Weatherly Index No. 002

CATALOG NO.

CA0060

April 2011

MACK ENGINES

Replacement Parts Catalog

RELY ON US

TO PROTECT

YOUR INVESTMENT.

Maximizing your equipment

investment means finding the

best replacement components.

That’s why OTR fleets choose

FP Diesel.

FP Diesel components and kits help fleets

of all sizes maximize their capital investment

by rebuilding rather than replacing their

hardest-working engines. They’re designed

using the latest in computer-aided design

(CAD) and computer-aided engineering (CAE)

technology, and are thoroughly researched to

meet the most demanding specifications.

And they’re proven to perform.

®

Complete Overhaul and In-frame kits | Cylinder kits | Pistons

Piston rings | Cylinder liners | Gaskets | Engine bearings

Crankshafts | Camshafts | Water pumps | Thermostats

Oil pumps | Fuel pumps | Fuel injectors | Valves

Valvetrain components

Call us today for the complete range of

FP Diesel replacement engine components!

With FP Diesel you’re getting a better

solution in the form of premium technologies

engineered to address the unique demands

and operating environments of each engine.

It’s an investment you can make

with confidence.

©2011 Federal-Mogul Corporation. All rights reserved.

Table of Contents

Using the Catalog

Table of Contents ........................................................................................... i

How to Use This Catalog ...............................................................................ii

Engine Model Designation ............................................................................iii

Application by Engine Model – 2 Valve .........................................................iv

Application by Engine Model – 4 Valve /

In-Frame Kits ............................................................................................ v

Product Information

Engine Kit Bill of Materials List .....................................................................34

Engine Line Card Quick Reference ..............................................................38

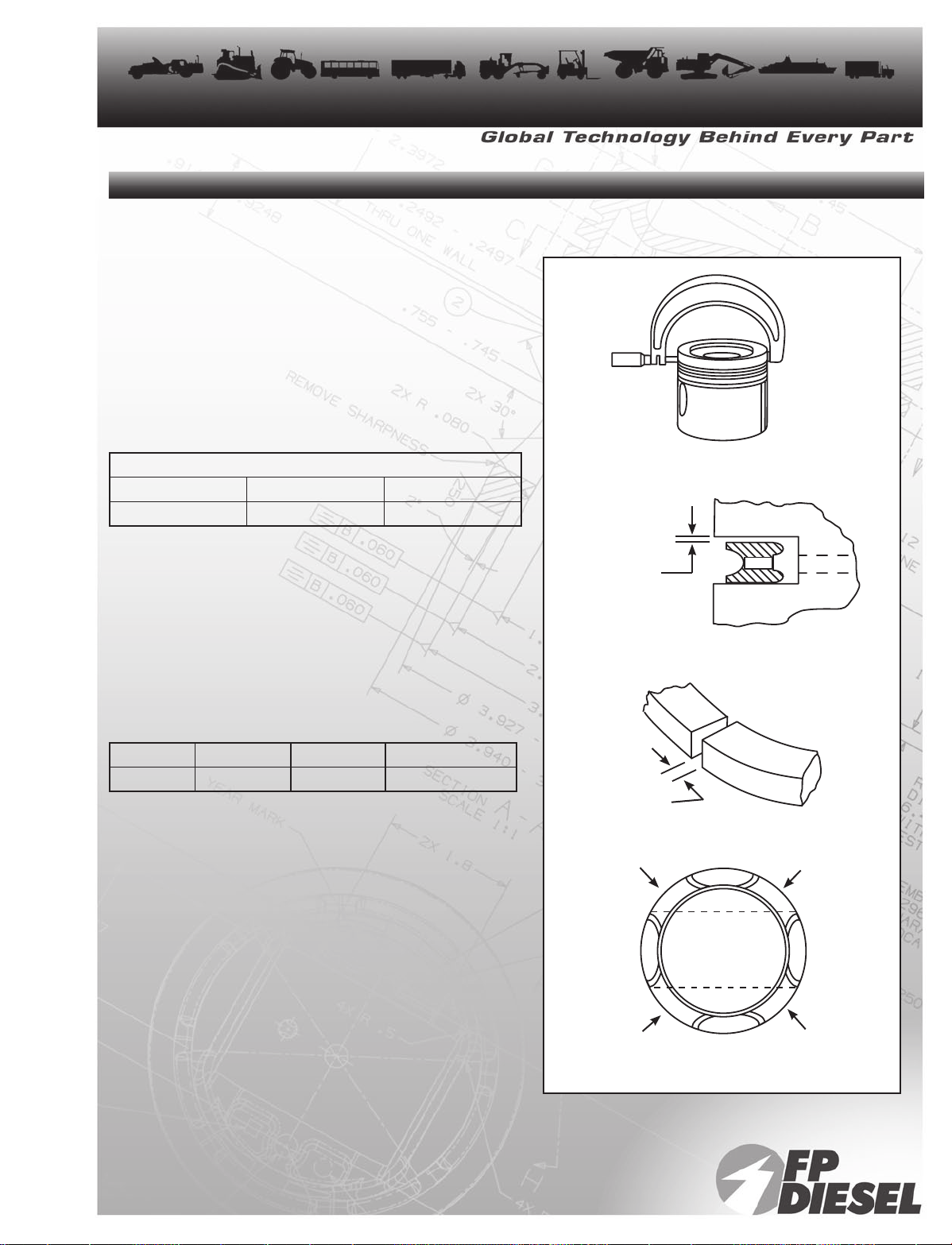

Engine Overhaul Tips ...................................................................................40

Numerical List ...............................................................................................35

Piston Ring Installation Instructions .............................................................39

Warranty

Warranty ..................................................................................................vi-viii

Mack Engines

EN/END Naturally Aspirated Engines ..........................................................13

EN/END Turbocharged Engines ................................................................. 15

E6 Engines ................................................................................................. 17

EN707 Engines ............................................................................................25

E7 PLN Engine ............................................................................................27

E7 E-Tech Engines ......................................................................................29

E7 A-Set Engines ........................................................................................ 31

END 864 Engines ........................................................................................32

END 865 Engines ........................................................................................32

i

How to Use This Catalog

The header for each block listed is designed to

help you identify the correct engine application.

Special information regarding a specific part is

located to the right of the part number listing.

Also included for help in finding the correct parts

are engine illustrations that include reference

numbers corresponding to the reference numbers

located next to the part number listings. If

available, ENGINE KIT listings are located at the

back of the catalog.

Engine components are grouped in the

following order:

1st Engine Block and Parts

2nd Cylinder Head and Parts

3rd Crankshaft/Oil Pump and Related Parts

4th Cylinder Components (incl. Rod Bearings,

Cylinder Sleeves, Pistons, Piston Rings)

General Information

This catalog is designed to identify the major

components, assemblies and kits used in Mack

engines including the E6 and E7 Series engines

and their respective variants.

The catalog includes all of the parts and kits

available from FP Diesel for the Mack engines.

For reference purposes, the illustrations and

tables in this catalog may also include parts and

assemblies not currently available from

FP Diesel, so that you can identify other parts

as needed.

The catalog is organized by engine model. Each

section is subdivided into groups that coincide

with the various engine assemblies

and components.

®

5th Camshaft Group

6th Valvetrain Components

7th Fuel System, Fuel Injectors, Governors

and Parts

8th Intake & Exhaust Manifolds including

Blowers and Parts

9th Oil Pump and Related Parts

10th Cooling System including Raw, Fresh

Water Pumps and Parts

11th Intake & Exhaust Manifolds

The catalog is sorted by ENGINE SERIES with

serial number identification charts in front of each

section.

