Page 1

Pod XT Live

Bass Pod XT Live

Service Manual

Page 2

3850-A Royal Ave.

Simi Valley, CA 93063-3380

818-575-3922

818-575-3961 (Fax)

Attention:

Before replacing the mainboard on any

POD XT family unit

(POD XT / POD XT Pro / POD XT Live / Bass POD XT

/ Bass POD XT Pro / Bass POD XT Live)

See Tech Bulletin

#26!!!

Page 3

Technical Bulletin 026:

Product: Pod XT FAMILY;

Pod XT/ Pod XT Pro /Pod XT Live / Bass

Pod XT/ Bass Pod XT Pro/ Bass Pod XT

Live

Application: To be implemented during all main pcba replacements of all Pod XT family

units.

Objective: To ensure each unit’s specific Identification is retained for online use.

Parts affected : Secure Memory IC = 15-79-0088. For Pod XT/ Bass Pod XT = U17. For

Pod XT Pro/ Bass Pod XT Pro = U8. For Pod XT Live/ Bass Pod XT Live = U24.

Tools/Supplies Required: A solder iron with a small tip. Solder.

Procedure : During main board replacement, carefully remove the secure memeory IC

from the old main board (see above for reference designator). Install the secure memory IC

just removed, onto the new main board before installing the new board into the unit.

Warranty Implications : This is a required step of a main board replacement for the Pod

XT Family of units, and can be part of either a warranty or a non – warranty repair.

1

Customer Service Tel: (818) 575-3600 • Customer Service Fax: (818) 676-1585

Line 6 Inc. • 29901 Agoura Road, Agoura Hills, CA 91301 • 6033 De Soto Ave.

Woodland Hills, CA, 91367

Page 4

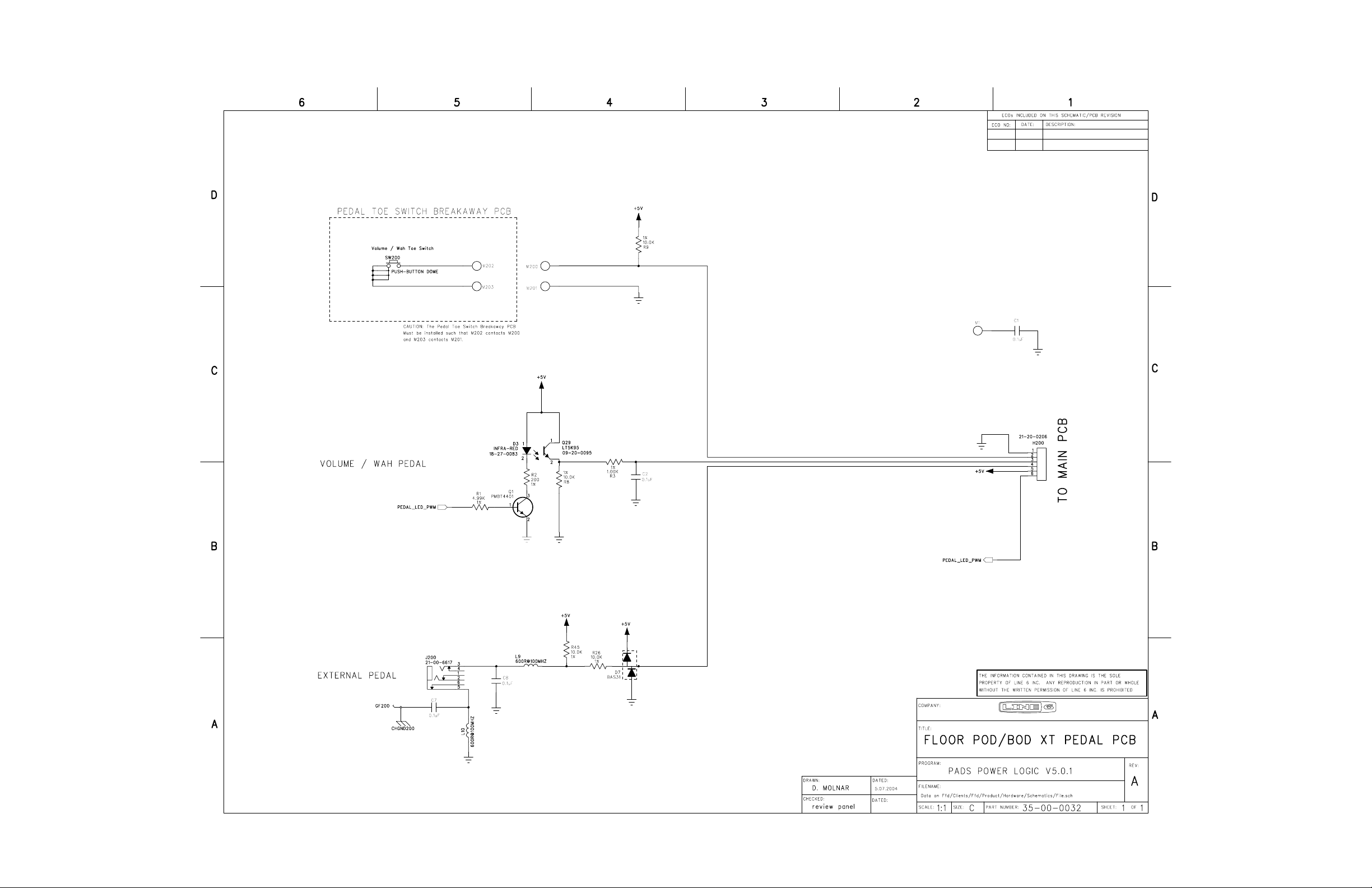

SCHEMATIC FLOORPOD XT PEDAL REV A.sch-1 - Fri May 07 10:58:51 2004

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

SCHEMATIC FLOORPOD XT SWITCH REV A.sch-1 - Fri May 07 11:00:01 2004

Page 15

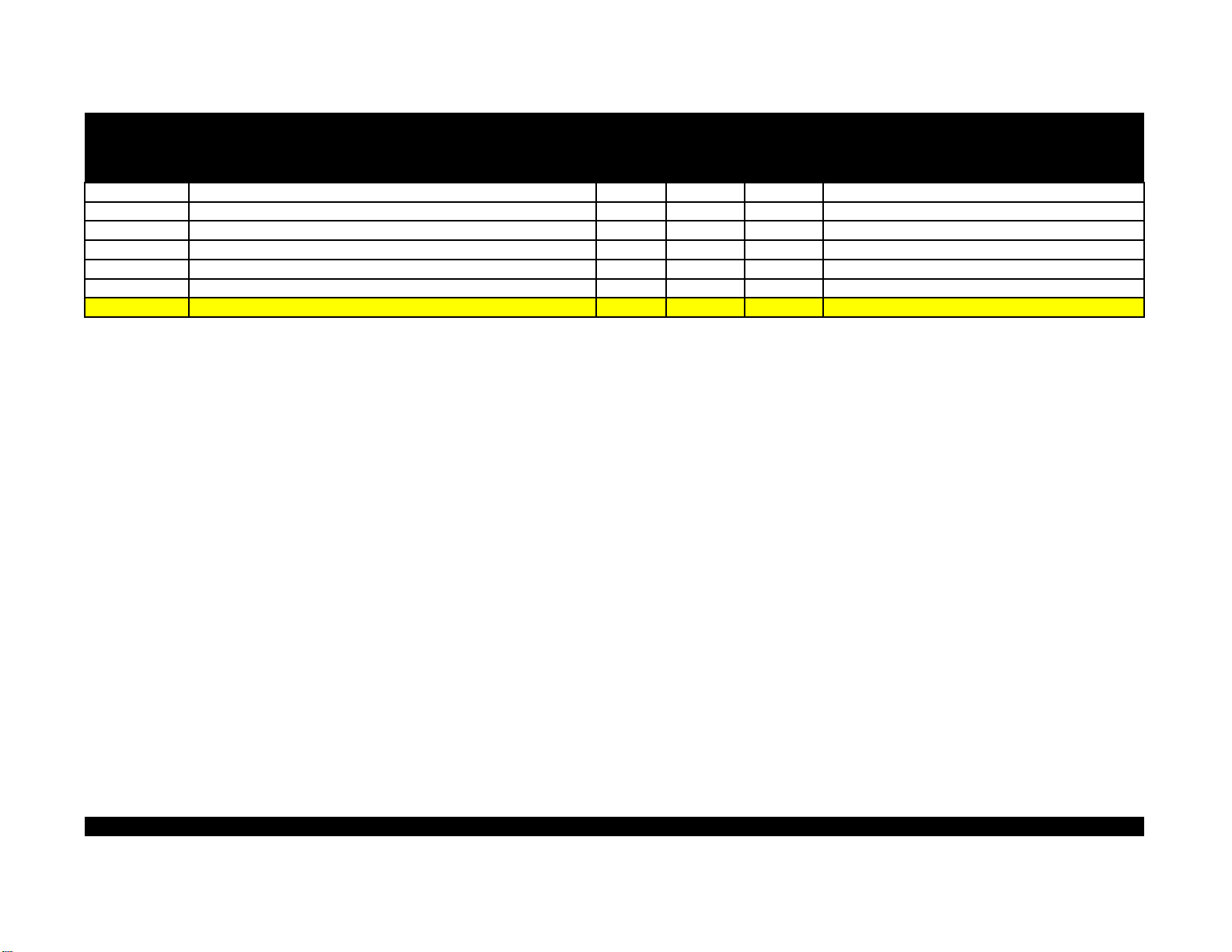

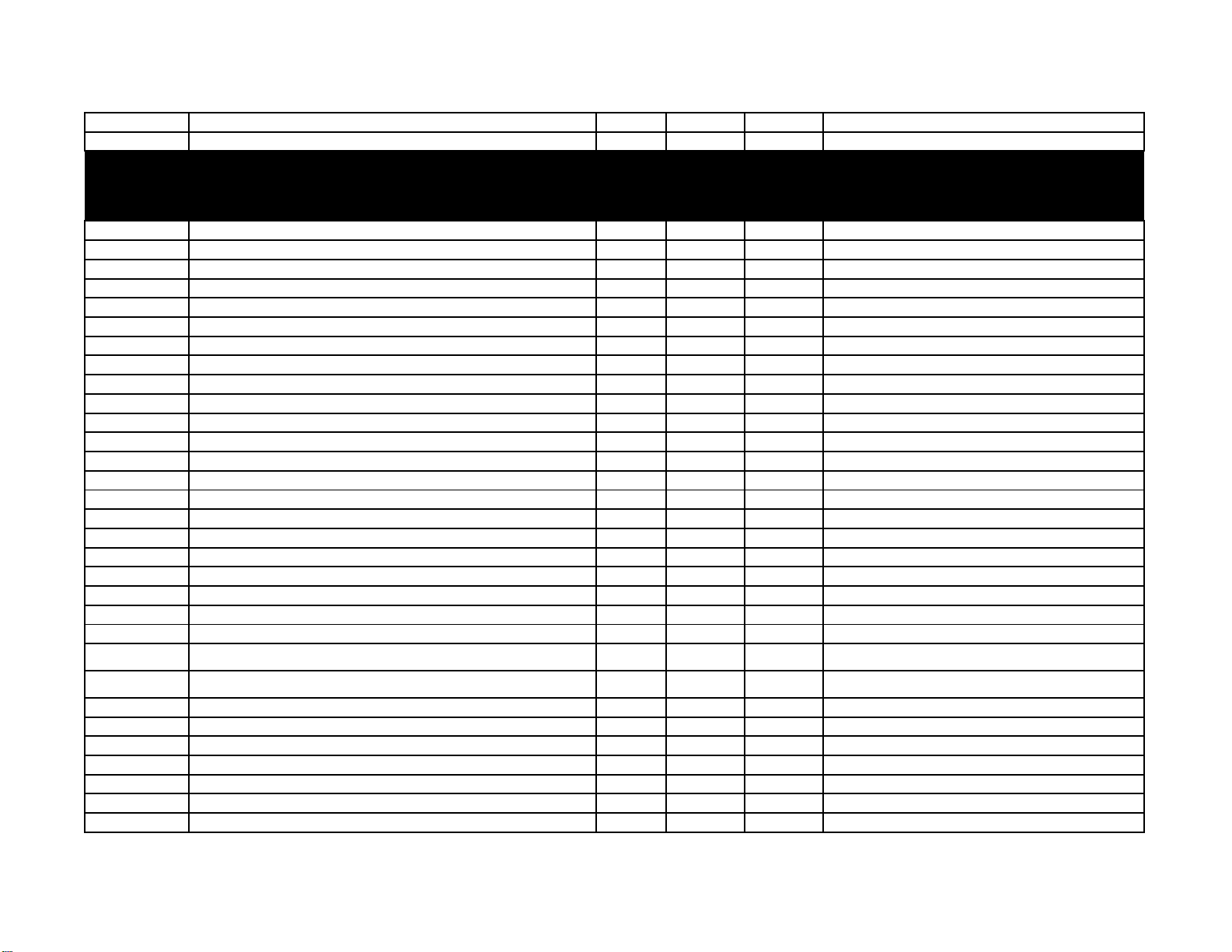

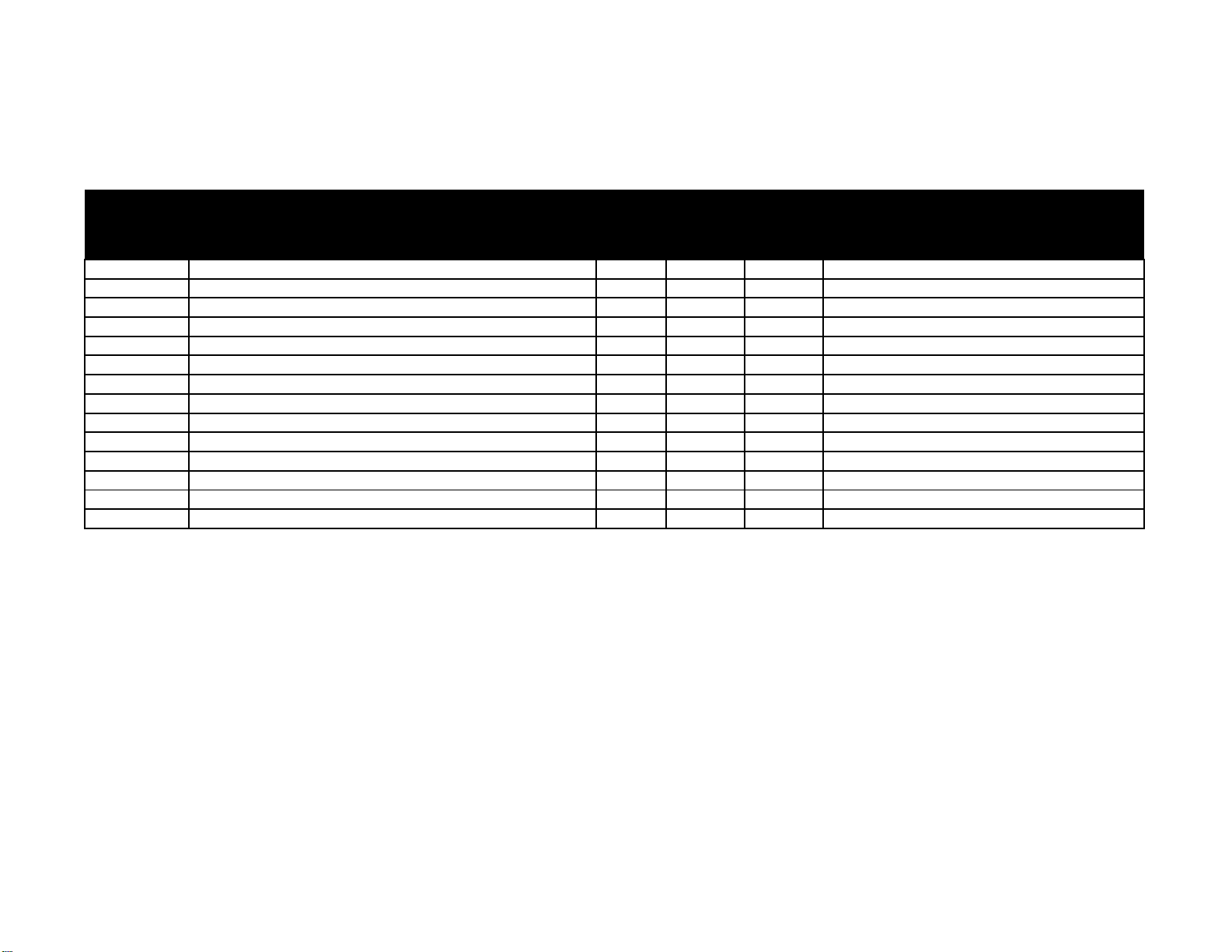

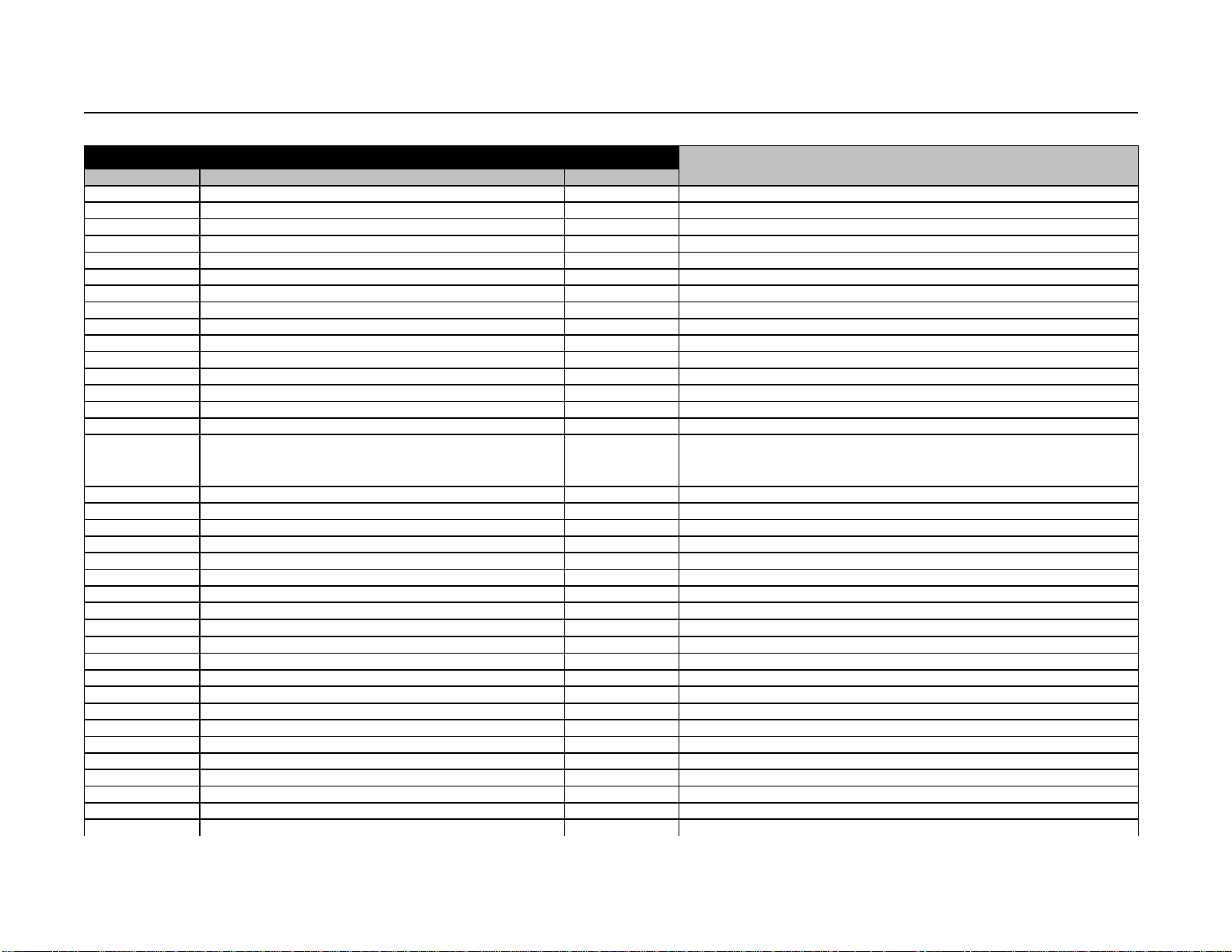

99-060-0605 POD XT LIVE Complete Unit w/Accessories

Part Number Description

11-32-0000

21-34-2000

30-75-0013

40-00-0054

40-06-0001-1

50-03-0018

59-00-0116

XFMR PX2 120VAC/60Hz 9VAC/2A UL 2464 VW-1 6FT. BLK US 1 $3.59 $5.38

CBL USB HIGH SPEED 2 METER BLK 1 $0.87 $1.31

CAP RJ45 JACK PROTECTOR VINYL .692-ODx.250-H BLACK 1 $0.03 $0.05

MANUAL USER FLOORPOD 1 $0.00 $0.00

INSERT FX-JUNKIE FLOORPOD-XT INTERNATIONAL-VERSION REV.A 1 $0.00 $0.00

ASSY PACK RJ45 PROTECTION 1 $0.00 $0.00

ASSY UNIT COMPLETE FLOORPOD-XT 1 $0.00 $0.00 This is NOT available as a replacement part

