Page 1

EDS94SPP101

.BTJ

Ä.BTJä

L-force Drives

Hardware Manual

9400

E94A...

Servo Drives 9400

Page 2

0Fig.0Tab. 0

Page 3

Contents i

1Preface 9..................................................................

1.1 The 9400 Servo Drives product range 10....................................

1.1.1 The system 10..................................................

1.1.2 Features 10.....................................................

1.1.3 System overview 10..............................................

1.2 About this Hardware Manual 12...........................................

1.2.1 Information provided by the Hardware Manual 12....................

1.2.2 Products to which the Hardware Manual applies 13...................

1.3 Legal regulations 17.....................................................

2Guide 19....................................................................

2.1 Terms and abbreviations used 20..........................................

2.2 Total index 22..........................................................

3 Safety instructions 27.........................................................

3.1 General safety and application notes for Lenze controllers 28..................

3.2 General safety and application instructions for Lenze motors 32................

3.3 Residual hazards 35.....................................................

3.4 Notes used 36..........................................................

4 Single-axis controllers 37......................................................

4.1 Device features 38......................................................

4.2 General data and operating conditions 39.................................

4.3 Rated data (devices for 400/500V mains) 47.................................

4.3.1 Overview 47....................................................

4.3.2 Operation at rated mains voltage 230 V 50..........................

4.3.3 Operation at rated mains voltage 400 V 53..........................

4.3.4 Operation at rated mains voltage 500 V 60..........................

4.3.5 Fuses and cable cross-sections 66..................................

4.3.6 Overcurrent operation 68.........................................

4.3.7 Current-time diagrams 75........................................

4.4 Device description 85....................................................

4.4.1 Devices in the range 2 ... 24 A (0.37 ... 11 kW) 86......................

4.4.2 Devices in the range 32 ... 104 A (15 ... 55 kW) 88.....................

4.4.3 Devices in the range 145 ... 695 A (75 ... 370 kW) 90...................

4.5 Mechanical installation 92................................................

4.5.1 Important notes 92..............................................

4.5.2 Devices in the range 2 ... 24 A (0.37 ... 11 kW) 92......................

4.5.3 Devices in the range 32 ... 104 A (15 ... 55 kW) 95.....................

4.5.4 Devices in the range 145 ... 366 A (75 ... 200 kW) 96...................

4.5.5 Devices in the range 460 ... 695 A (250 ... 400 kW) 97..................

EDS94SPP101 EN 7.1

3

Page 4

Contentsi

4.6 Wiring 98..............................................................

4.6.1 Important notes 98..............................................

4.6.2 Safety notes for the installation according to UL or UR 100.............

4.6.3 Earthing of internal EMC filters 103.................................

4.6.4 Devices in the range 2 ... 24 A (0.37 ... 11 kW) 107......................

4.6.5 Devices in the range 32 ... 104 A (15 ... 55 kW) 116.....................

4.6.6 Devices in the range 145 ... 695 A (75 ... 370 kW) 121...................

4.7 Control terminals 138.....................................................

5 Multi-axis controllers 155......................................................

5.1 Device features 156......................................................

5.2 General data and operating conditions 157.................................

5.3 Rated data 163..........................................................

5.3.1 Overview 163....................................................

5.3.2 Devices for 400/500V-mains 165....................................

5.3.3 Overcurrent operation 169.........................................

5.3.4 Current-time diagrams 173........................................

5.4 Mechanical installation 178................................................

5.4.1 Important notes 178..............................................

5.4.2 Devices in the range 2 ... 32 A (0.37 ... 15 kW) 182......................

5.5 Wiring 183..............................................................

5.5.1 Important notes 183..............................................

5.5.2 Safety notes for the installation according to UL or UR 185.............

5.5.3 Earthing of internal EMC filters 186.................................

5.5.4 Devices in the range 2 ... 32 A (0.37 ... 15 kW) 188......................

5.6 Installation of the standard device 196......................................

5.7 Control terminals 197.....................................................

6 Power supply module 213......................................................

6.1 Device features 214......................................................

6.2 General data and operating conditions 215.................................

6.3 Rated data (devices for 400/500V mains) 218.................................

6.3.1 Operation at rated mains voltage 230 V 219..........................

6.3.2 Operation at rated mains voltage 400 V 221..........................

6.3.3 Operation at a rated mains voltage of 500 V 223......................

6.3.4 Fuses and cable cross-sections 225..................................

6.3.5 Mains filters for power supply modules 227..........................

6.4 Device description 229....................................................

6.4.1 Devices in the range 10 ... 36 A (4 ... 18 kW) 230........................

6.4.2 Devices in the range 100 ... 245 A (48 ... 119 kW) 232...................

4

EDS94SPP101 EN 7.1

Page 5

Contents i

6.5 Mechanical installation 234................................................

6.5.1 Important notes 234..............................................

6.5.2 Devices in the range 10 ... 36 A (4 ... 18 kW) 234........................

6.5.3 Devices in the range 100 ... 245 A (48 ... 119 kW) 238...................

6.6 Wiring 242..............................................................

6.6.1 Important notes 242..............................................

6.6.2 Safety notes for the installation according to UL or UR 243.............

6.6.3 Design of the cables 244...........................................

6.6.4 Earthing of internal EMC filters 245.................................

6.6.5 Devices in the range 10 ... 36 A (4 ... 18 kW) 247........................

6.6.6 Connecting busbars 248...........................................

6.6.7 Terminal assignment 249..........................................

6.6.8 Devices in the range 100 ... 245 A (48 ... 119 kW) 251...................

6.6.9 Connecting busbars 252...........................................

6.6.10 Terminal assignment 253..........................................

6.7 Control terminals 256.....................................................

6.8 Final works 260..........................................................

7 Regenerative power supply modules 261.........................................

7.1 Device features 262......................................................

7.2 General data and operating conditions 263.................................

7.3 Rated data (devices for 400/500V mains) 265.................................

7.3.1 Operation at rated mains voltage 230 V 266..........................

7.3.2 Operation at rated mains voltage 400 V 268..........................

7.3.3 Operation at a rated mains voltage of 500 V 270......................

7.3.4 Regenerative feedback with brake chopper 272.......................

7.3.5 Fuses and cable cross-sections 274..................................

7.3.6 Current-time diagrams 275........................................

7.3.7 Mains filters for regenerative power supply modules 279...............

7.4 Device description 282....................................................

7.5 Mechanical installation 285................................................

7.5.1 Important notes 285..............................................

7.5.2 Dimensions 286..................................................

7.5.3 Arrangement of the devices 289....................................

7.5.4 Mounting steps 290..............................................

EDS94SPP101 EN 7.1

5

Page 6

Contentsi

7.6 Wiring 291..............................................................

7.6.1 Important notes 291..............................................

