Page 1

R216

Rotary Disc Header

Unloading and Assembly Instructions

214882 Revision C

Original Instruction

The harvesting specialists.

Page 2

R216 SP Rotary Disc Header

1028977

Published May 2019.

© 2019 MacDon Industries, Ltd.

The information in this publication is based on the information available and in effect at the time of printing. MacDon

Industries, Ltd. makes no representation or warranty of any kind, whether expressed or implied, with respect to the

information in this publication. MacDon Industries, Ltd. reserves the right to make changes at any time without notice.

Page 3

Introduction

This document describes the unloading, setup, and predelivery requirements for the MacDon R216 Rotary Disc Header.

To ensure your customers receive all of the performance and safety benefits from this product, carefully follow the

unloading and assembly procedure from the beginning through to completion.

Retain this instruction for future reference.

Carefully read all the material provided before attempting to unload, assemble, or use the machine.

This instruction is currently available in English only.

214882 i Revision C

Page 4

Summary of Changes

At MacDon, we’re continuously making improvements, and occasionally these improvements affect product

documentation. The following list provides an account of major changes from the previous version of this document.

Internal Use

Section Summary of Change

—

• 3.1 Removing Shipping

Supports, page 9

• 3.4 Removing Shipping

Stands, page 21

Revision B was never published. Previous publication is revision A.

Edited steps and rearranged between the two topics. Audit

Only

—

3.2 Lowering the Header, page

18

3.5 Adjusting Rear Baffle

Deflectors, page 23

4.1 Assembling and Installing

Forming Shield, page 27

4.2 Routing Electrical Harness,

page 35

4.3 Attaching Disc Header, page

38

• 4.4 Connecting Rotary Disc

Header Hydraulics Using

Quick Couplers, page 45

• 4.5 Connecting Disc Header

Hydraulics Using Hard

Plumbing, page 47

5.2 Crop Dividers Kit, page 56

Added note alerting readers to the potential for contact between

the lowering chains and hazard light brackets on the header.

Updated illustrations.

Edited details about hardware installation during forming shield

installation. Updated illustrations.

Edited procedure to include additional detail about installing cable

ties securing the electrical harness on the windrower.

Edited attaching procedure to include steps for positioning header

supports for connection, and adjusting forming shield height

according to whether a Double Windrow Attachment (DWA) option

is included on the machine. Added step to secure header harness.

Edited steps to clarify relief valve orientation on the windrower.

Edited procedure to include additional detail for removing/installing

hardware during crop divider installation.

Audit

Audit

Audit

Audit

Audit

Audit

Audit

214882 ii Revision C

Page 5

TABLE OF CONTENTS

Introduction ................................................................................................................................................i

Summary of Changes....................................................................................................................................ii

Chapter 1: Safety ........................................................................................................................................ 1

1.1 Signal Words .........................................................................................................................................1

1.2 General Safety .......................................................................................................................................2

1.3 Welding Precaution ................................................................................................................................4

1.4 Safety Signs ...........................................................................................................................................5

Chapter 2: Unloading the Header .............................................................................................................. 7

Chapter 3: Assembling the Header ............................................................................................................ 9

3.1 Removing Shipping Supports ....................................................................................................................9

3.1.1 Installing Adjustable Gauge Roller Kit..... .......................................................................................... 12

3.1.2 Installing Adjustable Skid Shoes Kit. ................................................................................................. 15

3.2 Lowering the Header............................................................................................................................. 18

3.3 Unpacking Hydraulic Hoses and Electrical Harness...................................................................................... 20

3.4 Removing Shipping Stands ..................................................................................................................... 21

3.5 Adjusting Rear Baffle Deflectors .............................................................................................................. 23

3.6 Unpacking Curtain ................................................................................................................................ 25

Chapter 4: Attaching Header to M1240 Windrower............................................................................... 27

4.1 Assembling and Installing Forming Shield.................................................................................................. 27

4.2 Routing Electrical Harness ...................................................................................................................... 35

4.3 Attaching Disc Header ........................................................................................................................... 38

4.4 Connecting Rotary Disc Header Hydraulics Using Quick Couplers .................................................................. 45

4.5 Connecting Disc Header Hydraulics Using Hard Plumbing ............................................................................ 47

4.6 Restoring Float for Disc Header ............................................................................................................... 50

4.7 Calibrating Windrower Knife Drive on the Harvest Performance Tracker Display .............................................. 52

Chapter 5: Installing Options.................................................................................................................... 55

5.1 Electric Remote Baffle Kit....................................................................................................................... 55

5.2 Crop Dividers Kit................................................................................................................................... 56

5.3 Adjustable Gauge Roller Kit .................................................................................................................... 58

5.4 Adjustable Skid Shoes Kit ....................................................................................................................... 59

Chapter 6: Lubricating the Disc Header ................................................................................................... 61

6.1 Lubrication Locations ............................................................................................................................ 62

Chapter 7: Performing Predelivery Checks.............................................................................................. 65

7.1 Conditioner Drive Belt ........................................................................................................................... 65

7.1.1 Inspecting Conditioner Drive Belt.................................................................................................... 65

7.1.2 Adjusting Conditioner Drive Belt ..................................................................................................... 66

214882 iii Revision C

Page 6

TABLE OF CONTENTS

7.2 Header Float .. ...................................................................................................................................... 68

7.2.1 Checking Float............................................................................................................................. 68

7.2.2 Setting the Float .......................................................................................................................... 69

7.3 Roll Timing .......................................................................................................................................... 70

7.3.1 Adjusting Roll Timing .................................................................................................................... 70

7.4 Roll Gap .............................................................................................................................................. 74

7.4.1 Adjusting Roll Gap ........................................................................................................................ 74

7.5 Roll Tension......................................................................................................................................... 75

7.5.1 Checking Roll Tension ................................................................................................................... 75

7.5.2 Adjusting Roll Tension................................................................................................................... 76

7.6 Hanging Drums .................................................................................................................................... 77

7.6.1 Checking and Adjusting Hanging Drum Drive..................................................................................... 77

7.7 Feed Roll Drive..................................................................................................................................... 78

7.7.1 Checking and Adjusting Feed Roll Drive............................................................................................ 78

7.8 Checking and Adding Conditioner Roll Timing Gearbox Oil ........................................................................... 79

7.9 Checking and Adding Oil in Header Drive Gearbox ...................................................................................... 80

7.10 Checking and Adding Lubricant in Cutterbar ............................................................................................ 82

7.11 Checking Lights................................................................................................................................... 85

7.12 Checking Manuals ............................................................................................................................... 86

7.13 Running up the Header ........................................................................................................................ 87

Chapter 8: Reference................................................................................................................................ 89

8.1 Recommended Lubricants ... ................................................................................................................... 89

8.2 Torque Specifications ............................................................................................................................ 90

8.2.1 Metric Bolt Specifications.. ............................................................................................................ 90

8.2.2 Metric Bolt Specifications Bolting into Cast Aluminum ........................................................................ 92

8.2.3 O-Ring Boss Hydraulic Fittings – Adjustable ...................................................................................... 93

8.2.4 O-Ring Boss Hydraulic Fittings – Non-Adjustable ................................................................................ 95

8.2.5 O-Ring Face Seal Hydraulic Fittings .................................................................................................. 96

8.2.6 Tapered Pipe Thread Fittings.......................................................................................................... 97

8.3 Conversion Chart .................................................................................................................................. 98

8.4 Definitions .......................................................................................................................................... 99

Predelivery Checklist .............................................................................................................................. 101

214882 iv Revision C

Page 7

Chapter 1: Safety

1.1 Signal Words

Three signal words, DANGER, WARNING, and CAUTION, are used to alert you to hazardous situations. Two signal words,

IMPORTANT and NOTE, identify non-safety related information. Signal words are selected using the following guidelines:

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. It may also be

used to alert against unsafe practices.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. It may be used

to alert against unsafe practices.

IMPORTANT:

Indicates a situation that, if not avoided, could result in a malfunction or damage to the machine.

NOTE:

Provides additional information or advice.

214882 1 Revision C

Page 8

SAFETY

1.2 General Safety

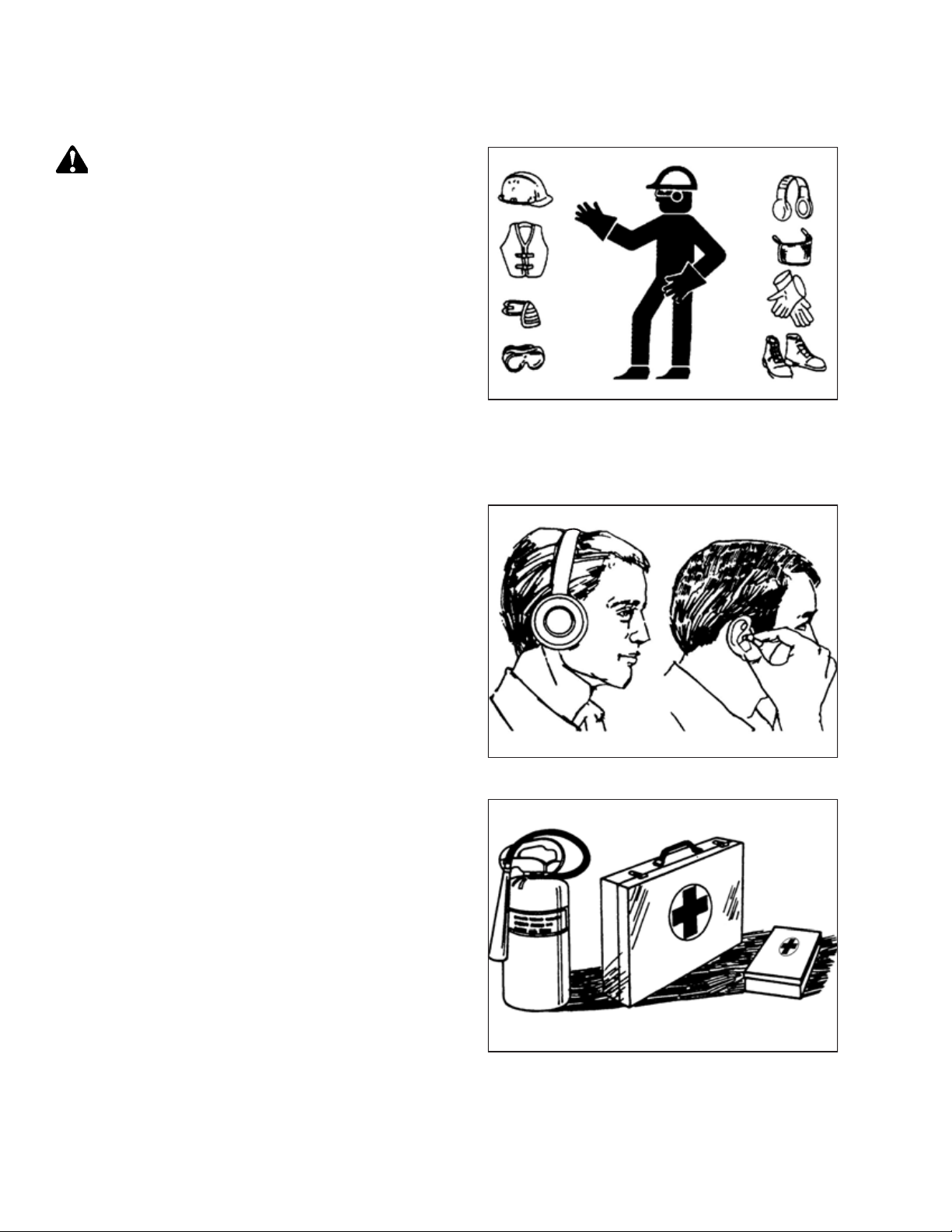

CAUTION

The following general farm safety precautions should be part of

your operating procedure for all types of machinery.

