Page 1

MPX G2

Guitar

Effects Processor

Service

Manual

Page 2

MPX G2 Service Manual

Precautions

Save these instructions for later use.

Follow all instructions and warnings marked on the unit.

Always use with the correct line voltage. Refer to the manufacturers operating instructions for power requirements. Be advised that

different operating voltages may require the use of a different line cord and/or attachment plug.

Do not install the unit in an unventilated rack, or directly above heat producing equipment such as power amplifiers. Observe the

maximum ambient operating temperature listed in the product specification.

Slots and openings on the case are provided for ventilation; to ensure reliable operation and prevent it from overheating, these

openings must not be blocked or covered. Never push objects of any kind through any of the ventilation slots. Never spill a liquid of

any kind on the unit.

This product is equipped with a 3-wire grounding type plug. This is a safety feature and should not be defeated.

Never attach audio power amplifier outputs directly to any of the unit’s connectors.

To prevent shock or fire hazard, do not expose the unit to rain or moisture, or operate it where it will be exposed to water.

Do not attempt to operate the unit if it has been dropped, damaged, exposed to liquids, or if it exhibits a distinct change in performance

indicating the need for service.

This unit should only be opened by qualified service personnel. Removing covers will expose you to hazardous voltages.

This triangle, which appears on your component, alerts you to the presence of uninsulated, dangerous voltage inside the

enclosure… voltage that may be sufficient to constitute a risk of shock.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

This triangle, which appears on your component, alerts you to important operating and maintenance Instructions in this

accompanying literature.

Notice

This equipment generates and uses radio frequency energy and if not installed and used properly, that is, in strict accordance with the

manufacturer's instructions, may cause interference to radio and television reception. It has been type tested and found to comply with

the limits for a Class B computing device in accordance with the specifications of Part 15 of FCC Rules, which are designated to

provide reasonable protection against such interference in a residential installation. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause interference to radio or television reception, which can be

determined by turning the equipment OFF and ON, the user is encouraged to try to correct the interference by one or more of the

following measures:

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions. The user may

find the following booklet prepared by the Federal Communications Commission helpful:

This booklet is available from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

Le présent appareil numérique n'émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de Ia

class B prescrites dans le Règlement sur le brouillage radioélectrique édicté par le ministère des Communications du Canada.

Reorient the receiving antenna

Relocate the computer with respect to the receiver

Move the computer away from the receiver

Plug the computer into a different outlet so that the computer and receiver are on different branch circuits.

“How to identify and Resolve Radio/TV Interference Problems.

Copyright © 1999 - 2001 Lexicon, Inc.

All Rights Reserved

Lexicon Inc. ● 3 Oak Park ● Bedford, MA 01730-1441 ● Tel (781) 280-0300 ● Customer Service Fax (781) 280-0499

Lexicon Part # 070-14395 Rev 0

Printed in the United States of America

Page 3

Lexicon

Safety Suggestions

Read Instructions Read all safety and operating

instructions before operating the unit.

Retain Instructions Keep the safety and

operating instructions for future reference.

Heed Warnings Adhere to all warnings on the

unit and in the operating instructions.

Follow Instructions Follow operating and use

instructions.

Heat Keep the unit away from heat sources such

as radiators, heat registers, stoves, etc., including

amplifiers which produce heat.

Ventilation Make sure that the location or

position of the unit does not interfere with its

proper ventilation. For example, the unit should

not be situated on a bed, sofa, rug, or similar

surface that may block the ventilation openings;

or, placed in a cabinet which impedes the flow of

air through the ventilation openings.

Wall or Ceiling Mounting Do not mount the unit

to a wall or ceiling except as recommended by

the manufacturer.

basement, near a swimming pool, near an open

window, etc.

Object and liquid entry Do not allow objects to

fall or liquids to be spilled into the enclosure

through openings.

Cleaning The unit should be cleaned only as

recommended by the manufacturer.

Servicing Do not attempt any service beyond

that described in the operating instructions. Refer

all other service needs to qualified service

personnel.

Damage requiring service The unit should be

serviced by qualified service personnel when:

• the power supply cord or the plug

has been damaged

• objects have fallen, or liquid has

been spilled into the unit

• the unit has been exposed to rain

• the unit does not appear to operate

normally or exhibits a marked change

in performance

• the unit has been dropped, or the

enclosure damaged

Power Sources Connect the unit only to a power

supply of the type described in the operating

instructions, or as marked on the unit.

Grounding or Polarization* Take precautions

not to defeat the grounding or polarization of the

unit’s power cord.

*Not applicable in Canada.

Power Cord Protection Route power supply

cords so that they are not likely to be walked on

or pinched by items placed on or against them,

paying particular attention to cords at plugs,

convenience receptacles, and the point at which

they exit from the unit.

Nonuse Periods Unplug the power cord of the

unit from the outlet when the unit is to be left

unused for a long period of time.

Water and Moisture Do not use the unit near

water — for example, near a sink, in a wet

Page 4

MPX G2 Service Manual

The following general safety precautions must be observed during all phases of operation, service and repair of this instrument. Failure to comply with

SAFETY SUMMARY

these precautions or with specific warnings elsewhere in these instructions violates safety standards of design manufacture and intended use of the

instrument. Lexicon assumes no liability for the customer’s failure to comply with these requirements.

GROUND THE INSTRUMENT

To minimize shock hazard the instrument chassis and cabinet

must be connected to an electrical ground. The instrument is

equipped with a three-conductor AC power cable. The power

cable must either be plugged into an approved three-contact

electrical outlet or used with a three-contact to two-contact

adapter with the grounding wire (green) firmly connected to an

electrical ground (safety ground) at the power outlet. The power

jack and mating plug of the power cable meet International

Electrotechnical Commission (IEC) safety standards.

DO NOT OPERATE IN AN EXPLOSIVE

ATMOSPHERE

Do not operate the instrument in the presence of flammable gases

or fumes. Operation of any electrical instrument in such an

environment constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers.

Component replacement and internal adjustments must be made

by qualified maintenance personnel. Do not replace components

with power cable connected. Under certain conditions, dangerous

voltages may exist even with the power cable removed. To avoid

injuries, always disconnect power and discharge circuits before

touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another

person, capable of rendering first aid and resuscitation, is present.

General definitions of safety symbols used on equipment or in

manuals.

Instruction manual symbol: the product will be marked

with this symbol when it is necessary for the user to refer to the

instruction manual in order to protect against damage to the

instrument.

Indicates dangerous voltage. (Terminals fed

from the interior by voltage exceeding 1000 volts must be so

marked.)

WARNING

The WARNING sign denotes a hazard. It calls attention to a

procedure, practice, condition or the like which, if not correctly

performed or adhered to, could result in injury or death to

personnel.

CAUTION

SAFETY SYMBOLS

DO NOT SUBSTITUTE PARTS OR MODIFY

INSTRUMENT

Because of the danger of introducing additional hazards, do not

install substitute parts or perform any unauthorized modification to

the instrument.

DANGEROUS PROCEDURE WARNINGS

Warnings, such as the example below, precede potentially

dangerous procedures throughout this manual. Instructions

contained in the warnings must be followed.

WARNING

Dangerous voltages, capable of causing death, are present in this

instrument. Use extreme caution when handling, testing and

adjusting.

The CAUTION sign denotes a hazard. It calls attention to an

operating procedure, practice, condition or the like which, if not

correctly performed or adhered to, could result in damage to or

destruction of part or all of the product.

NOTE:

The NOTE sign denotes important information. It calls attention to

procedure, practice, condition or the like which is essential to

highlight.

CAUTION

Electrostatic Discharge (ESD) Precautions

The following practices minimize possible damage to ICs resulting from

electrostatic discharge or improper insertion.

• Keep parts in original containers until ready for use.

• Avoid having plastic, vinyl or Styrofoam in the work area.

• Wear an anti—static wrist-strap.

• Discharge personal static before handling devices.

• Remove and insert boards with care.

• When removing boards, handle only by non-conductive surfaces

and never touch open-edge connectors except at a static-free

workstation.*

• Minimize handling of ICs.

• Handle each IC by its body.

• Do not slide ICs or boards over any surface.

• Insert ICs with the proper orientation, and watch for bent pins on

ICs.

• Use static shielding containers for handling and transport.

‘To make a plastic-laminated workbench anti-static, wash with a

solution of Lux liquid detergent, and allow drying without rinsing.

Page 5

Lexicon

Table of Contents

Chapter 1 Reference Documents, Required Equipment............................. 1-1

Reference Documents............................................................................................................................. 1-1

Required Equipment................................................................................................................................ 1-1

Tools .................................................................................................................................................... 1-1

Test Equipment.................................................................................................................................... 1-1

Chapter 2 General Information ................................................................... 2-1

Periodic Maintenance .............................................................................................................................. 2-1

Ordering Parts ......................................................................................................................................... 2-1

Returning Units to Lexicon for Service .................................................................................................... 2-1

Chapter 3 Specifications............................................................................. 3-1

Chapter 4 Performance Verification............................................................ 4-1

Diagnostics .............................................................................................................................................. 4-1

Analog Audio Performance:..................................................................................................................... 4-1

Setup:................................................................................................................................................... 4-1

Input to Send........................................................................................................................................ 4-3

Insert Return Inputs to Outputs:......................................................................................................... 4-16

Lexicon Audio Precision ATE Summary ............................................................................................ 4-33

Chapter 5 Troubleshooting ......................................................................... 5-1

http://www.lexicon.com/kbase/index.asp................................................................................................. 5-1

Diagnostics .............................................................................................................................................. 5-1

Power On Diagnostics: ........................................................................................................................ 5-1

Error Indication:.................................................................................................................................... 5-1

Test Descriptions: ................................................................................................................................ 5-2

Functional Tests / Extended Diagnostics................................................................................................. 5-5

Functional Test Descriptions ................................................................................................................... 5-6

Switch Test: ......................................................................................................................................... 5-6

Front Panel Pots .................................................................................................................................. 5-8

LED Test .............................................................................................................................................. 5-9

Display Character Test ........................................................................................................................ 5-9

Display Block Test ............................................................................................................................. 5-10

Auto Test Execution........................................................................................................................... 5-11

Burn In Loop ...................................................................................................................................... 5-11

Footpedal Test ................................................................................................................................... 5-12

MIDI Test ........................................................................................................................................... 5-13

DRAM Test ........................................................................................................................................ 5-14

WCS Test........................................................................................................................................... 5-15

