MPX 110

24 bit

Dual Channel Processor

Service

Manual

MPX 110 Service Manual

Precautions

Save these instructions for later use.

Follow all instructions and warnings marked on the unit.

Always use with the correct line voltage. Refer to the manufacturers operating instructions for power requirements. Be advised that

different operating voltages may require the use of a different line cord and/or attachment plug.

Do not install the unit in an unventilated rack, or directly above heat producing equipment such as power amplifiers. Observe the

maximum ambient operating temperature listed in the product specification.

Slots and openings on the case are provided for ventilation; to ensure reliable operation and prevent it from overheating, these

openings must not be blocked or covered. Never push objects of any kind through any of the ventilation slots. Never spill a liquid of

any kind on the unit.

This product is equipped with a 3-wire grounding type plug. This is a safety feature and should not be defeated.

Never attach audio power amplifier outputs directly to any of the unit’s connectors.

To prevent shock or fire hazard, do not expose the unit to rain or moisture, or operate it where it will be exposed to water.

Do not attempt to operate the unit if it has been dropped, damaged, exposed to liquids, or if it exhibits a distinct change in performance

indicating the need for service.

This unit should only be opened by qualified service personnel. Removing covers will expose you to hazardous voltages.

This triangle, which appears on your component, alerts you to the presence of uninsulated, dangerous voltage inside the

enclosure… voltage that may be sufficient to constitute a risk of shock.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

This triangle, which appears on your component, alerts you to important operating and maintenance Instructions in this

accompanying literature.

Notice

This equipment generates and uses radio frequency energy and if not installed and used properly, that is, in strict accordance with the

manufacturer's instructions, may cause interference to radio and television reception. It has been type tested and found to comply with

the limits for a Class B computing device in accordance with the specifications of Part 15 of FCC Rules, which are designated to

provide reasonable protection against such interference in a residential installation. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause interference to radio or television reception, which can be

determined by turning the equipment OFF and ON, the user is encouraged to try to correct the interference by one or more of the

following measures:

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions. The user may

find the following booklet prepared by the Federal Communications Commission helpful:

This booklet is available from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

Le présent appareil numérique n'émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de Ia

class B prescrites dans le Règlement sur le brouillage radioélectrique édicté par le ministère des Communications du Canada.

Reorient the receiving antenna

Relocate the computer with respect to the receiver

Move the computer away from the receiver

Plug the computer into a different outlet so that the computer and receiver are on different branch circuits.

“How to identify and Resolve Radio/TV Interference Problems.

Copyright © 2002 Lexicon, Inc.

All Rights Reserved

Lexicon Inc. ● 3 Oak Park ● Bedford, MA 01730-1441 ● Tel (781) 280-0300 ● Customer Service Fax (781) 280-0499

Lexicon Part # 070-15026 Rev 0

Printed in the United States of America

Safety Suggestions

Lexicon

Read Instructions Read all safety and operating

instructions before operating the unit.

Retain Instructions Keep the safety and

operating instruc tions for future reference.

Heed Warnings Adhere to all warnings on the

unit and in the operating instructions.

Follow Instructions Follow operating and use

instructions.

Heat Keep the unit away from heat sources such

as radiators, heat registers, stoves, etc., including

amplifiers which produce heat.

Ventilation Make sure that the location or

position of the unit does not interfere with its

proper ventilation. For example, the unit should

not be situated on a bed, sofa, rug, or similar

surface that may block the ventilation openings;

or, placed in a cabinet which impedes the flow of

air through the ventilation openings.

Wall or Ceiling Mounting Do not mount the unit

to a wall or ceiling except as recommended by

the manufacturer.

Power Sources Connect the unit only to a power

supply of the type described in the operating

instructions, or as marked on the unit.

Grounding or Polarization* Take precautions

not to defeat the grounding or polarization of the

unit’s power cord.

*Not applicable in Canada.

Power Cord Protection Route power supply

cords so that they are not likely to be walked on

or pinched by items placed on or against them,

paying particular attention to cords at plugs,

convenience receptacles, and the point at which

they exit from the unit.

Nonuse Periods Unplug the power cord of the

unit from the outlet when the unit is to be left

unused for a long period of time.

Water and Moisture Do not use the unit near

water — for example, near a sink, in a wet

basement, near a swimming pool, near an open

window, etc.

Object and liquid entry Do not allow objects to

fall or liquids to be spilled into the enclosure

through openings.

Cleaning The unit should be cleaned only as

recommended by the manufacturer.

Servicing Do not attempt any service beyond

that described in the operating instructions. Refer

all other service needs to qualified service

personnel.

Damage requiring service The unit should be

serviced by qualified service personnel when:

the power supply cord or the plug has been

damaged, objects have fallen, or liquid has been

spilled into the unit, the unit has been exposed to

rain, the unit does not appear to operate normally

or exhibits a marked change in performance, the

unit has been dropped, or the enclosure

damaged.

MPX 110 Service Manual

The following general safety precautions must be observed during all phases of operation, service and repair of this instrument. Failure to

SAFETY SUMMARY

comply with these precautions or with specific warnings elsewhere in these instructions violates safety standards of design manufacture and

intended use of the instrument. Lexicon assumes no liability for the customer’s failure to comply with these requirements.

To minimize shock hazard the instrument chassis and cabinet

GROUND THE INSTRUMENT

must be connected to an electrical ground. The instrument is

equipped with a three-conductor AC power cable. The power

cable must either be plugged into an approved three-contact

electrical outlet or used with a three-contact to two-contact

adapter with the grounding wire (green) firmly connected to an

electrical ground (safety ground) at the power outlet. The power

jack and mating plug of the power cable meet International

Electrotechnical Commission (IEC) safety standards.

DO NOT OPERATE IN AN EXPLOSIVE

ATMOSPHERE

Do not operate the instrument in the presence of flammable gases

or fumes. Operation of any electrical instrument in such an

environment constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers.

Component replacement and internal adjustments must be made

by qualified maintenance personnel. Do not replace components

with power cable connected. Under certain conditions, dangerous

voltages may exist even with the power cable removed. To avoid

injuries, always disconnect power and discharge circuits before

touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another

person, capable of rendering first aid and resuscitation, is present.

General definitions of safety symbols used on equipment or in

manuals.

Instruction manual symbol: the product will be marked

with this symbol when it is necessary for the user to refer to the

instruction manual in order to protect against damage to the

instrument.

Indicates dangerous voltage. (Terminals fed from the

interior by voltage exceeding 1000 volts must be so marked.)

WARNING

The WARNING sign denotes a hazard. It calls attention to a

procedure, practice, condition or the like which, if not correctly

performed or adhered to, could result in injury or death to

personnel.

CAUTION

SAFETY SYMBOLS

DO NOT SUBSTITUTE PARTS OR MODIFY

INSTRUMENT

Because of the danger of introducing additional hazards, do not

install substitute parts or perform any unauthorized modification to

the instrument.

DANGEROUS PROCEDURE WARNINGS

Warnings, such as the example below, precede potentially

dangerous procedures throughout this manual. Instructions

contained in the warnings must be followed.

WARNING

Dangerous voltages, capable of causing death, are present in this

instrument. Use extreme caution when handling, testing and

adjusting.

The CAUTION sign denotes a hazard. It calls attention to an

operating procedure, practice, condition or the like which, if not

correctly performed or adhered to, could result in damage to or

destruction of part or all of the product.

NOTE:

The NOTE sign denotes important information. It calls attention to

procedure, practice, condition or the like which is essential to

highlight.

CAUTION

Electrostatic Discharge (ESD) Precautions

The following practices minimize possible damage to ICs resulting

from electrostatic discharge or improper insertion.

• Keep parts in original containers until ready for use.

• Avoid having plastic, vinyl or styrofoam in the work area.

• Wear an anti—static wrist-strap.

• Discharge personal static before handling devices.

• Remove and insert boards with care.

• When removing boards, handle only by non-conductive

surfaces and never touch open-edge connectors except at a

static-free workstation .*

• Minimize handling of ICs.

• Handle each IC by its body.

• Do not slide ICs or boards over any surface.

• Insert ICs with the proper orientation, and watch for bent

pins on ICs.

• Use static shielding containers for handling and transport.

‘To make a plastic-laminated workbench anti-static, wash with a

solution of Lux liquid detergent, and allow drying without rinsing.

MPX 110 Service Manual

Table of Contents

Chapter 1 Reference Documents, Required Equipment..............................1-1

Reference Documents.....................................................................................................................1-1

Required Equipment........................................................................................................................1-1

Tools...........................................................................................................................................1-1

Test Equipment ...........................................................................................................................1-1

Chapter 2 General Information......................................................................2-1

Periodic Maintenance......................................................................................................................2-1

Ordering Parts.................................................................................................................................2-1

Returning Units to Lexicon for Service..............................................................................................2-1

Chapter 3 Specifications ................................................................................3-1

Chapter 4 Performance Verification ...............................................................4-1

Functional Tests..............................................................................................................................4-1

Initial Inspection...........................................................................................................................4-1

power supply...............................................................................................................................4-1

Power up .....................................................................................................................................4-1

Setup..........................................................................................................................................4-1

Encoder Test ...............................................................................................................................4-2

Switch/LED Test ..........................................................................................................................4-2

ACD Pot Test ..............................................................................................................................4-2

midi wraparound test....................................................................................................................4-2

listening test................................................................................................................................4-3

Effects listening test .....................................................................................................................4-3

shock test ...................................................................................................................................4-3

Audio Performance:.........................................................................................................................4-3

setup...........................................................................................................................................4-3

gain test......................................................................................................................................4-4

signal-to-noise test.......................................................................................................................4-4

thd+n..........................................................................................................................................4-4

frequency response test...............................................................................................................4-4

Lexicon Audio Precision ATE Summary .........................................................................................4-5

Chapter 5 Troubleshooting.............................................................................5-1

Diagnostics ..................................................................................................................................... 5-1

Introduction .................................................................................................................................5-1

DIAGNOSTICS TEST DESCRIPTIONS ........................................................................................5-1

Power On Diagnostics..................................................................................................................5-1

Diagnostic Failures ......................................................................................................................5-2

ROM Checksum Test (1)..............................................................................................................5-2

SRAM Test (2) .............................................................................................................................5-2

Lexichip3 WCS Test (3)................................................................................................................5-3

Lexichip3 Interrupt Timer Test (4)..................................................................................................5-3

Lexichip3 Audio Data File Test (5).................................................................................................5-4

EEPROM Checksum (8)...............................................................................................................5-4

EXTENDED DIAGNOSTICS ............................................................................................................5-5

ROM Checksum Test (1)..............................................................................................................5-6

SRAM Test (2) .............................................................................................................................5-7

Lexichip3 WCS Test (3)................................................................................................................5-7

Lexichip3 Interrupt Timer Test (4)..................................................................................................5-8

Lexichip3 Audio Data File Test (5).................................................................................................5-8

Encoder/Switch/LED Test (6) ........................................................................................................5-9

MPX 110 Service Manual

ADC Pot Test (7).......................................................................................................................5-11

EEPROM Checksum (8).............................................................................................................5-12

MIDI Tests (9) ............................................................................................................................5-13

LED Test (10)............................................................................................................................5-14

Lexichip3 External DRAM Test (11).............................................................................................5-14

Burn In Loop (12).......................................................................................................................5-15

Audio I/O (13)............................................................................................................................5-16

Exit Diagnostics (14) ..................................................................................................................5-16

Initialize (15)..............................................................................................................................5-16

Restoring Factory Settings.............................................................................................................5-16

Disassembly/Reassembly..............................................................................................................5-17

Disassemby...............................................................................................................................5-17

Reassembly ..............................................................................................................................5-17

Removal and installation of components......................................................................................5-17

Chapter 6 Theory of Operation......................................................................6-1

Sheet 1:..........................................................................................................................................6-1

Input Stage ..................................................................................................................................6-1

Output Stage ...............................................................................................................................6-1

Sheet 2...........................................................................................................................................6-2

Single-ended to differential converter ............................................................................................6-2

AK4528 CODEC ..........................................................................................................................6-2

Differential to Single-Ended Output Amplifiers ................................................................................6-3

Sheet 3...........................................................................................................................................6-3

L3 Initialization .............................................................................................................................6-3

Audio Memory .............................................................................................................................6-4

Master Clock Generator...............................................................................................................6-4

I/O..............................................................................................................................................6-4

SEEPROM..................................................................................................................................6-4

Z80 Memory Management ............................................................................................................6-5

Clocks.........................................................................................................................................6-5

DSP............................................................................................................................................6-5

Z80 RESET.................................................................................................................................6-5

Sheet 5...........................................................................................................................................6-6

Encoders.....................................................................................................................................6-6

Sheet 6...........................................................................................................................................6-6

Control Input (IAD).......................................................................................................................6-6

Sheet 7:..........................................................................................................................................6-6

Footswitch...................................................................................................................................6-6

LED/Switch Matrix........................................................................................................................6-6

Sheet 8:..........................................................................................................................................6-7

Power Fail/Reset .........................................................................................................................6-7

MIDI I/O ......................................................................................................................................6-7

S/PDIF Out..................................................................................................................................6-7

Chapter 7 Parts List........................................................................................7-1

MPX110 MAIN BOARD ASSEMBLY .................................................................................................7-1

MPX110 MECHANICAL ASSEMBLY................................................................................................7-2

MPX110 SHIP/PACKAGING MATERIAL...........................................................................................7-3

MPX110 TRANSFORMER OPTIONS...............................................................................................7-3

Chapter 8 Schematics and Drawings............................................................8-1

Schematics: .................................................................................................................................... 8-1

Drawings: .......................................................................................................................................8-1

Lexicon

Chapter 1 Reference Documents , Required Equipment

Reference Documents

MPX 110 Owner's Manual - Lexicon P/N 070-14956, latest revision

Required Equipment

TOOLS

The following is a minimum suggested technician's tool kit required for performing disassembly, assembly

and repairs:

• Clean, antistatic, well lit work area.

• #1 Phillips tips screwdriver

• 3/16” Hex Nut Driver,

• TORX T9 screwdriver

• Hex Nut Driver with 15mm socket.

• 5/16” Hex Nut driver, full hollow

• Plastic insert for the 5/16” nut driver to prevent Front Panel from scratches.

• Solder: 63/37 - Tin/Lead Alloy composition, low residue, no-clean solder.

• Magnification glasses and lamps

• SMT Soldering / Desoldering bench-top repair station

TEST EQUIPMENT

The following is a minimum suggested equipment list required to perform the proof of performance tests.

• Digital Volt Meter

• Low Distortion Sine Wave Audio Oscillator

• Distortion Analyzer and Level Meter with single-ended or balanced input, switchable 30kHz highpass filer or audio bandpass (20-20kHz) filter

• Stereo Headphone Amplifier

• 2 Audio cables unbalanced and shielded with phone plugs on one end and appropriate

connectors on the opposite ends for headphone amplifier input

• 2 Audio cables unbalanced and shielded with phone plugs on one end and appropriate

connectors on the opposite ends for the Audio Oscillator output

• 9V AC adapter (Lexicon type or equivalent; 1.9 amp)

• Lexicon Double Footswitch (Lexicon P/N 750-09277) w/15' ¼" phone plug cable configured for tip,

ring & sleeve or equivalent.

• Cable (6ft minimum) with 1/4" to 1/4 stereo phone plugs (Switchcraft # 10BK10 or equivalent)

1-1

Lexicon

Chapter 2 General Information

Periodic Maintenance

Under normal conditions the MPX 110 system requires minimal maintenance. Use a soft, lint-free cloth

slightly dampened with warm water and mild detergent to clean the exterior surfaces of the connector box.

Do not use alcohol, benzene or acetone-based cleaners or any strong commercial cleaners. Avoid

using abrasive materials such as steel wool or metal polish. It the unit is exposed to a dusty environment, a

vacuum or low-pressure blower may be used to remove dust from the unit's exterior.

Ordering Parts

When ordering parts, identify each part by type, price and Lexicon Part Number. Replacement parts can be

ordered from:

LEXICON, INC.

3 Oak Park

Bedford, MA 01730-1441

Telephone: 781-280-0300; Fax: 781-280-0499; email: csupport@lexicon.com

ATTN: Customer Service

Returning Units to Lexicon for Service

Before returning a unit for warranty or non-warranty service, consult with Lexicon Customer

Service to determine the extent of the problem and to obtain Return Authorization. No equipment

will be accepted without Return Authorization from Lexicon.

If Lexicon recommends that an MPX 110 be returned for repair and you choose to return the unit to Lexicon

for service, Lexicon assumes no responsibility for the unit in shipment from the customer to the factory,

whether the unit is in or out of warranty. All shipments must be well packed (using the original packing

materials if possible), properly insured and consigned, prepaid, to a reliable shipping agent.

When returning a unit for service, please include the following information:

• Name

• Company Name

• Street Address

• City, State, Zip Code, Country

• Telephone number (including area code and country code where applicable)

• Serial Number of the unit

• Description of the problem

• Preferred method of return shipment

• Return Authorization #, on both the inside and outside of the package

Please enclose a brief note describing any conversations with Lexicon personnel (indicate the name of the

person at Lexicon) and give the name and telephone daytime number of the person directly responsible for

maintaining the unit.

Do no include accessories such as manuals, audio cables, footswitches, etc. with the unit, unless

specifically requested to do so by Lexicon Customer Service personnel.

2-1

Chapter 3 Specifications

Analog Inputs (2)

Connectors: 1/4" unbalanced

Impedance: 500K unbalanced for Direct Instrument input (unit detects a mono input on the right

input)

A/D Dynamic Range: >95dB typical, 20Hz-20kHz, unweighted

Levels: -30dBu to +4dBu

Resolution: 24-Bit

Analog Outputs (2)

Connectors: 1/4" unbalanced

Impedance: 75 Ohms for Headphone output (Right only used for mono output ; Left only used for

stereo headphones)

D/A Dynamic Range: >100dB typical, 20Hz-20kHz, unweighted

Levels : +8dBu typical

Resolution: 24-Bit

Frequency Response: Wet/Dry 20Hz-20kHz, ±1dB

Crosstalk: >45dB

THD: <0.05%, 20Hz-20kHz

Lexicon

Digital Audio Interface

Output Connectors: Coaxial, RCA type; 24-bit Digital S/PDIF (always active)

Sample Rates: 44.1kHz

Internal Audio Data Path: DSP: 24-bit

Footswitch: Tip/Ring/Sleeve phone jack for Bypass and Tap (optional)

System Specifications

Power Requirements: 9VAC wall transformer provided in North America and Europe

No-transformer option available

Environment

Operating Temperature: 32° to 104° (0° to 40 °C)

Relative Humidity: 95% non-condensing

Dimensions: 19"W x 1.75"H x 4" D (483x45x102mm)

Weight: Unit: 2lbs, 2 ounces (0.959kg)

3-1

Lexicon

Chapter 4 Performance Verification

This section describes procedures to verify the operation of the MPX 110 and the integrity of its analog and

digital audio signal paths.

Functional Tests

INITIAL INSPECTION

Inspect the unit for any obvious signs of physical damage. Verify that the front panel controls operate

smoothly and correctly. (Refer to the MPX 110 Owner’s Manual for detailed explanations of functionality.)

Verify that all screws and rear panel jacks are secure, and inspect the AC power supply for any signs of

physical damage.

POWER SUPPLY

1. Remove cover as described in disassembly/reassembly section.

2. Plug the adapter into the MPX 110 and apply power.

3. Set the DMM to measure VD and check the regulated voltages for proper levels.

Supplies Location Range

+5 VD Marked test (4.85-5.25)

points to the

Right of C6

+5 VA Marked test (4.75-5.25)

points to the

Left of J6

-5 VA Marked test (-4.75-5.25)

points to the

Left of J6

POWER UP

1. Connect the 9VAC adapter (provided with the MPX 110) between the isolated variable output of the

Variac and the MPX 110 rear panel Power connector.

2. Verify that AC current draw is <0.1 Amps

On normal power up the MPX 110 will run the following Diagnostic Tests. This Diagnostic Test sequence is

displayed on the front panel LEDs for trouble-shooting purposes. If any of the red Clip LEDs remain lit, a

diagnostic failure has occurred and the MPX 110 should be repaired before proceeding.

Test No. Test Edit Bypass Store Tap

1 ROM Checksum l l l O

2 SRAM l l l O l

3 Lexichip 3 WCS l l O O l l

4 Lexichip 3 Interrupt Timer l l O l l

5 Lexichip 3 Audio Data File l l O l l O

8 EEPROM Checksum l O l l l

l =OFF

O =ON

SETUP

1. Connect a 5-pin MIDI cable between the MPX 110 rear panel MIDI IN and OUT/THRU connectors.

2. Connect a dual style 1/4" Footswitch to the MPX 110 rear panel Footswitch jack.

3. Turn the MPX 110 front panel VARIATION knob to 12.

4. Press and hold the MPX 110 front panel Bypass button while powering on the MPX 110.

5. When the green Level LEDs light, release Bypass.

6. Verify that the MPX 110 front panel Edit and Bypass LEDs are lit.

4-1

MPX 110 Service Manual

Edit Bypass Store Tap

O O l l

7. Turn VARIATION to 6 and verify that the Bypass, and Store LEDs are lit.

Edit Bypass Store Tap

l O O l

8. Press Store to initiate the Encoder Test.

ENCODER TEST

1. Verify that the green Level L LED is lit.

2. Turn the VARIATION encoder clockwise direction one position at a time, and verify that the green Level

L LED turns off after the encoder has been turned one complete revolution. This indicates successful

completion of the VARIATION encoder test. The Level R LED should now light.

3. Turn the PROGRAM encoder clockwise one position at a time, and verify that the Level R LED turns off

after the encoder has been turned one complete revolution. This indicates successful completion of the

PROGRAM encoder test.

4. Verify that all of the front panel LEDs are now off.

SWITCH/LED TEST

1. Press and hold down the Right button on the footswitch. Verify that the green Level R LED is on.

Release the footswitch and verify that the LED turns off.

2. Press and hold down the Left button on the footswitch. Verify that the green Level L LED is on.

Release the footswitch and verify that the LED turns off.

3. Press and hold the front panel Bypass button. Verify that its LED is on. Release Bypass and verify that

the LED turns off.

4. Press and hold the front panel Tap button. Verify that its LED is on. Release Tap and verify that the

LED turns off.

5. Press and hold the front panel Store button. Verify that its LED is on. Release Store and verify that the

LED turns off. Releasing Store also exits the test series and should cause both of the green Level

LEDs to turn on.

ACD POT TEST

Note: During the ADC Pot Test, each potentiometer must be varied over its entire range from fully counterclockwise to fully clockwise, and back to fully counter-clockwise within 5 seconds. Otherwise the test will fail

due to a time-out error. Be prepared, therefore, to move the Mix pot as soon as the test is initiated.

1. In preparation for the test, turn the Mix, Effects Lvl/Bal and Adjust pots fully counter-clockwise.

2. Turn VARIATION to 7 and verify that the Bypass, Store and Tap LEDs are on, as shown below.

Edit Bypass Store Tap

l l l l O O O

3. Press Store to initiate the ADC Pot Test. The Level L LED will light to indicate the test has begun and

the Mix pot is under test.

4. Move Mix from its fully counterclockwise position to fully clockwise, and back within 5 seconds. The

Level L LED will flash to indicate the Mix pot has passed and the Level R LED will light.

5. Move Effect Lvl/Bal from its fully counterclockwise position to fully clockwise, and back within 5

seconds. The Level R LED will flash to indicate the Effect Lvl/Bal pot has passed, then both Level

LEDs will light.

6. Move Adjust from its fully counterclockwise position to fully clockwise, and back within 5 seconds. Both

Level LEDs will flash to indicate the Adjust pot has passed, then the Level LEDs will light steadily to

indicate the ADC Pot Test is complete.

MIDI WRAPAROUND TEST

1. Turn VARIATION to the 9 and verify that the Edit and Tap LEDs are lit as shown below.

4-2

Lexicon

Edit Bypass Store Tap

O l l l l l O

2. Press Store to execute the test.

3. The Level LEDs will light to indicate the test has been successfully completed.

LISTENING TEST

This test involves running audio through the MPX 110 with and without effects processing. This is helpful in

differentiating audio problems in the analog from the digital circuitry. The first part of this test is performed

without effects.

1. Connect two audio cables between connect the MPX 110 rear panel Left and Right Outputs and the

headphone amplifier Left and Right Inputs.

2. Attach the single end of a Y-connector into the output of the sine wave audio oscillator, and the Y end

into the MPX 110 Left and Right Inputs.

3. Set the headphone amplifier volume control to its lowest level.

4. Press and hold down the front panel Bypass button while powering on the MPX 110. Continue to hold

Bypass until the Power On Diagnostics are completed and the green Level LEDs light.

5. Turn VARIATION to 13, and verify that the Edit, Bypass and Tap LEDs are on, as shown below.

Edit Bypass Store Tap

O l l l O l O

6. Press Store to execute the test.

7. Input a 1kHz sine wave at 0dBu to the MPX 110.

8. Turn the MPX 110 Input, Mix, Output, Effect Lvl/Bal, and Adjust knobs fully clockwise.

9. Put on headphones, then set the headphone amplifier volume to a comfortable listening level.

10. Individually adjust the MPX 110 Input and Output knobs over their entire range and verify that no pops,

clicks, or scratchiness is heard.

EFFECTS LISTENING TEST

1. Turn VARIATION to 14 and press Store to return to normal operating mode.

2. Verify that the processed audio has no audible pops, clicks, or distortion.

SHOCK TEST

1. Lift each corner of the MPX 110 off the bench 4 inches (4”) then drop. To prevent damaging the unit,

keep one corner of the unit touching the bench at all times.

2. Verify that no audio, or LED intermittence is caused by this action.

Audio Performance:

SETUP

Oscillator and Analyzer Default Settings

Unless otherwise noted the following settings are used for the audio performance tests:

Oscillator Analyzer

Waveform: Sine Filter: Off

Output: Unbal Bandwidth: 22Hz to 22kHz

–25Ω Inputs: 100κΩ

Float (except Gain=600W)

1. Connect the appropriate cable between the oscillator output and the MXP 100 Left input.

2. Connect the appropriate cable between the analyzer input and the MPX 110 Left output.

3. Turn the MPX 110 front panel Input and Output knobs fully clockwise.

4. Turn the MPX 110 front panel Mix knob fully counterclockwise.

5. Power cycle the MPX 110 while pressing and holding down the Bypass button. Wait until the Level

LEDs light, then release Bypass.

4-3

MPX 110 Service Manual

6. Turn VARIATION to 13 and press Store to set up the MPX 110 for the following tests.

GAIN TEST

This test verifies the input-to-output gain characteristic of the MPX 110 through the signal path.

1. Apply a 1kHz signal at 775mV to the MPX 110.

2. Verify 1.95 V +/- 0.05V at the MPX 110 Left output.

3. Connect the oscillator output to the MPX 110 Right input.

4. Connect the analyzer input to the MPX 110 Right output.

5. Verify an output of 1.95V +/- 0.05V at the MPX 110 Right output.

SIGNAL-TO-NOISE TEST

This test checks the signal-to-noise through the MPX 110 signal path.

1. Set the scale on the distortion analyzer to measure -50dBu signal.

2. Disconnect the oscillator from the MPX 110 input, or turn the oscillator off.

3. Verify that the noise floor is <90dBr.

4. Connect the oscillator output to the MPX 110 Left input.

5. Connect the analyzer input to the MPX 110 Left output.

6. Repeat the test, verifying the levels at the Left output.

THD+N

This test verifies THD+N through the MPX 110 signal path.

1. Apply a 1kHz signal at 220mV to the MPX 110 left input.

2. Adjust the scale on the distortion analyzer to measure % THD+N.

3. Verify a distortion level <0.05% THD+N at the Left output.

4. Connect the oscillator output to the MPX 110 right input.

5. Connect the analyzer input to the MPX 110 right output.

6. Verify a distortion level <0.05% THD+N at the right output.

FREQUENCY RESPONSE TEST

This test verifies the frequency response of the MPX 110 through the signal path at 20Hz, 3kHz, 5kHz, and

20kHz.

1. Apply a 220mV signal at 1kHz with the analyzer Bandwidth filters off to the MPX 110 Right input.

2. Use the output level at the MPX 110 Right output for the 0DB reference to check frequency response.

3. Verify that the signal level output is within ±0.5dB of the reference at the above frequencies.

4. Connect the oscillator output to the MPX 110 Left input.

5. Connect the analyzer input to the MPX 110 Left output.

6. Repeat the test, verifying levels for the MPX 110 Left output.

4-4

Lexicon

-11dBu

-44.94

-11dBu

Band Rej

-11dBu

20-20K

100k

10-500k

-11dBu

20-20K

100k

10-500k

-30.00

100k

10-500k

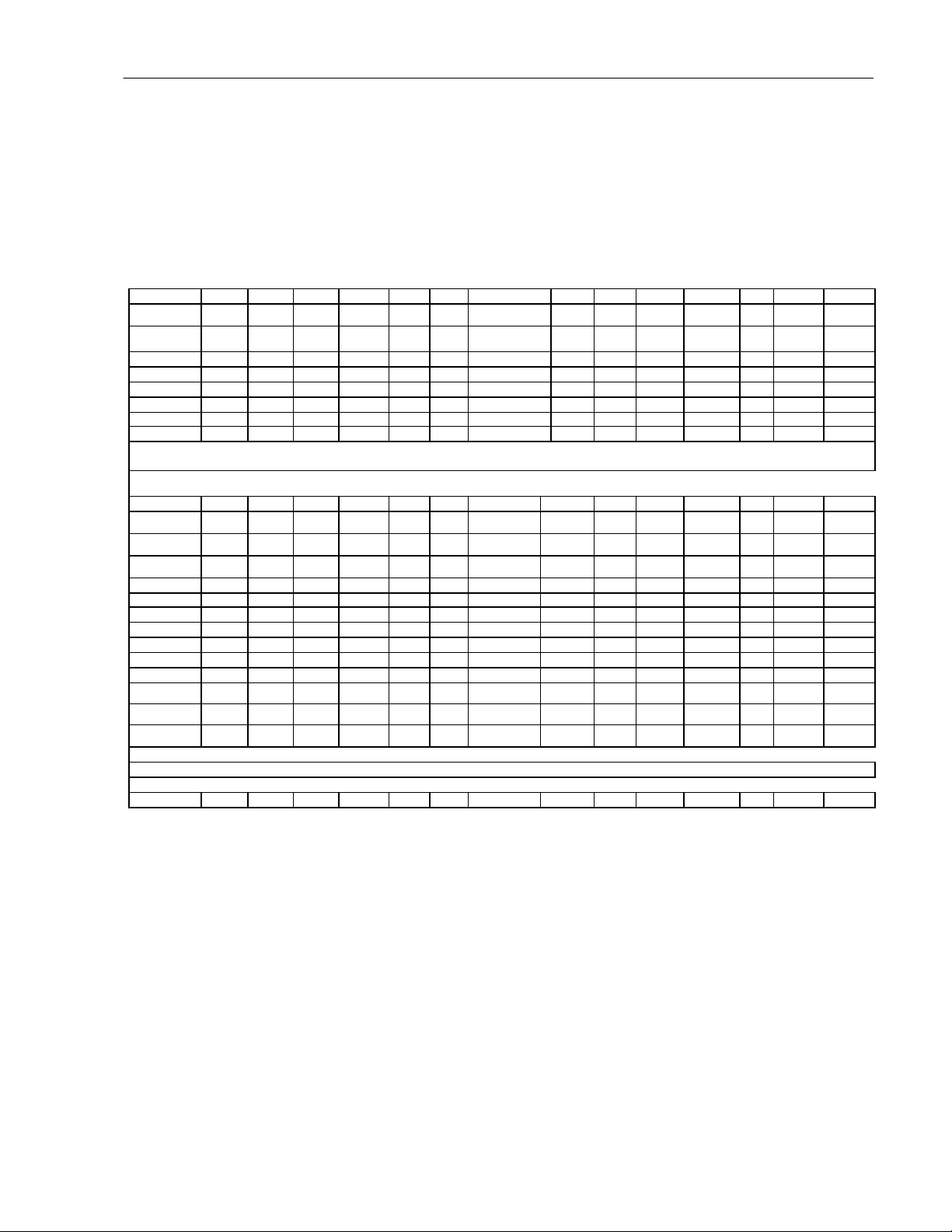

LEXICON AUDIO PRECISION ATE SUMMARY

This chart represents a summary of test Audio Precision test settings and parameters used by Lexicon

Manufacturing in production testing of all MPX 200 product. This is provided as a reference and supplement

to bench test settings found in the proof of performance in this manual.

A-D Files Source Analyzer

Left Right Bal / Gnd / Sample

Test Input Input Freq Imp. Unbal Float Level ReadingUpper Lower Filter Imp Band Rate

a-dgain -21dBu -21dBu 997 25 Ohm Unbal Float LEVEL(dBFS) -1.70 -0.64 -2.54 Off ------ -------- 44.1kHz

a-dfreq -31dBu -31dBu 20-20k 25 Ohm Unbal Float LEVEL(dBFS) 0 1.06 -1.06 Off ------ -------- 44.1Khz

adsetlvl -20dBu -20dBu 997 25 Ohm Unbal Float LEVEL(dBFS) -------- -20.00 -20.50 Off ------ -------- 44.1kHz

a-dxtalk* -11dBu

a-dthd* -11dBu

a-ddynr* -50dBu -50dBu 997 25 Ohm Unbal Float FLTLVL(dBFS) -------- -89.94 -120.00 Off ------ -------- 44.1kHz

A-A Files Source

Analyzer

20-20k 25 Ohm Unbal Float LEVEL(dBFS) -------20-20k 25 Ohm Unbal Float FLTLVL(%) -------- 0.05 0.0007

-120.0 Off ------ -------- 44.1kHz

------ -------- 44.1kHz

Left Right Bal / Gnd / Sample

Test Input Input Freq Imp. Unbal Float Level Reading Upper Lower Filter Imp Band Rate

a-again* 0dBu 0dBu 997 25 Ohm Unbal Float AMPL(dBu) 8.00 9.56 6.44 Off 100k 10-500k 44.1kHz

a-afreql* -11dBu

a-afreqr* -11dBu

a-axtalk* -11dBu -11dBu 20-20K 25 Ohm Unbal Float XTALK(dB) ------ -45 -120 Off 100k 20-22k 44.1kHz

a-athd* -11dBu -11dBu 20-20K 25 Ohm Unbal Float THD+N(%) ------ 0.05 0.0007 Off 100k 20-22k 44.1kHz

a-asnrl* 0dBu 0dBu 997 25 Ohm Unbal Float AMPL(dBr) ------ -90 -120 Off 100k 20-22k 44.1kHz

a-adynrl* -50dBu -50dBu 997 25 Ohm Unbal Float THD+N(dBr) ------ -90 -120 Off 100k 20-22k 44.1kHz

a-asnrr* 0dBu 0dBu 997 25 Ohm Unbal Float AMPL(dBr) ------ -90 -120 Off 100k 20-22k 44.1kHz

a-adynrr* -50dBu -50dBu 997 25 Ohm Unbal Float THD+N(dBr) ------ -90 -120 Off 100k 20-22k 44.1kHz

a-amute* 0dBu 0dBu 997 25 Ohm Unbal Float AMPL(dBu) -38.00

* The MPX 100 is set for analog to digital unity gain with ADSETLVL test.

Note: For analog testing only, the MPX 110 can be set for analog to analog unity gain using the AASETLVL test.

aasetlvl 0dBu 0dBu 997 25 Ohm Unbal Float AMPL(dBu) 8.00 9.56 6.44 Off 100k 10-500k 44.1kHz

25 Ohm Unbal Float AMPL(dBr) 0.00 1.06 -1.06 Off

25 Ohm Unbal Float AMPL(dBr) 0.00 1.06 -1.06 Off

-90.00 Off

44.1kHz

44.1kHz

44.1kHz

4-5

Lexicon

Chapter 5 Troubleshooting

Check the Lexicon web site for the latest software and information:

http://www.lexicon.com

The Lexicon Support Knowledgebase:

http://www.lexicon.com/kbase/index.asp

Diagnostics

INTRODUCTION

This document contains the complete diagnostics descriptions for the Lexicon MPX 110 product.

DIAGNOSTICS TEST DESCRIPTIONS

There are two categories of diagnostics that exist in the MPX 110 software: (1) Power On (automatic)

Diagnostics and (2) Functional Tests/Extended Diagnostics. As you might expect, the Power Up

Diagnostics will be executed automatically everytime the system is powered on. The Functional

Tests/Extended Diagnostics will be invoked by pressing and holding down the BYPASS button while

powering on the unit until the green level leds stay on.

POWER ON DIAGNOSTICS

Upon normal power on, all of the Front Panel LED’s will be turned on for approximately 200ms, and then

the MPX 110 will attempt to run the sequence of diagnostic tests listed in table 1 below. These diagnostic

tests have been designed to take less than 10 seconds.

During the execution of the Power On Diagnostics, the CPU (wherever possible) will display a test code on

the EDIT, BYPASS, STORE & TAP LED’s prior to the execution of the test (provided the LED’s are

functioning properly).

Throughout this document, Edit, Bypass, Store, and Tap LED’s will be referred to as the Binary LED’s.

These LED’s are used to display the binary value of the corresponding test number. This value is sent to

the Binary LED’s before each test is executed. Displaying the test/error code on the LED’s before the test is

executed, makes it possible to determine which test failed if the unit hangs or crashes during the test.

Test No. Test Edit Bypass Store Tap

1 ROM Checksum O O O

2 SRAM O O

3 Lexichip3 WCS O O

4 Lexichip3 Interrupt Timer O

5 Lexichip3 Audio Data File O

6 EEPROM Checksum

Table 1.

When the Power On Diagnostic tests have completed, the software version will flash on the Front Panel

Binary LED’s for approximately two seconds.

l

l

l

O O O

l

l l

O O

O

l

O

l

Note: The Binary LED’s are interrupt driven. Therefore, the ROM,SRAM, LEXICHIP 3 & CPU must

be working properly in order for the Binary LED’s to operate correctly.

5-1

MPX 110 Service Manual

DIAGNOSTIC FAILURES

When a failure is encountered during the test sequence:

- The test code is displayed on the Binary LED’s (Ref. Table 1).

- The Clip (red) Headroom LED’s are turned on to indicate a failure has occurred.

- The unit stops executing the Power On Diagnostic test sequence.

- The audio outputs are muted, and the unit will not become operational.

If the BYPASS button is pressed after a failure has occurred, the MPX 110 will attempt to continue on with

the next test of the Power On Diagnostic test sequence, and the MPX 110 will attempt to do this every time

the BYPASS button is pressed.

If the STORE button is pressed after a failure has occurred, the MPX 110 will enter the Extended

Diagnostics mode.

If the TAP button is pressed after a failure has occurred, the MPX 110 will run the test continuously.

The following diagram describes the Binary LED’s:

Edit Bypass Store Tap

O O l l

MSB LSB

LED Off = O (0)

LED On = l (1)

Figure 1.

This figure shows an example of the Binary LED’s Failure Code 3 (0011). This code indicates that the

Lexichip3 WCS Test has failed.

ROM CHECKSUM TEST (1)

The ROM checksum, is a byte size value that is stored in the last location of Bank 0. The test adds the

contents of the entire ROM including the Checksum byte. The result should equal zero (8 bit value).

Before the test is executed, a test code will be put out on the Binary LED’s. The code is:

Edit Bypass Store Tap

O O O l

MSB LSB

If a failure occurs, the Clip (red) headroom LED’s will be turned on in addition to the binary code, and the

CPU will attempt to continuously loop the test for troubleshooting purposes.

If the BYPASS button is pressed, the failure is ignored and the next test will be executed.

SRAM TEST (2)

The SRAM Test performed during the Power On Diagnostics is a destructive test. The entire contents of the

SRAM is tested by first writing 00 hex (00000000 binary) to all of the memory locations, and then verified by

reading back all of the memory locations. This write/read sequence is also performed using the following

5-2

Lexicon

patterns: 55 hex (01010101 binary), AA hex (10101010 binary) & FF hex (11111111 binary).

Before the test is executed, a test code will be put out on the Binary LED’s. The code is:

Edit Bypass Store Tap

O O O l

MSB LSB

If a failure occurs, the Clip (red) headroom LED’s will be turned on in addition to the binary code, and the

CPU will attempt to continuously loop the test for troubleshooting purposes.

If the BYPASS button is pressed, the failure is ignored and the next test will be executed.

LEXICHIP3 WCS TEST (3)

This test will check the RAM program memory space (writeable control store) of the Lexichip3. The WCS

(memory space) is first filled with the value 55 hex (01010101 binary), then each memory location is read to

see if it contains 55. If 55 is in the memory location, the location is filled with AA hex (10101010 binary), and

the next location is processed. Once the RAM has been checked for 55's and filled with AA's, the process is

then repeated checking for AA's and storing 0's into memory. Following this test an Address test is

performed to verify all the address lines are active. Finally, the memory is checked for 0's.

Before the test is executed, a test code will be displayed on the Binary LED’s. The code is:

Edit Bypass Store Tap

O O O l

MSB LSB

If a failure occurs, the Clip (red) headroom LED’s will be turned on in addition to the binary code.

If the BYPASS button is pressed, the failure is ignored and the next test will be executed.

If the TAP button is pressed, the CPU will attempt to go into a mode where it can execute the test

continuously.

LEXICHIP3 INTERRUPT TIMER TEST (4)

The Interrupt Timer test will verify that the interrupt (INT/) is working and occurring at the proper intervals.

The Lexichip3 will provide the MPX 110 with the interrupt (INT/) to the Z80's maskable interrupt line. The

interrupt test will be run for a period of time that allows 20 interrupts to occur. A count of the interrupts is

kept and compared for overshoot and undershoot. Greater than 21 interrupts means the interrupt is too

short and less than 19 interrupts means it's too long.

Before the test is executed, a test code will be put out on the Binary LED’s. The code is:

Edit Bypass Store Tap

O O O l

MSB LSB

If a failure occurs, the Clip (red) headroom LED’s will be turned on in addition to the binary code.

If the BYPASS button is pressed, the failure is ignored and the next test will be executed.

If the TAP button is pressed, the CPU will attempt to go into a mode where it can execute the test

continuously.

5-3

MPX 110 Service Manual

LEXICHIP3 AUDIO DATA FILE TEST (5)

The Audio Data File (ADF) is a fast synchronous 128-word SRAM that provides audio data buffering and

storage for: external memory references, Serial I/O, and the Host-to-Lexichip data port. ADF locations also

function as ARU Registers and as scratchpad memory. This test will verify that the Lexichip3 Audio Data

File is working properly.

Before the test is executed, a test code will be put out on the Binary LED’s. The code is:

Edit Bypass Store Tap

O O O l

MSB LSB

If a failure occurs, the Clip (red) headroom LED’s will be turned on in addition to the binary code.

If the BYPASS button is pressed, the failure is ignored and the next test will be executed.

If the TAP button is pressed, the CPU will attempt to go into a mode where it can execute the test

continuously.

EEPROM CHECKSUM (8)

This test will read each byte in the User Register portion of the EEPROM and add them together to

calculate a checksum. This value is compared with the checksum value stored in the EEPROM itself. This

checksum will be recalculated each time a register is stored.

