Page 1

Mobile crane

Product advantages

Max. load capacity: 160 t

Max. height under hook: 95 m

Max. radius: 70 m

LTM 1160-5.1

Page 2

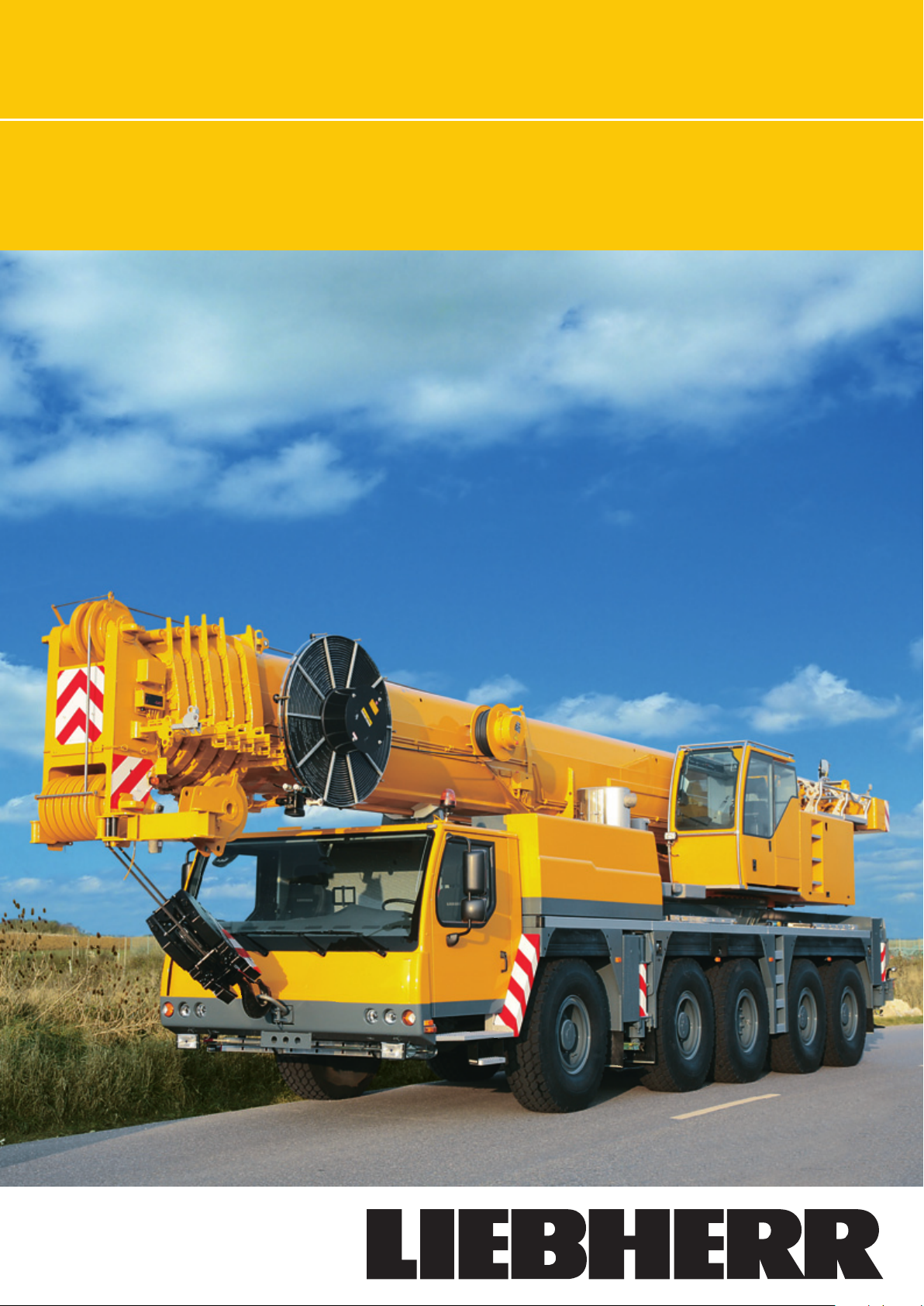

4000

21°

16.00 R 25

2394

15020

12 t 12 t 12 t 12 t 12 t

12346

14740

31364823

26°

Compact, maneuverable

and weight-optimized

• Overall length 15.02 m, chassis length 12.35 m

• Large overhang angle of up to 26°

• Minimum turning-circle radius 10.6 m with all-wheel steering

• Rear ballast radius only 4.22 m

• 60 t gross weight, incl. 6.5 t ballast, 10 x 8 driveline,

16-inch tires, 26 t hook block (axle load 5 x 12 t)

