Page 1

9400

E94AxHExxxx

Servo Drives 9400 HighLine_ _ _ _ _ _ _ _ _ _ _

Reference manual

EN

Ä.MvGä

13448538

L

Page 2

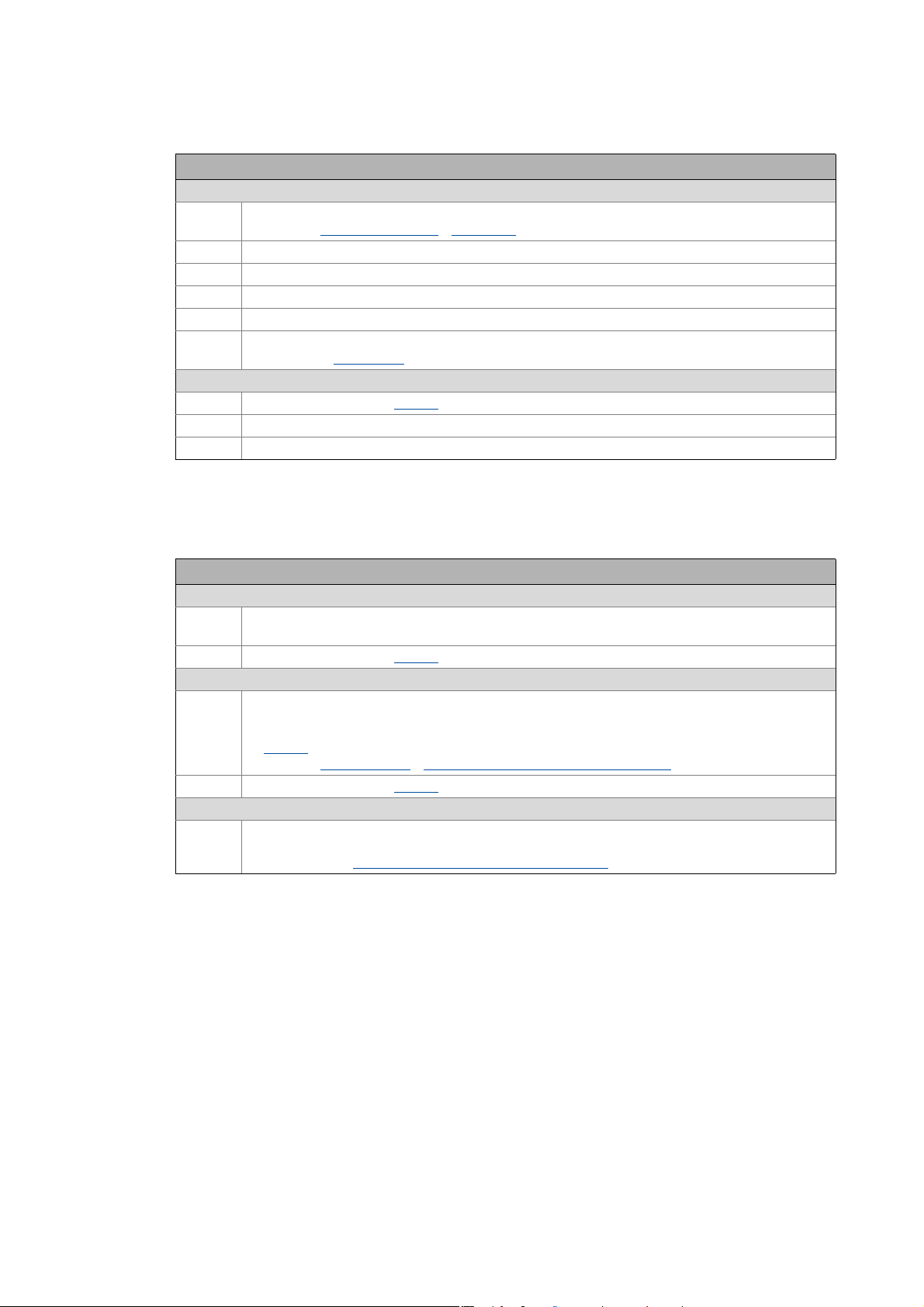

Overview of technical documentation for Servo Drives 9400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Project planning, selection & order Legend:

Hardware manual 9400 Printed documentation

Catalogue / electronic catalogue (DSC - Drive Solution Catalogue) Online documentation

(PDF/Engineer online help)

Mounting & wiring Abbreviations used:

MA - 9400 StateLine/HighLine BA Operating instructions

MA - communication module KHB Communication manual

MA - extension module MA Mounting instructions

MA - safety module SW Software Manual

MA - accessories

MA - remote maintenance components

Parameter setting

BA - keypad

SW - Lenze software »Engineer«

SW - controller (9400 StateLine/HighLine/PLC) This documentation

SW - regenerative power supply module

KHB - communication module

SW - extension module

SW - safety module

SW - Lenze technology application

SW - function library 9400

Configuring & programming

SW - Lenze software »Engineer«

SW - Lenze software »PLC Designer«

SW - controller (9400 HighLine/PLC) This documentation

KHB - communication module

SW - extension module

SW - safety module

SW - Lenze technology application

SW - function library 9400

Drive commissioning

Commissioning guide

SW - controller (9400 StateLine/HighLine/PLC) This documentation

Chapter "Commissioning

Chapter "Oscilloscope

Chapter "Diagnostics & fault analysis

Remote maintenance manual

Networking structure

KHB - communication medium used

" ( 22)

" ( 579)

" ( 598)

2 Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 3

Contents

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

1.1 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

1.2 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

1.3 Definition of notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

2Introduction _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

2.1 Parameter setting, configuring, or programming? _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

2.1.1 Basic functionalities _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

2.1.2 Technology applications _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

2.2 Communicating with the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

2.2.1 Going online via diagnostic adapter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

2.2.2 Going online via system bus (CAN on board) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

2.2.3 Use of other communication interfaces _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

2.3 Signal types & scaling _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

3 Commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

3.1 General information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

3.2 Notes on commissioning using the keypad _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

3.3 Initial commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

3.4 Standard set-up _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

3.5 Controller replacement _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.6 Motor replacement _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

