LG LP-F8081CL, LP-F8081HL, LP-F8081ZL Service manual

1. Preface

This service manual provides various service information, containing the mechanical and electrical parts and etc. This package air conditioner was manufactured and assembled under the strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 Safety Precautions

¤ When servicing the unit, set the main SWITCH to OFF and remove the POWER SUPPLY cables.

¤Ł Observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or damaged by the short circuit.

¤Ø After servicing the unit, make an insulation resistance test to protect the customer from being exposed to shock hazards.

1.2 Features

¤ Design for cooling and heating

¤ŁSuper energy efficiency

¤ØMicom Control

¤ŒWhisper quiet operation

¤ºRemovable air filter

¤3 minute delay circuit

¤7 hour timer

¤3 step speeds for cooling/heating

¤Auto Restart

–3–

1.3 Product Specifications

|

MODEL |

|

LP-F8081CL |

LP-F8081HL |

||

|

|

LP-F8081ZL |

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

POWER SOURCE (ø, V, Hz) |

3,380 – 415,50 |

3,380 – 415,50 |

||||

|

|

|

|

|

|

|

COOLING |

|

CAPACITY |

|

Btu/h |

71,400 |

71,400 |

|

|

|

|

|

|

|

|

|

|

|

W |

20,927 |

20,927 |

|

|

|

|

|

|

|

|

|

INPUT |

|

W |

6,900 |

7,000 |

|

|

|

|

|

|

|

|

|

CURRENT |

|

A |

12.0 |

13.0 |

|

|

|

|

|

|

|

HEATING |

|

CAPACITY |

|

Btu/h |

– |

74,000 |

(Including Electric |

|

|

(W) |

(8,000) |

||

|

|

|

||||

|

|

|

|

|

||

heater) |

|

|

|

W |

– |

21,680 |

|

|

|

|

|||

|

|

|

|

(W) |

(8,000) |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

INPUT |

|

W |

– |

6,500 |

|

|

|

|

(W) |

(8,000) |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

CURRENT |

|

A |

– |

12.5 |

|

|

|

|

(A) |

(12.0) |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

MAKER |

COPELAND |

COPELAND |

||

|

|

|

|

|

|

|

|

|

TYPE |

|

SCROLL |

SCROLL |

|

|

|

|

|

|

|

|

COMPRESSOR |

|

MODEL |

ZR94KC – TFD |

ZR94KC – TFD |

||

|

|

|

|

|

|

|

|

|

INPUT |

|

W |

6,990 |

6,990 |

|

|

|

|

|

|

|

|

|

CURRENT |

|

A |

13.6 |

13.6 |

|

|

|

|

|

|

|

|

|

CAPACITY |

|

Kcal/h |

19,732 |

19,732 |

|

|

|

|

|

|

|

NOISE |

|

INDOOR |

|

dB(A) |

56 |

56 |

|

|

|

|

|

|

|

LEVEL(1m) |

|

OUTDOOR |

|

|

65 |

65 |

|

|

|

|

|

|

|

AIR |

|

INDOOR |

|

CMM |

35 |

35 |

|

|

|

|

|

|

|

VOLUME |

|

OUTDOOR |

|

|

104 |

104 |

|

|

|

|

|

|

|

REFRIGERANT R-22 |

|

Kg |

5.9 |

7.2 |

||

|

|

|

|

|

|

|

HEAT |

|

INDOOR |

|

R/C/FPI |

3/33/17 |

3/33/17 |

|

|

|

|

|

|

|

EXCHANGER |

|

OUTDOOR |

|

R/C/FPI |

2/18/17 |

2/18/17 |

|

|

|

|

|

|

|

FAN |

|

INDOOR |

|

TYPE |

SIROCO |

SIROCO |

|

|

|

|

|

|

|

|

|

OUTDOOR |

|

|

PROPELLER |

PROPELLER |

|

|

|

|

|

||

ROOM TEMPERATURE CONTROL |

MICOM CONTROL |

MICOM CONTROL |

||||

|

|

|

|

|

|

|

NET |

|

INDOOR |

|

Kg |

132 |

132 |

|

|

|

|

|

|

|

WEIGHT |

|

OUTDOOR |

|

|

150 |

150 |

|

|

|

|

|

|

|

DIMENSIONS |

|

INDOOR |

|

mm |

1,050 × 1,880 × 495 |

1,050 × 1,880 × 495 |

(W × H × D) |

|

|

|

|

|

|

|

OUTDOOR |

|

|

1,000 × 965 × 370 |

1,000 × 965 × 370 |

|

|

|

|

|

|

|

|

SVC |

|

LIQUID |

|

Inch |

5/8 |

5/8 |

|

|

|

|

|

|

|

VALVE |

|

GAS |

|

(mm) |

1 |

1 |

|

|

|

|

|

|

|

–4–

1.4 Functions

Indoor Unit

Power Switch ON/OFF

Operation Mode Control

• Cooling, Soft Dry, Auto, Fan Cooling Model |

• Cooling, Heating, Soft Dry, Fan Heat Pump Model |

Sensing the room temperature

• Room temperature sensor (Thermistor)

Controlling the room temperature

• Maintains the room temperature in accordance with the setting temperature.

Starting Current Control

• Indoor fan is delayed for 3 sec at the starting.

Sensing Heat Exchanger Temperature

• Heat exchanger temperature sensor (Thermistor)

Timer Delay Safety Control

• Restarting is inhibited for approx. 3 minutes.

