Page 1

Crawler Loader LR 614

Engine output: 72 kW / 98 HP

Operating weight: 11,100 – 12,004 kg

24,471 – 26,464 lb

Bucket capacity: 1.20 – 1.25 m³

1.57 – 1.63 yd³

litronic

`

Page 2

2 LR 614 Litronic

Basic machine

Engine

John Deere 4045HF289

Diesel engine emission regulations according to 97/68/EC,

2004/26/EC Stage IIIA and EPA/CARB Tier 3

Net power (ISO 9249) 72 kW / 98 HP

Net power (SAE J1349) 72 kW / 97 HP

Engine rating 2,200 rpm

Displacement 4,5 l / 275 in³

Bore/stroke 106 mm / 127 mm (4.17 in / 5.00 in)

Design low emission water-cooled 4 cylinders in-

line, 2 valve cylinder head, turbo charger, air-

to-air after cooler, electronic engine control,

steel pistons, 2 countershafts, cold starting

aid automatically with heat flange

Fuel system Common Rail direct injection system

Lubrication pressurized lube system, engine lubrication

guaranteed for intermittent inclination up to

35°, 30° in duration

Operating voltage 24 V

Alternator 55 A, Heavy-Duty version

Starter 7.0 kW

Battery 2 x 100 Ah / 12 V

Air cleaner dry-type air cleaner with air-restriction indica-

tor, main and safety elements, air intake with

rain cap

Cooling system combination cooler with three cooling units

for cooling water, intake charge air and

hydraulic oil

Cooling fan hydrostatically driven, thermostatically

controlled

Travel drive / control

Drive system closed-loop infinitely variable hydrostatic

travel drive powered by two axial piston

variable displacement pumps and two axial

piston 2 positions-displacement motors in

swash-plate design, each track is driven

indepedently from each other

Travel speed infinitely variable electronic-controlled travel

speed

Speed range 1: 0–6.1 km/h/0–3.6 mph (work)

Speed range 2: 0–9.5 km/h/0–5.9 mph (travel)

Litronic-System electronic engine speed sensing control

(load-sensing feature) automatically adjusts

travel speed and drawbar pull to match

changing load conditions

Steering hydrostatic, unlimited maneuverability for full

power turns and counterrotation

Service brake hydrostatic, dynamic braking effect from

travel drive system

Parking/ multi-disc brake, wear-free, automatically

emergency brake applied with neutral joystick position

Cooling system hydraulic oil single unit built in combination

cooler

Filter system micro cartridge filters in cooling circuit

Final drive 3 phase heavy duty spur gear

Control single-lever travel control for all travel and

steering motions, as well as for counterrotation

Track frame

Chains sealed and lubricated, track chain tension via

grease tensioner and hydraulic cylinder

Chain links 38 each side

Sprocket screwed drive wheel

Track rollers 6 each side

Carrier roller 1 each side

Track shoes standard 457 mm / 18”, double grouser

Track shoes optional 508 mm / 20”, double grouser

Grouser height 42.5 mm / 1.67 in

Mount inelastic track roller frame

Operator’s cab

Heater and pressurized, with fresh air intake and recircuair conditioner lation air filter, 8 louvered vents for all temper-

ature controlled cab’s areas

ROPS/FOPS cab integral Rollover Protective Structure accord-

ing to EN ISO 3471 and Falling Objects Pro-

tective Structure according to EN ISO 3449

Operator’s seat adjustable, suspended seat adjustable to

operator’s weight, fabric seat cover

Monitoring System combination of analog and digital instrument

panel: LC-Display with scroll key for fuel con-

sumption, battery voltage, service codes; auto-

matic monitoring from operating pressures,

temperatures and fill levels; hour meter gauge

Tilting system

40° tiltable to the rear with hydraulic hand pump

Hydraulic equipment

Hydraulic system open-center load sensing

Pump type gear type pump

Pump flow max. 115 l/min / 30.4 US gpm

Pressure limitation 230 bar / 3,335 psi

Filter system return filter

Control single-lever implement control for all bucket

functions, with magnetic detent functions for

float position as well as for automatic bucket

positioner

Loader cycle times

Lifting 6.4 s

Bucket dumping 1.9 s

Lowering

1

3.1 s

Total cycle time² 8.5 s

1

Float position and empty bucket, 2Lifting and dumping together

Noise emission

Operator sound exposure LpA= 80 dB(A)

(ISO 6396) (emission at the operator’s position)

Exterior sound pressure L

wA

= 107 dB(A)

(2000/14/EC) (emission in the environment)

Page 3

LR 614 Litronic 3

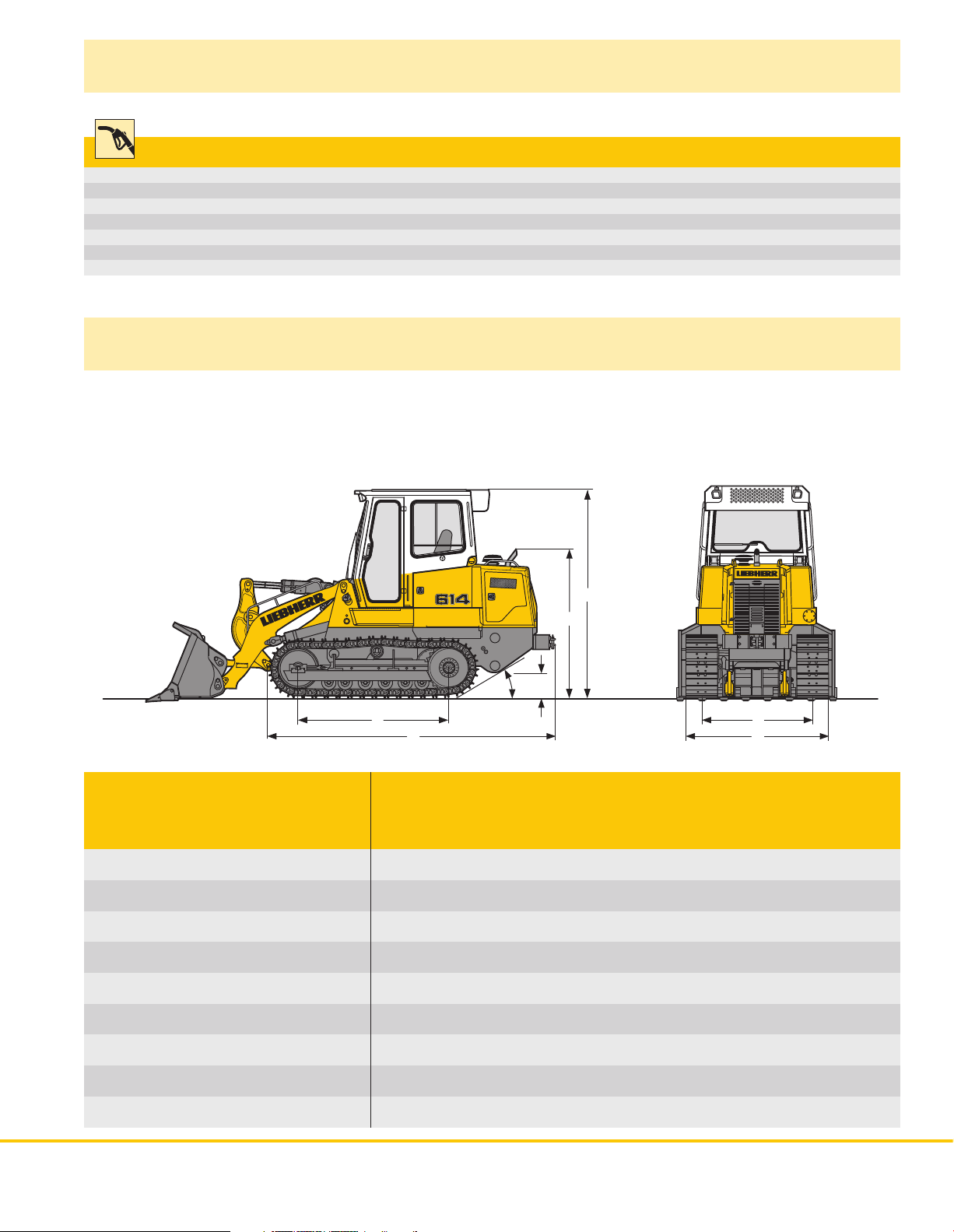

Dimensions

Dimensions LR 614

A Height over cab mm 2,998

ft-in 9’10”

B Height over exhaust pipe mm 2,276

ft-in 7’6”

C Length to front of track mm 3,859

ft-in 12’8”

D Distance idler/sprocket centre mm 2,174

ft-in 7’2”

E Ground clearance mm 408

ft-in 1’4”

F Track gauge mm 1,600

ft-in 5’3”

G Machine width, with track shoes mm 2,057

457 mm / 18” ft-in 6’9”

Machine width, with track shoes mm 2,108

508 mm / 20” ft-in 6’11”

H Approach angle 30°

D

C

E

B

A

H

F

G

Basic machine

Refill capacities

Fuel tank 210 l 55.4 US gal

Cooling system 24 l 6.3 US gal

Engine oil (with filter) 12 l 3.2 US gal

Splitter box 2 l 0.5 US gal

Hydraulic tank 102 l 26.9 US gal

Hydraulic tank + hydraulik system 163 l 43.0 US gal

Final drive, each 8,75 l 2.3 US gal

Page 4

4 LR 614 Litronic

Front attachment

Standard bucket LR 614

Version with bolt-on adapters bolt-on adapters,

and teeth segments and teeth

Nominal rated bucket capacity m³ 1.20 1.25

according to ISO 7546 yd³ 1.57 1.63

Nominal rated bucket capacity m³ 1.2 1.3

according to SAE J732 yd³ 1.57 1.7

Breakout force according to SAE J732 kN 100 90

lb 22,473 20,226

Static tipping load according to SAE J732 kg 7,517 7,337

lb 16,572 16,175

A Overall length bucket at ground mm 5,585 5,702

with rear bumper ft-in 18’4” 18’8”

B Bucket width, overall mm 2,300 2,300

ft-in 7’7” 7’7”

C Height of hinge pin, transport position mm 459 459

ft-in 1’6” 1’6”

D Height of hinge pin, max. mm 3,368 3,368

ft-in 11’1” 11’1”

E Digging depth, max. mm 130 155

ft-in 5.1” 6.1”

F Overall height with bucket at full lift mm 4,474 4,474

ft-in 14’8” 14’8”

G Dump clearance at full lift and mm 2,679 2,610

45° discharge according to ISO 7131 ft-in 8’9” 8’7”

H Reach at full lift and 45° discharge mm 890 923

according to ISO 7131 ft-in 2’11” 3’0”

Bucket weight kg 744 820

lb 1,640 1,808

Operating weight

1

kg 11,100 11,180

lb 24,471 24,648

Ground pressure

1

kg/cm² 0.56 0.56

psi 7.96 7.96

1

Machine with ROPS/FOPS cab, coolant and lubricants, operator (75 kg), bucket, rear bumper and track pads 457 mm / 18”

Page 5

LR 614 Litronic 5

Multi-purpose LR 614

bucket

bolt-on adapters, bolt-on adapters

and teeth segments and teeth

Version with

Nominal rated bucket capacity m³ 1.20 1.25

according to ISO 7546 yd³ 1.57 1.63

Nominal rated bucket capacity m³ 1.20 1.20

according to SAE J732 yd³ 1.57 1.57

Breakout force according to SAE J732 kN 95 86

lb 21,349 19,327

Static tipping load according to SAE J732 kg 6,988 7,154

lb 15,406 15,772

A Overall length bucket at ground mm 5,653 5,745

with rear bumper ft-in 18’7” 18’10”

B Bucket width, overall mm 2,300 2,300

ft-in 7’7” 7’7”

C Height of hinge pin, transport position mm 459 459

ft-in 1’6” 1’6”

D Height of hinge pin, max. mm 3,368 3,368

ft-in 11’1” 11’1”

E Digging depth, max. mm 140 165

ft-in 5.5” 6.5”

F Overall height with bucket at full lift mm 4,516 4,519

(bucket closed) ft-in 14’10” 14’10”

F1 Overall height with bucket at full lift mm 5,023 5,093

(bucket open) ft-in 16’6” 16’9”

G Dump clearance at full lift and 45° mm 2,647 2,578

discharge (bucket) according to ISO 7131 ft-in 8’8” 8’5”

G1 Dump clearance at full lift and 45° mm 3,017 3,017

discharge (blade) according to ISO 7131 ft-in 9’11” 9’11”

H Reach at full lift and 45° discharge mm 908 941

(bucket) according to ISO 7131 ft-in 3’0” 3’1”

H1 Reach at full lift and 45° discharge mm 542 542

(blade) according to ISO 7131 ft-in 1’9” 1’9”

I Width of opening mm 1,095 1,095

ft-in 3’7” 3’7”

Bucket weight kg 1,115 1,187

lb 2,458 2,617

Operating weight

1

kg 11,475 11,780

2

lb 25,298 25,970

2

Ground pressure

1

kg/cm² 0.58 0.59

2

psi 8.25 8.39

2

1

Machine with ROPS/FOPS cab, coolant and lubricants, operator (75 kg), bucket, rear bumper and track pads 457 mm / 18”

2

with heavier rearbumper (550 kg/1,213 lb)

Front attachment

Page 6

6 LR 614 Litronic

Rear attachment

3-shank ripper LR 614

radial

Standard bucket Multi-purpose bucket

A Beam width mm 1,732

ft-in 5’8”

B Ripping width mm 1,550

ft-in 5’1”

C Distance between teeth mm 750

ft-in 2’6”

D Penetration, max. mm 300

ft-in 1’

E Ground clearance, max. below teeth mm 669

ft-in 2’2”

F Additional length, ripper raised mm 614

ft-in 2’0”

G Additional length, transport position mm 756

ft-in 2’6”

H Approach angle, ripper raised 21°

Ripper weight

1

kg 574

lb 1,265

Change in operating weight kg 224 224

lb 494 494

Change in ground pressure kg/cm² 0.03 0.02

psi 0.43 0.28

Change in static tipping load kg 995 645

lb 2,194 1,422

1

If the ripper is mounted, no rear bumper will be fitted to the machine

Page 7

LR 614 Litronic 7

S = Standard

O = Option

Options and/or special attachments, supplied

by vendors other than Liebherr, are only to

be installed with knowledge and approval of

Liebherr to retain warranty.

Equipment

Basic machine SO

Towing system (air pressure cartridge) •

John Deere Diesel engine 4045HF289 •

Electronic engine management •

Diesel particle filter •

Cab tilting system •

Cold starting aid with heat flange •

Combination cooler for water,

hydraulic oil and intake charge air •

Radiator guard Heavy Duty •

Radiator guard, hinged •

Filling with bio-degradable

hydraulic oil •

Air pre-cleaner engine •

Hydrostatic fan, thermostatically

controlled •

Fan guard •

Engine access doors, hinged, lockable •

Lifting lugs •

Back up alarm •

Dry type air filter (quick change) •

Special paint •

Fuel priming pump •

Fuel water separator •

Fuel water separator, electric heater •

Vandalism protection (fuel tank cap

and service doors lockable) •

Tool kit (with towing kit) •

Towing hitch, front •

Towing hitch, rear •

Travel drive SO

3 phase heavy duty spur gear •

Electronic control •

Parking brake, automatic applied •

Liebherr hydrostatic travel drive •

Litronic control system •

Measure console for test points

connections •

Track frame SO

Track pads, double grouser,

457mm 18” •

Track pads, double grouser,

508 mm 20” •

Master link, two-piece •

Grease tensioner and hydraulic

cylinder •

Lubricated chains •

Track guards •

Center track guide •

Track guides, front and rear •

Track rollers, lifetime lubricated, x6 •

Track idler guards •

Track idlers, lifetime lubricated •

Carrier rollers, lifetime lubricated, x1 •

Sprocket segments, bolted, x1 •

Sprocket guards •

Electrical

system SO

Starter motor 7.0 kW •

Batteries 100 Ah, maintenance free, x2 •

Battery main switch •

Alternator 55 A Heavy Duty •

Anti-theft system, electronic •

Operator’s cab SO

Storage space near left armrest •

Armrests, adjustable •

Speed switch, work/travel modes •

Braking pedal for single-lever control •

Cab with heating and air conditioning •

Pressurized with air recirculation •

Louvered vents, adjustable, x8 •

Single-lever implement control with

integrated magnetic detent functions •

Single-lever travel control (travel speed,

all direction and steering motions) •

Air suspension seat •

Mechanical suspension seat •

Fire extinguisher •

Fresh air intake filter •

Working lights (halogen), front, x2 •

Working lights (halogen),additional,

front, x2 •

Working lights (halogen), rear, x2 •

Working lights (halogen), additional,

rear, x2 •

Horn •

Dome light •

Coat hook •

Engine rpm switch, infinitely variable •

Emergency stop •

Radio •

Radio installation provision •

ROPS/FOPS structures •

Seatback extension •

Rearview mirrors, outside, left and right •

Rearview mirror inside •

Windshield washer system with

intermittent function •

Windshield wipers front and rear •

Sliding side window left •

Sliding side window right •

Key start switch •

Seat belt, automatic retractable •

Park lock lever •

Safety glass, tinted •

Pull-down sunshade •

Power port 12 V •

Power port 24 V •

V-pattern travel control (travel speed,

direction) with steering pedals •

Heater and defroster •

Displays SO

Hour meter •

Hydraulic oil temperature •

Engine coolant temperature •

Digital LC-display electronic unit •

Digital LC-display with scroll key

(fuel consumption, battery voltage,

cooling water temp. and service codes) •

Engine oil pressure •

Fuel level •

Hydraulic

equipment SO

Hydraulic control multi-purpose bucket •

Hydraulic control 3-shank ripper •

Automatic bucket positioner •

Bucket quick drop •

Bucket float position •

Attachments SO

Rear drawbar hitch, rigid •

Bolt-on adapters •

Weld-on adapters, flush mounted •

3-shank ripper, radial •

Multi-purpose bucket •

Standard bucket with back blade edge •

Rear bumper •

Lifting cylinder guards •

Tilt cylinder guards •

Clamping cylinder guards,

multi-purpose bucket •

Bolt-on cutting segments, reversible •

Z-bar linkage •

Subject to changes.

Control and

warning lights SO

Electronic travel control system •

Parking brake •

Battery charging control •

Pump replenishing pressure •

Maintenance oil return filter •

Maintenance air filter •

Maintenance replenishing filter •

Main warning light •

Page 8

The Liebherr Group of Companies

Wide product range

The Liebherr Group is one of the largest construction

equipment manufacturers in the world. Liebherr’s highvalue products and services enjoy a high reputation in

many other fields, too. The wide range includes domestic appliances, aerospace and transportation systems,

machine tools and maritime cranes.

Exceptional customer benefit

Every product line provides a complete range of models

in many different versions. With both their technical excellence and acknowledged quality, Liebherr products offer

a maximum of customer benefits in practical application.

State-of-the-art technology

To provide consistent, top quality products, Liebherr

attaches great importance to each product area, its

components and core technologies. Important modules

and components are developed and manufactured inhouse, for instance the entire drive and control technology for construction equipment and mining trucks.

Worldwide and independent

Hans Liebherr founded the Liebherr family company in

1949. Since that time, the enterprise has steadily grown

to a group of more than 100 companies with over

32,000 employees located on all continents. The corporate

headquarters of the Group is Liebherr-International AG

in Bulle, Switzerland. The Liebherr family is the sole owner

of the company.

www.liebherr.us

Liebherr Construction Equipment Co.

4100 Chestnut Avenue, Newport News, VA 23607, USA

콯 +1 (757) 245 5251, Fax +1 (757) 928 8701

www.liebherr.us, E-Mail: info.lce@liebherr.com

Printed in Germany by Typodruck RG-BK-RP LWT/VM 10663787-0.5-02.10_enUS

Loading...

Loading...