Many of the part descriptions will include serial

number listings to provide absolute assurance

that the correct part is being used.

FP Diesel uses a part numbering system similar

to Mack’s OEM number. In most instances, the

number is the same except that the suffix of

the Mack number is omitted (when it serves no

applicable purpose). For example:

Mack OEM Part Number 57GC3124

FP Diesel Part Number FP-57GC3124

All manufacturer’s numbers, names, symbols and

descriptions are used for reference purposes only.

It is not implied that any part listed is the product

of any specific manufacturer.

All information contained in this catalog is based

on the latest data available at the time of printing.

Although care has been taken to ensure the

accuracy of the data compiled in this catalog,

Federal-Mogul does not assume liability for errors

or omissions.

IMPORTANT NOTICE:

This catalog does not replace the Mack parts

catalogs or service materials. If in doubt,

reference your Mack OEM publications.

ii

Mack® Engine Model Designation

Early Model Designations

E – MACK DIESEL ENGINE

D – DERATED VERSION OF ENGINE

T – TURBOCHARGED

B – MACK DYNATARD

A – SINGLE STAGE AFTERCOOLER

S – TWO STAGE AFTERCOOLER

EN – ENGINE

END – NATURALLY ASPIRATED DIESEL

ENDT – TURBOCHARGED DIESEL

ENDTB – TURBOCHARGED DIESEL WITH ENGINE BRAKE

ENDL – LIGHTWEIGHT VERSION OF END

ENDLT – LIGHTWEIGHT VERSION OF ENDT

®

ENGINE BRAKE

E T A Y B 676

EMISSION STANDARD DESIGNATIONS:

Z – MAXIMUM 10 GRAMS PER BHP/HR –

CALIFORNIA 1975 AND 1976.

FEDERAL STANDARD 16 GRAMS PER BHP/HR

1975-1977

Y – MAXIMUM 5 GRAMS PER BHP/HR

X – CALIFORNIA ENGINE IN COMPLIANCE WITH

1980-1982 6 GRAMS PER BHP/HR

NUMERICAL DIGITS – INDICATE CUBIC INCH

DISPLACEMENT (“5” AS A LAST DIGIT INDICATES

MAXIDYNE® TYPE ENGINE)

EXAMPLE

676 CUBIC INCHES

DYNATARD® ENGINE BRAKE

EMISSIONS STANDARD

SINGLE STAGE AFTERCOOLER

TURBOCHARGED

MACK DIESEL ENGINE

PREFIX LETTERS

.... E – MACK TURBOCHARGED DIESEL ENGINE

.... M – MAXIDYNE ENGINE

.... C – CALIFORNIA CERTIFIED

PREFIX NUMBERS (ENGINE DISPLACEMENT)

.... 6 – 672 CUBIC INCH

.... 7 – 728 CUBIC INCH

.... 9 – 998 CUBIC INCH

DIGITS

.... XXX – PEAK HORSEPOWER

SUFFIX LETTER

.... L – LOW SPEED MAXIDYNE

.... R – REDUCED ENGINE SPEED

EXAMPLE

E M C 6 285 R

REDUCED SPEED ENGINE

285 MAXIMUM BHP

ENGINE DISPLACEMENT

CALIFORNIA CERTIFIED

MAXIDYNE ENGINE

MACK TURBOCHARGED DIESEL ENGINE

ENGINE INFORMATION PLATE ON E6-2VH IS LOCATED BEHIND FUEL INJECTION PUMP

ENGINE INFORMATION PLATE ON E6-4VH IS LOCATED ON VALVE COVER

Current Model Designations

iii

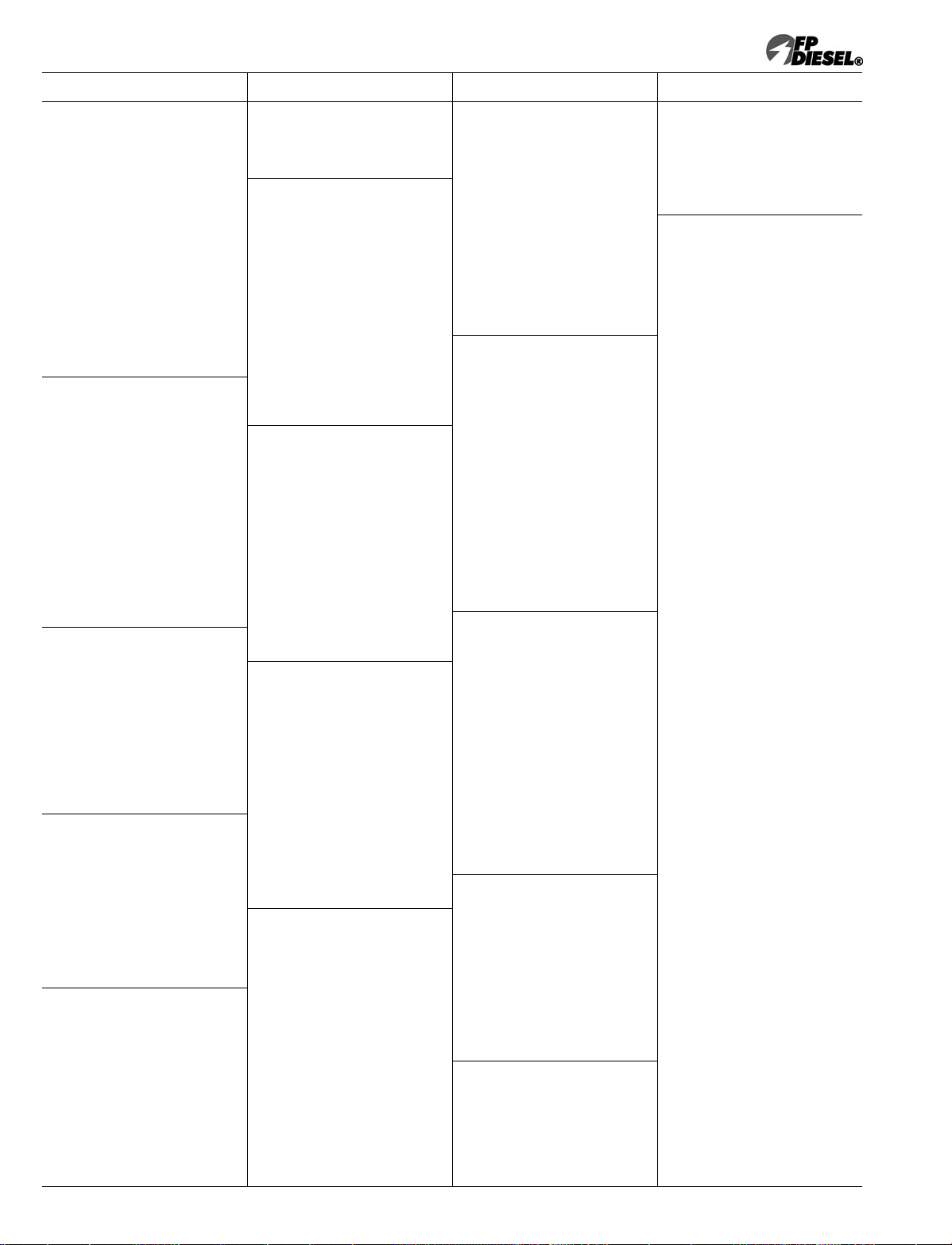

Application by Engine Model

2 Valve Head

ENGINE MODEL

PISTON BODY /

ASSY.