Lo SRAM Test.................................................................................................................................... 5-15

ROM Test........................................................................................................................................... 5-16

TOP LEVEL MENU UTILITIES & TOOLS ............................................................................................. 5-16

Exit Diags........................................................................................................................................... 5-17

Scope Loops ...................................................................................................................................... 5-17

Software Err Log ................................................................................................................................ 5-17

Clear Err Log...................................................................................................................................... 5-18

2186 Tools ......................................................................................................................................... 5-18

View Alg Nums................................................................................................................................... 5-19

UTILITY MENU (Options Button) .......................................................................................................... 5-19

Repeat Test ....................................................................................................................................... 5-19

Test Result Menu............................................................................................................................... 5-20

View DRAM........................................................................................................................................ 5-26

MIDI Scope ........................................................................................................................................ 5-26

EMERGENCY DIAGNOSTICS.............................................................................................................. 5-26

Removing the Top Cover:...................................................................................................................... 5-27

Page 6

MPX G2 Service Manual

Power Supply: ........................................................................................................................................5-27

Battery Voltage:......................................................................................................................................5-28

Systems Clocks:.....................................................................................................................................5-29

APPENDIX A: Software Error Messages ...............................................................................................5-29

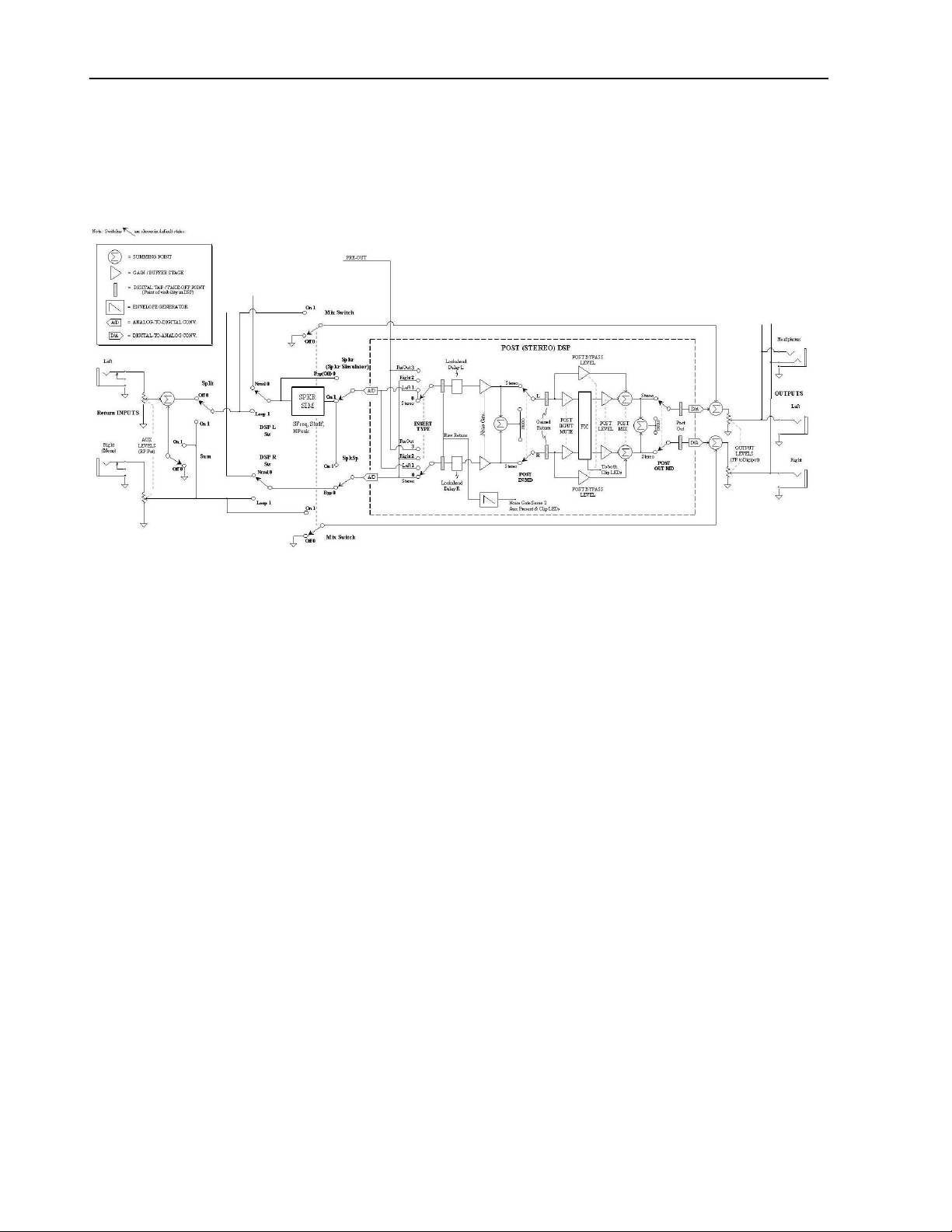

Chapter 6 Theory of Operation ................................................................... 6-1

Analog ......................................................................................................................................................6-1

Overview...............................................................................................................................................6-1

Input......................................................................................................................................................6-2

Tone Block............................................................................................................................................6-3

Dynamic Gain .......................................................................................................................................6-3

Send .....................................................................................................................................................6-4

Aux Inputs (including Speaker Simulator).............................................................................................6-5

Output ...................................................................................................................................................6-6

Supplies ................................................................................................................................................6-6

Digital .......................................................................................................................................................6-7

ARCHITECTURE..................................................................................................................................6-7

SCHEMATIC WALK-THROUGH ........................................................................................................6-14

DETAILS.............................................................................................................................................6-17

Chapter 7 - Parts List.................................................................................. 7-1

Main Board ...............................................................................................................................................7-1

Display Board ...........................................................................................................................................7-5

Front Panel Input Board ...........................................................................................................................7-6

Chassis/Mechanical .................................................................................................................................7-6

Packaging/Miscellaneous.........................................................................................................................7-7

Power Cords.............................................................................................................................................7-7

Chapter 8 Schematics and Drawings ......................................................... 8-1

Schematics:..............................................................................................................................................8-1

Drawings: .................................................................................................................................................8-1

Page 7

Lexicon

Chapter 1 Refe rence Documents, Required Equipment

Reference Documents

MPX G2 Owner's Manual - Lexicon P/N 070-11542 latest revision

Required Equipment

Tools

The following is a minimum suggested technician's tool kit required for performing disassembly, assembly

and repairs:

• Clean, antistatic, well lit work area.

• (1) #1 Phillips tips screwdriver

• (1) 14mm socket nut driver

• Solder: 63/37 - Tin/Lead Alloy composition, low residue, no-clean solder.

• Magnification glasses and lamps

• SMT Soldering / De-soldering bench-top repair station

Test Equipment

The following is a minimum suggested equipment list required to perform the proof of performance tests.

• Amplifier with speakers or headphones.

• Cables: (dependent on your signal source)

• 2 shielded audio cables with 1/4" plugs on one end (T/S for single ended, T/R/S for

balanced) and appropriate connections on the opposite ends for connection to Low

Distortion Oscillator.

• RCA male-to-male braided shield style cable

• 1 MIDI cable: male 5 pin DIN to male 5 pin DIN, 3ft minimum

• (1) Low Distortion Oscillator with a single-ended or balanced output < 600 (output impedance),

<0.005% THD+N with a Tone Burst function.

• (1) Analog distortion analyzer and level meter with single-ended or balanced input, switchable

30kHz low pass filter or audible band-pass (20-20kHz) filter.

• (1) DMM ( Digital Multimeter)

• (1) Frequency Counter

• (1) 100 MHz oscilloscope with 1x, 10x probes and storage features

• (1) Footpedal with a 10-100k range with cable

• (1) Stereo footswitch T/R/S momentary closed style and cable

• (1) Bench power supply providing a variac adjustment and transformer isolation

1-1

Page 8

Page 9

Lexicon

Chapter 2 Gene ral Information

Periodic Maintenance

Under normal conditions the MPX G2 system requires minimal maintenance. Use a soft, lint-free cloth

slightly dampened with warm water and mild detergent to clean the exterior surfaces of the connector box.

Do not use alcohol, benzene or acetone-based cleaners or any strong commercial cleaners. Avoid

using abrasive materials such as steel wool or metal polish. It the unit is exposed to a dusty environment, a

vacuum or low-pressure blower may be used to remove dust from the unit's exterior.

Ordering Parts

When ordering parts, identify each part by type, price and Lexicon Part Number. Replacement parts can be

ordered from:

LEXICON, INC.

3 Oak Park

Bedford, MA 01730-1441

Telephone: 781-280-0300; Fax: 781-280-0499; email: csupport@lexicon.com

ATTN: Customer Service

Returning Units to Lexicon for Service

Before returning a unit for warranty or non-warranty service, consult with Lexicon Customer

Service to determine the extent of the problem and to obtain Return Authorization. No equipment

will be accepted without Return Authorization from Lexicon.

If Lexicon recommends that a MPX G2 be returned for repair and you choose to return the unit to Lexicon

for service, Lexicon assumes no responsibility for the unit in shipment from the customer to the factory,

whether the unit is in or out of warranty. All shipments must be well packed (using the original packing

materials if possible), properly insured and consigned, prepaid, to a reliable shipping agent.

When returning a unit for service, please include the following information:

• Name

• Company Name

• Street Address

• City, State, Zip Code, Country

• Telephone number (including area code and country code where applicable)

• Serial Number of the unit

• Description of the problem

• Preferred method of return shipment

• Return Authorization #, on both the inside and outside of the package

Please enclose a brief note describing any conversations with Lexicon personnel (indicate the name of the

person at Lexicon) and give the name and telephone daytime number of the person directly responsible for

maintaining the unit.

Do no include accessories such as manuals, audio cables, footswitches, etc. with the unit, unless

specifically requested to do so by Lexicon Customer Service personnel.

