Page 1

Accessories

EtherNet/IP™

Inverter Drives 8400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

E84AYCEO

Communication Manual EN

Ä.M?*ä

13443009

L

Page 2

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 5

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 7

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

1.3 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

1.4 Definition of the notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

2Safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

2.1 General safety and application notes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

2.2 Device and application-specific safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

2.3 Residual hazards _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

3 Product description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

3.1 Application as directed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

3.2 Identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

3.3 Product features _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

3.4 Connections and interfaces _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

4 Technical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

4.1 General data and operating conditions of the EtherNet/IP _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

4.2 Protective insulation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

4.3 Protocol data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

4.4 Communication time _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

4.5 Internal switch latency _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

4.6 Dimensions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

5Installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

5.1 Mechanical installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

5.1.1 Mounting for standard devices of 0.25 kW and 0.37 kW _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

5.1.2 Mounting for standard devices of 0.55 kW or more _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

5.1.3 Replacing the communication module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

5.2 Electrical installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

5.2.1 Wiring according to EMC guidelines _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

5.2.2 Network topology _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

5.2.3 EtherNet/IP connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

5.2.4 Ethernet cable specification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

5.2.5 External voltage supply _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

6 Commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 35

6.1 Before initial switch-on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 35

6.2 Configuring the host system (scanner) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

6.2.1 EDS files _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

6.2.2 Example: IP configuration of the Allen-Bradley 1769-L32E CompactLogix controller _ _ _ 38

6.3 Setting node addresses by means of rotary coding switches _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 40

6.4 Setting the IP configuration of the Inverter Drive 8400 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

6.4.1 Setting via the EtherNet/IP configurator of the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

6.4.2 Setting via codes in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

6.4.3 Setting via a BOOTP/DHCP server _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

6.4.4 Setting via the TCP/IP Interface Object (0xF5) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

6.4.5 Setting the multicast configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

6.5 Establishing an online connection via EtherNet/IP with the Lenze »Engineer« _ _ _ _ _ _ _ _ _ _ _ 49

6.6 Initial switch-on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

2 Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

7.1 Communication channels _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

7.2 Telegram types _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

7.3 EtherNet/IP state diagram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

8 I/O data transfer (implicit messages) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 56

8.1 I/O data mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

8.2 Technology applications (TA) / drive profiles _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

8.2.1 Lenze technology applications / user-definable parameter sets _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

8.2.2 "AC Drive Profile" application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 59

8.3 I/O assemblies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 60

8.4 I/O configuration in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 62

8.4.1 Lenze technology application / configuring user-definable parameter sets _ _ _ _ _ _ _ _ 62

8.4.2 Configuring "AC Drive Profile" application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 67

8.5 I/O configuration with »RSLogix 5000« version 19 or lower _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

8.6 I/O configuration with »RSLogix 5000« version 20 or higher _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 73

8.7 Saving the I/O configuration in »RSLogix 5000« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 83

9 Parameter data transfer (explicit messages) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 84

9.1 Write parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 85

9.2 Read parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 86

10 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 88

11 Diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 89

11.1 LED status displays _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 89

11.1.1 Module status displays _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 90

11.1.2 CIP™ status displays _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 91

11.1.3 Status indicators at the RJ45 sockets (X259, X260) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 94

11.2 Diagnostics with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 95

12 Error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

12.1 Short overview of the EtherNet/IP error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

12.2 Possible causes and remedies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 97

12.3 CIP™ error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 101

12.4 Mapping of Lenze device errors to DRIVECOM errors _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 102

13 Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 106

13.1 Parameters of the communication module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 106

13.2 Table of attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 122

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 3

Page 4

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

14 Implemented CIP™ objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 124

14.1 General CIP objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

14.1.1 Identity Object (1 / 0x01) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

14.1.2 Message Router Object (2 / 0x02) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 128

14.1.3 Assembly Object (4 / 0x04) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 129

14.1.4 Connection Manager Object (6 / 0x06) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 135

14.2 EtherNet/IP objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 137

14.2.1 Device Level Ring (DLR) Object (71 / 0x47) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 137

14.2.2 Quality of Service (QoS) Object (72 / 0x48) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 139

14.2.3 TCP/IP Interface Object (245 / 0xF5) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 141

14.2.4 Ethernet Link Object (246 / 0xF6) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 145

14.3 "AC Drive Profile" objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 148

14.3.1 Motor Data Object (40 / 0x28) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 149

14.3.2 Control Supervisor Object (41 / 0x29) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 150

14.3.3 AC Drive Object (42 / 0x2A) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 152

14.3.4 Write "DriveMode" attribute _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 154

14.4 Lenze objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 155

14.4.1 Lenze Class (101 / 0x65) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 155

14.4.2 Lenze Class (103 / 0x67) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

14.4.3 Lenze Class (104 / 0x68) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 158

14.4.4 Lenze Class (110 / 0x6E) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 159

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 160

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 164

4 Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 5

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

Contents

This documentation only contains descriptions of the E84AYCEO (EtherNet/IP™) communication

module.

Note!

This documentation supplements the mounting instructions supplied with the

communication module and the hardware manual "Inverter Drives 8400".

The hardware manual contains safety instructions that must be observed!

The features and functions of the communication module are described in detail.

Examples illustrate typical applications.

The theoretical context is only explained as far as it is required for understanding the function of

the communication module.

This documentation does not describe the software of another manufacturer. No

guarantee can be given for corresponding information in this documentation. Information

on the use of the software can be found in the documents for the host (PLC, scanner).

All brand names mentioned in this documentation are trademarks of their corresponding owners.

Tip!

Detailed information on EtherNet/IP can be found on the website of the user organisation

ODVA (Open DeviceNet Vendor Association):

www.odva.org

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 5

Page 6

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Target group

This documentation is intended for all persons who plan, install, commission and maintain the

networking and remote servicing of a machine.

Tip!

Current documentation and software updates with regard to Lenze products can be found

in the download area at:

www.Lenze.com

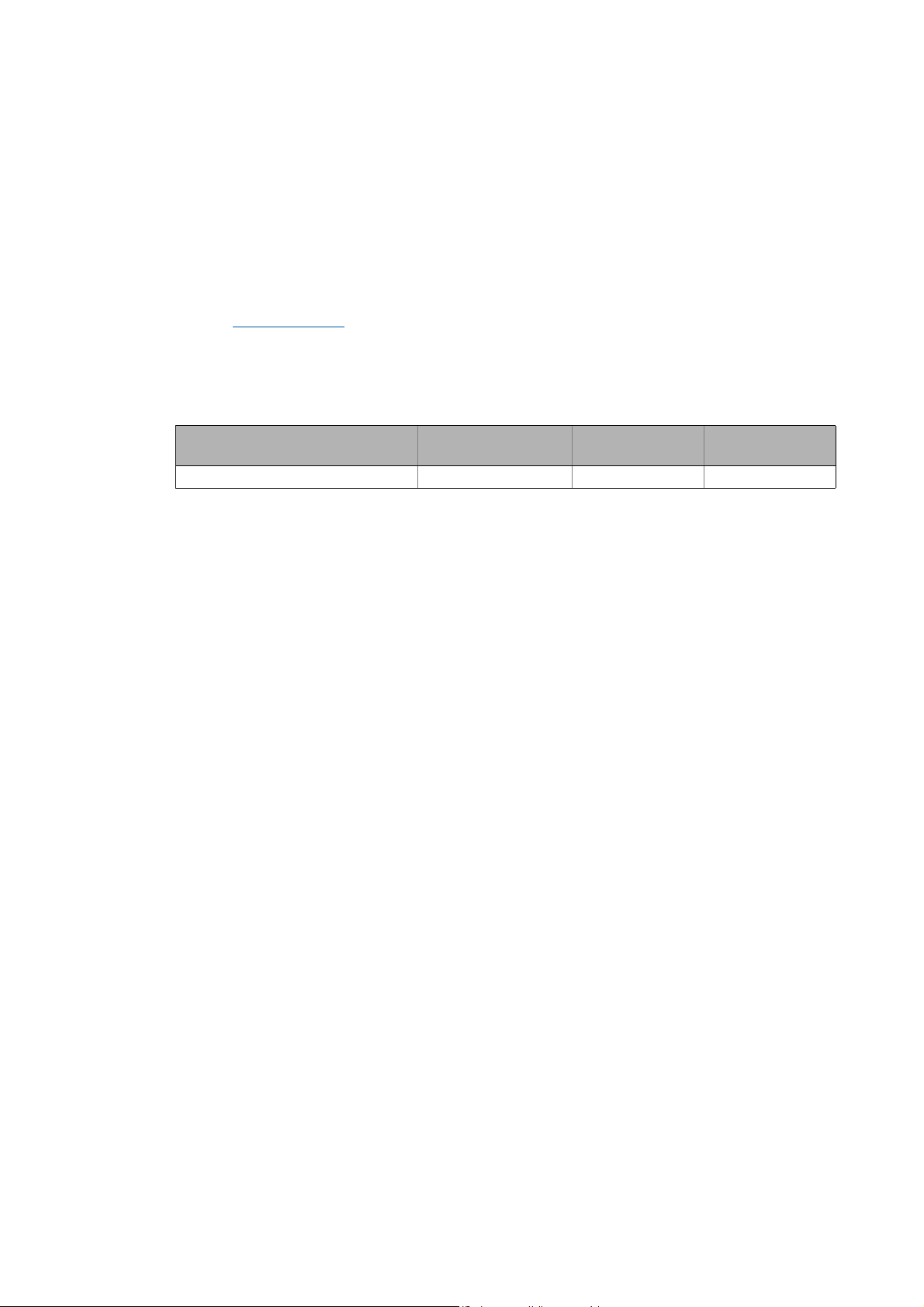

Information regarding the validity

The information given in this documentation is valid for the following devices:

Extension module Type designation From hardware

Communication module EtherNet/IP E84AYCEO VA 01.01

From software version 01.02, the "AC Drive Profile" of the Inverter Drives 8400 is supported from

version V13.00.

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the firmware

version of the communication module and software version of the installed engineering tools

(»Engineer«, »RSLogix 5000«), the screenshots in this documentation may differ from the screen

representation.

version

From software

version

6 Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 7

1 About this documentation

1.1 Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

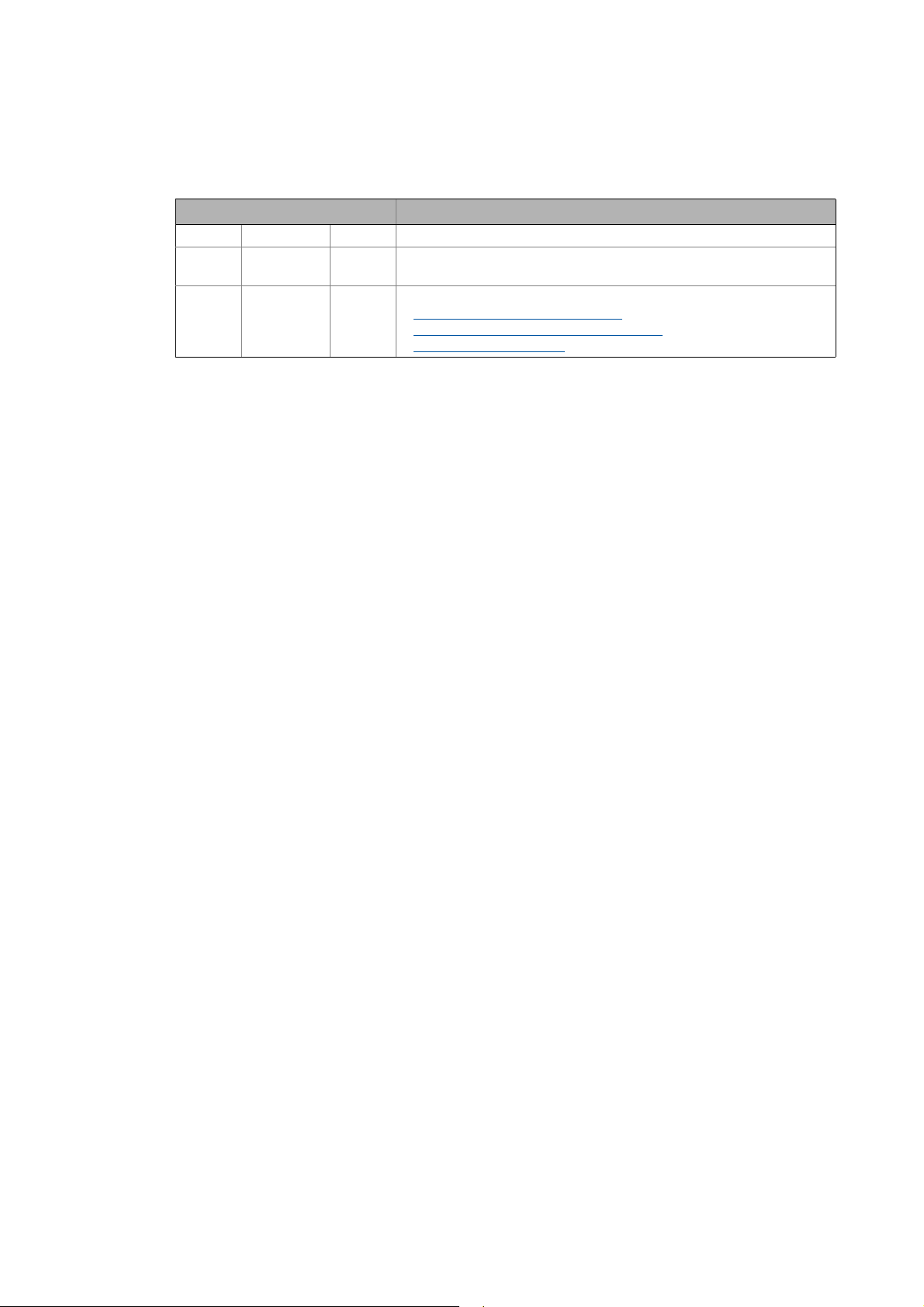

1.1 Document history

Version Description

1.0 08/2012 TD17 First edition

2.0 12/2012 TD17 • Revision for software version 01.02

•New layout

3.0 10/2013 TD17 Revised chapters:

I/O data transfer (implicit messages)

Parameter data transfer (explicit messages)

Implemented CIP™ objects

( 124)

( 56)

( 84)

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 7

Page 8

1 About this documentation

1.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

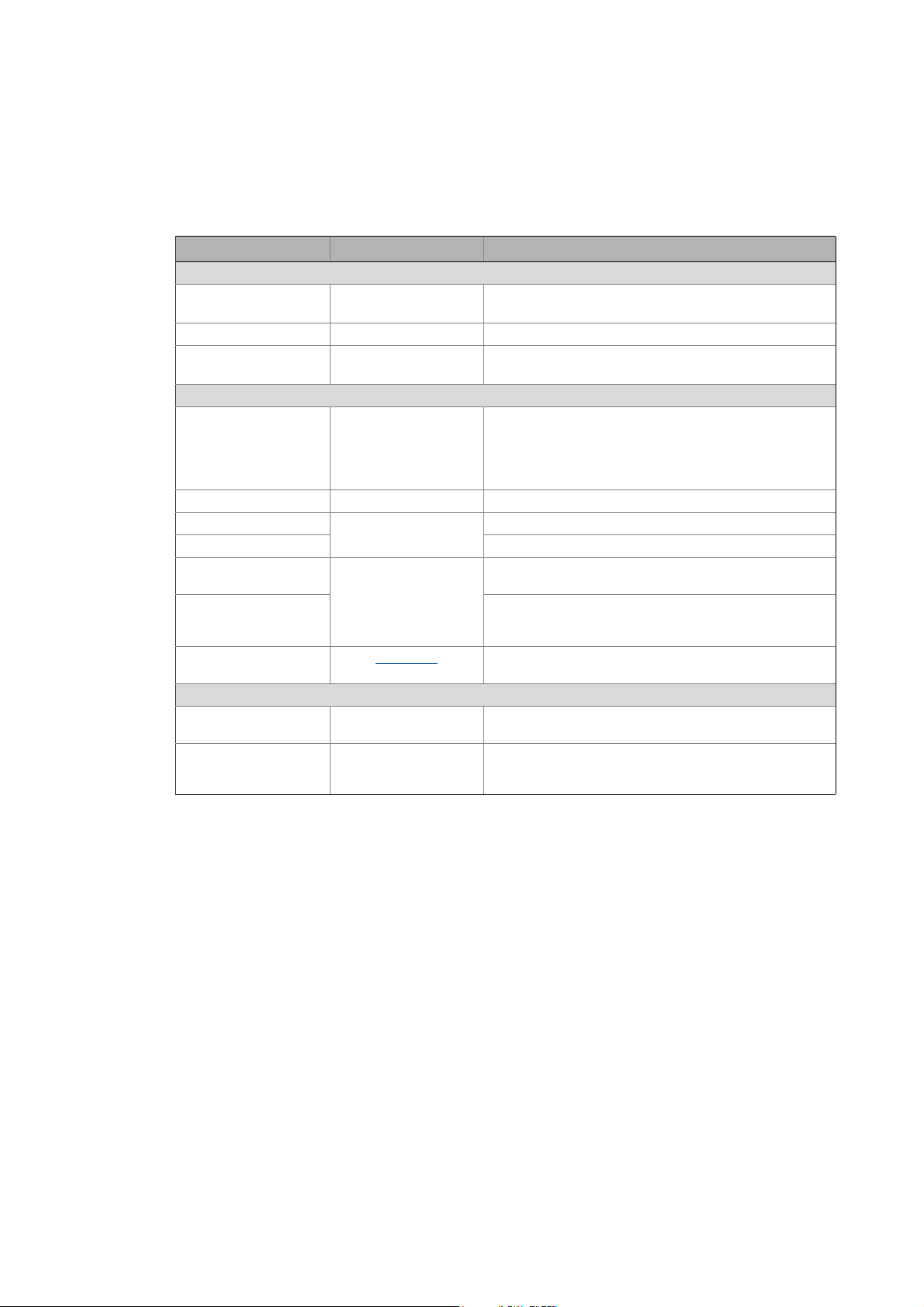

1.2 Conventions used

This documentation uses the following conventions to distinguish between different types of

information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal separator Point The decimal point is always used.

For example: 1234.56

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

• Nibble

Text

Version information Blue text colour All information that applies to from a certain software

Program name » « The Lenze PC software »Engineer«...

Window italics The Message window... / The dialog box Options...

Variable names By setting bEnable to TRUE...

Control element bold The OK button... / the Copy command... / the Characteristics

Sequence of menu

commands

Hyperlink underlined

Icons

Page reference ( 9) Optically highlighted reference to another page. In this

Step-by-step instructions

In inverted commas

Point

Example: ’100’

Example: ’0110.0100’

version of the drive onwards are marked accordingly in this

documentation.

Example: This function extension is available from software

version V3.0 onwards!

tab... / the Name input field...

If several commands are required to execute one function,

the single commands are separated by an arrow: Select the

Open command to...

File

Optically highlighted reference to another topic. It is

activated with a mouse-click in this online documentation.

online documentation activated via mouse-click.

Step-by-step instructions are indicated by a pictograph.

8

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 9

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Terminology used

Term Meaning

ACD Address Conflict Detection

Adapter EtherNet/IP slave

Inverter / Drive Lenze inverters of the "Inverter Drives 8400" series

Standard device

ARP Address Resolution Protocol

Use BOOTP Bootstrap Protocol

Code Parameter which serves to parameterise and monitor the drive. In normal usage,

the term is usually referred to as "Index".

Subcode If a code contains several parameters, they are stored in "subcodes".

In the documentation, the slash "/" is used as a separator between the code and

the subcode (e.g. "C00118/3").

In everyday language, the term is also referred to as "subindex".

»Engineer« Software from Lenze which supports you throughout the whole machine life

cycle - from planning to maintenance.

EtherNet/IP™ (EtherNet Industrial Protocol) is a fieldbus system based on

Ethernet which uses the Common Industrial Protocol™ (CIP™) for data exchange.

EtherNet/IP™ and Common Industrial Protocol™ (CIP™) are trademarks and

patented technologies, licensed by the user organisation ODVA (Open

DeviceNet Vendor Association), USA.

Use DHCP Dynamic Host Configuration Protocol

DSCP Differentiated Services Codepoints

EDS Electronic Data Sheet

Explicit messages Explicit Messages are used to transfer parameter data.

HW Hardware

IGMP Internet Group Management Protocol

Implicit messages Implicit Messages are used to transfer I/O data.

"Class 1" connection I/O connection

"Class 3" connection Explicit connection

Level 2 EtherNet/IP performance level 2:

I/O Message Server including Explicit Message Server

Lenze setting Default settings of the device, preconfigured ex works.

Basic setting

PLC Programmable Logic Controller

QoS Quality of Service

RPI Requested Package Interval:

Interval requested between 2 telegrams for cyclic data transmission

»RSLogix 5000« Programming and development software from Rockwell for hosts (scanners) in

EtherNet/IP networks (e.g. Allen-Bradley Logix controllers).

Scanner EtherNet/IP master or client

Host

SW Software

TTL Time To Live:

Validity time of data packets in the EtherNet/IP network

UCMM Unconnected Message Manager

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 9

Page 10

1 About this documentation

1.4 Definition of the notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Definition of the notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

Safety instructions

Layout of the safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for easy handling

Reference to another document

10

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 11

2 Safety instructions

2.1 General safety and application notes

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Note!

It is absolutely vital that the stated safety measures are implemented in order to prevent

serious injury to persons and damage to material assets.

Always keep this documentation to hand in the vicinity of the product during operation.

2.1 General safety and application notes

Danger!

If the following basic safety measures are disregarded, severe injuries to persons and

damage to material assets may result.

Lenze drive and automation components ...

• must only be used as directed.

• must never be commissioned if they display signs of damage.

• must never be technically modified.

• must never be commissioned if they are not fully mounted.

• must never be operated without required covers.

• during and after operation can have live, moving and rotating parts, depending on their degree

of protection. Surfaces can be hot.

The following applies to Lenze drive components ...

• only use the accessories approved.

• Only use original manufacturer spare parts.

Observe all specifications contained in the enclosed documentation and related documentation.

• This is the precondition for safe and trouble-free operation and for obtaining the product

features specified.

Product features

• The specifications, processes, and circuitry described in this document are for guidance only and

must be adapted to your own specific application. Lenze does not take responsibility for the

suitability of the process and circuit proposals.

All works on and with Lenze drive and automation components must only be carried out by qualified

personnel. According to IEC 60364 or CENELEC HD 384 these are persons who ...

• are familiar with installing, mounting, commissioning, and operating the product.

• who have the corresponding qualifications for their work.

( 14)

• who know and can apply all regulations for the prevention of accidents, directives, and laws

applicable at the place of use.

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 11

Page 12

2 Safety instructions

2.2 Device and application-specific safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2 Device and application-specific safety instructions

• During operation, the communication module must be securely connected to the standard

device.

• With external voltage supply, always use a separate power supply unit, safely separated to EN

61800-5-1 in every control cabinet (SELV/PELV).

• Only use cables corresponding to the given specifications.

Ethernet cable specification

( 31)

Documentation for the standard device, host, system/machine

All the other measures prescribed in this documentation must also be implemented.

Observe the safety instructions and application notes contained in this manual.

2.3 Residual hazards

Protection of persons

If the Inverter Drives 8400 are used on a phase earthed mains with a rated mains voltage 400 V,

protection against accidental contact is not ensured without implementing external measures.

Protective insulation

Device protection

The communication module contains electronic components which may be damaged or destroyed

by electrostatic discharge.

Installation

( 23)

( 17)

12

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 13

3 Product description

3.1 Application as directed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Product description

3.1 Application as directed

The communication module ...

• is an accessory module that can be used in conjunction with the following standard devices:

Product series Type designation From software version

Inverter Drives 8400 StateLine E84AVSCxxxxx 11.00

Inverter Drives 8400 HighLine E84AVHCxxxxx 11.00

Inverter Drives 8400 TopLine E84AVTCxxxxx 02.00

• is a device intended for use in industrial power systems.

• should only be used under the operating conditions prescribed in this documentation.

• can only be used in EtherNet/IP networks.

Any other use shall be deemed inappropriate!

3.2 Identification

The type designation as well as the hardware and software version of the communication module

are indicated on the nameplate:

[3-1] Identification data

E84AYCEO006

1 Type designation (type)

E84 Product series

AVersion

Y Module identification: Extension module

C Module type: Communication module

EO EtherNet/IP

V/S V: Coated version

S: Standard version

2 MAC address (MAC)

00-0A-86-xx-yy-zz:

Hardware address of the communication

module for unique identification in the

network

3 Hardware version (HW)

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 13

Page 14

3 Product description

3.3 Product features

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3 Product features

• Interface module for the EtherNet/IP communication system, for attachment to the expansion

slots of Inverter Drives 8400

• The communication module can either be supplied internally by the standard device or

externally by a separate voltage source.

• The Inverter Drive 8400 is always an adapter device:

EtherNet/IP adapter with "Level 2" functionality

• 2-port interface with integrated switch functionality

• Access to all Lenze parameters (configurable via TCP/IP using the Lenze »Engineer«)

• Up to 3 TCP/IP socket connections for communication with the Lenze »Engineer«

• Support of "IP Config Pending" (activation of changed IP configuration by "power off/on" or

"type 0 reset")

• Support of the redundancy protocol DLR (Device Level Ring) as "beacon-based ring node"

• Up to 16 I/O data words (32 bytes) are possible.

• Further CIP features:

• Max. 8 CIP connections

• 1 "exclusive owner" connection

• I/O connection type: cyclic

•Minimum I/O cycle time: 4 ms

• Support of multicast messages, UCMM, ACD, BOOTP/DHCP, VLAN tagging/DSCP

14

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 15

3 Product description

3.4 Connections and interfaces

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

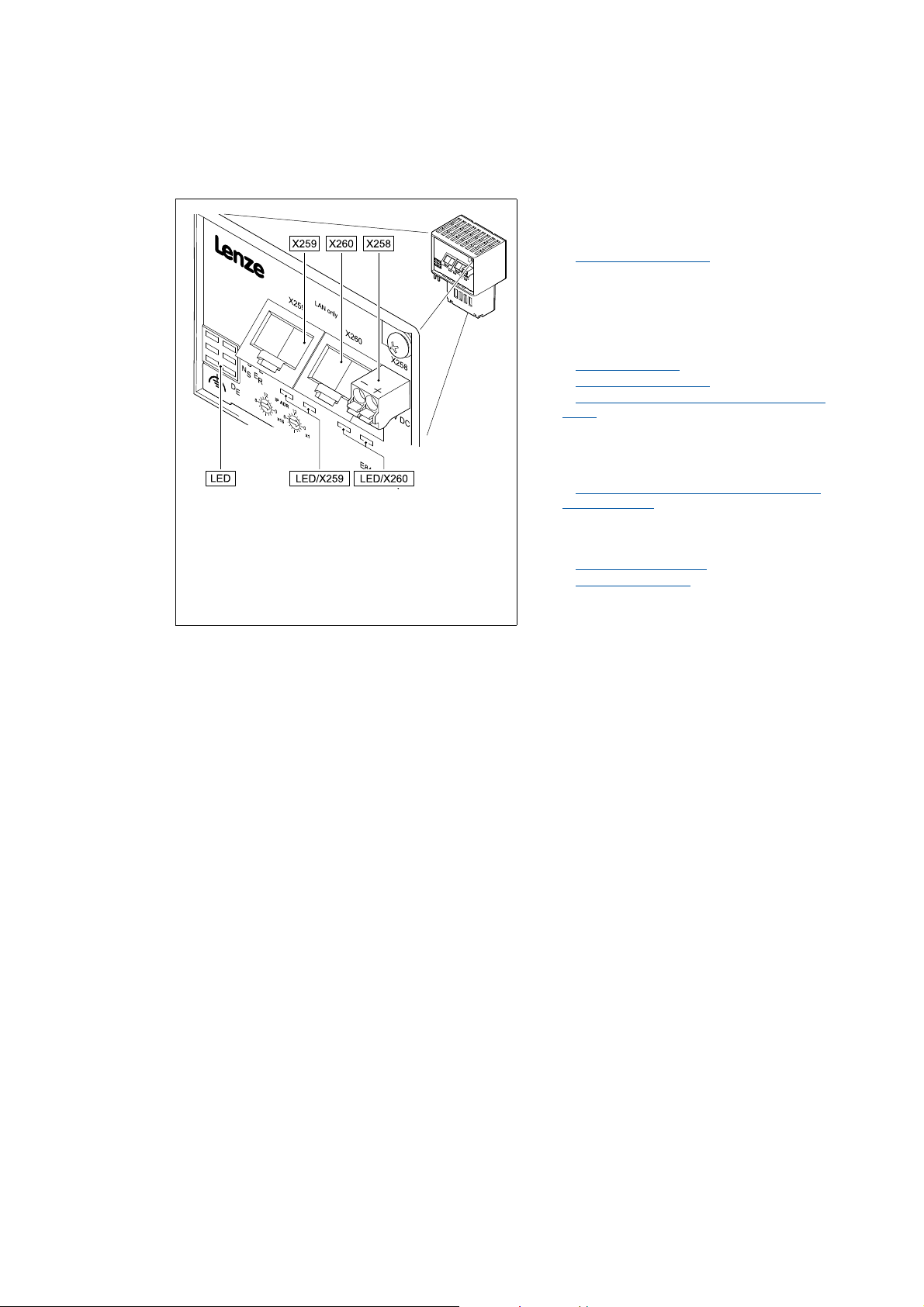

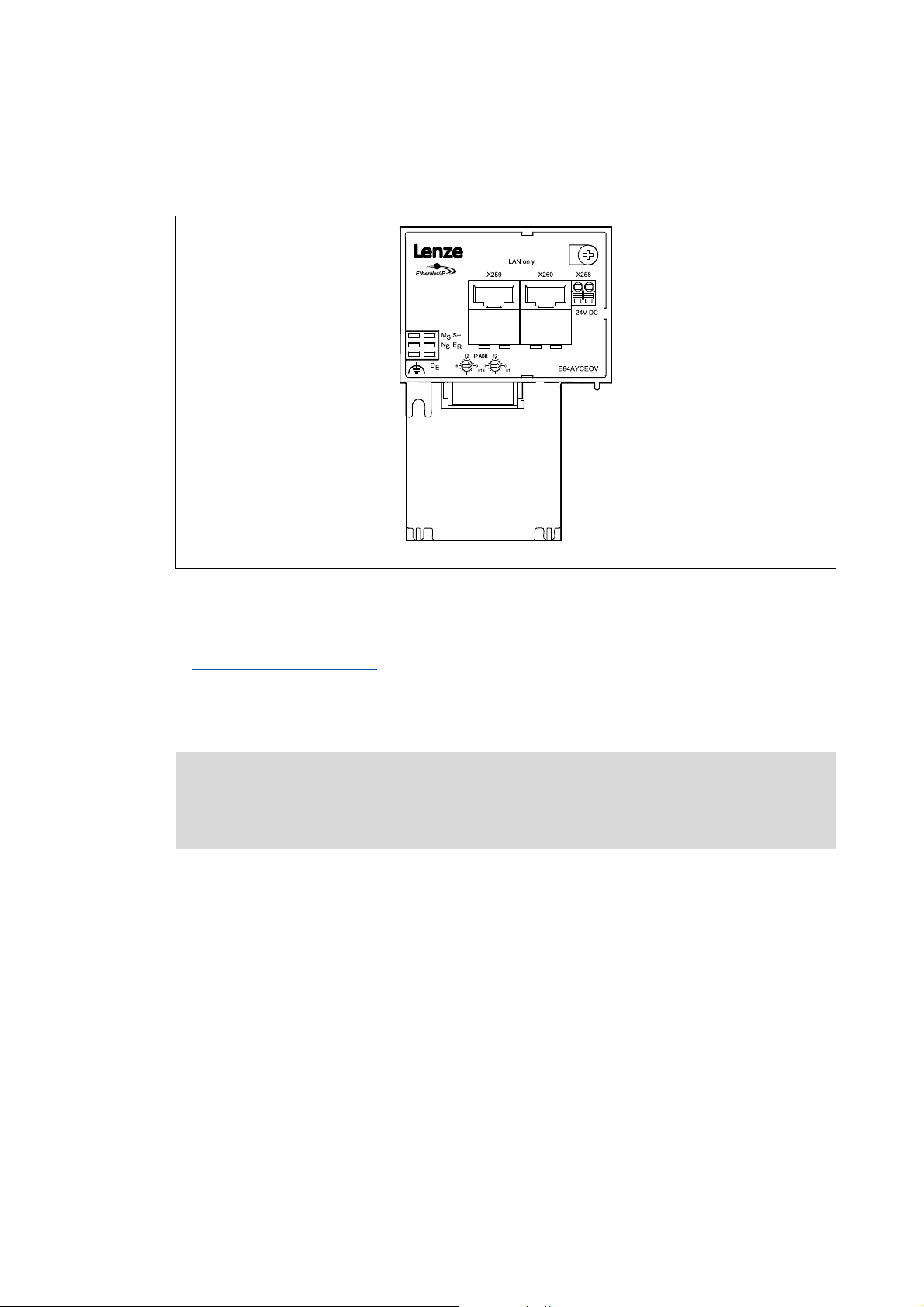

3.4 Connections and interfaces

X258 External voltage supply of the communication

module

• 2-pin plug connector with spring connection

E84AYCEO003

External voltage supply

X259

EtherNet/IP terminals

X260

• RJ45-sockets

• each with 2 LED status displays for

diagnostics

Network topology

EtherNet/IP connection

Status indicators at the RJ45 sockets (X259,

X260) ( 94)

x1

Rotary coding switches for node address

setting (IP ADR)

x16

Setting node addresses by means of rotary

coding switches ( 40)

( 33)

( 27)

( 29)

[3-2] E84AYCEO communication module (EtherNet/IP)

5 LED status displays for diagnostics

MS

Module status displays

ST

NS

CIP™ status displays

ER

DE

( 91)

( 90)

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 15

Page 16

4Technical data

4.1 General data and operating conditions of the EtherNet/IP

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

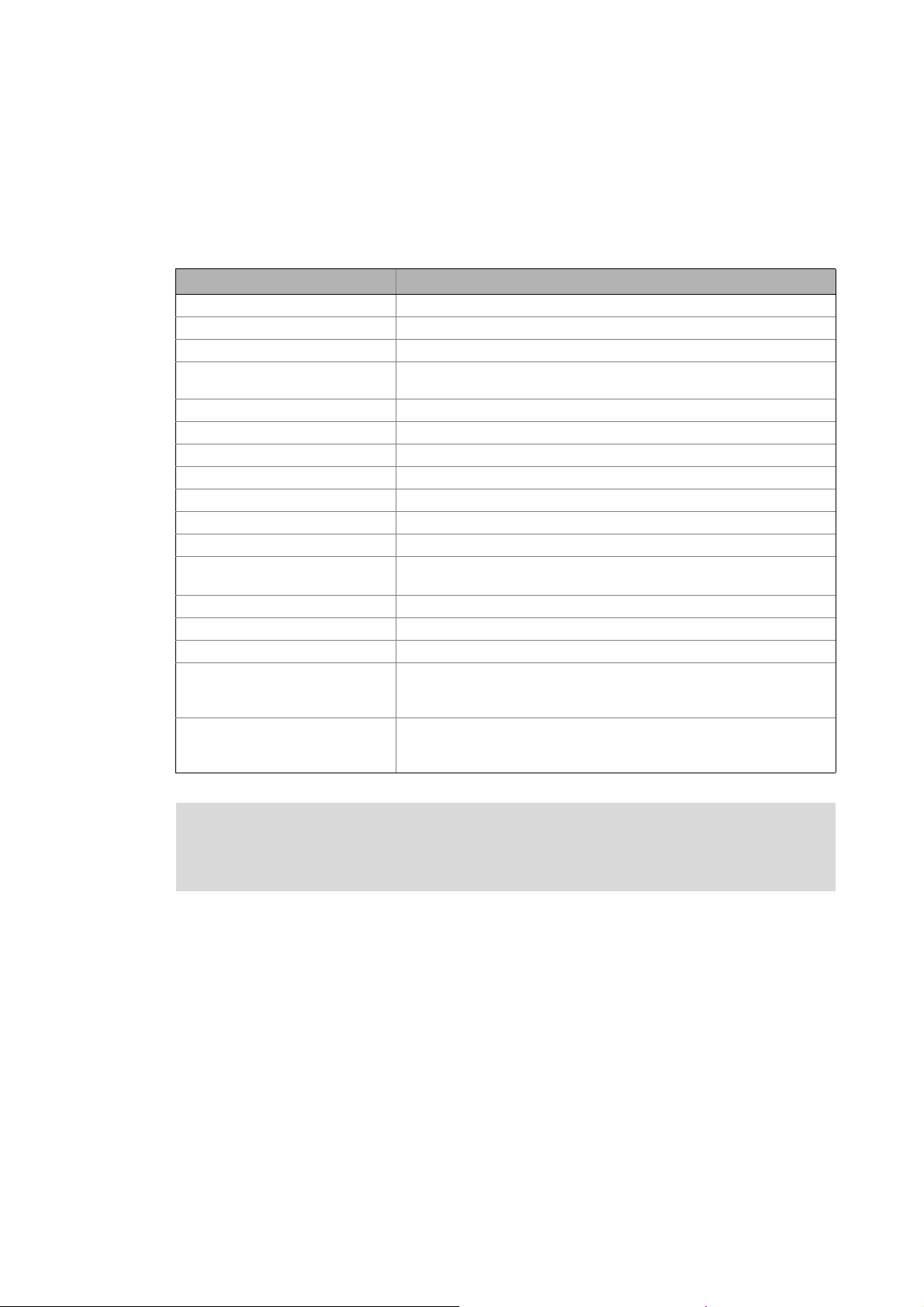

4 Technical data

4.1 General data and operating conditions of the EtherNet/IP

Range Values

Order designation E84AYCEO

Communication profile EtherNet/IP

Communication medium S/FTP (Screened Foiled Twisted Pair), ISO/IEC 11801 or EN 50173, CAT 5e

Interface for communication RJ45 Standard Ethernet (according to IEEE 802.3), 100Base-TX (Fast

Network topology Tree, star, and line

Type of node Adapter (slave)

Number of nodes Max. 254 in the subnetwork

Max. cable length 100 m

Vendor ID 587 (0x24B), Lenze (’Lenze AC Tech’ in older Rockwell data)

Device type 2 (0x02), AC Drive

Product code 8400 (0x20D0)

Baud rate • 10 Mbps

Transmission mode Half duplex / full duplex

Switching method Store-and-forward / cut-through

Switch latency Approx. 125 μs at max. telegram length

Voltage supply External supply via separate power supply unit

Conformities , approvals • CE

Ethernet)

• 100 Mbps

• + : U = 24 V DC (20.4 ... 28.8 V), I

• - : Reference potential for external voltage supply

•UL

(see also hardware manual)

= 140 mA

max

16

Hardware manual for Inverter Drives 8400

Here you can find the ambient conditions and data on the electromagnetic compatibility

(EMC), which also apply to the communication module.

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 17

4Technical data

4.2 Protective insulation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2 Protective insulation

Danger!

Dangerous voltage

If the Inverter Drives 8400 are operated on a phase-earthed mains with a rated mains

voltage of 400 V, external measures need to be implemented in order to ensure

protection against accidental contact.

Possible consequences:

Death or severe injuries

Protective measures:

If protection against accidental contact is required for the control terminals of the

inverter and the connections of the plugged device modules, ...

• a double isolating distance must exist.

• the components to be connected must be provided with the second isolating

distance.

Note!

The existing protective insulation in the Inverter Drives 8400 is implemented according

to EN 61800-5-1.

