Page 1

Crawler Loaders

LR 624 LR 634

Product Information

Refuse Loading and

Landfi ll Operation

Page 2

LR 624 Litronic LR 634 Litronic

2

Page 3

Liebherr offers a wide range of additional functions and

equipment for generation IV – crawler loaders.

Particularly at waste dumps and waste transfer stations,

the crawler loader becomes indispensable due to its universal operation possibilities. The crawler loader can be

used to shove and condense garbage, and also to load,

sort, break, and reduce material into smaller pieces. In

addition, the crawler loader can be used for many earthmoving purposes at landfi lls, such as refi lling, grading,

carrying material off, and building dams. Even trucks that

get stuck can easily be towed out by a crawler loader.

The Liebherr crawler loader can be individually confi gured with many additional options according to the

purpose of its use, which enables us to provide each

customer with the ideal machine.

The specifi c components were developed especially for

landfi ll usage and guarantee a high life expectancy of the

base machine even under diffi cult circumstances, such

as aggressive material or heavy pollution. The generation

IV- Liebherr crawler dozers guarantee maximum quality

since they combine the functions of power, reliability,

effi ciency and comfort all in one machine.

LR 624 Litronic LR 634 Litronic

3

Page 4

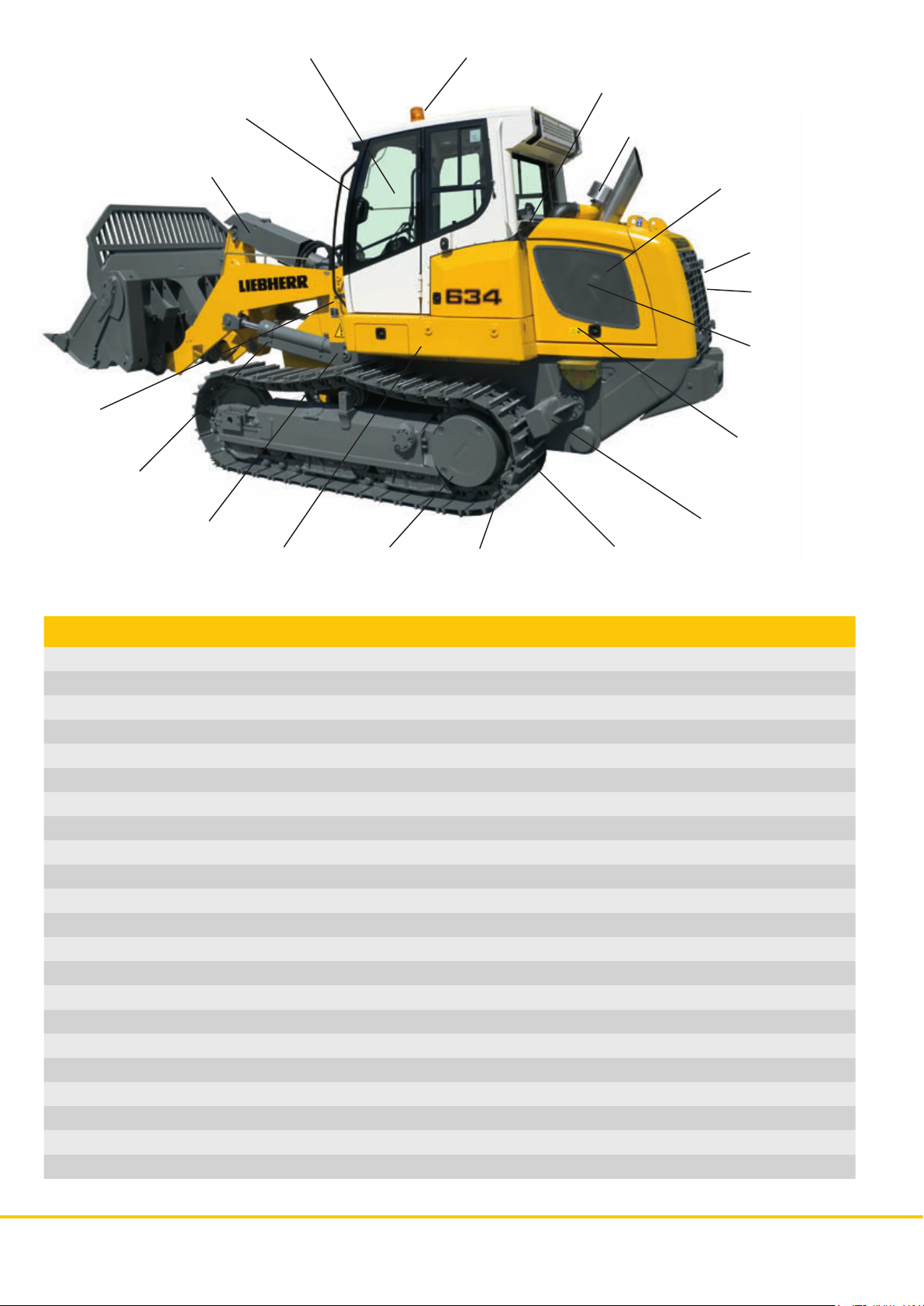

Hydraulic oil indicator Rotating beacon

Protective grille

Sealed ventilation slots

in operator’s cab

Air pre-cleaner engine

Tilt cylinder guard

Filler guard

Lifting cylinder guard

Lift cylinder covers

Tank guard

Protection rings

for fi nal drives

Sprocket segments

with recesses

Fine perforated

plates

Radiator

guard

Reversible fan

Exhaust manifold

isolation

External air

supply alternator

Rear striker bar

Track shoes with

trapezoidal holes

Landfi ll equipment LR 624/LR 634 Standard Recommandation Option

Lift cylinder covers •

Sealed ventilation slots in operator’s cab •

Rear striker bar •

Tank guard •

Track shoes with trapezoidal holes •

