaftertreatmentheatingfunctionusestheaftertreatment

hydrocarbondoser,toheatuptheexhaustsystemforparked

aftertreatmentdieselparticulatelter(DPF)regeneration.

Whentheaftertreatmenthydrocarbondoserisusedthe

hydrocarbons(HC)createanexothermintheaftertreatment

burnedfractionaremonitoredwhenEGRclosedloopcontrol

isactive.Slowresponseisdetectedwhenthedeviation

(high/low)abovethethresholdisdetected.

•Iffeedbackcontrolmodeisinhibited.

efciency.Thecalculatedefciencyisdeemedtoolowifitis

belowacertainconstantlimit.

dieseloxidationcatalyst(DOC).Theaftertreatment

hydrocarbondoserinjectionrate(dutycycle)ismonitoredand

usedtocalculatewhetherthereshouldbeacorresponding

exotherm.Astartingtemperaturevalueissetwhenthe

aftertreatmenthydrocarbondoserstartstoinjectfuel.Assoon

asthemodelsaysthatexothermshouldoccur,thedifference

iscalculatedtoidentifywhetherithasoccurred.

FilteringPerformance

Amalfunctionoftheaftertreatmentdieselparticulatelter

(DPF)canbedetectedbyanalysingthepressuredropoverthe

aftertreatmentDPF .DuringtheaftertreatmentDPFevaluation,

FuelSystem

TheD13Lengineusesaunitinjectorsystem(asopposed

toarailinjectorsystem)toinjectfuelinthecylinders.The

unitinjectorsarenotequippedwithanypressuresensors

andthereforeitisnotpossibletomeasurefuelpressure.

Diagnosticsofthefuelinjectionsystemisdoneusingthe

IdleSpeed,RationalityMonitors

Thetargetidleenginespeed(RPM)andfuelinjectionquantity

aremonitoredintheidlecontrolsystem.Thediagnosis

monitorscomparethemeasuredenginespeed(RPM)

(averagedovereachenginecycle)andtargetidleengine

speed(RPM).Theaccumulateddifferenceisaveragedovera

numberofrevolutions.Iftheaverageddifferenceisaboveor

IntakeManifoldPressure(IMP)ControlSystem

AIMPsensorlocatedintheintakemanifoldisusedto

measureIMP .TheIMPsystemismonitoredbycomparing

target/estimatedIMPwithactualmeasuredpressureduring

certainenginespeed(RPM)orload.

Thetarget/estimatedIMPiscontinuouslycalculatedbasedon

enginespeedandfuelangleandadjustedfortheinuenceof

variablegeometryturbocharger(VGT)nozzleposition,exhaust

gasrecirculation(EGR)positionandbarometricpressure

(BARO).

thelowerandupperlimitingvaluesofthemeasuredpressure

droparecalculated.Ifthepressuredropislowerorhigher

thanexpectedafaultindicationoccurs.

crankshaftposition(CKP)sensor.Theywheelofthe

enginehasslotsmachinedat6degreeintervalsaroundits

circumference.Threegapswheretwoslotsaremissing,are

equallyspacedarounditscircumferencealso.Thethreegaps

areusedtoidentifythenextcylinderinringorder.

belowthedenedfaultlimits,diagnostictroublecodes(DTCs)

willbesetforhighfaultandforlowfault,respectively.

Thesameholdstrueforthefuelquantity.Theaccumulated

fuelvalueisaveragedoveranumberofrevolutions.Ifthe

averageddifferenceisabove,DTCswillbesetforhighfault.

9

Group28

Misre

OnBoardDiagnostic(OBD)Monitors

ThemisremonitorisdisabledduringPowerTakeOff(PTO)

operation.Itisactiveduringpositivebraketorque,idle,and

highidle.Enginemisreeventsaremonitoredbymeasuring

toothtimesonthecrankwheelthatindicatescombustion

accelerationineachcylinder.Itisalsopossibletocomparethe

previousaccelerationcontributiononeachcylinderinorderto

examineiftherehasbeenamisreornot.

MissingSubstrate

Theaftertreatmentdieselparticulatelter(DPF)is

backpressuremonitored.Thismonitoringisusedtodetermine

Over-boost

Ifthemeasuredintakemanifoldpressure(IMP)isoverthe

deviationupperlimitthenthehighboostaveragecalculationis

positive.IfthemeasuredIMPisbelowthedeviationupperlimit

ParkingBrakeSwitch,Overview

Theparkingbrakeswitchisapressureswitchthatisphysically

connectedtothevehicle’sparkingbrakepneumaticcircuitand

isusedtodetermineiftheparkingbrakeisappliedorreleased.

Theparkingbrakeswitchsignalisreceivedbythevehicle

electroniccontrolunit(VECU).Whenthevehicle’sparking

Aftermonitoringmisreeventsduringidleconditionsforthe

accumulationoflessthan15seconds,thepercentageof

misreisevaluated.Ifthepercentageofmisreexceedsthe

thresholdlimit,themisrediagnostictroublecode(DTC)will

besetforthefault.

whethertheaftertreatmentDPFiseitherclogged,missingor

signicantlycracked.

thenthehighboostintegrationisnegative.Iftheintegrated

valueexceedsthemaximumlimitafaultforhighIMPisset.

brakeisappliedagroundsignalisappliedtotheinputandthe

VECUacknowledgestheparkingbrakeasbeingapplied.The

parkingbrakeswitchsignalisprovidedtotheenginecontrol

module(ECM)viatheSAEJ1939datalink.

PowerTake-off(PTO)EnableSwitch,Overview

ThePTOenableswitchisaninputthatisreadbythevehicle

electroniccontrolunit(VECU).When12Visappliedtothe

inputtheVECUacknowledgesthePTOfunctionisbeing

SAEJ1939(CAN1)DataLink,Overview

Communicationbetweentheelectroniccontrolunits(ECUs)is

performedviathevehicle’sSAEJ1939(CAN1)datalinkandis

accessiblefordiagnosticsthroughthevehicle’sSAEJ1939-13

datalinkconnector(DLC).Thisdatalinkisthemainpowertrain

communicationbus.

ThermostatMonitor

Thisfeaturemonitorsandcomparestheenginecoolant

temperature(ECT),enginespeed(RPM),enginetorque,fan

Time/DateOverview

Thetimeanddateiscalculatedfromaninternalclockwithin

theinstrumentcluster.Theinternalclockisbackedupby

aninternalbatterythereforethetimeanddateisretained

evenwhenvehiclebatterysupplytotheinstrumentclusteris

commandedon.ThePTOEnableswitchsignalisprovided

totheenginecontrolmodule(ECM)fromtheVECUbyvia

theSAEJ1939datalink.

Diagnostictroublecodes(DTCs)aresetforthisdatalinkwhen

anECUisfoundtonotbecommunicatingorrecognizedonthe

datalink(offbusmode)orwhenthereisanabnormalrateof

occurrenceoferrorsonthedatalink.

speedandambientairtemperature(AA T)toconcludewhen

thethermostatmaybestuckopenorclosed.

removed.Thetimeanddatesignalisprovidedtotheengine

controlmodule(ECM)fromtheinstrumentclusterviatheSAE

J1939datalink.

VariableGeometryTurbocharger(VGT)FeedbackControl

Thisfunctiondetects:

Ifanyofthefeedbackcontrolloopsarenotachieved.

Iffeedbackcontrolmodeisinhibited.

Iftheactuatorshaveusedupalltheadjustmentallowedwhen

infeedbackmode.

10

Group28

VehicleSpeedSensor(VSS),Overview

OnBoardDiagnostic(OBD)Monitors

Thevehicleroadspeediscalculatedbythevehicleelectronic

controlunit(VECU).Thesourceforcalculatingvehicleroad

speedcanbederivedfrommultiplesourcesdependingon

vehicleequipment.Sometrucksmayuseadedicatedspeed

Under-boost

Ifthemeasuredintakemanifoldpressure(IMP)islessthanthe

deviationlowerlimitthenthelowboostaveragecalculationis

negative.IfthemeasuredIMPisabovethedeviationlower

VariableGeometryTurbocharger(VGT)SlowResponse

TheVGTactuatorreportsafaulttotheenginecontrolmodule

(ECM)whenithasdetectedthattheVGTnozzleisnot

moving,orifithasnotbeenabletoclosetheset-pointerrorto

acceptablelimits.

sensor(whichmaybeinductiveorhalleffecttype)andsome

mayusethetransmissionoutputshaftspeed(OSS)sensor

signalwhichiscommunicatedacrosstheSAEJ1939datalink.

limitthenthelowboostintegrationispositive.Iftheintegrated

valuebecomeslessthantheminimumlimitafaultforlowIMP

isset.

