Page 1

Machine for

LH 80 M

Industrial Applications

litronic

Operating Weight: 76,200 – 78,100 kg

Engine Output: 230 kW / 313 HP

`

Page 2

Technical Data

Engine

Rating per ISO 9249

�������������������������������

Model

���������������������������������

Type

Bore/Stroke

Displacement

Engine operation

������������������������������

Cooling

Air cleaner

����������������������������

Fuel tank

Engine idling

Electrical system

Voltage

Batteries

Alternator

����������������������������

Standard

���������������

�������������������

�����������������

�������������������

��������������������������

������������������������

������������������������

����������������������

���������������������

Hydraulic System

Hydraulic pump

for attachment

and travel drive

Max. flow

Max. pressure

Pump regulation

Hydraulic pump

for swing drive

Max. flow

Max. pressure

Hydraulic tank

Hydraulic system

Hydraulic oil filter

Hydraulic oil cooler

MODE selection

S (Sensitive)

E (ECO)

P (Power)

Tool Control

���������������

����������������������

����������������

�������������������

����������������

����������������������

����������������

����������������������

������������������

������������������

����������������

��������������������

�������������������

������������������������

����������������������

������������������������

Hydraulic Controls

Power distribution

Servo circuit

Attachment and swing

Travel

Additional functions

�������������������������������

Option

�����������������

��������������������������

���������������

230 kW (313 HP) at 1,700 RPM

Liebherr D936 according to level IIIB / Tier 4i

6 cylinder in-line

122/150 mm

10.5 l

4-stroke diesel

Common-Rail

turbo-charged and after-cooled

reduced emissions

water-cooled with integrated motor oil cooler

dry-type air cleaner with pre-cleaner, primary and

safety elements

910 l

sensor controlled

24 V

2 x 170 Ah/12 V

three phase current 28 V/100 A

Liebherr particle filter

two Liebherr variable flow, swashplate pumps

(double construction)

2 x 350 l/min.

350 bar

electro-hydraulic with electronic engine speed sens-

ing regulation, pressure compensation, flow compen-

sation, automatic oil flow optimizer

reversible, variable flow, swashplate pump, closed-

loop circuit

185 l/min.

380 bar

390 l

910 l

2 full flow filters in return line with integrated fine filter

area (5 μm)

cooling system, consisting of a cooling unit for water

and charge air and a 2

with an infinitely variable, thermostatically controlled

fan drive system

adjustment of engine and hydraulic performance via

a mode pre-selector to match application, e.g. for

especially economical and environmentally friendly

operation or for maximum material handling and

heavy-duty jobs

for precision work and lifting through very sensitive

movements

for especially economical and environmentally friendly

operation

for maximum digging power and heavy duty jobs

ten preadjustable pump flows and pressures for add

on tools

via control valves in single block with integrated

safety valves

�������

with hydraulic pilot control and proportional joystick

levers

electroproportional via foot pedal

via switch or electroproportional foot pedals

Liebherr-Proportional-Control, proportionally acting

transmitters on the joysticks for additional hydraulic

functions

nd

cooler for hydraulic oil, each

Swing Drive

�����������������������������

Drive by

Transmission

Swing ring

Swing speed

Swing torque

Holding brake

Option

�����������������������

��������������������������

�����������������������

�����������������������

����������������������

�������������������������������

Operator’s Cab

����������������������������������

Cab

Operator’s seat Standard

Operator’s seat Comfort

�����������������������������

(Option)

Operator’s seat Premium

�����������������������������

(Option)

Control system

Operation and displays

Air-conditioning

Noise emission

ISO 6396

2000/14/EC

���������������������

��������������������

����������������������������

�������������������������

Undercarriage

���������������������������������

Type

��������������������������������

Drive

Travel speed

Driving operation

Axles

Service brake

Holding brake

Stabilization

������������������������

�������������������

��������������������������������

�����������������������

����������������������

������������������������

Liebherr swash plate motor in a closed system with

integrated brake valve

Liebherr planetary reduction gear

Liebherr, sealed single race ball bearing swing ring,

internal teeth

0 – 6.4 RPM stepless

154 kNm

spring applied – pressure released

pedal controlled positioning brake

safety cab structure with individual windscreens or

featuring a slide-in subpart under the ceiling, work

headlights integrated in the ceiling, a door with a side

window (can be opened on both sides), large stowing

and depositing possibilities, shockabsorbing suspen-

sion, sounddamping insulating, tinted laminated

safety glass, separate shades for the sunroof window

and windscreen

���������

air cushioned operator’s seat with headrest, lap belt,

seat heater, manual weight adjustment, adjustable

seat cushion inclination and length and mechanical

lumbar vertebrae support

in addition to operator’s seat standard: lockable hori-

zontal suspension, automatic weight adjustment,

adjustable suspension stiffness, pneumatic lumbar

vertebrae support and passive seat climatisation with

active coal

in addition to operator’s seat comfort: active elec-

tronic weight adjustment (automatic readjustment),

pneumatic low frequency suspension and active seat

climatisation with active coal and ventilator

joysticks with arm consoles and swivel seat

�����������

large high-resolution operating unit, selfexplanatory,

colour display with touchscreen, video-compatible,

numerous setting, control and monitoring options,

e.g. air conditioning control, fuel consumption,

machine and tool parameters

automatic air-conditioning, recirculated air function,

fast de-icing and demisting at the press of a button,

air vents can be operated via a menu; recirculated air

and fresh air filters can be easily replaced and are

accessible from the outside; heating-cooling unit,

designed for extreme out-side temperatures, sensors

for solar radiation, inside and outside temperatures

LpA (inside cab) = 71 dB(A)

LWA (surround noise) = 105 dB(A)

torsion-resistant box design made from high-strength

steel plate, designed for the toughest requirements

variable flow swashplate motor with automatic brake

valve

0 – 10 km/h stepless

automotive driving using accelerator pedal, cruise

control function: storage of variable accelerator pedal

positions

90 t drive axles; manual or automatic hydraulically

controlled front axle oscillation lock

wet, maintenance-free, low backlash multi disc

brakes

wet, maintenance-free multi disc brakes

4-point outriggers

Uppercarriage

���������������������������������

Type

2 LH 80 M Litronic Machine for Industrial Applications

slewing platform made from high-strength steel plate,

designed for the toughest requirements

Attachment

���������������������������������

Type

Hydraulic cylinders

Energy recovering cylinder

Bearings

Lubrication

����������������

����������������������������

�������������������������

high-strength steel plates at highlystressed points for

the toughest requirements. Complex and stable

mountings of attachment and cylinders.

Liebherr cylinders with special seal system. Shock

absorption

��������

Liebherr gas cylinder with special sealing and control

system

sealed, low maintenance

Liebherr full-automatic central lubrication system

(country-dependent)

Page 3

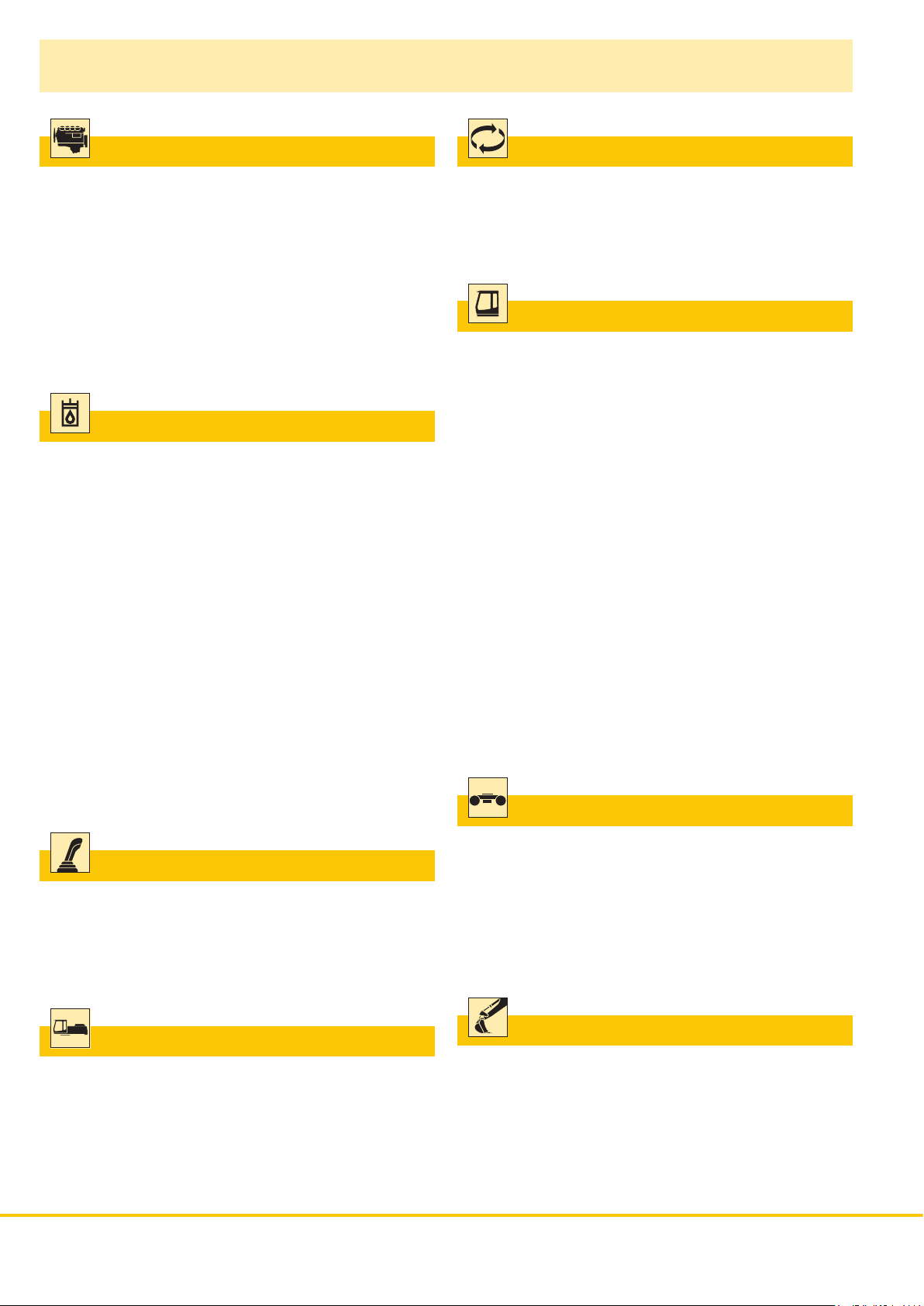

Dimensions

W

T4

X

mm

A 3,190

A1 4,530

B 3,800

B1 6,350

C 4,530

D 3,950

E 3,950

H 3,725

K 2,095

L 3,600

M 1,800

Q 535

T1 1,700

T4 1,775

U4 7,075

Z 7,525

E = Tail radius

Tires 23.5-25

A1

A

Q

B

B1

U4

E

D

H

K

M

L

Z

V

T1

Industrial-Type Straight Mono Boom 10.50 m

and Industrial Stick m 7.80 9.00

V mm 8,550 7,450

W mm 4,100 4,500

X mm 15,150 15,100

Industrial-Type Straight Mono Boom 11.50 m

and Industrial Stick m 9.00 10.00

V mm 8,300 7,600

W mm 4,200 5,300

X mm 16,150 16,050

Industrial-Type Angled Mono Boom 11.50 m

and Industrial Stick m 9.00 10.00

V mm 8,250 7,550

W mm 5,300 5,950

X mm 16,150 16,050

Industrial-Type Straight Mono Boom 12.50 m

and Industrial Stick m 9.00 10.00

V mm 9,100 8,350

W mm 3,850 4,500

X mm 17,100 17,100

C

LH 80 M Litronic Machine for Industrial Applications 3

Page 4

Industrial Attachment

with Industrial-Type Straight Mono Boom 10.50 m

ft m

70

65

60

55

50

45

40

35

30

25

20

15

10

-10

-15

-20

-25

22

20

18

16

14

12

10

8

6

4

2

5

0

0

-5

-2

-4

-6

-8

1

2

3

4

02468101214161820

m

Attachment Envelope

Kinematic variant 2A

1 with industrial stick 7.80 m

2 with industrial stick 9.00 m

3 with industrial stick 7.80 m and grapple model GMM 80-5

4 with industrial stick 9.00 m and grapple model GMM 80-5

Operating Weight

The operating weight includes basic machine with 4 pt. outriggers,

hydr. cab elevation, 4 solid tires and industrial attachment with industrial-type straight mono boom 10.50 m.