2-1

Page 10

Page 11

Chapter 3 Spec ifications

I/O

Instrument input: mono 1/4 inch 1megΩ unbalanced, with analog soft clipping circuit and front panel input level control

Levels: minimum +2.2dBu for full scale, maximum +10dBu max

A/D: 24-bit

Lexicon

Return Inputs: stereo, 1/4 inch, 50κΩ unbalanced, with analog soft clipping circuit and ganged level control on rear panel

Levels:

minimum

A/D:

Main L and R Outputs: 1/4 inch TRS balanced (2), XLR 3-wire balanced (2)

Nominal Level: front panel adjustable to +4dBu

Maximum Output Level: balanced: +18dBu into 600Ω; unbalanced: +21dBu into 100κΩ

D/A: 24-bit

Send Output: mono, 1/4 inch unbalanced

Nominal Level: software adjustable to +4dBu

Maximum Output Level: +18dBu into 100κΩ

D/A:

minimum –10dBu for full scale; maximum +18dBu max (for +4 nominal inputs); +18 dBu with rear level pot at

24-bit

24-bit

Audio performance

Frequency response: 20Hz to 20kHz;+1 to -1.5dB for input to send; +1 to -1.5dB for return to output

THD+N: <0.01%, at 1kHz nominal output level; <.01% at 1kHz insert returns to main output; .01% at 1kHz input to main

outputs

Dynamic Range: Instrument input to send:

Sample rate: 44.1kHz

Return Mix: When the Return Mix option is selected, MPX G2 will mix the analog Aux inputs with the post converter output

signal from the DSP.

Throughput delay without send/return loop: Input to Main Output <3ms, nominal

-110dB (unweighted) minimum Input to Send with Relay Bypass on

-120dB (unweighted) Input to Send with Noise Gate on

-97dB (unweighted) typical instrument to main outputs in Bypass

Internal Audio Data Paths

Conversion: 24-bit A/D, 24-bit D/A

DSP: 32 bits

Control Interface

MIDI: 7-pin DIN connector for MIDI IN/powered bi-directional remote 5-pin DIN connectors for MIDI THRU and OUT

Footswitch: 1/4 inch T/R/S phone jack for 3 independent footswitches

Foot pedal:

Remote Power In: 2.5mm barrel for 9VAC remote power

1/4 inch T/R/S phone jack (10κΩ min, 100κΩ max impedance)

General

Dimensions: 19.0"W x 1.75"H x 13"D (483 x 45 x 330mm); 19 inch rack mount standard, 1U high

Weight: Net: 7.2lbs (3.2kg); Shipping: 11lbs (4.98kg)

Power Requirements: 100-240VAC, 50-60Hz, 25W, 3-pin IEC power connector

Environment: Operating temperature: 32° to 104°F (0° to 40°C); Storage temperature: -20° to 170°F (-30° to 75°C); Humidity:

maximum 95% without condensation

Electrical Approvals

Safety Compliance:

73/23/EEC)

EMC Compliance:

Specifications subject to change without notice.

UL1419 and CSA 22.2 No. 1-94 (UL and C-UL marks); EN60065 (TUV-GS and CE marking per Directive

FCC Class B; EN55022 Class B and EN50082-1; (CE marking per Directive 89/336/EEC)

3-1

Page 12

Page 13

Lexicon

Chapter 4 Perfo rmance Verification

This section provides a procedure for verification of the normal operation of the MPX G2 internal processors

and the integrity of the analog and digital audio signal paths. This procedure does not require removal of

the MPX G2 covers.

Diagnostics

The MPX G2 contains three types of Diagnostics: Power On Diagnostics, Extended Diagnostics, and

Emergency Diagnostics. Each of these is described fully the chapter on Troubleshooting. When the MPX

G2 is powered on, Power On Diagnostics will run automatically to verify proper operation of its internal

system. The Power On Diagnostics consist of the following tests:

FPGA Test

Z80 CPU Test

ROM Checksum Test

Stack RAM Test

ADSP2186 Test

WCS Test

Lo SRAM Test

Lex-2186 Test

Sample Rate Test

Digipot Test

Analog Audio Performance:

NOTE: In order to properly test the MPX G2, every step in the Setup section must be set in order. This is to

insure proper troubleshooting of an MPX G2 if service is needed. Failure to set the unit up properly will

cause incorrect readings. Many of the tests in this procedure are provided to verify functional operation.

Test results given for tests intended to verify functionality do not necessarily represent any published

performance specification.

Setup:

1. Turn on the MPX G2 and wait for the Power On Diagnostics cycle to finish.

2. Turn the front panel knob to select program 250 Clean Slate.

3. Press the Edit button. The display should read: Edit select Mix. Turn the knob until the display reads:

Edit select Effects Order.

4. Press the Gain button. Once pressed its Led will flash off/on and the display will read Gain select: no

effect.

5. Turn the knob until the display reads: Gain select *Crunch. The Gain Led will start to flash more rapidly.

6. Press the Gain button. The '*' will disappear and the Gain Led will be flashing slower. This is an

indication that the Crunch effect is now loaded.

7. Press the Effect 1 button. The Effect 1 Led will flash off/on and the display will read FX 1 select: no

effect.

8. Turn the knob until the display reads: FX 1 select: 13 *Volume (S). The Effect 1 Led will start to flash

more rapidly.

9. Press the Effect 1 button. The '*' will disappear and the Effect 1 Led will be flashing slower. This is an

indication that the Volume (S) effect is now loaded.

10. Set the Gain pots (Low Mid Hi ) on the front panel so the levels are at 0 (the level will change on the

display as the pot each pot is turned).

11. Press the Edit button twice. The display reads: Edit Select: Mix.

12. Press the Yes button and the display reads: Send Level 0 (flashing). Turn the knob CCW to set the

Send Level to -18. Press the No button to get you back to the Edit select Mix.

13. Turn the knob until the display reads: Edit select Noise Gate. Press the Yes button 3 times. The display

reads: NoiseGate Thrsh. Turn the knob CW until the reading is -20dB.

14. Press the Yes button. The display reads: NoiseGate Atten. Turn the knob CCW for a -90dB setting.

15. Press the Yes button. The display reads: NoiseGate Offset the dB level should be at -3dB.

4-1

Page 14

MPX G2 Service Manual

16. Press the Yes button. The display reads: NoiseGate ATime. Press Yes and turn the knob CW until

setting is at 20.

17. Press the Yes button. The display reads: NoiseGate HTime. Press Yes and turn the knob CCW until

setting is at 20.

18. The MPX G2 now has to be placed in a test program called Development. This will require several

steps before the remaining settings for the Performance Section are set properly.

18.1. Press the System button. The display reads: System Select: Audio

18.2. Turn the knob CW until the display reads: System Select: MIDI.

18.3. Press the Yes button 4 times until the display reads: MIDI Ctl Send None = None

18.4. Press the Options button the display reads: MIDI Reset Press YES

18.5. Press and hold the Effect 1 button until the display reads: Debug Mode then release.

18.6. Press the Options button. The display reads: MIDI Ctl Send None=None.

18.7. Press the No button 4 times until the display reads: System Select: MIDI.

18.8. Turn the knob CW until the display reads: System Select :Development

19. The Development Diagnostics Menu will now be available.

20. Press the Yes button Twice until the display reads: Devel DSP Bypass. Turn the knob to set this to Byp

0.

21. Press the Yes button Five times until the display reads: Devel Insrt Type. Turn the knob CCW to set this

to Stereo.

22. Press the Yes button Eight times until the display reads: Devel LoCut. Turn the knob to set this to 0.

23. Press the Yes button Three times until the display reads: Devel HiCut. Turn the knob to set this to 0.

24. Press the Yes button once. The display reads: Devel Bass. Turn the knob to set this to 0.

25. Press the Yes button once. The display reads: Devel Trebl. Turn the knob to set this to 0.

26. Press the Yes button three times until the display reads: Devel Gtone. Turn the knob CCW to Byp 0.

27. Press the Yes button once. The display reads: Devel Fgood. Turn the knob to set this to Out 0.

28. Press the Yes button twice. The display reads: Devel Gain. Turn the knob CCW to Byp 0.

29. Press the Yes button twice. The display reads: Devel Send. Turn the knob to set this to Gn 0.

30. Press the Yes button once. The display reads: Devel Mute. Turn the knob CCW to Byp 0.

31. Press the Program button. The display reads: Clean Slate.

The MPX G2 is now ready for the tests that follow.

For each test, you will be instructed to make different setting changes to the above procedure, mainly in the

form of input levels. All measurements fall within a range containing both Upper and Lower limit rather than

a set number. The range values will be listed as Upper limit values first and Lower limit values.

Note: In the tests to follow, Input refers to the Rear Guitar Input Jack on the back of the MPX G2.

32. Connect an audio input cable between the Low Distortion Oscillator and the MPX G2 Rear Guitar Input

jack.

33. Connect an audio output cable from the Insert Send output jack on the rear of the MPX G2 to the

Distortion Analyzer.