11

Group28

SensorandComponentInformation

SectionContent

OnBoardDiagnostic(OBD)Monitors

•“AcceleratorPedalPosition(APP)Sensor,CircuitMonitors”,

page14

•“AcceleratorPedalPosition(APP)Sensor,Rationality

Monitors”,page14

•“AftertreatmentControlModule(ACM),Rationality

Monitors”,page14

•“AftertreatmentControlModule(ACM)5VoltSupply1,

CircuitMonitors”,page14

•“AftertreatmentControlModule(ACM)5VoltSupply2,

CircuitMonitors”,page14

•“AftertreatmentControlModule(ACM)ActuatorSupply

Voltage1,CircuitMonitors”,page14

•“AftertreatmentControlModule(ACM)ActuatorSupply

Voltage2,CircuitMonitors”,page14

•“AftertreatmentDieselExhaustFluid(DEF)DosingValve,

CircuitMonitors”,page14

•“AftertreatmentDieselExhaustFluid(DEF)DosingValve,

RationalityMonitors”,page14

•“AftertreatmentDieselExhaustFluid(DEF)Pressure

Sensor,CircuitMonitors”,page14

•“AftertreatmentDieselExhaustFluid(DEF)Pressure

Sensor,RationalityMonitors”,page15

•“AftertreatmentDieselExhaustFluid(DEF)Pump,Circuit

Monitors”,page15

•“AftertreatmentDieselExhaustFluid(DEF)Pump,

RationalityMonitors”,page15

•“AftertreatmentDieselExhaustFluid(DEF)ReturnValue,

CircuitMonitors”,page15

•“AftertreatmentDieselExhaustFluid(DEF)ReturnValve,

RationalityMonitors”,page15

•“AftertreatmentDieselExhaustFluid(DEF)T ankHeater

Valve,CircuitMonitors”,page15

•“AftertreatmentDieselExhaustFluid(DEF)T ankHeater

Valve,RationalityMonitors”,page15

•“AftertreatmentDieselExhaustFluid(DEF)T ank

TemperatureSensor,CircuitMonitors”,page15

•“AftertreatmentDieselExhaustFluid(DEF)T ank

TemperatureSensor,RationalityMonitors”,page15

•“AftertreatmentDieselParticulateFilter(DPF),Differential

PressureSensor,CircuitMonitoring”,page15

•“AftertreatementDieselParticulateFilter(DPF)Differential

PressureSensor,RationalityMonitors”,page16

•“AftertreatmentFuelPressureSensor,CircuitMonitors”,

page16

•“AftertreatmentFuelShutoffValve,CircuitMonitors”,page

16

•“AftertreatmentHydrocarbonDoser,CircuitMonitors”,page

16

12

•“AftertreatmentNitrogenOxides(NOx)Sensors,Circuit

Monitors”,page16

•“AftertreatmentNitrogenOxides(NOx)Sensors,Rationality

Monitors”,page16

•“AmbientAirTemperature(AAT)Sensor ,CircuitMonitors”,

page16

•“AmbientAirT emperature(AA T)Sensor,Rationality

Monitors”,page16

•“BarometricPressure(Baro)SensorCircuitMonitoring”,

page16

•“BarometricPressure(BARO)SensorRationalityMonitors”,

page16

•“CamshaftPosition(CMP)Sensor,CircuitMonitors”,page

17

•“CamshaftPosition(CMP)Sensor,RationalityMonitors”,

page17

•“CrankcasePressure(CCP)Sensor,CircuitMonitors”,

page17

•“CrankcasePressure(CCP)Sensor,RationalityMonitors”,

page17

•“CrankshaftPosition(CKP)Sensor,CircuitMonitors”,page

17

•“CrankshaftPosition(CKP)Sensor,RationalityMonitors”,

page17

•“EngineControlModule(ECM)5VoltSupplyA,Circuit

Monitors”,page17

•“EngineControlModule(ECM)5VoltSupplyB,Circuit

Monitors”,page17

•“EngineCoolantT emperature(ECT)Sensor,Circuit

Monitors”,page17

•“EngineCoolantT emperature(ECT)Sensor,Rationality

Monitors”,page17

•“EngineExhaustGasRecirculation(EGR),Differential

PressureSensor,CircuitMonitoring”,page17

•“EngineExhaustGasRecirculation(EGR),Differential

PressureSensor,RationalityMonitors”,page18

•“EngineExhaustGasRecirculation(EGR)T emperature

Sensor,CircuitMonitors”,page18

•“EngineExhaustGasRecirculation(EGR)T emperature

Sensor,RationalityMonitors”,page18

•“EngineExhaustGasTemperature(EGT)Sensors,Circuit

Monitors”,page18

Group28

OnBoardDiagnostic(OBD)Monitors

•“EngineExhaustGasT emperature(EGT)Sensors,

RationalityMonitors”,page18

•“EngineTurbochargerCompressorBypassValveSolenoid,

CircuitMonitors”,page18

•“EngineTurbochargerCompressorBypassValveSolenoid,

RationalityMonitors”,page18

•“EngineTurbochargerCompressorOutletT emperature

Sensor,CircuitMonitors”,page18

•“EngineTurbochargerCompressorOutletT emperature

Sensor,RationalityMonitors”,page18

•“EngineTurbochargerSpeedSensor,CircuitMonitors”,

page19

•“EngineTurbochargerSpeedSensor,RationalityMonitors”,

page19

•“EngineVariableGeometryTurbocharger(VGT)Actuator

Position,CircuitMonitors”,page19

•“EngineVariableGeometryTurbocharger(VGT)Actuator

Position,RationalityMonitors”,page19

•“ExhaustGasRecirculation(EGR)ValveActuator,Circuit

Monitors”,page19

•“ExhaustGasRecirculation(EGR)ValveActuator,

RationalityMonitors”,page19

•“Fan,CircuitMonitors”,page19

•“Fan,RationalityMonitors”,page19

•“Injector,CircuitMonitors”,page20

•“IntakeAirTemperature(IAT)Sensor,CircuitMonitors”,

page20

•“IntakeAirT emperature(IAT)Sensor ,RationalityMonitors”,

page20

•“IntakeManifoldPressure(IMP)SensorCircuitMonitoring”,

page20

•“IntakeManifoldPressure(IMP)SensorRationality

Monitors”,page20

•“Injector,RationalityMonitors”,page20

•“ParkingBrakeSwitch,CircuitMonitors”,page20

•“ParkingBrakeSwitch,RationalityMonitors”,page20

•“PowerT ake-off(PTO)EnableSwitch,CircuitMonitors”,

page20

•“PowerT ake-off(PTO)EnableSwitch,Rationality

Monitors”,page20

•“SAEJ1939(CAN1)DataLink,CircuitMonitors”,page21

•“SAEJ1939(CAN1)DataLink,RationalityMonitors”,page

21

•“SAEJ1939(CAN2)DataLink,Overview”,page21

•“SAEJ1939(CAN2)DataLink,CircuitMonitors”,page21

•“SAEJ1939(CAN2)DataLink,RationalityMonitors”,page

21

•“Time/Date,CircuitMonitoring”,page21

•“Time/Date,RationalityMonitoring”,page21

•“VehicleSpeedSensor(VSS),CircuitMonitors”,page21

•“VehicleSpeedSensor(VSS),RationalityMonitors”,page

21

13

Group28

AcceleratorPedalPosition(APP)Sensor,CircuitMonitors

OnBoardDiagnostic(OBD)Monitors

Bothsignalsarecontinuouslymonitored(sampled)bythe

vehicleelectroniccontrolunit(VECU)at50msintervalsto

detectanydistortionordisruptionofthesesignals.Signals

detectedasinvalidforaperiodextendingover500mstrigger

activefaultsthatarebroadcastbytheVECU.TheAPPsensor

circuitsaremonitoredtoidentifythefollowing:

AcceleratorPedalPosition(APP)Sensor,RationalityMonitors

Thevehicleelectroniccontrolunit(VECU)simultaneously

readstheAPPsensorandtheidlevalidation(IV)switchvalues

andperformingaplausibilitytoverifysensorperformance.

AftertreatmentControlModule(ACM),RationalityMonitors

IfelectricalpowertotheACMislostorverylowtheACMwill

stopfunctioning.Aftertreatmentdieselexhaustuid(DEF)

dosingwillstop.Theenginecontrolmodule(ECM)willloga

AftertreatmentControlModule(ACM)5VoltSupply1,CircuitMonitors

TheACM5voltsupply“1”circuitismonitoredtoidentifythe

following:

•Circuitlow

AftertreatmentControlModule(ACM)5VoltSupply2,CircuitMonitors

•Circuitopen

•Circuitlow

•Circuithigh

diagnostictroublecode(DTC)indicatingSAEJ1939datalink

(subdatalinkCAN2)communicationsfromtheACMismissing.

•Circuithigh

Wheneitherfaultisdetectedthesupplyisdisabled.

TheACM5voltsupply“2”circuitismonitoredtoidentifythe

following:

•Circuitlow

AftertreatmentControlModule(ACM)ActuatorSupplyV oltage1,CircuitMonitors

TheACMactuatorsupplyvoltage“1”circuitismonitoredto

identifythefollowing:

•Circuitopen

•Circuithigh

Whencircuithighorcircuitlowfaultsaredetectedthesupplyis

disabled.

•Circuithigh

Whencircuithighorcircuitlowfaultsaredetectedthesupplyis

disabled.

•Circuitlow

AftertreatmentControlModule(ACM)ActuatorSupplyV oltage2,CircuitMonitors

TheACMactuatorsupplyvoltage“2”circuitismonitoredto

identifythefollowing:

•Circuitopen

•Circuithigh

Whencircuithighorcircuitlowfaultsaredetectedthesupplyis

disabled.

•Circuitlow

AftertreatmentDieselExhaustFluid(DEF)DosingValve,CircuitMonitors

TheaftertreatmentDEFdosingvalvecircuitsaremonitored

toidentifythefollowing:

•Circuitlow

•Circuithigh

•Circuitopen

AftertreatmentDieselExhaustFluid(DEF)DosingValve,RationalityMonitors

TheaftertreatmentDEFpumpcontrolvalueismonitoredwhen

theaftertreatmentDEFdosingvalvedutycyclehasbeen

aboveapredeterminedthreshold,forashortduration.Ifthe

AftertreatmentDieselExhaustFluid(DEF)PressureSensor,CircuitMonitors

TheaftertreatmentDEFpressuresensorcircuitsaremonitored

toidentifythefollowing:

•Circuitopen/circuithigh

14

controlvalueistoolowadiagnostictroublecode(DTC)isset.

Thisindicatesacloggeddosingvalveorblockedaftertreatment

DEFline.

•Outofrangelow

•Outofrangehigh

•Circuitlow

Group28

AftertreatmentDieselExhaustFluid(DEF)PressureSensor,RationalityMonitors

OnBoardDiagnostic(OBD)Monitors

Duringpressurebuildup(aftertreatmentDEFpumpruns

withmaximumspeedwithnodosing)ifselectivecatalytic

reduction(SCR)systempressurestayslowforapreset

duration,adiagnostictroublecode(DTC)isset.Pressureis

AftertreatmentDieselExhaustFluid(DEF)Pump,CircuitMonitors

TheaftertreatmentDEFpumpcircuitsaremonitoredtoidentify

thefollowing:

•Circuitopen

AftertreatmentDieselExhaustFluid(DEF)Pump,RationalityMonitors

TheaftertreatmentDEFpumpgetsasignalfortherequired

pumpspeedfromtheaftertreatmentcontrolmodule(ACM).

Thepumphasinternaldiagnosiswhichevaluatesthepump

speedquality.Ifthepumpspeeddeviatesfromcommanded

speedforsometimeadiagnostictroublecode(DTC)isset.

