Page 1

Mobile Crane

LT M 112 0 0 - 9

Max. Capacity: 1,200 t

Max. Hoisting height: 188 m

Max. Radius: 136 m

.1

Page 2

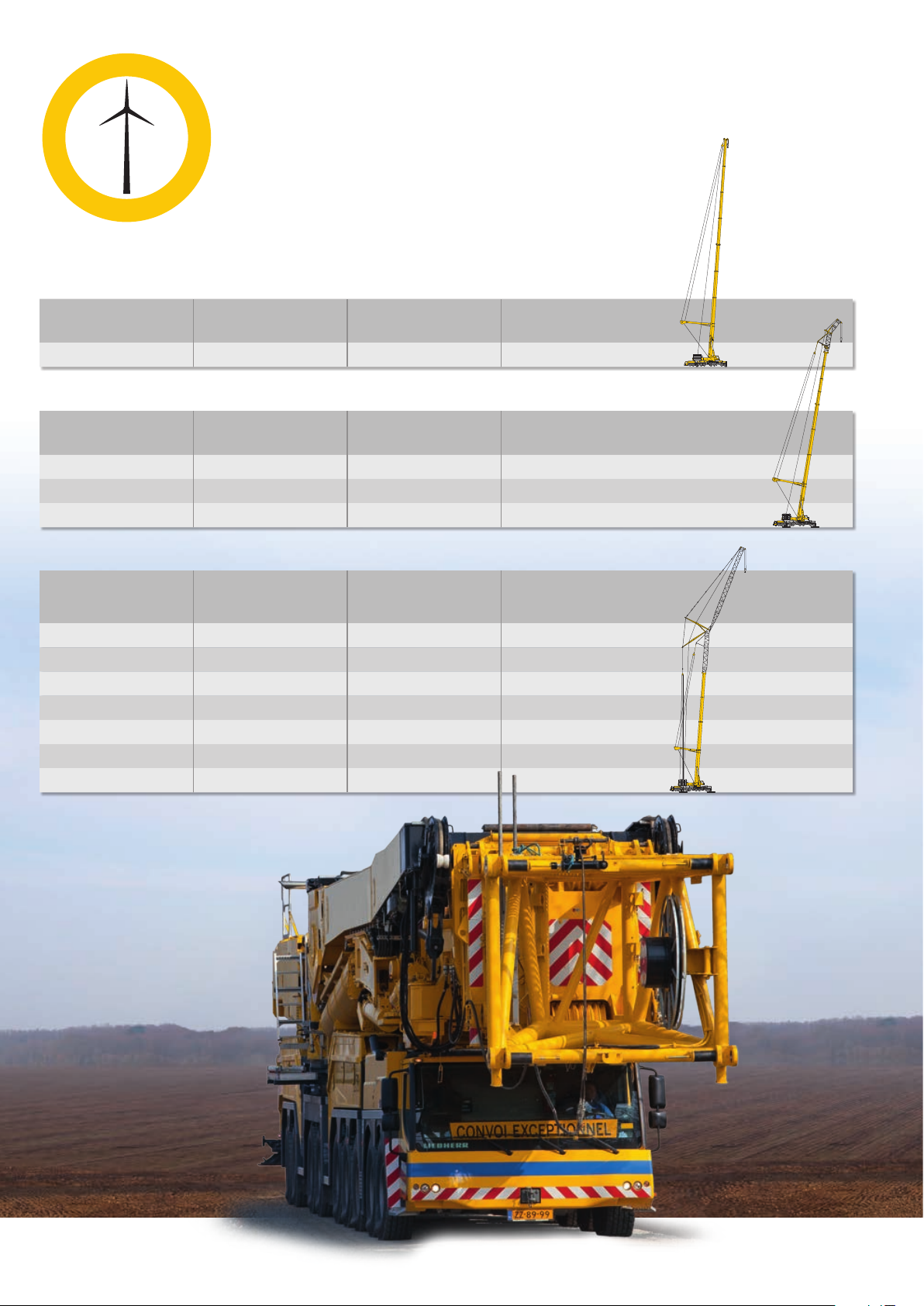

Mobile Crane LTM 11200-9.1

With maximum capacity

universally useable

2

LT M 11 20 0- 9.1

Page 3

The LTM 11200-9.1 with its capacity of 1,200 t is the strongest telescopic mobile crane in the market

and offers the worldwide longest telescopic boom. A remarkable increase of the capacity is realized

with the Y-telescopic boom suspension. Short erection times, an extraordinary mobility as well as a

comprehensive comfort and safety configuration distinguish the mobile crane LTM 11200-9.1 from

Liebherr.

• 100 m long telescopic boom and 22 m telescopic boom extension (10 m + 6 m + 6 m)

• Capacity 65 t at the 100 m long, suspended telescopic boom

• 126 m long luffing fly jib

• 60.5 m long fixed jib, optionally hydraulically adjustable

• Fast and comfortable erection with marginal required space

• Optimal for assemblies in the industry, in the wind power generation field and at

infrastructure projects

• Active, speed depending rear axle steering, all axles steered

• Economical transportation

LT M 11 20 0- 9.1

3

Page 4

Large operation spectrum with high

performance and variable boom systems

Erection of a portal crane

Load 129.5 t each crane at

max. 21 m radius

Cra n e 1:

System T3Y

Telescopic boom 55 m + Y-suspension

Crane 2:

System T7Y

Telescopic boom 53.3 m +

Y-suspension

4

LT M 11 20 0- 9.1

Page 5

Erection of a radio tower

Load 9.5 t to 154 m hoisting height at

31 m radi us

System T3YV2VEN

Telescopic boom 52.2 m + Y-suspension +

adapter 20.2 m + luffing fly jib 90 m

LT M 11 20 0- 9.1

5

Page 6

Erection of an

absorber column

Load 128 t at max. 21 m radius

System T7Y

Telescopic boom 65 m + Y-suspension

6

LT M 11 20 0- 9.1

Page 7

Outstanding capacities

at large radii with luffing fly jib

152 t 104 t 74 t 9,9 t 7,1 t59 t 46,5 t 36,5 t 26,2 t 20,3 t 14,3 t 2,1 t3,4 t

706050403020100 120 130 136 m1101009080

LT M 11 20 0- 9.1

7

Page 8

Optimized for the installation

of wind power generators

100 m-telescopic boom + Y-guying system

Height of hub of wind

power generator

80 m 84 t x 16 m 92 m T7Y

100 m-telescopic boom + Y-guying system + fixed jib

Height of hub of wind

power generator

80 m 94 t x 20 m 89 m T7YVENZF

100 m 76 t x 16 m 107 m T7YVEV2NZF

105 m 65 t x 16 m 114 m T7YVEV3V2NZF

52 m-telescopic boom + Y-guying system + luffing jib

Height of hub of wind

power generator

80 m 141 t x 18 m 90 m T3YVEN

100 m 97 t x 22 m 112 m T3YV2VEN

105 m 83 t x 24 m 117 m T3YV2VEN

120 m 58 t x 32 m 128 m T3Y V2VEN

130 m 38 t x 36 m 138 m T3Y V2VEN

140 m 26.1 t x 44 m 148 m T3YV2VEN

150 m 15.8 t x 50 m 158 m T3YV2VEN

Max. capacity

at radius

Max. capacity

at radius

Max. capacity

at radius

Hook height System

Hook height System

Hook height System

8

LT M 11 20 0- 9.1

Page 9

LT M 11 20 0- 9.1

9

Page 10

Economical transportation

The chassis drives on the road with

slewing platform, luffing cylinder and all

four folding beams.

The chassis weight and the axle loads

can further be reduced by dismantling

of equipment components.

Vehicle without telescopic boom 12 t 12 t 108 t

Vehicle without telescopic boom,

without winches

Vehicle without telescopic boom,

without winches, without swingout beams

Axle 1-2 Axle 3-9 Total weight

< 10 t < 12 t < 100 t

< 9 t < 9 t < 76 t

The boom is transported separately on a low bed trailer. For this different variations are possible.

Variable boom transportation concept (examples)

34 t

Heel section + telescope 1

52 t

52 m telescopic boom

77 t

52 m telescopic boom + Y-suspension

75 t

100 m telescopic boom

10 0 t

100 m telescopic boom + Y-suspension

Stated weights without boom lifting unit

10

LT M 11 20 0- 9.1

Page 11

LT M 11 20 0- 9.1

11

Page 12

Flexible driving

on the job site

The LTM 11200-9.1 can drive on the job site with the

better part of its equipment on board.

• Reduction of mobilisation times

• Driving inside of a width of 3 m

• Safe driving due to a low centre of gravity

• Boom assembly outside of the job site at limited

site space

Simple and speedy boom assembly

12

LT M 11 20 0- 9.1

Page 13

The assembly of the boom on the job site

can optionally be carried out without an auxiliary crane. By means of four special support jacks the boom is lifted so that the low

bed trailer can move off and the chassis of

the LTM 11200-9.1 can be positioned below

the boom to the front or the rear. The boom

can now be mounted to the chassis with a

few manual actions.

LT M 11 20 0- 9.1

13

Page 14

Economical crane

assignment logistic

A multitude of heavy duty crane operations can be performed with a small number of transportation vehicles.

For the erection of a wind power plant with a hub height

of 80 m and a component weight of up to 80 t for example

only four transportation units are necessary:

Crane LTM 11200-9.1 – self propelled

Transport of telescopic boom T7 – 100 m

Transport of the Y-suspension plus 30 t ballast

Transport of 52 t ballast incl. base plate

14

LT M 11 20 0- 9.1

Page 15

65

Y

360°

54

55

57

82 t

EN

35

22,5

34,5

T 100 m

35

21,2

21,7

T 94,2 m

T 88,3 m

5,5

7,3

2,6

3,8

100 m

T 100 m

T 94,2 m

T 88,3 m

T7

84

97

7,6

4,0

86°

0 4 8 12 16 20 24 28 32 36 40 44 48 52 56 60 64 68 72 76 m

S2528

108 m

104

100

96

92

88

84

80

76

72

68

64

60

56

52

48

44

40

36

32

28

24

20

16

12

8

4

0

LT M 11 20 0- 9.1

15

Page 16

Counterweight

The ballast concept of the LTM 11200-9.1 developed by Liebherr offers numerous advantages for

the crane operator.

• Dimensions and weights of the ballast plates are

ideally adapted to the low bed trailers

• Complete ballast assembly without an auxiliary

crane

• High economy due to compatibility of the ballast

weights with those of other large Liebherr cranes

• Comfortable and safe ballasting with the mobile

control and display unit BTT

16

Base plate 22 t

16 identical plates 10 t each 160 t

4 identical plates 5 t each 20 t

Total ballast 202 t

LT M 11 20 0- 9.1

Page 17

The large scale ballast distribution with two

ballast stacks on each side provides by the

low working height for improved safety and

ergonometric working conditions.