External air supply alternator •

Fine perforated plates •

Exhaust manifold isolation •

Radiator guard •

Air pre-cleaner engine •

Reversible fan •

Rear view monitoring camera •

Rotating beacon •

Protection rings for fi nal drives •

Filler guard •

Lifting cylinder guard •

Tilt cylinder guard •

Protective ventilation system •

Protective grille •

Hydraulic oil indicator •

Sprocket segments with recesses •

Central lubrication system •

Subject to technical modifi cations

LR 624 Litronic LR 634 Litronic

4

Page 5

Landfi ll equipment volume

Sealed ventilation slots

in operator’s cab

The front, rear, left and right ventilation slots of the cab are fi tted with

seals to ensure no dirt gets into the

recesses, thus reducing the number

of times cleaning is required.

Lift cylinder covers

The lift cylinders are enclosed

by covers to protect from dirt

and contamination.

Exhaust manifold isolation

The exhaust system is shrouded to

prevent the ignition of dust or waste

particles around the engine, as well

as fl ying sparks.

External air supply alternator

The alternator is provided with pure

cooling air by a hose to guarantee

best cooling results.

LR 624 Litronic LR 634 Litronic

5

Page 6

Landfi ll equipment volume

Protection rings for fi nal drives

The protection rings guarantee

additional protection of the fi nal

drives using a twin lifetime seal

and electronic density control

Radiator guard

A sturdy lateral swivel radiator guard with 45°angled ribs

and a standard skirting protection ensure ideal protection for the rear side and the radiator.

LR 624 Litronic LR 634 Litronic

6

Filler guard

A solid guard reduces the risk of damaging the

diesel fi ller neck. It can be fi tted in combination

with a tank guard.

Page 7

Landfi ll equipment volume

Air pre-cleaner engine

The centrifugal force of the precleaner removes dust particles

before they reach the fi lter. Especially in dust-intensive use,

e.g. at landfi lls, the pre-cleaner

ensures pure air is drawn in. The

system guarantees a longer life

of the fi lter cartridge, reduces

wear and increases the engine’s

life expectancy.