• 3 optional tire sizes

14.00 R 25 (vehicle width 3 m)

16.00 R 25 (vehicle width 3 m)

20.5 R 25 (vehicle width 3.1 m)

R = 10600

R = 11800

R = 12300

R = 4220

R = 5100

7984

5310

7500

5000

3000

600

34964488

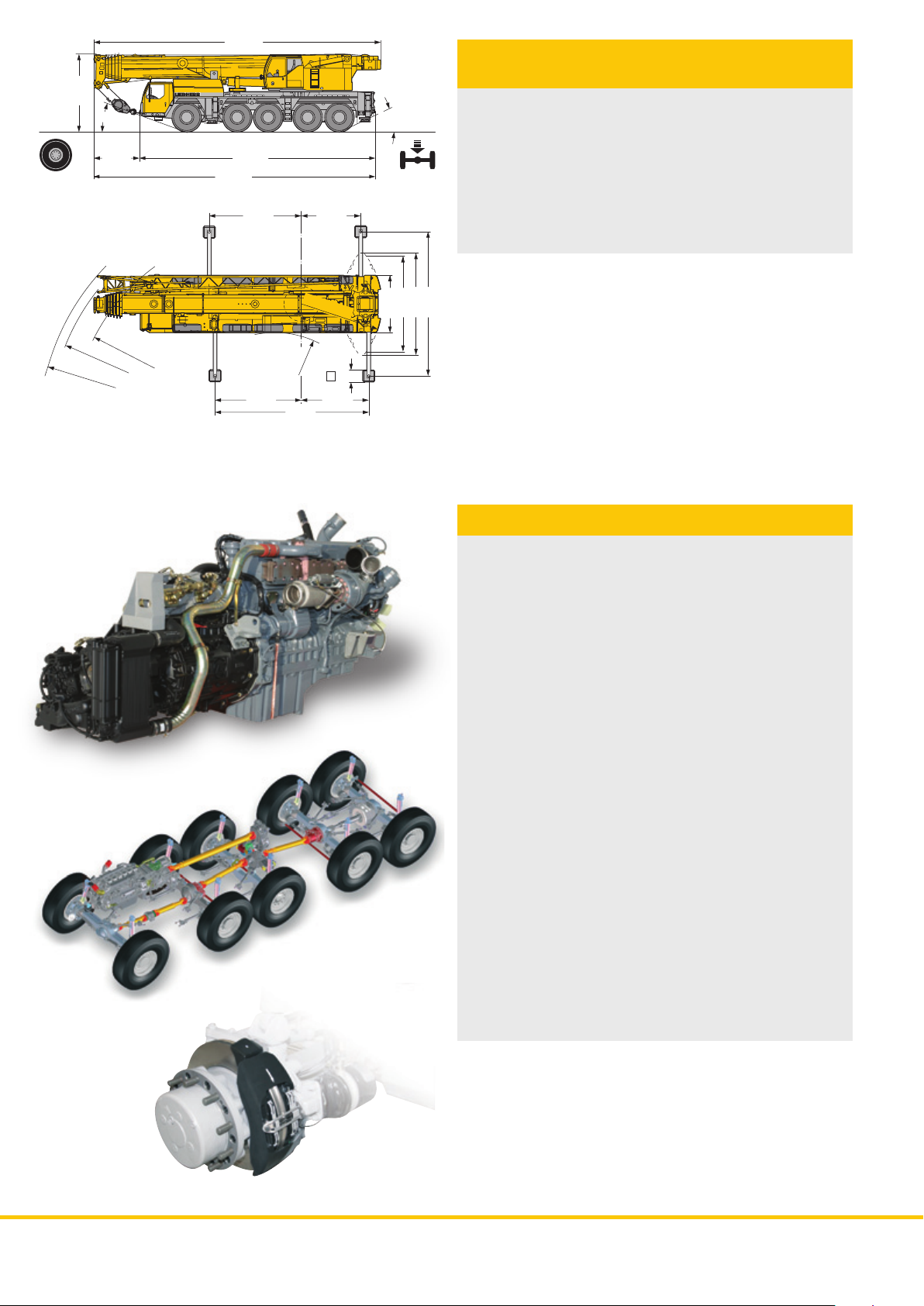

Modern drive concept

• Powerful, 6-cylinder Liebherr Type D846 A7 turbocharged

diesel engine, 370 kW/503 hp, exhaust emissions comply

with 97/68/EC Stage 3 and EPA/CARB Tier 3; robust and

reliable, with modern, electronic engine management

• ZF AS-TRONIC automated manual shift gearbox; ZF Intarder

fitted directly to gearbox; 12 forward and 2 reverse gears,

automated gear shift, high number of gear ratios helps to

reduce fuel consumption

• Robust 2-stage transfer box with lockable differential,

creep speed 0.78 km/h

• Drive 10 x 6: axles 2, 4 and 5 driven

• Drive 10 x 8 (optional): axles 2, 4 and 5 driven,

axle 1 can be engaged for off-road travel

• Robust, low-maintenance weight-optimized axles, special

arrangement of the maintenance-free suspension control

arms for excellent directional and lateral stability, steel and

rubber locating bushings

• Maintenance-free propeller shafts; easy and quick fitting

due to 70° degree cross-splines

• “Niveaumatik” hydropneumatic suspension, programcontrolled for raising crane onto outrigger supports, crane

travel with equipment and on-road crane travel; suspension

travel +150/-150 mm

• Maintenance-free suspension rams free from lateral forces,

piston rods protected against damage by plastic tubes

• Retarders:

Exhaust brake with additional Liebherr brake system (ZBS),

Intarder integrated in gearbox, Telma eddy current brake

(optional)

• Service brake:

All axles fitted with air-operated disc brakes, high braking

performance, extended maintenance intervals, rapid brake

pad renewal

LTM 1160-5.1 LTM 1160-5.1

Page 3

Variable steering concept

with „active rear-wheel

steering“

Axles 3, 4 and 5 incorporated into active rear-wheel steering

system; 5 steering methods can be preselected as fixed

programs (P):

P1: On-road steering

Axles 1 and 2 are steered mechanically from the steering

wheel, with hydraulic power assistance. Axles 3, 4 and 5 are

steered actively by a speed-dependent method according to

the front wheel lock angle. Above 30 km/h, axles 3 and 4 are

returned to the straight-ahead position and fixed. Above

60 km/h, axle 5 is also fixed in the straight-ahead position.

The change in steering lock angle according to road speed

results in precise, stable driving road behavior at higher speeds,

reduced tire abrasion and much-improved maneuverability

P2: All-wheel steering

Axles 3, 4 and 5, depending on the wheel lock angle of axle 1,

are turned by means of the steering wheel so that the smallest

turning-circle radius can be obtained

P3: Crabwise steering

Axles 3, 4 and 5 are turned into the same direction as axles 1

and 2 by means of the steering wheel

P4: Steering without superstructure

projection when turning

Axles 3, 4 and 5 are turned in accordance with the wheel lock

angle at axle 1, so that the rear of the vehicle does not project

when cornering

P5: Independent rear-axle steering

Axles 1 and 2 are turned by the steering wheel, axles 3, 4 and 5

are steered independent of the lock angle at 1 and 2 by

pushbuttons; at the same time the lock angle at axle 3 is

adapted to suit the actual situation

• A failure in the rear-axle steering shuts it down; the rear axles

are set to the straight-ahead position by centering rams

• Two independent hydraulic circuits with wheel-driven

and engine-driven hydraulic pumps for the maximum

level of safety

• Two independent control processors (by way of existing

input/output modules) and diversified sensor system

• The entire know-how for the active rear-wheel steering

comes from Liebherr

310

Page 4

700

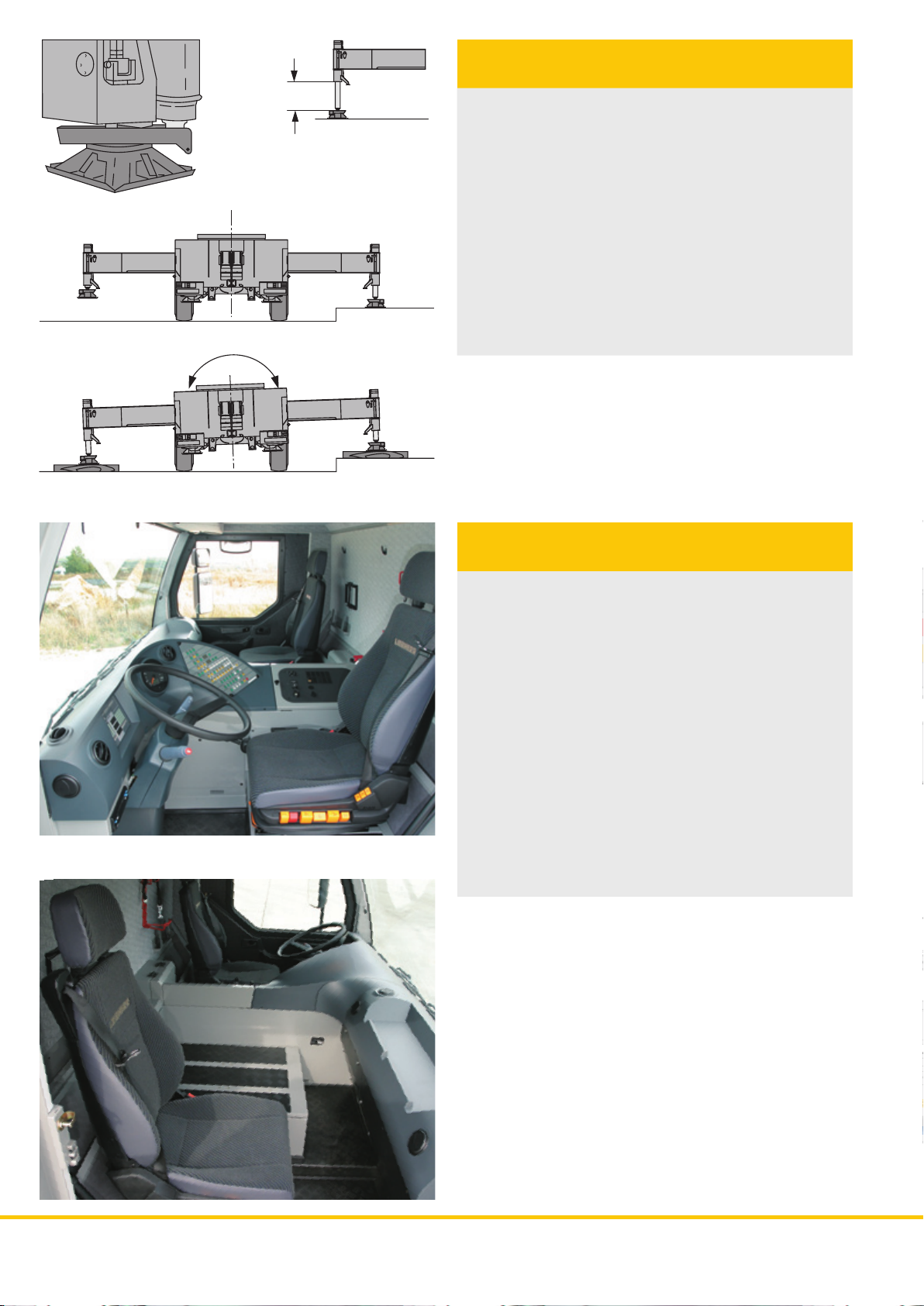

Supporting crane on outriggers –

quick, convenient and safe

• Variable support base width

Outriggers retracted

Support base area 5.0 m x 7.9 m

Support base area 7.5 m x 7.9 m

• Fixed support pads with splash guard

for protection against dirt

• Support jack extension range up to 700 mm

• Self-leveling of the outriggers, fully-automatic leveling of the

crane by pushbutton during the supporting procedure

•2 x 9° lateral inclination of crane chassis and superstructure

• Control panels at either side of the chassis with foil-covered

keyboard and electronic angle indicator, pushbuttons for

ENGINE/START/STOP and speed control are illuminated

and lockable

• Operation of the outrigger system in accordance with the

accident prevention regulations

• Illumination of the support area by 4 built-in lights

Comfortable, highly efficient

operator’s cab

• Modern, comfortable operator’s cab of highly efficient,

convincing design, corrosion-resistant sheet steel

construction, cataphoretic dip-primer coating, resilient rubber

front mountings, hydraulic damping at rear, sound and heat

absorbent interior paneling

• Safety glass all-round, sunproof green-tinted windshield and

side windows for heat absorption, electric window lifters

