Page 1

EDS84AYCEC

13417995

Ä.Jpôä

L-force Communication

Communication Manual

8400

E84AYCEC

Ethernet POWERLINK communication module

L

Page 2

2 L EDS84AYCEC EN 3.0 - 09/2012

Page 3

E84AYCEC communication manual (Ethernet POWERLINK)

Contents

Contents

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Document history

1.2 Conventions used

1.3 Terminology used

1.4 Notes used

2 Safety instructions

2.1 General safety and application instructions

2.2 Device and application-specific safety instructions

2.3 Residual hazards

3 Product description

3.1 Application as

3.2 Identification

3.3 Features

3.4 Connections and interfaces

4 Technical data

4.1 General data and operating conditions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

directed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Protective insulation

4.3 Ethernet POWERLINK communication data

4.4 Dimensions

5 Installation

5.1 Mechanical installation

5.2 Electrical installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1.1 Mounting for standard devices of 0.25 kW and 0.37 kW

5.1.2 Mounting for standard devices of 0.55 kW or more

5.1.3 Exchanging the communication module

5.2.1 Wiring according to EMC guidelines

5.2.2 Network topology

5.2.3 Ethernet POWERLINK

5.2.4 Basic Ethernet Mode

5.2.5 Ethernet POWERLINK connection

5.2.6 Ethernet cable specification

5.2.7 External voltage supply

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

EDS84AYCEC EN 3.0 - 09/2012 L 3

Page 4

E84AYCEC communication manual (Ethernet POWERLINK)

Contents

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1 Before initial switch-on

6.2 Node address setting

6.3 Setting and displays in the »Engineer«

6.4 Initial switch-on

6.5 Drive synchronisation

6.6 Optimisation of networks

7 Process data transfer

7.1 Access to process data / PDO mapping

7.2 Preconfigured port interconnection of the process data objects (PDO)

7.3 Freely configured port interconnection of the process data objects (PDO)

8 Monitoring

9 Diagnostics

9.1 LED status displays

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.1.1 Module status displays

9.1.2 Fieldbus status displays

9.1.3 Status displays at the RJ45 sockets (X251, X252)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . 47

. . . . . . . . . . . 48

9.2 Troubleshooting with module signalling

9.3 Diagnostic data

10 Error messages

10.1 Short overview of the Ethernet POWERLINK error messages

10.2 Possible causes and remedies

11 Parameter reference

11.1 Parameters of the communication module

11.2 Table of attributes

12 Index table

13 Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . 62

4 L EDS84AYCEC EN 3.0 - 09/2012

Page 5

E84AYCEC communication manual (Ethernet POWERLINK)

1 About this documentation

Contents

This documentation exclusively contains descriptions of the E84AYCEC communication

module (Ethernet POWERLINK).

Note!

This documentation supplements the mounting instructions supplied with the

communication module and the hardware manual for the Inverter Drives 8400.

The features and functions of the communication module Ethernet POWERLINK are

described in detail.

Typical applications are illustrated by means of examples.

This documentation also contains the following:

About this documentation

Safety instructions that must be observed

The basic technical data of the communication module

Information about the versions of the Lenze standard devices to be used

Notes on troubleshooting and fault elimination

The theoretical concepts are only explained to the level of detail required to understand

the function of the communication module.

This documentation does not describe any software provided by other manufacturers. No

liability can be accepted for corresponding data provided in this documentation. For

information on how to use the software, please refer to the host (PLC, Managing Node

documents.

All product names mentioned in this documentation are trademarks of their respective

owners.

Tip!

Detailed information about Ethernet POWERLINK can be found on the website of

the "Ethernet POWERLINK Standardization Group":

www.ethernet-powerlink.org

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the

firmware version of the field devices and the software version of the installed engineering

tools (»Engineer«), the screenshots in this documentation may differ from the screen

representation.

EDS84AYCEC EN 3.0 - 09/2012 L 5

Page 6

E84AYCEC communication manual (Ethernet POWERLINK)

About this documentation

Target group

This documentation is aimed at people involved in configuring, installing, commissioning

and maintaining the networking and remote servicing of a machine.

Tip!

Current documentation and software updates for Lenze products can be found in

the download area at:

www.Lenze.com

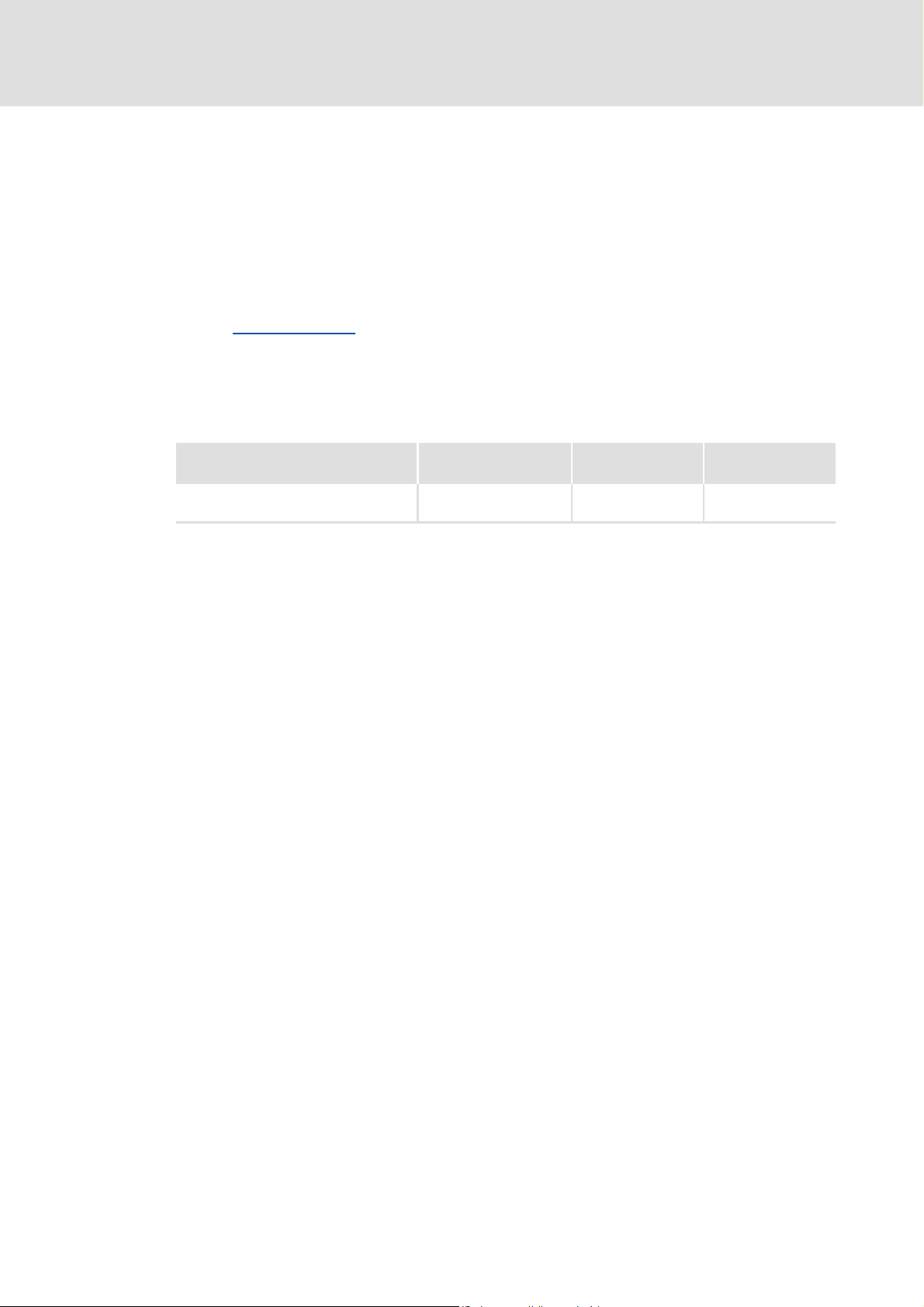

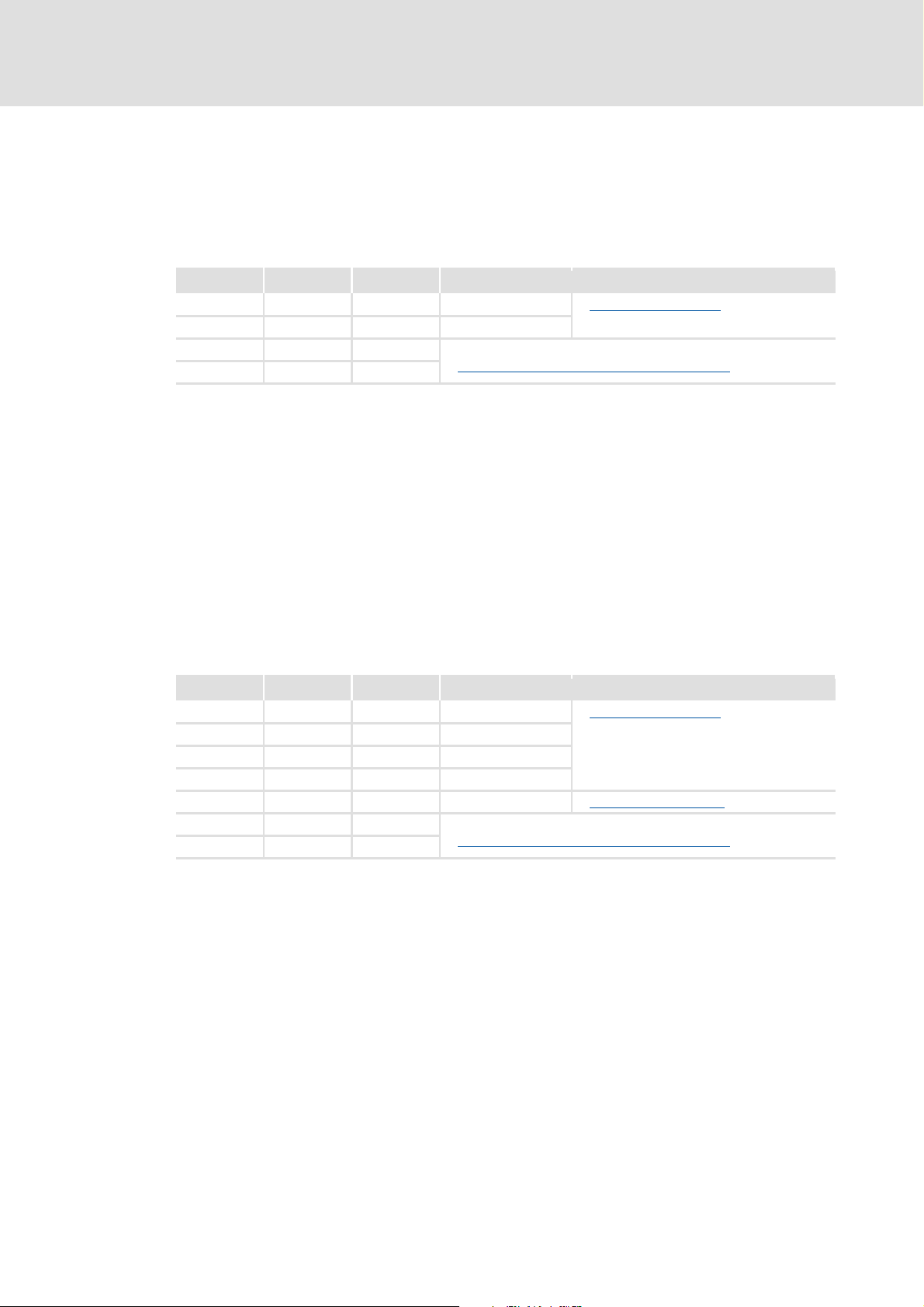

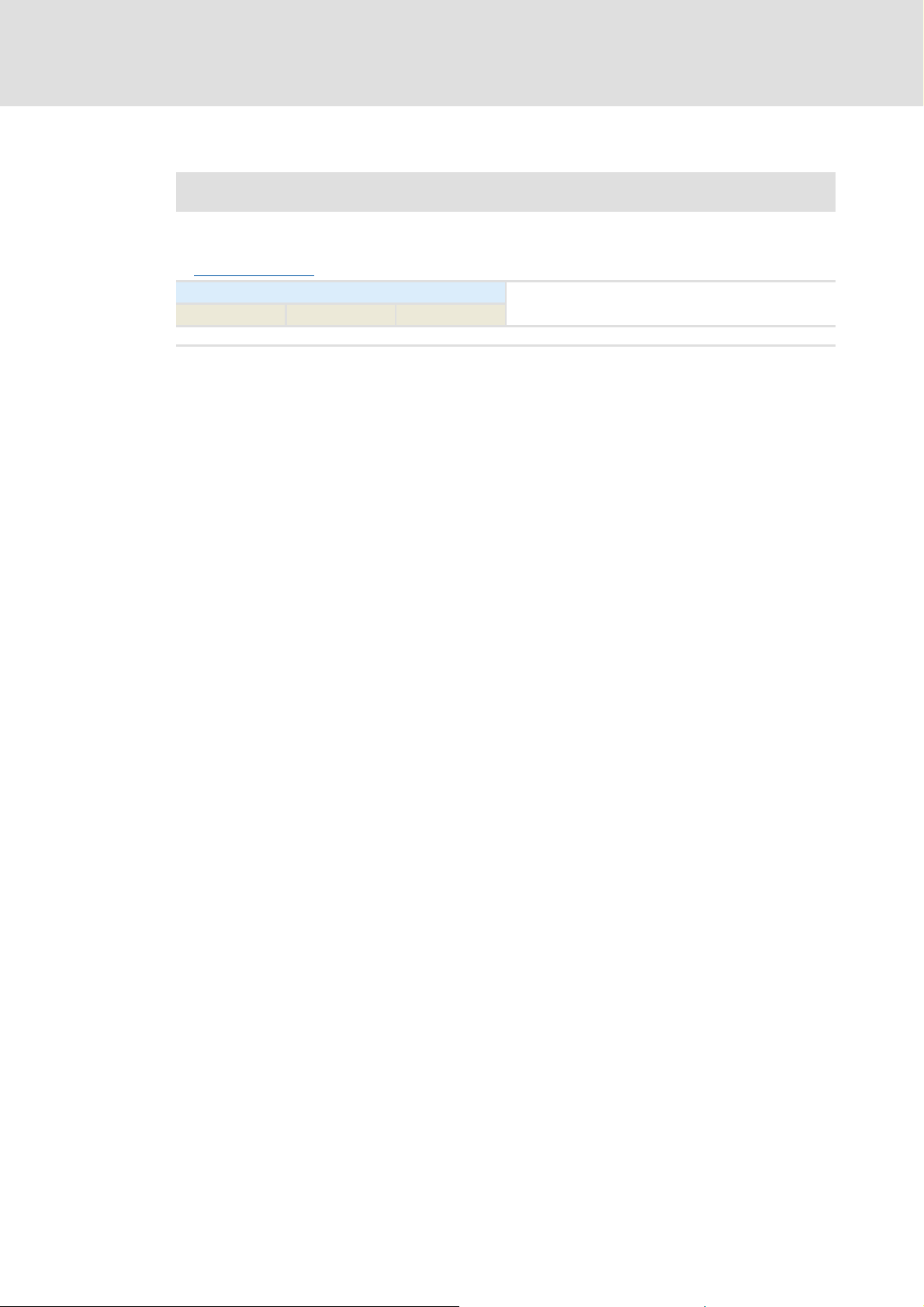

Validity information

The information in this documentation is valid for the following devices:

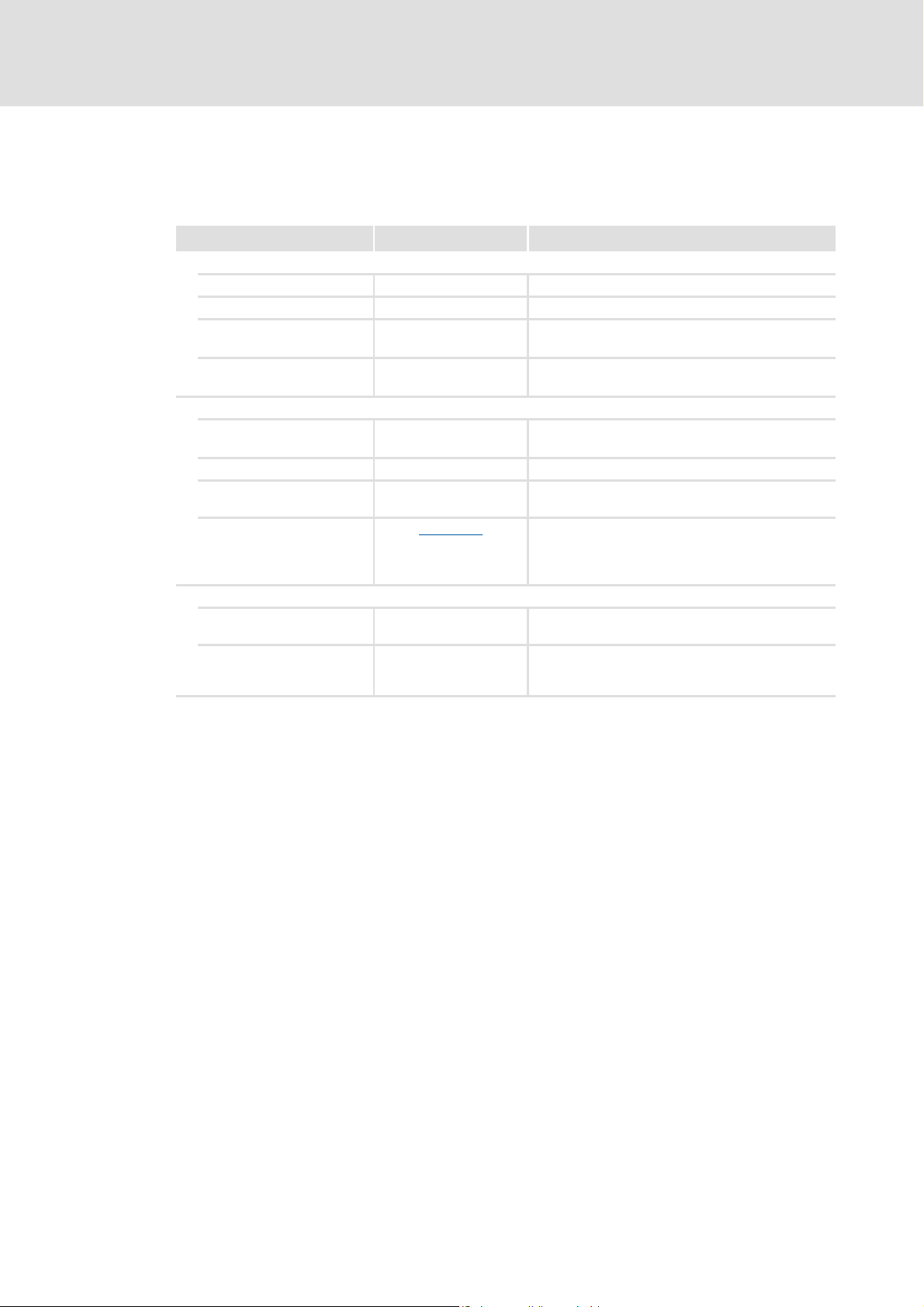

Extension module Type designation From hardware

Communication module

Ethernet POWERLINK

E84AYCEC VA 01.00

version

From software

version

6 L EDS84AYCEC EN 3.0 - 09/2012

Page 7

E84AYCEC communication manual (Ethernet POWERLINK)