4-2

Page 15

Input to Send

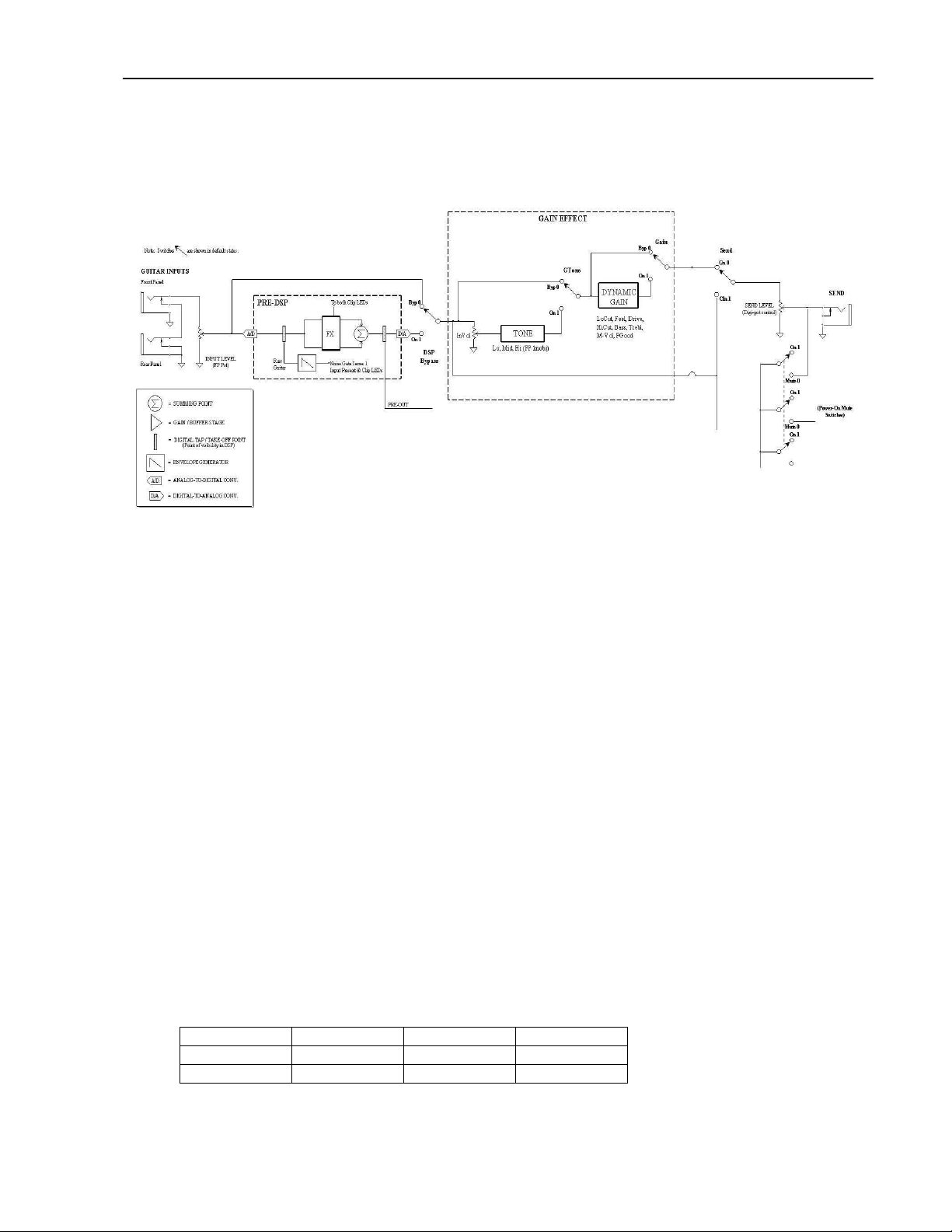

The following tests will be testing the Input to Send path as seen in the diagram below:

Lexicon

Input To Send Tests In Bypass:

This test will verify the Audio signal path from the Rear Input to the Send output of the MPX G2

In Bypass

Signal Levels:

1. Apply a 1kHz-sinewave signal at +0.5dBu (820 mVRMS) to the Rear Guitar Input jack of the MPX G2.

2. Press the Edit button. The display will read Edit select Mix. Press the Yes button once. The display will

read Send Level. Turn the knob for a setting of -10.

3. Verify an output level reading between -0.64 to -1.76 dBu (720 to 632 mVRMS).

4. Reset the Send Level in the Edit menu to +8.

5. Verify an output level reading between 17.36 to 16.24 dBu (5.72 to 5.03 Vrms).

6. Apply a 1kHz-sinewave signal at +1dBu (870 mVRMS).

7. Turn the Bypass on by pressing the Bypass button on the front panel.

8. Verify an output level reading between 1.56 to -0.44 dBu (927 to 736 mVRMS).

9. Reapply a 1kHz-sinewave signal at +0.5dBu (820 mVRMS).

10. Turn off the Bypass from the front panel.

11. Add a 600Ω load to the output signal feeding the analyzer.

12. Verify an output level reading between 11.36 to -9.24 dBu (2.87 to .267 Vrms).

Frequency Response Measurement:

1. Disable all Filters on the Distortion Analyzer.

2. Apply a 1kHz-sinewave signal at +1dBu (870 mVRMS).

3. Set the Analyzer for a 0dB reference.

4. Verify the output level reading is between 1.0 to -1.5 dBu (875 to 647 mVRMS) at the following

frequency settings.

20,000Hz 16,000Hz 12,000Hz 10,000Hz

4,000Hz 2,000Hz 250Hz 100Hz

60Hz 20Hz

4-3

Page 16

MPX G2 Service Manual

THD+N Measurement:

1. Set the Analyzer to measure THD+N.

2. Enable the Lo pass filters on the analyzer (30kHz or 20kHz).

3. Verify an output THD+N reading is between (0.15 to 0.0007%) at the following frequency settings.

20,000Hz 15,000Hz 10,000Hz 5,000Hz

3,000Hz 997Hz 100Hz 20Hz

4. Set the Analyzer back to measure level.

Signal to Noise Ratio:

1. Apply a 1kHz-sinewave signal at +2.2dBu (1.0 Vrms).

2. Set the Analyzer for a 0dB reference (@ 1kHz).

3. Turn off the oscillator.

4. Verify an output level reading between -99.94 to-120.00 dBu (7.6 to 0.8 uVRMS).

5. Turn the oscillator back on.

Signal Level with NoiseGate On/Off:

1. Apply a 1kHz-sinewave signal at -24dBu (49 mVRMS).

2. Press the Edit button and turn the knob CW to the Noise Gate menu.

3. Press the Yes button once. The display reads: NoiseGate Enable Off. Turn the knob CW to select

Guitar Input.

4. Press the Yes button once. The display reads: NoiseGate Send Off. Turn the knob CW to set this to

On.

5. Verify an output level reading range between -39.94 to -100.00 dBu (7.8m to 7.6u Vrms).

6. In the Edit menu turn the NoiseGate Send and Enable back to the Off position.

7. Apply a 1kHz-sinewave signal at -16.5dBu (115.9 mVRMS).

8. Verify an output level reading range between 1.06 to -1.06 dBu (875 to 686 mVRMS).

Input To Send Test With Tone On:

This test will verify the Audio signal path from the Rear Input to the Send output of the MPX G2

With the Tone circuit enabled. There are 3 parameters that must be set for this test.

Signal Levels:

1. Press the System button until the display reads: System Select Development.

2. Press the Yes button 23 times until the display reads Devel GTone Byp 0. Turn the Knob CW to turn

the Tone circuit On 1.

3. Press the Edit button. The display will read Noise Select Mix. Turn the knob CW until the display reads

Edit select Noise Gate. Press the Yes button once. The display will read NoiseGate Enable. Set it to

Off.

4. Press the Yes button once. The display will read NoiseGate Send. Set this to the Off setting.

5. Press the Edit button a few times until the display reads: Edit Select: Mix.

6. Press the Yes button once. The display reads: Send Level. Turn the knob CW to set the level to +8.

7. Apply a 1kHz-sinewave signal at +1dBu (870 mVRMS) to the Rear Guitar Input jack of the MPX G2.

8. Verify an output level reading between 17.26 to 16.24dBu (5.7 to 5.0 Vrms).

THD+N Measurement:

1. Set the Analyzer to measure THD+N.

2. Enable the Lo pass filters on the analyzer (30kHz or 20kHz).

3. Verify an output THD+N reading is between (0.15 to 0.0007%) at the following frequency settings.

20,000Hz 15,000Hz 10,000Hz 5,000Hz

3,000Hz 997Hz 100Hz 20Hz

4-4

Page 17

5. Set the Analyzer back to measure level.

Signal To Noise Ratio:

1. Apply a 1kHz-sinewave signal at +2.2dBu (1.0 Vrms).

2. Set the Analyzer for a 0dB reference (@ 1kHz).

3. Turn off the oscillator.

4. Verify an output level reading between -99.94 to-120.00 dBu (7.8 to 0.8 uVRMS).

5. Turn the oscillator back on.

Frequency Response Measurement:

1. Disable all Filters on the Distortion Analyzer.

2. Apply a 1kHz-sinewave signal at -15.5dBu (130 mVRMS).

3. Set the Analyzer for a 0dB reference.

4. Verify the output level reading is between 1.06 to -1.56 dBu (875 to 647 mVRMS) at the following

frequency settings.

20,000Hz 16,000Hz 12,000Hz 10,000Hz

4,000Hz 2,000Hz 250Hz 100Hz

60Hz 20Hz

5. Set the Low Gain to -25 using the front panel knob.

6. Verify the output level readings for each of the frequency settings in the table below.

Lexicon

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (1.1) 3.40 (.90) 1.28

16,000 (1.1) 3.39 (.90) 1.27

12,000 (1.1) 3.38 (.90) 1.26

10,000 (1.1) 3.37 (.90) 1.25

4,000 (1.1) 3.16 (.90) 1.04

2,000 (1.0) 2.51 (.81) 0.39

997 (.83) 0.62 (.65) -1.50

250 (.34) -7.07 (.27) -9.19

100 (.22) -10.79 (.17) -12.91

60 (.20) -11.59 (.16) -13.71

20 (.20) -12.05 (.15) -14.17

7. Set the Low Gain to +25 using the front panel knob.

8. Verify the output level readings for each of the frequency settings in the table below.

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (1.1) 3.41 (.90) 1.29

16,000 (1.1) 3.42 (.90) 1.30

12,000 (1.1) 3.43 (.90) 1.31

10,000 (1.1) 3.45 (.90) 1.33

4,000 (1.2) 3.64 (.92) 1.52

2,000 (1.3) 4.27 (1.0) 2.15

997 (1.6) 6.10 (1.2) 3.98

250 (3.8) 13.79 (3.0) 11.67

100 (5.8) 17.51 (4.6) 15.39

60 (6.4) 18.37 (5.0) 16.25

20 (6.8) 18.87 (5.4) 16.75

4-5

Page 18

MPX G2 Service Manual

9. Set the Low Gain to 0, then set the Mid Gain to -25 using the front panel knob.

10. Verify the output level readings for each of the frequency settings in the table below.

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (1.0) 2.24 (.80) 0.12

16,000 (1.0) 1.68 (.70) -0.44

12,000 (.84) 0.66 (.65) -1.46

10,000 (.76) -0.15 (.60) -2.27

4,000 (.38) -6.12 (.30) -8.24

2,000 (.20) -11.86 (.15) -13.98

997 (.10) -17.65 (.08) -19.77

250 (.19) -12.21 (.15) -14.33

100 (.45) -4.67 (.35) -6.79

60 (.67) -1.22 (.53) -3.34

20 (1.1) 2.66 (.82) 0.54

11. Set the Mid Gain to +25 using the front panel knob.

12. Verify the output level readings for each of the frequency settings in the table below.

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (1.3) 4.53 (1.0) 2.41

16,000 (1.4) 5.08 (1.1) 2.96

12,000 (1.6) 6.07 (1.2) 3.95

10,000 (1.7) 6.88 (1.3) 4.76

4,000 (3.4) 12.82 (2.7) 10.70

2,000 (6.5) 18.54 (5.1) 16.42

997 (12.5) 24.18 (9.8) 22.06

250 (6.8) 18.93 (5.4) 16.81

100 (3.0) 11.48 (2.3) 9.36

60 (2.0) 8.16 (1.6) 6.04

20 (1.3) 4.37 (1.0) 2.25

13. Apply a 1kHz-sinewave signal at -30.5dBu (23 mVRMS).

14. Set the Mid Gain to 0, then set the High Gain to +50 using the front panel knob.

4-6

Page 19

15. Verify the output level readings for each of the frequency settings in the table below.

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (6.2) 18.07 (4.8) 15.95

16,000 (7.3) 19.45 (5.7) 17.33

12,000 (8.6) 20.92 (6.7) 18.80

10,000 (9.4) 21.67 (7.4) 19.55

4,000 (11) 23.37 (8.9) 21.25

2,000 (10) 22.41 (8.0) 20.29

997 (7.2) 19.37 (5.6) 17.25

250 (2.2) 8.96 (1.7) 6.84

100 (.90) 1.28 (.70) -0.84

60 (.57) -2.73 (.44) -4.85

20 (.27) -9.27 (.21) -11.39

16. Set High Gain setting back to 0.

Input To Send Test With DSP On:

This test will verify the Audio signal path from the Rear Input to the Send output of the MPX G2

With the DSP circuit enabled.

