Page 1

SUMMIT 8800

Handbook

Flow Computer

Volume 3: Configuration

© KROHNE 08/2013 - MA SUMMIT 8800 Vol 3 R02 en

Page 2

SUMMIT 8800IMPRINT

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2013 by

KROHNE Messtechnik GmbH - Ludwig-KROHNE-Str. 5 - 47058 Duisburg (Germany)

2 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 3

SUMMIT 8800

CONTENTS

1 About this book 12

1.1 Volumes ............................................................................................................................. 12

1.2 Content Volume 1 .............................................................................................................. 12

1.3 Content Volume 2 .............................................................................................................. 12

1.4 Content Volume 3 .............................................................................................................. 13

1.5 Information in this handbook ............................................................................................ 13

2 General Information 14

2.1 Software versions used for this guide ...............................................................................14

2.2 Terminology and Abbreviations ......................................................................................... 14

2.3 General Controls and Conventions ................................................................................... 15

2.4 ID Data Tree ....................................................................................................................... 16

2.4.1 Type of data ..............................................................................................................................17

2.4.2 Colour codes .............................................................................................................................18

2.4.3 ID Lookup ................................................................................................................................. 19

2.5 Specific Requirements for Meters and Volume Convertors ............................................. 19

2.5.1 Numbering formats ..................................................................................................................19

2.5.2 Alarms ...................................................................................................................................... 19

2.5.3 Optional consequences ............................................................................................................ 20

3 CONFIGURATOR SOFTWARE 21

4 DATE & TIME 23

4.1 Initial setting of date and time ......................................................................................... 23

4.2 SNTP Time Synchronisation .............................................................................................. 24

4.3 Manually change date and time ....................................................................................... 25

5 DATA LOGGING 27

5.1 Alarm and audit log security ............................................................................................. 27

5.2 Alarm log ........................................................................................................................... 28

5.3 Audit trail log ..................................................................................................................... 28

5.3.1 Audit log extension ................................................................................................................... 29

5.4 Data log .............................................................................................................................. 31

5.4.1 Access to data log .....................................................................................................................34

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

3

Page 4

SUMMIT 8800CONTENTS

6 DISPLAY AND WEB ACCESS 36

6.1 System pages .................................................................................................................... 36

6.2 User defined pages ........................................................................................................... 40

6.3 Display ............................................................................................................................... 40

6.3.1 Main menu & submenus .......................................................................................................... 41

6.3.2 Display page & items ...............................................................................................................44

6.3.3 Set the page type ...................................................................................................................... 45

6.4 Security / edit mode .......................................................................................................... 49

6.4.1 Users & submenus ...................................................................................................................49

6.4.2 Display page and items ............................................................................................................ 50

6.5 Supervisor Mode ............................................................................................................... 51

6.6 Alarm/Audit Security Configuration .................................................................................. 53

6.7 Mimic Diagrams ................................................................................................................ 53

6.7.1 Mimic diagram selection .......................................................................................................... 54

6.7.2 New mimic item .......................................................................................................................55

6.7.3 Configure mimic item ............................................................................................................... 56

6.8 Display templates .............................................................................................................. 64

6.8.1 Template selection ................................................................................................................... 65

6.8.2 New template item ................................................................................................................... 66

6.9 3D Graphs .......................................................................................................................... 74

6.9.1 Graph selection ........................................................................................................................76

6.9.2 Graph settings and options ...................................................................................................... 76

6.9.3 3D graph profile ........................................................................................................................78

6.10 Keyboard Configuration ...................................................................................................80

6.11 Default ............................................................................................................................. 82

6.12 Translation to local language .......................................................................................... 83

6.12.1 Importing a language file ....................................................................................................... 85

6.12.2 Change a language in Excel ................................................................................................... 86

6.13 Web access ...................................................................................................................... 88

7 REPORTING 89

7.1 Serial ticket printing .......................................................................................................... 90

7.1.1 Serial port settings ................................................................................................................... 90

7.1.2 Print jobs .................................................................................................................................. 91

7.1.3 Configure report .......................................................................................................................93

7.1.4 Format the items ...................................................................................................................... 94

7.1.5 Add statistics ............................................................................................................................ 96

7.1.6 Multiple pages .......................................................................................................................... 97

7.2 Ethernet reporting ............................................................................................................. 97

7.2.1 FTP protocol .............................................................................................................................98

7.2.2 SMTP E-mail protocol ..............................................................................................................98

7.2.3 Print jobs .................................................................................................................................. 99

7.2.4 Configure HTML report ..........................................................................................................102

7.2.5 Configure XML Reports .......................................................................................................... 109

4 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 5

SUMMIT 8800

CONTENTS

7.3 Downloadable ID or active data reports .......................................................................... 117

7.3.1 Format the items .................................................................................................................... 118

7.3.2 Read a report ..........................................................................................................................119

8 COMMUNICATION 120

8.1 Type of protocols ............................................................................................................. 120

8.1.1 Standard protocol ................................................................................................................... 120

8.1.2 Meter protocols ......................................................................................................................120

8.1.3 Host protocols ........................................................................................................................120

8.2 Basic Communication setup ........................................................................................... 121

8.2.1 Port selection .........................................................................................................................121

8.2.2 Basic RS 232/485 serial port settings .................................................................................... 122

8.2.3 Basic Ethernet settings ......................................................................................................... 122

8.3 Modbus master ............................................................................................................... 123

8.3.1 Modbus master port selection and settings .......................................................................... 123

8.3.2 Modbus Master type ............................................................................................................... 124

8.3.3 Differential pressure meters .................................................................................................. 125

8.3.4 Ultrasonic and Coriolis meters .............................................................................................. 126

8.3.5 Provers ................................................................................................................................... 127

8.3.6 Gas chromatographs .............................................................................................................. 128

8.3.7 Redundancy master ............................................................................................................... 130

8.3.8 Custom Modbus master ......................................................................................................... 131

8.4 Modbus slave ................................................................................................................... 131

8.4.1 Modbus slave port selection and settings .............................................................................132

8.4.2 Modbus slave addresses ........................................................................................................ 135

8.4.3 Parameters .............................................................................................................................136

8.5 Enron Modbus ................................................................................................................. 139

8.5.1 Enron modbus settings: ......................................................................................................... 139

8.5.2 Create logs .............................................................................................................................140

8.5.3 Addressing scheme: .............................................................................................................. 143

8.5.4 Define Modbus alarms ........................................................................................................... 145

8.6 Pemex Modbus ................................................................................................................ 146

8.6.1 Logs ........................................................................................................................................ 146

8.6.2 Addressing scheme ................................................................................................................ 146

8.7 Instromet Ultrasonic protocol ......................................................................................... 147

8.8 Encoder protocol ............................................................................................................. 148

8.9 CTE Protocol .................................................................................................................... 149

8.10 DSfG Protocol ................................................................................................................ 152

8.11 SOAP protocol ................................................................................................................153

9 GENERAL INFORMATION 154

9.1 Unit Identification ............................................................................................................ 154

9.2 Date and time .................................................................................................................. 154

9.3 Translation .......................................................................................................................155

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

5

Page 6

SUMMIT 8800CONTENTS

9.4 Audit log ........................................................................................................................... 155

9.5 Settings ............................................................................................................................ 155

9.6 Product information ........................................................................................................ 156

9.7 Calculation code .............................................................................................................. 156

9.8 Factory acceptance test check ........................................................................................ 157

9.9 Security configuration ..................................................................................................... 159

9.10 ID report......................................................................................................................... 161

9.11 Maintenance .................................................................................................................. 161

9.12 Formatting ..................................................................................................................... 162

9.13 Customs strings ............................................................................................................ 163

9.14 Minimum & maximum ID’s ........................................................................................... 164

9.15 Redundancy ................................................................................................................... 166

9.16 Watchdog ....................................................................................................................... 166

9.17 Run-switching ............................................................................................................... 166

9.18 SOAP .............................................................................................................................. 166

9.19 Modbus time-out ........................................................................................................... 166

9.20 Modbus alarms .............................................................................................................. 167

9.21 CTE Configuration ......................................................................................................... 167

10 APPENDIX 1: SOFTWARE VERSIONS 168

10.1 Versions/ Revisions ....................................................................................................... 168

10.2 Current versions ............................................................................................................ 168

10.2.1 Latest version 0.35.0.0 .........................................................................................................168

10.2.2 Approved version MID2.4.0.0 ................................................................................................ 169

11 APPENDIX 2: TABLE OF LEGALLY-RELEVANT PARAMETERS 170

12 APPENDIX 3: MODBUS COMMUNICATION PROTOCOL 171

12.1 Number formats ............................................................................................................ 171

6 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 7

SUMMIT 8800

Figure 1 Example ID Tree ..................................................... 17

Figure 2 ID lookup ........................................................... 19