7.6.2 Connection plan 293..............................................

7.6.3 Earthing of internal EMC filters 294.................................

7.6.4 Connecting busbars 296...........................................

7.6.5 Design of the cables 297...........................................

7.6.6 How to connect the shield 297......................................

7.6.7 Terminal assignment 298..........................................

7.6.8 Wiring of control connections 300...................................

7.6.9 Communication modules 305......................................

7.6.10 Memory modules 306.............................................

7.6.11 Safety modules 307...............................................

7.7 Final works 308..........................................................

7.7.1 Initial commissioning on 400 V mains voltage 308.....................

7.7.2 Initial commissioning on 230 V or 500 V mains voltage 308.............

7.7.3 Further settings 308..............................................

8 DC-bus operation 309.........................................................

8.1 Introduction 310.........................................................

8.1.1 Terminology and abbreviations used 310.............................

8.1.2 Comparison single-axis controllers / multi-axis controllers 311..........

8.1.3 Advantages of a drive system 312...................................

8.1.4 General information on the accessories 313..........................

8.2 Conditions for trouble-free DC-bus operation 314.............................

8.2.1 Voltages 314....................................................

8.2.2 Number of feeding points 314......................................

8.2.3 Other conditions 314..............................................

8.3 DC-bus variants 315......................................................

8.3.1 Supply from a supply module 315...................................

8.3.2 Supply from controllers 316........................................

8.4 Rated data 317..........................................................

8.4.1 General data 317.................................................

8.4.2 DC-supply power 319.............................................

8.4.3 DC-power requirements 323.......................................

8.4.4 DC fuses 325.....................................................

6

EDS94SPP101 EN 7.1

Page 7

Contents i

8.5 Basic dimensioning 328...................................................

8.5.1 General information 328..........................................

8.5.2 Power distribution of controllers 329................................

8.5.3 Motor efficiency 330..............................................

8.5.4 Power loss of devices 330..........................................

8.5.5 Determining the power requirements 330............................

8.5.6 Determining the regenerative power requirements 330.................

8.5.7 Cable protection 331..............................................

8.5.8 Filters 331.......................................................

8.5.9 Cables 334......................................................

8.6 Braking operation in a drive system 335.....................................

8.6.1 Basic considerations 335..........................................

8.7 App lication examples 336.................................................

8.7.1 Example 1 - supply module with multi-axis controllers 336.............

8.7.2 Example 2 - single-axis controller with multi axes 337..................

9 Accessories (overview) 339.....................................................

9.1 Overview 341............................................................

9.1.1 System overview 341..............................................

9.1.2 Assignment of accessories 343.....................................

9.2 Type-specific accessories 345..............................................

9.3 Communication modules 346..............................................

9.3.1 Possible device module combinations 348............................

9.3.2 Ethernet interface 349............................................

9.3.3 DeviceNet 371...................................................

9.3.4 PROFIBUS 376....................................................

9.3.5 PROFINET 382...................................................

9.3.6 CAN port 386....................................................

9.4 Function modules 390....................................................

9.4.1 Digital frequency 392.............................................

9.5 Memory modules 396.....................................................

9.6 Safety modules 403......................................................

9.6.1 SM0 406........................................................

9.6.2 SM100 407......................................................

9.6.3 SM301 411......................................................

9.7 Motor holding brake control modules 419....................................

9.7.1 Motor holding brake control module E94AZHX0051 420................

9.7.2 Motor holding brake control module E94AZHY0101 429................

9.7.3 Motor holding brake control module E94AZHN0025 439................

9.7.4 Motor holding brake control module E94AZHY0025 446................

9.7.5 Motor holding brake control module E94AZHN0026 452................

9.7.6 Motor holding brake control module E94AZHY0026 460................

EDS94SPP101 EN 7.1

7

Page 8

Contentsi

9.8 Accessories for diagnostics 467.............................................

9.8.1 USB diagnostic adapter 467........................................

9.8.2 Keypad 469......................................................

9.8.3 Hand-held terminal 476...........................................

9.9 Components for operation in the DC-bus connection 481.......................

9.9.1 DC-feeding point 481.............................................

9.9.2 GG1 busbar mounting set 488......................................

9.9.3 GG2 busbar mounting set 490......................................

9.9.4 GG3 busbar mounting set 492......................................

9.10 Filters 494..............................................................

9.10.1 Mains filters for single-axis controllers 495...........................

9.10.2 Mains filters for power supply modules 501..........................

9.10.3 Mains filters for regenerative power supply modules 511...............

9.10.4 RFI filters for single-axis controllers 518..............................

9.10.5 RFI filters for power supply modules 527.............................

9.10.6 Sinusoidal filters 4 ... 16.5 A 538.....................................

9.10.7 Sinusoidal filter 23.5 ... 90 A 542....................................

9.10.8 Sinusoidal filter 115 ... 150 A 547....................................

9.10.9 Sinusoidal filter 180 ... 480 A 551....................................

9.11 General accessories 556...................................................

9.11.1 Introduction 556.................................................

9.11.2 Shield mounting 557..............................................

9.11.3 Brake resistors 560...............................................

9.11.4 Power supply unit 574............................................

8

EDS94SPP101 EN 7.1

Page 9

1Preface

1.1 The 9400 Servo Drives product range 10....................................

1.1.1 The system 10..................................................

1.1.2 Features 10.....................................................

1.1.3 System overview 10..............................................

1.2 About this Hardware Manual 12...........................................

1.2.1 Information provided by the Hardware Manual 12....................

1.2.2 Products to which the Hardware Manual applies 13...................

1.3 Legal regulations 17.....................................................

Preface 1

EDS94SPP101 EN 7.1

9

Page 10

1

Preface

The 9400 Servo Drives product range

The system

1.1 The 9400 Servo Drives product range

1.1.1 The system

9400 Servo Drives range is the product family with the components required for an

intelligent servo drive system in automation. The product range comprises

ƒ servo drive controllers

ƒ I/O components

ƒ software

ƒ accessories

ƒ motors

ƒ gearboxes

ƒ DC-supply modules

1.1.2 Features

The Servo Drives 9400 feature:

ƒ compact design

ƒ wide power range

ƒ innovative installation concept

ƒ intelligent technology functions

ƒ high control precision

ƒ scalable safety technology

1.1.3 System overview

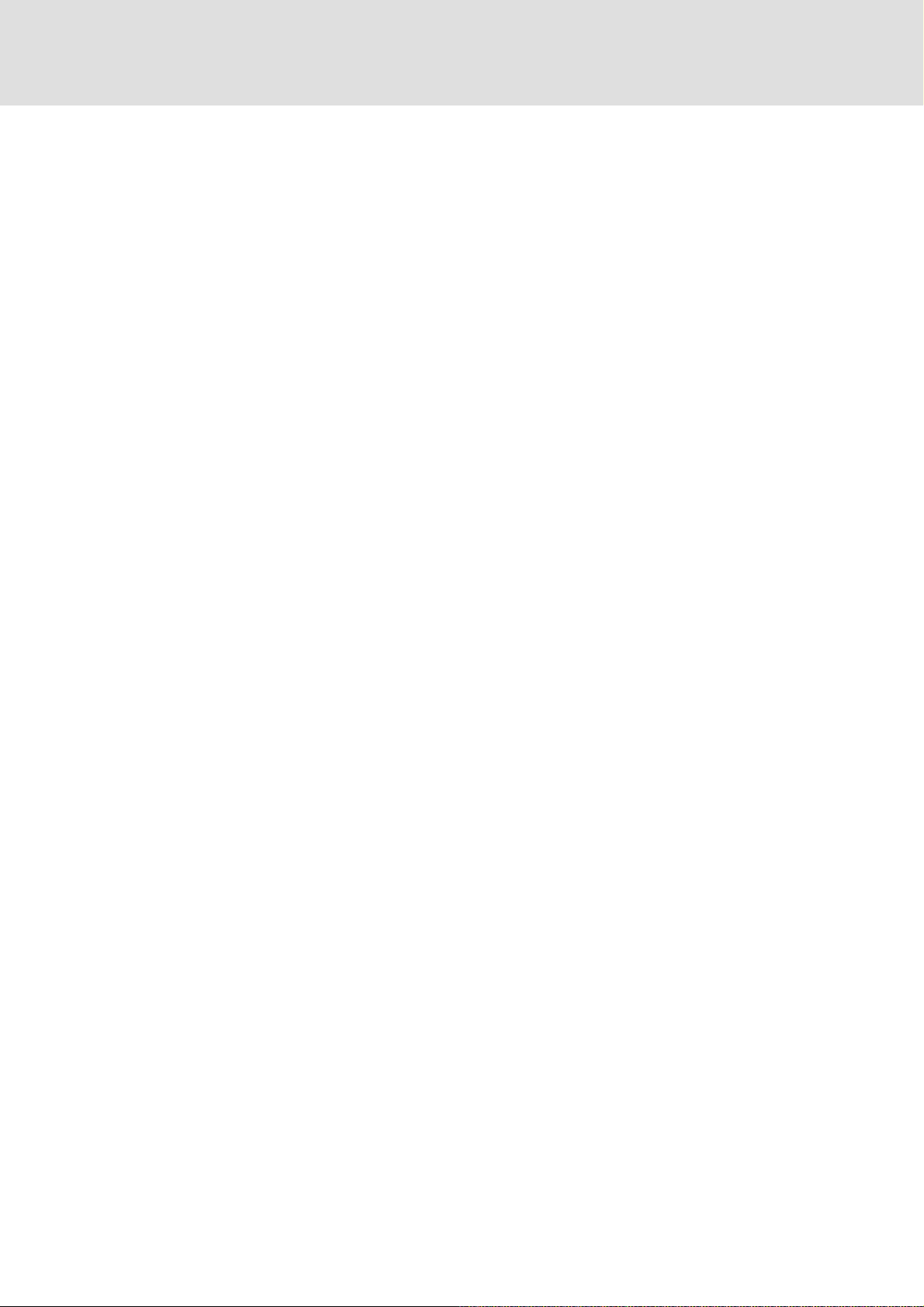

The following figure shows the most important components for the implementation of a

drive system with the Servo Drives 9400 product range.

On the way from the mains connection to the motor, you can see the basic principle of a

drive system on the left path. On the right path, the basic principle of a single-axis drive is

described.

In accordance with the requirements of your drive solution, your drive system can be

equipped or extended with specially adapted components.

10

EDS94SPP101 EN 7.1

Page 11

Preface

The 9400 Servo Drives product range

System overview

0

1

1

8

567

9

:

;

>?

=

@./

Mains voltage 3/PE AC 180 ... 550 V ±0 % or 3/PE AC 380 ... 550 V ±0 %

(depending on the device size/device power)

Mains fusing (not contained in the delivery programme)

Single Drives 9400 37

and corresponding installation backplanes

Mains filter for Single Drives 9400 495

RFI filter for Single Drives 9400 518

Multi Drives 9400 155

and corresponding installation backplanes

Power supply modules 9400

213, 261

(for DC bus installations with Multi Drives 9400)

Mains filter for power supply modules 9400 227

RFI filter for power supply modules 9400 527

2

3

4

<

=

SSP94SYS01

EDS94SPP101 EN 7.1

Equipment for all axis modules (device-dependent options):

Communication modules and extension modules 346

Memory modules 396

Safety modules 403

Motor holding brake control modules 419

Brake resistors 560

Diagnostic adapters 467

L-force Engineer (software)

Servo motors

Geared servo motors (”)

Standard geared motors (”)

Motor cables/system cables

(manual ”System cables”)

(motor catalogue)

11

Page 12

1

1.2 About this Hardware Manual

1.2.1 Information provided by the Hardware Manual

Preface

About this Hardware Manual

Information provided by the Hardware Manual

Target group

ThisHardware Manual is intended for all persons who install, commission, and adjust 9400

servo controllers.

Together with the catalog it forms the basis of project planning for the manufacturers of

machines and plants.

Contents

This Hardware Manual is meant as an addition to the Mounting Instructions included in

the scope of supply:

ƒ The features and functions are described in detail.

ƒ It provides detailed information on additional ranges of application.

How to find information

Each chapter forms a complete unit and informs you about an individual subject:

ƒ You therefore only have to read the chapter containing the information you need.

ƒ The Table of Contents and Index help you to find all information about a certain

topic.

ƒ Descriptions and data of other Lenze products (drive PLC, Lenze geared motors,

Lenze motors, ...) can be found in the corresponding catalogs, Operating Instructions

and Manuals. The required documentation can be ordered at your Lenze sales

partner or downloaded as PDF file from the Internet.

Availability

This Hardware Manual is designed as a loose-leaf collection and available as a PDF file on

the Internet. At the bottom of each page you can see the version and publication date.

Tip!

Documentation and software updates for further Lenze products can be found

on the Internet in the ”Services & Downloads” area under

http://www.Lenze.com

12

EDS94SPP101 EN 7.1

Page 13

About this Hardware Manual

Products to which the Hardware Manual applies

1.2.2 Products to which the Hardware Manual applies

Power modules

c

E94 x x x E xxx x x xx xx xx

Type / product range

9400 Servo Drives

Version

A=1.

N = not relevant

Design

S = single-axis controller (Single Drive)

M = multi-axis controller (Multi Drive)

P = power supply module

R = regenerative power supply module

Preface

1

Variant

H=HighLine

N = not relevant

P=PLC

Mechanical version

E = installation

Rated current (rounded)

e.g.

007=7A

024 = 23.5 A

...

Voltage class

2 = 230 V ~ / 300 V =

4 = 400 V ~ / 540 V =

Safety module

A ... D

Memory module

11 ... 44

Extension module 1

xx

EDS94SPP101 EN 7.1

Extension module 2

xx

13

Page 14

1

Preface

About this Hardware Manual

Products to which the Hardware Manual applies

Extension modules

c

E94 x Y x xx

Type / product range

9400 Servo Drives

Generation

A=1.

N = not relevant

Identification

Y=module

Module group

C = communication

I = I/O

F = feedback

M = memory

A=safety

Module identification

CA = CANopen

DN = DeviceNet

EN = Ethernet

EP = Ethernet Powerlink

ET = EtherCAT

PM = PROFIBUS MC

LF = digital frequency

1x = MM1x0memory module

2x = MM2x0memory module

3x = MM3x0memory module

4x = MM4x0memory module

x1 = MMx10 memory module with MC StateLevellicence

x2 = MMx20 memory module with MC HighLevellicence

x3 = MMx30 memory module with MC TopLevellicence

x4 = MMx40 memory module with PLClicence

A=SM0safetymodule

B = SM100 safety module

E = SM301safety module

14

EDS94SPP101 EN 7.1

Page 15

Power-related accessories

E94 A Z x x xxx x

Type / product range

9400 Servo Drives

Generation

Identification

Z = accessories

Component class 1

H = brake control

P = mounting backplane

M = mains filter

R = RFI filter

Preface

About this Hardware Manual

Products to which the Hardware Manual applies

c

1

Component class 2

M = multiple axes

P = power supply module

R = regenerative module

S = single axis

X,Y = type

N=notspecified

Rated current (rounded)

e.g.

008=8A

024 = 23.5 A

...

Voltage class

1=24V=

2 = 230 V ~ / 300 V =

4 = 400 V ~ / 540 V =

EDS94SPP101 EN 7.1

15

Page 16

1

Preface

About this Hardware Manual

Products to which the Hardware Manual applies

Power-independent accessories

c

E94 A Z x xxx

Type / product range

9400 Servo Drives

Generation

Identification

Z = accessories

Accessory group

J = mechanical components, other

S=software

K=keypad

N=notspecified

Module identification

16

EDS94SPP101 EN 7.1

Page 17

1.3 Legal regulations

Labelling

Lenze drive controllers are clearly labelled and defined by the contents of the nameplate.

Manufacturer

Lenze Automation GmbH, Hans-Lenze-Str. 1, D-31855 Aerzen

CE conformity

Complies with the ”Low voltage” EC Directive

Application as directed

The following applies to 9400 servo controllers and the accessories:

ƒ They must only be operated under the operating conditions described in this

Hardware Manual.

ƒ They are components for open and closed loop control of control variable speed

drives with asynchronous standard motors, asynchronous servo motors, PM

synchronous servo motors.

Preface

Legal regulations

1

ƒ They are components for installation into a machine.

ƒ They are components used for assembly together with other components to form a

machine.

ƒ They comply with the protection requirements of the ”Low Voltage” EC Directive.

ƒ They are not machines for the purposes of the ”EC ”Machinery” Directive.

ƒ They are not to be used as household appliances but for industrial purposes only.

The following applies to drives with 9400 servo controllers:

ƒ They comply with the EC ”Electromagnetic Compatibility” Directive if they are

installed according to the guidelines of CE-typical drive systems.

ƒ They can be used for operation at public and non-public mains.

ƒ They can be used in industrial premises as well as residential and commercial

premises.

ƒ The user is responsible for the compliance of his application with the EC Directives.

Any other use shall be deemed inappropriate!

EDS94SPP101 EN 7.1

17

Page 18

1

Preface

Legal regulations

Liability

The information, data, and notes in this Hardware Manual met the state of the art at the

time of printing. Claims referring to drive systems which have already been supplied

cannot be derived from the information, illustrations, and descriptions given in this

Manual.

The specifications, processes, and circuitry described in this Hardware Manual are for

guidance only and must be adapted to your own application. Lenze does not take any

responsibility for the suitability of the process and circuit proposals.

The specifications in this Hardware Manual describe the product features without

guaranteeing them.

Lenze does not accept any liability for damage and failures caused by:

ƒ Disregarding the Hardware Manual

ƒ Unauthorised modifications to the controller

ƒ Operating errors

ƒ Improper working on and with the controller

Warranty

See Terms of sale and delivery.

Warranty claims must be made to your Lenze representative immediately after detecting

the deficiency or fault.

The warranty is void in all cases where liability claims cannot be made.

18

EDS94SPP101 EN 7.1

Page 19

2Guide

2.1 Terms and abbreviations used 20..........................................

2.2 Total index 22..........................................................

Guide 2

EDS94SPP101 EN 7.1

19

Page 20

2

Guide

Terms and abbreviations used

2.1 Terms and abbreviations used

Cross-reference t o a chapter with the corresponding page number

AC AC current or AC voltage

Axis, drive Lenze controller combined with a motor or geared motor and other

Basic insulation Insulation for the basic protection against dangerous shock currents

CE Communauté Européene

Controller Any frequency inverter, servo inverter, or DC speed controller

Cxxxxx/y Subcode y of code Cxxxx

DC DC current or DC voltage

DIN Deutsches Institut für Normung

Double insulation Basic insulation and additional insulation

EMC Electromagnetic compatibility

EN European standard

[Hz]

f

max

Functional insulation Insulation for perfect operation

I

[A]

LN

[A]

I

aN

Lenze drive components

(e.g. C0410/3 = subcode 3 of code C0410)

Maximum frequency

Rated mains current

Rated output current

[A]

I

aM

IEC International Electrotechnical Commission

IP International Protection Code

[mA]

I

PE

L[mH] Inductance

M

[Nm]

N

NEMA National Electrical Manufacturers Association

[kW]

P

N

P

[W]

V

[kW]

P

DC

R[Ω] Resistance

Reinforced insulation Standardised insulating system, equivalent protection to double

S

[kVA]

N

Maximum output current

Discharge current

Rated torque

Rated motor power

Inverter power loss

Power on the DC voltage side

insulation

Apparent output power of controller

20

EDS94SPP101 EN 7.1

Page 21

Terms and abbreviations used

UL Underwriters Laboratories

Guide

2

[V]

U

DC

[V]

U

LN

[V]

U

M

VDE Verband deutscher Elektrotechniker

Xk/y Terminal y on terminal strip Xk (e.g. X3/28 = terminal 28 on terminal

DC voltage

Rated mains voltage

Output voltage / voltage on the motor terminals

strip X3)

EDS94SPP101 EN 7.1

21

Page 22

2

Guide

Total index

2.2 Total index

Zahlen

9400

- Features, 10

- System description, 10

A

Accessories, 335

- Brake resistors, 556

- General, 552

- Type-specific, 341

Address switch, 411

Application, as directed, 17

application as directed, 17

Application range, 388 , 403 , 408 , 466

Assignment of accessories, 339

B

Brake resistors, 556

Braking operation, in a drive system, 331

Bus c able length, 370

C

Cable specification, 377 , 384

Cables

- cross-section, 164

- fuse, 164

CAN port, 382

CE conformity, 17

Communication module, connections, 374 , 384

Communication modules, 342

- Overview, 301

Conformity, 17

Connection

- communication module connections, 374

- Connections of the communication module, 371

- Plug connector, 5-pole, 371

- Sub-D plug connector, 9-pin, 384

- Sub-D socket, 9-pin, 374

Connection plan, 423 , 433 , 441 , 447 , 455 , 462 , 495 ,

505 , 513 , 522 , 532 , 537 , 541 , 546 , 551 , 571

Connections, 346 , 349 , 355 , 359 , 363 , 368 , 373 , 379

, 383 , 463

Control terminals, 134 , 193 , 252

Controller

- application as directed, 17

- labelling, 17

D

DC-bus connection, Braking in, 331

DC-bus operation, 36 , 154 , 212 , 260 , 305

- accessories, 309

- Conditions, 310

- DC bus, 306

- DC-voltage level, 306

- Disconnecting the EMC filters from PE, 99 , 182 , 241 ,

290

- Multi-axis controllers, 306

- Power supply module, 306

- Regenerative power supply module, 306

- Several drives, 305

- Single-axis controllers, 306

Definition of notes used, 32

Definitions, Terms, 20 , 306

Device features, 34

Device protection, 31 , 94 , 134 , 179 , 193 , 252 , 296 ,

343 , 387

DeviceNet, 367

Dimensions, 235 , 282 , 366 , 440 , 453 , 473 , 480 , 493 ,

495 , 501 , 511 , 519 , 528 , 536 , 540 , 545 , 550 , 563 ,

567

Disposal, 27

E

Electrical installation, wiring of control connections, 296

Electrical isolation, 421

EMC filters, Disconnecting from PE, 99 , 182 , 241 , 290

Emergency operation, 43 , 159

EN 61000-3-2, 40 , 156

EtherCAT, 358

Ethernet, 345

Ethernet POWERLINK, 348

Ethernet POWERLINK hub, 362

Ethernet POWERLINK slave, 354

External voltage supply, 351 , 356 , 360 , 364 , 371 , 375 ,

380

F

Free space, 499 , 509 , 517 , 526

22

EDS94SPP101 EN 7.1

Page 23

Guide

Total index

2

Free spaces, 493

Function modules, 386

Fuses, 164

- Rated power operation, 400 V (UL), 62 , 63 , 221 , 222 ,

270

G

General accessories, 552

General data, 35 , 153 , 211 , 214 , 259 , 261 , 493 , 499 ,

509 , 517 , 526 , 535 , 539 , 544 , 549 , 560 , 562 , 566

Guide, 19

H

Harmonic currents, limitation according to EN 61000-3-2,

40 , 156

I

Identification, 345 , 348 , 354 , 358 , 362 , 367 , 372 ,

378 , 382 , 388 , 395 , 396 , 397 , 398 , 399 , 416 , 425 ,

435 , 442 , 448 , 456 , 463 , 465 , 477 , 492 , 498 , 508 ,

516 , 525 , 535 , 539 , 544 , 548 , 559 , 561 , 565

Increased continuous power, 52 , 59

Installation

- mechanical, 88 , 174 , 230 , 281

- standard device, 192

Interface, CAN, 382

IT system, Disconnecting the EMC filters from PE, 99 , 182 ,

241 , 290

L

Labelling, controller, 17

Legal regulations, 17

Liability, 18

M

Mains current

- with external mains choke, 46 , 49 , 50 , 56 , 57

- with/without mains choke, 46 , 49 , 50 , 56 , 57

Mains filter, 280 , 283

Manufacturer, 17

Mechanical installation, 88 , 174 , 230 , 281

Memory modules, 392

Monitoring functions, 419 , 429

Motor cable

- capacitance per unit length, 37 , 155

- requirements, 37 , 155

Motor holding brakes, Control module

- E94AZHN0025, 435

- E94AZHN0026, 448

- E94AZHX0051, 416

- E94AZHY0025, 442

- E94AZHY0026, 456

- E94AZHY0101, 425

Motorpower,typical,46,49,50,56,57

Motor protection, 31

Motors, suitable, 17

Mounting clearances, 35 , 153 , 212 , 260

Mounting conditions

- Dimensions, 493

- Free space, 499 , 509 , 517 , 526

- free space, 549

- Free spaces, 493

- mounting clearances, 436 , 449

- Mounting place, 493 , 499 , 509 , 517 , 526

- mounting place, 549

- Mounting position, 493 , 499 , 509 , 517 , 526

- mounting position, 436 , 449 , 549

- Weights, 493

Mounting place, 493 , 499 , 509 , 517 , 526

Mounting position, 35 , 153 , 212 , 260 , 493 , 499 , 509 ,

517 , 526

N

Nameplate data, 345 , 358 , 367 , 372 , 378 , 382 , 395 ,

396 , 397 , 399 , 416 , 425 , 435 , 442 , 448 , 456 , 463 ,

477 , 492 , 498 , 508 , 516 , 525 , 535 , 539 , 544 , 548 ,

559 , 561 , 565

Nameplate information, 348 , 354 , 362 , 388 , 465

Network of several driv es, Basic dimensioning, 324

Noise emission, 40 , 156

Noise immunity, 40 , 156 , 211 , 259

Notes, definition, 32

O

Operating conditions, 36 , 154 , 213 , 417 , 426 , 436 ,

443 , 449 , 457 , 478 , 558

- Mounting conditions

Dimensions, 493

Free space, 493 , 499 , 509 , 517 , 526

Mounting place, 493 , 499 , 509 , 517 , 526

Mounting position, 493 , 499 , 509 , 517 , 526

Weight, 493

EDS94SPP101 EN 7.1

23

Page 24

2

Guide

Total index

- mounting conditions

free space, 549

mounting clearances, 436 , 449

mounting place, 549

mounting position, 436 , 449 , 549

Operation with emergency voltage supply, 43 , 159

Operation with filters, Disconnecting the EMC filters from

PE, 99 , 182 , 241 , 290

Operation with increased continuous power, 52 , 59

Operation with power supply module, Disconnecting the

EMC filters from PE, 99 , 182 , 241 , 290

Output power, 46 , 49 , 50 , 56 , 57

output voltage, reduced, 44

output voltage , 44

Overspeeds, 31

Overview, Accessories, 335

P

Pluggable terminal strip, use, spring connection, 365

Pluggable terminal strips, use, 365

Possibledevicemodulecombinations, 344

Power regeneration

- Energy characteristics, 269

- Limit range, 268 , 269

- Power characteristics, 268

Product range, description, 10

Protection against accidental contact, 421

Protection of persons, 31

- Electrical isolation, 421

- Protection against accidental contact, 421

Protective insulation, 41 , 157

R

Rated data, 390 , 417 , 427 , 437 , 444 , 450 , 458 , 464 ,

466 , 479 , 494 , 500 , 510 , 518 , 527 , 536 , 540 , 544 ,

550 , 560 , 562 , 566

Requirements, motor cable, 37 , 155

Residual hazards, 31

S

Safety address, 411

Safety instructions, 23

- definition, 32

-layout,32

Safety modules, 399

Shield mounting, 553

- Alternative, 555

Shield mountings

- Accessories, 554

- Assignment, 554

- Clamping range, 554

- Scope of supply, 554

Signalling, 385

Specification of the transmission cable, 377 , 384

Standard device, installation, 192

Standards, 417 , 426 , 436 , 443 , 449 , 457 , 478 , 573

Step-by-step commissioning, 467

Sub-D plug connector, connections, 384

Sub-D socket, connections, 374

System description, 10

System overview, 10 , 337

T

Technical data

- features, 152

- standards, 417 , 426 , 436 , 443 , 449 , 457 , 478 , 573

Terminal data, 360 , 371 , 375 , 380 , 422 , 432 , 447 ,

454 , 461 , 496 , 503 , 504 , 512 , 520 , 530 , 537 , 541 ,

546 , 551 , 571

Terms

- controller, 20

- Definitions, 306

- definitions, 20

-drive,20

Total index, 22

Transmission cable, specification, 377 , 384

Type code, 345 , 348 , 354 , 358 , 362 , 367 , 372 , 378 ,

382 , 395 , 396 , 397 , 416 , 425 , 435 , 442 , 448 , 456 ,

463 , 465 , 477 , 492 , 498 , 508 , 516 , 525 , 535 , 539 ,

544 , 548 , 559 , 561 , 565

Type-specific accessories, 341

Typenschildangaben, 398

Typenschlüssel, 398

Types codes, 388

V

Voltage supply: external, 351 , 356 , 360 , 364 , 371 , 375

, 380

Preface, 9

24

EDS94SPP101 EN 7.1

Page 25

Guide

Total index

2

W

Warranty, 18

Weights, 493

Wiring of control connections, 296

EDS94SPP101 EN 7.1

25

Page 26

2

Guide

Total index

26

EDS94SPP101 EN 7.1

Page 27

Safety instructions 3

3 Safety instructions

3.1 General safety and application notes for Lenze controllers 28..................

3.2 General safety and application instructions for Lenze motors 32................

3.3 Residual hazards 35.....................................................

3.4 Notes used 36..........................................................

EDS94SPP101 EN 7.1

27

Page 28

3

Safety instructions

General safety and application notes for Lenze controllers

3.1 General safety and application notes for Lenze controllers

(in accordance with Low-Voltage Directive 2006/95/EC)

Foryourpersonalsafety

Disregarding the following safety measures can lead to severe injury to persons and

damage to material:

ƒ Only use the product as directed.

ƒ Nevercommissiontheproductintheeventofvisibledamage.

ƒ Never commission the product before assembly has been completed.

ƒ Do not carry out any technical changes on the product.

ƒ Only use the accessories approved for the product.

ƒ Only use original spare parts from Lenze.

ƒ Observe all regulations for the prevention of accidents, directives and laws

applicable on site.

ƒ Transport, installation, commissioning and maintenance work must only be carried

out by qualified personnel.

– Observe IEC 364 and CENELEC HD 384 or DIN VDE 0100 and IEC report 664 or

DIN VDE 0110 and all national regulations for the prevention of accidents.

– A ccording to the basic safety information, qualified, skilled personnel are persons

who are familiar with the assembly, installation, commissioning, and operation of

the product and who have the qualifications necessary for their occupation.

ƒ Observe all specifications in this documentation.

– This is the condition for safe and trouble-free operation and the achievement of

the specified product features.

– The procedural notes and circuit details described in this documentation are only

proposals. It is up to the user to check whether they can be transferred to the

particular applications. Lenze Automation GmbH does not accept any liability for

the suitability of the procedures and circuit proposals described.

ƒ Lenze controllers (frequency inverters, servo inverters, DC speed controllers) and the

accessory components can include live and rotating parts - depending on their type

of protection - during operation. Surfaces can be hot.

– Non-authorised removal of the required cover, inappropriate use, incorrect

installation or operation create the risk of severe injury to persons or damage to

material assets.

– For more information, please see the documentation.

28

ƒ High amounts of energy are produced in the controller. Therefore it is required to

wear personal protective equipment (body protection, headgear, eye protection, ear

protection, hand guard).

EDS94SPP101 EN 7.1

Page 29

Safety instructions

General safety and application notes for Lenze controllers

Application as directed

Controllers are components which are designed for installation in electrical systems or

machines. They are not to be used as domestic appliances, but only for industrial purposes

according to EN 61000-3-2.

When controllers are installed into machines, commissioning (i.e. starting ofthe operation

as directed) is prohibited until it is proven that the machine complies with the regulations

of the EC Directive 98/37/EC (Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting of the operation as directed) is only allowed when there is

compliance with the EMC Directive (2004/108/EC).

The controllers meet the requirements of the Low-Voltage Directive 2006/95/EC. The

harmonised standard EN 61800-5-1 applies to the controllers.

The technical data and supply conditions can be obtained from the nameplate and the

documentation. They must be strictly observed.

Warning: Controllers are products which can be i nstalled in drive systems of category C2

according to EN 61800-3.These products can cause radiointerferences inresidential areas.

In this case, special measures can be necessary.

Transport, storage

3

Please observe the notes on transport, storage, and appropriate handling.

Observe the climatic conditions according to the technical data.

Installation

The controllers must be installed and cooled according to the instructions given in the

corresponding documentation.

The ambient air must not exceed degree of pollution 2 according to EN 61800-5-1.

Ensure proper handling and avoid excessive mechanical stress. Do not bend any

components and do not change any insulation distances during transport or handling. Do

not touch any electronic components and contacts.

Controllers contain electrostatically sensitive devices which can easily be damaged by

inappropriate handling. Do not damage or destroy any electrical components since this

might endanger your health!

EDS94SPP101 EN 7.1

29

Page 30

3

Safety instructions

General safety and application notes for Lenze controllers

Electrical connection

When working on live controllers, observe the applicable national regulations for the

prevention of accidents (e.g. VBG 4).

The electrical installation must be carried out according to the appropriate regulations

(e.g. cable cross-sections, fuses, PE connection). Additional information can be obtained

from the documentation.

The documentation contains information on the installation according to EMC (shielding,

earthing, arrangement of filters, and installation of the cables). Also o bserve this

information with regard to drive controllers labelled with CE marking. The manufacturer

of the system or machine is responsible for the compliance of the limit values required in

connection with EMC legislation. In order to observe the limit values for radio interference

emissions effective at the installation site, you have to mount the drive controllers into

housings (e. g. control cabinets). The housingshave toenable an EMC-compliant structure.

Particularly observe that, for instance, control cabinet doors preferably are metallically

connected to the housing in a circumferential manner. Reduce openings or apertures

through the housing to a minimum.

Lenze controllers can cause a DC current in the PE conductor. If a residual current device

(RCD) is used for the protection in the case of direct or indirect contact on a three-phase

supplied controller, only one residual current device of type B is permissible on the current

supply side of the controller. If the controller is supplied with one phase, also a residual

current device (RCD) of type A may be used. Apart from the use of a residual current device

(RCD) also other protective measures can be used, like for instance isolation from the

environment by double or reinforced insulation or isolation from the supply system by a

transformer.

Operation

If necessary, systems including controllers must be equipped with additional monitoring

and protection devices according to the valid safety regulations (e.g. law on technical

equipment, regulations for the prevention of accidents). The controllers can be adapted to

your application. Please observe the corresponding information given in the

documentation.

After the controller has been disconnected from the supply voltage, all live components

and power connections must not be touched immediately because capacitors can still be

charged. Please observe the corresponding stickers on the controller.

All protection covers and doors must be shut during operation.

Notes for UL-approved systems with integrated controllers: UL warnings are notes that

only apply to UL systems. The documentation contains special UL notes.

Safety functions

Special controller variants support safety functions (e.g. ”safe torque off”, formerly ”safe

standstill”) according to the requirements of appendix I No. 1.2.7 of the EC Directive

”Machinery”98/37/EC, EN 954-1category 3 andEN 1037. Strictly observe thenotes on the

safety functions given in the documentation on the respective variants.

Maintenance and servicing

The controllers do not require any maintenance if the prescribed operating conditions are

observed.

30

EDS94SPP101 EN 7.1

Page 31

Safety instructions

General safety and application notes for Lenze controllers

Disposal

Recycle metals and plastics. Dispose of printed circuit board assemblies according to the

state of the art.

The product-specific safety and applicationnotesgivenintheseinstructionsmustbe

observed!

3

EDS94SPP101 EN 7.1

31

Page 32

3

3.2 General safety and application instructions for Lenze motors

Safety instructions

General safety and application i nstructions for Lenze motors

(According to: Low-Voltage Directive 2006/95/EC)

General

Low-voltage machines have hazardous live and rotating parts and possibly also hot

surfaces.

Synchronous machines induce voltages at open terminals during operation.

All operations concerning transport, connections, commissioning and maintenance must

be carried out by qualified, skilled personnel (EN 50110-1 (VDE 0105-100) and IEC 60364

must be observed). Inappropriate use creates the risk of severe injury to persons and

damage to material assets.

Low-voltage machines may only be operated under the c onditions that are indicated in the

section ”Application as directed”.

The conditions at the place of installation must comply with the data given on the

nameplate and in the documentation.

Application as directed

Low-voltage machines are intended for commercial installations. They comply with the

harmonised standards of the series EN 60034 (VDE 0530). Their use in potentially

explosive atmospheres is prohibited unless they are expressly intended for such use

(follow additional instructions).

Low-voltage machines are components for installation into machines as defined in the

Machinery Directive 2006/42/EC. Commissioning is prohibited until the conformity of the

end product with this directive has been established (follow i.a. EN 60204-1)

Low-voltage machines with IP23 protection orless are only intended for outdoor use when

applying special protective features.

The i ntegrated brakes must not be used as safety brakes.It cannot be ruledout that factors

which cannot be influenced, such as oil ingress due to a defective A-side shaft seal, cause

a brake torque reduction.

Transport, storage

Damages must be reported immediately upon receipt to the forwarder; if required,

commissioning must be excluded. Tightenscrewed-in ring boltsbefore transport. Theyare

designed for the weight of the low-voltage machines, do not apply extra loads. If

necessary, use suitable and adequately dimensioned means of transport (e. g. rope

guides).

Remove transport locking devices before commissioning. Reuse them for further

transport. When storing low-voltage machines, ensure a dry, dust-free and low-vibration

(v

≤ 0.2 mm/s) environment (damages while being stored).

eff

32

EDS94SPP101 EN 7.1

Page 33

Safety instructions

General safety and application i nstructions for Lenze motors

Installation

Ensure an even surface, solid foot and flange mounting and exact alignment if a direct

clutch is connected. Avoid resonances with the rotational frequency and double mains

frequency which may be caused by the assembly. Turn rotor by hand, listen for unusual

slipping noises. Check the direction of rotation when the clutch is not active (observe

section ”Electrical connection”).

Use appropriate means to mount or remove belt pulleys and clutches (heating) and cover

them with a touch guard. Avoid impermissible belt tensions.

The machines are half-key balanced. The clutch must be half-key balanced, too. The visible

jutting out part of the key must be removed.

If required, provide pipe connections. Designs with shaft end at bottom must be protected

with a cover which prevents the ingress o f foreign particles into the fan. Free circulation of

the cooling air must be ensured. The exhaust air - also the exhaust air of other machines

next to the drive system - must not be taken in immediately.

Electrical connection

3

All operations must only be carried out by qualified and skilled personnel on the

low-voltage machine at standstill and deenergised and provided with a safe guard to

prevent an unintentional restart.This also applies to auxiliary circuits (e. g. brake, encoder,

blower).

Check safe isolation from supply!

If the tolerances specified in EN 60034-1; IEC 34 (VDE 0530-1) - voltage ±5 %, frequency

±2 %, waveform, symmetry - are exceeded, m ore heat will be generated and the

electromagnetic compatibility will be affected.

Observe the data on the nameplate, operating notes, and the connection diagram in the

terminal box.

The connection must ensure a continuous and safe electrical supply (no loose wire ends);

use appropriate cable terminals. The connection to the PE conductor must be safe. The

plug-in connector must be bolt tightly (to stop).

The clearances between blank, live parts and to earth must not fall below 8 mm at

U

≤ 550 V, 10 mm at Ur≤ 725 V, 14 mm at Ur≤ 1000 V.

r

The terminal box must be free of foreign particles, dirt and moisture. All unused cable

entries and the box itself must be sealed against dust and water.

EDS94SPP101 EN 7.1

33

Page 34

3

Safety instructions

General safety and application i nstructions for Lenze motors

Commissioning and operation

Before commissioning after longer storage periods, measure the insulation resistance. In

case of values ≤ 1kΩ per volt of rated voltage, dry winding.

For trial run without output elements, lock the featherkey. Do not deactivate the

protective devices, not even in a trial run.

Check the correct operation of the brake before commissioning low-voltage machines

with brakes.

Integrated thermal detectors do not provide full protection for the machine. If necessary,

limit the maximum current. Parameterisethe controller so that the motor will be switched

off with I > I

Vibrational severities v

if the clutch is activated.

If deviations from normal operation occur, e.g. increased temperatures, noises, vibrations,

find the cause and, if required, contact the manufacturer. In case of doubt, switch off the

low-voltage machine.

after a few seconds of operation. especially at the risk of blocking.

r

≤ 3.5 mm/s (Pr≤ 15 kW) or 4.5 mm/s (Pr> 15 kW) are acceptable

eff

If the machine is exposed to dirt, clean the air channels regularly.

Shaft sealing rings and roller bearings have a limited service life.

Regrease bearings with relubricating devices while the low-voltage machine is running.

Only use the grease recommended by the manufacturer. If the grease drain holes are

sealed with a plug, (IP54 drive end; IP23 drive and non-drive end), remove plug before

commissioning. Seal bore holes with grease. Replace prelubricated bearings (2Z bearing)

after approx. 10,000 h - 20,000 h, at the latest however after 3 - 4 years.

The product-specific safety and applicationnotesgivenintheseinstructionsmustbe

observed!

34

EDS94SPP101 EN 7.1

Page 35

3.3 Residual hazards

Protection of persons

ƒ Before working on the controller, check that no voltage is applied to the power

terminals, because

–dependingonthecontroller-thepowerterminalsU,V,W,+UG,-UG,Rb1andRb2

carry hazardous voltages for up to 3 to 20 minutes after mains disconnection.

– the power terminals L1, L2, L3; U, V, W, +UG, -UG, Rb1 and Rb2 carry hazardous

voltages when the motor is stopped.

Device protection

ƒ Plug on or pull off all pluggable terminals only in deenergised condition!

ƒ Detach the controllers only in deenergised conditions from their installation

backplanes or the back panel of the control cabinet!

ƒ Cyclic switching on and off of the mains voltage can overload and destroy the input

current limitation of the controller:

– Cyclic mains switching of 5-times in 5 minutes is permissible without restrictions.

Safety instructions

Residual hazards

3

Motor protection

ƒ Depending on the controller settings, the connected motor can be overheated by:

– For instance, longer DC-braking operations.

– Longer operation of self-ventilated motors at low speed.

Protection of the machine/system

ƒ Drives can reach dangerous overspeeds (e.g. setting of high output frequencies in

connection with motors and machines unsuitable for such conditions):

– The controllers do not offer any protection against such operating conditions. Use

additional components for this purpose.

EDS94SPP101 EN 7.1

35

Page 36

3

3.4 Notes used

Safety instructions

Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Special safety instructions and application notes for U L and UR

Pictograph and signal word Meaning

Warnings!

Warnings!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

Safety or application note for the operation of a UL-approved

device in UL-approved systems.

Possibly the drive system is not operated in compliance with UL

if the corresponding measures are not taken.

Safety or application note for the operation of a UR-approved

device in UL-approved systems.

Possibly the drive system is not operated in compliance with UL

if the corresponding measures are not taken.

36

EDS94SPP101 EN 7.1

Page 37

Single-axis controllers 4

4 Single-axis controllers

4.1 Device features 38......................................................

4.2 General data and operating conditions 39.................................

4.3 Rated data (devices for 400/500V mains) 47.................................

4.3.1 Overview 47....................................................

4.3.2 Operation at rated mains voltage 230 V 50..........................

4.3.3 Operation at rated mains voltage 400 V 53..........................

4.3.4 Operation at rated mains voltage 500 V 60..........................

4.3.5 Fuses and cable cross-sections 66..................................

4.3.6 Overcurrent operation 68.........................................

4.3.7 Current-time diagrams 75........................................

4.4 Device description 85....................................................

4.4.1 Devices in the range 2 ... 24 A (0.37 ... 11 kW) 86......................

4.4.2 Devices in the range 32 ... 104 A (15 ... 55 kW) 88.....................

4.4.3 Devices in the range 145 ... 695 A (75 ... 370 kW) 90...................

4.5 Mechanical installation 92................................................

4.5.1 Important notes 92..............................................

4.5.2 Devices in the range 2 ... 24 A (0.37 ... 11 kW) 92......................

4.5.3 Devices in the range 32 ... 104 A (15 ... 55 kW) 95.....................

4.5.4 Devices in the range 145 ... 366 A (75 ... 200 kW) 96...................

4.5.5 Devices in the range 460 ... 695 A (250 ... 400 kW) 97..................

4.6 Wiring 98..............................................................

4.6.1 Important notes 98..............................................

4.6.2 Safety notes for the installation according to UL or UR 100.............

4.6.3 Earthing of internal EMC filters 103.................................

4.6.4 Devices in the range 2 ... 24 A (0.37 ... 11 kW) 107......................

4.6.5 Devices in the range 32 ... 104 A (15 ... 55 kW) 116.....................

4.6.6 Devices in the range 145 ... 695 A (75 ... 370 kW) 121...................

4.7 Control terminals 138.....................................................

EDS94SPP101 EN 7.1

37

Page 38

4

Single-axis controllers

Device features

4.1 Device features

ƒ Space-saving installation by compact design

ƒ Innovative installation concept

ƒ Power range: 370 W to 400 kW

ƒ Pluggable and uniform connection for control cables over the complete power range

ƒ Direct AC mains connection for ”Single Drive” design

ƒ DC busbar integrated or can be retrofit

(fordevicesupto24A/11kW)

ƒ Integrated brake chopper

ƒ Direct connection of resolver or encoder feedback

– Easy connection via predesigned system cable (accessories)

ƒ Integrated phase controller for drift-free standstill

ƒ Field-oriented control for asynchronous and synchronous motors

ƒ Digital synchronisation system via bus system or

digital frequency (extension module required)

ƒ User configuration for control functions and input/output signals

– Comprehensive library with function blocks

– High flexibility with regard to the adaptation of the internal control structure to

the drive task

ƒ Extension interfaces for

– Communication

– Controller functionality

– Safety engineering

ƒ System bus (CANopen) for

– servo inverter connection

– input and output terminal extensions

– connecting keypad and display units (HMI)

38

EDS94SPP101 EN 7.1

Page 39

General data and operating conditions

4.2 General data and operating conditions

General data

Conformity and approval

Conformity

CE

Approval

UL UL 508C Power Conversion Equipment, File No. 132659

GOST-R 51321.1-2000

Protection of persons and devices

Enclosure

Insulation resistance EN 61800-5-1 Overvoltage category III

Insulation of control

circuits

Short-circuit strength EN 61800-5-1 Motor connection: with restrictions, error acknowledgement

Motor - protective

measures against

Discharge current EN 61800-5-1 > 3.5 mA AC, > 10 mA DC Observe regulations and

Cyclic mains switching Cyclic mains switching of 5 times in 5 minutes is permissible

2006/95/EC Low-voltage directive

51321.3-99

EN 60529

NEMA 250 Protection against contact in

EN 61800-5-1 Safe mains isolation by double/reinforced insulation for

Single-axis controllers

No. POCC DE.AN30.B08815

IP 20

accordance with type 1

Reduction from 2000 m amsl onwards: Overvoltage category

II

mains with neutral earthing with a rated voltage for the

external conductor/star point up to 300 V.

required

Control connections: without restrictions

z Short circuit

z Earth fault

z Overvoltage

z Motor stalling

z Motor overtemperature

(PTC or thermal contact, I

without restrictions.

Not in the wire range of

the terminals on the

motor side

2

t monitoring)

safety instructions!

4

EDS94SPP101 EN 7.1

Design

Housing

Carrier housing

Carrier housing Device sizes

Dimensions see ”Mechanical installation”

Weight see ”Mechanical installation”

Mounting conditions

Mounting place

Mounting position Vertical

Mounting clearances

Above/below ≥ 80 mm / ≥ 120 mm

To the sides Side-by-side mounting without

Device sizes

1, 2 and 3

as of 6

Glass-fiber reinforced plastic

Metal

In the control cabinet

any clearance

Observe the device-related

notes on mounting.

39

Page 40

4

Single-axis controllers

General data and operating conditions

”Single Drive”

supply conditions

AC-mains operation

DC-bus operation Direct connection via terminals or busbars(can be retrofitted)

Power systems

TT

TN

With grounded phase Operation with additional measures permitted:

IT Additional device-internal measure required (see (”Earthing

Motors EN 60034 Only use motors suitable for inverter operation. Insulation

Direct connection

For more information, please see the chapter DC-bus

operation.

Operation permitted without restrictions.

z Overvoltage must be reduced to overvoltage category II

according to EN 61800-5-1.

z Measures described for IT systems must be applied.

of internal EMC filters”, 103)

resistance: max. û ≥ 1.5 kV, max. du/dt ≥ 5kV/μs

Operating conditions

Environmental conditions

Climate

Storage

Transport IEC/EN 60721-3-2 2K3 (-25 ... +70 °C)

Operation IEC/EN 60721-3-3 3K3 (-10 ... +55 °C)

Site altitude 0 ... 4000 m amsl

Pollution EN 61800-5-1 Degree of pollution 2

Vibration resistance (9.81 m/s

Transport

Operation

IEC/EN 60721-3-1 1K3 (-25 ... +60 °C)

Current derating at +45 ... +55 °C:

Device size 1 ... 7: 2.5 %/°C

Device size 8S ... 10: 1 %/°C

1000 ... 4000 m amsl: current derating of 5 %/1000 m

2

=1g)

IEC/EN 60721-3-2 2M2

EN 61800-2

Germanischer Lloyd 5...13.2Hz:amplitude±1mm

IEC/EN 60068-2-6

2...9Hz:amplitude3.5mm

10 ... 200 Hz: acceleration resistant up to 10 m/s

200 ... 500 Hz: acceleration resistant up to 15 m/s

13.2 ... 100 Hz: acceleration resistant up to 0.7 g

10 ... 57 Hz: amplitude 0.075 mm

57 ... 150 Hz: acceleration resistant up to 1 g

2

2

40

EDS94SPP101 EN 7.1

Page 41

Single-axis controllers

General data and operating conditions

General electrical data

Motor cable requirements

Capacitance per unit length

2

≤ 2.5 mm

≥ 4mm2/AWG 12 C

Electric strength

Maximum motor and feedback cable lengths

(for shielded motor cable with rated mains voltage)

Type Device size [m]

E94AMxE0024

E94AMxE0034

E94AMxE0044

E94ASxE0024

E94ASxE0034

E94AMxE0074

E94AMxE0094

E94ASxE0044

E94ASxE0074

E94AMxE0134

E94AMxE0174

E94AMxE0244

E94AMxE0324 3 100

E94ASxE0134

E94ASxE0174

E94ASxE0244

E94ASxE0324

E94ASxE0474

E94ASxE0594

E94ASxE0864

E94ASxE1044

E94ASxE1454 8S 150

E94ASxE1724

E94ASxE2024

E94ASxE2454

E94ASxE2924

E94ASxE3664

E94ASxE4604

E94ASxE5724

E94ASxE6354

E94ASxE6954

If EMC conditions must be met, the permissible cable lengths can be reduced.