Lexicon

Signal Level:

1. Press the System button on the front panel. The display will read Devel GTone On 1. Turn the knob

CCW to place the Tone circuit into Byp 0.

2. Press the No button 21 times until the display reads: Devel DSP Bypass Byp 0. Turn the Knob CW to

turn the DSP circuit On 1.

3. Apply a 1kHz-sinewave signal at +1dBu (870 Vrms) to the Rear Guitar Input jack of the MPX G2.

4. Verify an output level reading between 12.76 to 11.64 dBu (3.4 to 3.0 Vrms).

Frequency Response Measurement:

1. Disable all Filters on the Distortion Analyzer.

2. Apply a 1kHz-sinewave signal at +1dBu (870 Vrms).

3. Set the Analyzer for a 0dB reference.

4. Verify the output level reading is between 1.06 to -1.56 dBu (875 to 647 mVRMS) at the following

frequency settings.

20,000Hz 16,000Hz 12,000Hz 10,000Hz

4,000Hz 2,000Hz 250Hz 100Hz

60Hz 20Hz

Frequency Response Measurement with Gain On:

1. Press the Yes button 21 times until the display reads Devel GTone Byp 0. Turn the knob CW to turn the

GTone circuit On 1.

2. Disable all Filters on the Distortion Analyzer.

3. Apply a 1kHz-sinewave signal at +1dBu (870 Vrms).

4. Set the Analyzer for a 0dB reference.

4-7

Page 20

MPX G2 Service Manual

5. Verify the output level reading is between 1.06 to -1.56 dBu (875 to 647 mVRMS) at the following

frequency settings.

20,000Hz 16,000Hz 12,000Hz 10,000Hz

4,000Hz 2,000Hz 250Hz 100Hz

60Hz 20Hz

6. Turn the knob CCW to place the GTone circuit back into Byp 0.

THD+N Measurement:

1. Set the Analyzer to measure THD+N.

2. Enable the Lo pass filters on the analyzer (30kHz or 20kHz).

3. Verify an output THD+N reading is between (0.15 to 0.0007%) at the following frequency settings.

20,000Hz 15,000Hz 10,000Hz 5,000Hz

3,000Hz 997Hz 100Hz 20Hz

4. Set the Analyzer back to measure level.

THD+N Measurement with Soft Sat On:

1. Press the No button until the display reads: System Select Development. Turn the knob CCW until the

display reads: System Select Audio.

2. Press the Yes button once. The display reads: Audio Soft Sat Off. Turn the knob CW to turn the Soft

Sat circuit On.

3. Verify the output level readings for each of the input level settings in the table below.

Levels Upper Lower

(Vrms) % %

-3dBu (.55) 1.10 0.14

-2dBu (.60) 3.06 0.73

-1dBu (.70) 5.38 1.66

0dBu (.80) 7.54 2.60

+1dBu (.90) 9.38 3.42

5. Turn the knob CCW to turn the Soft Sat circuit back Off.

Signal To Noise Ratio:

1. Apply a 1kHz-sinewave signal at +2.2dBu (1.0 Vrms).

2. Set the Analyzer for a 0dB reference (@ 1kHz).

3. Turn off the oscillator.

4. Verify an output level reading between -99.94 to-120.00 dBu (7.8 to 0.8 uVRMS).

5. Turn the oscillator back on.

Input To Send Test with Dynamic Gain On:

This test will verify the Audio signal path from the Rear Input to the Send output of the MPX G2

with the Dynamic Gain circuit enabled. You will now need to set the following parameters for the following

tests

Setup:

1. Press the No Button once. The display reads: System Select Audio.

2. Turn the Knob CW until the display reads: System Select Development.

4-8

Page 21

Lexicon

3. Press the Yes button twice. The display reads: Devel DSP Bypass On 1. Turn the knob CCW to turn

the DSP circuit to Byp 0.

4. Press the Yes button 21 times. The display reads: Devel Gtone. Turn the knob and set the level to Byp

0.

5. Press the No button 4 times. The display reads: Devel Bass. Turn the knob and set the level to 0.

6. Press the Yes button once. The display reads: Devel Trebl. Turn the knob and set the level to 0.

7. Press the Yes button 6 times the display reads: Devel Gain Byp 0. Turn the knob CW to turn the Gain

circuit On 1.

8. Press the Edit button 3 times. The display reads: Edit Select Mix.

Signal Level:

1. Apply a 1kHz-sinewave signal at -5.5dBu (411 mVRMS).

2. Set the Analyzer for a 0dB reference (@ 1kHz).

3. Verify an output level reading between 10.7 to 11.76dBu (2.7 to 3.0 Vrms).

4. Press the System button. The display reads: Devel Gain On 1.

5. Press the No button 9 times until the display reads: Devel Drive 0. Turn the knob CW to set the Drive

level to 60.

6. Apply a 1kHz-sinewave signal at -70.5dBu (231 mVRMS).

7. Set the Analyzer for a 0dB reference (@ 1kHz).

8. Verify an output level reading between 4.4 to 2.2dBu (1.3 to 1.0 Vrms).

9. Turn the knob CCW and set the Drive level to 0.

10. Press the Yes button 4 times. The display reads: Devel M-Vol 42 Turn the knob CCW to set the Volume

level to -60.

11. Apply a 1kHz-sinewave signal at -10.5dBu (231 mVRMS).

12. Set the Analyzer for a 0dB reference (@ 1kHz).

13. Verify an output level reading between -54.34 to -55.46 dBu (1.5 to 1.3 mVRMS).

14. Turn the knob CW and set the Drive M-Vol to -14.

15. Press the Yes button 3 times. The display reads: Devel FGood Out 0. Turn the knob CW so the setting

is In 1. This will engage the Feel Good circuit.