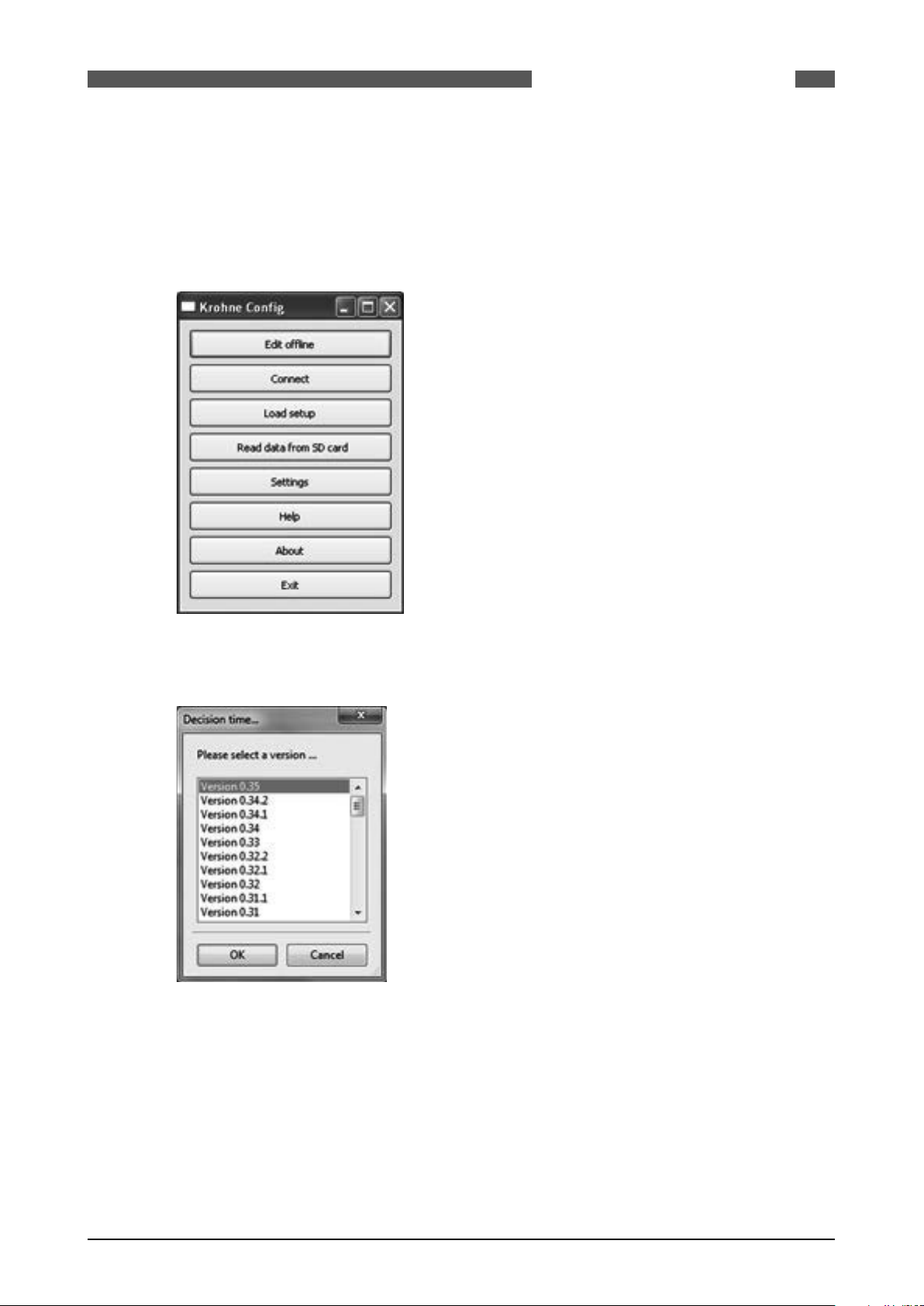

Figure 3 Configurator option selections ......................................... 21

Figure 4 Application firmware version ........................................... 21

Figure 5 Main Configurator display ............................................. 22

Figure 6 Date & time and contract time selection ................................. 23

Figure 7 SNTP Date & time general settings ..................................... 24

Figure 8 SNTP Date & time unicast settings ...................................... 25

Figure 9 SNTP Date & time broadcast settings .................................... 25

Figure 10 Manual Date & time settings .......................................... 26

Figure 11 Manual Date & time adjustment ....................................... 26

Figure 12 Display security window .............................................. 27

Figure 13 Alarm log .......................................................... 28

Figure 14 Audit trail log ....................................................... 29

Figure 15 Audit log extension .................................................. 30

Figure 16 Audit log select alarms ............................................... 30

Figure 17 Audit log select variables ............................................. 31

Figure 18 Audit log options .................................................... 31

Figure 19 Data logging ........................................................ 32

Figure 20 Data log select variables ............................................. 32

Figure 21 Data log settings .................................................... 33

Figure 22 Data log statistics ................................................... 33

Figure 23 Data log local log numbers ........................................... 34

Figure 24 Data log ID’s for FTP printing with log record selection .................... 35

Figure 25 Data log ID’s for modbus with index selection ............................ 35

Figure 26 Display, set the correct engineering units ............................... 36

Figure 27 Alarm and audit log .................................................. 37

Figure 28 Edit mode and system information ..................................... 38

Figure 29 Settings, display settings and touchscreen calibration .................... 39

Figure 30 Display main page ................................................... 40

Figure 31 Configurator main menu & submenu ................................... 41

Figure 32 Display main menu & submenu ........................................ 41

Figure 33 New menu, select template ........................................... 42

Figure 34 Edit a menu item .................................................... 43

Figure 35 Bit map editor ...................................................... 43

Figure 36 Import bit map ...................................................... 44

Figure 37 Configure display page ............................................... 44

Figure 38 Display item details ................................................. 45

Figure 39 Display page based on 8 centre template ................................ 46

Figure 40 Display page based on VU template .................................... 46

Figure 41 Display page based on a mimic ........................................ 47

Figure 42 Display page based on a mimic ........................................ 47

Figure 43 Display page based on log data (list). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 44 Display page based on log data (Graph) ................................. 48

Figure 45 Display page based on a X-Y-Z graph ................................... 48

Figure 46 Configurator security window ......................................... 49

Figure 47 Configurator users & submenus ....................................... 49

Figure 48 Summit users & submenu ............................................ 50

Figure 49 Edit users .......................................................... 50

Figure 50 Same page in normal and in supervisor mode ........................... 51

Figure 51 Setup supervisor mode .............................................. 52

Figure 52 Summit supervisor mode login and logout .............................. 53

Figure 53 Mimic display definition .............................................. 54

Figure 54 Create a mimic display canvas ........................................ 54

Figure 55 New mimic display .................................................. 55

Figure 56 Create a mimic display canvas ........................................ 55

Figure 57 New mimic item and right mouse click on an item ........................ 56

CONTENTS

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

7

Page 8

SUMMIT 8800TABLE OF FIGURES

Figure 58 Mimic item configure colour .......................................... 58

Figure 59 Mimic item colour palette ............................................ 59

Figure 60 Mimic item configure an alarm and warning ............................. 60

Figure 61 Mimic item configure image ........................................... 60

Figure 62 Mimic item edit image and crop/stretch image ........................... 61

Figure 63 Mimic item configure operators ....................................... 62

Figure 64 Mimic item configure condition ........................................ 62

Figure 65 Mimic item configure text ............................................. 63

Figure 66 Mimic item configure variable ......................................... 63

Figure 67 Mimic item configure format for a variable and for a button ................ 64

Figure 68 Mimic item configure format for a variable and for a button ................ 64

Figure 69 Display templates ................................................... 65

Figure 70 Create a template ................................................... 65

Figure 71 New display template ................................................ 66

Figure 72 Create a mimic display canvas ........................................ 66

Figure 73 A display template and right mouse click on item ........................ 66

Figure 74 Move and re-size an item ............................................. 67

Figure 75 Template: variable configuration and Summit screen ..................... 68

Figure 76 Template: VU meter configuration and Summit screen .................... 68

Figure 77 Template: VU meter configure limits and colours ......................... 69

Figure 78 Template: vertical bar graph configuration and Summit screen ............. 70

Figure 79 Template: horizontal bar graph configuration and Summit screen .......... 70

Figure 80 Template: two signed bar graphs for the configurator and Summit screen .... 70

Figure 81 Template: bar graphs configure limits and colours ....................... 71

Figure 82 Template: trend configuration and Summit screen ........................ 72

Figure 83 Template: trend configure limits and colours ............................ 73

Figure 84 3D graph settings ................................................... 74

Figure 85 Summit 3D graph; X-Y-Z and X-Y chart example. . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 86 Create a mimic display canvas ........................................ 76

Figure 87 New graph display .................................................. 76

Figure 88 New graph range settings ............................................ 76

Figure 89 New graph colour settings ............................................ 77

Figure 90 New graph options .................................................. 77

Figure 91 New graph profile ................................................... 78

Figure 92 Graph profile, Top ................................................... 78

Figure 93 Graph profiles for value and ID’s ....................................... 79

Figure 94 Graph profile, enter the X-Y pair for one line ............................. 79

Figure 95 Display keyboard customisation and use ................................ 80

Figure 96 Create a keyboard ................................................... 80

Figure 97 New display keyboard ................................................ 81

Figure 98 Display keyboard, key definition ....................................... 81

Figure 99 Display French keyboard in configuration and on the Summit .............. 82

Figure 100 Display default configuration ......................................... 82

Figure 101 Display default settings ............................................. 82

Figure 102 Translation to Spanish .............................................. 83

Figure 103 Selection of Spanish ................................................ 84

Figure 104 Create a language .................................................. 84

Figure 105 Name and search a language ........................................ 84

Figure 106 Language configuration ............................................. 85

Figure 107 Import a language file .............................................. 86

Figure 108 Select language to be exported ....................................... 86

Figure 109 Converting a language file in Excel .................................... 87

Figure 110 Save as an Excel language CSV file .................................... 87

Figure 111 Web access enabled ................................................ 88

Figure 112 Web access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 113 Web access setup for Ethernet port 1 .................................. 89

Figure 114 Ticket printer ...................................................... 90

8 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 9

SUMMIT 8800

Figure 115 Ticket printer settings .............................................. 91

Figure 116 Ticket printer print jobs ............................................. 91

Figure 117 Ticket printer print jobs ............................................. 92

Figure 118 Ticket printer print jobs ............................................. 92

Figure 119 Ticket printer print conditions ........................................ 92

Figure 120 Configure reports .................................................. 93