Qty Per

Parent

Dealer

Cost

MSRP Reference Designator

59-00-0116 POD XT LIVE Complete Unit

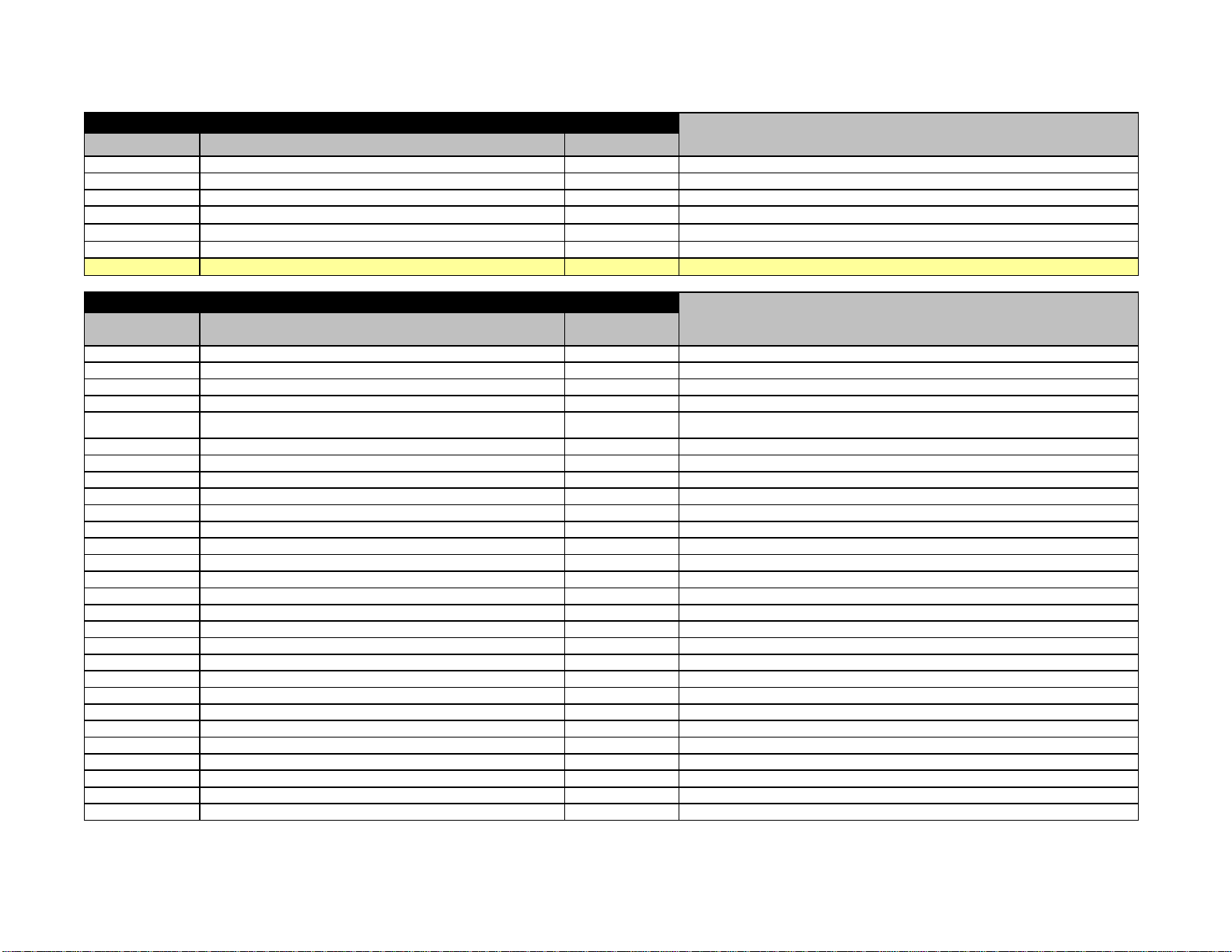

Page 16

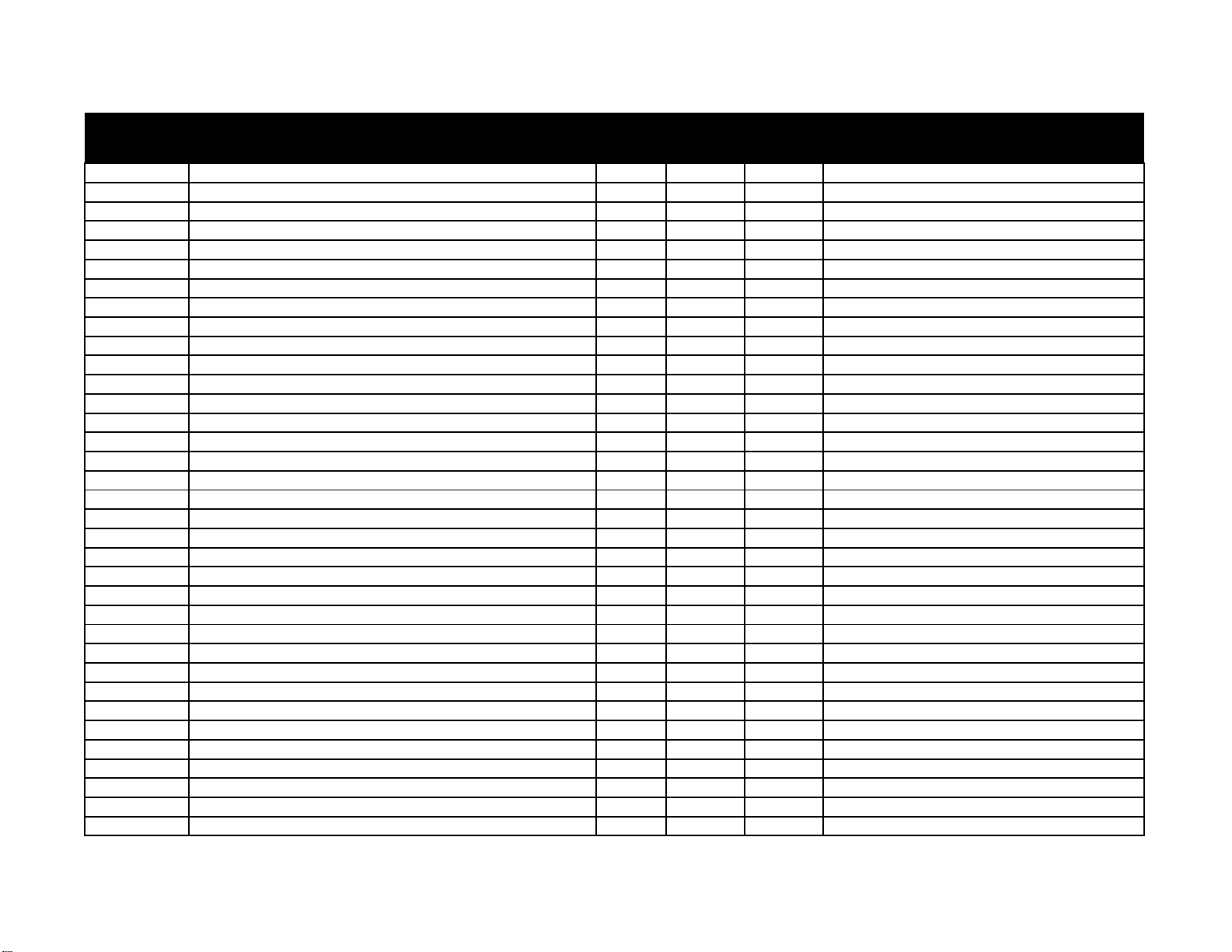

Part Number Description

21-30-0001 CBL DIL 16-COND .100 x 5.75-IN/ 7.25-IN 1 $0.00 $0.00 Main PCBA to Switch PCBA

21-34-0060 CBL SIL 6-COND 24AWG 2mm x 9.75-IN F-F-JST Z-TYPE 1 $0.00 $0.00 Main PCBA to Pedal

24-24-0606 SWITCH POWER ROCKER 6A/250VAC 10A/120VAC PNL-MNT BLK 1 $0.16 $0.24

30-00-0012 SCREW 1/4-20 x3.5IN STEEL SHCS BLK OXIDE 1 $0.00 $0.00 Pedal Shaft

30-00-0013 SCREW 6-32 x.25in STL PHH BLK OXIDE 4 $0.00 $0.00 Pedal

30-00-0042 SCREW SHEET METAL 4 x 0.375 INSELF-TAP PPB 39 $0.01 $0.02

30-00-0043 SCREW 6-32 x 5/16 w/LK WASH PPZ STL 22 $0.00 $0.00 PCBA Mounting

30-00-0062 SCREW 10-32 x 3/8-IN w/CAPTIVEWASHER PPZ 2 $0.00 $0.00 Knob guard mounting

30-00-0375 SCREW 6-32 x .375 PPB 17 $0.02 $0.02 15 Chassis ssy/ Bumpers

30-00-4250 SCREW SHEET METAL SELF-TAP #4 x .250IN PPB 6 $0.03 $0.04 Bezel mounting

30-03-0003 WASHER .473 x.260x .030 steel 4 $0.00 $0.00 Pedal Shaft Assy

30-03-0005 WASHER .500 x.260x .030 NYLON 2 $0.00 $0.00 Pedal Shaft Assy

30-03-0007 WASHER .500 x.260x .125 NYLON 2 $0.00 $0.00 Pedal Shaft Assy

30-03-0013 WASHER .50 x.170x .040 NYLON 4 $0.00 $0.00

30-06-0009 NUT 1/4-20 STL W/NYLON LOCK 1 $0.00 $0.00 Pedal

30-06-0623 NUT HEX 6-32 w/CAPTIVE STAR-WASHER 3 $0.02 $0.03 Pedal PCBA / Top FT Switch PCBA

30-15-0004 SPACER .13THKx.63OD NYLON 5 $0.08 $0.11

30-15-0005 SPACER .25 OD x NO.8 ID AL 2 $0.00 $0.00 Pedal PCBA

30-15-0006 INSULATOR .17 ODx.46 LG PLASTIC 1 $0.00 $0.00

30-15-0011 SPACER .39 Dia x 2.40 Lg Steel 1 $0.00 $0.00 Pedal

30-15-0023 SPACER 1/4-ODx1/8-L x #6 SCREW-ID NYLON 1 $0.00 $0.00 Top tier FootSwitch PCBA -

30-21-0004 STRAIN RELIEF-CABLE 3/8 x 0.5(ID)-IN NYLON BLK 1 $0.00 $0.00 Power Cable

30-24-0003 CABLE-TIE 4" CLEAR 2 $0.03 $0.04 For 21-34-0060

30-27-0025 KNOB SM ENCDR .55Dx.57 H IMP ABS MICROTEX 2 $0.19 $0.28

30-27-0056 LENS LED .19" DIA x.29" HT PLASTIC CLEAR SNAP-IN 2 $0.00 $0.00

30-27-0101 BEZEL U/I 6.30 x 2.52 x .31-INABS BLACK FLOORPOD 1 $0.00 $0.00

30-27-0105 LENS DISPLAY 3.73 x 1.13 x 0.52-IN PLASTIC CLEAR FLOORPOD 1 $0.00 $0.00

30-45-0011 KNOB POT .77 DIA x .76 HT PLASTIC CHROME-PLATED 6 $0.13 $0.20

30-48-5012 BUMPER RUBBER .465" O.D. BLK 14 $0.08 $0.11

30-51-0046 BRACKET PEDAL .85x2.54" 16 GA STL EG FLOORPOD 1 $0.00 $0.00

30-51-0078 TACTILE DOME 20mm SST NP 3 $0.44 $0.65 Pedal Switch

30-51-0178 FOOTSWITCH SUPPORT 2.0 x 2.0 x.55 CRS ZINC FLOORPOD-XT 2 $0.00 $0.00

30-51-0179 CHASSIS BASE 10.3 x 20.1 x 2.0.040 THK STL FLOORPOD-XT 1 $0.00 $0.00

30-51-0180 CHASSIS TOP 10.9 x 20.2 x 2.1 .060 THK STL FLOORPOD-XT 1 $0.00 $0.00

30-51-0181 PEDAL 8.0 x 1.7 x 3.0 16AWG CRS NICKEL FLOORPODXT 1 $0.00 $0.00 Pedal

Qty Per

Parent

Dealer

Cost

MSRP Reference Designator

Page 17

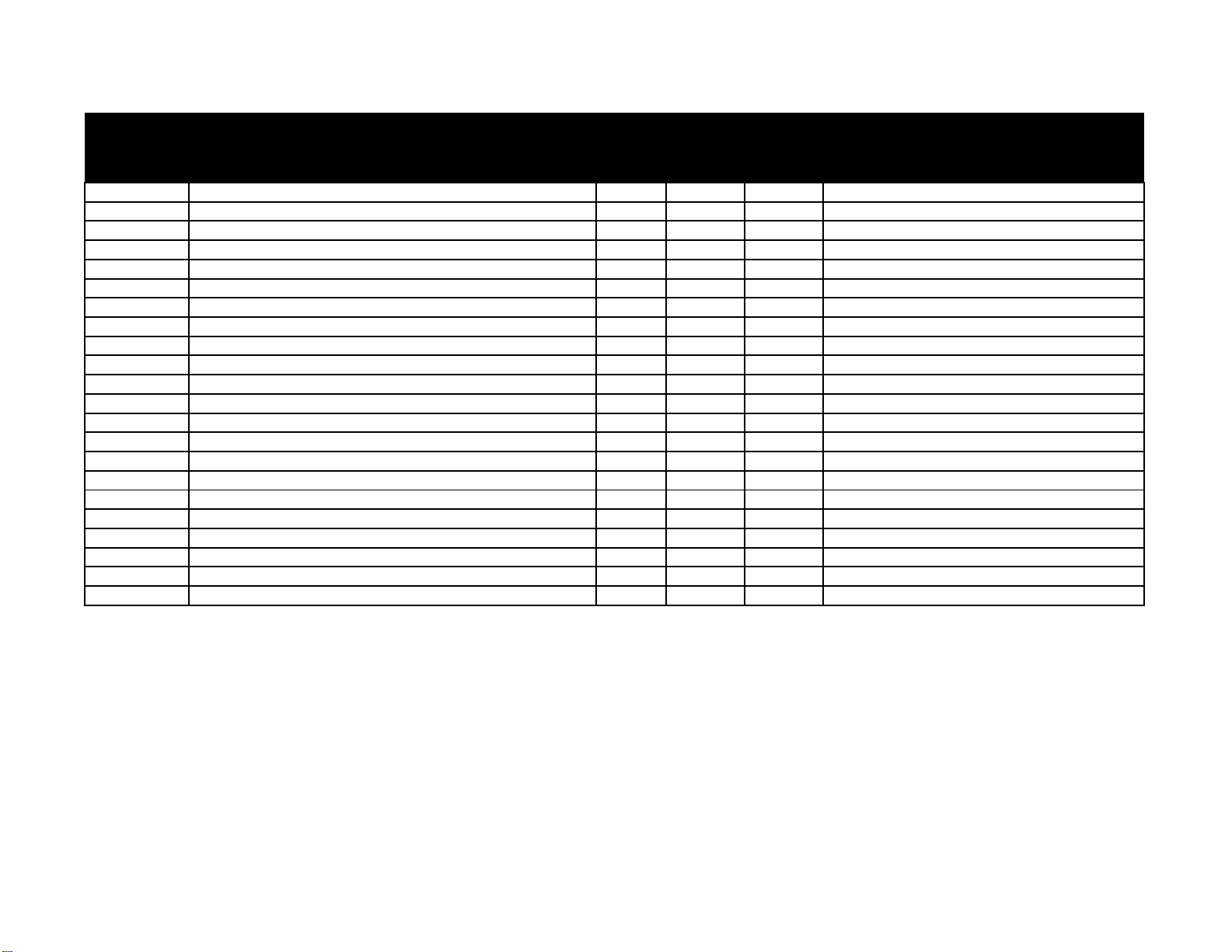

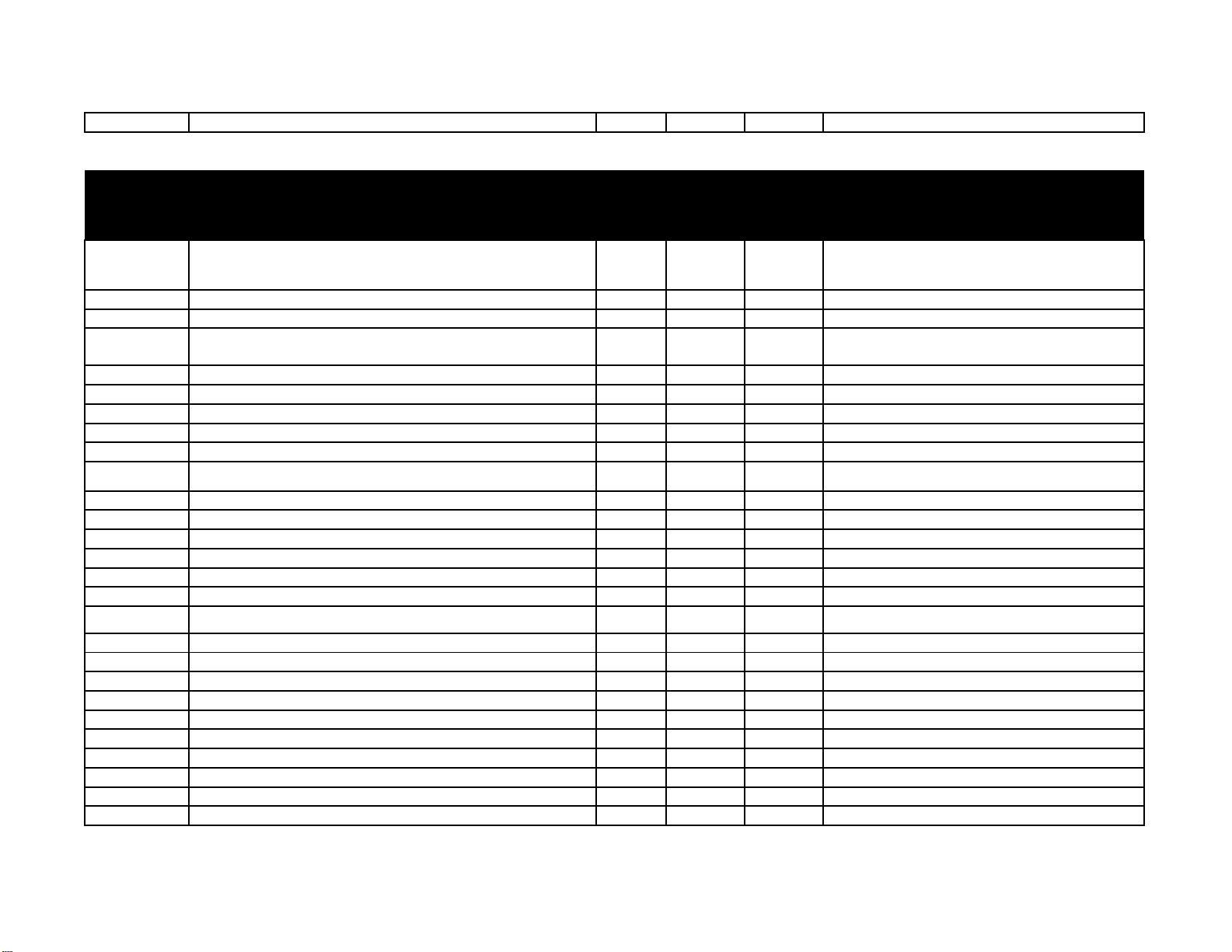

59-00-0116 POD XT LIVE Complete Unit

Part Number Description

30-51-0187 GUARD KNOB 6 x 1.06 x 0.38-IN ROUND STL-BAR CHROME 1 $0.00 $0.00

30-51-0197 BRACKET SUPPORT PEDAL 2.30 x 1.30 x 1.314-IN EG-STL 1 $0.00 $0.00

30-75-0002 FOOT RUBBER 2.87x7.70x.237 BLK 1 $0.00 $0.00 Pedal

30-75-0007 PEDAL STOP FOAM RUBBER 2.63x.25x.06 2 $0.00 $0.00

30-75-0011 STOP PEDAL RBR .81SQ x .52 BLK 2 $0.00 $0.00

40-25-0020 LABEL INSPECTION QUALITY 1 $0.06 $0.09

40-25-0037 LABEL CLING-DECAL USER PRESETS FLOORPOD-XT REV.B 1 $0.00 $0.00

40-25-0100 LABEL BAR CODE SERIAL NUMBER 4-PANEL LABEL 1 $0.15 $0.22

40-30-0020 LABEL S/N 0.1W x 0.5L 2-ACROSSDUROPOLY 613 GLOSS SILVER 1 $0.01 $0.02

50-02-0030-1 PCBA MAIN FLOORPOD-XT 1 $0.00 $0.00

50-02-0032 PCBA PEDAL FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-10 ASSY E/M FOOTSWITCH "A" w/LED FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-11 ASSY E/M FOOTSWITCH "B" w/LED FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-12 ASSY E/M FOOTSWITCH "C" w/LED FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-13 ASSY E/M FOOTSWITCH "D" w/LED FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-14 ASSY E/M FOOTSWITCH "TAP" w/LED FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-15 ASSY E/M FOOTSWITCH "AMP" w/LED FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-16 ASSY E/M FOOTSWITCH "STOMP" w/LED FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-17 ASSY E/M FOOTSWITCH "MOD" w/LED FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-18 ASSY E/M FOOTSWITCH "DELAY" w/LED FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-20 ASSY E/M FOOTSWITCH "B-DOWN" no/LED FLOORPOD-XT 1 $0.00 $0.00

50-04-0099-21 ASSY E/M FOOTSWITCH "B-UP" no/LED FLOORPOD-XT 1 $0.00 $0.00

Qty Per

Parent

Dealer

Cost

MSRP Reference Designator

Page 18

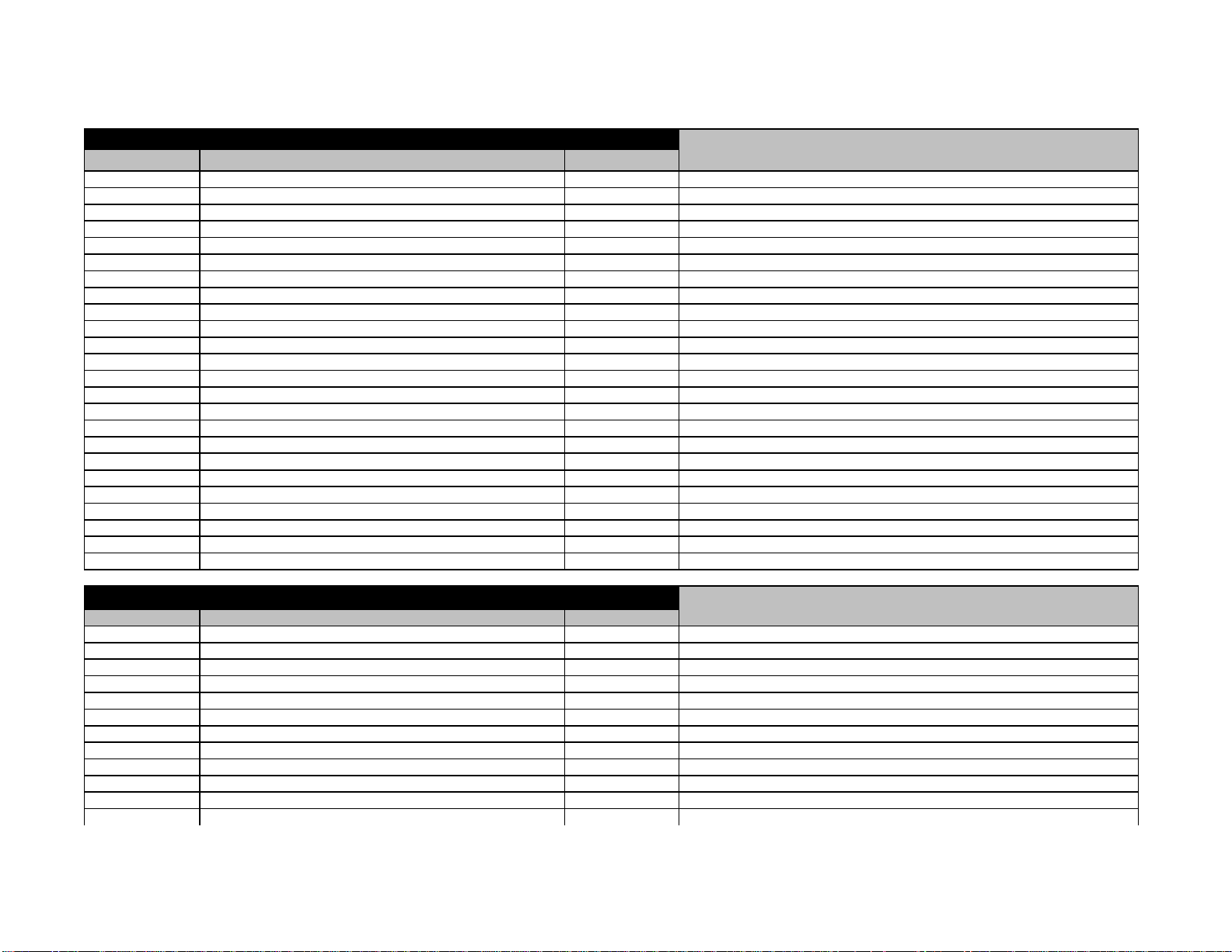

50-02-0030-1 Main PCBA

R1, R29, R32, R115, R118, R122, R123, R129, R140

Part Number Description

01-00-0000 RES 0R 5% 0805 1 $0.00 $0.00 R144.