4 Drive interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

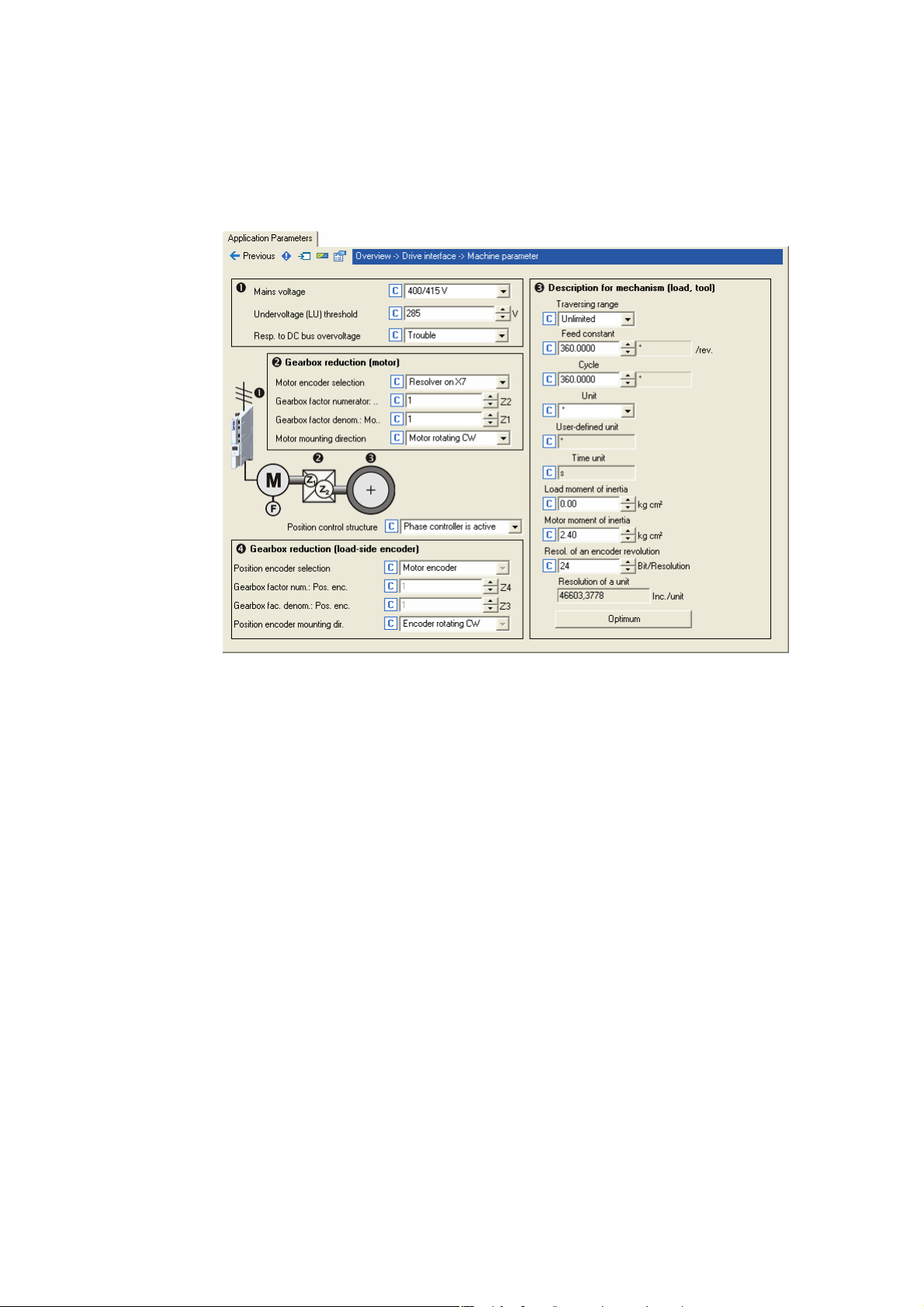

4.1 Machine parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

4.1.1 Mains voltage _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

4.1.2 Gearbox ratio _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

4.1.3 Motor mounting direction _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

4.1.4 Feedback configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

4.1.5 Unit/user-defined unit _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

4.1.6 Traversing range _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

4.1.7 Feed constant _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

4.1.8 Resolution of an encoder revolution _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

4.1.9 Max. position, speed, and acceleration that can be displayed internally _ _ _ _ _ _ _ _ _ _ 40

4.2 Device commands _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

4.2.1 Load Lenze setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

4.2.2 Load start parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

4.2.3 ENP:Load plant data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

4.2.4 Activate application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

4.2.5 Save selected application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

4.2.6 Save start parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

4.2.7 Delete logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

4.2.8 Archive logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

4.2.9 Start application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

4.2.10 Stop application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

4.2.11 Reset program _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

4.2.12 Delete program _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 56

4.2.13 Restart program _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

4.2.14 Reset runtime measurement _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

4.2.15 Inhibit controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 60

4.2.16 Enable controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

4.2.17 Reset error _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 62

4.2.18 Activate quick stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 63

4.2.19 Reset quick stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 64

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 3

Page 4

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.20 Identify pole position (360°) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 65

4.2.21 Identify pole position (min. motion) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 66

4.2.22 Resolver error identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

4.2.23 Load Lenze INV characteristic _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 69

4.2.24 Calculate inv. characteristic _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

4.2.25 Determine motor parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

4.2.26 Calculate current controller parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 72

4.2.27 Calculate speed controller parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 74

4.2.28 CAN on board: Reset Node _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 75

4.2.29 CAN module: Reset node _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 76

4.2.30 CAN on board: Pred.Connect.Set _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 77

4.2.31 CAN module: Pred.Connect.Set _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 78

4.2.32 CAN on board: Identify node _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 79

4.2.33 CAN module: Identify node _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 80

4.2.34 Unbind/bind Ethernet module MXI1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 81

4.2.35 Unbind/bind Ethernet module MXI2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 82

4.2.36 Activate parameter set 1 ... 4 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 83

4.2.37 Activate parameter set 1 ... 4 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 85

4.2.38 Load cam data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 87

4.2.39 Save cam data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 89

4.2.40 Calculate cam data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 91

4.2.41 Calculate cam data checksum _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 92

4.2.42 Format file system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 93

4.2.43 Restore file system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 94

4.2.44 Prepare firmware update _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 95

4.2.45 Restart controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

4.3 Device states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 97

4.3.1 "Initialisation active" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 99

4.3.2 "Safe torque off active" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 100

4.3.3 "Device is ready to switch on" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 100

4.3.4 "Device is switched on" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 101

4.3.5 "Operation" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 101

4.3.6 "Warning active" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 102

4.3.7 "Warning locked active" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 102

4.3.8 "Quick stop by trouble active" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 102

4.3.9 "Trouble active" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

4.3.10 "Fault active" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

4.3.11 "System fault active" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

4.4 Automatic restart after mains connection/trouble... _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 104

4.5 Behaviour after task overflow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 106

4.6 Device output power _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 107

4.6.1 Switching frequency _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 107

4.6.2 Monitoring of the device utilisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 108

4.6.3 Operation with increased continuous power _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 109

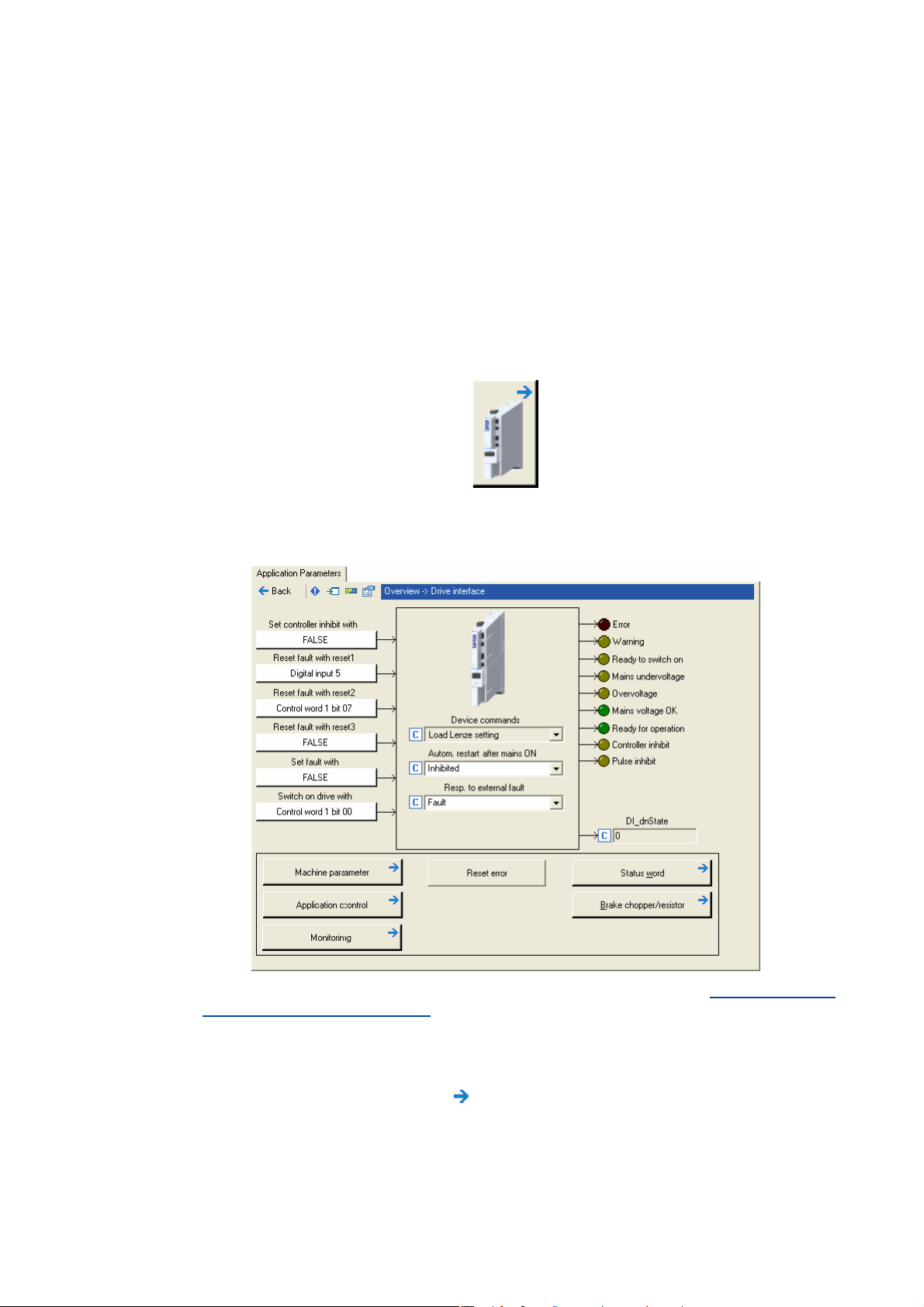

4.7 Internal interfaces | "LS_DriveInterface" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 110

4.7.1 Status signals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 113

4.7.2 Monitoring of external events _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 114

4 Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 5

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5Motor interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 115

5.1 General information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 117

5.1.1 Reading out motor data from the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 117

5.1.2 Selecting a motor from the motor catalogue in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ 118

5.1.3 Displaying/editing motor data in »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 119

5.2 Select motor control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 121

5.3 Adjusting motor and controller to each other _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 123

5.3.1 Accepting/adapting plant parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 124

5.3.2 Parameterising motor encoder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

5.3.3 Pole position identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 128

5.3.4 Optimising the switching performance of the inverter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 135

5.3.5 Determining the motor parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 138

5.4 Servo control (SC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 142

5.4.1 Optimising the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 143

5.4.2 Signal flow (servo control for synchronous motor) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 159

5.4.3 Signal flow (servo control for asynchronous motor) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 161

5.5 Sensorless vector control (SLVC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 163

5.5.1 Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 164

5.5.2 Optimising motor parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 166

5.5.3 Optimising the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 172

5.5.4 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 180

5.6 V/f control (VFCplus) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 181

5.6.1 Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 181

5.6.2 Optimising the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 188

5.6.3 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 196

5.7 V/f control (VFCplus) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 197

5.7.1 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 198

5.8 Parameterisable additional functions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 200

5.8.1 Correction of the stator leakage inductance... _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 201

5.8.2 Field weakening for synchronous machines _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 206

5.8.3 Flying restart function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 209

5.8.4 DC-injection braking _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 212

5.9 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 214

5.9.1 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 214

5.9.2 Motor monitoring (I

5.9.3 Motor temperature monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 222

5.9.4 Motor phase failure monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 226

5.9.5 Maximum current monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 230

5.10 Internal interfaces | "LS_MotorInterface" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 231

2

xt) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 215

6 Encoder evaluation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 236

6.1 Internal interfaces | "LS_Feedback" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 237

6.1.1 Use of an external position encoder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 239

6.2 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 240

6.3 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 241

6.3.1 Controller configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 243

6.3.2 System with motor encoder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 245

6.3.3 System with motor encoder and position encoder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 246

6.3.4 Position feedback with a linear distance measuring device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 248

6.3.5 Adaptation of the resolver evaluation dynamics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 250

6.3.6 Parameterisation of an unknown Hiperface® encoder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 251

6.3.7 Parameterisation of a Hiperface® encoder with increased initialisation time _ _ _ _ _ _ _ 251

6.3.8 Use of an SSI encoder at X8 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 252

6.3.9 Rotative encoder with SSI protocol _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 258

6.3.10 Provision of the encoder signal of input X8 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 260

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 5

Page 6

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.3.11 Resolver error compensation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 263