E6-315 / (R) FP-240GC542C /

FP-57GC283A

E6-320 FP-240GC542C /

FP-57GC283A

E6-325(R) FP-240GC542C /

FP-57GC283A

E6-335 FP-240GC542C /

FP-57GC283A

E6-350 / (R) FP-240GC542C /

FP-57GC283A

EC6-350(R) FP-240GC542C /

FP-57GC283A

EE6-260 FP-240GC542C /

FP-57GC283A

EE6-315 FP-240GC542C /

FP-57GC283A

EE6-335(B) FP-240GC542C /

FP-57GC283A

EM6-225 FP-240GC542C /

FP-57GC283A

EM6-237 FP-240GC542C /

FP-57GC283A

EM6-250 / (L)(R) FP-240GC542C /

FP-57GC283A

EM6-275(L)(R) FP-240GC542C /

FP-57GC283A

EM6-285 / (R) FP-240GC542C /

FP-57GC283A

EM6-300(R) FP-240GC542C /

FP-57GC283A

EMC6-300(R) FP-240GC542C /

FP-57GC283A

EME6-250(R) FP-240GC542C /

FP-57GC283A

EME6-285(R) FP-240GC542C /

FP-57GC283A

EME6-300(R) FP-240GC542C /

FP-57GC283A

EME6-310 FP-240GC542C /

FP-57GC283A

ETSZ(B)-673A FP-240GC542C /

FP-57GC283A

ETSZ(B)-676 / (A) FP-240GC542C /

FP-57GC283A

ETSZ(B)-677 FP-240GC542C /

FP-57GC283A

CYLINDER

KIT*

IN-FRAME

KIT

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

FP-57GC376 IFK-542C

ENGINE MODEL

PISTON BODY /

ASSY.

E6-200 FP-240GC545D /

FP-57GC282A

EC6-235 FP-240GC545D /

FP-57GC282A

EC6-265 FP-240GC545D /

FP-57GC282A

EC6-275 FP-240GC545D /

FP-57GC282A

EC6-330 FP-240GC545D /

FP-57GC282A

EM6-237(R) FP-240GC545D /

FP-57GC282A

EMC6-250 / (L) FP-240GC545D /

FP-57GC282A

EMC6-285(R) FP-240GC545D /

FP-57GC282A

ETSX-675 FP-240GC545D /

FP-57GC282A

ETSX-676 FP-240GC545D /

FP-57GC282A

ETSX-677 FP-240GC545D /

FP-57GC282A

ETX(B)-673D FP-240GC545D /

FP-57GC282A

ETY(B)-673E FP-240GC545D /

FP-57GC282A

ETY(B)-675

/ (B)

FP-240GC545D /

FP-57GC282A

ETZ(B)-675 / (B) FP-240GC545D /

FP-57GC282A

ENDT(B)(F)673(A,B,C)

FP-240GC562 /

FP-57GC253

ENDT(B)-675 FP-240GC562 /

FP-57GC253

ENDT(B)676(A,B)

FP-240GC562 /

FP-57GC253

ENDT-673C FP-240GC562 /

FP-57GC253

ET(B)-673 / (E) FP-240GC562 /

FP-57GC253

ETA(B)-673A FP-240GC562 /

FP-57GC253

ETA(B)676(B,E)

ETAY(B)673(A,B,C)

FP-240GC562 /

FP-57GC253

FP-240GC562 /

FP-57GC253

ETAY(B)-676(D) FP-240GC562 /

FP-57GC253

iv

* FOR CYLINDER KITS USING OVERSIZE LINERS,

PLEASE SEE NEXT PAGE.

CYLINDER KIT* IN-FRAME

KIT

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK-545D

FP-57GC355B IFK -545D

FP-57GC355B IFK-545D

FP-57GC366B IFK-562

FP-57GC366B IFK-562

FP-57GC366B IFK-562

FP-57GC366B IFK-562

FP-57GC366B IFK-562

FP-57GC366B IFK-562

FP-57GC366B IFK-562

FP-57GC366B IFK-562

FP-57GC366B IFK-562

Application by Engine Model

4 Valve Head

ENGINE MODEL

EM6-350 FP-240GC577 /

E6-315 / (R) FP-240GC579 /

E6-350 / (R) FP-240GC579 /

EC6-300 FP-240GC579 /

EC6-350 FP-240GC579 /

EM6-250L FP-240GC579 /

EM6-275 FP-240GC579 /

EM6-275L FP-240GC579 /

PISTON BODY /

ASSY.

57GC2105

57GC288

57GC288

57GC288

57GC288

57GC288

57GC288

57GC288

CYLINDER KIT*

FP-57GC380 IFK-577

FP-57GC373A IFK-579

FP-57GC373A IFK-579

FP-57GC373A IFK-579

FP-57GC373A IFK-579

FP-57GC373A IFK-579

FP-57GC373A IFK-579

FP-57GC373A IFK-579

IN-FRAME

KIT

ENGINE MODEL

EM6-285 / (R) FP-240GC579 /

EM6-300 / (R) FP-240GC579 /

EM6-300L FP-240GC579 /

ETSZ(B)-673A FP-240GC579 /

ETSZ(B)-676 FP-240GC579 /

ETSZ(B)-676A FP-240GC579 /

ETSZ(B)-677 FP-240GC579 /

* FOR CYLINDER KITS USING OVERSIZE LINERS,

PLEASE SEE BELOW.

PISTON BODY /

ASSY.

57GC288

57GC288

57GC288

57GC288

57GC288

57GC288

57GC288

CYLINDER KIT*

FP-57GC373A IFK-579

FP-57GC373A IFK-579

FP-57GC373A IFK-579

FP-57GC373A IFK-579

FP-57GC373A IFK-579

FP-57GC373A IFK-579

FP-57GC373A IFK-579

IN-FRAME

KIT

In-Frame Kits

2 VALVE HEAD

IFK-542C IFK-545D IFK-562 IFK-577 IFK-579

CYLINDER KITS

1) STD 6) FP-57GC376 6) FP-57GC355B 6) FP-57GC366B 6) FP-57GC380 6) FP-57GC373A

2) .002" 6) FP-57GC376P2 6) FP-57GC355P2 6) FP-57GC366P2 6) FP-57GC380P2 6) FP-57GC373P2

3) .006" 6) FP-57GC376P6 6) FP-57GC355P6 6) FP-57GC366P6 6) FP-57C380P6 6) FP-57GC373P6

4) .012" 6) FP-57GC376P12 6) FP-57GC355P12 6) FP-57GC366P12 6) FP-57GC380P12 6) FP-57GC373P12

5) .020" 6) FP-57GC376P20 6) FP-57GC355P20 6) FP-57GC366P20 6) FP-57GC380P20 6) FP-57GC373P20

MAIN BEARING SETS

1) STD 1) FP-215SB72DP1 1) FP-215SB72DP1 1) FP-215SB72DP1 1) FP-215SB72DP1 1) FP-215SB72DP1

2) .010" 1) FP-215SB72DP2 1) FP-215SB72DP2 1) FP-215SB72DP2 1) FP-215SB72DP2 1) FP-215SB72DP2

3) .020" 1) FP-215SB72DP3 1) FP-215SB72DP3 1) FP-215SB72DP3 1) FP-215SB72DP3 1) FP-215SB72DP3

4) .030" 1) FP-215SB72DP4 1) FP-215SB72DP4 1) FP-215SB72DP4 1) FP-215SB72DP4 1) FP-215SB72DP4

5) .040" 1) FP-215SB72DP5 1) FP-215SB72DP5 1) FP-215SB72DP5 1) FP-215SB72DP5 1) FP-215SB72DP5

ROD BEARINGS

1) STD 6) FP-62GB2382P1 6) FP-62GB2382P1 6) FP-62GB2382P1 6) FP-62GB2393P1 6) FP-62GB2393P1

2) .010" 6) FP-62GB2382P10 6) FP-62GB2382P10 6) FP-62GB2382P10 6) FP-62GB2393P10 6) FP-62GB2393P10

3) .020" 6) FP-62GB2382P20 6) FP-62GB2382P20 6) FP-62GB2382P20 6) FP-62GB2393P20 6) FP-62GB2393P20

4) .030" 6) FP-62GB2382P30 6) FP-62GB2382P30 6) FP-62GB2382P30 6) FP-62GB2393P30 6) FP-62GB2393P30

MAIN BEARING SETS INCLUDE THRUST BEARINGS AND LOCK PINS

4 VALVE HEAD

IN-FRAME GASKET

SET

1) PGM183A-IF 1) PGM183A-IF 1) PGM183A-IF 1) PGM187-IF 1) PGM187-IF

v

Warranty

The products listed in this catalog are warranted to be free from defects in material and workmanship, under

