Page 1

User Manual

for 1309 Multipoint

Sampler

BE1285-15

Page 2

Index

________________________________________________________________________

Index

Index ................................................................................................................................... 2

1309 Multipoint Sampler ........................................................................................................ 3

SAFETY CONSIDERATIONS .................................................................................................. 4

Safety Considerations ....................................................................................................... 4

Chapter 1 Description and Functions ....................................................................................... 6

1.1 Description and Function .......................................................................................... 7

1.1.1 The Sampler System .......................................................................................... 7

1.2 Front Panel ............................................................................................................. 8

1.3 Rear Panel .............................................................................................................. 9

Chapter 2 Preparing to Use the 1309 .................................................................................... 10

2.1 Preliminary ........................................................................................................... 11

2.1.1 Environment and Handling ................................................................................ 11

2.1.2 Connecting the Mains Supply ............................................................................. 11

2.1.3 Checking the Power Cord .................................................................................. 11

2.1.4 Checking the Fuses .......................................................................................... 11

2.2 Connecting the 1309 to the System Controller .......................................................... 12

2.3 System Use .......................................................................................................... 13

2.3.1 Setting the Interface Address of the 1309 ........................................................... 14

2.4 Connecting Tubing to the 1309 ............................................................................... 16

2.4.1 Connecting Sampling Tubing ............................................................................. 17

2.4.2 Connecting External Filters to the Sampling Tubes ............................................... 18

2.4.3 Connecting a Water-trap Filter ........................................................................... 18

2.4.4 Connecting the Sampler Outlet to the Gas Monitor ............................................... 19

2.5 Connecting Temperature Transducers to the 1309 ..................................................... 20

Chapter 3 Operation ........................................................................................................... 21

3.1 Switching-On ........................................................................................................ 22

3.2 General Principles of Controlling the 1309................................................................. 22

3.2.1 Syntax for Interface Jobs .................................................................................. 22

3.2.2 Output Jobs – Requesting Information from the 1309 ........................................... 25

3.3 Using the Sampler System ...................................................................................... 26

3.4 Temperature Measurement ..................................................................................... 27

3.5 Pressure Measurement ........................................................................................... 27

3.6 Checking the 1309 ................................................................................................. 27

3.6.1 Status? Interface Job........................................................................................ 27

3.6.2 Reset System Interface Job ............................................................................... 28

3.7 Error Conditions and Service Requests ..................................................................... 29

3.7.1 The Status Byte ............................................................................................... 29

3.7.2 Enabling Service Requests ................................................................................ 30

3.7.3 Resetting the Status Byte ................................................................................. 30

3.7.4 The Warning? Interface Job............................................................................... 31

3.7.5 The Error? Interface Job ................................................................................... 32

Chapter 4 The IEEE/IEC Interface and Interface Job Overview ................................................. 34

4.1 Introduction .......................................................................................................... 35

4.1.1 IEEE Functions Implemented in the 1309 ............................................................ 35

4.2 Overview of 1309 Interface Jobs ............................................................................. 36

4.2.1 Sampler System Jobs ....................................................................................... 37

4.2.2 Temperature Measurement Jobs ........................................................................ 37

4.2.3 Pressure Measurement Jobs .............................................................................. 37

4.2.4 1309 Check Jobs.............................................................................................. 38

4.2.5 Error Condition and Service Request Jobs ........................................................... 38

4.2.6 Standardised Jobs ............................................................................................ 38

Chapter 5 Maintenance ....................................................................................................... 40

5.1 Cleaning the Instrument ..................................................................................... 41

5.2 Service and repair ............................................................................................. 41

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 2 of 42

Page 3

1309

________________________________________________________________________

1309 Multipoint Sampler

From Serial number: 660-128

November 2011

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 3 of 42

Page 4

Safety Considerations

PLEASE READ THESE SAFETY CONSIDERATIONS CAREFULLY

TO AVOID THE POSSIBILITY OF AN EXPLOSION, MONITORING OF

before they enter the sampler channels of the 1309. This will remove

________________________________________________________________________

Safety Considerations

SAFETY CONSIDERATIONS

AND MAKE SURE YOU UNDERSTAND THEM PROPERLY BEFORE YOU START OPERATING THE 1309 MULTIPOINT SAMPLER.

EXPLOSION HAZARD

THE 1309 MULTIPOINT SAMPLER IS NOT DESIGNED FOR USE IN

POTENTIALLY EXPLOSIVE ENVIRONMENTS.

This means that the instrument must not be placed and operated in an

area with a potentially explosive atmosphere.

When monitoring potentially flammable or toxic gases it is essential that:

1) the instrument itself is placed in a well-ventilated area outside the

potentially hazardous zone; and

2) that a sufficiently long tube is connected to the “Sampler Waste Air

Outlet” so that the sampled gas is carried away to the open air or to

an extraction and/or filtration unit.

FLAMMABLE GASES IN EXPLOSIVE CONCENTRATIONS MUST NEVER

BE ATTEMPTED.

AVOID WATER CONDENSATION IN THE INSTRUMENT.

Liquids must be prevented from entering the instrument. It is therefore

important that warm humid gases are not drawn into a cold instrument

because condensation will take place. If such a situation is likely to occur

you should ensure that the gases are drawn through water-trap filters

water vapour in the gases and thus prevent condensation within the instrument. The water-trap filter should be used in the immediate environment of the instrument so it maintains either the same temperature,

or a lower temperature than the instrument.

Note: that some gases may be absorbed by the water trapped in the filter. This will reduce the gases’ concentration.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 4 of 42

Page 5

Safety Considerations

________________________________________________________________________

SAFETY CONSIDERATIONS

The 1309 Multipoint Sampler complies with EN/IEC 61010-1 3rd Ed.

(2010): Safety requirements for electrical equipment for measurement,

control and laboratory use. To ensure safe operation and retain the 1309

in safe condition, note the following:

APPLYING POWER

Before using the 1309 check that the available mains voltage match the

specified voltage and frequency for the instrument.

SAFETY SYMBOLS

The apparatus is marked with this symbol when it is important that

the user refer to the associated warning statements given in the User

Manual.

Frame or Chassis

WARNINGS

Before connecting or disconnecting interface cables, switch off the power

to all instruments.

If the correct function or operating safety of the 1309 is impaired, secure

the instrument against further use until the fault is repaired.

Any adjustment, maintenance or repair of the internal parts of the 1309

under power must be avoided as far as possible; if unavoidable, it must

only be done by qualified service personnel.