6.3.12 Encoder angular drift monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 264

7 Braking operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 266

7.1 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 267

7.1.1 Setting the voltage threshold for braking operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 267

7.2 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 268

7.2.1 Overcurrent protection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 268

7.2.2 Ixt utilisation - brake transistor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 269

7.2.3 I2t utilisation - brake resistor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 270

7.2.4 DC bus overvoltage _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 272

8I/O terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 273

8.1 Overview _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 273

8.2 Analog inputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 274

8.2.1 Terminal assignment/electrical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 274

8.2.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 275

8.2.3 Reconfiguring analog input 1 into current input _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 275

8.2.4 "LS_AnalogInput" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 276

8.3 Analog outputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 277

8.3.1 Terminal assignment/electrical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 277

8.3.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 278

8.3.3 "LS_AnalogOutput" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 278

8.4 Digital inputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 279

8.4.1 Terminal assignment/electrical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 279

8.4.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 279

8.4.3 "LS_DigitalInput" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 280

8.5 Digital outputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 281

8.5.1 Terminal assignment/electrical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 281

8.5.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 281

8.5.3 "LS_DigitalOutput" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 282

8.6 "State bus" monitoring function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 283

8.6.1 Detecting the current state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 284

8.6.2 Setting the state bus to the "Error" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 284

8.7 Touch probe detection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 285

8.7.1 Actual value interpolation (principle) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 286

8.7.2 Dead time compensation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 287

8.7.3 "LS_TouchProbe1...8" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 288

8.7.4 "LS_TouchProbeMotor" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 289

8.7.5 "LS_TouchProbeLoad" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 289

8.8 Configure exception handling of the outputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 290

6 Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 7

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9 "CAN on board" system bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 292

9.1 General information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 293

9.1.1 General data and application conditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 294

9.1.2 Supported protocols _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 294

9.1.3 Communication time _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 295

9.2 Possible settings by DIP switch _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 296

9.2.1 Setting the node address _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 296

9.2.2 Setting the baud rate _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 297

9.3 LED status displays for the system bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 298

9.4 Structure of the CAN data telegram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 299

9.4.1 Identifier _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 299

9.4.2 User data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 301

9.5 Communication phases/network management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 302

9.5.1 State transitions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 303

9.5.2 Network management telegram (NMT) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 304

9.5.3 Parameterising the controller as CAN master _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 305

9.6 Process data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 306

9.6.1 Identifiers of the process data objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 307

9.6.2 Transmission type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 308

9.6.3 Masking of the TPDOs for event control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 309

9.6.4 Monitoring of the RPDOs for data reception _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 309

9.6.5 Synchronisation of PDOs via sync telegram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 310

9.7 Parameter data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 315

9.7.1 Identifiers of the parameter data objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 316

9.7.2 User data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 316

9.7.3 Parameter data telegram examples _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 322

9.8 Diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 327

9.9 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 328

9.9.1 Node guarding protocol _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 328

9.9.2 Heartbeat protocol _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 334

9.9.3 Emergency telegram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 338

9.10 Implemented CANopen objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 339

9.11 System block "LS_SyncInput" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 364

9.11.1 Behaviour of the status signal bSyncInsideWindow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 365

10 Safety engineering _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 366

10.1 Integration into the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 367

10.2 Selecting the required safety module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 368

10.3 System block "LS_SafetyModuleInterface" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 368

10.3.1 Status information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 369

10.3.2 I/O status information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 370

10.3.3 Control information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 370

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 7

Page 8

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11 Basic drive functions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 372

11.1 General information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 373

11.1.1 Internal state machine _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 373

11.1.2 Function states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 375

11.1.3 Interrupting/replacing states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 377

11.1.4 Priorities _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 378

11.1.5 Requesting control via a basic function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 379

11.1.6 Start acceleration/acceleration reduction when the basic function changes _ _ _ _ _ _ _ 380

11.1.7 Setting the S-ramp time _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 382

11.2 Stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 384

11.2.1 Internal interfaces | "LS_Stop" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 385

11.2.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 386

11.2.3 Behaviour of the function (example) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 387

11.3 Quick stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 388

11.3.1 Internal interfaces | "LS_Quickstop" system block" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 388

11.3.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 389

11.3.3 Activate/deactivate quick stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 391

11.3.4 DC-injection braking _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 392

11.4 Manual jog _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 395

11.4.1 Internal interfaces | "LS_ManualJog" system block" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 396

11.4.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 399

11.4.3 Executing manual jogging _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 401

11.5 Manual job, encoderless _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 407

11.5.1 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 408

11.5.2 Carrying out encoderless manual jogging _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 409

11.5.3 Internal interfaces | "LS_ManualJogOpenLoop" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 414

11.6 Homing _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 416

11.6.1 Internal interfaces | "LS_Homing" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 418

11.6.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 420

11.6.3 Overview of the Lenze homing modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 427

11.6.4 Overview of DS402 homing modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 440

11.6.5 Execute homing _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 471

11.7 Positioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 474

11.7.1 Internal interfaces | "LS_Positioner" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 475

11.7.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 480

11.7.3 Carrying out positioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 482

11.8 Position follower _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 485

11.8.1 Internal interfaces | "LS_PositionFollower" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 486

11.8.2 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 487

11.8.3 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 489

11.8.4 Activating setpoint interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 491

11.9 Speed follower _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 492

11.9.1 Internal interfaces | "LS_SpeedFollower" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 492

11.9.2 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 494

11.9.3 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 495

11.9.4 Activating setpoint interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 496

11.10 Torque follower _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 497

11.10.1 Internal interfaces | "LS_TorqueFollower" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 498

11.10.2 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 499

11.10.3 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 500

11.10.4 Activating setpoint interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 501

11.11 Limiter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 502

11.11.1 Internal interfaces | "LS_Limiter" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 502

11.11.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 507

8 Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 9

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11.12 Brake control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 517

11.12.1 Internal interfaces | "LS_Brake" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 519

11.12.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 521

11.12.3 Mode 0: Brake control is switched off _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 537

11.12.4 Mode 1/11: Direct control of the brake _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 538

11.12.5 Mode 2/12: Automatic control of the brake _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 539

11.12.6 Mode 22: Automatic DC-injection braking _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 544

11.12.7 Grinding the brake _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 547

11.12.8 Carrying out brake test _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 549

11.12.9 Control of two motor holding brakes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 551

11.13 Cam data management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 552

11.13.1 "Online" tab for cam data management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 553

11.13.2 Internal interfaces | "LS_CamInterface" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 558

11.13.3 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 560

11.13.4 Product/track change-over _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 567

11.13.5 Invalid cam data due to changed machine parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 568

11.13.6 Behaviour after mains switching _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 569

11.14 Pole position identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 570

11.14.1 Internal interfaces | System block "LS_PolePositionIdentification" _ _ _ _ _ _ _ _ _ _ _ _ _ 571

11.14.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 573

11.14.3 Execute pole position identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 573

11.14.4 Signal characteristics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 575

11.14.5 Impacts of parameter changes on the signal PPI_bPolePositionAvailable _ _ _ _ _ _ _ _ _ 577

12 Oscilloscope _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 579

12.1 Technical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 579

12.2 Functional description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 580

12.3 User interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 581

12.4 Operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 582

12.4.1 Selecting the variables to be recorded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 582

12.4.2 Selecting the recording time/sample rate _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 584

12.4.3 Selecting the trigger condition _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 585

12.4.4 Starting recording _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 586

12.4.5 Adjusting the representation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 587

12.4.6 Cursor function: Reading individual measured values _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 589

12.5 Managing oscillograms (measured data records) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 590

12.5.1 Commenting the oscillogram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 590

12.5.2 Saving the oscillogram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 591

12.5.3 Loading an oscillogram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 592

12.5.4 Closing an oscillogram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 593

12.5.5 Overlay function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 593

12.5.6 Deleting a data record saved in the project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 594

12.6 Variables of the motor control (oscilloscope signals) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 595

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 9

Page 10

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

13 Diagnostics & fault analysis _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 598

13.1 LED status displays _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 598

13.1.1 LED status displays for the device state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 599

13.2 Drive diagnostics with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 600

13.3 Drive diagnostics via keypad/bus system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 601

13.4 Logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 603

13.4.1 Functional description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 604

13.4.2 Filtering logbook entries _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 604

13.4.3 Reading out logbook entries _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 605

13.4.4 Export logbook entries to a file _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 606

13.5 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 607

13.5.1 Setting the error response _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 608

13.6 Maloperation of the drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 609

13.7 Error messages of the operating system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 610

13.7.1 Structure of the error number (bit coding) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 610

13.7.2 Reset error message _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 614

13.7.3 Short overview (A-Z) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 615

13.7.4 Cause & possible remedies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 623

14 Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 713

14.1 Structure of the parameter descriptions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 714

14.1.1 Data type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 714

14.1.2 Parameters with read-only access _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 715

14.1.3 Parameters with write access _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 715

14.1.4 Parameter attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 719

14.1.5 Abbreviations used in parameter & selection texts _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 719

14.2 Parameter list _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 720

14.3 Attribute table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 913

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 927

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 952

10 Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 11

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

Danger!