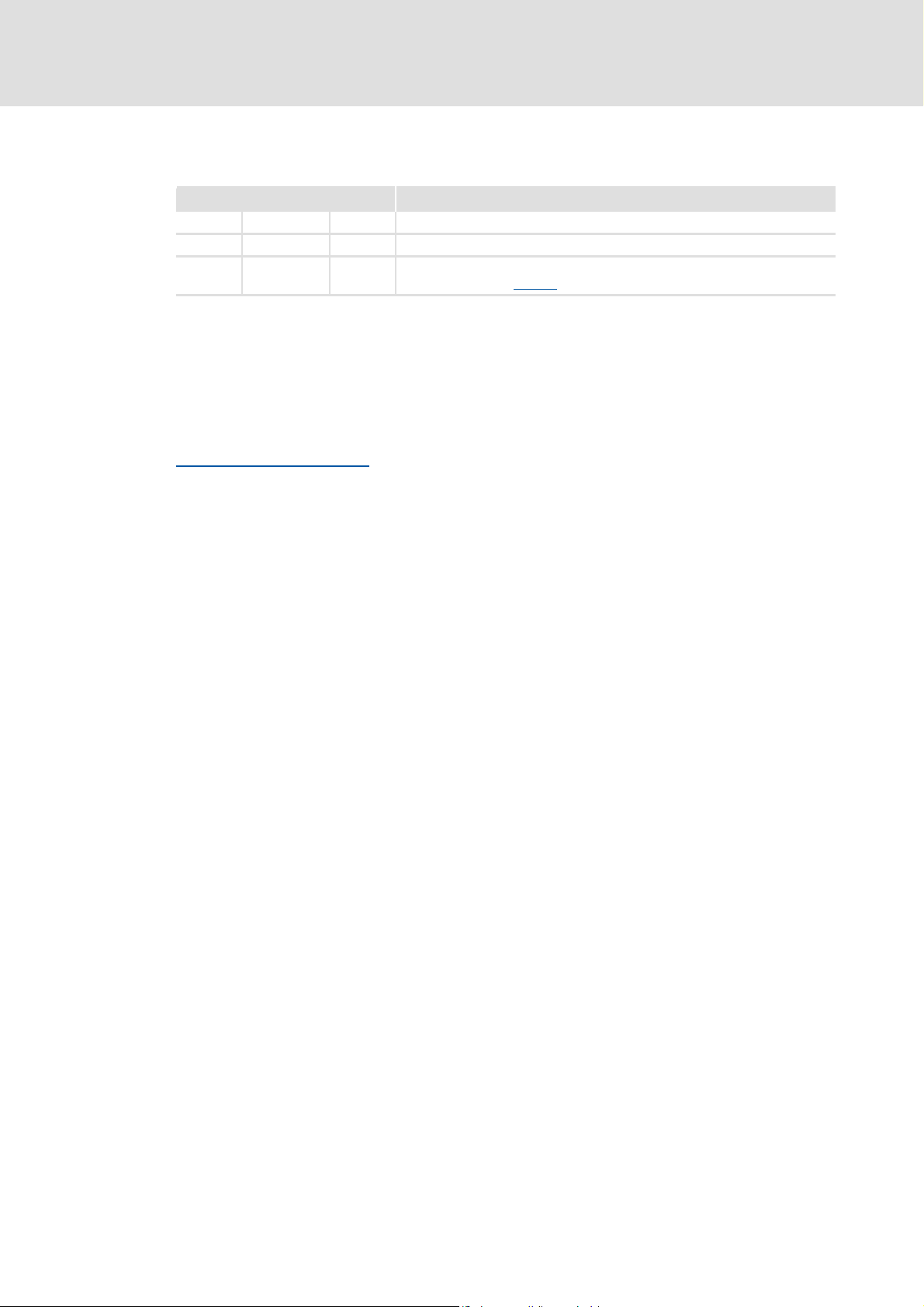

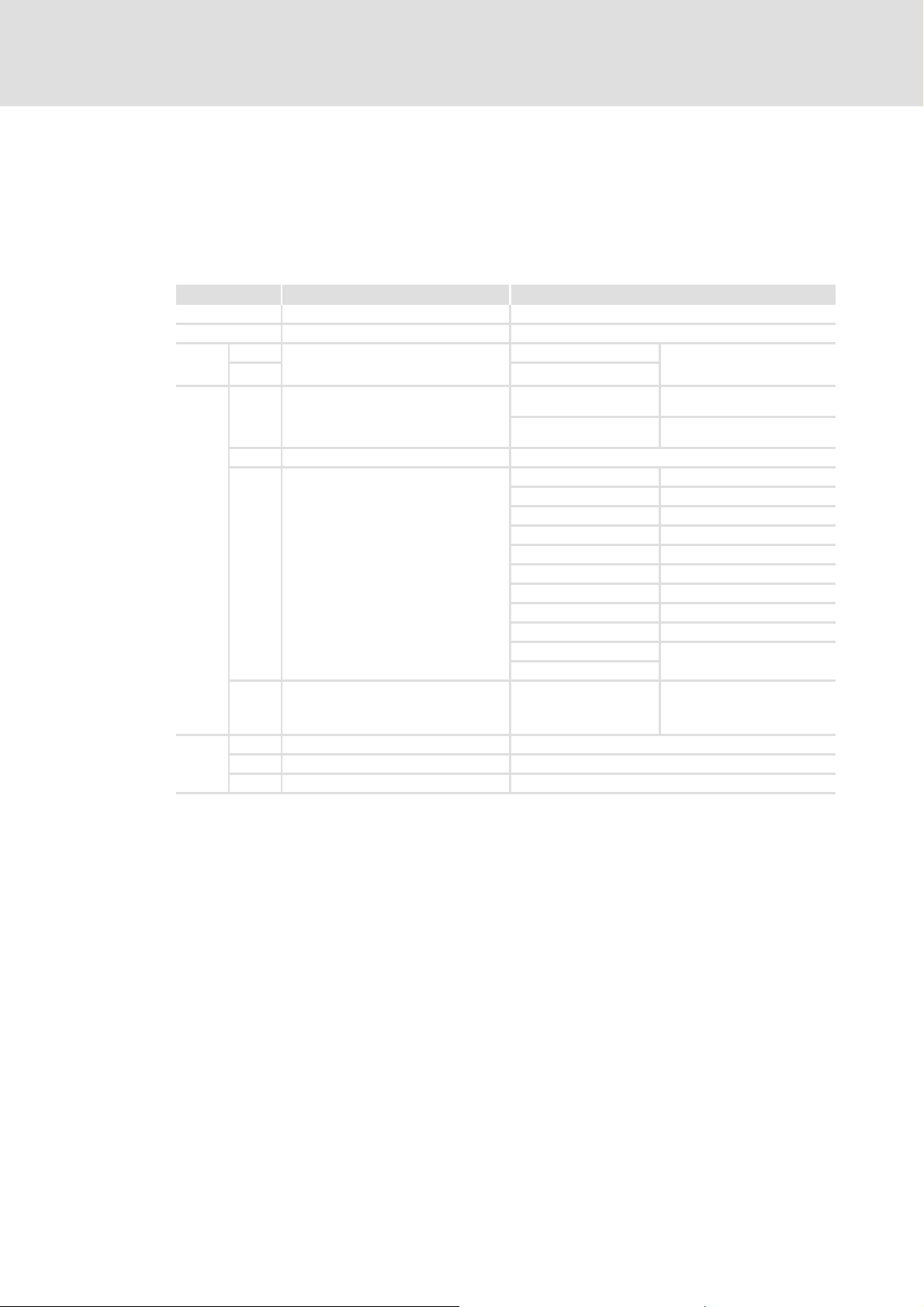

1.1 Document history

Version Description

1.0 11/2010 TD17 First edition

2.0 02/2011 TD17 General revision

3.0 09/2012 TD17 General updates

Your opinion is important to us!

These instructions were created to the best of our knowledge and belief to give you the

best possible support for handling our product.

Perhaps we have not succeeded in achieving this objective in every respect. If you notice

this, please send us your suggestions and criticism in a short e-mail to:

feedback-docu@Lenze.de

Thank you for your support.

Description of code C13060

About this documentation

Document history

(0x1006 cycle time) corrected.

Your Lenze documentation team

EDS84AYCEC EN 3.0 - 09/2012 L 7

Page 8

E84AYCEC communication manual (Ethernet POWERLINK)

About this documentation

Conventions used

1.2 Conventions used

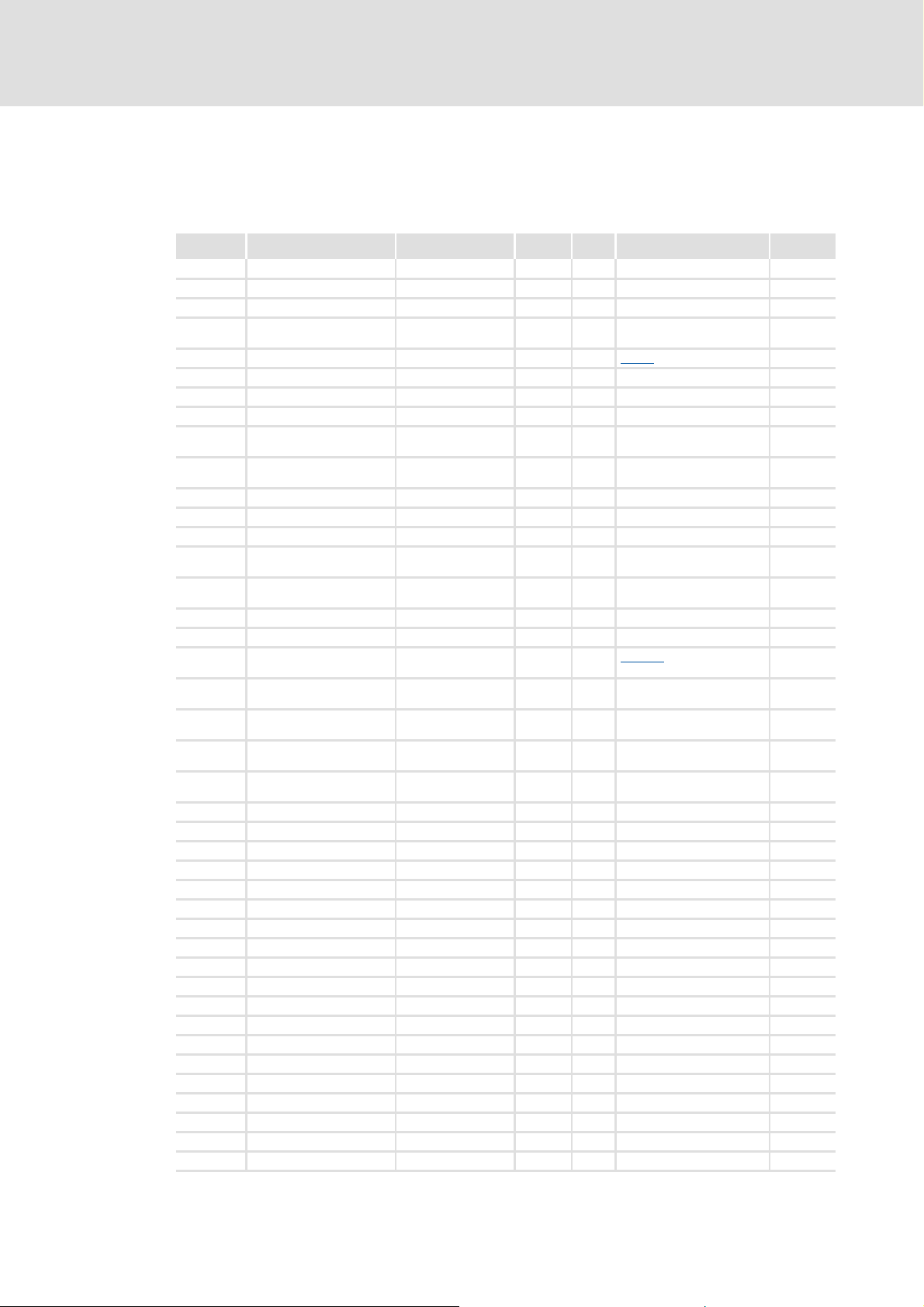

This documentation uses the following conventions to distinguish between different types

of information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal Standard notation Example:1234

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

• Nibble

Decimal separator Point The decimal point is always used.

Text

Program name » « PC software

Window Italics The message window... / The Options dialog box...

Control element Bold The OK button ... / The Copy command ... / The

Hyperlink Underlined

In quotation marks

Point

Example: ’100’

Example: ’0110.0100’

Example: 1234.56

Example: Lenze »Engineer«

Properties tab ... / The Name input field ...

Optically highlighted reference to another subject

which is activated with a mouse click.

Symbols

Page reference ( 8) Optically highlighted reference to another page

Step-by-step instructions

which is activated with a mouse click.

Step-by-step instructions are indicated by a

pictograph.

8 L EDS84AYCEC EN 3.0 - 09/2012

Page 9

E84AYCEC communication manual (Ethernet POWERLINK)

1.3 Terminology used

Term Meaning

Controller Lenze controllers of the "Inverter Drives 8400" series

Standard device

»Engineer« Lenze PC software which supports you in "engineering" (parameterisation,

Code Parameter used for controller parameter setting or monitoring. The term is

Subcode If a code contains more than one parameter, these parameters are stored in so-

Lenze setting This setting is the default factory setting of the device.

Basic setting

HW Hardware

SW Software

EPL Abbreviation for "Ethernet POWERLINK"

(EPL) nodes Ethernet POWERLINK nodes (Managing Node, Controlled Nodes)

CN Controlled node (EPL slave)

MN Managing node (EPL master)

Node ID EPL node address

About this documentation

Terminology used

diagnostics and configuration) throughout the whole life cycle, i.e. from

planning to maintenance of the commissioned machine.

usually called "index".

called "subcodes".

In this documentation a slash "/" is used as a separator between code and

subcode (e.g. "C00118/3").

The term is usually called "subindex".

The Managing Node accepts the control function for the data communication of

the decentralised field devices. Typically, the Managing Node is the

communication interface of a PLC.

EDS84AYCEC EN 3.0 - 09/2012 L 9

Page 10

E84AYCEC communication manual (Ethernet POWERLINK)

About this documentation

Notes used

1.4 Notes used

The following signal words and symbols are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Pictograph and signal word!

(characterise the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note for trouble-free operation

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for simple handling

Reference to another documentation

10 L EDS84AYCEC EN 3.0 - 09/2012

Page 11

E84AYCEC communication manual (Ethernet POWERLINK)

2 Safety instructions

Note!

Always observe the specified safety measures to prevent severe injury to

persons and damage to property!

Always keep this documentation near the product during operation.

2.1 General safety and application instructions

Danger!

Safety instructions

General safety and application instructions

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

Lenze drive and automation components ...

– must only be used as directed.

Application as directed

– must never be commissioned in the event of visible damage.

– must never be technically modified.

– must never be commissioned before they have been mounted completely.

– must never be operated without the required covers.

– can - depending on the degree of protection - have live, movable or rotating parts

during and after operation. Surfaces can be hot.

For Lenze drive components ...

– use only the accessories approved.

– use only original spare parts from the manufacturer.

Observe all specifications given in the attached and associated documentation.

– This is the precondition for safe and trouble-free operation and for achieving the

product features specified.

Features

– The procedural notes and circuit details described in this document are only

proposals. It is up to the user to check whether they can be adapted to the particular

applications. Lenze does not take any responsibility for the suitability of the

procedures and circuit proposals described.

( 14)

( 13)

EDS84AYCEC EN 3.0 - 09/2012 L 11

Page 12

E84AYCEC communication manual (Ethernet POWERLINK)

Safety instructions

Device and application-specific safety instructions

Only qualified personnel may work with and on Lenze drive and automation

components. According to IEC 60364 or CENELEC HD 384, these are persons ...

– who are familiar with the installation, assembly, commissioning and operation of

the product.

– who have the corresponding qualifications for their work.

– who know all regulations for the prevention of accidents, directives and laws

applicable on site and are able to apply them.

2.2 Device and application-specific safety instructions

During operation, the communication module must be firmly connected to the

standard device.

Always use a separate power supply unit safely separated according to EN 61800-5-1

("SELV/PELV") in every control cabinet for external voltage supply.

Only use cables that comply with the listed specifications.

Ethernet cable specification

( 33)

Documentation for the standard device, control system, system/machine

All other measures prescribed in these documents must also be implemented.

Observe the safety instructions and application notes specified in the

documents.

2.3 Residual hazards

Protection of persons

If the Inverter Drives 8400 are operated on a phase-earthed mains with a rated mains

voltage of 400 V, external measures need to be implemented in order to ensure

protection against accidental contact.

Protective insulation

Device protection

The communication module contains electronic components that can be damaged or

destroyed by electrostatic discharge.