Reversible fan

The reversible fan is benefi cial

in dirt-intense usage due to its

self-cleansing abilities. By reversing the air stream the fan blows

dirt particles off, which increases

the cooling power and reduces

cleaning intervals.

Fine perforated plates

The fi ne perforated plates surrounding the engine prevent intrusion of

dirt particles. Sucked-in material is

blown off by the reversible fan.

Hydraulic oil indicator

The indicator allows monitoring

of the hydraulic oil to prevent

overheating.

LR 624 Litronic LR 634 Litronic

7

Page 8

Front attachments

Strong steel cutter and wear plates provide the necessary longer life guarantee, since they need to resist extremely

corrosive and aggressive material at landfi lls. No matter if used for loading, grading or pushing, all the bucket

versions provide excellent fi lling and penetration attributes.

Standard bucket

The standard bucket is the

most frequently used front

end attachment for crawler

loaders. The shape and

capacity of the bucket has

been designed in a way that

makes it usable for any kind

of material. The standard

bucket is available with an

optional trash rack, which

increases the loading capacity.

Multi purpose bucket

The multi purpose bucket

is a high-performance

multifunctional tool. It can

be used for loading, shoving, grabbing, as well as

grading. The bucket allows

bulky material to be easily

picked up and transported

securely. An optional trash

rack and tilt cylinder protection guard are also available.

Waste handling bucket

The waste handling bucket offers a higher fi lling capacity

and is therefore best suited for material of low weight or

low density. Depending on its specifi c use it is available

with or without teeth.

LR 624 Litronic LR 634 Litronic

8

Page 9

Front attachments

Bolt-on adapters and

teeth segments

create a smooth surface

and increase the bucket

capacity.

Bolt-on adapters

and teeth

provide excellent ground

penetration.

Flush mounted weld-on

adapters and teeth

merge to an even surface

with the main bucket and

provide an excellent fi nish

when levelling.

Bolt-on cutting edges

don’t have as much penetration power, but are

suitable for stockpiling

and clearing tasks.

Bucket options Standard 4in1 Waste handling

bucket bucket bucket

Trash rack • • Standard

Bolt-on adapters and teeth • • •

Bolt-on adapters and teeth segments • •

Flush mounted weld-on adapters and teeth • •

Bolt-on cutting edges • • •

• Optional

Rear attachments

The radial 3-shank ripper provides excellent penetration

and ripping behaviour. At landfi lls, it is mainly used for

loosening the overburden before it is removed to make

room for more waste.

LR 624 Litronic LR 634 Litronic

9

Page 10

Landfi ll equipment options

Tank guard

A 10mm thick protection surrounds

the hydraulic tank and tread-plate

to avoid damage from outside. The

smooth surface prevents objects

from getting entangled.

Track shoes with trapezoidal holes

The trapezoidal holes provide better dispersal of material adhering to

bushings and track shoes.

Rear striker bar

Bars at the rear side optimize the

track’s self-cleaning abilities. In addition, they prevent material from

getting tangled in the chains and

being dragged over the track.

Lifting cylinder guard

The hydraulic pipes of both lifting

cylinders are protected by robust

covers.

Sprocket segments

with recesses

The segment recesses improve

the bushings’ running abilities, as

material on the wearing surface is

automatically pressed through the

lateral openings.

Tilt cylinder guard

The tilt cylinder is protected by a

robust cover that is attached to the

cylinder’s piston.

Protective grille

The windshield, made of safety

glass, is provided with extra protection from falling objects by a

strong metal grille.

LR 624 Litronic LR 634 Litronic

10

Rear view monitoring camera

A display inside the cabin shows

a picture of the area behind the

machine, thus providing the driver

with a detailed rear view and improving comfort.

