Page 1

EDS94TA10060xxxx

13277862

Ä.<o_ä

L-force Runtime Software

Software Manual

9400

Technology application "positioning sequence control"

L

Page 2

9400 Technology applications | Positioning sequence control

Overview of the technical documentation for Servo Drives 9400

Overview of the technical documentation for Servo Drives 9400

Project planning, selecting & ordering Legend:

9400 Hardware Manual Printed documentation

Catalogue / electronic catalogue (DSC - Drive Solution Catalogue) Online documentation

(PDF/Engineer online help)

Mounting & wiring Abbreviations used:

MA 9400 StateLine/HighLine BA Operating Instructions

MA for communication module KHB Communication Manual

MA for extension module MA Mounting Instructions

MA for safety module SW Software Manual

MA for accessories

MA for remote maintenance components

Parameter setting

BA keypad

SW for Lenze »Engineer« software

SW for controller (9400 StateLine/HighLine)

SW for regenerative power supply module

KHB for communication module

SW for extension module

SW for safety module

SW for Lenze technology application Í This documentation

SW 9400 function library

Configuring

SW for Lenze »Engineer« software

SW for controller (9400 HighLine)

KHB for communication module

SW for extension module

SW for safety module

SW for Lenze technology application Í This documentation

SW 9400 function library

Commissioning of the drive

Commissioning guide

SW for controller (9400 StateLine/HighLine)

Remote Maintenance Manual

Networking

KHB for communication medium used

2 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 3

9400 Technology applications | Positioning sequence control

Contents

Contents

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Conventions used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Definition of notes used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Brief description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Example: Positioning sequence control with networking via PROFIBUS. . . . . . . . . . . . . 11

4 Short setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Application example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Connection diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Step 1: Creating a project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Step 2: Parameterising the application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.6 Step 3: Parameterising the program flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6.1 Program step 1: Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6.2 Program step 2: Setting counter 1 to "0" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6.3 Program step 3: Positioning action 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6.4 Program step 4: Counting the sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.6.5 Program step 5: Setting the status output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.6.6 Program step 6: Positioning action 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6.7 Program step 7: Resetting the status output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.6.8 Program step 8: Going back to program step 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.7 Step 4: Parameterising the multiplexer for the digital outputs . . . . . . . . . . . . . . . . . . . . . 25

4.8 Step 5: Transferring the application to the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.9 Step 6: Controlling the application via terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

EDS94TA10060xxxx EN 1.2 - 03/2010 L 3

Page 4

9400 Technology applications | Positioning sequence control

Contents

5 Parameter setting & configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 Basic signal flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Basic settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2.1 Machine parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2.2 Traversing range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2.3 Position control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3 Program flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3.1 Overview of action types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.3.2 Action type "Homing". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3.3 Action type "Positioning". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3.4 Action type "Variable branching" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.5 Sequencer inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.6 Sequencer outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.3.7 Parameter setting of the program flow in the Engineer . . . . . . . . . . . . . . . . . . . . 42

5.3.8 Control of the sequence table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4 Profile data management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4.1 Profile parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4.2 Variable tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.4.3 Positioning modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.4.4 Positioning with final speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.4.5 Touch probe positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.4.6 "Teach" function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.5 Speed/acceleration override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.6 Following error monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.7 Manual jog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.8 Quick stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.9 Limiter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.10 Brake control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.11 Signal configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.11.1 Drive and motor interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.11.2 Output ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.12 Actual value and status signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.13 Application error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 5

9400 Technology applications | Positioning sequence control

Contents

5.14 Parameterisable function blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.14.1 ActualSpeedScaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.14.2 ApplicationError1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.14.3 ApplicationError2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.14.4 FollowingErrorScaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.14.5 HysteresisFollowingError1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.14.6 HysteresisFollowingError2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.14.7 L_PosPositionerTable1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.14.8 L_PosSequencer1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.14.9 L_SdSwitchPoint1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.14.10 LimitFollowingError1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.14.11 LimitFollowingError2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.14.12 MonitFollowError1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.14.13 MonitFollowError2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.14.14 PosStarted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.14.15 RestartPosTransition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Your opinion is important to us. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

EDS94TA10060xxxx EN 1.2 - 03/2010 L 5

Page 6

9400 Technology applications | Positioning sequence control

About this documentation

1 About this documentation

This documentation contains information about the technology application "Positioning

sequence control" for the Servo Drives 9400 series.

Note!

This documentation supplements the mounting instructions supplied with the

controller, the hardware manual and the software manual for the controller.

The Mounting Instructions contain safety information which must be observed!

The information in this documentation applies to:

Technology application Appl. ID Required runtime software licence

Positioning sequence control 100602103 Motion Control TopLevel or higher

The technology application can be used with the following controllers:

Product series Type designation From hardware

version

9400 Servo Drives E94AxHExxxx PD 1.35

From software

version

Target group

This documentation is directed at qualified personnel according to IEC 364.

Document history

Version Description

1.0 04/2007 TD05 First edition

1.1 10/2008 TD05 New subchapter "Parameterisable function blocks

1.2 03/2010 TD05 Error corrections & supplements

"

6 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 7

9400 Technology applications | Positioning sequence control

1.1 Conventions used

This documentation uses the following conventions to distinguish between different types

of information:

Type of information Writing Examples/notes

Numbers

Decimal separator Point The decimal point is always used.

Text

Program name » « The Lenze PC software »Engineer«...

Window pane Italics The Message window... / the Options dialog box...

Control element Bold The OK button... / The Copy command... / The

Sequence of menu

commands

Keyboard command <Bold> Use <F1> to open the Online Help.

Program listings Courier

Keyword Courier bold

About this documentation

Conventions used

Example: 1234.56

Properties tab... / The Name input field...

If the execution of a function requires several

commands, the individual commands are separated

by an arrow: Select File

If a command requires a combination of keys, a "+" is

placed between the key symbols: Use <Shift>+<ESC>

to...

IF var1 < var2 THEN

a = a + 1

END IF

Open to...

Hyperlink Underlined

Symbols

Page reference ( 7) Optically highlighted reference to another page. It is

Step-by-step instructions

Optically highlighted reference to another topic. It is

activated with a mouse click in this online

documentation.

activated with a mouse click in this online

documentation.

Step-by-step instructions are indicated by a

pictograph.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 7

Page 8

9400 Technology applications | Positioning sequence control

About this documentation

Definition of notes used

1.2 Definition of notes used

The following signal words and symbols are used in this documentation to indicate

dangers and important information:

Safety instructions

Layout of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and suggests how to avoid the danger)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of material damage

Indicates an impending danger that may lead to death or severe personal injury

if the corresponding measures are not taken.

Indicates an impending danger that may lead to death or severe personal injury

if the corresponding measures are not taken.

Indicates a potential danger that may lead to material damage if the

corresponding measures are not taken.

Application notes

Pictograph Signal word Meaning

Note! Important note for trouble-free operation

Tip! Useful tip for easy handling

Reference to another document

8 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 9

9400 Technology applications | Positioning sequence control

2 Brief description

The technology application "Positioning sequence control" enables the drive to execute

parameterisable travel profiles. The program sequence is defined by a sequence table.

Functions

Sequence control for several successive positioning steps with a break and stop

functions and different auxiliary functions (e. g. deriving, counting, waiting).

Positioning in different positioning modes

– Point-to-point positioning

– Touch probe positioning (residual path positioning)

– Profile chaining with velocity changeover (overchange)

Homing in different homing modes

Profile data management

– Support of S profiles (jerk limitation)

– Separate setting for acceleration and deceleration

– "Teach" function

Brief description

Speed/acceleration override

Path-dependent switching of outputs

Following error monitoring

Support of absolute value encoders

Support of the basic drive functions "Manual jog" and "Quick stop"

Monitoring of travel range limits with the basic drive function "Limiter"

Optional control of a holding brake with the basic drive function "Brake control"

Application range

Transport units

Rotary tables

Storage and retrieval units

Feed drives

Dosing machines

Hoists

Required license/delivery

License stage Motion Control TopLevel or higher required.

The technology application can be selected in the »Engineer« application catalog.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 9

Page 10

9400 Technology applications | Positioning sequence control

Introduction

3 Introduction

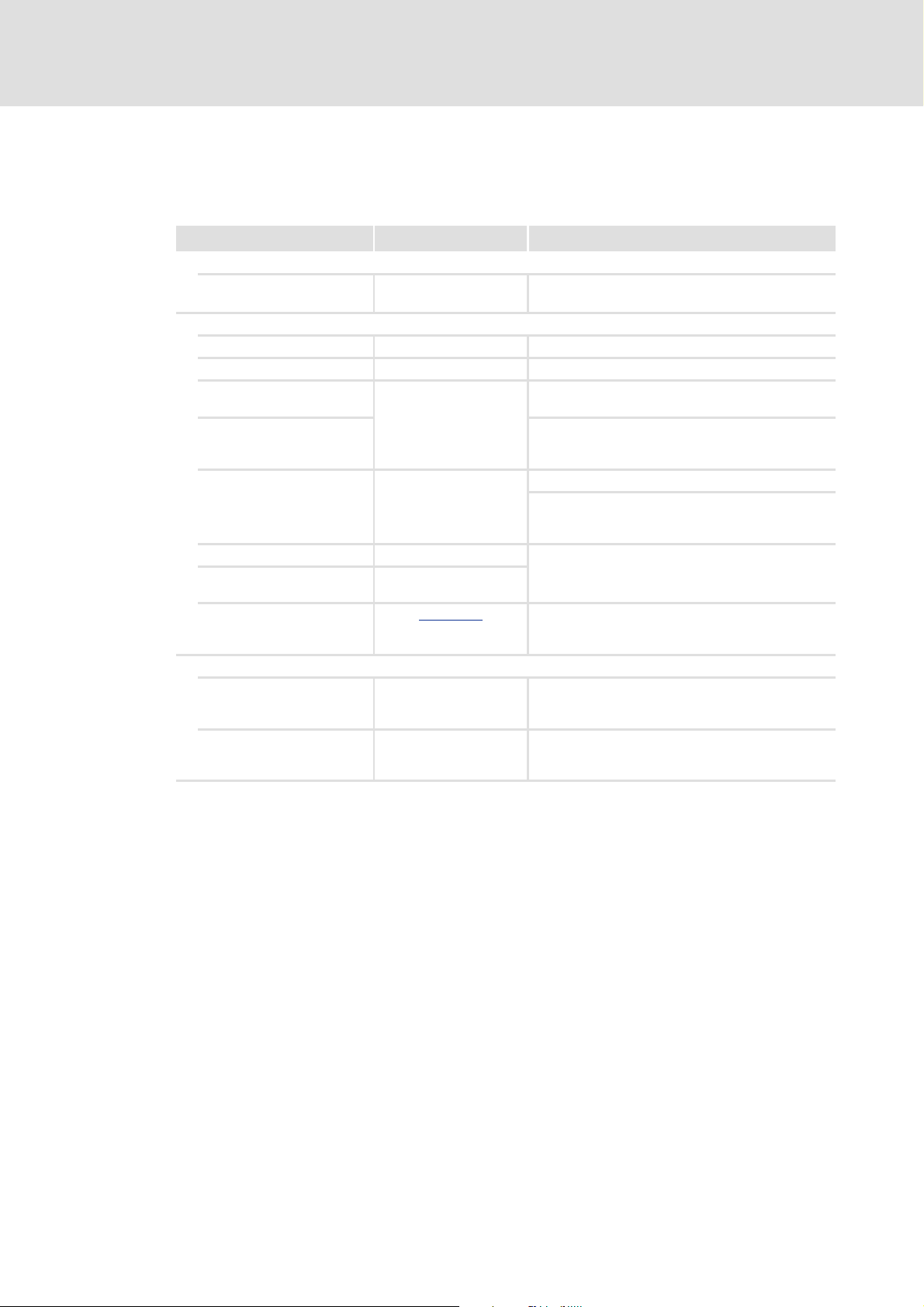

Positioning means to move a workpiece/tool or a piece of material from a starting

position n to a defined targeto.

For this purpose a travel profile is to be provided in the controller, for which at least the

following profile parameters are required:

v [m/s]

B

C D

Symbol Profile parameters

Position

A

Target position or path distance to be traversed.

Speed

B

Maximum speed with which the target is to be approached.

Acceleration

C

Selection of the change in speed by which acceleration is to be carried out maximally.

Deceleration

D

Selection of the change in speed by means of which deceleration to standstill is to be maximally effected

again.

A

t [s]

A positioning can consist of several profiles which are executed in a specified mode.

For a detailed explanation of the profile parameters, please see the section "Profile

parameters". ( 44)

10 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 11

9400 Technology applications | Positioning sequence control

Example: Positioning sequence control with networking via PROFIBUS

3.1 Example: Positioning sequence control with networking via PROFIBUS

Master control

Sequence control for machine (PLC)

PROFIBUS

Drive 1 Drive 2

Positioning sequence control for single drives Positioning sequence control for single drives

Introduction

Table positioning Table positioning

Firmware Firmware

Motion Control - basic drive functions:

• Positioning

•Homing

•Manual jog

•etc.