Installation

( 17)

( 22)

12 L EDS84AYCEC EN 3.0 - 09/2012

Page 13

E84AYCEC communication manual (Ethernet POWERLINK)

HW:

SW:

8400

Type:

Ser.No.:

HW:

SW:

MAC-ID:

3 Product description

3.1 Application as directed

The communication module ...

is an accessory module which can be used in conjunction with the following standard

devices:

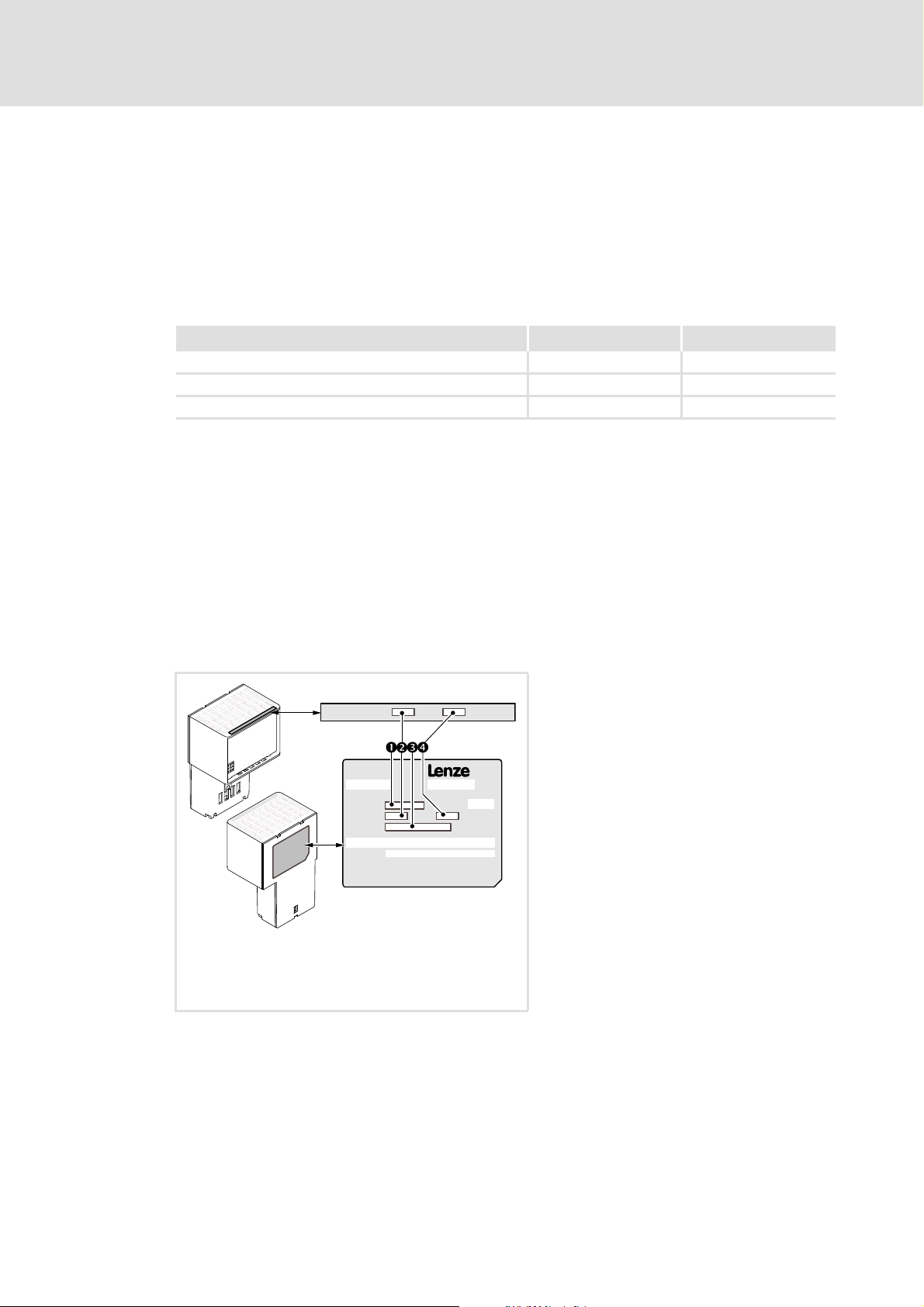

Product series Type designation From software version

Inverter Drives 8400 StateLine E84AxSCxxxx 5.00

Inverter Drives 8400 HighLine E84AxHCxxxx 5.00

Inverter Drives 8400 TopLine E84AxTCxxxx 1.00

is a device for use in industrial power systems.

may only be operated under the operating conditions specified in this documentation.

Product description

Application as directed

may only be used in Ethernet POWERLINK networks.

Any other use shall be deemed inappropriate!

3.2 Identification

Type designation and hardware and software version of the communication module are

indicated on the nameplate:

[3-1] Identification data

E84YCEC004

1 Type designation (type)

E84 Product series

AVersion

Y Module identification: extension module

C Module type: communication module

EC Ethernet POWERLINK CN

V/S V: Coated version

S: Standard version

2 Hardware version (HW)

3 MAC address (MAC-ID)

00-0A-86-xx-yy-zz:

Hardware address of the communication

module for unique identification in the

network

4 Software version (SW)

EDS84AYCEC EN 3.0 - 09/2012 L 13

Page 14

E84AYCEC communication manual (Ethernet POWERLINK)

Product description

Features

3.3 Features

Interface module for the Ethernet POWERLINK communication system, for attachment

to the expansion slots of Inverter Drives 8400

The communication module can either be supplied internally by the standard device or

externally by a separate voltage source.

Real-time Ethernet with the Ethernet POWERLINK V2 communication profile for

motion and general applications

A line topology can be implemented by means of the integrated 2-port hub.

Supported functions:

– Ethernet POWERLINK CN

Use of max. 6 PDO crosslinks for the managing node or the controlled node to create

systems with "distributed intelligence"

Very short CN response times for optimal network performance

Parallel Ethernet communication between the Lenze »Engineer« and the Inverter Drive

8400 if an EPL router is used.

Access to all Lenze parameters

14 L EDS84AYCEC EN 3.0 - 09/2012

Page 15

E84AYCEC communication manual (Ethernet POWERLINK)

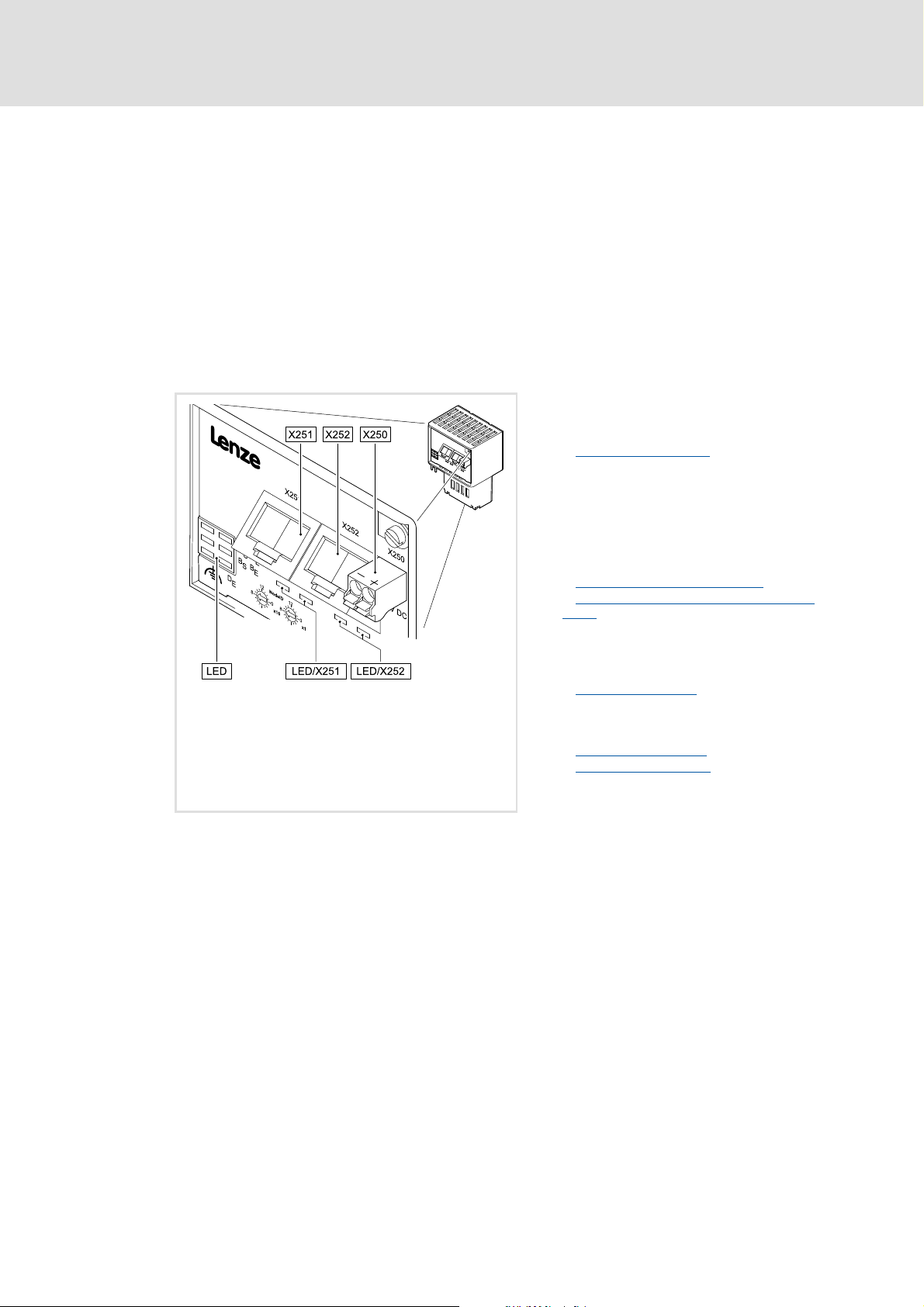

3.4 Connections and interfaces

2 RJ45 sockets for the Ethernet POWERLINK connection

2-pin plug connector for external voltage supply of the communication module.

2 rotary coding switches for setting the node address (node ID)

Front panel LEDs for diagnosing the ...

– voltage supply of the communication module;

– connection to the standard device;

– Ethernet POWERLINK connection;

– Ethernet POWERLINK activity.

Product description

Connections and interfaces

X250 External voltage supply of the communication

module

• 2-pin plug connector with spring connection

External voltage supply

( 35)

E84YCEC001D

[3-2] Communication module E84AYCEC (Ethernet POWERLINK)

X251 Ethernet POWERLINK port 1

X252 Ethernet POWERLINK port 2

• RJ45 sockets according to IEC/EN 60603-7

• each with 2 LED status displays for

diagnostics

Ethernet POWERLINK connection

Status displays at the RJ45 sockets (X251,

X252) ( 56)

x1

Rotary coding switch for setting the node

address (node ID)

x16

Node address setting

5 LED status displays for diagnostics

MS

Module status displays

ME

BS

Fieldbus status displays

BE

DE

( 38)

( 54)

( 55)

( 31)

EDS84AYCEC EN 3.0 - 09/2012 L 15

Page 16

E84AYCEC communication manual (Ethernet POWERLINK)

Technical data

General data and operating conditions

4 Technical data

4.1 General data and operating conditions

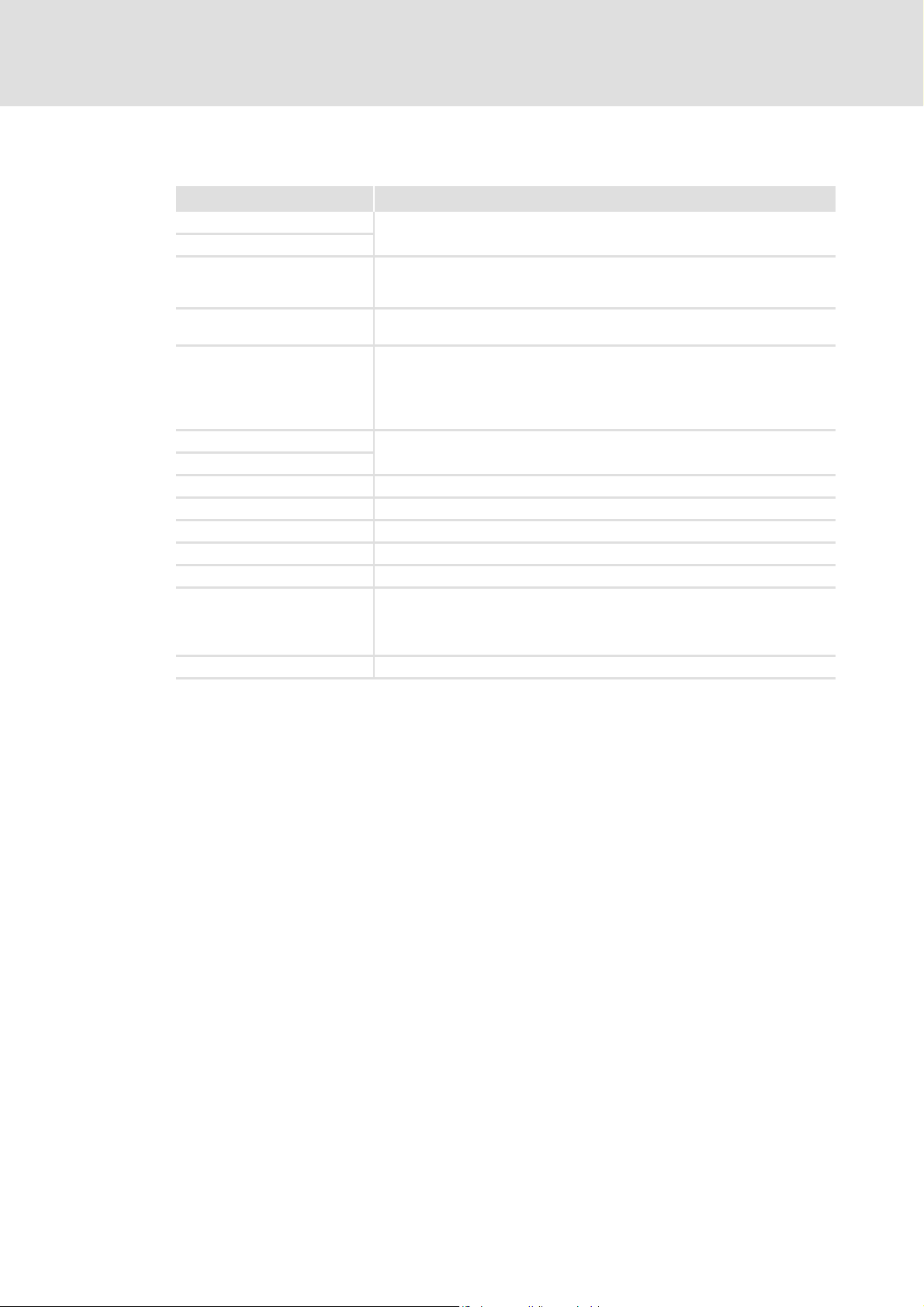

Field Values

Order designation E84AYCEC

Communication profile Ethernet POWERLINK

Communication medium S/FTP (screened foiled twisted pair, ISO/IEC 11801 or EN 50173), CAT 5e

Interface RJ45: Standard Ethernet (according to IEEE 802.3), 100Base-TX (Fast

Network topology Tree, star, and line

Node type Controlled node

Node addresses (node IDs) 1 … 239

Transmission mode Half duplex

Baud rate 100 Mbps

Voltage supply External supply via separate power supply unit

Conformities, approvals CE

Ethernet)

• "+": U = 24 V DC (20.4 V - 0 % ... 28.8 V + 0 %), I = 140 mA

• "-": Reference potential for external voltage supply

Hardware manual for Inverter Drives 8400

Here you can find the ambient conditions and data on the electromagnetic

compatibility (EMC), which also apply to the communication module.

16 L EDS84AYCEC EN 3.0 - 09/2012

Page 17

E84AYCEC communication manual (Ethernet POWERLINK)

4.2 Protective insulation

Danger!

Dangerous voltage

If the Inverter Drives 8400 are operated on a phase-earthed mains with a rated

mains voltage of 400 V, external measures need to be implemented in order to

ensure protection against accidental contact.

Possible consequences:

• Death or severe injury

Protective measures:

• If protection against accidental contact is required for the control terminals

of the controller and the connections of the plugged-in device modules, ...

– a double isolating distance must exist.

– the components to be connected must be provided with the second

isolating distance.

Technical data

Protective insulation

Note!

The existing protective insulation in the Inverter Drives 8400 is implemented

according to EN 61800-5-1.

EDS84AYCEC EN 3.0 - 09/2012 L 17

Page 18

E84AYCEC communication manual (Ethernet POWERLINK)