16. Press the No button 7 times. The display reads: Devel Drive 0. Turn the knob CW for a setting of 10.

17. Press the No button once. The display reads: Devel Feel 0. Turn the knob CW for a setting of 8.

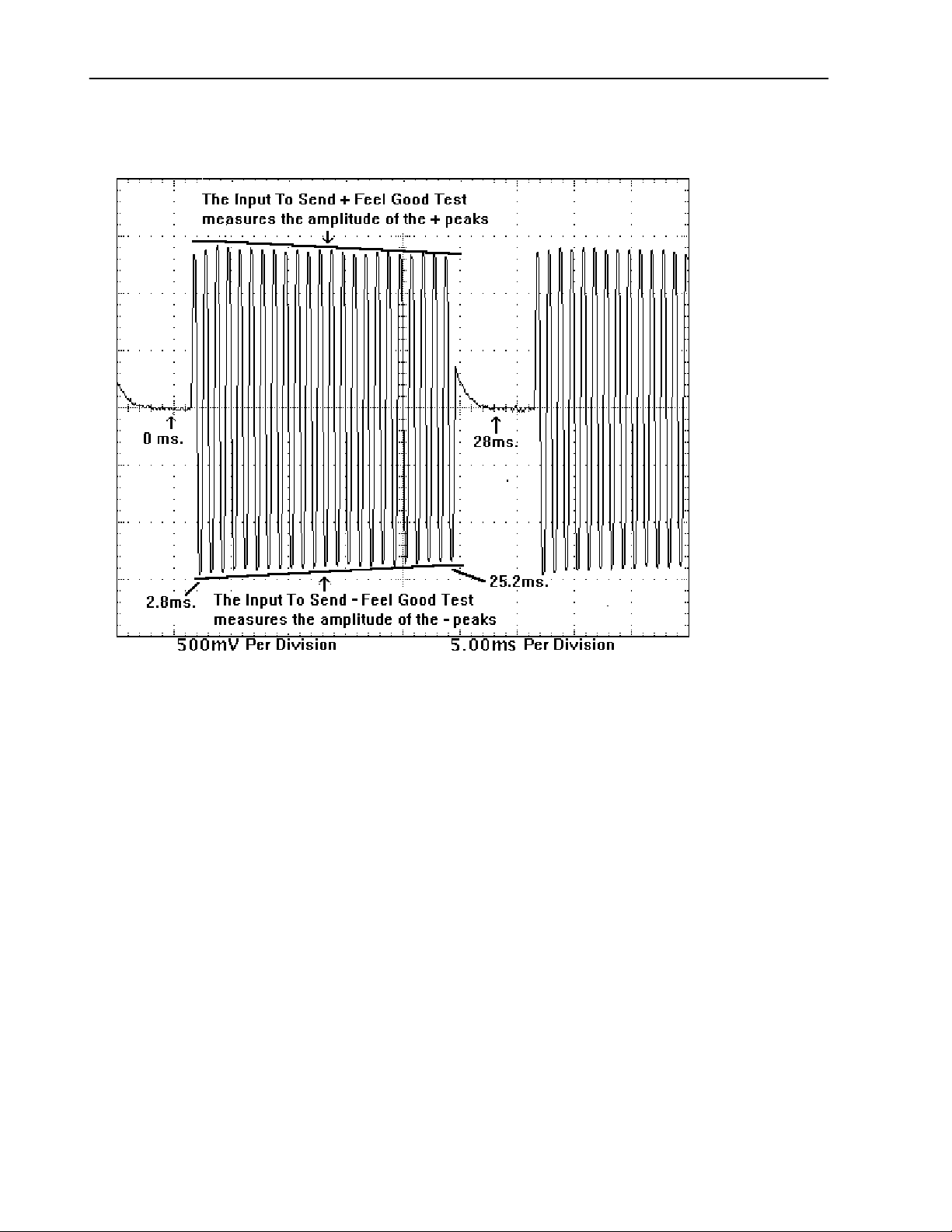

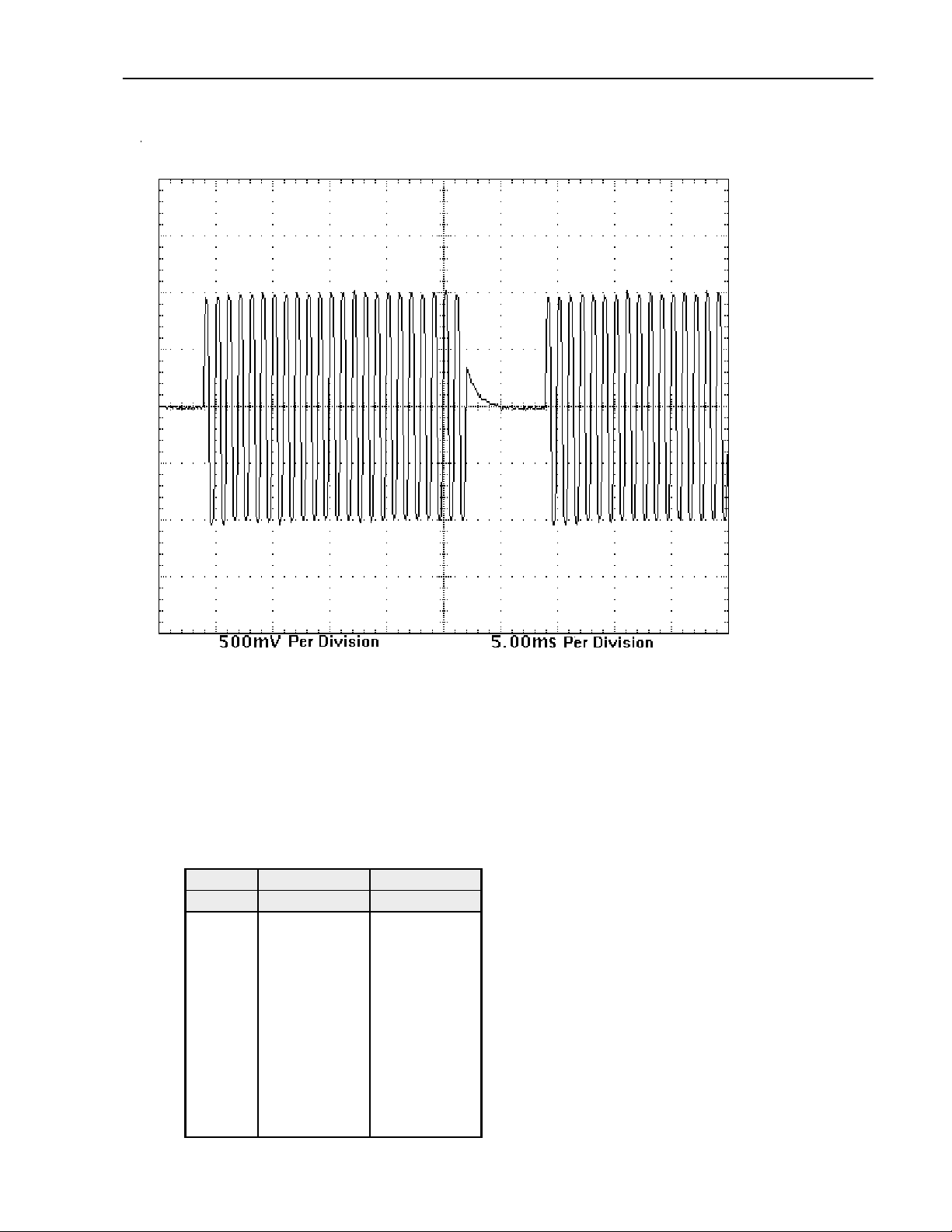

Note: In the following part of this test an oscillator with a tone burst function must be set for the specs below

in step 18. The resulting output from the MPX G2 must be feed to a storage oscilloscope that is capable of

measuring and storing the information in time domain as indicated in the 2 graphs below.

18. Apply a 1kHz-sinewave signal Burst at -6dBu (388 mVRMS).

19. Set the Analyzer for a 0dB reference (@ 1kHz).

20. The tone burst is measured in a time domain. Measure the positive peak amplitude at various times

during the test from (0-28ms). The waveform measurement should look like the following signal in the

figure below. Notice that the amplitude of each peak in the burst decreases over time.

4-9

Page 22

MPX G2 Service Manual

Feel Good Circuit On

21. Press the Yes button 8 times. The display reads: Devel FGood In 1. Turn the knob CCW so the setting

is Out 0 this will disengage the Feel Good circuit.

22. Again apply a 1kHz-sinewave signal Burst at -6dBu (388 mVRMS).

23. Set the Analyzer for a 0dB reference (@ 1kHz).

24. Verify the waveform measurement looks like the following signal in the figure below with the Feel Good

circuit off.

4-10

Page 23

Lexicon

Feel Good Circuit Off

Frequency Response Measurements:

1. Press the No button 9 times. The display will read Devel LoCut 0. Turn the knob CW so the setting is

20.

2. Apply a 1kHz-sinewave signal at -20.5dBu (73 mVRMS).

3. Set the Analyzer for a 0dB reference (@ 1kHz). Verify the output level readings for each of the

frequency settings in the table below.

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (.37) -6.32 (.30) -8.44

16,000 (.41) -5.41 (.33) -7.53

12,000 (.46) -4.58 (.36) -6.70

10,000 (.48) -4.22 (.37) -6.34

4,000 (.50) -3.86 (.39) -5.98

2,000 (.43) -5.13 (.34) -7.25

997 (.30) -8.33 (.23) -10.45

250 (.09) -18.85 (.07) -20.97

100 (.036) -26.74 (.028) -28.86

60 (.021) -31.28 (.016) -33.40

20 (.006) -41.92 (.005) -44.04

4-11

Page 24

MPX G2 Service Manual

4. Turn the knob CCW to set LoCut back to 0.

5. Press the Yes button 3 times. The display will read Devel HiCut. Turn the knob CW so the setting is 35.

6. Verify the output level readings for each of the frequency settings in the table below.

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (.01) -37.93 (.007) -41.05

16,000 (.01) -36.00 (.009) -39.12

12,000 (.02) -33.49 (.01) -36.61

10,000 (.02) -31.90 (.01) -35.02

4,000 (.05) -23.98 (.03) -27.10

2,000 (.10) -18.05 (.07) -21.17

997 (.18) -12.41 (.13) -15.53

250 (.40) -5.74 (.28) -8.86

100 (.30) -8.14 (.20) -11.26

60 (.20) -11.54 (.18) -14.66

20 (.06) -21.51 (.05) -24.63

7. Turn the knob CCW to set Hi Cut back to 0.

8. Press the Yes button 2 times. The display will read Devel Trebl 0. Turn the knob CW so the setting is

25.

9. Verify the output level readings for each of the frequency settings in the table below.

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (20) 28.25 (12) 24.13

16,000 (18) 27.44 (11) 23.32

12,000 (16) 26.06 (10) 21.94

10,000 (14) 24.99 (9) 20.87

4,000 (6) 18.31 (4) 14.19

2,000 (3) 12.78 (2) 8.66

997 (2) 7.75 (1.2) 3.63

250 (1.1) 2.74 (.66) -1.38

100 (1.0) 2.27 (.63) -1.85

60 (1.0) 2.11 (.62) -2.01

20 (1.0) 2.10 (.62) -2.02

10. Turn the knob CCW to set Treble to -25.

4-12

Page 25

11. Verify the output level readings for each of the frequency settings in the table below.

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (.05) -24.44 (.03) -28.56

16,000 (.05) -23.55 (.03) -27.67

12,000 (.06) -22.09 (.04) -26.21

10,000 (.07) -20.98 (.04) -25.10

4,000 (.15) -14.11 (.10) -18.23

2,000 (.30) -8.55 (.20) -12.67

997 (.50) -3.55 (.30) -7.67

250 (.90) 1.38 (.60) -2.74

100 (1.0) 1.94 (.60) -2.18

60 (1.0) 2.02 (.60) -2.10

20 (1.0) 2.06 (.60) -2.06

12. Turn the knob CW to set Treble to 0.

13. Press the No button once. The display will read Devel Bass 0. Turn the knob CW to set it to 25.

14. Verify the output level readings for each of the frequency settings in the table below.

Lexicon

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (.90) 1.31 (.70) -1.31

16,000 (.90) 1.31 (.70) -1.31

12,000 (.90) 1.32 (.70) -1.30

10,000 (.90) 1.32 (.70) -1.30

4,000 (.90) 1.36 (.70) -1.26

2,000 (.90) 1.48 (.70) -1.14

997 (1.0) 1.93 (.70) -0.69

250 (1.7) 6.44 (1.2) 3.82

100 (3.2) 12.24 (2.3) 9.62

60 (4.3) 14.84 (3.2) 12.22

20 (5.6) 17.15 (4.1) 14.53

15. Turn the knob CCW to set Bass to -25.

16. Verify the output level readings for each of the frequency settings in the table below.

Freq. Upper Lower

Hz (Vrms) dBu (Vrms) dBu

20,000 (.90) 1.31 (.70) -1.31

16,000 (.90) 1.31 (.70) -1.31

12,000 (.90) 1.30 (.70) -1.32

10,000 (.90) 1.30 (.70) -1.32

4,000 (.90) 1.26 (.65) -1.36

2,000 (.90) 1.14 (.65) -1.48

997 (.80) 0.67 (.60) -1.95

250 (.50) -3.96 (.36) -6.58

100 (.25) -9.59 (.20) -12.21

60 (.20) -12.04 (.20) -14.66

20 (.20) -13.60 (.10) -16.22

4-13

Page 26

MPX G2 Service Manual

THD+N Measurement:

1. Apply a 1kHz-sinewave signal at -10.0dBu (245 mVRMS).

2. Set the Analyzer for a 0dB reference (@ 1kHz).

3. Set the Analyzer to measure THD+N.

4. Enable the Lo pass filters on the analyzer (30kHz or 20kHz).

5. Verify an output THD+N reading is between (0.15 to 0.0007%) at the following frequency settings.

20,000Hz 15,000Hz 10,000Hz 5,000Hz

3,000Hz 997Hz 100Hz 20Hz

6. Set the Analyzer back to measure level.

Signal To Noise Ratio:

1. Apply a 1kHz-sinewave signal at +2.2dBu (1.0 Vrms).

2. Set the Analyzer for a 0dB reference (@ 1kHz).

3. Turn off the oscillator.

4. Verify an output level reading between -99.94 to-120.00 dBu (7.8 to 0.8 uVRMS).

5. Turn the oscillator back on.

Signal To Noise Ratio with Tone Enabled:

1. Press the No button 17 times. The display reads: Devel DSP Bypass Byp 0. Turn the knob CW so DSP

is On 1.