AftertreatmentDieselExhaustFluid(DEF)ReturnValue,CircuitMonitors

TheaftertreatmentDEFreturnvalvecircuitsaremonitored

toidentifythefollowing:

alsoevaluatedduringnormaloperationwithaftertreatment

DEFpumpturnedoff.Ifthepressureistoohighforapreset

durationaDTCisset

•Circuitlow

•Circuithigh

•Batteryvoltage

TheaftertreatmentDEFreturnvalueismonitoredduring

specicconditionstoidentifyifaleakinthesystemis

present.ADTCissetifaleakconditionisidentied.The

leakcanbeinvisible(internaltothepumporvalve)orvisible

(aftertreatmentDEFlinesorconnections).

•Circuitlow

•Circuithigh

•Circuitopen

AftertreatmentDieselExhaustFluid(DEF)ReturnValve,RationalityMonitors

DuringreverseDEFowconditionsonapressurizedselective

catalyticreduction(SCR)system,pressuredropisevaluated.

IfDEFpressuredropistoolow,theaftertreatmentDEFreturn

AftertreatmentDieselExhaustFluid(DEF)T ankHeaterValve,CircuitMonitors

TheaftertreatmentDEFtankheatervalvecircuitsare

monitoredtoidentifythefollowing:

valveisconsideredtohaveamechanicalfault(blockedor

stuck)andadiagnostictroublecode(DTC)isset.

•Circuitlow

•Circuithigh

•Circuitopen

AftertreatmentDieselExhaustFluid(DEF)TankHeaterValve,RationalityMonitors

AftertreatmentDEFtankheatervalvediagnosticsevaluatesif

tankheateristakingplace,whendemanded.Acomparison

ofaninitialaftertreatmentDEFtanktemperaturewithout

heatingandthenatanktemperaturewithaftertreatmentDEF

AftertreatmentDieselExhaustFluid(DEF)TankTemperatureSensor,CircuitMonitors

TheaftertreatmentDEFtanktemperaturesensorcircuitsare

monitoredtoidentifythefollowing:

•Circuitopen/circuithigh

AftertreatmentDieselExhaustFluid(DEF)TankTemperatureSensor,RationalityMonitors

AftertreatementDEFtanktemperatureischeckedforhigh

frequencyoscillationswithhighamplitudethatissolarge

thatisphysicallyimpossibleforatemperaturetoachieve.A

faultissetwhenthisbehaviorisobserved.Aftertreatement

DEFtanktemperaturediagnosticsisalsoevaluatingifthe

tankheatervalveopenforsomedurationisperformed.If

theincreaseintemperatureissmallerthanthethreshold,a

diagnostictroublecode(DTC)isset.

•Outofrangelow

•Outofrangehigh

•Circuitlow

aftertreatementDEFtemperatureistoohighandwillactivate

reverseow(toprotectaftertreatmentselectivecatalytic

reduction(SCR)systemcomponents)andatimerisstarted.If

thetemperaturestayshighforashortduration,afaultisset.

AftertreatmentDieselParticulateFilter(DPF),DifferentialPressureSensor,CircuitMonitoring

TheaftertreatmentDPFdifferentialpressuresensorcircuits

aremonitoredtoidentifythefollowing:

•Circuithigh

•Circuitopen

•Circuitlow

15

Group28

AftertreatementDieselParticulateFilter(DPF)DifferentialPressureSensor,RationalityMonitors

OnBoardDiagnostic(OBD)Monitors

Theevaluationofthepressure-dropsensoriscarriedoutas

follows.Whenthepressuremodelindicatesalowpressurethe

sensorshouldalsoshowalowpressureotherwisethereisa

(large)positiveoffsetfault.Combiningthiswithacheckthat

AftertreatmentFuelPressureSensor,CircuitMonitors

Theaftertreatmentfuelpressuresensorcircuitsaremonitored

toidentifythefollowing:

•Circuitopen

•Outofrangelow

AftertreatmentFuelShutoffValve,CircuitMonitors

Theaftertreatmentfuelshutoffvalvecircuitsaremonitored

toidentifythefollowing:

•Circuitopen

AftertreatmentHydrocarbonDoser,CircuitMonitors

Theaftertreatmenthydrocarbondosercircuitsaremonitored

toidentifythefollowing:

•Circuitopen

AftertreatmentNitrogenOxides(NOx)Sensors,CircuitMonitors

TheNOxsensorscircuitsaremonitoredtoidentifythe

following:

•opencircuit

thesensorshowshighvalueswhenthemodelishighgivesa

sensorstuckcheck.Thesecondstepcanalsond(large)

negativeoffsetfaults.

•Outofrangehigh

•Circuitlow

•Circuithigh

•Circuitlow

•Circuithigh

•Circuitlow

•Circuithigh

•highvoltage

•circuitloworhigh

AftertreatmentNitrogenOxides(NOx)Sensors,RationalityMonitors

Therearetwodifferentmonitorswhichdiagnoseaftertreatment

NOxsensorrationality .Onecomparestheaftertreatment

intakeNOxsensorvaluetoacalculatedengineNOxoutput

value.Thisisonlyperformwithinagivensetofpredetermined

conditions.IftheNOxsensorvalueisnotdeemedwithin

range,afaultyisset.

AmbientAirT emperature(AAT)Sensor,CircuitMonitors

TheAA Tsensorcircuitsaremonitoredbytheinstrument

clustermoduletoidentifythefollowing:

•Currentbelownormaloropen

AmbientAirT emperature(AAT)Sensor,RationalityMonitors

Plausibilityofthesensorvalueisdeterminedbycomparingthe

AATwiththeintakeairtemperature(IA T).

BarometricPressure(Baro)SensorCircuitMonitoring

TheBAROsensorcircuitsaremonitoredtoidentifythe

following:

•Circuitlow

BarometricPressure(BARO)SensorRationalityMonitors

TheothercomparestheaftertreatmentintakeNOxsensor

valuetotheaftertreatmentoutletNOxsensorvalueto

determinerationality.Thisisonlyperformwithinagivensetof

predeterminedconditions.IfeitheroftheaftertreatmentNOx

sensorvaluesaredeemednotplausible,adiagnosticfaulty

code(DTC)isset.

•Currentabovenormalorgrounded

NoneoftheAATsensorcircuitsaremonitoredbytheECM

ortheVECU.

•Circuithigh

•Circuitopen

TheBAROsensor ,intakemanifoldpressure(IMP)sensor,

andcrankcasepressure(CCP)sensorshouldshowthesame

pressurewhenenginespeed(RPM)andtorqueislow.The

diagnosiscalculatesthedifferencebetween:

•BAROandIMP

16

•BAROandCCP

•IMPandCCP

Thesecomparisonsareusedtoidentifydefects.

Group28

CamshaftPosition(CMP)Sensor,CircuitMonitors

OnBoardDiagnostic(OBD)Monitors

TheCMPsensorcircuitsaremonitoredtoidentifythefollowing:

•Circuitopen

CamshaftPosition(CMP)Sensor,RationalityMonitors

TheCMPsensorismonitoredbycomparingit’soutputsignal

totheoutputsignalofthecrankshaftposition(CMP)sensor.

ThiscomparisonisusedtoidentifyabnormalCKPandCMP

CrankcasePressure(CCP)Sensor,CircuitMonitors

TheCCPcircuitsaremonitoredtoidentifythefollowing:

•Circuitopen

•Outofrangelow

CrankcasePressure(CCP)Sensor,RationalityMonitors

TheBAROsensor ,intakemanifoldpressure(IMP)sensor,

andcrankcasepressure(CCP)sensorshouldshowthesame

pressurewhenenginespeed(RPM)andtorqueislow.The

diagnosiscalculatesthedifferencebetween:

CrankshaftPosition(CKP)Sensor,CircuitMonitors

TheCKPsensorcircuitsaremonitoredtoidentifythefollowing:

•Circuitopen

•Circuitlow

•Circuithigh

sensorfrequencyaswellascamshafttocrankshaftphasing

(calculatedtopdeadcenter(TDC).Abnormalsensorfrequency

andshaftphasinganglewillsetfaults.

•Outofrangehigh

•Circuitlow

•Circuithigh

•BAROandIMP

•BAROandCCP

•IMPandCCP

•Circuitlow

•Circuithigh

CrankshaftPosition(CKP)Sensor,RationalityMonitors

TheCKPsensorismonitoredbycomparingit’soutputsignal

totheoutputsignalofthecamshaftposition(CMP)sensor.

ThiscomparisonisusedtoidentifyabnormalCKPandCMP

EngineControlModule(ECM)5VoltSupplyA,CircuitMonitors

TheECM5voltsupply“A”circuitismonitoredtoidentifythe

following:

•Circuitlow

EngineControlModule(ECM)5VoltSupplyB,CircuitMonitors

TheECM5voltsupply“B”circuitismonitoredtoidentifythe

following:

•Circuitlow

EngineCoolantT emperature(ECT)Sensor,CircuitMonitors

TheECTsensorcircuitsaremonitoredtoidentifythefollowing:

•Circuitopen

•Outofrangelow

EngineCoolantT emperature(ECT)Sensor,RationalityMonitors

TheECTsensorismonitoredforrationalityatkeyONby

comparingtheECTwithengineoiltemperature(EOT)and

engineturbochargercompressoroutlettemperature.For

sensorfrequencyaswellascamshafttocrankshaftphasing

(calculatedtopdeadcenter(TDC).Abnormalsensorfrequency

andshaftphasinganglewillsetfaults.

•Circuithigh

Wheneitherfaultisdetectedthesupplyisdisabled.

•Circuithigh

Wheneitherfaultisdetectedthesupplyisdisabled.

•Circuitlow

•Circuithigh

moreinformationreferto“EngineCoolantT emperature(ECT)

SensorOverview”,page8.

EngineExhaustGasRecirculation(EGR),DifferentialPressureSensor,CircuitMonitoring

TheengineEGRdifferentialpressuresensorcircuitsare

monitoredtoidentifythefollowing:

•Circuitopen

•Circuitlow

•Circuithigh

17

Group28

EngineExhaustGasRecirculation(EGR),DifferentialPressureSensor,RationalityMonitors

OnBoardDiagnostic(OBD)Monitors

EngineEGRdifferentialpressureisestimatedbasedonengine

speed(RPM)ortorqueandcorrectedforvariablegeometry

turbocharger(VGT)position,EGRvalveposition,intake

manifoldpressure(IMP)andbarometricpressure(BARO).