01-16-0272 RES CARBON FILM 2.7K 1/2W 5% TH 1 $0.00 $0.00 R153

01-23-0270

01-24-1000 RES 100R 1% 0805 11 $0.00 $0.00

01-24-1001 RES 1.00K 1% 0805 4 $0.00 $0.00 R23, R28, R94, R112

01-24-1002 RES 10.0K 1% 0805 7 $0.00 $0.01 R26, R61, R62, R96, R98, R99, R151

01-24-1003 RES 100K 1% 0805 4 $0.00 $0.00 R40, R41, R42, R45

01-24-1004 RES 1.00M 1% 0805 1 $0.00 $0.01 R22

01-24-10R0 RES 10.0R 1% 0805 3 $0.00 $0.01 R21, R120, R121

01-24-1100 RES 110R 1% 0805 1 $0.00 $0.00 R117

01-24-1210 RES 121R 1% 0805 1 $0.00 $0.00 R152

01-24-1241 RES 1.24K 1% 0805 2 $0.00 $0.00 R36, R38

01-24-1501 RES 1.50K 1% 0805 2 $0.00 $0.00 R39, R142

01-24-15R0 RES 15R 1% 0805 2 $0.00 $0.00 R76, R80

01-24-1620 RES 162R 1% 0805 1 $0.00 $0.00 R89

01-24-1621 RES 1.62K 1% 0805 1 $0.00 $0.00 R113

01-24-2001 RES 2.00K 1% 0805 10 $0.00 $0.00 R47, R48, R49, R50, R54, R55, R57, R58, R124, R130

01-24-2002 RES 20.0K 1% 0805 18 $0.00 $0.00

01-24-2210 RES 221R 1% 0805 3 $0.00 $0.01 R92, R101, R107

01-24-2211 RES 2.21K 1% 0805 1 $0.00 $0.01 R24

01-24-22R1 RES 22.1R 1% 0805 10 $0.00 $0.00

01-24-2551 RES 2.55K 1% 0805 2 $0.00 $0.00

01-24-3011 RES 3.01K 1% 0805 1 $0.00 $0.01 R35

01-24-3321 RES 3.32K 1% 0805 1 $0.00 $0.00 R25

01-24-3323 RES 332K 1% 0805 1 $0.00 $0.00 R31

01-24-4321 RES 4.32K 1% 0805 2 $0.00 $0.01 R27, R95

01-24-4750 RES 475R 1% 0805 1 $0.00 $0.00 R93

01-24-4751 RES 4.75K 1% 0805 7 $0.00 $0.01 R109, R111, R139, R143, R145, R146, R147

01-24-4752 RES 47.5K 1% 0805 7 $0.01 $0.01 R20, R63, R64, R114, R119, R149

01-24-47R5 RES 47.5R 1% 0805 8 $0.01 $0.01 R75, R77, R78, R79, R82, R84, R86, R85, R87

01-24-4991 RES 4.99K 1% 0805 1 $0.00 $0.00 R30

RES METAL OXIDE 27R 3W 5% TH FORMED LEADS @ 20mm

SPACING

Qty Per

Parent

2 $0.00 $0.00 R71, R88

Dealer

Cost

MSRP Reference Designator

R9, R19, R90, R100, R102, R103, R105, R106, R125,

R134, R136

R2, R3, R4, R5, R6, R7, R8, R10, R11, R67, R68, R69,

R70, R73, R74, R81, R83, R150

,

R13, R16

Page 19

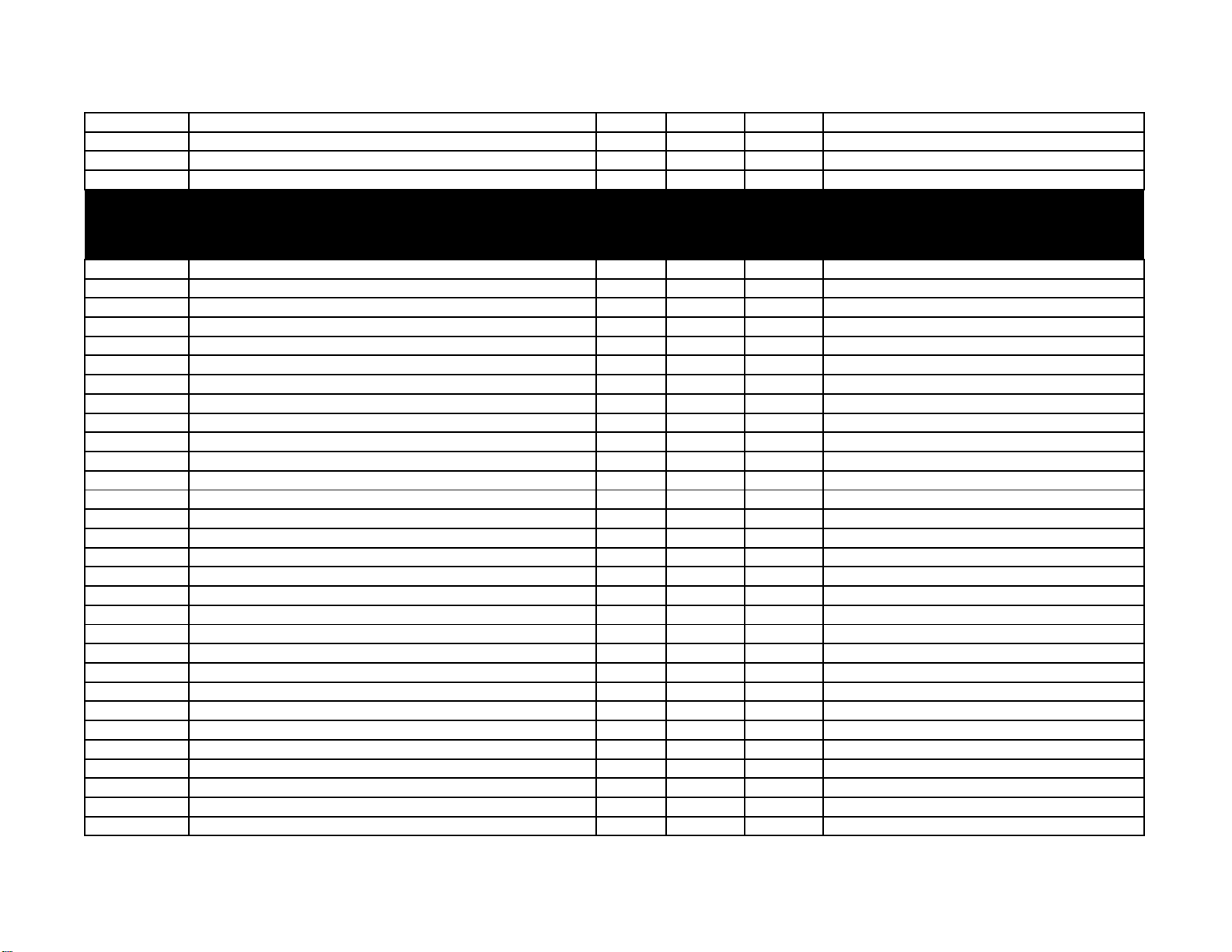

01-24-5110 RES 511R 1% 0805 2 $0.00 $0.00 R43, R110

,

01-24-51R1 RES 51.1R 1% 0805 8 $0.00 $0.00 R126, R127, R128, R131, R132, R133, R135, R137

50-02-0030-1 Main PCBA

Part Number Description

01-24-5360 RES 536R 1% 0805 1 $0.00 $0.00 R18

01-24-5R11 RES 5.11R 1% 0805 1 $0.00 $0.00 R46

01-24-6041 RES 6.04K 1% 0805 1 $0.00 $0.00 R34

01-24-6810 RES 681R 1% 0805 2 $0.00 $0.00 R15, R17

01-24-69R8 RES 69.8R 1% 0805 3 $0.00 $0.00 R97, R104, R108

01-24-7501 RES 7.50K1% 0805 2 $0.01 $0.01 R37, R91

01-24-8871 RES 8.87K 1% 0805 5 $0.00 $0.01 R51, R52, R56, R59, R138

01-24-9090 RES 909R 1% 0805 2 $0.00 $0.00 R12, R14

01-48-0103 POT MONO 10KB LINEAR TAPER 25 mm D-SHAFT 6 $0.10 $0.15 R33, R44, R53, R66, R72, R85

01-48-9103 POT DUAL 10KA AUDIO TAPER HORIZ MT 25mm RND PLASTIC 1 $0.43 $0.64 R60

01-60-0472 RES NETWORK 4.7K BUSSED 1/8W 5% SM 1 $0.00 $0.00 R116

03-10-6108 CAP ELEC 1000uF 6.3V 20% RADIAL 8/11.5/5 1 $0.00 $0.00 C126

03-12-0107 CAP ELEC 100uF 16V 20% RADIAL 6.3/11/5 4 $0.04 $0.05 C34, C38, C66, C145

03-12-0108 CAP ELEC 1000uF 16V 20% RADIAL10/16/5 2 $0.17 $0.26 C45, C69, C39

03-12-0688 CAP ELEC 6800uF 16V 20% RADIAL18/35.5/7.5 1 $0.68 $1.02 C81

03-13-0228 CAP ELEC 2200uF 16V 20% 105C LowZ 0.030R RADIAL 12.5/25/5 3 $0.00 $0.00 C70, C107, C39 added ECO# 0416101

03-13-0477 CAP ELEC 470uF 16V 20% 105C LowZ 0.085R RADIAL 8/15/5 6 $0.00 $0.00 C49, C59, C60, C164, C165, C166

03-16-2108 CAP ELEC 1000uF 35V 20% 105C RADIAL 12.5/25/5 2 $0.00 $0.00 C42, C47

03-18-0105 CAP ELEC 1uF 50V 20% RADIAL 5/11/5 5 $0.01 $0.02 C43, C44, C46, C48, C98

03-18-0106 CAP ELEC 10uF 50V 20% RADIAL 5/11/5 8 $0.02 $0.03 C63, C65, C71, C84, C85, C95, C99, C119

03-24-0273 CAP MET-POLY 27nF 50V 5% TH 7.3/3.2/5/5 1 $0.00 $0.00 C37

03-36-0224 CAP ESTR 0.22uF 50V 5% TH 11/6/11.5/7.5 1 $0.07 $0.11 C157

03-50-0101 CAP NPO 100pF 50V 10% 0805 5 $0.01 $0.01

03-50-0102 CAP NPO 1nF 50V 5% 0805 16 $0.02 $0.04

03-50-0220 CAP NPO 22pF 50V 20% 0805 2 $0.02 $0.02 C144, C148

03-50-0272 CAP NPO 2.7nF 50V 5% 0805 2 $0.02 $0.03 C74, C75

03-50-0391 CAP NPO 390pF 50v 5% 0805 4 $0.00 $0.00 C72, C73, C76, C77

03-50-0470 CAP NPO 47pF 50V 10% 0805 3 $0.11 $0.17 C32, C78, C79

03-52-0100 CAP X7R 10pF 50V 20% 0805 2 $0.02 $0.02 C167, C168

03-52-0101 CAP X7R 100pF 50V 20% 0805 2 $0.01 $0.01 C82, C83

03-52-0102 CAP X7R 1nF 50V 20% 0805 1 $0.01 $0.02 C163

Qty Per

Parent

Dealer

Cost

MSRP Reference Designator

C16, C18, C54, C56, C142, C8, C9, removed ECO#

0416902

C2, C6, C7, C8, C9, C10, C11, C12, C14, C24, C26, C51,

C53

C86, C88, C140 C7, C8, added ECO# 0416902

Page 20

03-52-0103 CAP X7R 10nF 50V 20% 0805 3 $0.01 $0.02 C116, C117, C160

C1, C3, C4, C5, C13, C15, C17, C19, C20, C21, C22

,

50-02-0030-1 Main PCBA

Part Number Description

03-52-0104 CAP X7R 0.1uF 50V 20% 0805 74 $0.02 $0.04

03-52-0334 CAP X7R 0.33uF 25V 20% 0805 1 $0.15 $0.23 C108

03-52-0472 CAP X7R 4.7nF 50V 20% 0805 1 $0.02 $0.04 C109

03-52-0473 CAP X7R 47nF 50V 20% 0805 17 $0.02 $0.03

04-04-0001 FERRITE BEAD 3-TURN 600R@ 100MHz MATERIAL-61 RADIAL TH 2 $0.37 $0.56 L25, L26

06-20-0099 DIODE GEN PUR DUAL 70V 215mA 6nS SOT-23 SM BAV99 8 $0.02 $0.02 D15, D16, D26, D29, D30, D33, D36, D38

06-23-0054 DIODE SCHOTTKY DUAL 30V 200mA 5nS SOT-23 SM BAT54S 1 $0.00 $0.00 D17

06-32-0340 DIODE SCHOTTKY 3A 40V SMB SM B340B 4 $0.13 $0.19 D7, D8, D19, D20

06-32-4006 DIODE RECTIFIER 800V 1A SMA SM MRA4006T3 10 $0.06 $0.08 D9, D10, D11, D12, D13, D14, D42, D43, D44, D45

06-34-0016 DIODE SWITCHING 75V 200mA 6nS SOT-23 SM BAS16LT1 17 $0.01 $0.02

09-03-0032 TRANS PNP MED POWER TIP32C TH 1 $0.22 $0.33 Q9

09-10-4401 TRANS NPN SMALL-SIGNAL MBT4401SOT-23 SM 4 $0.01 $0.02 Q2, Q3, Q7, Q8

09-10-4403 TRANS PNP SMALL-SIGNAL MBT4403SOT-23 SM 1 $0.03 $0.05 Q1

09-10-6102 TRANS N-CHANNEL MOSFET ZXM61N02 SOT-23 SM 3 $0.10 $0.15 Q4, Q5, Q66

11-00-3000 CRYSTAL OSCILLATOR 30MHz 3.3V DIP4 METAL-CAN TH 1 $0.89 $1.34 Y1

11-10-0501 FERRITE BEAD 500R @100mHZ 2.5A 1206 SM 2 $0.05 $0.07 L17, L18

11-10-2012 FERRITE BEAD 600R@100MHZ 300mA 0805 SM 22 $0.03 $0.04

12-00-0317 IC VREG ADJ 1.2-37V 1.5 AMP TO-220 LM317 TH 1 $0.15 $0.23 U12

12-02-0015 IC REG +15V 1.5AMP TO-220F TH NJM7815FA 1 $0.25 $0.38 U2

12-02-0115 IC REG -15V 1.5AMP TO-220F TH NJM7915FA 1 $0.38 $0.57 U3

12-02-1088 IC REG ADJ TO-220 TH LM1086 1 $0.38 $0.57 U7

12-02-7805 IC REG +5v 1.5 Amp TH 2 $0.09 $0.14 U5, U10

12-54-0082 IC OP AMP DUAL TL082CD SO-8 SM 1 $0.13 $0.20 U8

12-54-0084 IC OP AMP QUAD TL084CD SM 3 $0.22 $0.33 U6, U9, U11

12-54-2134 IC OP-AMP DUAL OPA2134UA SM SO-8 1 $1.16 $1.74 U1

12-64-4528 IC CONVERTER 24B 48/96KHz AUDIO CODEC SM AK4528 1 $2.30 $3.45 U4

12-64-7890 IC ADC 12 BIT / 8 CHANNEL SM TSSOP-16 ADC78H90 1 $1.17 $1.76 U31

Qty Per

Parent

Dealer

Cost

MSRP Reference Designator

C23, C30, C31, C62, C64, C67, C68, C90, C91, C92,

C93, C94, C96, C97, C100, C101, C102, C103, C105,

C27,C29,C33,C35-36,C40-41,C50,C52,C55,C5758,C61,C87,C80,C89C104

D6, D18, D21, D22, D23, D24, D25, D27, D28, D31, D32,

D34, D35, D37, D39, D40, D41

L1, L2, L3, L4, L5, L6 , L7, L8, L9, L10, L11, L12, L13,

L14

L15, L16, L19, L20, L21, L22, L23, L24

,

Page 21

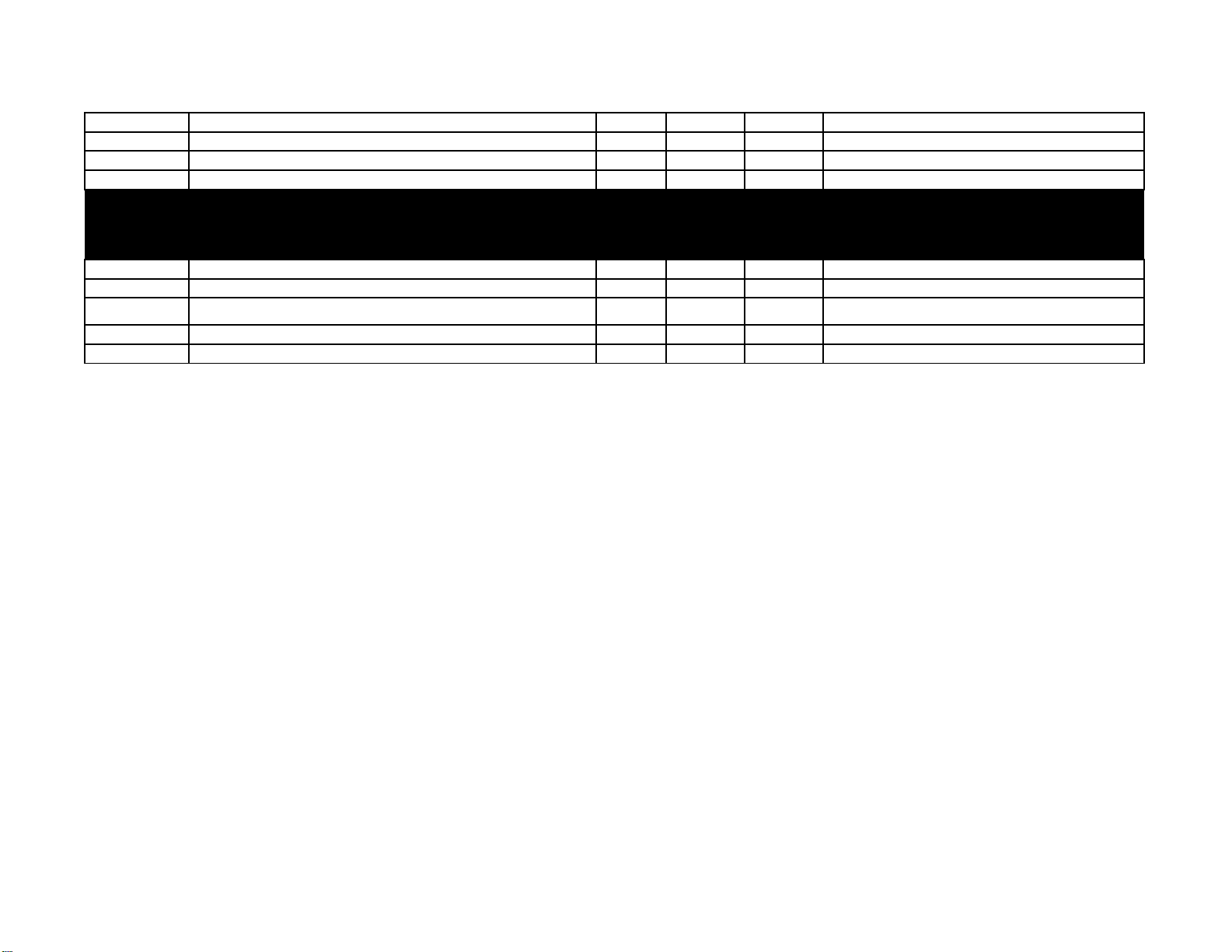

15-40-6138 IC 6N138 OPTO-ISOLATOR DIP-8 TH 1 $0.49 $0.73 U15

15-64-0273 IC 74HCT273 FLIP-FLOP D-TYPE 8-BIT SO-20 SM 2 $0.10 $0.15 U16, U18

15-65-0004 IC 74LVC04 LOW VOLTAGE CMOS HEX INVERTER SO-14 SM 1 $0.07 $0.11 U30

15-68-1020 IC CONTROLLER USB TAS1020BPFB SM 1 $2.95 $4.43 U25

50-02-0030-1 Main PCBA

Part Number Description

15-70-1610 IC DRAM 1M X 16 SDRAM HY57V161610DTC-7 SM 2 $4.60 $6.90 U27, U28

15-72-1009 IC SRAM 128K X 8 CY7C1009B 15nS SOJ-32 (V32) SM 1 $1.83 $2.75 U14

15-78-4128 IC EEPROM 128KBIT I2C SERIAL 24LC128-I/SN SOIC8 SM 1 $0.90 $1.35 U23

15-79-0088 IC MEMORY SECURE AT88SC153-00 -2.7 8S1 (SO-8) SM 1 $0.49 $0.74 U24

15-86-1065 IC DSP SHARC ADSP-21065LKS-240 MQFP208 SM 1 $10.00 $15.00 U26

15-86-8420 IC DIGITAL AUDIO SAMPLE RATE CONVERTER SM Mfg# CS8420-CS 1 $9.30 $13.95 U20

15-92-5810 IC RESET 5V 5% ACTIVE-HI SOT-23 SM LM810 1 $0.27 $0.40 U22

15-96-0128 IC PLD 128 CELL/96 I/O ISPLSI5128VE-100LT128 TQFP128 1 $3.65 $5.48 U21

18-12-0001 LED 3-DIGIT 7-SEG YEL w/DP Ledtech LM3633-11-11BWRN TH 1 $0.66 $0.99 D2