with grapple model GMM 80-5/1.70 m

and industrial stick 7.80 m 76,200 kg

and industrial stick 9.00 m 76,700 kg

3

semi-closed tines Weight

65 60 55 50 45 40 35 30 25 20 15 10 5 0

Kinematic Variant 2A

Hole A

ft

2A2A

Hole 2

Energy recovery with

kinematic variant 2A

4 LH 80 M Litronic Machine for Industrial Applications

Page 5

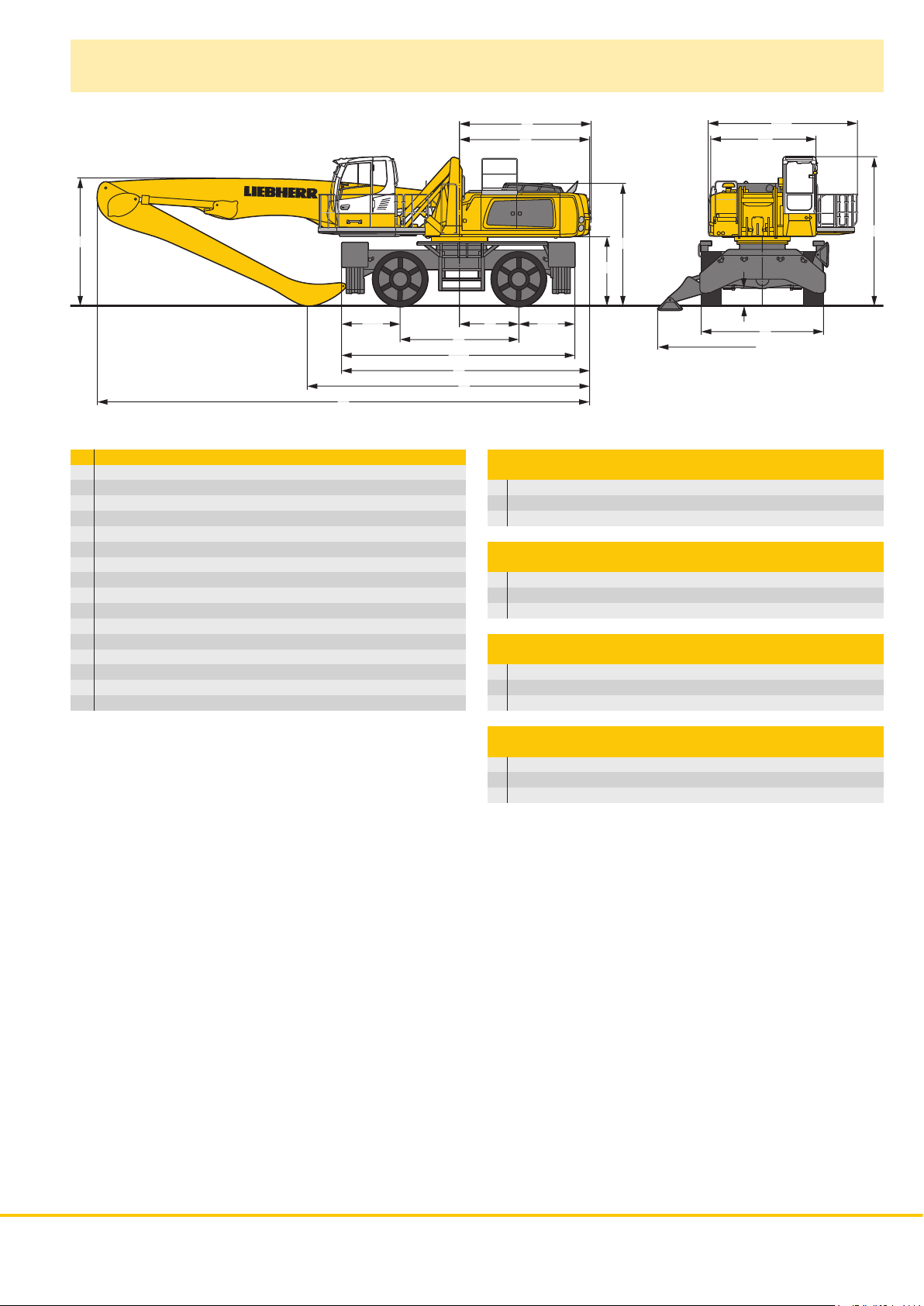

Lift Capacities

with Industrial-Type Straight Mono Boom 10.50 m (Kinematic Variant 2A)

Industrial Stick 7.80 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m

m Undercarriage m

Stabilizers raised

24.0

4 pt. outriggers down

Stabilizers raised

22.5

4 pt. outriggers down

Stabilizers raised

21.0

4 pt. outriggers down

Stabilizers raised

19.5

4 pt. outriggers down

Stabilizers raised

18.0

4 pt. outriggers down

Stabilizers raised

16.5

4 pt. outriggers down

Stabilizers raised

15.0

4 pt. outriggers down

Stabilizers raised

13.5

4 pt. outriggers down

Stabilizers raised

12.0

4 pt. outriggers down

Stabilizers raised

10.5

4 pt. outriggers down

Stabilizers raised

9.0

4 pt. outriggers down

Stabilizers raised

7.5

4 pt. outriggers down

Stabilizers raised

6.0

4 pt. outriggers down

Stabilizers raised

4.5

4 pt. outriggers down

Stabilizers raised

3.0

4 pt. outriggers down

Stabilizers raised

1.5

4 pt. outriggers down

Stabilizers raised

0

4 pt. outriggers down

Stabilizers raised

– 1.5

4 pt. outriggers down

Stabilizers raised

– 3.0

4 pt. outriggers down

Stabilizers raised

– 4.5

4 pt. outriggers down

Stabilizers raised

– 6.0

4 pt. outriggers down

Stabilizers raised

– 7.5

4 pt. outriggers down

15.0* 15.0* 13.0* 13.0*

15.0* 15.0* 13.0* 13.0*

14.8* 14.8* 12.6* 12.6* 10.6* 10.6*

14.8* 14.8* 12.6* 12.6* 10.6* 10.6*

15.7* 15.7* 14.4* 14.4* 11.6 12.5* 9.0 9.5*

15.7* 15.7* 14.4* 14.4* 12.5* 12.5* 9.5* 9.5*

15.4* 15.4* 11.9 13.1 9.2 10.2 7.2 8.1

15.4* 15.4* 13.8* 13.8* 12.1* 12.1* 8.8* 8.8*

15.3* 15.3* 11.9 13.2 9.3 10.3 7.3 8.1 6.1 6.8

15.3* 15.3* 13.7* 13.7* 12.5* 12.5* 11.4* 11.4* 8.4* 8.4*

15.4* 15.4* 11.9 13.1 9.3 10.3 7.4 8.2 5.8 6.5 5.3 6.0

15.4* 15.4* 13.8* 13.8* 12.5* 12.5* 11.5* 11.5* 10.0* 10.0* 8.1* 8.1*

17.3* 17.3* 15.1 15.7* 11.6 12.8 9.1 10.1 7.3 8.1 5.8 6.5 4.8 5.4

17.3* 17.3* 15.7* 15.7* 13.9* 13.9* 12.6* 12.6* 11.5* 11.5* 10.6* 10.6* 7.9* 7.9*

18.6* 18.6* 14.6 16.1 11.2 12.4 8.8 9.8 7.1 7.9 5.7 6.4 4.6 5.3 4.3 4.9

18.6* 18.6* 16.1* 16.1* 14.2* 14.2* 12.8* 12.8* 11.6* 11.6* 10.7* 10.7* 9.6* 9.6* 7.9* 7.9*

19.4* 19.4* 18.6 19.5* 13.8 15.3 10.7 11.9 8.5 9.4 6.8 7.7 5.6 6.3 4.6 5.2 4.0 4.6

19.4* 19.4* 19.5* 19.5* 16.7* 16.7* 14.6* 14.6* 13.0* 13.0* 11.8* 11.8* 10.7* 10.7* 9.7 9.8* 7.9* 7.9*

26.3* 26.3* 24.3 25.5* 17.1 19.2 12.9 14.4 10.1 11.2 8.1 9.0 6.6 7.4 5.4 6.1 4.4 5.1 3.8 4.4

26.3* 26.3* 25.5* 25.5* 20.6* 20.6* 17.4* 17.4* 15.1* 15.1* 13.3* 13.3* 12.0* 12.0* 10.8* 10.8* 9.6 9.8* 7.9* 7.9*

19.0* 19.0* 21.5 24.5 15.6 17.5 11.9 13.3 9.4 10.5 7.6 8.5 6.2 7.0 5.2 5.9 4.3 4.9 3.7 4.2

19.0* 19.0* 27.5* 27.5* 21.8* 21.8* 18.1* 18.1* 15.5* 15.5* 13.6* 13.6* 12.1* 12.1* 10.9* 10.9* 9.4 9.7* 8.1* 8.1*

3.9* 3.9* 19.0 20.2* 14.0 16.0 10.9 12.3 8.7 9.9 7.1 8.1 5.9 6.7 5.0 5.6 4.2 4.8 3.6 4.1

3.9* 3.9* 20.2* 20.2* 22.7* 22.7* 18.7* 18.7* 15.9* 15.9* 13.8* 13.8* 12.2* 12.2* 10.7 10.8* 9.3 9.6* 8.1* 8.1*

3.2* 3.2* 10.5* 10.5* 12.8 14.7 10.1 11.5 8.2 9.3 6.7 7.7 5.6 6.4 4.8 5.5 4.1 4.7 3.6 4.1

3.2* 3.2* 10.5* 10.5* 23.2* 23.2* 19.0* 19.0* 16.1* 16.1* 13.9* 13.9* 12.1* 12.1* 10.5 10.7* 9.1 9.2* 7.6* 7.6*

4.0* 4.0* 9.0* 9.0* 12.0 13.8 9.5 10.9 7.7 8.8 6.4 7.3 5.4 6.2 4.6 5.3 4.0 4.6 3.6 4.2

4.0* 4.0* 9.0* 9.0* 20.9* 20.9* 18.8* 18.8* 15.9* 15.9* 13.7* 13.7* 11.9* 11.9* 10.3* 10.3* 8.6* 8.6* 7.0* 7.0*

9.4* 9.4* 11.5 13.3 9.1 10.4 7.4 8.5 6.2 7.1 5.2 6.0 4.5 5.2 3.9 4.5 3.8 4.4

9.4* 9.4* 17.8* 17.8* 18.0* 18.0* 15.3* 15.3* 13.1* 13.1* 11.2* 11.2* 9.5* 9.5* 7.6* 7.6* 6.8* 6.8*

11.3 13.1 8.8 10.2 7.2 8.3 6.0 6.9 5.1 5.9 4.4 5.1 4.3 4.9

17.4* 17.4* 16.3* 16.3* 14.0* 14.0* 11.9* 11.9* 10.1* 10.1* 8.2* 8.2* 7.5* 7.5*

7.2 8.3 6.0 6.9

11.9* 11.9* 10.1* 10.1*

7.0

9.9

11.9

13.4

14.6

15.6

16.3

16.9

17.4

17.7

17.9

17.9

17.8

17.6

17.0

15.5

12.0

Industrial Stick 9.00 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m

m Undercarriage m

Stabilizers raised

24.0

4 pt. outriggers down

Stabilizers raised

22.5

4 pt. outriggers down

Stabilizers raised

21.0

4 pt. outriggers down

Stabilizers raised

19.5

4 pt. outriggers down

Stabilizers raised

18.0

4 pt. outriggers down

Stabilizers raised

16.5

4 pt. outriggers down

Stabilizers raised

15.0

4 pt. outriggers down

Stabilizers raised

13.5

4 pt. outriggers down

Stabilizers raised

12.0

4 pt. outriggers down

Stabilizers raised

10.5

4 pt. outriggers down

Stabilizers raised

9.0

4 pt. outriggers down

Stabilizers raised

7.5

4 pt. outriggers down

Stabilizers raised

6.0

4 pt. outriggers down

Stabilizers raised

4.5

4 pt. outriggers down

Stabilizers raised

3.0

4 pt. outriggers down

Stabilizers raised

1.5

4 pt. outriggers down

Stabilizers raised

0

4 pt. outriggers down

Stabilizers raised

– 1.5

4 pt. outriggers down

Stabilizers raised

– 3.0

4 pt. outriggers down

Stabilizers raised

– 4.5

4 pt. outriggers down

Stabilizers raised

– 6.0

4 pt. outriggers down

Stabilizers raised

– 7.5

4 pt. outriggers down

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the stick end without attachment are stated in metric tons (t) and are valid on a firm, level supporting surface with blocked oscillating axle. These

capacities can be slewed through 360° with the undercarriage in the transverse position. Capacities in the longitudinal position of the undercarriage (+/– 15°) are specified over the steering axle with the stabilizers raised and over the rigid axle with the stabilizers down. Indicated loads comply with the ISO 10567 standard and do not

exceed 75 % of tipping or 87 % of hydraulic capacity. The lift capacity values indicated are attained at the corresponding operating temperature. This operating temperature is ensured by continuous movement of the boom. Weights of fitted working tools (grabs, load hooks, etc.) and load accommodation equipment are to be

deducted from the lift capacity values. The lift capacity of the unit is limited by its stability, the lifting capability of the hydraulic elements, or the maximum permissible

lifting capacity of the load hook.

In accordance with the harmonised EU Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe rupture protection devices on

the hoist cylinders and an overload warning device.

13.1* 13.1* 12.4* 12.4*

13.1* 13.1* 12.4* 12.4*

12.9* 12.9* 10.9* 10.9* 9.6* 9.6*

12.9* 12.9* 10.9* 10.9* 9.6* 9.6*

12.6* 12.6* 10.9* 10.9* 8.4* 8.4*

12.6* 12.6* 10.9* 10.9* 8.4* 8.4*

13.3* 13.3* 12.2* 12.2* 9.5 10.5 7.3 7.9* 7.2 7.7*

13.3* 13.3* 12.2* 12.2* 10.6* 10.6* 7.9* 7.9* 7.7* 7.7*

12.5 13.0* 9.7 10.7 7.6 8.4 6.0 6.7

13.0* 13.0* 11.9* 11.9* 10.1* 10.1* 7.2* 7.2*

12.5 12.9* 9.8 10.8 7.7 8.6 6.1 6.8 5.1 5.8

12.9* 12.9* 11.8* 11.8* 10.9* 10.9* 9.3* 9.3* 6.9* 6.9*

12.4 12.9* 9.7 10.7 7.7 8.5 6.1 6.8 4.8 5.5 4.5 5.1

12.9* 12.9* 11.8* 11.8* 10.8* 10.8* 10.1* 10.1* 7.9* 7.9* 6.7* 6.7*

14.6* 14.6* 12.2 13.1* 9.5 10.5 7.6 8.4 6.1 6.8 4.8 5.5 4.1 4.6

14.6* 14.6* 13.1* 13.1* 11.9* 11.9* 10.9* 10.9* 10.1* 10.1* 9.4* 9.4* 6.6* 6.6*

15.1* 15.1* 11.8 13.0 9.2 10.2 7.4 8.2 5.9 6.6 4.8 5.4 3.8 4.4 3.7 4.3

15.1* 15.1* 13.4* 13.4* 12.1* 12.1* 11.0* 11.0* 10.2* 10.2* 9.4* 9.4* 7.1* 7.1* 6.5* 6.5*

15.8* 15.8* 14.6 15.7* 11.2 12.4 8.8 9.8 7.1 7.9 5.7 6.4 4.7 5.3 3.8 4.3 3.5 4.0

15.8* 15.8* 15.7* 15.7* 13.8* 13.8* 12.4* 12.4* 11.2* 11.2* 10.3* 10.3* 9.4* 9.4* 8.3 8.5* 6.5* 6.5*

16.6* 16.6* 18.4 19.3* 13.6 15.1 10.5 11.7 8.4 9.3 6.7 7.6 5.5 6.2 4.5 5.1 3.7 4.2 3.3 3.8

16.6* 16.6* 19.3* 19.3* 16.4* 16.4* 14.3* 14.3* 12.7* 12.7* 11.4* 11.4* 10.4* 10.4* 9.5* 9.5* 8.2 8.6* 6.6* 6.6*

30.4* 30.4* 23.6 25.5* 16.7 18.7 12.5 14.0 9.8 11.0 7.8 8.8 6.4 7.2 5.2 5.9 4.3 4.9 3.6 4.1 3.1 3.7

30.4* 30.4* 25.5* 25.5* 20.5* 20.5* 17.2* 17.2* 14.8* 14.8* 13.0* 13.0* 11.6* 11.6* 10.5* 10.5* 9.4 9.5* 8.1 8.5* 6.7* 6.7*

12.6* 12.6* 20.6 23.5 14.9 16.9 11.4 12.9 9.0 10.2 7.3 8.3 6.0 6.8 5.0 5.7 4.1 4.8 3.5 4.0 3.1 3.6

12.6* 12.6* 27.4* 27.4* 21.6* 21.6* 17.9* 17.9* 15.3* 15.3* 13.3* 13.3* 11.8* 11.8* 10.6* 10.6* 9.2 9.5* 8.0 8.3* 6.8* 6.8*

5.1* 5.1* 17.8* 17.8* 13.4 15.3 10.4 11.8 8.3 9.5 6.8 7.8 5.6 6.4 4.7 5.4 4.0 4.6 3.4 3.9 3.0 3.5

5.1* 5.1* 17.8* 17.8* 22.4* 22.4* 18.4* 18.4* 15.6* 15.6* 13.5* 13.5* 11.9* 11.9* 10.5 10.5* 9.0 9.3* 7.9 8.0* 6.9* 6.9*

4.7* 4.7* 11.1* 11.1* 12.2 14.1 9.6 11.0 7.7 8.9 6.4 7.3 5.3 6.1 4.5 5.2 3.8 4.4 3.3 3.8 3.0 3.6

4.7* 4.7* 11.1* 11.1* 22.7* 22.7* 18.6* 18.6* 15.7* 15.7* 13.5* 13.5* 11.8* 11.8* 10.3 10.3* 8.9 9.0* 7.5* 7.5* 6.4* 6.4*

5.4* 5.4* 10.0* 10.0* 11.4 13.3 9.0 10.4 7.3 8.4 6.0 7.0 5.1 5.9 4.3 5.0 3.7 4.3 3.2 3.8 3.1 3.7

5.4* 5.4* 10.0* 10.0* 20.7* 20.7* 18.3* 18.3* 15.4* 15.4* 13.2* 13.2* 11.4* 11.4* 9.9* 9.9* 8.4* 8.4* 6.6* 6.6* 5.9* 5.9*

6.4* 6.4* 10.2* 10.2* 11.0 12.8 8.6 10.0 7.0 8.1 5.8 6.7 4.9 5.7 4.2 4.9 3.6 4.3 3.4 4.0

6.4* 6.4* 10.2* 10.2* 18.1* 18.1* 17.3* 17.3* 14.6* 14.6* 12.5* 12.5* 10.7* 10.7* 9.1* 9.1* 7.4* 7.4* 6.3* 6.3*

10.8 12.6 8.4 9.8 6.8 7.9 5.7 6.6 4.8 5.6 4.2 4.8 4.0 4.7

17.8* 17.8* 15.4* 15.4* 13.2* 13.2* 11.2* 11.2* 9.5* 9.5* 7.7* 7.7* 7.3* 7.3*

6.4

9.7

11.9

13.6

14.9

16.0

16.9

17.6

18.2

18.6

18.9

19.0

19.1

19.0

18.8

18.4

17.3

15.4

LH 80 M Litronic Machine for Industrial Applications 5

Page 6

Industrial Attachment

with Industrial-Type Straight Mono Boom 11.50 m

ft m

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-5

-10

-15

-20

-25

-30

-10

24

22

20

18

16

14

12

10

8

6

4

2

0

-2

-4

-6

-8

657075 60 55 50 45 40 35 30 25 20 15 10 5 0

1

2

3

4

0246810121416182022

m

ft

Attachment Envelope

Kinematic variant 2A

1 with industrial stick 9.00 m

2 with industrial stick 10.00 m

3 with industrial stick 9.00 m and grapple model GMM 80-5

4 with industrial stick 10.00 m and grapple model GMM 80-5

Operating Weight

The operating weight includes basic machine with 4 pt. outriggers,

hydr. cab elevation, 4 solid tires and industrial attachment with industrial-type straight mono boom 11.50 m.

with grapple model GMM 80-5/1.70 m

and industrial stick 9.00 m 77,300 kg

and industrial stick 10.00 m 77,600 kg

3

semi-closed tines Weight

Kinematic Variant 2A

Hole A

2A2A

Hole 2

Energy recovery with

kinematic variant 2A

6 LH 80 M Litronic Machine for Industrial Applications

Page 7

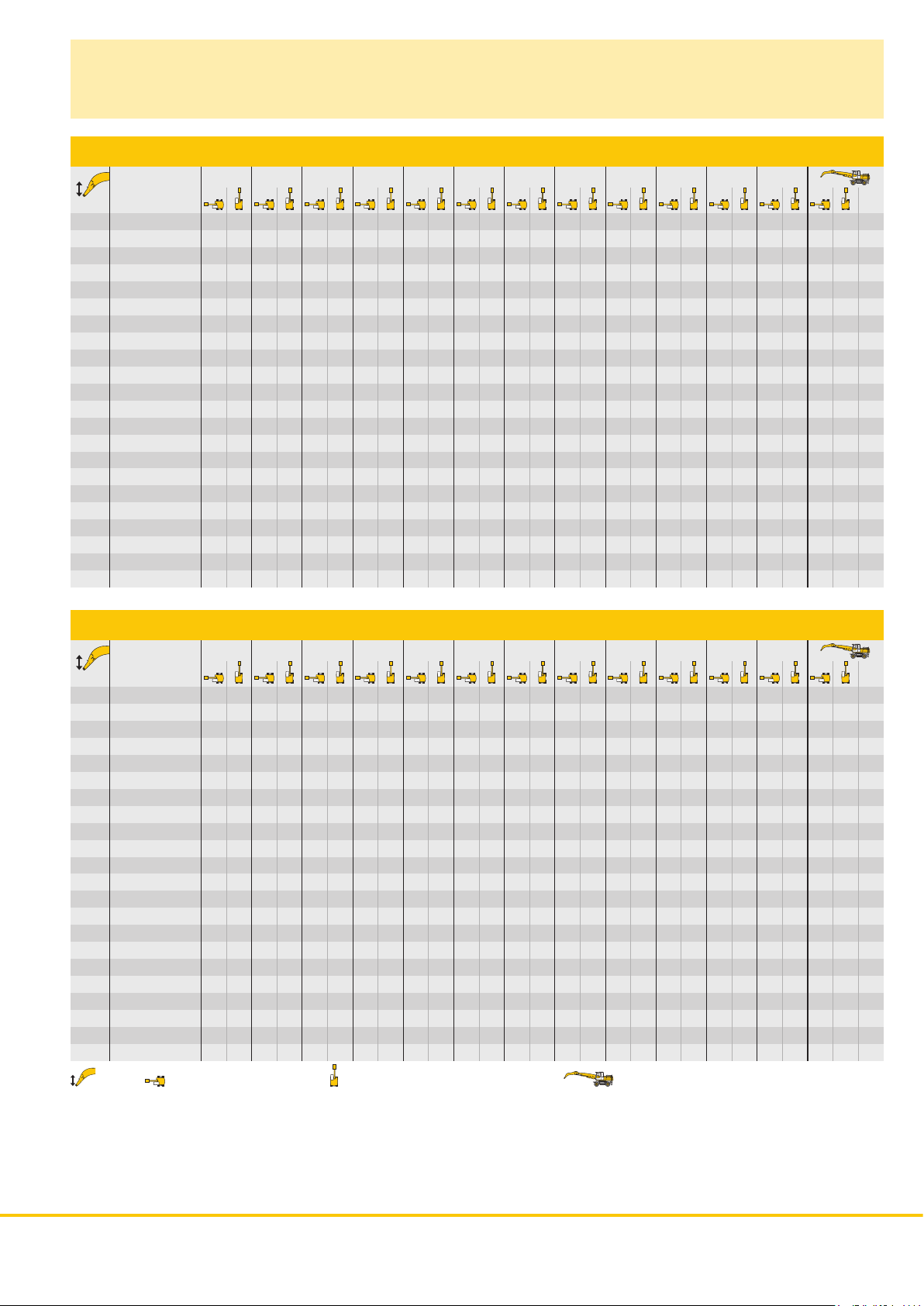

Lift Capacities

with Industrial-Type Straight Mono Boom 11.50 m (Kinematic Variant 2A)

Industrial Stick 9.00 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m

m Undercarriage m

Stabilizers raised

24.0

4 pt. outriggers down

Stabilizers raised

22.5

4 pt. outriggers down

Stabilizers raised

21.0

4 pt. outriggers down

Stabilizers raised

19.5

4 pt. outriggers down

Stabilizers raised

18.0

4 pt. outriggers down

Stabilizers raised

16.5

4 pt. outriggers down

Stabilizers raised

15.0

4 pt. outriggers down

Stabilizers raised

13.5

4 pt. outriggers down

Stabilizers raised

12.0

4 pt. outriggers down

Stabilizers raised

10.5

4 pt. outriggers down

Stabilizers raised

9.0

4 pt. outriggers down

Stabilizers raised

7.5

4 pt. outriggers down

Stabilizers raised

6.0

4 pt. outriggers down

Stabilizers raised

4.5

4 pt. outriggers down

Stabilizers raised

3.0

4 pt. outriggers down

Stabilizers raised

1.5

4 pt. outriggers down

Stabilizers raised

0

4 pt. outriggers down

Stabilizers raised

– 1.5

4 pt. outriggers down

Stabilizers raised

– 3.0

4 pt. outriggers down

Stabilizers raised

– 4.5

4 pt. outriggers down

Stabilizers raised

– 6.0

4 pt. outriggers down

Stabilizers raised

– 7.5

4 pt. outriggers down

12.5* 12.5* 10.3* 10.3*

12.5* 12.5* 10.3* 10.3*

12.3* 12.3* 10.5* 10.5* 8.8* 8.8*

12.3* 12.3* 10.5* 10.5* 8.8* 8.8*

13.1* 13.1* 12.0* 12.0* 9.3 10.3 7.2 7.9*

13.1* 13.1* 12.0* 12.0* 10.4* 10.4* 7.9* 7.9*

12.5 12.8* 9.7 10.7 7.5 8.3 5.8 6.6

12.8* 12.8* 11.6* 11.6* 10.1* 10.1* 7.4* 7.4*

12.6 12.7* 9.8 10.8 7.7 8.5 6.0 6.7 4.9 5.5

12.7* 12.7* 11.5* 11.5* 10.5* 10.5* 9.5* 9.5* 7.1* 7.1*

12.5 12.7* 9.7 10.7 7.7 8.5 6.1 6.8 4.7 5.4 4.2 4.8

12.7* 12.7* 11.5* 11.5* 10.4* 10.4* 9.6* 9.6* 8.5* 8.5* 6.8* 6.8*

14.4* 14.4* 12.3 12.8* 9.6 10.6 7.6 8.4 6.0 6.7 4.8 5.4 3.7 4.3

14.4* 14.4* 12.8* 12.8* 11.5* 11.5* 10.5* 10.5* 9.6* 9.6* 8.9* 8.9* 6.7* 6.7*

14.8* 14.8* 11.9 13.0* 9.3 10.3 7.4 8.2 5.9 6.6 4.7 5.3 3.7 4.3 3.3 3.9

14.8* 14.8* 13.0* 13.0* 11.7* 11.7* 10.6* 10.6* 9.6* 9.6* 8.9* 8.9* 8.2* 8.2* 6.6* 6.6*

15.1* 15.1* 14.9 15.2* 11.4 12.6 8.9 9.9 7.1 7.9 5.7 6.4 4.6 5.2 3.7 4.2 3.0 3.5

15.1* 15.1* 15.2* 15.2* 13.3* 13.3* 11.9* 11.9* 10.7* 10.7* 9.7* 9.7* 8.9* 8.9* 8.2* 8.2* 6.5* 6.5*

15.0* 15.0* 17.5* 17.5* 13.9 15.5 10.7 11.9 8.4 9.4 6.7 7.6 5.4 6.2 4.4 5.0 3.6 4.1 2.8 3.3 2.8 3.3

15.0* 15.0* 17.5* 17.5* 15.7* 15.7* 13.7* 13.7* 12.1* 12.1* 10.8* 10.8* 9.8* 9.8* 9.0* 9.0* 8.2 8.2* 6.8* 6.8* 6.5* 6.5*

18.0* 18.0* 22.3* 22.3* 17.2 19.2 12.8 14.3 9.9 11.1 7.9 8.8 6.3 7.2 5.1 5.9 4.2 4.8 3.4 4.0 2.8 3.3 2.6 3.1

18.0* 18.0* 22.3* 22.3* 19.5* 19.5* 16.3* 16.3* 14.1* 14.1* 12.3* 12.3* 11.0* 11.0* 9.9* 9.9* 9.0* 9.0* 8.0 8.2* 6.9 7.3* 6.6* 6.6*

19.4* 19.4* 21.2 24.1 15.2 17.2 11.6 13.0 9.1 10.2 7.3 8.2 5.9 6.7 4.8 5.5 4.0 4.6 3.3 3.8 2.7 3.2 2.5 3.0

19.4* 19.4* 25.9* 25.9* 20.5* 20.5* 16.9* 16.9* 14.4* 14.4* 12.6* 12.6* 11.2* 11.2* 10.0* 10.0* 9.0* 9.0* 7.8 8.1* 6.8 7.1* 6.5 6.7*

2.9* 2.9* 15.7* 15.7* 13.3 15.3 10.3 11.8 8.2 9.4 6.7 7.6 5.5 6.3 4.5 5.2 3.8 4.4 3.1 3.7 2.6 3.1 2.4 2.9

2.9* 2.9* 15.7* 15.7* 21.2* 21.2* 17.4* 17.4* 14.8* 14.8* 12.8* 12.8* 11.3* 11.3* 10.0* 10.0* 8.9 9.0* 7.7 8.0* 6.7 6.9* 6.4* 6.4*

2.1* 2.1* 7.7* 7.7* 11.8 13.7 9.3 10.7 7.5 8.6 6.1 7.1 5.1 5.9 4.2 4.9 3.6 4.2 3.0 3.5 2.5 3.0 2.4 2.9

2.1* 2.1* 7.7* 7.7* 21.6* 21.6* 17.7* 17.7* 14.9* 14.9* 12.9* 12.9* 11.3* 11.3* 10.0* 10.0* 8.6 8.8* 7.5 7.8* 6.5* 6.5* 6.0* 6.0*

2.7* 2.7* 6.5* 6.5* 10.7 12.5 8.5 9.8 6.9 8.0 5.7 6.6 4.7 5.5 4.0 4.7 3.4 4.0 2.9 3.4 2.5 3.0 2.4 2.9

2.7* 2.7* 6.5* 6.5* 14.7* 14.7* 17.6* 17.6* 14.9* 14.9* 12.8* 12.8* 11.1* 11.1* 9.8 9.8* 8.5 8.6* 7.4* 7.4* 5.9* 5.9* 5.5* 5.5*

3.7* 3.7* 6.7* 6.7* 10.0 11.8 7.9 9.3 6.4 7.5 5.3 6.3 4.5 5.3 3.8 4.5 3.2 3.9 2.8 3.3 2.5 3.0

3.7* 3.7* 6.7* 6.7* 12.6* 12.6* 17.0* 17.0* 14.4* 14.4* 12.4* 12.4* 10.8* 10.8* 9.4* 9.4* 8.1* 8.1* 6.7* 6.7* 5.0* 5.0*

7.5* 7.5* 9.6 11.4 7.5 8.9 6.1 7.2 5.1 6.0 4.3 5.1 3.7 4.4 3.2 3.8 2.8 3.3 2.7 3.2

7.5* 7.5* 12.3* 12.3* 15.8* 15.8* 13.5* 13.5* 11.7* 11.7* 10.1* 10.1* 8.7* 8.7* 7.3* 7.3* 5.7* 5.7* 5.4* 5.4*

9.5 11.3 7.4 8.7 6.0 7.1 5.0 5.9 4.2 5.0 3.6 4.3 3.2 3.8

12.7* 12.7* 13.8* 13.8* 12.1* 12.1* 10.4* 10.4* 9.0* 9.0* 7.5* 7.5* 6.1* 6.1*

8.9

11.5

13.4

14.9

16.1

17.1

18.0

18.6

19.2

19.6

19.8

20.0

20.0

20.0

19.8

19.4

18.3

16.4

Industrial Stick 10.00 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m

m Undercarriage m

Stabilizers raised

24.0

4 pt. outriggers down

Stabilizers raised

22.5

4 pt. outriggers down

Stabilizers raised

21.0

4 pt. outriggers down

Stabilizers raised

19.5

4 pt. outriggers down

Stabilizers raised

18.0

4 pt. outriggers down

Stabilizers raised

16.5

4 pt. outriggers down

Stabilizers raised

15.0

4 pt. outriggers down

Stabilizers raised

13.5

4 pt. outriggers down

Stabilizers raised

12.0

4 pt. outriggers down

Stabilizers raised

10.5

4 pt. outriggers down

Stabilizers raised

9.0

4 pt. outriggers down

Stabilizers raised

7.5

4 pt. outriggers down

Stabilizers raised

6.0

4 pt. outriggers down

Stabilizers raised

4.5

4 pt. outriggers down

Stabilizers raised

3.0

4 pt. outriggers down

Stabilizers raised

1.5

4 pt. outriggers down

Stabilizers raised

0

4 pt. outriggers down

Stabilizers raised

– 1.5

4 pt. outriggers down

Stabilizers raised

– 3.0

4 pt. outriggers down

Stabilizers raised

– 4.5

4 pt. outriggers down

Stabilizers raised

– 6.0

4 pt. outriggers down

Stabilizers raised

– 7.5

4 pt. outriggers down

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the stick end without attachment are stated in metric tons (t) and are valid on a firm, level supporting surface with blocked oscillating axle. These

capacities can be slewed through 360° with the undercarriage in the transverse position. Capacities in the longitudinal position of the undercarriage (+/– 15°) are specified over the steering axle with the stabilizers raised and over the rigid axle with the stabilizers down. Indicated loads comply with the ISO 10567 standard and do not

exceed 75 % of tipping or 87 % of hydraulic capacity. The lift capacity values indicated are attained at the corresponding operating temperature. This operating temperature is ensured by continuous movement of the boom. Weights of fitted working tools (grabs, load hooks, etc.) and load accommodation equipment are to be

deducted from the lift capacity values. The lift capacity of the unit is limited by its stability, the lifting capability of the hydraulic elements, or the maximum permissible

lifting capacity of the load hook.

In accordance with the harmonised EU Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe rupture protection devices on

the hoist cylinders and an overload warning device.

10.9* 10.9* 10.3* 10.3*

10.9* 10.9* 10.3* 10.3*

10.9* 10.9* 9.1* 9.1* 8.3* 8.3*

10.9* 10.9* 9.1* 9.1* 8.3* 8.3*

11.7* 11.7* 10.6* 10.6* 9.1* 9.1* 7.3* 7.3*

11.7* 11.7* 10.6* 10.6* 9.1* 9.1* 7.3* 7.3*

11.4* 11.4* 9.9 10.4* 7.7 8.5 6.0 6.7*

11.4* 11.4* 10.4* 10.4* 8.9* 8.9* 6.7* 6.7*

11.8* 11.8* 10.1 11.1* 7.9 8.8 6.2 6.9 5.0 5.6

11.8* 11.8* 11.1* 11.1* 10.1* 10.1* 8.5* 8.5* 6.3* 6.3*

12.1* 12.1* 10.2 11.0* 8.0 8.9 6.3 7.1 4.9 5.6 4.2 4.8

12.1* 12.1* 11.0* 11.0* 10.0* 10.0* 9.2* 9.2* 7.8* 7.8* 6.1* 6.1*

12.2* 12.2* 10.2 11.0* 8.0 8.9 6.4 7.1 5.0 5.6 3.9 4.4 3.7 4.2

12.2* 12.2* 11.0* 11.0* 10.0* 10.0* 9.2* 9.2* 8.5* 8.5* 6.6* 6.6* 5.9* 5.9*

12.3* 12.3* 10.0 11.0 7.9 8.8 6.3 7.0 5.0 5.6 3.9 4.5 3.2 3.8

12.3* 12.3* 11.1* 11.1* 10.1* 10.1* 9.2* 9.2* 8.5* 8.5* 7.9* 7.9* 5.7* 5.7*

12.5 12.5* 9.7 10.7 7.7 8.5 6.1 6.9 4.9 5.5 3.9 4.4 3.0 3.5 2.9 3.4

12.5* 12.5* 11.2* 11.2* 10.1* 10.1* 9.3* 9.3* 8.5* 8.5* 7.9* 7.9* 6.2* 6.2* 5.7* 5.7*

13.5* 13.5* 11.9 12.8* 9.3 10.3 7.4 8.2 5.9 6.6 4.7 5.4 3.8 4.4 3.0 3.5 2.6 3.1

13.5* 13.5* 12.8* 12.8* 11.4* 11.4* 10.3* 10.3* 9.4* 9.4* 8.6* 8.6* 7.9* 7.9* 7.1 7.3* 5.6* 5.6*

13.3* 13.3* 14.8 15.0* 11.3 12.5 8.8 9.8 7.0 7.8 5.6 6.4 4.5 5.2 3.7 4.2 2.9 3.4 2.4 2.9

13.3* 13.3* 15.0* 15.0* 13.1* 13.1* 11.6* 11.6* 10.4* 10.4* 9.5* 9.5* 8.6* 8.6* 7.9* 7.9* 7.1 7.2* 5.6* 5.6*

13.7* 13.7* 16.6* 16.6* 13.6 15.1 10.4 11.6 8.2 9.2 6.6 7.4 5.3 6.0 4.3 4.9 3.5 4.1 2.8 3.3 2.3 2.8

13.7* 13.7* 16.6* 16.6* 15.6* 15.6* 13.5* 13.5* 11.9* 11.9* 10.6* 10.6* 9.6* 9.6* 8.7* 8.7* 7.9* 7.9* 6.9 7.2* 5.7* 5.7*

26.0* 26.0* 23.4 24.6* 16.4 18.5 12.3 13.8 9.5 10.7 7.6 8.5 6.1 6.9 5.0 5.7 4.1 4.7 3.3 3.9 2.7 3.2 2.2 2.6

26.0* 26.0* 24.6* 24.6* 19.6* 19.6* 16.3* 16.3* 13.9* 13.9* 12.2* 12.2* 10.8* 10.8* 9.7* 9.7* 8.8* 8.8* 7.9 7.9* 6.8 7.1* 5.8* 5.8*

8.3* 8.3* 19.8 22.7 14.3 16.3 10.9 12.4 8.6 9.8 6.9 7.9 5.6 6.4 4.6 5.3 3.8 4.4 3.1 3.7 2.6 3.1 2.1 2.6 2.1 2.6

8.3* 8.3* 26.1* 26.1* 20.5* 20.5* 16.8* 16.8* 14.3* 14.3* 12.4* 12.4* 11.0* 11.0* 9.8* 9.8* 8.8* 8.8* 7.7 7.9* 6.7 7.0* 5.9 5.9* 5.9 5.9*

3.4* 3.4* 12.1* 12.1* 12.5 14.4 9.7 11.2 7.8 8.9 6.3 7.3 5.2 6.0 4.3 5.0 3.5 4.2 2.9 3.5 2.4 3.0 2.1 2.5

3.4* 3.4* 12.1* 12.1* 21.1* 21.1* 17.3* 17.3* 14.6* 14.6* 12.6* 12.6* 11.0* 11.0* 9.8* 9.8* 8.7 8.7* 7.5 7.8* 6.6 6.8* 5.5* 5.5*

3.2* 3.2* 7.9* 7.9* 11.1 12.9 8.7 10.1 7.0 8.2 5.8 6.7 4.8 5.6 4.0 4.7 3.3 3.9 2.8 3.3 2.3 2.9 2.1 2.5

3.2* 3.2* 7.9* 7.9* 19.8* 19.8* 17.4* 17.4* 14.7* 14.7* 12.6* 12.6* 11.0* 11.0* 9.7* 9.7* 8.4 8.6* 7.3 7.5* 6.4* 6.4* 5.1* 5.1*

3.8* 3.8* 7.2* 7.2* 10.1 11.9 8.0 9.3 6.5 7.6 5.3 6.3 4.4 5.2 3.7 4.4 3.1 3.8 2.7 3.2 2.3 2.8 2.1 2.6

3.8* 3.8* 7.2* 7.2* 14.3* 14.3* 17.1* 17.1* 14.5* 14.5* 12.4* 12.4* 10.8* 10.8* 9.5* 9.5* 8.2 8.3* 7.1* 7.1* 5.8* 5.8* 4.6* 4.6*

4.7* 4.7* 7.5* 7.5* 9.5 11.3 7.5 8.8 6.0 7.1 5.0 5.9 4.2 5.0 3.5 4.2 3.0 3.6 2.6 3.1 2.3 2.8 2.2 2.7

4.7* 4.7* 7.5* 7.5* 12.8* 12.8* 16.4* 16.4* 13.9* 13.9* 11.9* 11.9* 10.3* 10.3* 9.0* 9.0* 7.7* 7.7* 6.4* 6.4* 4.8* 4.8* 4.7* 4.7*

8.1* 8.1* 9.2 11.0 7.2 8.5 5.8 6.9 4.8 5.7 4.0 4.8 3.4 4.1 2.9 3.6 2.6 3.1 2.5 3.1

8.1* 8.1* 12.6* 12.6* 14.9* 14.9* 12.8* 12.8* 11.0* 11.0* 9.5* 9.5* 8.1* 8.1* 6.8* 6.8* 5.3* 5.3* 5.2* 5.2*

7.1 8.4 5.7 6.8 4.7 5.6 4.0 4.7 3.4 4.1 3.2 3.8

12.8* 12.8* 11.1* 11.1* 9.6* 9.6* 8.2* 8.2* 6.9* 6.9* 6.2* 6.2*

7.9

10.9

13.1

14.8

16.2

17.3

18.3

19.0

19.7

20.2

20.6

20.8

21.0

21.0

20.9

20.8

20.5

19.6

18.1

15.7

LH 80 M Litronic Machine for Industrial Applications 7

Page 8

Industrial Attachment

with Industrial-Type Angled Mono Boom 11.50 m

ft m

70

65

60

55

50

45

40

35

30

25

20

15

10

-10

-15

-20

-25

-30

-35

22

20

18

16

14

12

10

8

6

4

2

5

0

0

-5

-2

-4

-6

-8

-10

-12

6570 60 55 50 45 40 35 30 25 20 15 10 5 0

1

2

3

4

0246810121416182022

m

ft

Attachment Envelope

Kinematic variant 2D

1 with industrial stick 9.00 m

2 with industrial stick 10.00 m

3 with industrial stick 9.00 m and clamshell model GM 22C

4 with industrial stick 10.00 m and clamshell model GM 22C

Operating Weight

The operating weight includes basic machine with 4 pt. outriggers,

hydr. cab elevation, 4 solid tires and industrial attachment with industrial-type angled mono boom 11.50 m.

with clamshell model GM 22C/2.50 m

shells for loose material Weight

and industrial stick 9.00 m 77,700 kg

and industrial stick 10.00 m 78,000 kg

3

Kinematic Variants 2D/2C

Energy recovery with

kinematic variant

Hole C

Hole D

Hole 2

Energy recovery with

kinematic variant

2D

2D

2C

2C

2D

2C

Kinematic Variant 2D Kinematic Variant 2C

Altered range curve with additional reach

depth, e.g. for unloading from ships

8 LH 80 M Litronic Machine for Industrial Applications

Page 9

Lift Capacities

with Industrial-Type Angled Mono Boom 11.50 m (Kinematic Variant 2D)

Industrial Stick 9.00 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m

m Undercarriage m

Stabilizers raised

24.0

4 pt. outriggers down

Stabilizers raised

22.5

4 pt. outriggers down

Stabilizers raised

21.0

4 pt. outriggers down

Stabilizers raised

19.5

4 pt. outriggers down

Stabilizers raised

18.0

4 pt. outriggers down

Stabilizers raised

16.5

4 pt. outriggers down

Stabilizers raised

15.0

4 pt. outriggers down

Stabilizers raised

13.5

4 pt. outriggers down

Stabilizers raised

12.0

4 pt. outriggers down

Stabilizers raised

10.5

4 pt. outriggers down

Stabilizers raised

9.0

4 pt. outriggers down

Stabilizers raised

7.5

4 pt. outriggers down

Stabilizers raised

6.0

4 pt. outriggers down

Stabilizers raised

4.5

4 pt. outriggers down

Stabilizers raised

3.0

4 pt. outriggers down

Stabilizers raised

1.5

4 pt. outriggers down

Stabilizers raised

0

4 pt. outriggers down

Stabilizers raised

– 1.5

4 pt. outriggers down

Stabilizers raised

– 3.0

4 pt. outriggers down

Stabilizers raised

– 4.5

4 pt. outriggers down

Stabilizers raised

– 6.0

4 pt. outriggers down

Stabilizers raised

– 7.5

4 pt. outriggers down

8.3* 8.3*

8.3* 8.3*

10.0* 10.0* 8.1* 8.1* 7.5* 7.5*

10.0* 10.0* 8.1* 8.1* 7.5* 7.5*

10.6* 10.6* 9.7* 9.7* 7.9 7.9* 7.1* 7.1*

10.6* 10.6* 9.7* 9.7* 7.9* 7.9* 7.1* 7.1*

9.5* 9.5* 8.1 8.8* 6.3 7.0 6.0 6.7

9.5* 9.5* 8.8* 8.8* 7.3* 7.3* 6.8* 6.8*

9.5* 9.5* 8.1 8.8* 6.4 7.1 5.1 5.8

9.5* 9.5* 8.8* 8.8* 8.2* 8.2* 6.6* 6.6*

10.6* 10.6* 9.6* 9.6* 8.0 8.8 6.3 7.1 5.0 5.7 4.5 5.1

10.6* 10.6* 9.6* 9.6* 8.8* 8.8* 8.2* 8.2* 7.7* 7.7* 6.5* 6.5*

10.8* 10.8* 9.8* 9.8* 7.8 8.6 6.2 6.9 5.0 5.6 4.0 4.5

10.8* 10.8* 9.8* 9.8* 8.9* 8.9* 8.3* 8.3* 7.7* 7.7* 6.5* 6.5*

12.6* 12.6* 11.1* 11.1* 9.4 10.0* 7.5 8.3 6.0 6.7 4.8 5.5 3.8 4.4 3.6 4.1

12.6* 12.6* 11.1* 11.1* 10.0* 10.0* 9.1* 9.1* 8.4* 8.4* 7.8* 7.8* 7.3* 7.3* 6.5* 6.5*

15.4* 15.4* 13.2* 13.2* 11.3 11.5* 8.9 9.9 7.1 7.9 5.7 6.4 4.6 5.3 3.7 4.3 3.3 3.8

15.4* 15.4* 13.2* 13.2* 11.5* 11.5* 10.3* 10.3* 9.3* 9.3* 8.5* 8.5* 7.9* 7.9* 7.4* 7.4* 6.6* 6.6*

26.9* 26.9* 20.3* 20.3* 16.4* 16.4* 13.5 13.8* 10.4 11.6 8.3 9.3 6.7 7.5 5.4 6.1 4.4 5.0 3.6 4.1 3.0 3.5

26.9* 26.9* 20.3* 20.3* 16.4* 16.4* 13.8* 13.8* 12.0* 12.0* 10.6* 10.6* 9.6* 9.6* 8.7* 8.7* 8.0* 8.0* 7.5* 7.5* 6.8* 6.8*

30.6* 30.6* 22.2 22.3* 16.0 17.6* 12.1 13.6 9.5 10.7 7.6 8.6 6.2 7.0 5.1 5.8 4.2 4.8 3.4 4.0 2.8 3.3

30.6* 30.6* 22.3* 22.3* 17.6* 17.6* 14.6* 14.6* 12.5* 12.5* 11.0* 11.0* 9.8* 9.8* 8.9* 8.9* 8.2* 8.2* 7.5* 7.5* 7.0* 7.0*

6.9* 6.9* 18.8 21.6 14.0 15.9 10.8 12.3 8.6 9.8 7.0 7.9 5.7 6.5 4.7 5.4 3.9 4.5 3.2 3.8 2.7 3.2

6.9* 6.9* 23.2* 23.2* 18.7* 18.7* 15.3* 15.3* 13.0* 13.0* 11.4* 11.4* 10.1* 10.1* 9.1* 9.1* 8.3* 8.3* 7.6* 7.6* 6.9 7.0*

4.8* 4.8* 11.4* 11.4* 12.2 14.1 9.7 11.1 7.8 8.9 6.4 7.3 5.3 6.1 4.4 5.1 3.7 4.3 3.1 3.6 2.6 3.1

4.8* 4.8* 11.4* 11.4* 19.6* 19.6* 16.0* 16.0* 13.5* 13.5* 11.7* 11.7* 10.3* 10.3* 9.3* 9.3* 8.4* 8.4* 7.6* 7.6* 6.8 7.0*

4.9* 4.9* 9.1* 9.1* 11.0 12.8 8.7 10.1 7.1 8.2 5.9 6.8 4.9 5.7 4.1 4.8 3.4 4.1 2.9 3.5 2.6 3.1

4.9* 4.9* 9.1* 9.1* 18.0* 18.0* 16.4* 16.4* 13.8* 13.8* 11.9* 11.9* 10.5* 10.5* 9.4* 9.4* 8.4* 8.4* 7.5 7.5* 6.8 6.9*

5.5* 5.5* 8.7* 8.7* 10.1 12.0 8.0 9.4 6.6 7.7 5.4 6.4 4.6 5.4 3.9 4.6 3.3 3.9 2.8 3.3 2.6 3.1

5.5* 5.5* 8.7* 8.7* 14.8* 14.8* 16.6* 16.6* 14.0* 14.0* 12.1* 12.1* 10.6* 10.6* 9.4* 9.4* 8.3* 8.3* 7.3 7.4* 6.8* 6.8*

6.3* 6.3* 9.0* 9.0* 9.6 11.4 7.6 9.0 6.2 7.3 5.1 6.1 4.3 5.1 3.7 4.4 3.1 3.8 2.7 3.3 2.6 3.2

6.3* 6.3* 9.0* 9.0* 13.8* 13.8* 16.4* 16.4* 13.9* 13.9* 12.0* 12.0* 10.4* 10.4* 9.2* 9.2* 8.1* 8.1* 7.0* 7.0* 6.7* 6.7*

9.5* 9.5* 9.4 11.2 7.3 8.7 5.9 7.0 4.9 5.9 4.2 5.0 3.6 4.3 3.1 3.7 2.8 3.3

9.5* 9.5* 13.7* 13.7* 15.8* 15.8* 13.4* 13.4* 11.6* 11.6* 10.1* 10.1* 8.8* 8.8* 7.6* 7.6* 6.5* 6.5*

9.4 11.2 7.2 8.6 5.8 6.9 4.8 5.8 4.1 4.9 3.5 4.2 3.1 3.7

14.1* 14.1* 14.6* 14.6* 12.5* 12.5* 10.8* 10.8* 9.4* 9.4* 8.0* 8.0* 6.7* 6.7*

10.2

12.3

14.0

15.3

16.3

17.2

17.9

18.4

18.9

19.1

19.3

19.4

19.3

19.1

18.8

18.3

17.7

16.5

Industrial Stick 10.00 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m

m Undercarriage m

Stabilizers raised

24.0

4 pt. outriggers down

Stabilizers raised

22.5

4 pt. outriggers down

Stabilizers raised

21.0

4 pt. outriggers down

Stabilizers raised

19.5

4 pt. outriggers down

Stabilizers raised

18.0

4 pt. outriggers down

Stabilizers raised

16.5

4 pt. outriggers down

Stabilizers raised

15.0

4 pt. outriggers down

Stabilizers raised

13.5

4 pt. outriggers down

Stabilizers raised

12.0

4 pt. outriggers down

Stabilizers raised

10.5

4 pt. outriggers down

Stabilizers raised

9.0

4 pt. outriggers down

Stabilizers raised

7.5

4 pt. outriggers down

Stabilizers raised

6.0

4 pt. outriggers down

Stabilizers raised

4.5

4 pt. outriggers down

Stabilizers raised

3.0

4 pt. outriggers down

Stabilizers raised

1.5

4 pt. outriggers down

Stabilizers raised

0

4 pt. outriggers down

Stabilizers raised

– 1.5

4 pt. outriggers down

Stabilizers raised

– 3.0

4 pt. outriggers down

Stabilizers raised

– 4.5

4 pt. outriggers down

Stabilizers raised

– 6.0

4 pt. outriggers down

Stabilizers raised

– 7.5

4 pt. outriggers down

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the stick end without attachment are stated in metric tons (t) and are valid on a firm, level supporting surface with blocked oscillating axle. These

capacities can be slewed through 360° with the undercarriage in the transverse position. Capacities in the longitudinal position of the undercarriage (+/– 15°) are specified over the steering axle with the stabilizers raised and over the rigid axle with the stabilizers down. Indicated loads comply with the ISO 10567 standard and do not

exceed 75 % of tipping or 87 % of hydraulic capacity. The lift capacity values indicated are attained at the corresponding operating temperature. This operating temperature is ensured by continuous movement of the boom. Weights of fitted working tools (grabs, load hooks, etc.) and load accommodation equipment are to be

deducted from the lift capacity values. The lift capacity of the unit is limited by its stability, the lifting capability of the hydraulic elements, or the maximum permissible

lifting capacity of the load hook.

In accordance with the harmonised EU Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe rupture protection devices on

the hoist cylinders and an overload warning device.

7.9* 7.9*

7.9* 7.9*

8.6* 8.6* 6.9* 6.9*

8.6* 8.6* 6.9* 6.9*

8.6* 8.6* 6.8* 6.8* 6.4* 6.4*

8.6* 8.6* 6.8* 6.8* 6.4* 6.4*

9.1* 9.1* 8.4 8.4* 6.5* 6.5* 6.1* 6.1*

9.1* 9.1* 8.4* 8.4* 6.5* 6.5* 6.1* 6.1*

9.0* 9.0* 8.3* 8.3* 6.7 7.4 5.3 5.9*

9.0* 9.0* 8.3* 8.3* 7.8* 7.8* 5.9* 5.9*

9.0* 9.0* 8.3* 8.3* 6.7 7.4 5.3 5.9 4.5 5.1

9.0* 9.0* 8.3* 8.3* 7.8* 7.8* 7.3* 7.3* 5.7* 5.7*

9.1* 9.1* 8.3 8.4* 6.6 7.4 5.3 5.9 4.1 4.7 4.0 4.5

9.1* 9.1* 8.4* 8.4* 7.8* 7.8* 7.3* 7.3* 6.1* 6.1* 5.6* 5.6*

9.2* 9.2* 8.1 8.5* 6.5 7.2 5.2 5.8 4.1 4.7 3.5 4.1

9.2* 9.2* 8.5* 8.5* 7.8* 7.8* 7.3* 7.3* 6.9* 6.9* 5.6* 5.6*

10.5* 10.5* 9.5* 9.5* 7.8 8.6* 6.2 7.0 5.0 5.6 4.0 4.6 3.2 3.7

10.5* 10.5* 9.5* 9.5* 8.6* 8.6* 8.0* 8.0* 7.4* 7.4* 6.9* 6.9* 5.6* 5.6*

12.4* 12.4* 10.9* 10.9* 9.3 9.8* 7.4 8.2 5.9 6.7 4.8 5.4 3.8 4.4 3.0 3.6 2.9 3.4

12.4* 12.4* 10.9* 10.9* 9.8* 9.8* 8.9* 8.9* 8.1* 8.1* 7.5* 7.5* 7.0* 7.0* 6.5* 6.5* 5.7* 5.7*

15.4* 15.4* 13.1* 13.1* 11.0 11.4* 8.7 9.7 6.9 7.8 5.6 6.3 4.5 5.2 3.7 4.2 2.9 3.4 2.7 3.2

15.4* 15.4* 13.1* 13.1* 11.4* 11.4* 10.1* 10.1* 9.1* 9.1* 8.3* 8.3* 7.6* 7.6* 7.1* 7.1* 6.6* 6.6* 5.8* 5.8*

27.8* 27.8* 20.7* 20.7* 16.5* 16.5* 12.9 13.8* 10.0 11.2 8.0 9.0 6.4 7.3 5.2 5.9 4.3 4.9 3.5 4.0 2.8 3.3 2.5 3.0

27.8* 27.8* 20.7* 20.7* 16.5* 16.5* 13.8* 13.8* 11.9* 11.9* 10.5* 10.5* 9.4* 9.4* 8.5* 8.5* 7.8* 7.8* 7.2* 7.2* 6.7* 6.7* 6.0* 6.0*

16.2* 16.2* 20.8 22.6* 15.1 17.1 11.5 13.0 9.1 10.2 7.3 8.2 5.9 6.7 4.8 5.6 4.0 4.6 3.2 3.8 2.6 3.2 2.4 2.8

16.2* 16.2* 22.6* 22.6* 17.7* 17.7* 14.6* 14.6* 12.4* 12.4* 10.9* 10.9* 9.7* 9.7* 8.7* 8.7* 7.9* 7.9* 7.3* 7.3* 6.7* 6.7* 6.2* 6.2*

6.7* 6.7* 17.5* 17.5* 13.1 15.0 10.2 11.6 8.1 9.3 6.6 7.6 5.4 6.2 4.5 5.2 3.7 4.3 3.0 3.6 2.5 3.0 2.3 2.8

6.7* 6.7* 17.5* 17.5* 18.7* 18.7* 15.3* 15.3* 12.9* 12.9* 11.2* 11.2* 9.9* 9.9* 8.9* 8.9* 8.1* 8.1* 7.4* 7.4* 6.6 6.7* 6.2 6.4*

5.5* 5.5* 10.9* 10.9* 11.5 13.4 9.1 10.5 7.3 8.5 6.0 6.9 5.0 5.8 4.1 4.8 3.4 4.1 2.9 3.4 2.4 2.9 2.2 2.7

5.5* 5.5* 10.9* 10.9* 19.5* 19.5* 15.9* 15.9* 13.4* 13.4* 11.5* 11.5* 10.1* 10.1* 9.0* 9.0* 8.1* 8.1* 7.4* 7.4* 6.5 6.6* 6.2 6.4*

5.7* 5.7* 9.4* 9.4* 10.4 12.2 8.2 9.6 6.7 7.8 5.5 6.4 4.6 5.4 3.8 4.5 3.2 3.8 2.7 3.3 2.3 2.8 2.2 2.7

5.7* 5.7* 9.4* 9.4* 16.9* 16.9* 16.2* 16.2* 13.6* 13.6* 11.7* 11.7* 10.3* 10.3* 9.1* 9.1* 8.2* 8.2* 7.3 7.3* 6.4 6.5* 6.3 6.3*

6.2* 6.2* 9.1* 9.1* 9.6 11.4 7.6 9.0 6.2 7.3 5.1 6.0 4.3 5.1 3.6 4.3 3.0 3.7 2.6 3.1 2.3 2.8

6.2* 6.2* 9.1* 9.1* 14.6* 14.6* 16.3* 16.3* 13.7* 13.7* 11.8* 11.8* 10.3* 10.3* 9.1* 9.1* 8.1* 8.1* 7.1* 7.1* 6.2* 6.2*

6.8* 6.8* 9.3* 9.3* 9.2 11.0 7.2 8.5 5.8 6.9 4.8 5.7 4.0 4.8 3.4 4.1 2.9 3.5 2.5 3.1 2.3 2.9

6.8* 6.8* 9.3* 9.3* 13.8* 13.8* 15.9* 15.9* 13.5* 13.5* 11.6* 11.6* 10.1* 10.1* 8.9* 8.9* 7.8* 7.8* 6.7* 6.7* 6.1* 6.1*

9.7* 9.7* 9.0 10.8 7.0 8.3 5.6 6.7 4.6 5.6 3.9 4.7 3.3 4.0 2.9 3.5 2.5 3.1 2.5 3.1

9.7* 9.7* 13.8* 13.8* 15.1* 15.1* 12.9* 12.9* 11.1* 11.1* 9.6* 9.6* 8.4* 8.4* 7.2* 7.2* 5.9* 5.9* 5.8* 5.8*

9.1 10.9 6.9 8.3 5.6 6.7 4.6 5.5 3.9 4.7 3.3 4.0 3.1 3.7

14.2* 14.2* 13.7* 13.7* 11.8* 11.8* 10.2* 10.2* 8.8* 8.8* 7.5* 7.5* 6.8* 6.8*

9.4

11.9

13.7

15.2

16.4

17.4

18.2

18.9

19.4

19.8

20.1

20.2

20.3

20.2

20.0

19.7

19.3

18.7

18.0

15.8

LH 80 M Litronic Machine for Industrial Applications 9

Page 10

Industrial Attachment

with Industrial-Type Straight Mono Boom 12.50 m

ft m

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

-5

-10

-15

-20

-25

-30

-35

-10

24

22

20

18

16

14

12

10

8

6

4

2

0

-2

-4

-6

-8

657075 60 55 50 45 40 35 30 25 20 15 10 5 0

1

2

3

4

024681012141618202224

m

ft

Attachment Envelope

Kinematic variant 2A

1 with industrial stick 9.00 m

2 with industrial stick 10.00 m

3 with industrial stick 9.00 m and grapple model GMM 80-5

4 with industrial stick 10.00 m and grapple model GMM 80-5

Operating Weight

The operating weight includes basic machine with 4 pt. outriggers,

hydr. cab elevation, 4 solid tires and industrial attachment with industrial-type straight mono boom 12.50 m.

with grapple model GMM 80-5/1.40 m

and industrial stick 9.00 m 77,800 kg

and industrial stick 10.00 m 78,100 kg

3

semi-closed tines Weight

Kinematic Variant 2A

Hole A

2A2A

Hole 2

Energy recovery with

kinematic variant 2A

10 LH 80 M Litronic Machine for Industrial Applications

Page 11

Lift Capacities

with Industrial-Type Straight Mono Boom 12.50 m (Kinematic Variant 2A)

Industrial Stick 9.00 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m

m Undercarriage m

Stabilizers raised

24.0

4 pt. outriggers down

Stabilizers raised

22.5

4 pt. outriggers down

Stabilizers raised

21.0

4 pt. outriggers down

Stabilizers raised

19.5

4 pt. outriggers down

Stabilizers raised

18.0

4 pt. outriggers down

Stabilizers raised

16.5

4 pt. outriggers down

Stabilizers raised

15.0

4 pt. outriggers down

Stabilizers raised

13.5

4 pt. outriggers down

Stabilizers raised

12.0

4 pt. outriggers down

Stabilizers raised

10.5

4 pt. outriggers down

Stabilizers raised

9.0

4 pt. outriggers down

Stabilizers raised

7.5

4 pt. outriggers down

Stabilizers raised

6.0

4 pt. outriggers down

Stabilizers raised

4.5

4 pt. outriggers down

Stabilizers raised

3.0

4 pt. outriggers down

Stabilizers raised

1.5

4 pt. outriggers down

Stabilizers raised

0

4 pt. outriggers down

Stabilizers raised

– 1.5

4 pt. outriggers down

Stabilizers raised

– 3.0

4 pt. outriggers down

Stabilizers raised

– 4.5

4 pt. outriggers down

Stabilizers raised

– 6.0

4 pt. outriggers down

Stabilizers raised

– 7.5

4 pt. outriggers down

11.9* 11.9* 11.2* 11.2*

11.9* 11.9* 11.2* 11.2*

13.3* 13.3* 12.0* 12.0* 10.0* 10.0* 9.2* 9.2*

13.3* 13.3* 12.0* 12.0* 10.0* 10.0* 9.2* 9.2*

12.9* 12.9* 11.8* 11.8* 9.2 10.2 7.4 8.2*

12.9* 12.9* 11.8* 11.8* 10.2* 10.2* 8.2* 8.2*

13.4* 13.4* 12.4 12.7* 9.6 10.6 7.4 8.2 5.8 6.5

13.4* 13.4* 12.7* 12.7* 11.3* 11.3* 10.0* 10.0* 7.6* 7.6*

12.6 12.6* 9.7 10.8 7.6 8.4 5.9 6.6 4.7 5.4

12.6* 12.6* 11.2* 11.2* 10.1* 10.1* 9.3* 9.3* 7.2* 7.2*

12.6 12.6* 9.8 10.8 7.6 8.5 6.0 6.7 4.6 5.3 4.0 4.6

12.6* 12.6* 11.2* 11.2* 10.1* 10.1* 9.2* 9.2* 8.5* 8.5* 6.9* 6.9*

14.3* 14.3* 12.4 12.6* 9.6 10.6 7.6 8.4 6.0 6.7 4.7 5.3 3.6 4.2 3.4 4.0

14.3* 14.3* 12.6* 12.6* 11.2* 11.2* 10.1* 10.1* 9.2* 9.2* 8.4* 8.4* 7.5* 7.5* 6.7* 6.7*

14.6* 14.6* 12.1 12.7* 9.4 10.4 7.4 8.2 5.9 6.6 4.6 5.3 3.6 4.2 3.0 3.5

14.6* 14.6* 12.7* 12.7* 11.3* 11.3* 10.1* 10.1* 9.2* 9.2* 8.4* 8.4* 7.7* 7.7* 6.6* 6.6*

14.9* 14.9* 11.5 12.8 9.0 10.0 7.1 8.0 5.7 6.4 4.5 5.2 3.6 4.1 2.8 3.3 2.7 3.2

14.9* 14.9* 12.9* 12.9* 11.4* 11.4* 10.2* 10.2* 9.3* 9.3* 8.4* 8.4* 7.7* 7.7* 6.9 7.0* 6.5* 6.5*

16.3* 16.3* 14.3 15.2* 10.9 12.1 8.5 9.5 6.8 7.6 5.4 6.1 4.3 5.0 3.5 4.0 2.7 3.2 2.4 2.9

16.3* 16.3* 15.2* 15.2* 13.2* 13.2* 11.6* 11.6* 10.3* 10.3* 9.3* 9.3* 8.5* 8.5* 7.7* 7.7* 6.9 7.0* 6.4 6.5*

13.9* 13.9* 18.2* 18.2* 17.7 18.8* 13.1 14.6 10.1 11.3 7.9 8.9 6.3 7.2 5.1 5.8 4.1 4.8 3.3 3.9 2.6 3.1 2.2 2.7

13.9* 13.9* 18.2* 18.2* 18.8* 18.8* 15.7* 15.7* 13.4* 13.4* 11.8* 11.8* 10.5* 10.5* 9.4* 9.4* 8.5* 8.5* 7.7* 7.7* 6.8 7.0* 6.1 6.4*

33.6* 33.6* 22.1 24.6* 15.7 17.7 11.8 13.2 9.2 10.3 7.3 8.2 5.9 6.7 4.8 5.5 3.9 4.5 3.1 3.7 2.5 3.0 2.0 2.5

33.6* 33.6* 24.6* 24.6* 19.5* 19.5* 16.1* 16.1* 13.7* 13.7* 12.0* 12.0* 10.6* 10.6* 9.5* 9.5* 8.5* 8.5* 7.7* 7.7* 6.7 6.9* 5.8 6.1*

16.6* 16.6* 13.5 15.4 10.4 11.8 8.2 9.4 6.6 7.6 5.4 6.2 4.4 5.1 3.6 4.2 2.9 3.5 2.4 2.9 1.9 2.4

16.6* 16.6* 20.1* 20.1* 16.5* 16.5* 14.0* 14.0* 12.1* 12.1* 10.7* 10.7* 9.5* 9.5* 8.5* 8.5* 7.5 7.7* 6.5 6.8* 5.7 5.8*

5.2* 5.2* 11.5 13.4 9.1 10.5 7.3 8.5 6.0 6.9 4.9 5.7 4.1 4.8 3.3 4.0 2.8 3.3 2.3 2.8 1.9 2.3 1.9 2.3

5.2* 5.2* 20.0* 20.0* 16.8* 16.8* 14.2* 14.2* 12.2* 12.2* 10.7* 10.7* 9.5* 9.5* 8.5 8.5* 7.3 7.6* 6.4 6.7* 5.5* 5.5* 5.5* 5.5*

0.2* 0.2* 3.7* 3.7* 10.0 10.7* 8.0 9.4 6.5 7.7 5.4 6.3 4.5 5.3 3.7 4.4 3.1 3.7 2.6 3.2 2.2 2.7 1.8 2.3

0.2* 0.2* 3.7* 3.7* 10.7* 10.7* 16.8* 16.8* 14.2* 14.2* 12.2* 12.2* 10.7* 10.7* 9.4* 9.4* 8.2 8.3* 7.1 7.4* 6.3 6.4* 5.1* 5.1*

1.2* 1.2* 3.9* 3.9* 8.6* 8.6* 7.2 8.6 5.9 7.0 4.9 5.8 4.1 4.9 3.5 4.2 2.9 3.5 2.5 3.0 2.1 2.6 1.8 2.3

1.2* 1.2* 3.9* 3.9* 8.6* 8.6* 16.4* 16.4* 13.9* 13.9* 12.0* 12.0* 10.4* 10.4* 9.2* 9.2* 8.0 8.1* 7.0 7.0* 6.0* 6.0* 4.7* 4.7*

4.6* 4.6* 8.4* 8.4* 6.7 8.1 5.5 6.6 4.6 5.5 3.8 4.6 3.2 3.9 2.8 3.4 2.3 2.9 2.0 2.5 1.9 2.3

4.6* 4.6* 8.4* 8.4* 15.5* 15.5* 13.3* 13.3* 11.5* 11.5* 10.0* 10.0* 8.8* 8.8* 7.6* 7.6* 6.5* 6.5* 5.3* 5.3* 4.2* 4.2*

8.3 8.8* 6.4 7.8 5.2 6.3 4.3 5.2 3.6 4.4 3.1 3.8 2.6 3.3 2.3 2.8 2.0 2.6

8.8* 8.8* 14.1* 14.1* 12.3* 12.3* 10.7* 10.7* 9.3* 9.3* 8.1* 8.1* 6.9* 6.9* 5.7* 5.7* 4.5* 4.5*

6.3 7.7 5.1 6.2 4.2 5.1 3.5 4.3 3.0 3.7 2.6 3.2 2.4 3.0

12.1* 12.1* 10.8* 10.8* 9.5* 9.5* 8.3* 8.3* 7.1* 7.1* 5.9* 5.9* 5.2* 5.2*

7.9

10.9

13.1

14.8

16.2

17.3

18.3

19.1

19.7

20.2

20.6

20.8

21.0

21.0

20.9

20.8

20.4

19.3

17.4

Industrial Stick 10.00 m

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m

m Undercarriage m

Stabilizers raised

24.0

4 pt. outriggers down

Stabilizers raised

22.5

4 pt. outriggers down

Stabilizers raised

21.0

4 pt. outriggers down

Stabilizers raised

19.5

4 pt. outriggers down

Stabilizers raised

18.0

4 pt. outriggers down

Stabilizers raised

16.5

4 pt. outriggers down

Stabilizers raised

15.0

4 pt. outriggers down

Stabilizers raised

13.5

4 pt. outriggers down

Stabilizers raised

12.0

4 pt. outriggers down

Stabilizers raised

10.5

4 pt. outriggers down

Stabilizers raised

9.0

4 pt. outriggers down

Stabilizers raised

7.5

4 pt. outriggers down

Stabilizers raised

6.0

4 pt. outriggers down

Stabilizers raised

4.5

4 pt. outriggers down

Stabilizers raised

3.0

4 pt. outriggers down

Stabilizers raised

1.5

4 pt. outriggers down

Stabilizers raised

0

4 pt. outriggers down

Stabilizers raised

– 1.5

4 pt. outriggers down

Stabilizers raised

– 3.0

4 pt. outriggers down

Stabilizers raised

– 4.5

4 pt. outriggers down

Stabilizers raised

– 6.0

4 pt. outriggers down

Stabilizers raised

– 7.5

4 pt. outriggers down

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities on the stick end without attachment are stated in metric tons (t) and are valid on a firm, level supporting surface with blocked oscillating axle. These

capacities can be slewed through 360° with the undercarriage in the transverse position. Capacities in the longitudinal position of the undercarriage (+/– 15°) are specified over the steering axle with the stabilizers raised and over the rigid axle with the stabilizers down. Indicated loads comply with the ISO 10567 standard and do not

exceed 75 % of tipping or 87 % of hydraulic capacity. The lift capacity values indicated are attained at the corresponding operating temperature. This operating temperature is ensured by continuous movement of the boom. Weights of fitted working tools (grabs, load hooks, etc.) and load accommodation equipment are to be

deducted from the lift capacity values. The lift capacity of the unit is limited by its stability, the lifting capability of the hydraulic elements, or the maximum permissible

lifting capacity of the load hook.

In accordance with the harmonised EU Standard EN 474-5, hydraulic excavators used for lifting operations must be equipped with pipe rupture protection devices on

the hoist cylinders and an overload warning device.

12.3* 12.3* 11.5* 11.5*

12.3* 12.3* 11.5* 11.5*

10.5* 10.5* 8.8* 8.8*

10.5* 10.5* 8.8* 8.8*

11.6* 11.6* 10.4* 10.4* 8.8* 8.8* 7.7* 7.7*

11.6* 11.6* 10.4* 10.4* 8.8* 8.8* 7.7* 7.7*

11.2* 11.2* 9.8 10.2* 7.5 8.4 6.1 6.8

11.2* 11.2* 10.2* 10.2* 8.7* 8.7* 7.0* 7.0*

11.7* 11.7* 10.1 10.9* 7.8 8.7 6.1 6.8 4.9 5.5

11.7* 11.7* 10.9* 10.9* 9.9* 9.9* 8.4* 8.4* 6.5* 6.5*

12.0* 12.0* 10.2 10.8* 8.0 8.9 6.3 7.0 4.8 5.5 4.0 4.6

12.0* 12.0* 10.8* 10.8* 9.8* 9.8* 8.9* 8.9* 7.9* 7.9* 6.2* 6.2*

12.2* 12.2* 10.2 10.8* 8.0 8.9 6.3 7.1 4.9 5.6 3.8 4.3 3.4 3.9

12.2* 12.2* 10.8* 10.8* 9.7* 9.7* 8.9* 8.9* 8.1* 8.1* 7.0* 7.0* 6.0* 6.0*

12.2* 12.2* 10.1 10.8* 7.9 8.8 6.3 7.0 4.9 5.6 3.8 4.4 2.9 3.4

12.2* 12.2* 10.8* 10.8* 9.7* 9.7* 8.9* 8.9* 8.1* 8.1* 7.5* 7.5* 5.8* 5.8*

12.3* 12.3* 9.8 10.8 7.7 8.6 6.1 6.9 4.9 5.5 3.8 4.4 2.9 3.4 2.6 3.1

12.3* 12.3* 10.9* 10.9* 9.8* 9.8* 8.9* 8.9* 8.1* 8.1* 7.5* 7.5* 6.9* 6.9* 5.7* 5.7*

13.1* 13.1* 12.1 12.5* 9.4 10.4 7.4 8.3 5.9 6.6 4.7 5.3 3.7 4.3 2.9 3.4 2.3 2.8

13.1* 13.1* 12.5* 12.5* 11.0* 11.0* 9.9* 9.9* 8.9* 8.9* 8.1* 8.1* 7.5* 7.5* 6.9* 6.9* 5.6* 5.6*

14.3* 14.3* 11.5 12.7 8.9 9.9 7.1 7.9 5.6 6.4 4.5 5.1 3.6 4.1 2.8 3.3 2.1 2.6 2.0 2.5

14.3* 14.3* 12.7* 12.7* 11.2* 11.2* 10.0* 10.0* 9.0* 9.0* 8.2* 8.2* 7.5* 7.5* 6.8* 6.8* 5.9 6.2* 5.6* 5.6*

12.4* 12.4* 14.9* 14.9* 14.0 15.1* 10.7 11.9 8.3 9.3 6.6 7.4 5.3 6.0 4.3 4.9 3.4 4.0 2.7 3.2 2.1 2.5 1.9 2.3

12.4* 12.4* 14.9* 14.9* 15.1* 15.1* 13.0* 13.0* 11.4* 11.4* 10.1* 10.1* 9.1* 9.1* 8.2* 8.2* 7.5* 7.5* 6.8* 6.8* 5.9 6.1* 5.5 5.6*

14.5* 14.5* 18.9* 18.9* 17.0 18.7* 12.6 14.1 9.7 10.9 7.6 8.6 6.1 6.9 4.9 5.6 4.0 4.6 3.2 3.8 2.5 3.1 2.0 2.5 1.7 2.2

14.5* 14.5* 18.9* 18.9* 18.7* 18.7* 15.6* 15.6* 13.3* 13.3* 11.6* 11.6* 10.2* 10.2* 9.2* 9.2* 8.3* 8.3* 7.5* 7.5* 6.7 6.8* 5.8 6.1* 5.3 5.6*

12.2* 12.2* 20.5 23.5 14.7 16.7 11.1 12.6 8.7 9.9 6.9 7.9 5.6 6.4 4.5 5.2 3.7 4.3 3.0 3.5 2.4 2.9 1.9 2.4 1.6 2.1

12.2* 12.2* 24.8* 24.8* 19.4* 19.4* 16.0* 16.0* 13.6* 13.6* 11.8* 11.8* 10.4* 10.4* 9.2* 9.2* 8.3* 8.3* 7.5* 7.5* 6.5 6.7* 5.7 6.0* 5.2 5.4*

1.7* 1.7* 10.6* 10.6* 12.5 14.4 9.7 11.1 7.7 8.9 6.2 7.2 5.1 5.9 4.1 4.8 3.4 4.0 2.8 3.3 2.2 2.8 1.8 2.3 1.6 2.0

1.7* 1.7* 10.6* 10.6* 20.0* 20.0* 16.4* 16.4* 13.8* 13.8* 11.9* 11.9* 10.4* 10.4* 9.3* 9.3* 8.3* 8.3* 7.3 7.4* 6.4 6.6* 5.6 5.8* 5.1* 5.1*

1.2* 1.2* 5.4* 5.4* 10.7 12.5 8.4 9.8 6.8 7.9 5.6 6.5 4.6 5.4 3.8 4.5 3.1 3.7 2.6 3.1 2.1 2.6 1.7 2.2 1.5 2.0

1.2* 1.2* 5.4* 5.4* 15.9* 15.9* 16.5* 16.5* 13.9* 13.9* 12.0* 12.0* 10.5* 10.5* 9.2* 9.2* 8.2* 8.2* 7.1 7.3* 6.2 6.5* 5.5 5.5* 4.7* 4.7*

1.7* 1.7* 4.6* 4.6* 9.4 10.4* 7.5 8.8 6.1 7.2 5.0 5.9 4.1 4.9 3.4 4.1 2.9 3.5 2.4 2.9 2.0 2.5 1.6 2.1 1.5 2.0

1.7* 1.7* 4.6* 4.6* 10.4* 10.4* 16.4* 16.4* 13.8* 13.8* 11.9* 11.9* 10.4* 10.4* 9.1* 9.1* 8.0 8.0* 6.9 7.1* 6.1 6.2* 5.1* 5.1* 4.3* 4.3*

2.5* 2.5* 4.8* 4.8* 8.5 9.1* 6.7 8.1 5.5 6.6 4.5 5.5 3.8 4.6 3.2 3.9 2.7 3.3 2.2 2.8 1.9 2.4 1.6 2.1 1.5 2.0

2.5* 2.5* 4.8* 4.8* 9.1* 9.1* 15.9* 15.9* 13.5* 13.5* 11.6* 11.6* 10.1* 10.1* 8.8* 8.8* 7.7 7.7* 6.7* 6.7* 5.7* 5.7* 4.4* 4.4* 3.9* 3.9*

5.5* 5.5* 8.0 8.9* 6.3 7.6 5.1 6.2 4.2 5.1 3.5 4.3 3.0 3.7 2.5 3.1 2.1 2.7 1.8 2.3 1.7 2.1

5.5* 5.5* 8.9* 8.9* 14.8* 14.8* 12.7* 12.7* 11.0* 11.0* 9.6* 9.6* 8.3* 8.3* 7.2* 7.2* 6.2* 6.2* 5.0* 5.0* 4.0* 4.0*

7.9 9.4* 6.1 7.4 4.9 6.0 4.0 4.9 3.4 4.1 2.8 3.5 2.4 3.0 2.1 2.6 1.9 2.4

9.4* 9.4* 13.2* 13.2* 11.6* 11.6* 10.1* 10.1* 8.8* 8.8* 7.6* 7.6* 6.5* 6.5* 5.3* 5.3* 4.3* 4.3*

6.0 7.3 4.8 5.9 3.9 4.8 3.3 4.1 2.8 3.5 2.4 3.0 2.4 3.0

11.0* 11.0* 9.9* 9.9* 8.7* 8.7* 7.5* 7.5* 6.4* 6.4* 5.3* 5.3* 5.2* 5.2*

6.5

10.2

12.7

14.6

16.2

17.4

18.5

19.4

20.1

20.7

21.2

21.5

21.8

21.9

22.0

21.9

21.7

21.5

20.6

19.1

16.6

LH 80 M Litronic Machine for Industrial Applications 11

Page 12

Choice of Cab Elevation

and Cab Protection

C2

B2

C1

B1

D

Cab Elevation LFC

(Rigid Elevation)

Height mm 1,200 1,500 2,000

C

B

A

D2

D1

A mm 4,365 4,665 5,165

B mm 4,750 5,050 5,550

C mm 5,230 5,530 6,030

D mm 1,110 1,110 1,110

A rigid cab elevation has a fixed eye level height. For a lower transport height, the shell of the cab can be removed and replaced by a

transport device. The dimension C is in this machine design for all

rigid cab elevations 4,340 mm.

Cab Elevation

(

Hydraulic Elevation

Elevation type 360-50

Intermediate piece 500 mm

B1 4,050 mm

B2 7,620 mm

C1 4,530 mm

C2 8,100 mm

D1 2,835 mm

D2 2,985 mm

E 4,510 mm

The hydraulically adjustable cab allows the driver, that he can choose

his field of view freely and at any time within the stroke.

E

LHC

)

Grille above Grilles in front

12 LH 80 M Litronic Machine for Industrial Applications

Page 13

Variety of Tools

Shells for loose material with

Shells for Loose Material

cutting edge (without teeth)

Clamshell Model GM 22C

Cutting width of shells mm 1,500 2,000 1,500 2,000

Capacity m

For loose material, specific weight up to t/m

Weight kg 2,300 2,350 2,400 2,550

Multiple Tine Grapples open tines semi-closed tines closed tines

Grapple Model GMM 80-4 (4 tines)

Capacity m

Weight kg 1,990 2,050 2,195 2,250

Grapple Model GMM 80-5 (5 tines)

Capacity m

Weight kg 2,240 2,310 2,480 2,550 2,600 2,720

3

1.85 2.00 2.20 2.50

3

1.5 1.35 1.2 1.0

3

1.40 1.70 1.40 1.70

3

1.40 1.70 1.40 1.70 1.40 1.70

Crane Hook with Suspension

Max. load t 25

Height with suspension mm 1,200

Weight kg 410

Magnet Devices/Lifting Magnets

Generator kW 20 20

Electromagnets with Suspension

Power kW 12.5 17.5

Diameter of magnet mm 1,550 1,700

Height with suspension mm 1,100 1,550

Weight kg 2,550 3,300

LH 80 M Litronic Machine for Industrial Applications 13

Page 14

Equipment

Undercarriage

Independent outrigger control +

Outrigger cylinder rod guards +

Shuttle axle lock, automatic •

Outrigger monitoring system +

Choice of tires •

Tool equipment, extended •

Two lockable storage boxes •

Customized colors +

Uppercarriage

Refuelling system with filling pump +

Railing on uppercariage +

Liebherr central lubrication system, fully automatic •

Positioning swing brake +

Rear space monitoring (country-dependent) •/+

Beacon +

Protection for headlight, front +

Side surveillance with camera +

Customized colors +

Flashing light (xenon) +

Hydraulics

Electronic pump regulation •

Hydraulic oil pre-heating +

Liebherr hydraulic oil +

Liebherr hydraulic oil, bio-degradable +

Bypass filter +

Engine

Fuel theft protection +

Fuel pre-heating +

Coolant pre-heating +

Liebherr particle filter •

Reversible fan drive +

Air pre-cleaner +

Engine oil pre-heating +

Operator’s Cab

Working lights, cab, rear, halogen +

Working lights, cab, rear, xenon +

Working lights, cab, front, halogen •

Working lights, cab, front, xenon +

Operator’s seat Standard •

Operator’s seat Comfort +

Operator’s seat Premium +

Fire extinguisher +

Joystick steering +

Hydraulic cab elevation +

Rigid cab elevation •

Automatic air conditioning system •

Electric cool box +

LiDAT Plus (extended Liebherr data transfer system) * •

Liebherr proportional control +

Bullet-proof windows +

Radio Comfort (control via display) +

Preparation for radio installation •

Back-up alarm (can not be switched off) +

Beacon +

Wiper on roof window +

Safety guard +

Auxiliary heating +

Flashing light (xenon) +

Immobilizer, electronic +

Attachment

Working lights on boom, halogen •

Working lights on boom, xenon +

Working lights on stick, halogen •

Working lights on stick, xenon +

AutoLift +

ERC system •

Camera on stick +

Piston rod guard, ERC +

Piston rod guard, lifting cylinder +

Load eyelet on handle +

Liebherr lightweight handle +

Multi-coupling system +

Quick change system MH110 +

Quick change system MH40 +

Customized colors +

Stick shut-down •

Tool Control +

Overload warning device +

Cylinders with shock absorber •

• = Standard, + = Option

* = optionally extendable after one year

Options and/or special attachments, supplied by vendors other than Liebherr, are only to be installed with the

knowledge and approval of Liebherr in order to retain warranty.

14 LH 80 M Litronic Machine for Industrial Applications

Page 15

Liebherr ERC-System

as standard

ERC System – More performance, less consumption

Efficiency

Performance

The energy stored by the lowering of the equipment in

the ERC System gives the machine additional performance capacity. This is re leased again when the equipment is raised, and is also reflected in more powerful

and more homogenous work sequences. The result is a

clear sav ing on fuel – and, at the same time, even greater

performance.

With the award-winning ERC system

Economy

The ERC System supports the equipment when lifting.

This means that engine speeds can be lower, while at the

same time smaller lifting cylinders can be fitted. That in

turn substantially reduces the machine’s fuel consumption, and leads to even greater economy.

As well as this, pollution and noise emission are perceptibly reduced. This helps safeguard the environment and

saves energy resources.

The principle is simple: As the equipment fitting is lowered, this causes the gas present in the cylinder to be compressed. When the attachment fitting is raised, the energy stored in the gas cylinder provides support for the two lifting cylinders, and less performance is required.

1. Attachment fitting raised /

Energy released

LH 80 M Litronic Machine for Industrial Applications 15

2. Lower attachment fitting / Store energy

4. Raise attachment fitting / Release energy

3. Attachment fitting lowered /

Energy stored

Page 16

The Liebherr Group of Companies

Wide Product Range

The Liebherr Group is one of the largest construction

equipment manufacturers in the world. Liebherr’s

high-value products and services enjoy a high reputation

in many other fields. The wide range includes domestic

appliances, aerospace and transportation systems,

machine tools and maritime cranes.

Exceptional Customer Benefit

Every product line provides a complete range of models

in many different versions. With both their technical

excel lence and acknowledged quality, Liebherr products

offer a maximum of customer benefits in practical

application.

State-of-the-art Technology

To provide consistent, top quality products, Liebherr

attaches great importance to each product area, its

components and core technologies. Important modules

and components are developed and manufactured

in-house, for instance the entire drive and control

techno logyfor construction equipment.

Worldwide and Independent

Hans Liebherr founded the Liebherr family company in

1949. Since that time, the enterprise has steadily grown

to a group of more than 120 companies with over

35,000employees located on all continents. The corporate

headquarters of the Group is Liebherr-International AG

inBulle, Switzerland. The Liebherr family is the sole owner

of the company.

www.liebherr.com

Printed in Germany by Schirmer RG-BK-RP LHB/VF 11212921-2-06.12_enGB

Liebherr-Hydraulikbagger GmbH

Liebherrstraße 12, D-88457 Kirchdorf/Iller

S +49 7354 80-0, Fax +49 7354 80-72 94

www.liebherr.com, E-Mail: info.lhb@liebherr.com

All illustrations and data may differ from standard equipment. Subject to change without notice.

Loading...

Loading...