X4

X6

X5

X3

Bus

Ext. DC

MCI

X4

X6

X5

X3

X1X1

X105X105

X100X100

MMI

X106X106X106X106

X106X106X106X101

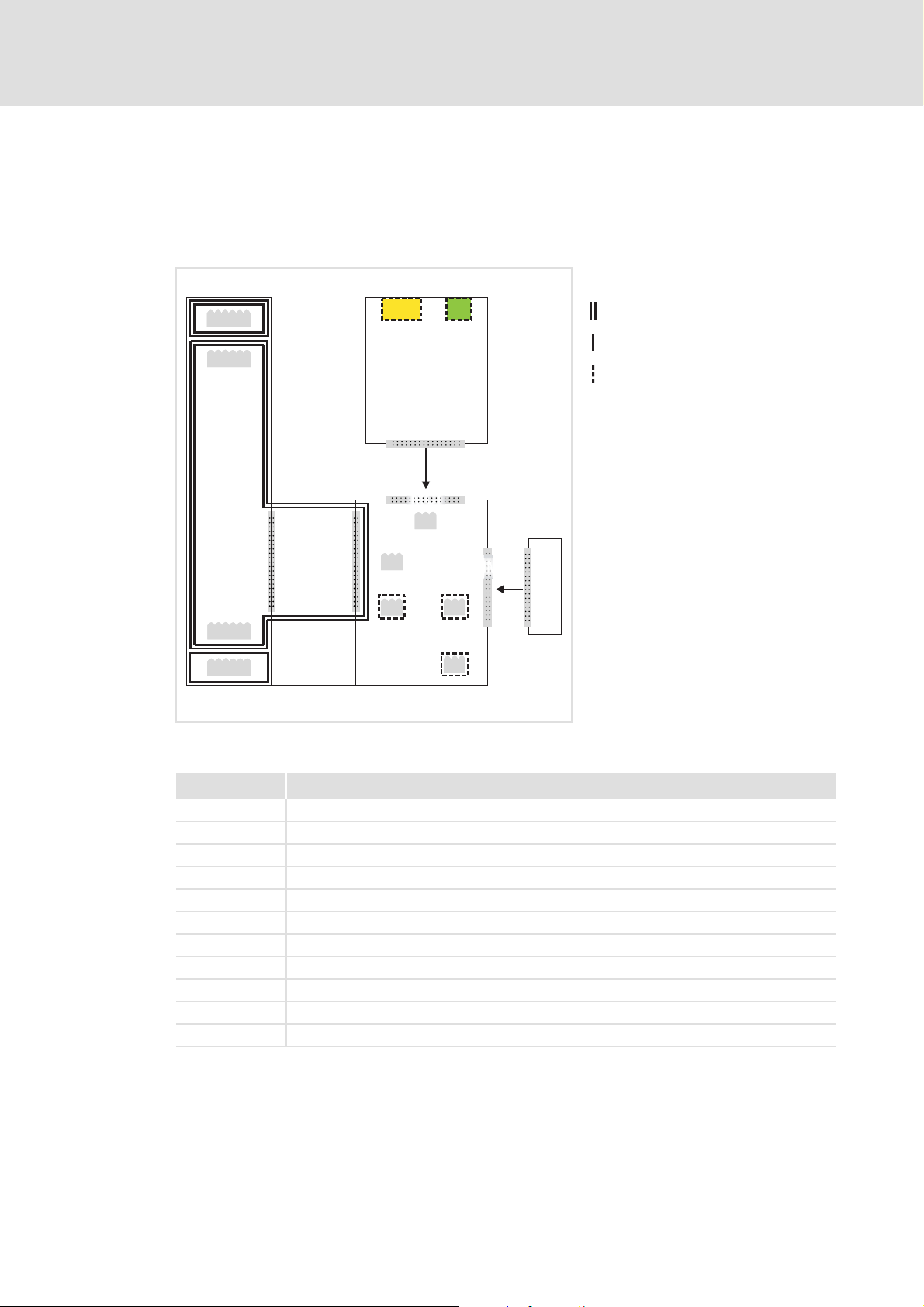

Technical data

Protective insulation

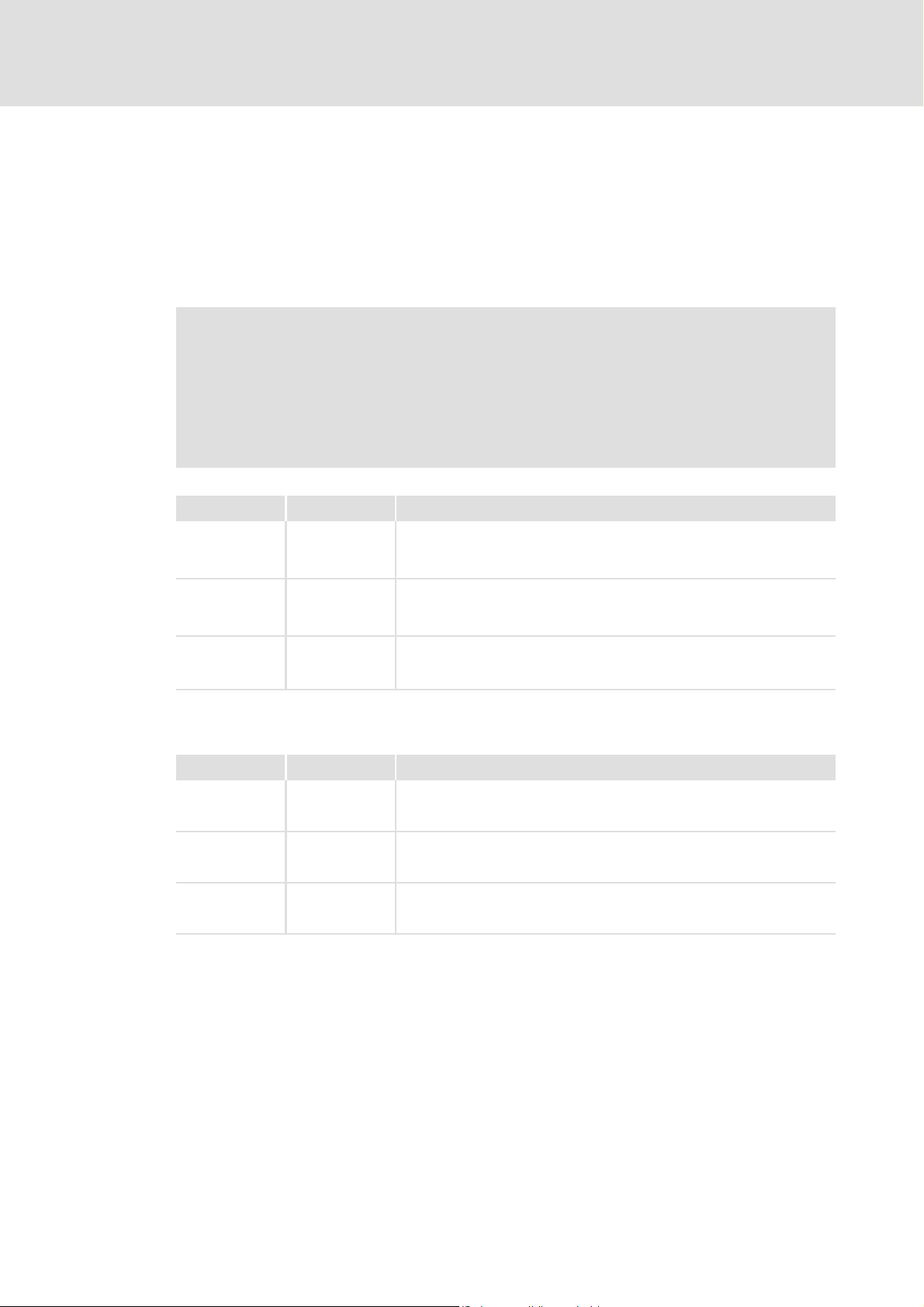

The following illustration ...

shows the arrangement of the terminal strips and the separate potential areas of the

Inverter Drive 8400.

serves to determine the decisive protective insulation between two terminals located

in differently insulated separate potential areas.

Reinforced insulation

Basic insulation

Functional insulation

[4-1] Protective insulation to EN61800-5-1

Terminal strip Connection

X100 Mains/DC-bus connection

X101 Relay contact

X105 Motor/brake resistor

X106 Motor PTC

X1 System bus (CANopen)

X3 Analog inputs/outputs

X4 Digital outputs

X5 Digital inputs

X6 Diagnostics

MCI Slot for the communication module

MMI Slot for the memory module

E84YCXX007

18 L EDS84AYCEC EN 3.0 - 09/2012

Page 19

E84AYCEC communication manual (Ethernet POWERLINK)

Technical data

Protective insulation

Example

Which type of protective insulation is used between the bus terminal of the device module

in slot MCI and the X100 mains terminal?

The separate potential area with the better protective insulation is decisive.

– The separate potential area of the bus terminal of the device module has a

"functional insulation".

– The separate potential area of the mains terminal has a "reinforced insulation".

Result: The insulation between the X100 mains terminal and the bus terminal is a

"reinforced insulation".

EDS84AYCEC EN 3.0 - 09/2012 L 19

Page 20

E84AYCEC communication manual (Ethernet POWERLINK)

Technical data

Ethernet POWERLINK communication data

4.3 Ethernet POWERLINK communication data

Field Values

Min. cycle time 400 s

Total cycle times 0.4 / 0.5 / 1.0 / 2.0 / 3.0 … 20.0 ms

Buffer size • Tx-iso: max. 1490 bytes

• Rx-iso: max. 1490 bytes

(max. 32 bytes of PDO user data)

Delay time • Controlled node (T

• Controlled node (T

Frame size Max. asynchronous frame size (MTU): 1518 bytes

SDO communication method UDP/IP or ASND

Number of RPDOs Max. 6 channels

RPDO user data per application (all

RPDOs)

Number of TPDOs 1 channel (data access of all nodes by broadcasting)

TPDO user data per application Max. 16 objects (32 bytes)

CN operating modes Support of ...

Max. 16 objects (max. 32 bytes)

•Multiplex CNs

•Optional CNs

Preq

SoA

- T

): approx. 2.6 s

Res

- T

): approx. 2.6 s

ASnd

Communication time

The communication time is the time between the start of a request and the arrival of the

corresponding response.

The communication times in the Ethernet POWERLINK network depend on ...

the processing time in the controller;

the telegram runtime (baud rate / telegram length);

the nesting depth of the network.

Processing time in the controller

Data Processing time

Process data approx. 2 ms

+ 0 ... 1 ms

+ 1 ... x ms

Parameter data approx. 30 ms + 20 ms tolerance (typical)

• For some codes, the processing time may be longer (see software

manual/»Engineer« online help for the Inverter Drive 8400).

Update cycle

Processing time in the module

Runtime of the application task of the technology

application used (tolerance)

There are no interdependencies between parameter data and process data.

20 L EDS84AYCEC EN 3.0 - 09/2012

Page 21

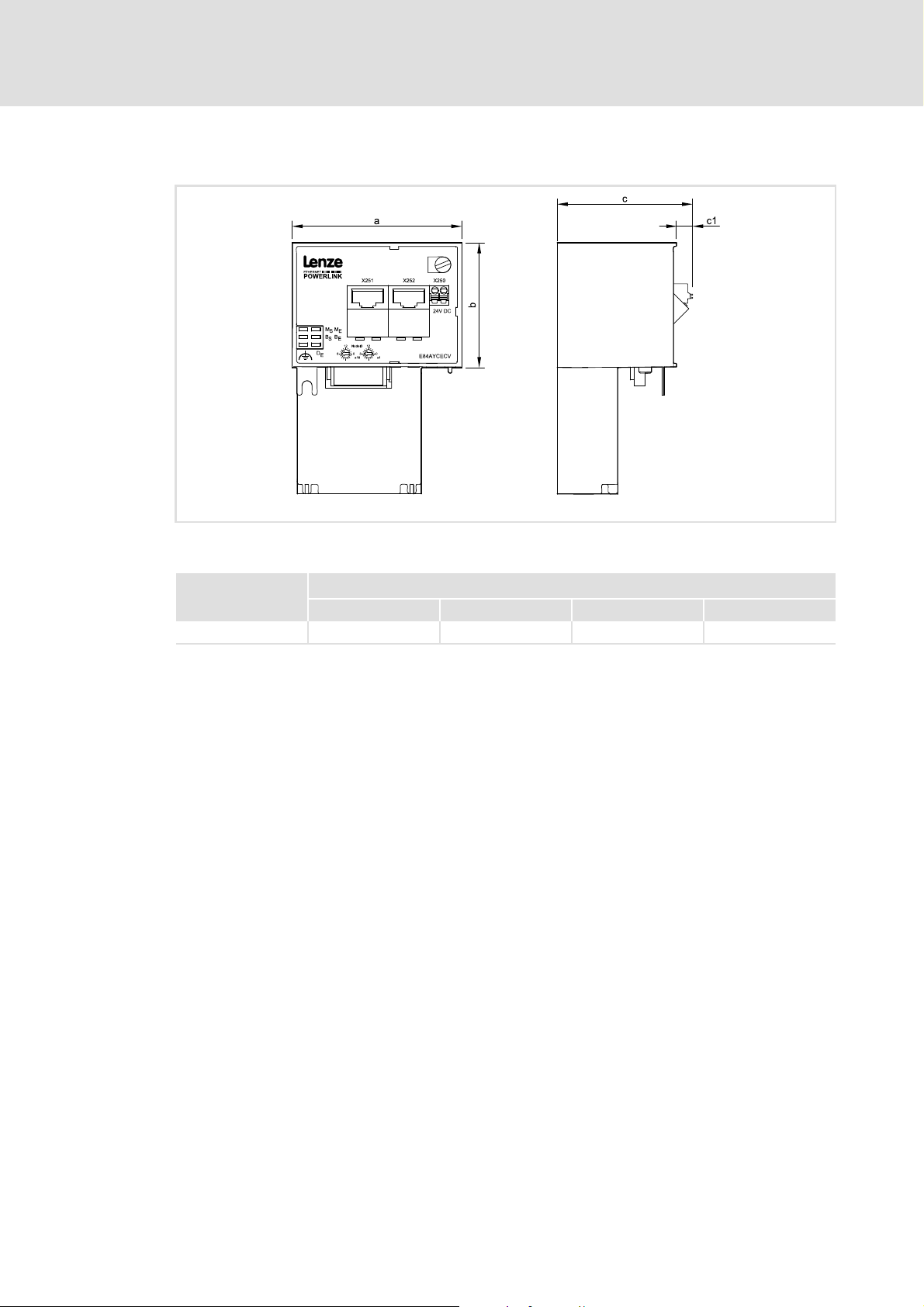

4.4 Dimensions

E84AYCEC communication manual (Ethernet POWERLINK)

Technical data

Dimensions

[4-2] Dimensions

E84AYCEC 67 50 57 8

E84YCER001B

Type Dimensions [mm]

a b c c1

EDS84AYCEC EN 3.0 - 09/2012 L 21

Page 22

E84AYCEC communication manual (Ethernet POWERLINK)

Installation

5 Installation

Stop!

Electrostatic discharge

Electronic components within the communication module can be damaged or

destroyed by electrostatic discharge.

Possible consequences:

• The communication module is defective.

• Fieldbus communication is not possible or faulty.

Protective measures

• Free yourself from any electrostatic charge before you touch the module.

22 L EDS84AYCEC EN 3.0 - 09/2012

Page 23

E84AYCEC communication manual (Ethernet POWERLINK)

5.1 Mechanical installation

The communication module can be plugged in or unplugged from the MCI slot when the

controller is switched on. When the module is plugged in, it is detected automatically, and

a function and version plausibility check is executed.

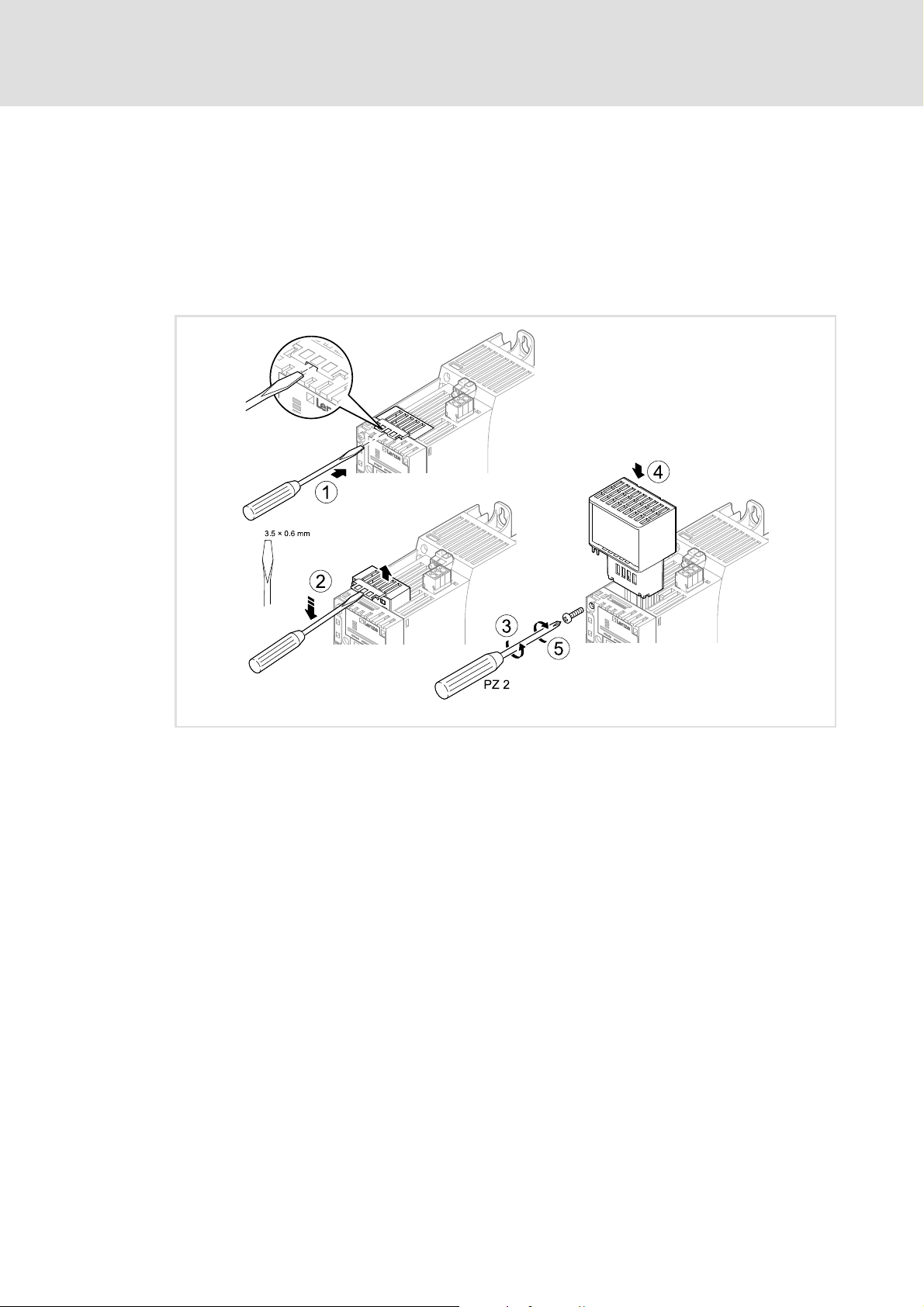

5.1.1 Mounting for standard devices of 0.25 kW and 0.37 kW

Installation

Mechanical installation

[5-1] Mounting for standard devices of 0.25 kW and 0.37 kW

Mounting steps

1. Use a screwdriver to lever out the cover of the MCI slot of the standard device and

remove it (1, 2).

2. Loosen the securing screw for the communication module at the standard device (3).

3. Insert the communication module into the MCI slot of the standard device (4).

4. Tighten the securing screw again (5).

E84YCPM002D

EDS84AYCEC EN 3.0 - 09/2012 L 23

Page 24

E84AYCEC communication manual (Ethernet POWERLINK)

Installation

Mechanical installation

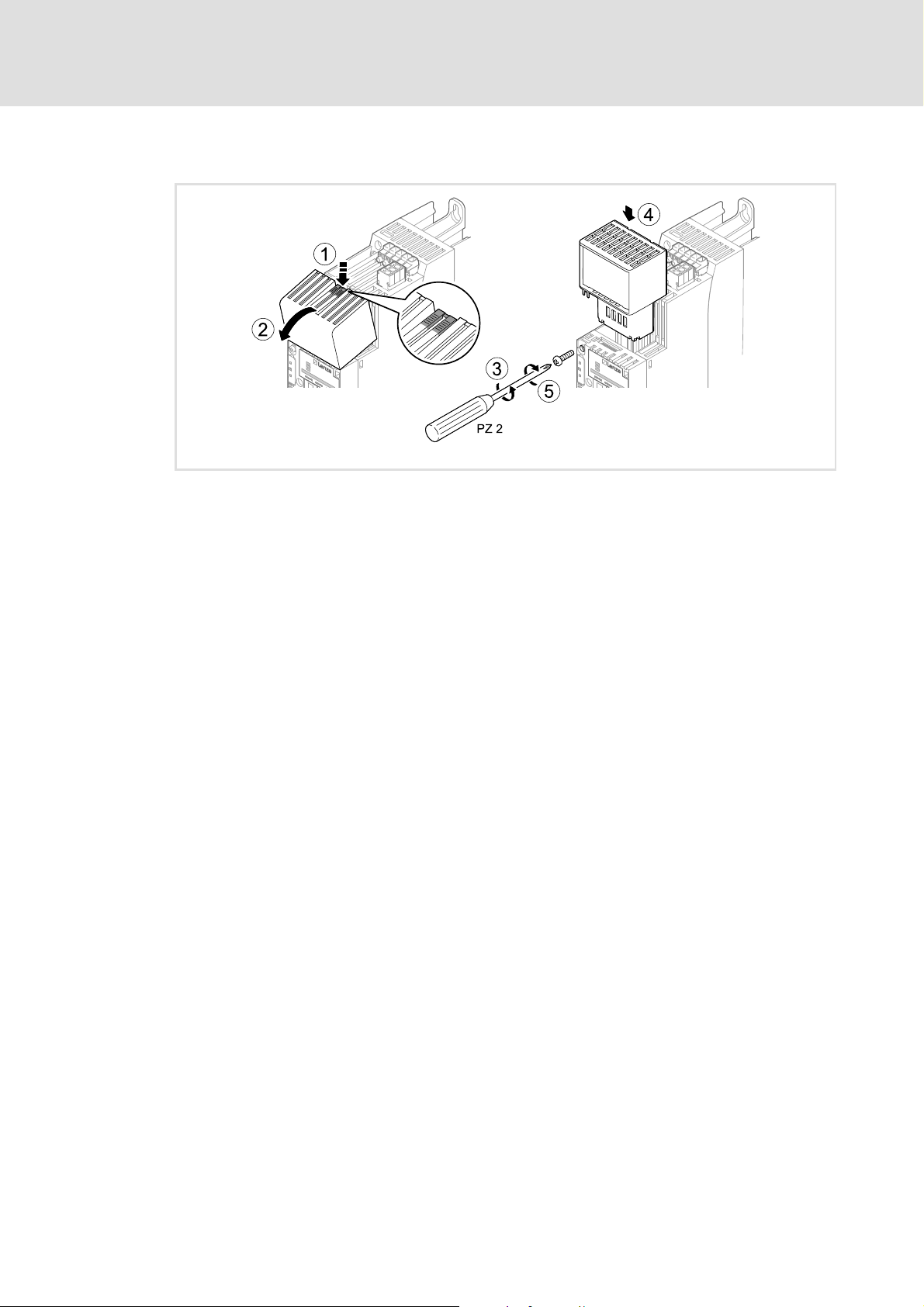

5.1.2 Mounting for standard devices of 0.55 kW or more

[5-2] Mounting for standard devices of 0.55 kW or more

E84YCPM002A

Mounting steps

1. Slightly press on the marked spot on the top of the MCI slot cover of the standard

device (1).