Protective earth Hazardous Voltage

Copyright © 2011 LumaSense Technologies A/S

All rights reserved. No part of this publication may be reproduced or distributed in

any form or by any means without prior consent in writing from LumaSense Technologies A/S, Ballerup, Denmark.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 5 of 42

Page 6

Chapter 1

________________________________________________________________________

Chapter 1

Description and Functions

November 2011

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 6 of 42

Page 7

Chapter 1

________________________________________________________________________

1.1 Description and Function

1.1.1 The Sampler System

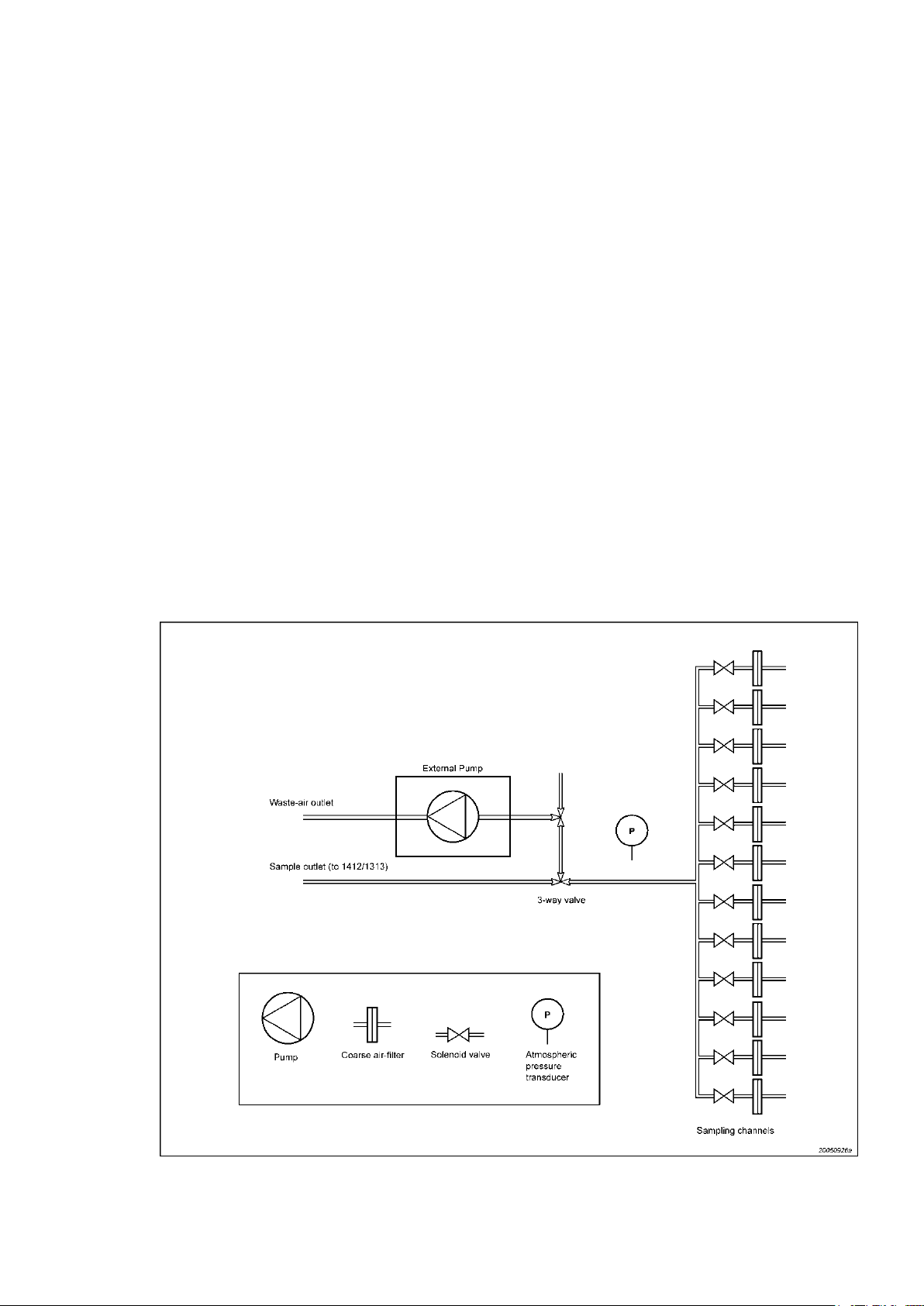

The pneumatic system of the 1309 is shown schematically in Fig.1.1.

The sampler system is constructed of stainless steel (AISI 316) and

PTFE (PolyTetraFluoroEthylene) tubing to minimize adsorption of samples. The system has 12 inlet channels, each with a solenoid valve.

Each inlet channel has a tube-mounting stub on the front-plate of the

1309; to connect each channel to the respective sampling point. The 12

inlet channels converge into one; a three-way valve then directs the

gas sample to the Gas Monitor for analysis, or through the external

pump via the waste-air outlet on the 1309’s back-plate.

The 1309’s sampler system functions efficiently, transporting gas samples from the sampling point at approximately 4 metres per second.

However, this speed depends on the type of pump, the diameter of the

tubing and the length of tubing attached to the 1309. An air-filter is attached to the end of each sampling tube to keep the samples free of

particles.

Fig. 1.1 A schematic diagram of the 1309’s pneumatic system.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 7 of 42

Page 8

Chapter 1

________________________________________________________________________

1.2 Front Panel

Fig.1.2 The front panel of the 1309

Sampler: 12 mounting stubs for connection of tubing to sampling

points. Each stub is numbered, and has a correspondingly-numbered lamp. When the lamp is lit, it indicates

that the corresponding sampling valve is open, see sec-

tion 3.3. The Analyzer/Waste Air lamps indicate which

way the internal 3 way valve is set, see section 3.3.

Temperature Sensors Input:

6 inputs suitable for use with the INNOVA Air Temperature Transducer type MM0034, Surface Temperature

Transducer MM0035 or Operative Temperature Transducer type MM0060.

Interface: 3 lamps which indicate the function of the IEEE inter-

face. If the Listen lamp is lit, the 1309 is receiving instructions or data from the system controller. If the Talk