Indoor Fan Speed Control

• High, Low, Duct

Operation Indication lamps

Temperature Setting

•Up : up to 30°C

•Down : down to 16°C

Airflow Direction Control

• Airflow direction Manual control

Room temperature Display

• Low, 10° ~ 35°C, Hi

Timer Control

• Off Timer (1, 2, 3....7 hour)

–5–

Outdoor Unit

Deice Control

• De-ice PCB

Outdoor Fan Speed Control

• One speed

Sensing Heat Exchanger Temperature

• Heat exchanger temperature sensor (Thermistor)

–6–

2. Dimensions

Indoor Unit

|

1051 |

Air Outlet |

951 |

|

|

Vent |

|

|

268 |

Window |

|

Display |

|

|

568 |

|

1890 |

Air Inlet |

|

Vent |

990 |

|

Outdoor Unit

|

496 |

|

|

|

|

75 |

75 |

193 |

|

|

|

|

||

|

130 |

|

121 |

|

|

|

|

|

Earth |

|

|

|

|

Screw |

|

36 |

|

36 |

|

|

|

|

|

|

131 |

345 |

|

60 |

93.8 |

|

|

|

36 |

75 |

|

|

93.8 |

145.8 |

|

58.5 |

|

|

109.5 |

|

|

525 |

|

Air Outlet Vent

Air Inlet Vent

6 |

|

54 |

|

650 |

700 |

260 |

|

|

|

|

|

930 |

963 |

95 80 |

582 |

|

|

125 |

185 |

|

|

|

700 |

50 |

|

|

1245 |

|

|

|

|

–7– |

|

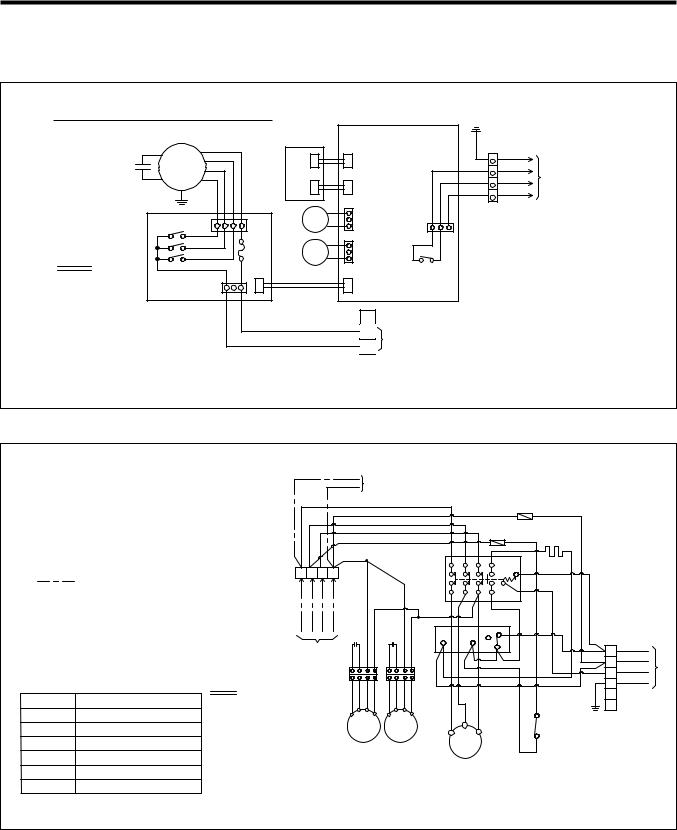

3. Wiring Diagram

Indoor & Outdoor Unit Circuit Diagram

(1) LD-F8081CL

INDOOR UNIT CIRCUIT DIAGRAM |

|

|

|

|

|

|

||

|

|

|

|

|

MAIN PCB ASM |

|

|

|

CAPACITOR |

YL |

OR |

ASMPCB |

DISPLAY |

CN2 |

GN/YL |

||

BK |

213 4 |

BR |

||||||

|

BR |

|

|

|

|

|

GN/YL |

|

|

INDOOR |

BK |

|

|

CN1 |

|

|

|

|

FAN MOTOR |

BL |

|

|

|

RD |

|

BK |

|

|

RD |

|

|

|

WH |

|

BL |

|

|

|

|

|

|

|

||

|

|

|

|

ROOM |

|

|

|

CONNECT TO |

|

|

|

|

|

|

|

OUTDOOR UNIT |

|

|

RY3 |

|

|

TH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RY2 |

FUSE |

|

EVA |

|

RY3 |

|

|

|

RY1 |

|

|

|

|

|||

NOTE |

(10A) |

|

TH |

|

|

|

||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

BL : BLUE |

|

|

|

|

CN3 |

|

|

|

BK : BLACK |

SUB PCB ASM |

|

|

|

|

|

||

|

|

|

|

|

|

|||

BR : BROWN |

|

|

|

|

3 |

|

|

|

OR : ORANGE |

|

|

|

YL |

|

|

|

|

RD : RED |

|

|

|

2 |

CONNECT TO CONTACT "R" "N" OF |

|||

|

|

|

BL |

|||||

WH : WHITE |

|

|

|

1 |

OUTDOOR TERMINAL BLOCK "Tmo1" |

|||

|

|

|

|

|||||

YL : YELLOW |

|

|

|

|

|

|

|

|

GN/YL : GREEN/YELLOW |

|

|

|

|

|

|

|

|

FIELD WIRING

NOTE

1.This product is 3ø ,4W,380-415V,50Hz.