2. Tilt the cover forward and remove it from the standard device (2).

3. Loosen the securing screw for the communication module at the standard device (3).

4. Insert the communication module into the MCI slot of the standard device (4).

5. Tighten the securing screw again (5).

24 L EDS84AYCEC EN 3.0 - 09/2012

Page 25

E84AYCEC communication manual (Ethernet POWERLINK)

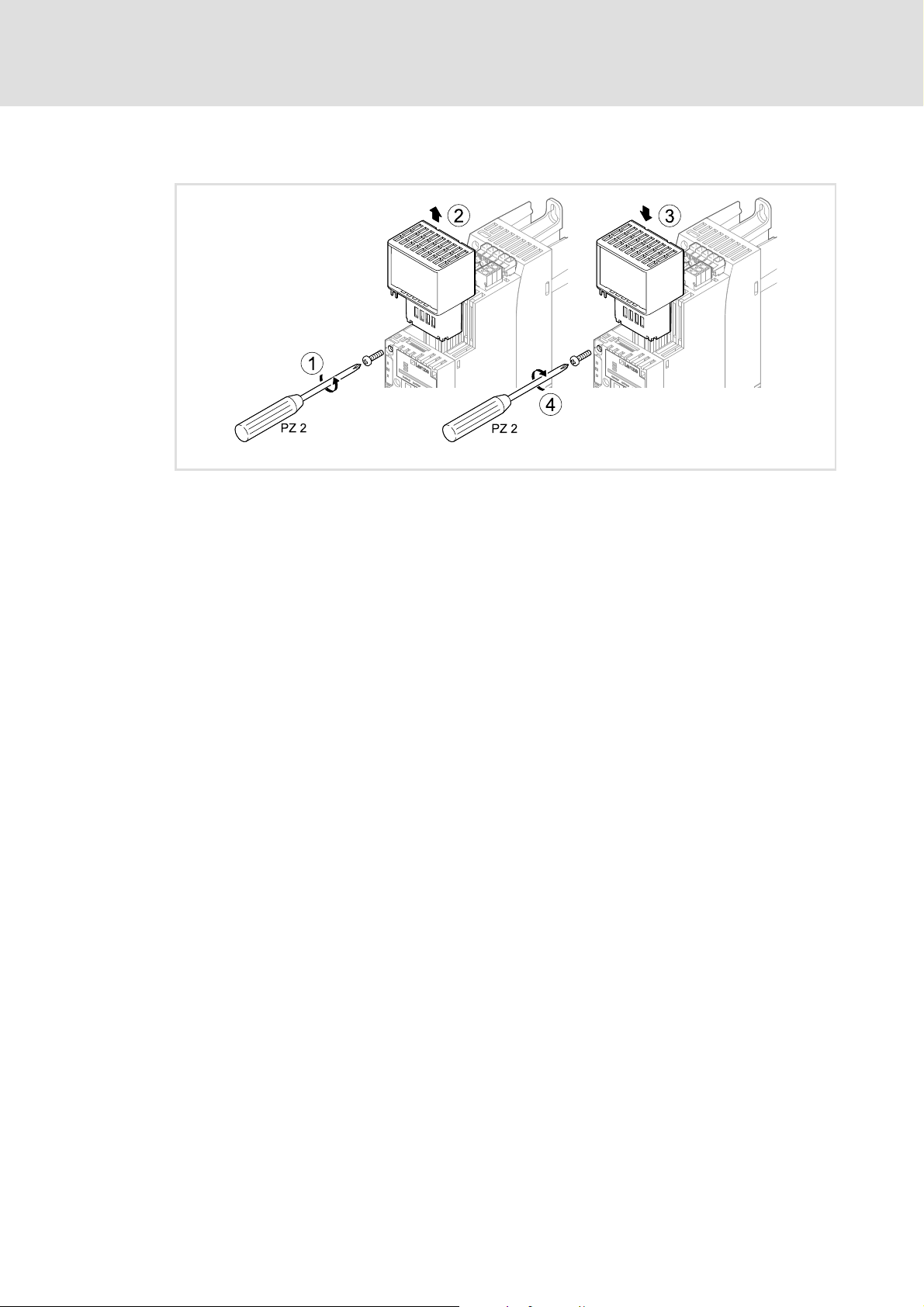

5.1.3 Exchanging the communication module

[5-3] Exchanging the communication module

Installation

Mechanical installation

E84YCPM002B

Mounting steps

1. Loosen the securing screw for the communication module at the standard device (1).

2. Pull the communication module out of the MCI slot of the standard device (2).

3. Insert the new communication module into the MCI slot of the standard device (3).

4. Tighten the securing screw again (4).

EDS84AYCEC EN 3.0 - 09/2012 L 25

Page 26

E84AYCEC communication manual (Ethernet POWERLINK)

Installation

Electrical installation

5.2 Electrical installation

Documentation for the standard device, control system, system/machine

Observe the notes and wiring instructions provided therein.

5.2.1 Wiring according to EMC guidelines

In typical systems a standard shielding of the Ethernet cable is sufficient.

In environments with very strong interferences, the EMC compatibility can be improved by

an additional earthing of the cable shield on both sides.

Observe the following notes:

1. Remove the plastic sheath of the cable at a length of 2 cm.

2. Fasten the cable shield to the shield support of the standard device.

26 L EDS84AYCEC EN 3.0 - 09/2012

Page 27

E84AYCEC communication manual (Ethernet POWERLINK)

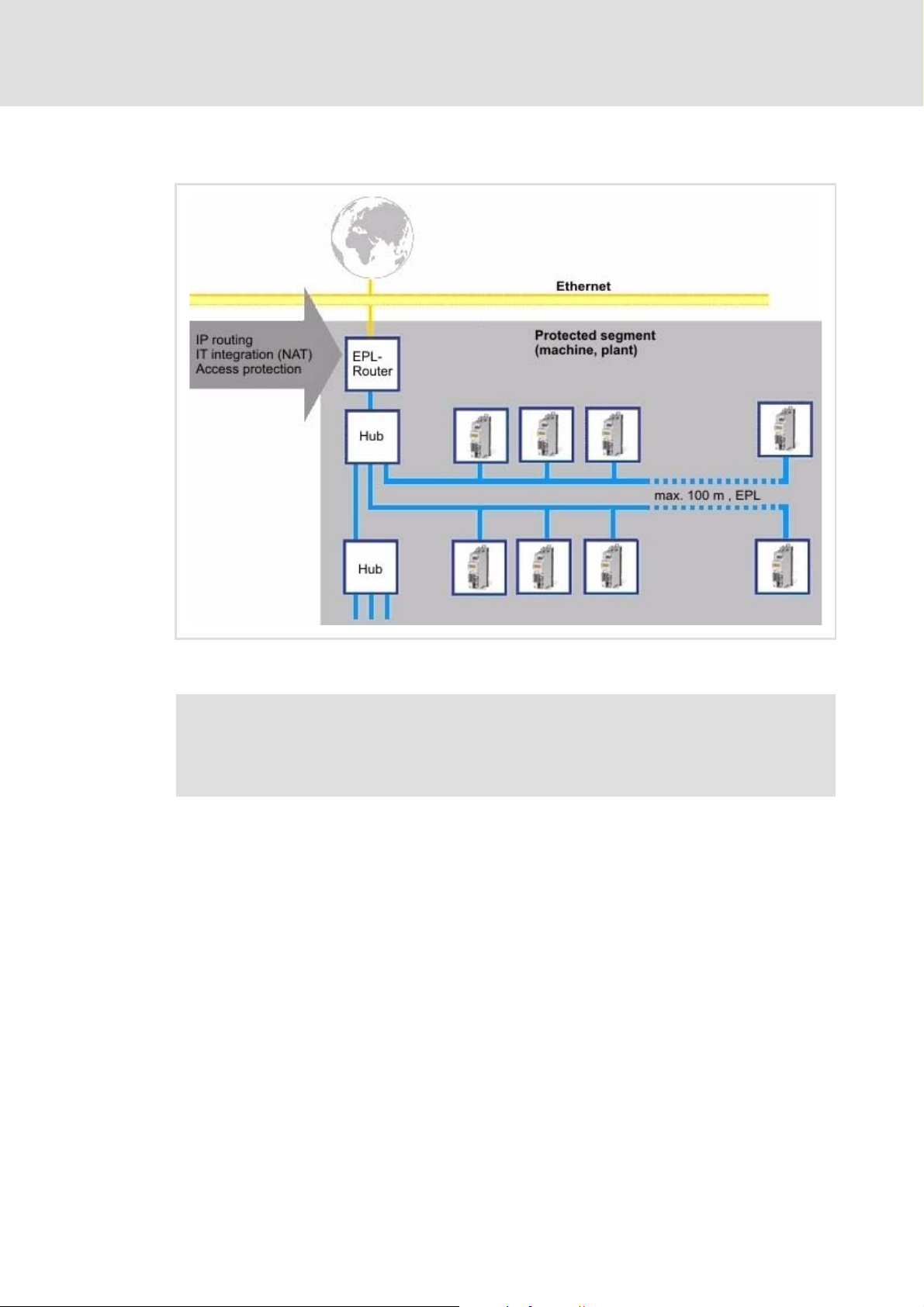

5.2.2 Network topology

Installation

Electrical installation

[5-4] Network topology for Ethernet POWERLINK

Note!

The use of class I hubs and switches inside the EPL network segment is not

permitted.

Inside the segment only Ethernet hubs may be used as infrastructure elements. The hubs

must meet the requirements on class II repeaters acc. to IEEE 802.3u.

For this purpose Lenze offers the dual hub integrated into the communication module and

the separate eight-fold hub, type E94AZCEH.

Class I hubs and switches are not permissible since they have considerably longer delay

times for the frame forwarding and a bigger jitter. Both sizes reduce the real-time

capability and dynamics.

The cable length between both nodes is limited to 100 m.

The topology rules (IEEE 802.3u) required for controlling the collisions may be violated in

the EPL network segment since according to the EPL access order frame collisions are

prevented. This enables a structure of lines and any hybrid forms between star and line

topology.

EDS84AYCEC EN 3.0 - 09/2012 L 27

Page 28

E84AYCEC communication manual (Ethernet POWERLINK)

1. CN group

2. CN group

Managing

Node

Hub

Installation

Electrical installation

Recommended topology

For an easy configuration and due to many possible topology variants we recommend to

create networks according to the following rules:

1. Create CN groups with up to 10 nodes.

2. Connect CN groups in star shape to the managing node.

3. Connect CN groups to the managing node via one external hub each.

– For more than 2 CN groups, use an external 8-port hub (e.g. Lenze hub E94AZCEH).

– For max. 7 CN groups one hub is sufficient.

– For more than 7 CN groups, use further hubs.

– The groups can be distributed on the hubs just as you like.

– Observe the restrictions of the used managing node.

Note!

E94AYCEP communication module als Managing Node

With maximally 2 CN groups and the use of an E94AYCEP communication

module as Managing Node, connect the CN group(s) directly to the Ethernet

POWERLINK terminals X211 and X212 of the E94AYCEP communication module.

[5-5] Star topology for 1 to 2 CN groups

E94YCEP033

28 L EDS84AYCEC EN 3.0 - 09/2012

Page 29

E84AYCEC communication manual (Ethernet POWERLINK)

5.2.3 Ethernet POWERLINK

Note!

Standard Ethernet nodes are not permitted in the Ethernet POWERLINK network

segment.

In order to use the real-time capability of the Ethernet POWERLINK technology, Ethernet

POWERLINK nodes must be interconnected in a separate network segment.

In accordance with the EPL rules, only the managing node controls the network access of

EPL nodes. The managing node is the only node that transmits autonomously. The slave

nodes (i.e. all controlled nodes) only transmit when they are entitled to transmit by the

managing node.

Non-EPL nodes (e.g. PCs) typically violate these rules by sending frames independently of

the managing node. These frames interfere with the cyclic frame exchange of the EPL

nodes and impede the real-time capability of Ethernet POWERLINK.

Installation

Electrical installation

Connection to the standard Ethernet network

The connection to an external standard Ethernet network is carried out via an Ethernet

POWERLINK router or an Ethernet POWERLINK gateway.

These infrastructure components separate the network traffic in the Ethernet POWERLINK

network segment from the one in the standard Ethernet. The handling of the frames

depend on their direction:

Standard Ethernet ---> EPL network segment:

Only frames that are addressed to nodes in the EPL network segment are forwarded.

The forwarding takes place in the asynchronous area of the EPL cycle.

EPL network segment ---> standard Ethernet:

Only asynchronous frames that are not addressed to nodes in the EPL network segment

are forwarded.

Tip!

Detailed information on the function and setting of the router or gateway can be

found in the documentation of the component manufacturer.

EDS84AYCEC EN 3.0 - 09/2012 L 29

Page 30

E84AYCEC communication manual (Ethernet POWERLINK)

Installation

Electrical installation

5.2.4 Basic Ethernet Mode

Note!

Operation in the "Basic Ethernet Mode" does not permit any real-time

communication.

The communication module can be operated in the "Basic Ethernet Mode" for a basic

parameter setting provided that the following applies:

1. Operation of the module with network address 239.

– IP address: 192.168.100.[EPL address]

– see Node address setting

2. No operation with real-time EPL must be carried out.

3. No integration of a managing node (EPL address 240) into the standard Ethernet

network.

( 38)

30 L EDS84AYCEC EN 3.0 - 09/2012

Page 31

E84AYCEC communication manual (Ethernet POWERLINK)

5.2.5 Ethernet POWERLINK connection

Ethernet POWERLINK is connected via the RJ45 sockets X251 (P1) and X252 (P2).

Installation

Electrical installation

[5-6] Ethernet POWERLINK connections X251 (P1) and X252 (P2)

If possible, do not wire more than 10 nodes in a row in a network line.

In case of more than 10 nodes you should deactivate the automatic calculation of the

hub level in the »Engineer« and enter it manually to increase the performance.

With a cycle time of 1 ms, 25 nodes can be operated.

– The number of nodes can be increased if the EPL cycle time is increased as well.

You can use a standard Ethernet patch cable to connect the communication module to

the Ethernet POWERLINK fieldbus (see Ethernet cable specification

The installation and removal of the Ethernet cables is optimised for use of connectors

according to the "Automation Initiative of German Domestic Automobile

Manufacturers" (AIDA).

Note!

To prevent the RJ45 socket from being damaged, hold the Ethernet cable

connector straight (at a right angle) when inserting it into or removing it from

the socket.

E84YCEC001E

( 33)).

EDS84AYCEC EN 3.0 - 09/2012 L 31

Page 32

E84AYCEC communication manual (Ethernet POWERLINK)

Installation

Electrical installation

Pin assignment of the RJ45 sockets

RJ45 socket Pin Signal

1Tx +

2Tx -

3Rx +

4-

5-

6Rx -

E94AYCXX004C

7-

8-

Tip!

The Ethernet POWERLINK interfaces feature an auto MDIX function. This function

adjusts the polarity of the RJ45 interfaces so that a connection is established

irrespective of the polarity of the opposite Ethernet POWERLINK interface, and

irrespective of the type of cable used (standard patch cable or crossover cable).

32 L EDS84AYCEC EN 3.0 - 09/2012

Page 33

E84AYCEC communication manual (Ethernet POWERLINK)

5.2.6 Ethernet cable specification

Note!

Only use cables that meet the listed specifications.

Ethernet cable specification

Ethernet standard Standard Ethernet (in accordance with IEEE 802.3), 100Base-TX (Fast

Cable type S/FTP (screened foiled twisted pair, ISO/IEC 11801 or EN 50173), CAT 5e

Damping 23.2 dB (at 100 MHz and per 100 m)

Crosstalk damping 24 dB (at 100 MHz and 100 m each)

Return loss 10 dB (100 m each)

Surge impedance 100

Installation

Electrical installation

Ethernet)

Structure of the Ethernet cable

[5-7] Structure of the Ethernet cable (S/FTP, CAT 5e)

E94YCEP016

A Cable insulation

B Braid

C Foil shield

TP1

Twisted core pairs 1 ... 4

...

Colour code of the Ethernet cable

TP4

( 34)

EDS84AYCEC EN 3.0 - 09/2012 L 33

Page 34

E84AYCEC communication manual (Ethernet POWERLINK)

Installation

Electrical installation

Colour code of the Ethernet cable

Note!

The wiring and colour codes are standardised in EIA/TIA 568A/568B.

4-pin Ethernet cables according to industry standard are permissible. This cable

type only connects the assigned pins 1, 2, 3 and 6.

[5-8] Ethernet connector in accordance with EIA/TIA 568A/568B

Pair Pin Signal EIA/TIA 568A EIA/TIA 568B

3 1 Tx + White/green White/orange

2 Tx - Green Orange

2 3 Rx + White/orange White/green

1 4 Blue Blue

5 White/blue Blue/white

2 6 Rx - Orange Green

47 White/brown White/brown

8Brown Brown

E94YCEI004A

34 L EDS84AYCEC EN 3.0 - 09/2012

Page 35

E84AYCEC communication manual (Ethernet POWERLINK)

5.2.7 External voltage supply

The communication module can be externally supplied with voltage via separate supply

cables at the 2-pin plug connector X250.

Note!

Always use a separate power supply unit safely separated according to

EN 61800-5-1 ("SELV/PELV") in every control cabinet for external voltage supply.

External voltage supply of the communication module is required if the

communication via the bus should be maintained when the supply of the standard

device fails.

The parameters of a standard device separated from the mains cannot be accessed.

Wiring of the X250 plug connector

Installation

Electrical installation

Stop!

Only wire the plug connector if the standard device is disconnected from the

mains.