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 17

Page 18

4Technical data

X4

X6

X5

X3

Bus

Ext. DC

MCI

X4

X6

X5

X3

X1X1

X105X105

X100X100

MMI

X106X106X106X106

X106X106X106X101

4.2 Protective insulation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

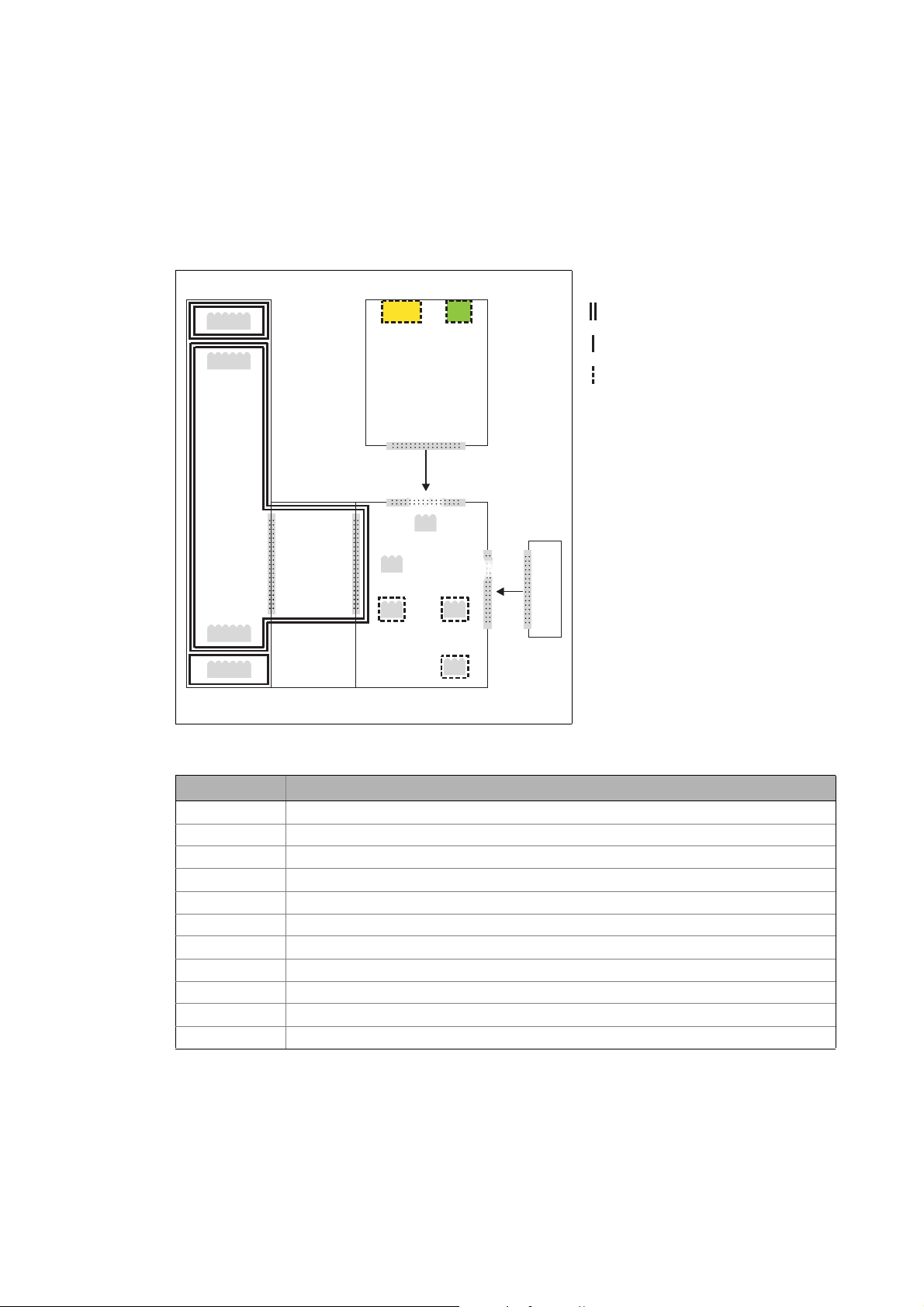

The following illustration ...

• shows the arrangement of the terminal strips and the separate potential areas of the Inverter

Drive 8400.

• serves to determine the decisive protective insulation between two terminals located in

differently insulated separate potential areas.

Reinforced insulation

Basic insulation

Functional insulation

E84YCXX007

[4-1] Protective insulation in accordance with EN61800-5-1

Terminal strip Connection

X100 Mains / DC bus connection

X101 Relay contact

X105 Motor/brake resistor

X106 Motor PTC

X1 System bus (CANopen)

X3 Analog inputs/outputs

X4 Digital outputs

X5 Digital inputs

X6 Diagnostics

MCI Slot for communication module

MMI Slot for the memory module

18

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 19

4Technical data

4.2 Protective insulation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Example

Which type of protective insulation is used between the bus terminal of the device module in slot

MCI and the X100 mains terminal?

The separate potential area with the better protective insulation is decisive.

• The separate potential area of the bus terminal of the device module has a "functional

insulation".

• The separate potential area of the mains terminal has a "reinforced insulation".

Result: The insulation between mains terminal X100 and the bus terminal is of the "reinforced

insulation" type.

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 19

Page 20

4Technical data

4.3 Protocol data

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3 Protocol data

Range Values

I/O data words 1 ... 16 words (max. 32 bytes, 16 bits/word)

Supported CIP services • Get_Attributes_All

• Get_Attribute_Single

• Set_Attribute_Single

• Reset (types ’0’ and ’1’ only)

•Forward_Open

•Forward_Close

• Get_Member

4.4 Communication time

The communication time is the time between the start of a request and the arrival of the

corresponding response.

The communication times in an EtherNet/IP network depend on the ...

• processing time in the inverter;

• telegram runtime (baud rate / telegram length);

• nesting depth of the network.

processing time within the inverter

Data Processing time

Process data (I/O data) 10 ms

+ 0 ... 1 ms

+ 1 ... x ms

Parameter data Approx. 30 ms + a tolerance of 20 ms (typically)

For some codes, the processing time may be longer (see software manual/

»Engineer« online help for Inverter Drives 8400).

Lenze standard update cycle (can be changed in the Rockwell

engineering tool)

Processing time in the module

Runtime of the application task of the technology

application used (tolerance)

There are no interdependencies between parameter data and I/O data.

20

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 21

4Technical data

4.5 Internal switch latency

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.5 Internal switch latency

The integrated 2-port switch causes runtime delays. For "store-and-forward" and 100 Mbps, these

runtime delays can be calculated as follows.

Runtime delay for an output data packet of the scanners incl.

sequence counter:

Runtime delay = ((66 permanent bytes + I/O data in bytes) x 8 x 10 nsec) + 4 μsec

Runtime delay for an output data packet of an adapter without

Runtime delay = ((62 permanent bytes + I/O data in bytes) x 8 x 10 nsec) + 4 μsec

Example

Delay of an output data packet of the scanners with 8 output data words (16 bytes):

• ((66 permanent bytes + 16 bytes) x 8 x 10 nsec) + 4 μsec

• (82 bytes x 8 x 10 nsec) + 4 μsec

• 6.56 μsec + 4 μsec = 10.56 μsec

32-bit "run/idle header" with 16-bit

32/bit "run/idle header":

Note!

The use of external switches can also lead to runtime delays. Depending on the system

constellation, it may be useful to create a star topology or a line/mix topology.

Network topology

( 27)

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 21

Page 22

4Technical data

4.6 Dimensions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

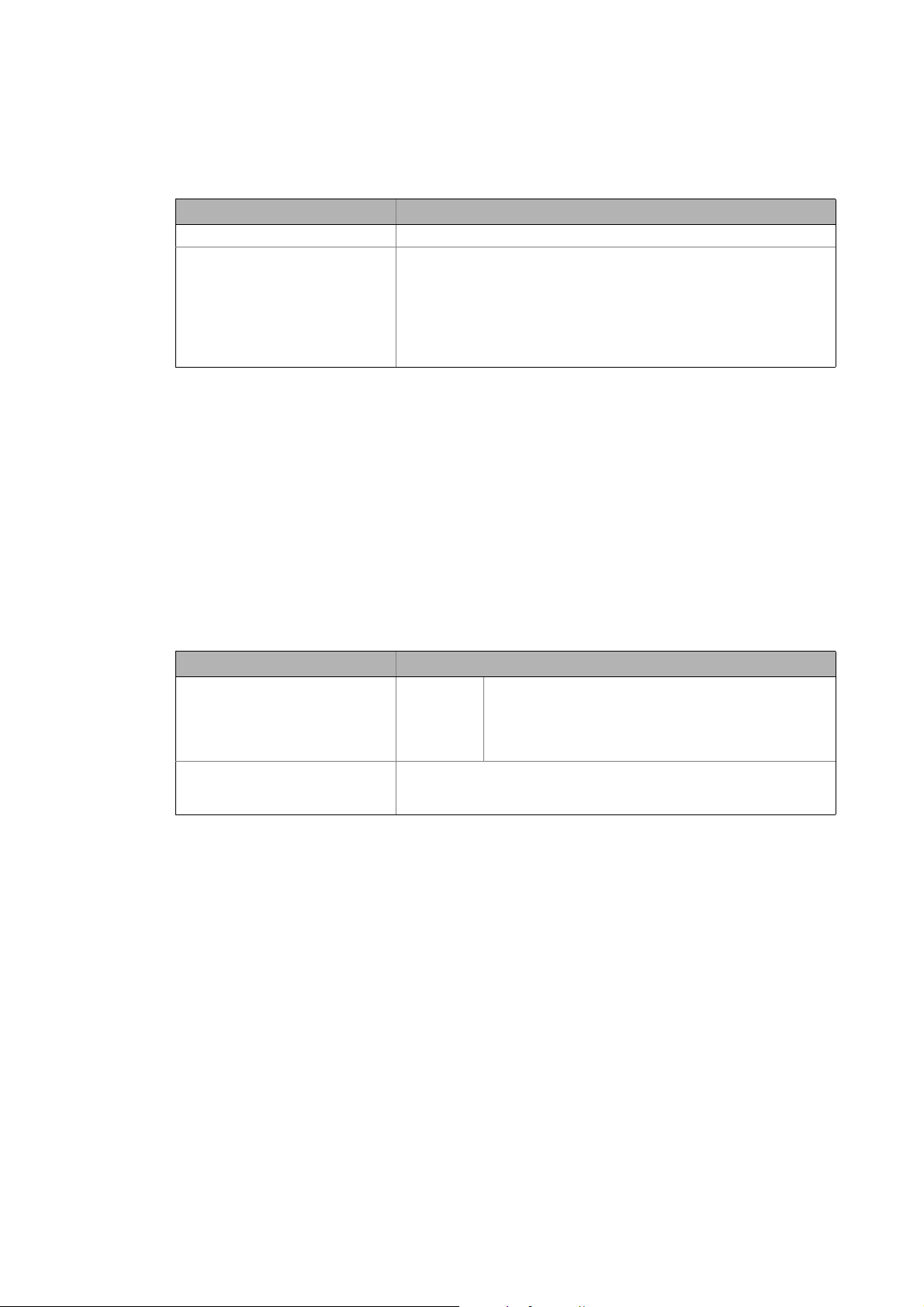

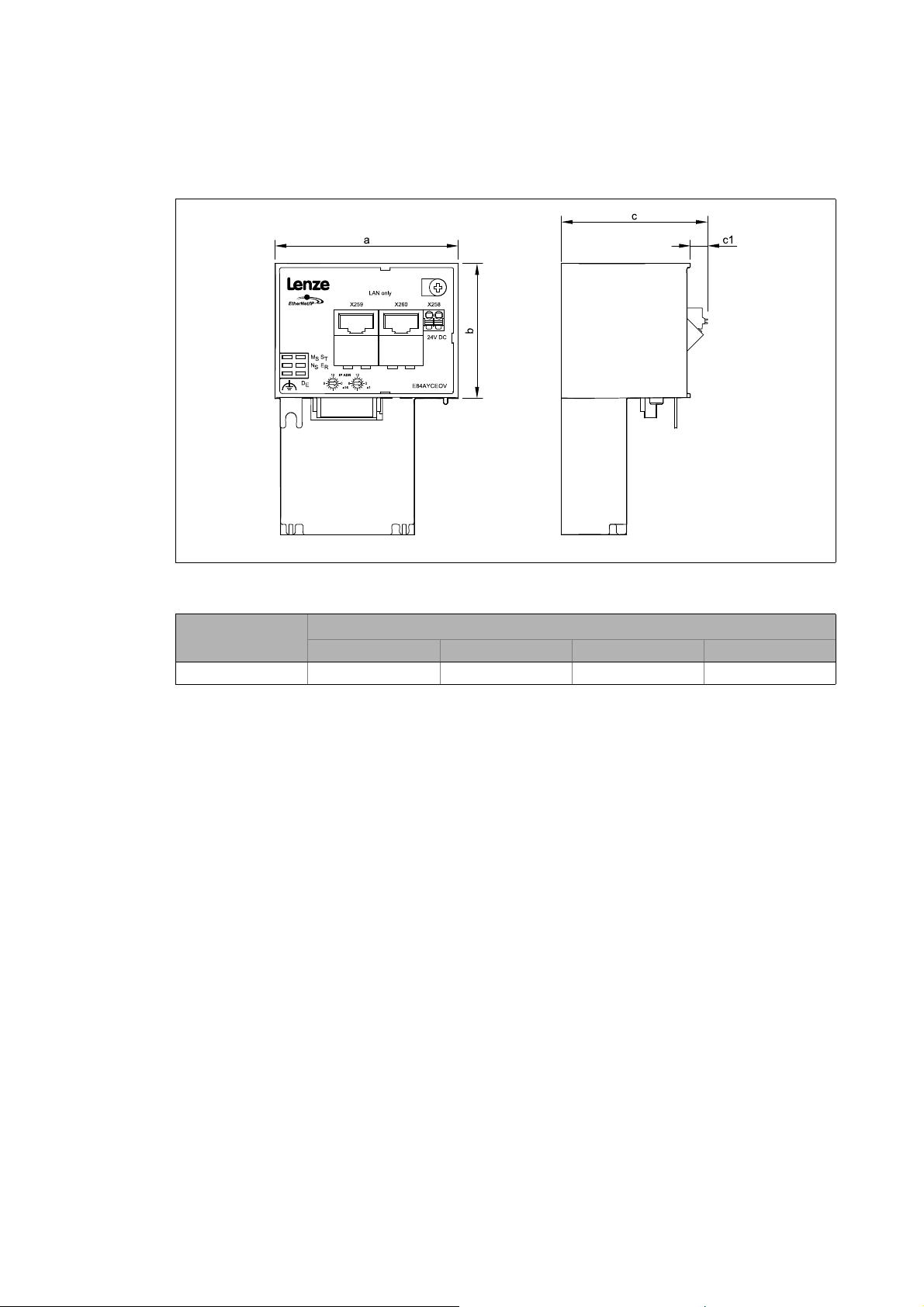

4.6 Dimensions

E84AYCEO005_1

[4-2] Dimensions

Type Dimensions [mm]

E84AYCEO 67 50 57 8

a b c c1

22

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 23

5 Installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 Installation

Stop!

Electrostatic discharge

Electronic components within the communication module can be damaged or destroyed

by electrostatic discharge.

Possible consequences:

• The communication module is defective.

• Fieldbus communication is not possible or faulty.

Protective measures

Before touching the module, be sure that you are free of electrostatic charge.

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 23

Page 24

5 Installation

5.1 Mechanical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.1 Mechanical installation

The communication module can be plugged in or unplugged from the MCI slot when the drive is

switched on. When the module is plugged in, it is detected automatically, and a function and

version plausibility check is executed.