The controller is a source of danger which may cause death or serious personal injury.

In order to ensure protection against this danger, observe the safety instructions before

switching on the controller.

Please read the safety instructions in the mounting instructions and hardware manual

of the Servo-Inverter 9400 HighLine. Both instructions are included in the scope of

supply.

Target group

This documentation addresses to all persons who want to parameterise, configure, and diagnose

the 9400 HighLine controller by means of the engineering software L-force »Engineer« and the

keypad.

Validity

The information in this documentation are valid for the following standard devices:

Product series Type designation from software version

9400 Servo Drives E94AxHExxxx 1.5

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the firmware

version of the 9400 HighLine and the software version of the engineering tools installed

(»Engineer« or » Easy Starter«), the screenshots in this documentation may deviate from the screen

representation.

Document history

Version Description

10.0 11/2013 TD05 Error corrections; parameter reference V12.00.xx

9.0 12/2012 TD06 Extended by new functions for 9400 HighLine V11

8.0 12/2011 TD06 Extended by new functions for 9400 HighLine V10

7.1 10/2010 TD06 Error corrections & supplements

7.0 04/2010 TD06 Extended by new functions for 9400 HighLine V8

6.1 08/2009 TD05 Error corrections & supplements

6.0 08/2009 TD05 Extended by new functions for 9400 HighLine V7

5.2 01/2009 TD05 Error corrections & supplements

5.1 12/2008 TD05 Error corrections

5.0 11/2008 TD05 Extended by new functions for 9400 HighLine V5

4.1 07/2008 TD05 New main chapter: "CAN on board" system bus

4.0 06/2008 TD05 Supplemented with new functions for 9400 HighLine V4

3.0 11/2007 TD05 Supplemented with new functions for 9400 HighLine V3

2.0 05/2007 TD05 Extended edition

1.0 12/2006 TD05 First edition for 9400 HighLine V1.5

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 11

Page 12

1 About this documentation

1.1 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.1 Conventions used

This documentation uses the following conventions to distinguish between different types of

information:

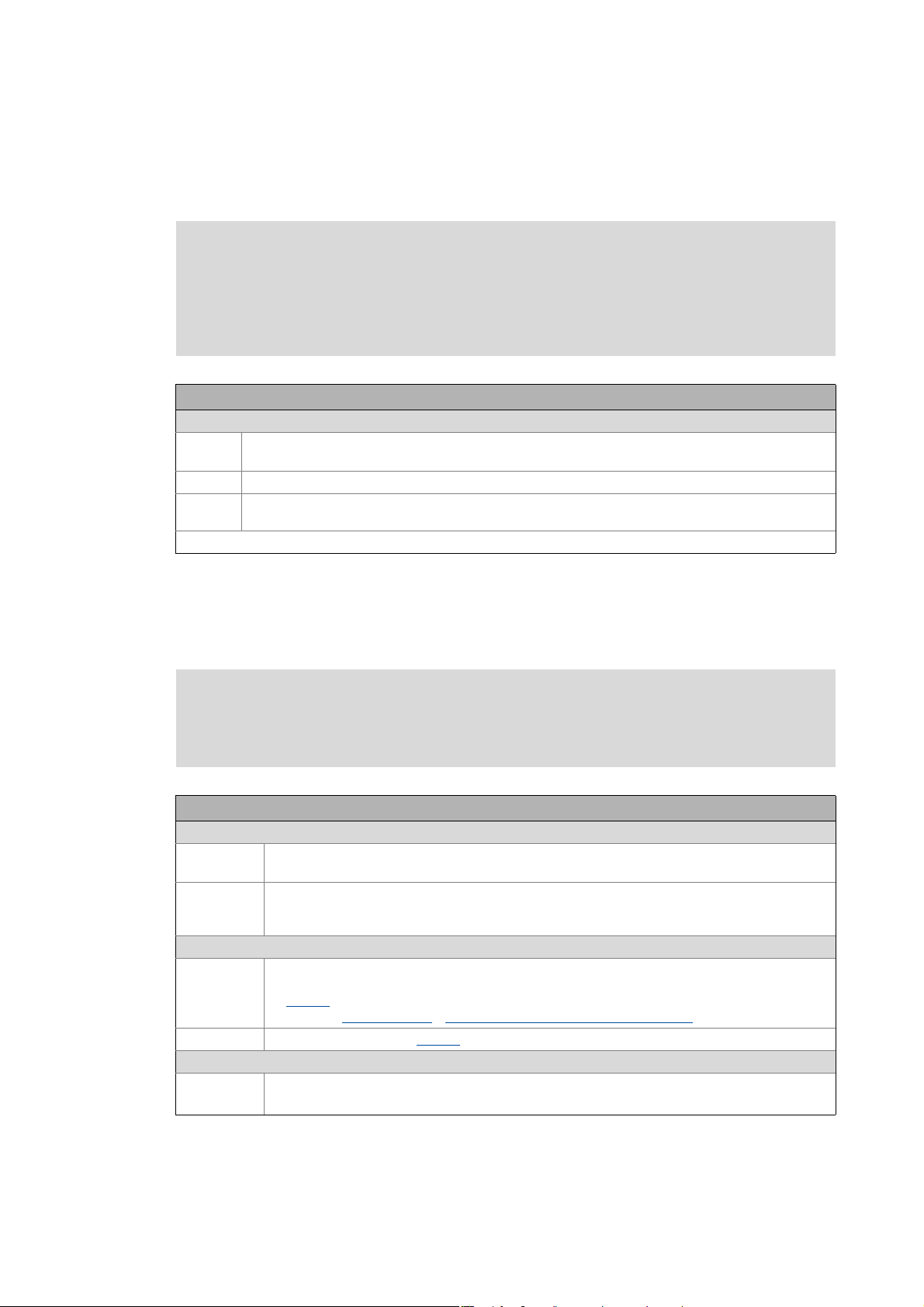

Type of information Writing Examples/notes

Spelling of numbers

Decimal separators Point The decimal point is generally used.

For example: 1234.56

Text

Version information Blue text colour Information that is only valid for or from a certain software

Program name » « The Lenze PC software »PLC Designer«...

Window italics The Message window ... / The Options dialog box...

Variable identifier By setting bEnable to TRUE...

Control element bold The OK button... / The Copy command... / The Properties

Sequence of menu

commands

Shortcut <bold> Press <F1> to open the online help.

Program code Courier

Keyword Courier bold

version of the controller is marked accordingly in this

manual.

Example: This function extension is available from software

version V3.0!

tab... / The Name input field...

If the execution of a function requires several commands,

the individual commands are separated by an arrow: Select

Open to...

File

If a command requires a combination of keys, a "+" is placed

between the key symbols: Use <Shift>+<ESC> to...

IF var1 < var2 THEN

a = a + 1

END IF

Hyperlink Underlined

Icons

Page reference ( 12) Optically highlighted reference to another page. In this

Step-by-step instructions

Optically highlighted reference to another topic. In this

documentation activated by mouse-click.

documentation activated by mouse-click.

Step-by-step instructions are indicated by a pictograph.

12

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 13

1 About this documentation

1.2 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Terminology used

Term Meaning

Engineering tools Software solutions for easy engineering in all project stages

»EASY Navigator« – provides a good guide to the user

• All convenient Lenze engineering tools at a glance

• Tools can be selected quickly

• The clear structure simplifies the engineering process from the start

»EASY Starter« – easy-to-use tool for service technicians

• Specially designed for the commissioning and maintenance of Lenze

devices

• Graphical user interface with just a few buttons

• Easy online diagnostics, parameterisation, and commissioning

• No risk of an unintended change in applications

• Loading of ready-to-use applications to the device

»Engineer« – multi-device engineering

• For all products in our L-force portfolio

• Practical user interface

• Graphic interfaces make it easy to navigate

• Can be applied in every phase of a project (project planning,

commissioning, production)

• Parameter setting and configuration

L-force Controller The L-force controller is the central component of the automation system which (by

means of the runtime software) controls the Logic and Motion functionalities.

The L-force Controller uses the fieldbus to communicate with the field devices.

Engineering PC The Engineering PC and the engineering tools installed on it serve to configure and

parameterise the system.

The Engineering PC uses Ethernet to communicate with the L-force Controller.

Code "Container" for one or several parameters used for controller parameter setting or

monitoring.

Subcode If a code contains several parameters, the individual parameters are stored under

"subcodes".

This Manual uses a slash "/" as a separator between code and subcode (e.g. "C00118/3").