Figure 121 Variable and log data ID selection ..................................... 94

Figure 122 Zoom function ..................................................... 94

Figure 123 Variable item options with formatting details ........................... 94

Figure 124 Data log item options with changed time period and format ............... 95

Figure 125 Data log item Select statistics ....................................... 96

Figure 126 Page selection ..................................................... 97

Figure 127 Ethernet port configuration ......................................... 98

Figure 128 Ethernet port FTP configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Figure 129 Ethernet port SMTP configuration .................................... 99

Figure 130 Ethernet printjob configuration ...................................... 100

Figure 131 Ethernet reporting print jobs ......................................... 100

Figure 132 Ethernet reporting print conditions ................................... 101

Figure 133 Ethernet reporting select printer and print data ......................... 101

Figure 134 Ticket printer print jobs ............................................. 102

Figure 135 Configure Ethernet reports .......................................... 102

Figure 136 Configure Ethernet reports, select report .............................. 103

Figure 137 Configure Ethernet reports, format the paper .......................... 103

Figure 138 Configure Ethernet reports, format the report data ...................... 103

Figure 139 Select items ....................................................... 104

Figure 140 Select a text ....................................................... 104

Figure 141 Select a variable from a list .......................................... 104

Figure 142 Select log data from a list ........................................... 105

Figure 143 Select alarm log data ............................................... 105

Figure 144 Select audit log data ............................................... 106

Figure 145 Select an image ................................................... 106

Figure 146 Create a graph ..................................................... 107

Figure 147 Format an item .................................................... 107

Figure 148 Data log item Select statistics ....................................... 108

Figure 149 Configure Ethernet reports, page selection ............................. 109

Figure 150 XML report configuration ............................................ 110

Figure 151 Configure Ethernet reports, select xml report .......................... 110

Figure 152 Configure Ethernet reports, select file name ........................... 111

Figure 153 Configure Ethernet reports, xml report data ............................ 111

Figure 154 Configure Ethernet reports, xml report data ............................ 112

Figure 155 Begin XML tag window and result ..................................... 112

Figure 156 End XML tag normal and error result .................................. 112

Figure 157 ID configuration window and result ................................... 113

Figure 158 Log data configuration window and results ............................. 114

Figure 159 Audit log data configuration window ................................... 115

Figure 160 Format an item .................................................... 117

Figure 161 ID report configuration .............................................. 117

Figure 162 Configure ID reports, select report .................................... 118

Figure 163 Configure ID reports, report data ..................................... 118

Figure 164 Format an item .................................................... 119

Figure 165 Read an ID report .................................................. 119

Figure 166 Communication board and port selection .............................. 121

Figure 167 Serial port type selection and a typical setting .......................... 122

Figure 168 Ethernet configuration page ......................................... 122

Figure 169 Example Modbus and Modbus over TCP/IP master port settings ........... 123

Figure 170 Modbus device selection ............................................ 124

Figure 171 Modbus Bristol 3808 MVT ............................................ 125

TABLE OF FIGURES

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

9

Page 10

SUMMIT 8800TABLE OF FIGURES

Figure 172 Modbus device selection ............................................ 126

Figure 173 Modbus master, selection of gas coriolis meter ......................... 127

Figure 174 Modbus master GC device settings .................................... 129

Figure 175 Modbus master GC component settings ................................ 130

Figure 176 Modbus redundancy master ......................................... 130

Figure 177 LUA script page .................................................... 131

Figure 178 Example RS232/485 Modbus serial and TCP/IP port settings .............. 132

Figure 179 Modbus slave enable timeout ........................................ 133

Figure 180 Modbus slave timeout settings ....................................... 133

Figure 181 Modbus slave log settings ........................................... 134

Figure 182 Modbus slave address offset settings ................................. 134

Figure 183 Modbus slave register configuration .................................. 135

Figure 184 Modbus slave ID lists: variables, log data, status bits .................... 135

Figure 185 Modbus slave registers ............................................. 136

Figure 186 Modbus slave im- and export ........................................ 137

Figure 187 Modbus serial settings .............................................. 138

Figure 188 Modbus register parameter functions ................................. 138

Figure 189 Modbus parameter settings .......................................... 139

Figure 190 Enron modbus serial settings ........................................ 140

Figure 191 Enron event log .................................................... 141

Figure 192 Enron daily log ..................................................... 142

Figure 193 Enron hourly log ................................................... 143

Figure 194 Enron modbus log selections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 195 Enron modbus log addressing ........................................ 144

Figure 196 Enron modbus addressing ........................................... 145

Figure 197 Enron Modbus alarms .............................................. 146

Figure 198 Figure 198 Instromet protocol serial settings .......................... 147

Figure 199 Encoder setting .................................................... 148

Figure 200 CTE protocol hardware setting ....................................... 149

Figure 201 CTE protocol setting ................................................ 150

Figure 202 CTE protocol setting ................................................ 150

Figure 203 CTE protocol variables .............................................. 151

Figure 204 CTE protocol log data ............................................... 151

Figure 205 Figure 205 DSfG block diagram ....................................... 152

Figure 206 Ethernet configuration page ......................................... 153

Figure 207 Soap user configuration ............................................. 153

Figure 208 General unit identifier .............................................. 154

Figure 209 General settings ................................................... 155

Figure 210 Calculation code and help ........................................... 157

Figure 211 Configure a FAT check .............................................. 158

Figure 212 User authorization and security configuration selection .................. 160

Figure 213 Read and modify a secure configuration in partial mode .................. 160

Figure 214 Maintenance configuration .......................................... 161

Figure 215 Formatting configuration ............................................ 162

Figure 216 Configure string ID’s and resulting variables ........................... 163

Figure 217 Configure string ID’s formatting ...................................... 164

Figure 218 Min/max ID setting and resulting variables ............................. 165

10 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 11

SUMMIT 8800

IMPORTANT INFORMATION

KROHNE Oil & Gas pursues a policy of continuous development and product improvement. The

Information contained in this document is, therefore subject to change without notice. Some

display descriptions and menus may not be exactly as described in this handbook. However, due

the straight forward nature of the display this should not cause any problem in use.

To the best of our knowledge, the information contained in this document is deemed accurate

at time of publication. KROHNE Oil & Gas cannot be held responsible for any errors, omissions,

inaccuracies or any losses incurred as a result.

In the design and construction of this equipment and instructions contained in this handbook,

due consideration has been given to safety requirements in respect of statutory industrial regulations.

ABOUT THIS HANDBOOK

01

Users are reminded that these regulations similarly apply to installation, operation and maintenance, safety being mainly dependent upon the skill of the operator and strict supervisory

control.

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

11

Page 12

1. About this book

1.1 Volumes

This is Volume 3 of 3 of the SUMMIT 8800 Handbook:

Volume 1

Volume 1 is targeted to the electrical, instrumentation and maintenance engineer

This is an introduction to the SUMMIT 8800 flow computer, explaining its architect and layout providing the user with familiarity and the basic principles of build. The volume describes the

Installation and hardware details, its connection to field devices and the calibration.

The manual describes the operation via its display, its web site and the configuration software.

Also the operational functional of the Windows software tools are described, including the configurator, the Firmware wizard and the display monitor.

Volume 2

Volume 2 is targeted to the metering software configuration by a metering engineer.

The aim of this volume is to provide information on how to configure a stream and the associated hardware.

The handbook explains the configuration for the different metering technologies, including meters, provers, samplers, valves, redundancy etc.. A step by step handbook using the Configurator

software, on the general and basic setup to successfully implement flow measurement based on

all the applications and meters selections within the flow computer.

SUMMIT 8800ABOUT THIS HANDBOOK01

Volume 3

Volume 3 is targeted to the software configuration of the communication to the outside world.

The manual covers all advance functionality of the SUMMIT 8800 including display configuration,

reports, communication protocols, remote access and many more advance options.

1.2 Content Volume 1

Volume 1 concentrates on the daily use of the flow computer

• Chapter 2: Basic functions of the flow computer

• Chapter 3: General information on the flow computer

• Chapter 4: Installation and replacement of the flow computer

• Chapter 5: Hardware details on the computer, its components and boards

• Chapter 6: Connecting to Field Devices

• Chapter 7: Normal operation via the touch screen

• Chapter 8: How to calibration the unit

• Chapter 9: Operation via the optional web site

• Chapter 10: Operational functions of the configuration software, more details in volume 2

• Chapter 11: How to update the firmware

• Chapter 12: Display monitor software to replicate the SUMMIT 8800 screen on a PC and make

screen shots

1.3 Content Volume 2

Volume 2 concentrates on the software for the flow computer.

• Chapter 2: General information on the software aspects of the flow computer

• Chapter 3: Details on metering principles

• Chapter 4: Basic functions of configurator

• Chapter 5: Configuration of the hardware of the boards

• Chapter 6: Stream configuration

• Chapter 7: Run switching

• Chapter 8: Watchdog

12 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 13

SUMMIT 8800

• Chapter 9: Configure a station

• Chapter 10: Configure a prover or master meter

• Chapter 11: Configure valves

• Chapter 12: Configure a sampler

• Chapter 13: Set-up batching

• Chapter 14: Set two flow computers in redundant configuration

1.4 Content Volume 3

Volume 3 concentrates on the configuration of the SUMMIT 8800

• Chapter 3; Configurator software

• Chapter 4: Date & Time

• Chapter 5: Data Logging

• Chapter 6: Display and web access

• Chapter 7: Reporting

• Chapter 8: Communication

• Chapter 9: General Information

1.5 Information in this handbook

ABOUT THIS HANDBOOK

01

The information in this handbook is intended for the integrator who is responsible to setup and

configure the SUMMIT 8800 flow computer for Liquid and or Gas and or Steam application:

Integrators (hereafter designated user) with information of how to install, configure, operate and

undertake more complicated service tasks.

This handbook does not cover any devices or peripheral components that are to be installed and

connected to the SUMMIT 8800 it is assumed that such devices are installed in accordance with

the operating instructions supplied with them.

Disclaimer

KROHNE Oil & Gas take no responsibility for any loss or damages and disclaims all liability for

any instructions provided in this handbook. All installations including hazardous area installations are the responsibility of the user, or integrator for all field instrumentation connected to

and from the SUMMIT 8800 Flow computer.

Trademarks

SUMMIT 8800 is a trade mark of KROHNE Oil & Gas.

Notifications

KROHNE Oil & Gas reserve the right to modify parts and/or all of the handbook and any other

documentation and/ or material without any notification and will not be held liable for any damages or loss that may result in making any such amendments.

Copyright

This document is copyright protected.

KROHNE Oil & Gas does not permit any use of parts, or this entire document in the creation of

any documentation, material or any other production. Prior written permission must be obtained

directly from KROHNE Oil & Gas for usage of contents. All rights reserved.

Who should use this handbook?

This handbook is intended for the integrator or engineer who is required to configure the flow

computer for a stream including devices connected to it.

Versions covered in this handbook

All Versions

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

13

Page 14

2. General Information

2.1 Software versions used for this guide

This handbook is based on the software versions as mentioned in Appendix 1: software versions

2.2 Terminology and Abbreviations

AGA American Gas Association

API American Petroleum Institute

Communication board Single or dual Ethernet network board

Configurator Windows software tool to configure and communicate to the SUMMIT 8800

CP Control Panel

CPU Central Processing Unit

CRC32 Cyclic Redundancy Check 32 bits. Checksum to ensure validity of information

FAT Factory Acceptance Test

FDS Functional Design Specification

HMI Human-Machine Interface

HOV Hand Operated Valve

I/O Input / Output

ISO International Standards Organization

KOG KROHNE Oil and Gas

KVM Keyboard / Video / Mouse

MOV Motor Operated Valve

MSC Metering Supervisory Computer

MUT Meter Under Test

Navigator 360 optical rotary dial

PC Personal Computer

PRT Platinum Resistance Thermometers

PSU Power Supply Unit

PT Pressure Transmitter

Re-try Method to repeat communication a number of times before giving an alarm

RTD: Resistance Temperature Device

Run: Stream/Meter Run

SAT Site Acceptance Test

SUMMIT 8800 Flow computer

Timestamp Time and date at which data is logged

Time-out Count-down timer to generate an alarm if software stopped running

TT Temperature Transmitter

UFC Ultrasonic Flow Converter

UFM Ultrasonic Flow Meter

UFP Ultrasonic Flow Processor (KROHNE flow computer )

UFS Ultrasonic Flow Sensor

VOS Velocity of Sound

ZS Ball detector switch

XS Position 4-way valve

XV Control 4-way valve

SUMMIT 8800GENERAL INFORMATION02

14 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 15

SUMMIT 8800

2.3 General Controls and Conventions

In the configurator several conventions are being used:

Numeric Data Entry Box

Clear background, black text, used for entering Numeric Data, a value must be entered here

Optional: Coloured background, black text used for entering optional Numeric Data. If no value

is entered then right click mouse key and select Invalidate, box will show and no number will be

entered.

An invalid Number will be shown on the SUMMIT 8800 display as “---------“ and is read serially

as 1E+38

Pull-Down Menu

Select a function or option from a list functions or options

GENERAL INFORMATION

02

Icon

Selects a function or a page.

Tabs

Allows an individual page, sub-page or function to be selected from a series of pages, sub-pages or functions.

Expanded item Fewer items shown.

Non Expanded item +

More items shown.

Option Buttons

Red cross means OFF or No

Green tick means ON or Yes

Data Tree

Items from the Data Tree can be either selected or can be “Dragged and dropped” from the Tree

into a selection box; for example when setting up a logging system or a Modbus list, etc.

Yellow Data circle means Read Only. Red data circle means Read and Write.

Hover over

Hold the cursor arrow over any item, button or menu, etc. Do not click any mouse button, the

item will be lightly highlighted and information relating to the selection will be illustrated.

Grey Text

Indicates that this item has no function or cannot be entered in this particular mode of the system. The data is shown for information purposes only.

Help Index

Display information that assists the user in configuration.

Naming convention of Variables

In the KROHNE SUMMIT 8800 there are variables used with specific naming.

This naming is chosen to identify a variable and relate it to the correct stream.

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

15

Page 16

SUMMIT 8800GENERAL INFORMATION02

The most complex variable is explained below and this explanation can be used to interpret all

the other variable names.

Example: + ph uVN . 1

+ Positive (+) or negative (-)

Ph Previous (P) or Current (C) period

Pqh – previous 15 minutes

Ph – previous hour

Pd – previous Day

Pm – previous month

Pq – previous quarter of a year

Cqh – current 15 minutes

Ch – current hour

Cd – current Day

Cm – current month

Cq – current quarter of a year

u Type of totals

u – Unhaltable, counts always

m – Maintenance, counts when maintenance is active (optional)

n – Normal, fiscal counters during normal operation

e – Error, fiscal counters with an accountable error

t1 –> t4 – Tarif , fiscal counters based on fiscal thresholds

VN Type of flow

VPulses, pulses counted

Vline, gross volume flow

Vmon, monitored grass volume flow

Vbc (p/t) pressure and temperature corrected gross volume flow

Vbc, linearization corrected (Vbc(p/t))gross volume flow

VN, Normalized volume flow

VN(net), Nett normalized flow

VM, Mass flow

VE, Energy flow

VCO2, carbon dioxide flow

1 Stream/ Run number

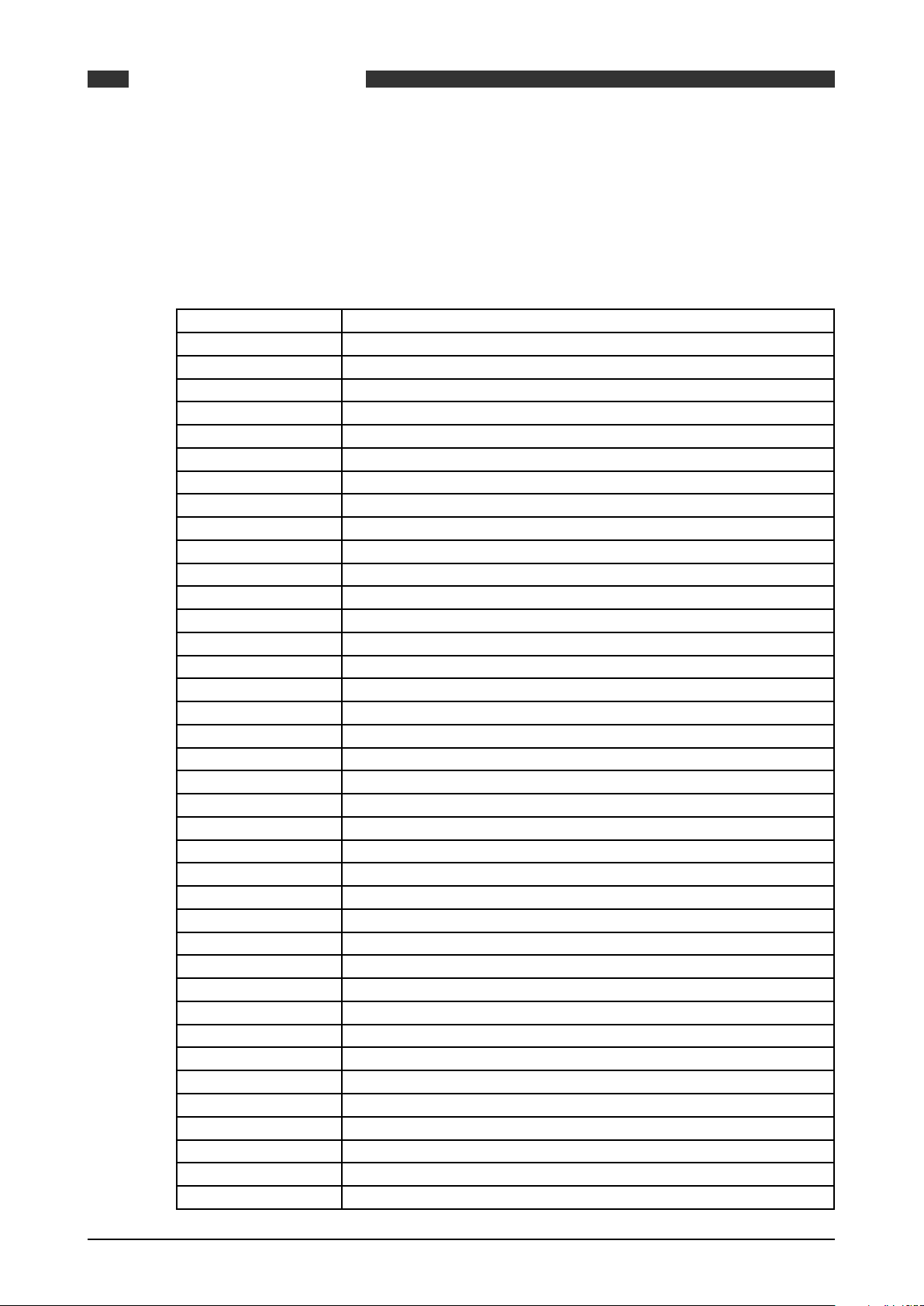

2.4 ID Data Tree

When selecting parameters and options in the Configurator software, the user will be presented

with a tree structure for instance:

16 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 17

SUMMIT 8800

GENERAL INFORMATION

02

Figure 1 Example ID Tree

This is referred to as the ID tree which, depending on its context, includes folders and several

parameters:

2.4.1 Type of data

The rest of this chapter will explain the folders available, the type of selection within the folder

and any other corresponding data.

Preset Data

Essential to the configuration of the flow computer. Typical data would be keypad values, operating limits, equation selection, calibration data for Turbines and Densitometers and Orifice

plates.

This data would be present in a configuration report, and enables you to see what the flow computer is configured to do.

Used for validation and will form the Data Checksum (visible on the System Information Page).

E.g., if a data checksum changes, the setup of the flow computer has changed and potentially

calculating different results to what is expected.

Typically configured and left alone, only updated after validation e.g. every 6 month / 1 year.

Active Data

These values cover inputs to the flow computer. E.g. from GC, pressure & temperature transmitters, meters etc..

Also Values calculated in the flow computer. E.g. Flow rates, Z, Averages, Density etc..

Local Data

Data that an operator can change locally to perform maintenance tasks. E.g., turn individual

transmitters off without generating alarms. Setting Maintenance mode or Proving Mode.

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

17

Page 18

Totals

Totals for the streams and station.

Contents of this folder are stored in the non-volatile RAM and are protected using the battery.

Custom

User defined variables.

Allows calculations, made in a LUA script, to be used in a configuration.

For details, see volume 3.

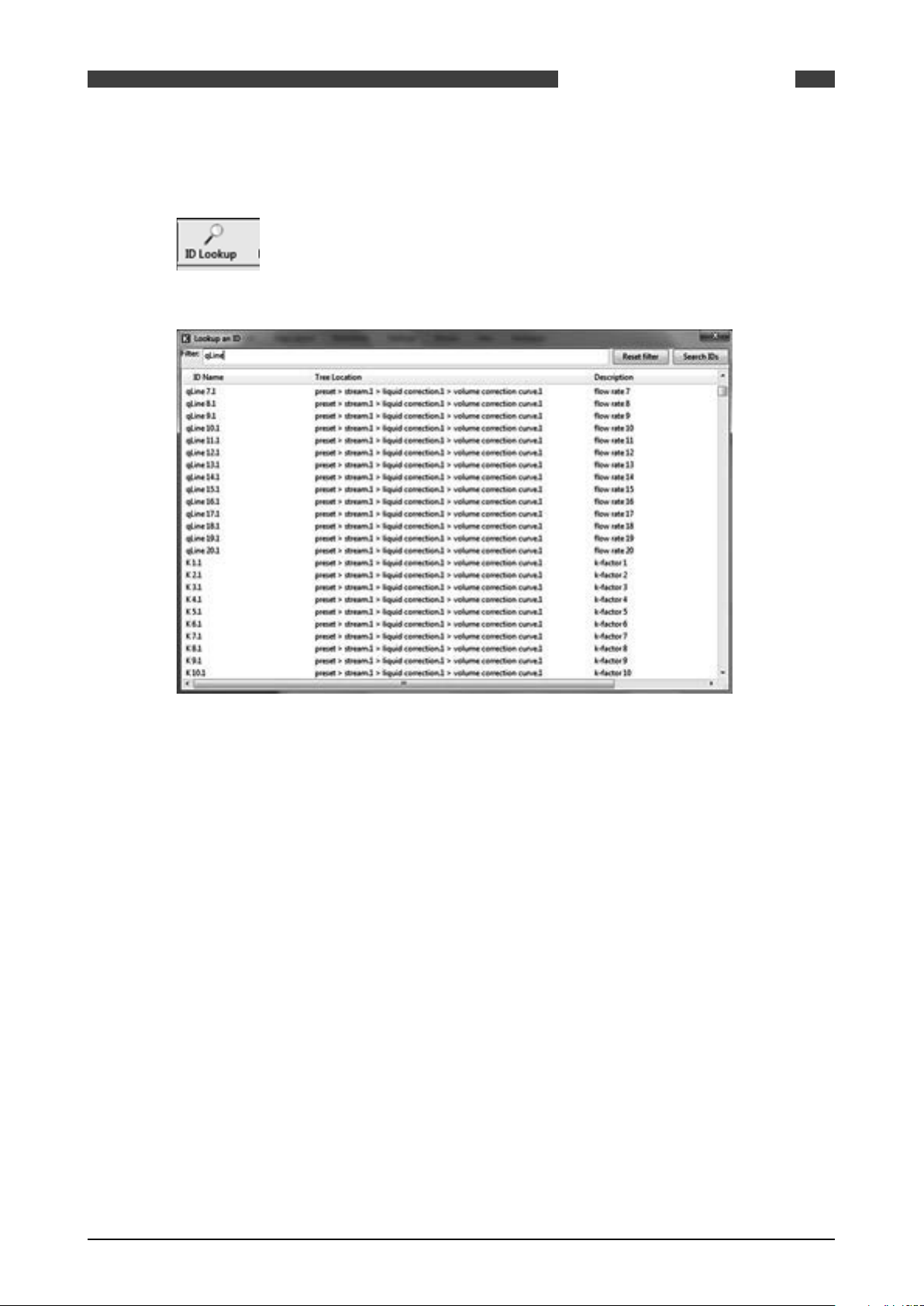

2.4.2 Colour codes

With each parameter and option, there are corresponding coloured dots that represent the access and status of the particular selection.

General ID tree

Please note that it might be possible to change the values via the screen

SUMMIT 8800GENERAL INFORMATION02

Red Dot Data is Read/Write and can be changed over Modbus.

Yellow Dot Data is Read-Only and cannot be changed over Modbus

90% of the data will be Read Only, but items such as Serial Gas Compositions, Time/Date, MF

are commonly written over Modbus.

NOTE: Although the ID may be read/write, the security setting determines whether the ID indeed

can be written.

Alarm Tree

The alarm tree is built of all the registers that hold alarm data. Alarm registers are 32-bit integers, where each bit represents a different alarm.

Red Dot Represents an accountable alarm visible on the alarm list.

Dark Blue Dot Represents a non-accountable alarm visible on the alarm list.

Orange Dot Represents a warning visible on the alarm list.

Light Blue Dot Represents a status alarm, not visible on the alarm list.

Black/Grey Dot Represents a hard- or software fault alarm visible on the alarm list.

An example of typical usage would be the General Alarm Register. This is a 32 bit register that

indicates up to 32 different alarms in the flow computer. This will contain Status Alarms, for example, 1 bit will indicate if there is a Pressure alarm or not. If the Pressure Status bit is set the

user will know that there is a problem with the Pressure.

This should be sufficient information, however if it is not satisfactory, the user can look at the

Pressure alarm, this contains 32 different alarms relating to the Pressure measurement, these

would be Red Dots as they each can create an entry in the alarm list. By reading this register

the user can view exactly what is wrong with the Pressure measurement.

The Light Blue Dots are generally an OR of several other dots. By reading the General register

you can quickly see if the unit is healthy, more information can be provided by reading several

more registers associated with that parameter.

18 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 19

SUMMIT 8800

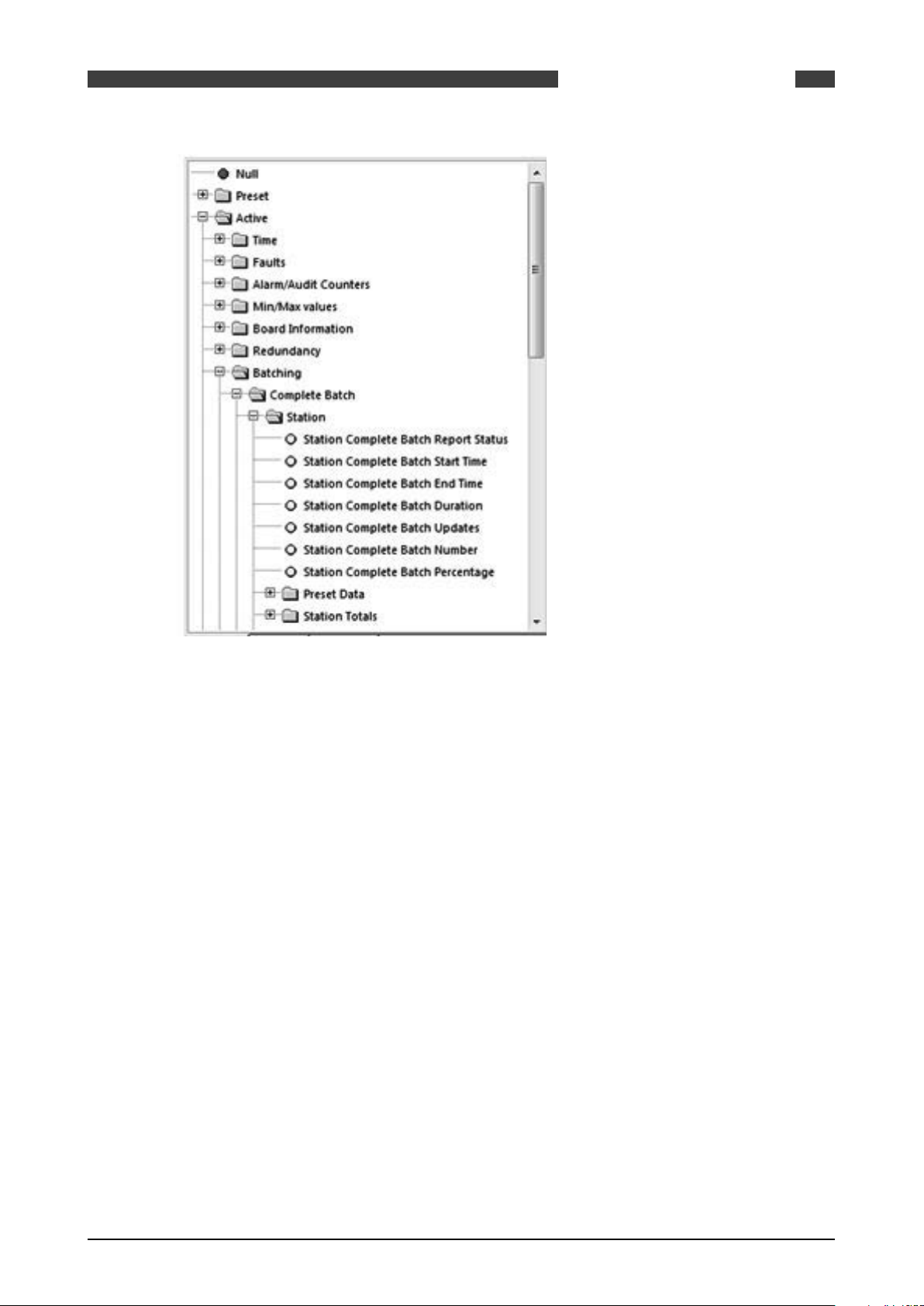

2.4.3 ID Lookup

When pressing the ID lookup button on top of the screen, a lookup table will be generated:

GENERAL INFORMATION

02

Figure 2 ID lookup

As there are very many ID’s, it is possible to filter for a required ID.

2.5 Specific Requirements for Meters and Volume Convertors

2.5.1 Numbering formats

The number formats used internally in the unit are generally IEEE Double Precision floating

point numbers of 64 bit resolution.

It is accepted that such numbers will yield a resolution of better than 14 significant digits.

In the case of Totalisation of Gas, Volumes, Mass and Energy such numbers are always shown to

a resolution of 8 digits before the decimal point and 4 after, i.e. 12 significant digits.

Depending upon the required significance of the lowest digit, these values can be scaled by a

further multiplier.

2.5.2 Alarms

Each of the various modules that comprise the total operating software, are continuously monitored for correct operation. Depending upon the configuration, the flow computer will complete its allotted tasks within the configured cycle time, 250mS, 500mS or 1 second. Failure to

complete the tasks within the time will force the module to complete, and where appropriate, a

substitute value issued together with an alarm indication.

For example, if a Calculation fails to complete correctly then a result of 1 or similar will be

returned, which allows the unit to continue functioning whilst an accountable alarm is raised,

indicating an internal problem.

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

19

Page 20

2.5.2.1 Accountable alarm

When the value of any measurement item or communication to an associated device that is providing measurement item to the SUMMIT 8800 goes out of range, the flow computer will issue

an Accountable Alarm.

When any calculation module or other item that in some way affects the ultimate calculation result goes outside its operating band, i.e. above Pressure Maximum or below Pressure minimum,

then the SUMMIT 8800 will issue an Accountable Alarm.

When the SUMMIT 8800 issues an Accountable alarm a number of consequences will occur as

follows:

Front panel accountable alarm will turn on and Flash.

Nature of accountable alarm will be shown on the top line of the alarm log.

Alarm log will wait for user acknowledgement of alarm.

During the period of the alarm, main totalisation will occur on the alarm counters.

2.5.3 Optional consequences

Depending upon the configuration of the SUMMIT 8800 the following optional Consequences will

also occur:

SUMMIT 8800GENERAL INFORMATION02

An Entry will be made in the Audit Log, with Time and Date of occurrence.

The “Used” value of the Parameter in Alarm will be substituted by an alternative value, either

from an alternative measurement source that is in range, or from a pre-set value.

A digital Alarm output will indicate an Alarm condition.

20 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 21

SUMMIT 8800

3. CONFIGURATOR SOFTWARE

For initial installation of the software refer to Volume 1 of the handbook.

For Hardware and instrumentation, refer to Volume 2 of the handbook

Alter starting the configuration software, the option menu appears:

CONFIGURATOR SOFTWARE

03

Figure 3 Configurator option selections

Select Edit Offline, this function allows the user to create or modify a new configuration without

actually being connected to the flow computer.

Figure 4 Application firmware version

Select the correct software version. The software must be compliant to the connected Summit

8800 firmware version, details of system information can be found in volume 1. We assume that

the version mentioned in append 1 is selected.

The main configuration page of the Configurator software is displayed and will be the starting

point for this manual.

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

21

Page 22

SUMMIT 8800CONFIGURATOR SOFTWARE03

Figure 5 Main Configurator display

22 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 23

SUMMIT 8800 DATE & TIME

4. DATE & TIME

The Summit has a battery backed real-time clock. The clock can be set in several ways:

- Initially a fixed value via the configuration software

- Initially the time of the computer downloading the configuration software..

- Automatically synchronized via an SNTP server

- Manually via the screen

The format of the time can be changed to fit international needs.

The Summit also knows a contract time as often a buyer and seller have different moment of a

day that they like to generate reports, e.g. at 00:00 hours and 06:00 hours. Only required if more

than one report time is needed.

4.1 Initial setting of date and time

04

In the configuration software the initial settings for date and time can be set together with and

the display format and the contract time:

Figure 6 Date & time and contract time selection

Set date from Select from

• Don’t send Leave the Summit clock untouched.

• Set from PC’s date/time Change the Summit clock to the PC date/time when downloading the

• Set from custom settings Change the Summit clock to a manual settings when downloading

Date/ time Date and time for manual setting

Date / time format Select the format needed

Contract time Select the time as per customer needs.

08/2013 - MA SUMMIT 8800 Vol3 R02 en

software

www.krohne.com

23

Page 24

4.2 SNTP Time Synchronisation

The SNTP or Simple Network Time Protocol is available to synchronise the internal clock with a

network time server. While the internal clock’s accuracy is limited to about 3 ppm/°C, these time

servers are based on atomic clocks to guarantee the best accuracy. This function also ensures

that all flow computers in a network are using the same time.

The flow computer works with time servers using version 3 or 4 of the SNTP protocol, either

Unicast or Broadcast:

• Unicast is where the flow computer will request the time from a specified time server.

• Broadcast is when the flow computer waits for a broadcast packet from a time server, and

then confirms the results by using a unicast request.

The SNTP can be setup in the hardware section under the Ethernet SNTP:

SUMMIT 8800DATE & TIME04

Figure 7 SNTP Date & time general settings

Enable Click the box to enable SNTP

Operating mode Set the mode as unicast or multicast

Port The port used for SNTP standard specifies that this should be 123.

Min time adjustment Minimum amount of time the flow computer clock can be adjusted

Max time adjustment Maximum amount of time the flow computer clock can be adjusted

Max time without adjustment Maximum number of seconds that the flow computer can be expected

to operate without receiving a new time from the time server. If this time

is exceeded without receiving a new time then the flow computer will

give a warning.

Invalid time update limit Maximum number of bad updates that can be received before a warning

is given.

Ignore max adjust on startup Indicates if the maximum time adjustment value should be ignored for

the first valid time received by the flow computer after power up.

Offset from GMT The time zone of the local time as an offset from the atom clock +/-

GMT minutes

24 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 25

SUMMIT 8800 DATE & TIME

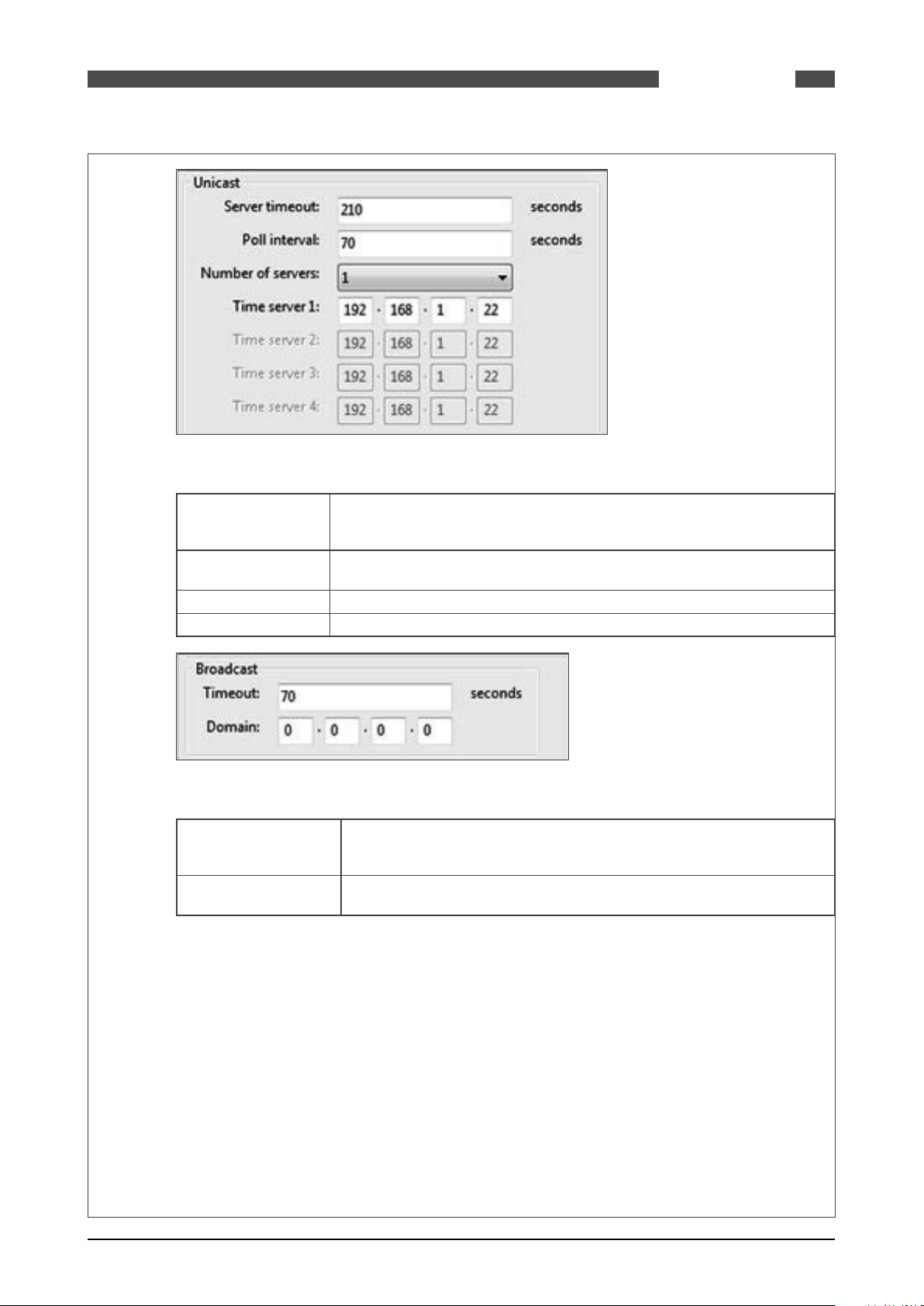

Figure 8 SNTP Date & time unicast settings

Server timeout The timeout that applies to each server, after which the next available server in