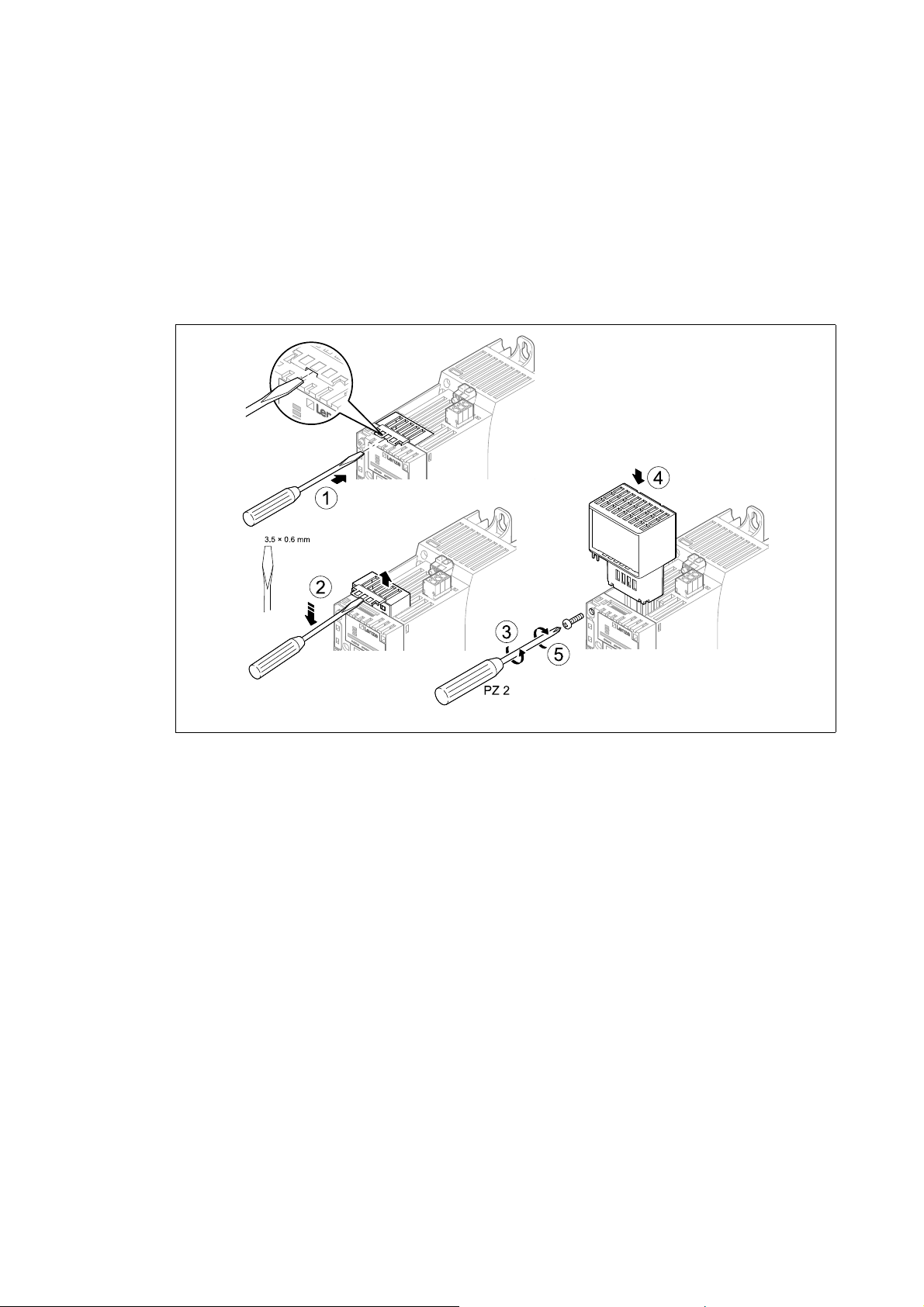

5.1.1 Mounting for standard devices of 0.25 kW and 0.37 kW

E84YCPM002D

[5-1] Mounting for standard devices of 0.25 kW and 0.37 kW

Mounting steps

1. Use a screwdriver to lever out the cover of the MCI slot of the standard device and remove it (1,

2).

2. Loosen the securing screw for the communication module at the standard device (3).

3. Insert the communication module into the MCI slot of the standard device (4).

4. Tighten the securing screw again (5).

24

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 25

5 Installation

5.1 Mechanical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

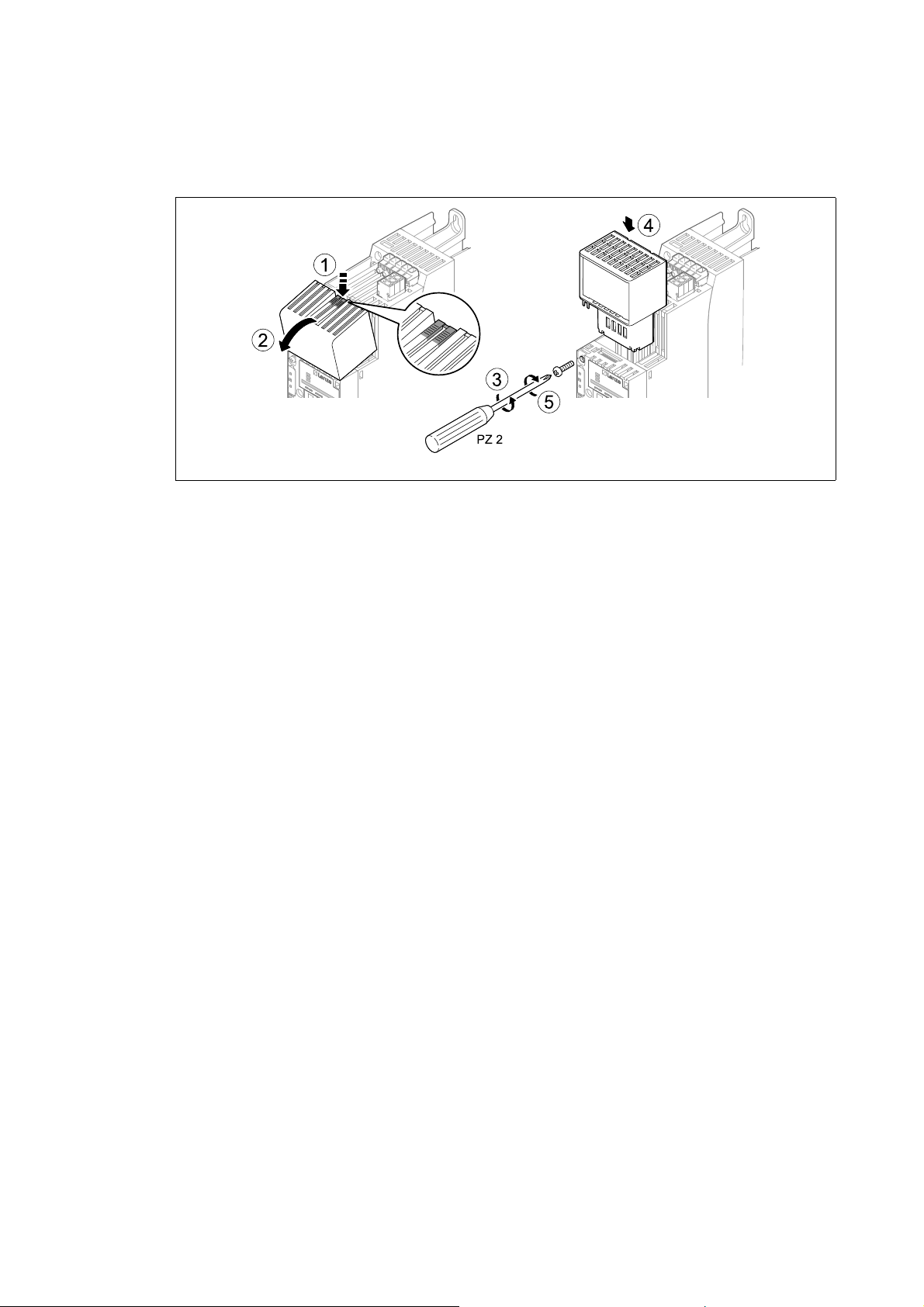

5.1.2 Mounting for standard devices of 0.55 kW or more

E84YCPM002A

[5-2] Mounting for standard devices of 0.55 kW or more

Mounting steps

1. Slightly impress the pressure surface of the top side of the MCI slot cover of the standard

device (1).

2. Tilt the cover forward and remove it from the standard device (2).

3. Loosen the securing screw for the communication module at the standard device (3).

4. Insert the communication module into the MCI slot of the standard device (4).

5. Tighten the securing screw again (5).

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 25

Page 26

5 Installation

5.1 Mechanical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

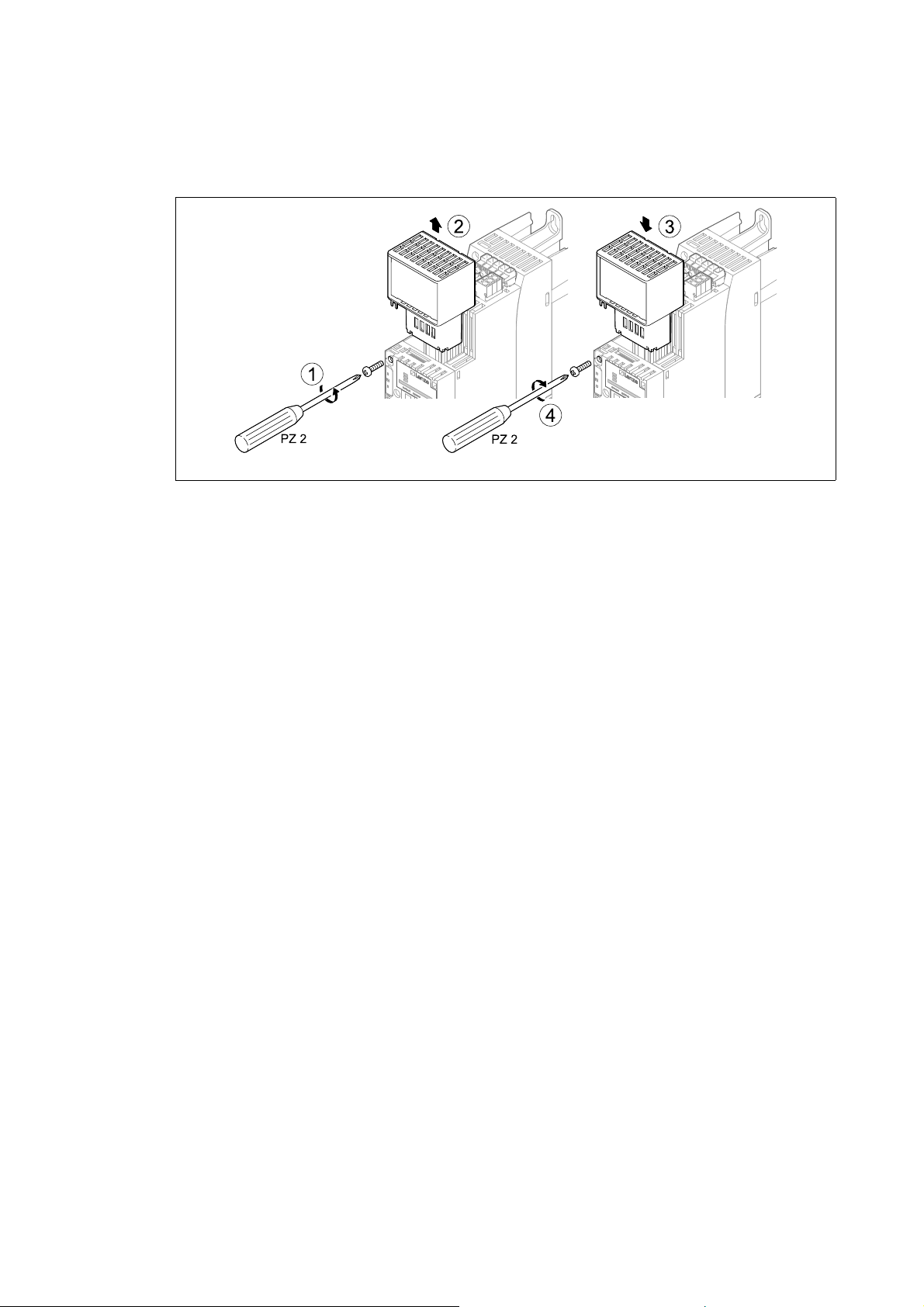

5.1.3 Replacing the communication module

E84YCPM002B

[5-3] Replacing the communication module

Mounting steps

1. Loosen the securing screw for the communication module at the standard device (1).

2. Pull the communication module out of the MCI slot of the standard device (2).

3. Insert the new communication module into the MCI slot of the standard device (3).

4. Tighten the securing screw again (4).

26

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 27

5 Installation

AA

S

A

A

SW

AAA

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2 Electrical installation

Documentation for the standard device, host, system/machine

Observe the notes and wiring instructions contained in this documentation.

5.2.1 Wiring according to EMC guidelines

In typical systems, standard shielding is sufficient for Ethernet cables.

However, in environments with a very high level of interference, EMC resistance can be improved

by additionally earthing the cable shield on both sides.

For this observe the following notes:

1. Remove the plastic sheath of the cable at a length of 2 cm.

2. Fasten the cable shield to the shield support of the standard device.

5.2.2 Network topology

It is typical of EtherNet/IP to have a rather free topology the limiting factor of which is large

message latencies due to e.g. switches connected in series.

Internal switch latency

The combination of a line and a stub is useful for system wiring.

EtherNet/IP supports the following topologies:

•Line

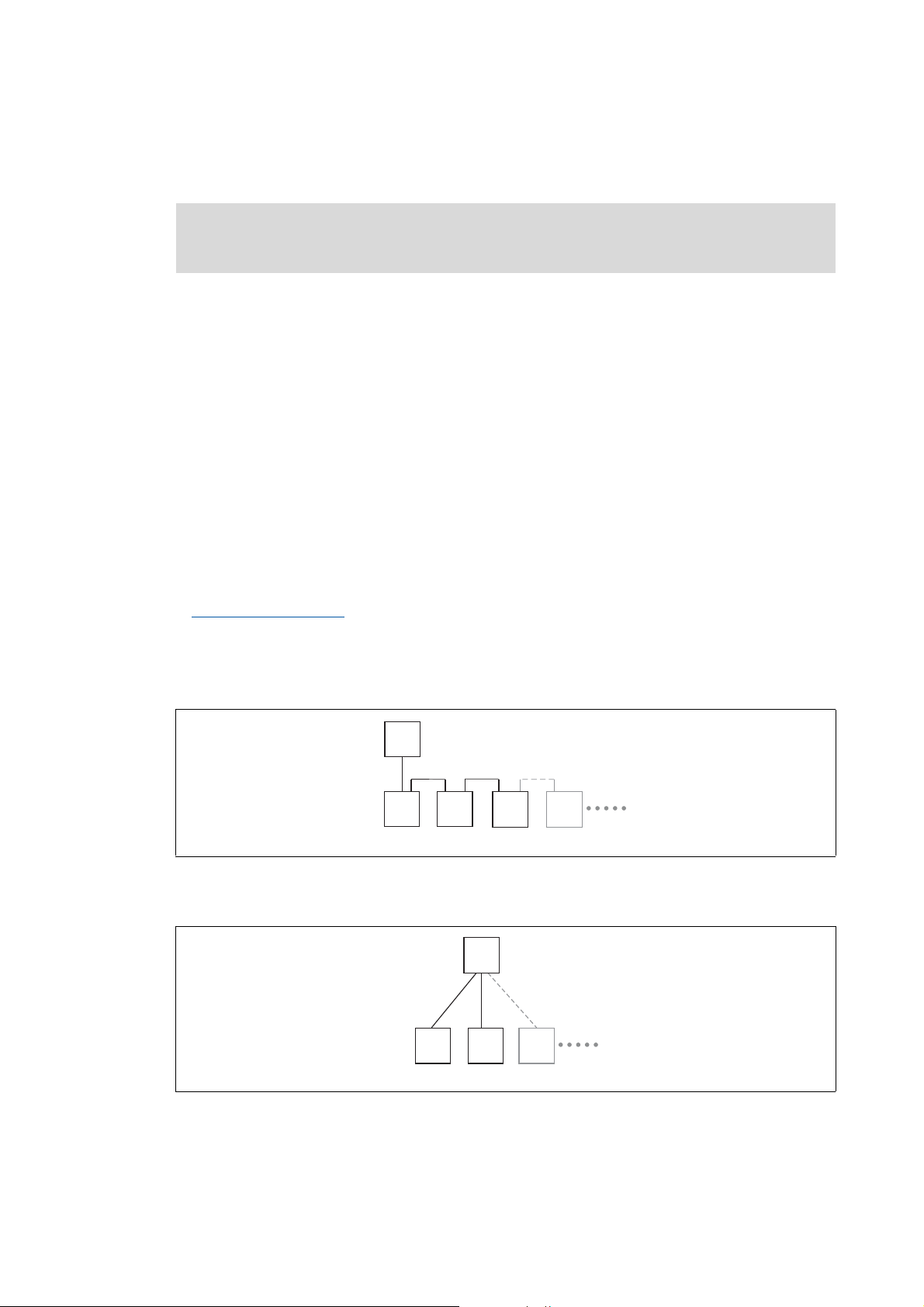

[5-4] Line topology (S = scanner, A = adapter)

•Switch / star

( 21)

E94AYCEO008

[5-5] Switch / star topology (SW = switch, A = adapter)

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 27

E94AYCEO005

Page 28

5 Installation

S

SWSWSW

SW

SWSW

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

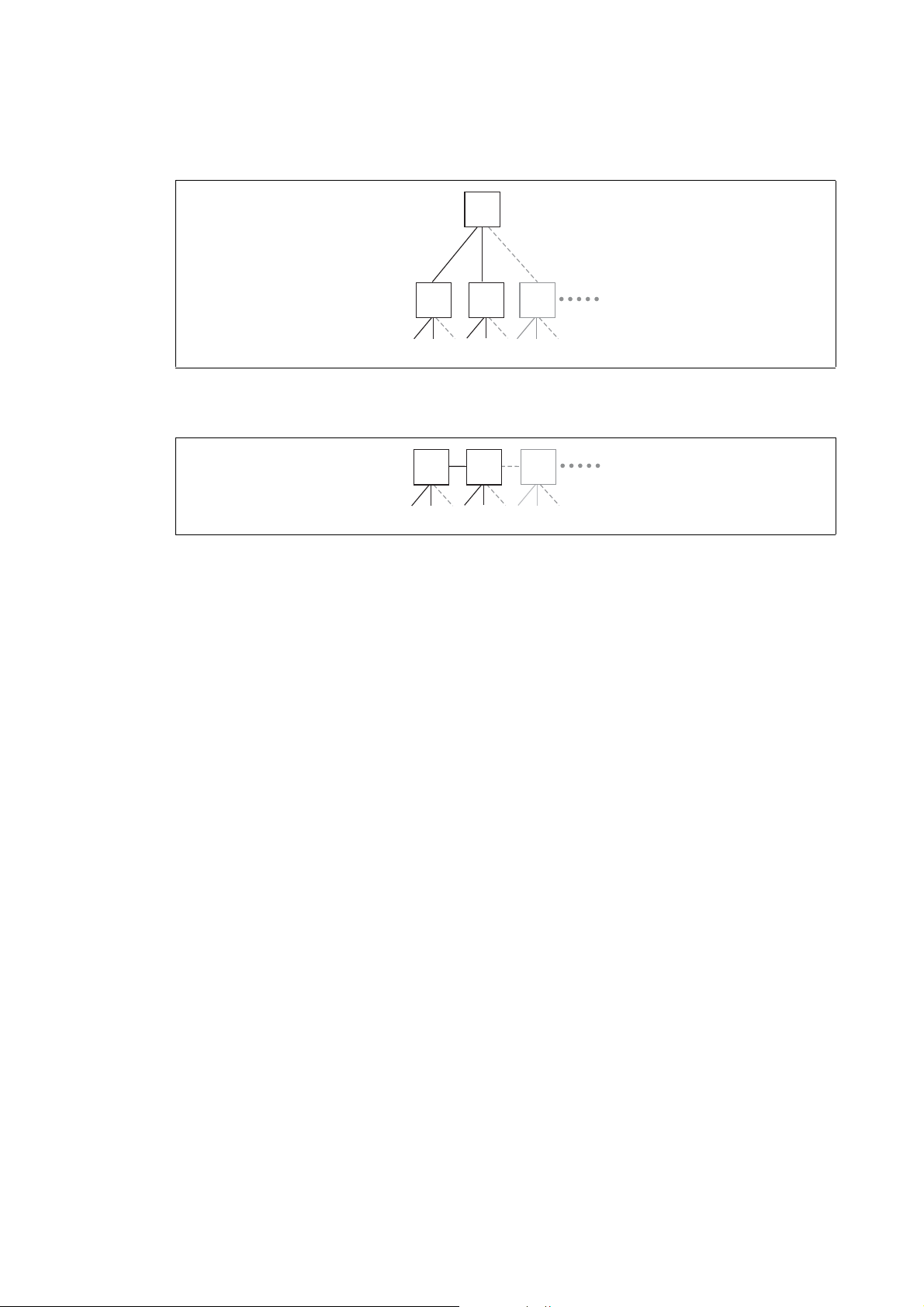

•Tree via switches

E94AYCEO006

[5-6] Tree topology (S = scanner, SW = switch)

•Switch / switch

E94AYCEO007

[5-7] Switch / switch topology (SW = switch)

28

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 29

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.3 EtherNet/IP connection

A connection to the EtherNet/IP network is established via RJ45 sockets X259 and X260.

[5-8] EtherNet/IP terminals X259 and X260

For connection of the communication module to the EtherNet/IP fieldbus, a standard Ethernet

patch cable is suitable.

Ethernet cable specification

The installation and removal of the Ethernet cables is optimised for the use of connectors in

accordance with the "Automation Initiative of German Domestic Automobile Manufacturers"

(AIDA).

( 31)

Note!

To prevent the RJ45 socket from being damaged, insert or remove the Ethernet cable

connector straight (at a right angle) into or from the socket.

E84AYCEO005_2

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 29

Page 30

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

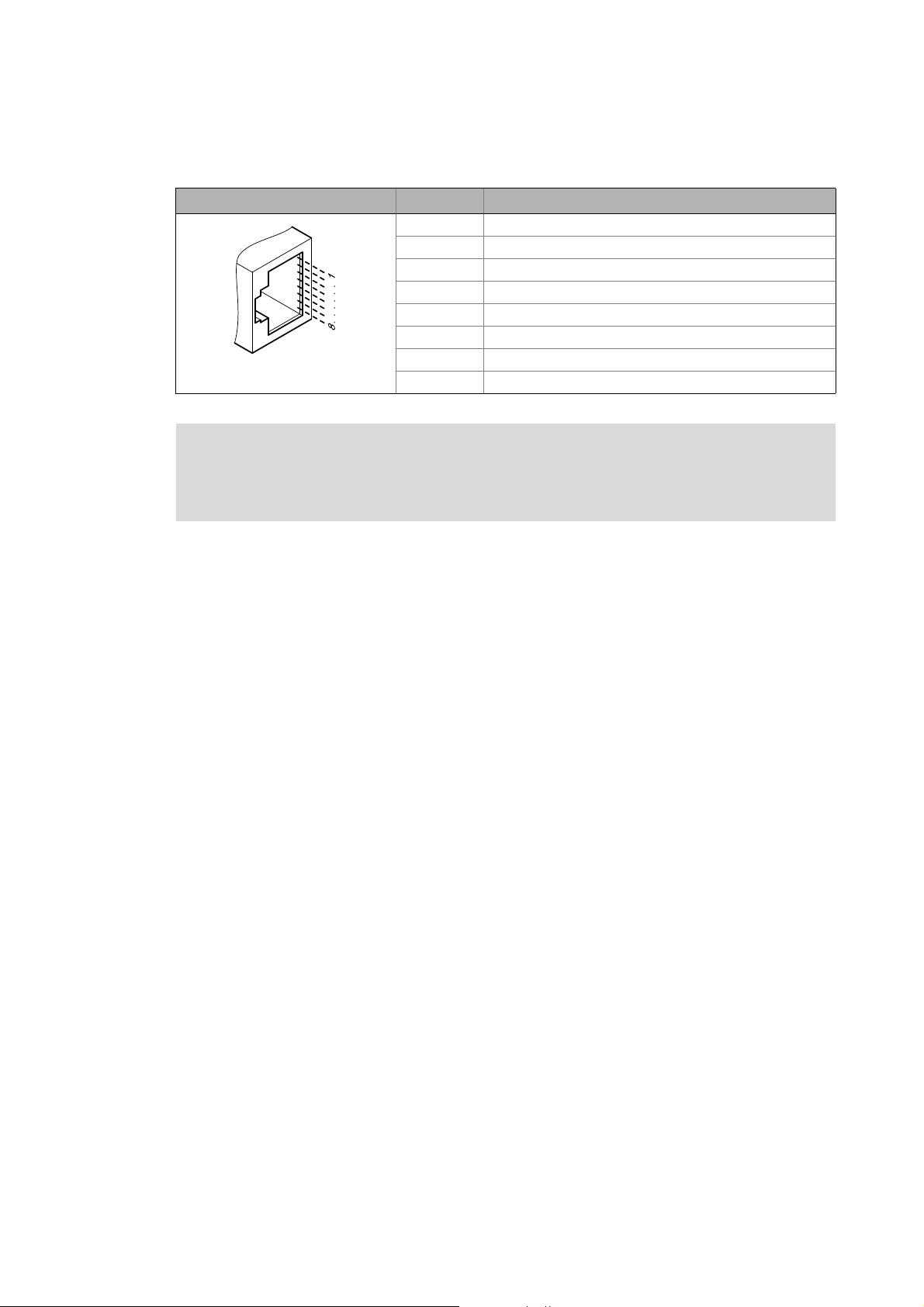

Pin assignment of the RJ45 sockets

RJ45 socket Pin Signal

1Tx +

2Tx -

3Rx +

4-

5-

6Rx -

E94AYCXX004C

7-

8-

Note!

Dependent on the configuration of the Ethernet port of the device to be connected, we

recommend the use of a cross-over cable.

Tip!

The EtherNet/IP interfaces feature an auto-MDIX function. This function adjusts the

polarity of the RJ45 interfaces so that a connection can be established irrespective of the

polarity of the opposite EtherNet/IP interface and irrespective of the type of cable used

(standard patch cable or crossover cable).

30

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 31

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.4 Ethernet cable specification

Note!

Only use cables that meet the listed specifications.

Ethernet cable specification

Ethernet standard Standard Ethernet (in accordance with IEEE 802.3), 100Base-TX (Fast

Cable type S/FTP (Screened Foiled Twisted Pair), ISO/IEC 11801 or EN 50173, CAT 5e

Damping 23.2 dB (for 100 MHz and 100 m each)

Crosstalk damping 24 dB (at 100 MHz and per 100 m)

Return loss 10 dB (per 100 m)

Surge impedance 100

Ethernet)

Structure of the Ethernet cable

[5-9] Structure of the Ethernet cable (S/FTP, CAT 5e)

E94YCEP016

A Cable insulation

B Braid

C Foil shielding

TP1

Twisted core pairs 1 ... 4

...

Colour code of the Ethernet cable

TP4

( 32)

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 31

Page 32

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Colour code of the Ethernet cable

Note!

Wiring and colour code are standardised in EIA/TIA 568A/568B.

In accordance with the industrial standard, the use of 4-pin Ethernet cables is

permissible. The cable type only connects the assigned pins 1, 2, 3 and 6 to one another.

E94YCEI004A

[5-10] Ethernet plug in accordance with EIA/TIA 568A/568B

Pair Pin Signal EIA/TIA 568A EIA/TIA 568B

3 1 Tx + white / green white / orange

2 Tx - green orange

2 3 Rx + white / orange white / green

1 4 blue blue

5 white / blue blue / white

2 6 Rx - orange green

4 7 white / brown white / brown

8brown brown

32

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 33

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.5 External voltage supply

The communication module can be externally supplied with voltage via separate supply cables at

the 2-pin plug connector X258.

Note!

With external voltage supply, always use a separate power supply unit, safely separated

to EN 61800-5-1 in every control cabinet (SELV/PELV).

The external voltage supply of the communication module is necessary if the power supply for the

basic device fails but communication via the fieldbus is to be maintained.

The parameters of a standard device separated from the mains cannot be accessed.

Wiring of the X258 plug connector

Stop!

Only wire the plug connector if the standard device is disconnected from the mains.

[5-11] Wiring of the 2-pin plug connector with spring connection

How to wire the plug connector with spring connection:

1. Press a screwdriver into the notch below the terminal and keep it pressed.

2. Place the supply cable in the terminal.

E84AYCXX010

3. Remove the screwdriver from the notch.

Assignment of the X258 plug connector

Name Description

+ U = 24 V DC (20.4 V - 0 % ... 28.8 V + 0 %)

I = 140 mA

- Reference potential for the external voltage supply

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 33

Page 34

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Terminal data

Range Values

Electrical connection 2-pin plug connector with spring connection

Possible connections Rigid:

0.2 ... 1.5 mm

Flexible:

Without wire end ferrule

0.2 ... 1.5 mm

2

(AWG 24 ... 16)

2

(AWG 24 ... 16)

With wire end ferrule, without plastic sleeve

0.2 ... 1.5 mm

With wire end ferrule, with plastic sleeve

0.2 ... 1.5 mm

Stripping length 10 mm

2

(AWG 24 ... 16)

2

(AWG 24 ... 16)

34

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 35

6 Commissioning

6.1 Before initial switch-on

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6 Commissioning

During commissioning, plant-specific data such as motor parameters, operating parameters,

responses, and parameters for fieldbus communication are defined for the inverter. Lenze devices

use codes for this purpose.

The codes of the inverter and for communication are saved to the memory module in a non-volatile

data set.

In addition, there are codes for diagnosing and monitoring the stations.

Parameter reference

6.1 Before initial switch-on

( 106)

Stop!

Before you switch on the Inverter Drive 8400 with the communication module for the

first time, check all the wiring for completeness, short-circuits and earth faults.

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 35

Page 36

6 Commissioning

6.2 Configuring the host system (scanner)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2 Configuring the host system (scanner)

To be able to communicate with the communication module, the host (scanner) must be configured

first.

The configuration of EtherNet/IP networks always requires an EtherNet/IP configuration software

(e.g. »RSLogix 5000« from Rockwell) for the host system (scanner).

The configuration software is necessary for the programming of controller programs, EtherNet/IP

configuration, real-time execution and diagnostics.

The basic parameters of the communication module are stored in the internal configuration

memory and can be used for node detection by the scanner.

For node detection (fieldbus scan), the corresponding device descriptions of the Lenze device family

are used.

Tip!

Here you will find information on configuring with the »RSLogix 5000« programming

software from Rockwell:

I/O configuration with »RSLogix 5000« version 19 or lower

( 68)

I/O configuration with »RSLogix 5000« version 20 or higher

( 73)

36

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 37

6 Commissioning

6.2 Configuring the host system (scanner)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2.1 EDS files

Depending on the EtherNet/IP scanner configuration software, the EDS files (Electronic Data Sheet)

may be used for the configuration of the network profile, the communication with the participating

devices and the automatic generation of tags. For this purpose, the EDS files have to be imported

into the controller project of the EtherNet/IP configuration software.

The EDS file required for the configuration can be found in the download area at:

www.Lenze.com

Tip!

From version 20 onwards, Rockwell's »RSLogix 5000« programming software features an

"EDS Hardware Installation Tool" that can be used to ...

• install/import EDS files;

• create EDS files;

• carry out EDS uploads;

• delete EDS files from your controller project.

In »RSLogix 5000«, the dialog for the "EDS Hardware Installation Tool" is self-explanatory

and not described further in this documentation.

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 37

Page 38

6 Commissioning

6.2 Configuring the host system (scanner)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

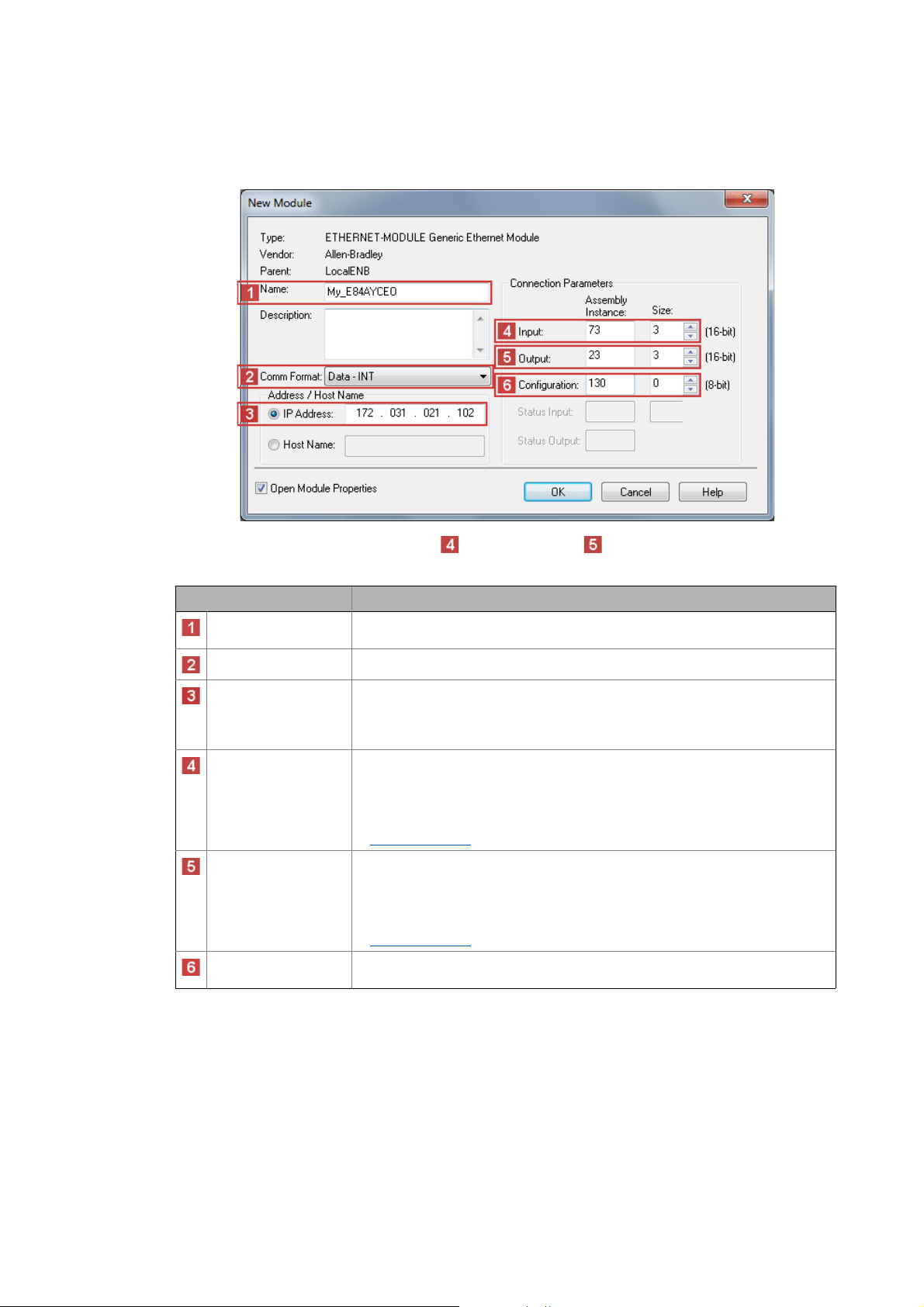

6.2.2 Example: IP configuration of the Allen-Bradley 1769-L32E CompactLogix controller

In this example, the Allen-Bradley CompactLogix control unit 1769-L32E with integrated EtherNet/

IP interface is used for communication with the Inverter Drives 8400.

The »RSLogix 5000« programming software from Rockwell is used for the configuration.

To establish communication via an EtherNet/IP network, add the controller and its scanner to the I/

O configuration.

How to set the IP configuration of the 1769-L32E CompactLogix controller using the

»RSLogix 5000« programming software:

1. Click on the I/O Configuration folder in the configuration tree.

2. Right click on "1769-L32E Ethernet Port LocalENB" and select "Properties" from the context

menu.

3. Go to the General tab of the "Module Properties: ..." dialog window and enter the IP address

of the scanner.

4. Then click OK.

38

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 39

6 Commissioning

6.2 Configuring the host system (scanner)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5. Go to the Port Configuration tab and enter the IP configuration, BOOTP setting, Ethernet

baud rate and duplex mode.

6. Then click OK.

• Now, the scanner is configured for the EtherNet/IP network.

• Here you will find information on project planning with the »RSLogix 5000«

programming software from Rockwell:

I/O configuration with »RSLogix 5000« version 19 or lower

I/O configuration with »RSLogix 5000« version 20 or higher

( 68)

( 73)

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 39

Page 40

6 Commissioning

6.3 Setting node addresses by means of rotary coding switches

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.3 Setting node addresses by means of rotary coding switches

Note!

• Each network node address must only be used once.

• Adjustable address range: 1 ... 254

You can set the node address (IP address) by means of the two "IP ADR" rotary coding switches

located on the front.

E84AYCEO004

[6-1] "IP ADR" rotary encoding switches

The inscription on the rotary coding switches corresponds to the valencies for determination of the

IP address.

The associated IP address of the communication module is the result of address setting by means of

the rotary encoder switches, e.g. IP address 192.168.100.[IP ADR]

In the default state, the rotary coding switches have been set to "0".

The rotary coding switch is re-evaluated when the following events occur:

• Type 0 reset service to the Identity Object (1 / 0x01)

• Type 1 reset service to the Identity Object (1 / 0x01)

• Switch the voltage supply for the communication module off and then on again.

The current value of the rotary coding switch is indicted in code C13920

( 126);

( 126);

.

40

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 41

6 Commissioning

6.3 Setting node addresses by means of rotary coding switches

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Possible settings of the rotary coding switches

Position of the rotary coding switches Description

Default status:

0 × 16 0 × 1

0 ... 15 1 ... 14

15 15

•Value from code C13005 (IP configuration reference, 1: BOOTP)

• The setting can also be made by means of write-access to

attribute 3 (Configuration Control) of instance 1 of the TCP/IP

Interface Object (245 / 0xF5) ( 141).

IP address 1 ... 254

• The static address stored in subcode C13000/1...3

•The subcode C13000/4

coding switch.

This setting resets the codes for IP configuration:

• C13000

• C13001

• C13002

• C13005

• C13006

• C13017

• C13018

• C13021

• C13846

(IP address)

(subnet mask)

(gateway address)

(IP configuration reference)

(Multicast IP start address)

(Ethernet setting: Autonegotiation)

(Multicast setting: Default algorithm)

(Quality of Service (VLAN tagging): deactivated)

(Address conflict detection (ACD): activated)

is replaced with the value of the rotary

is used.

Example: Setting of the node address ’52’

Position of the rotary coding switches Resulting node address

3 × 16 4 × 1(3 × 16) + (4 × 1) = 52

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 41

Page 42

6 Commissioning

6.4 Setting the IP configuration of the Inverter Drive 8400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.4 Setting the IP configuration of the Inverter Drive 8400

IP configuration is necessary in order to assign an address to the Inverter Drive 8400 so that

communication between the PC/»Engineer« or the scanner and the drive is possible via EtherNet/

IP. For this purpose, an IP address, subnet mask and gateway address have to be assigned. You can

assign these IP parameters for the Inverter Drive 8400 in the following ways:

• Setting via the EtherNet/IP configurator of the »Engineer«

• Setting via codes in the »Engineer«

• Setting via a BOOTP/DHCP server

• Setting via the TCP/IP Interface Object (0xF5)

( 45)

( 47)

( 47)

( 43)

Note!

• The assignment of invalid combinations of IP address, subnet mask, and gateway

address can have the consequence that no connection to the EtherNet/IP network can

be established.

•Codes C13010

C13016

• In the case of impermissible settings, the error message EtherNet/IP: Invalid IP

parameters [0x01bc6533] ( 99) is output.

(IP address), C13011 (subnet mask), C13012 (gateway address), and

(multicast IP address) show the IP parameters currently used.

42

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 43

6 Commissioning

6.4 Setting the IP configuration of the Inverter Drive 8400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.4.1 Setting via the EtherNet/IP configurator of the »Engineer«

Note!

• Changes in the IP parameters will become effective immediately.

• An already existing IP connection to the Inverter Drive 8400 is interrupted.

How to set the IP parameters via the EtherNet/IP configurator:

1. Execute the menu command Online PROFINET /EtherNet/IP configurator addresses ....

The "Assign IP addresses" dialog window is opened and all Lenze EtherNet/IP nodes

connected are listed.

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 43

Page 44

6 Commissioning

6.4 Setting the IP configuration of the Inverter Drive 8400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2. A double-click on a EtherNet/IP node opens the "Configure nodes" dialog window.

Here you can set the IP parameters.

3. Click on Transferred.

• The IP configuration is transferred to the corresponding EtherNet/IP node.

• The communication module carries out a stack reset.

•The IP parameters are written to codes C13000

C13002

•Code C13005

transferred address can be used.

(gateway address).

(IP configuration reference) is set to ’0: Saved address’ to ensure that the

(IP address), C13001 (subnet mask), and

Tip!

Check whether the configuration has been transferred successfully.

For this purpose, open the "Assign IP addresses" dialog window (see step 1) and click the

Find device button.

44

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 45

6 Commissioning

6.4 Setting the IP configuration of the Inverter Drive 8400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.4.2 Setting via codes in the »Engineer«

You can also set the IP parameters manually in the »Engineer« under the Settings tab. The values

will be transferred to the corresponding codes.

Settings / Display Description

Rotary coding switch Display of the value set by means of the rotary coding switches (C13920

Setting node addresses by means of rotary coding switches

IP Config Control Selection (C13005

• 0: The IP configuration currently stored in the communication module is

used.

• 1: The IP configuration is assigned by a BOOTP server using the BOOTP.

• 2: The IP configuration is assigned by a DHCP server using the DHCP.

IP Address Setting of the IP address (C13000

Subnet mask Setting of the subnet mask (C13001

Gateway Address Setting of the gateway address (C13002

Multicast IP Start Address Setting of the Multicast IP start address (C13006

Setting the multicast configuration

Multicast Config TTL Value Setting of the multicast TTL value (C13019

) of how the IP configuration is to be made:

)

)

)

)

( 48)

)

How to activate changed settings in the »Engineer«:

1. Execute device command C00002 = "11: Save all parameter sets".

The current IP configuration is stored in the memory module of the drive.

2. Carry out a "Type 0 reset" for the Identity Object (1 / 0x01)

voltage supply of the communication module off and on again.

( 126) of the node, or switch the

( 40)

).

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 45

Page 46

6 Commissioning

6.4 Setting the IP configuration of the Inverter Drive 8400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

IP address

The IP address is set/changed in C13000

The IP address currently used is displayed in C13010/1...4

Example: Display of the IP address 192.168.124.16

Code C13010/1

Value 192 168 124 16

.

.

C13010/2 C13010/3 C13010/4

Subnet mask

The subnet mask indicates which part of the IP address is evaluated as net ID or host ID.

Valid subnet masks are defined in accordance with RFC 1878

The subnet mask is set/changed in C13001

The subnet mask currently used is displayed in C13011/1...4

Example: Display of the subnet mask 255.255.255.0

Code C13011/1

Value 255 255 255 0

.

.

C13011/2 C13011/3 C13011/4

Gateway address

The gateway address is valid if the network address of the IP address and the gateway address are

identical.

If the gateway address and the IP address are identical or if the address is ’0.0.0.0’, gateway

functionality is not used.

The gateway address is set/changed in C13002

The gateway address currently used is displayed in C13012/1...4

.

.

Example: Display of the gateway address 192.168.124.16

Code C13012/1

Value 192 168 124 16

C13012/2 C13012/3 C13012/4

46

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 47

6 Commissioning

6.4 Setting the IP configuration of the Inverter Drive 8400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.4.3 Setting via a BOOTP/DHCP server

DHCP is the acronym for "Dynamic Host Configuration Protocol". This protocol is defined in

RFC 2131 and is a compatible advancement of the "Bootstrap Protocol" (BOOTP) according to

RFC 951.

Both protocols enable network nodes to query information about the network configuration (e.g.

the IP address) from a server via a TCP/IP network. The BOOTP/DHCP server assigns the IP address

to the client dynamically from a defined address range. This means that the client receives an

unambiguous IP address.

Code C13005

• Value ’0’: The IP configuration currently saved in the communication module is used.

• Value ’1’: BOOTP is used. (Lenze standard setting)

• Value ’2’: DHCP is used.

The setting can also be selected by write access to attribute 3 (configuration control) of instance 1

of the TCP/IP Interface Object (245 / 0xF5)

is used to select how the IP configuration is to be made:

( 141).

6.4.4 Setting via the TCP/IP Interface Object (0xF5)

With a scanner, the IP configuration can be set via attribute 5 (interface configuration) of instance 1

of the TCP/IP Interface Object (245 / 0xF5)

After the IP configuration, carry out a node reset ("power off/on" or "Type 0 reset" for the Identity

Object (1 / 0x01) ( 126)).

In the »Engineer«, codes C13010

and C13016

(multicast IP address) show the IP parameters currently used.

(IP address), C13011 (subnet mask), C13012 (gateway address),

( 141).

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 47

Page 48

6 Commissioning

6.4 Setting the IP configuration of the Inverter Drive 8400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.4.5 Setting the multicast configuration

Several scanners ("Listen only" or "Input only" connections) can access multicast telegrams which

are sent by drives. Settings for multicast configuration have to be carried out as well in the

EtherNet/IP configuration software (z. B. »RSLogix 5000« from Rockwell).

By default, the communication module automatically generates the Multicast IP start address for I/

O data transfer. The standard TTL value for Multicast transfer is ’1’; the Multicast I/O data packages

are therefore distributed solely via the local network.

Note!

You can also explicitly set the multicast IP start address and the multicast TTL value. We

recommend, however, not to change the default settings in order to ensure a secure

multicast transmission.

The following multicast codes are configurable:

Code Description

C13018

C13019

C13020

Multicast IP Start Address

Multicast IP start addresses serve to send a message to the members of a certain group (i.e. possibly

to several nodes).

The multicast IP start address is set/changed in C13006

The currently used multicast IP address of the drive is displayed in C13016/1...4

Example: Display of the multicast IP address 239.64.2.224

Code C13016/1

Value 239 64 2 224

Selection for multicast IP addressing via instance attribute 9 (Mcast Config) in the TCP/IP

Interface Object (245 / 0xF5) ( 141)

• Value ’0’: The default algorithm is used.

• Value ’1’: The address from code C13006

Setting of the multicast TTL value for the validity time of data packets in the EtherNet/IP

network

(Instance attribute 8 (TTL Value) in the TCP/IP Interface Object (245 / 0xF5)

Used to set how many multicast IP addresses will be assigned.

(Instance attribute 9 (Num Mcast) in the TCP/IP Interface Object (245 / 0xF5)

C13016/2 C13016/3 C13016/4

is used as multicast IP start address.

( 141))

( 141))

.

.

48

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 49

6 Commissioning

6.5 Establishing an online connection via EtherNet/IP with the Lenze »Engineer«

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.5 Establishing an online connection via EtherNet/IP with the Lenze »Engineer«

Note!

• In order to ensure perfect operation of cyclic EtherNet/IP communication, online

access with the »Engineer« should be executed via an IEEE 802.1Q-capable switch.

• The IEEE 802.1Q-capable switch integrated in the communication module can

manage cyclical EtherNet/IP-communication primarily for normal TCP/IP

communication. In the case of EtherNet/IP, this is done by means of the VLAN

identification in the Ethernet frame (can be set in C13021

• If the redundancy protocol DLR (Device Level Ring) is used, the switch also must be

DLR-compliant.

).

[6-2] Example set-up with an Allen Bradley CompactLogix Controller 1769-L32E (scanner)

For an online connection between the »Engineer« and the drive, the drive must have an IP address

(see Setting the IP configuration of the Inverter Drive 8400

( 42)).

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 49

Page 50

6 Commissioning

6.5 Establishing an online connection via EtherNet/IP with the Lenze »Engineer«

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

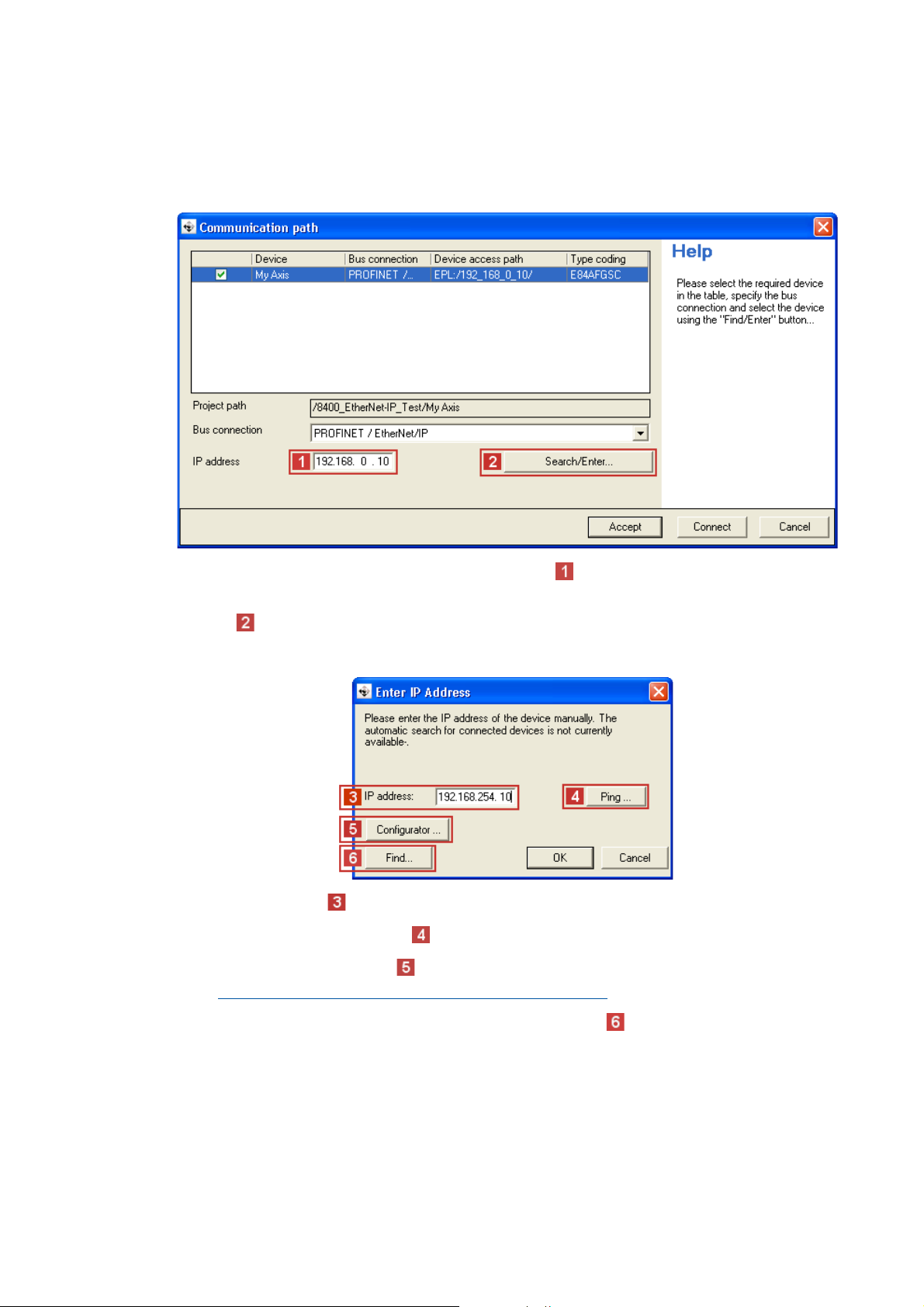

In the »Engineer«, you can use the Online Set communication path and go online menu command

to select the EtherNet/IP communication path. The previously configured EtherNet/IP nodes are

shown in the "Communication path" dialog window:

If the device access path is not configured correctly, the IP address of the drive selected in the

display field can be entered manually here.

Via the Search/Enter button, you can establish a connection to devices which have not

appeared in the display field. Corresponding settings for this can be made in the "Enter IP Address"

dialog window that will appear:

Here you can enter an IP address manually or execute the following actions using the buttons:

• Execute the console command Ping.

• Assign the IP address via the Configurator.

Setting via the EtherNet/IP configurator of the »Engineer«

( 43)

50

• Select the device access path to the desired drive by clicking Find.

After having established the online connection, you can continue work with the »Engineer« as

usual.

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 51

6 Commissioning

6.6 Initial switch-on

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.6 Initial switch-on

Documentation for the Inverter Drive 8400

Observe the safety instructions and information on residual hazards.

Note!

Establishing communication

In order to establish communication via an externally supplied communication module,

the standard device must be switched on as well.

For further communication of the externally supplied module it is not relevant whether

the standard device is switched on or not.

Activating changed setting

In order to activate any changed settings, ...

• execute the device command "11: Save all parameter sets" via the standard device

code C00002 and ...

• Carry out a "Type 0 reset" for the Identity Object (1 / 0x01)

switch the voltage supply of the communication module off and on again.

Protection against uncontrolled restart

After a fault (e.g. short-term mains failure), it is sometimes undesirable or even

impermissible for the drive to restart.

The restart protection is activated in the Lenze setting of the Inverter Drives 8400.

You can set the restart behaviour of the drive via C00142 ("Autostart Option"):

C00142 = 9 (Lenze setting)

• The inverter remains inhibited (even if the fault is no longer active).

• Bit 0 (inhibit at "power-on") and bit 3 (inhibit in the case of undervoltage) are set.

• An explicit inverter enable causes the drive to start up in a controlled manner: LOWHIGH edge at digital input X4/RFR.

( 126) of the node, or

C00142 = 8 (enabled)

• In order to directly enable the device at switch-on, bit 0 must be set to zero (FALSE).

• An uncontrolled restart of the drive is possible.

Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17 51

Page 52

7 Data transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Data transfer

EtherNet/IP uses CIP™ (Common Industrial Protocol) for the data exchange between devices via an

Ethernet network – just like the closely related bus systems DeviceNet and ControlNet.

Lenze implements the CIP following the ODVA standard (Open DeviceNet Vendor Association,

www.odva.org

• Explicit messaging (for parameter data)

• Implicit messaging (for I/O data)

) and supports the two main types of EtherNet/IP communication:

52 Lenze · E84AYCEO communication module (EtherNet/IP™) · Communication Manual · DMS 3.0 EN · 10/2013 · TD17

Page 53

7 Data transfer

7.1 Communication channels

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.1 Communication channels

Note!

The terms "input" and "output" refer to the point of view of the scanner:

• Input data is produced by the adapter and consumed by the scanner.

• Output data is produced by the scanner and consumed by the adapter.

EtherNet/IP transmits parameter data and I/O data between the host system (scanner) and the

drives (adapters) connected to the fieldbus. The data are transmitted via corresponding

communication channels depending on their time-critical behaviour.

The I/O data channel transmits I/O data by means of "implicit messages".

• The inverter is controlled by means of the I/O data.

• The transmission of I/O data is time-critical.

• I/O data are transmitted cyclically between the host system (scanner) and the drives (adapters)

(permanent exchange of current input and output data).

• The host system (scanner) has direct access to the I/O data (the data are, for example, stored

directly in the I/O area).

• In the case of Inverter Drives 8400, a maximum of 16 data words (max. 32 bytes) can be

exchanged per direction.

• I/O data are not stored in the inverter.