• Ergonomically correct arrangement of controls and displays

for safe and convenient handling for long periods

• Digital display and key-panel units interconnected with the

functional blocks by data bus technology

• Air-sprung driver’s seat with pneumatic lumbar

support and head restraint

• Steering wheel adjustable for height and angle

• Heated, electrically adjustable outside mirrors

• Seat belts for driver and co-driver

• 3 windshield wipers with automatic wipe/wash system and

intermittent-wipe setting

• Delayed switch-off of interior lighting

• Various storage shelves and compartments

• Preparation for radio

LTM 1160-5.1 LTM 1160-5.1

Page 5

Comfortable, highly efficient

crane cab

• Crane cab made from corrosion-resistant galvanized sheet

steel, powder-coated, with sound and heat absorbent internal

paneling, modern interior design, tinted windows all round,

opening windshield with large wiper and wipe/wash system,

armored-glass skylight with large parallel-action wiper and

wipe/wash system, roller sunblinds on windshield and

skylight, space-saving sliding door

• Green tinted windshield and side windows for heat absorption

• Pneumatically extending step for safe access to chassis

• Crane cab can be tilted to the rear by 20°

to improve view of work area

• 1 work-area light, 70 Watt, at front of the cab

• Sprung, hydraulically damped crane operator’s seat with

pneumatic lumbar support and head restraint

• Operator-friendly controls integrated into armrests, vertically

and horizontally adjustable joystick selector consoles and

armrests, ergonomically adjustable operating consoles

• Ergonomically designed control levers with integrated winch

rotation and slewing gear feedback device

• Modern instrument panel with integral LICCON monitor,

display of all relevant operating data on the LICCON screen

• Preparation for radio

58

Page 6

Crane driveline with

field-proven components

• Crane engine: 4-cylinder Liebherr Type D934S A6

turbocharged diesel engine developing 145 kW/197 hp,

exhaust emissions in accordance with 97/68/EC Stage 3

and EPA/CARB Tier 3, robust and reliable, located opposite

to the crane cab for reduced noise level, electronic engine

management, optimized fuel consumption, stainless steel

exhaust system

• Hydraulic system with 5 axial-piston variable displacement

pumps with servo control and output regulation, electric oil

cooler as standard feature

• Standard high-efficient noise insulation for diesel-hydraulic

crane drive

Winch technology by Liebherr

• Winches of Liebherr’s own make (hoisting gear 1 and 2) with

special rope grooving, built-in planetary gears and springaction multi-disk hold-on brakes