Protect yourself.

• When assembling, operating, and servicing machinery, wear

all protective clothing and personal safety devices that could

be necessary for job at hand. Do NOT take chances. You may

need the following:

• Hard hat

• Protective footwear with slip-resistant soles

• Protective glasses or goggles

• Heavy gloves

• Wet weather gear

• Respirator or filter mask

• Be aware that exposure to loud noises can cause hearing

impairment or loss. Wear suitable hearing protection devices

such as earmuffs or earplugs to help protect against loud

noises.

1000004

Figure 1.1: Safety Equipment

Figure 1.2: Safety Equipment

• Provide a first aid kit in case of emergencies.

• Keep a properly maintained fire extinguisher on the machine.

Be familiar with its proper use.

• Keep young children away from machinery at all times.

• Be aware that accidents often happen when the operator is

tired or in a hurry. Take time to consider safest way. NEVER

ignore warning signs of fatigue.

Figure 1.3: Safety Equipment

214882 2 Revision C

1000005

1010391

Page 9

1000007

1000008

1000009

SAFETY

• Wear close-fitting clothing and cover long hair. NEVER wear

dangling items such as scarves or bracelets.

• Keep all shields in place. NEVER alter or remove safety

equipment. Make sure driveline guards can rotate

independently of shaft and can telescope freely.

• Use only service and repair parts made or approved by

equipment manufacturer. Substituted parts may not meet

strength, design, or safety requirements.

• Keep hands, feet, clothing, and hair away from moving parts.

NEVER attempt to clear obstructions or objects from a

machine while engine is running.

• Do NOT modify machine. Unauthorized modifications may

impair machine function and/or safety. It may also shorten

machine’s life.

Figure 1.4: Safety around Equipment

• To avoid injury or death from unexpected startup of machine,

ALWAYS stop the engine and remove the key from the

ignition before leaving the operator’s seat for any reason.

• Keep service area clean and dry. Wet or oily floors are

slippery. Wet spots can be dangerous when working with

electrical equipment. Be sure all electrical outlets and tools

are properly grounded.

• Keep work area well lit.

• Keep machinery clean. Straw and chaff on a hot engine is a

fire hazard. Do NOT allow oil or grease to accumulate on

service platforms, ladders, or controls. Clean machines before

storage.

• NEVER use gasoline, naphtha, or any volatile material for

cleaning purposes. These materials may be toxic and/or

flammable.

• When storing machinery, cover sharp or extending

components to prevent injury from accidental contact.

Figure 1.5: Safety around Equipment

Figure 1.6: Safety around Equipment

214882 3 Revision C

Page 10

SAFETY

1.3 Welding Precaution

Welding should never be attempted on the header while it is connected to a windrower.

WARNING

Severe damage to sensitive, expensive electronics can result from welding on the header while it is connected to the

windrower. It can be impossible to know what effect high current could have with regard to future malfunctions or

shorter lifespan. It is very important that welding on the header is not attempted while the header is connected to the

windrower.

If you need to do any welding on the header, it should first be disconnected and removed from the windrower.

If it is unfeasible to disconnect the header from the windrower before attempting welding,for welding precautions detailing

all electrical components that must be disconnected first for safe welding.

214882 4 Revision C

Page 11

1.4 Safety Signs

1000694

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or illegible.

• If original part on which a safety sign was installed is

replaced, be sure the repair part displays the current

safety sign.

SAFETY

Figure 1.7: Operator’s Manual Decal

214882 5 Revision C

Page 12

Page 13

Chapter 2: Unloading the Header

1013855

A

B

C

1028160

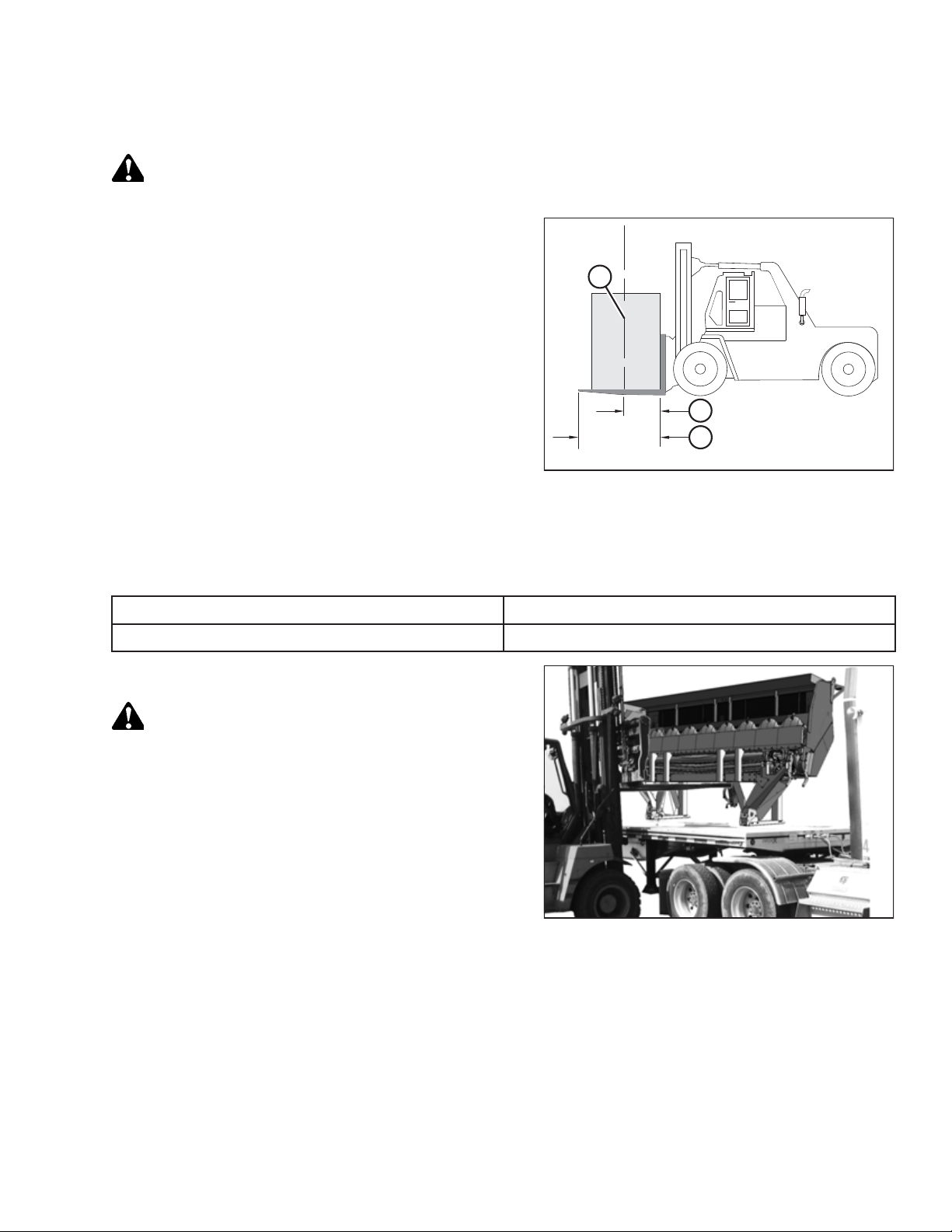

WARNING

To avoid injury to bystanders from being struck by machinery, do NOT allow people to stand in unloading area.

IMPORTANT:

Equipment used for unloading the header must meet or exceed

the requirements specified below. Using inadequate equipment

may result in chain breakage, machine damage, or the vehicle

tipping.

NOTE:

Forklifts are normally rated for a load located 610 mm (24 in.)

ahead of the back end of the forks. To obtain the forklift

capacity at 1220 mm (48 in.), check with your forklift distributor.

Figure 2.1: Minimum Lifting Capacity

A - Load Center of Gravity

B - Load Center 1220 mm (48 in.) from Back of Forks

C - Minimum Fork Length 1981 mm (78 in.)

Table 2.1 Lifting Vehicle

Minimum Capacity

Minimum Fork Length

1. Remove the hauler’s tie-down straps and chains.

WARNING

Be sure forks are secure before moving away from load. Stand

clear when lifting.

2. Approach the rotary disc header from its underside and

slide the forks under the lifting framework as far as

possible.

IMPORTANT:

If the load is two units wide, take care to avoid contacting

the other machine.

3. Raise the rotary disc header off the deck.

3630 kg (8000 lb.)

198 cm (78 in.)

Figure 2.2: Lifting Rotary Disc Header off Trailer

214882 7 Revision C

Page 14

UNLOADING THE HEADER

4. Back up until the rotary disc header clears the trailer, and

slowly lower it to 150 mm (6 in.) from the ground.

5. Take the rotary disc header to the storage or setup area.

6. Set the rotary disc header down on secure, level ground. Do

NOT lower the header into working position.

7. Check for shipping damage and missing parts.

1028097

Figure 2.3: Moving Disc Header with Forklift

214882 8 Revision C

Page 15

Chapter 3: Assembling the Header

1027916

A

A

A

A

B

B

B

Follow each procedure in this chapter in order.