2."Check List" before test run.

1st: Reconfirm the wiring connecting of compressor, outdoor unit motor.

2nd: Fasten the screw of "Terminal Block Tmo1,2" once more.

Tmo1,2 TERMINAL BLOCK

52C MAGNETIC CONTACTOR

51C EOCR(COMP.)

63H HIGH PRESSURE SWITCH

CH CRANKCASE HEATER

FMo1,2 OUTDOOR FAN MOTOR

Co1,2 RUN CAPACITOR FOR FAN(OUTDOOR)

CONNECT TO

INDOOR UNIT

BK |

|

|

|

|

|

|

|

|

|

FUSE(5A) |

|

|

||

WH |

|

|

|

|

|

|

|

|

|

|

|

|||

|

WH |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

RD |

|

|

|

|

|

|

WH |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

WH |

|

|

FUSE(5A) WH |

|

|

|

|||

|

|

|

|

|

|

|

|

CH |

|

|

||||

|

|

|

|

|

|

52C |

1 |

3 |

5 |

31 |

BK |

|

|

|

Tmo1 R S T N |

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

OR |

|

|

|

|

|

|

|

|

|

|

BK |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

B |

|

RD |

|

|

|

|

|

|

|

OR |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

2 |

4 |

6 |

|

|

|

|

||

|

|

|

BK |

|

|

32 |

|

BK |

|

|

||||

|

|

|

|

BK |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

51C |

BK |

|

|

|

||

|

|

|

|

|

|

|

|

|

BK |

CONNECT TO |

||||

|

|

|

|

|

|

|

|

L2 Tb |

Ta |

|

||||

Co1 |

|

Co2 |

|

L1 |

|

|

INDOOR UNIT |

|||||||

|

|

|

|

|

||||||||||

3Ø, 4W |

|

|

|

|

|

|

|

|

|

Tc |

|

|

1 BR |

|

380-415V, 50Hz |

|

|

|

|

|

|

|

|

|

|

|

|

2 |

BL |

POWER SUPPLY |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

BK |

NOTE |

|

|

|

|

|

WH |

|

|

|

|

|

|

4 |

GN/YL |

YL |

OR |

BK |

YL |

OR |

BK |

|

|

|

|

|

GN/YL |

5 |

|

|

BL : BLUE |

BR |

|

BR |

|

|

|

|

|

WH |

6 |

|

|||

|

|

|

|

|

BK WH T3 RD |

|

|

|||||||

BK : BLACK |

FMo1 |

|

FMo2 |

|

|

63H |

Tmo2 |

|||||||

BR : BROWN |

|

T1 |

|

|

T2 |

|

|

|

|

|||||

OR : ORANGE |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

COMP |

|

|

|

|

|

|

||

RD : RED |

|

|

|

|

|

|

|

|

BK |

|

|

|

||

WH : WHITE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YL : YELLOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GN : GREEN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GN/YL : GREEN/YELLOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