Function block editor Graphical interconnection tool which is provided for controllers in the MotionControl

HighLevel and TopLevel license level in the »Engineer« on the FB editor tab and by means

of which the technology applications supplied can also be reconfigured and extended by

individual functions.

Function block A function block (FB) can be compared with an integrated circuit that contains a specific

control logic and delivers one or several values when being executed.

• A n in stan ce ( repro ducti on, co py) of the f unc tion b lock i s alw ays inser ted in the ci rcuit .

• It is also possible to insert several instances of a function block in a circuit.

• Each instance has an unequivocal identifier (the instance name) and a processing

number which defines the position at which the function block is calculated during

the task cycle.

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 13

Page 14

1 About this documentation

1.3 Definition of notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Definition of notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

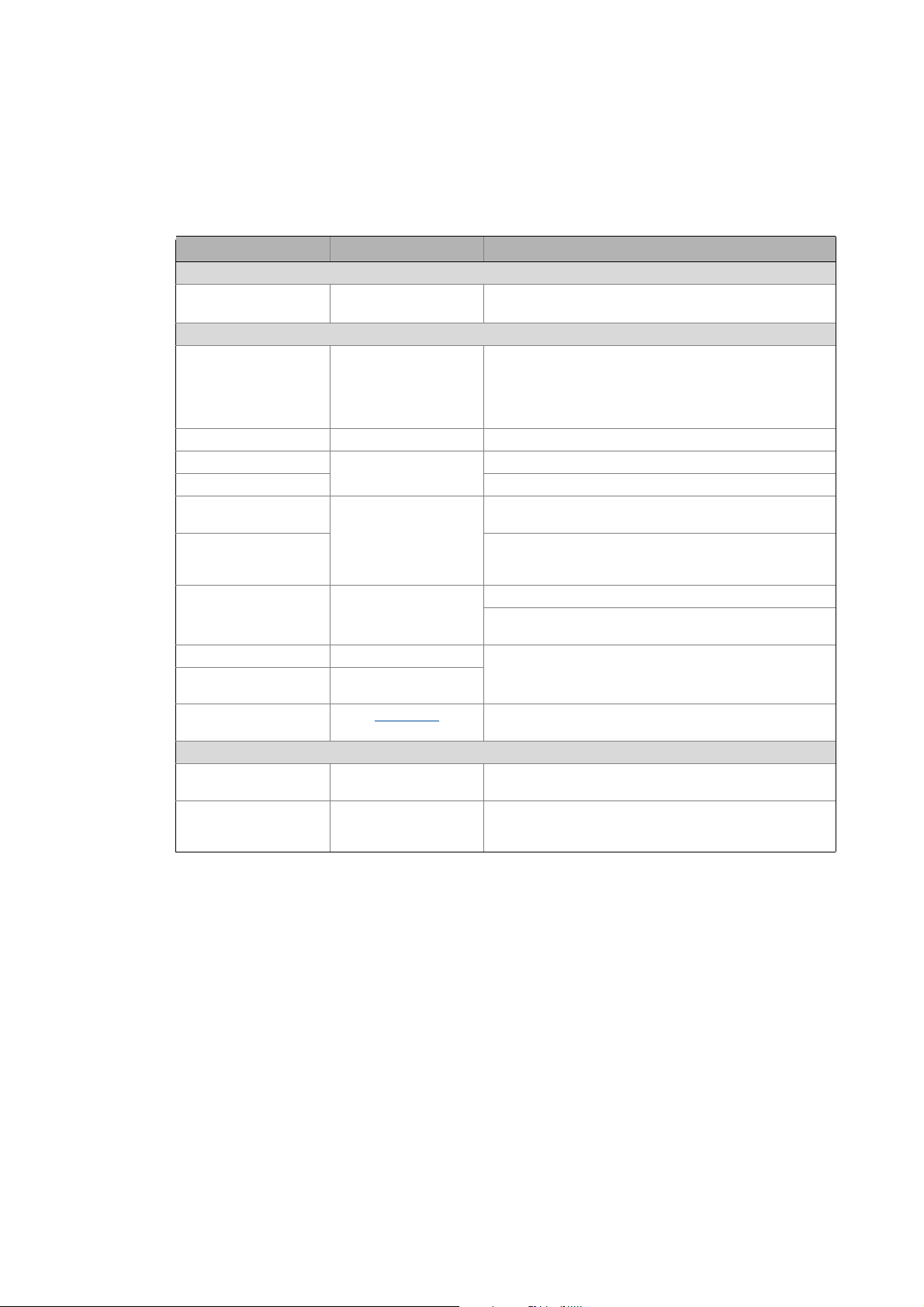

Safety instructions

Layout of the safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for simple handling

Reference to other documentation

14

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 15

2Introduction

2.1 Parameter setting, configuring, or programming?

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Introduction

The basis of every L-force application is an easy and quick parameter setting of prepared technology

applications and solutions*.

This chapter contains basic information on the runtime software model of L-force and on how you

can establish an online connection between the PC and controller for parameter setting with

»Engineer« very easily.

At the end of this chapter you will find an overview of the different signal types & scaling which

serve to process physical values (e.g. a speed or position) within the application.

* In preparation!

2.1 Parameter setting, configuring, or programming?

The graded runtime software model of L-force provides a simple and consistent solution for motion

and process tasks as well as for complex machine functions:

Runtime software

PLC level Programming*

Freely programmable open and closed

loop control functions*

Technology level Configuring

Motion Control TopLevel

Additional motion and process control

modes for complex drive tasks.

Motion Control HighLevel

Individual extensibility of the basic

functions & technology applications by

means of the function block editor and

the comprehensive function library.

Motion Control StateLevel

Parameterisable basic functions &

technology applications.

The HighLevel and TopLevel licenses enable you to

extend the provided technology applications by

individual functions using the graphic function block

editor of »Engineer«. Here you can access the

comprehensive function libraries of Lenze which

among other things contain process controllers,

arithmetic functions, logic blocks, and ramp

generators and integrators.

Parameter setting

The StateLevel license includes a range of technology

applications which can be put into operation easily

with a keypad or via dialogs in »Engineer«.

* In preparation!

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 15

Page 16

2Introduction

2.1 Parameter setting, configuring, or programming?

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.1.1 Basic functionalities

Important basic drive functions and further basic functions are implemented in the firmware of the

controller and thus are always provided, irrespective of the runtime software licence available.

Firmware

Motion Control basic drive functions Further basic functionalities

• Stop

• Quick stop

• Manual jog

• Homing

• Positioning

• Position follower

• Speed follower

• Torque follower

• Limiter

• Brake control

• Drive interface

• Motor interface

• Encoder evaluation

• I/O terminals

• Safety engineering

• Logbook

• Oscilloscope

2.1.2 Technology applications

Technology applications (TAs) are applications prepared by Lenze which can serve as a basis for

solving typical applications.

• The technology applications available for the Servo Drives 9400 can be selected in »Engineer«

from the application catalogue.

Runtime software

Technology level Each higher license contains additional technology

Motion Control TopLevel

• TA "Positioning sequence control"

• TA "Electronic cam" *

• TA "Register control" *

•TA "Winding technology" *

Motion Control HighLevel

•TA "Electronic gearbox"

•TA "Synchronism with mark

synchronisation"

Motion Control StateLevel

• TA "Actuator – speed"

• TA "Actuator – torque"

• TA "Table positioning"

applications for further application fields.

16

* In preparation!

Tip!

Detailed information about the individual technology applications can be found in the

corresponding software manuals.

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 17

2Introduction

2.2 Communicating with the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2 Communicating with the controller

The following interfaces/communication modules can be used to establish communication

between the PC and controller:

• Diagnostic interface X6/Going online via diagnostic adapter

• CAN on board interface/Going online via system bus (CAN on board) ( 20)

• Optional interfaces which are provided by corresponding communication modules in the

module slots MXI1/MXI2 of the controller.

Note!

For communication with the controller, at least the control electronics of the controller

must be supplied with 24 V low voltage via plug X2. For detailed information, please see

the Mounting Instructions for the controller.

Stop!

If you change parameters in the »Engineer« while the controller is connected online, the

changes will be directly accepted by the controller!

Tip!

Detailed information about the individual interfaces can be found in the corresponding

Communication Manuals (KHB).

2.2.1 Going online via diagnostic adapter

For initial commissioning of the controller you can for instance use the diagnostic adapter offered

by Lenze:

Note!

Please observe the documentation for the diagnostic adapter!

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 17

Page 18

2Introduction

2.2 Communicating with the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Preconditions:

• The diagnostic adapter is connected to the controller at the diagnostic interface X6 and to the

PC at a free USB port.

• The driver required for the diagnostic adapter is installed.

• The control electronics of the controller is supplied with 24 V low voltage via plug X2.