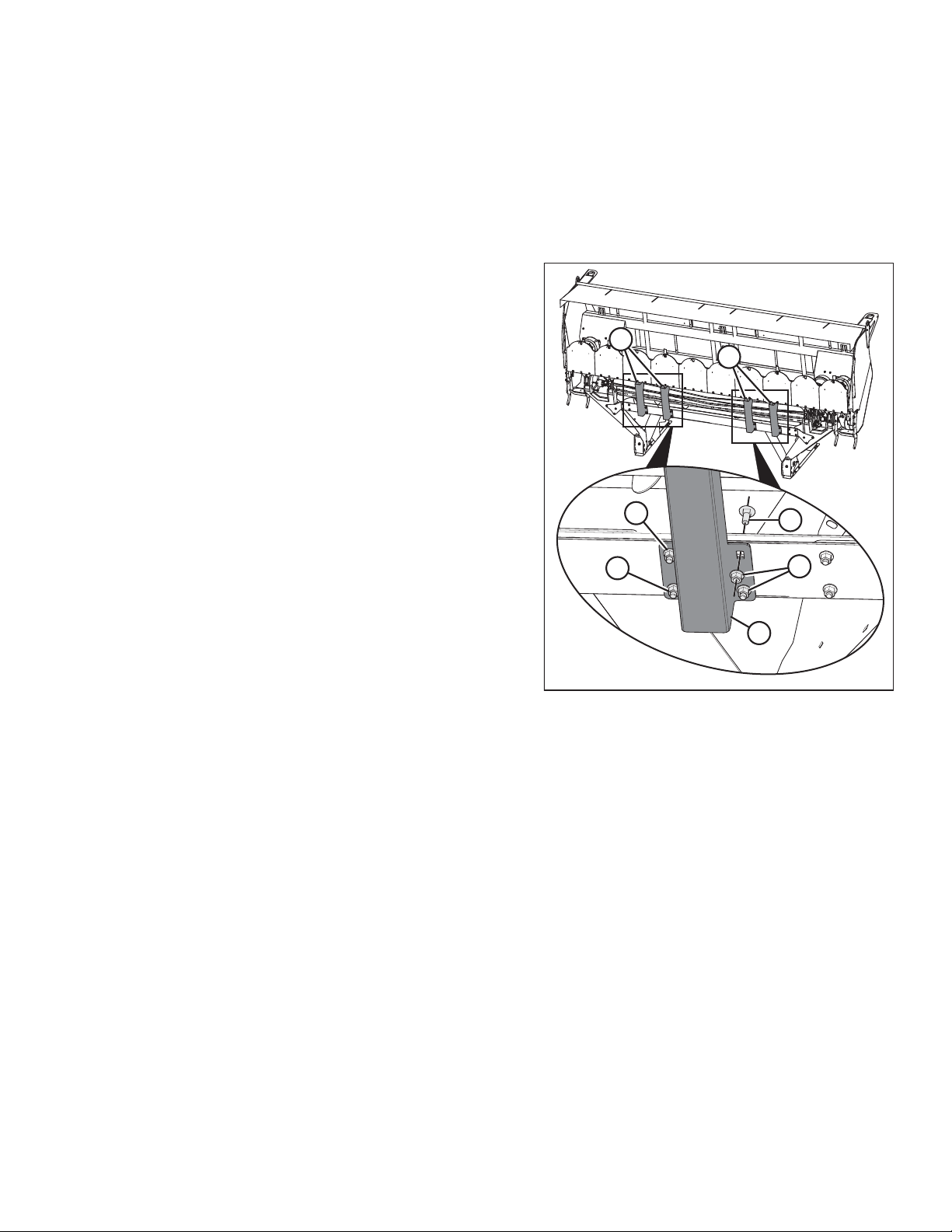

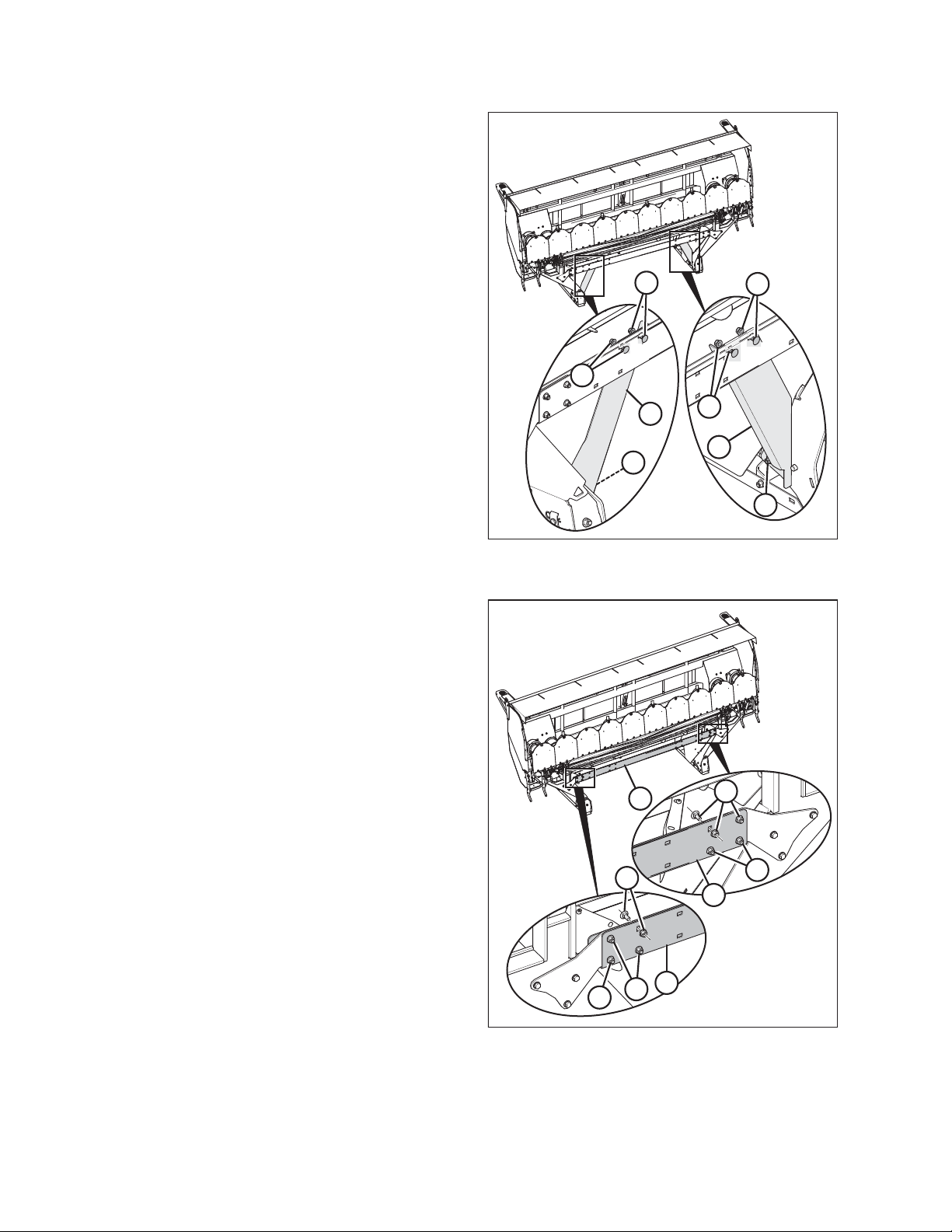

3.1 Removing Shipping Supports

To remove the shipping supports from the cutterbar side of the header, follow these steps:

1. Remove four bolts and nuts (A) from each yellow shipping

support (B) and remove the four supports from the

disc header.

Figure 3.1: Shipping Supports

214882 9 Revision C

Page 16

ASSEMBLING THE HEADER

2. Remove nuts and bolts (A) from the yellow channel and

header supports.

3. Remove yellow braces (B) from the header.

4. Remove four nuts and bolts (A) holding yellow channel (B)

in place against the plates on both sides of the header.

5. Remove channel (B) from the header.

A

A

A

B

A

B

A

A

Figure 3.2: Shipping Stand Brace – Right Side Shown,

Left Side Opposite

1029718

B

A

A

A

B

B

A

A

Figure 3.3: Shipping Channel – Right Side Shown, Left

Side Opposite

214882 10 Revision C

1029724

Page 17

1029728

A

A

A

A

A

B

B

ASSEMBLING THE HEADER

6. Remove three bolts and washers (A) holding each yellow

plate (B) onto the header supports.

7. Remove plates (B) from the header.

8. Each header is shipped with either gauge rollers or skid

shoes (but not both). Refer to the relevant installation

procedure listed below:

• 3.1.1 Installing Adjustable Gauge Roller Kit, page 12

• 3.1.2 Installing Adjustable Skid Shoes Kit, page 15

Figure 3.4: Plates

214882 11 Revision C

Page 18

ASSEMBLING THE HEADER

3.1.1 Installing Adjustable Gauge Roller Kit

Follow these steps and install the Adjustable Gauge Roller kit (MD #B6666) while the header is still set on the ground on its

shipping stands:

NOTE:

If you are installing the Adjustable Skid Shoe kit (MD #B6667), refer to 3.1.2 Installing Adjustable Skid Shoes Kit, page 15.

1. Remove the gauge rollers from the shipping crate and

remove lynch pin (A) and bar (B) from each gauge roller (C).

Retain the bars and lynch pins.

B

C

A

C

B

Figure 3.5: Gauge Rollers

1028056

214882 12 Revision C

Page 19

1028810

A

A

B

B

C

F

D

E

E

F

C

1028035

A

B

C

C

D

ASSEMBLING THE HEADER

2. Remove and retain clevis pins (A) and lynch pins (B) from

holes (C) on both ends of gauge roller (D).

3. Align holes (C) with holes (E) in the header’s support

bracket (F).

4. Secure gauge roller (A) to support bracket (B) using

retained clevis pins (C) and lynch pins (D).

NOTE:

Insert clevis pins (C) from outside gauge roller (A) and

secure with lynch pins (D) from inside gauge roller (A).

Figure 3.6: Gauge Roller Assembly

Figure 3.7: Clevis Pins and Lynch Pins

214882 13 Revision C

Page 20

ASSEMBLING THE HEADER

5. Fully insert retained bar (A) into slot (B) from the inboard

side of the gauge roller.

B

6. Secure bar (A) with retained lynch pin (B).

7. Repeat the installation on the opposite side of the

disc header.

8. Continue to 3.2 Lowering the Header, page 18.

A

1028033

Figure 3.8: Bar and Support Bracket

A

B

1028030

Figure 3.9: Bar and Lynch Pin

214882 14 Revision C

Page 21

1028048

A

B

C

D

A

B

D

C

ASSEMBLING THE HEADER

3.1.2 Installing Adjustable Skid Shoes Kit

Follow these steps and install the Adjustable Skid Shoes kit (MD #B6667) while the disc header is still set on the ground on

its shipping stands:

NOTE:

If you are installing the Adjustable Gauge Roller kit (MD #B6666), refer to 3.1.1 Installing Adjustable Gauge Roller Kit, page

12.

1. Remove the skid shoes from the shipping crate and remove

bolts (A), washers (B), spacers (C), and nuts (D). Retain the

hardware.

Figure 3.10: Skid Shoe

214882 15 Revision C

Page 22

A

B

C

D

E

F

F

E

D

C

ASSEMBLING THE HEADER

2. Secure the back of skid shoe (A) to bracket (B) in two

locations with retained bolts (C), washers (D), spacers (E),

and nuts (F).

NOTE:

Bolt heads should be set outside the skid shoes.

3. Position skid shoe (A) on bracket (B) in fully raised position

(as shown) by aligning skid shoe mounting holes (C) with

bracket mounting holes (D).

Figure 3.11: Skid Shoe

D

B

C

D

A

C

Figure 3.12: Fully Raised Alignment Position

1028834

1027935

214882 16 Revision C

Page 23

1027927

A

A

B

1027925

A

B

A

ASSEMBLING THE HEADER

4. Insert clevis pins (A) from outside the skid shoe (B).

5. Secure each clevis pin (A) with a lynch pin (B).

NOTE:

Lynch pins should be inserted in the clevis pin from inside

the skid shoe.

6. Repeat the installation on the opposite side of the

disc header.

Figure 3.13: Clevis Pins

7. Continue to 3.2 Lowering the Header, page 18.

Figure 3.14: Clevis Pin and Lynch Pin

214882 17 Revision C

Page 24

ASSEMBLING THE HEADER

3.2 Lowering the Header

Complete the following steps to lower the header into working position after it has been lifted off its shipping trailer and

set down on the ground.

CAUTION

Ensure spreader bar is secured to the forks so that it cannot slide off the forks or towards the mast as the header is

lowered to the ground.

Table 3.1 Lifting Vehicle

Chain Type

Minimum Working Load

1. Place wood blocks (A) at a distance of 42 cm (16 1/2 in.) (B)

on the outboard side of each shipping stand (C).

NOTE:

Wood blocks should be 2 x 4 in. and 1–1.5 m (3–5 ft.) in

length.

Overhead lifting quality (1/2 in.)

2270 kg (5000 lb.)

A

B

C

Figure 3.15: Block Placement

A

B

C

1028066

214882 18 Revision C

Page 25

1028261

A

B

B

C

1028609

A

B

B

ASSEMBLING THE HEADER

2. Attach spreader bar (A) to forks.

IMPORTANT:

Length of spreader bar must be approximately 457 cm

(15 ft.).

3. Approach the header from its underside with the forklift.

4. Attach chains with hooks to the spreader bar (A) and hook

into shipping brackets (B) on both sides of the disc header.

CAUTION

Stand clear when lowering the disc header.

IMPORTANT:

Chain length must be sufficient to provide a minimum

clearance (C) of 1219 mm (48 in.) between the disc header

and the spreader bar.

IMPORTANT:

Do NOT attach chain hooks to the hazard light standards.

5. Raise forks until lift chains are fully tensioned.

Figure 3.16: Spreader Bar Attached to Disc Header

6. Back up the forklift SLOWLY, and lower the disc header (A)

into working position on the wooden blocks (B) placed in

Step 1, page 18.

NOTE:

Watch out for contact between hazard light brackets and

the lowering chains while the header is being lowered. Take

care to avoid damaging the lights and brackets.

7. Remove chains from the header.

Figure 3.17: Lowering Disc Header to the Ground

214882 19 Revision C

Page 26

ASSEMBLING THE HEADER

3.3 Unpacking Hydraulic Hoses and Electrical Harness

Follow these steps to unpack the hydraulic hoses and electrical harness.

1. Remove shipping wire securing hose ends (A) to secured

hoses (B) and remove all packing foam from the hose ends.

NOTE:

Packing foam not shown in illustration at right.

2. Remove packing foam from hose support (C).

NOTE:

Packing foam not shown in illustration at right.

Figure 3.18: Hydraulic Hose Bundle in Shipping

Position

3. Remove shipping wire cross ties (A) securing hoses (B) to

center-link (C) near shipping stands (D), and pull the hoses

out from under the center-link.

NOTE:

Shipping wire cross ties not shown in illustration at right.

A

C

B

C

1028196

B

E

4. Remove shipping wire (E) from center-link (C) and move

hoses (B) away from the center-link. Rest hoses (B) on top

of the header.

5. Remove shipping wire and remove coiled electrical

harness (A) from the center-link (B). Place the harness in a

safe and clean spot until it’s time to install on an M1240

Windrower.

A

D

1028227

Figure 3.19: Hydraulic Hose Bundle in Shipping

Position

B

A

1028228

Figure 3.20: Center-Link

214882 20 Revision C

Page 27

1028173

A

B

C

1028176

A

A

B

B

A

A

B

B

C

C

A

A

B

B

A

B

A

B

ASSEMBLING THE HEADER

3.4 Removing Shipping Stands

Complete the following steps to remove the remaining shipping stands from the header.

NOTE:

This procedure must be completed on both sides of the header near the forming shields.

1. Remove nut (A) from the outboard side of the right header

boot and bolt (B) from the inboard side of the right

shipping stand (C). Repeat on the opposite side of the

header.

Figure 3.21: Shipping Stand – Right Side Shown, Left

Side Opposite

2. Remove four nuts (A) and bolts (B) from top of shipping

stands (C) and remove the shipping stands from the header.

Figure 3.22: Shipping Stand

214882 21 Revision C

Page 28

ASSEMBLING THE HEADER

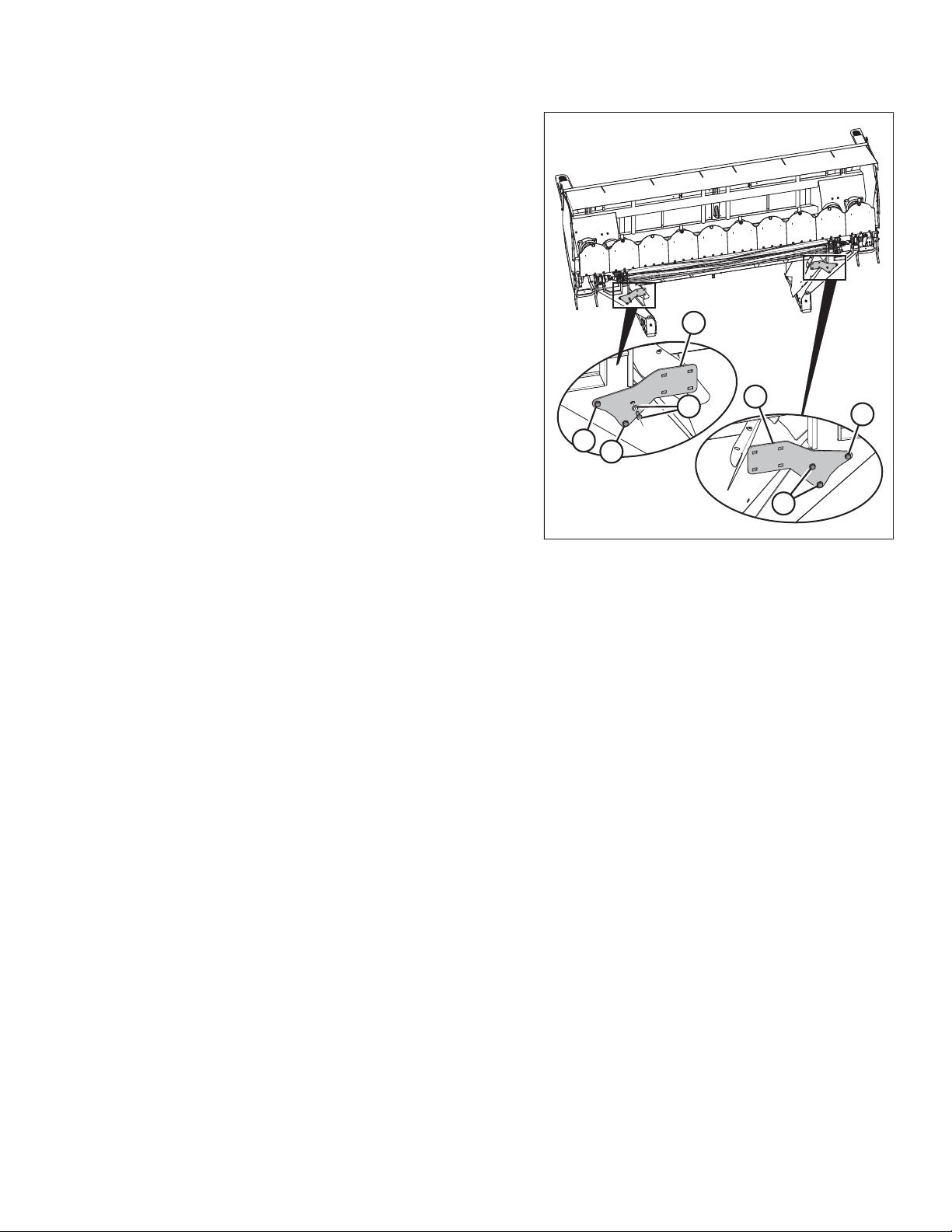

3. Remove and retain bolts (A) and remove shipping plate (B).

Discard plate (B) and reinstall bolts (A) on the header.

Repeat for the other side of the header.

B

A

A

1028182

Figure 3.23: Shipping Plate – Right Side Shown, Left

Side Opposite

214882 22 Revision C

Page 29

1028618

A

B

A

A

A

A

A

C

1028619

A

B

C

1029740

A

B

C

ASSEMBLING THE HEADER

3.5 Adjusting Rear Baffle Deflectors

Four rear baffle deflector fins are located under the baffle. The baffle and its deflectors require adjustment from shipping

configuration to field position.

To adjust the rear baffle and deflector fins, follow these steps:

1. Remove and retain hardware (A) securing deflector (B) to

rear baffle (C). Remove and retain deflector (B) from the

header. Repeat on the opposite side of the header.

NOTE:

There are three sets of hardware (A) on the baffle, but only

two sets hold deflector (B) in place in shipping position.

Ensure all three sets of hardware (A) are removed and

retained.

Figure 3.24: Deflector and Rear Baffle — View of

Deflector Underside, Right Side of the Header

2. Remove pin (A) from baffle handle (B), and adjust the rear

baffle by placing handle (B) in center position on baffle

bracket (C).

3. Replace pin (A) in baffle handle (B) to secure the handle in

fully raised position on baffle bracket (C).

Figure 3.25: Baffle Handle and Baffle Bracket

Figure 3.26: Baffle Handle

214882 23 Revision C

Page 30

ASSEMBLING THE HEADER

4. Turn over deflector (A) and place on rear baffle (B) and

between fixed deflector plate (C) and outer plate (D).

5. Loosely secure deflector (A) in place with retained

hardware (E) in three locations. Do NOT tighten hardware.

Repeat on the opposite side of the header.

6. Adjust the placement of deflector (A) as far inboard as

possible so that it contacts fixed deflector plate (C) welded

in place on the header. Tighten hardware (E) once deflector

is properly placed. Repeat on the opposite side of the

header.

E

D

E

E

A

B

C

1028813

Figure 3.27: Deflector and Rear Baffle

214882 24 Revision C

Page 31

1028348

A

A

A

A

A

A

C

C

A

A

C

B

D

C

1028357

B

B

B

B

B

B

B

B

C

A

ASSEMBLING THE HEADER

3.6 Unpacking Curtain

Follow these steps to unpack the cutterbar curtain on the rotary disc header:

1. Loosen 12 nuts (A) under the disc header top shield

2–3 turns to loosen bumper (B).

IMPORTANT:

Do NOT remove nuts (A) from the disc header; the

hardware should be loosened only enough so cable ties (C)

can be removed.

2. Cut and remove six cable ties (C) securing cutterbar

curtain (D) at the front of the disc header.

Figure 3.28: Cutterbar Curtain

3. Ensure bumper (A) aligns with the disc header top shield

and tighten all loosened hardware (B) to 39 Nm (28.7 lbf·ft)

so bumper (A) and cutterbar curtain (C) are held snugly

in place.

Figure 3.29: Cutterbar Curtain

214882 25 Revision C

Page 32

ASSEMBLING THE HEADER

WARNING

Ensure the cutterbar is completely clear of foreign objects. These objects can be ejected with considerable force when

the machine is started and may result in serious injury or machine damage.

4. Check the cutterbar area for debris and foreign objects. Ensure all shipping material is removed.

5. Ensure that the curtain hangs properly and completely encloses the cutterbar area. Minor creases in the curtain will

eventually straighten out.

214882 26 Revision C

Page 33

Chapter 4: Attaching Header to M1240 Windrower

1028681

A

B

1029658

A

A

B

B

C

D

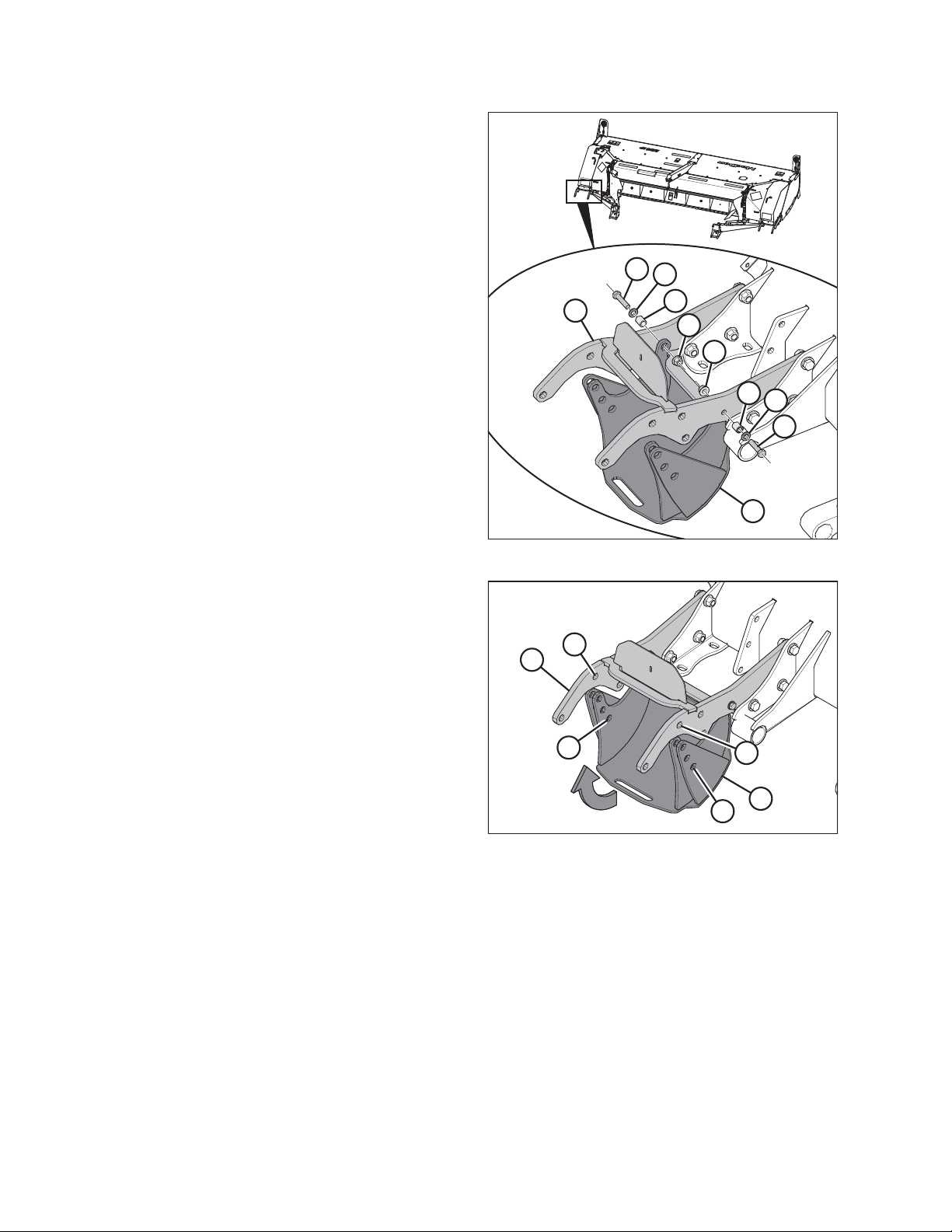

4.1 Assembling and Installing Forming Shield

Unpack and assemble the forming shield as follows:

1. Unpack and remove shipping material from deflectors (A)

and remove deflectors from cover (B).

2. Locate and open the included hardware bag.

Figure 4.1: Forming Shield in Shipping Configuration

3. Remove cotter pins (A) and deflector hinge rod (B) from the

right side bracket (C) and side deflector (D). Retain rod

and pins.

Figure 4.2: Deflector Hinge Rod and Cotter Pins

214882 27 Revision C

Page 34

ATTACHING HEADER TO M1240 WINDROWER

4. Lay the cover upside down on an even work surface and

Install right side bracket (A) on the right side of the forming

shield with five 25 mm-long short neck M10 bolts (B) and

five nuts (C). Repeat this step and install the left side

bracket on the left side of the forming shield.

NOTE:

Install bolts (B) from the forming shield’s underside and

install nuts (C) on the forming shield’s top side.

B

B

B

C

C

B

A

B

C

C

C

5. Secure baffle (A) to side bracket (B) with bolt (C) and

nut (D). Repeat on the other side of the header.

Figure 4.3: Right Side Bracket

B

A

C

Figure 4.4: Right Side Bracket and Baffle

1028688

D

D

1028710

214882 28 Revision C

Page 35

1028701

A

A

B

B

C

D

C

D

1028704

A

B

C

C

ATTACHING HEADER TO M1240 WINDROWER

6. Install bolt (A) and nut (B) through plate (C) and forming

shield angle (D). Repeat this step on the left side of the

forming shield.

7. Flip the forming shield over so the forming shield is right

side up and set on an even work surface.

8. Slide the angled end of deflector adjustment cover (A)

under top sheet support (B) on the top of the forming

shield. Repeat on other side of the forming shield.

Figure 4.5: Plate and Forming Shield Angle

NOTE:

Hardware (C) securing top sheet support (B) may need to

be loosened to fit deflector adjustment cover (A)

underneath. Retighten any loosened hardware to hold the

deflector adjustment covers (A) in place on the forming

shield.

Figure 4.6: Deflector Adjustment Cover — Right

Side Up

214882 29 Revision C

Page 36

ATTACHING HEADER TO M1240 WINDROWER

9. Flip the forming shield upside down and set on an even

work surface.

10. Install side deflector (A) on the right side of the forming

shield with one 30 mm-long short neck M10 bolt (B).

B

11. Secure bolt (B) near the front of the forming shield with

washer (C) and two jam nuts (D). Snug nuts (D) against the

forming shield, but keep them loose enough to rotate

freely.

NOTE:

Washer (C) and nuts (D) should be on top of the forming

shield when the forming shield is set upright.

12. Use one 25 mm-long square neck M12 bolt (E) near the

rear of the forming shield in deflector adjustment cover (F)

to secure two washers (G), rubber washer (H), and

handle (J). Repeat steps for the left side of the forming

shield.

NOTE:

Handle (J) should be on top of the forming shield when the

forming shield is set upright.

13. At the rear of the forming shield, insert deflector hinge

rod (A) through the hinges on installed side deflector (B)

and side bracket (C).

14. Secure deflector hinge rod (A) in place with two cotter

pins (D), one placed at the top and the bottom of the

hinge rod.

15. Repeat steps on the other side of the forming shield.

C

D

Figure 4.7: Right Side Bracket

D

B

A

E

F

G

H

G

J

1029659

A

C

D

Figure 4.8: Deflector Hinge Rod

214882 30 Revision C

1028706

Page 37

1028707

A

F

D

B

B

C

E

1028686

A

B

C

C

C

C

1028716

ATTACHING HEADER TO M1240 WINDROWER

16. Install handle (A) with two flat washers (B) and one rubber

washer (C) using bolt (D) installed through baffle (E) and

right side bracket (F). Repeat installation at the left side of

the forming shield.

17. Lay cover (A) upside down on a flat surface.

18. Install right deflector (B) on the right side of cover (A) using

two bolts and nuts (C). Repeat step to install the left

deflector at left side of cover (A).

NOTE:

The narrower deflector end faces the front of cover (A),

while the wider end faces the rear.

Figure 4.9: Baffle Handle

NOTE:

Deflector removed from illustration for clarity.

Figure 4.10: Forming Shield Cover Upside Down —

Right Side Shown

19. Flip the forming shield right side up and into installation

position.

Figure 4.11: Forming Shield Right Side Up

214882 31 Revision C

Page 38

ATTACHING HEADER TO M1240 WINDROWER

20. Install shield mount plates (A) on the inside of the

windrower legs with two hex head bolts (B) and

nuts (C) each.

NOTE:

Make sure the top bolt (B) is installed in the foremost

setting hole on the shield mounting plate (A). This ensures

the forming shield is set at its highest setting.

21. Place the forming shield in position under the windrower.

C

B

B

C

22. Remove and retain clevis pins (A) from the front corners of

the forming shield.

C

A

B

C

Figure 4.12: Shield Mount Plates

Figure 4.13: Clevis Pin

B

A

1029662

A

A

1028723

214882 32 Revision C

Page 39

1028725

A

B

C

D

E

1028726

A

A

B

C

ATTACHING HEADER TO M1240 WINDROWER

23. Using spacer (A), hex head bolt (B), and nut (C), attach

forming shield (D) to shield mount plate (E) installed on the

inside of the windrower legs. Repeat on other side of the

windrower and forming shield.

24. Install retained clevis pin (A) to hold forming shield in place.

Repeat on the other side of the forming shield.

NOTE:

Clevis pin (A) should pass under hex head bolt (B) and

spacer installed in the previous step, with its lynch pin (C)

set towards the interior of the header.

Figure 4.14: Shield Mount Plate and Attaching

Hardware

Figure 4.15: Clevis Pin

214882 33 Revision C

Page 40

ATTACHING HEADER TO M1240 WINDROWER

25. Install rubber strap (A) on side bracket (B) using bolt (C),

washer (D), and nut (E). Repeat on the left side of the

forming shield.

26. Pull rubber strap (A) up towards windrower frame and

place onto straight pin (F).

27. Secure rubber strap (A) in place with washer (G) and hair

pin (H).

28. Repeat Step 25, page 34 to Step 27, page 34 for the left

side of the forming shield.

F

G

A

H

B

C

D

E

Figure 4.16: Rubber Strap — Right Side of

Forming Shield

1028728

214882 34 Revision C

Page 41

1028736

A

A

A

A

A

A

B

1018900

A

ATTACHING HEADER TO M1240 WINDROWER

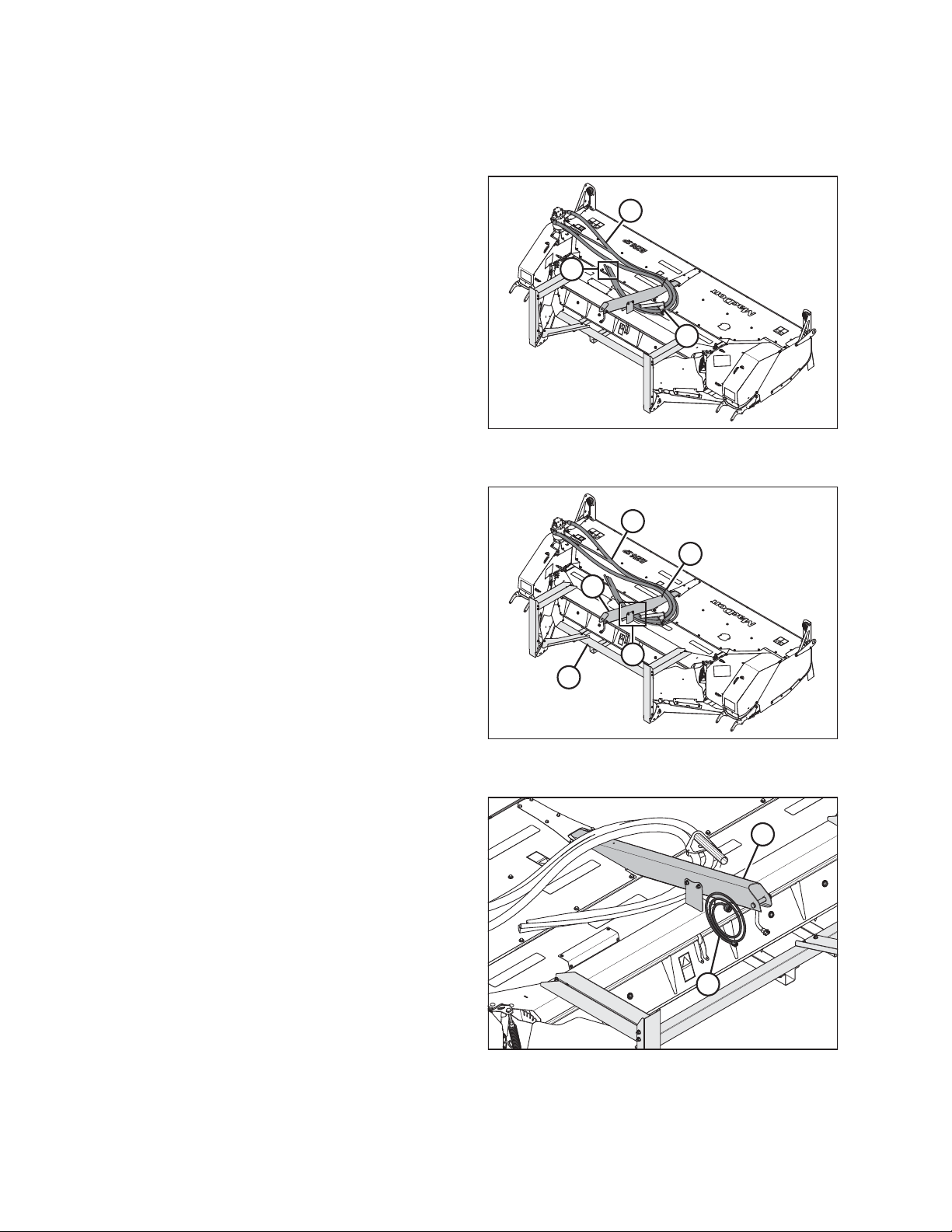

4.2 Routing Electrical Harness

A total of seven cable ties (A) will secure the routed header

electrical harness (B) in place alongside the windrower main

harness and avoid rub/wear points that could damage the

harnesses. Keep cable ties (A) loose on harness until the entire

harness has been routed on the header.

NOTE:

Windrower main harness is not shown in the illustration

at right.

To route the R216 Rotary Disc Header electrical harness on the

M1240 Windrower, follow these steps:

Figure 4.17: Cable Ties Securing Header Electrical

Harness

1. Move windrower left (cab-forward) platform (A) to the

OPEN position. For instructions, refer to the windrower

operator’s manual.

Figure 4.18: Windrower with Left Platform in Open

Position

214882 35 Revision C

Page 42

ATTACHING HEADER TO M1240 WINDROWER

2. Retrieve electrical harness (A) and loosely attach it to

center-link (B) with two cable ties (C).

NOTE:

Cable ties (C) should bundle electrical harness (A) with

other hydraulic hoses from the windrower. The other

hydraulic hoses are not shown in the illustration at right.

B

NOTE:

Do NOT tighten cable ties (C) on harness at this point.

3. Route electrical harness (A) over the windrower forward

cross member and loosely secure it to the windrower main

harness (B) with three cable ties (C).

NOTE:

Do NOT tighten cable ties (C) on harness at this point.

NOTE:

The windrower main harness is only partially illustrated.

A

C

C

1028847

Figure 4.19: Electrical Harness Routed Along CenterLink with Cable Ties

B

C

C

A

C

1028745

Figure 4.20: Forward Cross Member and Cable Ties

214882 36 Revision C

Page 43

1028751

A

B

C

D

1028754

A

B

E

C

D

ATTACHING HEADER TO M1240 WINDROWER

4. Route electrical harness (A) over windrower frame (B)

towards the multicoupler base.

5. Loosely secure electrical harness (A) to the windrower main

harness (C) with one cable tie (D) near the

windrower frame.

NOTE:

Do NOT tighten cable tie (D) on harness at this point.

6. Connect header electrical harness (A) to plug (B) set in

multicoupler base (C).

7. Secure harness (A) to windrower harness (D) with cable

tie (E) to avoid rub/wear points that could damage the

harnesses.

Figure 4.21: Electrical Harness Routing

NOTE:

Ensure there is enough slack in harness (A) before securing

with cable tie (E) to maintain a minimum bend radius of

50 mm (2 in.) and avoid contact with multicoupler base (C).

Figure 4.22: Electrical Connection

214882 37 Revision C

Page 44

ATTACHING HEADER TO M1240 WINDROWER

4.3 Attaching Disc Header

The M1240 Windrower may have an optional self-aligning hydraulic center-link that allows vertical position control of the

center-link from the cab.

WARNING

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key

from the ignition before leaving the operator’s seat for any reason.

1. Hydraulic Center-Link without Self-Alignment: Remove

pin (A) and raise center-link (B) until hook is above the

attachment pin on disc header. Replace pin (A) to hold

center-link in place.

IMPORTANT:

If the center-link is too low, it may contact the disc header

as the windrower approaches the disc header for hookup.

A

B

1016889

2. Remove hairpin (A) from clevis pin (B), and remove pin

from disc header support (C) on both sides of disc header.

Figure 4.23: Hydraulic Center-Link

C

B

A

1021177

Figure 4.24: Disc Header Support

214882 38 Revision C

Page 45

1029675

B

A

C

1015853

1015851

A

B

ATTACHING HEADER TO M1240 WINDROWER

3. Lift header support (A) and place 2 x 4 in. blocks (B) under

the header support. A total of four 2 x 4 in. blocks (B) will

be necessary to raise the boot up and into field position.

Ensure the boot’s bottom edge (C) is parallel with the

ground.

NOTE:

Do NOT stack blocks (B) crosswise as doing so can make the

header unstable when attempting to connect the header

and windrower. Stack blocks (B) parallel with each other.

NOTE:

To better show placement of blocks (B) under the header

supports (A), the illustration at right does not show the two

2 x 4 blocks placed in Step 1, page 18.

4. Repeat Step 3, page 39 on opposite side.

CAUTION

Check to be sure all bystanders have cleared the area.

5. Start the windrower engine.

Figure 4.25: Header Boot — Right Side, Left Opposite

CAUTION

When lowering header lift legs without a header or weight box

attached to the windrower, ensure the float springs tension is

fully released to prevent damage to the header lift linkages.

6. Press rotary scroll knob (A) on the Harvest Performance

Tracker (HPT) display to highlight QuickMenu options.

7. Rotate scroll knob (A) to highlight the HEADER FLOAT

symbol (B), and press scroll knob to select. The header float

adjust screen displays.

Figure 4.26: Header Float Spring

Figure 4.27: HPT Display

214882 39 Revision C

Page 46

ATTACHING HEADER TO M1240 WINDROWER

8. Press soft key 3 (A) to remove the header float.

NOTE:

If the header float is active, the icon at soft key 3 will

display REMOVE FLOAT; if header float has been removed,

the icon will display RESUME FLOAT.

9. Press HEADER DOWN switch (E) on the ground speed

lever (GSL) to fully retract header lift cylinders.

10. Self-Aligning Hydraulic Center-Link: Press the REEL UP

switch (B) on the GSL to raise the center-link until the hook

is above the attachment pin on the header.

Figure 4.28: HPT Display

A

1019607

F

B

IMPORTANT:

If the center-link is too low, it may contact the header as

the windrower approaches the header for hookup.

11. Lift the tractor lift linkage (A) to align with header

supports (B).

12. Drive the windrower slowly forward until lift linkage

feet (A) enter the supports (B). Continue to drive slowly

forward until feet engage the supports and the header

nudges forward.

13. Ensure that feet (A) are properly engaged in supports (B).

C

E

Figure 4.29: GSL

A - Reel Down B - Reel Up

C - Header Tilt Down D - Header Tilt Up

E - Header Down F - Header Up

A

B

A

D

1018911

Figure 4.30: Header Support

214882 40 Revision C

1021743

Page 47

1016903

A

B

C

1028766

A

B

1028763

A

ATTACHING HEADER TO M1240 WINDROWER

14. Self-Aligning Hydraulic Center-Link:

a. Adjust position of the center-link cylinder (A) with the

switches on the GSL until hook (B) is above the header

attachment pin.

IMPORTANT:

Hook release (C) must be down to enable self-locking

mechanism.

b. If the hook release (C) is open (up), stop the engine

and remove the ignition key. Manually push the hook

release (C) down after the hook engages the

header pin.

15. Self-Aligning Hydraulic Center-Link:

a. Lower center-link (A) onto the header with REEL DOWN

switch on the GSL until the center-link locks into

position and the hook release (B) is down.

b. Check that the center-link is locked onto the header by

pressing the REEL UP switch on the GSL.

Figure 4.31: Hydraulic Center-Link

c. Turn off the windrower engine and remove the key

from the ignition.

16. Self-Aligning Hydraulic Center-Link: Connect header

electrical harness (A) to header.

Figure 4.32: Hydraulic Center-Link

Figure 4.33: Header Electrical Harness

214882 41 Revision C

Page 48

ATTACHING HEADER TO M1240 WINDROWER

17. Hydraulic Center-Link without Self-Alignment:

a. Press the HEADER TILT UP or HEADER TILT DOWN

cylinder switches on the GSL to extend or retract the

center-link cylinder until the hook is aligned with the

header attachment pin.

b. Turn off the windrower engine and remove the key.

c. Push down on the rod end of link cylinder (B) until the

hook engages and locks onto the header pin.

A

IMPORTANT:

The hook release must be down to enable the selflocking mechanism. If the hook release is open (up),

manually push it down after the hook engages the pin.

d. Check that center-link (A) is locked onto the header by

pulling upward on rod end (B) of the cylinder.

18. Hydraulic Center-Link without Self-Alignment: Connect

header electrical harness (A) to the header.

19. Install clevis pin (A) through the support and windrower lift

arm and secure with hairpin (B). Repeat for opposite side.