2. Press the Yes button 21 times. The display reads: Devel Gtone. Verify the circuit is set to On 1.

3. Press the Yes button 3 times. The display reads: Devel Gain. Verify the gain is set to On 1.

4. Apply a 1kHz-sinewave signal at +2.2dBu (1.0 Vrms).

5. Set the Analyzer for a 0dB reference (@ 1kHz).

6. Turn off the oscillator.

7. Verify an output level reading between -89.94 to-120.00 dBu (24.2 to 0.8 Vrms).

8. Turn the oscillator back on.

Signal To Noise Ratio Noise Gate On No Input:

1. Press the Edit button. The display reads: Edit Select Mix. Turn the knob CW until it reads: Edit Select

Noise Gate.

2. Press the Yes button once. The display reads: NoiseGate Enable Off. Turn the knob CW so the display

reads Guitar Input. This enables the NoiseGate circuit.

3. Press the Yes button once. The display reads: NoiseGate Send Off. Turn the knob CW to On to enable

the circuit.

4. Press the System button. The display reads: Devel Gain. Verify the gain is set to On 1.

5. Apply a 1kHz-sinewave signal at +2.2dBu (1.0 Vrms).

6. Set the Analyzer for a 0dB reference (@ 1kHz).

7. Turn off the oscillator.

8. Verify an output level reading between -119.94 to-140.00 dBu (0.8 to 0.08 uVRMS).

Input To Send Tests With Clean On:

These tests will verify the Audio signal path from the Rear Input to the Send output of the MPX G2 with the

Clean circuit enabled. The following tests parameters will be needed in order to perform these tests.

Setup

1. Press the Yes button 2 times. The display reads: Devel Send Gn 0. Turn the knob CW to select Cln 1.

The Clean circuit is now enabled.

2. Press the Edit button. The display reads: NoiseGate Send On. Turn the knob CCW to Off.

3. Press the No button once. The display reads: NoiseGate Enable Guitar Input. Turn the knob CCW to

Off.

4-14

Page 27

Signal Level:

1. Apply a 1kHz-sinewave signal at +1.0dBu (870 mVRMS).

2. Set the Analyzer for a 0dB reference.

3. Verify an output level reading between 17.36 to 16.24 dBu (5.72 to 5.0 Vrms).

Frequency Response Measurements:

1. Disable all Filters on the Distortion Analyzer.

2. Apply a 1kHz-sinewave signal at +1dBu (870 Vrms).

3. Set the Analyzer for a 0dB reference.

4. Verify the output level reading is between 1.06 to -1.56 dBu (875 to 647 mVRMS) at the following

frequency settings.

20,000Hz 16,000Hz 12,000Hz 10,000Hz

4,000Hz 2,000Hz 250Hz 100Hz

60Hz 20Hz

THD+N Measurement:

1. Set the Analyzer to measure THD+N.

2. Enable the Lo pass filters on the analyzer (30kHz or 20kHz).

3. Verify an output THD+N reading is between (0.15 to 0.0007%) at the following frequency settings.

Lexicon

20,000Hz 15,000Hz 10,000Hz 5,000Hz

3,000Hz 997Hz 100Hz 20Hz

4. Set the Analyzer back to measure level.

Signal To Noise Ratio:

1. Set the Analyzer for a 0dB reference (@ 1kHz).

2. Turn off the oscillator.

3. Apply a 1kHz sinewave signal at 2.2dBu (1.0 Vrms).

4. Verify an output level reading between -104.94 to-120.00 dBu (3.8 to 1.2 uVRMS).

4-15

Page 28

MPX G2 Service Manual

Insert Return Inputs to Outputs:

The following tests will be testing the Insert Return to Output path as seen in the diagram below:

Insert Return Inputs to Outputs with Mix On:

The following tests verify the integrity of the Left/Right Insert Return Inputs to the Left/Right Main Outputs of

the MPX G2. As described in the above Input to Sends tests the MPX G2 must be setup with Program 250

Clean Slate loaded and the Development Row available in the System Menu. Once these are loaded the

following parameters must be set before testing.

Setup:

1. Press the System button then turn the knob CW to the end until the display reads: System Select

Development.

2. Press the Yes button three times. The display reads: Devel Sum On 1. Turn the knob CCW to set the

Sum to Off.

3. Press the Yes button once. The display reads: Devel DSP R Sw. Verify that it is set for Nrm 10 (If not,

use the knob to change).

4. Press the Yes button once. The display reads: Devel DSP L Sw. Verify that it is set for Nrm 10 (If not,

use the knob to change).

5. Press the Yes button once. The display reads: Devel Mix Switch Off 0. Turn the knob CW to set this to

On 1.

6. Press the Yes button 8 times. The display reads: Devel SpkrSim BP On 1.Turn the knob CW to set this

to Byp 0.

7. On the Front panel, turn the Input Level Pot to Minimum (fully CCW).

8. Set the Output Level Pot to Maximum (fully CW).

9. On the back of the MPX G2 set the Insert Return Pot to 10 (fully CW).

10. Connect an audio input cable between the Low Distortion Oscillator and the MPX G2 Left Insert Return

jack.

11. Connect an audio output cable from the Left Main 1/4 Output jack on the rear of the MPX G2 to the

Distortion Analyzer.

Signal Level:

1. Apply a 1kHz-sinewave signal at -11dBu (218 mVRMS).

2. Verify an output level reading between 27.06 to 24.94 dBu (17.5 to 13.7 Vrms).

3. Move the cable from the Left Insert Return jack to the Right Insert Return jack.

4-16

Page 29

4. Move the cable from the Left Main Output jack to the Right Main Output Jack.

5. Verify its output level reading is between 27.06 to 24.94 dBu (17.5 to 13.7 Vrms).

Signal Level with 600Ω Load:

1. Apply a 1kHz-sinewave signal with a 600Ω load at -11dBu (218 mVRMS).

2. Verify an output level reading between 17.86 to 15.74 dBu (6 to 4.7 Vrms).

3. Move the cable from the Right Insert Return jack to the Left Insert Return jack.

4. Move the cable from the Right Main Output Jack to the Left Main Output Jack.

5. Verify its output level reading is between 17.86 to 15.74 dBu (6 to 4.7 Vrms).

6. Remove the 600Ω load.

Frequency Response Measurement:

1. Disable all Filters on the Distortion Analyzer.

2. Apply a 1kHz-sinewave signal at -11dBu (218 mVRMS).

3. Set the Analyzer for a 0dB reference.

4. Verify the output level reading is between 1.06 to -1.56 dBu (875 to 647 mVRMS) at the following

frequency settings.

20,000Hz 16,000Hz 12,000Hz 10,000Hz

4,000Hz 2,000Hz 250Hz 100Hz

60Hz 20Hz

Lexicon

5. Move the cable from the Left Insert Return jack to the Right Insert Return jack.

6. Move the cable from the Left Main Output jack to the Right Main Output Jack.

7. Verify the output level reading is between 1.06 to -1.56 dBu (875 to 647 mVRMS) at the following

frequency settings.

20,000Hz 16,000Hz 12,000Hz 10,000Hz

4,000Hz 2,000Hz 250Hz 100Hz

60Hz 20Hz

8. Enable the Lo pass filters on the analyzer (30kHz or 20kHz).

Crosstalk Left/Right Measurements:

1. Move the cable from the Right Main Output Jack to the Left Main Output Jack.

2. Verify the crosstalk output level reading is between -62.94 to -120 dBu (552 to 1.2 uVRMS) at the

following frequency settings.

20,000Hz 15,000Hz 10,000Hz 5,000Hz

3,000Hz 997Hz 100Hz 20Hz

3. Move the cable from the Right Insert Return jack to the Left Insert Return jack.

4. Move the cable from the Left Main Output jack to the Right Main Output Jack.

5. Verify the crosstalk output level reading is between -62.94 to -120 dBu (552 to 1.2 uVRMS) at the

following frequency settings.

20,000Hz 10,000Hz

997Hz 100Hz

THD+N Measurement:

1. Connect an audio input cable between the Low Distortion Oscillator and the MPX G2 Left Insert Return

jack.

2. Connect an audio output cable from the Left Main ¼” Output jack on the rear of the MPX G2 to the

Distortion Analyzer.

4-17

Page 30

MPX G2 Service Manual

3. Apply a 1kHz-sinewave signal at -11dBu (218 mVRMS).

4. Set the Analyzer to measure THD+N.

5. Verify an output THD+N reading is between 0.01 - 0.0001% at the following frequency settings.

20,000Hz 15,000Hz 10,000Hz 5,000Hz

3,000Hz 997Hz 100Hz 20Hz

6. Move the cable from the Left Insert Return jack to the Right Insert Return jack.

7. Move the cable from the Left Main Output jack to the Right Main Output Jack.

8. Verify an output THD+N reading is between (0.01 to 0.0001%) at the following frequency settings.

20,000Hz 15,000Hz 10,000Hz 5,000Hz

3,000Hz 997Hz 100Hz 20Hz

9. Set the Analyzer back to measure level.

Signal To Noise Ratio:

1. Apply a 1kHz-sinewave signal at -10dBu (245 mVRMS).

2. Set the Analyzer for a 0dB reference (@ 1kHz).

3. Turn off the oscillator.

4. Verify an output level reading between -82.94 to-120.00 dBu (55 to 0.8 uVRMS).

5. Move the cable from the Right Insert Return jack to the Left Insert Return jack.

6. Move the cable from the Right Main Output jack to the Left Main Output Jack.

7. Verify an output level reading between -82.94 to-120.00 dBu (55 to 0.8 uVRMS). Turn the oscillator

back on.

Insert Return Inputs to Outputs with Sum On:

The following test verifies the Inserts to Outputs with the Sum circuit engaged. The following parameters

must be set up before testing.

Setup/Test:

1. Press the System button then turn the knob CW to the end until the display reads: System Select

Development.