18-21-0002 LED ORANGE 3mmX2mm SM Kingbrite APK3020SEC 4 $0.14 $0.21 D1, D3, D4, D5

21-00-0015 DNU - use 21-00-0014 - JACK BARREL PCB MT 2.5mm 1 $0.34 $0.50 J1

21-00-6617 JACK 1/4" TRS 6-PIN PCB MT HORIZ TH W/CHROME HRDWARE 4 $0.38 $0.57 J6, J7, J8, J10

21-04-5075 JACK DIN 5-PIN FEMALE MIDI PCB-MNT RT-ANG LN 05075 2 $0.15 $0.23 J4, J5

21-12-0035 JACK 3.5mm STEREO 5 PIN CRIMPED LEADS NON-THREADED 1 $0.12 $0.18 J9

21-16-0001 JACK RJ-45 9-PIN IN XLR SHELL PCB-MNT HORIZ TH 1 $2.15 $3.23 J3

21-18-0002 TERMINAL SCREW PCB MOUNT RT ANGLE SNAP-IN TH 1 $0.00 $0.00 BR1

21-20-0206 HDR SIL PCB-MT 6-PIN x 2mm MALE SHRD VERT MT TH 1 $0.11 $0.17 H3

21-21-0001 JACK USB-B SHIELDED PCB-MNT BLACK WIESON 3700-4ABN4S1W 1 $0.22 $0.33 J2

21-21-1016 HDR DIL PCB-MT 16-PIN 2x8x.100MALE SHRD LOCKING VERT MT TH 1 $1.55 $2.33 H4

21-34-0061-1 CBL 1-COND 18AWG 3.O-IN FM- QUICK DISCONNECT/S-T BLK 1 $0.00 $0.00

21-34-0061-2 CBL 1-COND 18AWG 3.O-IN FM- QUICK DISCONNECT/S-T WHT 1 $0.00 $0.00

21-44-0044 SOCKET 44 PIN PLCC - .050 LOW PROFILE SMT 1 $0.16 $0.24 S1

24-09-0222 SWITCH SLIDE DPDT 4.5mm SHAFT HORIZ MT 2 $0.11 $0.16 SW2, SW9

24-12-0001 ENCODER 24-STEP W/25mm SHFT RE120-40-25F-24P TH 1 $0.33 $0.49 E2

24-12-0002 ENCODER 12-STEP W/25mm SHFT RE120-40-25F-12P TH 1 $0.30 $0.45 E1

30-00-0607 SCREW 6-32 x 7/16IN w/LK WASH PPZ STL 2 $0.02 $0.03 U5, U7

30-00-3125 SCREW 4-40 x .3125 PPB STL 2 $0.01 $0.02 HS1, HS2

30-03-0004 WASHER LOCK w/EXTERNAL TOOTH 2 x #4 x .017IN STL 2 $0.01 $0.01 HS1, HS2

30-06-0440 NUT HEX .242 4-40 STL/ZNC 2 $0.00 $0.00 HS1, HS2

30-12-2210 STANDOFF HEX .250 6-32 F-F .500 LG AL 2 $0.10 $0.15 U5, U7

Qty Per

Parent

Dealer

Cost

MSRP Reference Designator

Page 22

30-18-3030 CLIP GND PCB .30x.30x.07 8 $0.02 $0.03 GF1, GF2, GF4, GF5, GF6, GF7, GF8, GF9

30-51-0057 HEAT SINK, BLACK ANODIZED AL, WAKEFIELD #287-1AB 2 $0.30 $0.45 HS1, HS2

30-65-0009 TAPE INSULATING 1/8W x 2 INL (NON-SPECIFIC) 1 $0.00 $0.00 J2

30-75-0023 KEYPAD RUBBER w/SILKSCREEN 5.91x2.48 x0.7-IN BLK FLOORPOD 1 $0.00 $0.00

50-02-0030-1 Main PCBA

Part Number Description

35-00-0030 PCB MAIN FLOORPOD-XT REV.B 1 $0.00 $0.00

40-30-2000 LABEL S/N 38.10 x 6.35mm THERMAL XFR GLOSSY WHITE 1 $0.01 $0.01 (on PCB artwork "Place Barcode Label Here")

45-01-0002

45-02-0016 IC PROGRAMMED FLASH v2.14 c/s=0xC0D63B8 FLOORPOD-XT 1 $0.00 $0.00 U29

50-02-0240 1 $0.00 $0.00 LCD1

IC PROGRAMMED MCU v1.03 c/s= 96FB SHARC/FLOORPOD/BODSERIES

Qty Per

Parent

1 $3.95 $5.93 U17

Dealer

Cost

MSRP Reference Designator

Page 23

50-02-0032 Pedal Switch PCBA

Part Number Description

01-24-1001 RES 1.00K 1% 0805 1 $0.00 $0.01 R3

01-24-1002 RES 10.0K 1% 0805 4 $0.01 $0.01 R8, R9, R26, R45

01-24-2000

01-24-4991 RES 4.99K 1% 0805 1 $0.00 $0.01 R1

03-52-0104 CAP X7R 0.1uF 50V 20% 0805 4 $0.04 $0.05 C1, C2, C7, C8

06-20-0099 DIODE GEN PUR DUAL 70V 215mA 6nS SOT-23 SM BAV99 1 $0.02 $0.03 D7

09-10-4401 TRANS NPN SMALL-SIGNAL MBT4401SOT-23 SM 1 $0.02 $0.02 Q1

09-20-0095 PHOTOTRANSISTOR, SMD Blue Lens Ledtech LT5K95-AA-0125 1 $0.30 $0.45 Q29

11-10-2012 FERRITE BEAD 600R@100MHZ 300mA 0805 SM 2 $0.04 $0.06 L9, L10

18-27-0083 LED INFRA-RED, 880nm CLEAR LENS LT5K83-AA-880 1 $0.27 $0.41 D3

21-00-6617 JACK 1/4" TRS 6-PIN PCB MT HORIZ TH W/CHROME HRDWARE 1 $0.57 $0.86 J200

21-20-0206 HDR SIL PCB-MT 6-PIN x 2mm MALE SHRD VERT MT TH 1 $0.17 $0.25 H200

30-18-3030 CLIP GND PCB .30x.30x.07 1 $0.03 $0.05 GF200

35-00-0032 PCB PEDAL FLOORPOD-XT REV.A 1 0 $0.00

RES 200R 1% 0805 1 $0.00 $0.00 R2

Qty Per

Parent

Dealer

Cost

MSRP Reference Designator

Page 24

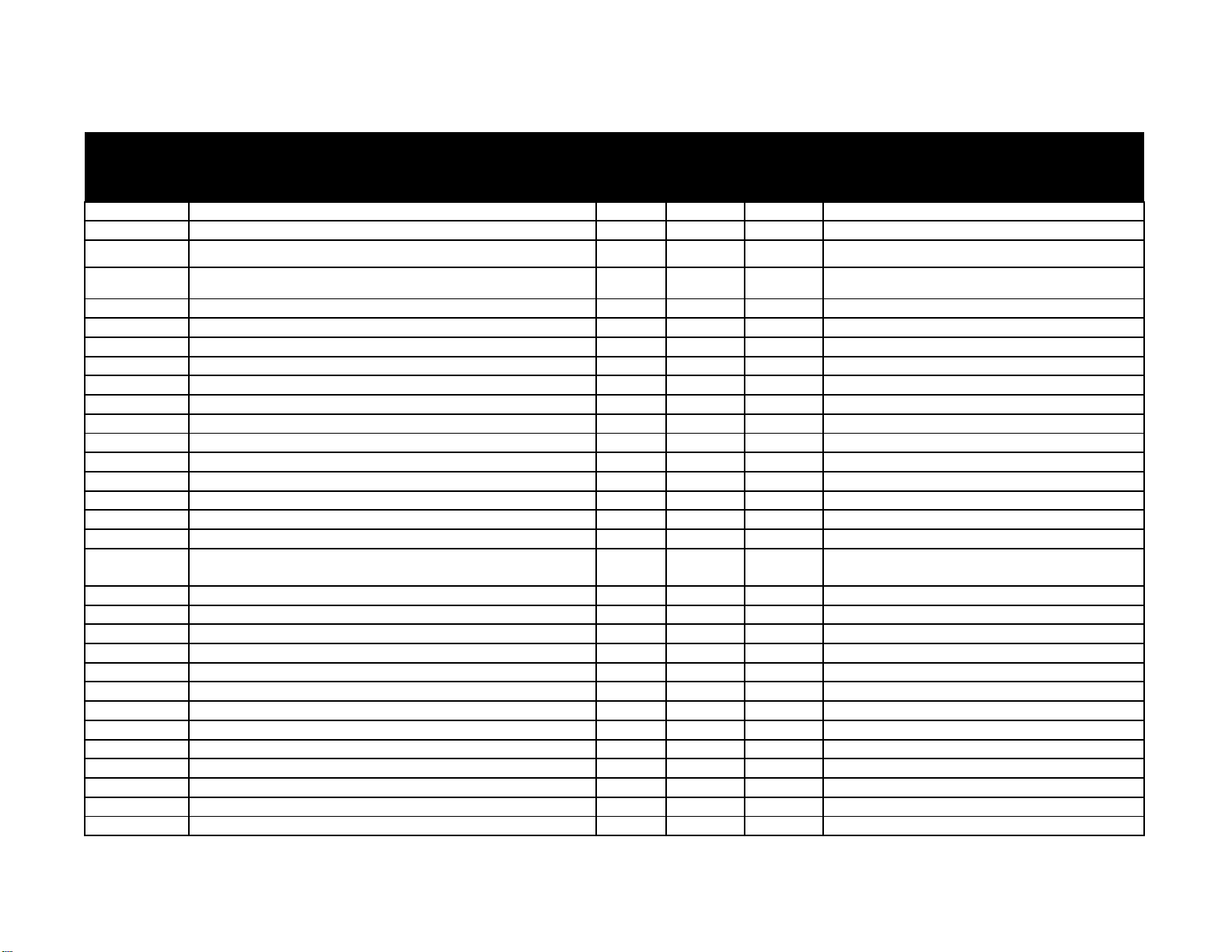

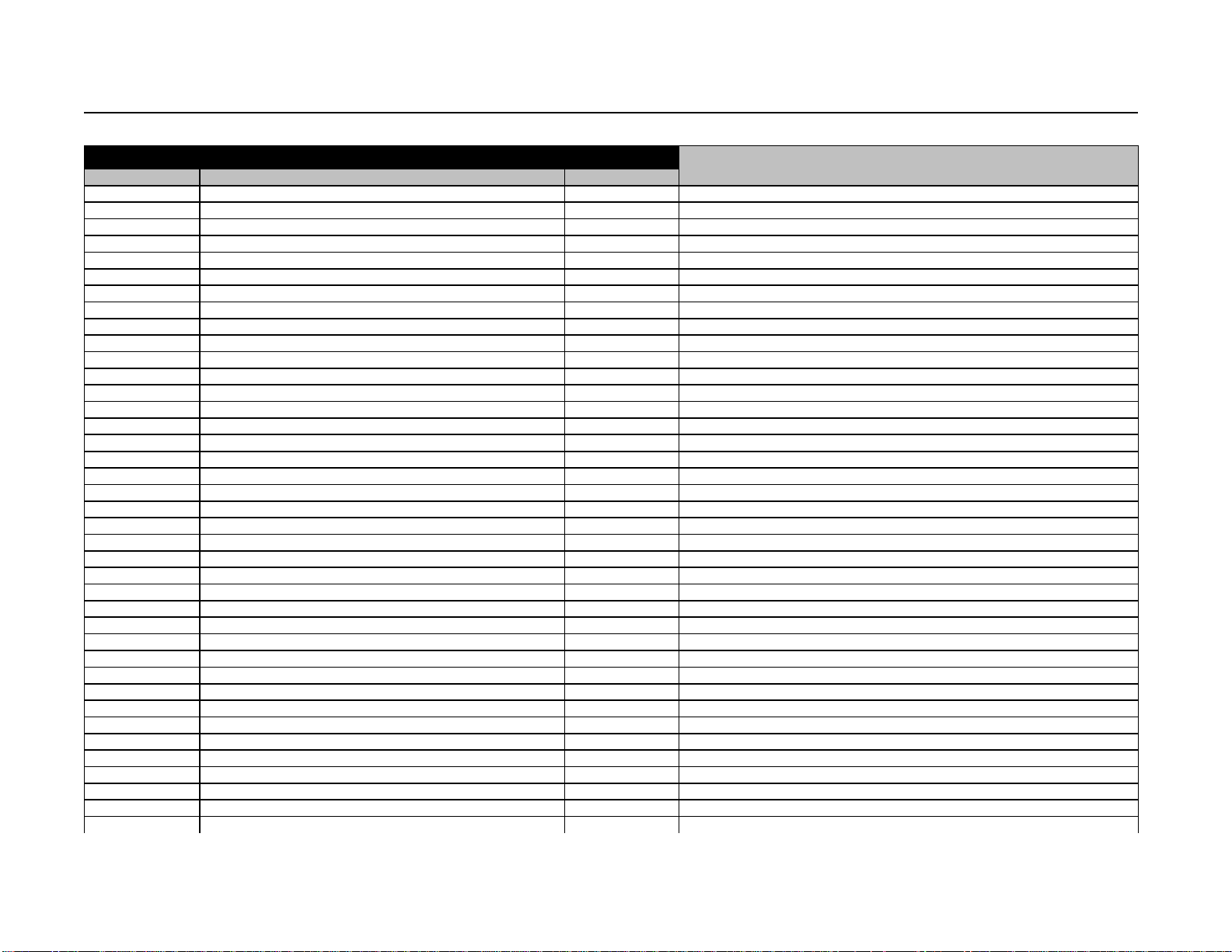

99-060-0705 Bass Pod XT Live Complete Unit w/Accessories

Part Number Description Qty. Per Parent

11-32-0000

21-34-2000

30-75-0013

40-00-0083

40-01-0016

50-03-0018

59-00-0118

XFMR PX2 120VAC/60Hz 9VAC/2A UL 2464 VW-1 6FT. BLK US 1

CBL USB HIGH SPEED 2 METER BLK 1

CAP RJ45 JACK PROTECTOR VINYL .692-ODx.250-H BLACK 1

MANUAL USER BASS PODxt LIVE P2-1 ENGLISH 1

CARD LICENSE-AGREEMNT END-USERALL-PRODUCTS 1

ASSY PACK RJ45 PROTECTION 1

ASSY UNIT COMPLETE BASS POD-LIVE P2-1 1

59-00-0118 Bass Pod XT Live Complete Unit…

Reference Designator

Not Available As A Replacement Part

Part Number Description Qty. Per Parents

21-30-0001

21-34-0060

24-24-0606

30-00-0012

30-00-0042

30-00-0043

30-00-0062

30-00-0375

30-00-4250

30-03-0003

30-03-0005

30-03-0007

30-03-0013

30-06-0009

30-06-0623

30-15-0004

30-15-0005

30-15-0011

30-15-0023

30-21-0004

30-27-0025

30-27-0056

30-27-0101

30-27-0105

30-45-0011

30-48-5012

30-51-0046

30-51-0078

CBL DIL 16-COND .100 x 5.75-IN/ 7.25-IN 1

CBL SIL 6-COND 24AWG 2mm x 9.75-IN F-F-JST Z-TYPE 1

SWITCH POWER ROCKER 6A/250VAC 10A/120VAC PNL-MNT BLK 1

SCREW 1/4-20 x3.5IN STEEL SHCS BLK OXIDE 1

SCREW SHEET METAL 4 x 0.375 INSELF-TAP PPB 35

SCREW 6-32 x 5/16 w/LK WASH PPZ STL 22

SCREW 10-32 x 3/8-IN w/CAPTIVEWASHER PPZ 2

SCREW 6-32 x .375 PPB 21

SCREW SHEET METAL SELF-TAP #4 x .250IN PPB 6

WASHER .473 x.260x .030 steel 4

WASHER .500 x.260x .030 NYLON 2

WASHER .500 x.260x .125 NYLON 2

WASHER .50 x.170x .034 NYLON 4

NUT 1/4-20 STL W/NYLON LOCK 1

NUT HEX 6-32 w/CAPTIVE STAR-WASHER 3

SPACER .13THKx.63OD NYLON 5

SPACER .25 OD x NO.8 ID AL 2

SPACER .39 Dia x 2.40 Lg Steel 1

SPACER 1/4-ODx1/8-L x #6 SCREW-ID NYLON 1

STRAIN RELIEF-CABLE 3/8 x 0.5(ID)-IN NYLON BLK 1

KNOB SM ENCDR .55Dx.57 H IMP ABS MICROTEX 2

LENS LED .19" DIA x.29" HT PLASTIC CLEAR SNAP-IN 2

BEZEL U/I 6.30 x 2.52 x .31-INABS BLACK FLOORPOD 1

LENS DISPLAY 3.73 x 1.13 x 0.52-IN PLASTIC CLEAR FLOORPOD 1

KNOB POT .77 DIA x .76 HT PLASTIC CHROME-PLATED 6

BUMPER RUBBER .465" O.D. BLK 14

BRACKET PEDAL .85x2.54" 16 GA STL EG FLOORPOD 1

TACTILE DOME 20mm SST NP 3

Reference Designator

MAIN PCBA TO SWITHC PCBA

MAIN PCBA TO PEDAL

FOR PEDAL SHAFT

2-RJ45,22-FOOTSWITCH ASSY 2-PER,11-FOOTS,2 SWITCH PCBA's 11 MOUNTING SCREWS, 5

FOR UPPER ROW & 6 FOR BOTTOM ROW

FOR PCBA MOUNTING

FOR KNOB GUARD MOUNTING

15-FOR CHASSIS ASSY/BUMPERS,6-FOR PEDAL

FOR BEZEL MOUNTING

FOR PEDAL SHAFT ASSY

FOR PEDAL SHAFT ASSY

FOR PEDAL SHAFT ASSY

FOR PEDAL

FOR PEDAL PCBA/TOP FTSWITCH PCBA

FOR 1/4" JACKS

FOR PEDAL PCBA

FOR PEDAL

FOR TOP TIER FOOTSWITCH PCBA

FOR POWER CABLE

FOR DISPLAY

FOR PEDAL SWITCH

Page 25

59-00-0118 Bass Pod XT Live Complete Unit (Continued)

r

r

Part Number Description Qty. Per Parents

30-51-0178

30-51-0181

30-51-0187

30-51-0197

30-51-0221

30-51-0222

30-63-0017

30-75-0002

30-75-0007

30-75-0011

50-02-0030-2

50-02-0032

50-02-0033

50-04-0099-10

50-04-0099-11

50-04-0099-12

50-04-0099-13

50-04-0099-14

50-04-0099-15

50-04-0099-16

50-04-0099-17

50-04-0099-19

50-04-0099-20

50-04-0099-21

FOOTSWITCH SUPPORT 2.0 x 2.0 x.55 CRS ZINC FLOORPOD-XT 2

PEDAL 8.0 x 1.7 x 3.0 16AWG CRS NICKEL FLOORPODXT 1

GUARD KNOB 6 x 1.06 x 0.38-IN ROUND STL-BAR CHROME 1

BRACKET SUPPORT PEDAL 2.30 x 1.30 x 1.314-IN EG-STL 1

CHASSIS BASE 10.3 x 20.1 x 2.0.040 THK STL BASSPOD-LIVE P2-1 1

CHASSIS TOP 10.9 x 20.2 x 2.1 .060 THK STL BASSPOD-LIVE P2-1 1

FOAM W/ADH .55" x 0.25" x 0.06" VOLARAPOLOLEFIN 4

FOOT RUBBER 2.87x7.70x.237 BLK 1

PEDAL STOP FOAM RUBBER 2.63x.25x.06 2

STOP PEDAL RBR .81SQ x .52 BLK 2

PCBA MAIN BASS PODxt LIVE PROGRAMMED P2-1 1

PCBA PEDAL FLOORPOD-XT 1

PCBA SWITCH FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "A" w/LED FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "B" w/LED FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "C" w/LED FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "D" w/LED FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "TAP" w/LED FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "AMP" w/LED FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "STOMP" w/LED FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "MOD" w/LED FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "DLY/VRB" w/LED FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "B-DOWN" no/LED FLOORPOD-XT 1

ASSY E/M FOOTSWITCH "B-UP" no/LED FLOORPOD-XT 1

Reference Designator

FOR PEDAL

FOR 2-PER EACH SUPPORT

FOR PEDAL

FOR PEDAL

Part Numbe

01-00-0000

01-16-0272

01-23-0270

01-23-0270

01-24-1000

01-24-1001

01-24-1002

01-24-1003

01-24-1004

01-24-10R0

01-24-1100

01-24-1210

50-02-0030-2 PCBA Main ………..