B

1016901

Figure 4.34: Hydraulic Center-Link

A

1028763

Figure 4.35: Header Electrical Harness

IMPORTANT:

Ensure clevis pin (A) is fully inserted, and the hairpin is

installed behind the bracket.

B

CAUTION

A

Check to be sure all bystanders have cleared the area.

20. Start the windrower engine and fully extend the windrower

tilt cylinder.

21. Stop the engine and remove the key from the ignition.

Figure 4.36: Header Support

214882 42 Revision C

1023024

Page 49

1029657

B

B

B

B

B

B

A

C

1029687

A

C

D

A

C

B

B

D

ATTACHING HEADER TO M1240 WINDROWER

22. Pull back on routed header harness (A) to minimize slack in

the routing. Ensure the harness is not under tension and

tighten all cable ties (B) accordingly.

NOTE:

Any excess harness length can be secured under the

windrower’s cab with two additional cable ties provided in

shipping material. A total of nine cable ties are located in

the header’s manual box.

NOTE:

Refer to the installation instructions included in the Electric

Remote Baffle Control kit (MD #B6664) to connect the

electrical harness (A) to the baffle control option. If this

option is not installed on the header, tie the loose end of

the harness at the header to the main header connector

and keep this connector clean and capped for future use.

Figure 4.37: Cable Ties Securing Header Electrical

Harness

For headers without the DWA installed:

23. On both sides of the header, remove and retain bolts (A)

and nuts (B) from the forming shield mounting plates (C).

Loosen bolts and nuts (D) on the mounting plates (C).

NOTE:

Support the forming shield while adjusting the mounting

plates. The forming shield is not shown in the illustration to

better show the mounting plates and their hardware.

24. Pull the mounting plates so they turn downward and install

bolts (A) and nuts (B) through the forming shield frame and

the cutout on shield mounting plate (C). Tighten bolts (D).

This ensures the forming shield is set at its lowest setting.

Figure 4.38: Setting for R216 SP Disc Header without

DWA Option

214882 43 Revision C

Page 50

ATTACHING HEADER TO M1240 WINDROWER

CAUTION

Check to be sure all bystanders have cleared the area.

25. Start the windrower engine and raise the header slightly.

26. Turn off the windrower engine and remove the key from the ignition.

DANGER

To avoid bodily injury from fall of raised header, always engage safety props when working on or around raised header,

and before going under header for any reason.

27. Remove all wooden blocks from beneath the header.

CAUTION

Check to be sure all bystanders have cleared the area.

28. Start the windrower engine and lower the header fully to the ground.

29. Turn off the windrower engine and remove the key from the ignition.

214882 44 Revision C

Page 51

1028852

A

B

C

1028679

A

ATTACHING HEADER TO M1240 WINDROWER

4.4 Connecting Rotary Disc Header Hydraulics Using Quick Couplers

To connect the R216 Rotary Disc Header hydraulic hoses to the M1240 Windrower using quick couplers, follow these steps:

If your windrower is equipped with hard plumb connections, refer to 4.5 Connecting Disc Header Hydraulics Using Hard

Plumbing, page 47 for connection instructions.

1. Route hose bundle (A) from the disc header, under the

windrower frame, then insert pin (B) into hole (C) in the

windrower frame.

NOTE:

Route hoses as straight as possible and avoid rub/wear

points that could damage the hydraulic hoses.

NOTE:

Adding anti-seize to the hose holder pin will make future

removal easier.

Figure 4.39: Hydraulic Hoses

2. Remove protective plugs (A) from the ends of the

hydraulic hoses.

Figure 4.40: Protective Shipping Plugs on R216

Hydraulic Hoses

214882 45 Revision C

Page 52

ATTACHING HEADER TO M1240 WINDROWER

3. Use a clean rag to remove dirt and moisture from the

couplers on the left side of the windrower frame.

4. Make the following hydraulic and electrical connections to

the windrower:

a. Connect disc pressure hose (A) with coupler (B) and

torque to 205–226 Nm (151–167 lbf·ft).

b. Connect disc return hose (C) with coupler (D) and

torque to 205–226 Nm (151–167 lbf·ft).

c. Connect case drain hose (E) to fitting (F), with relief

valve pointing towards the ground. Loosen fitting (F)

and retighten as needed to ensure relief valve is

pointing straight down as shown.

NOTE:

Parts removed from illustration for clarity.

C

A

E

F

B

D

1028759

Figure 4.41: Hydraulic Connections on Rotary Disc

Header and M1240 Windrower

5. Move left windrower platform (A) to the CLOSED position.

For instructions, refer to the windrower operator’s manual.

6. Proceed to 4.6 Restoring Float for Disc Header, page 50.

A

1018914

Figure 4.42: Windrower with Left Platform in Closed

Position

214882 46 Revision C

Page 53

1019114

B

A

B

1028852

A

B

C

ATTACHING HEADER TO M1240 WINDROWER

4.5 Connecting Disc Header Hydraulics Using Hard Plumbing

Hard plumbing helps reduce the potential for leaks at the hydraulic connection sites and helps the header drive run more

efficiently. To connect the R216 Rotary Disc Header to the M1240 Windrower with hard plumb fittings, follow these steps:

If your windrower is equipped with quick coupler connections, refer to 4.4 Connecting Rotary Disc Header Hydraulics Using

Quick Couplers, page 45 for connection instructions.

1. Use a clean rag to remove dirt and moisture from

fittings (B) on the left side of the windrower frame and

remove protective caps (A).

NOTE:

Fittings should be factory-set to 30° to allow hoses to pass

by the multicoupler.

NOTE:

Parts removed from illustration for clarity.

Figure 4.43: Protective Shipping Plugs on M1240 Hard

Plumb Fittings

2. Route hose bundle (A) from the disc header, under the

windrower frame, then insert pin (B) into hole (C) in the

windrower frame.

NOTE:

Route hoses as straight as possible and avoid rub/wear

points that could damage the hydraulic hoses.

NOTE:

Adding anti-seize to the hose holder pin will make future

removal easier.

Figure 4.44: Hydraulic Hoses

214882 47 Revision C

Page 54

ATTACHING HEADER TO M1240 WINDROWER

3. Remove protective plugs (A) from ends of hydraulic hoses.

A

1028679

Figure 4.45: Protective Shipping Plugs on R216

Hydraulic Hoses

4. Make the following hydraulic and electrical connections to

the windrower:

a. Connect disc pressure hose (A) marked with a red cable

tie (B) to hard plumb fitting marked with a red cable

tie (C) and torque to 205–226 Nm (151–157 lbf·ft)

b. Connect disc return hose (D) to hard plumb fitting (E)

and torque to 205–226 Nm (151–167 lbf·ft)

c. Connect case drain hose (F) to fitting (G), with relief

valve pointing towards the ground. Loosen fitting (G)

and retighten as needed to ensure relief valve is

pointing straight down as shown.

NOTE:

Parts removed from illustration for clarity.

D

F

C

G

B

E

Figure 4.46: Hydraulic Connections on Disc Header

and M1240 Windrower using Hard Plumb Fittings

A

1028760

214882 48 Revision C

Page 55

1018914

A

ATTACHING HEADER TO M1240 WINDROWER

5. Move windrower platform (A) to the CLOSED position. For

instructions, refer to the windrower operator’s manual.

Figure 4.47: Windrower with Left Platform in Closed

Position

214882 49 Revision C

Page 56

ATTACHING HEADER TO M1240 WINDROWER

4.6 Restoring Float for Disc Header

Follow these steps to restore the float for an R216 Rotary Disc Header used with an M1240 Windrower:

WARNING

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key

from the ignition before leaving the operator’s seat for any reason.

1. Disengage safety props by turning lever (A) away from the

disc header to raise the safety prop until the lever locks

into vertical position. Repeat for opposite cylinder.

CAUTION

Before starting the machine, check to be sure all bystanders

have cleared the area.

A

1019357

2. Start the engine and press HEADER DOWN switch (A) on

ground speed lever (GSL) to fully lower the disc header.

Figure 4.48: Safety Props

A

1014802

Figure 4.49: GSL

214882 50 Revision C

Page 57

1015851

A

B

1019607

A

ATTACHING HEADER TO M1240 WINDROWER

3. If not prompted by the Harvest Performance Tracker (HPT)

display to restore the header float, restore the header float

manually by doing the following:

a. Press rotary scroll knob (A) on HPT to highlight the

QuickMenu options.

b. Rotate scroll knob (A) to highlight HEADER FLOAT

symbol (B), and press the scroll knob to select. The

screen changes.

4. Press soft key 3 (A) to restore the header float.

NOTE:

If the header float is active, the icon at soft key 3 will

display REMOVE FLOAT; if header float has been removed,

the icon will display RESUME FLOAT.

Figure 4.50: HPT Display

5. Stop the engine and remove the key.

Figure 4.51: HPT Display

214882 51 Revision C

Page 58

ATTACHING HEADER TO M1240 WINDROWER

4.7 Calibrating Windrower Knife Drive on the Harvest Performance Tracker Display

When the R216 Rotary Disc Header is attached to an M1240 Windrower, the Harvest Performance Tracker (HPT) will

recognize the header ID and configure the windrower accordingly. The disc header must be calibrated to ensure that the

knife drive pump output is accurate.

CAUTION

Before starting the machine, check to be sure all bystanders have cleared the area.

NOTE:

To calibrate the knife drive, the rotary disc header must be attached and engaged. If the rotary disc header is disengaged

when calibration is selected, the message ENGAGE HEADER will appear on the screen.

1. Start the engine, and engage the header.

2. Press soft key 5 (A) to open the Harvest Performance

Tracker (HPT) main menu.

3. Use HPT scroll knob (B) or the ground speed lever (GSL)

scroll wheel to scroll to settings icon (C).

B

C

4. Press HPT scroll knob (B) or the GSL SELECT button (not

shown) to activate the settings menu options.

5. Scroll to WINDROWER SETTINGS icon (A) and press SELECT.

6. Scroll to CALIBRATION icon (B), and press SELECT to open

the adjustment page.

NOTE:

The F3 shortcut button on the operator’s console will also

open the WINDROWER SETTINGS menu.

7. Select KNIFE DRIVE.

A

1016140

Figure 4.52: Opening the Main Menu

B

A

1016143

Figure 4.53: Windrower Settings Icon and Calibration

Submenu Icon

214882 52 Revision C

Page 59

1014673

A

ATTACHING HEADER TO M1240 WINDROWER

8. Press the PLAY button to begin the calibration process.

NOTE:

During the calibration sequence, the engine rpm and

header speed will increase and decrease multiple times.

NOTE:

Press the X button (A) on the screen or use the HEADER

DISENGAGE switch at any time during the calibration

process to exit calibration without saving. The engine speed

will return to the original rpm prior to starting the

calibration process.

Figure 4.54: Calibration Page

214882 53 Revision C

Page 60

Page 61

Chapter 5: Installing Options

1028576

5.1 Electric Remote Baffle Kit

The Electric Remote Baffle kit (MD #B6664), allows the operator to adjust the disc header baffle electronically from inside

the windrower.