Page 11

Technical data

Standard bucket

Version with

Nominal rated bucket capacity according to ISO 7546

Nominal rated bucket capacity according to SAE J732

Nominal rated bucket capacity according

to ISO 7546 with trash rack

Nominal rated bucket capacity according

to SAE J732 with trash rack

Breakout force according to ISO 8313

Static tipping load according to ISO 8313

Bucket width, overall

Digging depth, max

Bucket weight

Operating weight ¹

Ground pressure ¹

cu.in

cu.in

cu.in

cu.in

kg/cm²

bolt-on adapters,

segments and teeth

m

m

m

m

kN

kg

mm

ft-in

mm

kg

kg

PSI

3

3

3

3

lb

lb

in

lb

lb

1,8 / 2,4

2.35 / 3.14

1,8 / 2,5

2.35 / 3.27

1,9 / 2,5

2.49 / 3.27

2,0 / 2,6

2.62 / 3.40

127 / 164

28,541 / 36,856

11.765 / 14.148

25,937 / 31,191

2.444 / 2.529

8’0’’ / 8’4’’

136 / 150

5.35’’ / 5.91’’

1.238/ 1.707

2,729 / 3,763

17.006 / 20.914

37,492 / 46,107

0,67 / 0,73

9.53 / 10.38

4 in 1 bucket

Version with

Nominal rated bucket capacity according to ISO 7546

Nominal rated bucket capacity according to SAE J732

Nominal rated bucket capacity according to ISO 7546

with trash rack

Nominal rated bucket capacity according to SAE J732

with trash rack

Breakout force according to ISO 8313

Static tipping load according to ISO 8313

Bucket width, overall

Digging depth, max

Bucket weight

Operating weight ¹

Ground pressure ¹

¹ Machine with ROPS/FOPS cab, coolant and lubricants, full fuel tank, operator (75kg/165lb), bucket without trash rack), rear bumper and track shoes (LR 624 508mm / 20”, LR 634 560mm / 22”)

² If the ripper is mounted, no rear bumper will be fi tted to the machine (weight rear bumper)

cu.in

cu.in

cu.in

cu.in

kg/cm²

bolt-on adapters,

segments and teeth

m

m

m

m

kN

kg

mm

ft-in

mm

kg

kg

PSI

3

3

3

3

lb

lb

in

lb

lb

1,6 / 2,0

2.09 / 2.62

1,6 / 2,1

2.09 / 2.75

1,7 / 2,1

2.22 / 2.75

1,8 / 2,2

2.35 / 2.88

113 / 156

25,394 / 35,058

10.376 / 12.839

22,875 / 28,305

2.448 / 2.529

8’0” / 8’4”

196 / 220

7.72” / 8.66”

1.782 / 2.247

3,929 / 4,954

17.614 / 21.531

38,832 / 47,468

0,70 / 0,75

9.95 / 10.67

LR 624 / LR 634

fl ush mounted weld-on

adapters and teeth

1,7 / 2,3

2.22 / 3.01

1,7 / 2,3

2.22 / 3.01

1,9 / 2,5

2.49 / 3.27

2,0 / 2,6

2.62 / 3.40

138 / 180

31,013 / 40,451

12.011 / 14.514

26,480 / 31,998

2.450 / 2.500

8’0’’ / 8’2’’

111 / 120

4.37’’ / 4.72’’

1.126 / 1.539

2,482 / 3,393

16.849 / 20.746

37,146 / 45,737

0,67 / 0,72

9.53 / 10.24

LR 624 / LR 634

fl ush mounted weld-on

adapters and teeth

1,5 / 1,9

1.96 / 2.49

1,5 / 1,9

1.96 / 2.49

1,7 / 2,1

2.22 / 2.75

1,8 / 2,2

2.35 / 2.88

123 / 169

27,642 / 37,979

10.610 / 13.191

23,391 / 29,081

2.450 / 2.500

8’0” / 8’2”

161 / 190

6.34” / 7.48”