normal use and service, for two years from date of installation in an engine, without mileage or hour qualification

in accordance with the following limited warranty. This warranty is the sole and exclusive warranty for failure of

the above parts. This exclusive remedy shall not be deemed to have failed of its essential purpose so long as

Federal-Mogul is willing and able to provide the remedy provided below.

WARRANTY LIMITATIONS

Federal-Mogul agrees to only pay for parts and labor needed to repair engine damages that result from the

defined warranty failure. The costs are limited to parts and labor necessary for restoring the engine to its

condition immediately prior to the failure. Labor costs are determined by current published rates and standards

in the geographic area in which repairs are performed. Overtime or holiday rate charges are not allowed.

We will also pay for maintenance products such as oil, antifreeze, belts, hoses and filter elements that are

damaged because of a defined warranty failure.

Federal-Mogul is not responsible for engine failure resulting from owner, operator or third party neglect or abuse,

improper installation or repair procedures, alteration or misapplication of parts, failure to properly service or

maintain the engine and vehicle in accordance with applicable OEM operation and maintenance manuals or use

in engine modified for competition purposes or used in competition.

OTHER THAN AS EXPRESSLY PROVIDED HEREBY, FEDERAL-MOGUL SHALL NOT, UNDER ANY

CIRCUMSTANCES, BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, INCLUDING, BUT NOT LIMITED TO, DAMAGE OR LOSS OF OTHER PROPERTY OR

EQUIPMENT, LOSS OF PROFITS OR REVENUE, TRANSPORTATION AND TOWING COSTS, COST OF

PURCHASED OR REPLACED GOOD, OR CLAIMS OF CUSTOMERS OF THE PURCHASER, WHICH MAY

ARISE OR RESULT FROM THE SALE, INSTALLATION, OR USE OF THESE PARTS. Some jurisdictions

do not allow limitations on how long an implied warranty will last or the exclusion or limitation of incidental or

consequential damages, so the limitations or exclusions contained herein may or may not apply to you. This

warranty gives you specific legal rights. You may also have other rights depending on the state or province in

which you reside.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS AND/OR IMPLIED, INCLUDING,

WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR

PURPOSE AND THEY ARE EXCLUDED TO THE EXTENT THEY EXCEED THE WARRANTY COVERAGE

DESCRIBED BY THIS WARRANTY.

This warranty and remedy apply to new FP Diesel engine parts from Federal-Mogul sold directly to our

authorized aftermarket customers as evidenced by completed claim documentation.

No agent or sales representative of Federal-Mogul Corporation has the authority to modify this warranty.

Other Federal-Mogul parts may carry different warranties.

Federal-Mogul must be notified by the customer: (i) before filing a warranty claim, (ii) within one year of the date

that the claim accrues, and (iii) before any work has been performed. All claims must be submitted in writing

and Federal-Mogul reserves the right to examine all parts, systems and related information associated with the

claim. (Note all shipping charges are the responsibility of the end-user or distributor, Federal-Mogul will not

accept collect shipments). See your sales representative for detailed claim submission procedures and forms.

Use parts only for applications and interchanges in this catalog.

Failure to heed this warning could result in reduced life or failure of the part. All parts listed in this catalog

are not for use in space program, atomic energy/nuclear reactor equipment, medical or aircraft applications.

Federal-Mogul reserves the right to make product improvements/changes, with respect to similar products

previously manufactured, without notice and without incurring liability.

vi

Warranty

Les produits indiqués dans ce catalogue sont garantis contre toute défectuosité de matériel et de fabrication, dans

des conditions d’utilisation et d'entretien normales, sur une période de deux ans à partir de la date d'installation dans

un moteur, sans qualification de kilométrage ou horaire, conformément à la garantie limitée suivante.

Cette garantie est la garantie unique et exclusive pour la défaillance des pièces précitées.

Ce recours exclusif ne doit pas être présumé comme ayant échoué à son objectif essentiel,

tant que Federal-Mogul approuve et est capable de fournir le recours fourni ci-dessous.

LIMITATIONS DE GARANTIE

Federal-Mogul accepte uniquement de payer les pièces et la main-d’œuvre nécessaires pour réparer les dommages

de moteur qui résultent de la défaillance de la garantie définie. Les coûts sont limités aux pièces et à la main-d’œuvre

nécessaires pour la restauration du moteur à l'état auquel il se trouvait juste avant la défaillance.

Les frais de main-d’œuvre sont déterminés par les prix et normes publiés à l'heure actuelle dans la zone

géographique dans laquelle les réparations sont effectuées. Les heures supplémentaires ou les frais de jours fériés

ne sont pas permis. Nous payons également les produits d'entretien, tels que l’huile, l’antigel, les courroies,

les tuyaux et les éléments de filtre qui sont endommagés en raison d’une défaillance de garantie définie.

Federal-Mogul décline toute responsabilité pour une défaillance de moteur découlant d’une négligence ou d’un abus

infligés par le propriétaire, l’opérateur ou une tierce partie, de procédures d'installation ou de réparations incorrectes,

de l'altération ou d'une application incorrecte de pièces, d'un manque de réparation ou d'entretien adéquat du moteur

et du véhicule conformément aux manuels d’utilisation et d’entretien OEM applicables, ou de l’utilisation dans un

moteur modifié à des fins de compétition ou utilisé en compétition.

SAUF SUR SPÉCIFICATION EXPRESSE DANS LA PRÉSENTE, FEDERAL-MOGUL NE SERA RESPONSABLE,

EN AUCUNE CIRCONSTANCE, POUR DES DOMMAGES SPÉCIAUX, INDIRECTS,

ACCESSOIRES OU CONSÉCUTIFS, Y COMPRIS, SANS S’Y LIMITER, DES DOMMAGES OU LA PERTE D’UNE

AUTRE PROPRIÉTÉ OU D’UN AUTRE ÉQUIPEMENT, LA PERTE DE PROFITS OU DE REVENUS,

LES FRAIS DE TRANSPORT ET DE REMORQUAGE, LES FRAIS DE BIENS ACHETÉS OU REMPLACÉS,

OU LES DEMANDES DE CLIENTS DE L’ACHETEUR, QUI PEUVENT SE PRÉSENTER OU RÉSULTER

DE LA VENTE, DE L’INSTALLATION OU DE L’UTILISATION DE CES PIÈCES.

Certaines juridictions ne permettent pas les limites sur la durée d’une garantie implicite, ni l’exclusion ou la limitation

de dommages accessoires ou consécutifs, et, par conséquent, les limitations ou exclusions ci-incluses peuvent

s'appliquer ou non pour votre cas. Cette garantie vous octroie des droits légaux spécifiques.