• Drive interface

• Motor interface

• Encoder evaluation

•I/O terminals

• Safety engineering

• Logbook

[3-1] Example: Positioning sequence control with networking via PROFIBUS

The positioning sequence control utilises the traversing blocks of the table positioning

and like this activates the basic function "Positioning" containing the profile

generation.

Here, the positioning sequence control only control the "own motor".

The sequence of the motor/tool/material control are defined in the positioning

sequence control.

Motion Control - basic drive functions:

• Positioning

•Homing

•Manual jog

•etc.

• Drive interface

•Motor interface

• Encoder evaluation

•I/O terminals

• Safety engineering

• Logbook

EDS94TA10060xxxx EN 1.2 - 03/2010 L 11

Page 12

9400 Technology applications | Positioning sequence control

Short setup

Application example

4Short setup

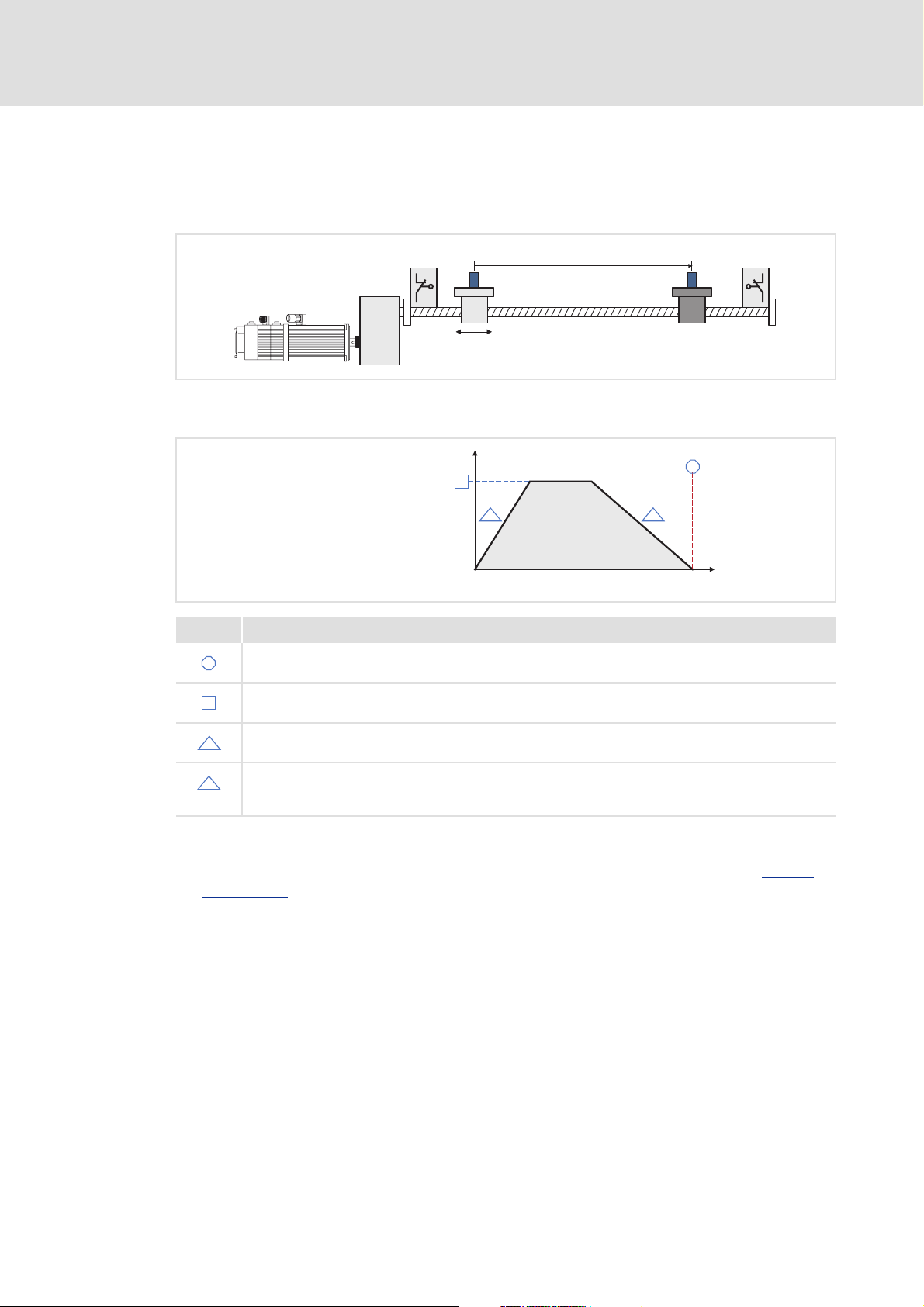

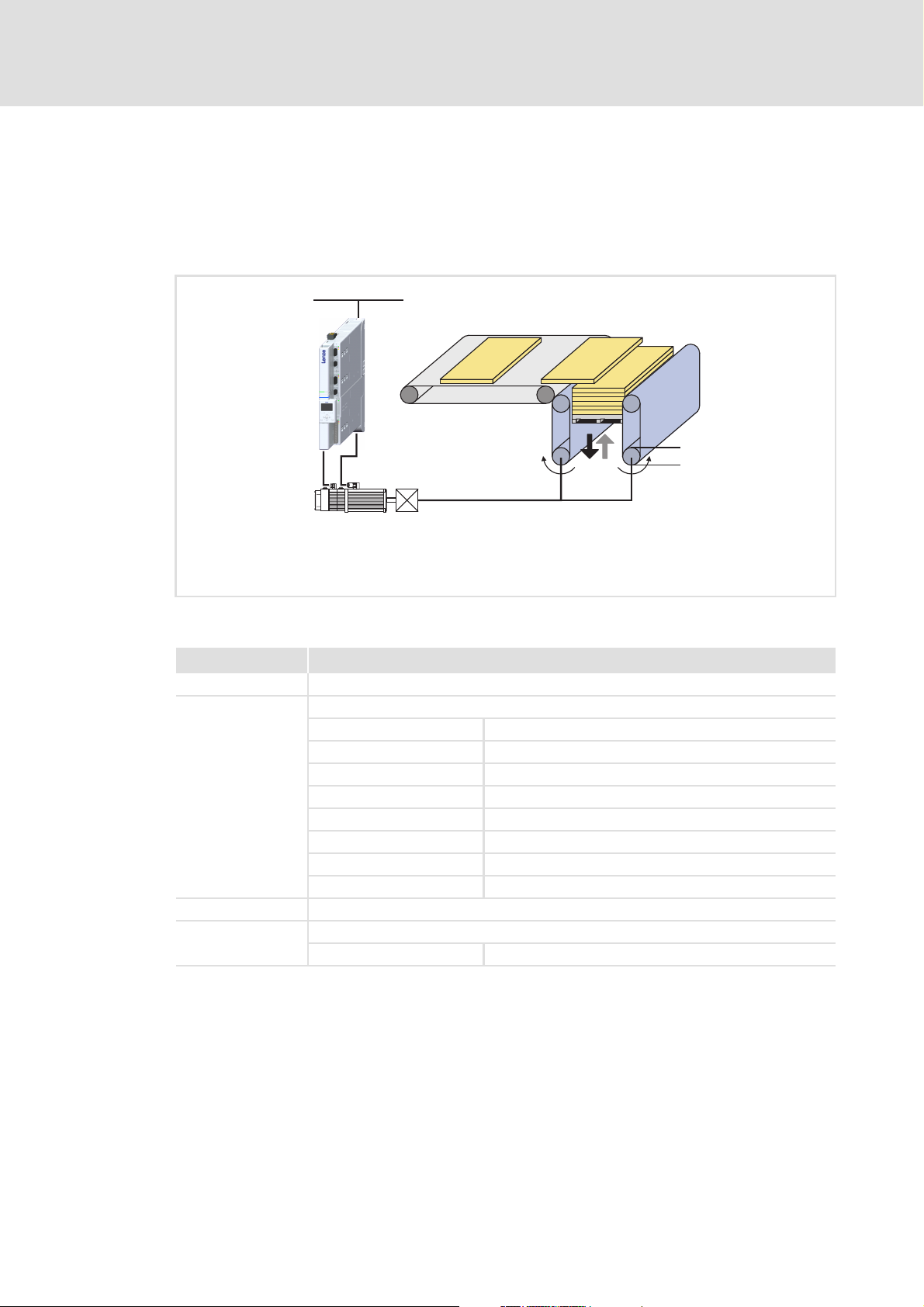

4.1 Application example

A sheet stacker is used as an application example for short setup:

3 x AC 400 V

i

1

d

1

N

= 1680 rpm

motor

i

= 12.612

1

d

= 80 mm

1

Feed constant = 250 mm/rev.

[4-1] Schematic diagram

Component Technical data

Controller 9400 SingleDrive HighLine with brake module

Motor MDFKA-090-22, 60

Type: Asynchronous servo motor

Connection: Y

Power factor: 0.8

Rated current: 8.5 A

Rated frequency: 60 Hz

Rated power: 3.8 kW

Rated speed: 1680 rpm

Rated voltage: 390 V

Brake 24 V DC

Gearbox GKS06

Gearbox factor: 12.612

12 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 13

9400 Technology applications | Positioning sequence control

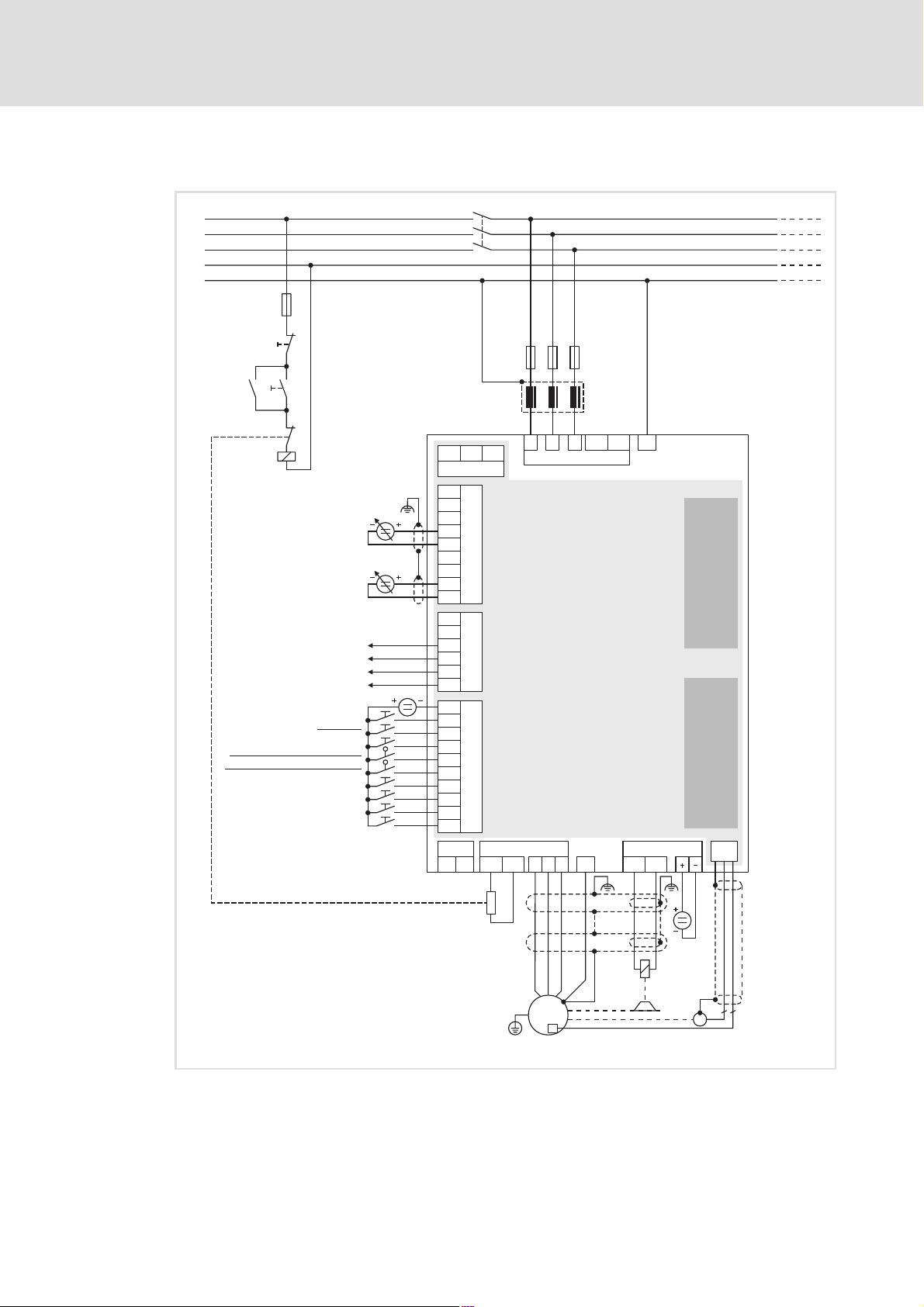

4.2 Connection diagram

Short setup

Connection diagram

L1

L2

L3

N

PE

F4

O

I

K1

J

R

B

K1

Acceleration override

Homing completed (start position)*

Max. number of sheets reached*

Positive travel range limit switch

Negative travel range limit switch

Reference switch

Reset positioning program

Start/back to start position

Stop positioning program

Speed override

Drive ready

Error active

Enable controller

Quick stop

Lower table

SB

GA

AO1

AO2

A1+

A1-

A1A1R

A2+

A2-

GO

24O

DO1

DO2

DO3

DO4

GI

RFR

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

X106

T1

K1

24E GE

X2

X3

X4

X5

T2

F1...F3

Z1

L1 L2

L3

X100

E94ASxExxxx

X105

Rb1

Rb2

U V

W

+

+UG

-UG

BD1

+

X107

BD2

E94AZPxxxxx

MXI1

MXI2

X7

R

B

EYF...

Y

M

3~

J

27

R

* Signal must be parameterised

[4-2] Connection diagram

EDS94TA10060xxxx EN 1.2 - 03/2010 L 13

Page 14

9400 Technology applications | Positioning sequence control

Short setup

Connection diagram

Designation Component

E94ASxExxxx 9400 Single Drive servo axis module

E94AZPxxxxx Mounting backplane

k1 Mains contactor

F1 ... F4 Fuses

Z1 Mains filter/RFI filter (option)

HF-shield termination through large-surface connection to functional earth

EYF... System cable for resolver feedback

R Resolver

R

B

Y Motor holding brake (at optional motor brake control)

Brake resistor

14 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 15

4.3 Sequence

1. After power-on, the drive indicates the status "Drive ready" by setting digital output

DO1 to HIGH level.

2. After controller enable, the positioning program is started by setting digital input DI6

to HIGH level.

3. The table traverses upwards until reaching the home switch.

– The home switch is 10 mm above the start position and connected to digital input

DI2.

4. After the homing mark has been detected, the table traverses downwards until

reaching the start position (first pick-up position).

5. The drive indicates the status "Homing completed/table in start position" by setting

digital output DO2 to HIGH level.

6. The internal sheet counter is reset to zero and stacking can start.

7. When a sheet has been added, digital input DI8 changes to HIGH level.

– After this, the table is lowered by one sheet thickness each.

9400 Technology applications | Positioning sequence control

Short setup

Sequence

8. 10 sheets can be piled up before the drive indicates the status "Maximum number of

sheets reached" by setting digital output DO3 to HIGH level.

– Then, the stack must be removed.

9. After the stack has been removed and digital input DI6 has been set to HIGH level, the

table traverses back to the start position (first pick-up position).

– A new stacking process can be started.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 15

Page 16

9400 Technology applications | Positioning sequence control

Short setup

Step 1: Creating a project

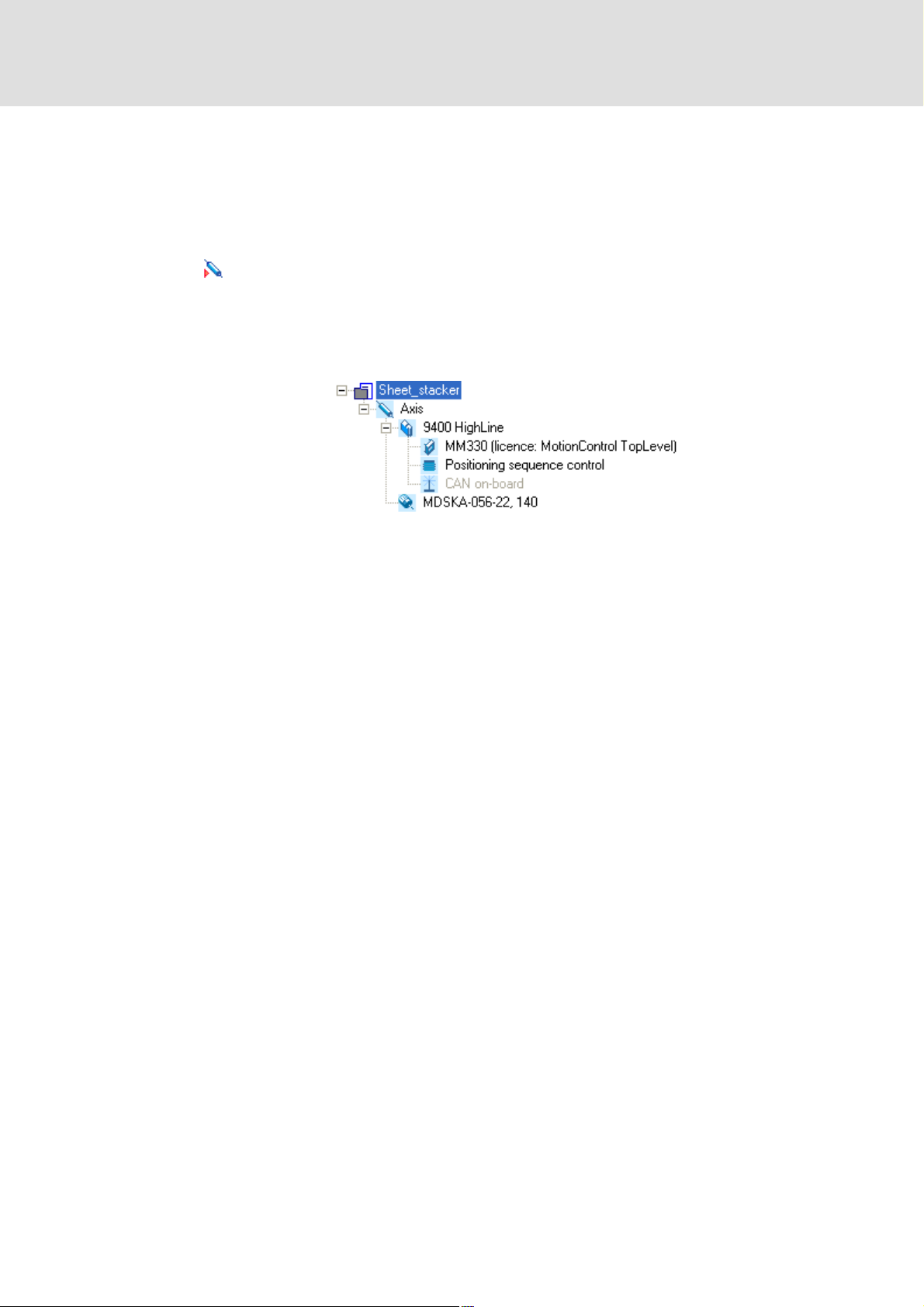

4.4 Step 1: Creating a project

1. Start »Engineer«.

2. Go to Start-up wizard and select the option "New project (empty)" and enter a name for

the project in a next step.

3. Insert the axis for the sheet stacker.

– Add the corresponding components (controller, motor, extension module) to the

axis.

– Select the application "Positioning sequence control" for the controller.

–Example project view in the »Engineer«:

16 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 17

9400 Technology applications | Positioning sequence control

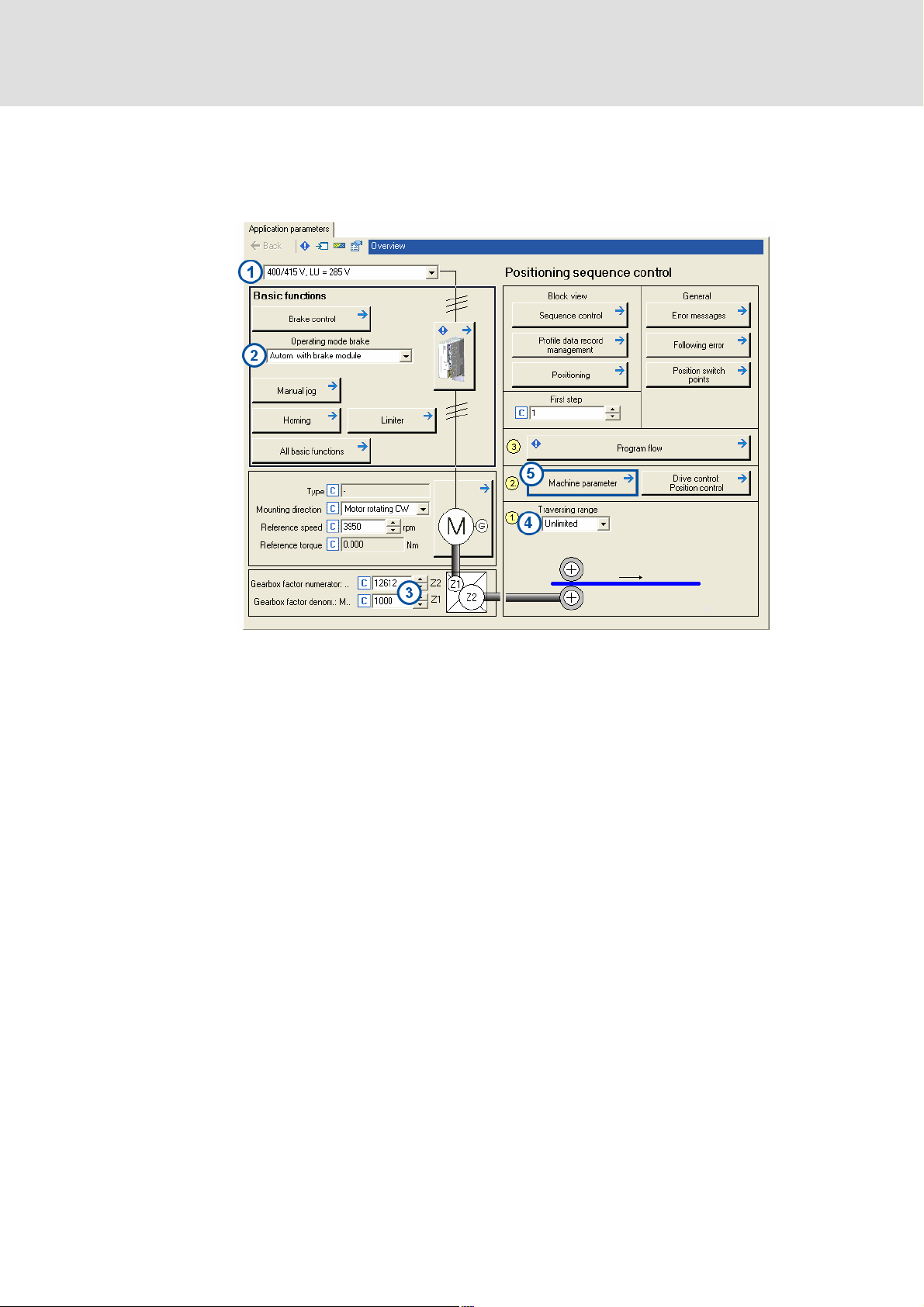

4.5 Step 2: Parameterising the application

For parameterising the application in the »Engineer«, use the Application parameters tab

which will be displayed by default when selecting the controller in the project view:

Short setup

Step 2: Parameterising the application

1. Select the mains voltage (C00173).

2. Activate automatic brake control via brake module (C02580 = "Autom. with brake

module").

3. Enter gearbox ratio as a quotient (numerator and denominator): i

1000

– Numerator (C02520) = 12612

– Denominator (C02521) = 1000

4. Select "Unlimited" as traversing range (C02528).

5. Click Machine parameter to change to the dialog level Overview Machine parameter

for further parameter setting.

= 12.612 = 12612/

1

EDS94TA10060xxxx EN 1.2 - 03/2010 L 17

Page 18

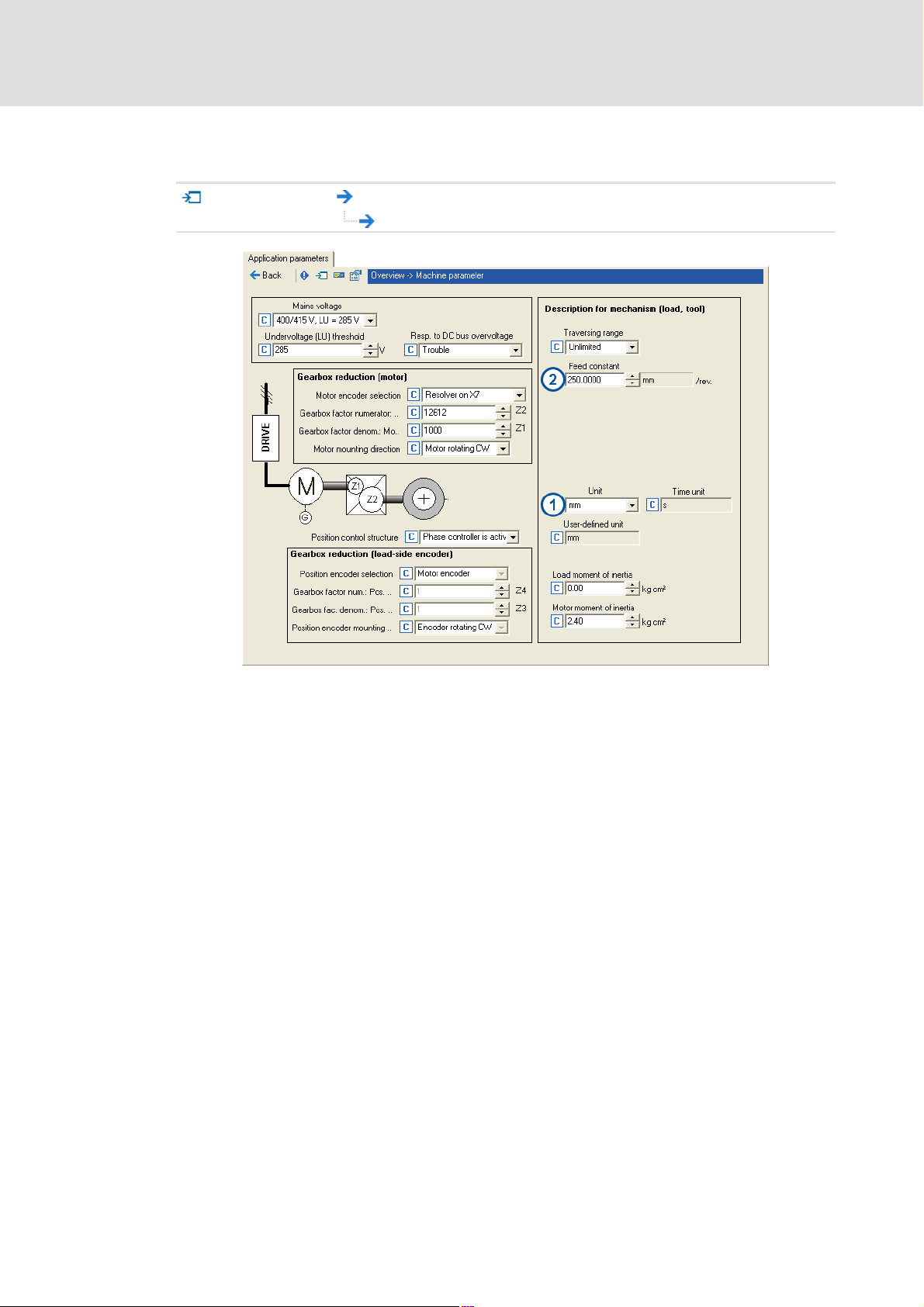

9400 Technology applications | Positioning sequence control

Short setup

Step 2: Parameterising the application

Setting the machine parameters

Go to dialog:

Overview

Machine parameter

1. Set the selection "mm" as unit (C02525).

– This parameter is used to define the real unit of the machine for the selection of

physical values (e. g. speeds, accelerations and decelerations).

2. Set feed constant (C02524).

– The feed constant corresponds to the motion of the machine at one revolution of the

gearbox output shaft.

– For the sheet stacker: Feed constant = 250 mm/rev.

3. Click Back to go back to the Overview dialog level.

4. In the Overview dialog level, click Program flow to change to the dialog level Overview

Program flow and select the positioning program.

18 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 19

9400 Technology applications | Positioning sequence control

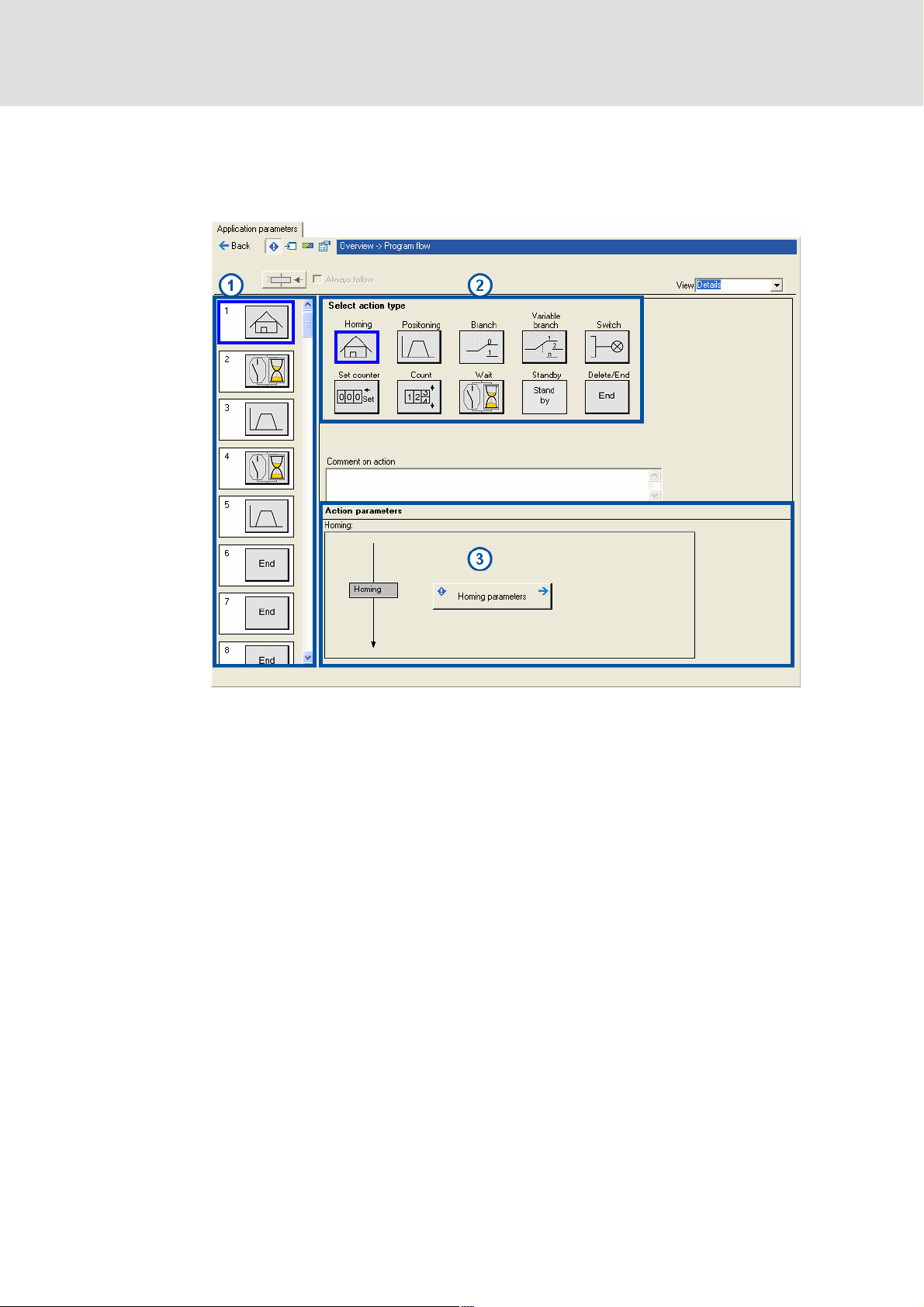

4.6 Step 3: Parameterising the program flow

The program flow of the positioning sequence control is parameterised in the dialog level

Overview Program flow:

Short setup

Step 3: Parameterising the program flow

Basic procedure

In the default setting the sequence table contains a small "Positioning program", which

first rotates the axis 360° clockwise and afterwards 360° counter-clockwise.

Proceed as follows to define the desired program flow:

1. Select the program step (1 .... 100) to be edited on the left in the sequence table.

2. Select the action type for the selected program step by clicking it.

– If the selected action type provides more than one action, the next free action will be

automatically suggested in the Selection Action Number list field.

– Enter a comment on the action (option).

3. Set parameters of the action.

– If required, call the corresponding subsequent dialogs.

4. Repeat steps 1 ... 3 until all actions required for the program flow have been

parameterised (see the following sections).

5. Click Back to go back to the Overview dialog level.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 19

Page 20

9400 Technology applications | Positioning sequence control

Short setup

Step 3: Parameterising the program flow

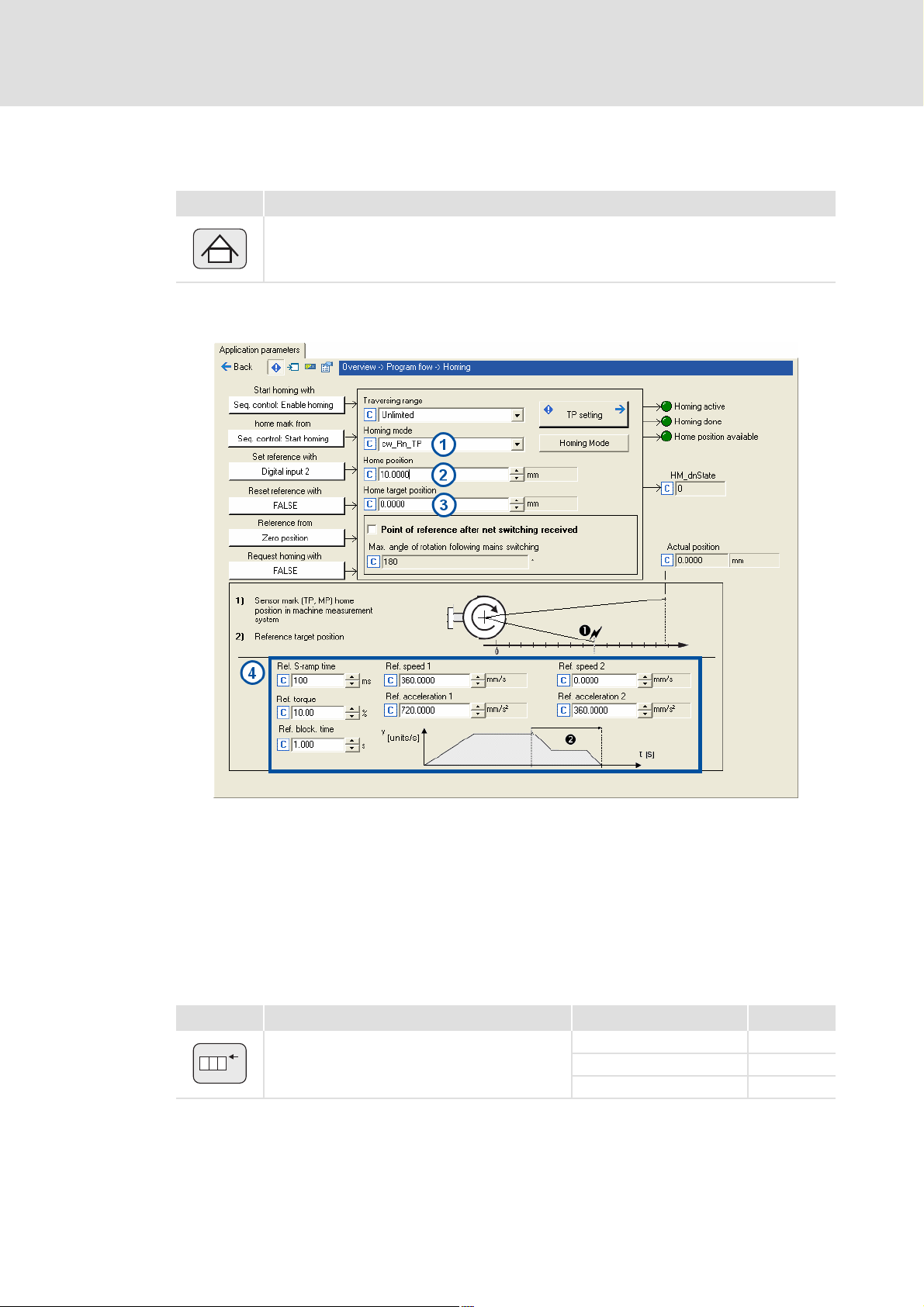

4.6.1 Program step 1: Homing

Action Comment

Homing with homing mark (home switch at digital input DI2), after homing, approach start position

(0 mm).

The "Homing" action does not have its own parameters. The settings for homing are made

via the parameters of the basic function "Homing":

1. Select "cw_Rn_TP" as homing mode (C02640).

2. Select the position of the home switch (10 mm) as home position (C02642).

3. Select the position of the first sheet (0 mm) as home target position (C02643).

4. If necessary, adapt the profile parameters for homing to your application.

4.6.2 Program step 2: Setting counter 1 to "0"

Action Comment Parameter Setting

Step 2: Set counter 1 to "0". Selection Action Number: 1

0

00

Set

Counter no.: 1

Start value: 0

20 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 21

9400 Technology applications | Positioning sequence control

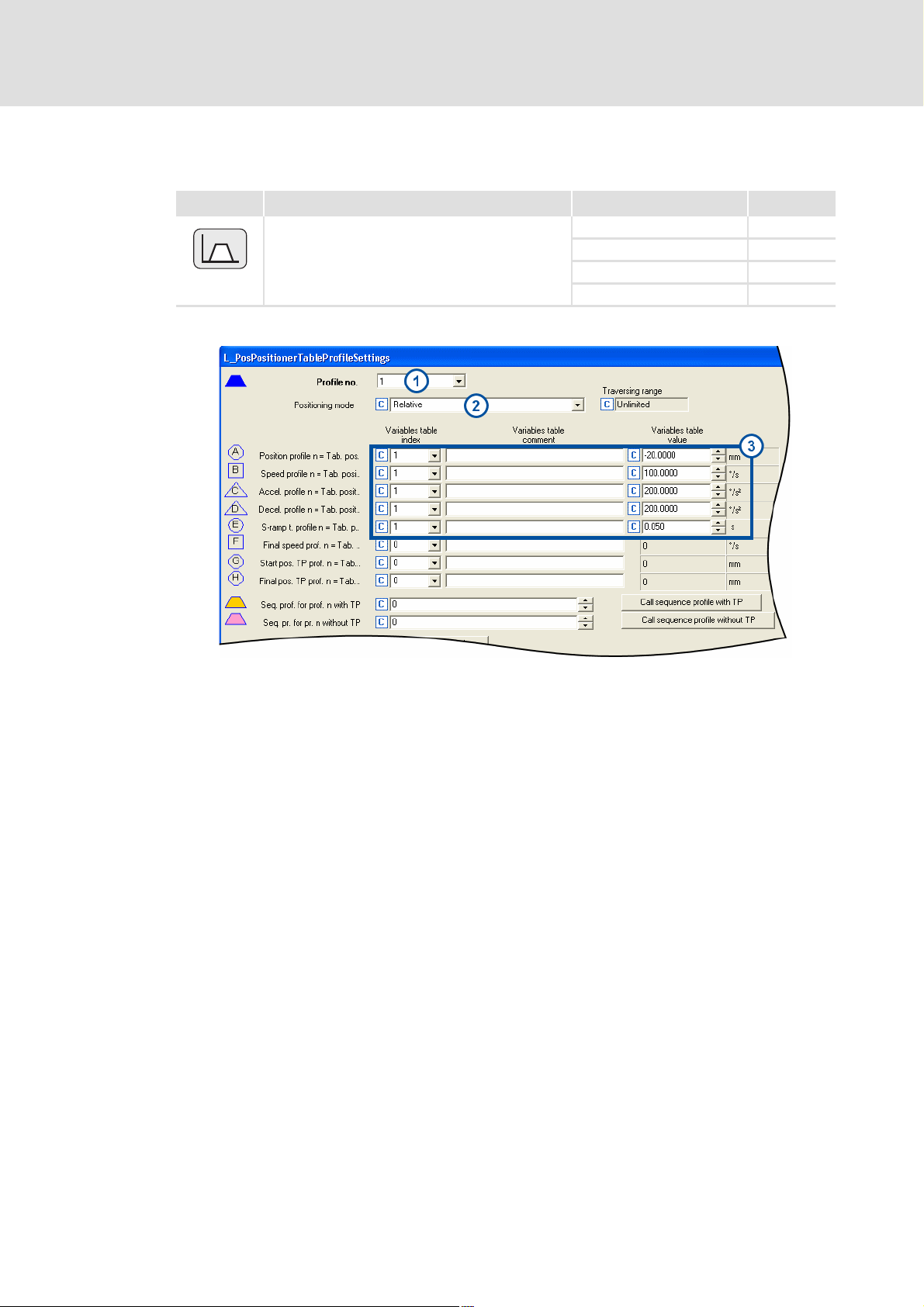

4.6.3 Program step 3: Positioning action 1

Action Comment Parameter Setting

When input 8 of sequence control is set to "1", lower

table relatively by 20 mm.

In the Lenze setting, sequence control input 8 is

connected to digital input DI8.

Click Profile settings to open the following dialog box:

Short setup

Step 3: Parameterising the program flow

Selection Action Number: 1

Start with: Input 8

Profile no.: 1

Jump destination: 0

1. Select Profile no. 1.

2. Select "Relative" as positioning mode.

3. Select the profile parameters as described above.

4. Click Back to close the dialog box again.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 21

Page 22

9400 Technology applications | Positioning sequence control

Short setup

Step 3: Parameterising the program flow

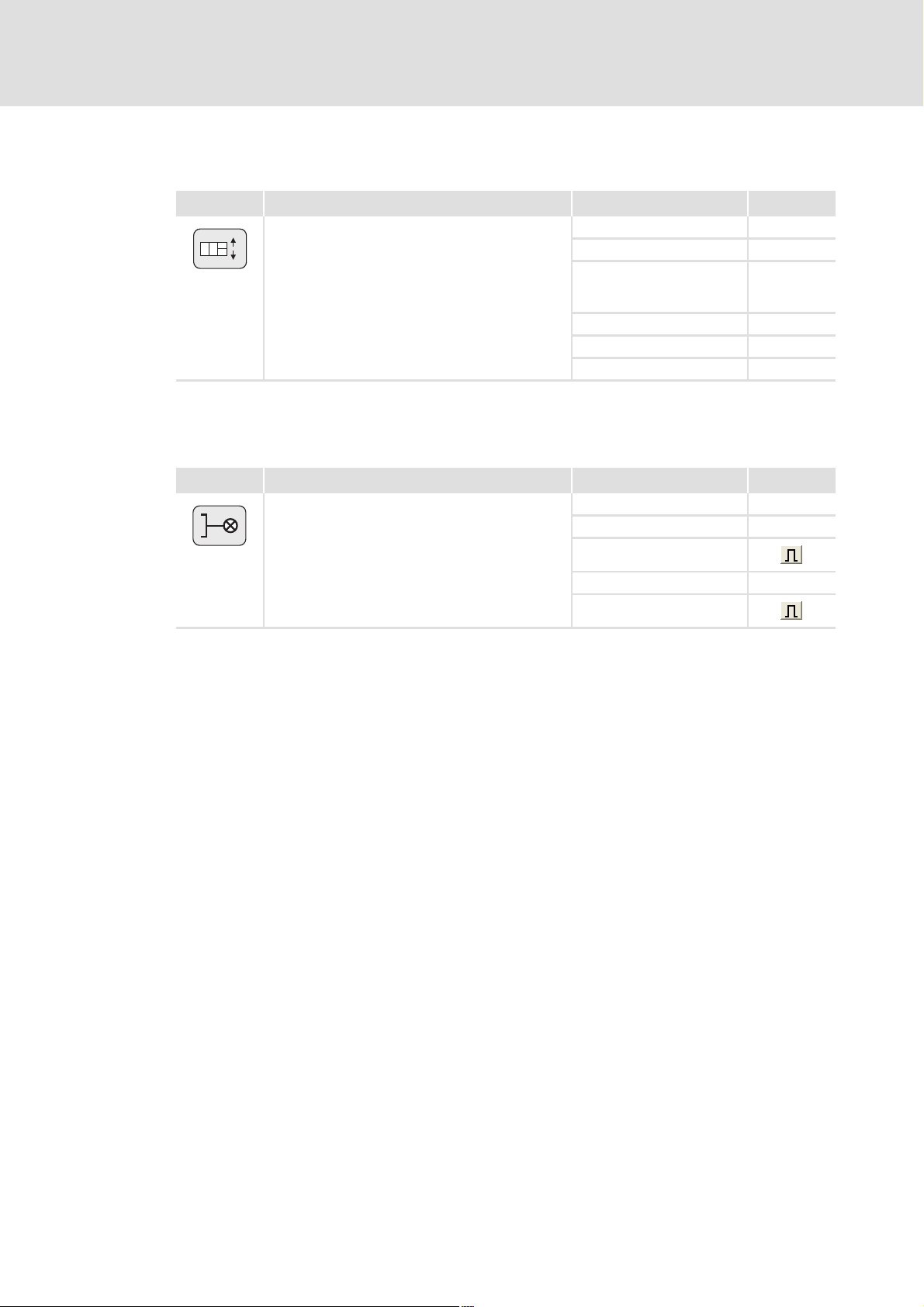

4.6.4 Program step 4: Counting the sheets

Action Comment Parameter Setting

Count the sheets and go back to program step 3,

3

1

2

4

unless 10 sheets are reached.

4.6.5 Program step 5: Setting the status output

Action Comment Parameter Setting

Set sequence control output 1 to "1", when

maximum number of sheets (10) is reached.

Selection Action Number: 1

Comparison function: Count <

Comparison value: 10

Selection Action Number: 1

Output for A switching: Output 1

Signal state for A switching:

Counter no.: 1

comparison

value

Step value: 1

Sequence step: 3

Output for B switching: Deactivated

Signal state for B switching:

Tip!

In a later step, sequence control output 1 will be connected with digital output

DO3.

22 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 23

9400 Technology applications | Positioning sequence control

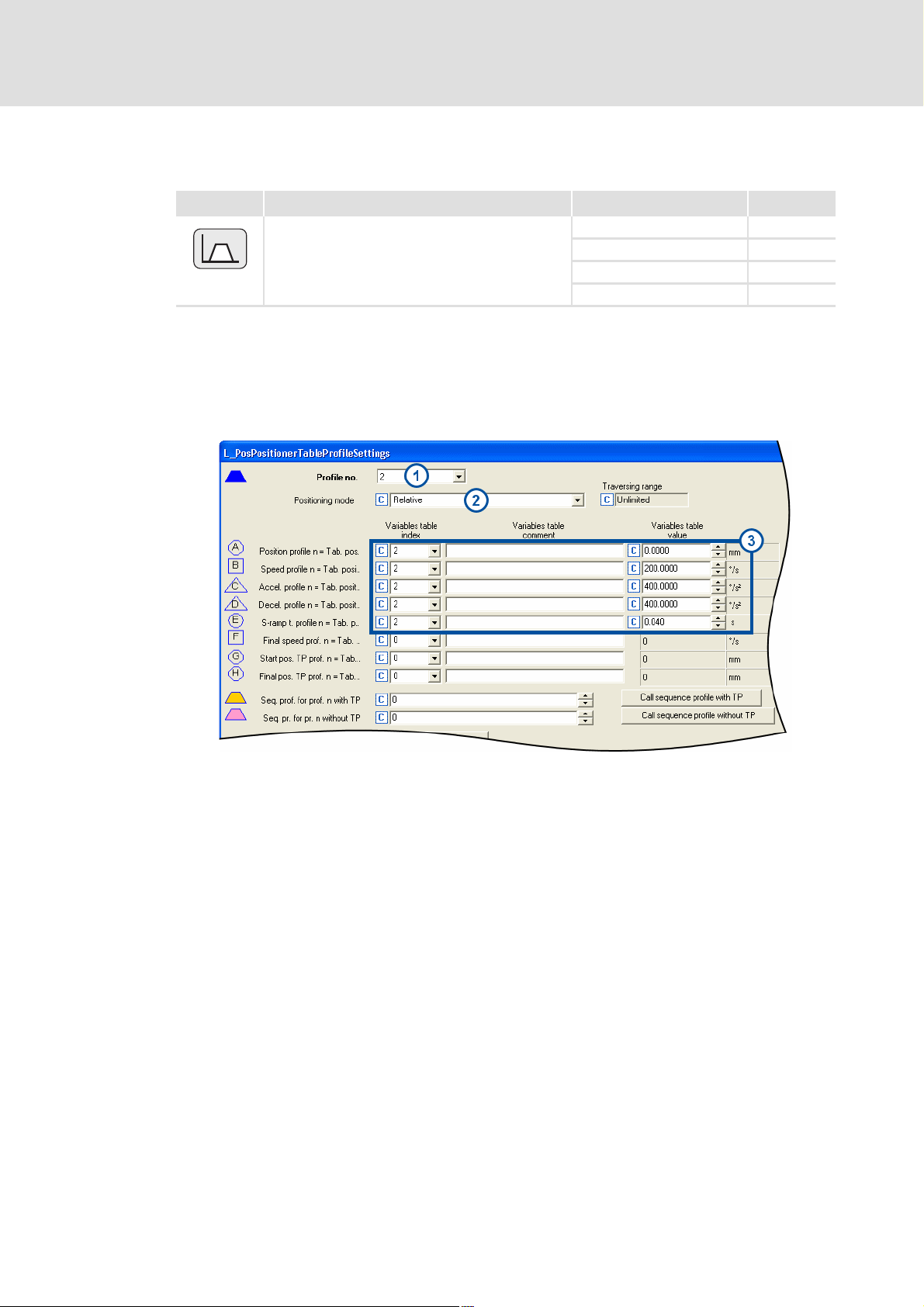

4.6.6 Program step 6: Positioning action 2

Action Comment Parameter Setting

When sequence control input 6 is set to "1", go back

to start position.

Tip!

In a later step, sequence control input 6 will be connected with digital input DO6.

Click Profile settings to open the following dialog box:

Short setup

Step 3: Parameterising the program flow

Selection Action Number: 2

Start with: Input 6

Profile no.: 2

Jump destination: 0

1. Select Profile no. 2.

2. Select "Absolute" as positioning mode.

3. Select the profile parameters as described above.

4. Click Back to close the dialog box again.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 23

Page 24

9400 Technology applications | Positioning sequence control

Short setup

Step 3: Parameterising the program flow

4.6.7 Program step 7: Resetting the status output

Action Comment Parameter Setting

Reset sequence control output 1 to "0", when start

position is reached.

4.6.8 Program step 8: Going back to program step 2

Action Comment Parameter Setting

Go back to program step 2. Selection Action Number: 1

0

1

Selection Action Number: 2

Output for A switching: Output 1

Signal state for A switching:

Output for B switching: Deactivated

Signal state for B switching:

Jump destination: 2

Jump input: Continue

with next

step

24 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 25

9400 Technology applications | Positioning sequence control

Step 4: Parameterising the multiplexer for the digital outputs

4.7 Step 4: Parameterising the multiplexer for the digital outputs

1. Go to the All parameters tab.

2. Set the following multiplexer parameters:

Parameter Setting

C03100/2 X digital output 2 of Homing completed

C03100/3 X digital output 3 of Sequence control output 1

Short setup

EDS94TA10060xxxx EN 1.2 - 03/2010 L 25

Page 26

9400 Technology applications | Positioning sequence control

Short setup

Step 5: Transferring the application to the controller

4.8 Step 5: Transferring the application to the controller

Note!

The transferred application is always stored in the first application memory

location in the memory module of the controller.