• Axial-piston constant displacement pumps of Liebherr’s

own make, specially designed for crane operation and

subjected successfully to tough endurance tests

• Display of winch rotation on the LICCON screen

• Low-twist hoisting rope

7.25 t

Ballasting in a matter

of minutes

• High number of ballast variants from 4.6 t - 46.5 t

• Ballasting controlled from the crane cab

• Quick ballasting by the “key-hole” method

• Compact ballast weight dimensions,

e.g. only 3 m wide for 32 t of ballast

• Ballast slewing radius only 4.22 m

0.9 t

1.85 t

2.3 t

1.85 t

2.2 t

10.8 t

8.6 t

7.25 t

1.6 t

1.9 t

LTM 1160-5.1 LTM 1160-5.1

Page 7

Lifting loads precisely

and safely

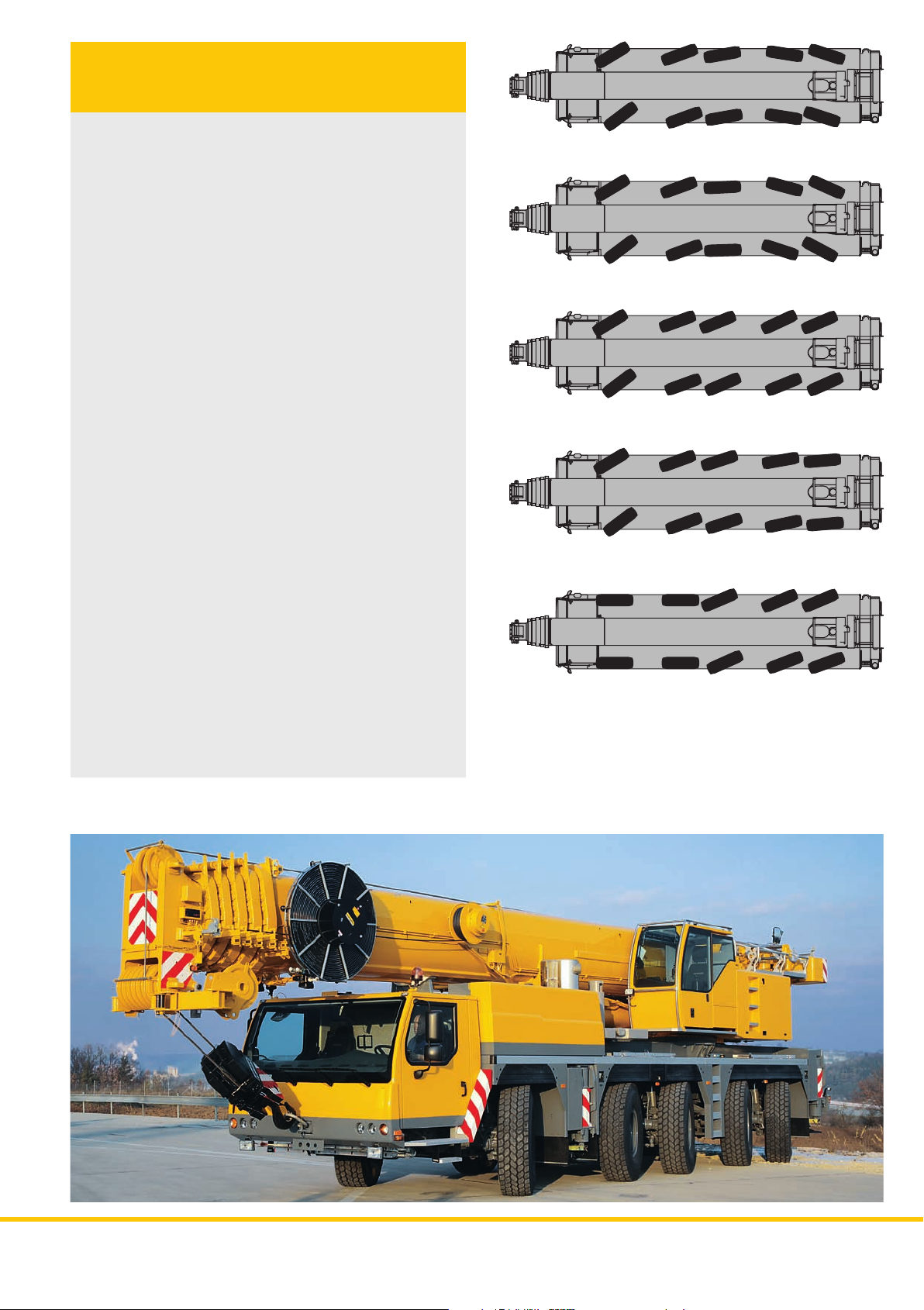

• 6-section, 62 m long telescopic boom and 12.2 m - 22 m

long double folding jib, can be extended to 29 m or 36 m

• One 7 m long intermediate telescopic boom extension

section for operation with folding jib

• Telescopic boom with rounded oval lower chord for high

lateral stability

• Optimal utilization of the telescopic boom thanks to a large

program of extension variants

• Folding jib can be installed at 0°, 22.5° or 45°; hydraulic

erecting aid, hydraulic ram for continuous luffing of folding

jib from 0° - 45° (optional)

• Luffing under load (with load interpolation)

• Erecting jib 5.3 m long, integrated into folding jib

• Easy and quick re-reeving of hoisting rope

with socket connection

• Load hook with socket connection, cylindrical hook pattern,

can be rolled easily for erecting purposes

62 m

58.1 m

60 m

53.6 m

49.1 m

50 m

44.6 m

40 m

oviform boom profile

40 m

30 m

20 m

35.5 m

31 m

26.5 m

22 m

17.5 m

13 m

10 m

76

Page 8

• Electric and electronic components are interconnected by

the latest data bus transmission technology

• Instead of the traditional electric wiring, data transmission

to the individual function blocks is performed digitally along

just a few data cables, thus improving reliability thanks to

a much-reduced number of contacts

• Bus systems of Liebherr’s own manufacture (LSB), specially

suited to mobile crane requirements

• Diesel engine and automatic transmission are controlled by

a CAN data bus. All-electronic driveline management reduces

fuel consumption and exhaust emissions

• The chassis and crane electrical systems and all cockpit

functions and the outrigger and boom sensor systems are

interconnected by 4 Liebherr system bus lines

• Control of the function blocks is by I/O modules programmed

by the Liebherr system bus lines. The control intelligence is

integrated into the central LICCON unit

• Comprehensive diagnostic facilities, quick fault localization,

operating error display

• Programs for functional test of keyboard and display unit

and for testing the engine and transmission management

control units, additional Liebherr brake system, hydraulic

fan, hydraulic suspension and outrigger control panels

• This new data bus technology greatly enhances the

functionality and efficiency of the mobile crane

17

LSB 1

LSB 3

18

16

Legend:

LSB - Liebherr system bus 1

LSB - Liebherr system bus 2

LSB - Liebherr system bus 3

CAN - Busses

SCI - Serial Communication Interface

1 Input/output module for control of the suspension, Liebherr

diesel engine, automatic transmission, control functions,

compressed air monitoring for brake functions

1a Instrument panel key unit in driver’s cab

2 Input/output module for differential locks, display functions

2a Instrument panel key unit in driver’s cab

3 Input/output module for outrigger system - right

3a Control unit for outrigger system - right

4 Input/output module for outrigger system - left

4a Control unit for outrigger system - left

5 Input/output module for engine brake, cruise control,

speed holder, electronic control of diesel engine

(right steering column switch) and automatic transmission

6 Control of Liebherr diesel engine (chassis) and

automatic transmission

7 Tilt angle sensor for automatic leveling

8 Rotation sensor in slipring unit

9 Connection to Liebherr system bus (LSB 1, 2, 3, 4)

10 LICCON central unit

11 LICCON monitor in crane cab

12 Length sensor and cable drum/energy cable for

interlocking gripper/telescopic boom

13 a Inductive sensors (6 x)

13 b Track sensors (2x)

14 Angle sensor on boom pivot section

15 Cable drum for items 16, 17, 18

16 Wind sensor

17 Hoisting limit switch

18 Angle sensor

19 Input/output module for electronic control of diesel engine

(superstructure), air flap, fan clutch, exhaust flap valve

20 Injection pump control – Liebherr diesel engine

(superstructure)

21 Control sensor

22 Pressure sensor (4 x) for output management and LMB

(safe load indicator)

23 Valve for active rear-axle steering

1a

14

LSB 4

20

11

19

9

10

LSB 2

21 21

15

6

22

CAN-Bus

5

3a

1

3

8

13b

CAN-Bus

13a

12

2a

LSB 1

7

2

LSB 1

23

LTM 1160-5.1 LTM 1160-5.1

CAN-Bus

4

4a

98

Page 9

LICCON setting-up and

operating program

• Standard application programs: safe load indicator (LMB),

setting-up program with image, operating program with

image, telescoping program with image, test parameter

program, test system; support load indication and work area

limiting as optional features

• Setting-up program values selected by

convenient interactive functions

• Safe and reliable acknowledgement of the setting-up values

• All essential data shown by graphic symbols

on the operating image

• With integrated wind force measurement

• Reliable shut-down device if admissible load

moments are exceeded

• Load capacity values for any intermediate boom length

• Winch displays for precise lifting/lowering of the load

LICCON-assisted

telescoping system

• Telescoping by single-stage hydraulic ram with hydraulic

actuating pins (patented internal locking system)

• Telescoping controllable by convenient operator

guidance on the monitor screen, precise approach

to pin locking positions

• Loads that can be telescoped are shown on the

LICCON operating display

• Rapid-cycle telescoping system with automatic mode, i.e.

all-automatic telescoping to each desired boom length

• Extremely compact, lightweight telescoping system for

increased load capacities, especially with long booms and

large radii

• Automatic damping at limit positions during telescoping and

retracting, to minimize loads on structural members

LTM 1160-5.1 LTM 1160-5.1

Page 10

The LICCON test system

• This test system assists the servicing personnel to localize

faults in the crane sensory system quickly without the need

for measuring instruments

• Service work starts at the display screen:

troubleshooting takes only a few moments

• Faults are indicated by codes and descriptions

on the display screen

• Convenient interactive functions permit observation of all

inputs and outputs to and from the entire system; they can

be displayed in different forms on the display screen even

during crane operation. The system also visualizes the

position of the system’s individual sensors and actuators

and their functions

The LICCON work area

limiting system

• This reduces the crane operator’s workload, by monitoring

the work area limits, especially in situations where the

handling of loads requires close attention. Work areas can

be restricted to allow for buildings, bridges, roofs, hightension power lines, pipelines or adjacent cranes. The

automatic work area limiting system (optional) can easily be

programmed. Four different limiting functions are practicable:

• Height limit for pulley head

• Radius limit

• Slewing angle limit

• Border limits

The LICCON work planner

• The LICCON work planner consists of a software program

on CD for the planning, simulation and documentation of

crane applications on the display screen (optional)

• The 2D planner program permits buildings to be drawn, text

entered and a true to scale crane model represented, including

all movements within a simulated construction site

• The work planner creates greater clarity when preparing

offers, facilitates the briefing of crane operators and can be

run on a laptop at the construction site

112

Page 11

Electric/electronic PLC crane control

with test system

• Control of winches, slewing gear and luffing and telescoping

movements by the LICCON computer system (PLC control)

• Four working movements can be performed independently

• 5-step preselection of lifting/lowering, luffing and slewing speeds

• Very rapid response rates when crane movements are selected

• Hoisting and slewing gear run in closed circuits. This permits

very sensitive lifting/lowering of loads and slewing movements.

Single-stage

LICCON

monitor

Joystick

selector

Engine

control

telescoping

ram with

hydraulic

interlocking

device

When lowering loads, the energy generated is not converted

into heat but can be re-used for a second movement. This

saves fuel and the oil is exposed to less heat than when

operating in an open circuit

• Functional test of all essential components by means of the

LICCON test system

Luffing ram

Liebherr-

Control block

hoist winch I

Transmitters

Sensors

slewing gear

LICCON-

control

3 variable

displacement pumps

Liebherr

1 double variable

displacement

pump

Diesel engine D934S A6

Optional features make the crane even more versatile

and increase operating convenience and safety

On the chassis:

• Additional heater with engine preheating

• Eddy-current brake

• Support load indicator on the chassis and

in the operator’s cab

• Rope storage box

• Air conditioning

• D12/D19 trailer tow hitch

• Preparation for intercom radio

• Seat heating for driver and co-driver

• Radio with CD player

On the crane superstructure:

• Additional heater with engine preheating

• 2nd hoisting gear

• Air conditioning

• Seat heating

• Work area limiting

• Aircraft warning light

• Xenon work-area light, electrically adjustable,

on boom pivot section

• GSM module for tele-diagnostics

• Radio with CD player

• Emergency actuation

Liebherr-

hoist winch II

Subject to modifications.

Liebherr-Werk Ehingen GmbH

Postfach 1361, 89582 Ehingen, Germany

콯 +49 7391 5 02- 0, Fax +49 73 91 5 02-33 99

www.liebherr.com, E-Mail: info.lwe@liebherr.com

Further optional extras on request.

PN 162.01.E07.2007

Loading...

Loading...