ThisestimatedengineEGRdifferentialpressureiscompared

withactualmeasuredpressure.Thiscomparisonisusedto

EngineExhaustGasRecirculation(EGR)TemperatureSensor,CircuitMonitors

TheengineEGRtemperaturesensorcircuitsaremonitored

toidentifythefollowing:

•Circuitopen

identifyiftheengineEGRdifferentialpressuresensorisfaulty.

DuringcertainconditionstheengineEGRdifferentialpressure

shouldbezero.TheengineEGRdifferentialpressuresensor

isalsomonitoredduringtheseconditionstoverifythatthe

engineEGRisclosingasnecessaryaswellastoverifyproper

engineEGRdifferentialpressuresensoroperation.

•Outofrangehigh

•Circuitlow

•Circuithigh

•Outofrangelow

EngineExhaustGasRecirculation(EGR)TemperatureSensor,RationalityMonitors

ForinformationabouttheengineEGRtemperaturesensor

rationalityreferto

RationalityMonitors”,page20.

EngineExhaustGasTemperature(EGT)Sensors,CircuitMonitors

Theexhaustsystemisequippedwiththefollowingthree

engineEGTsensors:

1EngineEGTsensor

2Aftertreatmentdieselparticulatelter(DPF)intake

temperaturesensor

3AftertreatmentDPFoutlettemperaturesensor

“IntakeAirT emperature(IAT)Sensor,

TheengineEGTsensorcircuitsaremonitoredtoidentifythe

following:

•Circuitopen

•Outofrangelow

•Outofrangehigh

•Circuitlow

•Circuithigh

EngineExhaustGasTemperature(EGT)Sensors,RationalityMonitors

Therearetwoindependentteststhatcanevaluatetemperature

sensorplausibilityintheexhaustsystem.Oneisperformed

whilestationaryandtheotherisperformedatcoldstart.Each

sensorsoutputvalueisusedtocompareagainsttheother

EngineTurbochargerCompressorBypassValveSolenoid,CircuitMonitors

Theengineturbochargercompressorbypassvalvesolenoid

circuitsaremonitoredtoidentifythefollowing:

sensorvalues.Thisinturnisusedtodeterminetheplausibility

ofthesensors.Ifthetemperaturesreceivedbyanyofthe

sensorsisdeemedtobeoutofrange,aplausibilityfaultisset.

•Circuitlow

•Circuithigh

•Circuitopen

EngineTurbochargerCompressorBypassValveSolenoid,RationalityMonitors

Theengineturbochargercompressorbypassvalvesolenoid

faultdetectionisperformedduringthephasewherethevalve

EngineTurbochargerCompressorOutletTemperatureSensor,CircuitMonitors

Theengineturbochargercompressoroutlettemperature

sensorcircuitsaremonitoredtoidentifythefollowing:

•Circuitopen

isopened,theintakemanifoldpressure(IMP)ismonitored

andcomparedtothemaximumallowed.

•Outofrangehigh

•Circuitlow

•Circuithigh

•Outofrangelow

EngineTurbochargerCompressorOutletTemperatureSensor,RationalityMonitors

Theengineturbochargercompressoroutlettemperature

sensor,ismonitoredforrationalitybycomparingthesensor

outputvalueagainstanestimatedtemperaturebasedon

ambientairtemperature(AAT),intakemanifoldpressure(IMP),

18

barometricpressure(BARO)andacalculatedefciencyof

theturbocharger.

Group28

EngineTurbochargerSpeedSensor,CircuitMonitors

OnBoardDiagnostic(OBD)Monitors

Theengineturbochargerspeedsensorcircuitsaremonitored

toidentifythefollowing:

•Circuitopen

•Outofrangehigh

•Circuitlow

•Circuithigh

•Outofrangelow

EngineTurbochargerSpeedSensor,RationalityMonitors

Anengineturbochargerspeedsensortestisrunwithina

setofconditionstoevaluatethespeedsensoroutputvalue.

Theengineturbochargerspeedsensorvalueiscomparedto

EngineVariableGeometryT urbocharger(VGT)ActuatorPosition,CircuitMonitors

TheengineVGTactuatorpositionpositionactuatorcircuitsare

monitoredtoidentifythefollowing:

acalculatedspeedvaluethatisbasedonintakemanifold

pressure(IMP).Ifthesensoroutputvalueisdeemedoutof

rangeafaultisset.

•Circuitlow

•Circuithigh

•Circuitopen

EngineVariableGeometryT urbocharger(VGT)ActuatorPosition,RationalityMonitors

TheengineVGThasasmartactuatorpositionthatischecked

withinSmartRemoteActuator(SRA)unit.EngineVGT

ExhaustGasRecirculation(EGR)ValveActuator,CircuitMonitors

TheEGRvalveactuatorcircuitsaremonitoredtoidentifythe

following:

positionisthencommunicatedtoenginecontrolmodule(ECM)

viatheSAEJ1939(CAN)datalink.

•Circuitlow

•Circuithigh

•Circuitopen

ExhaustGasRecirculation(EGR)ValveActuator,RationalityMonitors

WhenEGRvalveiscommandedtobeclosed,theEGR

differentialpressuresensorismonitoredandexpectsno

pressuredifferencebetweenupstreamanddownstreamof

EGRventure.Afaultoccurswhendifferentialpressuregreater

thanafaultlimitduetoastuck-openEGRvalveoraleaking

Fan,CircuitMonitors

Thefancircuitsaremonitoredtoidentifythefollowing:

•Circuitopen

•Circuitlow

•Circuithigh

Electricalpowerissuppliedtothefandrivefromthechassis.

Circuitmonitoringisperformedonthelowsidedrive.Thefan

circuitryissuch,thatwhenthelowsidedriveisopenedthefan

willbeon.Closingthepathtogroundcausesthefantoturnoff.

Sincethelowsideismonitoredthechecksareonlyperformed

undercertainconditions:

•Opencircuitmonitoringisonlyperformedwhenthefanis

ON(opencircuitlow).Theopencircuitfaultdetectswhen

powerisnotsuppliedtothehighsideofthefandrive

EGRvalveisdetectedforaperiodoftime.Astuck-closed

EGRvalvecanbedetectedifthedifferencefromtheactual

burnedfractiontothedemandedburnedfractionislower

thanafaultlimitforaperiodoftime.ThereisnoEGRV alve

positionfeedback.

•CircuitlowmonitoringisonlyperformedwhenthefanisON

(opencircuitlow).Thecircuitlowfaultdetectswhenthelow

sidecontrollineisshortedtoground

•Circuithighmonitoringisonlyperformedwhenthefanis

OFF(closedcircuitlow).Thecircuithighfaultdetectsan

over-currentconditiononthelowsidecontrolline.Ifthis

over-currentconditionisdetectedthedriveisdisabled(fan

ON)untilthekeyiscycled

Somefansalsohaveafanspeedsensor.Ifthefanisequipped

withaspeedsensorcircuithighisalsosupported.This

diagnosticisusedforanyelectricalcauseofamissingsignal.

Ifthefandoesnotsupportaspeedsensorthiscircuitmonitor

isnotsupported.

Fan,RationalityMonitors

Fanspeediscalculatedfromthecommandedpercent

engagement,theenginespeedandthefandriveratio.Ifafan

speedsensorispresentthesensorspeedsignalissent.

19

Group28

Injector,CircuitMonitors

OnBoardDiagnostic(OBD)Monitors

Theinjectorcircuitsaremonitoredtoidentifythefollowing:

•Circuitopen

IntakeAirT emperature(IAT)Sensor,CircuitMonitors

TheIATsensorcircuitsaremonitoredtoidentifythefollowing:

•Circuitopen

•Outofrangelow

IntakeAirT emperature(IAT)Sensor,RationalityMonitors

TheIATsensorisusedtocalculateenginechargeaircooler

(CAC)ambientairtemperature(AA T).TheCACAATcanbe

calculatedinthetwofollowingways,

•Usingengineexhaustexhaustgasrecirculation(EGR)

temperatureandIATwiththeircorrespondingmassow

rates.

IntakeManifoldPressure(IMP)SensorCircuitMonitoring

TheIMPsensorcircuitsaremonitoredtoidentifythefollowing:

•Circuitopen

•Outofrangelow

IntakeManifoldPressure(IMP)SensorRationalityMonitors

•Circuitlow

•Circuithigh

•Circuitlow

•Circuithigh

•UsingAAT ,engineturbochargercompressoroutlet

temperatureandthemassairow(MAF)rate.

Ifthereisamismatchinthesetwoestimatedtemperatures

itisconcludedthatthemostprobablycauseisonofthe

temperaturesensors.Thesystemthenrationalizeswhich

sensorisfaulty.

•Outofrangehigh

•Circuitlow

•Circuithigh

TheIMPsensor,BAROsensor,andcrankcasepressure(CCP)

sensorshouldshowthesamepressurewhenenginespeed

andtorqueislow.Thediagnosiscalculatesthedifference

between:

Injector,RationalityMonitors

Forinjectorrationalitymonitorinformationreferto“Fuel

System”,page9.

ParkingBrakeSwitch,CircuitMonitors

Thevehicleelectroniccontrolunit(VECU)doesnotsupport

comprehensivecircuitmonitoringonparkingbrakeswitch.

ParkingBrakeSwitch,RationalityMonitors

Thevehicleelectroniccontrolunit(VECU)doesnotsupport

rationalitymonitorsontheparkingbrakeswitch.

PowerTake-off(PTO)EnableSwitch,CircuitMonitors

Thevehicleelectroniccontrolunit(VECU)doesnotsupport

comprehensivecircuitmonitoringforthePTOenableswitch

input.However,basedonthetypeoffailuremodestothe

circuitthePTOoperationwillbeorbecomenon-functional.

Thefailuremodebehaviorsaredenedas:

•ShorttoGround–Ashortcircuittogroundwillresultina

non-functionalPTOoperation.