–8–

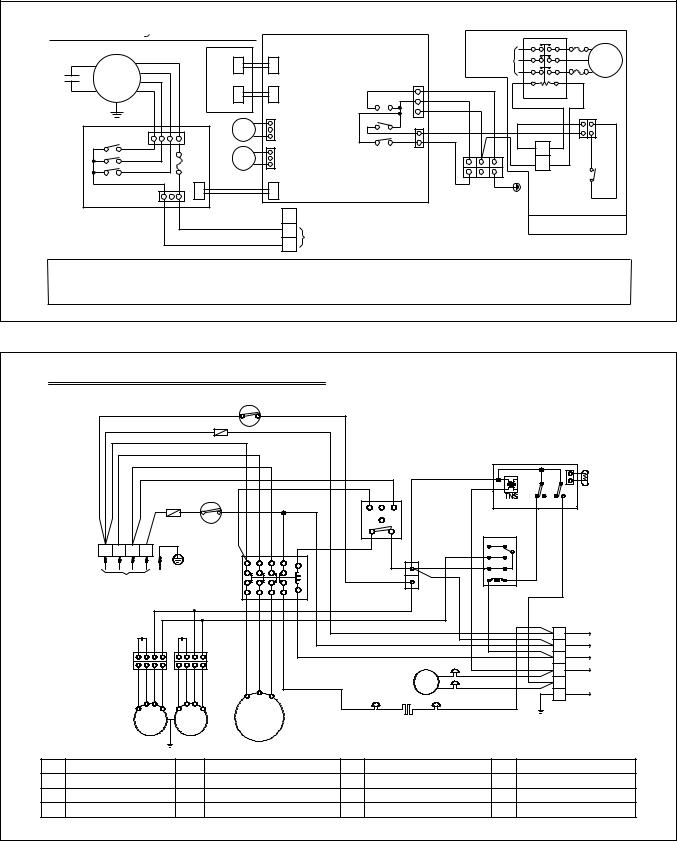

(2) LD-F8081HL/ZL |

|

|

|

|

|

|

|

|

|

|

|

|

|||

INDOOR UNIT CIRCUIT DIAGRAM |

|

|

|

|

|

|

|

|

|

TF |

|||||

|

|

|

|

|

MAIN PCB ASM |

|

|

|

|

|

|

|

|||

CAPACITOR |

|

|

OR |

ASMPCB |

DISPLAY |

CN2 |

Ry3 |

|

POWER SUPPLY |

L1 |

|

T1 |

EH |

||

BR |

|

|

3Ø 380~415V |

|

|

|

|||||||||

|

|

|

|

CN1 |

|

|

L2 |

|

T2 |

||||||

|

INDOOR |

BK |

|

|

|

|

|

50Hz |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

BL |

|

|

|

|

|

|

|

|

L3 |

|

T3 |

TF |

|

|

|

FAN MOTOR |

|

|

|

|

|

|

|

|

|

||||

|

YL |

|

|

|

|

|

|

|

|

a |

|

b |

|||

|

|

RD |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

Ry6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

ROOM |

|

|

BK |

|

|

|

|

|

|

|

|

|

|

|

|

TH |

|

|

BL |

WH |

|

|

BK |

5 BK |

|

|

|

|

RY3 |

|

|

|

|

|

RD |

|

|

|||||

|

|

|

|

EVA |

|

Ry7 |

BK |

|

|

||||||

|

|

RY2 |

|

FUSE |

|

|

|

1 |

2 |

3 |

BK |

4 |

BK |

|

|

|

|

|

|

TH |

|

|

|

|

|||||||

|

|

RY1 |

|

(10A) |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

4 |

5 |

6 |

|

|

TP |

|||

|

|

|

|

|

|

|

|

|

|

Tmi |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

CN3 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

CONNECT TO OUTDOOR |

|

|

|

|||||

|

SUB PCB ASM |

|

|

|

|

|

|

|

|||||||

|

|

Tmi |

|

|

(HOUSING ASM) |

|

|

|

|

||||||

|

|

|

|

|

3 |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Option part |

||||

|

|

|

|

|

YL |

2 |

CONNECT TO CONTACT "T" "N" OF |

|

|

|

|

||||

|

|

|

|

|

BL |

|

|

|

|

|

|

|

|||

|

|

|

|

|

1 |

OUTDOOR TERMINAL BLOCK "A" |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