Vous disposez également d’autres droits en fonction de l’état ou de la province de votre résidence.

LA PRÉSENTE GARANTIE REMPLACE TOUTES AUTRES GARANTIES, EXPRESSES ET/OU IMPLICITES,

Y COMPRIS, SANS S’Y LIMITER, LES GARANTIES DE QUALITÉ MARCHANDE OU D’ADAPTATION À UN USAGE

PARTICULIER, ET ELLES SONT EXCLUES SI ELLES DEVAIENT DÉPASSER LA COUVERTURE DE GARANTIE

DÉCRITE PAR LA PRÉSENTE GARANTIE.

Cette garantie et le recours s’appliquent aux nouvelles pièces du moteur diesel FP de Federal-Mogul vendu

directement à nos clients de pièces de rechange autorisés, tel qu’attesté par les documents de demande dûment

remplis. Aucun agent ou représentant de ventes de Federal-Mogul Corporation ne dispose du droit de modifier la

présente garantie. D’autres pièces de Federal-Mogul peuvent être couvertes par des garanties différentes.

PROCƒ DURES DE DEMANDE

Le client doit notifier Federal-Mogul : (i) avant de remplir une demande au titre de la garantie, (ii) en l’espace d’un

an à partir de la date à laquelle la demande est exercée, et (iii) avant l’exécution d’un travail quelconque.

Toutes les demandes doivent être soumises par écrit et Federal-Mogul se réserve le droit d’examiner toutes les

pièces, tous les systèmes et toutes les informations associées à la demande.

(Veuillez noter que l’utilisateur final ou le distributeur est responsable pour tous les frais d’expédition;

Federal-Mogul n’accepte aucun envoi en port-dû). Veuillez consulter votre représentant des ventes pour les

formulaires et les procédures de soumission de demande détaillés.

AVERTISSEMENT

Utilisez uniquement les pièces pour les applications et les échanges de ce catalogue.

Un manque de respect de cet avertissement pourrait résulter en une durée de vie réduite ou une défaillance de la

pièce. Aucune des pièces indiquées dans ce catalogue n’est destinée à être utilisée dans un programme d’espace,

pour du matériel de réacteur nucléaire/d’énergie atomique, ou des applications médicales ou d’aéronefs.

Federal-Mogul se réserve le droit d'effectuer des améliorations/changements de produits, en ce qui concerne des

produits similaires fabriqués auparavant, sans avis et sans assumer de responsabilité.

vii

Warranty

Se garantiza que todos los productos presentados en este catálogo no presentaran defecto alguno, ya sea en su

material ni en su fabricación, bajo condiciones de uso y servicio normales. La garantía es de dos años de la fecha de

la instalación en el motor, sin límites en el kilometraje o en las horas de funcionamiento. Esta es la única y exclusiva

garantía si alguna de las partes listadas fuese a fallar. Este recurso exclusivo no se tomará como una falta, siempre y

cuando Federal Mogul pueda remediarlo con las provisiones enumeradas mas abajo.

LIMITACIONES DE LA GARANTIA

Federal-Mogul pagará solo por las partes y la mano de obra necesarias para reparar daños al motor que resulten de

una falla definida sobre la parte vendida. Los costos quedarán limitados a las partes y la mano de obra necesarias

para restaurar el motor a la condición en la cual se encontraba inmediatamente antes de la falla.

Los costos de la mano de obra se determinarán por medio de precios publicados y estándares del área geográfica en

la cual las reparaciones se lleven a cabo. No se permitirá agregar costos de tiempo extra ni por trabajo durante días

festivos. Pagaremos por productos de mantenimiento tales como aceite, anti-congelantes,

correas, mangueras y filtros dañados debido a alguna falla definida del producto vendido.

Federal-Mogul no se hará responsable por una falla de motor causada por el dueño, operador o un tercero, ya

sea por su propia negligencia, abuso o instalación inadecuada o procedimientos de reparación inadecuados, por

alteración o aplicación incorrecta de las partes, falta de servicio necesario o mantenimiento del motor o de el vehículo

de acuerdo a los manuales de operación y mantenimiento de acuerdo fabricante original, o por la modificación de un

motor para su uso en competencias o por haber sido usado en competencias.

FEDERAL-MOGUL NO SERÁ RESPONSABLE, BAJO NINGUNA CIRCUNSTANCIA, OTRO QUE NO SEA LO QUE

SE HA MENCIONADO EXPLÍCITAMENTE EN ÉSTA GARANTÍA, POR CUALQUIER DAÑO INDIRECTO, ESPECIAL,

ACCIDENTAL O CÓMO CONSECUENCIA DE OTROS DAÑOS, INCLUYENDO, PERO SIN QUE QUÉDE LIMITADO

A DAÑOS O PÉRDIDAS DE BIENES O DE EQUIPO, PÉRDIDA DE GANANCIAS O INGRESOS, COSTOS DE

GRÚA O TRANSPORTACIÓN, DE PARTES REEMPLAZADAS , O RECLAMOS DE CLIENTES DEL COMPRADOR,

QUE PUEDAN RESULTAR DE LA VENTA, INSTALACIÓN, O USO DE ÉSTAS PARTES.

Algunas jurisdicciones no permiten limitaciones con respecto a la duración de garantías implícitas, o a la exclusión

o limitación de daños accidentales, por lo tanto puede que las limitaciones o exclusiones contenidas en el presente

no le apliquen a Ud. Esta garantía le ofrece derechos específicos. Ud. puede gozar de derechos adicionales

dependiendo del estado o provincia en la cual viva.

ÉSTA GARANTIA REEMPLAZARA CUALQUIER Y TODA OTRA GARANTÍA, YA SEA EXPLÍCITA U IMPLÍCITA,

INCLUYENDO, PERO NO LIMITANDOSE A GARANTÍAS PARA LA MERCANCÍA Y USO DE LA MISMA CON

UN PROPÓSITO EN PARTICULAR, Y ESAS MISMAS QUEDARAN EXCLUIDAS SI EXCEDEN LA COBERTURA

DESCRITA EN ÉSTA GARANTÍA.

Ésta garantía y recurso aplican a partes nuevas de motores de FP Diésel, vendidas directamente a nuestros clientes

autorizados del mercado de reposición, lo cual será corroborado por medio de documentación usada en el reclamo.

Ningún agente o representante de la empresa Federal-Mogul tiene autoridad para modificar ésta garantía.

Otras partes de Federal-Mogul pueden tener garantías diferentes.

PROCEDIMIENTO PARA PRESENTAR UN RECLAMO

Federal-Mogul debe ser notificado por el cliente: (i) antes de presentar un reclamo cubierto en la garantía, (ii) dentro

del plazo de un año de ocurrida la falla, y (iii) antes de que se haya hecho algún trabajo.

Todo reclamo debe ser entregado por escrito y Federal-Mogul reserva el derecho a examinar todas las partes,

sistemas e información relacionados y asociados al reclamo. (Todo cargo de envío será responsabilidad del usuario

final o distribuidor, Federal-Mogul no aceptará envíos a cobrar). Contacte a su representante de ventas para

conseguir el formulario de reclamos con el procedimiento detallado.