Description Qty Pe

RES 0R 5% 0805 1

RES CARBON FILM 2.7K 1/2W 5% TH 1

RES METAL OXIDE 27R 3W 5% TH FORMED LEADS @ 20mm SPACING 2

RES METAL OXIDE 27R 3W 5% TH FORMED LEADS @ 20mm SPACING 2

RES 100R 1% 0805 11

RES 1.00K 1% 0805 4

RES 10.0K 1% 0805 7

RES 100K 1% 0805 4

RES 1.00M 1% 0805 1

RES 10.0R 1% 0805 3

RES 110R 1% 0805 1

RES 121R 1% 0805 1

Reference Designator(s)

R144

R153

R71, R88

R71, R88

R9, R19, R90, R100, R102, R103, R105, R106, R125, R134, R136

R23, R28, R94, R112

R26, R61, R62, R96, R98, R99, R151

R40, R41, R42, R45

R22

R21, R120, R121

R117

R152

Page 26

Part Numbe

r

r

01-24-1241

01-24-1501

01-24-15R0

01-24-1620

01-24-1621

01-24-2001

01-24-2002

01-24-2210

01-24-2211

01-24-22R1

01-24-2551

01-24-3011

01-24-3321

01-24-3323

01-24-4321

01-24-4750

01-24-4751

01-24-4752

01-24-47R5

01-24-4991

01-24-5110

01-24-51R1

01-24-5360

01-24-5R11

01-24-6041

01-24-6810

01-24-69R8

01-24-7501

01-24-8871

01-24-9090

01-48-0103

01-48-9103

01-60-0472

03-10-6108

03-12-0107

03-12-0108

03-12-0688

03-13-0228

03-13-0477

50-02-0030-2 PCBA Main (Continued)

Description Qty Pe

RES 1.24K 1% 0805 2

RES 1.50K 1% 0805 2

RES 15R 1% 0805 2

RES 162R 1% 0805 1

RES 1.62K 1% 0805 1

RES 2.00K 1% 0805 10

RES 20.0K 1% 0805 18

RES 221R 1% 0805 3

RES 2.21K 1% 0805 1

RES 22.1R 1% 0805 10

RES 2.55K 1% 0805 2

RES 3.01K 1% 0805 1

RES 3.32K 1% 0805 1

RES 332K 1% 0805 1

RES 4.32K 1% 0805 2

RES 475R 1% 0805 1

RES 4.75K 1% 0805 7

RES 47.5K 1% 0805 6

RES 47.5R 1% 0805 8

RES 4.99K 1% 0805 1

RES 511R 1% 0805 2

RES 51.1R 1% 0805 8

RES 536R 1% 0805 1

RES 5.11R 1% 0805 1

RES 6.04K 1% 0805 1

RES 681R 1% 0805 2

RES 69.8R 1% 0805 3

RES 7.50K1% 0805 2

RES 8.87K 1% 0805 5

RES 909R 1% 0805 2

POT MONO 10KB LINEAR TAPER 25 mm D-SHAFT 6

POT DUAL 10KA AUDIO TAPER HORIZ MT 25mm RND PLASTIC 1

RES NETWORK 4.7K BUSSED 1/8W 5% SM 1

CAP ELEC 1000uF 6.3V 20% RADIAL 8/11.5/5 1

CAP ELEC 100uF 16V 20% RADIAL 6.3/11/5 4

CAP ELEC 1000uF 16V 20% RADIAL10/16/5 2

CAP ELEC 6800uF 16V 20% RADIAL18/35.5/7.5 1

CAP ELEC 2200uF 16V 20% 105C LowZ 0.030R RADIAL 12.5/25/5 3

CAP ELEC 470uF 16V 20% 105C LowZ 0.085R RADIAL 8/15/5 6

Reference Designator(s)

R36, R38

R39, R142

R76, R80

R89

R113

R47, R48, R49, R50, R54, R55, R57, R58, R124, R130

R2, R3, R4, R5, R6, R7, R8, R10, R11, R67, R68, R69, R70, R73, R74, R81, R83, R150

R92, R101, R107

R24

R1, R29, R32, R115, R118, R122, R123, R129, R140, R141

R13, R16. ADDED PER ECO#0428601.

R35

R25

R31

R27, R95

R93

R109, R111, R139, R143, R145, R146, R147

R20, R63, R64, R114, R119, R149

R75, R77, R78, R79, R82, R84, R86, R87

R30

R43, R110

R126, R127, R128, R131, R132, R133, R135, R137

R18

R46

R34

R15, R17

R97, R104, R108

R37, R91

R51, R52, R56, R59, R138

R12, R14. ADDED PER ECO#0428601.

R33, R44, R53, R66, R72, R85

R60

R116

C126

C34, C38, C66, C145

C45, C69, C39, removed ECO# 0416101

C81

C70, C107, C39, added ECO# 0416101

C49, C59, C60, C164, 165, C166

Page 27

Part Numbe

r

r

,,,,,,,,,,,,,,, ,,

03-16-2108

03-18-0105

03-18-0106

03-24-0273

03-36-0224

03-50-0101

03-50-0102

03-50-0220

03-50-0272

03-50-0391

03-50-0470

03-52-0100

03-52-0101

03-52-0102

03-52-0103

03-52-0104

03-52-0334

03-52-0472

03-52-0473

04-04-0001

06-20-0099

06-23-0054

06-32-0340

06-32-4006

06-34-0016

09-03-0032

09-10-4401

09-10-4403

09-10-6102

11-00-3000

11-10-0501

11-10-2012

12-00-0317

12-02-0115

12-02-1088

12-02-7805

12-54-0082

50-02-0030-2 PCBA Main (Continued)

Description Qty Pe

CAP ELEC 1000uF 35V 20% 105C LowZ RADIAL 12.5/25/5 2

CAP ELEC 1uF 50V 20% RADIAL 5/11/5 5

CAP ELEC 10uF 50V 20% RADIAL 5/11/5 8

CAP MET-POLY 27nF 50V 5% TH 7.3/3.2/5/5 1

CAP ESTR 0.22uF 50V 5% TH 11/6/11.5/7.5 1

CAP NPO 100pF 50V 5% 0805 5

CAP NPO 1nF 50V 5% 0805 16

CAP NPO 22pF 50V 5% 0805 2

CAP NPO 2.7nF 50V 5% 0805 2

CAP NPO 390pF 50v 5% 0805 4

CAP NPO 47pF 50V 5% 0805 3

CAP X7R 10pF 50V 10% 0805 2

CAP X7R 100pF 50V 10% 0805 2

CAP X7R 1nF 50V 10% 0805 1

CAP X7R 10nF 50V 10% 0805 3

CAP X7R 0.1uF 50V 10% 0805 74

CAP X7R 0.33uF 25V 10% 0805 1

CAP X7R 4.7nF 50V 10% 0805 1

CAP X7R 47nF 50V 10% 0805 17

FERRITE BEAD 3-TURN 600R@ 100MHz MATERIAL-61 RADIAL TH 2

DIODE GEN PUR DUAL 70V 215mA 6nS SOT-23 SM BAV99 8

DIODE SCHOTTKY DUAL 30V 200mA 5nS SOT-23 SM BAT54S 1

DIODE SCHOTTKY 3A 40V SMB SM B340B 4

DIODE RECTIFIER 800V 1A SMA SM MRA4006T3 10

DIODE SWITCHING 75V 200mA 6nS SOT-23 SM BAS16LT1 17

TRANS PNP MED POWER TIP32C TH 1

TRANS NPN SMALL-SIGNAL MBT4401SOT-23 SM 4

TRANS PNP SMALL-SIGNAL MBT4403SOT-23 SM 1

TRANS N-CHANNEL MOSFET ZXM61N02 SOT-23 SM 3

CRYSTAL OSCILLATOR 30MHz 3.3V DIP4 METAL-CAN TH 1

FERRITE BEAD 500R @100mHZ 2.5A 1206 SM 2

FERRITE BEAD 600R@100MHZ 300mA 0805 SM 22

IC VREG ADJ 1.2-37V 1.5 AMP TO-220 LM317 TH 1

IC REG -15V 1.5AMP TO-220F TH NJM7915FA 1

IC REG ADJ TO-220 TH LM1086 1

IC REG +5v 1.5 Amp TH 2

IC OP AMP DUAL TL082CD SO-8 SM 1

Reference Designator(s)

C42, C47

C43, C44, C46, C48, C98

C63, C65, C71, C84, C85, C95, C99, C119

C37

C157

C16, C18, C54, C56, C142, C8, C9 removed ECO# 0416902

0416902

C144, C148

C74, C75

C72, C73, C76, C77

C32, C78, C79

C167, C168

C82, C83

C163

C116, C117, C160

C1, C3, C4, C5, C13, C15, C17, C19, C20, C21, C22, C23, C30, C31, C62, C64, C67, C68, C90, C91,

C92, C93, C94, C96, C97, C100, C101, C102, C103, C105, C106, C110, C111, C112, C113, C114,

C115, C118, C120, C121, C122, C123, C124, C125, C127, C128, C129, C130, C131, C132, C133,

C134, C135, C136, C 137, C138, C139, C141, C143, C146, C147, C149, C150, C151, C152, C153,

C108

C109

C27, C29, C33, C35, C36, C40, C41, C50, C52, C55, C57, C58, C61, C87, C80, C89, C104

L25, L26

D15, D16, D26, D29, D30, D33, D36, D38

D17

D7, D8, D19, D20

D9, D10, D11, D12, D13, D14, D42, D43, D44, D45

D6, D18, D21, D22, D23, D24, D25, D27, D28, D31, D32, D34, D35, D37, D39, D40, D41

Q9

Q2, Q3, Q7, Q8

Q1

Q4, Q5, Q6

Y1

L17, L18

L1, L2, L3, L4, L5, L6, L7, L8, L9, L10, L11, L12, L13, L14, L15, L16, L19, L20, L21, L22, L23, L24

U12

U3

U7

U5, U10

U8

Page 28

Part Numbe

r

r

12-54-0084

12-54-2134

12-64-4528

12-64-7890

15-40-6138

15-64-0273

15-65-0004

15-68-1020

15-70-1610

15-72-1009

15-78-4128

15-79-0088

15-86-1065

15-86-8420

15-92-5810

15-96-0128

18-12-0001

18-21-0002

21-00-0015

21-00-6617

21-04-5075

21-12-0035

21-16-0001

21-18-0002

21-20-0206

21-21-0001

21-21-1016

21-34-0061-1

21-34-0061-2

21-44-0044

24-09-0222

24-12-0001

24-12-0002

30-00-0607

30-00-3125

30-03-0004

30-06-0440

30-12-2210

30-18-3030

50-02-0030-2 PCBA Main (Continued)

Description Qty Pe

IC OP AMP QUAD TL084CD SM 3

IC OP-AMP DUAL OPA2134UA SM SO-8 1

IC CONVERTER 24B 48/96KHz AUDIO CODEC SM AK4528 1

IC ADC 12 BIT / 8 CHANNEL SM TSSOP-16 ADC78H90 1

IC 6N138 OPTO-ISOLATOR DIP-8 TH 1

IC 74HCT273 FLIP-FLOP D-TYPE 8-BIT SO-20 SM 2

IC 74LVC04 LOW VOLTAGE CMOS HEX INVERTER SO-14 SM 1

IC CONTROLLER USB TAS1020BPFB SM 1

IC DRAM 1M X 16 SDRAM HY57V161610DTC-7 SM 2

IC SRAM 128K X 8 CY7C1009B 15nS SOJ-32 (V32) SM 1

IC EEPROM 128KBIT I2C SERIAL 24LC128-I/SN SOIC8 SM 1

IC MEMORY SECURE AT88SC153-00 -2.7 8S1 (SO-8) SM 1

IC DSP SHARC ADSP-21065LKS-240 MQFP208 SM 1

IC DIGITAL AUDIO SAMPLE RATE CONVERTER SM Mfg# CS8420-CS 1

IC RESET 5V 5% ACTIVE-HI SOT-23 SM LM810 1

IC PLD 128 CELL/96 I/O ISPLSI5128VE-100LT128 TQFP128 1

LED 3-DIGIT 7-SEG YEL w/DP Ledtech LM3633-11-11BWRN TH 1

LED ORANGE 3mmX2mm SM Kingbrite APK3020SEC 4

DNU - use 21-00-0014 - JACK BARREL PCB MT 2.5mm 1

JACK 1/4" TRS 6-PIN PCB MT HORIZ TH W/CHROME HRDWARE 4

JACK DIN 5-PIN FEMALE MIDI PCB-MNT RT-ANG LN 05075 2

JACK 3.5mm STEREO 5 PIN CRIMPED LEADS NON-THREADED 1

JACK RJ-45 9-PIN IN XLR SHELL PCB-MNT HORIZ TH 1

TERMINAL SCREW PCB MOUNT RT ANGLE SNAP-IN TH 1

HDR SIL PCB-MT 6-PIN x 2mm MALE SHRD VERT MT TH 1

JACK USB-B SHIELDED PCB-MNT BLACK WIESON 3700-4ABN4S1W 1

HDR DIL PCB-MT 16-PIN 2x8x.100MALE SHRD LOCKING VERT MT TH 1

CBL 1-COND 18AWG 3.O-IN FM- QUICK DISCONNECT/S-T BLK 1

CBL 1-COND 18AWG 3.O-IN FM- QUICK DISCONNECT/S-T WHT 1

SOCKET 44 PIN PLCC - .050 LOW PROFILE SMT 1

SWITCH SLIDE DPDT 4.5mm SHAFT HORIZ MT 2

ENCODER 24-STEP W/25mm SHFT RE120-40-25F-24P TH 1

ENCODER 12-STEP W/25mm SHFT RE120-40-25F-12P TH 1

SCREW 6-32 x 7/16IN w/LK WASH PPZ STL 2

SCREW 4-40 x .3125 PPB STL 2

WASHER LOCK w/EXTERNAL TOOTH 2 x #4 x .017IN STL 2

NUT HEX .242 4-40 STL/ZNC 2

STANDOFF HEX .250 6-32 F-F .500 LG AL 2

CLIP GND PCB .30x.30x.07 8

Reference Designator(s)

U6, U9, U11

U1

U4

U31

U15

U16, U18

U30

U25

U27, U28

U14

U23

U24

U26

U20

U22

U21

D2

D1, D3, D4, D5

J1

J6, J7, J8, J10

J4, J5

J9

J3

BR1

H3

J2

H4

S1

SW2, SW9

E2

E1

U5, U7

HS1, HS2

HS1, HS2

HS1, HS2

U5, U7

GF1, GF2, GF4, GF5, GF6, GF7, GF8, GF9

Page 29

Part Numbe

r

r

r

r

r

30-51-0057

30-65-0009

30-75-0023

35-00-0030

40-30-2000

45-00-0006

45-01-0002

45-02-0017

50-02-0240

01-24-1001

01-24-1002

01-24-2000

01-24-4991

03-52-0104

06-20-0099

09-10-4401

09-20-0095

11-10-2012

18-27-0083

21-00-6617

21-20-0206

30-18-3030

35-00-0032

50-02-0030-2 PCBA Main (Continued)

Description Qty Pe

HEAT SINK, BLACK ANODIZED AL, WAKEFIELD #287-1AB 2

TAPE INSULATING 1/8W x 2 INL (NON-SPECIFIC) 1

KEYPAD RUBBER w/SILKSCREEN 5.91x2.48 x0.7-IN BLK FLOORPOD 1

PCB MAIN FLOORPOD-XT REV.B 1

LABEL S/N 38.10 x 6.35mm THERMAL XFR GLOSSY WHITE 1

EEPROM Programmed USB v1.12 Bass Podxt live P2-1 1

IC PROGRAMMED MCU v1.03 c/s= 96FB SHARC-ALL/FLOORPOD/P2-1 1

IC PROGRAMMED FLASH v1.04 c/s=0x047 ACCB9 Bass Podxt Live P2-1 1

PCBA DISPLAY LCD GRAPHIC W/20PMALE HDR 6-O'CLOCK XMIS POS 1

50-02-0032 PCBA Pedal Bass Pod XT Live

Description Qty Pe

RES 1.00K 1% 0805 1

RES 10.0K 1% 0805 4

RES 200R 1% 0805 1

RES 4.99K 1% 0805 1

CAP X7R 0.1uF 50V 10% 0805 4

DIODE GEN PUR DUAL 70V 215mA 6nS SOT-23 SM BAV99 1

TRANS NPN SMALL-SIGNAL MBT4401SOT-23 SM 1

PHOTOTRANSISTOR BLUE LENS LEDTECH LT5K95-AA-0125 SMD 1

FERRITE BEAD 600R@100MHZ 300mA 0805 SM 2

LED INFRA-RED 880nm CLEAR LENS LT5K83-AA-880 1

JACK 1/4" TRS 6-PIN PCB MT HORIZ TH W/CHROME HRDWARE 1

HDR SIL PCB-MT 6-PIN x 2mm MALE SHRD VERT MT TH 1

CLIP GND PCB .30x.30x.07 1

PCB PEDAL FLOORPOD-XT REV.A 1

Reference Designator(s)

HS1, HS2

J2

(on PCB artwork "Place Barcode Label Here")

U23

U17

U29

LCD1

Reference Designator(s)

R3

R8, R9, R26, R45

R2

R1

C1, C2, C7, C8

D7

Q1

Q29

L9, L10

D3

J200

H200

GF200

Not Available As A Replacement Part

Part Numbe

18-20-0002

18-24-0003

21-21-1016

24-31-1105

35-00-0033

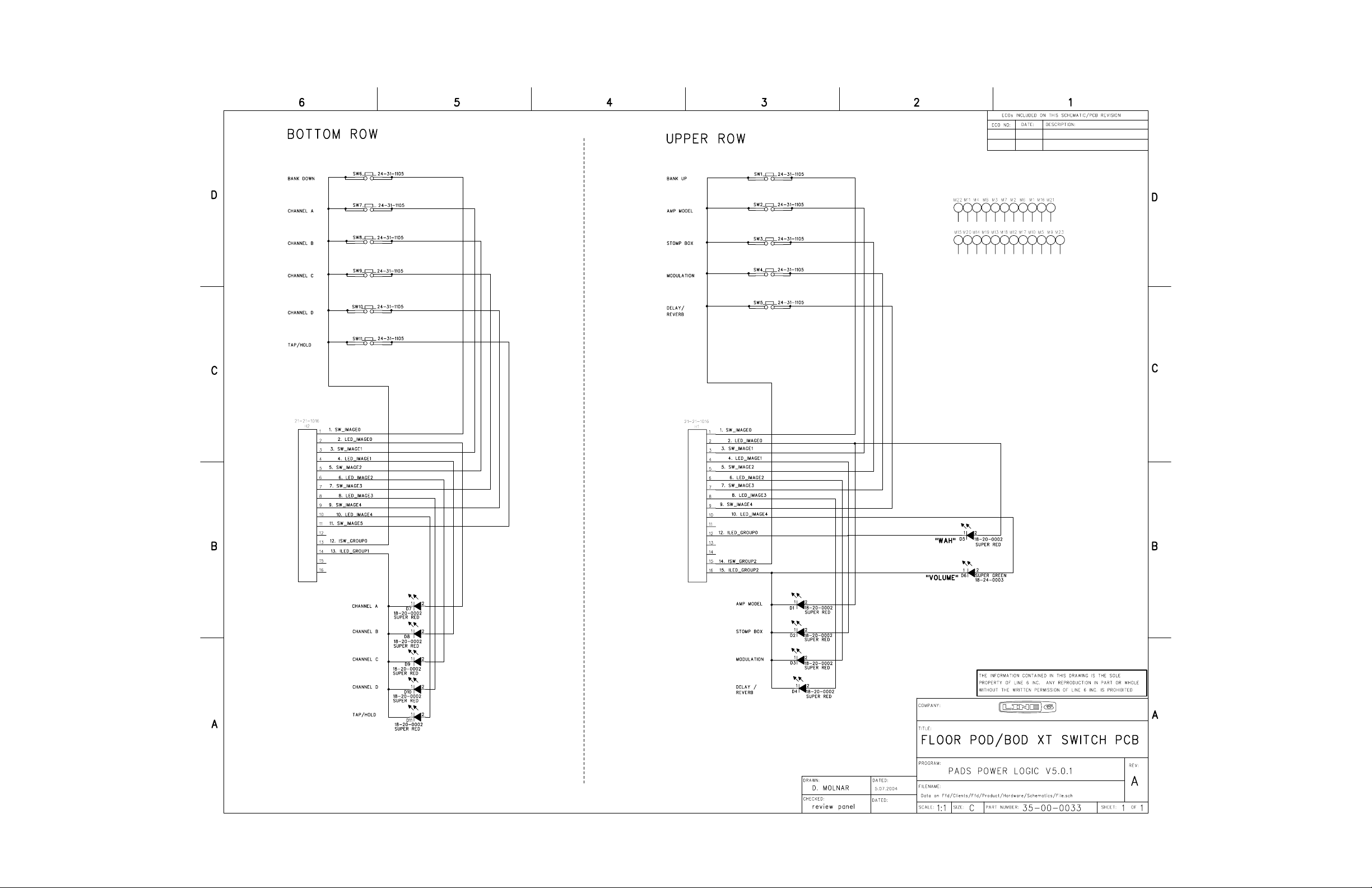

50-02-0033 PCBA Main Switch Bass Pod XT Live

Description Qty Pe

LED RED SUPER SML-LX0805SRC-TR 0805 SM 10

LED GREEN SUPER SML-LX0805SGC-TR 0805 SM 1

HDR DIL PCB-MT 16-PIN 2x8x.100MALE SHRD LOCKING VERT MT TH 2

SWITCH TACT 6mm SQ 4-PIN TH 11

PCB SWITCH FLOORPOD-XT REV.A 1

Reference Designator(s)

D1, D2, D3, D4, D5, D7, D8, D9, D10, D11

D6

H1, H2

SW1, SW2, SW3, SW4, SW5, SW6, SW7, SW8, SW9, SW10, SW11

Not Available As A Replacement Part

Page 30

Pod XT Live

Bass Pod XT Live

Technical

Training

Manual

Page 31

SECTION 1

THEORY OF OPERATION

Page 32

Engineering

CONFIDENTIAL

POD XT LIVE: Theory of Operation D.H.M. (with M.D., G.K. and A.M.) AUGUST 2004

Background:

- The POD XT LIVE and BASS POD XT LIVE (not yet released) share the same electronic

hardware.

- The POD XT LIVE Line 6 Engineering project codename is FloorPOD XT.

- The POD XT LIVE electronics is distributed across 3 PCBs: the “FLOOR POD/BOD XT

MAIN (rev B)”, the “FLOOR POD/BOD XT PEDAL (rev A)”, and the “FLOOR POD/BOD

XT SWITCH (rev A)” PCBs (breaks apart into two pieces).

- In this document, the * sign next to a control signal name indicates an active low signal.

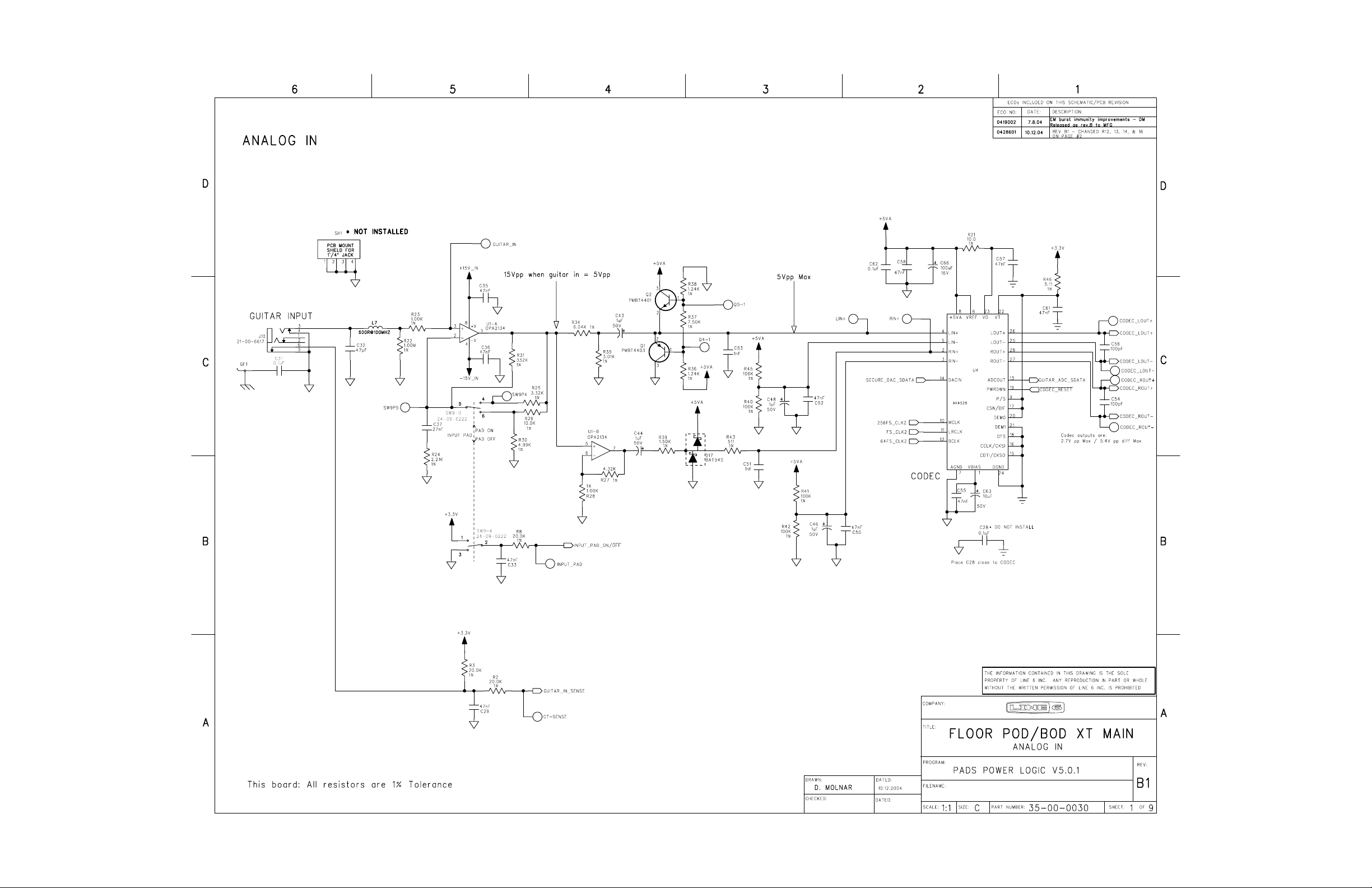

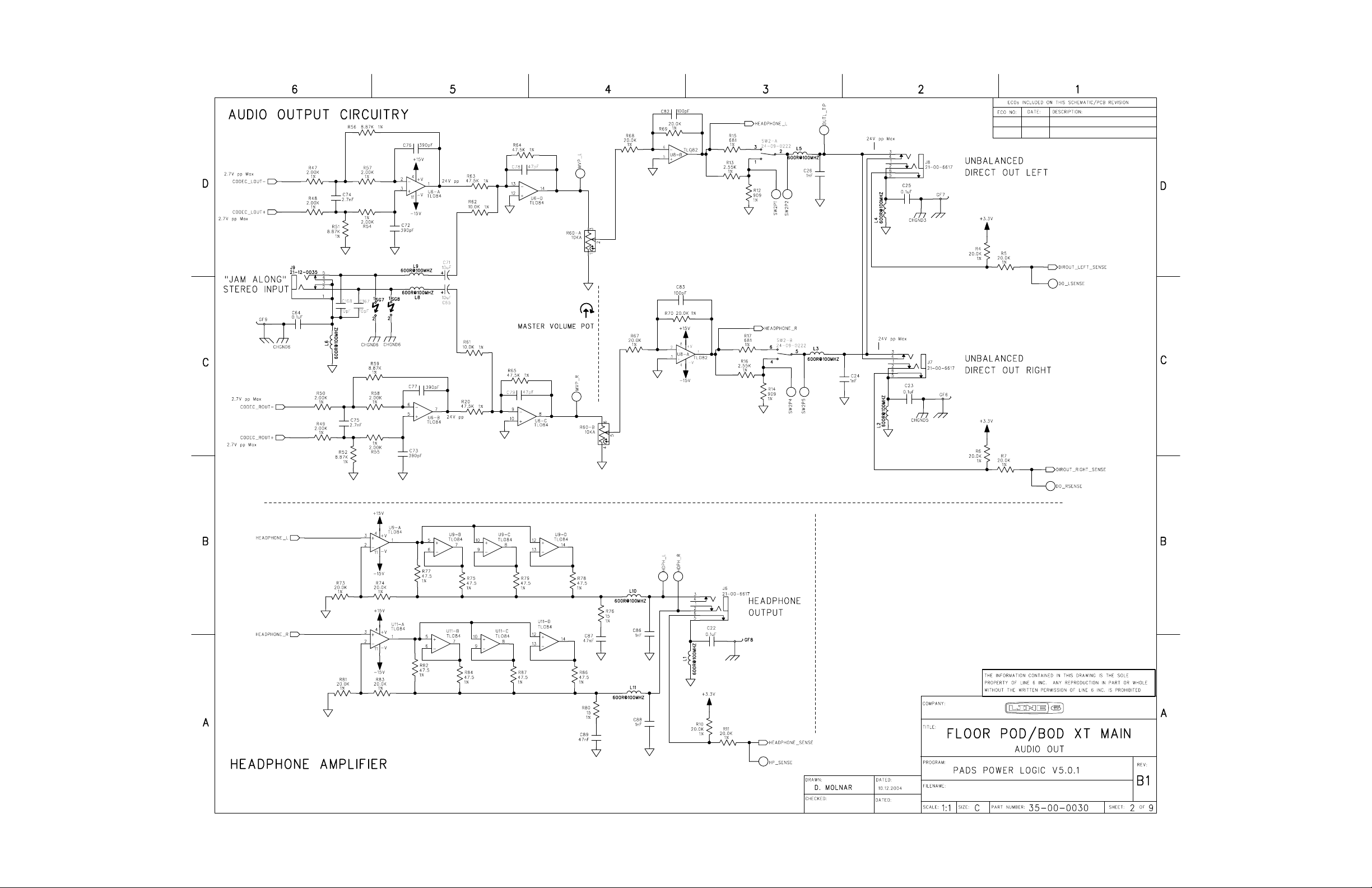

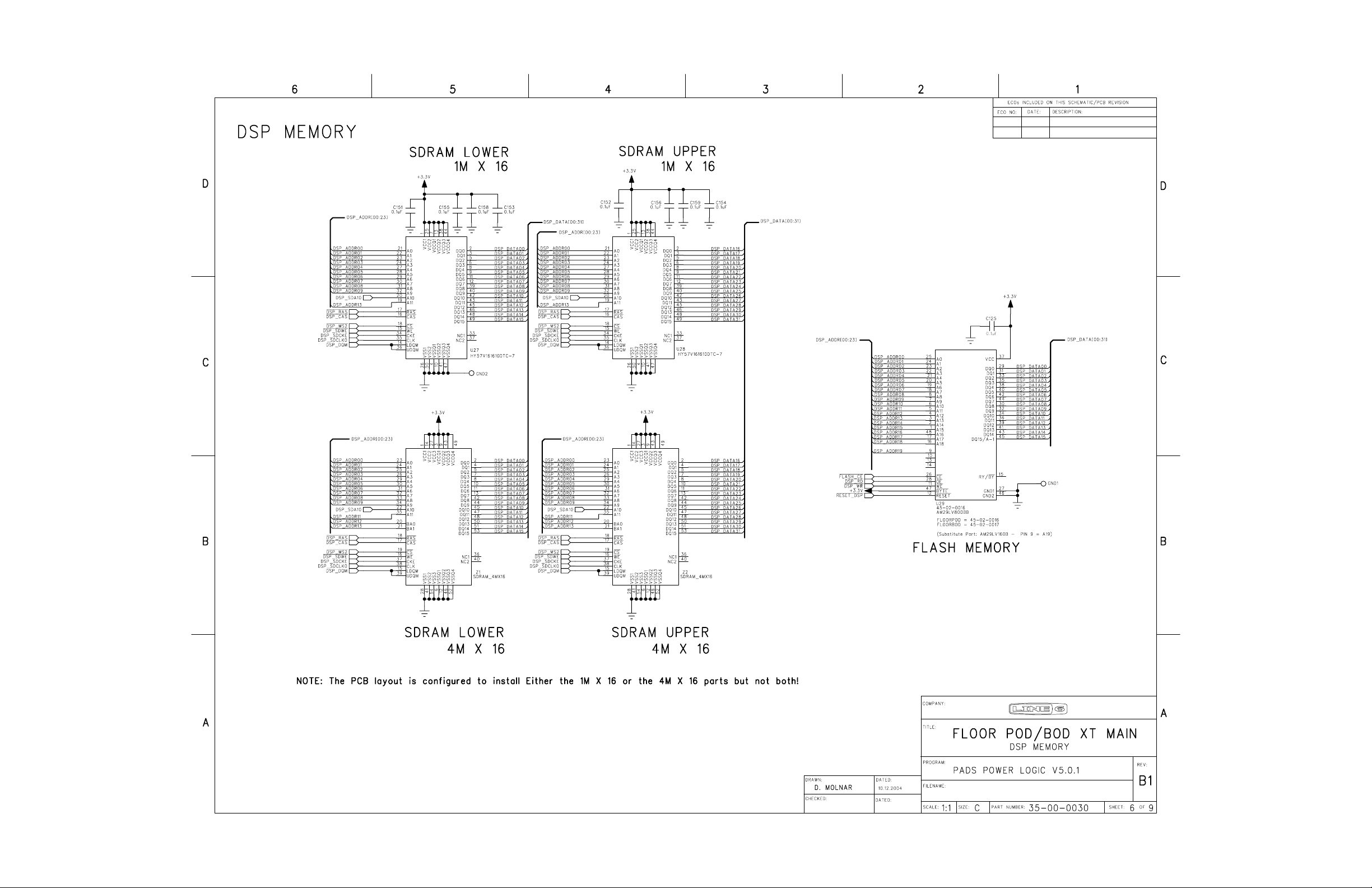

Audio system (see pages 1-2 of the MAIN schematic):

All of the analog audio system is contained in the MAIN PCB. Refer to the Audio System

diagram below for a block diagram of the system.

Guitar Input:

The guitar input (J10) is buffered and amplified by U1A by either a gain of 3 when the

front panel input level is set to NORMAL, or by a gain of 1 when the switch is set to PAD

(= Low Gain). At the same time, U1-A adds high frequency pre-emphasis gain starting at

about 200Hz. U1-A output is spliced into two branches:

- On the upper branch, R34 and R35 attenuate the signal for a +/-2.5 VPP range (@ 5Vpp,

100Hz at guitar input). C43 allows this signal to be DC biased at +2.5V by the ADC

input. Q1 and Q1 clip the signal to a maximum range of 0/5V. The signal drives the left

channel of the ADC section of CODEC U4.

- In the lower branch, U1B adds a gain of 5.32 to the signal. C44 allows this signal to be

DC biased at +2.5V by the ADC input. The double diode D17 limits the maximum signal

swing to a -0.6V /+5.6V range before entering the right channel ADC section of CODEC

U4. Note that the signal on this branch will clip for guitar input level above 0.310 Vpp.

The net result is two signals with a gain difference of 16, each feeding one of the two ADC

inputs. Once these signals are converted and moved into the DSP, the DSP code will monitor

the amplitude of the signals and use one of the two versions most appropriate for the current

input level. The DSP will also apply a de-emphasis filter complementary to the filter function

implemented by U1A. This scheme allows for significantly improving the signal noise and

low-level distortion performance of the ADC.

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 1 of 16

Page 33

Audio Outputs:

The DAC portion of CODEC U4 sends a stereo pair of differential signals to two low pass

reconstruction filters composed of U6A for the left channel and U6B for the right channel.

Each filter has a cutoff frequency Fc of 20KHz. The two filters then each feed an analog

summation node/buffer (U6-D&C) where the output audio is mixed with the “Jam Along

Input” audio from the AUX IN jack (J9). These two buffers feed the master volume

potentiometer. (Note: This way, the “Jam Along Input” AUX IN level is controlled by the

master volume pot just as the main system audio). The master volume pot feeds the output

buffer stage (U8B for LEFT and U8A for RIGHT). The output of each output buffer stage is

passed through a resistor network and switch that controls the output level for “LINE” level

or “AMP” level. For the “LINE” level the output buffer merely feeds a 681 ohm resistor

(R15 for LEFT and R17 for RIGHT). For the “AMP” level, the output buffer feeds a resistor

divider (R12&R13 for LEFT and R14&R16 for right) which cuts the level by a gain of .091.

The output buffers U8A and U8B also feed the headphone amplifier (U9 for left and U11 for

right).

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 2 of 16

Page 34

J6

J7

J6

Hz

Gain from each input

4.435

Reconstruction Low Pass Filter

0 20K

Master

Volume

Pot

Left -

Left -

CLipping

Switch

Line/Amp

gain = 1.0

U6-D

U6-A

Q1 & Q2

Unbalanced Out L

gain = .091

U8-B

DAC

Left +

Left +

+2.5V

U4

CODEC

ADC

Gain Difference: 16

Line

Amp

Right -

Right -

D17

CLipping

U6-C

U6-B

Unbalanced Out R

gain = 1.0

Right +

Right +

+2.5V

gain = .091

U8-A

To DSP

Headphone Output

U9

U11

gain = 5.32

U1-B

Switch

Input Pad

Pad Gain = 1

Normal Gain = 3

"Jam Along" Input

(AUX IN)

J9

POD XT LIVE AUDIO SUBSYSTEM

Gain

2.5

Pre-Emphasis Filter

gain = 0.332

Hz

U1-A

0 200 20K

1

Guitar Input

J10

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 3 of 16

Page 35

POD XT LIVE Audio Characteristics:

1) Audio Inputs Max Level:

- Guitar Input max Level in normal mode:

From DC to 200 Hz = 5.0 Vpp, at 1KHz = 4.0 Vpp, at 2KHz = 3.0 Vpp, at 10KHz =

2.0 Vpp, at 20 KHz = 2.0 Vpp

- Guitar Input max Level in pad mode:

From DC to 200 Hz =15.0 Vpp, at 1KHz = 12.0 Vpp, at 2KHz = 9.0 Vpp, at 10KHz =

6.0 Vpp, at 20 KHz = 6.0 Vpp

- Jam Along Input (Aux IN): 5.3Vpp

2) Inputs / Outputs nominal impedance:

- Guitar in nominal input impedance: 1Meg Ohm (for both input PAD ON and PAD

OFF)

- Output ¼” jack Unbalanced nominal output impedance: Stereo = 681 Ohm

- Jam Along Input (Aux IN): 10K Ohm

3) Output signal levels:

Test condition A: Test mode, Guitar input = 1.0Vpp= -9.03dBV, 200Hz

- ¼”Jack Unbalanced Out Left and Right Level for test condition A: 3.8 Vpp =2.56dBV

- Headphone out Level (either side) for test condition A (no load) = 7.7 Vpp = +8.7 dBV

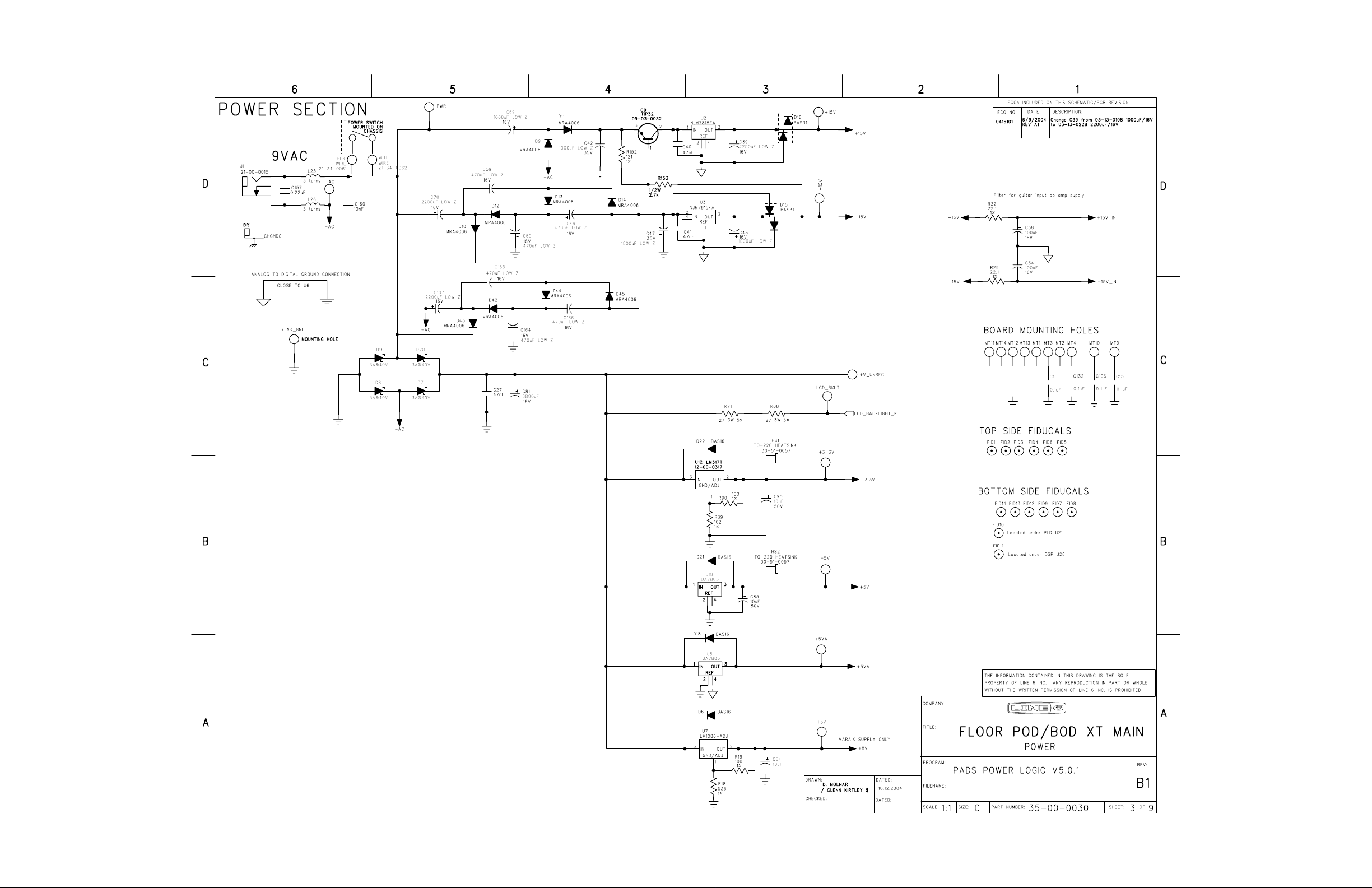

Power supply (page 3 of MAIN schematic):

Refer to the SUPPLY SYSTEM FLOWCHART diagram below.

The POD XT LIVE uses the same external step-down transformer as the POD XT and BASS

POD XT. This transformer supplies 9 VAC to the POD XT LIVE. The 9 VAC is split into

three branches:

- On the +15V branch, the 9VAC is rectified and voltage doubled to approximately +20VDC

with respect to ground by C69, D9, D11, and C42. The transistor Q9 with R152 and R153

acts as a delay such that the +15V supply rail will not come up until the –15V supply rail is

stable. This delay helps reduce the audio thump that may otherwise occur when the unit is

turned ON. Voltage regulator U2 takes +20VDC and produces the +15V rail.

- The –15V branch is a bit more complicated

Since the +AC net is positively offset with respect to ground due to the full-wave rectifier,

a simple voltage “doubler” is not adequate to get the approximate +9V to a value less than

–15VDC. Therefore, the voltage is simply doubled, (C70, D10, C59, D12 and C60) giving

around –10V, and then it is doubled again to produce around –20V by D13, C49, D14 and

C47. In order to help insure symmetrical current draw from the external transformer and at

the same time provide adequate current output of the –15V rail, a second voltage

“quadrupler” is used in parallel and out-of-phase with the other “quadrupler” just

described. This second multiplier consists of components C107, D43, D42, C165, C164,

D44, C166, and D45. Its output is also around –20VDC, but it draws current during the

negative going AC peak.

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 4 of 16

Page 36

- The third branch of the 9VAC feeds a full wave bridge rectifier (D7, D8, D19, and D20).

The output of this rectifier is smoothed to around +10VDC mostly by C81. This +10VDC

output is labeled +V_UNREG on the schematic.

- The +V_UNREG is current limited by two 27 ohm 3W resistors and sent to supply the

backlight for the LCD module. Since the LCD backlight supply is not regulated the

LCD backlight intensity my vary slightly with the AC main voltage.

- The +V_UNREG is regulated by adjustable regulator U12 down to +3.3V (digital

supply).

- The +V_UNREG is regulated down to +5V by U10 for the +5V digital supply.

- The +V_UNREG is regulated down to +5V by U5 for the +5V analog supply for the

Codec and immediate circuitry.

- The +V_UNREG is regulated down to +8V by the adjustable regulator U7 for the

Variax supply that is sent out the RJ-45 jack on the rear panel. Note that care has been

taken to assure that shorting the contacts of the RJ-45 jack (and thus short circuiting the

+8V Variax supply) does not damage the POD XT LIVE in any capacity.

The +15V and –15V rails are further filtered by the R32/C38 and R29/C34 networks to

generate the +15V_IN and –15V_IN which are used to supply a very clean power supply for

the input op amp U1 for the guitar input.

Without special care, a 1KHz audio tone may appear on the audio signals when the USB

connection is used and a ground loop is present between the host PC and the audio system. To

avoid this problem, the USB section has its own 3.3V supply (+3.3V_USB) made of Q8 and its

associated circuitry, and an insulation resistance (R121) between the digital ground and the

USB ground (see page 4 of the Main PCB). With this circuit, the 3.3V_USB current is derived

from the +5V supply and the +3.3V is only used as a voltage reference.

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 5 of 16

Page 37

+3.3V_USB

USB Section

Supply

USB

+15V_IN

Low

Pass

+15V

+15V

DELAY

Regulator

Op Amp

To: Audio Input

Filter

R32, C38

Op Amps,

To: Audio Output

Headphones, etc...

U2

Q9

-15V_IN

Low

Pass

-15V

-15V

Filter

R29, C34

U3

Regulator

LCD BACKLIGHT

Supply

R71 R88

+3.3V

reference

3.3V Digital Supply

DSP, PLD, SDRAM,

FLASH, etc...

U12

+3.3V

Regulator

Regulator

Q8

5V Digital Supply:

MCU U17, MIDI I/F

+5V

R21

LEDs, POTs, LCD,

AES RCVR/SRC U20, etc...

5V Analog Supply

for Analog Circuitry

U10

Regulator

+5V

Regulator

U5

Variax Supply on

RJ-45 Jack

U7

+8V

Regulator

Digital to Analog Ground Connection

and

D9, D11, C69, C42

Voltage Doubler

Positive Rectifier

POD XT LIVE POWER SUPPLY BLOCK DIAGRAM

and

D10, D12, D13, D14,

C70, C59, C60, C49,

D43, D42, D44, D45,

Voltage Multiplier

Negative Rectifier

9V AC IN

J1

C107, C164, C166

Full

Wave

Bridge

Rectifier

C81

D19

C27

D20D8D7

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 6 of 16

Page 38

Input / Output System and Control:

The following Input and Output (I/O) signals control the POD XT LIVE operation and system

mode.

GUITAR_IN_SENSE (MAIN PCB):

The status of the Guitar Input Jack is read from the GUITAR_IN_SENSE line by I/O pin 78 of

the DSP U26. It is high when a jack is plugged in the guitar input and low otherwise.

When this signal is read low (= no jack plugged in), and the Variax input is unplugged, the

DSP mutes the audio signal path in order to keep the noise on the audio outputs at a minimum

DIROUT LEFT_SENSE and DIROUT RIGHT_SENSE (MAIN PCB):

The status of the Direct Output Jacks is read from the DIROUT LEFT_SENSE and DIROUT

RIGHT_SENSE lines by I/O pin 199 and 201 of the DSP U26. Each line is high when the

corresponding jack is plugged in, and low otherwise. Currently the state of these lines has no

effect on the operation of the unit.

HEADPHONE_SENSE (HEADPHONE OUTPUT PCB):

The status of the Headphone output Jack is read from the HEADPHONE_SENSE line by I/O

pin 79 of the DSP U26. It is high when a jack is plugged in the headphone output and low

otherwise. Whenever headphones are plugged in, the DSP is set to “STUDIO DIRECT” mode.

User Interface Potentiometers and Pedals (MAIN PCB):

The POD XT Live has six user interface potentiometers, a variable position pedal, and an

external expression pedal input. The pots and pedals provide a voltage from 0 to 5Vdc. These

voltages are digitized by the 12-bit resolution ADC (U31). This ADC sends the results over a

digital serial stream to the MCU (U17) on the SPI_DATA_MISO line clocked and gated by the

SPI_CLK and SPI_AD_CS* lines.

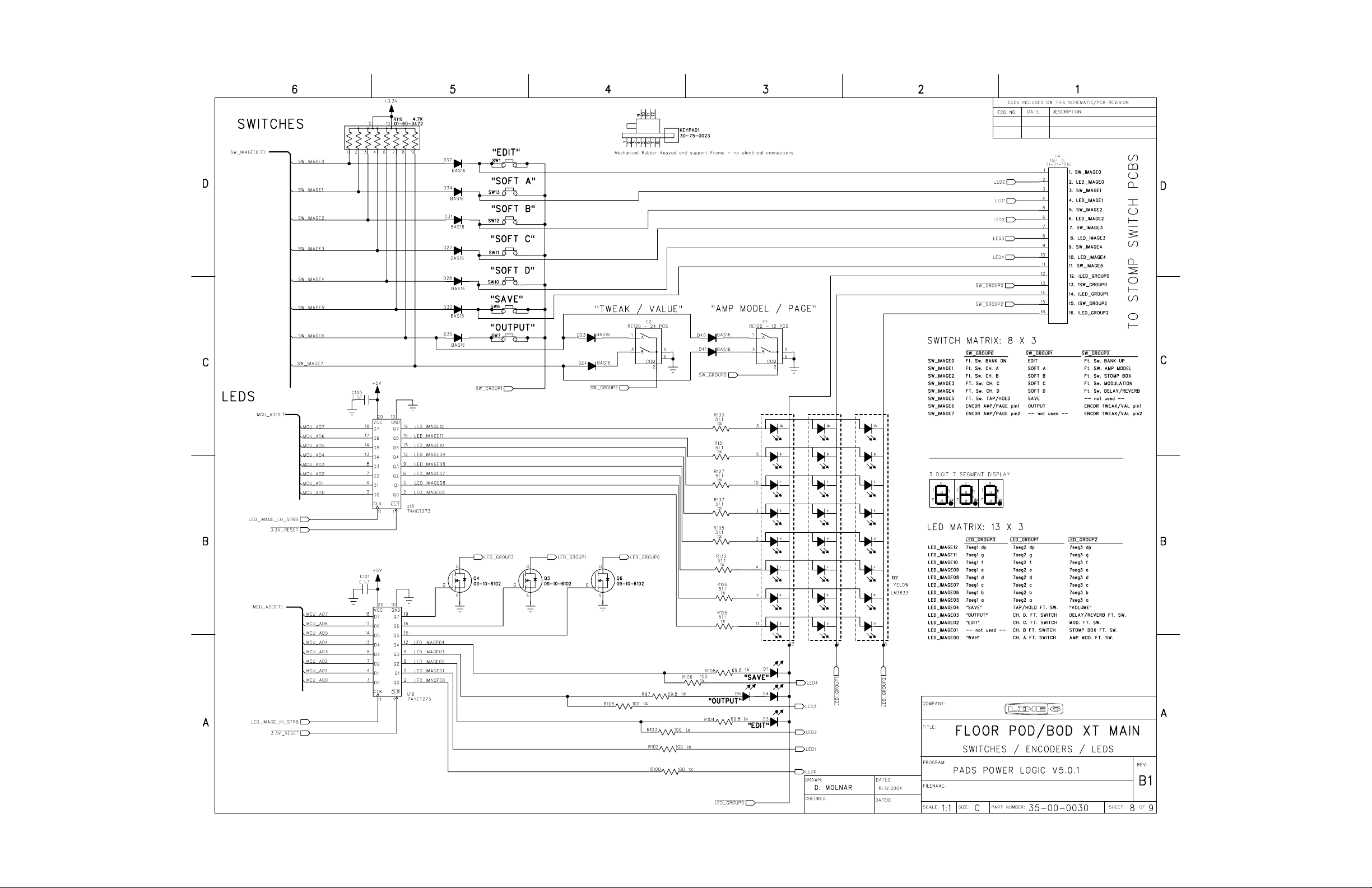

User Interface LEDs / Seven Segment Display (MAIN PCB, SWITCH PCB):

All of the user interface LEDs and seven segment display are grouped in a 3 X 13 multiplexed

matrix under control of the MCU (U17). The LED_IMAGE00…LED_IMAGE12 lines drive

the matrix rows (via drivers U16 and U18). The LED_GROUP0*…LED_GROUP1* lines

drive the matrix columns using FET transistors Q4, Q5, and Q6 to sink the column current.

Under software control, only one LED group line is active at a time. For each LED group a

different LED image is presented in the LED_IMAGExx lines. This matrix multiplexing

happens so fast that the eye perceives all of the LEDs on at the same time. The LED matrix

chart is presented on the MAIN schematic page 8. Most of the LEDs including the LED seven

segment display are on page 8 of the MAIN schematic. Some of the LEDs go off board to the

two halves of the SWITCH PCB via a ribbon cable that connects to H4 of the MAIN PCB.

User Interface Switches and encoders (MAIN PCB, SWITCH PCB):

All of the user interface’s switches and two encoders are read using an 8 by 3 multiplexing

matrix. The 8 switch matrix rows are read by the MCU (U17) using the lines

SW_IMAGE0…SW_IMAGE7 via the PLD (U21). The MCU selects which group of 8

switches (or encoder) to read using the SW_GROUP0*…SW_GROUP2* lines. The two

encoders are each different – E1 has 12 steps and E2 has 24 steps.

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 7 of 16

Page 39

User Interface LCD (MAIN PCB):

The LCD module is written to and read from through the MCU’s main bus MCU_AD[0:7].

The MCU firmware can adjust the contrast of the LCD by varying the duty cycle of a 1KHz

pulse generated on the LCD_CONTRAST_PULSE line. This pulse is filtered and summed

with a minus 5V supply available at pin 4 of the LCD module. This results in an adjustable

negative to positive DC voltage at the contrast control input of the LCD (pin3).

The backlight LED array is supplied on pin 20 of the LCD module. Two 27 ohm resistors in

series (R71 and R88) set the backlight brightness.

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 8 of 16

Page 40

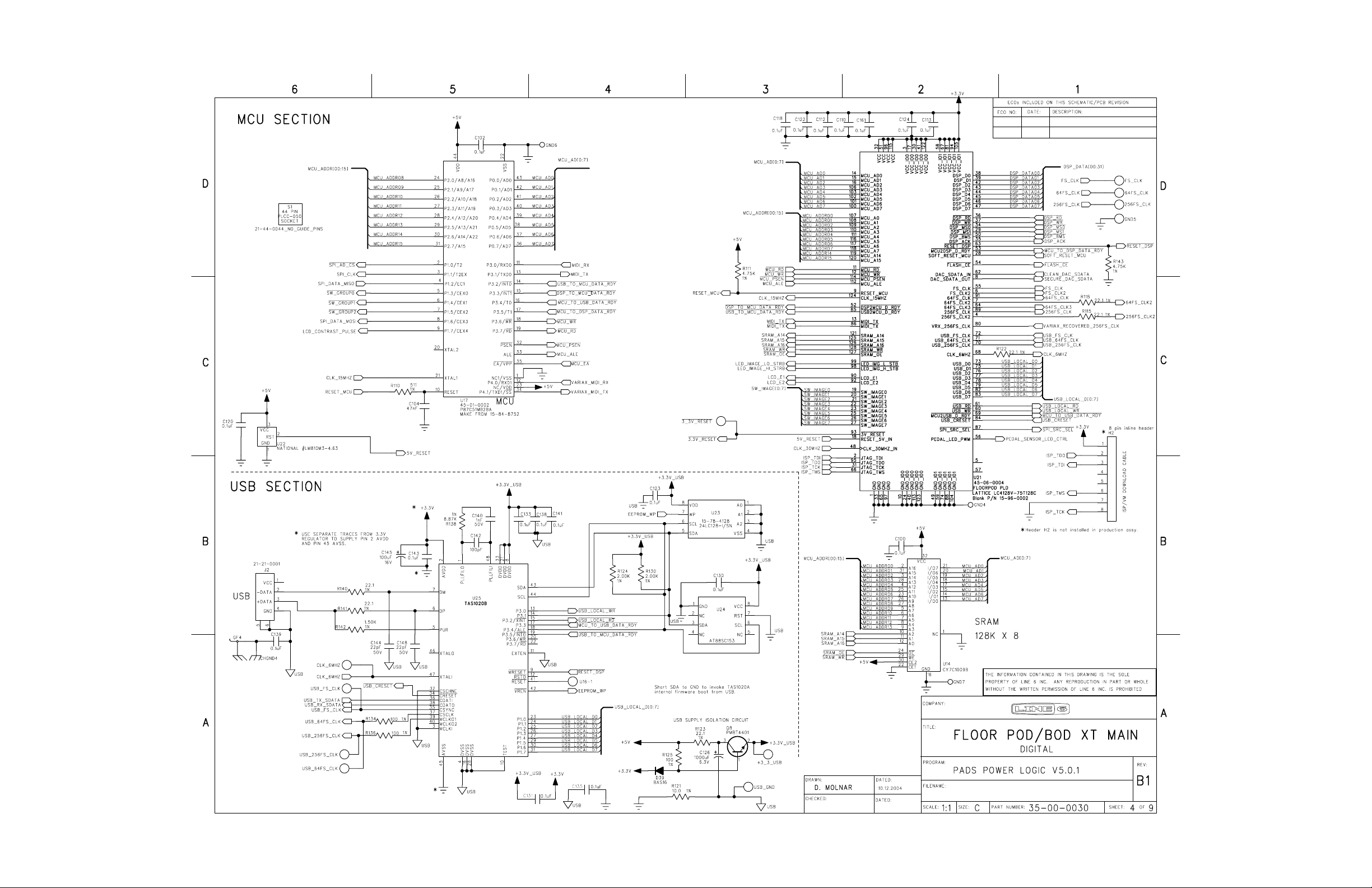

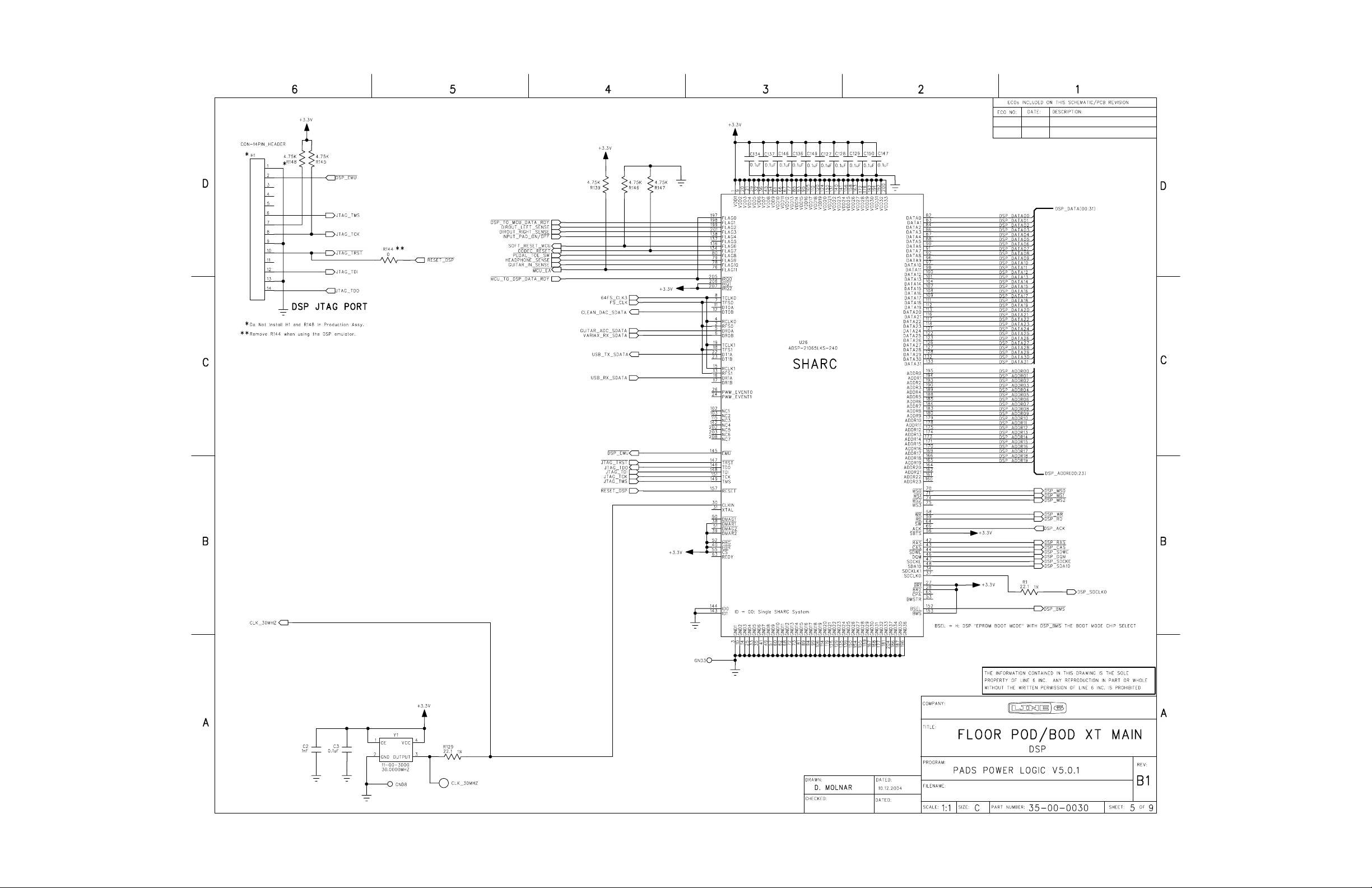

Clock system (Pages 4,5, and 9 of the MAIN PCB):

The drawing below details the clock distribution structure of the POD XT LIVE:

Rx

Audio

Digital

Variax

Input Clock

MCU

U17

USB Controller

FS_CLK

CLK_6MHZ

U25

USB_64FS_CLK

USB_256FS_CLK

U4

CODEC 1

256FS_CLK = 10MHz

64FS_CLK = 2.5MHz

Sample

Output Clocks

U20: SRC & AES IN

FS_CLK = 39.0625KHz

USB Clocks

Internal Clocks

Divide By 64

Rate

Converter

U26

DSP

VARIAX_RECOVERED_256FS_CLK

Variax Recoverd Clock

Divide By 2

CLK_30MHZ CLK_15MHZ

Divide By 5

Internal Clock

Divide By 3

Divide By 4

Inside PLD U21

Y1

30 MHZ

The 30 MHz Oscillator Y1 (via the PLD) generates the bulk of the on board system clocks.

PLD U21 derives several clocks from Y1 including: CLK_15MHZ for the MCU U17,

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 9 of 16

Page 41

CLK_6MHZ for the USB controller U25, and the three internal digital audio clocks. The three

internal digital audio clocks are 256FS_CLK (10MHz), 64FS_CLK (2.5 MHz digital audio bit

clock), and FS_CLK (39.0625 KHz sample rate). These internal digital audio clocks are used

by the DSP, the CODECs, and the Internal side of the Sample Rate Converter IC for the

Variax receiver. When the USB controller is active and connected to a PC with an audio

application, the three clocks 256FS_CLK, 64FS_CLK, and FS_CLK are generated by the USB

controller (see above diagram). When the Variax is plugged in the

VARIAX_RECOVERED_256FS_CLK is used in place of the internal clock. When both the

Variax and USB are active, the recovered Variax clock is NOT used and instead the Variax

digital audio signal is passed through a sample rate converter and synchronized to the USB

clocks.

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 10 of 16

Page 42

Bus system:

The drawing below details the interconnecting busses between the subsystems of the POD XT

LIVE:

1M X 16 U28

4M X 16 Z1

1M X 16 U27

4M X 16 Z2

Only the 1M X 16 or

4M X 16 SDRAMs

are installed at a

time.

SHARC DSP

U26

0..31

16..31

DSP_DATA[00..31]

0..15

SDRAM LO

SDRAM HI

\MCU_TO_DSP_DATA_RDY

\DSP_TO_MCU_DATA_RDY

P87C51MB2A

OTP MCU

U17

0..7

8 bit latch

w/busy flag

\MCU_TO_USB_DATA_RDY

\USB_TO_MCU_DATA_RDY

0..15

0..7

8 bit latch

w/busy flag

MCUAD[0..7]

FLASH

U29

INTERFACE

INSIDE PLD

w/busy flag

w/busy flag

SRAM

U14

BUS

U21

8 bit latch

8 bit latch

USB_LOCAL_D[0..7]

TAS1020A

Controller

I2C BUS

ISP

Cable

I / F

H2

for PLD

USB

JACK

USB

U25

EEPROM

U23

SECURE

MEM

U24

8 Ch. ADC

U31

...

MIDI

Variax

MIDI

POTs

LCDLEDs

Switches

and

Encoders

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 11 of 16

Page 43

The Micro-controller (MCU U17) is the master host controller for the POD XT LIVE. Its data

bus (MCU_AD[0..7]) interfaces locally to 128K X 8 of SRAM (U14). All of the user interface

components: LCD, LEDs, the Switches, and Encoders are connected to this bus either directly

to this bus (LCD), through drivers (LEDs), or via a bus buffer (switches) in the PLD (U21)

(pages 7 and 8 of main schematic). This bus is also bridged to both the DSP and USB

subsystems via bidirectional latches inside the PLD U21. All address decoding for the MCU is

performed inside the PLD. (Note: The above diagram does not show the address bus and

control lines).

The MCU U17 is a One Time Programmable microcontroller (OTP). It contains the BOOT

CODE ROM for the POD-XT PRO system as well as some internal SRAM. VERY

IMPORTANT - This chip must be programmed like and EPROM before it can be used in the

POD XT LIVE system.

The interface between the MCU and DSP is located inside the PLD U21. If the MCU wishes

to send a byte to the DSP, it writes a byte to the MCU-to-DSP latch inside the PLD. Writing

this byte causes a busy flag to become asserted (MCU_TO_DSP_DATA_RDY*). When this

flag is asserted, the DSP receives an interrupt, which tells the DSP to read the byte from the

MCU-to-DSP latch. The MCU_TO_DSP_DATA_RDY* flag is deasserted when the DSP

reads the MCU-to-DSP latch. The MCU polls the MCU_TO_DSP_DATA_RDY* line and

cannot write another byte until this line is deasserted. This same process works for the

DSP_TO_MCU_DATA_RDY* for sending bytes from the DSP to the MCU.

The DSP local bus (DSP_DATA[00..31] is a 32 bit bus that interfaces 32 bit wide SDRAM in

2 1MX16 chips U27 and U28 (note that you can substitute 4MX16 chips in the overlapping IC

locations Z1 and Z2 but this is not currently used) and the FLASH memory U1 to the DSP.

This bus is bridged to the MCU bus via the bidirectional latch inside the PLD U21 described in

the paragraph above.

The interface between the MCU and USB subsystem is also located inside the PLD U21. This

interface bridge is identical to the interface between the MCU and DSP subsystem. The USB

local bus (USB_LOCAL_D[0..7]) is only used to bridge the USB subsystem to the MCU bus

via the bidirectional latch inside the PLD. All peripherals in the USB subsystem are interfaced

via an I2C (Inter IC) bus. The I2C bus is a 2 wire bus used for local low speed serial

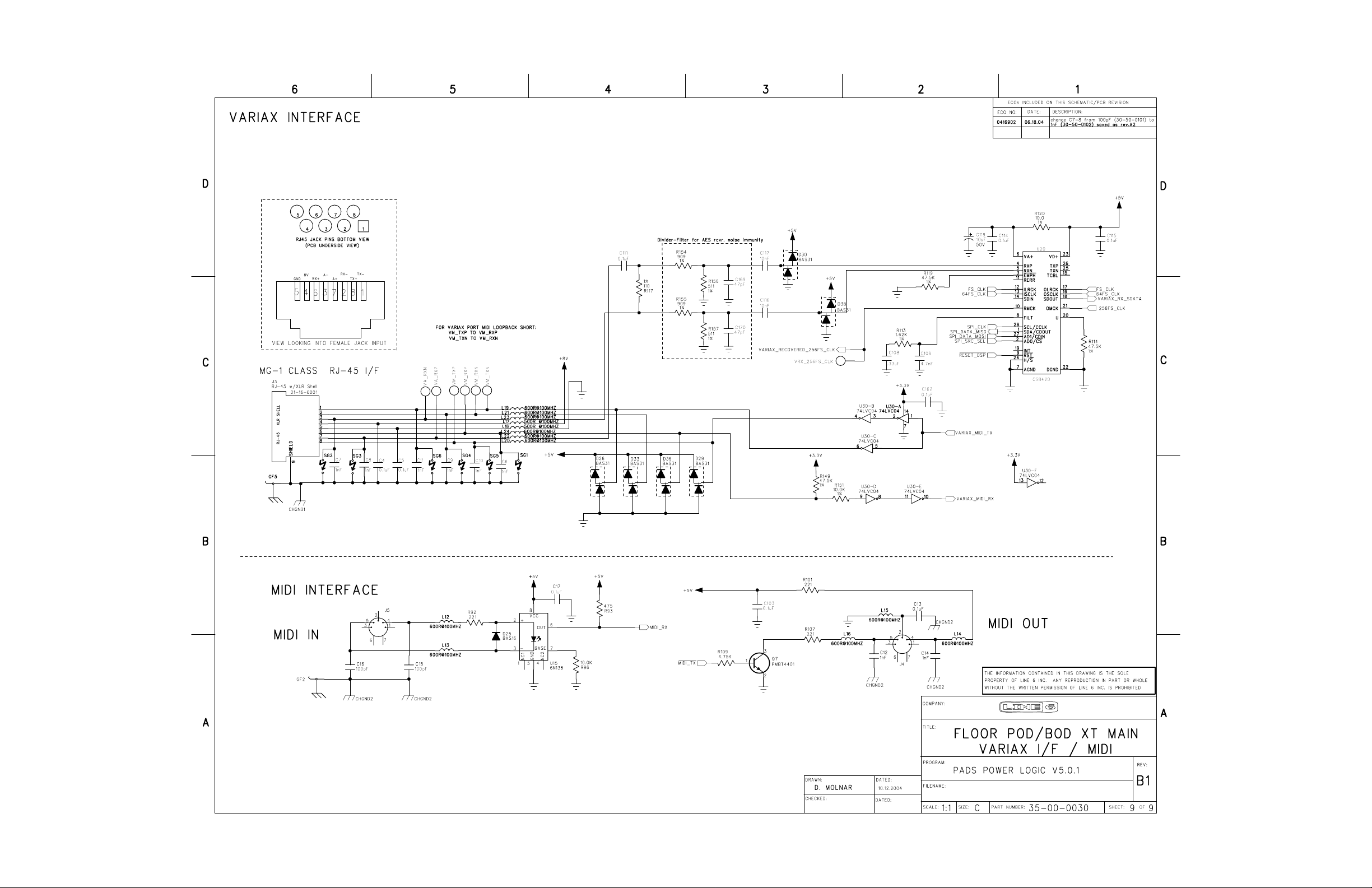

communication between all I2C compatible chips on a pc board. The I2C bus connects the

EEPROM U23 and Secure Memory U24 to the TAS1020A USB controller U25.

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 12 of 16

Page 44

Boot Up Sequence:

The POD XT LIVE has quite a sophisticated boot up sequence, which is outlined below:

1. On power up, the reset IC U22 generates an active HIGH reset. This is the master reset

for the entire POD XT LIVE system.

2. When this “master reset” line is deasserted, the MCU polls the MCU_EA* during the

falling edge of its reset. This line will be HIGH causing the MCU to execute code from

its internal OTP ROM.

3. The MCU will deassert the RESET_DSP* line (via the PLD) thus taking both the DSP

and USB controller out of reset (see next section below for USB reset process).

4. The MCU will then send the DSP’s boot code to the DSP via the MCU to DSP bridge

inside the PLD. This DSP boot code is stored in the MCU’s OTP ROM during power

down.

5. Once the DSP has received all of its boot code from the MCU, it loads its runtime code

from the FLASH memory located on its data bus and begins execution.

6. The DSP will then send the MCU’s runtime code to the MCU where the MCU will

store it in the volatile SRAM U14.

7. Once all of the MCU runtime code is received by the MCU, the DSP will RESET the

MCU. The DSP drives MCU_EA* to the LOW state, then asserts SOFT_RESET_MCU

to reset the MCU. After the reset period, the DSP deasserts SOFT_RESET_MCU and

drives MCU_EA* HIGH again. The MCU will now begin to run its runtime code from

the external SRAM U14. The MCU uses the state of the MCU_EA* line during the

falling edge of its reset line to determine if it will run its OTP ROM boot code or

execute code externally from the SRAM. This time it runs code externally because the

DSP held the MCU_EA* low during the falling edge of its reset.

The USB subsytem is reset by the active low signal RESET_DSP*. This signal is a product of

the master reset IC so the USB subsystem is reset only during a board power up.

1. When reset is removed from the USB controller U25, its special internal firmware

checks the EEPROM U23 to see if it contains the USB controller runtime code. If the

EEPROM is blank then the USB controller attempts to load its code via USB jack. If

the USB controller is able to load code from the USB jack it loads this code into the

EEPROM (This is how the POD XT LIVE tester loads code for the USB into the

board.)

2. Once there is valid code in the EEPROM and it is loaded into the USB controller, the

USB controller will begin executing this code.

3. Upon executing its runtime code, the USB controller checks the secure memory U8 to

see if it is sealed. If it is sealed then USB encryption is enabled. (The secure memory

is “Sealed” during the production test process. The “sealing” process ensures

appropriate serial numbers are written to the USB encryption subsystem)

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 13 of 16

Page 45

Troubleshooting:

This section outlines some common problems that may be encountered when troubleshooting a

POD XT LIVE.

1. Since the USB jack is located next to the RJ-45 jack it was noticed that one can very

easily plug the USB cable into the RJ-45 jack. Now, of course, this will not work but

the shield of the USB plug will short all 8 lines of the RJ-45 jack. Special care was

taken when designing the circuitry of the RJ-45 jack such that shorting the power and

ground will not damage the board. The added circuitry should provide adequate

protection. If a board is damaged by inserting the USB plug into the RJ-45 jack please

notify engineering.

2. The FLASH memory on the POD XT LIVE is updated every seven seconds with any

setting changes (eg. MIDI channel, LCD contrast, knob change, etc…). This means

that if the POD XT LIVE is powered down in less then seven seconds after a setting is

changed then the item will not be stored correctly in the FLASH memory. When the

POD XT LIVE is powered back on, its previous setting will be restored.

3. The board powers up and the LCD backlight turns on but the LCD is blank or garbled –

if the rest of the system seems to be functioning correctly (TAP tempo light flashes,

buttons work, audio passes, etc.) then the LCD reset circuitry may be at fault (Q3) or

the LCD module itself may be defective.

4. If the LCD’s backlight does not turn on but the rest of the system work properly - check

that the 27R resistors on LCD_BACKLIGHT_K are the correct value or are not open

circuit. The LCD module’s backlight itself may be defective – in this case the only fix

is to replace the LCD module.

5. The board powers up but the LCD reports “ERROR CODE 2” or “ERROR CODE 1”.

This means that the FLASH memory is empty or invalid. “ERROR CODE 1” means

that the MCU runtime code that is stored in the DSP’s FLASH is invalid. “ERROR

CODE 2” means that the DSP runtime code that is stored in FLASH is invalid. See

previous section on POWER UP SEQUENCE for more information. If either of these

messages are displayed, then try reprogramming the FLASH memory. If it fails again,

then check for faulty soldering on the DSP’s bus or MCU bus (see section on BUS

SUBSYSTEM for more information). Note also that a faulty device on either of these

busses may be at fault.

6. The board is powered up but the LCD is blank and the rest of the system is frozen.

First, make sure that the MCU is installed. Second, try another MCU. Third, check for

faulty soldering on the MCU bus (especially the MCU socket S1). Fourth, make sure

the PLD is programmed properly. This can only be verified with the PLD

programming cable and accompanying PC software. One other way to verify that the

PLD is ok is to check for all of the clocks that the PLD drives (the clocks can be found

on an number of test points throughout the board). Fifth, check the master oscillator Y3

to see if it is generating the 30MHz clock. Sixth, check for faulty components on the

MCU bus side. Finally, check that a proper reset is generated by the reset IC U22.

7. The board powers up, the LCD is displaying the correct items, the buttons, knobs, and

LEDs work, but there is NO AUDIO. First check that the pedal is in the toe down

position and that there is no external expression pedal plugged in. Second, check that

the Variax input is unplugged because this will override the guitar input. Third, check

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 14 of 16

Page 46

that the signal GUITAR_IN_SENSE is HIGH (HIGH means that a jack is plugged into

the POD XT LIVE’s guitar input.). If this signal is not HIGH then the guitar in jack

J10 or the support circuitry for the sense line is faulty. If the system thinks that a plug is

not plugged into the guitar jack it will automatically mute the audio. Fourth, check the

audio input circuitry and make sure audio makes it through the input op-amp U1 all the

way to the CODEC (U4) inputs. Third, make sure that the codec has the appropriate

clocks driving it (See section CLOCK SYSTEM above). Fifth, check the audio path

from the output of the codec to the unbalanced direct outs and the headphone circuitry.

Sixth, the audio is correct all the way to the codec and the clocks are correct then it is

possible that the DSP or an item on its bus is malfunctioning. At this point check for

faulty soldering on the DSP or other items on its bus.

8. The buttons and encoders work but the pots do not. First power down and then power

up in test mode (Press the SOFT D button under the LCD on power up). If the pots fail

in test mode check the ADC U31 and the clocks and\or signals going between this ADC

and the MCU.

9. The board seems to be working properly but the LED’s do not work. First power down

and then power up in test mode (Press the SOFT D button under the LCD on power

up). If the LEDs fail in test mode check the U16 and U18 latches as well as FETs Q4,

Q5, and Q6. If the LEDs under the UI keypad buttons work but the stomp switch LEDs

do not then check the ribbon cable between the MAIN PCB and the SWITCH PCB

halves and also check the SWITCH PCB halves themselves.

10. The board seems to be working but the buttons and encoders do not work. First power

down and then power up in test mode (Press the SOFT D button under the LCD on

power up). If the buttons and encoders do not work in test mode check anything in the

SW_IMAGE[0:7] bus and MCU_AD[0:7] bus, resistor pack R116, and any of the

switch matrix diodes (see MAIN schematic page 8).

11. The board is running but the USB does not work. Check for faulty soldering on the

USB controller U25 as well as the EEPROM U23 and secure memory U24 and pull-up

resistors R124 and R130. Check the special USB supply isolation circuit (See

schematic page 4). Finally check for faulty components in the USB subsystem.

12. The board is running but the VARIAX interface does not work: Check the AES

Receiver/SRC U20 and check the Variax MIDI transceiver U30.

13. The board is running but the MIDI interface does not work. Check the MIDI I/O

section for faulty soldering (See schematic page 9). Check for faulty soldering on the

MCU U17, the PLD U21, etc.

14. The unit works ok except for the pedal:

?? First: Make sure that the pedal is calibrated properly – you can do this by powering

up with the “BANK UP” stomp switch held. This puts the unit into a special pedal

calibration test mode. The LCD will display several fields of numbers. Press the

“AMP ON/OFF” stomp switch to reset the calibration. Move the pedal to the heel

position. Move the pedal to the toe position and depress the pedal’s toe switch.

Move the pedal back to the heel position. When in the heel position now the “7

MAPPED xxx” number on the LCD should read 0. Move the pedal back to the toe

down position(you do not have to depress the toe switch). With the pedal now in

the toe down position the “7 MAPPED xxx” number should read 127. You should

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 15 of 16

Page 47

also see this number sweep from 0 to 127 as the pedal is moved from heel down to

toe down.

?? Second: If the pedal fails to calibrate properly you should check the metal lance

that moves above the IR sensor. The long part of the lance should be at a 90 degree

angle to the plane of the pedal. If the long part of the lance is not at a 90 degree

angle to the plane of the pedal you may try adjusting it accordingly.

?? Third: After trying all of the above - there may be a problem with the IR emitter or

IR phototransistor on the PEDAL PCB. Also, the interconnecting cable between the

MAIN PCB and PEDAL PCB may be defective.

POD XT LIVE Theory of Operation………Line 6 confidential ……………. Page 16 of 16

Page 48

Line 6 Manufacturing

Floorpod XT Assembly Instructions Rev B

Document # L6D000017

LEFT

FRONT

BACK

RIGHT

Forward and Notes

The information in this booklet applies the Floorpod XT (also known as: PODxt LIVE). It is

suggested that the steps for assembly follow the order presented in these instructions.

These instructions deal with the assembling the major sub-assemblies, the final product, and

quality/inspection considerations. See also the Related Electrical assembly documentation, for

major considerations in assembling the electrical components of the PCBs (through the soldering

process and preparation of the board for addition of custom components).

A note on the text: the illustrations in this book are for reference only. In some cases, color and

geometry of illustrations may not accurately reflect the color or exact geometry of actual parts.

?? Unless otherwise noted, all dimensions are in inches.

?? Part identifying notes are in this format: Description (Part Number)

?? Drawings are not to scale.

?? Torque value tolerance +/- .5 in.-lbs. Do not over tighten any components.

?? For clarity, not all component details are shown. This is especially true with respect to

cable assemblies. They are often omitted from views to provide a clearer picture of the

material discussed. Do not be confused by the absence (or unexpected presence) of any

component in the illustrations in this book.

Confidential Page 1 of 41 9/7/2004

Page 49

Line 6 Manufacturing

Floorpod XT Assembly Instructions Rev B

Document # L6D000017

Revision Comment Sheet

Revision Changes

A N/A

B Miscellaneous typographical errors corrected

Step 3. Added 1 each pedal support bracket and 2 each nylon washers

Added exploded assembly view to Figure 1

Fastener torque values changed

Step 4. Fastener torque values changed

Step 5. Fastener torque values changed

Step 6. Fastener torque values changed

Added 2 each steel washers

Figure 1 revised

Step 8. Instructions Updated with correct part numbers.

Step 9. Fastener torque values changed

Step 10. Added Lens inspection note

Step 11. Fastener torque values changed

Step 15. Fastener torque values changed

Step 17. Part quantity changed

Fastener torque values changed

Step 19. UPC/Serial Number label part number corrected.

Confidential Page 2 of 41 9/7/2004

Page 50

Line 6 Manufacturing

Please notice the placement

should be placed close to the

Floorpod XT Assembly Instructions Rev B

Document # L6D000017

STEP 1. PEDAL SUB-ASSEMBLY

P/N required:

1 each 30-75-0002 Foot Rubber

1 each 30-51-0181 Pedal

2 each 30-75-0011 Rubber Pedal stop

1 each 30-75-0007 Pedal Stop Foam Rubber

1.1 Install Foot Rubber onto the Pedal

1.1.1. Install FOOT RUBBER to the PEDAL top surface. Press firmly. The Pedal shall

be clean and dry. DO NOT BEND THE LANCE.

Pedal Sub-Assembly

To complete the Pedal sub-assembly the following must be attached to the Pedal. Each

rubber part has pressure sensitive adhesive on the side to be attached to the Pedal.

2 each Rubber Pedal Stops

1 each Pedal Stop Foam Rubber

1 each Foot Rubber

of the Pedal Stops between

the small rectangular

cutouts. Also make sure

that they as close to the

Pedal edge as possible.

Confidential Page 3 of 41 9/7/2004

The Foam Rubber Stop

bottom edge of the Pedal as

Page 51

Line 6 Manufacturing

Floorpod XT Assembly Instructions Rev B

Document # L6D000017

STEP 2. PEDAL PCBA and PEDAL SWITCH PCBA

P/N required:

1 each 35-00-0032 Switch PCB (break away part)

3 each 30-51-0078 Tactile Domes

1 each Scotch Transparent Tape 144 or equivalent

2.1. To complete this sub-assembly place three (3) Tactile Domes aligned on top of each

other (make sure there are exactly 3 Tactile Domes used, they are thin and easily misscounted) and tape them to the Pedal Switch PCB so that the feet of the bottom Tactile

Dome rest on the conductive pads.

Break away switch PCB

Tactile Domes

Clear tape used to hold

Tactile Domes in place for

assembly. Please notice the

alignment of Tactile Domes

and placement of Tape.

Confidential Page 4 of 41 9/7/2004

Page 52

Line 6 Manufacturing

Nylon Washers

work if the insulator is not on the correct

chassis

Floorpod XT Assembly Instructions Rev B

Document # L6D000017

2.2. Pedal Switch PCB to Chassis Assembly

P/N required:

2 each 30-03-0013 Nylon Washers .5 x .170 x .04 thick

2 each 30-15-0005 Round Aluminum Spacers 1/4 OD X .166 ID X .460

1 each 30-15-0006 Insulator Plastic .17 OD X .156 ID X .460 LNG

PEM for

Pedal PCBA

Back surface of the Chassis

30-03-0013

Round Plastic Insulator

IMPORTANT: Note the location of the

insulator. The pedal activation will not

stud.

PCB breakaway tabs point to BACK of the

Pedal Switch PCB sub-assembly

Round Aluminum Spacers

Confidential Page 5 of 41 9/7/2004

Page 53

Line 6 Manufacturing

Floorpod XT Assembly Instructions Rev B

Document # L6D000017

STEP 3. PEDAL PCBA to CHASSIS Assembly

P/N required:

1 each 50-02-0032 Pedal PCBA

2 each 30-03-0013 Nylon Washer

1 each 30-51-0197 Pedal Support Bracket

1 each 30-00-0043 6-32 x 5/16 Screw with captive star washer

2 each 30-06-0623 6-32 Hex nuts with captive star washer

1 each 30-15-0004 Spacer .13 x.63 OD Nylon Black

3.1. Install Pedal PCBA

3.1.1. Position the PCBA onto the 2 threaded studs

3.1.2. Install 2 each Nylon Washers on to the threaded studs.

3.1.3. Install the Pedal Support Bracket onto the threaded studs. Note: the Bracket has

a FRONT side that must be positioned toward the Chassis Front.

3.1.4. Install 2 each 6-32 nuts onto the threaded studs. Only finger tight.

3.1.5. Install 1 each 6-32 x 5/16 PPH machine screw to secure the PCBA to the standoff.

Only finger tight.

3.1.6. Install Black Nylon Spacer, Black Finishing Washer and Chrome Nut onto ¼” jack

on the BACK of the chassis. See figure 1 on next sheet.

FASTENER TORQUE VALUE = 5-6 in/lbs

3.1.7. Torque screw (30-00-0043) & 2 nuts (30-06-0623).

FASTENER TORQUE VALUE = 10-12 in/lbs

Confidential Page 6 of 41 9/7/2004

Page 54

Line 6 Manufacturing