[5-9] Wiring of the 2-pin plug connector with spring connection

How to wire the plug connector with spring connection:

1. Press a screwdriver into the notch below the terminal and keep it pressed.

E84AYCXX010

2. Place the supply cable in the terminal.

3. Remove the screwdriver from the notch.

EDS84AYCEC EN 3.0 - 09/2012 L 35

Page 36

E84AYCEC communication manual (Ethernet POWERLINK)

Installation

Electrical installation

Assignment of the X250 plug connector

Designation Description

+ U = 24 V DC (20.4 V - 0 % ... 28.8 V + 0 %)

I = 140 mA

- Reference potential for external voltage supply

Terminal data

Field Values

Electrical connection 2-pin plug connector with spring connection

Possible connections rigid:

0.2 ... 1.5 mm

flexible:

without wire end ferrule

0.2 ... 1.5 mm

with wire end ferrule, without plastic sleeve

0.2 ... 1.5 mm

with wire end ferrule, with plastic sleeve

0.2 ... 1.5 mm

2

(AWG 24 ... 16)

2

(AWG 24 ... 16)

2

(AWG 24 ... 16)

2

(AWG 24 ... 16)

Bare end 10 mm

36 L EDS84AYCEC EN 3.0 - 09/2012

Page 37

E84AYCEC communication manual (Ethernet POWERLINK)

6 Commissioning

During commissioning, system-related data such as motor parameters, operating

parameters, responses, and parameters for fieldbus communication are defined in the

controller. For Lenze devices, this is done by means of codes.

The codes of the controller and of the communication are stored as a non-volatile data set

in the memory module.

In addition, other codes are available for diagnosing and monitoring the nodes.

Commissioning

Before initial switch-on

Parameter reference

6.1 Before initial switch-on

Stop!

Before switching on the Inverter Drive 8400 and the communication module for

the first time, check the entire wiring for completeness, short circuit and earth

fault.

( 66)

EDS84AYCEC EN 3.0 - 09/2012 L 37

Page 38

E84AYCEC communication manual (Ethernet POWERLINK)

Commissioning

Node address setting

6.2 Node address setting

Note!

• Each network node address must only be used once.

• The node address setting in the configuration software (e.g. »Engineer«) and

the rotary encoder switches must be identical for each node.

• Adjustable address range: 1 ... 239

• Switch the voltage supply of the communication module off and on again to

activate changed settings.

The node address is set via the two front panel rotary coding switches "Node ID".

[6-1] Rotary coding switches "Node ID"

The labelling of the rotary coding switches corresponds to the values for determining

the node address.

Valid addresses for the communication module in the EPL network:

– 1 … 100: Controlled node with Lenze module E94AYCEP as managing node

– 1 … 239: Controlled node with managing node of another manufacturer

The corresponding Ethernet IP address of the communication module results from the

address setting of the rotary coding switches:

– IP address: 192.168.100.[EPL address]

Symbol_NodeID

38 L EDS84AYCEC EN 3.0 - 09/2012

Page 39

E84AYCEC communication manual (Ethernet POWERLINK)

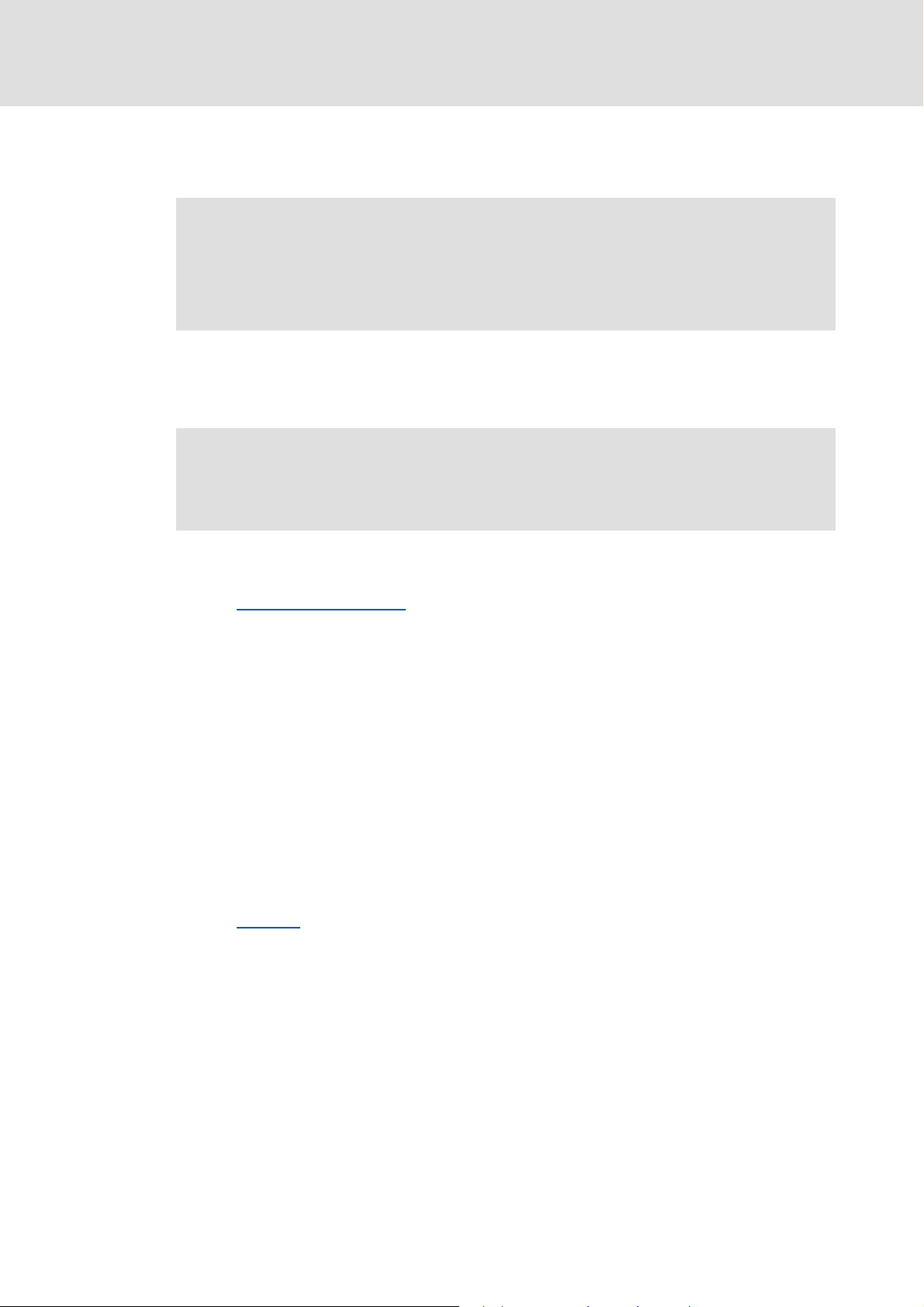

Possible settings of the rotary coding switches

Position of the rotary coding switches Resulting node address

Commissioning

Node address setting

0

0 ... 14 1 ... 15 1 ... 239

15 0 ... 15 239

× 16

0

Value from code C13899

× 1

[6-2] Internal check of the rotary coding switch setting after the system start

Example: Setting of the node address "52"

Position of the rotary coding switches Resulting node address

3 × 16 4 × 1(3 × 16) + (4 × 1) = 52

EDS84AYCEC EN 3.0 - 09/2012 L 39

Page 40

E84AYCEC communication manual (Ethernet POWERLINK)

Commissioning

Setting and displays in the »Engineer«

6.3 Setting and displays in the »Engineer«

The IP address (C13000

Settings tab.

) and the MAC address (C13004) are displayed on the

40 L EDS84AYCEC EN 3.0 - 09/2012

Page 41

6.4 Initial switch-on

Documentation for the standard device

Observe the safety instructions and information on residual hazards contained

in this documentation.

Note!

Establishing communication

When the communication module is externally supplied, the standard device

must also be switched on to establish communication.

After communication has been established, communication of the externally

supplied module is independent of the switching status of the standard device.

E84AYCEC communication manual (Ethernet POWERLINK)

Commissioning

Initial switch-on

Activating changed setting

In order to activate any changed settings, ...

• execute the device command "11: Save all parameter sets" via the standard

device code C00002 and ...

• then execute a "reset node" of the node or switch off and then on again the

voltage supply of the communication module.

Protection against uncontrolled restart

Following a fault (short-term mains failure, for example), it is sometimes

undesirable or even impermissible for the drive to restart.

The restart protection is activated in the Lenze setting of the Inverter Drives

8400.

You can set the restart behaviour of the controller via C00142 ("Autostart

Option"):

• C00142 = 9 (Lenze setting)

– The controller remains inhibited (even if the fault is no longer active).

– Bit 0 (inhibit when device On) and bit 3 (inhibit in case of undervoltage) are

set.

– The drive restarts in a controlled mode through explicit controller enable:

LOW-HIGH edge at digital input X4/RFR.

• C00142 = 8 (Enabled)

– In order to enable the device directly when switching it on, bit 0 must be set

to zero (FALSE).

– An uncontrolled restart of the drive is possible.

EDS84AYCEC EN 3.0 - 09/2012 L 41

Page 42

E84AYCEC communication manual (Ethernet POWERLINK)

Commissioning

Initial switch-on

Initial switch-on and diagnosing

1. Switch on the controller and check whether it is ready for operation using the

diagnostic LEDs of the communication module.

• Red diagnostic LEDs must not be on.

• The following signalling should be visible:

LED Colour Status Meaning

MS Green On Module Status Module status displays

DE - Off Device Error

X251 Green On LED is lit if a connection to the node has been established.

X252 Green On

2. If not already done, load the EPL configuration into the controller.

3. Repeat steps 1 and 2 for all EPL nodes.

4. Start network.

Status displays at the RJ45 sockets (X251, X252)

( 54)

( 56)

The network starts automatically if you set the managing node last.

Otherwise there are two options:

• Switch off the network nodes and switch them on together or

• execute a fault reset on the managing node (EPL address 240).

5. Check the EPL network again using the diagnostic LEDs of the communication

module.

The following signalling should be visible:

LED Colour Status Meaning

MS Green On Module Status Module status displays

ME - Off Module Error

BE - Off Bus Error

DE - Off Device Error

BS Green On Bus Status Fieldbus status displays

X251 Green On LED is lit if a connection to the node has been established.

X252 Green On

Status displays at the RJ45 sockets (X251, X252)

( 54)

( 55)

( 56)

42 L EDS84AYCEC EN 3.0 - 09/2012

Page 43

E84AYCEC communication manual (Ethernet POWERLINK)

6.5 Drive synchronisation

Examples of the use of drive synchronisation via Ethernet POWERLINK:

Implementation of the "electrical shaft"

Specification of cyclic position information

Exactly simultaneous data processing of several drives

Optimisation of the processing times of cyclic process data (PDO).

Settings in the »Engineer«

Commissioning

Drive synchronisation

Set "MCI" as synchronisation source in code C01120 of the controller.

The cycle time setpoint C01121 and the phase position C01122 are automatically

calculated from the communication module. Default settings of these parameters are

ignored.

It is not necessary to adjust the sync window C01123 and the sync correction width

C01124.

Software manual/»Engineer« online help for the Inverter Drive 8400

Here you can find detailed information on drive synchronisation and the

corresponding parameters.

EDS84AYCEC EN 3.0 - 09/2012 L 43

Page 44

E84AYCEC communication manual (Ethernet POWERLINK)

Commissioning

Optimisation of networks

6.6 Optimisation of networks

SDO bandwidth

Note!

The channel bandwidth should only be increased if the network is below

capacity limit.

The SDO channel width (C13075

parameter setting and diagnostics. A higher value improves the transmission of large

amounts of data (e.g. parameter downloads) and at the same time reduces the number of

possible nodes.

Maximum time for device search

During the device search, the managing node has to wait until all controlled nodes have

been found.

Unless all controlled nodes are available in the defined EPL cycle time, the

"EPL_BOOTUP_1" error message is generated. The managing node remains in this

status.

If the managing node has found all controlled nodes, it starts the network.

Due to machine or system-specific switch-on sequences, it may be required to adapt the

following EPL objects:

CN object 0x1F99: NMT_CNBasicEthernetTimeout_U32 (C13078

MN object 0x1F89: NMT_BootTime_REC

) is the size of the asynchronous channel used for

)

Note!

In order to avoid a too quick change to the "Basic Ethernet Mode" ( 30), the value

of the 0x1F99 object (NMT_CNBasicEthernetTimeout_U32) must be higher than

the value of the 0x1F89 object (NMT_BootTime_REC) which is the case by

default.

Index table

( 83)

44 L EDS84AYCEC EN 3.0 - 09/2012

Page 45

E84AYCEC communication manual (Ethernet POWERLINK)

7 Process data transfer

Ethernet POWERLINK transmits process data, parameter data, configuration data and

diagnostic data between the managing node and the controlled nodes. Depending on their

time-critical behaviour, the data are transmitted via different communication channels.

Process data are transmitted via the process data channel.

Process data serve to control the Inverter Drive 8400.

The transfer of process data is time-critical.

Process data are cyclically transferred between the managing node and the controlled

nodes (permanent exchange of current input and output data).

The managing node can directly access the process data. In the PLC, for instance, the

data are directly assigned to the I/O area.

Up to 16 process data words (16 bit/word) can be exchanged per direction.

Process data are not saved on the controller.

Process data transfer

Process data are, for instance, setpoints, actual values, control and status words.

EDS84AYCEC EN 3.0 - 09/2012 L 45

Page 46

E84AYCEC communication manual (Ethernet POWERLINK)

/3B0FL,Q

"

E&WUOB%

E&WUOB%

Z&WUO

E,QB%

E,QB%

Z,Q

Z,Q

GQ,QBS

/3B0FL2XW

E6WDWHB%

E6WDWHB%

Z6WDWH

E2XWB%

E2XWB%

Z2XW

Z2XW

GQ2XWBS

"

)LHOGEXV

$SSOLFDWLRQ

)%LQWHUFRQQHFWLRQ

&RPPXQLFDWLRQPRGXOH

0&,LQWHUIDFH

Process data transfer

Access to process data / PDO mapping

7.1 Access to process data / PDO mapping

Process data (MCI-PDOs) are transferred via the MCI interface.

A maximum of 16 words are exchanged per direction.

The process data are accessed via the port blocks LP_MciIn and LP_MciOut. These port

blocks are also referred to as process data channels.

The port block LP_MciIn maps the received MCI-PDOs.

The port block LP_MciOut maps the MCI-PDOs to be sent.

The port/function block interconnection for the process data objects (PDO) is carried

out with the Lenze »Engineer«.

[7-1] Outer and inner data transfer between bus system, controller and application

Software manual / »Engineer« online help for the Inverter Drive 8400

Here you can find detailed information on the port/function block

interconnection in the »Engineer« and on the port blocks.

46 L EDS84AYCEC EN 3.0 - 09/2012

Page 47

E84AYCEC communication manual (Ethernet POWERLINK)

Preconfigured port interconnection of the process data objects (PDO)

Note!

The »Engineer« screenshots shown on the following pages are only examples of

the setting sequence and the resulting displays.

The data in the display fields may differ from the ones of your project.

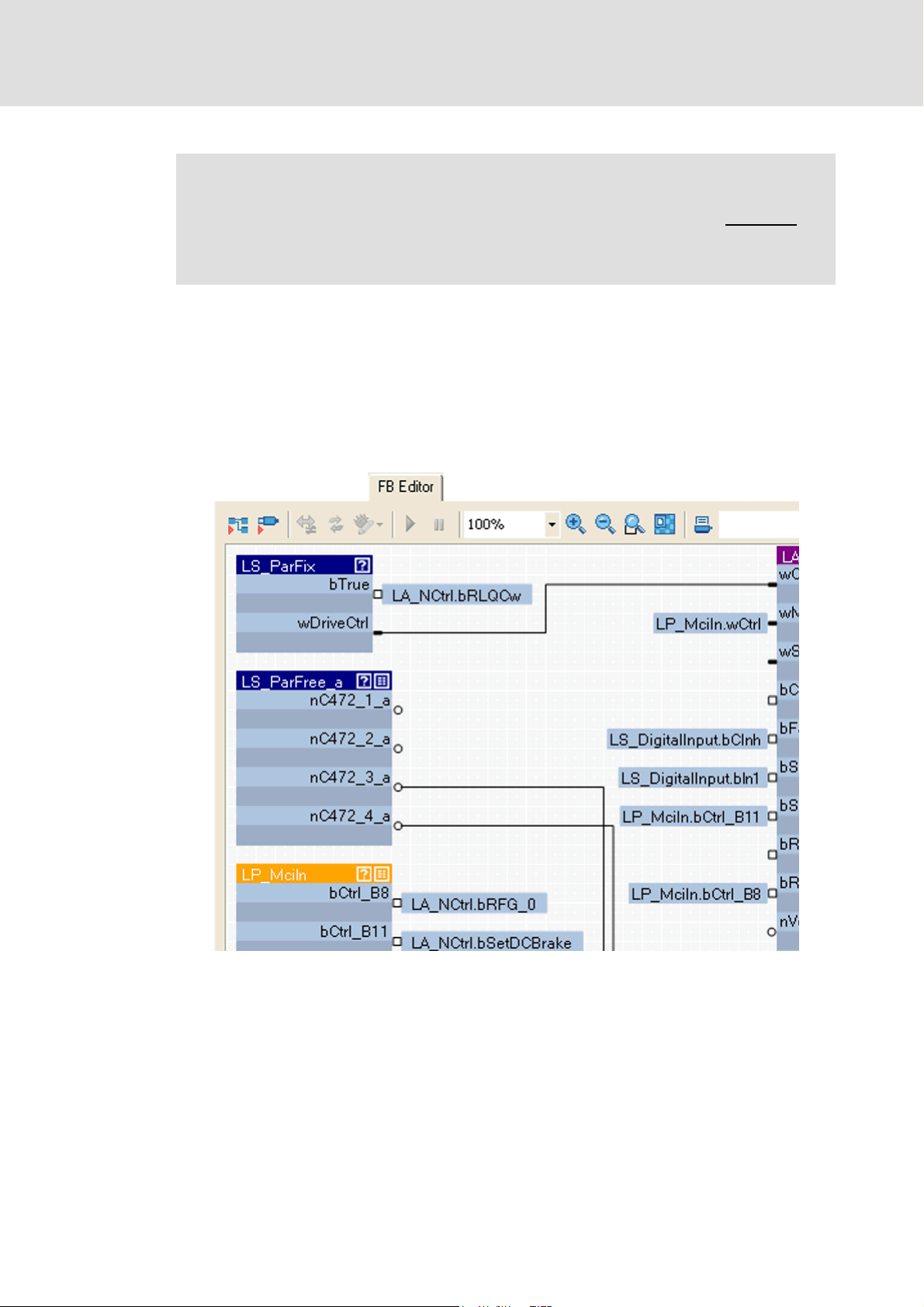

7.2 Preconfigured port interconnection of the process data objects (PDO)

The preconfigured port interconnection of the process data objects can be activated by

setting the standard device code C00007 = "40: MCI".

The function block editor (FB Editor) can be used to display the port blocks LP_MciIn and

LP_MciOut with the preconfigured interconnections:

Process data transfer

EDS84AYCEC EN 3.0 - 09/2012 L 47

Page 48

E84AYCEC communication manual (Ethernet POWERLINK)

Process data transfer

Freely configured port interconnection of the process data objects (PDO)

7.3 Freely configured port interconnection of the process data objects (PDO)

How to configure the port interconnection freely in the »Engineer«:

1. Go to the project view of the »Engineer« and select the application (A).

2. Select the port blocks MCI_IN or MCI_OUT on the Ports tab with a mouse-click and

activate them with the Activate button (B).