How to build up an online connection via the diagnostic adapter:

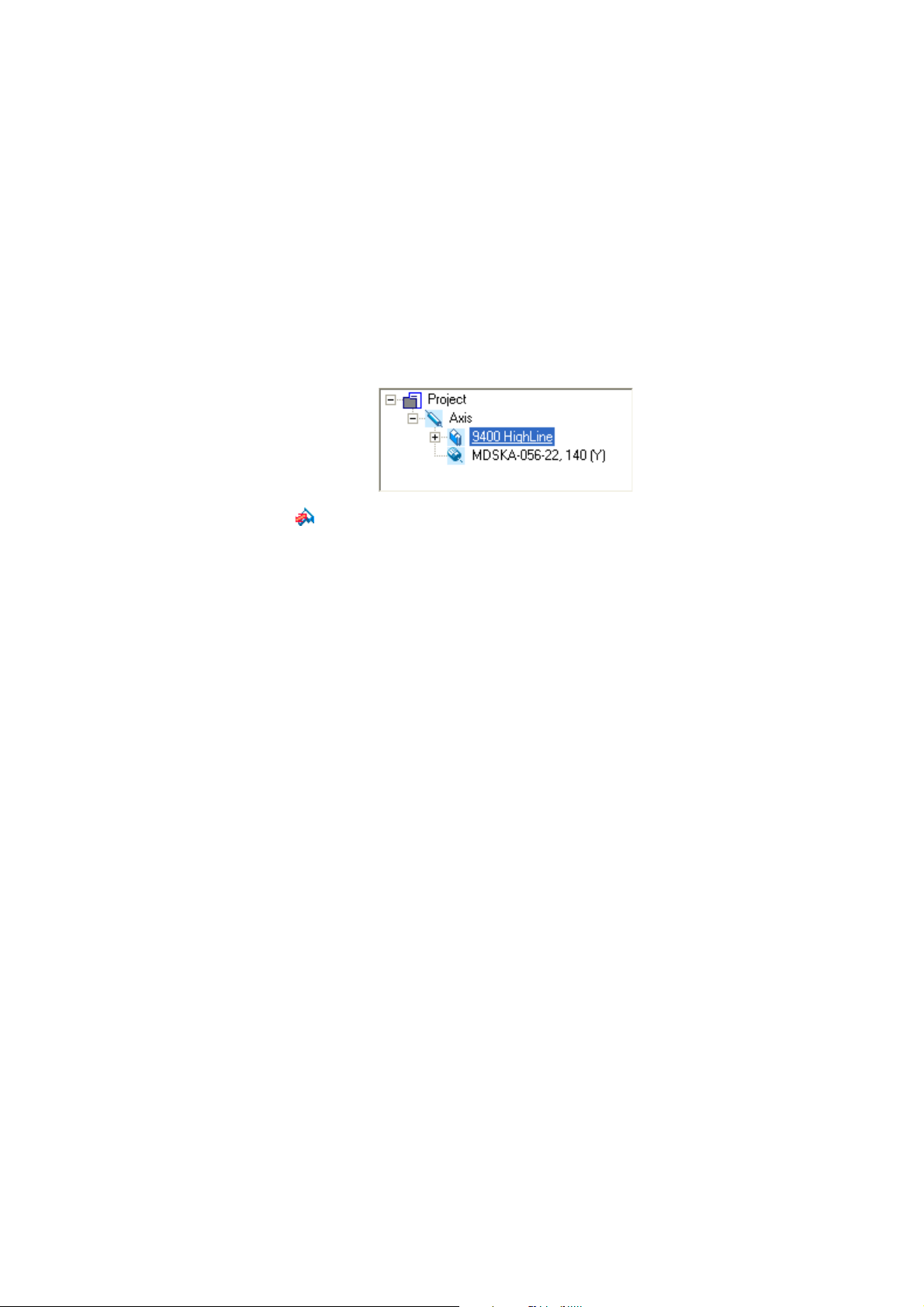

1. Select the 9400 HighLine controller to which you want to build up an online connection in

the Project view of the »Engineer«:

2. Click the icon.

If the changes you have made on the project have not been accepted yet, first a query on

whether an update is to be carried out is effected.

If an update is to be carried out:

•Click on Yes to open the Update project dialog box.

•Press the Create button in the Update project dialog box to update the changed project

elements.

• After the update a note is shown, saying whether the update was carried out

successfully.

18

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 19

2Introduction

2.2 Communicating with the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

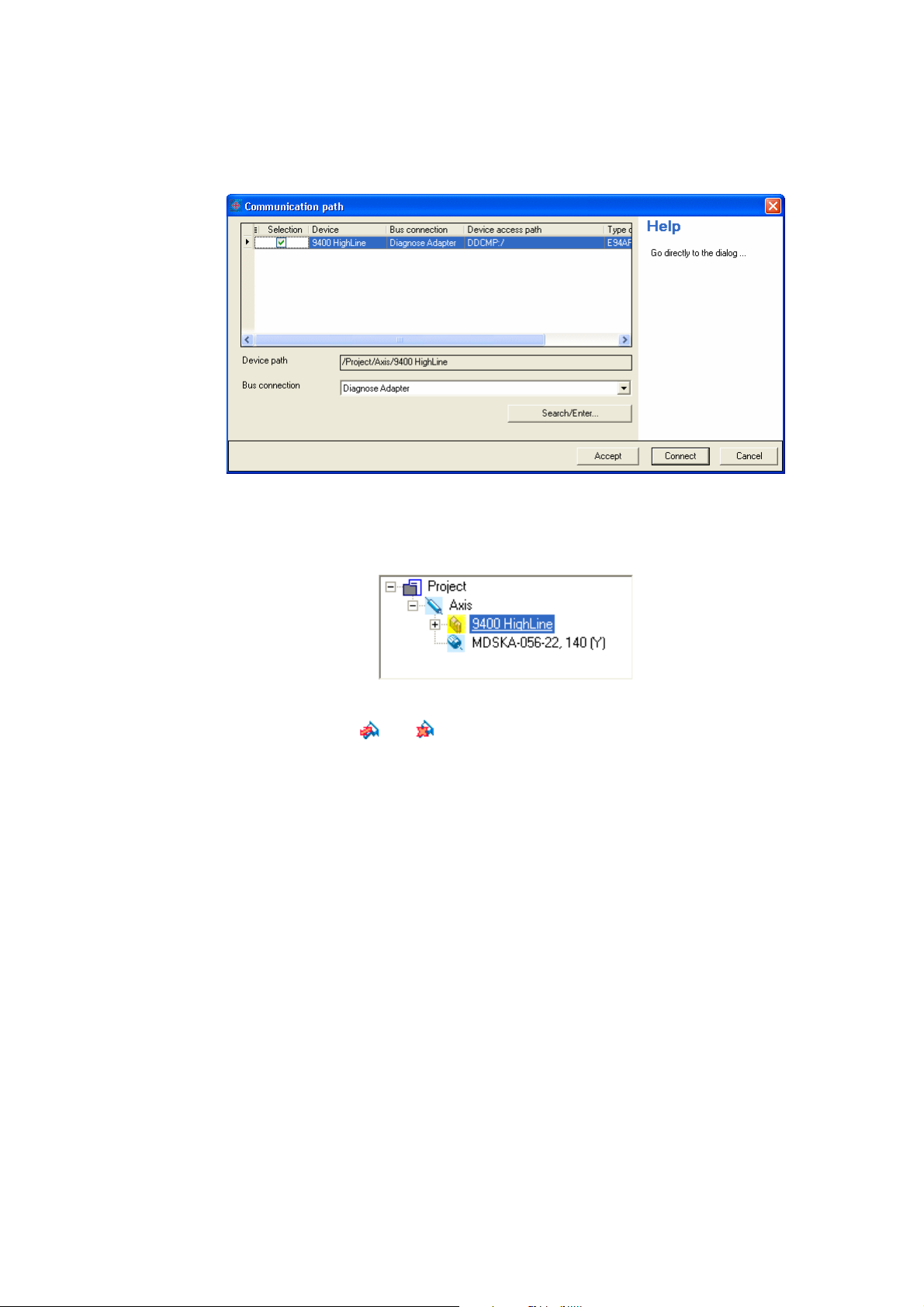

If no communication path was configured yet for the controller selected, the

Communication path dialog box is shown after the update has been carried out:

• The "Diagnostic adapter" bus connection is already preset.

3. Click on Connect.

• The dialog box is closed and the online connection with the controller is built up.

•In the Project view a yellow icon indicates the online connection with the controller:

Now you can use the icons and to easily build up and end a connection with the controller.

The communication settings are only required when communication with a controller is built up for

the first time.

• If you want to change the configured communication path, select the command Online Set

communication path and go online to open the Communication path dialog box and change the

settings.

• When an online connection has been established, the »Engineer« displays the current

parameter settings of the controller with a yellow background colour.

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 19

Page 20

2Introduction

2.2 Communicating with the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2.2 Going online via system bus (CAN on board)

As an alternative to the diagnostic adapter, you can use the integrated system bus interface (CAN on

board, terminal X1) of the controller for communication.

• Lenze offers the following communication accessories for connection to the PC:

Communication accessories PC interface

PC system bus adapter 2173

incl. connection cable and voltage supply adapter

• for DIN keyboard connection (EMF2173IB)

• for PS/2 keyboard connection (EMF2173IBV002)

• for PS/2 keyboard connection with electrical isolation (EMF2173IBV003)

PC system bus adapter 2177

incl. connection cable (EMF2177IB)

Parallel interface

(LPT port)

USB

(Universal Serial Bus)

Note!

• For detailed information about the PC system bus adapter, please see the "CAN

Communication Manual".

• Please observe the documentation for the PC system bus adapter!

• The online connection is established as described in the previous chapter "Going

online via diagnostic adapter", only that this time the entry "CAN system bus" is to be

selected in the Bus connection list field of the Communication path dialog box.

( 18)

2.2.3 Use of other communication interfaces

The controller can be extended by further communication interfaces, if required, e.g. Ethernet,

ETHERNET Powerlink, or PROFIBUS.

• For this the controller is provided with the module slots MXI1 and MXI2 for accepting

communication modules.

• Detailed information on this subject can be found in the Hardware Manual and Communication

Manual for the corresponding communication system.

20

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 21

2Introduction

2.3 Signal types & scaling

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

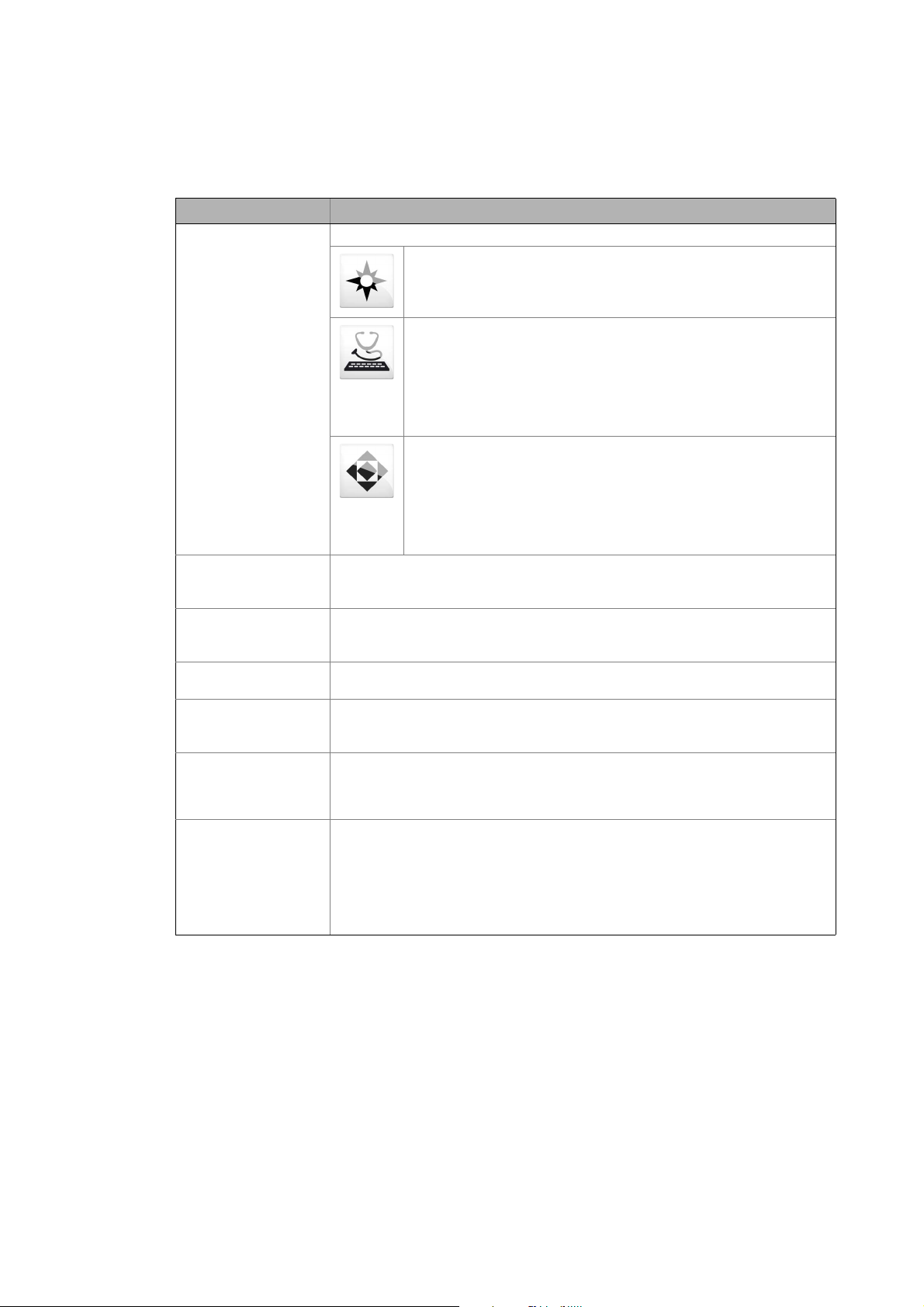

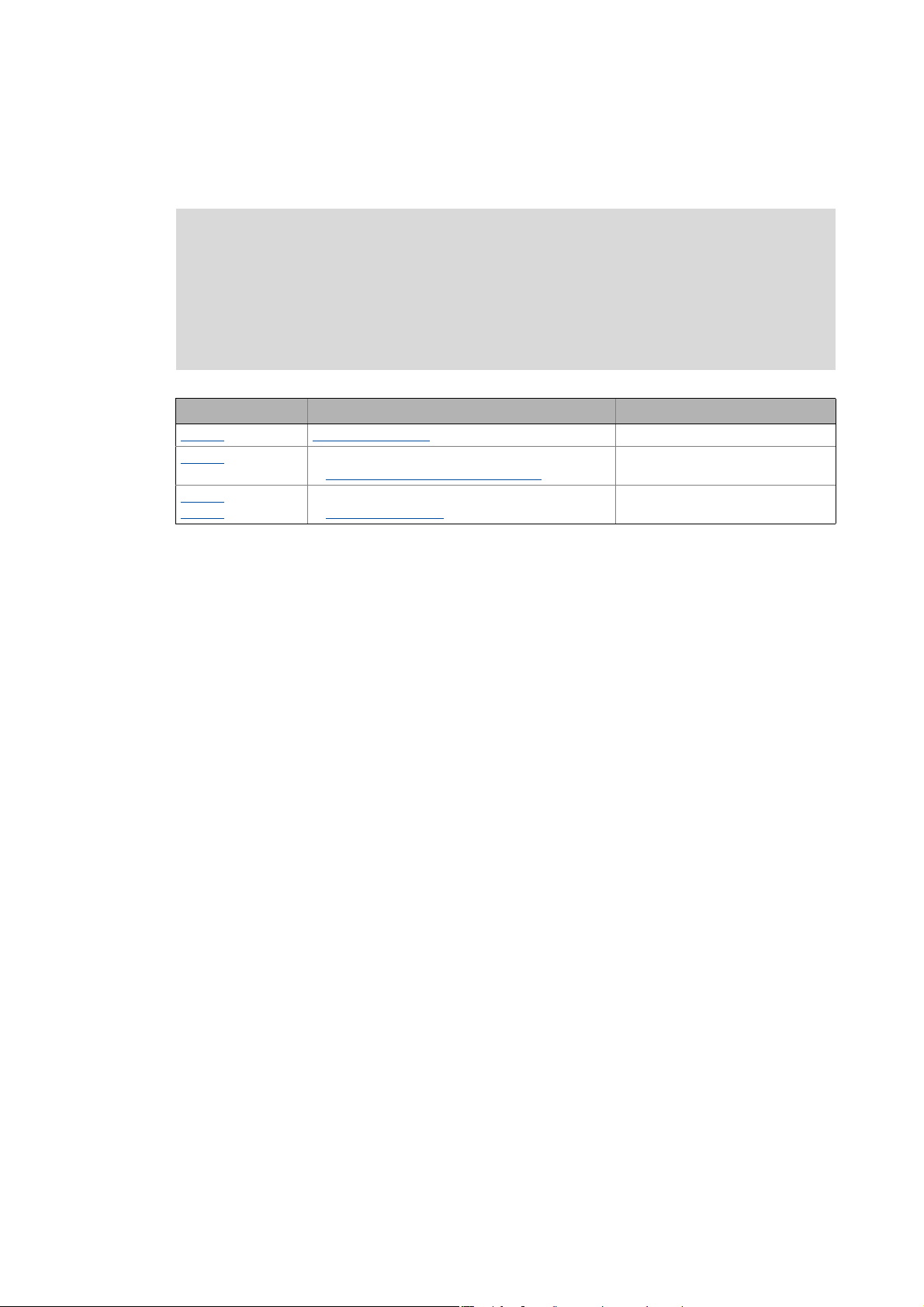

2.3 Signal types & scaling

It is very helpful for the parameterisation & configuration of the controller to know the signal types

and their scaling listed below, which serve to process physical quantities (e.g. a speed or position)

within the function block interconnection.

Note!

From software version V3.0 the resolution of an encoder revolution can be

parameterised in C00100

(Lenze setting: 16 bits/encoder revolution).