lamp is lit, the 1309 is outputting data. If the SRQ lamp

is lit, the 1309 has generated a Service Request, see

section 3.7. Full details of the IEEE Interface are given in

Chapter 4.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 8 of 42

Page 9

Chapter 1

00061-02-110311

________________________________________________________________________

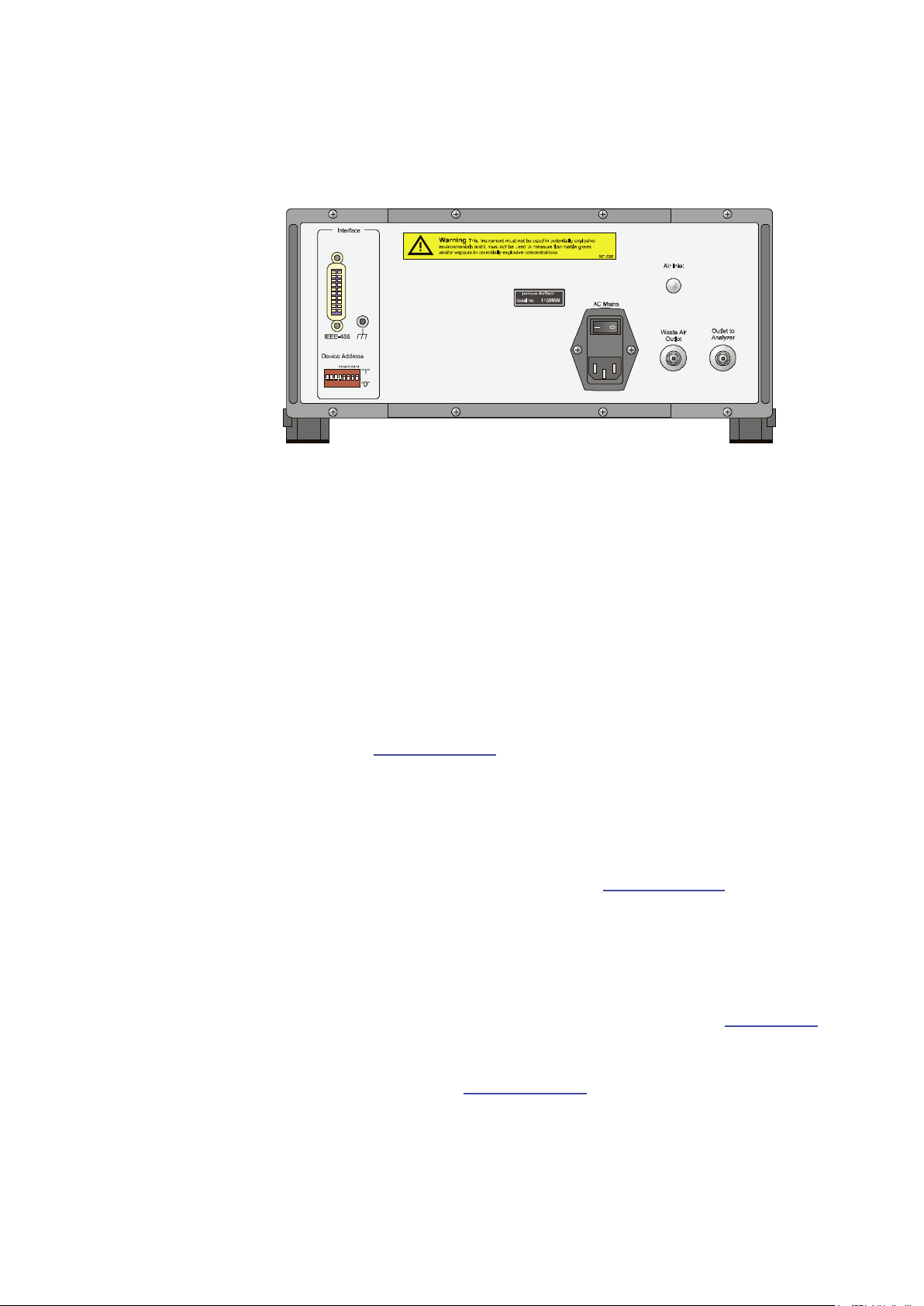

1.3 Rear Panel

Fig.1.3 The rear panel of the 1309

100 - 240 Vac

Fuses: T1.6AL

50-60Hz 70VA

AC Mains: A 3-pin connector accepting Power Cable for connection

to a single phase AC mains supply with protective Earth.

Mains Voltage: Connect 1309 to mains supply with 100-240 Vac, 50/60

Hz.

Outlet to Analyzer: Mounting stub for connecting the sampler system of the

1309 to the inlet of an INNOVA Gas Monitor via tubing.

See section 2.4.4. Usable models are 1302, 3425, 3426,

1312, 1314 or 1412. In the following referred to as “Gas

Monitor”. Please contact LumaSense Technologies A/S

for available models.

Waste Air Outlet: Mounting stub for connecting the external pump to the

1309’s sampler system. See section 2.4.4.

Interface IEEE-488: Digital interface designed in accordance with IEEE 488-

1978. The IEEE interface is identical in use to that described in IEC 625-1; full compatibility is only a matter

of using the correct cables and connectors. For more detail about the IEEE/IEC interface, refer to Chapter 4.

Device Address: Bank of 8 DIP switches which decide the 1309’s interface

address. See section 2.3.1 for details of how to set the

interface address.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 9 of 42

Page 10

Chapter 2

________________________________________________________________________

Chapter 2

Preparing to Use the 1309

November 2011

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 10 of 42

Page 11

Chapter 2

________________________________________________________________________

2.1 Preliminary

2.1.1 Environment and Handling

The Type 1309 Multipoint Sampler is designed for use in environments

with temperatures between +5°C and +40°C (+41°F and +104°F) and

with up to 90% relative humidity (non-condensing) at 40°C.

Make sure to leave some space between the Rear Panel and the Wall,

or other obstacles, to ensure easy access to the mains supply. No other

special handling precautions are necessary.

2.1.2 Connecting the Mains Supply

The 1309 is operated from a 50 to 60 Hz single phase AC mains supply.

Voltage 100 – 240 Vac.

Before connecting the mains supply, the following checks and adjustments should be performed to ensure safe operation of the 1309.

2.1.3 Checking the Power Cord

Use the Power Cord delivered with the 1309 or check that the Cord

used is rated minimum 10A / 250V.

2.1.4 Checking the Fuses

Use a small flat-bladed screwdriver to prise open the flap surrounding

the AC Mains switch. See Fig. 2.1.

Fig.2.1. Accessing the 1309’s fuses

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 11 of 42

Page 12

Chapter 2

________________________________________________________________________

Again using the screwdriver, gently lever the fuse-holders out from

their slots. See Fig. 2.2.

Fig.2.2. Inserting the fuses into the 1309’s fuse holder

Use two 1.6A slow-blow fuses (LumaSense No. VF0007), they are sup-

plied with the instrument.

When replacing the fuse-holders, ensure that the direction of the white

arrows on each holder matches the arrows marked on the covering flap.

2.2 Connecting the 1309 to the System Controller

The 1309 is connected to the System Controller by the IEEE interface

bus, over which the 1309 receives the commands and data which control it. Further information about the cables available from LumaSense

to connect the 1309 to the IEEE interface bus, and about the IEEE interface of the 1309, are given in section 4.1.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 12 of 42

Page 13

Chapter 2

________________________________________________________________________

2.3 System Use

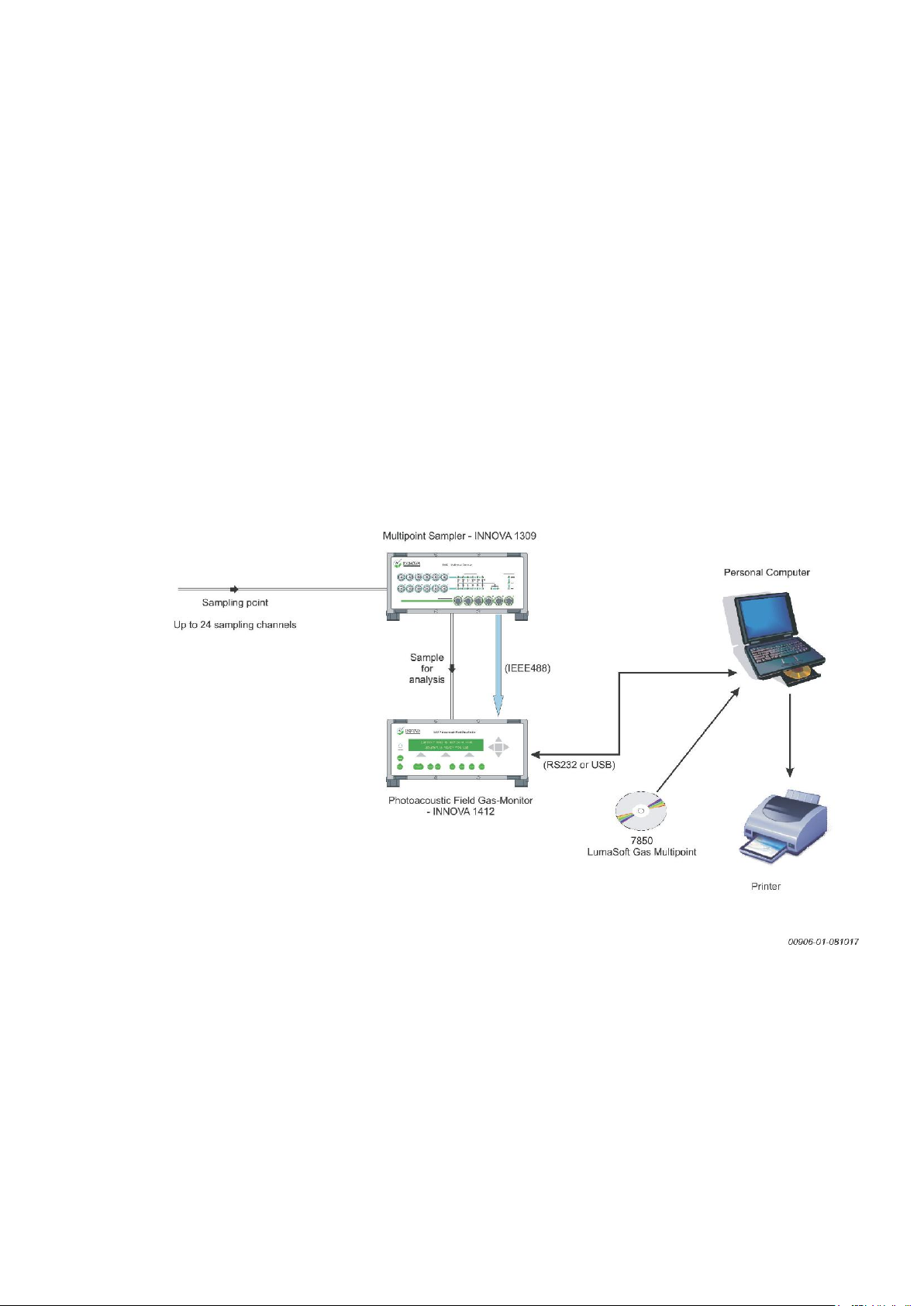

The 1309 combined with a Gas Monitor and a controlling computer provides a system that offers wide-ranging monitoring capabilities. The

1309 makes it possible to perform multipoint monitoring tasks in many

different situations and environments, without changing the system

components.

An example of a multipoint, multi-gas monitoring system is shown in

fig. 2.3. In such a system, the sampler system takes a sample of the

return-air from the room, and delivers it to the 1412 for analysis. While

the 1412 performs one analysis, the 1309 takes the next sample for

analysis from the room.

Fig. 2.3 A typical sampling system, shown with an application example.

Up to 12 analyses can be performed simultaneously using one

1309. LumaSoft Gas Multipoint Innova 7850 Application Software gives control of all the functions of the system.

LumaSense Technologies has a 7850 Application Software to give full

coordination and control of all the sampling and monitoring functions of

such a system. The application software package can control one 1309

unit and one 1412.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 13 of 42

Page 14

Chapter 2

________________________________________________________________________

2.3.1 Setting the Interface Address of the 1309

The 1309 uses a single interface address. The address is set using the

bank of eight DIP switches on the rear panel of the 1309. The last five

switches on the bank decide the interface address. These switches are

marked A1 (the least significant bit) to A5 (the most significant bit).

The switches represent binary values, as follows:

If the switch is down, it represents a binary “0”. See Fig. 2.5.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 14 of 42

Page 15

Chapter 2

________________________________________________________________________

Fig. 2.5. Dipswitch settings binary “0”

If the switch is up, it represents a binary “1”. See Fig. 2.6.

Fig. 2.6 Dipswitch settings binary “1”

The default interface address of the 1309 is set to 01111 (decimal value 15), see Fig. 2.7. If this is not suitable for your system, use the

switches to set an address appropriate to your system.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 15 of 42

Page 16

Chapter 2

________________________________________________________________________

Fig. 2.7. Interface address 15

2.4 Connecting Tubing to the 1309

The 1309 is connected via tubing to:

the sampling points;

to the gas-monitor being used to analyse the gases that are sampled;

to the external pump.

Note: the performance of the 1309’s sampling system is dependant on

the type of external pump used and the length and diameter of the

sampling tubing.

Sampler tubing for use with the 1309 is available from LumaSense:

polytetrafluoroethylene (PTFE), 50m roll, accessory number AF0614.

Using this tubing material minimizes the risk of gases being adsorbed

onto the tube’s surface, which would result in inaccurate measurements.

WARNING! Avoid water condensation in the instrument.

Liquids must be prevented from entering the instrument. It is therefore

important that warm humid gases are not drawn into a cold instrument

because condensation will take place. If such a situation is likely to occur, you must ensure that the gases are drawn through water-trap filters before they enter the sampler channels of the 1309. This will remove the water vapour in the gases and thus prevent condensation

within the instrument. Use the water-trap filter in the immediate envi-

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 16 of 42

Page 17

Chapter 2

________________________________________________________________________

ronment of the instrument so it maintains either the same temperature,

or a lower temperature than the instrument. See section 2.4.3 for details of how to fit a water-trap filter.

2.4.1 Connecting Sampling Tubing

Before connecting sampling tubing to the 1309, determine approximately where the sampling points will be in the area to be monitored.

This will allow you to estimate the length of tubing you need to connect

to the mounting-stubs of the 1309.

To connect sampling tubing (see Fig.2.8):

Fig.2.8 Attaching sampling tubing to the 1309’s mounting stubs

1. Remove the knurled nut from the mounting stub of the sampler

channel you wish to use, on the front panel of the 1309.

2. Push one end of the length of PTFE through the non-threaded end

of the nut.

3. Push the end of the tubing onto the mounting stub as far as it will

go, and secure the tube by re-tightening the knurled nut onto the

threads of the mounting stub.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 17 of 42

Page 18

Chapter 2

________________________________________________________________________

2.4.2 Connecting External Filters to the Sampling Tubes

The external filters, comprising filter, LumaSense accessory number

DS2306, and fitting, LumaSense accessory number UD5041 (optional

accessories), protect the 1309’s sampling airways from airborne particles such as dust, thus helping to prevent blockage of the airways.

The filter unit is attached to the tubing as follows (see Fig.2.9):

Fig.2.9 Attaching Fitting UD5041 and Filter DS2306 to sampling tubing

1. Push the Fitting UD5041 into the tubing.

2. Screw the short stub of the Filter DS2306 into the Fitting.

2.4.3 Connecting a Water-trap Filter

The In-line Genie Membrane Separator (LumaSense order no. UA1365)

avoids condensation in the sampling and measuring instruments. Use

the filter in the immediate environment of the instrument so it maintains either the same temperature, or a lower temperature than the instruments.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 18 of 42

Page 19

Chapter 2

________________________________________________________________________

Note: some gases may be absorbed by the water trapped in the filter.

This will reduce the gases’ concentrations.

To connect sampling tubing to the water-trap filter

Push the sampling tubing into the connector as far as it will go and

tighten the nut.

Fig. 2.10 Attaching tubing to the In-line Genie Membrane Separator.

Note: make sure that the gas flows through the filter in the direction

indicated - shown by the arrows on the filter.

To disconnect the sampling tubing

Loosen the nut and pull the sampling tubing out of the connector.

2.4.4 Connecting the Sampler Outlet to the Gas Monitor

This connection uses the same tubing (PTFE, LumaSense No. AF0614)

as for the sampling tubes, section 2.4.1. The tubing is connected to the

Outlet to Analyzer stub on the rear panel of the 1309, and to the Air

Inlet stub on the rear panel of the Gas Monitor. The tubing is connect-

ed as described in section 2.4.1.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 19 of 42

Page 20

Chapter 2

________________________________________________________________________

The Waste Air Outlet stub, next to the Outlet to Analyzer, (see fig.

1.3) stub on the rear panel of the 1309, connects the external pump to

the 1309’s sampler system. If you do not wish the waste air from the

pump to mix with the air in the room where the 1309 is positioned,

connect a length of PTFE tubing (LumaSense no. AF0614) to the waste

air outlet stub on the external pump and direct the tubing to a suitable

exhaust-point: for example, out of a window.

2.5 Connecting Temperature Transducers to the 1309

The 1309 has 6 temperature-sensor inputs mounted on its front panel,

(see fig. 1.2) suitable for direct use with the INNOVA Air Temperature

Transducer MM0034, Surface Temperature Transducer MM0035 or Operative Temperature Transducer MM0060.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 20 of 42

Page 21

Chapter 3

________________________________________________________________________

Chapter 3

Operation

November 2011

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 21 of 42

Page 22

Chapter 3

________________________________________________________________________

All tasks performed by the 1309 are controlled over the IEEE/IEC interface from a System Controller; there is no other control possibility. This

chapter deals with the control of the 1309 from the user’s point of

view; for details of the IEEE/IEC interface specifications, refer to Chap-

ter 4 of this manual.

Sections 3.1 and 3.2 deal with switching-on and the general principles

of controlling the 1309. Sections 3.3 to 3.7 deal with the specific commands and requests, known as interface jobs, which set-up and control

the 1309. Each interface job is dealt with by giving an example which

states the effect of the job. For quick reference, an overview of all interface jobs is given in section 4.2 of this manual.

3.1 Switching-On

The 1309 can be switched on using the AC Mains switch on the backplate. After switching-on, the 1309 is set as follows:

The sampling-valves closed.

Internal three-way valve set to Waste Air Outlet.

3.2 General Principles of Controlling the 1309

The 1309’s functions are controlled over the IEEE/IEC interface using a

range of commands and data requests, each of which is specific to a

particular function or item of data. These commands and requests are

known as interface jobs. This section describes the structure of the in-

terface jobs used to control the 1309. Further details about the

IEEE/IEC interface of the 1309 are given in Chapter 4 of this manual.

3.2.1 Syntax for Interface Jobs

Fig.3.1 shows a diagram representing a single interface job, sent from

the system controller to the 1309. Each constituent part of the interface

job is explained below.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 22 of 42

Page 23

Chapter 3

________________________________________________________________________

Fig.3.1. General syntax diagram for interface jobs

Job Headers

The job header specifies the function you want the 1309 to perform. It

consists of one or more words. The ASCII underline character “_” is

used to separate individual words in the job header. For example:

OPEN_SAMPLING_VALVE

A hyphen “-“ or a full stop”.” can also be used to separate words in the

job header.

The words making up the job header do not need to be sent in full to

the 1309; they can be shortened to a code-form, for example:

OP_SA_VALVE

O_S_V

The minimum code for each job header is usually the first character of

each word in the job header. This is written in bold characters in the list

of interface jobs given in section 4.2 of this manual. The 1309 accepts

job headers in both upper- and lower-case characters.

The Data Field

The data field contains further information specific to the interface job

defined by the job header. The data field is separated from the job

header by a space character (“SP”) or a comma “,”. In the following

examples, the separator will always be the space character, represented by the symbol “ ”. The data field will normally contain a numerical

value. For example:

OPEN_SAMPLING_VALVE

2

Some jobs may require more than one item of data. In this case, the

data is given item by item, separated by commas. For example:

OPEN_SAMPLING_VALVE 2,3,4

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 23 of 42

Page 24

Chapter 3

________________________________________________________________________

Numerical data for interface jobs sent to the 1309 can be in NR1, NR2

or NR3 form. This is a format for describing how the numerical data is

represented, for example:

NR1 data: 250 (number without decimal fraction or exponent)

NR2 data: 249.85 (number with decimal fraction, without expo-

nent)

NR3 data: 2.499E-2 (number with fraction and exponent).

Generally, any of these data formats can be used, unless specifically

stated otherwise in the interface job overview given in section 4.2.

The number of characters in the non exponent part of the data field

must not be greater than 8.

Job Terminators

Each interface job must have a terminator (signified by Te in Fig.3.1)

which tells the 1309 that it has received the complete interface job.

When the 1309 receives the terminator, it checks the whole job and, if

it is a valid job, carries it out.

The terminator for communication with the 1309 is an ASCII control

character, such as “LF”. This is the default terminator character used in

communication with the 1309. The terminator character can be

changed, as follows.

To select a terminator character other than the default, use the interface job Define_Terminator, followed by the decimal value of the character you wish to use. The possible terminator characters, with the corresponding decimal values, are shown in Table 3.1.

DEF_TERMINATOR

3<LF> Selects the control character ETX

(decimal value 3) as the terminator

character.

All of the following interface job examples assume the use of “LF” as

the terminator character.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 24 of 42

Page 25

Chapter 3

r-

Decimal Code

r-

Decimal Code

________________________________________________________________________

Table 3.1. The range of ASCII terminator-characters which can be used

in communication with the 1309

ASCII Cha

acter

ASCII Cha

acter

SOH 1 DC1 17

STX 2 DC2 18

ETX 3 DC3 19

EOT 4 DC4 20

ENQ 5 NAK 21

ACK 6 SYN 22

BELL 7 ETB 23

BS 8 CAN 24

HT 9 EM 25

LF 10 SUB 26

VT 11 ESC 27

FF 12 FS 28

SO 14 GS 29

SI 15 RS 30

DLE 16 US 31

3.2.2 Output Jobs – Requesting Information from the 1309

Interface output jobs request specific data from the 1309. The output

jobs allow checks of the 1309’s functions and set-up parameters. Output jobs consist of a job header followed by a question-mark; more

specific information is requested by including a data field. An example

of an output-job is:

PRESSURE?<LF>

To which the 1309 responds with the required data. The general syntax

for data output from the 1309 is shown in Fig.3.2.

Fig.3.2. General syntax diagram for data-output from the 1309

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Generally, numerical data output from the 1309 is in NR2 form unless

specifically stated otherwise in the interface job overview given in sec-

Page 25 of 42

Page 26

Chapter 3

________________________________________________________________________

tion 4.2. The default terminator character used is the control character

“<LF>”. The terminator character can be changed, as described in sec-

tion 3.2.1.

3.3 Using the Sampler System

Using the 1309’s sampler system, see Fig. 1.1, to deliver a sample to

the Gas Monitor is a 3-stage process:

1. The required sample valve is opened; all other sample valves are

closed automatically.

2. The sample valve is connected to the external pump via the

1309’s internal 3-way valve, allowing the waste air to be exhausted from the sample channel (via the Waste Air Outlet,

section 2.4.4) and drawing the new sample.

3. When the new sample has been drawn to the 1309, the internal

3-way valve is set to direct the sample to the Gas Monitor. The

Gas Monitor’s pump draws the sample for analysis.

While the Gas Monitor is analysing this sample, the next sample can

then be drawn ready for the next analysis.

Three interface jobs control the sampling process.

Examples:

OPEN_SAMP_VALVE

CONNECT_SAMP_VALVE

TO_SAMPLING_PUMP<LF>

CONNECT_SAMP_VALVE

TO_MONITOR<LF>

1<LF>

Opens sample valve 1, closes all

other sample valves. If no sample valve is specified, all sample

valves are closed.

Connects the sample valve to

the external pump, and exhausts

the waste air from the sample

channel.

Directs the new sample to the

Gas Monitor for analysis.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 26 of 42

Page 27

Chapter 3

________________________________________________________________________

The time taken to draw a sample depends upon the type of external

pump and the diameter and length of the sampling tube.

3.4 Temperature Measurement

The temperature measured by the Air Temperature Transducer

MM0034, Surface Temperature Transducer MM0035 or Operative Temperature Transducer MM0060 is read out from the 1309 as follows:

Example:

SENSOR_TEMP?

1<LF> Reads-out the temperature data in

3.5 Pressure Measurement

The 1309 contains a pressure transducer. The atmospheric pressure

around the multiplexer is read out as follows:

Example:

PRESSURE?

1<LF> Reads-out the atmospheric pressure

3.6 Checking the 1309

°C from the temperature transducer

connected to input number 1. If no

transducer is connected to the particular input, the 1309 outputs 100°C.

in kPa.

3.6.1 Status? Interface Job

This job reads-out the 1309’s current mechanical condition. The 1309’s

current condition is shown as a “flag”, i.e. a word-value comprising 16

bits, each of which represents a specific mechanical component. If a bit

is set, the 1309 is currently using the corresponding component. The

flag is output from the 1309 as the total of the decimal equivalents of

the binary values of the bits which are set. See Table 3.2 for the components represented by each bit in the Status flag, and their corresponding decimal values.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 27 of 42

Page 28

Chapter 3

Bit

1

2

4

8

16

32

64

128

256

512

Sampling valve 10

1024

Sampling valve 11

2048

Sampling valve 12

4096

14

8192

16384

32768

________________________________________________________________________

Table 3.2. The 1309’s Status Flag. Each bit represents a particular

1309 component; when set, the 1309 is currently using that

component.

Status Flag

Current function when set

Sampling valve 10 open

Sampling valve 11 open

Sampling valve 12 open

no.

1

2

3

4

5

6

7

8

9

10

11

12

13

Dec.

value

Bit name

Sampling valve 1 Sampling valve 1 open

Sampling valve 2 Sampling valve 2 open

Sampling valve 3 Sampling valve 3 open

Sampling valve 4 Sampling valve 4 open

Sampling valve 5 Sampling valve 5 open

Sampling valve 6 Sampling valve 6 open

Sampling valve 7 Sampling valve 7 open

Sampling valve 8 Sampling valve 8 open

Sampling valve 9 Sampling valve 9 open

3-way valve 3-way valve set to analyzer

Not used Not used

15

16

Not used Not used

Not used Not used

Example:

STATUS?<LF> Outputs the Status flag of the 1309

If the 1309 outputs 4352, using Table 3.2 shows that 4352 = 256 +

4096. Therefore, bits 9 and 13 are set. The mechanical condition of the

1309 is: sampling valve number 9 open, and 3-way valve set to Analyzer.

3.6.2 Reset System Interface Job

This job restarts the 1309. The 1309 restarts as described in section

3.1. Resetting the 1309 cancels any task which the 1309 was perform-

ing prior to the reset.

Example:

as described above. Refer to Table

3.2 for the decimal values of each

bit. Refer also to the examples given below.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

RESET_SYSTEM<LF> Resets the 1309.

Page 28 of 42

Page 29

Chapter 3

Bit no.

l-

r-

The 1309 is in an abnormal condition. The

________________________________________________________________________

3.7 Error Conditions and Service Requests

If an error arises in the 1309’s hardware, processor system or software,

the 1309 can signal the system controller by generating a Service Request. The exact nature of the error condition can then be investigated

by using the Warning? or Error? interface jobs.

3.7.1 The Status Byte

The status byte is an eight-bit byte, read out by the system controller

as part of the serial poll sequence. The status byte gives the first indication of the cause of the service request. The status byte for the 1309

is shown in Table 3.3. For an error to generate a Service Request, the

corresponding bit in the status byte must be enabled to request service. The procedure for this is described in the following section.

When a service request is enabled, all bits in the status byte except bit

6 are reset by a serial poll read-out or resetting the status byte. Bit 6 is

only reset when the abnormal condition of the 1309 (identified by the

Warning? or Error? interface jobs, sections 3.7.4 to 3.7.5) is corrected.

When a service request is generated, bit 7 of the status byte is always

set; it cannot be disabled.

Table 3.3 The 1309’s Status Byte showing the error conditions which

results in the individual bits being set

Status Byte

Dec. Va

ue

1 1 Not used

2 2 Set when the 1309 has completed a reset

3 4 Set when the 1309 has completed an inte

face job

4 8 Not used

5 16 Set when the 1309 has not completed the

previous interface job when a new job is

read-in

6 32

interface jobs Warning? or Error? give more

information about the abnormal condition –

see sections 3.7.4 and 3.7.5.

7 64 Indicates the 1309 has set the interface

SRQ line

8 128 Not used

Error Condition

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 29 of 42

Page 30

Chapter 3

________________________________________________________________________

3.7.2 Enabling Service Requests

The specified bits in the status byte are enabled using the interface job

Service_Request_Enable. The required bits are specified by using the

decimal equivalent of their binary value, as shown in Table 3.3. See also the job examples below for further clarification.

Note that the relevant bits are always set whenever the corresponding

condition occurs; this job only enables or disables the generation of a

service request by that condition.

Examples:

S_R_E

S_R_E

S_R_E

The bits which are enabled in the status byte can be read-out using the

Service_Request_Enable? interface job:

S_R_E?<LF> Outputs the sum of the decimal val-

32<LF> Service request is generated by the

setting of bit 6 (bit pattern

00100000 = 25 = 32 decimal) in

Table 3.3.

160<LF> Service request is generated by the

setting of bit 6 and bit 8 (bit pattern

10100000 = 25 + 27 = 32 + 128 =

160 decimal).

0<LF> All bits are disabled (except bit 7).

ues of the bits which are enabled.

For example, if the decimal readout is 48, the enabled bits are bit 5

and bit 6 (bit pattern 00110000 =

25 + 26 = 16 + 32 = 48 decimal).

3.7.3 Resetting the Status Byte

The job Reset_Status_Byte is used for this task.

Example:

R_S_B<LF> Resets the bits in the status byte to

zero.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 30 of 42

Page 31

Chapter 3

Dec. Value

________________________________________________________________________

3.7.4 The Warning? Interface Job

This job reads-out an 8-bit byte (the Warning Flags) which gives information about error conditions which affect the efficient operation of the

1309. The 1309 is still able to operate, but the error should be rectified

as soon as possible. The Warning Flag byte is shown in Table 3.4.

Table 3.4 The 1309’s Warning Flags byte

WARNING FLAGS

Bit no.

1 1 Reset Done Flag

2 2 Temperature Flag

3 4 Power Fail Flag

4 8 Not used

5 16 Not used

6 32 Not used

7 64 Not used

8 128 Not used

Flag Description

Warning Flags are set when either the 1309’s self-check procedures or

the Check_System interface job identify an error condition. This in turn

sets bit 6 of the Status Byte (generating a service request, if enabled)

to indicate that an error condition exists. The Warning? job can then

give more information about the cause of the error condition.

Example:

Warning?<LF> Outputs the Warning Flags from the

The conditions which cause the Warning Flags to be set, and the appropriate action to be taken, are dealt with in turn below.

Reset Done Flag

Indicates that the 1309 has completed a reset, following either the Reset_System interface job (section 3.6.2) or switching on the 1309. This

flag is reset when the Warning Flags are read-out from the 1309.

1309. A “1” indicates that the flag is

set; a “0” indicates the flag is not

set.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Temperature Flag

Is set when the internal temperature of the 1309 is outside the range

+2°C to +60°C. The 1309 must not be used until the internal temperature is within the normal operating limits of +5°C to +40°C. This flag is

reset when the internal temperature is again within the normal operating limits, or by resetting the 1309, or switching the 1309 off and the

on.

Page 31 of 42

Page 32

Chapter 3

Dec. Value

________________________________________________________________________

Power Fail Flag

Is set if the power is outside the range 13.25V to 15.75V. This flag is

reset when the voltage is back within the above range, or by resetting

the 1309, or switching the 1309 off and then on. If the error is persistent, have the 1309 serviced.

3.7.5 The Error? Interface Job

This job reads-out an 8-bit byte (the Error Flags) which gives information about errors which cause the 1309 to stop working. If any of

these errors exist, the 1309 is unable to function until the error is rectified. The Error Flag byte is shown in Table 3.5.

Table 3.5 The 1309’s Error Flags byte

ERROR FLAGS

Bit no.

1 1 ADC Flag

2 2 RAM Flag

3 4 PROM Flag

4 8 Not used

5 16 Not used

6 32 Job Specification Error

7 64 Software Error Flag

8 128 Power up Flag

Flag Description

Error Flags are set when the 1309’s self-check procedures identify an

error condition. This in turn sets bit 6 of the Status Byte (generating a

service request, if enabled) to indicate that an error condition exists.

The Error? job can then give more information about the cause of the

error condition.

Example:

The conditions which cause the Error Flags to be set are dealt with in

turn below.

ADC Flag

Is set when the ADC (analogue-digital converter) develops an error.

This results in a software-error, which automatically resets the 1309.

The flag is reset by reading-out the Error Flags, or by switching the

1309 off and then on. If the error persists, have the 1309 serviced.

Error?<LF> Outputs the Error Flags from the

1309. A “1” indicates that the flag is

set; a “0” indicates the flag is not

set.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 32 of 42

Page 33

Chapter 3

________________________________________________________________________

RAM Flag

Indicates that the RAM (random access memory) of the 1309, which

stores the 1309’s set-up data, has been corrupted. The flag is reset by

switching the 1309 off and then on. If the error persists, have the 1309

serviced.

PROM Flag

Indicates that the CRC (cyclic redundancy check) for the PROM (programmable read-only memory) has identified incorrect data. The flag is

reset by switching the 1309 off and then on. If the error persists, have

the 1309 serviced.

Job Specification Flag

Is set if an interface job sent to the 1309 is not recognised. This can be

due to an incorrect job header, incorrect syntax, or incorrect or missing

data. A job cannot be carried out by the 1309 if this flag is set. The

job’s syntax should be checked carefully and the job sent again. The

flag is reset by reading-out the Error Flags, or by switching the 1309 off

and then on.

Software Error Flag

Is set when the 1309’s software develops an error when running. When

this flag is set, the 1309 is reset automatically. The flag is reset by

reading-out the Error Flags, or by switching the 1309 off and then on.

If the error persists, have the 1309 serviced.

Power up Flag

This flag is set when the 1309 has been switched off and then on. This

flag is reset by reading-out the Error Flags. If the error persists, have

the 1309 serviced.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 33 of 42

Page 34

Chapter 4

________________________________________________________________________

Chapter 4

The IEEE/IEC Interface and

Interface Job Overview

November 2011

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 34 of 42

Page 35

Chapter 4

________________________________________________________________________

4.1 Introduction

The digital interface of the 1309 Multipoint Sampler is designed according to ANSI/IEEE Std 488-1978, “IEEE Standard Digital Interface for

Programmable Instrumentation”. The only significant difference between this and the digital interface of IEC Publication 625-1 is in the

type of connector specified; a full range of connectors and adaptors

from LumaSense ensures compatibility between instruments fitted with

either connector.

The 1309 is connected to other instruments with IEEE/IEC interfaces

using the following LumaSense cables and connectors.

Cable AO0265, which has an IEEE standard connector at each

end, connects the 1309 to other instruments equipped with the

IEEE connector.

Cable WL0845, which has IEEE connectors at both ends, is used

to connect the 1309 to the IEEE connector of the Gas Monitor.

The codes and formats used in sending and receiving data to and from

the 1309 over the IEEE/IEC interface have been designed according to

the recommendations of IEEE Std 728-1982, “IEEE Recommended

Practice for Code and Format Conventions (For Use with ANSI/IEEE Std

488-1978)”. Note in particular that the 1309 carries out all communications other than defined bus command sequences using ASCII (ISO

7-bit) coded messages.

It is important to note that although the digital interface of the 1309 is

designed according to IEEE Std 488 and follows the recommendations

of IEEE Std 728, absolute compatibility with IEEE/IEC interfaces designed by other manufacturers cannot be unconditionally guaranteed,

since differences can occur within the limits of the specifications. Any

problems encountered, however, will be of a software rather than a

hardware nature. Where compatibility is in doubt, contact your local

LumaSense representative for further information.

4.1.1 IEEE Functions Implemented in the 1309

The interface of the 1309 implements the following functions as specified in IEEE-488. The sections referred to are the relevant sections of

the IEEE Std 488-1978 which specify the functions. The equivalent

clauses of IEC Publication 625-1 are given in parentheses.

Section 2.3 Source Handshake (SH) Interface Function,

(Clause 6)

SH 1 – complete capability

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 35 of 42

Page 36

Chapter 4

________________________________________________________________________

Section 2.4 Acceptor Handshake (AH) Interface Function,

(Clause 7)

AH 1 – complete capability

Section 2.5 Talker (T) Interface Function, (Clause 8)

T 5 – basic talker, serial poll, talk only mode, unaddress if MLA

Section 2.6 Listener (L) Interface Function, (Clause 9)

L 3 – basic listener, listen only mode, unaddress if

MTA

Section 2.7 Service Request (SR) Interface Function, (Clause

10)

SR 1 – complete capability

Section 2.9 Parallel Poll (PP) Interface Function, (Clause 12)

PP 1 – complete capability

Section 2.10 Device Clear Interface Function, (Clause 13)

DC 1 – complete capability

All other functions – no capability

For further details of the above functions refer to the relevant section of

the IEEE or IEC standards.

4.2 Overview of 1309 Interface Jobs

In this section, each 1309 interface job is grouped according to its function, with a short description of its effect. The correct syntax for each

job is given, with the minimum code for each job-header, in bold upper-case characters. The data for input jobs can be in NR1, NR2 or NR3

format, see section 3.2.1, unless specifically stated otherwise. The data

for output jobs is in NR2 format unless specifically stated otherwise.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 36 of 42

Page 37

Chapter 4

alveUp to 12 sampling

-

sample

a-

________________________________________________________________________

4.2.1 Sampler System Jobs

These jobs control the 1309’s sampler system. Further information

about these jobs is given in section 3.3.

Table 4.1 The interface jobs which control the 1309’s sampler system

Job Header Data Effect on 1309

Open_Sampling_V

Con-

nect_Sampling_Valv

e

valve numbers

To_Monitor

To_Sampling_Pump

Opens the specified

sampling valves

Routes the aireither to the gas monitor, or to the Waste

Air Outlet.

4.2.2 Temperature Measurement Jobs

This job controls temperature measurement with the 1309.

Table 4.2 The interface jobs which control the 1309’s temperature-

measurement function.

Job Header Data Effect on 1309

Sen-

sor_Temperature

?

Specific temperaturesensor number

4.2.3 Pressure Measurement Jobs

This job measures the atmospheric pressure around the 1309.

Table 4.3 The interface jobs which control the 1309’s pressure-

measurement function.

Job Header Data Effect on 1309

Pressure? No data Reads-out the atmos-

Reads-out the temper

ture (°C) at the specified

temperature-sensor.

pheric pressure (kPa)

surrounding the 1309.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 37 of 42

Page 38

Chapter 4

out the 1309’s

nable

Decimal value of bits

Selectively enables bits

the status byte to zero.

________________________________________________________________________

4.2.4 1309 Check Jobs

Table 4.4 The interface jobs which check the 1309’s functions.

Job Header Data Effect on 1309

Status? No data. Reads-

status-flag.

Reset_System No data. Resets the 1309.

For further information, refer to section 3.6.

4.2.5 Error Condition and Service Request Jobs

These jobs allow the identification of error conditions in the 1309. For

further information, refer to section 3.7.

Table 4.5 The interface jobs which investigate error conditions and al-

low generation of service requests.

Job Header Data Effect on 1309

Ser-

vice_Request_E

Ser-

vice_Request_Enable

?

Reset_Status_Byte No data. Resets all the bits of

Warning? No data. Reads-out the 1309’s

Error? No data Reads-out the 1309’s

4.2.6 Standardised Jobs

These jobs do not directly affect the operation of the 1309. The Define_Terminator job is detailed in section 3.2.1. The Output_Header job

is detailed in section 3.2.2.

you want to enable.

No data Reads-out from the

in the status byte.

1309 the enabled bits

of the status byte.

Warning flags.

Error flags.

The jobs with syntax of the type “*RST” are standardised IEEE 488.2

jobs. Most of these jobs are identical to normal 1309 jobs in operation;

the function description refers you to the appropriate 1309 job.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 38 of 42

Page 39

Chapter 4

Indicates if the Warning

jobs.

________________________________________________________________________

Table 4.6 Standardised interface jobs which perform various secondary

functions of the 1309.

Job Header Data Effect on 1309

De-

fine_Terminator

Decimal value of the

ASCII control character

Selects the terminator

character for interface

jobs.

Identify? No data Outputs INNOVA 1309

Output_Header EXclusive

Inclusive

Disables/enables the

1309 to output the minimum code of the job

header with the appropriate data, in response

to the output jobs listed,

section 3.2.2.

*IDN? No data. Outputs

INNOVA

1309,0,VPXXXX

*RST No data. Identical to Re-

set_System.

*SRE Identical to the job Ser-

vice_Request_Enable.

*SRE? No data Identical to the job Ser-

vice_Request_Enable?

*STB? No data Reads-out the status

byte from the 1309.

*TST? No data

or Error flags are set.

The 1309’s condition is

given as follows;

0: Normal

1: Warning flag(s) set

-1: Error flag(s) set

The flags can then be

read-out using the

Warning? or Error?

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 39 of 42

Page 40

Chapter 5

________________________________________________________________________

Chapter 5

Maintenance

November 2011

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 40 of 42

Page 41

Chapter 5

________________________________________________________________________

5.1 Cleaning the Instrument

It is recommended to clean the Instrument using a soft damped cloth.

5.2 Service and repair

The Type 1309 Multipoint Sampler is designed and constructed to provide the user with many years of safe, trouble-free operation. However,

should a fault occur which impairs its correct function and operating

safety, then it should be immediately disconnected at the mains source

and secured against further operations. For repair contact your local

LumaSense Technologies A/S service representative. Under no circum-

stances should repair be attempted by persons not qualified in the service of electronic instrumentation.

________________________________________________________________________

BE1285-15 1309 Multipoint Sampler LumaSense Technologies A/S

Page 41 of 42

Page 42

1309

LumaSense Technologies A/S Tel.:(+45) 44 20 01 00

Energivej 30 Fax: (+45) 44 20 01 01

DK-2750 Ballerup, Denmark http://www.lumasense.dk

Loading...

Loading...