DEF TH |

THERMISTER FOR DISCHARGE AIR |

Ry3 |

RELAY FOR COMP |

Tmi |

TERMINAL BLOCK(INDOOR) |

NOTE |

|

EH |

ELECTRIC HEATER |

Ry6 |

RELAY FOR HEATER |

TP |

BIMETAL SWITCH FOR HEATER |

|

|

BK:BLACK |

YL :YELLOW |

||||||

EVA TH |

THERMISTER FOR EVA TEMP. |

Ry7 |

RELAY FOR HEATING |

TF |

THERMAL FUSE |

BL:BLUE |

WH:WHITE |

ROOM TH |

THERMISTER FOR EVA INDOOR TEMP |

THi |

THERMISTOR FOR INDOOR TEMP |

|

|

BR:BROWN |

|

OUTDOOR UNIT WIRING DIAGRAM

|

|

|

BK |

|

63H2 |

|

|

|

BK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

BK |

|

F2 |

|

|

|

BK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

BK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RD |

|

|

|

|

|

|

|

|

|

|

WH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BK |

|

|

|

BK |

|

|

|

C TH |

|

|

|

|

|

63H1 |

|

|

|

|

|

|

3.P.D |

|

|

|

|

|

|

|

|

|

F2 |

|

|

|

|

|

|

|

|

|

|

|

|

NC NO NC NO |

||||

|

RD |

RD |

|

RD |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

R |

S |

T |

|

|

D.P |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

A |

|

B |

|

52F1 |

|

|

|

|

|

GN/YL |

|

|

|

|

|

|

|

|

|

|

1 |

2 |

|

|

|

|||

TM R S T N |

|

|

|

|

|

|

|

|

YL |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YL |

BL |

|

||

|

|

|

|

|

1 |

|

3 |

5 |

31 |

A |

|

WH |

WH |

3 |

4 |

|

|||

|

|

|

|

|

|

|

|

5 |

6 |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

POWER SUPPLY |

|

|

|

|

|

|

|

|

|

|

|

|

WH |

7 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

3ø ,380-415V,50Hz |

|

|

|

|

2 |

4 6 32 B |

|

|

|

|

|

|

|

|

|||||

TERMINAL(4P) |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

52C |

|

|

|

|

|

|

|

|

|

OR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BK |

|

|

|

|

1 |

BR |

YL BR OR |

BK |

YL |

BR OR |

BK |

|

|

|

|

|

|

|

|

WH |

|

|

|

|

2 |

BL |

|

|

|

|

|

|

|

|

BK |

|

|

|

|

BR |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BL |

|

|

|

|

|

|

BK |

|

WH |

RD |

|

|

|

|

|

|

BL |

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

L3 |

L2 |

|

|

|

|

|

20SV |

BL |

|

|

5 |

|

|

YL BR OR |

BK |

YL |

BR OR |

BK |

L1 |

|

|

|

|

|

|

|

|

|

6 GN/YL |

||||

|

|

|

|

|

|

|

|

|

|

|

BK |

|

|

|

BK |

|

|

|

|

FMo |

|

FMo |

COMP |

|

|

|

|

|

|

NOTE |

|

|

|

|

|||||

49FMo |

49FMo |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

BL : BLUE |

RD |

: RED |

|

|

|

|

|

|

BK : BLACK |

WH |

: WHITE |

|

|

|

|

|

|

BR : BROWN |

YL |

: YELLOW |

|

|

|

|

|

|

OR : ORANGE |

GN/YL : GREEN/YELLOW |

||

CH |

CRANKCASE HEATER |

D.P |

DEICER PCB |

52F1 |

RELAY FOR FMo |

TM |

MAIN TERMINAL BLOCK |

|

F1,2 |

FUSE (250V, 5A) |

C TH |

THERMISTOR FOR PIPE TEMP.(OUTDOOR) |

63H1 |

HIGH PRESSURE SWITCH |

52C |

MAGNETIC CONTACTOR |

|

Co |

RUN CAPACITOR FOR FMo |

20SV |

REVERSING COIL |

63H2 |

HIGH PRESSURE SWITCH FOR HEATING |

3.P.D |

3 PHASE DETECTOR |

|

FMo |

OUTDOOR FAN MOTOR |

49FMo |

INERNAL T.P FOR FMo |

49C |

INTERNAL O.L.P FOR COMP. |

|

|

|

–9–

4.OPERATION DETAILS

(1)The function of main control

1. Time Delay Safety Control

• 3min... The compressor is ceased for 3 minutes to balance the pressure in the refrigeration cycle. (Protection of compressor)

• 3sec... The indoor fan is ceased for 1~3 seconds to prevent relay noise. (Protection of fan relay and micro chip)

• 1min... The 4-way valve is ceased for 30 sec. to prevent the refrigerant-gas abnormal noise when the Heating operation is OFF or switched to the other operation mode.

2. Cooling Mode Operation

•When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the controller and the operation diagram is as following

) Mode Operation, the unit will operate according to the setting by the controller and the operation diagram is as following

Intake Air temp.

Setting Temp. +1°C |

|

|

|

|

|

|

(Compressor ON) |

|

|

|

|

|

|

Setting Temp. -1°C |

|

|

|

|

|

|

(Compressor OFF) |

|

|

|

|

|

|

|

|

3 minutes |

|

3 minutes |

|

|

Indoor Fan Speed |

Selecting |

Selecting |

Selecting |

Selecting |

Selecting |

|

fan speed |

fan speed |

fan speed |

fan speed |

fan speed |

||

|

||||||

Compressor |

ON |

OFF |

ON |

OFF |

ON |

– 10 –

3. Auto Operation (Cooling Model only)

ƒUThe operation procedure is as following.

Press Start/Stop Button

Select Auto Operation Mode

Check the Room temperature

ƒUAuto Operation for Cooling

Operation Condition |

Intake-air Temperature |

Setting temperature |

Fan speed |

||

|

|

|

|

|

|

|

|

Over 26°C |

25°C |

|

|

|

|

|

|

Controlled |

|

When Switch to |

|

Over 24°C~below 25.5°C |

Intake air -1.0°C |

||

|

|||||

|

|

by Fuzzy logic |

|||

Auto Operation |

Over 22°C~below 23.5°C |

Intake air -0.5°C |

|||

|

|||||

|

|

below 21.5°C |

Intake air Temperature(18°C, MAX) |

|

|

|

|

|

|

|

|

Intake Air Temp. |

|

Setting Temp. +1°C |

|

(Compressor ON) |

|

Setting Temp. -1°C |

|

(Compressor OFF) |

|

3 minutes |

3 minutes |

|

Indoor Fan Speed |

|

|

Fuzzy Speed |

|

|

|

|

|

|

|

|

|

|

Compressor |

ON |

OFF |

|

ON |

OFF |

|

|

|

|

|

|

|

– 11 –

4. Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as following.

Intake Air Temp.

Setting Temp. +1°C

(Compressor OFF)

A |

A |

Setting Temp. |

|

|

|

|

|

|

|

|

|

|

|

|

|

(Compressor ON) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Setting Temp. -1°C |

|

|

|

|

|

|

minimum |

|

minimum |

|

|||

|

|

|

|

|

|

|

|

|

|||||

|

Hot |

|

|

minimum |

10sec. |

|

|

10sec. |

|

|

|||

|

Start |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1min |

|

|

|

|

|

|

|

|

Indoor Fan Speed |

OFF |

LOW |

|

Selecting |

LOW |

|

OFF |

Selecting |

LOW |

OFF |

|||

|

fan speed |

|

fan speed |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

Compressor |

|

|

ON |

|

|

|

OFF |

ON |

OFF |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electric Heater(Option) |

OFF |

|

ON |

|

OFF |

ON |

OFF |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• A point: The indoor pipe temperature to be less then 35°C or Discharge air Temperature to be less than 29°C. The indoor fan operates for minimum 10sec. even if the indoor pipe temperature falls lower than35°C or the discharge air Temperature falls lower than 29°C.

¡ During heating operation, the operating procedure of the indoor fan is as the following.

Stop(VI) |

Low(V) |

Selecting Fan Speed(IV) |

39˚C

Discharge Air Temp.

34˚C

|

|

28˚C |

|

|

(Hot-Start Release Point) |

|

|

|

|||

|

Indoor Pipe Temp. |

|

|

|

|

|

|

|

|

||

|

|

26˚C |

|

|

|

|

|

|

|

|

|

|

|

|

Heating Start |

|

|

|

|||||

|

|

|

Stop(I) |

|

|

Low(II) |

|

|

Selecting Fan Speed(III) |

||

|

|

(Hot-Start Operating) |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|||||

Step |

Indoor fan speed |

|

|

Pipe temp. |

|

Air discharge temp. |

|||||

|

|

|

|

|

|

|

|||||

¥ |

Off |

|

|

≤ 28°C(Hot start operating) |

|

– |

|||||

|

|

|

|

|

|

|

|

|

|||

¥– |

Low |

|

|

|

|

≥28°C |

|

<39°C |

|||

|

|

|

|

|

|

|

|||||

¥† |

Selecting speed |

|

|

≥28°C |

|

≥39°C |

|||||

|

|

|

|

|

|

|

|||||

¥‡ |

Selecting speed |

|

|

≥28°C |

|

>34°C |

|||||

|

|

|

|

|

|

|

|

|

|||

¥· |

Low |

|

|

|

|

≥26°C |

|

≤ 34°C |

|||

|

|

|

|

|

|

|

|

|

|||

¥ |

Off |

|

|

|

|

≤ 26°C |

|

– |

|||

– 12 –

5. Hot-Start Control

•The indoor fan stops until the evaporator piping temperature will be reached to 28°C.

•During heating operation, if piping temperatures fall below 26°C fan stops.

•The operation diagram is as following.

|

|

Maximum |

|

|

|

INDOOR PIPE |

|

1min |

|

|

|

|

|

|

|

||

TEMP. |

|

|

|

|

|

28°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

26°C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INDOOR FAN |

OFF |

LOW |

|

Selecting |

OFF |

SPEED |

|

fan speed |

|||

|

|

|

|

||

COMPRESSOR |

|

|

ON |

|

|

|

|

|

|

|

|

6. Defrost Control

•Defrost operation is controlled by timer and sensing temperature of outdoor pipe.

•The first defrost starts only when the outdoor pipe temperature falls below -6°C after 45 minutes passed from starting of heating operation and more than.

•Defrost ends after 10 minutes pass from starting of defrost operation or when the outdoor pipe temperature rises over 12°C even if before 10 minutes.

•The second defrost starts only when the outdoor pipe temperature falls below -6°C after 45 minutes pass from ending of the first defrost and more than.

|

|

|

More than 45 minutes of |

Within |

More than 45 minutes of |

|

|

Outdoor Pipe Temp. |

|

heating operation |

10minutes |

heating operation |

Defrost |

||

|

|

Defrost |

Less than 5 minutes |

|

|

||

12°C |

|

|

|

|

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

(Defrost OFF) |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

-6°C |

|

|

|

|

(Defrost ON) |

|

|

|

|

|

|

|

HOT- |

|

|

|

|

START |

|

Indoor Fan |

ON |

OFF |

ON |

OFF |

Compressor |

ON |

ON |

ON |

ON |

4-Way Valve |

ON |

OFF |

ON |

OFF |

|

|

– 13 – |

|

|

7.Soft Dry Operation Mode

•During Soft Dry Operation, the compressor ON temperature is the setting temperature plus 2°C, the compressor OFF temperature is the setting temperature minus 1°C.

•When the room temperature rises over the compressor ON temperature, the operation mode is switched to the Cooling mode.

•When the room temperature falls between the compressor ON temperature and OFF temperature, the operation mode is switched to the Soft Dry Operation.

•The operation diagram is shown below.

Intake Air Temp. |

Operation |

|

Dry operation |

|

Cooling |

|

|

|

|

Cooling |

|

|

operation |

|

|

|

|||

|

|

|

|

|

|

||||

Setting Temp. +2°C |

|

|

|

|

|

|

|

|

|

(Compressor ON) |

|

|

|

|

|

|

|

|

|

Setting Temp. -1°C |

|

3 min. |

10 min. |

maximum |

|

3 min. |

maximum |

|

|

(Compresso OFF) |

|

|

|

||||||

|

7 min. |

|

10 min. |

|

|||||

|

|

|

|

|

|

|

|||

Indoor Fan Speed |

Selecting |

LOW |

LOW |

LOW |

Selecting |

LOW |

LOW |

LOW |

|

fan speed |

fan speed |

||||||||

|

|

|

|

|

|

|

|||

Compressor |

ON |

OFF |

ON |

OFF |

ON |

OFF |

ON |

OFF |

8. Protection of the evaporator pipe from frosting

• Compressor and outdoor fan stop when indoor pipe temperature is below -2°C and restart at the pipe temperature is above 12°C.

9. Child Lock function

This function is to operate Air conditioner only by Remocon. The procedure is as the following

1st: Press the 2 buttons of the temperature control simultaneously, to raise-to lower on the Display Panel of the product for more 3 seconds.

2nd: The buzzer sounds and then the window of Display Panel shows LOC (LOC) mark.

3rd: To release this function, the reverse again the operating procedure could be done.

¡During this function is operating, any buttons of Display Panel don't work. But it is possible to operate with Remote controller.

10.Off Timer Function

This function is to set the time of stopping the unit operation.

The procedure is as the following.

1st: Press the timer set button on the Remocon.

2nd: The buzzer sounds and then the display window shows the Off-Time to be set as 1:00¡ ... ¡ |

7:00 ¡ 0:00. |

|||||||||||||||||

- The Off-Time is shifted as the following by each press. |

|

|

|

|

|

|

|

|

||||||||||

|

|

1:00 |

|

2:00 |

|

3:00 |

|

4:00 |

|

5:00 |

|

6:00 |

|

7:00 |

|

|

0:00 |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-If you select '0:00', the Off-Timer function will be cancelled.

-During Off-Timer Operation, if you repress the timer set button, the rest time will be displayed.

–14 –

11. Alarm mode display / only displayed while operating.

CH0 : The sensor for sensing room temperature is open or short.

CH1 : The sensor for sensing piping temperature of evaporator is open or short.

12. Function for test operation.

This function shall be operated while the set not operating and start while set temperature set button(▼) down and start/stop buttons pressing continuously for 3 seconds.

If you press start/stop button continuously for 3 seconds while set temp down button pressing once more test operation and the set shall be stopped.

After test operation operating and 18 minutes, test operation and the set shall be stopped.

If you press start/stop button while test operation operating, test operation shall be stopped and the set shall start.

When test operation operating, the display of 88:88 shall be shifted to tESt

4-way valve is always off when test operation.

Fan speed is high, air purifying system and auto air flow operations are off when test operation. Regardless of outside temperature, the set operates when test operation.

All but start/stop and air purifying system buttons cannot be set.

13. Function of changing set temperature when re-operation after stop.

Heating operation is set to the previous set temperature when re-operation after stop. Cooling operation is set to the previous set temperature when re-operation with start/stop button.

1.Operation mode.

Cooling/soft dry mode → Cooling mode Heating mode → Heating mode

2.Setting the set temperature when cooling operation.

Room temperature > Set temperature: to be set to the previous set temperature. Room temperature ≤ Set temperature

a)Room temperature ≥ 26°C: to be set to 24°C

b)22°C ≤ Room temperature ≤ 25°C: to be set to 21°C

c)Room temperature ≤ 21°C:to be set to -1°C less than room temperature.

3.Setting the set temperature when heating operation. Set the previous set temperature when stopped.

14.Auto Restart

In case the power comes on again a power failure, Auto Restarting Operation is the function to operate procedures automatically to the previous operating conditions.

– 15 –

5. Installation

5-1. Installation of Indoor, Outdoor unit

1) Selection of the best location

Indoor unit

•There should not be any heat source or steam near the unit.

•There should not be any obstacles to prevent the air circulation.

•A place where air circulation in the room will be good.

•A place where drainage can be easily obtained.

•A place where noise prevention is taken into consideration.

•Do not install the unit near the door way.

•Ensure the spaces indicated by arrows from the wall, ceiling, fence, or other obstacles.

Outdoor unit

•If an awning is built over the unit to prevent direct sunlight or rain exposure, be careful that heat radiation from the condenser is not restricted.

•There should not be any animals or plants which could be affected by discharged hot air.

•Ensure the space indicated by arrows from the wall, ceiling, fence, or other obstacles.

Piping length and the elevation

MODEL |

PIPE SIZE |

Max. |

Max. |

||

|

|

Length |

Elevation |

||

|

|

|

|||

|

GAS SIDE |

LIQUID SIDE |

A (m) |

B (m) |

|

|

|

|

|

|

|

80K |

1" |

5/8" |

50 |

35 |

|

(Btu/h) |

|||||

|

|

|

|

||

|

|

|

|

|

|

100cm |

5cm |

5cm |

40cm |

|

|

|

150cm |

50cm |

50cm |

|

50cm |

Indoor unit

A

B |

Outdoor unit |

–16–

2)Indoor Unit installation

The mounting floor should be strong and solid enough to prevent it from vibration.

Drill the piping hole with 70mm diameter holecore drill at either the right or the left of indoor unit. The hole should be sightly slant to the outdoor side.

|

200mm |

|

70mm |

90mm |

70mm |

|

||

|

|

|

|

|

Wall |

Core Drill

3)Outdoor unit Installation

Install the outdoor unit on the concrete or any solid base securely and horizontally.

If there is any vibration transmitted to the building, mount the rubber underneath the outdoor unit.

4)Refrigerant amount

Before shipment, this air conditioner is filled with the rated amount of refrigerant including additional amount required for air-purging, subject to 5m piping length. (The rated amount of refrigerant is indicated on the name plate.) But when the piping length exceeds 5 meters, additional charge is required according to the following table.

|

(Unit: g) |

|

|

|

|

MODEL |

REFRIGERANT CHARGE |

|

|

|

|

80K |

80 per 1m |

|

|

|

|

Example) 72K~80K

In case of 10m long pipe(one-way), the amount of refrigerant to be replenished is:

(10 - 5) × 80 = 400g

–17–

5-2. Installation Method

1) Procedure

No. |

Installation works |

Descriptions |

|

|

|

1 |

Preparation of tools and installation parts |

Preparation of installation |

|

|

|

2 |

Flaring the pipes |

To insert the flare nuts, mounted on the |

|

|

connection parts of both indoor and |

|

|

outdoor unit, onto the copper pipes. |

|

|

|

3 |

Pipe bending |

To reduce the flow resistance of refrigerant. |

|

|

|

4 |

Connection of installation parts |

Connection of long piping |

|

(elbows, socket etc) |

|

|

|

|

5 |

Tighten the flare nut (outdoor) |

Connecting the pipings of the outdoor unit. |

|

|

|

6 |

Blowing the pipings |

To remove dust and scale in working. |

|

|

|

7 |

Tighten the flare nut (indoor) |

Connecting the pipings of the indoor unit. |

|

|

|

8 |

Check a gas-leakage of the connecting |

|

|

part of the pipings. |

|

|

|

|

9 |

Air purging of the piping and indoor unit |

The air which contains moisture and which |

|

|

remains in the refrigeration cycle may cause a malfunction on the |

|

|

compressor |

|

|

|

10 |

Open the 3-way (liquid side) and |

|

|

3-way (gas side) valves. |

|

|

|

|

11 |

Form the pipings |

To prevent heat loss and sweat |

|

|

|

12 |

Checking the drainage (indoor unit) |

To ensure if water flow drain hose of indoor unit. |

|

|

|

13 |

Connecting the cable between outdoor |

Preparation of the operating |

|

and indoor unit |

|

|

|

|

14 |

Connecting the main cable to outdoor unit |

|

|

|

|

15 |

Supply the power to the crankcase heater |

To prevent the liquid back to the compressor. |

|

(Before the operating the unit) |

(Heat pump only) |

|

|

|

16 |

Cooling operation |

|

|

(Use the remote control or display of the |

|

|

indoor unit) |

|

|

|

|

–18–

2) Preparation of installation parts and tools

No. |

Installation Parts, Tools |

Use |

|

|

|

1 |

Pipe cutter (MAX 35mm Copper pipe) |

Cutting the pipings |

|

|

|

2 |

Remear |

Remove burrs from cut edges of pipes. |

|

|

|

3 |

Wrench (H5, H4 hexagonal wrench) |

To open the service valve |

|

|

|

4 |

Pipe bender |

Bending the pipings |

|

|

|

5 |

Leak detector |

Check a gas-leakage of connecting part |

|

|

of the pipings |

|

|

|

6 |

Manifold gauge |

To measure the pressure, to charge the refrigerant |

|

|

|

7 |

Charge-nipple |

To connect the bombe |

|

|

|

8 |

Vacuum pump |

To remove the air in the pipe. |

|

|

|

9 |

Charge cylinder balance |

To measure the refrigerant amount |

|

|

|

10 |

Bombe (Freon-22) |

Gas charge |

|

|

Air purge |

|

|

Cleaning the pipe |

|

|

|

11 |

Spanner |

To tighten the connecting parts of the pipings |

12Monkey spanner

13Driver(  ,

,  )

)

14 |

Benchi (150mm) |

Cutting the wires |

|

|

|

15 |

Tapeline |

To measure the length |

|

|

|

16 |

Core drill |

To make holes through the concrete wall and blocks |

|

|

|

17 |

Voltmeter, Amperemeter, Clampmeter |

To measure the current and voltage |

|

|

|

18 |

Insulation resistance tester |

To measure the insulation resistance |

|

|

|

19 |

Glass thermometer |

To measure the intake and outlet air temperature of the indoor unit |

|

|

|

20 |

Copper tubes |

To use the connecting pipings |

|

|

|

21 |

Insulation material |

To cover the connecting pipings |

|

|

|

22 |

Tape |

To finish the connecting pipings |

|

|

|

23 |

Electrical Leakage Breaker |

To shut off the main power |

|

|

|

24 |

Cable |

To connect the cable from outdoor unit to indoor unit |

|

|

|

27 |

Drain hose sockets, elbows |

To remote the condensing water |

–19–

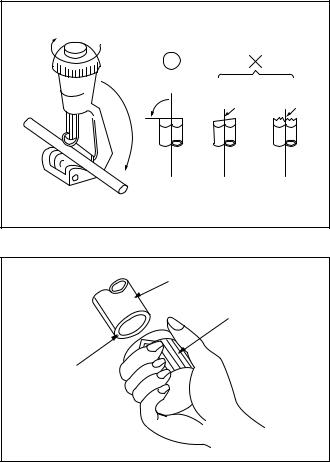

5-3. Piping of Indoor Unit

1) Preparation of piping

Cut the pipes and the cable

•Use the accessory piping kit or the pipes purchased locally.

•Measure the distance between the indoor and the outdoor unit.

•Cut the pipes a little longer than measured distance.

•Cut the cable 1.5m longer than the pipe length.

Remove burrs.

•Remove burrs from cut edges of pipes.

•Turn the pipe end down to avoid the metal powder entering the pipe.

Caution:

If burrs are not removed, they may cause a gas leakage.

Pipe cutter

90°  Slanted Rough

Slanted Rough

Pipe

Reamer

Point down

2) Connection of piping

Move the indoor tubing and drain hose to the hole

•Remove tubing holder and pull the tubing out of the chassis.

Replace the tubing holder into original position

Route the tubing and the drain hose staight backwards.

Insert the connecting cable into the indoor unit through the hole.

•Do not connect the cable to the indoor unit

•Make a small loop with the cable for easy connection later.

Tape the tubing and the connecting cable.

Indoor unit installation.

Connecting the pipings to the indoor unit.

•Align the center of the pipings and suffciently tighten the flare nut with fingers.

•Finally, tighten the flare nut with troque wrench until the wrench clicks.

When tightening the flare nut with troque wrench, ensure the direction for tightening follows the arrow on the wrench.

–20–

3) Precautions in bending |

|

|

If it is necessary to bend or stretch the tubing, |

Spring |

|

use the spring which is attached to the tubing in |

||

|

||

stead of pipe bender. |

|

• Please make a careful notice to make a smooth line.

•Hold the tubing with your two hands closely and then bend or stretch it slowly not to make any crack.

•Remember that the radius (R) should not exceed 70mm (Refer to Fig. 1)

Do not repeat the bending process to prevent the tubing from cracking or crushing.

Keep in mind that the bending part should not be cracked and make the radius (R) as long as possible (Refer to Fig. 2)`

R70mm

(Fig. 1)

R

(Fig. 2)

5-4. Connecting Piping to Outdoor Unit

1) Connecting pipings to the outdoor unit

Upon connecting 4-way valves, please weld connecting pipes using elbows instead of connecting pipes with flare nuts.

5-5. Connecting the Cable

Open the control board cover from the outdoor unit by removing the screws.

Connect wires to the terminals on the control board individually and secure the cables onto the control board with clamp.

–21–

Loading...

Loading...