Resolution of an encoder revolution

Signal type (data type)

Scaled (INT) 16 bits ± 199.99 % 2 _a

Scaled (DINT) 32 bits ± 200.00 % 2 _n

Speed (INT) / 16 bits ± 30000.0 rpm 1 _v

Speed (DINT) 32 bits ± 480000.0 rpm 1 _s

Position/angle (DINT) / 32 bits -2

Digital (BOOL) Bit 1 0 ≡ FALSE; 1 ≡ TRUE 0

Acceleration (DINT) 32 bits ± 7.69 * 10

Time 28 bits 0 ... 268435.456 s 3

Other (BYTE) 8 bits 0 ... 255 0

Other (WORD) 16 bits 0 ... 65535 0

Other (DWORD) 32 bits 0 ... 4294967295 0

Other (INT) 16 bits -32768 ... 32767 0

Other (DINT) 32 bits -2147483648 ... 2147483647 0

Connection

symbol in

the FB editor

Resolution

( 37)

Value range (external)

31

... 231-1 increments 3 _p

9

rpm/s 3 _x

Decimal positions/

signal type suffix

in the identifier

Scaling of physical units

Signal type

Scaled (INT) 16 bits 100 % ≡ 2

Scaled (DINT) 32 bits 100 % ≡ 2

Speed (INT) / 16 bits 15000 rpm ≡ 2

Speed (DINT) 32 bits 15000 rpm ≡ 2

Position/angle (DINT) / 32 bits 1 encoder revolution ≡ 2

Acceleration (DINT) 32 bits 15000000 rpm/s ≡ 2

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 21

Connection

symbol in

the FB editor

Resolution

Scaling

External value ≡ internal value

14

≡ 16384

30

≡ 1073741824

14

≡ 16384

26

≡ 67108864

16

increments

22

≡ 4194304

Page 22

3 Commissioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Commissioning

This documentation contains detailed information on parameter setting and configuration of the

controller. Sequential reading is not required.

In order to obtain the information relevant for initial commissioning, this chapter describes

different commissioning scenarios which can also be used as a guide through this manual:

A. Initial commissioning

• Target: Adapting the controller to the electromechanics and the control system.

B. Standard set-up

• Target: Taking over the application and parameter set of an already preconfigured "Engineer"

project into several controllers.

( 25)

( 26)

C. Controller replacement

• Target: Replacing a controller which has failed in a running system by a replacement device

using the "old" memory module.

D. Motor replacement

• Target: Replacing a motor which has failed in a running system.

( 27)

( 27)

22 Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 23

3 Commissioning

3.1 General information

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.1 General information

Note!

Some parameters of the controller have a setting range depending on the device type.

If parameterisation is carried out offline or if the memory module is exchanged between

different 9400 HighLine device types, always check the settings of the parameters listed

in the following table and adapt them, if required, to prevent a parameter error after the

parameter set download or module change!

Parameter Info Lenze setting

C00018

C00022

C00173

C00174

Switching frequency 8 kHz variable

Maximum current

Accepting/adapting plant parameters

Mains voltage and undervoltage threshold (LU)

Machine parameters

( 29)

( 124)

0.00 A

400/415 V, LU = 285 V

Tip!

The rated data of the different device types can be found in the Hardware Manual in the

"Rated data" chapter.

Term definition of "Plant parameters"

The term "plant parameters" which is frequently used in the following chapters summarises all

parameters which result from the combination of motor and load. They characterise the transfer

behaviour of the entire controlled system including the desired monitoring functions. The plant

parameters depend on the application in which the controller and motor are used.

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 23

Page 24

3 Commissioning

3.2 Notes on commissioning using the keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.2 Notes on commissioning using the keypad

For a motor with an electronic nameplate (ENP)

• A display of the plant parameters offered by ENP via keypad is not provided. The plant

parameters must be edited and optimised individually.

• To avoid that the motor starts unintentionally without adjusting the plant parameters, the

maximum current in the Lenze setting is set to "0 A" in C00022

• After setting the plant parameters, they have to be saved on the memory module of the

controller with mains failure protection, just as the motor data that have been read out from

the ENP (C00002

For a motor without an electronic nameplate (ENP)

• The motor data and plant parameters must be edited and set individually.

• To avoid that the motor starts unintentionally without adjusting the plant parameters, the

maximum current is set to "0 A" in C00022

• After setting the motor data and plant parameters, they have to be saved on the memory

module of the controller with mains failure protection (C00002

= "11: Save start parameters").

by the factory.

.

= "11: Save start parameters").

Commissioning of the application

• The application must already be stored on the memory module of the controller. Otherwise

commissioning by only using the keypad is not possible.

• All application parameters which deviate from the factory adjustment have to be edited

individually. For this the project planner has to provide a corresponding list to the commissioner

(including the motor and plant data).

• In the case of a standard set-up, a pole position identification may have to be carried out for

synchronous motors of a third party manufacturer or Lenze synchronous motors with a

Stegmann absolute value encoder.

• After setting the parameters, they have to be saved on the memory module of the controller

with mains failure protection (C00002

= "11: Save start parameters").

Tip!

Detailed information on the individual technology applications can be found in the

corresponding Software Manual for the technology application and the »Engineer« online

help in the chapter "L-force Servo Drives 9400 Technology applications".

24

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 25

3 Commissioning

3.3 Initial commissioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3 Initial commissioning

Worksteps

Parameterising motor control:

1. Read out the motor data of the controller or select them via the »Engineer« motor catalogue.

• If the motor connected to the controller is provided with an electronic nameplate (ENP), all motor

data are automatically read out from the ENP and a selection in the motor catalogue is not required.

Reading out motor data from the controller

• If a motor without ENP or a motor by a third-party manufacturer is used, the selection is carried out

via the »Engineer« motor catalogue. Selecting a motor from the motor catalogue in the »Engineer«

( 118)

2. Select motor control

• Servo control is preset for the synchronous motor.

3. Adjusting motor and controller to each other

4. Carry out settings for selected motor control.

• For this see description for the corresponding motor control:

• Servo control (SC)

• Sensorless vector control (SLVC) (from software version V3.0)

• V/f control (VFCplus)

• V/f control (VFCplus)

Parameterise/configure application:

5. Load & parameterise technology application.

Detailed information on the individual technology applications can be found in the corresponding

Software Manual for the technology application and the »Engineer« online help in the chapter "L-force

Servo Drives 9400 Technology applications".

6. If required, reconfigure the interconnection of the technology application with the function block editor.

Optimise control mode:

7. Optimise control mode of the selected motor control.

• By means of traversing profile from the application and oscilloscope.

• For this see description for the corresponding motor control:

• Servo control (SC)

• Sensorless vector control (SLVC) (from software version V3.0)

• V/f control (VFCplus)

• V/f control (VFCplus)

Save project and parameter set:

8. Execute device command C00002

9. Save »Engineer« project.

. ( 121)

(from software version V3.0)

(from software version V3.0)

(from software version V3.0)

(from software version V3.0)

= "11: Save start parameters".

( 117)

( 123)

More (optional) worksteps

Worksteps

Establish network:

1. Insert network and machine application into the »Engineer« project.

2. Interconnect port blocks reasonably to each other within the machine application.

3. Configure network (set addresses, baud rate, and process data channels in a reasonable manner).

4. Establish communication with the control system.

5. Establish communication with other drive components (e.g. HMIs, I/O extensions and other controllers).

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 25

Page 26

3 Commissioning

3.4 Standard set-up

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Worksteps

Check & optimise application/DC-bus operation:

1. Traverse axis in manual operation.

•See chap. Basic drive functions

2. Check area boundaries (path, speed, torque).

3. Traverse axis in automatic operation with set-up speed, possibly together with coupled axes.

4. Check coupling with other movements (master/slave axes, tools, …).

5. Optimisation of the process at higher speeds.

6. Recording of typical signal characteristics using the oscilloscope function for the documentation.

•See chapter Oscilloscope

Save & archive project and parameter set:

1. Execute device command C00002

2. Save »Engineer« project.

3. Deposit a backup copy of the »Engineer« project, e.g. on CD ROM, in the control cabinet.

Manual jog ( 395)

( 579)

= "11: Save start parameters".

3.4 Standard set-up

Worksteps

Transfer application and parameter set to the controller:

1. Transfer the application preconfigured in »Engineer« and the corresponding parameter set to the

For a motor with an electronic nameplate (ENP):

For a motor without an electronic nameplate (ENP):

2. Execute device command C00002

3. Restart controller with connected motor to read out the motor data from the electronic nameplate

4. Execute device command C00002

memory module of the controller.

= "11: Save start parameters".

(ENP).

• Either by switching off/switching on again the voltage supply or by means of device command

•See chap. Motor interface

Note:

The motor is operated with the motor data and plant parameters identified during initial

commissioning. Adjusting motor and controller to each other

= "11000: Restart controller".

C00002

Reading out motor data from the controller ( 117)

= "11: Save start parameters".

( 123)

26

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06

Page 27

3 Commissioning

3.5 Controller replacement

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.5 Controller replacement

Scenario: The controller has failed in a running system.

Note!

For the procedure described in the following it is assumed that the memory module and

possibly available extension modules in the controller, as well as the motor are not

affected by the failure and that all parameters have been saved with mains failure

protection.

Worksteps

Replacement of the controller:

1. Replace controller.

See Mounting Instructions for the controller!

2. Insert the memory module of the failed controller into the replacement device.

3. If further extension modules are plugged into the failed controller, they must be inserted into the

replacement device as well.

Further steps are not required since all data required are on the memory module.

3.6 Motor replacement

Scenario: The motor has failed in a running system.

Note!

For the procedure described in the following it is assumed that the controller is not

affected by the failure.

Worksteps

Replacement of the motor:

1. Replace the motor.

See Mounting Instructions for the controller!

Note:

The motor connection on the controller is accessible without having to remove the standard device

from the installation backplane.

For a motor with an electronic nameplate (ENP):

2. Restart controller with connected motor to read out the motor data from the electronic nameplate.

• Either by switching off/switching on again the voltage supply or by means of device command

C00002

• See chap. Motor interface

3. Execute device command C00002

For a motor without an electronic nameplate (ENP):

Note: