Page 1

TD03D

EN

Operating Instructions

DE

Betriebsanleitung

FR

Instructions de Mise en Service

IT

Istruzioni di funzionamento

ES

Instrucciones de funcionamiento

Tmd001

Tmd - flux vector drive

0.37 kW… 7.5 kW

Page 2

Contents

About these instructions ............................................................2

1 Safety information ................................................................3

1.1 Pictographs used in these instructions .....................................................4

2 Technical data ......................................................................5

2.1 Standards and application conditions ......................................................5

2.2 Ratings ......................................................................................................6

3 Installation ............................................................................7

3.1 Mechanical installation .............................................................................7

3.1.1 Dimensions and mounting ........................................................................7

3.2 Electrical installation .................................................................................8

3.2.1 Installation according to EMC requirements ............................................8

3.2.2 Fuses/cable cross-sections ......................................................................8

3.2.3 Connection diagram .................................................................................9

3.2.4 Control terminals .....................................................................................10

4 Commissioning ..................................................................11

4.1 Parameter setting ....................................................................................11

4.2 Electronic programming module (EPM) .................................................11

4.3 Parameter menu .....................................................................................12

4.4 Vector mode ...........................................................................................20

4.4.1 Vector speed and torque modes ............................................................20

4.4.2 Enhanced V/Hz mode ............................................................................20

5 Troubleshooting and fault elimination .............................21

ENGLISH

1

Page 3

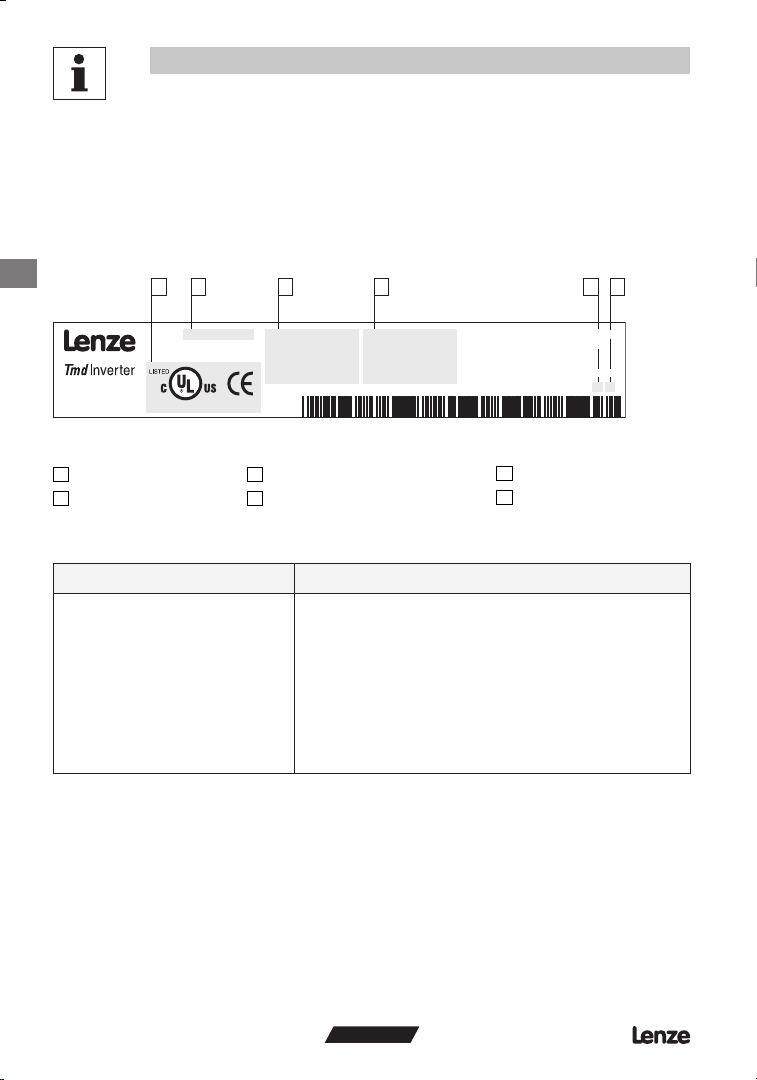

About these instructions

This documentation applies to the Tmd vector frequency inverter, and contains important technical data

and describes installation, operation, and commissioning.

These instructions are only valid for Tmd frequency inverters with software rev 11 (see drive

nameplate).

Please read the instructions before commissioning.

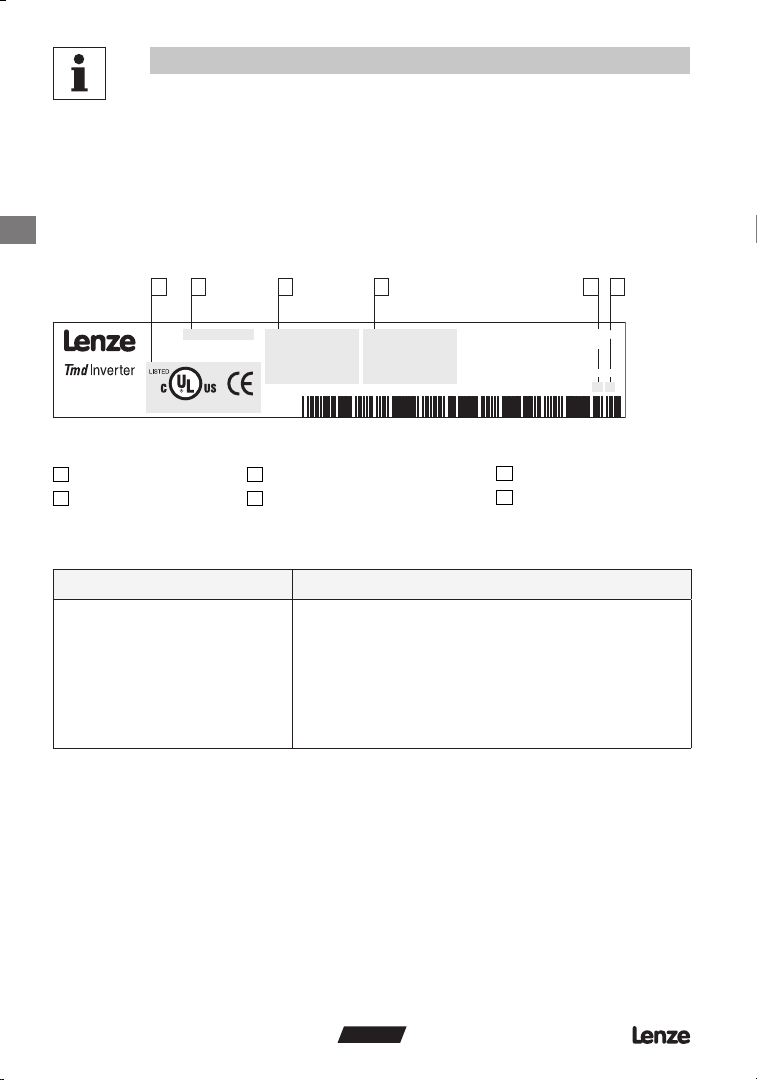

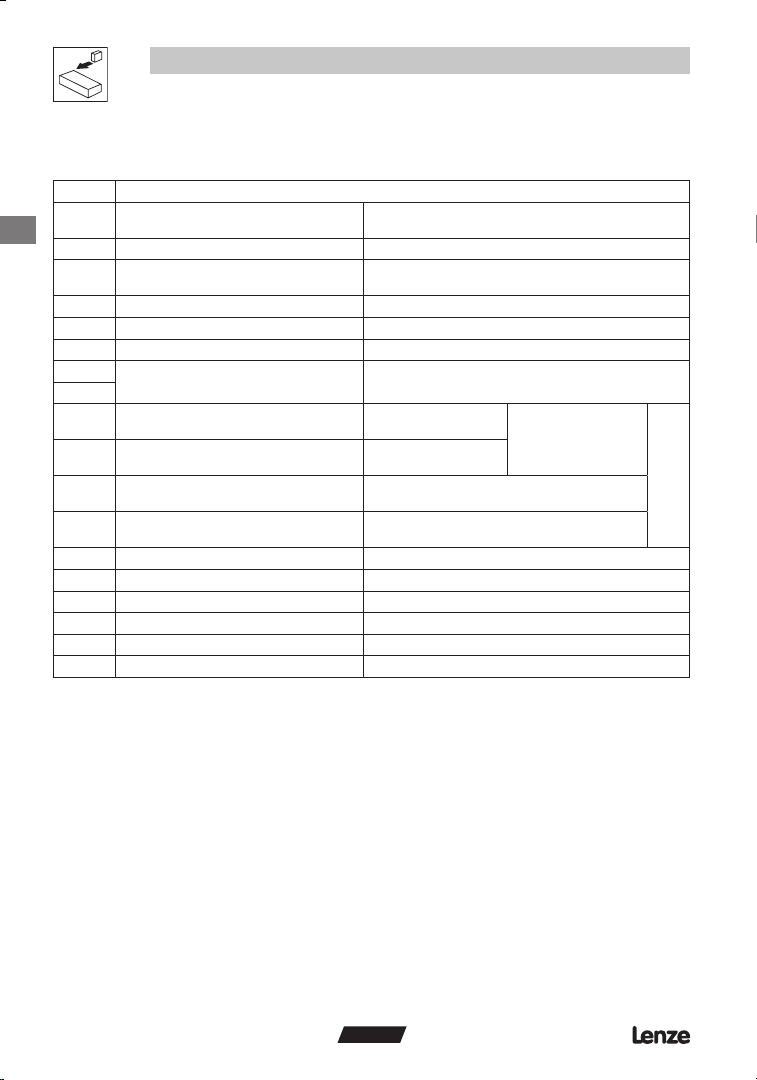

A B C D E F

For detailed information refer to

instruction manual TD03

004605460364930305

ETMD152L4TXA000XXXX

Hardware Version

E

Software Version

F

Tmd011

Made in USA

Certifications

A

Type

B

Type: ETMD152L4TXA

Id-No: 00000 000

IND CONT EQ

Input: Output:

3/PE

AC 400/480 V

4.8 / 4.0 A

50 / 60 Hz

Input Ratings

C

Output Ratings

D

3/PE

AC 400/480 V

4.1 / 3.4 A

1.5 kW

0 - 240 Hz

Scope of delivery Important

• 1 Tmd vector inverter (ETMD...)

with EPM installed (see Section 4.2)

• 1 Operating Instructions

After receipt of the delivery, check immediately whether the items

delivered match the accompanying papers. Lenze does not accept

any liability for deficiencies claimed subsequently.

Claim

• visible transport damage immediately to the forwarder.

• visible deciencies/incompleteness immediately to your Lenze

representative.

© 2004 Lenze AG

No part of this documentation may be copied or made available to third parties without the explicit written approval of

Lenze AG.

All information given in this documentation has been carefully selected and tested for compliance with the hardware and

software described. Nevertheless, discrepancies cannot be ruled out. We do not accept any responsibility nor liability for

damages that may occur. Any necessary corrections will be implemented in subsequent editions.

2

ENGLISH

Page 4

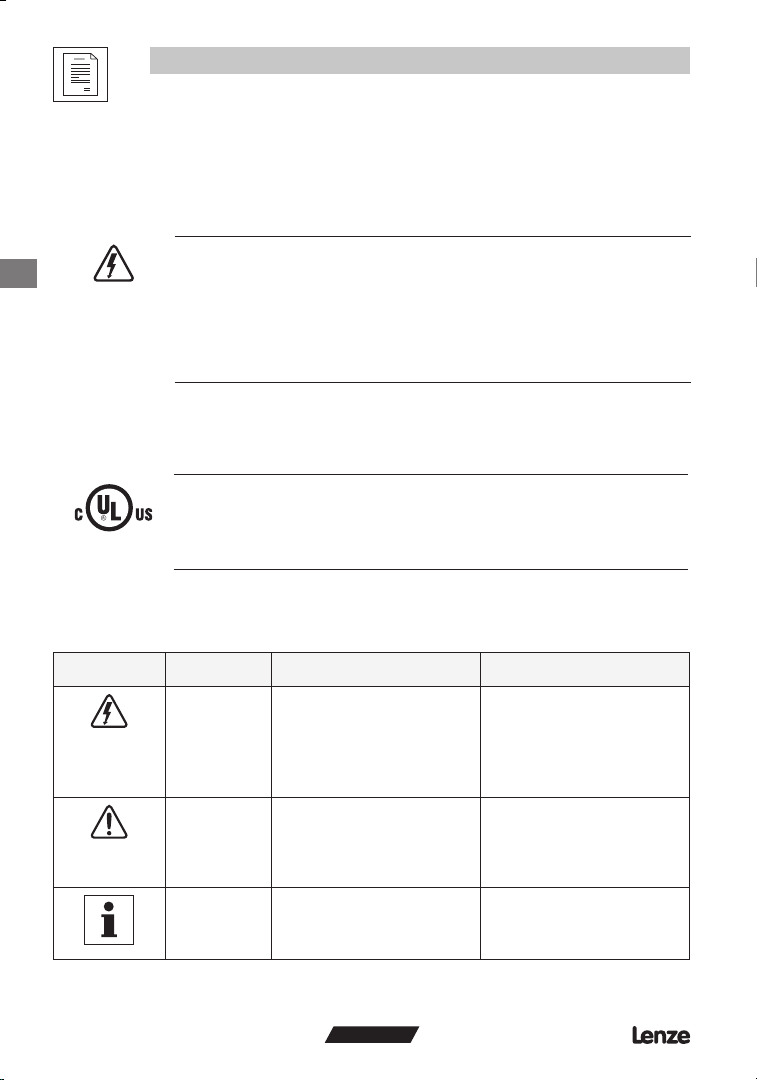

Safety information

1 Safety information

General

Some parts of Lenze controllers (frequency inverters, servo inverters, DC controllers) can be live,

moving and rotating. Some surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, and incorrect installation or operation

creates the risk of severe injury to personnel or damage to equipment.

All operations concerning transport, installation, and commissioning as well as maintenance must

be carried out by qualied, skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE 0100 and

IEC report 664 or DIN VDE0110 and national regulations for the prevention of accidents must be

observed).

According to this basic safety information, qualified skilled personnel are persons who are familiar with

the installation, assembly, commissioning, and operation of the product and who have the qualifications

necessary for their occupation.

Application as directed

Drive controllers are components which are designed for installation in electrical systems or machinery.

They are not to be used as appliances. They are intended exclusively for professional and commercial

purposes according to EN 61000-3-2. The documentation includes information on compliance with

the EN 61000-3-2.

When installing the drive controllers in machines, commissioning (i.e. the starting of operation as

directed) is prohibited until it is proven that the machine complies with the regulations of the EC Directive

98/37/EC (Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting of operation as directed) is only allowed when there is compliance with

the EMC Directive (2004/108/EC).

The drive controllers meet the requirements of the Low Voltage Directive 2006/95/EC. The harmonised

standards of the series EN 61800-5-1 / DIN VDE 0160 apply to the controllers.

Note: The availability of controllers is restricted according to EN 61800-3. These products can cause

radio interference in residential areas. In this case, special measures can be necessary.

Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components and

do not change any insulation distances during transport or handling. Do not touch any electronic

components and contacts.

Controllers contain electrostatically sensitive components, which can easily be damaged by inappropriate

handling. Do not damage or destroy any electrical components since this might endanger your

health!

Electrical connection

When working on live drive controllers, applicable national regulations for the prevention of accidents

(e.g. VBG 4) must be observed.

The electrical installation must be carried out according to the appropriate regulations (e.g. cable crosssections, fuses, PE connection). Additional information can be obtained from the documentation.

The documentation contains information about installation in compliance with EMC (shielding, grounding,

filters and cables). These notes must also be observed for CE-marked controllers.

The manufacturer of the system or machine is responsible for compliance with the required limit values

demanded by EMC legislation.

ENGLISH

3

Page 5

Safety information

Operation

Systems including controllers must be equipped with additional monitoring and protection devices according

to the corresponding standards (e.g. technical equipment, regulations for prevention of accidents, etc.).

You are allowed to adapt the controller to your application as described in the documentation.

DANGER!

• After the controller has been disconnected from the supply voltage, live components

and power connection must not be touched immediately, since capacitors could be

charged. Please observe the corresponding notes on the controller.

• Do not continuously cycle input power to the controller more than once every three

minutes.

• Please close all protective covers and doors during operation.

Note for UL approved system with integrated controllers

UL warnings are notes which apply to UL systems. The documentation contains special information

about UL.

• Suitable for use on a circuit capable of delivering not more than 5000 rms

symmetrical amperes, 240 V maximum (240 V devices) or 500 V maximum

(400/500 V devices) respectively

Warnings!

1.1 Pictographs used in these instructions

• Use minimum 75 °C copper wire only.

• Shall be installed in a pollution degree 2 macro-environment.

Pictograph Signal word Meaning Consequences if ignored

DANGER!

WARNING!

NOTE

4

Warning of Hazardous Electrical Voltage.

Impending or possible danger

for persons.

Possible damage to equipment

Useful tip: If observed, it will

make using the drive easier

ENGLISH

Reference to an imminent

danger that may result in death

or serious personal injury if the

corresponding measures are

not taken.

Death or injury.

Damage to drive system or its

surroundings.

Page 6

Technical Data

2 Technical data

2.1 Standards and application conditions

Conformity

Approvals

Max. permissible motor cable

(1)

length

Input voltage phase imbalance

Humidity

Output frequency

Environmental conditions

Temperature range

Installation height

Vibration resistance

Earth leakage current

Enclosure (EN 60529)

Protection measures against

Operation in public supply networks

(Limitation of harmonic currents

according to EN 61000-3-2)

(1) For compliance with EMC regulations, the permissible cable lengths may change.

(2) The additional measures described only ensure that the controllers meet the requirements of the EN 61000-3-2.

The machine/system manufacturer is responsible for the compliance with the regulations of the machine!

CE Low Voltage Directive (2006/95/EC)

UL 508C Underwriters Laboratories - Power Conversion Equipment

shielded: 50 m (low-capacitance)

unshielded: 100 m

< 2%

< 95% non-condensing

0...240 Hz

Class 3K3 to EN 50178

Transport -25 … +70 °C

Storage -20 … +70 °C

Operation 0 … +55 °C (with 2.5 %/°C current derating above +40 °C)

0 … 4000 m a.m.s.l. (with 5 %/1000 m current derating above 1000 m a.m.s.l.)

acceleration resistant up to 0.7 g

> 3.5 mA to PE

IP 20

short circuit, earth fault, overvoltage, motor stalling, motor overload

Total power

connected to

the mains

< 0.5 kW With mains choke

0.5 … 1 kW With active filter (in preparation)

> 1 kW Without additional measures

Compliance with the requirements

(2)

ENGLISH

5

Page 7

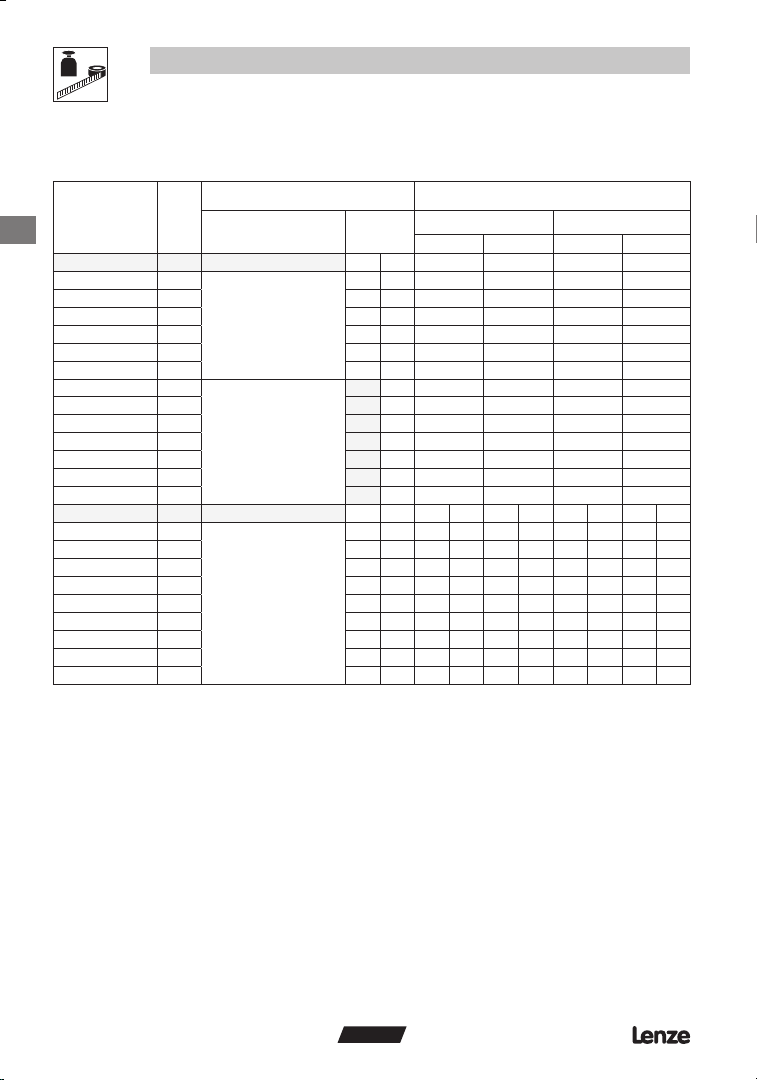

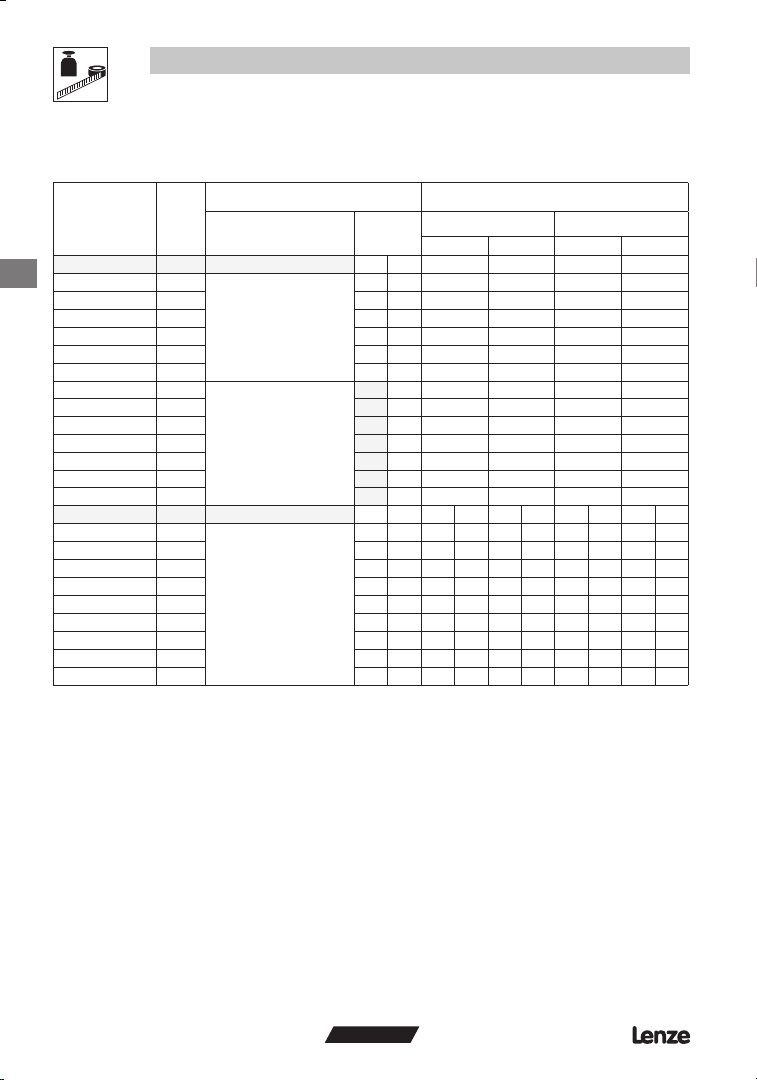

2.2 Ratings

Technical data

Mains

Current

Type

Power

[kW]

Voltage, frequency

1~ 3~ 3~ 3~ 3~ 3~

ETMD371L2YXA

ETMD551L2YXA

ETMD751L2YXA

ETMD112L2YXA

ETMD152L2YXA

ETMD222L2YXA

ETMD751L2TXA

ETMD112L2TXA

ETMD152L2TXA

ETMD222L2TXA

ETMD402L2TXA

ETMD552L2TXA

ETMD752L2TXA

0.37

0.55 6.0 3.9 3.0 2.8 4.5 4.2

0.75 9.2 5.1 4.2 3.9 6.3 5.9

1.1 12.0 6.9 6.0 5.5 9.0 8.3

1.5 12.9 7.9 7.0 6.4 10.5 9.6

2.2 17.1 11.0 9.6 8.8 14.4 13.2

1/N/PE 230 V

OR

3/PE 230 V

(180 V -0%…264 V +0%)

50/60 Hz

(48 Hz -0%…62 Hz +0%)

0.75

1.1 6.9 6.0 5.5 9.0 8.3

1.5 7.9 7.0 6.4 10.5 9.6

2.2 11.0 9.6 8.8 14.4 13.2

4.0 17.1 15.2 14.0 23 21

5.5 25 22 20 33 30

3/PE 230 V

(180 V -0%…264 V +0%)

50/60 Hz

(48 Hz -0%…62 Hz +0%)

7.5 32 28 26 42 39

4.7 2.7 2.4 2.2 3.6 3.3

400V 480V 400V 480V 400V 480V 400V 480V 400V 480V

ETMD371L4TXA

ETMD751L4TXA

ETMD112L4TXA

ETMD152L4TXA

ETMD222L4TXA

ETMD302L4TXA

ETMD402L4TXA

ETMD552L4TXA

ETMD752L4TXA

(1) For rated mains voltage and carrier frequencies 4, 6, and 8 kHz

(2) For rated mains voltage and carrier frequency 10 kHz

(3) Maximum current is a function of setting c73 (input voltage selection)

0.37

0.75 3.0 2.5 2.5 2.1 2.3 1.9 3.8 3.2 3.5 2.9

1.1 4.3 3.6 3.6 3.0 3.3 2.8 5.4 4.5 5.0 4.2

3/PE 400/480 V

1.5 4.8 4.0 4.1 3.4 3.8 3.1 6.2 5.1 5.7 4.7

(320 V -0%…528 V +0%)

2.2 6.4 5.4 5.8 4.8 5.3 4.4 8.7 7.2 8.0 6.6

3.0 8.3 7.0 7.6 6.3 7.0 5.8 11.4 9.5 10.5 8.7

4.0 10.6 8.8 9.4 7.8 8.6 7.2 14.1 11.7 12.9 10.8

50/60 Hz

(48 Hz -0%…62 Hz +0%)

5.5 14.2 12.4 12.6 11.0 11.6 10.1 18.9 16.5 17.4 15.2

7.5 18.1 15.8 16.1 14.0 14.8 12.9 24 21 22 19.4

1.6 1.4 1.3 1.1 1.2 1.0 2.0 1.7 1.8 1.5

[A]

Output Current

I

[A]

N

(1)

[A]

(2)

(3)

[A]

I

(3)

max

(1)

5.1 4.2 3.9 6.3 5.9

for 60 s

[A]

(2)

6

ENGLISH

Page 8

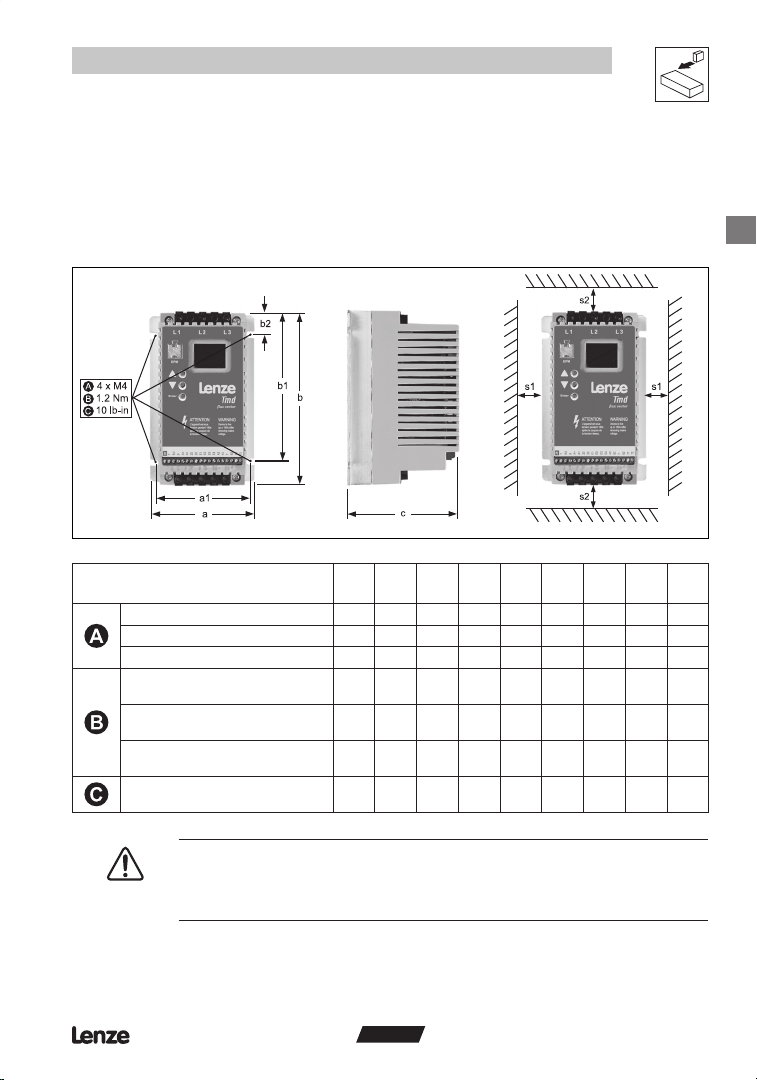

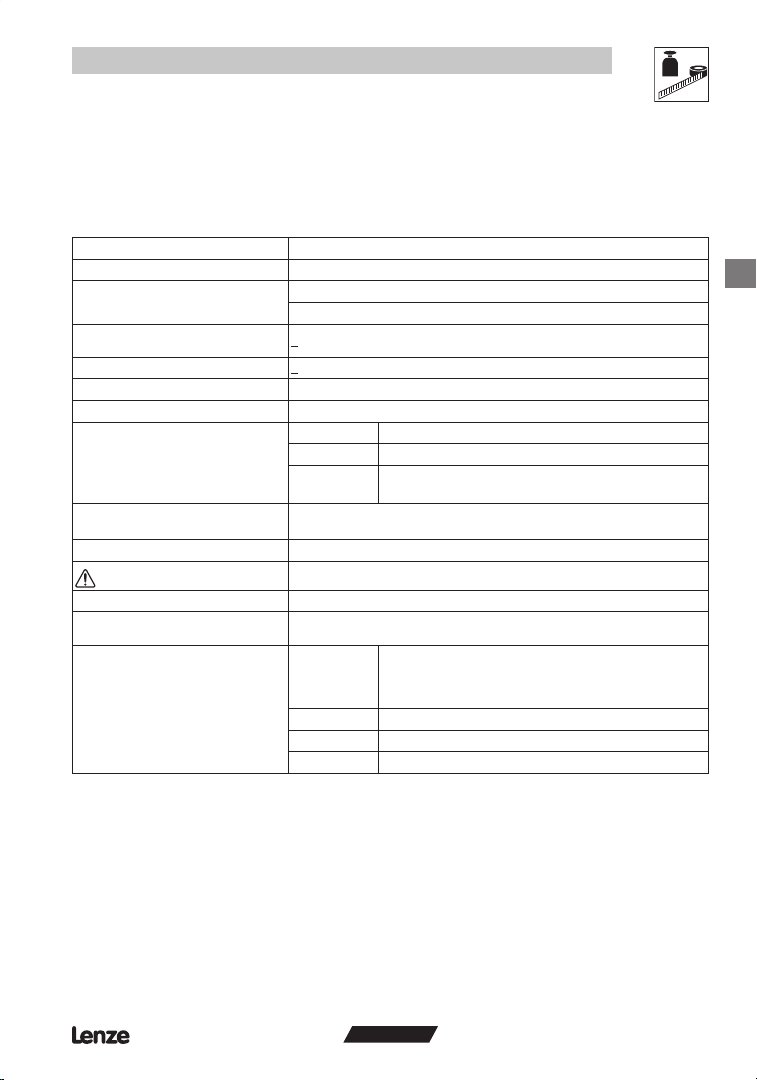

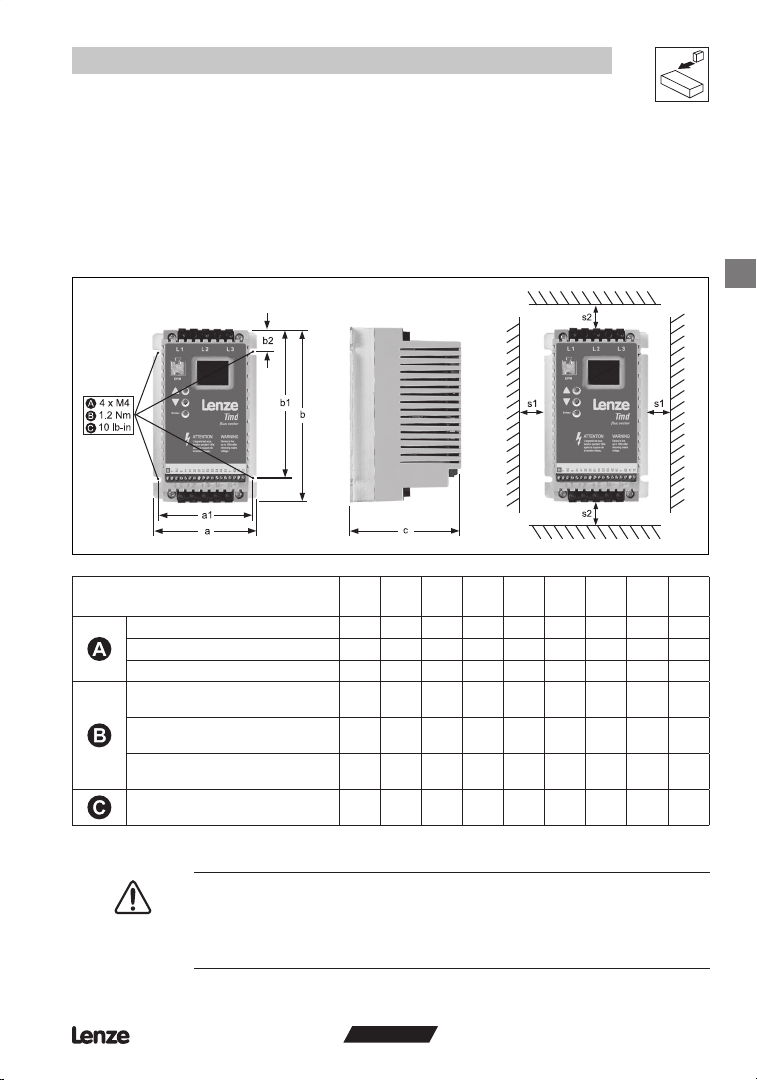

Installation

3 Installation

3.1 Mechanical installation

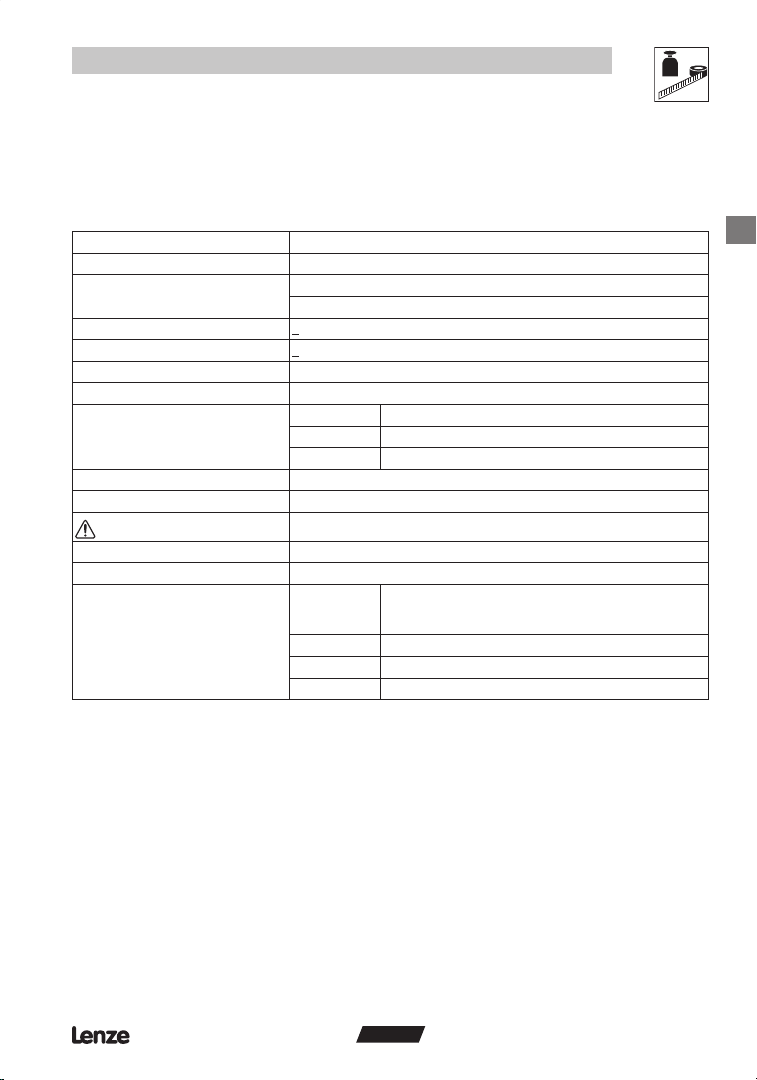

3.1.1 Dimensions and mounting

a

Type

ETMD371L2YXA 93 84 146 128 17 100 15 50 0.6

ETMD551L2YXA, ETMD751L2_XA

ETMD112L2TXA 93 84 146 128 17 146 15 50 1.1

ETMD112L2YXA

ETMD371L4TXA...ETMD112L4TXA

ETMD152L2_XA

ETMD152L4TXA

ETMD222L2_XA

ETMD222L4TXA...ETMD402L4TXA

ETMD552L2TXA, ETMD752L2TXA

ETMD552L4TXA, ETMD752L4TXA

(1) “_” = Y or T; the dimensions are the same for either model.

(1)

(1)

, ETMD402L2TXA

(1)

WARNING!

Drives must not be installed where subjected to adverse environmental conditions

such as: combustible, oily, or hazardous vapors or dust; excessive moisture; excessive

vibration or excessive temperatures. Contact Lenze for more information.

a1

[mm]

[mm]b [mm]b1 [mm]b2 [mm]c [mm]

93 84 146 128 17 120 15 50 0.9

114 105 146 128 17 133 15 50 1.4

114 105 146 128 17 171 15 50 1.9

114 105 146 100 17 171 15 50 2.0

146 137 197 140 17 182 30 100 3.4

Tmd002

s1

[mm]s2 [mm]m [kg]

ENGLISH

7

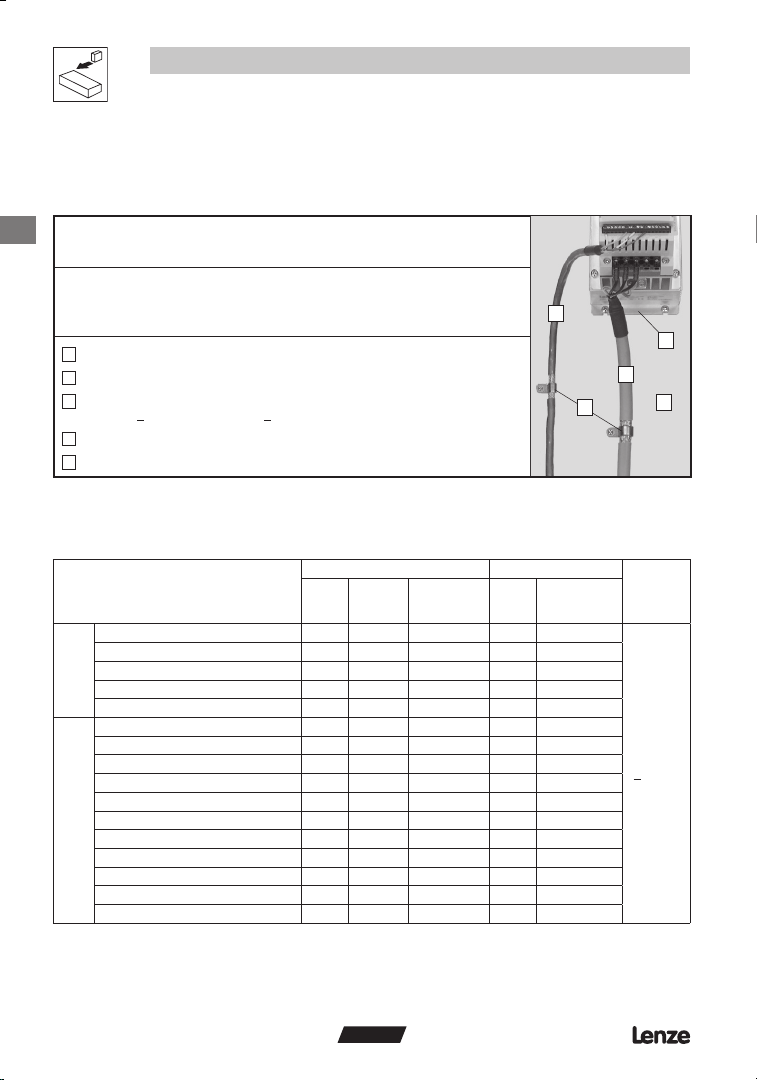

Page 9

Installation

3.2 Electrical installation

3.2.1 Installation according to EMC requirements

EMC

Compliance with EN 61800-3/A11

Noise emission

Compliance with limit value class A according to EN 55011 if installed in a control

cabinet with the appropriate footprint filter and the motor cable length does not exceed

10m

Screen clamps

A

Control cable

B

Low-capacitance motor cable

C

(core/core < 75 pF/m, core/screen < 150 pF/m)

Electrically conductive mounting plate

D

Filter

E

B

E

C

A

D

Tmd005

Miniature

circuit

breaker

ENGLISH

(1)

L1, L2, L3, PE

[mm²]

Fuse

L1, L2, L3, PE

(3)

[AWG]

3.2.2 Fuses/cable cross-sections

Installation to EN 60204-1 Installation to UL

Type

ETMD371L2YXA, ETMD551L2YXA M10 A C10 A 1.5 10 A 14

ETMD751L2YXA M16 A C16 A 2.5 15 A 14

1/N/PE

ETMD112L2YXA M20 A C20 A 2.5 15 A 12

ETMD152L2YXA M25 A C25 A 2.5 20 A 12

ETMD222L2YXA M30 A C30 A 4.0 30 A 10

ETMD371L2YXA...ETMD112L2_XA

ETMD152L2_XA

ETMD222L2_XA

ETMD402L2TXA M25 A C25 A 4.0 25 A 10

ETMD552L2TXA M40 A C40 A 6.0 35 A 8

3/PE

ETMD752L2TXA M50 A C50 A 10 45 A 8

ETMD371L4TXA...ETMD222L4TXA M10 A C10 A 1.5 10 A 14

ETMD302L4TXA M16 A C16 A 1.5 12 A 14

ETMD402L4TXA M16 A C16 A 2.5 15 A 14

ETMD552L4TXA M20 A C20 A 2.5 20 A 12

ETMD752L4TXA M25 A C25 A 4.0 25 A 10

(1) Observe the applicable local regulations

(2) Pulse-current or universal-current sensitive earth leakage circuit breaker

(3) UL Class CC or T fast-acting current-limiting type fuses, 200,000 AIC, required. Bussman KTK-R, JJN, JJS, or equivalent

(4) “_” = Y or T; the ratings are the same for either model with 3/PE input

(4)

(4)

8

Fuse

(4)

M10 A C10 A 1.5 10 A 14

M16 A C16 A 1.5 12 A 14

M16 A C16 A 2.5 15 A 12

E.l.c.b.

> 30 mA

(2)

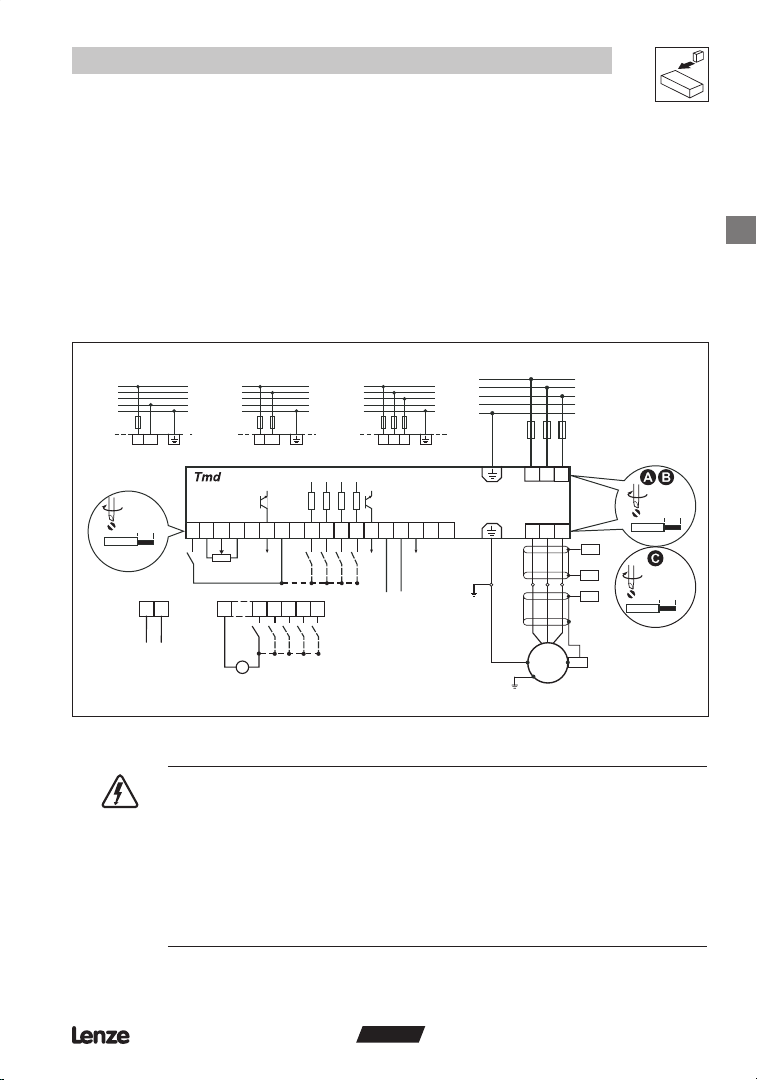

Page 10

Installation

Observe the following when using E.l.c.b:

• Installation of E.l.c.b only between supplying mains and controller.

• The E.l.c.b can be activated by:

- capacitive leakage currents between the cable screens during operation (especially with long,

screened motor cables)

- connecting several controllers to the mains at the same time

- RFI lters

3.2.3 Connection diagram

1/N/PE 180V 0% 264V + 0 %

48 Hz 62 Hz

L1

L2

L3

N

PE

L2/N

L1

0 2 Nm/2 b in

6 mm/0 24 in

< 1mm²/AWG 26 16

8U7

0 … +5 V

0 … +10 V

-10 … +10 V

DANGER!

• Hazard of electrical shock! Circuit potentials are up to 480 VAC above earth ground.

Capacitors retain charge after power is removed. Disconnect power and wait until

the voltage between B+ and B- is 0 VDC before servicing the drive.

• Do not connect mains power to the output terminals (U,V,W)! Severe damage to the

drive will result.

• Do not cycle mains power more than once every three minutes. Damage to the

drive will result.

2/PE 180V 0% 264V + 0 %

AIN

COM

8U

28 7

1k …10k

7

_

+12 V DC - 0 %

+30 V DC + 0 %

L1

L2

L3

N

PE

+10 V

9

A+ A1

…

48 Hz 62 Hz

L2/N

L1

COM

+12 V

+15 V

+15 V

2020

E1 E2 E3 71627 72

DIGOUT

28

E3 E4

E1 E2

+

3/PE 180V 0% 264V + 0 %

48 Hz 62 Hz

L1

L2

L3

N

PE

L3

L1 L2

COM

AIN

COM

E4 A2

8I

AOUT

DIGOUT

0 … 20 mA

4 … 20 mA

3/PE 320V 0 % 528V + 0 %

L1

L2

L3

N

PE

TXB

TXA

PE

48 Hz 62 Hz

PE

L1 L2

U V W

M

3~

L3

0 5 Nm/4 5 lb in

6 mm/0 24 in

PES

PES

1 2 Nm/10 lb n

PES

9 mm/0 35 in

PES

Tmd003

ENGLISH

9

Page 11

Installation

3.2.4 Control terminals

Terminal

Protection against contact

Data for control connections (printed in bold = Lenze setting)

28

Digital input Start/Stop

7

Reference common

Analog input

8U

0 … 10 V (changeable under C34)

9

Internal DC supply for setpoint potentiometer +10 V, max. 10 mA

A+

Internal DC supply for external devices +12 V, max. 50 mA

A1

Digital output congurable with c17 DC 24 V / 50 mA

20

Internal DC supply for digital inputs +15 V, max. 20 mA

20

Digital input configurable with CE1

E1

Activate fixed setpoint 1 (JOG1)

Digital input configurable with CE2

E2

Activate fixed setpoint 2 (JOG2)

Digital input configurable with CE3

E3

Activate DC injection brake (DCB)

Digital input configurable with CE4

E4

Direction of rotation

A2

Digital output congurable with c18 DC 24 V / 50 mA

8I Analog input (changeable under C34) input resistance: 150 Ω

7

Reference common

62

Analog output congurable with c08...c11 0...10 V or 2...10 V, max. 20mA

71

RS-485 serial communication input RXB/TXB (B+)

72

RS-485 serial communication input RXA/TXA (A-)

LOW = Stop; HIGH = Run Enable

input resistance = 3.3 kΩ

input resistance: >40 kΩ

HIGH = JOG1 active

HIGH = JOG2 active

HIGH = DCB active

LOW = CW rotation

HIGH = CCW rotation

Both HIGH = JOG3 active

LOW = 0 … +3 V, HIGH = +12 … +30 V

• All terminals have a basic isolation (single insulating distance)

• Protection against contact can only be ensured by additional measures (i.e. double insulation)

= 3.3 kΩ

i

R

10

ENGLISH

Page 12

4 Commissioning

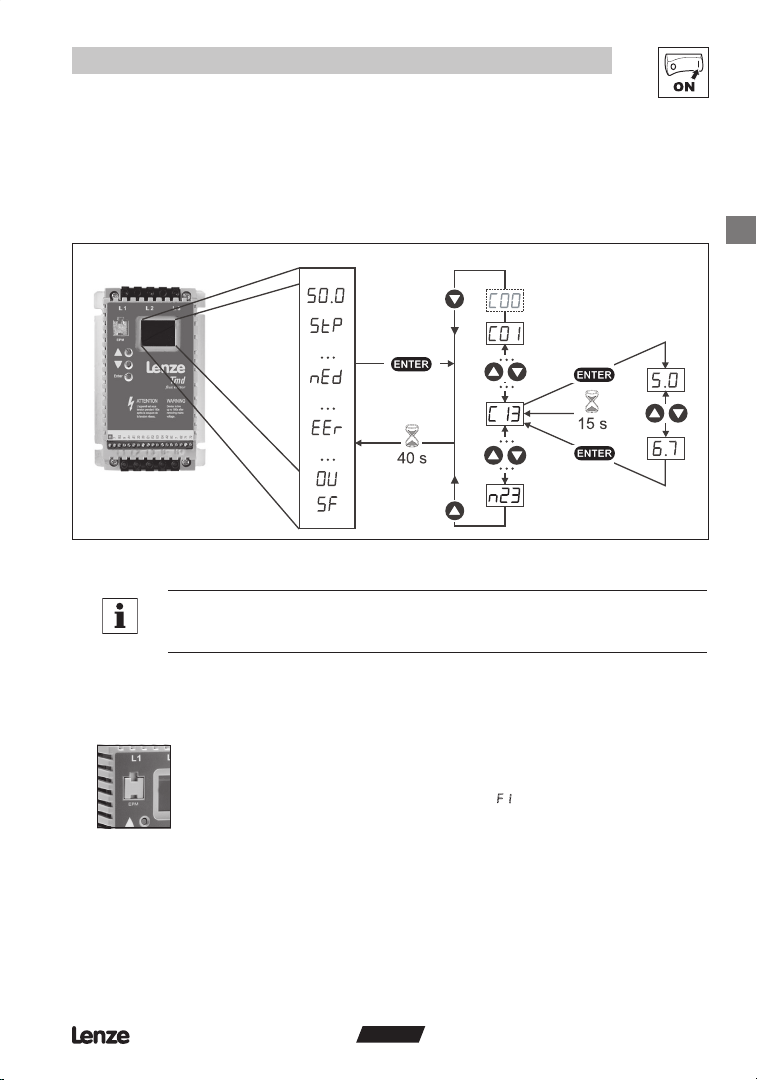

4.1 Parameter setting

Status/fault messages Change parameters

Note

If the password function is enabled, the password must be entered into C00 to access

the parameters. C00 will not appear unless the password function is enabled. See C94.

Commissioning

Tmd004

4.2 Electronic programming module (EPM)

The EPM contains the controller’s memory. Whenever parameter settings are changed,

the values are stored in the EPM. It can be removed, but must be installed for the

controller to operate (a missing EPM will trigger an fault). The controller ships with

Tmd007

An optional EPM Programmer (model ESMD01EP; manual EP03) is available that allows: the controller to

be programmed without power; OEM settings to be default settings; fast copying of EPMs when multiple

controllers require identical settings. It can also store up to 60 custom parameter les for even faster

controller programming.

protective tape over the EPM that can be removed after installation.

ENGLISH

11

Page 13

Commissioning

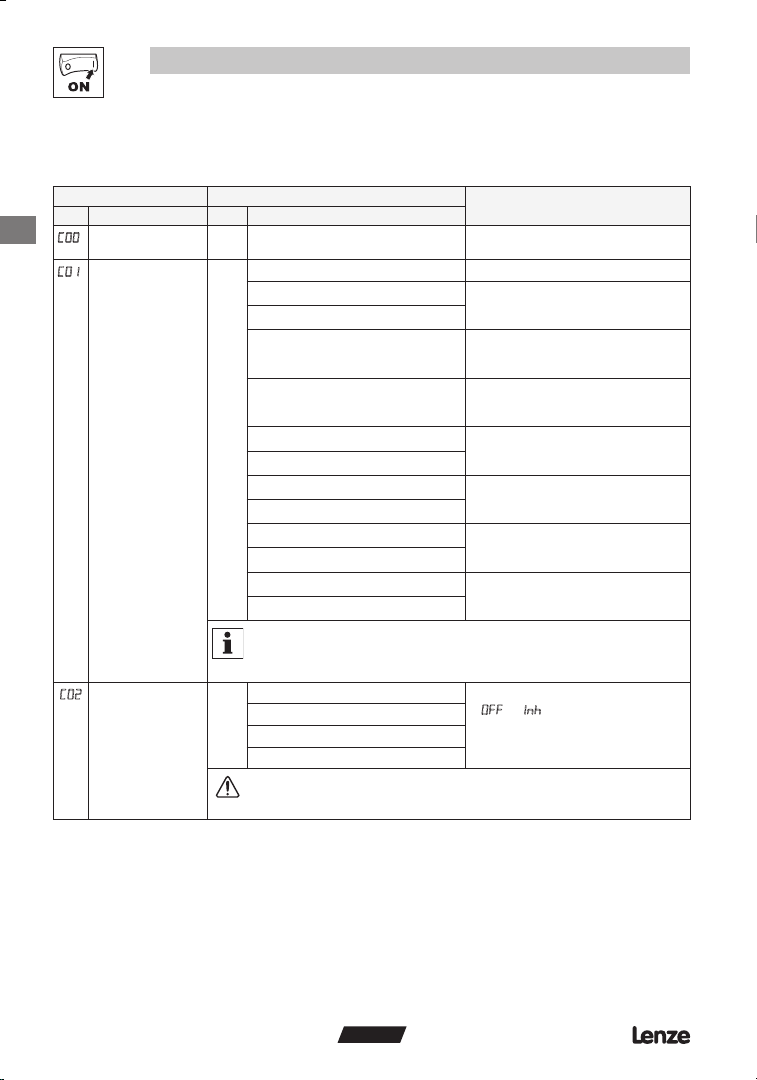

4.3 Parameter menu

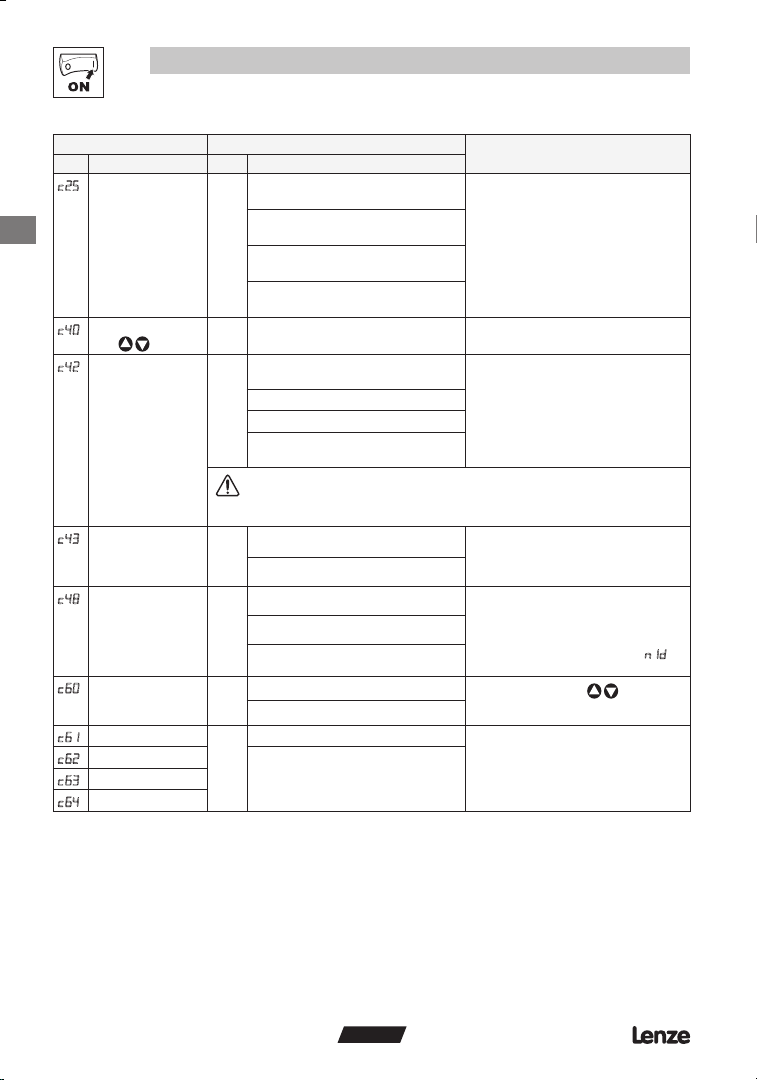

Code Possible Settings

No. Name Lenze Selection

Password entry

Setpoint and control

1

source

Load Lenze setting 0 No action/loading complete • C02 = 1, 2, 3 only possible with

0

0 999 Visible only when password is active

0

Setpoint source: Control configuration:

0 Analog input (8U / 8I; see C34) Control = terminals

1 Code c40 / Code C47

2 Analog input (8U / 8I; see C34) Control = terminals

3 LECOM Control = LECOM

4 Analog input (8U / 8I; see C34) Control = terminals

5 Code c40 / Code C47

6 Analog input (8U / 8I; see C34) Control = remote keypad

7 Code c40 / Code C47

8 Analog input (8U / 8I; see C34) Control = terminals

9 Code c40 / Code C47

10 Analog input (8U / 8I; see C34) Control = Modbus

11 Code c40 / Code C47

Note

• When C01 = 1, 5, 7, 9, or 11 and C14 = 0...4, 6, 7, use c40 for speed setpoint

• When C01 = 1, 5, 7, 9, or 11 and C14 = 5, use C47 for torque setpoint

• When C01 = LECOM (3), write speed command to C46 or torque command to C47.

1 Load 50 Hz Lenze settings

2 Load 60 Hz Lenze settings

3 Load OEM settings (if present)

WARNING!

C02 = 1...3 overwrites all settings! TRIP circuitry may be disabled!

Check codes CE1...CE4.

(see C94)

Programming = keypad

Monitoring = LECOM

Programming = LECOM / keypad

Monitoring = LECOM

Programming = LECOM / keypad

Monitoring = LECOM

Programming = remote keypad

Monitoring = remote keypad

Programming = remote keypad

Monitoring = remote keypad

Programming = Modbus / keypad

Monitoring = Modbus

Programming = Modbus / keypad

Monitoring = Modbus

• C02 = 2 : C11, C15 and C89 = 60 Hz

and C87 = 1750RPM

IMPORTANT

or

12

ENGLISH

Page 14

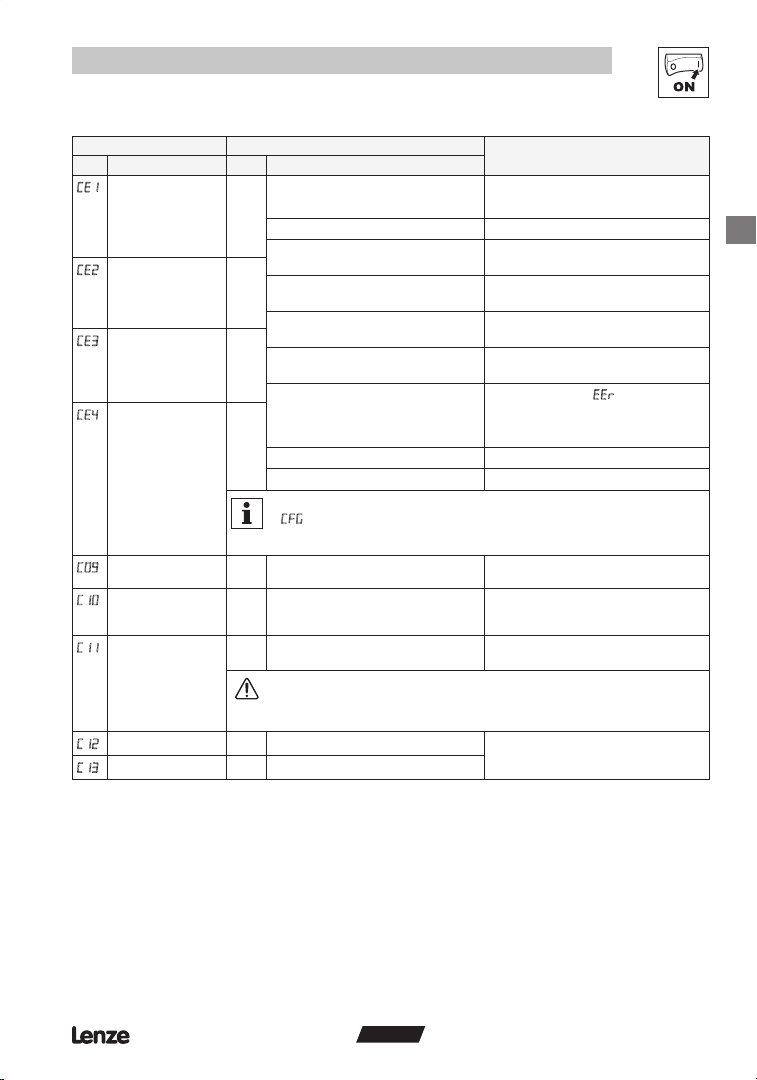

Commissioning

Code Possible Settings

No. Name Lenze Selection

Configuration -

Digital input E1

Configuration -

Digital input E2

Configuration -

Digital input E3

Configuration -

Digital input E4

Network address 1 1 247 Each controller on network must have

Minimum output

C1

frequency

Maximum output

frequency

Acceleration time 1 5.0 0.0 {s} 999 • C12 = frequency change 0 Hz...C11

Deceleration time 1 5.0 0.0 {s} 999

1 1 Activate xed setpoint 1 (JOG1)

2 Activate xed setpoint 2 (JOG2)

3 DC braking (DCB) see also C36

4 Direction of rotation LOW = CW rotation

2

5 Quick stop Controlled deceleration to standstill, active

6 CW rotation

7 CCW rotation

3

8 UP (setpoint ramp-up)

9 DOWN (setpoint ramp-down)

10 TRIP set

4

11 TRIP reset see also c70

12 Accel/decel 2 see c01 and c03

Note

A

fault will occur under the following conditions:

• E1...E4 settings are duplicated (each setting can only be used once)

• One input is set to UP and another is not set to DOWN, or vice-versa

0.0 0.0 {Hz} 240 • Output frequency at 0% analog setpoint

50.0 7.5 {Hz} 240 • Output frequency at 100% analog setpoint

WARNING!

Consult motor/machine manufacturer before operating above rated frequency.

Overspeeding the motor/machine may cause damage to equipment and injury to

personnel!

Activate JOG3: Both terminals = HIGH

HIGH = CCW rotation

LOW; Set decel rate in C13 or c03

CW rotation = LOW and CCW rotation =

LOW: Quick stop; Open-circuit protected

UP = LOW and DOWN = LOW: Quick stop;

Use momentary NC contacts

Active LOW, triggers

standstill)

NOTE: NC thermal contact from the motor

can be used to trigger this input

unique address

• C10 not active for xed setpoints or

setpoint selection via c40

• C11 is never exceeded

• C13 = frequency change C11...0 Hz

• For S-ramp accel/decel, adjust c82

IMPORTANT

(motor coasts to

ENGLISH

13

Page 15

Commissioning

Code Possible Settings

No. Name Lenze Selection

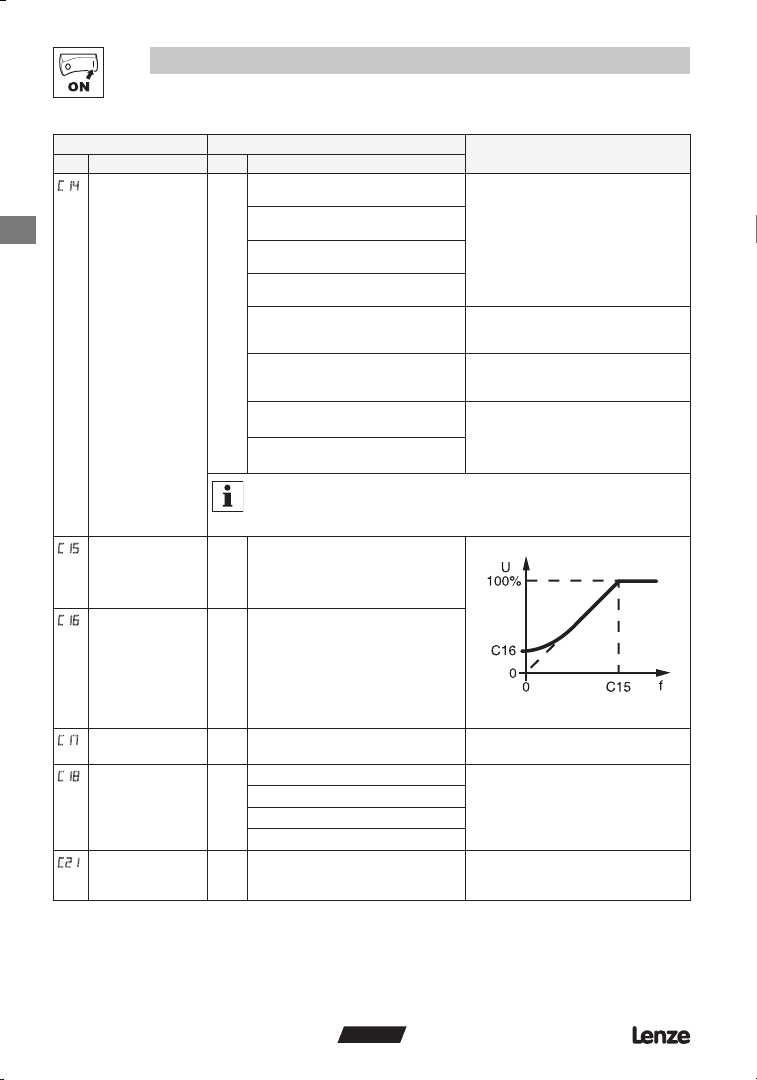

Operating Mode 2 0 Linear characteristic with

V/f reference point 50.0 25.0 {Hz} 999

V

boost

(optimization

min

of torque behavior)

Frequency threshold

C 7

(Q

)

min

Chopper frequency 2 0 4 kHz • As chopper frequency is increased, motor

C

Slip compensation 0.0 0.0 {%} 40.0

1

Auto-Boost

1 Square-law characteristic with

Auto-Boost

2 Linear characteristic with constant

boost

V

min

3 Square-law characteristic with

constant V

4 Vector speed control • Vector speed control: for single-motor

5 Vector torque control • Vector torque control: for single-motor

6 Enhanced linear characteristic

with Auto-Boost

7 Enhanced linear characteristic with

constant V

Note

• Settings 4...7 require Motor Calibration using c48

• Settings 4 and 5 require proper setting of C86...C91 prior to calibration

• Settings 6 and 7 require proper setting of C88...C90 prior to calibration

Set the rated motor frequency

(nameplate) for standard applications

0.0 {%} 40.0

C16 not active in Vector mode (see C14)

Set after commissioning: The unloaded

motor should run at slip frequency (approx.

5 Hz), increase C16 until motor current

(C54) = 0.8 x rated motor current

0.0 0.0 {Hz} 240 See c17 and c18, selection 7

1 6 kHz

2 8 kHz

3 10 kHz

C21 not active in Vector mode (see C14)

min

min

boost

boost

• Linear characteristic: for standard

applications

• Square-law characteristic: for fans and

pumps with square-law load characteristic

• Auto boost: load-dependent output voltage

for low-loss operation

applications requiring higher starting

torque and better speed regulation

applications requiring torque control

independent of speed

• Enhanced: for single or multiple

motor applications that require better

performance than settings 0...3, but

cannot operate in vector mode

noise is decreased

• Observe derating in Section 2.2

• Automatic derating to 4 kHz at 1.2 x Ir

Change C21 until the motor speed no longer

changes between no load and maximum

load

IMPORTANT

smd006

14

ENGLISH

Page 16

Commissioning

Code Possible Settings

No. Name Lenze Selection

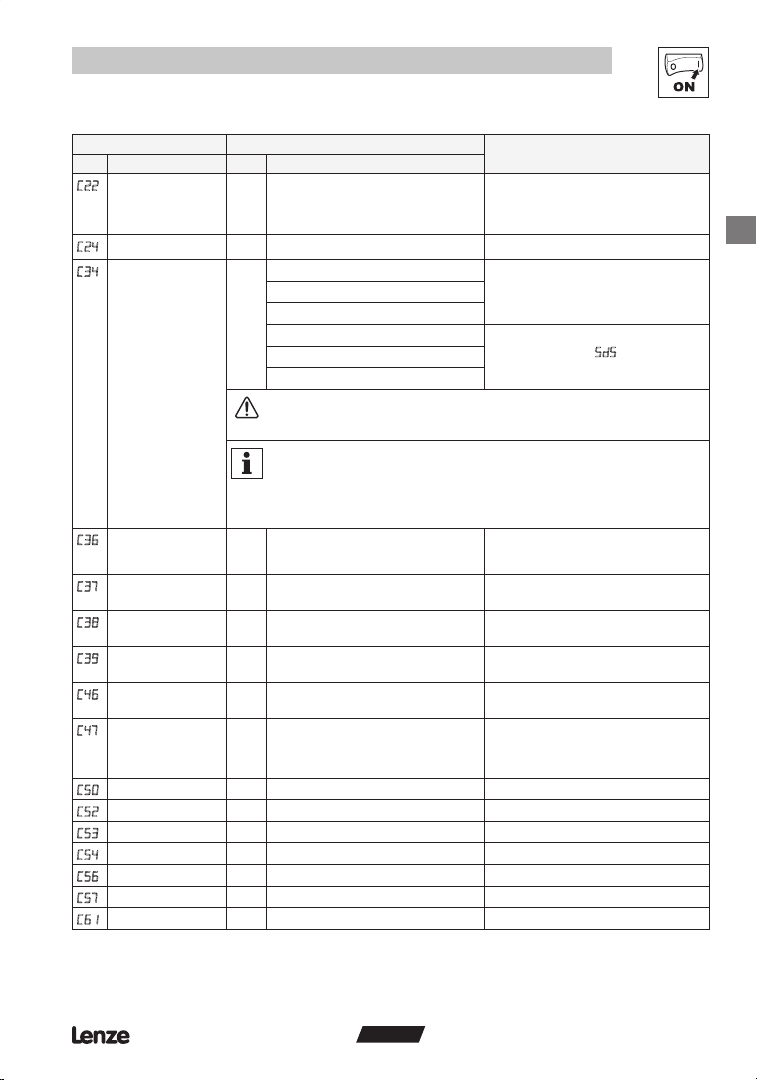

Current limit 200 30 {%} 200

Reference: Tmd rated output current

Accel boost 0.0 0.0 {%} 20.0 Accel boost is only active during acceleration

Configuration -

analog input

Voltage - DC injection

C

brake (DCB)

Fixed setpoint 1

(JOG 1)

Fixed setpoint 2

(JOG 2)

Fixed setpoint 3

(JOG 3)

Frequency setpoint 0.0 {Hz} 240 Display: Setpoint via analog input, function

Torque setpoint/range 100 0 {%} 400 • When C14 = 5 and C01 = 1, 5, 7, 9, 11,

Output frequency 0.0 {Hz} 240 Display

C

Motor voltage 0 {V} 999 Display

DC bus voltage 0 {V} 999 Display

Motor current 0.0 {A} 400 Display

Controller load 0 {%} 255 Display

Motor torque 0 {%} 400 Display: vector mode only (C14 = 4, 5)

C

Heatsink temp 0 {C} 255 Display

0 0 0...10 V • Voltage reference applied to 8U

1 0...5 V

2 -10...+10 V

3 0...20 mA • Current reference applied to 8I

4 4...20 mA

5 4...20 mA monitored

WARNING!

When running with -10...+10V reference (C34=2), a loss of reference will result in 5%

motor speed (0.05xC11).

Note

When C34 = 2:

• Rotation is determined by the polarity of the -10...+10 V signal:

+0.1...+10 V = CW and -0.1...-10 V = CCW (all other rotation commands are disabled)

• C11 sets maximum frequency in both directions (C10 is not active)

• CE1...CE4 = 6 or 7 will only start the controller, not select rotation

4.0 0.0 {%} 50.0 • See CE1...CE4 and c06

20.0 0.0 {Hz} 240 Lenze setting: active at E1 = HIGH

30.0 0.0 {Hz} 240 Lenze setting: active at E2 = HIGH

40.0 0.0 {Hz} 240 Lenze setting: active at E1 = HIGH and E2

• When the limit value is reached, either the

acceleration time increases or the output

frequency decreases

• When c73 = 0, max setting is 167%

• Tmd does not provide -10 V supply for

C34 = 2

• C34 = 2 disabled in vector torque mode

• C34 = 5 will trigger

below 2 mA

• Conrm motor suitability for use with DC

braking

= HIGH

UP/DOWN, or LECOM

sets the torque setpoint

• When C14 = 5 and C01 = 0, 2, 4, 6, 8, 10,

sets the torque range for C34

IMPORTANT

fault if signal falls

ENGLISH

15

Page 17

Commissioning

Code Possible Settings

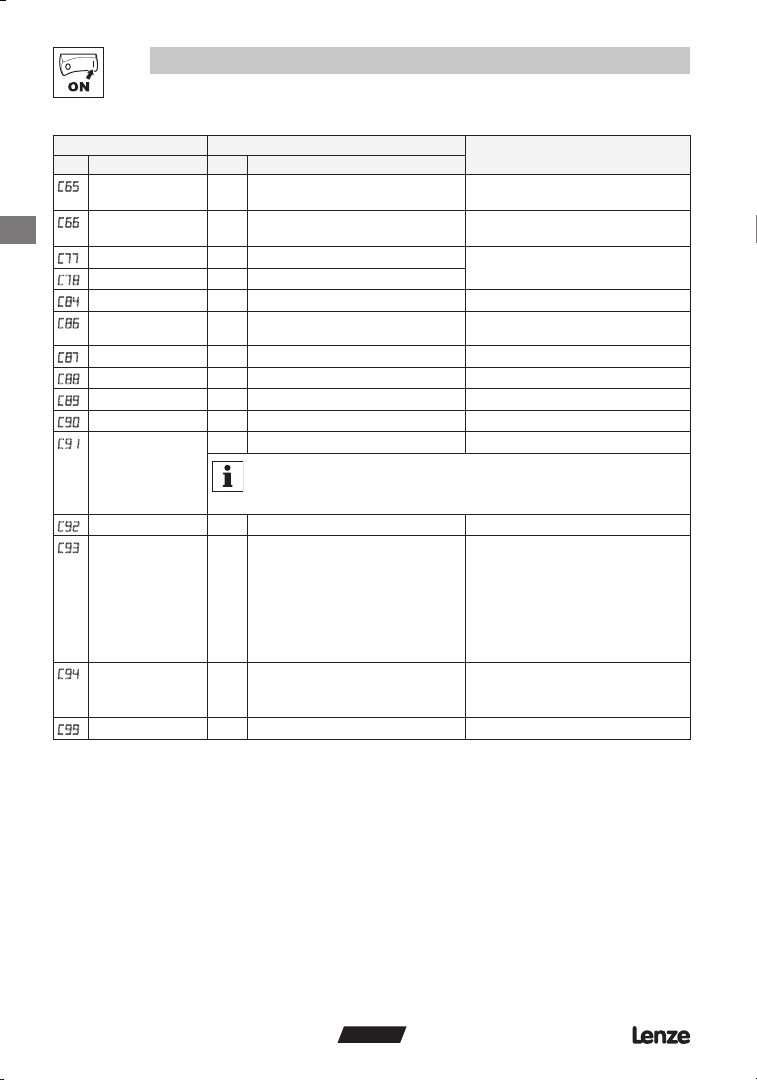

No. Name Lenze Selection

Vector speed control

loop gain

Vector speed stability 30.0 0.0 100 Optimizes steady-state speed stability in

I

gain 0.25 0.00 16.0 For most applications, there is no need to

7

max

Integral action time 65 12 {ms} 9990

Motor stator resistance 0.00 0.00 {Ω} 64.0 Will be automatically programmed by c48

Motor rated power 0.00 {kW} 99.9 • Set to motor nameplate kW

Motor rated speed 1390 300 {RPM} 65000 Set to motor nameplate speed

7

Motor rated current 0.0 0.0 {A} 480 Set to motor nameplate current

Motor rated frequency 50 10 {Hz} 999 Set to motor nameplate frequency

Motor rated voltage 0 0 {V} 600 Set to motor nameplate voltage

Motor cosine phi 0.80 0.40 1.00 Set to motor power factor

1

Motor stator inductance 0.0 0.0 {mH} 2000 Will be automatically programmed by c48

Drive identification

User password 0 0 999

Software version Display, format: x.yz

30.0 0.0 100 Optimizes dynamic performance in vector

Note

If motor power factor is not known, use the following formulas:

cos phi = motor Watts / (motor efciency X C90 X C88 X 1.732)

cos phi = cos [ sin-1 (magnetizing current / motor current) ]

Changing from “0” (no password), value will

start at 763

mode

vector mode

change the Lenze settings

• Lenze setting = Tmd rated kW

• Indicates controller rating, format: xyz,

xy.z, x.yz, or x.y.z

• x. or x = voltage (2. = 200/240V, 1~;

2 = 200/240V, 3~; 4 = 400/480V, 3~)

• yz or y.z = kW rating

Examples:

2.0.3 = 200/240 V, 1~, 0.37 kW

47.5 = 400/480 V, 3~, 7.5 kW

When set to a value other than 0, must enter

password at C00 to access parameters

IMPORTANT

(1)

(1)

(1)

(1) Changing these settings can adversely affect performance. Contact Lenze technical support prior to changing.

16

ENGLISH

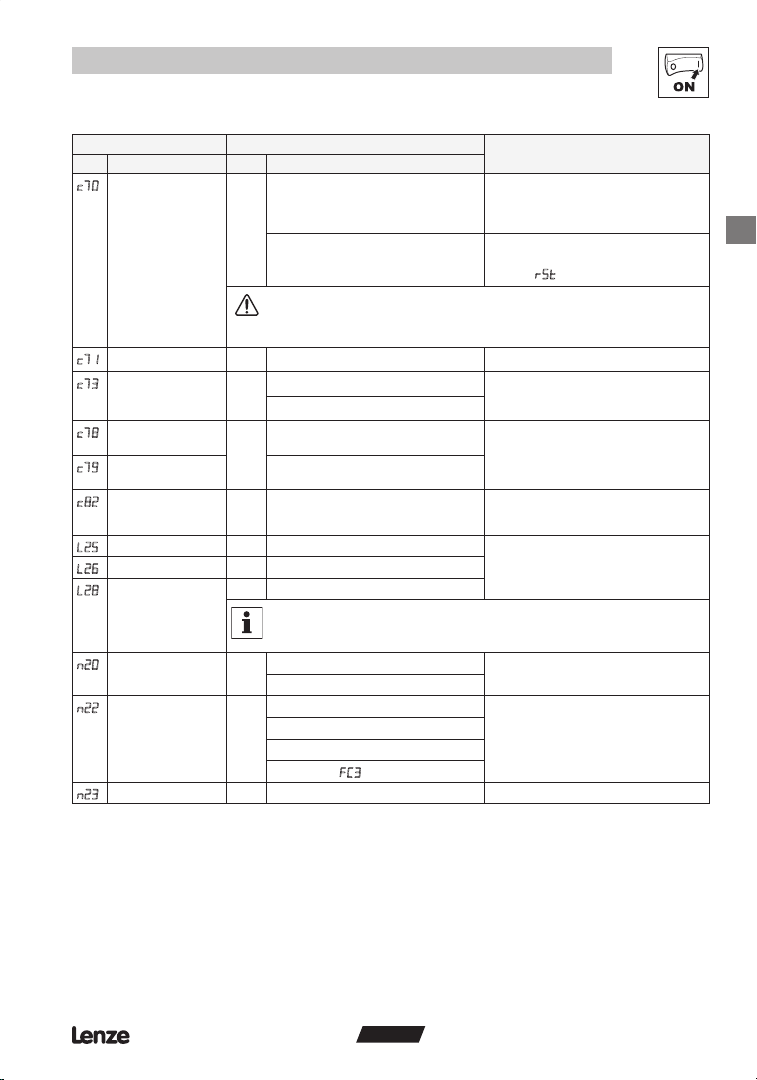

Page 18

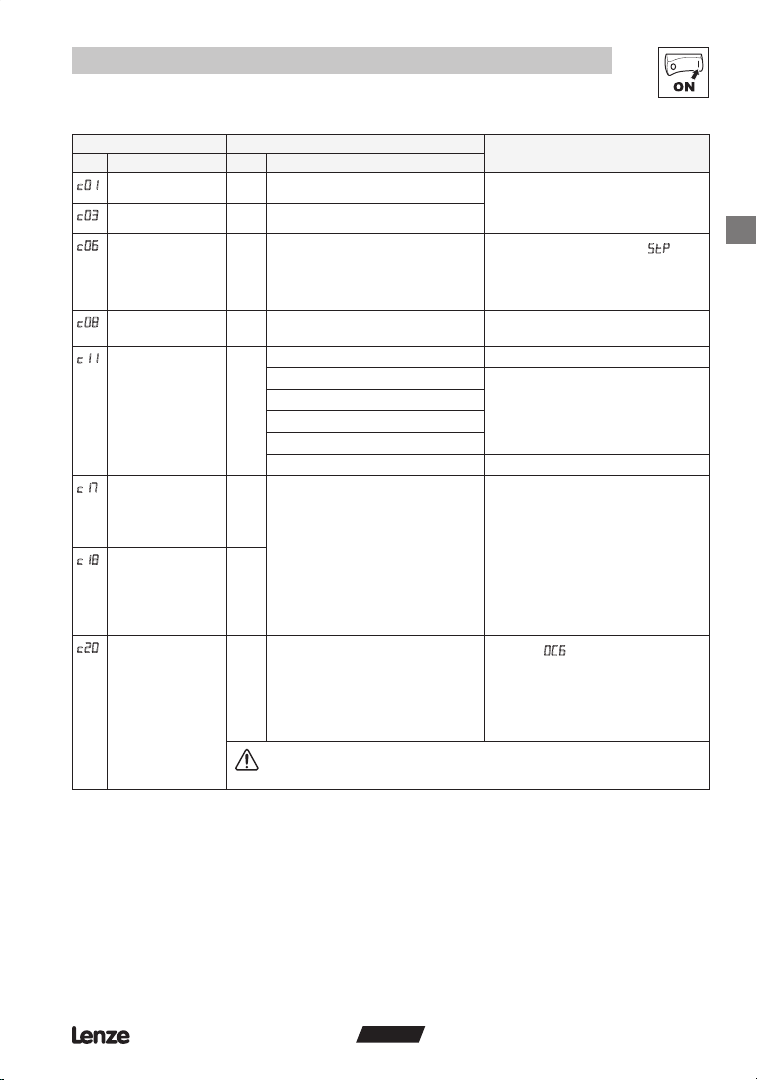

Commissioning

Code Possible Settings

No. Name Lenze Selection

Acceleration time 2 5.0 0.0 {s} 999 • Activated using CE1...CE4

Deceleration time 2 5.0 0.0 {s} 999

Holding time -

automatic DC injection

brake (Auto-DCB)

Analog output scaling 100 0.0 999 When 10 VDC is output at terminal 62, it will

Configuration -

Analog output (62)

Configuration - Digital

output (A1)

Configuration - Digital

output (A2)

I2t switch-off (thermal

motor monitoring)

0.0 0.0 {s} 999

0.0 = not active

999 = continuous brake

0 0 None

1 Output frequency 0-10 VDC Use c08 to scale signal

2 Output frequency 2-10 VDC

3 Load 0-10 VDC

4 Load 2-10 VDC

5 Dynamic braking Only used with DB option

0 Output is energized if

0 Ready

1 Fault

2 Motor is running

3 Motor is running - CW rotation

4 Motor is running - CCW rotation

1

5 Output frequency = 0 Hz

6 Frequency setpoint reached

7 Frequency threshold (C17) exceeded

8 Current limit (motor or generator

mode) reached

100 30 {%} 100

100% = Tmd rated output current

WARNING!

Maximum setting is rated motor current (see nameplate). Does not provide full motor

protection!

• c01 = frequency change 0 Hz...C11

• c03 = frequency change C11...0 Hz

• For S-ramp accel/decel, adjust c82

• Automatic motor braking after by

means of motor DC current for the entire

holding time (afterwards: U, V, W inhibited)

• Conrm motor suitability for use with DC

braking

equal this value (see c11)

Example: c11 = 1 and c08 = 100:

At 50 Hz, terminal 62 = 5 VDC

At 100 Hz, terminal 62 = 10 VDC

• Triggers

exceeds c20 for too long

• Correct setting = (motor nameplate current)

/ (Tmd output current rating) X 100%

• Example: motor = 6.4 amps and

Tmd = 7.0 amps; correct setting = 91%

(6.4 / 7.0 = 0.91 x 100% = 91%)

IMPORTANT

fault when motor current

ENGLISH

17

Page 19

Commissioning

Code Possible Settings

No. Name Lenze Selection

Serial baud rate 0 0 LECOM: 9600 bps

Frequency setpoint via

keys or Modbus

Start condition

(with mains on)

Flying restart selection 0 0 Search range: C11...0 Hz If c42 = 2 or 3, the controller will start the

Motor auto-calibration 0 0 Calibration not done • If C14 = 4...7, motor calibration must

Mode selection for c61 0 0 Monitoring only

6

Present status/error status/error message • Display

1

Last error error message

Last error but one

Last error but two

Modbus: 9600,8,N,2

1 LECOM: 4800 bps

Modbus: 9600,8,N,1

2 LECOM: 2400 bps

Modbus: 9600,8,E,1

3 LECOM: 1200 bps

Modbus: 9600,8,O,1

0.0 0.0 {Hz} 240 Only active if C01 is set properly

1 0 Start after LOW-HIGH

change at terminal 28

1 Auto start if terminal 28 = HIGH

2 Flying restart (auto start disabled)

3 Auto start if terminal 28 = HIGH,

with flying restart

WARNING!

Automatic starting/restarting may cause damage to equipment and/or injury to personnel!

Automatic starting/restarting should only be used on equipment that is inaccessible to

personnel.

1 Search range: last frequency...0 Hz

1 Calibration enabled

2 Calibration complete

1 Monitoring and editing

• See C01

• LECOM if C01 = 0...3

• Modbus if C01 = 8...11

(C01 = 1, 5, 7, 9, 11)

See also c43 and c70

motor speed search at C11, or at the last

output frequency before the fault, depending

on the setting of c43

be performed, but C86...C91 must be

programmed first (see C14)

• If motor calibration is attempted before

programming C86...C91, triggers

fault

c60 = 1 allows the keys

speed setpoint (c40) while monitoring c61

• Refer to Section 5 for explanation of status

and error messages

IMPORTANT

to adjust

18

ENGLISH

Page 20

Commissioning

Code Possible Settings

No. Name Lenze Selection

Conguration TRIP

7

reset (error reset)

Auto-TRIP reset delay 0.0 0.0 {s} 60.0 See c70

7

Input voltage selection 0 Low (for 200 or 400 V input) • Lenze setting depends on C93

7

Operating time counter Display

7

Mains connection time

7

counter

S-ramp integration

time

Skip frequency 1 0.0 0.0 {Hz} 240 • L25 and L26 dene the start of the skip

Skip frequency 2 0.0 0.0 {Hz} 240

Skip frequency

bandwidth

LECOM power up

state

Serial time-out action 0

Serial fault time 50 50 {ms} 65535 Sets the serial timeout length

0 0 TRIP reset after LOW-HIGH change at

terminal 28, mains switching, or after

LOW-HIGH change at digital input

“TRIP reset”

1 Auto-TRIP reset • Auto-TRIP reset after the time set in c71

WARNING!

Automatic starting/restarting may cause damage to equipment and/or injury to personnel!

Automatic starting/restarting should only be used on equipment that is inaccessible to

personnel.

1 High (for 230 or 480 V input)

Total time in status “Start”

Display

Total time of mains = on

0.0 0.0 {s} 50.0 • c82 = 0.0: Linear accel/decel ramp

0.0 0.0 {Hz} 10.0

Note

Bandwidth (Hz) = fs (Hz) + L28 (Hz) fs = L25 or L26

Example: L25 = 18 Hz and L28 = 4 Hz; the bandwidth = 18...22 Hz

0 0 Quick stop

1 Inhibit

0 Not active

1 Inhibit

2 Quick stop

3 Trip fault

• More than 8 errors in 10 minutes will

trigger

• During commissioning, conrm

correct setting based on mains voltage

0...999 h: format xxx

1000...9999 h: format x.xx (x1000)

10000...99999 h: format xx.x (x1000)

• c82 > 0.0: Adjusts S-ramp curve for

smoother ramp

range

• L28 denes the bandwidth of the skip

range

Selects controller reaction to serial timeout

IMPORTANT

S fault

ENGLISH

19

Page 21

Commissioning

4.4 Vector mode

Use the following procedures to select either Vector mode or Enhanced V/Hz mode. Enhanced V/Hz

mode should be used in the following cases:

1. Multiple motor applications

2. Where required motor data is not available (especially C91)

3. Where running in Vector mode causes unstable motor operation

4.4.1 Vector speed and torque modes

1. Connect the controller to the motor according to the diagram in Section 3.2.3.

2. Apply power to the controller.

3. Set C14 to 4 for Vector speed mode, or 5 for Vector torque mode.

4. Set C86...C91 according to the motor’s nameplate data.

5. Set c48 to 1 to enable the motor calibration function.

6. Make sure the motor is cold (rotor and windings are at room temperature of 20º to 25º C), and apply

a HIGH signal at terminal 28. The display will show for about 40 seconds. Once the calibration

is complete, the display will show or . Apply another HIGH signal to terminal 28 to actually

start the motor.

4.4.2 Enhanced V/Hz mode

Follow the procedure in 4.4.1 above, replacing steps 3 and 4 with those below:

3. Set C14 to 6 for Enhanced with Auto-Boost, or 7 for Enhanced with constant boost.

4. Set C88...C90 according to the motor’s nameplate data.

Note

• If the motor is hot when the motor calibration is performed, the controller will not

be able to achieve maximum performance.

• In Vector speed and Vector torque modes, if an attempt is made to start the

controller before performing the motor calibration, the controller will display

and the motor will not operate.

20

ENGLISH

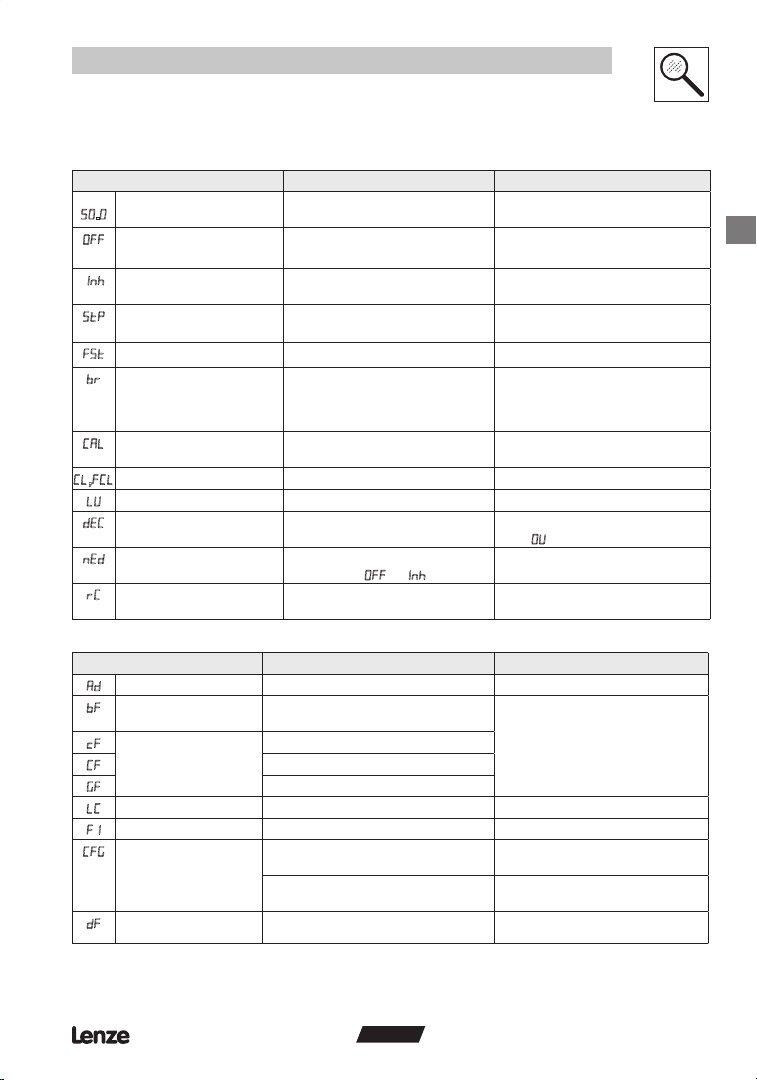

Page 22

Troubleshooting and fault elimination

5 Troubleshooting and fault elimination

e.g.

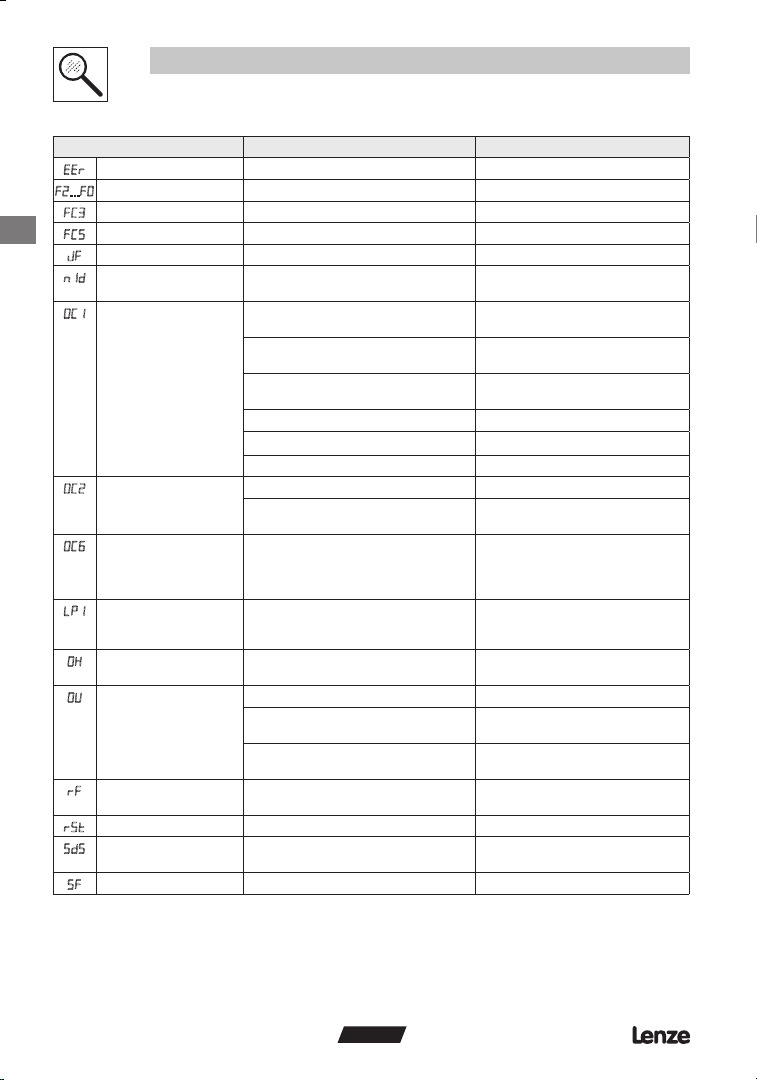

Status Cause Remedy

Present output frequency Trouble free operation

Stop

O

(outputs U, V, W inhibited)

Inhibit

1

(outputs U, V, W inhibited)

Output frequency = 0 Hz

(outputs U, V, W inhibited)

Flying restart attempt c42 = 2, 3

DC-injection brake active DC-injection brake activated

Motor calibration is in process c48 = 1 and terminal 28 = HIGH Only perform the motor calibration

L

Current limit reached Controllable overload Automatically (see C22)

Undervoltage on DC bus Mains voltage too low Check mains voltage

Overvoltage on DC bus during

deceleration (warning)

No access to code Can only be changed when the

Remote keypad is active Attempt to use buttons on front of

Error Cause Remedy

A/D converter error Please contact Lenze

Identication fault C93 value stored on EPM does not match

Data on EPM not valid

Automatic start inhibited c42 = 0, 2 LOW-HIGH signal change at terminal 28

L

EPM error EPM missing or defective Power down and replace EPM

Digital inputs not

uniquely assigned

Dynamic braking fault Dynamic braking resistors are overheating Increase deceleration time

(1) The drive can only be restarted if the error message has been reset; see c70

LOW signal at terminal 28 Set terminal 28 to HIGH

Controller is set up for remote

keypad or serial control (see C01)

Quick stop activated through digital

input or serial link

• via digital input

• automatically

Excessively short deceleration time

(C13, c03)

controller is in or

controller

controller model

Data not valid for controller

Data error

OEM data not valid

E1...E4 assigned with the same digital

signals

Either just “UP” or “DOWN” used Assign the missing digital signal to a

Start the controller via the remote

keypad or serial link

Deactivate Quick stop

Deactivate DC-injection brake

• digital input = LOW

• automatically after holding time c06

has expired

when C14 = 4...7

Automatically if overvoltage

< 1 s, U, if overvoltage > 1 s

Set terminal 28 to LOW or inhibit by

serial link

Buttons on front of controller are

disabled when remote keypad is

• Use EPM providing valid data

• Load Lenze setting

Each digital signal can only be used

once

second terminal

active

(1)

ENGLISH

21

Page 23

Troubleshooting and fault elimination

Error Cause Remedy

External error Digital input “TRIP set” is active Remove external error

Internal fault Please contact Lenze

0

Communication error Serial timer has timed out Check serial link connections

Communication error Serial communication failure Please contact Lenze

Remote keypad fault Remote keypad disconnected Check remote keypad connections

Drive identification fault Attempt was made to perform motor

1

Short-circuit or overload Short-circuit Find reason for short-circuit; check

1

Earth fault Grounded motor phase Check motor/motor cable

Motor overload (I2t

C

overload)

Loss of motor phase Open-circuit on controller output when in

LP1

Controller

H

overtemperature

Overvoltage on DC bus Mains voltage too high Check mains voltage

U

Flying restart fault Controller was unable to synchronize with

Faulty auto-TRIP reset More than 8 errors in 10 minutes Depends on the error

Loss of 4-20 mA

reference

Single phase fault A mains phase has been lost Check mains voltage

(1) The drive can only be restarted if the error message has been reset; see c70

calibration before setting C86...C91

Excessive capacitive charging

current of the motor cable

Acceleration time (C12, c01) too short • Increase acceleration time

Defective motor cable Check wiring

Internal fault in motor Check motor

Frequent and long overload Check controller selection

Excessive capacitive charging

current of the motor cable

Motor is thermally overloaded, due to:

• impermissable continuous current

• frequent or too long acceleration

processes

vector mode (C14 = 4, 5)

Controller too hot inside • Reduce controller load

Excessively short deceleration time or

motor in generator mode

Earth leakage on the motor side Check motor/motor cable

motor during restart attempt

4-20 mA signal (terminal 8I) is below 2

mA (C34 = 5)

Must set C86...C91 before performing

motor calibration (see c48)

motor cable

Use shorter motor cables with lower

charging current

• Check controller selection

Use shorter motor cables with lower

charging current

• Check controller selection

• Check setting of c20

• Motor must be connected in vector

mode

• Check motor/motor cable

• Improve cooling

Increase deceleration time or use

dynamic braking option

(separate motor from controller)

Check motor/load

Check signal/signal wire

(1)

22

ENGLISH

Page 24

Inhalt

Info zu diesen Anweisungen ......................................................2

1 Sicherheitsinformationen ....................................................3

1.1 In diesen Anweisungen verwendete Piktogramme ..................................4

2 Technische Daten .................................................................5

2.1 Normen und Anwendungsbedingungen ..................................................5

2.2 Bemessungsdaten ....................................................................................6

3 Installation ............................................................................7

3.1 Mechanische Installation ..........................................................................7

3.1.1 Abmessungen und Montage ....................................................................7

3.2 Elektroinstallation ......................................................................................8

3.2.1 Installation gemäß EMV-Richtlinien ...........................................................8

3.2.2 Sicherungen/Leitungsquerschnitte ..........................................................8

3.2.3 Schaltplan .................................................................................................9

3.2.4 Steuerungsklemmen ...............................................................................10

4 Inbetriebnahme ...................................................................11

4.1 Parametrierung .......................................................................................11

4.2 Elektronisches Programmiermodul (EPM) ..............................................11

4.3 Parametermenü ......................................................................................12

4.4 Vektorbetrieb ..........................................................................................20

4.4.1 Drehzahl- und Drehmomentregelung im Vektorbetrieb ..........................20

4.4.2 Erweiterter U/f-Betrieb ............................................................................20

5 Fehlersuche und -behebung .............................................21

DEUTSCH

1

Page 25

Info zu diesen Anweisungen

Diese Dokumentation gilt für den vektorgeregelten Frequenzumrichter Tmd. Sie beinhaltet wichtige

technische Daten und beschreibt die Installation, die Inbetriebnahme sowie den Betrieb.

Diese Anweisungen gelten ausschließlich für Frequenzumrichter Tmd mit der Softwareversion 11 (siehe

Typenschild des Antriebs).

Bitte lesen Sie vor der Inbetriebnahme die Anweisungen.

A B C D E F

For detailed information refer to

instruction manual TD03

004605460364930305

ETMD152L4TXA000XXXX

Hardwarestand

E

Softwarestand

F

Tmd011

Made in USA

Approbationen

A

Typ

B

Type: ETMD152L4TXA

Id-No: 00000 000

IND CONT EQ

Input: Output:

3/PE

AC 400/480 V

4.8 / 4.0 A

50 / 60 Hz

Eingangsbemessungsdaten

C

Ausgangsbemessugsdaten

D

3/PE

AC 400/480 V

4.1 / 3.4 A

1.5 kW

0 - 240 Hz

Lieferumfang Wichtig

• 1 Frequenzumrichter Tmd Vector

control (ETMD...)

mit installiertem EPM (siehe Abschnitt

4.2)

• 1 Betriebsanleitung

© 2004 Lenze AG

Diese Dokumentation darf ohne ausdrückliche schriftliche Genehmigung der Lenze AG weder ganz noch auszugsweise

kopiert oder Dritten zur Verfügung gestellt werden.

Alle in dieser Dokumentation enthaltenen Informationen wurden sorgfältig ausgewählt und auf Übereinstimmung mit der

beschriebenen Hardware und Software hin getestet. Fehler können jedoch nicht vollkommen ausgeschlossen werden.

Wir übernehmen keinerlei Verantwortung für eventuell auftretende Schäden. Erforderliche Korrekturen werden in folgende

Ausgaben dieser Dokumentation aufgenommen.

Prüfen Sie unmittelbar nach Erhalt der Lieferung, ob alle gelieferten Objekte den Angaben auf den beiliegenden Unterlagen entsprechen. Lenze haftet nicht für im Nachhinein gemeldete Mängel.

Melden Sie

• erkennbare Transportschäden umgehend dem

Transportunternehmen.

• erkennbare Mängel/unvollständige Lieferungen umgehend

Ihrem Lenze-Vertreter.

2

DEUTSCH

Page 26

Sicherheitsinformationen

1 Sicherheitsinformationen

Allgemeine Informationen

Einige Bauteile in Lenze-Reglern (Frequenzumrichter, Servoumrichter, DC-Steuerungen) können

stromführend sein, sich bewegen oder rotieren. Einige Oberflächen können heiß werden.

Unbefugtes Entfernen der erforderlichen Abdeckung, unsachgemäße Verwendung und nicht

vorschriftsmäßige Installation oder Bedienung können schwere Personen- oder Sachschäden

verursachen.

Sämtliche Tätigkeiten bei Transport, Installation und Inbetriebnahme sowie Wartungsarbeiten

müssen von qualifiziertem und geschultem Fachpersonal durchgeführt werden (IEC 364 und

CENELEC HD 384 oder DIN VDE 0100 und IEC-Report 664 oder DIN VDE 0110 sowie nationale

Unfallverhütungsvorschriften müssen beachtet werden).

Gemäß diesen grundlegenden Sicherheitsinformationen handelt es sich bei qualifiziertem und

geschultem Fachpersonal um Personen, die mit der Installation, der Montage, der Inbetriebnahme und

dem Betrieb des Produkts vertraut sind und die über die für ihre Tätigkeit erforderlichen Qualifikationen

verfügen.

Anwendung wie vorgeschrieben

Antriebsregler sind Bauteile, die für die Installation in elektrischen Systemen oder Maschinen vorgesehen

sind. Sie dürfen nicht als separate Geräte verwendet werden. Sie sind ausschließlich für professionelle

und kommerzielle Zwecke gemäß EN 61000-3-2 gedacht. Die Dokumentation enthält Informationen zur

Einhaltung der Norm EN 61000-3-2.

Bei der Installation der Antriebsregler in Maschinen ist die Inbetriebnahme (d. h. der Start des Betriebs

wie vorgeschrieben) untersagt, bis nachgewiesen wurde, dass die Maschine den Bestimmungen

der EG-Richtlinie 98/37/EG (Maschinenrichtlinie) entspricht und die harmonisierte Norm EN 60204

eingehalten wird.

Die Inbetriebnahme (d. h. der Start des Betriebs wie vorgeschrieben) ist nur dann zulässig, wenn die

EMV-Richtlinie 2004/108/EWG eingehalten wird.

Die Antriebsregler genügen den Anforderungen der Niederspannungsrichtlinie 2006/95/EWG. Für die

Regler gelten die harmonisierten Normen der Serie EN 61800-5-1 / DIN VDE 0160.

Hinweis: Die Verfügbarkeit von Reglern ist gemäß Norm EN 61800-3 eingeschränkt. Diese Produkte

können in Wohngebieten Funkstörungen verursachen. In diesem Fall sind eventuell besondere

Vorkehrungen zu treffen.

Installation

Sorgen Sie für sachgemäßen Umgang und vermeiden Sie übermäßige mechanische Beanspruchung.

Vermeiden Sie ein Verbiegen von Bauteilen und das Ändern von Isolationsabständen beim Transport

oder dem Umgang mit der Einheit. Berühren Sie keine elektronischen Bauteile und Kontakte.

Regler enthalten elektrostatisch empfindliche Bauteile, die bei unsachgemäßem Umgang leicht beschädigt

werden können. Beschädigen oder zerstören Sie keine elektrischen Bauteile, da dadurch Ihre Gesundheit

gefährdet werden könnte!

Elektrische Anschlüsse

Wenn Arbeiten an stromführenden Antriebsreglern durchgeführt werden, müssen die geltenden nationalen

Unfallverhütungsvorschriften (z. B. VBG 4) eingehalten werden.

Die Elektroinstallation muss im Sinne der geltenden Bestimmungen (z. B. Leitungsquerschnitte,

Sicherungen, PE-Anschlüsse) durchgeführt werden. Zusätzliche Informationen können der

Dokumentation entnommen werden.

Die Dokumentation enthält Informationen über die Installation gemäß den EMV-Richtlinien

(Abschirmung, Erdung, Filter und Leitungen). Diese Hinweise gelten auch für mit dem CE-Zeichen

gekennzeichnete Regler.

Der Hersteller des Systems oder der Maschine ist für die Einhaltung der erforderlichen Grenzwerte

gemäß den EMV-Richtlinien verantwortlich.

DEUTSCH

3

Page 27

SicherheitsinformationenSicherheitsinformationen

Betrieb

Systeme mit Reglern müssen mit zusätzlichen Überwa chungs- und Schutzvorr ichtungen

ausgerüstet werden, die den geltenden Normen (z. B. Normen für technische Einrichtungen,

Unfallverhütungsvorschriften usw.) entsprechen. Der Regler darf wie in der Dokumentation beschrieben

für Ihre Anwendung angepasst werden.

GEFAHR!

• Nachdem die Stromversorgung des Reglers unterbrochen wurde, dürfen

stromführende Bauteile und Netzverbindungen nicht sofort berührt werden,

da Kondensatoren noch geladen sein können. Beachten Sie hierzu die

entsprechenden Hinweise auf dem Regler.

• Schalten Sie den Regler nicht öfter als einmal alle drei Minuten ein und wieder

aus.

• Schließen Sie beim Betrieb alle Schutzabdeckungen und -türen.

Hinweis für UL-zugelassene Systeme mit integrierten Reglern

UL-Warnungen sind Hinweise, die für UL-Systeme gelten. Die Dokumentation enthält spezielle Informationen

über UL.

• Geeignet für die Anwendung in Stromkreisen mit maximal 5000 A effektiv

Dauerkurzschlussstrom und maximal 240 V (240 V-Geräte) bzw. maximal 500 V

(400/500 V-Geräte) Betriebsspannung.

WARNUNG!

1.1 In diesen Anweisungen verwendete Piktogramme

• Verwenden Sie ausschließlich minimale 75 °C-Kupferdraht.

• Vorgesehen für Umgebungen mit Verunreinigungsgrad 2.

Piktogramm Signalwort Bedeutung Folgen bei Missachtung

GEFAHR!

WARNUNG!

Hinweis

4

Gefar von Personenschäden

durch gefährliche elektriche

Spannung

Mögliche drohende

Personenschäden

Mögliche Sachschäden

Nützlicher Tipp: Das Befolgen

dieser Tipps vereinfacht den

Umgang mit dem Antrieb.

DEUTSCH

Hinweis auf eine unmittelbar

drohende Gefahr, die den Tod

oder schwere Verletzungen

zur Folge haben kann, wenn

nicht die entsprechenden Maßnahmen getroffen werden.

Tod oder Verletzungen

Schäden am Antriebssystem

oder seiner Umgebung

Page 28

Technische Daten

2 Technische Daten

2.1 Normen und Anwendungsbedingungen

Konformität

Zulassungen

Max. zulässige Motorleitungslänge

Phasenabweichung

Eingangsspannung

Feuchtigkeit

Ausgangsfrequenz

Umgebungsbedingungen

Temperaturbereich

Installationshöhe

Vibrationsfestigkeit

Ableitstrom

Schutzart durch Gehäuse (EN 60529)

Schutzmaßnahmen gegen

Betrieb am öffentlichen

Versorgungsnetz

(Einschränkung harmonischer

Ströme gemäß EN 61000-3-2)

(1) Zur Einhaltung der EMV-Richtlinien können die zulässigen Leitungslängen geändert werden.

(2) Die beschriebenen zusätzlichen Maßnahmen stellen lediglich sicher, dass die Regler den Anforderungen gemäß EN 61000-3-2

entsprechen. Der Hersteller der Maschine/des Systems ist verantwortlich für die Einhaltung der für die Maschine/das System

geltenden Anforderungen!

CE Niedrigspannungsrichtlinie (2006/95/EWG)

UL 508C Underwriters Laboratories - Power Conversion Equipment

Geschirmt: 50 m (niedrige Kapazität)

(1)

Ungeschirmt: 100 m

< 2%

< 95% (ohne Betauung)

0...240 Hz

Klasse 3K3 nach EN 50178

Transport -25 … +70 °C

Lagerung -20 … +70 °C

Betrieb

0 … 4000 m üNN (über 1000 m üNN Ausgangsbemessungsstrom um 5 %/1000

m reduzieren)

Beschleunigungsfest bis 0,7 g

> 3,5 mA gegen PE

IP 20

Kurzschluss, Erdschluss, Überspannung, Abwürgen des Motors, Überlastung

des Motors

Gesamtleistung

an Hauptver-

sorgung

< 0,5 kW mit Netzdrossel

0,5 … 1 kW mit aktivem Filter (in Vorbereitung)

> 1 kW ohne zusätzliche Maßnahmen

0 … +55 °C (über +40 °C Ausgangsbemessungsstrom um

2,5 %/°C

Einhaltung der Anforderungen

(2)

DEUTSCH

5

Page 29

Technische Daten

2.2 Bemessungsdaten

Typ

ETMD371L2YXA

ETMD551L2YXA

ETMD751L2YXA

ETMD112L2YXA

ETMD152L2YXA

ETMD222L2YXA

ETMD751L2TXA

ETMD112L2TXA

ETMD152L2TXA

ETMD222L2TXA

ETMD402L2TXA

ETMD552L2TXA

ETMD752L2TXA

ETMD371L4TXA

ETMD751L4TXA

ETMD112L4TXA

ETMD152L4TXA

ETMD222L4TXA

ETMD302L4TXA

ETMD402L4TXA

ETMD552L4TXA

ETMD752L4TXA

(1) Für Netznennspannung und Trägerfrequenzen von 4, 6 und 8 kHz

(2) Für Netznennspannung und eine Trägerfrequenz von 10 kHz

(3) Die maximale Stromstärke ist eine Funktion der Einstellung c73 (Auswahl der Eingangsspannung).

Leistung

[kW]

0,37

0,55 6,0 3,9 3,0 2,8 4,5 4,2

0,75 9,2 5,1 4,2 3,9 6,3 5,9

1,1 12,0 6,9 6,0 5,5 9,0 8,3

1,5 12,9 7,9 7,0 6,4 10,5 9,6

2,2 17,1 11,0 9,6 8,8 14,4 13,2

0,75

1,1 6,9 6,0 5,5 9,0 8,3

1,5 7,9 7,0 6,4 10,5 9,6

2,2 11,0 9,6 8,8 14,4 13,2

4,0 17,1 15,2 14,0 23 21

5,5 25 22 20 33 30

7,5 32 28 26 42 39

0,37

0,75 3,0 2,5 2,5 2,1 2,3 1,9 3,8 3,2 3,5 2,9

1,1 4,3 3,6 3,6 3,0 3,3 2,8 5,4 4,5 5,0 4,2

1,5 4,8 4,0 4,1 3,4 3,8 3,1 6,2 5,1 5,7 4,7

2,2 6,4 5,4 5,8 4,8 5,3 4,4 8,7 7,2 8,0 6,6

3,0 8,3 7,0 7,6 6,3 7,0 5,8 11,4 9,5 10,5 8,7

4,0 10,6 8,8 9,4 7,8 8,6 7,2 14,1 11,7 12,9 10,8

5,5 14,2 12,4 12,6 11,0 11,6 10,1 18,9 16,5 17,4 15,2

7,5 18,1 15,8 16,1 14,0 14,8 12,9 24 21 22 19,4

Hauptversorgungsnetz Ausgangsstrom

Spannung, Frequenz

1/N/PE 230 V

ODER

3/PE 230 V

(180 V -0%…264 V +0%)

50/60 Hz

(48 Hz -0%…62 Hz +0%)

3/PE 230 V

(180 V -0%…264 V +0%)

50/60 Hz

(48 Hz -0%…62 Hz +0%)

3/PE 400/480 V

(320 V -0%…528 V +0%)

50/60 Hz

(48 Hz -0%…62 Hz +0%)

Strom

(3)

[A]

1~ 3~ 3~ 3~ 3~ 3~

4,7 2,7 2,4 2,2 3,6 3,3

5,1 4,2 3,9 6,3 5,9

400V 480V 400V 480V 400V 480V 400V 480V 400V 480V

1,6 1,4 1,3 1,1 1,2 1,0 2,0 1,7 1,8 1,5

[A]

I

N

(1)

[A]

(3)

I

für 60 s

[A]

max

(1)

[A]

(2)

(2)

6

DEUTSCH

Page 30

3 Installation

3.1 Mechanische Installation

3.1.1 Abmessungen und Montage

a

Typ

ETMD371L2YXA 93 84 146 128 17 100 15 50 0,6

ETMD551L2YXA, ETMD751L2_XA

ETMD112L2TXA 93 84 146 128 17 146 15 50 1,1

ETMD112L2YXA

ETMD371L4TXA...ETMD112L4TXA

ETMD152L2_XA

ETMD152L4TXA

ETMD222L2_XA

ETMD222L4TXA...ETMD402L4TXA

ETMD552L2TXA, ETMD752L2TXA

ETMD552L4TXA, ETMD752L4TXA

(1) „_“ = Y oder T; die Abmessungen sind für beide Modelle identisch.

(1)

(1)

, ETMD402L2TXA

(1)

a1

[mm]

[mm]b [mm]b1 [mm]b2 [mm]c [mm]

93 84 146 128 17 120 15 50 0,9

114 105 146 128 17 133 15 50 1,4

114 105 146 128 17 171 15 50 1,9

114 105 146 100 17 171 15 50 2,0

146 137 197 140 17 182 30 100 3,4

Installation

Tmd002

s1

[mm]s2 [mm]m [kg]

WARNUNG!

Die Antriebe dürfen nicht an Orten installiert werden, an denen sie ungünstigen

Umgebungsbedingungen ausgesetzt sind. Hierzu gehören: brennbare, ölige oder

schädliche Dämpfe oder Staub; übermäßige Feuchtigkeit; extreme Vibrationen oder

Temperaturen. Für zusätzliche Informationen wenden Sie sich bitte direkt an Lenze.

DEUTSCH

7

Page 31

Installation

3.2 Elektroinstallation

3.2.1 Installation gemäß EMV-Richtlinien

EMV

Einhaltung von EN 61800-3/A11

Geräuschemission

Einhaltung der Grenzwerte Klasse A gemäß EN 55011 bei Installation in einem

Schaltschrank mit entsprechendem Unterbau-Filter und Motorleitungslängen unter 10

m.

Abschirmungsklemmen

A

Steuerleitung

B

Motorleitung mit niedriger Kapazität

C

(Kern/Kern < 75 pF/m, Kern/Abschirmung < 150 pF/m)

Elektrisch leitende Montageplatte

D

Filter

E

3.2.2 Sicherungen/Leitungsquerschnitte

Installation gemäß EN 60204-1 Installation gemäß UL

Typ

ETMD371L2YXA, ETMD551L2YXA M10 A C10 A 1,5 10 A 14

ETMD751L2YXA M16 A C16 A 2,5 15 A 14

1/N/PE

ETMD112L2YXA M20 A C20 A 2,5 15 A 12

ETMD152L2YXA M25 A C25 A 2,5 20 A 12

ETMD222L2YXA M30 A C30 A 4,0 30 A 10

ETMD371L2YXA...ETMD112L2_XA

ETMD152L2_XA

ETMD222L2_XA

ETMD402L2TXA M25 A C25 A 4,0 25 A 10

ETMD552L2TXA M40 A C40 A 6,0 35 A 8

3/PE

ETMD752L2TXA M50 A C50 A 10 45 A 8

ETMD371L4TXA...ETMD222L4TXA M10 A C10 A 1,5 10 A 14

ETMD302L4TXA M16 A C16 A 1,5 12 A 14

ETMD402L4TXA M16 A C16 A 2,5 15 A 14

ETMD552L4TXA M20 A C20 A 2,5 20 A 12

ETMD752L4TXA M25 A C25 A 4,0 25 A 10

(1) Beachten Sie die geltenden örtlichen Vorschriften.

(2) FI-Schutzschalter für Impulsstrom oder Dauerstrom

(3) Schnelle Strombegrenzungssicherungen gemäß UL, Klasse CC oder T, 200.000 AIC erforderlich. Bussmann KTK-R, JJN, JJS, oder entspr.

(4) „_“ = Y oder T; die Bemessungsdaten sind für beide Modelle mit 3/PE-Eingang identisch.

(4)

(4)

(4)

Sicherungs-

Sicherung

automat

M10 A C10 A 1,5 10 A 14

M16 A C16 A 1,5 12 A 14

M16 A C16 A 2,5 15 A 12

(1)

L1, L2, L3, PE

[mm²]

Sicherung

(3)

B

E

C

D

Tmd005

FI-

Schutz-

schalter

> 30 mA

A

L1, L2,

L3, PE

[AWG]

2)

8

DEUTSCH

Page 32

Installation

Beachten Sie bei der Verwendung von FI-Schutzschaltern Folgendes:

• Der FI-Schutzschalter darf nur zwischen dem Hauptversorgungsnetz und dem Regler installiert

werden.

• Der FI-Schutzschalter kann folgendermaßen ausgelöst werden:

- durch kapazitive Ableitströme zwischen den Leitungsabschirmungen im Betrieb (besonders bei langen,

abgeschirmten Motorleitungen),

- durch gleichzeitiges Anschließen mehrerer Regler an das Hauptversorgungsnetz,

- durch EMV-Filter.

3.2.3 Schaltplan

1/N/PE 180V 0% 264V + 0 %

48 Hz 62 Hz

L1

L2

L3

N

PE

L2/N

L1

0 2 Nm/2 lb in

6 mm/0 24 in

< 1mm²/AWG 26 16

8U7

0 … +5 V

0 … +10 V

-10 … +10 V

2/PE 180V 0% 264V + 0 %

AIN

COM

8U

28 7

L1

L2

L3

N

PE

+10 V

9

A+ A1

48 Hz 62 Hz

L2/N

L1

COM

+12 V

+15 V

+15 V

2020

E1 E2 E3 71627 72

3/PE 180V 0% 264V + 0 %

48 Hz 62 Hz

L1

L2

L3

N

PE

L3

L1 L2

COM

AIN

COM

E4 A2

8I

3/PE 320V 0 % 528V + 0 %

L1

L2

L3

N

PE

TXB

TXA

48 Hz 62 Hz

L1 L2

U V W

L3

0 5 Nm/4 5 lb in

6 mm/0 24 in

PES

1k …10k

7

_

+12 V DC - 0 %

…

+30 V DC + 0 %

DIGOUT

28

E3 E4

E1 E2

+

DIGOUT

0 … 20 mA

4 … 20 mA

AOUT

PES

PE

M

PES

3~

PE

PES

1 2 Nm/10 lb in

9 mm/0 35 in

GEFAHR!

• Gefahr durch Stromschlag! Die Potenziale im Stromkreis liegen bis zu 480

VAC über dem Erdungspotenzial. Die Kondensatoren können auch nach

dem Abschalten der Netzspannung noch geladen sein. Schalten Sie die

Stromversorgung ab und warten Sie, bis die Spannung zwischen B+ und B- 0

VDC beträgt, bevor Sie mit den Wartungsarbeiten am Antrieb beginnen.

• Schließen Sie die Hauptstromversorgung nicht an die Ausgänge (U, V, W) an!

Dies würde zu schweren Schäden am Antrieb führen.

• Ändern Sie die Hauptstromversorgung nicht mehr als einmal alle drei Minuten.

Dies führt zu Schäden am Antrieb.

Tmd003

DEUTSCH

9

Page 33

Installation

3.2.4 Steuerungsklemmen

Klemme

Schutz vor Berührung

Daten für Steuerungsanschlüsse (fett = Lenze-Einstellung)

28

Digitaleingang, Start/Stopp

7

Referenz (allgemein)

Analogeingang

8U

0 … 10 V (änderbar unter C34)

9

Interne DC-Versorgung für Sollwertpotentiometer +10 V, max. 10 mA

A+

Interne DC-Versorgung für externe Geräte +12 V, max. 50 mA

A1

Digitalausgang, kongurierbar über c17 DC 24 V/50 mA

20

Interne DC-Versorgung für Digitalausgänge +15 V, max. 20 mA

20

Digitaleingang, konfigurierbar über CE1

E1

Aktivierung fester Sollwert 1 (JOG1)

Digitaleingang, konfigurierbar über CE2

E2

Aktivierung fester Sollwert 2 (JOG2)

Digitaleingang, konfigurierbar über CE3

E3

Aktivierung Gleichstrombremse (DCB)

Digitaler Eingang, konfigurierbar über CE4

E4

Rotationsrichtung

A2

Digitalausgang, konfigurierbar über c18 DC 24 V / 50 mA

8I

Analogeingang (änderbar unter C34) Eingangswiderstand: 150 Ω

7

Referenz (allgemein)

62

Analogausgang, konfigurierbar über c08 ... c11 0 ... 10 V oder 2 ... 10 V, max. 20 mA

71

RS-485 serieller Kommunikationseingang RXB/TXB (B+)

72

RS-485 serieller Kommunikationseingang RXA/TXA (A-)

LOW = Stopp; HIGH = Betrieb aktivieren

Eingangswiderstand = 3,3 kΩ

Eingangswiderstand: >40 kΩ

HIGH = JOG1 aktiv

HIGH = JOG2 aktiv

HIGH = Gleichstrombremse aktiv

LOW = Rechtslauf

HIGH = Linkslauf

LOW = 0 … +3 V, HIGH = +12 … +30 V

Beide HIGH = JOG3 aktiv

• Alle Klemmen sind mit einer einfachen Isolierung ausgestattet (einfacher Isolierungsabstand).

• Der Schutz vor Berührung kann nur durch zusätzliche Maßnahmen sichergestellt werden

(d. h. durch doppelte Isolierung).

= 3,3 kΩ

i

R

10

DEUTSCH

Page 34

4 Inbetriebnahme

4.1 Parametrierung

Status-/Störungsmeldungen Parameter ändern

Hinweis

Falls die Passwortfunktion aktiviert ist, muss das Passwort unter C00 eingegeben

werden, um auf die Parameter zugreifen zu können. C00 wird nicht angezeigt,

wenn die Passwortfunktion deaktiviert ist (siehe C94).

Inbetriebnahme

Tmd004

4.2 Elektronisches Programmiermodul (EPM)

Das EPM enthält den Speicher des Reglers. Bei jeder Parameteränderung werden

die neuen Werte im EPM gespeichert. Es kann zwar ausgebaut werden, muss jedoch

für den Betrieb des Reglers installiert sein (bei fehlendem EPM wird eine -Störung

Tmd007

Für das EPM ist optional ein Programmiergerät (Modell ESMD01EP; Handbuch EP03) erhältlich. Dieses

Gerät verfügt über folgende Funktionen: Programmieren des Reglers ohne Stromversorgung; Festlegen

der Einstellungen des Maschinenherstellers als Standardeinstellungen; schnelles Kopieren der im EPM

gespeicherten Werte, wenn für mehrere Regler identische Werte erforderlich sind. Darüber hinaus kann das

EPM bis zu 60 benutzerdefinierte Parameterdateien speichern, um eine noch schnellere Programmierung

des Reglers zu ermöglichen.

ausgelöst). Beim Versand des Reglers ist das EPM mit einem Schutzband versehen,

das nach der Installation entfernt werden kann.

DEUTSCH

11

Page 35

Inbetriebnahme

4.3 Parametermenü

Code Mögliche Einstellungen

Nr. Benennung Lenze Auswahl

Passworteingabe 0 0 999 Nur bei aktiviertem Passwort sichtbar

Sollwert- und

1

Steuerungsquelle

Lenze-Einstellungen

2

laden

0 Sollwertquelle: Steuerungskonfiguration:

0 Analogeingang

(Klemme 8U/8I; siehe C34)

1 Code c40 / Code C47

2 Analogeingang (Klemme 8U/8I; siehe

C34)

3 LECOM Steuerung = LECOM

4 Analogeingang

(Klemme 8U/8I; siehe C34)

5 Code c40 / Code C47

6 Analogeingang

(Klemme 8U/8I; siehe C34)

7 Code c40 / Code C47

8 Analogeingang

(Klemme 8U/8I; siehe C34)

9 Code c40 / Code C47

10 Analogeingang

(Klemme 8U/8I; siehe C34)

11 Code c40 / Code C47

Hinweis

• Wenn C01 = 1, 5, 7, 9 oder 11 und C14 = 0 ... 4, 6, 7, dann c40 für Drehzahl-

Sollwertvorgabe verwenden

• Wenn C01 = 1, 5, 7, 9 oder 11 und C14 = 5, dann C47 für Drehmoment-

Sollwertvorgabe verwenden

• Wenn C01 = LECOM (3), dann Drehzahlbefehl an C46 oder Drehmomentbefehl an C47

0 Keine Aktion/Laden abgeschlossen

1 Lenze-Einstellungen für 50 Hz laden

2 Lenze-Einstellungen für 60 Hz laden

3 OEM-Einstellungen laden

(falls verfügbar)

WARNUNG!

C02 = 1...3 überschreibt sämtliche Einstellungen! TRIP-Schaltkreis wird eventuell

deaktiviert! Parameter CE1…CE4 prüfen.

(siehe C94).

Steuerung = Klemmen

Programmierung = Keypad

Überwachung = LECOM

Steuerung = Klemmen

Programmierung = LECOM/Keypad

Überwachung = LECOM

Programmierung = LECOM/Keypad

Überwachung = LECOM

Steuerung = Klemmen

Programmierung = Remote-Keypad

Überwachung = Remote-Keypad

Steuerung = Remote-Keypad

Programmierung = Remote-Keypad

Überwachung = Remote-Keypad

Steuerung = Klemmen

Programmierung = Modbus/Keypad

Überwachung = Modbus

Steuerung = Modbus

Programmierung = Modbus/Keypad

Überwachung = Modbus

• C02 = 1, 2, 3 nur bei

möglich

• C02 = 2 : C11, C15 and C89 = 60 Hz

and C87 = 1750 rpm

WICHTIG

oder1

12

DEUTSCH

Page 36

Inbetriebnahme

Code Mögliche Einstellungen

Nr. Benennung Lenze Auswahl

C

Konfiguration Digitaleingang E1

Konfiguration Digitaleingang E2

Konfiguration Digitaleingang E3

Konfiguration Digitaleingang E4

1 1 Aktivierung fester Sollwert 1 (JOG1)

2 Aktivierung fester Sollwert 2 (JOG2)

3 Gleichstrombremse (DCB) siehe auch C36

4 Drehrichtung LOW = Rechtslauf

2

5 Quickstop Gesteuerter Ablauf bis Stillstand, LOW aktiv;

6 Rechtslauf

7 Linkslauf

3

8 UP (Sollwert hochlaufen)

9 DOWN (Sollwert ablaufen)

10 TRIP set

4

11 TRIP reset siehe auch c70

12 Hochlauf/Ablauf 2 siehe c01 und c03

Aktivierung JOG3: Beide Klemmen = HIGH

HIGH = Linkslauf

Ablauframpe unter C13 oder c03 festlegen

Rechtslauf = LOW und Linkslauf = LOW:

Quickstop; Drahtbruchschutz

UP = LOW und DOWN = LOW: Quickstop;

aktuelle NC-Kontakte verwenden

LOW aktiv, löst

Stillstand aus)

HINWEIS: Der Thermokontakt (Öffner) des

Motors kann zum Auslösen dieser Eingabe

verwendet werden

WICHTIG

aus (Motor läuft in

Hinweis

Unter folgenden Bedingungen tritt ein -Fehler auf:

• Einstellungen E1 … E4 werden zweimal verwendet (jede der Einstellungen kann nur

einmal verwendet werden)

• Für einen Eingang ist UP festgelegt, für einen anderen aber nicht DOWN (oder

Netzwerkadresse 1 1 247 Jedem Regler im Netzwerk muss eine

C

Minimale

C

Ausgangsfrequenz

Maximale

Ausgangsfrequenz

Hochlaufzeit 1 5,0 0,0 {s} 999 • C12 = Frequenzänderung 0 Hz ... C11

Ablaufzeit 1 5,0 0,0 {s} 999

umgekehrt)

eindeutige Busadresse zugewiesen sein.

0,0 0,0 {Hz} 240 • Ausgangsfrequenz bei 0% des analogen

50,0 7,5 {Hz} 240 • Ausgangsfrequenz bei 100 % des

WARNUNG!

Wenden Sie sich an den Hersteller des Motors/der Maschine, bevor Sie den Antrieb

mit höheren Frequenzen als der Nennfrequenz betreiben. Überdrehzahlen können zu

Sachschäden oder Verletzungen von Personen führen.

Sollwerts

• C10 nicht aktiv für feste Sollwerte oder

Sollwertvorgabe über c40

analogen Sollwerts

• C11 wird nie überschritten

• C13 = Frequenzänderung C11 ... 0 Hz

• Für Hochlauf/Ablauf S-Rampe c82

einstellen

DEUTSCH

13

Page 37

Inbetriebnahme

Code Mögliche Einstellungen

Nr. Benennung Lenze Auswahl

Betriebsart

U/f-Nennfrequenz

U

-Anhebung

min

(optimiertes

Drehmomentverhalten)

Frequenzschwelle

7

(Q

)

min

Schaltfrequenz

Schlupfkompensation

1

0 Lineare U/f Kennlinie mit

2

automatischer U

1 Quadratische U/f Kennlinie mit

automatischer U

2 Lineare U/f Kennlinie mit konstanter

Umin Anhebung

3 Quadratische Kennlinie mit konstanter

-Anhebung

U

min

4 Drehzahlregelung im Vektorbetrieb • Drehzahlregelung im Vektorbetrieb: für

5 Drehmomentregelung im Vektorbetrieb • Drehmomentregelung im Vektorbetrieb:

6 Erweiterte lineare U/f Kennlinie

mit automatischer U

7 Erweiterte lineare Kennlinie mit

konstanter U

Hinweis

• Einstellungen 4 ... 7 erfordern Motorabgleich über c48.

• Einstellungen 4 und 5 erfordern vor Abgleich exakte Einstellung von C86 ... C91.

• Einstellungen 6 und 7 erfordern vor Abgleich exakte Einstellung von C88 ... C90.

25,0 {Hz} 999

50,0

Stellen Sie für Standardanwendungen die

Nennfrequenz (Typenschild) des Motors ein.

0,0 {%} 40,0

C16 ist im Vektorbetrieb nicht aktiv (siehe

C14).

Einstellungen nach der Inbetriebnahme:

Den Motor im Leerlauf bei Schlupffrequenz

(ca. 5 Hz) betreiben, C16 erhöhen, bis

Motorstrom (C54) = 0,8 x Motornennstrom

0,0 {Hz} 240 Siehe c17 und c18, Auswahl 7

0,0

0 4 kHz • Höhere Schaltfrequenzen senken das

2

1 6 kHz

2 8 kHz

3 10 kHz

0,0 {%} 40,0

0,0

C21 ist im Vektorbetrieb nicht aktiv

(siehe C14).

min

min

-Anhebung

min

-Anhebung

-Anhebung

-Anhebung

min

WICHTIG

• Lineare Kennlinie: für

Standardanwendungen

• Quadratische Kennlinie: für Lüfter und

Pumpen mit quadratischer Lastkennlinie

• Automatische Anhebung: lastabhängige

Ausgangsspannung für verlustarmen

Betrieb

Anwendungen mit nur einem Antrieb,

für die ein höheres Anlaufmoment und

bessere Drehzahlregelung erforderlich

sind

für Anwendungen mit nur einem Antrieb,

für die unabhängig von der Drehzahl eine

Drehmomentregelung erforderlich sind

• Erweitert: für Anwendungen mit nur

einem oder mit mehreren Antrieben, für

die bessere Leistungswerte als unter

den Einstellungen 0…3 angegeben

erforderlich sind, die jedoch nicht im

Vektorbetrieb betrieben werden können

smd006

Motorengeräusch.