1.671 / 2.080

3,684 / 4,586

17.502 / 21.363

38,585 / 47,097

0,69 / 0,74

9.81 / 10.52

bolt-on

cutting edge

1,8 / 2,4

2.35 / 3.14

1,8 / 2,5

2.35 / 3.27

1,9 / 2,5

2.49 / 3.27

2,0 / 2,6

2.62 / 3.40

127 / 164

28,541 / 36,856

11.863 / 14.268

26,153 / 31,456

2.420 / 2.490

7’11’’ / 8’2’’

136 / 150

5.35’’ / 5.91’’

1.140 / 1.587

2,513 / 3,499

16.908 / 20.794

37,276 / 45,843

0,67 / 0,72

9.53 / 10.24

bolt-on

cutting edge

1,6 / 2,0

2.09 / 2.62

1,6 / 2,1

2.09 / 2.75

1,7 / 2,1

2.22 / 2.75

1,8 / 2,2

2.35 / 2.88

113 / 155

25,394 / 34,833

10.473 / 12.959

23,089 / 28,570

2.420 / 2.490

7’11” / 8’2”

186 / 220

7.32” / 8.66”

1.685 / 2.127

3,715 / 4,689

17.517 / 21.411

38,618 / 47,203

0,69 / 0,75

9.81 / 10.67

LR 624 Litronic LR 634 Litronic

11

Page 12

Technical data

Waste handling bucket LR 624 / LR 634

Version with Trash rack without teeth

Nominal rated bucket capacity according to ISO 7546

for earth

Nominal rated bucket capacity according to SAE J732

for earth

Nominal rated bucket capacity according to ISO 7546

for waste

Nominal rated bucket capacity according to SAE J732

for waste

Breakout force ISO 8313

Static tipping load according ISO 8313

Bucket width, overall

Digging depth, max

Bucket weight

Operating weight ¹

Ground pressure ¹

m

cu.in

m

cu.in

m

cu.in

m

cu.in

kN

kg

mm

ft-in

mm

kg

kg

kg/cm²

PSI

3

3

3

3

lb

lb

in

lb

lb

2,1 / 2,8

2.75 / 3.66

2,1 / 2,8

2.75 / 3.66

3,4 / 4,6

4.45 / 6.02

3,6 / 4,6

4.71 / 6.02

99 / 143

22,248 / 32,136

11.395 / 13.830

25,122 / 30,490

2.736 / 3.000

9’00’’ / 9’10’’

216 / 240

8.5’’ / 9.45’’

1.327 / 1.681

2,926 / 3,706

17.095 / 20.868

37,688 / 46,006

0,68 / 0,73

9.67 / 10.38

3-shank ripper LR 624 / LR 634

radial

Beam width mm 2.096 / 2.100

ft-in 6’11’’ / 6’11’’

Ripping width mm 1.800 / 1.860

ft-in 5’11’’ / 6’1’’

Penetration, max. mm 354 / 390

in 13.94’’ / 15.35’’

Ground clearance, max. below teeth mm 721 / 826

ft-in 2’4’’ / 2’9’’

Additional length, transport position mm 638 / 740

ft-in 2’1’’ / 2’5’’

Ripper weight² kg 935 / 1.163

lb 2,061 / 2,564

Change in operating weight kg 876 / 705

lb 1,931 / 1,554

Change in ground pressure kg/cm2 0,03 / 0,02

PSI 0.43 / 0.28

Change in static tipping load kg 1.460 / 924

lb 3,219 / 2,037

¹ Machine with ROPS/FOPS cab, coolant and lubricants, full fuel tank, operator (75kg/165lb), bucket without trash rack), rear bumper and track shoes (LR 624 508mm / 20”, LR 634 560mm / 22”)

² If the ripper is mounted, no rear bumper will be fi tted to the machine (weight rear bumper)

Printed in Germany by Typodruck BK-RP LWT/VM 10450831-2-09.08

Liebherr-Werk Telfs GmbH

Hans Liebherrstraße 35, A-6410 Telfs

콯 +43 50809 6-100, Fax +43 50809 6-7772

www.liebherr.com, E-Mail: lwt.marketing@liebherr.com

Subject to technical modifi cations.

Loading...

Loading...