•BAROandIMP

•BAROandCCP

•IMPandCCP

Thesecomparisonsareusedtoidentifydefects.

•ShorttoBattery–Ashortcircuittobatteryvoltagewill

nothaveanimmediateaffecttothePTOoperation,but

willresultinanon-functionalPTOoperationafterexiting

thePTOfunctionorduringthenextVECUpowerdown/up

sequence(I.e.Cyclingoftheignitionkeyswitch).

•OpenCircuit–Anopenwillresultinanon-functionalPTO

operation.

PowerTake-off(PTO)EnableSwitch,RationalityMonitors

Thevehicleelectroniccontrolunit(VECU)doesnotsupport

rationalitymonitorsonthePTOenableswitch.

20

Group28

SAEJ1939(CAN1)DataLink,CircuitMonitors

OnBoardDiagnostic(OBD)Monitors

ErrordetectionoftheSAEJ1939(CAN1)datalinkisperformed

bymultipleelectroniccontrolunits(ECUs).AnECUdetecting

anerrorconditionsignalsthisbytransmittinganerrorag.

Thereare5typesoferrordetections:

•Biterror

SAEJ1939(CAN1)DataLink,RationalityMonitors

RationalitymonitorsdonotexistfortheSAEJ1939(CAN1)

datalink.

SAEJ1939(CAN2)DataLink,Overview

TheSAEJ1939(CAN2)datalinkisasub-datalinkthat

communicatesinformationdirectlytotheenginecontrolmodule

(ECM).There’snodirectcommunicationtootherelectronic

controlunits(ECUs)residingontheontheSAEJ1939(CAN1)

datalink.InformationthatissentacrosstheCAN2datalink

SAEJ1939(CAN2)DataLink,CircuitMonitors

ErrordetectionoftheSAEJ1939(CAN2)datalinkisperformed

bymultipleelectroniccontrolunits(ECUs).AnECUdetecting

anerrorconditionsignalsthisbytransmittinganerrorag.

Thereare5typesoferrordetections:

•Biterror

•Stufferror

•CyclicRedundancyCode(CRC)error

•Formerror

•Acknowledgementerror

canbesharedontheCAN1datalinkviatheECM.

Diagnostictroublecodes(DTCs)aresetwhenanECUisfound

tonotbecommunicatingorrecognizedonthedatalink(off

busmode)orwhenthereisanabnormalrateofoccurrenceof

errorsonthedatalink.

•Stufferror

•CyclicRedundancyCode(CRC)error

•Formerror

•Acknowledgementerror

SAEJ1939(CAN2)DataLink,RationalityMonitors

RationalitymonitorsdonotexistfortheSAEJ1939(CAN2)

datalink.

Time/Date,CircuitMonitoring

Theinstrumentclusterdoesnotsupportcomprehensivecircuit

monitoringfortheTime/Date.

Time/Date,RationalityMonitoring

Theenginecontrolmodule(ECM)doessupportrational

monitoringbycomparingtimeanddatefrominstrument

VehicleSpeedSensor(VSS),CircuitMonitors

Thecomprehensivecircuitmonitorsaresupportedbythe

vehicleelectroniccontrolunit(VECU)andaredetermined

bythevehicleroadspeedsource.Whenadedicatedspeed

sensorisused,electricalerrordetectionissupported.When

VehicleSpeedSensor(VSS),RationalityMonitors

Errordetectionisperformedbycomparinganothersource

ofvehiclespeedinformationtothecalculatedvehicleroad

speed.Atzerovehicleroadspeedanerrorisgeneratedwhen

thecomparisonvehiclespeedsource(ABS/EBS)ishigher

thanaspeciedlimit.Whenthevehicleroadspeedisgreater

thanzerothedifferencebetweenthecalculatedvehicleroad

speedandthecomparisonvehiclespeedsource(ABS/EBS)

isnotallowedtobegreaterthanaspeciedvalueorafault

isregistered.

cluster.Soaktimeisbasedonenginecoolingdownusing

temperaturesbeforeandaftersoak.

thetransmissionoutputshaftspeed(OSS)sensorisused

viatheSAEJ1939datalink,thediagnosticsarebasedona

communicationtimeoutandreceiving“errorindicator”agged

fromthetransmittingelectroniccontrolunit(ECU).

21

Group28

EngineControlModule(ECM)DiagnosticTrouble

Troubleshooting

EngineControlModule(ECM)DiagnosticTroubleCodes(DTCs)

Themanufacturerscantoolisthepreferredtoolfor

performingdiagnosticwork.Contactyourlocaldealerfor

moreinformationorvisit“www.premiumtechtool.com”.

Note:Theuseofascantoolisnecessarytoperformdiagnostic

workaswellasclearingofanydiagnostictroublecodes

(DTCs).DTC(s)cannolongerbeclearedusingthevehicles

instrumentclusterdigitaldisplayandstalkswitchcontrol.

SAEJ1939DataLinkCommunication

Theelectroniccontrolunits(ECUs)thatcommunicateonthe

SAEJ1939datalink,communicateaccordingtotheSAE

J1587standard.Thediagnostictroublecodes(DTCs)setby

theECUscontaininformationthatisdescribedbythefollowing

abbreviations.

SASourceAddress:

Identicationofacontrolmodule.

SPNSuspectParameterNumber:

Identicationofaparameter(value).

FMIFailureModeIdentier:

Identicationoffaulttypes.

Codes(DTCs)

22

Group28

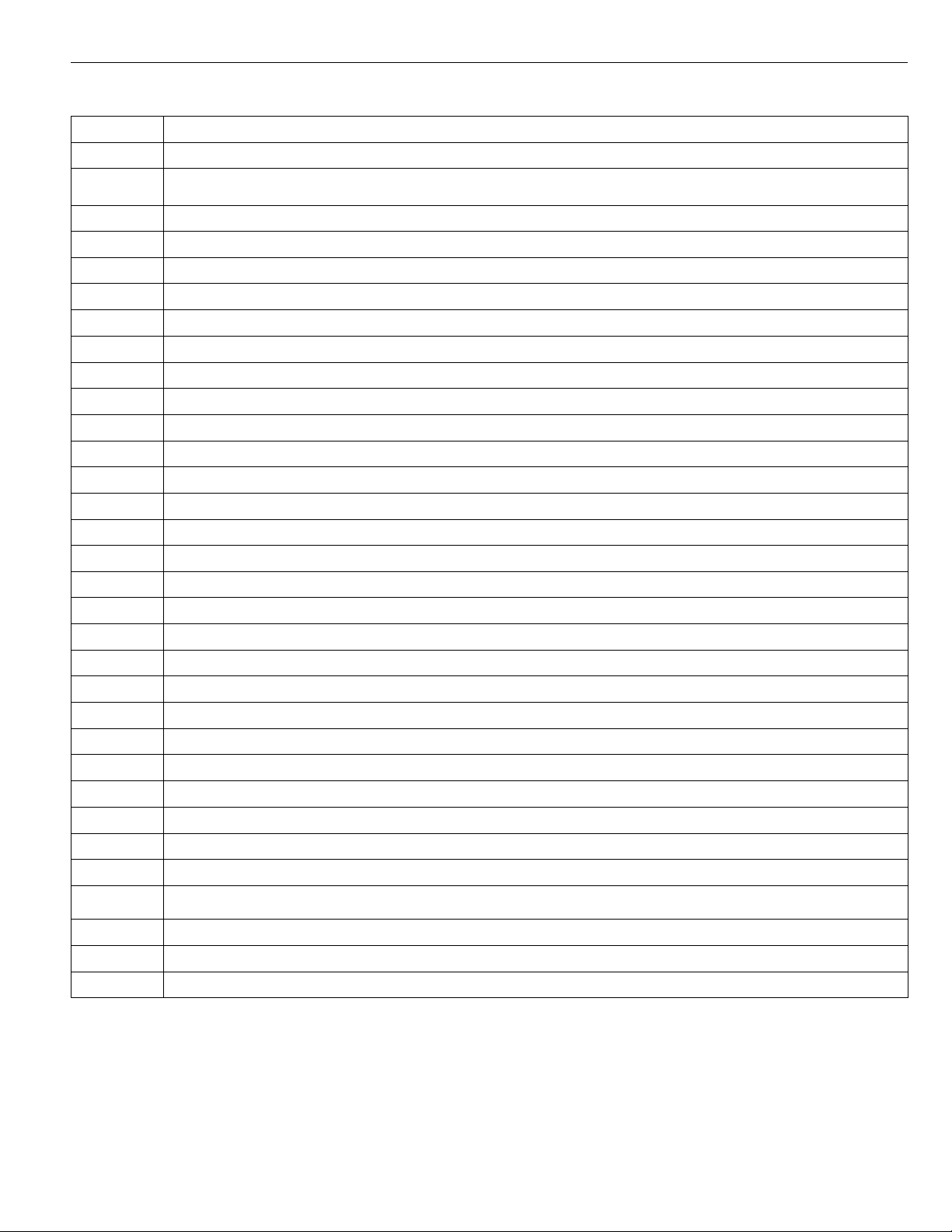

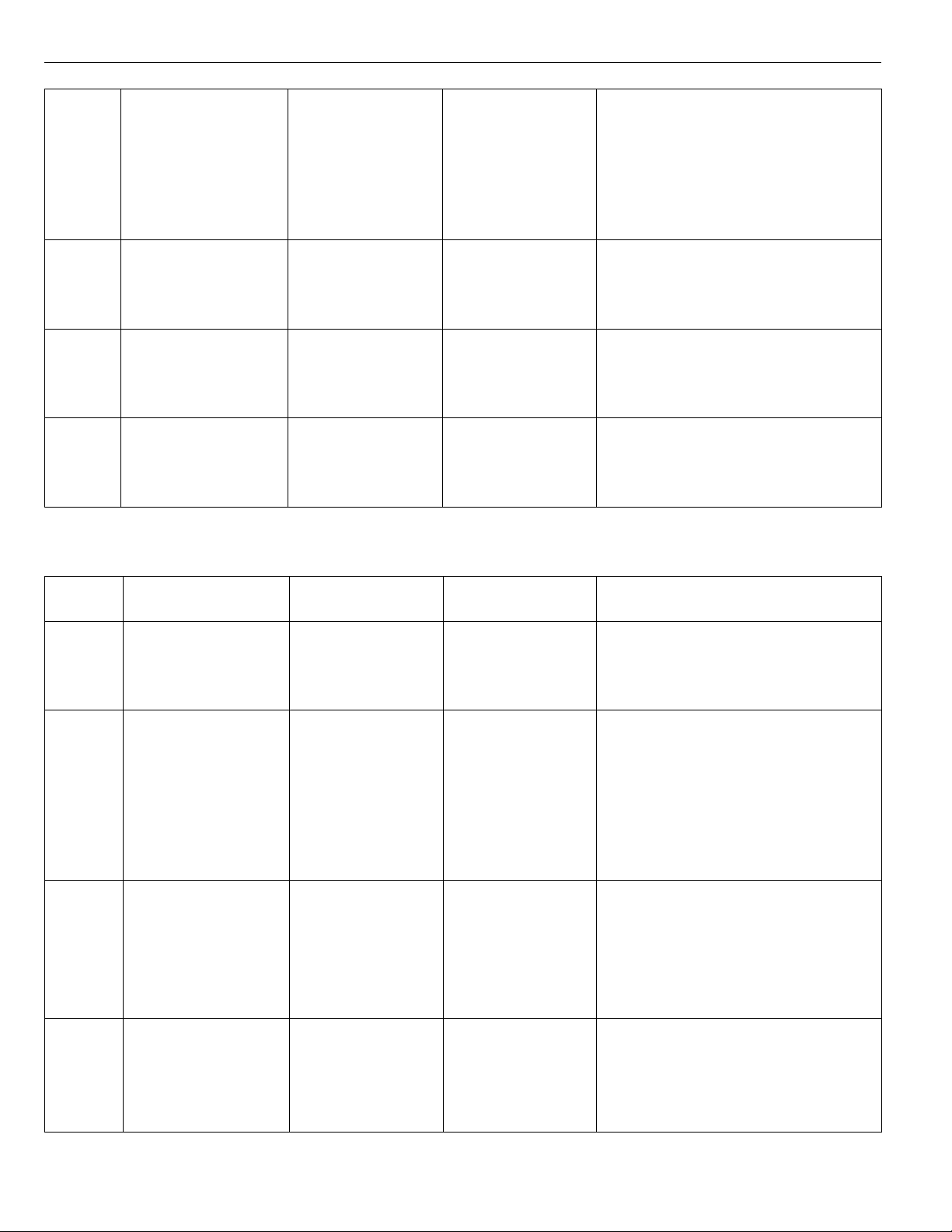

SAEJ1939FMITable

EngineControlModule(ECM)DiagnosticTrouble

Codes(DTCs)

FMI

0Datavalidbutabovenormaloperationalrange-Mostseverelevel

1Datavalidbutbelownormaloperationalrange-Mostseverelevel

2Dataerratic,intermittentorincorrect

3Voltageabovenormal,orshortedtohighsource

4Voltagebelownormal,orshortedtolowsource

5

6

7

8

9Abnormalupdaterate

10

11Rootcausenotknown

12Badintelligentdeviceorcomponent

13

14

15Datavalidbutabovenormaloperatingrange-Leastseverelevel

16Datavalidbutabovenormaloperatingrange-Moderatelyseverelevel

17Datavalidbutbelownormaloperatingrange-Leastseverelevel

18Datavalidbutbelownormaloperatingrange-Moderatelyseverelevel

19Receivednetworkdatainerror

20

21

22

23

24

25

26

27

28

SAET ext

Currentbelownormaloropencircuit

Currentabovenormalorgroundedcircuit

Mechanicalsystemnotrespondingoroutofadjustment

Abnormalfrequencyorpulsewidthorperiod

Abnormalrateofchange

Outofcalibration

Specialinstructions

ReservedforSAEassignment

ReservedforSAEassignment

ReservedforSAEassignment

ReservedforSAEassignment

ReservedforSAEassignment

ReservedforSAEassignment

ReservedforSAEassignment

ReservedforSAEassignment

ReservedforSAEassignment

29

30

31

ReservedforSAEassignment

ReservedforSAEassignment

Conditionexists

23

Group28

SAEJ1587DataLinkCommunication

EngineControlModule(ECM)DiagnosticTrouble

Codes(DTCs)

Theelectroniccontrolunits(ECUs)alsocommunicateonthe

SAEJ1587datalink.TheseECUscommunicateaccordingto

theSAEJ1587standard.Thestandardhasbeenextended

withMACK’ssupplement(PPID,PSID).Thediagnostictrouble

codes(DTCs)setbytheECUscontaininformationthatis

describedbythefollowingabbreviations.

MIDMessageIdenticationDescription:

Identicationofacontrolmodule.

PIDParameterIdenticationDescription:

Identicationofaparameter(value).

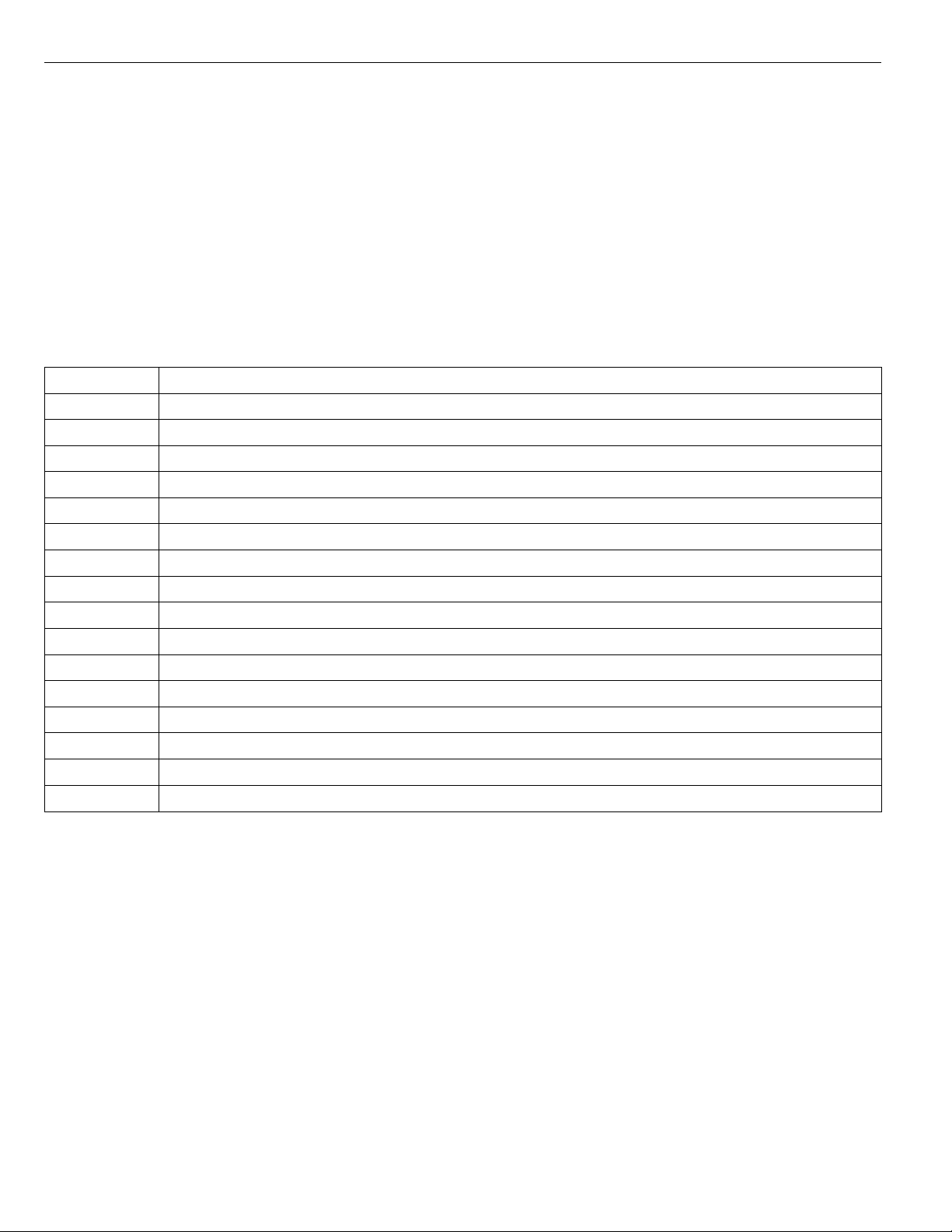

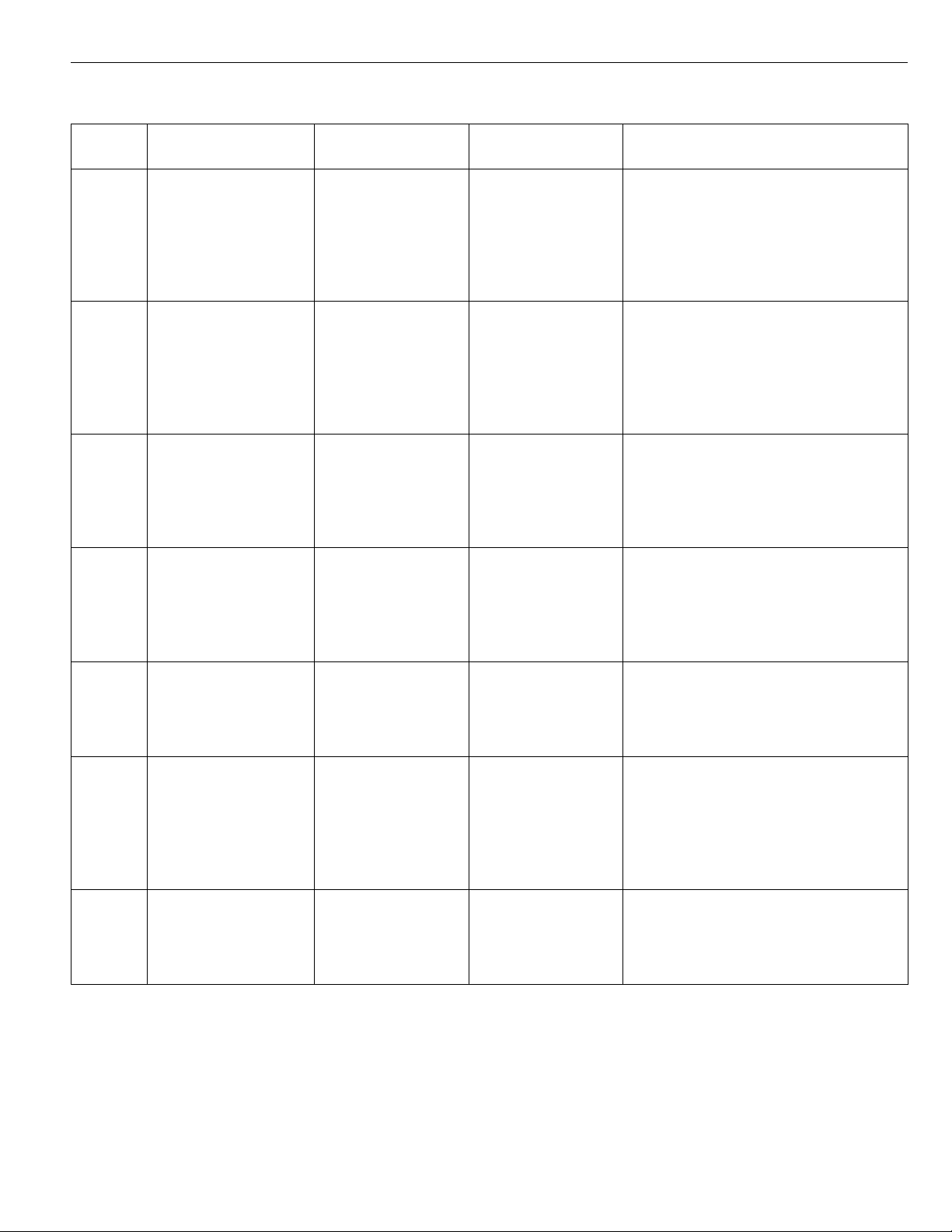

SAEJ1587FMITable

FMI

0Datavalid,butabovethenormalworkingrange

1Datavalid,butbelowthenormalworkingrange

2Intermittentorincorrectdata

3Abnormallyhighvoltageorshortcircuittohighervoltage

4Abnormallylowvoltageorshortcircuittolowervoltage

5

6Abnormallyhighcurrentorshortcircuittoground

7

8

9Abnormalupdaterate

10Abnormallystrongvibrations

11

12Faultymoduleorcomponent

13

14

15

SAET ext

Abnormallylowcurrentoropencircuit

Incorrectresponsefromamechanicalsystem

Abnormalfrequency

Non-identiablefault

Calibrationvaluesoutsidelimits

Specialinstructions

Reservedforfutureuse

PPIDProprietaryParameterIdentication

DescriptionMack:

Uniqueidenticationofaparameter(value).

SIDSubsystemIdenticationDescription:

Identicationofacomponent.

PSIDProprietarySubsystemIdentication

DescriptionMack:

Uniqueidenticationofacomponent.

FMIFailureModeIdentier:

Identicationoffaulttypes.

24

Group28

DiagnosticTroubleCode(DTC)Content

SPN0–500

•“ECMSPN84,Wheel-BasedVehicleSpeed–MID128

PID84”,page31

•“ECMSPN91,AcceleratorPedalPosition1–MID128

PID91”,page31

•“ECMSPN94,EngineFuelDeliveryPressure–MID128

PID94”,page31

•“ECMSPN97,WaterinFuelIndicator–MID128PID97”,

page32

•“ECMSPN98,EngineOilLevel–MID128PID98”,page

33

•“ECMSPN100,EngineOilPressure–MID128PID100”,

page33

•“ECMSPN102,EngineIntakeManifold1Pressure–MID

128PID102”,page34

•“ECMSPN103,EngineTurbocharger1Speed–MID128

PID103”,page35

•“ECMSPN105,EngineIntakeManifold1T emperature–

MID128PID105”,page36

•“ECMSPN108,BarometricPressure–MID128PID108”,

page36

•“ECMSPN110,EngineCoolantT emperature–MID128

PID1 10”,page37

•“ECMSPN111,EngineCoolantLevel–MID128PID111”,

page38

•“ECMSPN153,EngineHighResolutionCrankcase

Pressure–MID128PID153/PSID23”,page39

•“ECMSPN158,KeyswitchBatteryPotential–MID128

PID158/PSID124”,page39

•“ECMSPN171,AmbientAirT emperature–MID128PID

171”,page40

•“ECMSPN173,EngineExhaustGasT emperature(EGT)–

MID128PID173”,page42

•“ECMSPN175,EngineOilT emperature1–MID128PID

175”,page43

•“ECMSPN177,TransmissionOilTemperature–MID128

PID177”,page44

EngineControlModule(ECM)DiagnosticTrouble

Codes(DTCs)

25

Group28

•“ECMSPN188,EngineSpeedAtIdle,Point1(Engine

Congurations)–MID128PID188”,page44

•“ECMSPN190,EngineSpeed–MID128PID190”,page

44

•“ECMSPN228,SpeedSensorCalibration–MID128PID

228”,page45

•“ECMSPN237,V ehicleIdenticationNumber–MID128

PSID161/162”,page45

•“ECMSPN245,T otalV ehicleDistance–MID128PID

245”,page45

•“ECMSPN251,Time–MID128PID251”,page46

•“ECMSPN252,Date–MID128PID252”,page47

•“ECMSPN41 1,EngineExhaustGasRecirculation

DifferentialPressure–MID128PID41 1”,page47

•“ECMSPN412,EngineExhaustGasRecirculation

Temperature–MID128PID412”,page48

EngineControlModule(ECM)DiagnosticTrouble

Codes(DTCs)

SPN500–999

•“ECMSPN558,AcceleratorPedal1IdleValidationSwitch

–MID128SID230”,page49

•“ECMSPN626,IntakeAirHeater(IAH)Relay–MID128

PID45”,page50

•“ECMSPN628,ProgramMemory–MID128SID240”,

page50

•“ECMSPN629,ElectronicControlUnit(ECU)1–MID

128SID254”,page51

•“ECMSPN630,CalibrationMemory–MID128SID253”,

page51

•“ECMSPN631,CalibrationModule–MID128PSID

77/PSID124”,page52

•“ECMSPN633,EngineFuelActuator1ControlCommand

–MID128SID18”,page52

•“ECMSPN636,CamshaftPositionSensor(CMP)–MID

128SID21”,page53

•“ECMSPN637,CrankshaftPositionSensor(CKP)–MID

128SID22”,page54

•“ECMSPN639,SAEJ1939DataLink1–MID128SID

231”,page55

•“ECMSPN641,EngineVariableGeometryTurbocharger

(VGT)Actuator1–MID128SID27”,page55

•“ECMSPN642,EngineVariableGeometryTurbocharger

(VGT)Actuator2–MID128PPID89”,page56

•“ECMSPN647,EngineFanClutchOutputDeviceDriver–

MID128SID33”,page56

•“ECMSPN651,EngineInjectorCylinder1–MID128SID

1”,page57

•“ECMSPN652,EngineInjectorCylinder2–MID128SID

2”,page58

26

Group28

•“ECMSPN653,EngineInjectorCylinder3–MID128SID

3”,page58

•“ECMSPN654,EngineInjectorCylinder4–MID128SID

4”,page59

•“ECMSPN655,EngineInjectorCylinder5–MID128SID

5”,page60

•“ECMSPN656,EngineInjectorCylinder6–MID128SID

6”,page61

•“ECMSPN677,EngineStarterMotorRelay–MID128

SID39”,page61

•“ECMSPN729,IntakeAirHeater(IAH)1–MID128SID

70”,page62

•“ECMSPN730,IntakeAirHeater(IAH)2–MID128SID

71”,page62

•“ECMSPN975,EstimatedPercentFanSpeed–(MID128

PID26)”,page63

SPN1000–1999

EngineControlModule(ECM)DiagnosticTrouble

Codes(DTCs)

•“ECMSPN1072,EngineCompressionBrakeOutput#1–

MID128PPID122”,page64

•“ECMSPN1127,EngineTurbochargerIntakeManifold

Pressure(IMP)–MID128PSID98”,page65

•“ECMSPN1 136,EngineControlModule(ECM)

Temperature–MID128PPID55”,page66

•“ECMSPN1198,Anti–theftRandomNumber–MID128

PID224”,page66

•“ECMSPN1231,SAEJ1939DataLink2–MID128PSID

229/232”,page67

•“ECMSPN1265,EnginePistonCoolingOilPressure

Actuator–MID128SID85”,page67

•“ECMSPN1322,EngineMisreforMultipleCylinders–

MID128PSID27”,page68

•“ECMSPN1659,EngineCoolantSystemThermostat–

MID128PSID109”,page68

•“ECMSPN1675,EngineStarterMode–MID128SID

39”,page68

•“ECMSPN1677,AftertreatmentDPFAuxiliaryHeater

Mode–MID128PSID25”,page69

•“ECMSPN1761,AftertreatmentDieselExhaustFluid

(DEF)T ankLevel–PPID278”,page69

27

Group28

SPN2000–2999

•“ECMSPN2003,TransmissionControlModule(TCM)

Status–MID128PSID205”,page70

•“ECMSPN2017,CruiseControlStatus–MID128PID

85”,page70

•“ECMSPN2029,InvalidorMissingDatafromVehicleECU

–MID128PSID201”,page70

•“ECMSPN2629,EngineTurbochargerCompressorOutlet

Temperature–MID128PID404”,page71

•“ECMSPN2659,EngineExhaustGasRecirculation(EGR)

MassFlowRate–MID128PPID35”,page71

•“ECMSPN2791,EngineExhaustGasRecirculation(EGR)

ValveControl–MID128SID146”,page72

•“ECMSPN2836,BatteryPotential/SwitchedVoltage–MID

128PSID49”,page72

EngineControlModule(ECM)DiagnosticTrouble

Codes(DTCs)

28

Group28

SPN3000–3999

•“ECMSPN3031,AftertreatmentDieselExhaustFluid

(DEF)T ankTemperature–MID128PPID274”,page73

•“ECMSPN3064,AftertreatmentDPFSystemMonitor–

MID128PPID326”,page73

•“ECMSPN3216,AftertreatmentIntakeNOx–MID128

PPID348”,page74

•“ECMSPN3226,AftertreatmentOutletNOx–MID128

PPID270/PSID90”,page74

•“ECMSPN3245,AftertreatmentDPFOutletT emperature–

MID128PPID436”,page75

•“ECMSPN3249,AftertreatmentDPFIntakeT emperature

–MID128PPID387”,page76

•“ECMSPN3251,AftertreatmentDPFDifferentialPressure

–MID128PID81”,page77

•“ECMSPN3363,AftertreatmentDieselExhaustFluid

(DEF)T ankHeater–MID128PSID75”,page77

•“ECMSPN3471,AftertreatmentFuelPressureControl

Actuator–MID128PPID328”,page78

•“ECMSPN3480,AftertreatmentDieselParticulateFilter

(DPF)FuelPressure–MID128PPID437/PSID108”,page

79

•“ECMSPN3483,AftertreatmentRegenerationStatus–

MID128PSID47”,page80

•“ECMSPN3509,SensorSupplyVoltage1–MID128SID

232”,page81

•“ECMSPN3510,SensorSupplyVoltage2–MID128SID

211”,page81

•“ECMSPN351 1,SensorSupplyVoltage3–MID128PSID

113”,page81

•“ECMSPN3512,SensorSupplyVoltage4–MID128

PSID126”,page81

•“ECMSPN3522,AftertreatmentT otalFuelUsed–MID

128PSID91”,page82

•“ECMSPN3556,AftertreatmentHydrocarbonDoser–MID

128PPID329”,page83

•“ECMSPN3597,AftertreatmentDieselParticulateFilter

(DPF)RegenerationtooFrequent–MID128PSID119”,

page84

•“ECMSPN3675,EngineTurbochargerCompressor

BypassValvePosition–MID128PPID330”,page85

•“ECMSPN3720,AftertreatmentDPFAshLoadPercent–

MID128PPID337”,page86

•“ECMSPN3936,AftertreatmentDPFSystem–MID128

PSID28”,page86

EngineControlModule(ECM)DiagnosticTrouble

Codes(DTCs)

29

Group28

SPN4000–5500

•“ECMSPN4094,NOxLimitsExceededDuetoInsufcient

DieselExhaustFluid(DEF)Quality–MID128PSID90”,

page86

•“ECMSPN4095,NOxLimitsExceededDuetoInterrupted

DieselExhaustFluid(DEF)Dosing–MID128PSID90”,

page87

•“ECMSPN4334,AfterteatmentDieselExhaustFluid(DEF)

DosingAbsolutePressure–MID128PPID273”,page87

•“ECMSPN4339,AftertreatmentSCRFeedbackControl

Status–MID128PSID90”,page87

•“ECMSPN4354,AftertreatmentDieselExhaustFluid

(DEF)LineHeater1–MID128PSID103”,page88

•“ECMSPN4356,AftertreatmentDieselExhaustFluid

(DEF)LineHeater3–MID128PSID102”,page88

•“ECMSPN4374,AftertreatmentDieselExhaustFluid

(DEF)PumpMotorSpeed–MID128PSID87”,page89

•“ECMSPN4375,AftertreatmentDieselExhaustFluid

Pump(DEF)DrivePercentage–MID128PSID121”,page

89

•“ECMSPN4376,AftertreatmentDieselExhaustFluid

(DEF)ReturnValve–MID128PSID105”,page90

•“ECMSPN4752,EngineExhaustGasRecirculation(EGR)

CoolerEfciency–MID128SID282”,page91

•“ECMSPN4811,EnginePistonCoolingOilPressure–

MID128PPID8”,page91

•“ECMSPN4813,EngineOilThermostatBypassValve

Opening–MID128PSID72”,page91

•“ECMSPN4815,EngineCoolingFanThermalSwitch

Position–MID128PPID333”,page92

•“ECMSPN5246,AftertreatmentSCROperatorInducement

Severity–MID128PSID46”,page92

•“ECMSPN5285,ChargeAirCooler(CAC)T emperature–

MID128PID52”,page93

•“ECMSPN5298,AftertreatmentDieselOxidationCatalyst

(DOC)ConversionEfciency–MID128PSID99”,page93

•“ECMSPN5392,AftertreatmentDieselExhaustFluid

(DEF)DosingValveLossofPrime–MID128PSID121”,

page94

•“ECMSPN5394,AftertreatmentDieselExhaustFluid

(DEF)DosingValve–MID128PSID89”,page94

•“ECMSPN5394,AftertreatmentDieselExhaustFluid

(DEF)DosingValve–MID128PSID90”,page95

•“ECMSPN5485,AftertreatmentDieselExhaustFluid

(DEF)PumpOrice–MID128PSID121”,page95

EngineControlModule(ECM)DiagnosticTrouble

Codes(DTCs)

30

Group28

EngineControlModule(ECM)DiagnosticTrouble

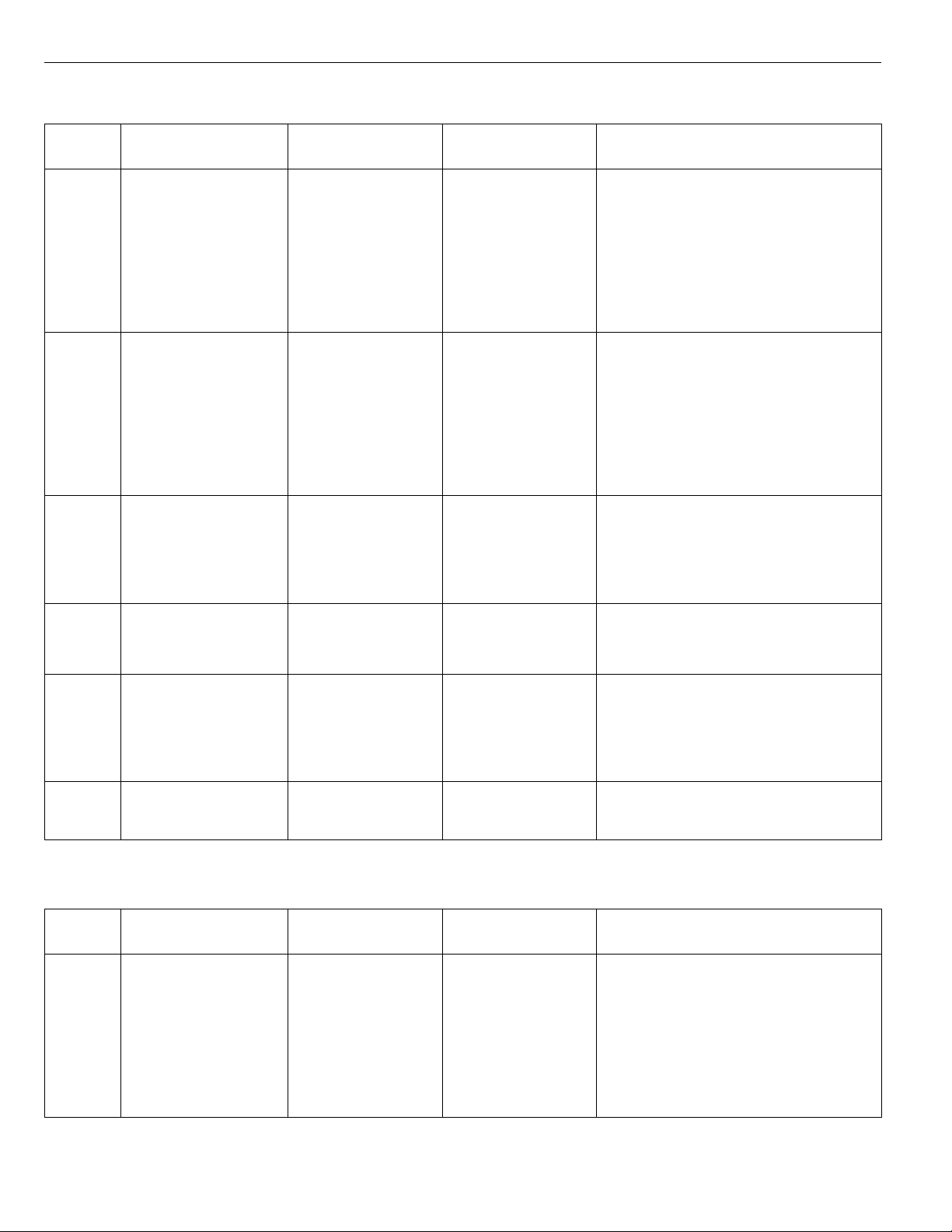

ECMSPN84,Wheel-BasedVehicleSpeed–MID128PID84

Codes(DTCs)

Typeof

fault:

FMI9

FMIDescription:

•Abnormalupdate

rate

FaultCondition:

•Missingsignal

fromVECU

Possible

Symptoms:

PossibleCause:

•Enginederate•SAEJ1587datalinkvehiclespeed

messagedoesnotexist,(VECUerror)

•VECU

FMI10

FMI13

FMI19

•Abnormalrateof

change

•Vehiclespeed

deemed

inaccurateby

VECU

•Outofcalibration•Novehiclespeed

availabletoVECU

•Receivednetwork

datainerror

•Vehiclespeed

deemed

inaccurateby

VECU

•MILilluminated

(13Lengineonly)

•MILilluminated

(13Lengineonly)

•MILilluminated

(13Lengineonly)

•Vehiclespeedsensor(VSS)

•VECU

•Vehiclespeedsensor(VSS)

•VECU

•Vehiclespeedsensor(VSS)

•VECU

ECMSPN91,AcceleratorPedalPosition1–MID128PID91

Typeof

fault:

FMI9

FMI13

FMI10

FMI19

FMIDescription:

•Abnormalupdate

rate

FaultCondition:

•Missingsignal

fromVECU

•Outofcalibration•Pedalnot

connectedto

VECU

•Abnormalrateof

change

•Receivednetwork

datainerror

•Pedalposition

deemed

inaccurateby

VECU

•Pedalposition

deemed

inaccurateby

VECU

Possible

Symptoms:

PossibleCause: