Page 1

LanciaKappa2.0Sedan

1995,107Kw,Petr ol

Page 2

Technical

data

Page 3

Notes Specified value Measured value

Vehicle identification

No. of cylinders Type 5/DOHC

Capacity (Fiscal) cc 1998

Compression ratio :1 10,0

Suitable for unleaded petrol Yes

Minimum octane rating RON 95

Ignition system Type Motronic

Ignition system Description Map-DI

Trigger location Cam/ Crankshaft

Fuel system Make Bosch

Fuel System Type Motronic M2.10

Fuel System Description MFI-s

Air metering Type Mass

Combined ignition and fuel ECM Yes

Diagnostic socket Yes

Ignition system

Ignition coil Make Bosch

Ignition coil Type 0 221 152 067

Ignition coil supply voltage + with ballast V 11,0

Primary resistance Ohm 0,4

Secondary resistance Ohm 8500

Firing order 1-2-4-5-3

Tuning and emissions

Ignition timing - basic BTDC °Engine/rpm Not adjustable

Ignition advance checks °Engine/rpm ECM Controlled

Idle speed rpm Not adjustable

Oil temperature for CO test °C 60

CO level at idle speed - tailpipe (Cat) Vol. % CO 0,35 Max Not adjustable

CO level at idle speed - sample pipe Vol. % CO 0,4±0,1

HC level at idle speed ppm 90 Max

CO2 level at idle speed Vol. % CO2 13 Min

O2 level at idle speed Vol. % O2 0,1-0,5

Increased idle speed for CO test rpm 2500-2900

CO content at increased idle speed Vol. % 0,3

Lambda at increased idle λ 0,97-1,03

Spark plugs

Spark plugs Original equipment Champion

Spark plug Type RC7BMC

Electrode gap mm 0,5

Spark plugs Make Autolite

Spark plug Type APP3922

Electrode gap mm 0,9

Spark plugs Make Beru

Spark plug Type 14FR-6LDU

Electrode gap mm 0,8

Spark plugs Make Champion

Spark plug Type RC7BMC

Electrode gap mm 0,5

Spark plugs Make NGK

Spark plug Type BKR6EKC

Electrode gap mm 0,9

Fuel system

System pressure without vacuum bar 3,0

RPM/TDC sensor Ohm 774-946

Oxygen sensor heater Ohm 2,5-4,5

Service checks and adjustments

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 4

Valve clearance -INLET mm 0,38±0,04 cold

Valve clearance -EXHAUST mm 0,43±0,04 cold

Oil pressure bar/rpm 4,0/4000

Lubricants and capacities

Engine oil grade - moderate climate SAE 15W/40

Engine oil classification API/ACEA SG/A2-96

Engine oil grade - alternative - moderate climate SAE 10W/30 Semi-Synth.

Engine oil classification - alternative - moderate climate API/ACEA SG/A3-96

Engine with filter litres 5,4

Gearbox oil grade SAE 75W/90

Gearbox 4/5 speed litres 2,0

Cooling system litres 8,3

Brake fluid Type DOT 3/4

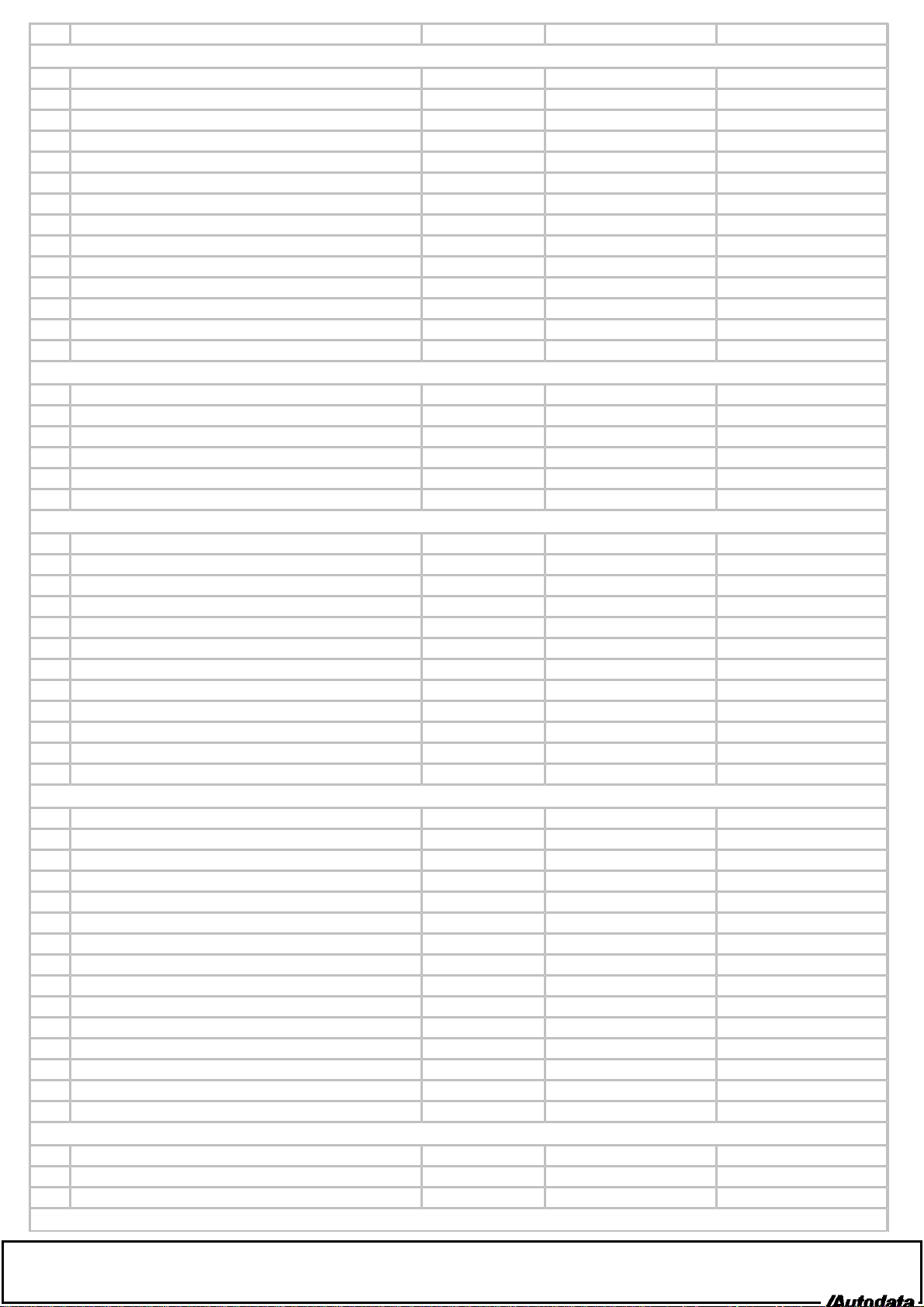

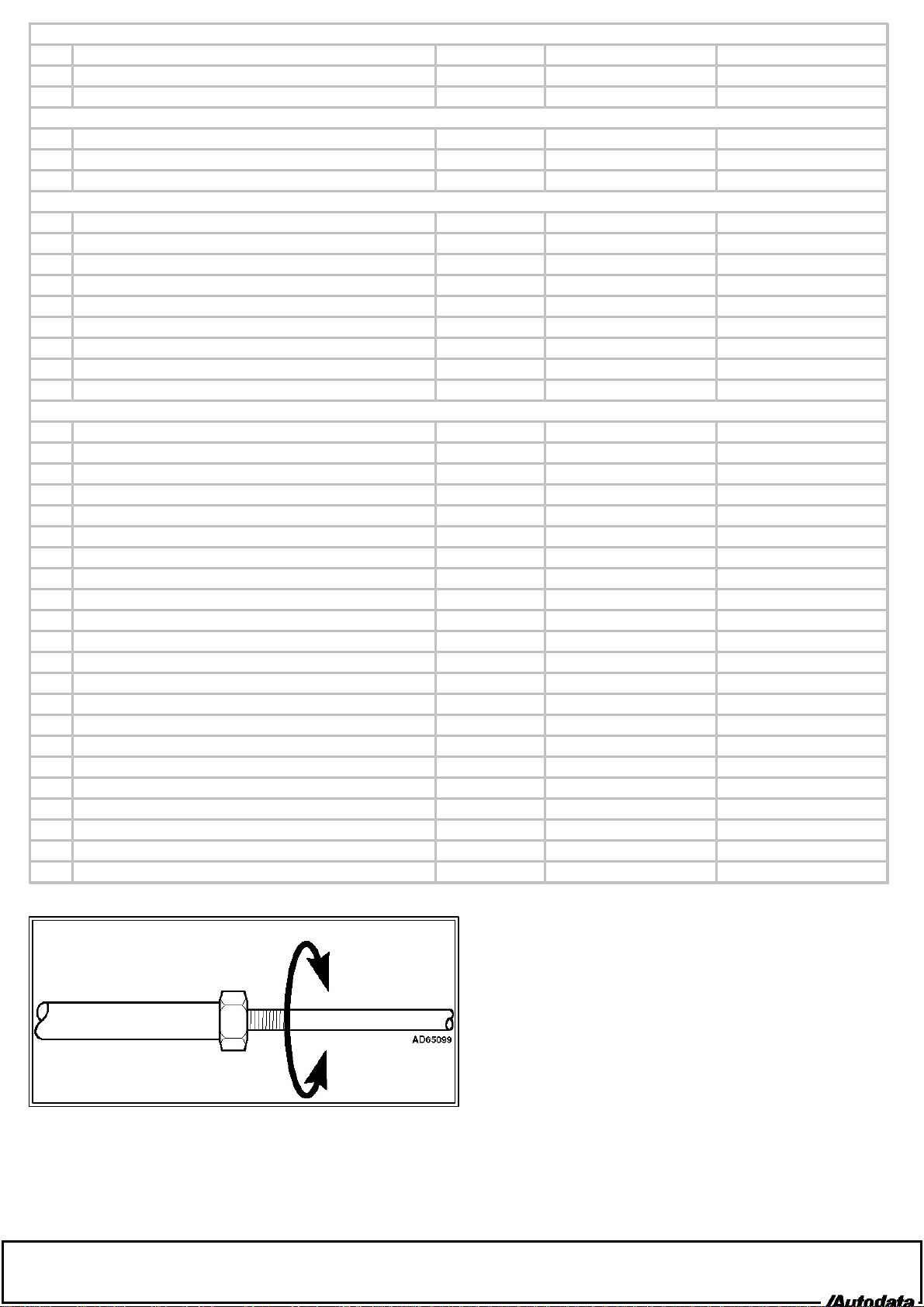

Tightening torques

Cylinder head instructions

Cylinder head

Renew bolts No

Stage 1 Tighten 40 Nm

Stage 2 Tighten 90°

Stage 3 Tighten 90°

Stage 4 Tighten 90°

Other tightening torques

Main bearings Renew bolts/nuts No

Main bearings Stage 1 25 Nm

Main bearings Stage 2 100°

Big end bearings Renew bolts/nuts No

Big end bearings Stage 1 25 Nm+60°

Oil pump to cylinder block 9 Nm

39 Sump bolts

Sump drain bolt 20 Nm

Flywheel/driveplate 160 Nm

Crankshaft pulley/damper 360 Nm

Camshaft sprocket/gear 118 Nm

Camshaft/rocker cover 8 Nm

Inlet manifold to cylinder head 25 Nm

Exhaust manifold to cylinder head 25 Nm

Spark plugs 27 Nm

Engine coolant temperature (ECT) sensor 20 Nm

Oxygen sensor (Lambda) 50-60 Nm

Knock sensor (KS) 25 Nm

Engine oil pressure switch 22 Nm

Front hub 60 Nm+52°

Rear hub 320 Nm

Steering track rod end 38 Nm

Brake disc to hub Front 20 Nm

Brake caliper carrier to hub Front 160 Nm

Brake disc to hub Rear 12 Nm

Brake caliper carrier to hub Rear 55 Nm

ABS sensor Front 10 Nm

ABS sensor Rear 10 Nm

Road wheels 98 Nm

Starting and charging

Battery V/RC(Ah) 12/90 (60)

Starter motor Make Marelli

Starter motor Type E70R-12v-1,4kW

Minimum starting voltage V 8,1

Maximum cranking amps A 162-198

Alternator/Regulator Make Marelli

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 5

Alternator/Regulator Type A127I

Alternator output at engine speed A/V/rpm 100/14/3500

Voltage regulator Type 24TR/B

Regulated voltage V 14,3-14,6

Brake disc and drum dimensions

Minimum disc thickness - ventilated Front 20,2 mm

Minimum disc thickness Rear 9,2 mm

Disc runout Front 0,15 mm

Disc runout Rear 0,15 mm

Minimum pad thickness Front 1,5 mm

Minimum pad thickness Rear 1,5 mm

Handbrake travel No. of notches 5-6

Air conditioning

Air conditioning refrigerant Type R134a

32 Air conditioning refrigerant quantity grams

33 Air conditioning oil Type

38 Air conditioning oil quantity cmł

Cylinder layout Tightening sequence

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 6

Wheelalignment

Page 7

Kappa 1995-02

Rim size Tyre size Model Front bar(psi) Rear bar(psi)

4x15 125/90 R 15 96M 4,2 (60) 4,2 (60)

6,5x15 195/65 R 15 91V 2,2 (31) 2,2 (31)

6,5x15 205/60 R 15 91V 2,2 (31) 2,2 (31)

6,5x15 205/60 R 15 91W 2,2 (31) 2,2 (31)

6,5x16 205/55 R 16 89W 2,2 (31) 2,2 (31)

7,5x16 205/55 R 16 91W 2,2 (31) 2,2 (31)

7,5x16 215/55 R 16 91W 2,2 (31) 2,2 (31)

Telephone:

Fax:

VAT Registration No.:

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.12.02.

V5.500-

Page 8

Dimensions

Notes Specified value Measured value

Wheelbase mm 2700

Track - front/rear mm 1546/1527

Tightening torques

Notes Specified value Measured value

Tightening torque - steel wheels 98 Nm

Tightening torque - alloy wheels 98 Nm

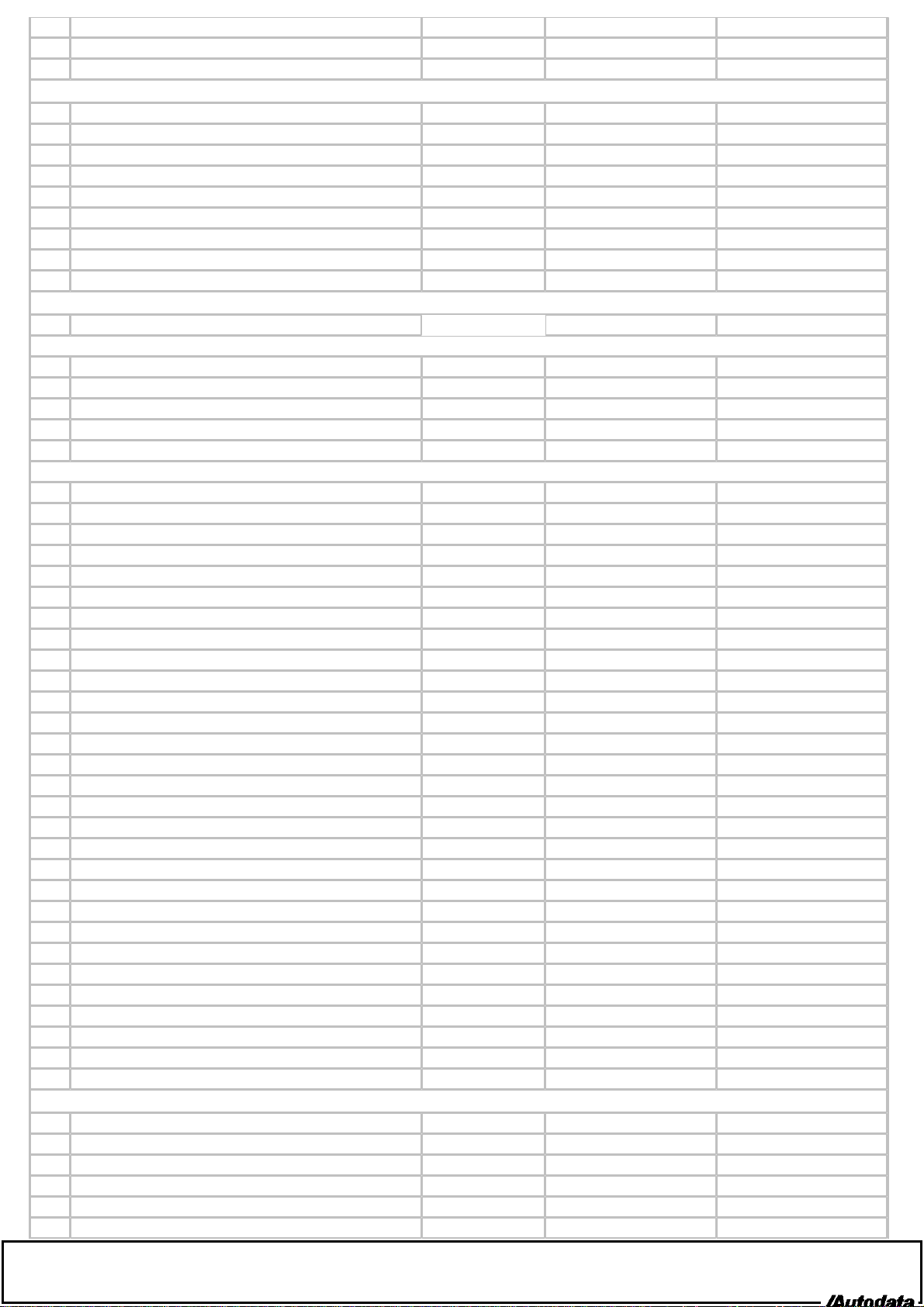

Checking range - Front wheels

Notes Specified value Measured value

Load positioning unladen

Toe-in (N = negative, toe-out) mm 0 - 2

Toe-in deg 0° - 0°20'

Toe-in deg-1/100 0 - 0,33

Camber deg 0°35'N - 1°15'N

Camber deg-1/100 0,58N - 1,25N

Castor deg 2°50' - 3°30'

Castor deg-1/100 2,83 - 3,50

Setting data - Four wheels

Notes Specified value Measured value

Load positioning unladen

Toe-in (N = negative, toe-out) mm 1±1

Toe-in deg 0°10'±10'

Toe-in deg-1/100 0,17±0,17

Camber deg 0°55'N±20'

Camber deg-1/100 0,92N±0,33

Camber adjustment Not adjustable

Castor deg 3°10'±20'

Castor deg-1/100 3,17±0,33

Castor adjustment Not adjustable

Lock angles - max. inner deg 37°±30'

Lock angles - max. inner deg-1/100 37±0,50

Lock angles - max. outer deg 32°40'

Lock angles - max. outer deg-1/100 32,67

Rear toe-in mm 2,5±1

Rear toe-in deg 0°23'±10'

Rear toe-in deg-1/100 0,38±0,17

Rear toe-in adjustment $ADJ

Rear camber deg 0°45'N±20'

Rear camber deg-1/100 0,75N±0,33

Rear camber adjustment Not adjustable

Rear toe-in adjustment

Manufacturer:

Engine code:

Tuned for:

Lancia

838A1.000

R-Cat

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 9

Timingbelt

replacement

intervals

Page 10

Important note

Important note

The intervals and procedures given are subject to alteration by the manufacturer at any time.

Check the regularly updated Timing Belts section on our website to ensure that you are kept

informed of any changes that may occur between issues of the Autodata CD.

http://www.autodata-cd.com

Timing belt replacement intervals

The information relating to timing belt replacement intervals is additional to the main purpose of this CD, but is included to

provide guidance to garages and for customer advice.

Where possible the recommended intervals have been compiled from vehicle manufacturers' information. In a few instances no

recommendation has been made by the manufacturer and the decision to replace the belt must be made from the evidence of

a thorough examination of the condition of the existing belt.

Apart from the visible condition of the belt, which is explained fully later in this section, there are several other factors which

must be considered when checking a timing belt:

Is the belt an original or a replacement.1.

When was the belt last replaced and was it at the correct mileage.2.

Is the service history of the vehicle known.3.

Has the vehicle been operated under arduous conditions which might warrant a shorter replacement interval.4.

Is the general condition of other components in the camshaft drive, such as the tensioner, pulleys, and other ancillary

5.

components driven by the timing belt, typically the water pump, sound enough to ensure that the life of the replacement

belt will not be affected.

If the condition of the existing belt appears good, can you be satisfied that the belt will not fail before the next check or

6.

service is due.

If the belt does fail, have you considered the consequences. If the engine is an INTERFERENCE type then considerable

7.

expensive damage may well be the result.

The cost of replacing a belt as part of a routine service could be as little as 5 to 10% of the repair cost following a belt

8.

failure. Make sure your customer is aware of the consequences.

If in doubt about the condition of the belt - RENEW it.9.

Replacement Interval Guide

Replacement Interval Guide

Lancia recommend check & replace if necessary every 60,000 km and replacement every 105,000 km.

The previous use and service history of the vehicle must always be taken into account.

Check For Engine Damage

Check For Engine Damage

CAUTION: This engine has been identified as an INTERFERENCE engine in which the possibility of valve-to-piston

damage in the event of a timing belt failure is MOST LIKELY to occur.

A compression check of all cylinders should be performed before removing the cylinder head.

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

Year:

Kappa 2,0

107 (145) 6100

1994-02

© Autodata Limited 2004

V5.500-

2006.10.21.

Page 11

Repair Times - hrs

Repair Times - hrs

Kappa 2,0/2,4 5 Cyl. 1995-04

Remove and install 2,45

Remove and install - AC 2,65

Special Tools

Special Tools

Tensioner pulley locking pin - Lancia No.1860830000.

Camshaft locking tools - Lancia No.1860819000.

Special Precautions

Special Precautions

Disconnect battery earth lead.

DO NOT turn crankshaft or camshaft when timing belt removed.

Remove spark plugs to ease turning engine.

Turn engine in normal direction of rotation (unless otherwise stated).

DO NOT turn engine via camshaft or other sprockets.

Observe all tightening torques.

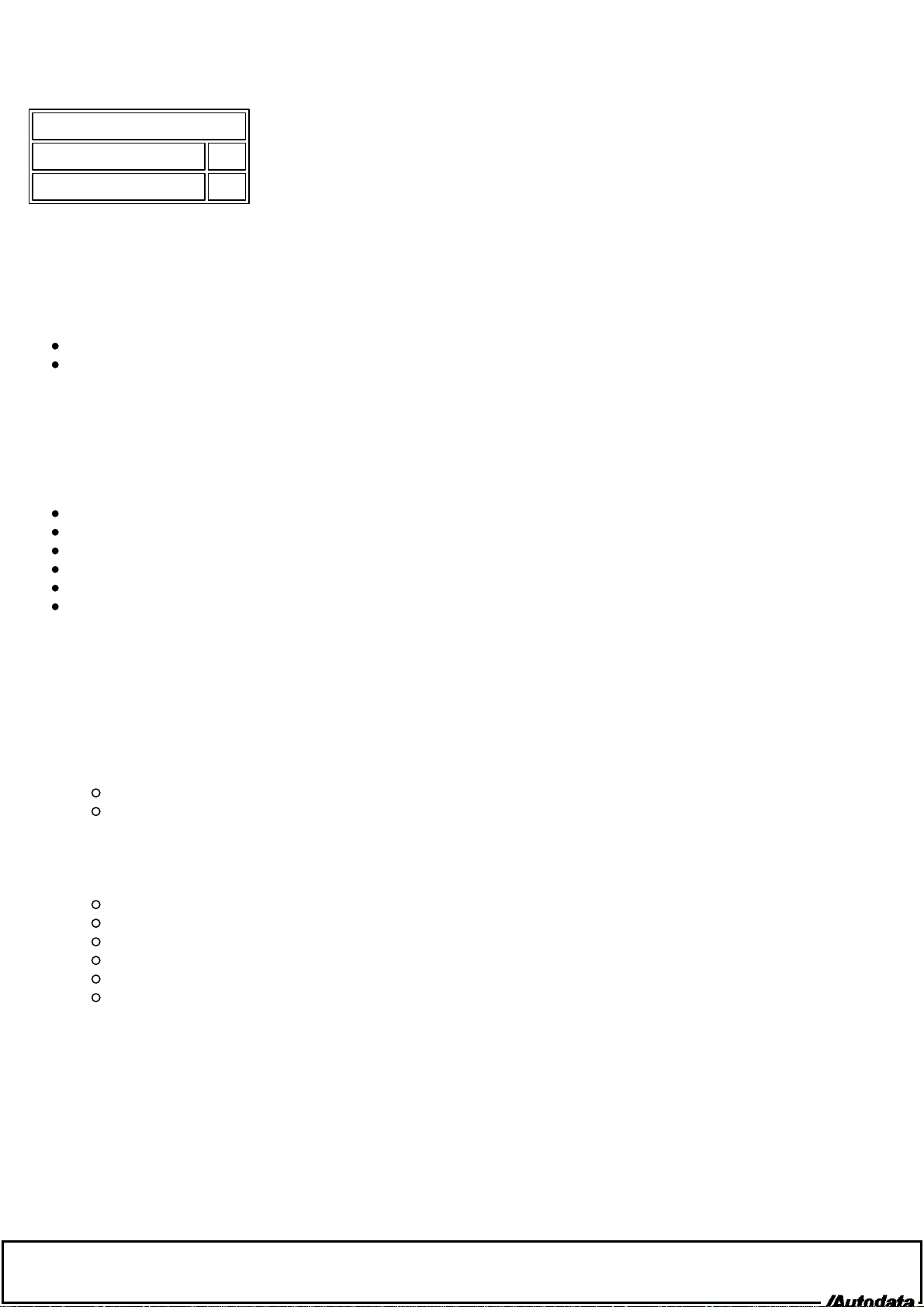

Removal

Removal

Raise and support front of vehicle.1.

2.

Remove:

RH front wheel.

Wheel arch liner.

Turn auxiliary drive belt tensioner pulley anti-clockwise. Use suitable spanner.3.

Lock tensioner pulley. Use tool No.1860830000 [1] .4.

5.

Remove:

Auxiliary drive belt.

Engine upper torque link.

Spark plug cover.

Cylinder head covers.

Timing belt cover [2] .

Crankshaft pulley (6 bolts) [3] .

Turn crankshaft to TDC on No.1 cylinder [4] .6.

Ensure both camshafts at TDC on No.1 cylinder. If not: Turn crankshaft one turn clockwise.7.

Remove third bearing cap from exhaust camshaft [5] .8.

Remove fourth bearing cap from inlet camshaft [7] .

9.

NOTE: Mark bearing caps before removal for identification.

Fit locking tools in place of bearing caps [6] & [8] . Tool No.1860819000.

10.

NOTE: Locking tools are marked 'exhaust' and 'inlet'. Ensure locking tools aligned with respective cam profiles

to prevent damage.

Slacken tensioner sprocket nut [9] . Turn tensioner sprocket anti-clockwise to release tension on belt. Lightly tighten nut.11.

Remove timing belt.12.

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 12

Installation

Installation

Ensure crankshaft at TDC on No.1 cylinder. Ensure timing marks aligned [4] .1.

Ensure locking tools located correctly in camshafts [6] & [8] .2.

Slacken bolts of each camshaft sprocket [10] .3.

4.

Fit timing belt in following order:

Crankshaft sprocket.

Guide pulley.

Exhaust camshaft sprocket.

Inlet camshaft sprocket.

Water pump sprocket.

Tensioner sprocket.

Ensure marks on belt aligned with marks on sprockets [11] .5.

Slacken tensioner sprocket nut [9] .6.

Push on tensioner sprocket to pre-tension belt [12] . Lightly tighten nut.7.

Tighten bolts of each camshaft sprocket [10] . Tightening torque: 28 Nm.8.

Remove locking tools from camshafts [6] & [8] .9.

Fit bearing caps in correct locations. Tighten bolts to 15 Nm.10.

Turn crankshaft two turns in normal direction of rotation.11.

Ensure timing marks aligned [4] .12.

Slacken tensioner sprocket nut [9] .13.

Tensioner sprocket should operate and marks align [13] .14.

Tighten tensioner sprocket nut [9] . Tightening torque: 25 Nm.15.

Install components in reverse order of removal.16.

Fit auxiliary drive belt. Remove locking pin from tensioner pulley.17.

Tighten crankshaft pulley bolts. Tightening torque: 28 Nm.18.

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 13

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 14

Service

indicator

Page 15

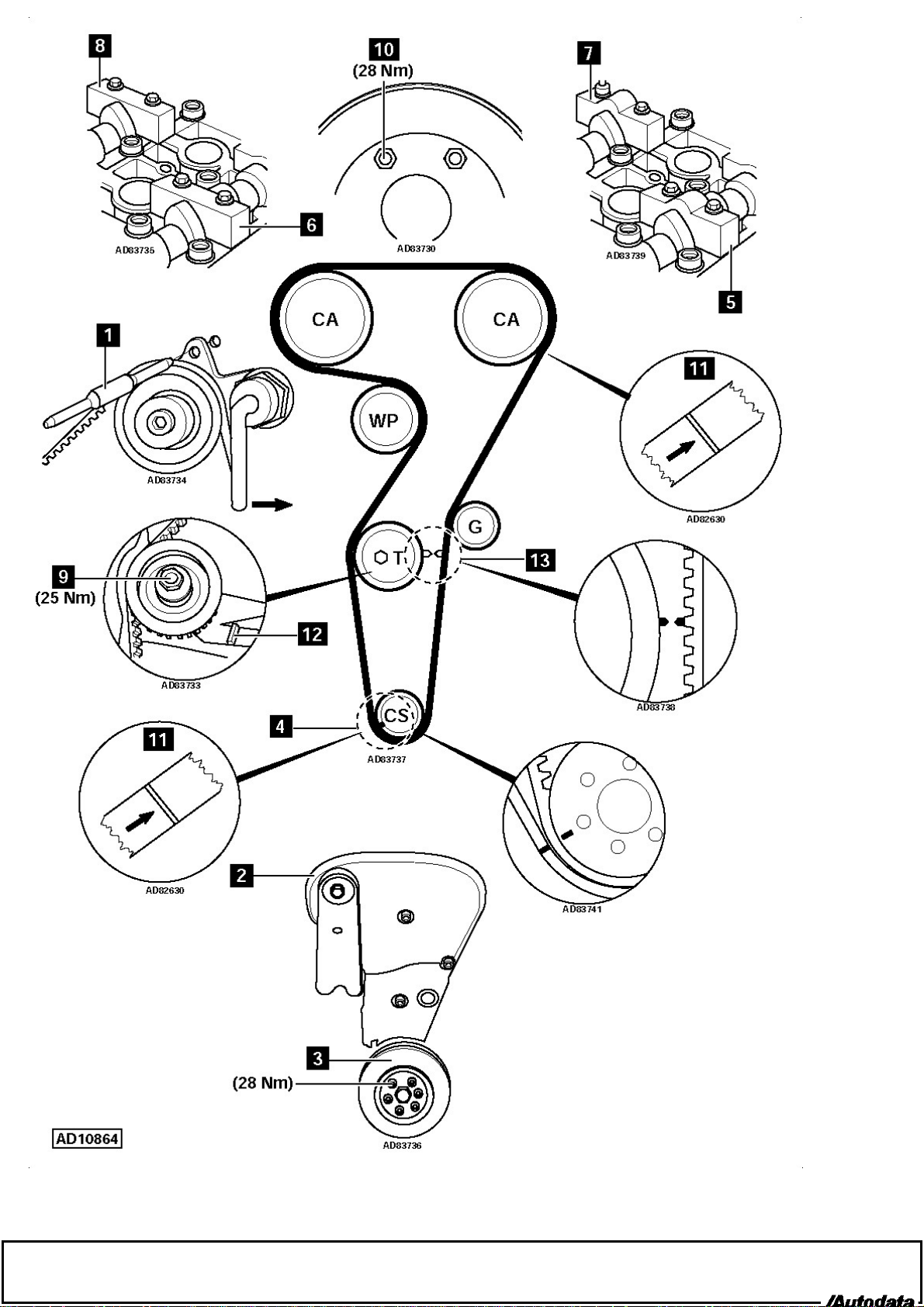

Switch ignition ON.

Press button [A] Fig. 26994

.

Press button [B] to reset the display.

Switch ignition OFF.

Fig. 26994

26994

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 16

Engine

management

pindata

Page 17

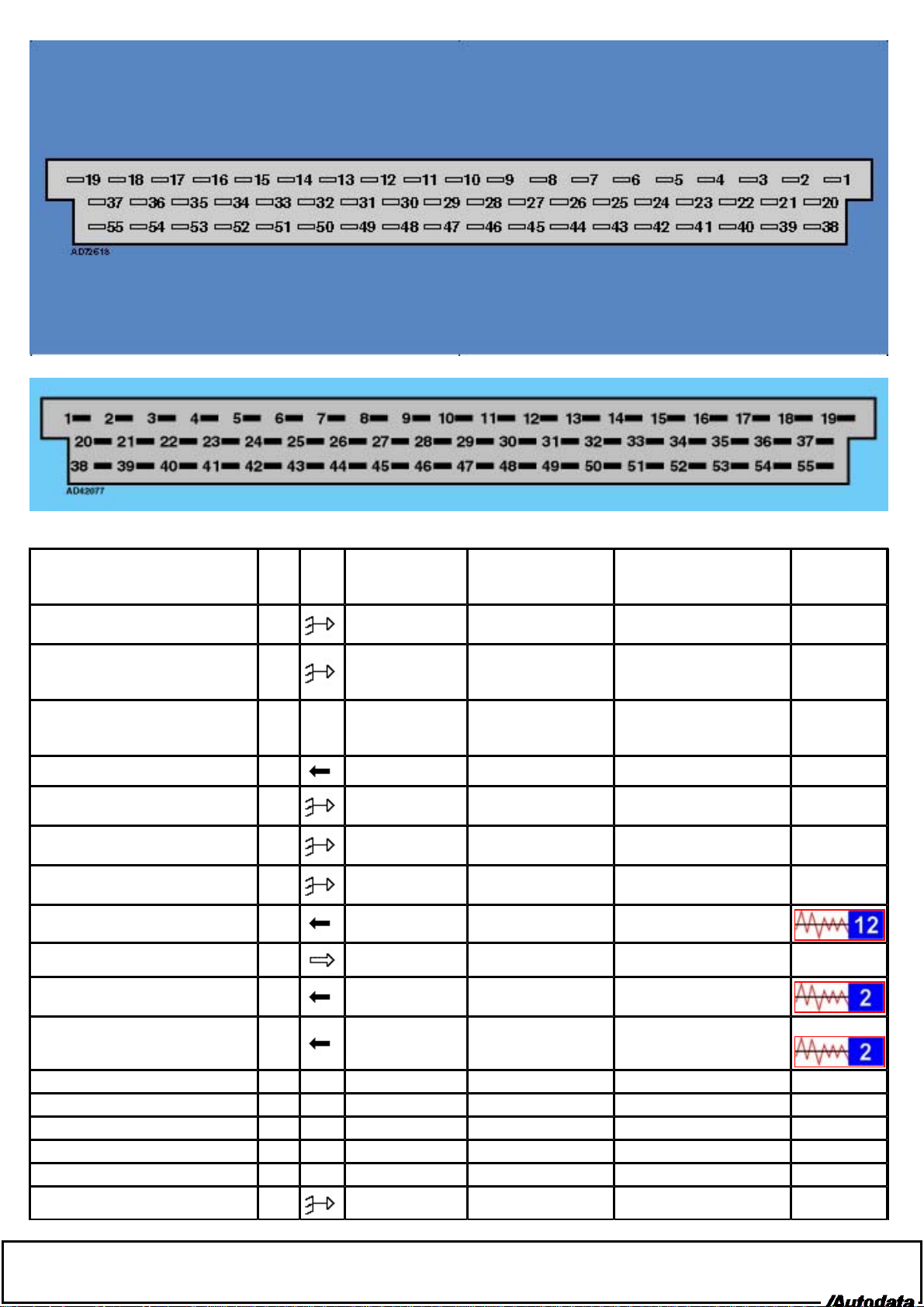

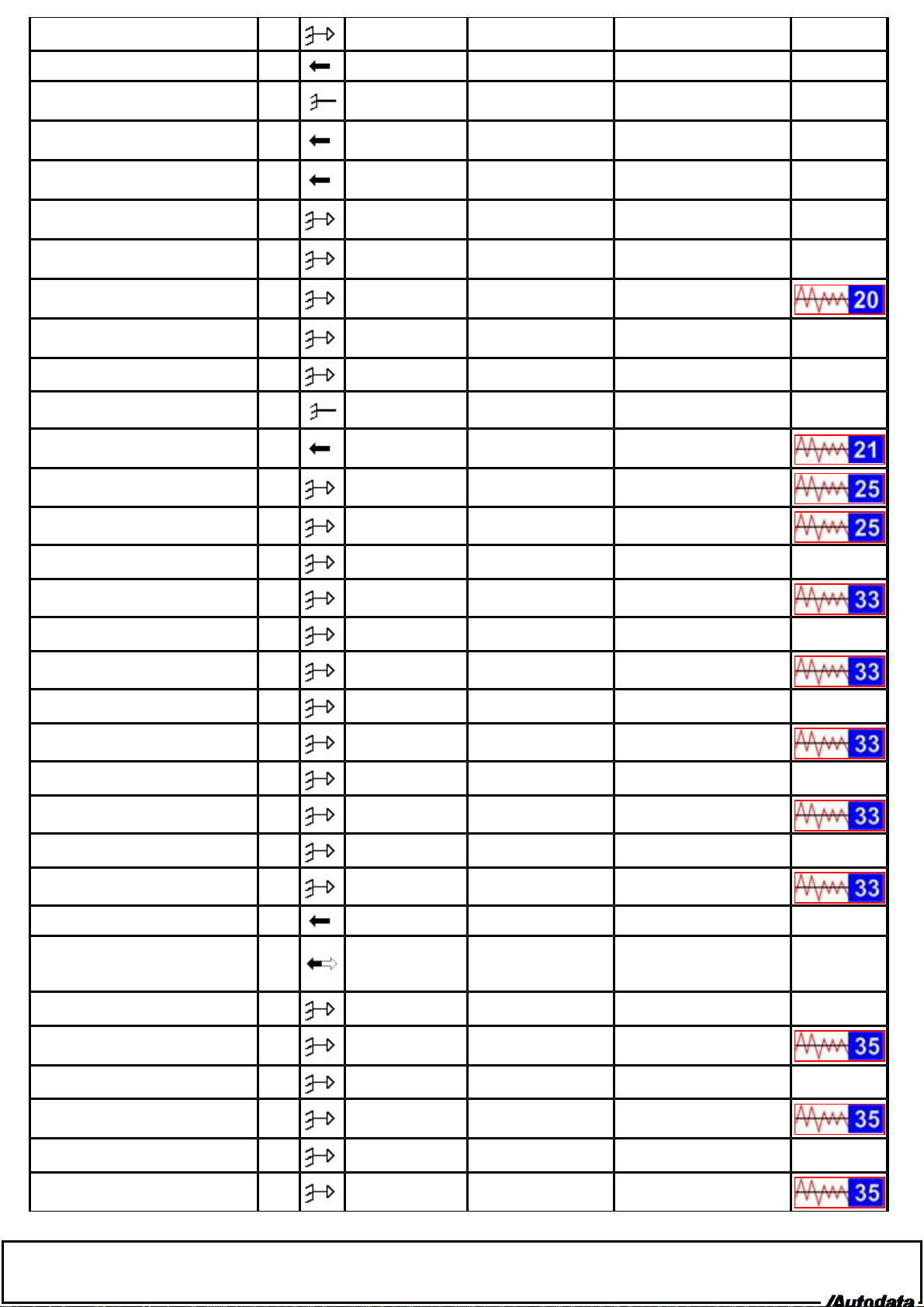

Terminal side

Wire side

Component/circuit description

AC compressor clutch relay 32

AC compressor clutch relay 32

AC refrigerant pressure switch 40

Battery 18 Ignition OFF 11-14 V

Camshaft position (CMP) actuator

relay

Camshaft position (CMP) actuator

relay

Camshaft position (CMP) actuator

relay

Camshaft position (CMP) sensor 8 Engine idling 2 V/50 ms

Camshaft position (CMP) sensor 12 Ignition ON 5 V

Crankshaft position (CKP) sensor

Crankshaft position (CKP) sensor

ECM

Signal Condition Typical value

pin

Engine idling - AC

OFF

Engine idling - AC

ON - AC

compressor ON

52 Ignition ON 11-14 V

52 Engine idling 11-14 V

52

48

(49)

49

(48)

Engine idling accelerate briefly

Engine idling 5 V/2 ms

Engine idling 5 V/2 ms

11-14 V

0-1 V

Connected pin - no test

data available or

random digital signal

0-1 V briefly

Oscilloscope setting

(Suggested settings -

Voltage/time per division)

Wave form

Reversed

Earth 2 Ignition ON 0 V

Earth 14 Ignition ON 0 V

Earth 19 Ignition ON 0 V

Earth 24 Ignition ON 0 V

Earth 42 Ignition ON 0 V

Engine control relay 36 Ignition OFF 11-14 V

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

Year:

Kappa 2,0

107 (145) 6100

1994-02

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 18

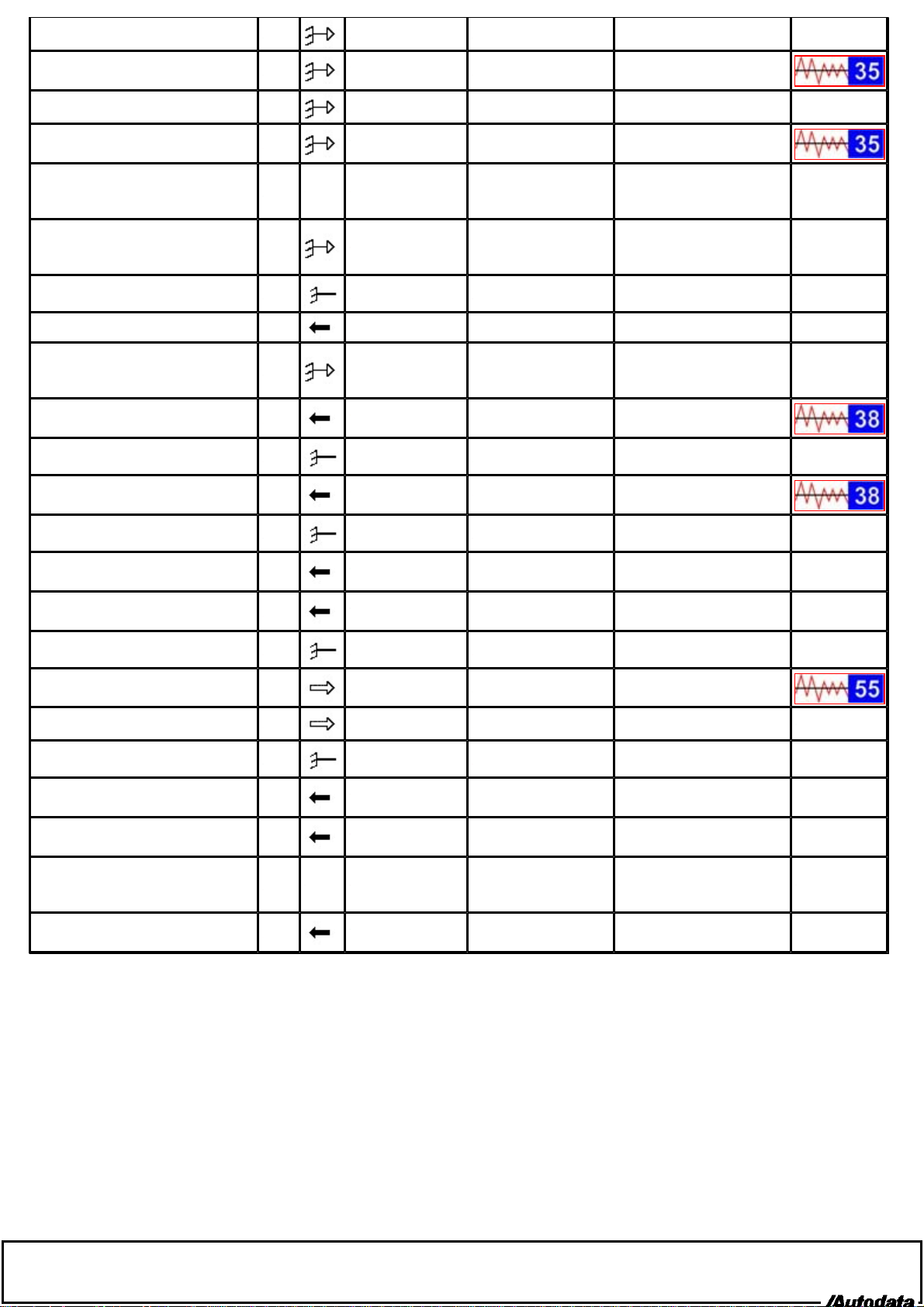

Engine control relay 36 Ignition ON 0 V

Engine control relay 37 Ignition ON 11-14 V

Engine coolant temperature (ECT)

sensor

Engine coolant temperature (ECT)

sensor

Engine coolant temperature (ECT)

sensor

Evaporative emission (EVAP) canister

purge valve

Evaporative emission (EVAP) canister

purge valve

Evaporative emission (EVAP) canister

purge valve

Fuel pump relay 3 Ignition ON

Fuel pump relay 3 Engine cranking 0-1 V

Heated oxygen sensor (HO2S) 10 Engine idling 0 V

Heated oxygen sensor (HO2S) 28

Idle air control (IAC) valve 4 Engine idling 5 V/5 ms

Idle air control (IAC) valve 22 Engine idling 5 V/5 ms

30 Ignition ON 0 V

45

45

5 Ignition ON 11-14 V

5 Engine idling 11-14 V

5

Ignition ON coolant temp. 10°C

Ignition ON coolant temp. 80°C

Engine hot - valve

operating

Engine idling engine hot

3,5 V

0,6 V

0-1 V briefly then 11-14

V

0,1-1 V fluctuating 0,2 V/1 sec.

10 V/20 ms

Ignition coil - cylinder 1 1 Ignition ON 11-14 V

Ignition coil 1 Engine idling 5 V/2 ms

Ignition coil - cylinder 2 20 Ignition ON 11-14 V

Ignition coil 20 Engine idling 5 V/2 ms

Ignition coil - cylinder 3 39 Ignition ON 11-14 V

Ignition coil 39 Engine idling 5 V/2 ms

Ignition coil - cylinder 4 21 Ignition ON 11-14 V

Ignition coil 21 Engine idling 5 V/2 ms

Ignition coil - cylinder 5 38 Ignition ON 11-14 V

Ignition coil 38 Engine idling 5 V/2 ms

Ignition switch 27 Ignition ON 11-14 V

Immobilizer control module diagnostic link

Injector 1 17 Ignition ON 11-14 V

55

Connected pin - no test

data available or

random digital signal

Model:

Output:

1994-02

Year:

Engine idling engine hot

Engine idling engine hot

Engine idling engine hot

Kappa 2,0

107 (145) 6100

Injector 1 17

Injector 2 16 Ignition ON 11-14 V

Injector 2 16

Injector 3 15 Ignition ON 11-14 V

Injector 3 15

Manufacturer:

Engine code:

Tuned for:

Lancia

838A1.000

R-Cat

2,5-3,5 ms 10 V/2 ms

2,5-3,5 ms 10 V/2 ms

2,5-3,5 ms 10 V/2 ms

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 19

Injector 4 35 Ignition ON 11-14 V

Injector 4 35

Injector 5 34 Ignition ON 11-14 V

Injector 5 34

Instrumentation control module/heater

function control module

Instrumentation control module/heater

function control module - malfunction

indicator signal

Intake air temperature (IAT) sensor 30 Ignition ON 0 V

Intake air temperature (IAT) sensor 54 Ignition ON - 20°C 3 V

Intake manifold air control relay - 2,4 23

Knock sensor (KS) 1 11

Knock sensor (KS) 1 30 Engine running 0 V

Knock sensor (KS) 2 29

41

51

Engine idling engine hot

Engine idling engine hot

Engine idling accelerate briefly

Engine idling accelerate briefly

2,5-3,5 ms 10 V/2 ms

2,5-3,5 ms 10 V/2 ms

Connected pin - no test

data available or

random digital signal

Connected pin - no test

data available or

random digital signal

Connected pin - no test

data available or

random digital signal

50 mV/1 ms

50 mV/1 ms

Knock sensor (KS) 2 30 Engine running 0 V

Mass air flow (MAF) sensor 7

Mass air flow (MAF) sensor 7

Mass air flow (MAF) sensor 26 Ignition ON 0 V

Tachometer 6 Engine idling 30 Hz 2 V/20 ms

Throttle position (TP) sensor 12 Ignition ON 5 V

Throttle position (TP) sensor 30 Ignition ON 0 V

Throttle position (TP) sensor 53

Throttle position (TP) sensor 53

Transmission control module (TCM) 43

Vehicle speed sensor (VSS) 9

Engine idling engine hot

Engine idling accelerate briefly

Ignition ON throttle closed

Ignition ON throttle fully open

Ignition ON vehicle pushed

0,7-1,3 V

4,2 V briefly

0,1-0,7 V

4-4,8 V

Connected pin - no test

data available or

random digital signal

0 V or 11-14 V

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 20

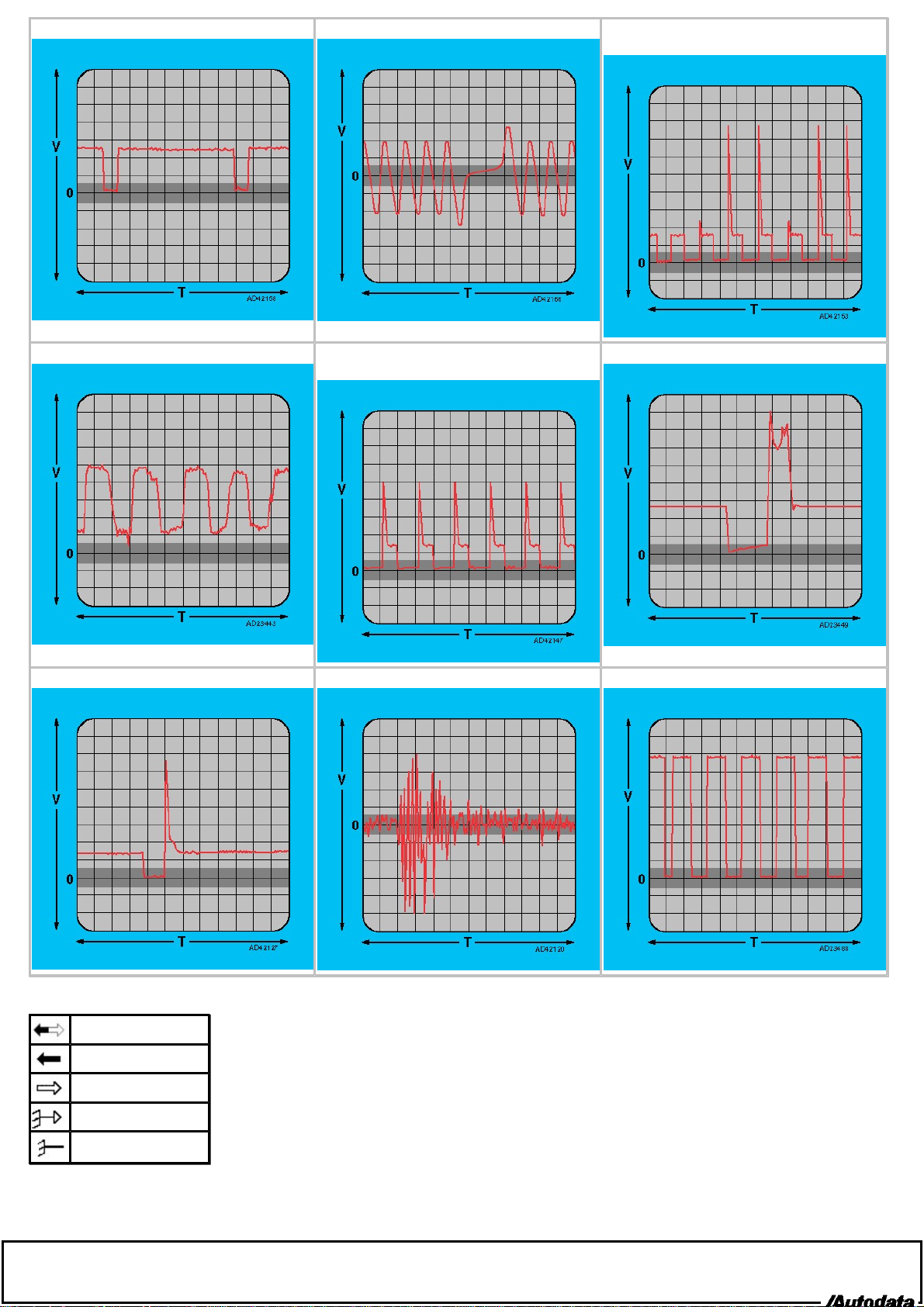

12. Digital, DC, frequency modulated 2. Analogue, AC, frequency modulated

20. Digital, DC, pulse width modulated or

digital, DC, frequency modulated

21. Analogue, DC

35. Digital, DC, pulse width modulated 38. Analogue, AC 55. Digital, DC, frequency modulated

25. Digital, DC, pulse width modulated or

digital, DC, frequency modulated

33. Digital, DC, frequency modulated

input/output signal

input signal

output signal

ECM switched earth

ECM earth circuit

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 21

Battery

replacement

Page 22

Fig. 3

3

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 23

Immobilizer

Page 24

System operation

Arms automatically when ignition key is removed.

Programming

When

Key remote control added or replaced.

System malfunction.

How

NOTE: A maximum of 8 keys can be programmed. NOTE: Immobilizer LED located in centre console.

Obtain all keys.

Insert master key into ignition switch.

Switch ignition ON.

Wait for LED to extinguish.

Switch ignition OFF.

Carry out the following within 10 seconds:

Remove master key.

Insert non programmed key into ignition switch.

Switch ignition ON.

Wait for LED to extinguish.

Switch ignition OFF.

Remove key.

Repeat above procedure to program remaining keys.

After programming last key proceed as follows:

Insert master key into ignition switch.

Switch ignition ON.

Wait for LED to extinguish.

Switch ignition OFF.

Switch ignition ON. Wait approximately 3 seconds.

Ensure immobilizer LED illuminates for approximately 0,7 second and then goes out to indicate correct programming.

3

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 25

Remote alarm

Page 26

System operation

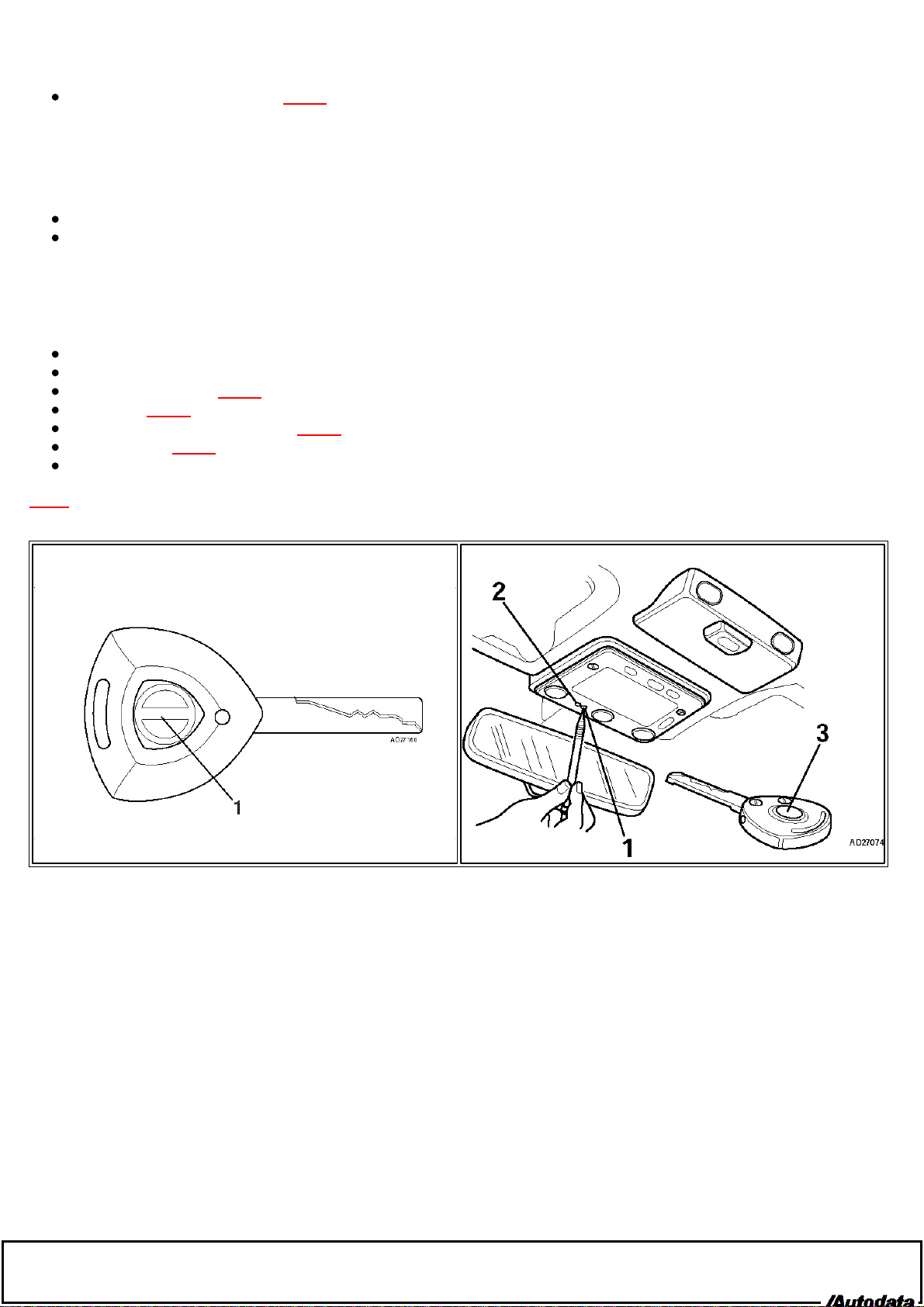

Pressing key lock/unlock button Fig. 1

[1] activates alarm and central locking.

Programming

When

Key added or replaced.

System malfunction.

How

NOTE: A maximum of 8 keys can be programmed.

Obtain all keys.

Distance from receiver: At least 20 cm.

Press and hold button Fig. 2 [1].

Check LED Fig. 2 [2] flashes.

Press and hold lock/unlock button Fig. 2 [3] until LED [2] illuminates.

Release button Fig. 2 [1].

Repeat above procedure to program remaining keys.

Fig. 2

2

1

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 27

Diagnostic

Page 28

Accessing and erasing

The engine control module (ECM) fault memory can be accessed and erased using diagnostic equipment connected to

the data link connector (DLC).

Trouble code identification

P type

Fault location Probable cause

P0

Refer to EOBD trouble code table -

1

EOBD codes

All EOBD codes starting with P zero have standard meanings irrespective of vehicle make or model.

For EOBD codes, other than those starting P zero, refer to model specific chapters.

The following list covers all P0 codes allocated at the time of publication.

Trouble

code

Fault location Probable cause

P0000 No fault found P0001 Fuel volume regulator control - circuit open Wiring, regulator control solenoid

P0002 Fuel volume regulator control - circuit range/performance Wiring, regulator control solenoid

P0003 Fuel volume regulator control - circuit low Wiring short to earth, regulator control solenoid

P0004 Fuel volume regulator control - circuit high

Wiring open circuit/short to positive, regulator control

solenoid

P0005 Fuel shut-off valve - circuit open Wiring open circuit, fuel shut-off valve

P0006 Fuel shut-off valve - circuit low Wiring short to earth, fuel shut-off valve

P0007 Fuel shut-off valve - circuit high Wiring short to positive, fuel shut-off valve

P0008 Engine position system, bank 1 - engine performance Mechanical fault

P0009 Engine position system, bank 2 - engine performance Mechanical fault

P0010

P0011

P0012

P0013

Camshaft position (CMP) actuator, intake/left/front, bank

1 - circuit malfunction

Camshaft position (CMP), intake/left/front, bank 1 - timing

over-advanced/system performance

Camshaft position (CMP), intake/left/front, bank 1 - timing

over-retarded

Camshaft position (CMP) actuator, intake/left/front, bank

1 - circuit malfunction

Wiring, CMP actuator, ECM

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Wiring, CMP actuator, ECM

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 29

P0014

P0015

P0016

P0017

P0018

P0019

P0020

P0021

P0022

P0023

P0024

P0025

P0026

P0027

P0028

P0029

P0030

P0031

P0032

P0033

P0034

P0035

P0036

P0037

P0038

P0039

P0040

Camshaft position (CMP) actuator, exhaust/right/rear,

bank 1 - timing over-advanced/system performance

Camshaft position (CMP) actuator, exhaust/right/rear,

bank 1 - timing over-retarded

Crankshaft position/camshaft position, bank 1 sensor A correlation

Crankshaft position/camshaft position, bank 1 sensor B correlation

Crankshaft position/camshaft position, bank 2 sensor A correlation

Crankshaft position/camshaft position, bank 2 sensor B correlation

Camshaft position (CMP) actuator, intake/left/front, bank

2 - circuit malfunction

Camshaft position (CMP), intake/left/front, bank 2 - timing

over-advanced/system performance

Camshaft position (CMP), intake/left/front, bank 2 - timing

over-retarded

Camshaft position (CMP) actuator, exhaust/right/rear,

bank 2 - circuit malfunction

Camshaft position (CMP), exhaust/right/rear, bank 2 timing over-advanced/system performance

Camshaft position (CMP), exhaust/right/rear, bank 2 timing over-retarded

Intake valve control solenoid circuit, bank 1 range/performance

Exhaust valve control solenoid circuit, bank 1 range/performance

Intake valve control solenoid circuit, bank 2 range/performance

Exhaust valve control solenoid circuit, bank 2 range/performance

Heated oxygen sensor (HO2S) 1, bank 1, heater control circuit malfunction

Heated oxygen sensor (HO2S) 1, bank 1, heater control circuit low

Heated oxygen sensor (HO2S) 1, bank 1, heater control circuit high

Turbocharger (TC) wastegate regulating valve - circuit

malfunction

Turbocharger (TC) wastegate regulating valve - circuit

low

Turbocharger (TC) wastegate regulating valve - circuit

high

Heated oxygen sensor (HO2S) 2, bank 1, heater control circuit malfunction

Heated oxygen sensor (HO2S) 2, bank 1, heater control circuit low

Heated oxygen sensor (HO2S) 2, bank 1, heater control circuit high

Turbo/super charger bypass valve, control circuit range/performance

Oxygen sensor signals swapped, bank 1 sensor 1/bank 2

sensor 1

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CMP actuator, ECM

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Wiring, CMP actuator, ECM

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Wiring, intake valve control solenoid

Wiring, exhaust valve control solenoid

Wiring, intake valve control solenoid

Wiring, exhaust valve control solenoid

Wiring, HO2S, ECM

Wiring short to earth, HO2S, ECM

Wiring short to positive, HO2S, ECM

Wiring, TC wastegate regulating valve, ECM

Wiring short to earth, TC wastegate regulating valve,

ECM

Wiring short to positive, TC wastegate regulating valve,

ECM

Wiring, HO2S, ECM

Wiring short to earth, HO2S, ECM

Wiring short to positive, HO2S, ECM

Wiring, bypass valve

Wiring

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 30

P0041

P0042

P0043

P0044

Oxygen sensor signals swapped, bank 1 sensor 2/bank 2

sensor 2

Heated oxygen sensor (HO2S) 3, bank 1, heater control circuit malfunction

Heated oxygen sensor (HO2S) 3, bank 1, heater control circuit low

Heated oxygen sensor (HO2S) 3, bank 1, heater control circuit high

Wiring

Wiring, HO2S, ECM

Wiring short to earth, HO2S, ECM

Wiring short to positive, HO2S, ECM

P0045 Turbo/super charger boost control solenoid - circuit open Wiring, boost control solenoid

P0046

Turbo/super charger boost control solenoid - circuit

range/performance

Wiring, boost control solenoid, mechanical fault

P0047 Turbo/super charger boost control solenoid - circuit low Wiring short to earth, boost control solenoid

P0048 Turbo/super charger boost control solenoid - circuit high Wiring short to positive, boost control solenoid

P0049 Turbo/super charger turbine - over-speed Mechanical fault

P0050

P0051

P0052

P0053

P0054

P0055

P0056

P0057

P0058

P0059

P0060

P0061

P0062

P0063

P0064

Heated oxygen sensor (HO2S) 1, bank 2, heater control circuit malfunction

Heated oxygen sensor (HO2S) 1, bank 2, heater control circuit low

Heated oxygen sensor (HO2S) 1, bank 2, heater control circuit high

Heated oxygen sensor (HO2S), bank 1, sensor 1 - heater

resistance

Heated oxygen sensor (HO2S), bank 1, sensor 2 - heater

resistance

Heated oxygen sensor (HO2S), bank 1, sensor 3 - heater

resistance

Heated oxygen sensor (HO2S) 2, bank 2, heater control circuit malfunction

Heated oxygen sensor (HO2S) 2, bank 2, heater control heater circuit low

Heated oxygen sensor (HO2S) 2, bank 2, heater control circuit high

Heated oxygen sensor (HO2S), bank 2, sensor 1 - heater

resistance

Heated oxygen sensor (HO2S), bank 2, sensor 2 - heater

resistance

Heated oxygen sensor (HO2S), bank 2, sensor 3 - heater

resistance

Heated oxygen sensor (HO2S) 3, bank 2, heater control circuit malfunction

Heated oxygen sensor (HO2S) 3, bank 2, heater control circuit low

Heated oxygen sensor (HO2S) 3, bank 2, heater control circuit high

Wiring, HO2S, ECM

Wiring short to earth, HO2S, ECM

Wiring short to positive, HO2S, ECM

Wiring, HO2S

Wiring, HO2S

Wiring, HO2S

Wiring, HO2S, ECM

Wiring short to earth, HO2S, ECM

Wiring short to positive, HO2S, ECM

Wiring, HO2S

Wiring, HO2S

Wiring, HO2S

Wiring, HO2S, ECM

Wiring short to earth, HO2S, ECM

Wiring short to positive, HO2S, ECM

P0065 Air assisted injector - range/performance problem Air assisted injector

P0066 Air assisted injector - circuit malfunction/circuit low Wiring short to earth, air assisted injector, ECM

P0067 Air assisted injector - circuit high Wiring short to positive, air assisted injector, ECM

P0068

P0069

Manifold absolute pressure (MAP) sensor/mass air flow

(MAF) sensor/throttle position correlation

Manifold absolute pressure (MAP) sensor/barometric

pressure (BARO) sensor correlation

Wiring, MAP sensor, MAF sensor, mechanical fault

MAP sensor, mechanical fault

P0070 Outside air temperature sensor - circuit malfunction Wiring, outside air temperature sensor, ECM

P0071

Outside air temperature sensor - range/performance

problem

Outside air temperature sensor

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 31

P0072 Outside air temperature sensor - low input

P0073 Outside air temperature sensor - high input

P0074 Outside air temperature sensor - circuit intermittent

Wiring short to earth, outside air temperature sensor,

ECM

Wiring short to positive, outside air temperature sensor,

ECM

Wiring, poor connection, outside air temperature

sensor, ECM

P0075 Intake valve control solenoid, bank 1 - circuit malfunction Wiring, intake valve control solenoid, ECM

P0076 Intake valve control solenoid, bank 1 - circuit low

P0077 Intake valve control solenoid, bank 1 - circuit high

P0078

Exhaust valve control solenoid, bank 1 - circuit

malfunction

P0079 Exhaust valve control solenoid, bank 1 - circuit low

P0080 Exhaust valve control solenoid, bank 1 - circuit high

Wiring short to earth, intake valve control solenoid,

ECM

Wiring short to positive, intake valve control solenoid,

ECM

Wiring, exhaust valve control solenoid, ECM

Wiring short to earth, exhaust valve control solenoid,

ECM

Wiring short to positive, exhaust valve control solenoid,

ECM

P0081 Intake valve control solenoid, bank 2 - circuit malfunction Wiring, intake valve control solenoid, ECM

P0082 Intake valve control solenoid, bank 2 - circuit low

P0083 Intake valve control solenoid, bank 2 - circuit high

P0084

Exhaust valve control solenoid, bank 2 - circuit

malfunction

P0085 Exhaust valve control solenoid, bank 2 - circuit low

P0086 Exhaust valve control solenoid, bank 2 - circuit high

P0087 Fuel rail/system pressure too low

P0088 Fuel rail/system pressure too high

Wiring short to earth, intake valve control solenoid,

ECM

Wiring short to positive, intake valve control solenoid,

ECM

Wiring, exhaust valve control solenoid, ECM

Wiring short to earth, exhaust valve control solenoid,

ECM

Wiring short to positive, exhaust valve control solenoid,

ECM

Fuel pump, fuel pressure regulator, fuel supply pipe

blockage, mechanical fault

Fuel pump, fuel pressure regulator, fuel return pipe

blockage, mechanical fault

P0089 Fuel pressure regulator - performance problem Fuel pressure regulator, mechanical fault

P0090 Fuel metering solenoid - open circuit Wiring open circuit, fuel metering solenoid, ECM

P0091 Fuel metering solenoid - short to earth Wiring short to earth, fuel metering solenoid, ECM

P0092 Fuel metering solenoid - short to positive Wiring short to positive, fuel metering solenoid, ECM

P0093 Fuel system leak - large leak detected Wiring, fuel pressure sensor, mechanical fault

P0094 Fuel system leak - small leak detected Wiring, fuel pressure sensor, mechanical fault

P0095 Intake air temperature (IAT) sensor 2 - circuit malfunction Wiring, poor connection, IAT sensor, ECM

P0096

Intake air temperature (IAT) sensor 2 - circuit

range/performance

Wiring, poor connection, IAT sensor, ECM

P0097 Intake air temperature (IAT) sensor 2 - circuit low input Wiring short to earth, IAT sensor, ECM

P0098 Intake air temperature (IAT) sensor 2 - circuit high input Wiring short to positive, IAT sensor, ECM

P0099

P0100

P0101

P0102

P0103

Intake air temperature (IAT) sensor 2 - circuit

intermittent/erratic

Mass air flow (MAF) sensor/volume air flow (VAF) sensor

- circuit malfunction

Mass air flow (MAF) sensor/volume air flow (VAF) sensor

- range/performance problem

Mass air flow (MAF) sensor/volume air flow (VAF) sensor

- low input

Mass air flow (MAF) sensor/volume air flow (VAF) sensor

- high input

Wiring, poor connection, IAT sensor, ECM

Wiring, MAF/VAF sensor, ECM

Intake leak/blockage, MAF/VAF sensor

Wiring short to earth, MAF/VAF sensor, ECM

Wiring short to positive, MAF/VAF sensor, ECM

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 32

P0104

P0105

P0106

P0107

P0108

P0109

Mass air flow (MAF) sensor/volume air flow (VAF) sensor

- circuit intermittent

Manifold absolute pressure (MAP) sensor/barometric

pressure (BARO) sensor - circuit malfunction

Manifold absolute pressure (MAP) sensor/barometric

pressure (BARO) sensor - range/performance problem

Manifold absolute pressure (MAP) sensor/barometric

pressure (BARO) sensor - low input

Manifold absolute pressure (MAP) sensor/barometric

pressure (BARO) sensor - high input

Manifold absolute pressure (MAP) sensor/barometric

pressure (BARO) sensor - circuit intermittent

Wiring, poor connection, MAF/VAF sensor, ECM

Wiring, MAP sensor, BARO sensor, ECM

Intake/exhaust leak, wiring, MAP sensor, BARO sensor

Wiring short to earth, MAP sensor, BARO sensor, ECM

Wiring short to positive, MAP sensor, BARO sensor,

ECM

Wiring, poor connection, MAP sensor, BARO sensor,

ECM

P0110 Intake air temperature (IAT) sensor - circuit malfunction Wiring, IAT sensor, ECM

P0111

Intake air temperature (IAT) sensor - range/performance

problem

IAT sensor

P0112 Intake air temperature (IAT) sensor - low input Wiring short to earth, IAT sensor, ECM

P0113 Intake air temperature (IAT) sensor - high input

Wiring open circuit/short to positive, earth wire

defective, IAT sensor, ECM

P0114 Intake air temperature (IAT) sensor - circuit intermittent Wiring, poor connection, IAT sensor, ECM

P0115

P0116

Engine coolant temperature (ECT) sensor - circuit

malfunction

Engine coolant temperature (ECT) sensor range/performance problem

Wiring, ECT sensor, ECM

Coolant thermostat, poor connection, wiring, ECT

sensor

P0117 Engine coolant temperature (ECT) sensor - low input Coolant thermostat, wiring short to earth, ECT sensor

P0118 Engine coolant temperature (ECT) sensor - high input

P0119

P0120

P0120

P0121

P0121

P0122

P0122

P0123

P0123

P0124

P0124

P0125

Engine coolant temperature (ECT) sensor - circuit

intermittent

Throttle position (TP) sensor A/accelerator pedal position

(APP) sensor A - circuit malfunction

Throttle position (TP) switch A/accelerator pedal position

(APP) switch A - circuit malfunction

Throttle position (TP) sensor A/accelerator pedal position

(APP) sensor A - range/performance problem

Throttle position (TP) switch A/accelerator pedal position

(APP) switch A - range/performance problem

Throttle position (TP) sensor A/accelerator pedal position

(APP) sensor A - low input

Throttle position (TP) switch A/accelerator pedal position

(APP) switch A - low input

Throttle position (TP) sensor A/accelerator pedal position

(APP) sensor A - high input

Throttle position (TP) switch A/accelerator pedal position

(APP) switch A - high input

Throttle position (TP) sensor A/accelerator pedal position

(APP) sensor A - circuit intermittent

Throttle position (TP) switch A/accelerator pedal position

(APP) switch A - circuit intermittent

Insufficient coolant temperature for closed loop fuel

control

Coolant thermostat, wiring open circuit/short to positive,

earth wire defective, ECT sensor

Wiring, poor connection, ECT sensor, ECM

Wiring, TP/APP sensor, ECM

Wiring, TP/APP switch, ECM

Accelerator cable adjustment, TP/APP sensor

Accelerator cable adjustment, TP/APP switch

Wiring short to earth, TP/APP sensor, ECM

Wiring short to earth, TP/APP switch, ECM

Wiring short to positive, TP/APP sensor, ECM

Wiring short to positive, TP/APP switch, ECM

Wiring, poor connection, TP/APP sensor, ECM

Wiring, poor connection, TP/APP switch, ECM

Wiring, cooling system, coolant thermostat, ECT sensor

P0126 Insufficient coolant temperature for stable operation Wiring, cooling system, coolant thermostat, ECT sensor

P0127 Intake air temperature too high

Wiring short to earth, IAT sensor 2, mechanical fault,

ECM

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 33

P0128

Coolant thermostat - coolant temperature below

thermostat regulating temperature

Mechanical fault

P0129 Barometric pressure too low Wiring, BARO sensor, mechanical fault

P0130

Heated oxygen sensor (HO2S) 1, bank 1 - circuit

malfunction

Heating inoperative, poor connection, wiring, HO2S

P0130 Oxygen sensor (O2S) 1, bank 1 - circuit malfunction Wiring, O2S, ECM

P0131 Heated oxygen sensor (HO2S) 1, bank 1 - low voltage Exhaust leak, wiring short to earth, HO2S, ECM

P0131 Oxygen sensor (O2S) 1, bank 1 - low voltage Exhaust leak, wiring short to earth, O2S, ECM

P0132 Heated oxygen sensor (HO2S) 1, bank 1 - high voltage Wiring short to positive, HO2S, ECM

P0132 Oxygen sensor (O2S) 1, bank 1 - high voltage Wiring short to positive, O2S, ECM

P0133 Heated oxygen sensor (HO2S) 1, bank 1 - slow response Heating inoperative, wiring, HO2S

P0133 Oxygen sensor (O2S) 1, bank 1 - slow response Wiring, O2S

P0134

Heated oxygen sensor (HO2S) 1, bank 1 - no activity

detected

Wiring open circuit, heating inoperative, HO2S

P0134 Oxygen sensor (O2S) 1, bank 1 - no activity detected Wiring, O2S

P0135

P0136

Heated oxygen sensor (HO2S) 1, bank 1, heater control circuit malfunction

Heated oxygen sensor (HO2S) 2, bank 1 - circuit

malfunction

Fuse, wiring, HO2S, ECM

Heating inoperative, wiring, HO2S, ECM

P0136 Oxygen sensor (O2S) 2, bank 1 - circuit malfunction Wiring, O2S, ECM

P0137 Heated oxygen sensor (HO2S) 2, bank 1 - low voltage Exhaust leak, wiring short to earth, HO2S, ECM

P0137 Oxygen sensor (O2S) 2, bank 1 - low voltage Exhaust leak, wiring short to earth, O2S, ECM

P0138 Heated oxygen sensor (HO2S) 2, bank 1 - high voltage Wiring short to positive, HO2S, ECM

P0138 Oxygen sensor (O2S) 2, bank 1 - high voltage Wiring short to positive, O2S, ECM

P0139 Heated oxygen sensor (HO2S) 2, bank 1 - slow response Heating inoperative, wiring, HO2S

P0139 Oxygen sensor (O2S) 2, bank 1 - slow response Wiring, O2S

P0140

Heated oxygen sensor (HO2S) 2, bank 1 - no activity

detected

Wiring, heating inoperative, HO2S, ECM

P0140 Oxygen sensor (O2S) 2, bank 1 - no activity detected Wiring, O2S, ECM

P0141

P0142

Heated oxygen sensor (HO2S) 2, bank 1, heater control circuit malfunction

Heated oxygen sensor (HO2S) 3, bank 1 - circuit

malfunction

Wiring, HO2S, ECM

Wiring, HO2S, ECM

P0143 Heated oxygen sensor (HO2S) 3, bank 1 - low voltage Exhaust leak, wiring short to earth, HO2S, ECM

P0143 Oxygen sensor (O2S) 3, bank 1 - low voltage Exhaust leak, wiring short to earth, O2S, ECM

P0144 Heated oxygen sensor (HO2S) 3, bank 1 - high voltage Wiring short to positive, HO2S, ECM

P0144 Oxygen sensor (O2S) 3, bank 1 - high voltage Wiring short to positive, O2S, ECM

P0145 Heated oxygen sensor (HO2S) 3, bank 1 - slow response Heating inoperative, wiring, HO2S

P0145 Oxygen sensor (O2S) 3, bank 1 - slow response Wiring, O2S

P0146

Heated oxygen sensor (HO2S) 3, bank 1 - no activity

detected

Wiring, HO2S, ECM

P0146 Oxygen sensor (O2S) 3, bank 1 - no activity detected Wiring, O2S, ECM

P0147

Heated oxygen sensor (HO2S) 3, bank 1, heater control circuit malfunction

Wiring, HO2S, ECM

P0148 Fuel delivery error Fuel pump/fuel injection pump

P0149 Fuel timing error Fuel pump/fuel injection pump

P0150

Heated oxygen sensor (HO2S) 1, bank 2 - circuit

malfunction

Wiring, HO2S, ECM

P0150 Oxygen sensor (O2S) 1, bank 2 - circuit malfunction Wiring, O2S, ECM

P0151 Heated oxygen sensor (HO2S) 1, bank 2 - low voltage Exhaust leak, wiring short to earth, HO2S, ECM

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 34

P0151 Oxygen sensor (O2S) 1, bank 2 - low voltage Exhaust leak, wiring short to earth, O2S, ECM

P0152 Heated oxygen sensor (HO2S) 1, bank 2 - high voltage Wiring short to positive, HO2S, ECM

P0152 Oxygen sensor (O2S) 1, bank 2 - high voltage Wiring short to positive, O2S, ECM

P0153 Heated oxygen sensor (HO2S) 1, bank 2 - slow response Heating inoperative, wiring, HO2S

P0153 Oxygen sensor (O2S) 1, bank 2 - slow response Wiring, O2S

P0154

Heated oxygen sensor (HO2S) 1, bank 2 - no activity

detected

Wiring, HO2S, ECM

P0154 Oxygen sensor (O2S) 1, bank 2 - no activity detected Wiring, O2S, ECM

P0155

P0156

Heated oxygen sensor (HO2S) 1, bank 2, heater control circuit malfunction

Heated oxygen sensor (HO2S) 2, bank 2 - circuit

malfunction

Wiring, HO2S, ECM

Heating inoperative, wiring, HO2S, ECM

P0156 Oxygen sensor (O2S) 2, bank 2 - circuit malfunction Wiring, O2S, ECM

P0157 Heated oxygen sensor (HO2S) 2, bank 2 - low voltage Exhaust leak, wiring short to earth, HO2S, ECM

P0157 Oxygen sensor (O2S) 2, bank 2 - low voltage Exhaust leak, wiring short to earth, O2S, ECM

P0158 Heated oxygen sensor (HO2S) 2, bank 2 - high voltage Wiring short to positive, HO2S, ECM

P0158 Oxygen sensor (O2S) 2, bank 2 - high voltage Wiring short to positive, O2S, ECM

P0159 Heated oxygen sensor (HO2S) 2, bank 2 - slow response Heating inoperative, wiring, HO2S

P0159 Oxygen sensor (O2S) 2, bank 2 - slow response Wiring, O2S

P0160

Heated oxygen sensor (HO2S) 2, bank 2 - no activity

detected

Wiring, HO2S, ECM

P0160 Oxygen sensor (O2S) 2, bank 2 - no activity detected Wiring, O2S, ECM

P0161

P0162

Heated oxygen sensor (HO2S) 2, bank 2, heater control circuit malfunction

Heated oxygen sensor (HO2S) 3, bank 2 - circuit

malfunction

Wiring, HO2S, ECM

Wiring, HO2S, ECM

P0162 Oxygen sensor (O2S) 3, bank 2 - circuit malfunction Wiring, O2S, ECM

P0163 Heated oxygen sensor (HO2S) 3, bank 2 - low voltage Exhaust leak, wiring short to earth, HO2S, ECM

P0163 Oxygen sensor (O2S) 3, bank 2 - low voltage Exhaust leak, wiring short to earth, O2S, ECM

P0164 Heated oxygen sensor (HO2S) 3, bank 2 - high voltage Wiring short to positive, HO2S, ECM

P0164 Oxygen sensor (O2S) 3, bank 2 - high voltage Wiring short to positive, O2S, ECM

P0165 Heated oxygen sensor (HO2S) 3, bank 2 - slow response Heating inoperative, wiring, HO2S

P0165 Oxygen sensor (O2S) 3, bank 2 - slow response Wiring, O2S

P0166

Heated oxygen sensor (HO2S) 3, bank 2 - no activity

detected

Wiring, HO2S, ECM

P0166 Oxygen sensor (O2S) 3, bank 2 - no activity detected Wiring, O2S, ECM

P0167

Heated oxygen sensor (HO2S) 3, bank 2, heater control circuit malfunction

Wiring, HO2S, ECM

P0168 Fuel temperature too high Wiring, fuel temperature sensor, mechanical fault

P0169 Incorrect fuel composition Wiring, fuel composition sensor, mechanical fault

P0170 Fuel trim (FT), bank 1 - malfunction

P0171 System too lean, bank 1

P0172 System too rich, bank 1

P0173 Fuel trim (FT), bank 2 - malfunction

P0174 System too lean, bank 2

Intake leak, AIR system, fuel pressure/pump,

injector(s), EVAP canister purge valve, HO2S

Intake/exhaust leak, AIR system, MAF/VAF sensor, fuel

pressure/pump, injector(s), HO2S

Intake blocked, EVAP canister purge valve, fuel

pressure, EGR system, injector(s), HO2S

Intake leak, AIR system, fuel pressure/pump,

injector(s), EVAP canister purge valve, HO2S

Intake/exhaust leak, fuel pressure/pump, injector(s),

AIR system, hose connection(s)

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 35

P0175 System too rich, bank 2

Intake blocked, EVAP canister purge valve, fuel

pressure, EGR system, injector(s), HO2S

P0176 Fuel composition sensor - circuit malfunction Wiring, fuel composition sensor, ECM

P0177 Fuel composition sensor - range/performance problem Fuel composition sensor

P0178 Fuel composition sensor - low input Wiring short to earth, fuel composition sensor, ECM

P0179 Fuel composition sensor - high input Wiring short to positive, fuel composition sensor, ECM

P0180 Fuel temperature sensor A - circuit malfunction Wiring, fuel temperature sensor, ECM

P0181 Fuel temperature sensor A - range/performance problem Fuel temperature sensor

P0182 Fuel temperature sensor A - low input Wiring short to earth, fuel temperature sensor, ECM

P0183 Fuel temperature sensor A - high input Wiring short to positive, fuel temperature sensor, ECM

P0184 Fuel temperature sensor A - circuit intermittent Wiring, poor connection, fuel temperature sensor, ECM

P0185 Fuel temperature sensor B - circuit malfunction Wiring, fuel temperature sensor, ECM

P0186 Fuel temperature sensor B - range/performance problem Fuel temperature sensor

P0187 Fuel temperature sensor B - low input Wiring short to earth, fuel temperature sensor, ECM

P0188 Fuel temperature sensor B - high input Wiring short to positive, fuel temperature sensor, ECM

P0189 Fuel temperature sensor B - circuit intermittent Wiring, poor connection, fuel temperature sensor, ECM

P0190 Fuel rail pressure (FRP) sensor - circuit malfunction Wiring, fuel rail pressure sensor, ECM

P0191

Fuel rail pressure (FRP) sensor - range/performance

problem

Wiring, FRP sensor

P0192 Fuel rail pressure (FRP) sensor - low input Wiring short to earth, FRP sensor

P0193 Fuel rail pressure (FRP) sensor - high input Wiring short to positive, FRP sensor

P0194 Fuel rail pressure (FRP) sensor - circuit intermittent Wiring, poor connection, FRP sensor

P0195 Engine oil temperature (EOT) sensor - circuit malfunction Wiring, EOT sensor, ECM

P0196

Engine oil temperature (EOT) sensor range/performance problem

EOT sensor

P0197 Engine oil temperature (EOT) sensor - low input Wiring short to earth, EOT sensor

P0198 Engine oil temperature (EOT) sensor - high input Wiring short to positive, EOT sensor

P0199 Engine oil temperature (EOT) sensor - circuit intermittent Wiring, poor connection, EOT sensor, ECM

P0200 Injector - circuit malfunction Wiring, injector, ECM

P0201 Injector 1 - circuit malfunction Wiring, injector, ECM

P0202 Injector 2 - circuit malfunction Wiring, injector, ECM

P0203 Injector 3 - circuit malfunction Wiring, injector, ECM

P0204 Injector 4 - circuit malfunction Wiring, injector, ECM

P0205 Injector 5 - circuit malfunction Wiring, injector, ECM

P0206 Injector 6 - circuit malfunction Wiring, injector, ECM

P0207 Injector 7 - circuit malfunction Wiring, injector, ECM

P0208 Injector 8 - circuit malfunction Wiring, injector, ECM

P0209 Injector 9 - circuit malfunction Wiring, injector, ECM

P0210 Injector 10 - circuit malfunction Wiring, injector, ECM

P0211 Injector 11 - circuit malfunction Wiring, injector, ECM

P0212 Injector 12 - circuit malfunction Wiring, injector, ECM

P0213 Cold start injector 1 - circuit malfunction Wiring, cold start injector, ECM

P0214 Cold start injector 2 - circuit malfunction Wiring, cold start injector, ECM

P0215 Fuel shut-off solenoid - circuit malfunction Wiring, fuel shut-off solenoid, ECM

P0216 Fuel injection timing control - circuit malfunction Wiring, fuel injection timing control solenoid, ECM

P0217 Engine over temperature condition Wiring, cooling system, coolant thermostat, ECT sensor

P0218 Transmission over temperature condition Wiring, TFT sensor, ECM

P0219 Engine over speed condition Incorrect gear change

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 36

P0220

P0220

P0221

P0221

P0222

P0222

P0223

P0223

P0224

P0224

P0225

P0225

P0226

P0226

P0227

P0227

P0228

P0228

P0229

P0229

Throttle position (TP) sensor B/accelerator pedal position

(APP) sensor B - circuit malfunction

Throttle position (TP) switch B/accelerator pedal position

(APP) switch B - circuit malfunction

Throttle position (TP) sensor B/accelerator pedal position

(APP) sensor B - range/performance problem

Throttle position (TP) switch B/accelerator pedal position

(APP) switch B - range/performance problem

Throttle position (TP) sensor B/accelerator pedal position

(APP) sensor B - low input

Throttle position (TP) switch B/accelerator pedal position

(APP) switch B - low input

Throttle position (TP) sensor B/accelerator pedal position

(APP) sensor B - high input

Throttle position (TP) switch B/accelerator pedal position

(APP) switch B - high input

Throttle position (TP) sensor B/accelerator pedal position

(APP) sensor B - circuit intermittent

Throttle position (TP) switch B/accelerator pedal position

(APP) switch B - circuit intermittent

Throttle position (TP) sensor C/accelerator pedal position

(APP) sensor C - circuit malfunction

Throttle position (TP) switch C/accelerator pedal position

(APP) switch C - circuit malfunction

Throttle position (TP) sensor C/accelerator pedal position

(APP) sensor C - range/performance problem

Throttle position (TP) switch C/accelerator pedal position

(APP) switch C - range/performance problem

Throttle position (TP) sensor C/accelerator pedal position

(APP) sensor C - low input

Throttle position (TP) switch C/accelerator pedal position

(APP) switch C - low input

Throttle position (TP) sensor C/accelerator pedal position

(APP) sensor C - high input

Throttle position (TP) switch C/accelerator pedal position

(APP) switch C - high input

Throttle position (TP) sensor C/accelerator pedal position

(APP) sensor C - circuit intermittent

Throttle position (TP) switch C/accelerator pedal position

(APP) switch C - circuit intermittent

Wiring, TP/APP sensor, ECM

Wiring, TP/APP switch, ECM

Accelerator cable adjustment, TP/APP sensor

Accelerator cable adjustment, TP/APP switch

Wiring short to earth, TP/APP sensor, ECM

Wiring short to earth, TP/APP switch, ECM

Wiring short to positive, TP/APP sensor, ECM

Wiring short to positive, TP/APP switch, ECM

Wiring, poor connection, TP/APP sensor, ECM

Wiring, poor connection, TP/APP switch, ECM

Wiring, TP/APP sensor, ECM

Wiring, TP/APP switch, ECM

Accelerator cable adjustment, TP/APP sensor

Accelerator cable adjustment, TP/APP switch

Wiring short to earth, TP/APP sensor, ECM

Wiring short to earth, TP/APP switch, ECM

Wiring short to positive, TP/APP sensor, ECM

Wiring short to positive, TP/APP switch, ECM

Wiring, poor connection, TP/APP sensor, ECM

Wiring, poor connection, TP/APP switch, ECM

P0230 Fuel pump relay - circuit malfunction Wiring, fuel pump relay, ECM

P0231 Fuel pump relay - circuit low Wiring short to earth, fuel pump relay, ECM

P0232 Fuel pump relay - circuit high Wiring short to positive, fuel pump relay, ECM

P0233 Fuel pump relay - circuit intermittent Wiring, poor connection, fuel pump relay, ECM

P0234 Engine boost condition - limit exceeded

P0235 Engine boost condition - limit not reached

P0236

P0237

P0238

Manifold absolute pressure (MAP) sensor A, TC system range/performance problem

Manifold absolute pressure (MAP) sensor A, TC system low input

Manifold absolute pressure (MAP) sensor A, TC system high input

Hose connection(s), wiring, TC wastegate regulating

valve, TC wastegate

Hose connection(s), wiring, TC wastegate regulating

valve, TC wastegate, TC

Intake/exhaust leak, hose connection(s), MAP sensor

Wiring short to earth, MAP sensor, ECM

Wiring short to positive, MAP sensor, ECM

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 37

P0239

P0240

P0241

P0242

P0243

P0244

P0245

P0246

P0247

P0248

P0249

P0250

Manifold absolute pressure (MAP) sensor B, TC system circuit malfunction

Manifold absolute pressure (MAP) sensor B, TC system range/performance problem

Manifold absolute pressure (MAP) sensor B, TC system low input

Manifold absolute pressure (MAP) sensor B, TC system high input

Turbocharger (TC) wastegate regulating valve A - circuit

malfunction

Turbocharger (TC) wastegate regulating valve A range/performance problem

Turbocharger (TC) wastegate regulating valve A - circuit

low

Turbocharger (TC) wastegate regulating valve A - circuit

high

Turbocharger (TC) wastegate regulating valve B - circuit

malfunction

Turbocharger (TC) wastegate regulating valve B range/performance problem

Turbocharger (TC) wastegate regulating valve B - circuit

low

Turbocharger (TC) wastegate regulating valve B - circuit

high

Wiring, MAP sensor, ECM

Intake/exhaust leak, hose connection(s), MAP sensor

Wiring short to earth, MAP sensor, ECM

Wiring short to positive, MAP sensor, ECM

Wiring, TC wastegate regulating valve, ECM

TC wastegate regulating valve

Wiring short to earth, TC wastegate regulating valve,

ECM

Wiring short to positive, TC wastegate regulating valve,

ECM

Wiring, TC wastegate regulating valve, ECM

TC wastegate regulating valve

Wiring short to earth, TC wastegate regulating valve,

ECM

Wiring short to positive, TC wastegate regulating valve,

ECM

P0251 Injection pump A, rotor/cam - circuit malfunction Wiring, injection pump, ECM

P0252 Injection pump A, rotor/cam - range/performance problem Injection pump

P0253 Injection pump A, rotor/cam - circuit low Wiring short to earth, injection pump, ECM

P0254 Injection pump A, rotor/cam - circuit high Wiring short to positive, injection pump, ECM

P0255 Injection pump A, rotor/cam - circuit intermittent Wiring, poor connection, injection pump, ECM

P0256 Injection pump B, rotor/cam - circuit malfunction Wiring, injection pump, ECM

P0257 Injection pump B, rotor/cam - range/performance problem Injection pump

P0258 Injection pump B, rotor/cam - circuit low Wiring short to earth, injection pump, ECM

P0259 Injection pump B, rotor/cam - circuit high Wiring short to positive, injection pump, ECM

P0260 Injection pump B, rotor/cam - circuit intermittent Wiring, poor connection, injection pump, ECM

P0261 Injector 1 - circuit low Wiring short to earth, injector, ECM

P0262 Injector 1 - circuit high Wiring short to positive, injector, ECM

P0263 Cylinder 1 - contribution/balance fault Wiring, fuel system, ECM

P0264 Injector 2 - circuit low Wiring short to earth, injector, ECM

P0265 Injector 2 - circuit high Wiring short to positive, injector, ECM

P0266 Cylinder 2 - contribution/balance fault Wiring, fuel system, ECM

P0267 Injector 3 - circuit low Wiring short to earth, injector, ECM

P0268 Injector 3 - circuit high Wiring short to positive, injector, ECM

P0269 Cylinder 3 - contribution/balance fault Wiring, fuel system, ECM

P0270 Injector 4 - circuit low Wiring short to earth, injector, ECM

P0271 Injector 4 - circuit high Wiring short to positive, injector, ECM

P0272 Cylinder 4 - contribution/balance fault Wiring, fuel system, ECM

P0273 Injector 5 - circuit low Wiring short to earth, injector, ECM

P0274 Injector 5 - circuit high Wiring short to positive, injector, ECM

P0275 Cylinder 5 - contribution/balance fault Wiring, fuel system, ECM

P0276 Injector 6 - circuit low Wiring short to earth, injector, ECM

P0277 Injector 6 - circuit high Wiring short to positive, injector, ECM

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 38

P0278 Cylinder 6 - contribution/balance fault Wiring, fuel system, ECM

P0279 Injector 7 - circuit low Wiring short to earth, injector, ECM

P0280 Injector 7 - circuit high Wiring short to positive, injector, ECM

P0281 Cylinder 7 - contribution/balance fault Wiring, fuel system, ECM

P0282 Injector 8 - circuit low Wiring short to earth, injector, ECM

P0283 Injector 8 - circuit high Wiring short to positive, injector, ECM

P0284 Cylinder 8 - contribution/balance fault Wiring, fuel system, ECM

P0285 Injector 9 - circuit low Wiring short to earth, injector, ECM

P0286 Injector 9 - circuit high Wiring short to positive, injector, ECM

P0287 Cylinder 9 - contribution/balance fault Wiring, fuel system, ECM

P0288 Injector 10 - circuit low Wiring short to earth, injector, ECM

P0289 Injector 10 - circuit high Wiring short to positive, injector, ECM

P0290 Cylinder 10 - contribution/balance fault Wiring, fuel system, ECM

P0291 Injector 11 - circuit low Wiring short to earth, injector, ECM

P0292 Injector 11 - circuit high Wiring short to positive, injector, ECM

P0293 Cylinder 11 - contribution/balance fault Wiring, fuel system, ECM

P0294 Injector 12 - circuit low Wiring short to earth, injector, ECM

P0295 Injector 12 - circuit high Wiring short to positive, injector, ECM

P0296 Cylinder 12 - contribution/balance fault Wiring, fuel system, ECM

P0297 Vehicle over-speed condition Wiring, VSS, mechanical fault

P0298 Engine oil temperature too high Wiring, EOT sensor, mechanical fault

P0299 Turbo/super charger - low boost Mechanical fault

P0300 Random/multiple cylinder(s) - misfire detected

P0301 Cylinder 1 - misfire detected

P0302 Cylinder 2 - misfire detected

P0303 Cylinder 3 - misfire detected

P0304 Cylinder 4 - misfire detected

P0305 Cylinder 5 - misfire detected

P0306 Cylinder 6 - misfire detected

P0307 Cylinder 7 - misfire detected

P0308 Cylinder 8 - misfire detected

P0309 Cylinder 9 - misfire detected

P0310 Cylinder 10 - misfire detected

P0311 Cylinder 11 - misfire detected

P0312 Cylinder 12 - misfire detected

Spark plug(s), HT lead(s), injector(s), ignition coil(s),

low compression, wiring

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

Engine mechanical fault, wiring, ignition/fuel system,

injector, ECT/MAF sensor, ECM

P0313 Misfire detected - low fuel level Fuel system, mechanical fault

P0314 Single cylinder misfire - cylinder not specified

Engine mechanical fault, wiring, ignition/fuel system,

injector

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 39

P0315 Crankshaft position system - variation not learned Engine mechanical fault, wiring

P0316 Misfire detected during start-up - first 1000 revolutions

Engine mechanical fault, wiring, ignition/fuel system,

injector

P0317 Rough road hardware not present Wiring, ECM

P0318 Rough road sensor signal A - circuit malfunction Wiring, rough road sensor A, mechanical fault

P0319 Rough road sensor signal B - circuit malfunction Wiring, rough road sensor B, mechanical fault

P0320

P0321

P0322

P0323

Crankshaft position (CKP) sensor/engine speed (RPM)

sensor - circuit malfunction

Crankshaft position (CKP) sensor/engine speed (RPM)

sensor - range/performance problem

Crankshaft position (CKP) sensor/engine speed (RPM)

sensor - no signal

Crankshaft position (CKP) sensor/engine speed (RPM)

sensor - circuit intermittent

Wiring, CKP/RPM sensor, ECM

Air gap, metal particle contamination, insecure

sensor/rotor, wiring, CKP/RPM sensor

Wiring, CKP/RPM sensor, ECM

Wiring, poor connection, CKP/RPM sensor, ECM

P0324 Knock control system error Wiring, poor connection, KS, ECM

P0325 Knock sensor (KS) 1, bank 1 - circuit malfunction Wiring, poor connection, KS

P0326

P0327 Knock sensor (KS) 1, bank 1 - low input

P0328 Knock sensor (KS) 1, bank 1 - high input

Knock sensor (KS) 1, bank 1 - range/performance

problem

Wiring, KS incorrectly tightened, KS

Insecure KS, poor connection, wiring short to earth,

incorrectly tightened, KS, ECM

Wiring short to positive, KS incorrectly tightened, KS,

ECM

P0329 Knock sensor (KS) 1, bank 1 - circuit intermittent Wiring, poor connection, KS, ECM

P0330 Knock sensor (KS) 2, bank 2 - circuit malfunction Wiring, KS, ECM

P0331

P0332 Knock sensor (KS) 2, bank 2 - low input

P0333 Knock sensor (KS) 2, bank 2 - high input

Knock sensor (KS) 2, bank 2 - range/performance

problem

Wiring, KS incorrectly tightened, KS

Insecure KS, poor connection, wiring short to earth, KS

incorrectly tightened, KS, ECM

Wiring short to positive, KS incorrectly tightened, KS,

ECM

P0334 Knock sensor (KS) 2, bank 2 - circuit intermittent Wiring, poor connection, KS, ECM

P0335 Crankshaft position (CKP) sensor - circuit malfunction Wiring, CKP sensor, ECM

P0336

Crankshaft position (CKP) sensor - range/performance

problem

Insecure sensor/rotor, air gap, wiring, CKP sensor

P0337 Crankshaft position (CKP) sensor - low input Wiring short to earth, CKP sensor, ECM

P0338 Crankshaft position (CKP) sensor - high input Wiring short to positive, CKP sensor, ECM

P0339 Crankshaft position (CKP) sensor - circuit intermittent Wiring, poor connection, CKP sensor, ECM

P0340

P0341

Camshaft position (CMP) sensor A, bank 1 - circuit

malfunction

Camshaft position (CMP) sensor A, bank 1 range/performance problem

Wiring, CMP sensor, ECM

Insecure sensor/rotor, air gap, wiring, CMP sensor

P0342 Camshaft position (CMP) sensor A, bank 1 - low input Wiring short to earth, CMP sensor, ECM

P0343 Camshaft position (CMP) sensor A, bank 1 - high input Wiring short to positive, CMP sensor, ECM

P0344

P0345

P0346

Camshaft position (CMP) sensor A, bank 1 - circuit

intermittent

Camshaft position (CMP) sensor A, bank 2 - circuit

malfunction

Camshaft position (CMP) sensor A, bank 2 range/performance problem

Wiring, poor connection, CMP sensor, ECM

Wiring, CMP sensor, ECM

Insecure sensor/rotor, air gap, wiring, CMP sensor

P0347 Camshaft position (CMP) sensor A, bank 2 - low input Wiring short to earth, CMP sensor, ECM

P0348 Camshaft position (CMP) sensor A, bank 2 - high input Wiring short to positive, CMP sensor, ECM

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 40

P0349

Camshaft position (CMP) sensor A, bank 2 - circuit

intermittent

Wiring, poor connection, CMP sensor, ECM

P0350 Ignition coil, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0351 Ignition coil A, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0352 Ignition coil B, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0353 Ignition coil C, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0354 Ignition coil D, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0355 Ignition coil E, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0356 Ignition coil F, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0357 Ignition coil G, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0358 Ignition coil H, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0359 Ignition coil I, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0360 Ignition coil J, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0361 Ignition coil K, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0362 Ignition coil L, primary/secondary - circuit malfunction Wiring, ignition coil, ECM

P0363 Misfire detected - fuelling disabled Fuel system, mechanical fault

P0365

P0366

P0367

P0368

P0369

Camshaft position (CMP) sensor B, bank 1 - circuit

malfunction

Camshaft position (CMP) sensor B, bank 1 - circuit

range/performance

Camshaft position (CMP) sensor B, bank 1 - circuit low

input

Camshaft position (CMP) sensor B, bank 1 - circuit high

input

Camshaft position (CMP) sensor B, bank 1 - circuit

intermittent

Wiring, poor connection, CMP sensor, ECM

Wiring, poor connection, CMP sensor

Wiring short to earth, CMP sensor, ECM

Wiring short to positive, CMP sensor, ECM

Wiring, poor connection, ECM

P0370 Timing reference, high resolution signal A - malfunction Wiring, CKP/RPM/CMP sensor, ECM

P0371

P0372

P0373

Timing reference, high resolution signal A - too many

pulses

Timing reference, high resolution signal A - too few

pulses

Timing reference, high resolution signal A - intermittent

erratic pulses

Wiring, CKP/RPM/CMP sensor, ECM

Wiring, CKP/RPM/CMP sensor, ECM

Wiring, poor connection, CKP/RPM/CMP sensor, ECM

P0374 Timing reference, high resolution signal A - no pulses Wiring, CKP/RPM/CMP sensor, ECM

P0375 Timing reference, high resolution signal B - malfunction Wiring, CKP/RPM/CMP sensor, ECM

P0376

P0377

P0378

Timing reference, high resolution signal B - too many

pulses

Timing reference, high resolution signal B - too few

pulses

Timing reference, high resolution signal B - intermittent

erratic pulses

Wiring, CKP/RPM/CMP sensor, ECM

Wiring, CKP/RPM/CMP sensor, ECM

Wiring, poor connection, CKP/RPM/CMP sensor, ECM

P0379 Timing reference, high resolution signal B - no pulses Wiring, CKP/RPM/CMP sensor, ECM

P0380 Glow plugs, circuit A - malfunction Wiring, glow plug relay, fuse, glow plugs, ECM

P0381 Glow plug warning lamp - circuit malfunction Wiring, glow plug warning lamp, ECM

P0382 Glow plugs, circuit B - malfunction Wiring, glow plug relay, glow plugs, ECM

P0385 Crankshaft position (CKP) sensor B - circuit malfunction Wiring, CKP sensor, ECM

P0386

Crankshaft position (CKP) sensor B - range/performance

problem

Insecure sensor/rotor, air gap, wiring, CKP sensor

P0387 Crankshaft position (CKP) sensor B - low input Wiring short to earth, CKP sensor, ECM

P0388 Crankshaft position (CKP) sensor B - high input Wiring short to positive, CKP sensor, ECM

P0389 Crankshaft position (CKP) sensor B - circuit intermittent Wiring, poor connection, CKP sensor, ECM

Manufacturer:

Engine code:

Tuned for:

R-Cat

Lancia

838A1.000

Model:

Output:

1994-02

Year:

Kappa 2,0

107 (145) 6100

© Autodata Limited 2004

2006.10.21.

V5.500-

Page 41

P0390