Tab. 4-1

/AWG 14 C

VDE 0250-1 U0/U=0.6/1.0 kV

UL U ≥ 600 V

1

2 100

3 100

3 100

6 100

7 100

8 150

9 150

10 150

Core/core/CCore/shield

Core/core/CCore/shield

(U0= r.m.s. value of external conductor to PE,

U = r.m.s. value of external conductor to external conductor)

(U = r.m.s. value of external conductor to external conductor)

< 75/150 pF/m

< 150/300 pF/m

4

50

EDS94SPP101 EN 7.1

41

Page 42

4

Single-axis controllers

General data and operating conditions

Max. shielded motor cable lengths for compliance with

Type with RFI filter with mains filter without filter

E94ASxE0024

E94ASxE0034

E94ASxE0044

E94ASxE0074

E94ASxE0134

E94ASxE0174

E94ASxE0244 E94AZMS0314

E94ASxE0324

E94ASxE0474

E94ASxE0594

E94ASxE0864

E94ASxE1044

E94ASxE1454

E94ASxE1724

E94ASxE2024

E94ASxE2454

E94ASxE2924

E94ASxE3664

E94ASxE4604

E94ASxE5724

E94ASxE6354

E94ASxE6954

E94AZRS0044

-/50 m

E94AZRS0104

-/50 m

E94AZRS0294

-/50 m

E94AZRS0544

50 m/100 m

E94AZRS0954

50 m/100 m

- -

EMC protection requirement C1/C2

E94AZMS0034

25 m/50 m

E94AZMS0094

25 m/100 m

E94AZMS0184

25 m/100 m

25 m/100 m

-

-

-/10 m

-/10 m

-/10 m

-/10 m

-/50 m

-/50 m

-/150 m

Tab. 4-2

EMC limit value class for conducted noise emission in TN/TT systems:

C2 to EN 61800-3 corresponds to class A to EN 55011

C1 to EN 61800-3 corresponds to class B to EN 55011

42

EDS94SPP101 EN 7.1

Page 43

Single-axis controllers

General data and operating conditions

Longer motor cables can be achieved when line filters are used in combination with

sinusoidal filters. Further conditions to be observed:

ƒ V/f control mode

ƒ Switching frequency is permanently set (C00018)

Motor cable lengths when sinusoidal filters and line filters are used

Compliance with the EMC protection requirement C2

Type

E94ASxE0024

E94ASxE0034

E94ASxE0044

E94ASxE0074

E94ASxE0134

E94ASxE0174

E94ASxE0244 - E94AZMS0314 EZS3-037A200

E94ASxE0324

E94ASxE0474 EZS3-061A200

E94ASxE0594 EZS3-072A200

E94ASxE0864

E94ASxE1044

E94ASxE1454 - - EZS3-180A200

E94ASxE1724 - - EZS3-250A200

E94ASxE2024 - - EZS3-250A200

E94ASxE2454 - - EZS3-350A200

E94ASxE2924 - - EZS3-350A200

E94ASxE3664 - - EZS3-480A200

E94ASxE4604

E94ASxE5724

E94ASxE6354

E94ASxE6954

Tab. 4-3

EMC limit value class for conducted noise emission in TN/TT systems:

C2 to EN 61800-3 corresponds to class A to EN 55011

RFI filter Mains filter Sinusoidal filter shielded

-

-

- E94AZMS0184 EZS3-024A200

E94AZRS0544 -

E94AZRS0954 -

- -

- -

- -

- -

E94AZMS0034 EZS3-004A200

E94AZMS0094 EZS3-010A200

EZS3-048A200

EZS3-115A200

EZS3-150A200

EZS3-350A200

(2 in parallel)

EZS3-480A200

(2 in parallel)

EZS3-480A200

(2 in parallel)

EZS3-350A200

(3 in parallel)

unshielded

100 m

300 m

150 m

300 m

150 m

300 m

150 m

-m

Switching

frequency

4kHz

or

8kHz

4kHz

or

8kHz

2kHz

or

4kHz

2kHz

or

4kHz

4

EDS94SPP101 EN 7.1

43

Page 44

4

Single-axis controllers

General data and operating conditions

EMC

Operation on public supply

systems

Noise emission, in cables

Design

”Single Drive”

Design

”Multi Drive”

Noise immunity (to EN 61800-3)

Electrostatic discharge

(ESD)

Radio frequency

Cable-guided EN 61000-4-6 150 kHz ... 80 MHz, 10 V 80 % AM (1 kHz)

Interference (housing) EN 61000-4-3 80 MHz ... 1000 MHz, 10 V/m 80 % AM (1 kHz)

Burst

Power terminals and

interfaces

Signal interfaces EN 61000-4-4 1kV/5kHz

Control connections EN 61000-4-4 2kV/5kHz

Surge (surge voltage)

Power terminals EN 61000-4-5 1.2/50 μs,

EN 61800-3

EN 61800-3 see Tab. 4-2 EMC protection requirements

EN 61000-4-2 8 kV with air discharge,

EN 61000-4-4 2kV/5kHz

The controllers are designed for use in an industrial

environment. Operation on public networks requires

measures to be taken for limiting the expected emission of

radio interferences.

Depending on the filter at the central DC supply module.

4 kV with contact discharge against housing

1 kV phase/phase, 2 kV phase/PE

44

EDS94SPP101 EN 7.1

Page 45

Protective insulation

Danger!

Operation of the controller o n a phase earthed mains with a rated mains

voltage of ≥ 400 V:

ƒ The protection against accidental contact is not ensured without external

measures.

ƒ If protection against accidental contact acc. to EN 61800-5-1 is required for

the control terminals of the controller and the terminals for the plugged-in

device modules,

– an additional basic insulation must be available.

– the components to be connected must have the second basic insulation.

Danger!

Dangerous electrical voltage

When one common voltage source is used for control voltages in separate

potential areas, the protective insulation between the separate potential areas

is deactivated.

Possible consequences:

ƒ The specified protective insulations are not complied with.

Protective measures:

ƒ Use independent voltage sources.

Single-axis controllers

General data and operating conditions

4

EDS94SPP101 EN 7.1

45

Page 46

4

Single-axis controllers

General data and operating conditions

The available protective insulation within the controller of the ” 9400 Servo Drives” series

in accordance with EN 61800-5-1 is implemented with a rated voltage for the external

conductor/star point of up to 300 V for mains with neutral earthing.

The following graphic representation

ƒ shows the arrangement of the terminal strips and the separate potential areas of

the controller.

ƒ serves to determine the relevant protective insulation between two terminals in

differently insulated separate potential areas.

X2

X1

X100

X3

MXI1

X4

MXI2

X5

Bus

Ext. DC

Protective insulation acc. to

EN 61800-5-1

(Definition of terms: s ee glossary)

Functional insulation

X6X6

X107

X106

X105X105

Terminal strip Terminal Terminal strip Terminal

X100 z L1, L2, L3 (only single drive)

X105 z U, V, W

X106 Motor PTC X4 Digital outputs

X107 Control of motor holding

X7X7

X8X8

MMI

MSI

I/O

Ext. DC

z +UG, -UG

z Rb1, Rb2 (only single drive)

brake

Basic insulation

Reinforced insulation

X1 CAN on board 9400

X2

X3 Analog input/output

X5 Digital inputs

X6 Diagnostics

X7 Resolver

X8 Encoder

MXI1, MXI2 Extension module

MMI Memory module

MSI Safety module

z State bus

z 24 V (ext.)

Example

E94YCXX007zl

46

Which typeof protective insulation is used between the bus terminal of the device module

in slot MXI1 or MXI2 and the mains terminal X100?

The separate potential area with the better protective insulation is decisive.

ƒ The separate potential area of the device module bus terminal is ”functionally

insulated”.

ƒ The separate potential area of the mains terminal has a ”reinforced insulation”.

Result: The insulation between the mains terminal X100 and the bus terminal is of the

”reinforced insulation” type.

EDS94SPP101 EN 7.1

Page 47

Rated data (devices for 400/500V mains)

4.3 Rated data (devices for 400/500V mains)

The E94ASxExxx4 devices can be used in the voltage range of 180 V ... 550 V AC.

Note!

To ensure a faultless operation of the devices the code C00173 must be set

according to the mains voltage connected.

Emergency operation

Operation of the E94ASxxxx4 devices with an emergency voltage supply at +UG, -UG, is

possible from U

accordingly.

Operation of the E94AMxxxx4 devices with an emergency voltage supply at +UG, -UG, is

possible with U

accordingly. A 24-V supply at X2 is required.

≥ 260 V. The settings in C00173 and C00174 are to be adapted

DC

≤ 260 V. The settings in C00173 and C00174 are to be adapted

DC

Single-axis controllers

Overview

4

4.3.1 Overview

Input data

E94ASxE0024 230/400/500 50/60 2.1/2.1/1.8 1.6/1.6/1.4 3