the list is tried. It is recommended that this value is a factor of the maximum

time without adjustment.

Poll interval Frequency of the flow computer polling the time server. It is recommended that

this value is not divisible by 60.

Number of servers The number of time servers the flow computer can connect to.

Time server IP address of each server.

04

Figure 9 SNTP Date & time broadcast settings

Broadcast timeout The flow computer the waits for a broadcast before giving an alarm. It is

recommended that this value is a factor of the maximum time without

adjustment.

Broadcast domain. IP address on the client subnet for the client operating in broadcast mode to

listen for time updates from broadcast servers.

4.3 Manually change date and time

To be able to set the date and time manually, a display item has to be created under “Security”

with the time in it. (see also next chapter).

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

25

Page 26

SUMMIT 8800DATE & TIME04

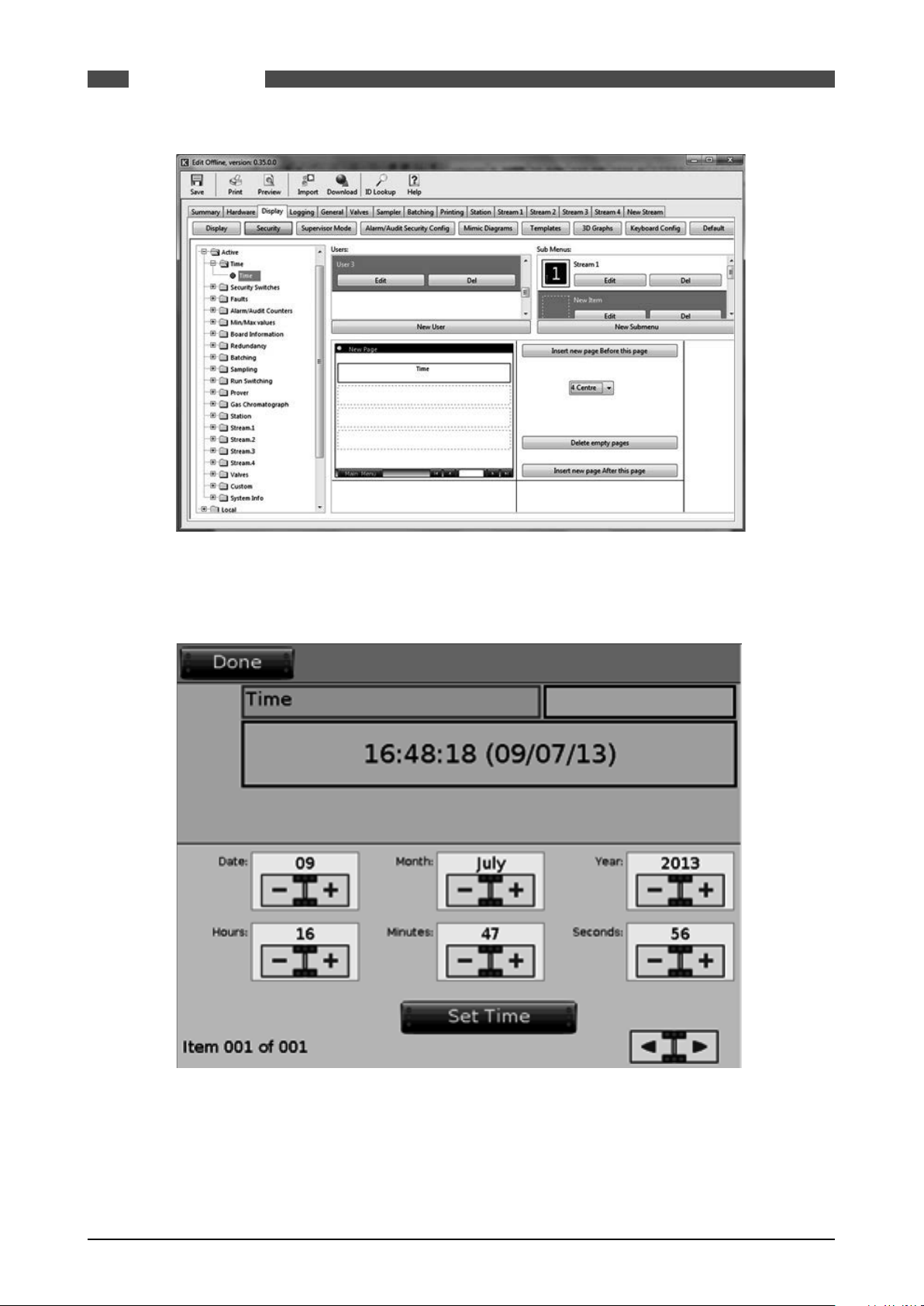

Figure 10 Manual Date & time settings

If the operator then goes into Edit mode, he can change the time as follows:

Figure 11 Manual Date & time adjustment

26 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 27

SUMMIT 8800 DATA LOGGING

5. DATA LOGGING

To store historical data is one of the major functions of a flow computer. The Summit 8800 is has

3 types of log’s:

Alarm log Storage of current and historical alarms.

Audit trail log Storage of any change made to the unit that has metrological significance.

Data log Storage of user defined data, either periodically or event diven.

The first two are system logs and cannot be changed, however an audit log can be extended with

user defined data.

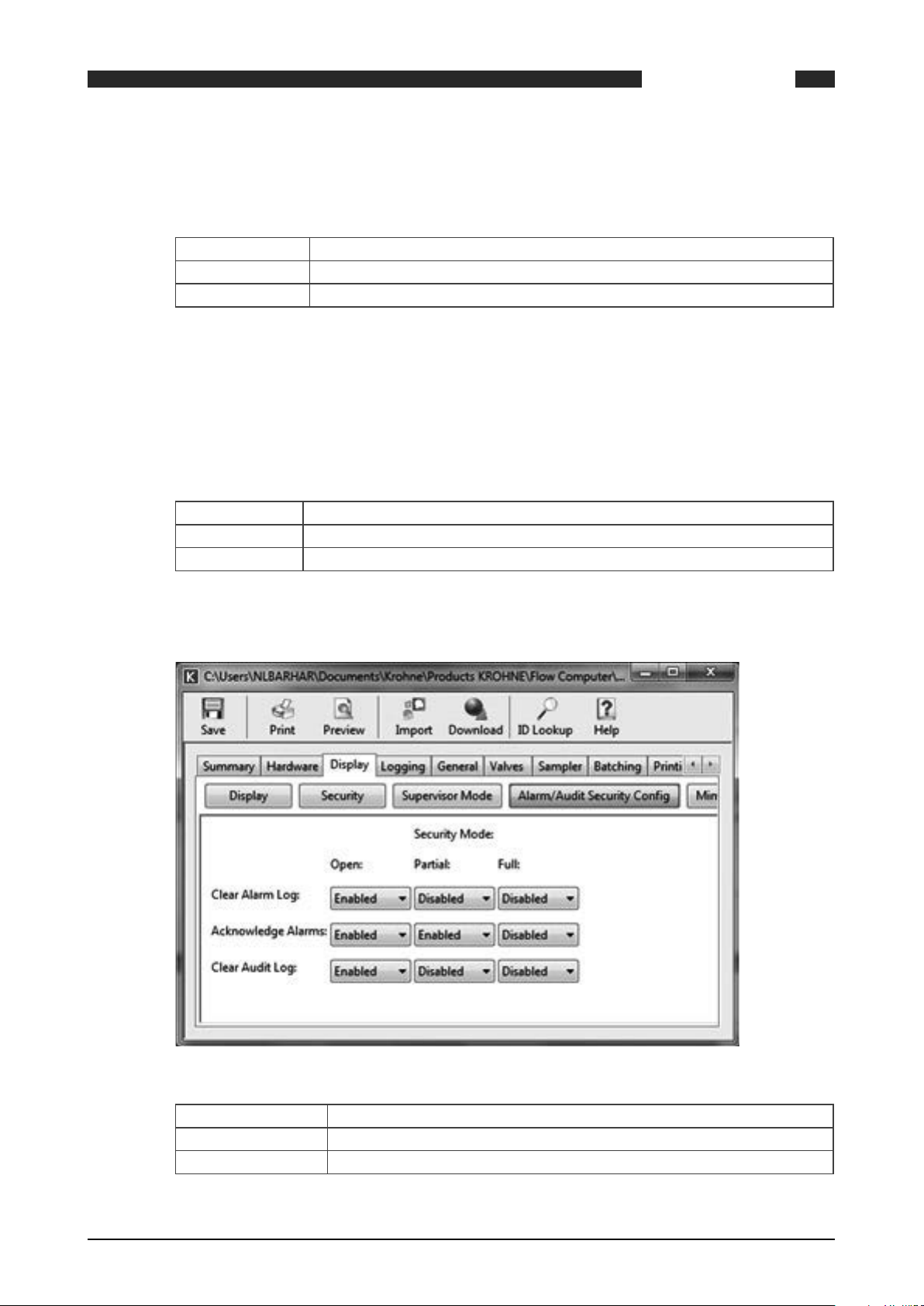

5.1 Alarm and audit log security

It is possible to define what to do with alarm acknowledgment and clearing alarm and audit logs

depending on the 4 hardware security switches on the back of the Summit. Two of them determine the security mode of the Summit:

Open Any changes can be made (using user passwords) and applications can be loaded.

Partial Changes can be made except calibration data. No new application can be loaded.

Full No changes in parameters, values or any other data is not possible.

05

The different security mode also effects the alarm/ audit clearing and acknowledgment and can

be set under “display, alarm/audit security configuration“

Figure 12 Display security window

Clear Alarm Log Determines if the alarm log may be cleared in open/ partial/ full mode.

Acknowledge Alarms Determines if the alarms may be acknowledged in open/ partial/ full mode.

Clear Audit Log Determines if the audit log may be cleared in open/ partial/ full mode.

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

27

Page 28

5.2 Alarm log

Every time an alarm or warning occurs, it will be stored in the alarm log. The log contains a

maximum of 200 entries consisting of time and date when the alarm occurred and vanished plus

a description of the alarm or warning.

SUMMIT 8800DATA LOGGING05

Figure 13 Alarm log

As the alarm log is a system functions, it does not need any configuration, exept for the alarm

acknowledge and clear, which is depending on the security configuration (see previous chapter)

All alarm information stored in the Summit’s internal data flash memory. Each record contains

a CRC 32 check which is generated when the log record is created and checked for validity each

time data is read from the Unit.

5.3 Audit trail log

Any change made in the Summit which influences the flow measurement in any way is stored in

an audit trail to be able to track back what went wrong and possibly recalculate the results.This

log contains a maximum of 200 kbyte of internal memory, typically good at least 2000 entries.

Each entry consists of time and date when the event occurred, the operator name, the description of the event and the value before and after change:

28 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 29

SUMMIT 8800 DATA LOGGING

Figure 14 Audit trail log

05

Each record contains a CRC 32 check which is generated when the log record is created and

checked for validity each time data is read from the unit.

As the audit trail log is a system functions, it does not need any configuration. However, configuration of the audit acknowledge, which is depending on the security configuration, is possible

(see chapter Alarm and audit log security).

5.3.1 Audit log extension

For diagnostic purposes, the user can extend the audit trail with alarms and with up to 10 additional data items per event. These data will be stored on an external SD card only. Configuration

can be done under “general” :

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

29

Page 30

SUMMIT 8800DATA LOGGING05

Figure 15 Audit log extension

The user can select which alarm types are to be included in the audit log:

Figure 16 Audit log select alarms

Accountable alarms Alarms (min or max exceeded) which influence the flow measurements

Non-accountable alarms Alarms which do not influence the flow measurements

Warnings Warnings (hi or low exceeded) which do not influence the flow

measurements

Faults Hardware faults, such as wrong hardware cards inserted for this

application

Select which additional data is to be recorded for each audit event, often these are the flow

totals at time of event:

30 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 31

SUMMIT 8800 DATA LOGGING

Figure 17 Audit log select variables

Drag the variables from the ID’s in the list to record the variable when an audit event occurs.

Determine what to do with the data:

05

Figure 18 Audit log options

%SD card to use The % memory on the external SD card before the log start from the

Read access level An access level for reading these data (for SOAP protocol only yet)

Write access level An access level for writing these data (for SOAP protocol only yet)

5.4 Data log

It is also possible to create logs to store user defined historical data periodically or at events.

Each data log will contain a time and date stamp of the time of the record plus user selected

data items:

beginning

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

31

Page 32

SUMMIT 8800DATA LOGGING05

Figure 19 Data logging

In total 10 data logs on internal memory and 5 data logs in external SD memory can be defined,

each with:

Figure 20 Data log select variables

Up to 50 variables, selectable form the ID tree. The logs settings are:

32 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 33

SUMMIT 8800 DATA LOGGING

Figure 21 Data log settings

Read access level An access level for reading these data (for SOAP protocol only)

Write access level An access level for writing these data (for SOAP protocol only)

Setup name A name for this data log

Log every If the log is periodically, set here the log interval between 5 minutes and 1 year

Num. records The number of records after which the log start from the beginning again

Log change of If the log is event driven, select which variable, from the ID tree, triggers the

event

Be careful to select an variable which changes state, such as end of prove

Default display page Press when page must be displayed after the screen is not used for a period of

time

Add to display menu If checked, this mimic will be placed in the menu item “data logs”

If not checked, the mimic can be used as a display page.

05

The statistics of memory used is indicated on this page, in terms of time and amount of memory

used.

Figure 22 Data log statistics

The period of time the total record will cover

• How much memory is used for this log record

• How much memory is used for all log records

• How much memory is still free

• The maximum amount of memory available for logging.

Please note:

• All data log items are stored in either internal data flash memory or removable SD card

memory depending upon the configuration. Each record contains a CRC 32 which is generated

when the log record is created and checked for validity each time data is read from the Unit.

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

33

Page 34

• The Internal (DF) memory has a capacity of approximately 6 MB or approximately to 300,000

data records, with time and date for each.

• The SD memory used, depends on the size of the card and the % of SD card to use set for this

log record, e.g. 200.000.000 for a 4 GB card.

5.4.1 Access to data log

Log data are available for reporting and communication, but not for display. In many cases, data

logs are specifically used to allow re-print of data.

The logs have records with an index. The first index 1 is latest (youngest) record, the highest

index is the oldest.

Under the normal local variables there are two for log numbers:

SUMMIT 8800DATA LOGGING05

Figure 23 Data log local log numbers

Generate log Set to generate a log

Log counter Number of logs generated

For printing, ID’s can be added from the data, alarm and audit log after which the log record can

be chosen:

34 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 35

SUMMIT 8800 DATA LOGGING

Figure 24 Data log ID’s for FTP printing with log record selection

For modbus, there is a special log data tab for ID’s from the data log and after entering the index

may be changed:

05

Figure 25 Data log ID’s for modbus with index selection

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

35

Page 36

6. DISPLAY AND WEB ACCESS

The Summit 8800 display capabilities can be accessed locally via its touch screen or remotely via

a web browser connected to the build-in Summit web browser. This means that it can be used

via a large local display, a phone, a tablet or a PC. It is also possible to download alarm and audit

logs and real-time ID reports. For details on operator display and web access, see volume 1.

The display screen capabilities of the SUMMIT 8800 represents a quantum leap for flow computers. Not only is it a colour display, but it is also fully graphics, presenting text, mimics, trends,

X-Y-Z charts etc. and it is also fully configurable.

When starting a new application, the configurator will automatically generate a default menu

depending on the type of streams/ prover chosen. Because the menu is created in the default

engineering units, it is very important to make sure that the correct engineering units are

chosen, otherwise the menu items have to be changed manually. So please check if they are set

correctly under “settings” of the configurator start menu:

SUMMIT 8800DISPLAY & WEB ACCESS06

Figure 26 Display, set the correct engineering units

Please note that the menu will not automatically be adjusted when adding a stream to prevent

damaging any changes made. If desired, it is possible to create a new application and import any

changes desired or just create new menu items using the appropriate templetes.

There are two type of display pages:

System pages These pages are deemed essential and will always be available

User defined pages All other pages are fully configurable

6.1 System pages

The Summit has standard pages which cannot be changed and will always be available. They

handle the system functions, such as:

36 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 37

SUMMIT 8800 DISPLAY & WEB ACCESS

06

Figure 27 Alarm and audit log

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

37

Page 38

SUMMIT 8800DISPLAY & WEB ACCESS06

Figure 28 Edit mode and system information

Although the edit mode page to protect secure pages will always be there, the menu and pages

behind it are user definable.

38 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol3 R02 en

Page 39

SUMMIT 8800 DISPLAY & WEB ACCESS

06

Figure 29 Settings, display settings and touchscreen calibration

08/2013 - MA SUMMIT 8800 Vol3 R02 en

www.krohne.com

39

Page 40

6.2 User defined pages

Except for system pages, there are pages which are fully user defined. With the configurator

software menu’s can be changed, added and deleted:

SUMMIT 8800DISPLAY & WEB ACCESS06

Figure 30 Display main page

There are 9 selections to change the screen navigation to access data within the flow computer:

Display To define the display pages for normal operation

Security To define the display pages for secure / edit mode operation

Supervisor Mode Sets supervisory mode for secure fields in normal operation

Alarm/Audit Security

Configuration

Mimic Diagrams To define graphic pages for normal mode

Templates Defines templates for formatting display pages

3D Graphs To define X-Y-Z charts for normal operation

Keyboard Configuration Defines the keyboard layout to adapt it to international keyboards

Default Set which page must be displayed when not used for a period of time

6.3 Display

The display main page, as depicted in Figure 30, allows to add, change or delete any display item

for normal operation.

The display has the following elements:

Determines actions allowed depending on the security dip switches

Main menu The vertical menu on the display when “main menu” is pressed

Submenu The horizontal menu when one of the main menu items with a right

arrow is pressed

Display page One of the information pages that can presented