Page 1

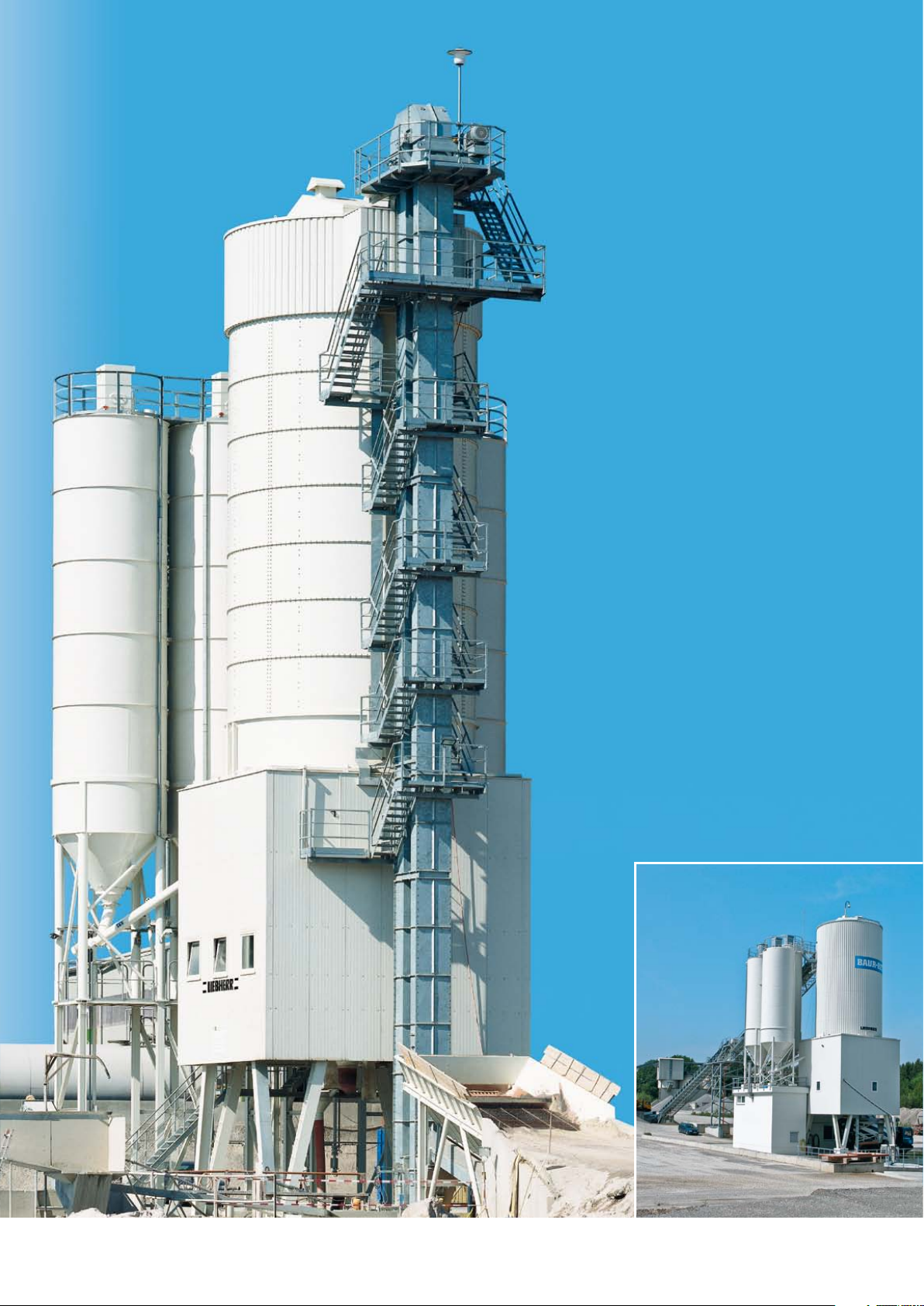

Betomat vertical

concrete production plant

Page 2

Vertical concrete production

plant from Liebherr: a concept

with many advantages

Betomat tower mixers have been used successfully throughout the world for many years, both to produce premixed concrete and in precast element and concrete product manufacturing.

Their well-proven modular construction principle permits plant to be planned individually from 55 to 240 cu.

m/h set weight of concrete. Versions with two intensive-action mixers operating alternately are also available,

or with the second unit used as a pre-mixer in concrete element production. Liebherr’s full range of options

and accessories satisfies every requirement. A tandem plant can be installed to double the output again. The

complete concept is geared to the cost-effective production of high-quality concrete in a plant with low rates

of wear.