This kit includes a linear actuator and support which will need

to be installed and adjusted on the disc header. Refer to the

instructions included in the kit.

Figure 5.1: Electric Remote Baffle Kit

214882 55 Revision C

Page 62

INSTALLING OPTIONS

5.2 Crop Dividers Kit

To install the Crop Dividers kit (MD #B6665), follow these steps:

WARNING

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key

from the ignition before leaving the operator’s seat for any reason.

1. Lower the disc header fully.

2. Stop the engine and remove the key from the ignition.

3. Unpack the Crop Dividers kit.

4. Open the cutterbar curtain.

NOTE:

The left crop divider is shown in the following steps. The right side is the opposite.

5. Disconnect hazard light (A) from the header harness.

6. Remove and retain bolt (B) and nut (C) securing hazard light

support (D) to the top of the disc header.

7. Remove and retain bolts (E) and nuts (F) from the disc

header. Discard the washers between bolts (E) and nuts (F).

8. Remove and retain two bolts (G) from the outboard side of

the disc header.

9. Align left crop divider bracket (A) with one crop divider

rod (B) and secure in place with two bolts (C) and nuts (D)

from the kit.

A

D

B

E

C

G

F

G

F

Figure 5.2: Hazard Light Assembly

B

D

C

D

C

E

1028238

A

1028241

Figure 5.3: Installing Crop Divider Hardware

214882 56 Revision C

Page 63

1028245

A

B

C

B

C

1028231

A

B

B

C

D

E

1028251

D

E

F

A

B

C

INSTALLING OPTIONS

10. Position left crop divider (A) on the front left corner of the

disc header.

11. Install using two retained bolts (B) and nuts (C).

12. Reinstall hazard light assembly (A) using retained

hardware (B) over the installed crop divider (C). Apply

®

medium-strength threadlocker (Loctite

242 or equivalent),

to retained hardware (B), and torque to 100 Nm

(73.75 lbf·ft).

Figure 5.4: Crop Divider on R216

13. Install bolt (D) and nut (E) from the kit, securing hazard

light assembly (A) to crop divider (C).

14. Secure the hazard light assembly (A) in place on the disc

header with retained bolt (B) and nut (C).

15. Reconnect the hazard light (D), routing the harness through

hole (E) in the crop divider (F).

16. Repeat for the right side of the disc header and close the

cutterbar curtain.

Figure 5.5: Hazard Light Assembly Reinstallation

Figure 5.6: Hazard Light

214882 57 Revision C

Page 64

INSTALLING OPTIONS

5.3 Adjustable Gauge Roller Kit

The Adjustable Gauge Roller kit (MD #B6666) allows the R216 Rotary Disc Header to achieve the desired cutting height for

optimum cutting performance.

This kit is installed after removing the header shipping supports. To review installation and adjustment instructions, refer to

3.1.1 Installing Adjustable Gauge Roller Kit, page 12.

214882 58 Revision C

Page 65

INSTALLING OPTIONS

5.4 Adjustable Skid Shoes Kit

The Adjustable Skid Shoes kit (MD #B6667) allows the R216 Rotary Disc Header to achieve the desired cutting height for

optimum cutting performance.

This kit is installed after removing the header shipping supports. To review installation and adjustment instructions, refer to

3.1.2 Installing Adjustable Skid Shoes Kit, page 15.

214882 59 Revision C

Page 66

Page 67

Chapter 6: Lubricating the Disc Header

WARNING

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key

from the ignition before leaving the operator’s seat for any reason.

The disc header has been lubricated at the factory. However, you should lubricate the disc header prior to delivery to offset

the effects of weather during outside storage and transport, and to familiarize yourself with the machine. Unless otherwise

specified, use high-temperature, extreme-pressure (EP2) performance grease with 1% max molybdenum disulphide (NLGI

grade 2) lithium base.

Refer to 6.1 Lubrication Locations, page 62 for a list of grease points on both the right and left side of the header.

214882 61 Revision C

Page 68

6.1 Lubrication Locations

Figure 6.1: Left Side Lubrication Locations

A

LUBRICATING THE DISC HEADER

G

F

B

C

C

B

D

E

A - Idler/Tensioner Pivot B - Bearing, Roller Conditioner (2 Places) C - U-Joint, Conditioner Driveline (2 Places)

D - Slip Joint, Conditioner Driveline

G - Tensioner Arm

1

E - Idler/Tensioner Pivot F - Bearing, Feed Roll

1028280

1. Use high-temperature, extreme-pressure (EP2) performance grease with 10% max molybdenum disulphide (NLGI

grade 2) lithium base.

214882 62 Revision C

Page 69

Figure 6.2: Right Side Lubrication Locations

LUBRICATING THE DISC HEADER

E

A

B

B

C

D

C

A

A - Bearing, Roller Conditioner (2 Places) B - U-Joint, Upper Driveline (2 Places) C - Slip Joints, Conditioner Drivelines

D - U-Joint, Lower Driveline (2 Places) E - Idler Pivot

D

1028316

2

2. Use high-temperature, extreme-pressure (EP2) performance grease with 10% max molybdenum disulphide (NLGI

grade 2) lithium base.

214882 63 Revision C

Page 70

Page 71

Chapter 7: Performing Predelivery Checks

1028480

A

1028323

A

B

C

1. Perform final checks and adjustments as listed on the yellow sheet attached at the back of this instruction, to ensure

the machine is field-ready. Refer to the referenced pages as indicated on the checklist for detailed instructions.

2. The Operator or the Dealer should retain the completed checklist.

7.1 Conditioner Drive Belt

The conditioner drive belt is located inside the left driveshield and is tensioned with a spring tensioner.

7.1.1 Inspecting Conditioner Drive Belt

The conditioner drive belt tension is set at factory and should not require adjustment. To inspect the conditioner drive belt,

follow these steps:

WARNING

To avoid bodily injury or death from unexpected startup of machine, always stop the engine and remove the key from

the ignition before leaving the operator’s seat for any reason.

1. Lower the disc header fully.

2. Shut down the engine, and remove the key from the ignition.

3. Open left driveshield (A).

Figure 7.1: Left Driveshield

4. Inspect drive belt (A) and replace if damaged or cracked.

5. Check that jam nut (B) and adjuster nut (C) are tight.

Figure 7.2: Conditioner Drive

214882 65 Revision C

Page 72

PERFORMING PREDELIVERY CHECKS

6. Measure the length of belt tensioner spring (A) and ensure

spring length (B) is 17 mm (11/16 in.) in accordance with

C

B

spring tension decal (C). If the spring length requires

adjustment, refer to 7.1.2 Adjusting Conditioner Drive Belt,

page 66, otherwise close the drive shield and proceed

to 7.2 Header Float, page 68.

A

Figure 7.3: Belt Tension Spring

7.1.2 Adjusting Conditioner Drive Belt

WARNING

To avoid bodily injury or death from unexpected startup of machine, always stop the engine and remove the key from

the ignition before leaving the operator’s seat for any reason.

1. Lower the header fully.

1028334

2. Shut down the engine, and remove the key from the ignition.

3. Open left driveshield (A).

A

1028480

Figure 7.4: Left Driveshield

214882 66 Revision C

Page 73

1028349

A

B

C

1029381

A

B

C

D

E

1029373

A

C

D

B

E

PERFORMING PREDELIVERY CHECKS

4. Ensure drive belt (A) is in the grooves on drive pulley (B)

and driven pulley (C).

NOTE:

If necessary, loosen the jam nut and adjuster nut to relieve

belt tension while checking.

5. Loosen M16 hex head bolt and lock nuts (A) on pulley

mount bracket (B), and adjust position of bracket until the

center-to-center distance (C) between drive pulley (D) and

driven pulley (E) is 724 mm (28 1/2 in.).

6. Torque hardware to 170 Nm (126 lbf∙ft).

Figure 7.5: Conditioner Drive

Figure 7.6: Conditioner Drive

7. With hardware fully loosened, slide threaded rod (E) up and

backward into the reel speed sensor bracket, then snug

hardware to engage the rod pivot point with the bracket.

8. Measure the length of tensioner spring (C). For proper belt

tension, dimension (D) should be set to 17 mm (11/16 in.).

9. To adjust spring tension, loosen jam nut (A) by turning it

counterclockwise.

10. Turn adjuster nut (B) clockwise to increase tensioner

spring/belt tension or turn adjuster nut (B)

counterclockwise to decrease tensioner spring/belt tension.

11. Once the correct spring measurement has been achieved,

hold adjuster nut (B) in place and tighten jam nut (A)

against it by turning the jam nut clockwise.

12. Close the driveshield.

Figure 7.7: Conditioner Drive

214882 67 Revision C

Page 74

PERFORMING PREDELIVERY CHECKS

7.2 Header Float

7.2.1 Checking Float

WARNING

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key

from the ignition before leaving the operator’s seat for any reason.

CAUTION

Before starting the machine, check to be sure all bystanders have cleared the area.

1. Start the engine.

2. Use the HEADER TILT switches (A) on the ground speed

lever (GSL) to set the center-link to the mid-range position

(5.0 on the Harvest Performance Tracker [HPT]).

3. Using the HEADER DOWN switch (B), lower the disc header

fully and with the header lift cylinders fully retracted.

NOTE:

Ensure header is level with ground with zero tilt.

4. Turn the engine off, and remove the ignition key.

5. Grasp one end of the header and lift. Lifting force should be

426–471 N (95–105 lbf) and should be the same at

both ends.

6. Restart the engine, and adjust float as required. For instructions, refer to 7.2.2 Setting the Float, page 69.

NOTE:

Increasing the float value on the HPT makes the header feel lighter.

A

B

Figure 7.8: GSL

A

1015816

214882 68 Revision C

Page 75

1015027

A

B

1019608

A

B

C

D

PERFORMING PREDELIVERY CHECKS

7.2.2 Setting the Float

The optimum float setting lets the disc header follow the contour of the terrain. Proceed as follows:

1. Press rotary scroll knob (A) on the Harvest Performance

Tracker (HPT) to display the QuickMenu system.

2. Rotate scroll knob (A) to highlight header float icon (B) and

press scroll knob to select.

Figure 7.9: HPT Run Screen

3. Turn scroll knob (A) to highlight left (B) or right (C) float and

press knob (A) to activate selection.

4. Rotate scroll knob (A) to adjust float setting and press knob

when finished. Float is now set.

NOTE:

Float adjustments of 1.0 (out of 10) change the header

weight at the cutterbar by approximately 91 kg (200 lb.).

Adjust float in increments of 0.05 to optimize field

performance.

5. Use soft key 3 (D) to remove/resume float and deck

position to previous setting for the attached header.

Figure 7.10: HPT Left and Right Float Settings

214882 69 Revision C

Page 76

PERFORMING PREDELIVERY CHECKS

7.3 Roll Timing

For proper conditioning, the rolls must be properly timed with the bar on one roll centered between two bars on the other

roll. The factory setting should be suitable for most crop conditions.

IMPORTANT:

Roll timing is critical when the roll gap is decreased because

conditioning is affected and the bars may contact each other.

Figure 7.11: Properly Timed Rolls

1029004

7.3.1 Adjusting Roll Timing

WARNING