The preinstalled technology applications on the following memory locations are

still available.

1. Update devices.

– Set the checkmark in the control field Recreate all.

–Click Create to start the compiling process.

2. Go online and transfer the application to the controller.

– With an online connection, the »Engineer« displays the current controller parameter

settings with a yellow background colour.

26 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 27

9400 Technology applications | Positioning sequence control

Step 6: Controlling the application via terminals

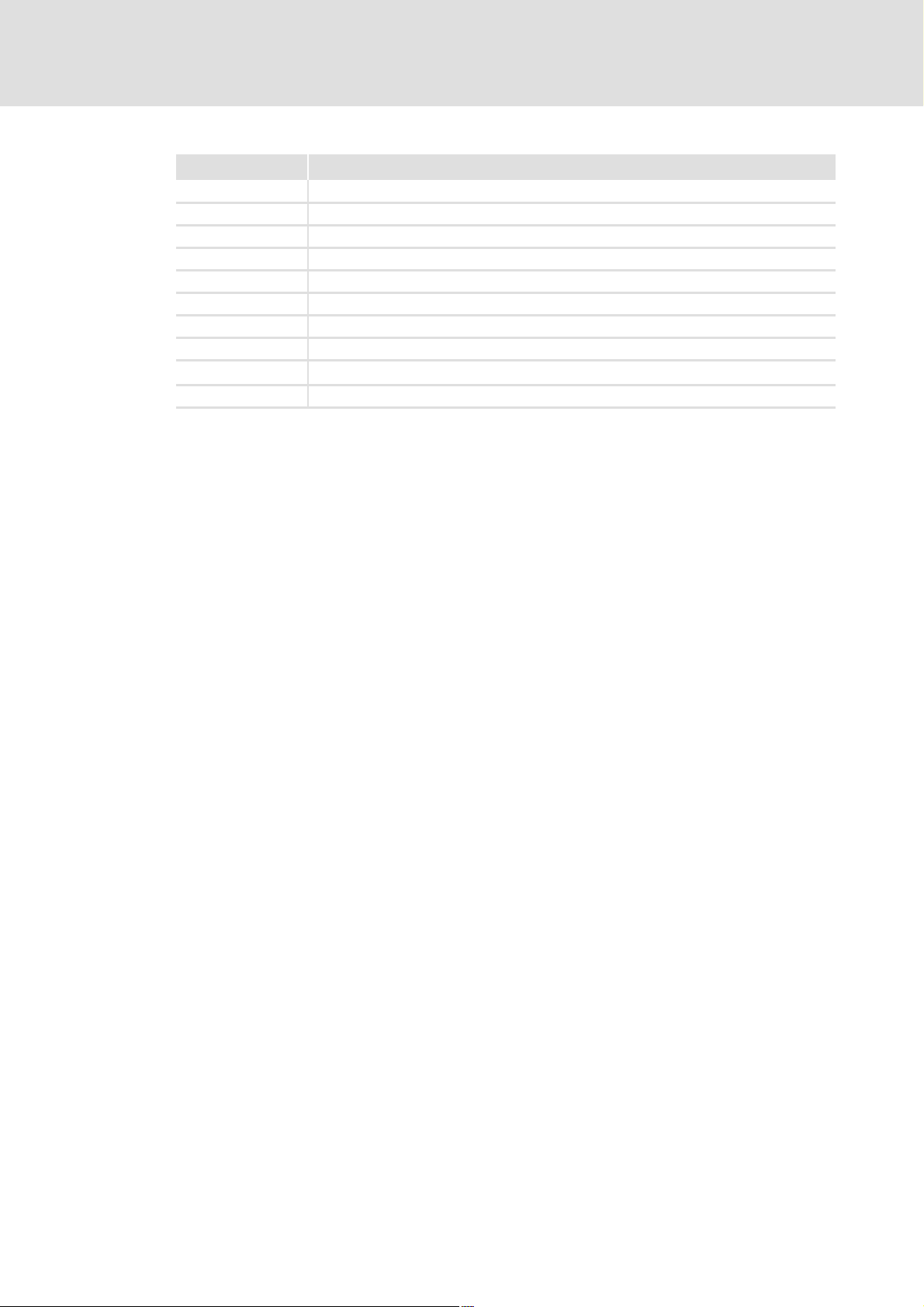

4.9 Step 6: Controlling the application via terminals

Terminal assignment

Terminal Signal (Lenze setting)

X3 AI1-

X5 DI1 Quick stop

Selection for speed override

AI1+

Speed/acceleration override

AI2-

Selection for acceleration override

AI2+

Speed/acceleration override

• If DI1 is set to LOW level, the positioning program is interrupted and drive is decelerated to

standstill within the deceleration time set for the quick stop function independent of the

setpoint selection.

• After the quick stop function is deactivated, a new LOW/HIGH edge is required at DI6 in order

that the positioning program is continued with the next step.

Quick stop

DI2 Connection of reference switch/touch probe sensor

Action type "Homing"

DI3

Connection of travel range limit switch for basic function "Limiter

DI4

• DI3 = positive travel range limit switch, DI4 = negative travel range limit switch.

• The inputs respond to the FALSE state (fail-safe).

DI5 Reset error and positioning program

• By means of a LOW-HIGH edge an existing error status can be reset if the cause of the fault is

removed. At the same time the positioning program is reset.

DI6 Start positioning program/back to start position

Control of the sequence table

DI7 Stop positioning program (break)

Control of the sequence table

DI8 Lower table

( 56)

( 53)

( 53)

( 36)

( 43)

( 43)

Short setup

". ( 57)

Procedure

1. Enable controller: Set digital input RFR to HIGH level.

2. Deactivate quick stop: Set digital input DI1 to HIGH level.

3. Start sequence control: Set digital input DI6 to HIGH level.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 27

Page 28

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Basic signal flow

5 Parameter setting & configuration

5.1 Basic signal flow

The functional core of the positioning sequence control is formed by the sequence table

and the profile data management, which transmit the required control signals and profile

data to the basic drive function "Positioning".

Positioning sequence control

DI2

Reset

Sequencer

input 8

Acceleration override

Sequencer

DI5

DI6

DI7

DI8

024

Speed override

PositionerTable

Profiles

Override

Enable

AIN1

AIN2

LS_Homing

3

LS_Positioner

n

LS_ManualJog

ç

n

5

[5-1] Signal flow of the TA " Positioning sequence control" (schematic diagram)

Basic drive functions

LS_Stop

internal

n

status machine

0-100 100 200

6

Status

machine

(basic drive

functions)

t

DI1

LS_Quickstop

è

n

STOP

t

78

LS_Brake

t

91

M

LS_Limiter

n

t

DI4

DI3

t

Positioning sequence control

Sequence table

Profile data management

Speed/acceleration override

Basic drive functions

Homing

Positioning

Manual jog

Stop

Quick stop

Limiter

Brake control (optional)

28 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 29

9400 Technology applications | Positioning sequence control

5.2 Basic settings

5.2.1 Machine parameters

The machine parameters describe e.g. the motor end of the mechanics

M

used.

The setting of the machine parameters in the »Engineer» is carried out on

the Application parameters tab in the dialog level Overview Machine

parameters.

Tip!

In the »Engineer« the most important machine parameters can be directly adapted

to the machine on the Application parameters tab in the topmost Overview dialog

level.

Parameter setting & configuration

Basic settings

Short overview of machine parameters

Parameter Lenze setting

Value Unit

C00173 Mains voltage 400/415 V

C00174 Undervoltage (LU) threshold 285 V

C00600 Resp. to DC bus overvoltage Trouble

C02520 Gearbox factor numerator: Motor 1

C02521 Gearbox factor denom: Motor 1

C02527 Motor mounting direction Motor rotating CW

C02570 Position control structure Phase control

C02522 Gearbox factor num.: Pos. enc. 1

C02523 Gearbox factor denom.: Pos. enc. 1

C02529 Mounting direction of position encoder Encoder rotating CW

Description of the mechanics (load, tool)

C02528 Traversing range Limited

C02524 Feed constant 360.0000 unit

C02525 Unit °

C02526 User-defined unit °

C02533 Time unit s

C00273/1 Motor moment of inertia Motor-dependent kg cm

C00273/2 Load moment of inertia 0.00 kg cm

2

2

EDS94TA10060xxxx EN 1.2 - 03/2010 L 29

Page 30

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Basic settings

5.2.2 Traversing range

By setting the traversing range the machine type/measuring system is set:

Traversing range

Unlimited The drive can traverse optionally in both directions without

M

Limited After reaching the position limits, the drive must travel in the

M

Modulo The measuring system is repeated.

M

reaching limitations.

• Positioning here generally is effected in the positioning

modes "Relative with/without TP" or "Speed with/

without TP".

• The positioning measuring system is reset to zero with

every new positioning process.

• By homing, the positioning measuring system receives a

fixed reference point (zero point), so that also the

positioning modes "Absolute with/without TP"can be

used. Then also the software limit positions for limiting

the traversing range are provided.

opposite direction again.

• For positioning, the home position has to be known. By

homing, the positioning measuring system receives a

fixed reference point (zero point).

• Basically, monitoring to the internally maximum usable

value range (±2

position monitoring of the internal value range). An

overflow of the value range results in the loss of the home

position.

• Additionally parameterisable software limit positions can

be activated on the user side for limiting the travel range.

• If the cycles n set are exceeded a defined overflow occurs.

The cycle typically corresponds to a rotation or tool

distance in a rotative system.

• For positioning, the home position has to be known.

• Software limit positions are not effective.

• Absolute targets can be approached by exceeding the

measuring system limit, e.g. from 10° via 0° to 350°.

31

increments) takes place (software limit

Parameter setting: Tab Application parameters dialog level Overview

Parameter Lenze setting

Value Unit

C02528 Traversing range Limited

C02536 Cycle (only relevant for traversing range "Modulo") 360.0000 unit

30 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 31

9400 Technology applications | Positioning sequence control

5.2.3 Position control

In the dialog level Overview LS_Positioner and the subordinate dialog levels, you can

adapt the parameters for the position control, if necessary.

Parameter Lenze setting

C00254 Phase controller gain 20.00 1/s

C02553 Position controller gain 20.00 1/s

C02556 Position controller limitation 214748.3647 unit/s

Parameter setting & configuration

Basic settings

Value Unit

EDS94TA10060xxxx EN 1.2 - 03/2010 L 31

Page 32

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Program flow

5.3 Program flow

The program flow of the positioning sequence control is selected according to a sequence

table which can contain up to 100 references to "actions".

Basic drive functions

n

0-100 100 200

t

LS_Quickstop

è

n

t

LS_Stop

internal

status machine

Status

machine

(basic drive

functions)

STOP

LS_Brake

t

M

LS_Limiter

n

t

t

Reset

Sequencer

input 8

Positioning sequence control

Sequencer

DI5

DI6

DI7

DI8

PositionerTable

Profiles

Override

Enable

LS_Homing

LS_Positioner

n

LS_ManualJog

ç

n

[5-2] Sequence table (schematic diagram)

What is an action?

An action comprises a clear functionality which is described with a few parameters.

Different action types are available which serve to implement, for instance, program

branching, switching operations, waiting times and counters.

0

1

1

2

n

0

00 1

Set

3

2

4

Standby End

Before every action type a defined number of actions is available which can be

individually parameterised. The parameters of the actions of the same type only differ

in the subcode.

An action can be used in several steps if always exactly the same task is to be carried

out.

After an action has been processed, the action in the next step of the sequence table is

automatically processed unless it is jumped to another step in the sequence table due

to a branch.

One action can be maximally processed per computing cycle.

32 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 33

9400 Technology applications | Positioning sequence control

5.3.1 Overview of action types

Action type Function/parameter

Homing

In order to execute a homing process, the action type "Homing" is available which activates the basic

function "Homing".

Note: The "Homing" action does not have its own parameters. The settings for homing are made via

the parameters of the basic function "Homing".

Positioning

To execute a profile, 50 actions of the "Positioning" type are available.

• The execution of the adjusted profile is only started with activated waiting function if the

sequencer input selected for the waiting function accepts the selected signal state.Sequencer

inputs ( 40)

Parameter Information

C04513/1...50 Profile number Specification of the profile to be executed.

C04511/1...50 Input for waiting

C04512/1...50 Signal state for

C04514/1...50 Sequence step Step inside the sequence table which will be processed after

C04515/1...50 Watchdog time Monitoring time within which positioning must be

C04516/1...50 Watchdog

Branching

25 actions of type "Branching" are available for conditional and unconditional branches (jumps).

0

• A branch to the indicated step is executed when the selected sequencer input has the selected

1

signal state at the time of processing. If not, the sequence step is processed in the sequence

table.Sequencer inputs

Parameter Information

C04530/1...25 Input for

C04531/1...25 Comparison

C04532/1...25 Sequence step in

function

waiting function

sequence step

( 40)

comparison

value

case of equality

Parameter setting & configuration

Program flow

• Press the "Set up profile" button to open a dialog box to

enter the corresponding profile parameters.

• In this dialog a sequence profile can also be set.

Sequencer input 1 ... 32 to be evaluated.

• With the default setting "0" the waiting function is

skipped and the profile execution is started immediately.

Profile processing is only started when the sequencer input

to be evaluated is in this state.

the profile has been executed.

completed. Otherwise, a branch to the watchdog sequence

step defined in C04516 is executed.

Executed when the watchdog time has expired.

Sequencer input 1 ... 32 to be evaluated.

• With the default setting "0" a branch to the adjusted

sequence step is executed.

State in which the sequencer input to be evaluated is

compared.

If the sequencer input to be evaluated equals the

comparison value, a branch to the step set here is executed.

In case of inequality or "0" setting, the next step in the

sequence table is processed.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 33

Page 34

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Program flow

Action type Function/parameter

Variable branching

For variable branches (jumps) 5 actions of type "Variable branching" are available.

1

• The branch to one of 20 possible steps is executed depending on the value in C03001 ... C03005

2

n

Switching

Set counter

0

00

Set

at the time or processing.

• The parameters C03001 ... C03005 are firmly assigned to the five available actions:

–C03001 determines the branch for action 1.

–C03002 determines the branch for action 2, etc.

Example:

If C03002 is assigned to the value "15" at the time of processing the action no. 2, it is branched to

the step which is entered in the parameter "Sequence step at branch value 15" for action no. 2

(C04554/2).

Parameter Information

C04540/1...5 Sequence step at

branch value 1

C04541/1...5 Sequence step at

branch value 2

... ... ...

C04559/1...5 Sequence step at

branch value 20

In order to switch digital output signals 25 actions of type "Switching" are available.

• Each action can set two selectable sequencer outputs independently of each other to FALSE or

TRUE. Sequencer outputs

Parameter Information

C04520/1...25 Output for A

switching

C04521/1...25 Signal state for A

switching

C04522/1...25 Output for B

switching

C04523/1...25 Signal state for B

switching

10 actions of type "Set counter" are available for setting one of the 10 available counters to a certain

starting value.

• The 10 actions of type "Set counter" are not firmly assigned to the 10 actions of the "Counting"

type.

• You can use, for instance, an action of type "Set counter" to set a counter to a value and later you

can set the same counter with another action of type "Set counter" to another value.

Parameter Information

C04580/1...10 Counter selection With the setting "0" the setting of the counter is deactivated.

C04581/1...10 New counter

content

C04582/1...10 Current counter

content

Step which is executed next when C03001 ... C03005 = "1".

• With the default setting "0" the branching is deactivated

(sequence step is processed).

Step which is executed next when C03001 ... C03005 = "2".

• In the default setting "0", branching is deactivated and

the next step in the sequence table is processed.

Step which is executed next when C03001 ... C03005 = "20".

• In the default setting "0", branching is deactivated and

the next step in the sequence table is processed.

( 41)

Sequencer output 1 ... 32 to be switched.

• With the setting "0" switching is deactivated.

State to which the sequencer output is to be set.

Sequencer output 1 ... 32 to be switched.

• With the setting "0" switching is deactivated.

State to which the sequencer output is to be set.

-2147483648 ... 2147483648

Read only

34 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 35

9400 Technology applications | Positioning sequence control

Action type Function/parameter

Count

25 actions of type "Count" are available for counting processes.

3

1

2

4

Wait

Stand-by

Standby

Program end

End

• With each action processing the counter content of the counter selected is increased or reduced

by the specified step value depending on the setting (count upwards or downwards).

• When the comparison condition for comparing the counter content with an adjustable

comparison value is fulfilled, a branch to any step is possible.

• 10 actions of type "Set counter" are available for setting a counter to a starting value.

Parameter Information

C04590/1...25 Counter selection With the setting "0" the setting of the counter is deactivated.

C04591/1...25 Step value Value by which the counter is increased or reduced.

C04592/1...25 Comparison

C04593/1...25 Sequence step When the set comparison condition is met, a branch to the

C04594/1...25 Comparison

25 actions of type "Wait" are available for the insertion of wait times into the program flow.

• The sequence step is only processed after the waiting time has elapsed or when the selected

sequencer input has the selected signal state at the time of processing.Sequencer inputs

( 40)

Parameter Information

C04571/1...25 Waiting time With setting "0", the waiting time is deactivated.

C04572/1...25 Input for waiting

C04573/1...25 Signal state for

5 actions of type "Stand-by" are available for the temporary activation of a setpoint follower.

• For a sensible use of the "Standby" action, appropriate signal combinations are required in the

(enabled) function block editor.

• The setpoint follower is enabled until the condition for exiting the stand-by is met.

Parameter Information

C04601/1...5 Input for "Stand-

C04602/1...5 Signal state for

To define the program end in the sequence table or delete a program step, the action of type

"Program end" is available.

value

condition

function

waiting function

by" end

"Stand-by" end

Parameter setting & configuration

Program flow

• Range: -2147483648 ... 2147483648

Value with which the counter is compared.

• Range: -2147483648 ... 2147483648

step set here is executed.

If the condition is not met, the next step in the sequence

table is processed instead.

Selection of the condition for the comparison of the counter

content with the comparison value.

Sequencer input 1 ... 32 to be evaluated.

• The sequence step will be processed when this input has

the set state, but no later than after the set waiting time

has elapsed.

Required state for completing the waiting function.

Sequencer input 1 ... 32 to be evaluated.

Only if the sequencer input to be evaluated has this state,

the standby step is exited, and the next step in the sequence

table is processed.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 35

Page 36

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Program flow

5.3.2 Action type "Homing"

In order to execute a homing process, the action type "Homing" is available for the

sequence table which activates the basic function "Homing".

Positioning sequence control

DI5

DI6

DI7

DI8

Sequencer

Enable/activate

homing

State "homing done"

Reset

Sequencer

input 8

[5-3] "Homing" (schematic diagram for limited traversing range)

Basic drive functions

DI2

LS_Homing

(basic drive

0-100 100 200

functions)

Status

machine

M

Note!

The "Homing" action for the sequence table does not have its own parameters.

The settings for homing are made via the parameters of the basic function

"Homing".

Parameter setting: Tab Application parameters dialog level Overview Homing

Parameter Lenze setting

C02528 Traversing range Limited

C02640 Homing mode Set home pos. directly

C02642 Home position 0.0000 unit

C02643 Homing: Target position 0.0000 unit

C02644 Homing: Speed 1 360.0000 unit/s

C02645 Homing: Acceleration 1 720.0000 unit/s

C02646 Homing: Speed 2 180.0000 unit/s

C02647 Homing: Acceleration 2 360.0000 unit/s

C02648 Homing: S-ramp time 100 ms

C02649 Homing: Torque limit 10.00 %

C02650 Homing: Blocking time 1.000 s

C02652 Ref. pos. after mains switching Delete

C02653 Max. rot. ang. aft. mns. swtch. 180 °

Value Unit

2

2

36 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 37

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Program flow

Control inputs of the function Signal configuration

Lenze setting Control input (Multiplexer parameters)

Sequencer

Enable Homing

Sequencer

Activate Homing

DIGIN 2 Home mark C03160/3

Zero position Home position C03163

+100 % Homing override C03186/4

Request homing C03160/1

Start homing C03160/2

FALSE Set home position C03160/4

FALSE Reset home position C03160/5

EDS94TA10060xxxx EN 1.2 - 03/2010 L 37

Page 38

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Program flow

5.3.3 Action type "Positioning"

In order to execute a positioning process, 50 actions of "Positioning" type are available for

the sequence table which activates the basic function "Positioning":

Positioning sequence control

DI5

DI6

DI7

DI8

Sequencer

Profile

number

State "positioning done"/"drive in target"

Enable/activate

positioning

PositionerTable

Profiles

Reset

Sequencer

input 8

[5-4] "Positioning" (schematic diagram for limited traversing range)

Basic drive functions

LS_Positioner

n

Profile

data

Status

machine

(basic drive

functions)

t

M

Use the parameter Profile number of the action to select the number or the table

position of the profile to be executed. The final profile data are then given to the basic

function by the Profile data management

. ( 44)

The execution of the adjusted profile is only started with activated waiting function if

the sequencer input selected for the waiting function accepts the selected signal

state.Sequencer inputs

( 40)

38 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 39

9400 Technology applications | Positioning sequence control

5.3.4 Action type "Variable branching"

For variable branches (jumps) 5 actions of type "Variable branching" are available for the

sequence table.

1

2

n

Branch 1 value

C03001

Parameter setting & configuration

Program flow

The branch to one of 20 possible steps

is executed in the Lenze setting

depending on the value in

C03001 ... C03005 at the time or

processing.

<1

>20

Following

step

[5.1] Principle of the variable branch (here for action no. 1)

12 20

Next step Next step Next step

C04540/1 C04541/1 C04559/1

Tip!

Instead of the parameters C03001 ... C03005 you can also assign other signal

sources of the application to the "branch" inputs via multiplexer parameters.

Parameter setting: Tab Application parameters dialog level Overview Sequence

control

Parameter Lenze setting

C03001 Branch value 1 1

C03002 Branch value 2 1

C03003 Branch value 3 1

C03004 Branch value 4 1

C03005 Branch value 5 1

The parameters C03001 ... C03005 are

firmly assigned to the five available

actions, i.e. C03001 determines the

branch for action 1, C03002 for

action 2, etc.

Value Unit

Control inputs of the function Signal configuration

Lenze setting Control input (Multiplexer parameters)

C03001 Sequencer branch 1 C03079/1

C03002 Sequencer branch 2 C03079/2

C03003 Sequencer branch 3 C03079/3

C03004 Sequencer branch 4 C03079/4

C03005 Sequencer branch 5 C03079/5

EDS94TA10060xxxx EN 1.2 - 03/2010 L 39

Page 40

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Program flow

Example

The following example illustrates the function of the variable branch based on a program

flow which contains, among other things, two actions of the "Variable branching" type.

Step 12

Step 13

[5.2] Example "Variable branch"

5.3.5 Sequencer inputs

In order to control conditional branches and the optional waiting function of some action

types during the program flow, 32 sequencer inputs of "BOOL" type.

The sequencer inputs 1 ... 16 can be linked with the signal sources of the application or

device interfaces in the dialog level Overview L_Sequencer Program inputs via

multiplexer parameters.

Step 14

Step 15

Step 16

Step 17

Action number:

1

2

n

Action number:

1

2

n

C030022=4

C04543/2 =16

C030033=20

C04559/3 =12

W jump to step number [C04543/2]

W jump to step number [C04559/3]

For the action types "positioning", "branching", "waiting" and "stand-by", you can

individually define for each action which of the sequencer inputs is to be called for the

corresponding function when the program is executed.

Note!

The sequencer input 8 in the Lenze setting is linked with the digital input DI8.

40 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 41

9400 Technology applications | Positioning sequence control

5.3.6 Sequencer outputs

Via a DWORD-to-BIT-converter, 32 sequencer outputs of type "BOOL" are available for

"switching" which can be set to FALSE or TRUE with the action type "switching".

These sequencer outputs can be connected with the inputs of the application or device

interfaces via multiplexer parameters.

The following table lists the corresponding module outputs of the FB interconnection

and the corresponding selection numbers for the multiplexer parameters:

Module output Signal type Selection no. Selection text

SequencerOutput.bBit0 551 Sequencer output 1

SequencerOutput.bBit1 552 Sequencer output 2

SequencerOutput.bBit2 553 Sequencer output 3

... ... ...

SequencerOutput.bBit31 582 Sequencer output 32

Parameter setting & configuration

Program flow

EDS94TA10060xxxx EN 1.2 - 03/2010 L 41

Page 42

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Program flow

5.3.7 Parameter setting of the program flow in the Engineer

Go to the »Engineer« to the Application parameter tab and click Program flow in the

topmost dialog level to change to the dialog for the sequence table:

Basic procedure

In the default setting the sequence table contains a small "Positioning program", which

first rotates the axis 360° clockwise and afterwards 360° counter-clockwise.

Proceed as follows to define the desired program flow:

1. Select the program step (1 .... 100) to be edited on the left in the sequence table.

2. Select the action type for the selected program step by clicking it.

3. If the selected action type provides more than one action, select the action to be

parameterised from the list field Selection of action number.

– The next free action is suggested automatically.

4. Enter a comment about the action (optional).

5. Set parameters of the action.

– If required, call the corresponding subsequent dialogs.

6. Repeat step 1 ... 5 until all actions required for the program flow are parameterised.

42 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 43

9400 Technology applications | Positioning sequence control

5.3.8 Control of the sequence table

A LOW/HIGH edge at the digital input DI6 starts the parameterised program flow if the

controller is enabled and no error is pending.

The first step set in C03000 of the sequence table is executed.

By setting the digital input DI7 to HIGH level, the program flow can be stopped, if

required (break).

Note!

In the following cases the program flow is interrupted:

• The controller inhibit is activated.

• Quick stop is activated.

• The drive interface changes to an error status.

If the controller is not inhibited, a shutdown of the drive via the basic function

"Quick stop" is effected.

Parameter setting & configuration

Program flow

After the interruption is deactivated again (e.g. because an activated quick stop

has been deactivated again), a renewed LOW/HIGH edge is required at the

digital input DI6 in order that the positioning program can be continued with

the sequence step.

Parameter setting: Tab Application parameters dialog level Overview L_Sequencer

Parameter Lenze setting

Value Unit

C03000 First step 1

C04504 Jump destination 0

Control inputs of the function Signal configuration

Lenze setting Control input (Multiplexer parameters)

C03000 First step C03079/6

DIGIN 6 Sequencer start C03070/1

DIGIN 7 Sequencer break C03070/2

FALSE Sequencer jump C03070/3

FALSE Sequencer abort C03070/4

FALSE Sequencer interruption C03070/5

Controller inhibit

Quick stop active

Error active

DIGIN 5 Reset program/error status C03070/8

Reset program status C03070/6

or

or

EDS94TA10060xxxx EN 1.2 - 03/2010 L 43

Page 44

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Profile data management

5.4 Profile data management

Positioning sequence control

Sequencer

PositionerTable

Profiles

Override

Enable

LS_Homing

LS_Positioner

n

LS_ManualJog

ç

n

Basic drive functions

n

0-100 100 200

t

LS_Quickstop

è

n

t

LS_Stop

internal

status machine

Status

machine

(basic drive

functions)

STOP

LS_Brake

t

M

LS_Limiter

n

t

t

[5-5] Profile data management (schematic diagram)

The profile data management serves to file and manage up to 75 (travel) profiles.

A profile describes a motion request which can be converted by the basic drive function

"Positioning" into a rotary motion.

To execute a profile, 50 actions of type "Positioning" are available for the sequence

table.

The profile data management also enables the "teaching" of speed, acceleration/

deceleration and S-ramp times. "Teach" function

( 52)

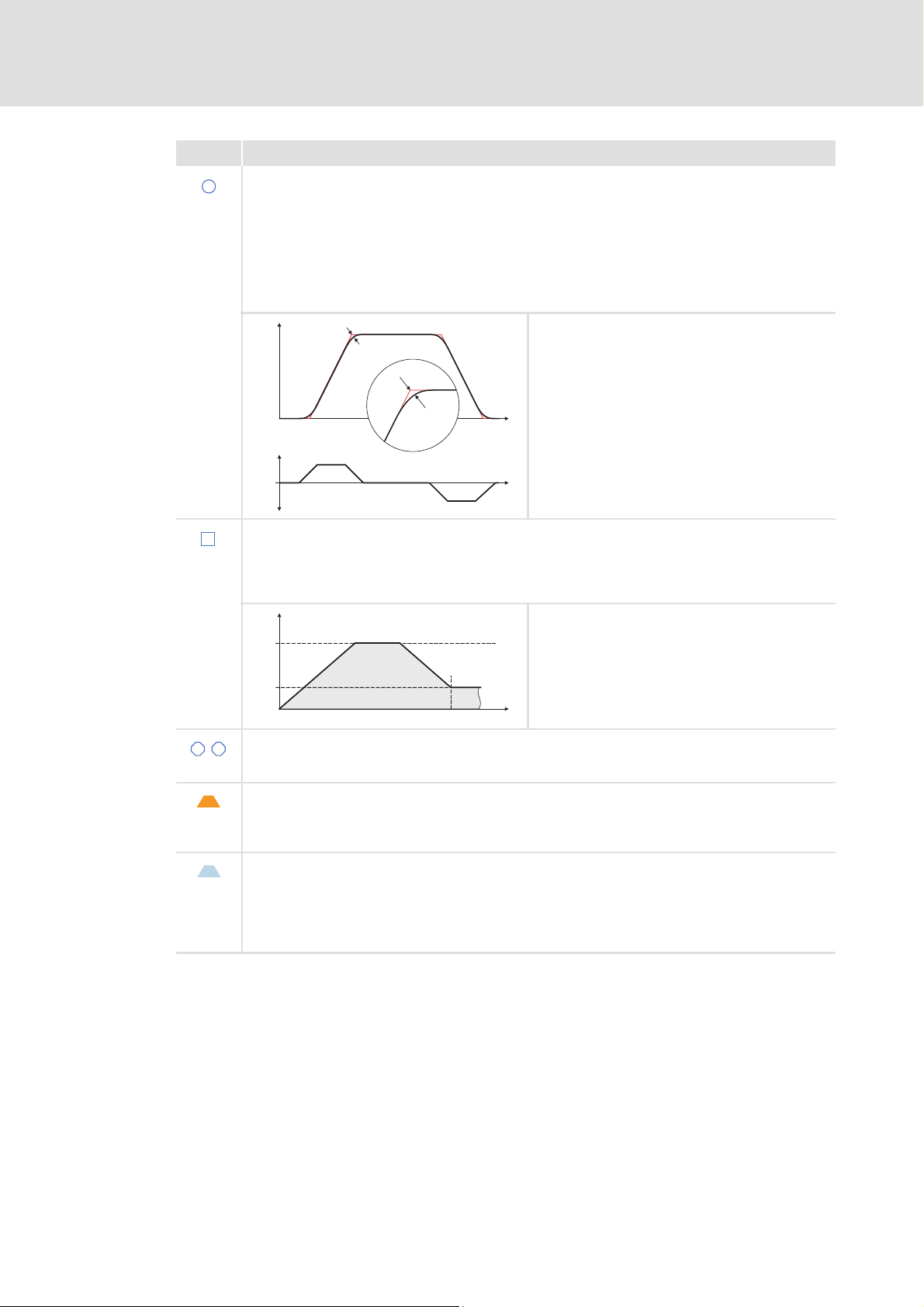

5.4.1 Profile parameters

A profile is described by the following profile parameters:

v [m/s]

B

C

F

E

[5-6] Profile parameters

v [m/s]

t [s]

B

C

E

F

E

E

A

D

E

E

TP window

G H

TP

E

A

D

E

t [s]

44 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 45

9400 Technology applications | Positioning sequence control

Symbol Profile parameters

(Standard) profile

Profile data set (profile no. 1 ... 75) in which the profile data are stored.

Mode

Selection of the positioning mode. Positioning modes

Position

A

Target position or path distance to be traversed.

The position is either indicated as absolute or relative position.

• An absolute position always specifies the distance to the zero position defined:

absolute position = target position

10

0

• A relative position indicates the distance to the starting position (current position):

Relative position = target position - starting position

10

Parameter setting & configuration

Profile data management

( 48)

30

P1

10 20 30 40 50 60 70 80 90 100

20 50

80

P2

P3

P3P2P1

10 20 30 40 50 60 70 80 90 100

0

Speed

B

Maximum speed with which the target is to be approached.

• Depending on the profile parameter position, acceleration and deceleration, it is possible that the

drive may not reach the maximum speed. In this case, the graph would display a triangle instead of

a trapezium.

v [m/s]

v

pos

n Acceleration

o Travelling speed (is not reached here)

p Deceleration

q Target position (or feed distance)

t [s]

Acceleration

C

Selection of the change in speed by which acceleration is to be carried out maximally.

• The following two acceleration types are distinguished:

–Constant acceleration: the speed increases linearly.

–Linearly increasing acceleration: The speed increases in S-shapes.

v [m/s]

v

pos

n Constant acceleration

o Linearly increasing acceleration

v [m/s]

t [s]

v

pos

t [s]

Deceleration

D

Selection of the change in speed by means of which deceleration to standstill is to be maximally effected

again.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 45

Page 46

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Profile data management

Symbol Profile parameters

S-ramp time

E

When the S-ramp time is selected for a profile, it is executed with S-shaped ramps, e.g. acceleration and

deceleration processes are started smoothly to reduce the jerk and thus prevent the drive components

from damage.

• The acceleration/deceleration specified in the profile are only reached after the defined S-ramp time

has elapsed.

• This type of acceleration/deceleration is required for e.g. sensitive machine parts with clearance.

• The slower acceleration increase with the S profile prolongs the positioning time compared to the

time optimal L profile.

v [m/s]

n without jerk limitation (L profile)

o with jerk limitation (S profile)

a

Final speed

F

Selection of the speed by which the drive is to start the next profile after reaching the target position.

t [s]

t [s]

"Velocity changeover" or "Overchange" can be implemented with a final speed that is non-zero, i.e.

when the target position is reached, a second positioning process is started immediately without the

drive being decelerated to standstill at the first target position:

v [m/s]

v

pos

n Target position

o Final speed (here unequal "0")

v

G H

end

Start of TP window / End of TP window

These profile parameters serve to restrict the range for a touch probe positioning (residual path

t [s]

positioning) in which touch probes are to be detected.

Sequence profile with TP

Profile data set (profile no. 1 ... 75) in which the profile data of the profile are stored which is to be

executed after a touch probe has been detected.

• For the setting "0" no further profile connection by touch probe is effected.

Sequence profile without TP

Profile data set (profile no. 1 ... 75) in which the profile data of the profile is stored which is to be

executed after the standard profile has been executed (profile chaining).

• With the setting "0" no profile chaining is carried out.

• The sequence profile defined in this profile parameter is executed even if no touch probe has been

detected within the defined TP window.

46 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 47

9400 Technology applications | Positioning sequence control

5.4.2 Variable tables

To simplify parameter handling, the four most important physical sizes for profile

parameters are stored in separate "variable tables".

Parameter setting & configuration

Profile data management

VTPOS

Positions

VTSPEED

Speeds

VTACC

Acceleration/

VTJERK

S-ramp times

deceleration

Unit unit unit/s unit/s

2

s

Data format DINT with four decimal positions

Memory locations75505050

Code C04711/1...75 C04712/1...50 C04713/1...50 C04714/1...50

For profile

parameters

Target position

TP window starting position

TP window end position

Speed

Final speed

Acceleration

Deceleration

S-ramp time

Note!

A value is assigned to a profile parameter by referring to a table position of the

assigned variable table.

• Hence, not the value itself is entered into the profile parameter but the index

of the table position which contains the value to be used.

• See the example in the illustration [5-7]

Profile 1

Mode

Position

Speed

Acceleration

Deceleration

Jerk time

End speed

TP window start position

TP window end position

Next TP profile

Next profile

3

3

1

1

2

1

50

6

7

12

2

VTPOS

VTACC

VTACC

VTJERK

VTPOS

VTPOS

. ( 47)

1

2

...

100

1

2

...

50

VTPOS

VTSPEED

200 [unit]/s

400 [unit]/s

50 [unit]/s

Mode

Position

Speed

Acceleration

Deceleration

Jerk time

End speed

TP window start position

TP window end position

Next TP profile

Next profile

Profile 2

4

4

2

1

3

1

50

6

8

13

5

VTPOS

VTACC

VTACC

VTJERK

VTPOS

VTPOS

VTACC

1

2

...

50

VTJERK

1

2

...

50

[5-7] Principle: References to variable tables (here: References to VTSPEED)

In case of several references to the same table position, a change of the value in this

table position affects several profiles at the same time. Thus, recurring profile

parameters only need to be changed on one position.

EDS94TA10060xxxx EN 1.2 - 03/2010 L 47

Page 48

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Profile data management

If e.g. in case of a profile linkage, several profiles are to be executed with the same

speed, the corresponding profile parameters "speed" can all refer to the same table

position.

For an easier assignment and identification of the entered values, each table position

can be optionally provided with a comment in the »Engineer«.

5.4.3 Positioning modes

Depending on the traversing range/application, you can select between different

positioning modes which are described in the below table.

Note!

For absolute positioning, the home position must be known!

• If an absolute positioning process (positioning modes 1 ... 2 and 11 ... 16) is

started although the home position is not known, an error message is

indicated.

– In this case a programming error has occurred and the program flow must

be reset.

– If the error only occurs in a sequence profile, the last valid deceleration is

used to decelerate the drive to standstill.

The modulo positioning modes may involve reversing processes!

• If a modulo positioning process (positioning modes 11 ... 16) is started at an

initial speed other than zero, the target position may be overtravelled and a

reversing process may follow, depending on the selected deceleration / Sramp time parameters. This would also cause e.g. counter-clockwise rotation

in the "Absolute CW (modulo)" positioning mode.

Positioning mode

1 Absolute

The axis travels to an absolute position.

• Reference for the absolute position is zero position.

• The home position must be known.

• The traversing range is limited:

–to 214748.3647 [unit]

–by the internal display area (±2

• Not possible with "modulo" traversing range.

2 Absolute TP

Like mode 1, but with profile change when a touch probe is detected.

Touch probe positioning

5 Relative

The axis is traversed by a distance.

• Reference for the distance is the target position of the profile executed before.

• The feed per positioning is limited:

–to 214748.3647 [unit]

–by the internal display area (±2

6 Relative TP

Like mode 5, but with profile change on touch probe detection.

Touch probe positioning

. ( 51)

. ( 51)

31

increments)

31

increments)

48 L EDS94TA10060xxxx EN 1.2 - 03/2010

Page 49

9400 Technology applications | Positioning sequence control

Parameter setting & configuration

Profile data management

Positioning mode

7 Speed

Continuous constant travel.

• Only possible with "unlimited" and "limited" traversing range

• This mode does not approach a defined position, but follows the profile.

• Acceleration and deceleration are based on profile values.

• The traversing direction is defined by the sign of the traversing speed.

• Stopped through break signal.

8 Speed TP

Like mode 7, but with profile change on touch probe detection.

Touch probe positioning

11 Absolute CW

The axis travels in CW direction to an absolute position.

• Only possible with "Modulo" traversing range.

• Reference for the absolute position is zero position.

• In this direction the zero position of the axis can be overtravelled.

12 Absolute CW TP

Like mode 11, but with profile change on touch probe detection.

Touch probe positioning