2. Press the Yes button 3 times. The display reads: Devel Sum Off 0. Turn the knob CW to On 1. This will

enable the Sum circuit.

3. Press the Yes button once. The display reads: Devel DSP R Sw Nrm10. Turn the knob CW to set the

left DSP to Loop 1.

4. Press the Yes button once. The display reads: Devel DSP L Sw Nrm10. Turn the knob CW to set the

left DSP to Loop 1.

5. Press the Yes button once. The display reads: Devel Mix Switch. Verify that Mix is set to Off 0.

6. Press the Yes button 4 times. The display reads: Devel SpkSp. Verify that Mix is set to Byp 0.

7. Press the Yes button 4 times. The display reads: Devel SpkrSim.BP. Verify that Mix is set to Byp 0.

8. Move the cable from the Left Insert Return jack to the Right Insert Return jack.

9. Apply a 1kHz-sinewave signal at -10dBu (245 mVRMS).

10. At the Left Main Output verify an output level reading between 27.06 to 24.94 dBu (17.5 to 14 Vrms).

Insert Return Inputs to Outputs with Split On:

The following test verifies the Inserts Return Inputs to Outputs with the Split circuit engaged. The following

parameters must be set up before testing.

Setup/Test:

1. Press the No button 11 times. The display reads: Devel Sum On 1. Turn the knob CCW to Off 0.

2. Press the No button 2 times. The display reads: Devel Split Off. Turn the knob CW to On this will

enable the Split switch. Note: The MPX G2 is already set for the proper input level from the last test.

4-18

Page 31

Lexicon

3. At the Left Main Output verify an output level reading between 27.06 to 24.94 dBu (17.5 to 14 Vrms).

4. Switch the cable from the Left Main Output to the Right Main output.

5. Verify an output level reading between 27.06 to 24.94 dBu (17.5 to 14 Vrms).

Insert Return Inputs to Outputs with DSP On:

The following tests verify the Inserts to Outputs with the DSP circuit engaged. The following parameter must

be set up before testing.

Setup:

1. Press the System button until the display reads: System Select Development.

2. Press the Yes button once. The display reads: Devel Split. Off. Turn the knob CCW to Off 0.

3. Press the Yes button 2 times. The display reads: Devel Sum On 1. Turn the knob CCW to Off 0.

4. Press the Yes button once. The display reads: Devel DSP R Sw Nrm10. Verify that the Mix is set to

Loop 1.

5. Press the Yes button once. The display reads: Devel DSP L Sw Nrm10. Verify that the Mix is set to

Loop 1.

6. Press the Yes button once. The display reads: Devel Mix Switch. Verify that it is set to Off 0.

7. Press the Yes button 4 times. The display reads: Devel SpkSp. Verify that it is set to Byp 0.

8. Press the Yes button 4 times. The display reads: Devel SpkrSim.BP. Verify that Mix is set to Byp 0.

9. Connect an audio input cable between the Low Distortion Oscillator and the MPX G2 Left Insert Return

jack.

10. Connect an audio output cable from the Left Main 1/4 Output jack on the rear of the MPX G2 to the

Distortion Analyzer.

Signal Level:

1. Apply a 1kHz-sinewave signal at -11dBu (218 mVRMS).

2. Verify an output level reading between 27.26 to 25.14 dBu (17.5 to 14 Vrms).

3. Move the cable from the Left Insert Return jack to the Right Insert Return jack.

4. Move the cable from the Left Main Output jack to the Right Main Output Jack.

5. Verify an output level reading between 27.26 to 25.14 dBu (17.5 to 14 Vrms).

Signal Level with Bypass Engaged:

1. Press the Bypass button on the front panel of the MPX G2.

2. Verify an output level reading at the Right Main Output between -64.94 to -120 dBu (439 to 1.3

uVRMS).

3. Move the cable from the Right Insert Return jack to the Left Insert Return jack.

4. Move the cable from the Right Main Output jack to the Left Main Output Jack.

5. Verify an output level reading between -64.94 to -120 dBu (439 to 1.3 uVRMS).

6. Press the Bypass button on the front panel again to turn it back off.

Frequency Response Measurement:

1. Disable all Filters on the Distortion Analyzer.

2. Apply a 1kHz-sinewave signal at -11dBu (218 mVRMS).

3. Set the Analyzer for a 0dB reference.

4. Verify the output level reading is between 1.06 to -1.56 dBu (875 to 647 mVRMS) at the following

frequency settings.

20,000Hz 16,000Hz 12,000Hz 10,000Hz

4,000Hz 2,000Hz 250Hz 100Hz

60Hz 20Hz

5. Move the cable from the Left Insert Return jack to the Right Insert Return jack.

4-19

Page 32

MPX G2 Service Manual

6. Move the cable from the Left Main Output jack to the Right Main Output Jack.

7. Verify the output level reading is between 1.06 to -1.56 dBu (875 to 647 mVRMS) at the following

frequency settings.

20,000Hz 16,000Hz 12,000Hz 10,000Hz

4,000Hz 2,000Hz 250Hz 100Hz

60Hz 20Hz

8. Enable the Lo pass filters on the analyzer (f30kHz or 20kHz).

Crosstalk Left/Right Measurements:

1. Move the cable from the Right Main Output Jack to the Left Main Output Jack.

2. Verify the crosstalk output level reading is between -62.94 to -120 dBu (552 to 1.2 uVRMS) at the

following frequency settings.

20,000Hz 10,000Hz

997Hz 100Hz

3. Move the cable from the Right Insert Return jack to the Left Insert Return jack.

4. Move the cable from the Left Main Output jack to the Right Main Output Jack.

5. Verify the crosstalk output level reading is between -62.94 to -120 dBu (552 to 1.2 uVRMS) at the

following frequency settings.

20,000Hz 10,000Hz

997Hz 100Hz

THD+N Measurement with Soft Sat On:

Because you have to leave the Development Row in this test to turn Soft Sat on, access to the

Development Row will have to be recalled and the settings for the DSP will have to be reset. Please

perform the following steps to insure proper set for this section of the test.

Setup:

1. Press the System button until the display reads: System select Development.

2. Turn the knob CCW until the display reads: System select Audio.

3. Press the Yes button once. The display reads: Audio Soft Sat Off. Turn the knob CW On.

4. Press the No button once to get back to the System Page. Select Audio.

5. The MPX G2 now has to be placed in a test program called Development. This will require several

steps before the remaining settings for the Performance Section are set properly.

5.1. Press the System button. The display reads: System select Audio.

5.2. Turn the knob CW until the display reads: System select MIDI.

5.3. Press the Yes button 4 times until the display reads: MIDI Ctl Send None = None.

5.4. Press the Options button. The display reads: MIDI Reset Press YES.

5.5. Press and hold the Effect 1 button until the display reads: Debug Mode then release.

5.6. Press the Options button. The display reads: MIDI Ctl Send None=None.

5.7. Press the No button 4 times until the display reads: System Select MIDI.

5.8. Turn the knob CW until the display reads: System select Development. The Development

Diagnostics Menu will now be available.

6. Connect an audio input cable between the Low Distortion Oscillator and the MPX G2 Left Insert Return

jack.

7. Connect an audio output cable from the Left Main 1/4 Output jack on the rear of the MPX G2 to the

Distortion Analyzer.

Check the following Parameters in the Development Row to insure settings are correct.

1. Press the System button until the display will reads: System Select Development.

2. Press the Yes button once. The display reads: Devel Split. Off. Turn the knob CCW to Off 0.

3. Press the Yes button 2 times. The display reads: Devel Sum On 1. Turn the knob CCW to Off 0.

4-20

Page 33

Lexicon

4. Press the Yes button once. The display reads: Devel DSP R Sw Nrm10. Verify that Mix is set to Loop 1.

5. Press the Yes button once. The display reads: Devel DSP L Sw Nrm10. Verify that Mix is set to Loop 1.

6. Press the Yes button once. The display reads: Devel Mix Switch. Verify that it is set to Off 0.

7. Press the Yes button 4 times. The display reads: Devel SpkSp. Verify that it is set to Byp 0.

8. Press the Yes button 4 times. The display reads: Devel SpkrSim.BP. Verify that Mix is set to Byp 0.

1. Set the Analyzer to measure THD+N.

2. Verify the output level readings for each of the input level settings in the table below.

Levels Upper Lower

(Vrms) % %

-15dBu (.14) 1.56 0.14

-14dBu (.15) 4.14 0.76

-13dBu (.17) 6.96 1.71

-12dBu (.19) 9.54 2.65

-11dBu (.21) 11.71 3.47

3. Move the cable from the Left Insert Return jack to the Right Insert Return jack.

4. Move the cable from the Left Main Output jack to the Right Main Output Jack.

5. Verify the output level readings for each of the input level settings in the table below.

Levels Upper Lower

(Vrms) % %

-15dBu (.14) 1.56 0.14

-14dBu (.15) 4.14 0.76

-13dBu (.17) 6.96 1.71

-12dBu (.19) 9.54 2.65

-11dBu (.21) 11.71 3.47

6. Set the Analyzer back to measure level.

7. At this time, in order to continue you will want to turn the Soft Sat back 0ff and reset the MPX G2 as

described at the top of this test.

THD+N Measurement – Soft Sat OFF:

1. Apply a 1kHz-sinewave signal at -14dBu (155 mVRMS).

2. Set the Analyzer to measure THD+N.

3. Verify an output THD+N reading is between (0.01 to 0.0007%) at the following frequency settings.

20,000Hz 15,000Hz 10,000Hz 5,000Hz

3,000Hz 997Hz 100Hz 20Hz

4. Move the cable from the Right Insert Return jack to the Left Insert Return jack.

5. Move the cable from the Right Main Output jack to the Left Main Output Jack.

6. Verify an output THD+N reading is between (0.01 to 0.0007%) at the following frequency settings.

20,000Hz 15,000Hz 10,000Hz 5,000Hz

3,000Hz 997Hz 100Hz 20Hz

7. Set the Analyzer back to measure level.

Signal To Noise Ratio:

1. Apply a 1kHz-sinewave signal at -10dBu (245 mVRMS).

2. Set the Analyzer for a 0dB reference (@ 1kHz).

4-21

Page 34

MPX G2 Service Manual

3. Turn off the oscillator.

4. Verify an output level reading between -92.94 to-120.00 dBu (18 to 0.8 uVRMS).

5. Move the cable from the Left Insert Return jack to the Right Insert Return jack.

6. Move the cable from the Left Main Output jack to the Right Main Output Jack.