ADVERTENCIA

Las partes deben ser usadas sólo para las aplicaciones mencionadas en éste catálogo. El no seguir ésta advertencia

puede que resulte en que le falle la parte o a que su vida quede reducida. Todas las partes listadas en éste catálogo

no están hechas para el uso en programas espaciales, para equipos de energía atómica, o reactores nucleares, o

para aplicaciones médicas ni en naves aéreas. Federal-Mogul se reserva el derecho de hacerle mejoras y cambios a

los productos, con respecto a productos similares que se hayan fabricado previamente,

sin notificación o responsabilidad legal alguna.

viii

Engine Finding Index

Engine Years

1.6L 98 OHV L4 3.125" Bore H/D Truck.........................................1

1.8L 113 OHV L4 3" Bore H/D Truck..............................................2

2.0L 123 OHV L4 3.125" Bore H/D Truck.......................................3

2.2L 133 OHV L4 3.25" Bore H/D Truck.........................................4

2.4L 145 OHV L4 3.25" Bore H/D Truck.........................................5

5.5L 335 (5491cc) OHV Turbo-Diesel L6 102mm

Bore (RVI Eng.) M/D Truck.................................... 1979-93 .......6

8.4L 510 OHV L6 4.4375" Bore H/D Truck............... 1948-63 .......7

11.0L 672 OHV Diesel L6 4.875" Bore H/D Truck..........................8

11.0L 672 OHV Turbo-Diesel L6 4.875" Bore H/D Truck............... 9

11.0L 672 OHV Turbo-Diesel L6 4.875" Bore H/D Truck............. 10

11.0L 672 OHV Turbo-Diesel L6 4.875" Bore H/D Truck............. 11

11.0L 672 OHV Turbo-Diesel L6 4.875" Bore H/D Truck............. 12

Line

No. Engine Years

Engine Code Index

Engine Code Engine Description No.

EC6-235 ................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

EC6-265 ................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

EC6-275 ................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

EC6-300 w/4 Valve Heads ....11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

EC6-330 ................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

EC6-350 w/4 Valve Heads ....11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

EC6-350(R) ...........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

EE6-260.................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

EE6-315.................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

EE6-335(B)............................ 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

EMC6-250 .............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

EMC6-285 .............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

EMC6-285(R) ........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

EME6-285(R).........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

EME6-285(R) w/4 Valve

Heads..................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

EM6-225................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

EM6-237................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

EM6-237(R)...........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

EM6-250................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

EM6-250 w/4 Valve Heads.... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

EM6-250(L) w/4 Valve

Heads..................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

EM6-250(R)...........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

EM6-275 w/4 Valve Heads.... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

EM6-275(L) w/4 Valve

Heads..................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

EM6-275(R)...........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

Line

(continued on next page)

Mack

Line

No.

11.0L 672 OHV Turbo-Diesel L6 4.875" Bore H/D Truck............. 13

11.6L 707 OHV L6 5" Bore H/D Truck..........................................14

11.6L 707 OHV Diesel L6 5" Bore H/D Truck...............................15

12.1L 728 OHV Turbo-Diesel L6 4.875" Bore (E7 PLN) H/D

Truck..........................................................................................16

12.1L 728 OHV Turbo-Diesel L6 4.875" Bore (E7

E-Tech) H/D Truck................................................. 1998-2002 .17

12.1L 728 OHV Turbo-Diesel L6 4.875" Bore (E7

A-Set) H/D Truck.................................................... 2002-2010.18

14.2L 864 OHV Diesel V8 5" Bore H/D Truck..............................19

14.2L 866 OHV Diesel V8 5.25" Bore H/D Truck.........................20

14.2L 866 OHV Turbo-Diesel V8 5.25" Bore H/D Truck...............21

Engine Code Engine Description No.

EM6-275(R) w/4 Valve

Heads..................................11.0L 672 OHV Turbo-Diesel L6

EM6-285................................11.0L 672 OHV Turbo-Diesel L6

EM6-285 w/4 Valve Heads.... 11.0L 672 OHV Turbo-Diesel L6

EM6-285(R)...........................11.0L 672 OHV Turbo-Diesel L6

EM6-285(R) w/4 Valve

Heads..................................11.0L 672 OHV Turbo-Diesel L6

EM6-300(R)...........................11.0L 672 OHV Turbo-Diesel L6

EM6-300(R) w/4 Valve

Heads..................................11.0L 672 OHV Turbo-Diesel L6

EN-510A................................8.4L 510 OHV L6 4.4375" Bore H/D

EN-672 ..................................11.0L 672 OHV Diesel L6 4.875"

EN-673T................................ 11.0L 672 OHV Turbo-Diesel L6

EN-707 ..................................11.6L 707 OHV L6 5" Bore H/D

EN-707A................................11.6L 707 OHV L6 5" Bore H/D

EN-707B................................11.6L 707 OHV L6 5" Bore H/D

EN-707C................................ 11.6L 707 OHV L6 5" Bore H/D

END-672................................ 11.0L 672 OHV Diesel L6 4.875"

END-672S .............................11.0L 672 OHV Diesel L6 4.875"

END-673................................ 11.0L 672 OHV Diesel L6 4.875"

END-673A .............................11.0L 672 OHV Diesel L6 4.875"

END-673B .............................11.0L 672 OHV Diesel L6 4.875"

END-673C............................. 11.0L 672 OHV Diesel L6 4.875"

END-673D............................. 11.0L 672 OHV Diesel L6 4.875"

END-673E .............................11.0L 672 OHV Diesel L6 4.875"

END-673P .............................11.0L 672 OHV Diesel L6 4.875"

END-673T..............................

END-707

................................11.6L 707 OHV Diesel L6 5" Bore

4.875" Bore H/D Truck ................. 13

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 13

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 13

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 13

Truck............................................... 7

Bore H/D Truck............................... 8

4.875" Bore H/D Truck ................... 9

Truck............................................. 14

Truck............................................. 14

Truck............................................. 14

Truck............................................. 14

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

H/D Truck ..................................... 15

Line

1

Mack

Engine Code Index

Engine Code Engine Description No.

END-711................................ 11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

END-864................................ 14.2L 864 OHV Diesel V8 5" Bore

H/D Truck ..................................... 19

END-865................................ 14.2L 866 OHV Diesel V8 5.25"

Bore H/D Truck............................. 20

END-866................................ 14.2L 866 OHV Diesel V8 5.25"

Bore H/D Truck............................. 20

ENDD-711............................. 11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

ENDL-673.............................. 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

ENDL-673P ...........................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

ENDL-711.............................. 11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

ENDLT-711............................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

ENDS-672 .............................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

ENDT(B)-675......................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

ENDT(B)-675C...................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

ENDT(B)-676......................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

ENDT(B)-676A ......................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

ENDT(B)-676B ......................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

ENDT(F)-673......................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

ENDT-673..............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

ENDT-673..............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

ENDT-673A........................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

ENDT-673A........................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

ENDT-673B........................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

ENDT-673B........................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

ENDT-673C...........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

ENDT-673C...........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

ENDT-673C...........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

ENDT-711..............................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

ENDT-865..............................14.2L 866 OHV Turbo-Diesel V8

5.25" Bore H/D Truck ................... 21

ENDT-866..............................14.2L 866 OHV Turbo-Diesel V8

5.25" Bore H/D Truck ................... 21

ENDTF-673 ...........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

ENF-707................................ 11.6L 707 OHV L6 5" Bore H/D

Truck............................................. 14

ENF-707................................ 11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

ENF-707A.............................. 11.6L 707 OHV L6 5" Bore H/D

Truck............................................. 14

ENF-707B.............................. 11.6L 707 OHV L6 5" Bore H/D

Truck............................................. 14

ENF-711................................ 11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

ENS-707................................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

ENS-711................................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

(continued on next page)

2

Line

Engine Code Engine Description No.