Advantages of the

Betomat concept

The vertical mixing-plant layout guarantees high

1

ciple permits numerous design variations and output ratings

to be supplied. Compact and self-contained, the vertical

plant layout is environmentally acceptable and also has advantages in winter operation.

production rates and ample storage volume on

even a limited site area. The modular-element prin-

3

The Betomat for pre-mixed concrete

Since it is made up of modular elements, the Betomat is not

only suitable for use as a permanently installed facility but can

often be employed temporarily on large-scale construction

2

control system, everything is geared to smooth filling and throughput of the

truck mixers. The twin-track option is of particular value when delivering premixed concrete.

The Betomat in the precast and

prefabricated concrete products industry

The generous materials storage capacity, with up to 10 silo compartments, is a genuine advantage for users in this industry. The

plant itself, its control system, dragline loader and requirement

indicating points, together form a convincing overall concept.

4

sites such as dams or tunnels. From the plant concept to its

The Betomat in detail

The selection and positioning of the high-quality

components has been planned to the last detail,

so that a perfect overall equipment complex results. The purpose-made options and additional

equipment satisfy the same high standards.

2

Page 3

3

Page 4

Advantages of the

1

The mixing plant’s vertical layout, with the aggregates located directly above the

weighing and mixing platform, guarantees high output and the necessary storage

capacity.

The tower layout occupies only a minimum of ground area. To suit customers’ needs,

numerous alternative versions are available, with one or two mixers and various

loading systems: bucket elevator, S-pattern conveyor or inclined belt.

Compact and self-contained, the vertical layout minimizes dust and noise, is therefore extremely pro-environmental and capable of working without problems in the

winter season as well.

Pre-assembled modular units make the plant extremely easy to assemble and keep

erection times to a minimum. Because of this, even temporary operation on a construction site is a viable proposition.

Betomat concept

Erecting a Betomat II-400 Betomat III-570

4

Page 5

Betomat II-235Betomat II-400

5

Page 6

The Betomat for

2

It would difficult to imagine the pre-mixed concrete industry without the Betomat. Plant size

and version can be precisely matched to the customer’s needs, and an on-site building incorporated into the layout if required. Modern control systems and software make the Betomat

extremely easy to use and can include a large number of additional procedures, for example

invoicing, vehicle movement control or a concrete-laboratory program. For top-quality concrete or for maximum output, Liebherr can supply the most suitable mixing system: ring pan

mixers with or without agitators, or its double-shaft mixer.

pre-mixed concrete

Betomat III-360 Betomat III-290 Betomat II-400

6

Page 7

Betomat II-400

7

Page 8

8

Page 9

The Betomat – a powerful plant with many options

The plant can be supplied on request with two discharge lines, for rapid truck-mixer filling. The appearance of the plant can of course also be varied too. There are various forms of loader available for

aggregate storage (belt conveyor, bucket elevator, S-pattern conveyor) and various discharge hoppers

as well. The aggregates are moved by the shortest route to their storage compartments, and the low

number of moving parts helps to guarantee reliable operation and minimum wear for a long period.

Other highly practical options from Liebherr include an automatically lowered extending nozzle (1), a

swivel chute for truck discharge (2) and a swivel collecting hopper (3) to accept water when the mixer

is being cleaned and thus minimize contamination of the plant.

Residual concrete returned to the plant and the water used to clean the truck mixers and the main

mixing plant have to be disposed of reliably and at moderate cost. Liebherr can supply two types of

concrete recycling plant (trough and screw patterns) with capacities between 4 and 22 cu. m/h. Sand

and gravel are washed out and the residual water containing cement trapped as a suspension in an

agitator tank. All these materials can then be re-used in concrete production.

Liebherr’s high-pressure mixer cleaning equipment greatly reduces the effort that would otherwise be

involved in performing this task. At the touch of a button, the mixer with its gate can be cleaned each

evening or before lengthy work breaks; this reduces the time-consuming task of manual cleaning with

a hose to an absolute minimum.

Swivel chute and extending nozzle

1

2

3

Concrete recycling Before and after cleaning

9

Page 10

The Betomat in the precast

3

element and prefabricated

product industries

Betomat mixing plant from Liebherr produces high-quality concrete for a vast number of

manufacturing applications throughout the world, for example paving stones, concrete

slabs, curbstones, drainage systems, bridge-building elements, cross-beams, house

walls, prefabricated garages or tower segments for wind-powered generators.

10

Page 11

The Betomat’s generous storage capacity, with up to 10 compartments, is a major advantage

for these industries. Since the Betomat occupies very little space, it is easy to integrate into a

precast element or concrete product factory and can be linked to existing buildings without difficulty. Aggregates can be supplied by inclined belt conveyor from points some distance away,

if necessary. As a systems supplier, Liebherr is a single source for the entire concept.

The mixing platform is of ample size to accommodate either one or two intensive-action mixers, or three in special circumstances. A second mixer is often invaluable for pre-mixing when

producing concrete products. Liebherr supplies intensive-action mixers that are ideal for the

most varied tasks. Even the smallest 0.5 cu. m RIM-M ring pan mixer is available with an agitator

system for excellent mixing results.

11

Page 12

Fully integrated into concrete product manufacturing

Liebherr is the single-source supplier for the entire concept, from aggregate loading to delivery of the freshly mixed concrete to the production areas. Many years of experience in this

field are a guarantee of success in the production of precast and prefabricated concrete

articles.

The requirement indicating point

The grade and quantity of concrete needed can

be called up with the aid of the precisely

where delivery is to take place.

12

Page 13

13

Page 14

“Just-in-time” concrete production

When all systems are perfectly coordinated, reliable production and delivery

of concrete precisely where and when it is needed presents no problems:

• Loading aggregates

• Calling for deliveries

• Concrete mixing

• Movement of the concrete to the production area

• Cleaning the mixing plant

• Cleaning the skip loader tracks

• Transferring residual concrete and cleaning water to the recycling unit

• Recycling residual concrete

• Re-use of the raw materials thus obtained

Skip loader track

14

Page 15

Production control Recycling unit

15

Page 16

The Betomat

4

The ideal mixer for every task

For more than 50 years, Liebherr has developed and built its own mixer systems. In the company’s technical mixing-plant

laboratory, these systems are tested with the most varied mix constituents, developed and optimized.

Based on the successful Type R ring pan mixer, there are now two further versions with additional agitators for higherquality grades of concrete. The Type RIM is supplied with either one or two mechanically-driven agitators (RIM-M / RIM-D).

The Type RIH has either one or two hydraulically driven actuators, which have the advantage that the speed of agitator

rotation can be continuously varied (RIH-M / RIH-D). Ring pan

mixers are available with capacities from 0.5 to 3.0 cu. m.

Liebherr’s double-shaft mixers are of extremely

robust construction and intended for high output

rates. The Type DW is available in sizes from

2.25 to 4.5 cubic meters (nominal

set-concrete volume). All Liebherr mixer

systems are exceptionally easy to service.

in detail

16

Page 17

Litronic MPS microprocessor control

Litronic MPS is an open-system concept using industrial standards on a broad basis.

This ensures that new hard- and software developments can be incorporated into the

system without difficulty. Every step in the process is clearly visualized on the computer

screen. Interfaces are provided for links to existing data processing systems. Extensive

additional software packages are available and can be retrofitted later if necessary.

Litronic FMS moisture measurement

For precise determination of the moisture content of aggregates, Liebherr uses intelligent, capacitive-action sensors developed in-house.

Litronic TMS temperature measurement

Liebherr supplies its Litronic TMS system for contactless measurement of the temperature of the material in the mixer.

Litronic TMS temperature measurement Sensor installed

Litronic FMS moisture sensors

17

Page 18

18

Water weigherCement weigherRotary distributor belt

Page 19

The machinery platform

Ample space is provided on the machinery platform for access to the mixer

inlets and other components, so that cleaning is an easy matter.

Rotary distributor

The individual aggregate silo compartments are filled from a rotary distributor or, on larger installations, a rotary distributor belt.

Weighing systems

The cement, water, aggregate and admixture weighers all supply precise

measured values to the control system. All weigher systems are suitable for

calibration. Rapid, accurate batching is essential if mix formulae are to be

complied with despite high output rates.

Up to six cement-screw inlets can be accommodated at a single cement

weigher. The aggregate weigher has protective rubber mats to prevent wear.

Other forms of material delivery

Additional batching devices can be used to supply steel, synthetic fibers,

micro-silicate slurry (compacted or loose) or dye to the mix.

Aggregate weigher Admixture weigher

Admixture tanks

19

Page 20

20

Cement filter systemsPositive dust extraction from mixerVersion with two truck discharge tracks

Page 21

Dewatering system

As an option, a dewatering system can be installed under the batching gates. Water from the aggregates is trapped and conducted away

downwards by a channel system.

Two discharge tracks

The version with two discharge tracks is available with either one or

two intensive-action mixers. It permits one truck mixer to be filled and

another driven into position ready for filling. Two gates are always provided on each intensive-action mixer, so that both mixers can supply

either truck filling point.

Environmental protection

To avoid contamination of the air in the vicinity of the mixing plant with

dust, Betomat plants have positive mixer dust extraction and the cement silos are fitted with air outlet filters.

Winter operation

Thanks to a precisely coordinated heating system for the plant and the

additive storage facilities, together with heat-retaining paneling, operation in the winter season can proceed without difficulties.