3. Click the Change Variable ... button.

48 L EDS84AYCEC EN 3.0 - 09/2012

Page 49

E84AYCEC communication manual (Ethernet POWERLINK)

Process data transfer

Freely configured port interconnection of the process data objects (PDO)

4. The button serves to assign signals to the process data words in the Signal

Assignment--> Function Block dialog box.

Select signals and confirm the selection by clicking the OK button.

EDS84AYCEC EN 3.0 - 09/2012 L 49

Page 50

E84AYCEC communication manual (Ethernet POWERLINK)

Process data transfer

Freely configured port interconnection of the process data objects (PDO)

Furthermore you can assign signals to the individual control and status bits of the

WORD_1 ... WORD_4 process data words via the and buttons.

Select signals and confirm the selection by clicking the OK button.

50 L EDS84AYCEC EN 3.0 - 09/2012

Page 51

E84AYCEC communication manual (Ethernet POWERLINK)

Process data transfer

Freely configured port interconnection of the process data objects (PDO)

Tip!

When the port blocks LP_MciIn and LP_MciOut are activated (see 1.), they will be

visible in the FB Editor. Here you can also assign signals to the process data words.

In order to improve the clarity, unassigned signals can be hidden for each block.

EDS84AYCEC EN 3.0 - 09/2012 L 51

Page 52

E84AYCEC communication manual (Ethernet POWERLINK)

Monitoring

8 Monitoring

Interruption of Ethernet POWERLINK communication

An interruption of Ethernet POWERLINK communication in the OPERATIONAL state, e.g. by

cable break or failure of the managing node, is detected by the controlled node. The

response to this interruption of communication depends on the following settings:

1. The watchdog monitoring time defined in the managing node is transferred to the

controlled node when the Ethernet POWERLINK communication is initialised.

If the controlled node being in the OPERATIONAL state does not receive valid process

data, the process data are handled according to the setting in C13885

sent by the managing node can either be used or set to zero.)

If communication fails, the controlled node state changes to PRE-OPERATIONAL (see

C13861

By default, there is no response in the controlled node

2. To cause a response by the controlled node, you additionally have to ...

– set a response of the controlled node (C13880/1

) and the red LED "BE" is activated (see Fieldbus status displays ( 55)).

.

).

. (The last data

52 L EDS84AYCEC EN 3.0 - 09/2012

Page 53

E84AYCEC communication manual (Ethernet POWERLINK)

9 Diagnostics

The LEDs on the front panel of the communication module serve to diagnose faults.

9.1 LED status displays

Note!

LED status displays for error-free operation:

•The LEDs MS

• The green LED at the RJ45 sockets X251 and X252 is permanently lit or

blinking

The following status displays are distinguished:

Diagnostics

LED status displays

( 54) and BS ( 55) are permanently lit.

( 56).

Module status displays

Fieldbus status displays ( 55)

Status displays at the RJ45 sockets (X251, X252) ( 56)

( 54)

EDS84AYCEC EN 3.0 - 09/2012 L 53

Page 54

E84AYCEC communication manual (Ethernet POWERLINK)

200 ms

200 ms

Diagnostics

LED status displays

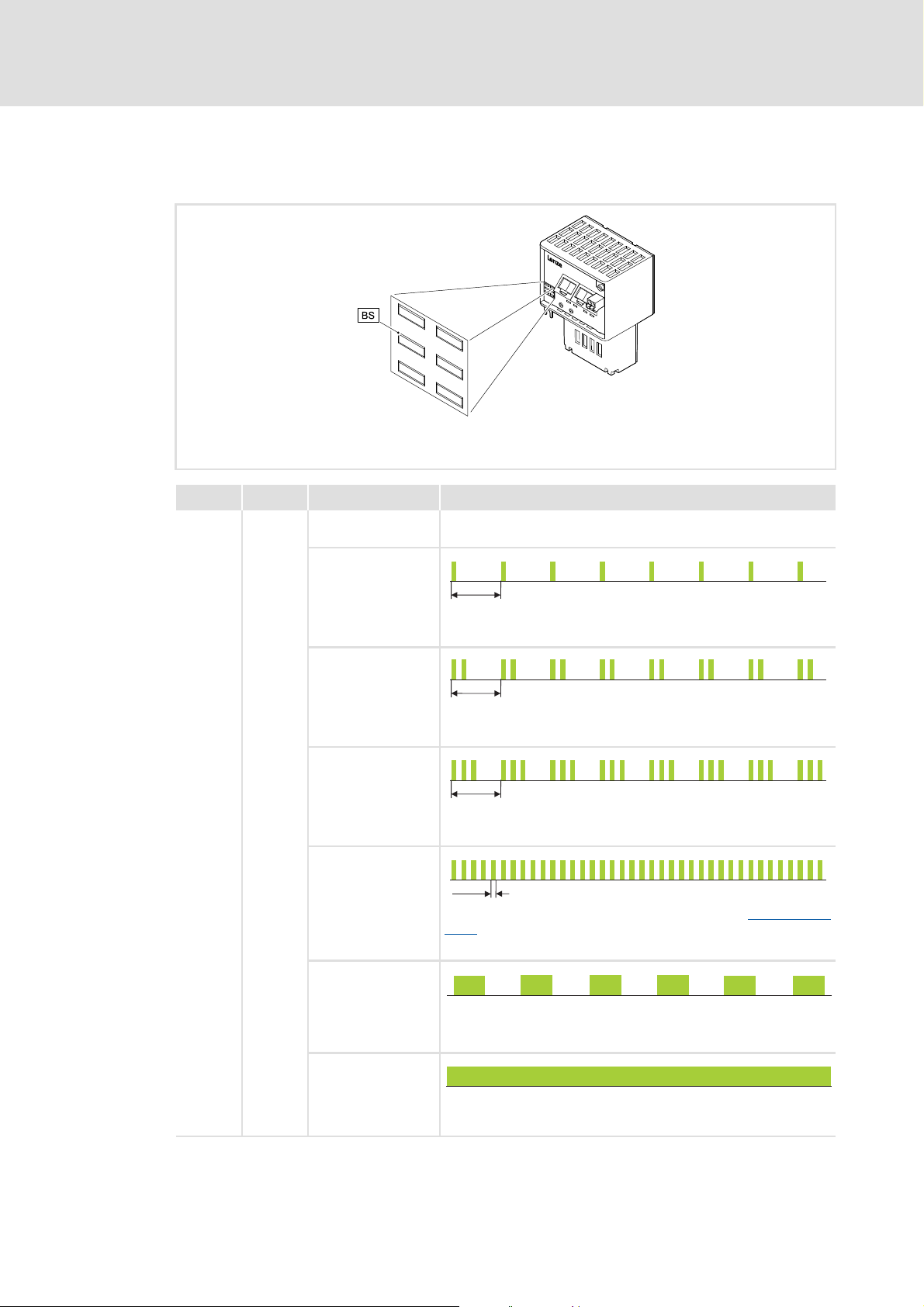

9.1.1 Module status displays

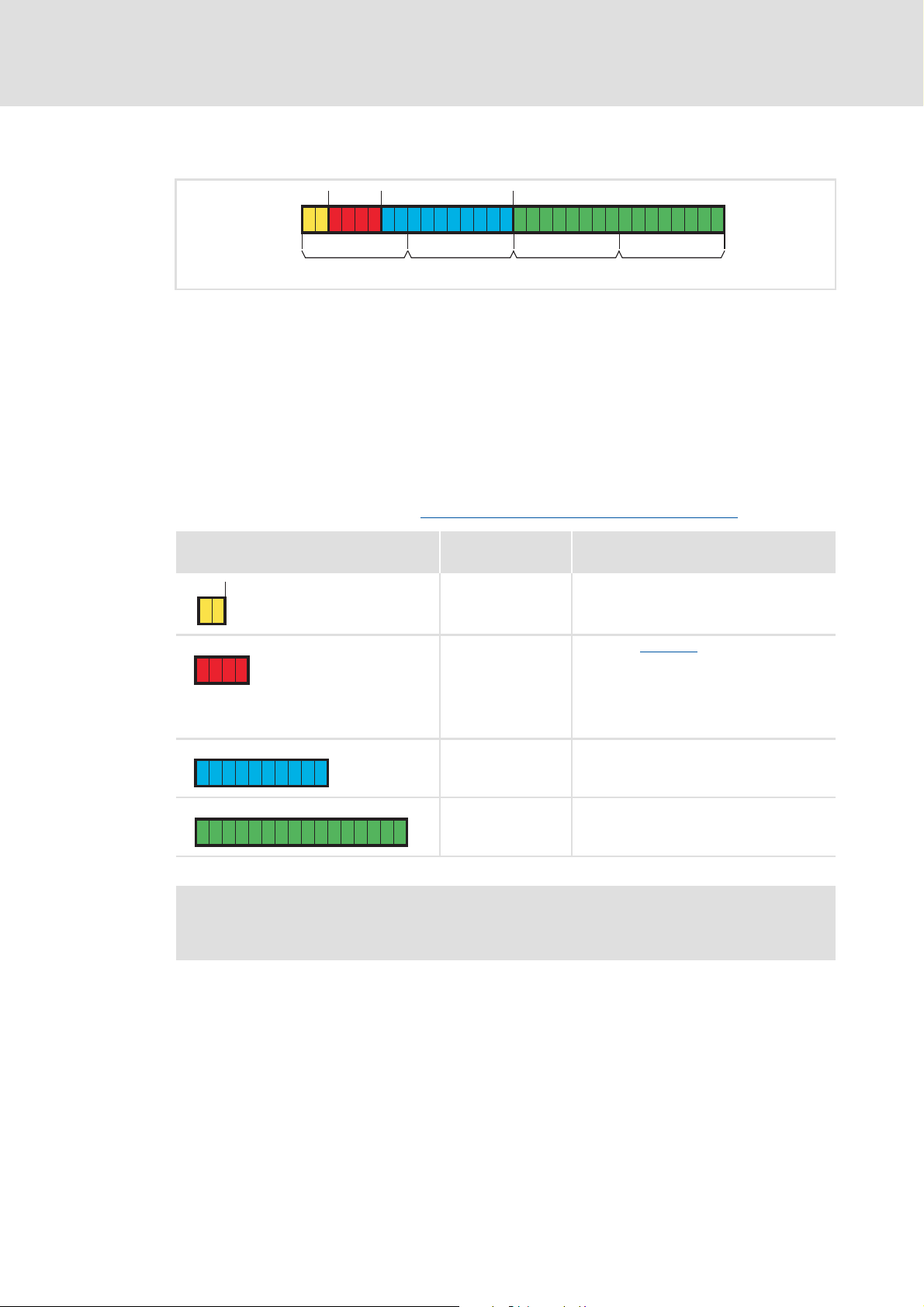

The LEDs MS, ME, BE and DE indicate the module status.

MS Module Status

ME Module Error

BE Bus Error

DE Device Error

E84YCEC003A

LED Colour Status Description

MS Green On

The communication module is supplied with voltage and has

established a connection to the standard device.

Blinking

The communication module is supplied with voltage, but has not

established a connection to the standard device. (Standard device is

switched off, initialising or not present.)

ME Red On

An error concerning the communication module has occurred.

BE Red On

A fieldbus error has occurred.

DE Red On

The communication module is not accepted by the standard device.

See notes given in the documentation for the standard device.

54 L EDS84AYCEC EN 3.0 - 09/2012

Page 55

E84AYCEC communication manual (Ethernet POWERLINK)

1 s

1 s

1 s

50ms

200 ms

200 ms

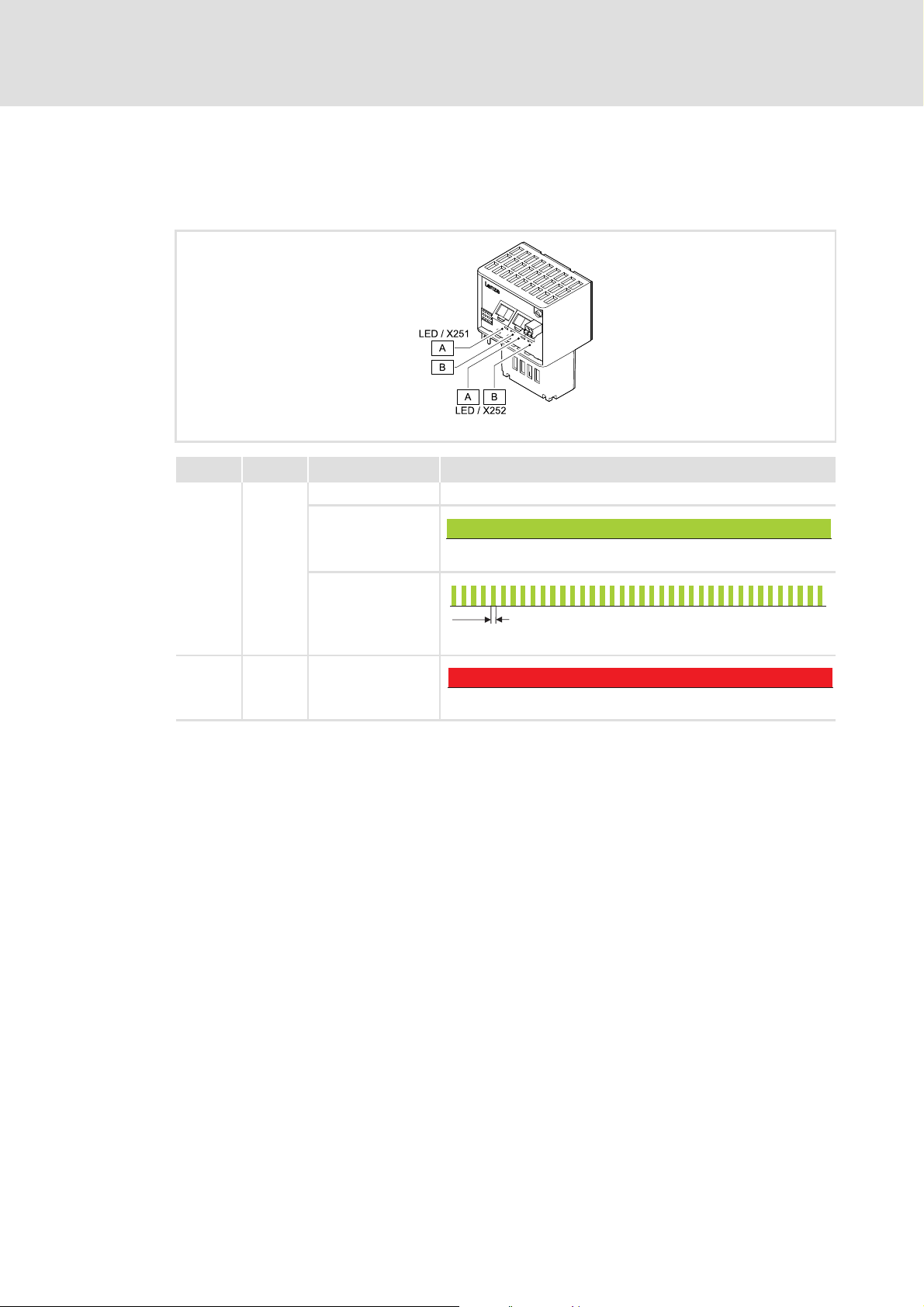

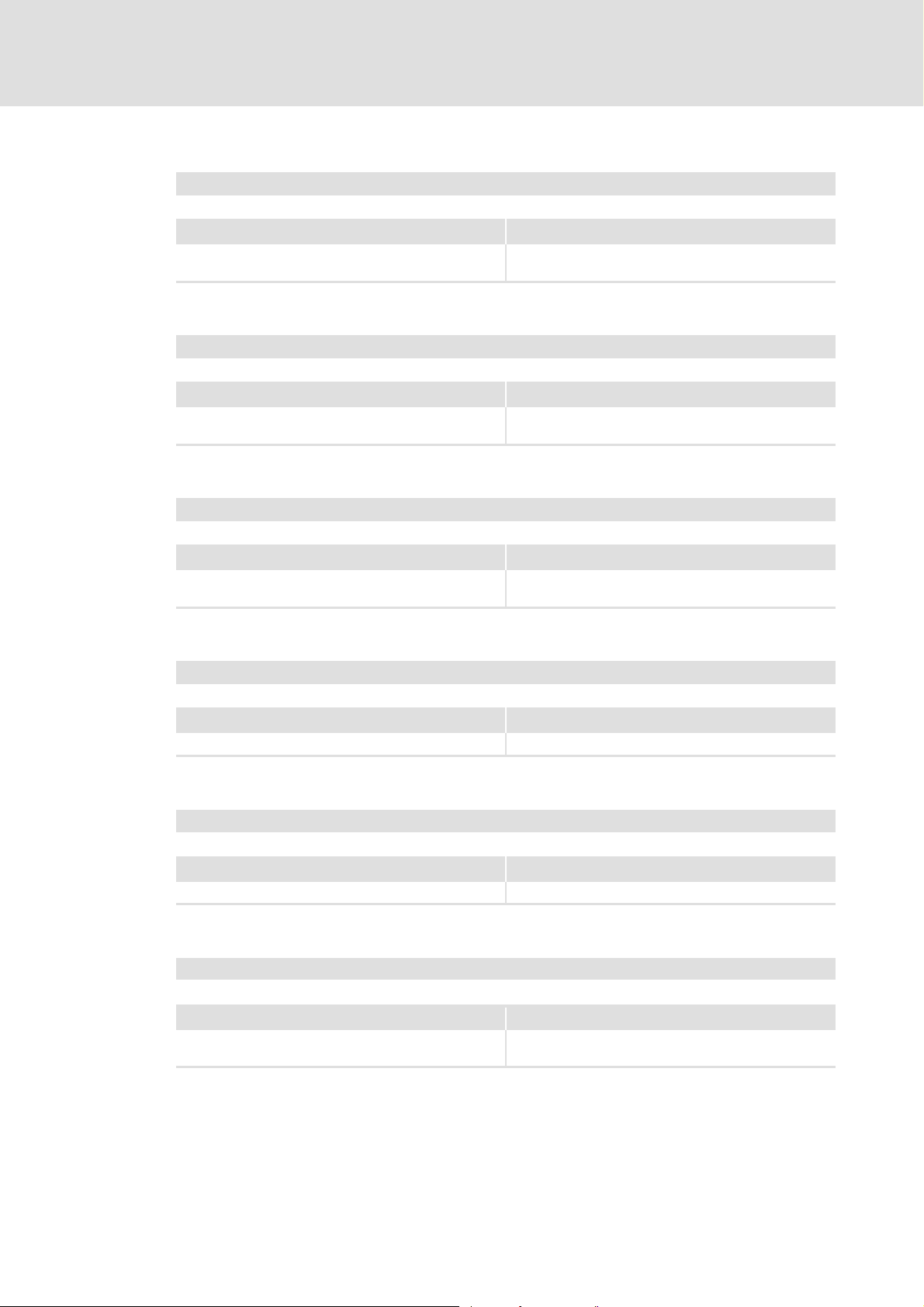

9.1.2 Fieldbus status displays

The BS LED indicates the fieldbus status.

BS Bus Status

Diagnostics

LED status displays

E84YCEC003B

LED Colour Status Description

BS Green Off The communication module is not active on the fieldbus or is in the

INIT state.