ET(B)-673..............................11.0L 672 OHV Turbo-Diesel L6

ET(B)-673E............................11.0L 672 OHV Turbo-Diesel L6

ET(B)-673E............................11.0L 672 OHV Turbo-Diesel L6

ETA(B)-673A......................... 11.0L 672 OHV Turbo-Diesel L6

ETA(B)-676............................11.0L 672 OHV Turbo-Diesel L6

ETA(B)-676B......................... 11.0L 672 OHV Turbo-Diesel L6

ETAY(B)-676......................... 11.0L 672 OHV Turbo-Diesel L6

ETAZ(B)-673 .........................11.0L 672 OHV Turbo-Diesel L6

ETAZ(B)-673A.......................11.0L 672 OHV Turbo-Diesel L6

ETAZ(B)-673B.......................11.0L 672 OHV Turbo-Diesel L6

ETAZ-677.............................. 11.0L 672 OHV Turbo-Diesel L6

ETSX-675..............................11.0L 672 OHV Turbo-Diesel L6

ETSX-676..............................11.0L 672 OHV Turbo-Diesel L6

ETSX-677..............................11.0L 672 OHV Turbo-Diesel L6

ETSZ(B)-673A.......................11.0L 672 OHV Turbo-Diesel L6

ETSZ(B)-673A w/4 Valve

Heads..................................

ETSZ(B)-676

ETSZ(B)-676 w/4 Valve

Heads..................................11.0L 672 OHV Turbo-Diesel L6

ETSZ(B)-676A.......................11.0L 672 OHV Turbo-Diesel L6

ETSZ(B)-676A w/4 Valve

Heads..................................11.0L 672 OHV Turbo-Diesel L6

ETSZ(B)-677 .........................11.0L 672 OHV Turbo-Diesel L6

ETSZ(B)-677 w/4 Valve

Heads..................................11.0L 672 OHV Turbo-Diesel L6

ETX(B)-673D.........................11.0L 672 OHV Turbo-Diesel L6

ETY(B)-673E......................... 11.0L 672 OHV Turbo-Diesel L6

ETY(B)-675............................11.0L 672 OHV Turbo-Diesel L6

ETY(B)-675B......................... 11.0L 672 OHV Turbo-Diesel L6

ETZ(B)-675............................ 11.0L 672 OHV Turbo-Diesel L6

ETZ(B)-675B .........................11.0L 672 OHV Turbo-Diesel L6

ETZ(B)F-673E....................... 11.0L 672 OHV Turbo-Diesel L6

E3-175...................................5.5L 335 (5491cc) OHV

E3-180...................................5.5L 335 (5491cc) OHV

E6-200...................................11.0L 672 OHV Turbo-Diesel L6

E6-315...................................11.0L 672 OHV Turbo-Diesel L6

.........................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 11

11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 13

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 13

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 13

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 12

Turbo-Diesel L6 102mm Bore (RVI

Eng.) M/D Truck ............................. 6

Turbo-Diesel L6 102mm Bore (RVI

Eng.) M/D Truck ............................. 6

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 11

Line

Engine Code Index

Line

Engine Code Engine Description No.

E6-315 w/4 Valve Heads.......11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

E6-315(R)..............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

E6-315(R) w/4 Valve Heads.. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

E6-320...................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

E6-325(R)..............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

E6-335...................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

E6-350...................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

E6-350 w/4 Valve Heads.......11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

E6-350(R)..............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

E6-350(R) w/4 Valve Heads.. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 13

E7 A-SET Engs. ....................12.1L 728 OHV Turbo-Diesel L6

4.875" Bore (E7 A-Set) H/D

Truck............................................. 18

E7 E-TECH (EUP) Engs........ 12.1L 728 OHV Turbo-Diesel L6

4.875" Bore (E7 E-Tech) H/D

Truck............................................. 17

Mack

Line

Engine Code Engine Description No.

E7 PLN Engs.........................12.1L 728 OHV Turbo-Diesel L6

4.875" Bore (E7 PLN) H/D Truck.. 16

E7-A-SET-AC........................ 12.1L 728 OHV Turbo-Diesel L6

4.875" Bore (E7 A-Set) H/D

Truck............................................. 18

E7-A-SET-AI.......................... 12.1L 728 OHV Turbo-Diesel L6

4.875" Bore (E7 A-Set) H/D

Truck............................................. 18

E7-380...................................12.1L 728 OHV Turbo-Diesel L6

4.875" Bore (E7 E-Tech) H/D

Truck............................................. 17

E7-410...................................12.1L 728 OHV Turbo-Diesel L6

4.875" Bore (E7 E-Tech) H/D

Truck............................................. 17

E7-427...................................12.1L 728 OHV Turbo-Diesel L6

4.875" Bore (E7 E-Tech) H/D

Truck............................................. 17

E7-460...................................12.1L 728 OHV Turbo-Diesel L6

4.875" Bore (E7 E-Tech) H/D

Truck............................................. 17

MIDR 06.02.12 ......................5.5L 335 (5491cc) OHV

Turbo-Diesel L6 102mm Bore (RVI

Eng.) M/D Truck ............................. 6

Model Index

Line

Model Engine Description No.

B15LT....................................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

B18X...................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B43S...................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B43X...................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B61LST..................................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

B61LT....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B61S...................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B61SE ...................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B61ST....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B61SX ...................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B61T......................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B61X...................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B613LST................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B613LT..................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B613S.................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B613ST..................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B613SX .................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B613T....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B63SX ...................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B63T......................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

(continued on next page)

Model Engine Description No.

Line

B633SX .................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B65T......................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B67LST..................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B67LST..................................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

B67LT....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B67LT....................................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

B67R......................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B67R......................................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

B67S...................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B67S...................................... 11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

B67ST....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B67ST....................................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

B673LST................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B673LT..................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B673ST..................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B673T....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B70LS.................................... 11.6L 707 OHV L6 5" Bore H/D

Truck............................................. 14

B70LT....................................11.6L 707 OHV L6 5" Bore H/D

Truck............................................. 14

B70S...................................... 11.6L 707 OHV L6 5" Bore H/D

Truck............................................. 14

B70ST....................................11.6L 707 OHV L6 5" Bore H/D

Truck............................................. 14

3

Mack

Model Index

Model Engine Description No.

B70T......................................11.6L 707 OHV L6 5" Bore H/D

Truck............................................. 14

B75LS.................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B75S...................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B75T......................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B753LS.................................. 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B753LST................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B753LT..................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B753S.................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B753T....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B81SX ...................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B81X...................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B813SX .................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B813X.................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B8136SX ...............................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B83ST....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B83SX ...................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B833...................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B833ST..................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B833SX .................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B85SX ...................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B87SX ...................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B873...................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

B873SX .................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

CF600F..................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

CF600F..................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

CF600F..................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

CS200P................................. 5.5L 335 (5491cc) OHV

Turbo-Diesel L6 102mm Bore (RVI

Eng.) M/D Truck ............................. 6

CS250P................................. 5.5L 335 (5491cc) OHV

Turbo-Diesel L6 102mm Bore (RVI

Eng.) M/D Truck ............................. 6

C33D .....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

C37D .....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

C41AD...................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

C43........................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

C43D .....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

C45AD...................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

C47D .....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

(continued on next page)

4

Line

Model Engine Description No.

C49D .....................................11.0L 672 OHV Diesel L6 4.875"

C49W.....................................11.0L 672 OHV Diesel L6 4.875"

C491D ...................................11.0L 672 OHV Diesel L6 4.875"

C607T.................................... 11.0L 672 OHV Diesel L6 4.875"

C609LST ...............................11.6L 707 OHV Diesel L6 5" Bore

C609LT.................................. 11.6L 707 OHV Diesel L6 5" Bore

C609ST .................................11.6L 707 OHV Diesel L6 5" Bore

C609T.................................... 11.6L 707 OHV Diesel L6 5" Bore

C611ST .................................11.0L 672 OHV Turbo-Diesel L6

C611ST .................................11.0L 672 OHV Turbo-Diesel L6

C611T.................................... 11.0L 672 OHV Turbo-Diesel L6

C611T.................................... 11.0L 672 OHV Turbo-Diesel L6

DML800.................................11.0L 672 OHV Turbo-Diesel L6

DML800.................................11.0L 672 OHV Turbo-Diesel L6

DMM6006EX......................... 11.0L 672 OHV Diesel L6 4.875"

DMM6006EX......................... 11.0L 672 OHV Turbo-Diesel L6

DMM6006EX

DMM6006S............................11.0L 672 OHV Turbo-Diesel L6

DMM6006S............................11.0L 672 OHV Turbo-Diesel L6

DMM6006SX......................... 11.0L 672 OHV Turbo-Diesel L6

DMM6006SX......................... 11.0L 672 OHV Turbo-Diesel L6

DM600S.................................11.0L 672 OHV Diesel L6 4.875"

DM600S.................................11.0L 672 OHV Turbo-Diesel L6

DM600S.................................11.0L 672 OHV Turbo-Diesel L6

DM600S.................................11.6L 707 OHV Diesel L6 5" Bore

DM600SX.............................. 11.0L 672 OHV Diesel L6 4.875"

DM600SX.............................. 11.0L 672 OHV Turbo-Diesel L6

DM600SX.............................. 11.0L 672 OHV Turbo-Diesel L6

DM600SX.............................. 11.6L 707 OHV Diesel L6 5" Bore

DM600X.................................11.0L 672 OHV Diesel L6 4.875"

DM600X.................................11.0L 672 OHV Turbo-Diesel L6

DM600X.................................11.0L 672 OHV Turbo-Diesel L6

DM6006X...............................11.0L 672 OHV Turbo-Diesel L6

DM6006X...............................11.0L 672 OHV Turbo-Diesel L6

DM607S.................................11.0L 672 OHV Turbo-Diesel L6

DM607S.................................11.0L 672 OHV Turbo-Diesel L6

.........................11.0L 672 OHV Turbo-Diesel L6

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

H/D Truck ..................................... 15

H/D Truck ..................................... 15

H/D Truck ..................................... 15

H/D Truck ..................................... 15

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 12

Bore H/D Truck............................... 8

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck .................

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 12

Bore H/D Truck............................... 8

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

H/D Truck ..................................... 15

Bore H/D Truck............................... 8

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

H/D Truck ..................................... 15

Bore H/D Truck............................... 8

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

Line

10

Model Index

Line

Model Engine Description No.

DM607SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

DM607SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

DM607X.................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

DM607X.................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

DM6076S...............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

DM6076S...............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

DM611S.................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

DM611S.................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

DM611SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

DM611SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

DM6116S...............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

DM6116S...............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

DM685...................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

DM685...................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

DM685SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

DM685SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

DM686S.................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

DM686S.................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

DM686SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

DM686SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

DM800S.................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

DM800S.................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

DM800SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

DM800SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

DM811SH..............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

DM811SH..............................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

DM886SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

DM886SX.............................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

F ............................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

F ............................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

F ............................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

F ............................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

FL ..........................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

FL ..........................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

FL700L ..................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

FL700L ..................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

(continued on next page)

Mack

Model Engine Description No.

FL700L ..................................11.0L 672 OHV Turbo-Diesel L6

FL700L ..................................11.0L 672 OHV Turbo-Diesel L6

FL700L ..................................11.0L 672 OHV Turbo-Diesel L6

FL700LS................................11.0L 672 OHV Diesel L6 4.875"

FL700LS................................11.0L 672 OHV Turbo-Diesel L6

FL700LS................................11.0L 672 OHV Turbo-Diesel L6

FL700LS................................11.0L 672 OHV Turbo-Diesel L6

FL700LS................................11.0L 672 OHV Turbo-Diesel L6

FL700LT................................ 11.0L 672 OHV Turbo-Diesel L6

FL700LT................................ 11.0L 672 OHV Turbo-Diesel L6

FS700L..................................11.0L 672 OHV Diesel L6 4.875"

FS700L..................................11.0L 672 OHV Turbo-Diesel L6

FS700L..................................11.0L 672 OHV Turbo-Diesel L6

FS700L..................................11.0L 672 OHV Turbo-Diesel L6

FS700L..................................11.0L 672 OHV Turbo-Diesel L6

FS700LS................................

FS700LS................................

FS700LS................................11.0L 672 OHV Turbo-Diesel L6

FS700LS................................11.0L 672 OHV Turbo-Diesel L6

FS700LS................................11.0L 672 OHV Turbo-Diesel L6

FS700LST .............................11.0L 672 OHV Turbo-Diesel L6

FS700LST .............................11.0L 672 OHV Turbo-Diesel L6

FS700LT................................ 11.0L 672 OHV Turbo-Diesel L6

FS700LT................................ 11.0L 672 OHV Turbo-Diesel L6

F600 ......................................11.6L 707 OHV Diesel L6 5" Bore

F600LT.................................. 11.0L 672 OHV Diesel L6 4.875"

F600LT.................................. 11.0L 672 OHV Turbo-Diesel L6

F600LT.................................. 11.0L 672 OHV Turbo-Diesel L6

F600LT.................................. 11.6L 707 OHV Diesel L6 5" Bore

F600T.................................... 11.0L 672 OHV Diesel L6 4.875"

F600T.................................... 11.0L 672 OHV Turbo-Diesel L6

F600T.................................... 11.0L 672 OHV Turbo-Diesel L6

F600T.................................... 11.6L 707 OHV Diesel L6 5" Bore

F607ST.................................. 11.0L 672 OHV Diesel L6 4.875"

F607T.................................... 11.0L 672 OHV Diesel L6 4.875"

F609T.................................... 11.6L 707 OHV Diesel L6 5" Bore

4.875" Bore H/D Truck ................. 10

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 12

Bore H/D Truck............................... 8

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

Bore H/D Truck............................... 8

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 12

11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

4.875" Bore H/D Truck ................. 11

4.875" Bore H/D Truck ................. 12

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

H/D Truck ..................................... 15

Bore H/D Truck............................... 8

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

H/D Truck ..................................... 15

Bore H/D Truck............................... 8

4.875" Bore H/D Truck ................... 9

4.875" Bore H/D Truck ................. 10

H/D Truck ..................................... 15

Bore H/D Truck............................... 8

Bore H/D Truck............................... 8

H/D Truck ..................................... 15

Line

5

Mack

Model Index

Model Engine Description No.

F700L ....................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

F700L ....................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

F700L ....................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

F700L ....................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

F700L ....................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

F700LS..................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

F700LS..................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

F700LS..................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

F700LS..................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

F700LS..................................11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

F700LST................................ 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

F700LST................................ 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

F700LST................................ 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

F700LST................................ 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

F700LST................................ 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

F700LST................................ 11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

F700LT.................................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

F700LT.................................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

F700ST.................................. 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

F700ST.................................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

F700ST.................................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

F700ST.................................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

F700ST.................................. 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

F700ST.................................. 11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

F700T.................................... 11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

F700T.................................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................... 9

F700T.................................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 10

F700T.................................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 11

F700T.................................... 11.0L 672 OHV Turbo-Diesel L6

4.875" Bore H/D Truck ................. 12

F700T.................................... 11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15

F707 ......................................11.0L 672 OHV Diesel L6 4.875"

Bore H/D Truck............................... 8

F709 ......................................11.6L 707 OHV Diesel L6 5" Bore

H/D Truck ..................................... 15