Simple pinning of the base plate to the

ballasting device

Self assembly of hoist gear 2

LT M 11 20 0- 9.1

17

Page 18

Chassis and drive technology

Hydro pneumatic axle suspension

„Niveaumatik“

• Maintenance-free suspension cylinders

• Large dimensions to cope with high axle loads

• Spring travel +175/-125 mm

• High side stability at cornering

• Choice of the driving conditions by fixed programmes

Air operated disk brakes

• Higher braking power, better brake control

• Improved track stability

• No brake fading at higher operation temperatures

• Higher service life

• Shorter working times for changing of the brake pads

• Brake pads with wear indication

Intarder and Telma-Eddy current

brake as standard

• No wear, low maintenance system

• Increased safety due to fast activation in milliseconds

• Reduction of operation costs

• High comfort due to braking absolutely without jolts

• Environmentally friendly brake system, no emission

and respirable dust

Chassis engine

• Powerful 8-cylinder turbo diesel engine with

500 kW/680 HP, max. torque 3,000 Nm

• Automated 12-speed-shift system ZF-TC-TRONIC with

torque converter and intarder directly at the gearbox

offers high efficiency and best comfort

• Axle 1, 2, 4 and 5 are driven axles

Superstructure engine

• 6-cylinder Liebherr turbo diesel engine,

270 kW/367 HP, max. torque 1,720 Nm

• Optimized fuel consumption due to electronic engine

management

18

LT M 11 20 0- 9.1

Page 19

Variable steering concept

Active rear axle steering

• Electro hydraulic steering of the rear axles depending

on the speed and the steering angle of the front axle

• Distinct reduction of the tyre wear

• Improvement of the manoeuvrability

• Stabile driving performance

• All 9 axles steerable, no lifting of the middle axles

during crab steering

High safety standards

• Centralizing cylinders for automatic straightening of the rear

axles in case of failure

• Two independent hydraulic circuits with wheel driven and motor

driven hydraulic pumps

• Two independent steering computers

5 steering programmes

• Programme selection by simple push button

• Clear arrangement of the control elements and displays

• Programmes changeable during driving

• Crab steering controlled comfortably by the steering wheel

P1 Road steering

P2 All-wheel steering

P3 Crab steering

P4 Reduced swing out

P5 Independent rear axle steering

LT M 11 20 0- 9.1

19

Page 20

Comfort and functionality

The modern driving cab as well as the movable crane cab offer a comfortable and functional working place. The control elements and displays are arranged according to ergonometric factors. Thus a safe and wear free working is assured.

The driver’s cab

• Corrosion resistant

• All around safety glazing

• Tinted windows

• Heatable and electrically adjustable

outside mirrors

• Air cushioned driver’s seat with lumbar

support

• Engine independent additional heating,

air condition

The crane cab

• Optimized heating and ventilation system,

automatic temperature control, engine

independent additional heating, air

condition

• Extended field of view due to large

screens

• Crane driver seat with lumbar support,

multiply adjustable

• 20° tiltable to the rear

• Can hydraulically be lowered for a

comfortable access

20

LT M 11 20 0- 9.1

Page 21

Crane supporting –

fast, comfortable and safe

• BTT – Bluetooth Terminal, mobile control and

display device

• Electronic inclination display

• Fully automatic leveling by push button

• Display of supporting forces

• Engine start/stop and speed regulation

• Lighting of the support area with 4 integrated

floodlights

• Stroke of supporting cylinders 750 mm

• Folding beams slewable, 2-fold telescopable

Safe working with

well-thought-out solutions

The supporting, the boom and counterweight assembly

as well as the attachment of additional equipment are designed for speed, safety and comfort. For the safety of the

operating personnel ascents, holding grips and railings

are furnished.

For the observation of the winches and the Y-suspension

in operation mode cameras are installed, which transfer

their pictures to the crane cab. Likewise a back-up camera

system for a safe and comfortable reversing is in place.

LT M 11 20 0- 9.1

21

Page 22

Intelligent

crane control

For functional and safe crane

operation, the LICCON computer

system

The soft- and hardware of the mobile crane control is developed by Liebherr in-house. The centre is the LICCON

computer system (Liebherr Computed Control).

• Integrated LML-load moment limiter

• Key components are in-house manufactured by

Liebherr

• Guaranteed availability of spare parts

• Worldwide proven under the most different climate

conditions

• Operator friendly

The data bus technology

Liebherr mobile cranes are completely interlaced by the

data bus system. All important electric and electronic

components are equipped with own micro processors

and communicate with each other by only limited data

cables. For the special demands of the mobile crane

Liebherr has developed own data bus systems (LSB –

Liebherr-System-Bus). The data bus technology improves

the reliability, the comfort and the safety for road driving

and crane operation:

• Higher reliability due to remarkable less electric cables

and contacts

• Continuous self testing of the „intelligent sensors“

• Comprehensive diagnosis possibilities, fast fault

finding

22

LT M 11 20 0- 9.1

Page 23

BTT-Bluetooth Terminal

For the remote control of crane assembly functions like e.g.

supporting, boom assembly and the ballasting

• Free view and proximity to the assembly work

• Higher comfort and economy

The LICCON work planner

• Computer programme for planning, simulation and

documentation of crane operations at the PC

• Display of all load charts belonging to a specific crane

• Automatic search for the suitable crane by input of the load case

parameters load, radius and hoisting height

• Simulation of crane operations with drawing functions and

display of support forces

LT M 11 20 0- 9.1

23

Page 24

LT M 112 0 0 - 9.1

PN 178 .0 0. E0 2. 2014

Liebherr-Werk Ehingen GmbH

Postfach 1361, 89582 Ehingen, Germany

+49 7391 502-0, Fax +49 7391 502-3399

www.liebherr.com, E-Mail: info.lwe@liebherr.com

www.facebook.com / LiebherrConstruction

The pictures contain als o accessories and speci al equipment not included in the stand ard scop e of delivery. Subjec t to modific ation

Loading...

Loading...