Blinking

EPL network is in the initialisation phase.

EPL status: NMT_CS_PREOPERATIONAL_1

Blinking

EPL network is in the initialisation phase with cyclic traffic.

EPL status: NMT_CS_PREOPERATIONAL_2

Blinking

EPL node is waiting for the start signal.

EPL status: NMT_CS_READY_TO_OPERATE

Blinking

The EPL node has not found a managing node and is in Basic Et hernet

Mode ( 30).

EPL status: NMT_CS_BASIC_ETHERNET

Blinking

EPL node is in the "Stopped" status (waiting for disconnection).

EPL status: NMT_CS_STOPPED

On

EPL node is in the operating phase.

EPL status: NMT_CS_OPERATIONAL

EDS84AYCEC EN 3.0 - 09/2012 L 55

Page 56

E84AYCEC communication manual (Ethernet POWERLINK)

50ms

Diagnostics

LED status displays

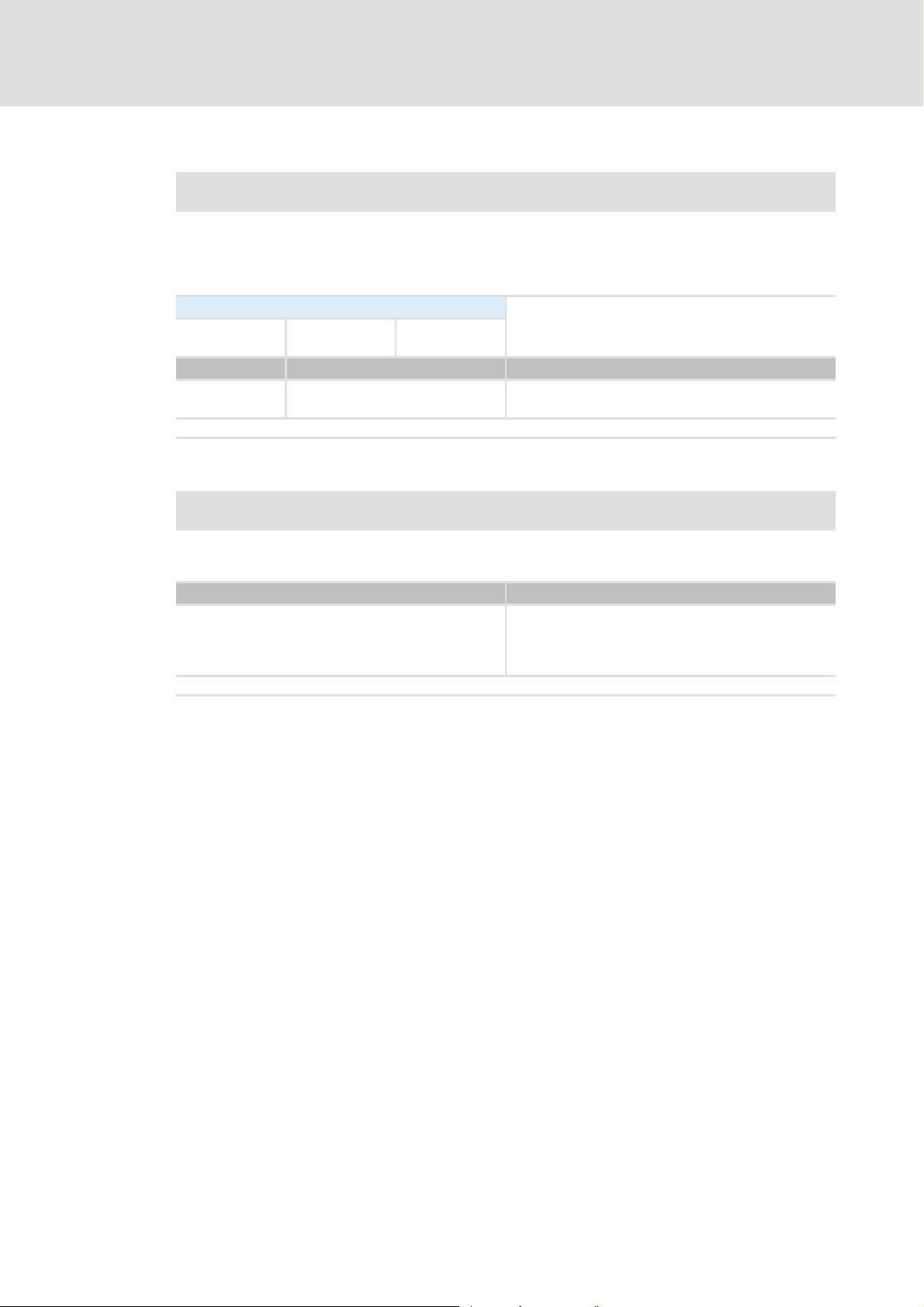

9.1.3 Status displays at the RJ45 sockets (X251, X252)

The LEDs at the RJ45 sockets X251 and X252 indicate the Ethernet POWERLINK connection

status.

LED Colour Status Description

A Green Off No Ethernet POWERLINK connection

On

E84YCER005

Flickers

BRed On

Ethernet POWERLINK connection has been established.

Data communication of Ethernet POWERLINK connection is active.

Ethernet POWERLINK collision has occurred.

56 L EDS84AYCEC EN 3.0 - 09/2012

Page 57

E84AYCEC communication manual (Ethernet POWERLINK)

1. Diagnostics - standard device / EPL module

Standard

device

switched

on?

Module or standard

device defect.

Please exchange.

Module or standard

device defect.

Please exchange.

Module does not

match the standard

device, maybe due

to a version conflict.

Use a suitable

combination.

Switch standard

device on and off

again.

Go back to point 1.

Switch on standard

device.

Go back to point 1.

Go back to point 1.

Go back to point 1.

Switch standard

device on and off

again.

Standard

device

switched

on?

MS

signal?

Module

plugged in

correctly?

Switch on standard

device.

Point 2

DE is lit?

Error still

existent?

yes

no

yes

blinking

no

off

on

no

yes

no

yes

yes

no

9.2 Troubleshooting with module signalling

In the following, troubleshooting via the module signals will be described.

Please particularly observe ...

the basic readiness for operation between the standard device and the communication

module;

the network wiring.

Diagnostics

Troubleshooting with module signalling

[9-1] Diagnostics - standard device / Ethernet POWERLINK module

EDS84AYCEC EN 3.0 - 09/2012 L 57

E94YCEP051

Page 58

E84AYCEC communication manual (Ethernet POWERLINK)

2. Diagnostics - network wiring

X251/252

green LED

blinking?

Check the cable

connection and the

cable.

Check EPL master,

see point 1.

Switch on the EPL

devices.

Go back to point 2.

Create EPL wiring.

Go back to point 1.

Is at least one

cable

plugged?

X251/252,

green LED on?

Is the

module

connected to

it switched

on?

Point 3

Check EPL

master.

BS on /

blinking?

yes

no

no

on

yes

no

yes

no

yes

off

Check EPL wiring to

EPL master.

Diagnostics

Troubleshooting with module signalling

[9-2] Diagnostics - network wiring

Note!

The BS (Bus State) LED refers to the Lenze communication module E94AYCEP as

managing node.

This status display applies analogously to the managing nodes of other

manufacturers.

E94YCEP052

58 L EDS84AYCEC EN 3.0 - 09/2012

Page 59

E84AYCEC communication manual (Ethernet POWERLINK)

3. Diagnostics - EPL operation

Make further error

search with the

Engineer.

Go back to point 3.

Standard device: Make a

fault reset.

Then wait 30 s.

EPL master:

ME on?

Make a fault reset

at the standard

Device.

End

Wait 30 s.

EPL master: BS

on / blinking?

yes

no

yes

on

blinking / off

no

End

on

Make further error

search with the

Engineer.

Wait 30 s.

EPL master: BS

on / blinking?

EPL master:

ME on?

BE on?

blinking / off

Diagnostics

Troubleshooting with module signalling

[9-3] Diagnostics - Ethernet POWERLINK operation

Note!

The LEDs ME (Module Error), BE (Bus Error) and BS (Bus State) refer to the Lenze

communication module E94AYCEP as managing node.

These status displays apply analogously to the managing nodes of other

manufacturers.

E94YCEP053

EDS84AYCEC EN 3.0 - 09/2012 L 59

Page 60

E84AYCEC communication manual (Ethernet POWERLINK)

Diagnostics

Diagnostic data

9.3 Diagnostic data

Pending diagnostic data are signalled from the controlled node to the managing node

by means of an emergency message.

Code C13887

serves to suppress sending emergency messages to the managing node.

You can select which type of error is to be suppressed.

Errors and warnings in the Inverter Drive 8400 and the plugged communication

module are sent to the managing node as extended diagnostic messages.

The diagnostic data are visible via the PLC Engineering software.

Bytes Meaning Value [hex]

1 ... 6 Diagnostic block header 0x0010 001C 0100

7 ... 8 Alarm type 0x0001 (Diagnosis)

9 ... 12 API (Application Programming Interface) 0x0000 0000

13, 14 Slot number 0x0001 / 0x0002

15, 16 Subslot number 0x0001

17 ... 20 Module ID ID corresponding to module

21 ... 24 Submodule number ID corresponding to module

25, 26 Alarm specification 0xB000

27, 28 User structure ID 0x0001

29 ... 32 Error code

60 L EDS84AYCEC EN 3.0 - 09/2012

Page 61

E84AYCEC communication manual (Ethernet POWERLINK)

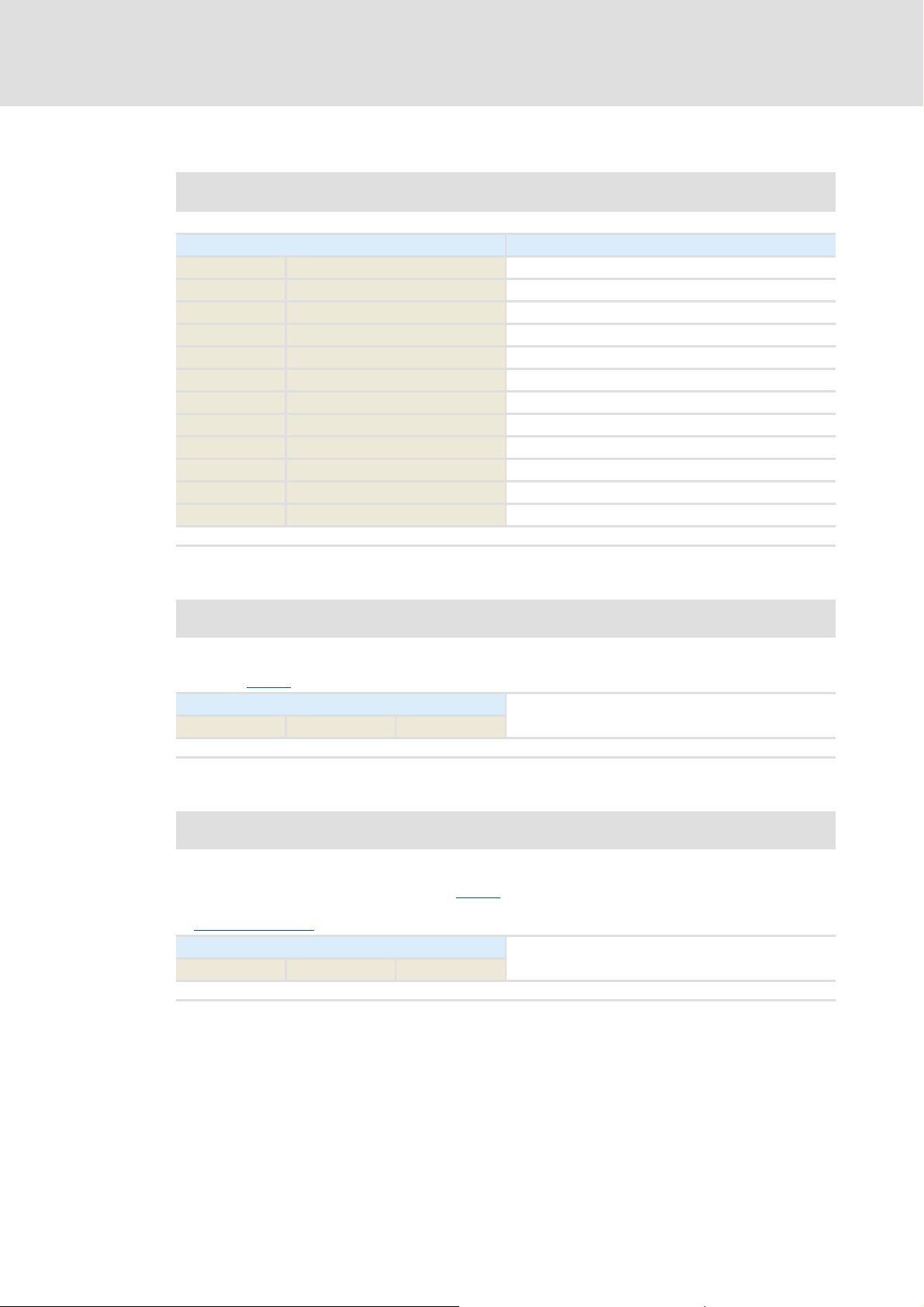

Byte 32 Byte 31 Byte 30 Byte 29

Bit

162526

31

015

29

30

Bit

31

30

00

26

29

XXX0

Bit

Bit

16

25

000

111111

0

0

15

000 1

11

00000000

11

Bit

Error code of Inverter Drive 8400

[9-4] Error code of Inverter Drive 8400

The error code of the Inverter Drive 8400 can be found in bytes 29 ... 32 of the

diagnostic message.

In the logbook and in code C00165 of the standard device, the error number is shown

in the following syntax in order to facilitate the readability:

[Error type].[Error subject area no.].[Error ID]

Example

Diagnostics

Diagnostic data

Diagnostic message of the error "EPL: State OPERATIONAL lost [0x01bc8131]

Bit assignment

(Bytes 29 ... 32)

Information Values from the example

Reserved 0

Error type / error

response

Error subject area 0x01bc (444

Error ID 0x8131 (33073

Setting via C13880/1

• 0: No error response

•1: Error

•3: Quick stop

• 4: Warning locked

•6: Information

)

dec

)

dec

:

Software manual/»Engineer« online help for Inverter Drive 8400

Here you can find detailed information on error codes.

":

EDS84AYCEC EN 3.0 - 09/2012 L 61

Page 62

E84AYCEC communication manual (Ethernet POWERLINK)

Error messages

Short overview of the Ethernet POWERLINK error messages

10 Error messages

This chapter supplements the error list in the software manual and the »Engineer« online

help for the Inverter Drive 8400 by the error messages of the communication module.

Software manual/»Engineer« online help for the Inverter Drive 8400

Here you will find general information on diagnostics & fault analysis and error

messages.

10.1 Short overview of the Ethernet POWERLINK error messages

The following table contains all error messages of the communication module in

numerical order of the error numbers. Moreover the preset error response and - if

applicable - the parameters for setting the error response are specified.

Tip!

When you click the cross-reference in the first column, you will get to the detailed

description (causes and remedies) of the corresponding error message.

Error no.

[hex]

0x01bc3100 444 12544 EPL: Lost connection to 8400 target 1: Error -

0x01bc5531

0x01bc5532

0x01bc5533

0x01bc6010

0x01bc6011

0x01bc6100

0x01bc6101

0x01bc6110

0x01bc641f

0x01bc6420

0x01bc6430

0x01bc8131

0x01bc8261 444 33377 EPL: Invalid address selected 1: Error -

0x01bc8265

0x01bc8266 444 33382 EPL: Frame error (CRC) 0: None C13880/3

Subject area

no.

[dec]

444 21809 EPL: NV memory: No access 1: Error -

444 21810 EPL: NV memory: Read error 1: Error -

444 21811 EPL: NV memory: Write error 1: Error -

444 24592 EPL: Restart after watchdog reset 1: Error -

444 24593 EPL: Watchdog reset 1: Error -

444 24832 EPL: Software error 1: Error -

444 24833 EPL: Fatal software error 1: Error -

444 24848 EPL: Invalid PDO mapping 1: Error -

444 25631 EPL: Invalid parameter set 1: Error -

444 25632 EPL: Default setting loaded 1: Error -

444 25648 EPL: Invalid module configuration 1: Error -

444 33073 EPL: OPERATIONAL status left 1: Error C13880/1

444 33381 EPL: Synchronisation of MN lost 0: None C13880/2

Error no.

[dec]

Error text Error type

(Error response)

adjustable in

62 L EDS84AYCEC EN 3.0 - 09/2012

Page 63

E84AYCEC communication manual (Ethernet POWERLINK)

10.2 Possible causes and remedies

This chapter contains all error messages of the communication module in numerical order

of the error number. Possible causes and remedies as well as responses to the error

messages are described in detail.

Error messages

Possible causes and remedies

Short overview of the Ethernet POWERLINK error messages

EPL: Lost connection to 8400 target [0x01bc3100]

Response (Lenze setting in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

MCI communication to Inverter Drive 8400 is

interrupted.

• Inverter Drive 8400 is switched off.

• The communication module is not connected

correctly at the MCI slot of the Inverter Drive 8400.

EPL: NV Memory: No access [0x01bc5531]

Response (Lenze setting in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Access via standard device to the parameter set in the

memory module failed.

EPL: NV Memory: Read error [0x01bc5532]

( 62)

• Switch on Inverter Drive 8400.

• Check screwed connection of the communication

module at the MCI slot of the Inverter Drive 8400.

• Send the communication module and Inverter Drive

8400 together with a description of the fault to Lenze.

Redownload the application (incl. module).

Response (Lenze setting in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Parameter in the memory module could not be read. Redownload the application (incl. module).

EPL: NV Memory: Write error [0x01bc5533]

Response (Lenze setting in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Parameter in the memory module could not be written. Redownload the application (incl. module).

EPL: Restart after watchdog reset [0x01bc6010]

Response (Lenze setting in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Communication module is defective. Send the communication module and a description of

the fault to Lenze.

EDS84AYCEC EN 3.0 - 09/2012 L 63

Page 64

E84AYCEC communication manual (Ethernet POWERLINK)

Error messages

Possible causes and remedies

EPL: Watchdog reset [0x01bc6011]

Response (Lenze setting in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Communication module is defective. Send the communication module and a description of

EPL: Software error [0x01bc6100]

Response (Lenze setting in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Communication module is defective. Send the communication module and a description of

EPL: Fatal software error [0x01bc6101]

the fault to Lenze.

the fault to Lenze.

Response (Lenze setting in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Communication module is defective. Send the communication module and a description of

EPL: PDO Mapping invalid [0x01bc6110]

Response (Lenze setting in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked warning Information

Cause Remedy

Invalid mapping configuration. Correct the mapping configuration.

EPL: Invalid parameter set [0x01bc641f]

Response (Lenze setting in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked warning Information

Cause Remedy

Loading of an active parameter set was not possible. Redownload the application (incl. module).

EPL: Factory settings loaded [0x01bc6420]

the fault to Lenze.

Response (Lenze setting in bold) Setting: not possible