Heating Weighing cell

21

Page 22

A well-planned program

for every purpose:

Components of the

3

Liebherr tower mixer

19

5

6

18

7

15

2

17

16

10

11

14

12

13

1.) Hopper with cover grid for

loading the silos

2.) Bucket elevator, belt conveyor

4

8

9

or S-pattern conveyor

3.) Rotary distributor for aggregate

storage in silo compartments

4.) Multi-compartment aggregate

silo

5.) Level indicator for monitoring

contents of aggregate silo

6.) Aggregate batching devices

7.) Additive multi-component

aggregate weigher

8.) Cement silos with pneumatic

filling system

9.) Cement loosener

10.) Cement screws

11.) Cement weigher

12.) Ring pan mixer

1

7

12

13

Version with 2 ring pan

mixers and twin weigher

Version with 2 ring pan mixers

12

Version with double-shaft mixer

12

13

12

13

20

13

13.) Discharge nozzle with rubber

extension tube for filling truck

mixers or open trucks

7

7

14.) Control room

15.) Air compressor for batching

gates and cement loosener

16.) Continuous level indicator for

monitoring cement silo content

17.) Exhaust air filters for

cement silos

18.) Water weigher

19.) Access stairs to aggregate

distribution platform

20.) Double-shaft mixer

22

Page 23

Modular-element system with

leading-edge technology

How to locate the correct size for your tower mixer

Type Effective

Betomat II

Betomat III

aggregate

volume

(m³)

180

235

290

345

400

455

220

290

360

430

500

570

Height*

H

m

21,0

22,5

24,0

25,5

27,0

28,5

21,0

22,5

24,0

25,5

27,0

28,5

* = Heights are quoted as a guide only

Max.

number of

silo compart-

ments

10

10

10

10

10

10

10

10

10

10

10

10

Type Effective

Betomat IV

Betomat V

aggregate

volume

(m³)

260

345

430

515

600

335

470

605

740

875

1010

Height*

H

m

21,0

23,0

24,0

26,0

27,0

21,0

22,5

24,0

25,5

27,0

28,5

Max.

number of

silo compart-

ments

10

10

10

10

10

12

12

12

12

12

12

Max. theoretical output and

equipment specification

Betomat II Betomat III Betomat IV Betomat V

1 mixer 2 mixers 1 mixer 2 mixers 1 mixer 2 mixers 1 mixer 2 mixers

RIM 1,0 55 / 69 110 / 138 55 / 69 110 / 138 55 / 69 110 / 138 55 / 69 110 / 138

RI M 1,5 75 / 94 150 / 188 75 / 94 150 / 188 75 / 94 150 / 188 75 / 94 150 / 188

RIM 2,0 90 / 112 180 / 224 90 / 112 180 / 224 90 / 112 180 / 224 90 / 112 180 / 224

RIM 2,25 100 / 125 200 / 250 100 / 125 200 / 250 100 / 125 200 / 250 100 / 125 200 / 250

RIM 3,0 120 / 150 — 120 / 150 — 120 / 150 240 / 300 120 / 150 —

DW 2,25 100 / 125 — 100 / 125 — 100 / 125

DW 3,0 120 / 150 — 120 / 150 — 120 / 150

DW 3,5

DW 3,5

DW 4,0

DW 4,0

DW 4,5

DW 4,5

The first value is the set-concrete output (m3/h) with a mixing time of 30 s

The second value is the output in freshly-mixed concrete (m

1) with truck-mixer discharge

2) with open-truck discharge

1)

140 / 175 — 140 / 175 — 140 / 175

2)

170 / 215 — 170 / 215 — 170 / 215

1)

150 / 190 — 150 / 190 — 150 / 190

2)

190 / 240 — 190 / 240 — 190 / 240

1)

160 / 200 — 160 / 200 — 160 / 200

2)

210 / 260 — 210 / 260 — 210 / 260

3

/h) with a mixing time of 30 s and compaction v = 1.25

on request

on request

on request

on request

on request

on request

on request

on request

100 / 125 —

120 / 150 —

140 / 175 —

170 / 215 —

150 / 190 —

190 / 240 —

160 / 200 —

210 / 260 —

ø 6,8 m ø 7,8 m ø 8,8 m ø 10,5 m

Betomat II Betomat III Betomat IV Betomat V

23

Page 24

Other examples of vertical

concrete production plants:

Printed i n Germany by Schirmer BK LMT-8203 049 05-01.13.enGB Subject to modification.

Liebherr-Mischtechnik GmbH

Postfach 145, D-88423 Bad Schussenried

+49 (0)7583 949-0, Fax: +49 (0)7583 949-3 99

www.liebherr.com, E-Mail: info.lmt@liebherr.com

Loading...

Loading...