The test will also verify that the EEPROM has been initialized properly. This is done by storing the software

version of the EPROM in the first five bytes of the EEPROM, and then verifying the stored value is correct

when the test is executed. If the stored value read from the first five bytes of the EEPROM is incorrect, the

EEPROM will be initialized.

Before the test is executed, a test code will be put out on the Binary LED's. The code is:

Edit Bypass Store Tap

O O O l

MSB LSB

If a failure occurs, the Clip (red) headroom LED's will be turned on in addition to the binary code.

If the BYPASS button is pressed, the failure is ignored and the next test will be executed.

If the TAP button is pressed, the CPU will attempt to go into a mode where it can execute the test

continuously.

5-4

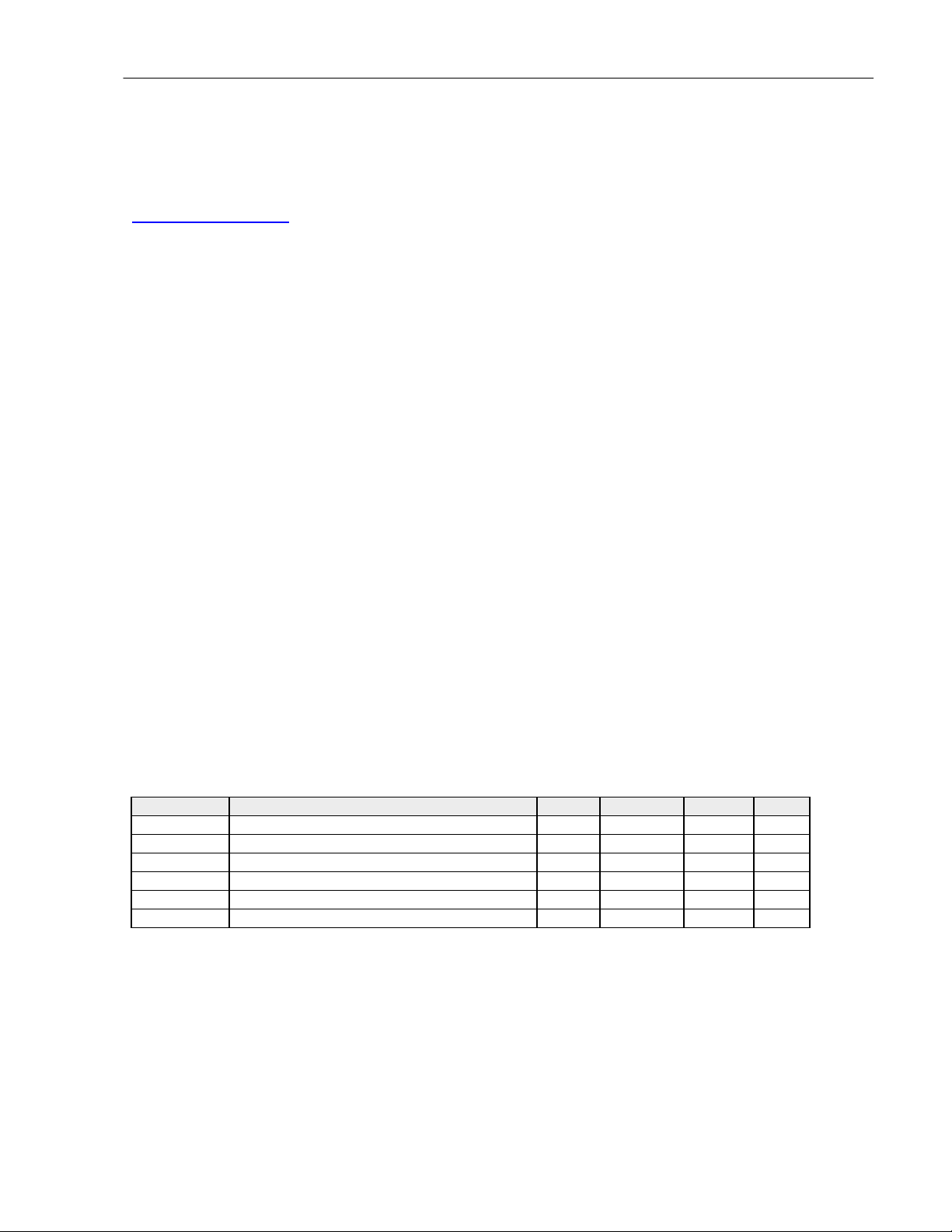

EXTENDED DIAGNOSTICS

The following tests are available in the Extended Diagnostics:

Lexicon

Test

Number

1 ROM Checksum 0 0 0 1 1

2 SRAM Test 0 0 1 0 1

3 Lexichip3 WCS 0 0 1 1 1

4 Lexichip3 Interrupt Timer 0 1 0 0 1

5 Lexichip3 Audio Data File 0 1 0 1 1

6 Encoder/Switch/LED 0 1 1 0 2

7 ADC Pot 0 1 1 1 3

8 EEPROM 1 0 0 0

9 MIDI 1 0 0 1

10 LED (for troubleshooting) 1 0 1 0 2

11 Lexichip3 External DRAM 1 0 1 1

12 Burn In Loop 1 1 0 0

13 Audio I/O 1 1 0 1

14 Exit Diagnostics 1 1 1 0

15 Initialize 1 1 1 1

NOTES:

1. These tests reside in the Power On Diagnostics.

2. These tests require operator interaction and judgment.

Doesn't generate any error messages.

Test Name Binary

LED’s

See

Note:

3. This test requires operator interaction and judgment.

Generates an error message.

The Extended Diagnostics will be invoked by pressing & holding the BYPASS button while powering on the

unit. When the L & R Level (green) LED’s are lit, release the BYPASS button. After the BYPASS button is

released, the Binary LED’s (EDIT, BYPASS, STORE & TAP) will display the current position of the

VARIATION knob in binary and the Level (green) LED’s will go off.

For example, if the VARIATION knob was set to 5, the LED’s would read the following:

Edit Bypass Store Tap

O O O l

MSB LSB

When a test is selected, the STORE button must be pressed to execute it. If the test passed, the L & R

Level (green) LED’s will light. If the test failed, the L & R Clip (red) LED’s will light.

5-5

Loading...

Loading...