Page 1

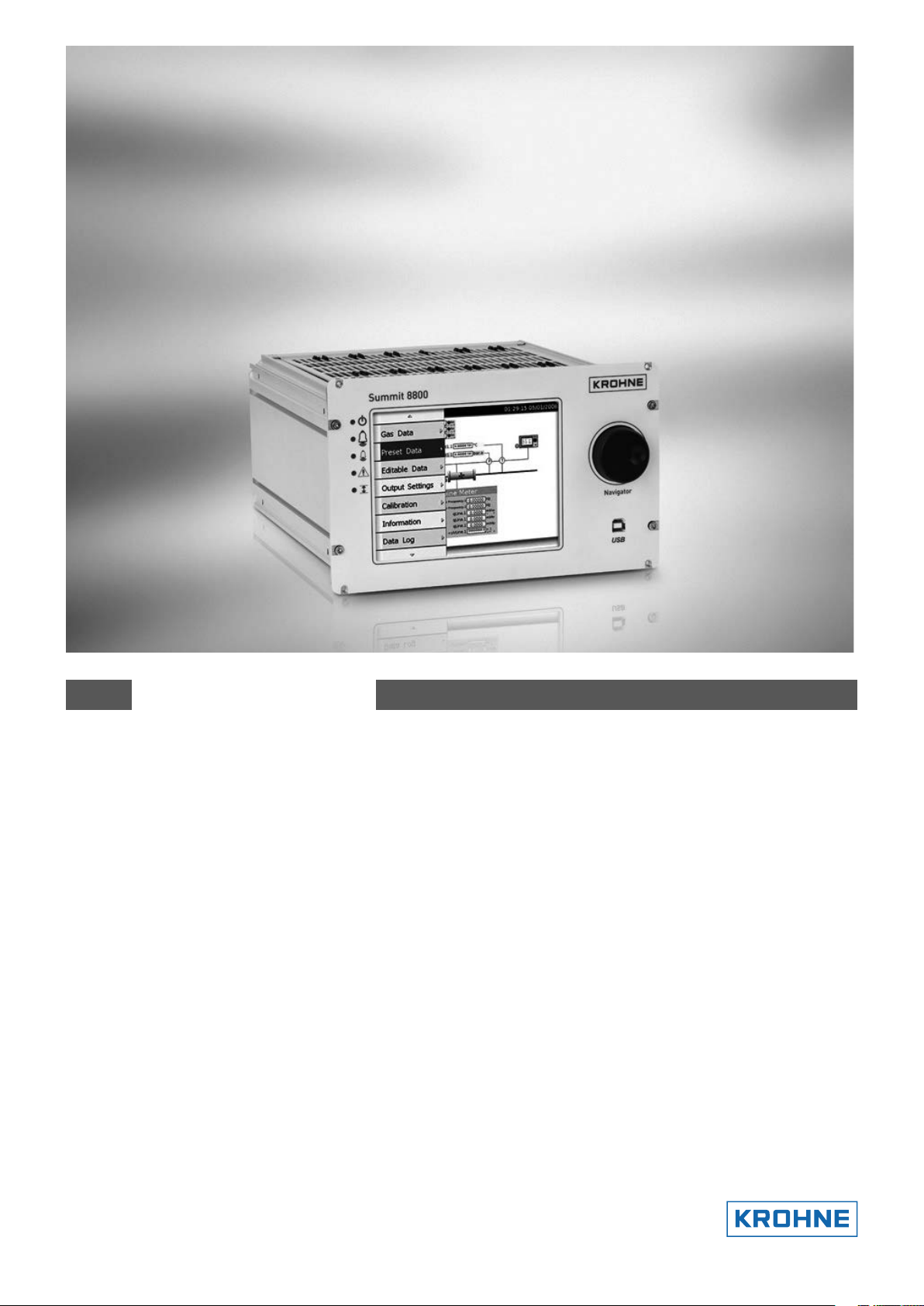

SUMMIT 8800

Flow Computer

Volume 2: Software

Handbook

© KROHNE 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 2

SUMMIT 8800IMPRINT

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2013 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 3

SUMMIT 8800

CONTENTS

1 About this book 13

1.1 Volumes ............................................................................................................................. 13

1.2 Content Volume 1 .............................................................................................................. 13

1.3 Content Volume 2 .............................................................................................................. 13

1.4 Content Volume 3 .............................................................................................................. 14

1.5 Information in this handbook ............................................................................................ 14

2 General Information 15

2.1 Software versions used for this guide ...............................................................................15

2.2 Terminology and Abbreviations ......................................................................................... 15

2.3 General Controls and Conventions ................................................................................... 16

2.4 ID Data Tree ....................................................................................................................... 17

2.4.1 Type of data ..............................................................................................................................18

2.4.2 Colour codes .............................................................................................................................19

2.5 Specific Requirements for Meters and Volume Convertors ............................................. 20

2.5.1 Numbering formats ..................................................................................................................20

2.5.2 Alarms ...................................................................................................................................... 20

2.5.3 Accountable alarm ...................................................................................................................20

2.5.4 Optional consequences ............................................................................................................ 20

3 Metering principles 21

3.1 Pulse based meters: e.g. turbine/ positive displacement / rotary meter ........................ 21

3.2 Ultrasonic meters ............................................................................................................. 22

3.3 Differential pressure (dP) meters: e.g. orifice, venturi and cone meter .......................... 23

3.3.1 Orifice Plate .............................................................................................................................. 25

3.3.2 Venturi nozzle ........................................................................................................................... 26

3.4 Coriolis meters .................................................................................................................. 26

3.5 Meter corrections .............................................................................................................. 28

3.5.1 Gas & steam ............................................................................................................................. 28

3.5.2 Liquid ........................................................................................................................................ 28

3.6 Liquid normalisation ......................................................................................................... 29

3.6.1 Mass and energy ......................................................................................................................30

3.7 Gas normalisation ............................................................................................................. 30

3.7.1 Equation of state ......................................................................................................................31

3.7.2 Line and base density ............................................................................................................... 32

3.7.3 Relative density/ specific gravity ..............................................................................................32

3.7.4 Mass and energy ......................................................................................................................32

3.7.5 Enthalpy .................................................................................................................................... 32

3.8 Stream, station and batch totals ....................................................................................... 33

3.9 Run switching .................................................................................................................... 35

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

3

Page 4

SUMMIT 8800CONTENTS

3.10 Proving ............................................................................................................................. 35

3.10.1 Unidirectional ball prover ....................................................................................................... 36

3.10.2 Bi-directional pipe prover ...................................................................................................... 36

3.10.3 Small volume / piston provers ............................................................................................... 37

3.10.4 Master meter .......................................................................................................................... 37

3.10.5 Proving procedure .................................................................................................................. 38

3.10.6 Meter factor and K – factor ....................................................................................................41

3.10.7 Proving sequence ...................................................................................................................42

3.10.8 Proving run (ball position) ...................................................................................................... 45

3.11 Sampling .......................................................................................................................... 46

4 The configurator 47

4.1 Applications ....................................................................................................................... 47

4.2 Measurement devices and signals ....................................................................................47

4.3 Create a new application ................................................................................................... 47

4.4 Main Screen ....................................................................................................................... 50

5 Hardware 51

5.1 I/O board Configuration ..................................................................................................... 52

5.1.1 HART Input ............................................................................................................................... 53

5.1.2 Analog Inputs............................................................................................................................54

5.1.3 PRT/ RTD/ PT-100 direct temperature input ...........................................................................55

5.1.4 Digital Inputs ............................................................................................................................ 55

5.1.5 Analog Outputs ......................................................................................................................... 56

5.1.6 Digital Outputs ..........................................................................................................................56

5.1.7 Serial Output ............................................................................................................................ 59

5.2 Stream hardware setup ..................................................................................................... 59

5.2.1 Flowmeters ..............................................................................................................................59

5.2.2 Temperature transmitter .........................................................................................................64

5.2.3 Pressure Transmitter ............................................................................................................... 66

5.2.4 Density Transducer ..................................................................................................................68

5.2.5 Density transmitter temperature and pressure ......................................................................69

5.3 Flow and totals output ....................................................................................................... 70

5.4 Alarm outputs .................................................................................................................... 71

6 Stream configuration 72

6.1 Units .................................................................................................................................. 72

6.2 Meter selection .................................................................................................................. 73

6.2.1 Pulse based meters: Turbine / PD ...........................................................................................73

6.2.2 Ultrasonic ................................................................................................................................. 75

6.2.3 Differential Pressure ................................................................................................................ 80

6.2.4 Coriolis ..................................................................................................................................... 86

6.3 Product information ..........................................................................................................90

4 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 5

SUMMIT 8800

CONTENTS

6.4 Flow rates and totals ......................................................................................................... 92

6.4.1 Flow rate limits & scaling ........................................................................................................92

6.4.2 Liquid flow rate correction .......................................................................................................93

6.4.3 Gas and steam flow rate correction ......................................................................................... 95

6.5 Tariff ...................................................................................................................................97

6.6 Pressure ............................................................................................................................ 98

6.6.1 Sensor calibration constants ...................................................................................................99

6.6.2 Advanced ..................................................................................................................................99

6.7 Temperature .................................................................................................................... 100

6.7.1 Sensor calibration constants .................................................................................................101

6.7.2 Advanced ................................................................................................................................102

6.8 Line density ..................................................................................................................... 103

6.8.1 Ratio of specific heats (liquid and gas) .................................................................................. 104

6.8.2 Viscosity (steam): ...................................................................................................................104

6.8.3 Solartron/Sarasota transmitter ............................................................................................. 105

6.8.4 TAB measured ....................................................................................................................... 106

6.8.5 TAB serial (liquid only) ...........................................................................................................106

6.8.6 Line density table (includes TAB when liquid) ....................................................................... 106

6.8.7 TAB calculated (liquid only) .................................................................................................... 107

6.8.8 TAB Z-equation (gas only) ......................................................................................................107

6.9 Liquid line density at the metering conditions ............................................................... 109

6.10 Gas base density, relative density and specific gravity ................................................. 110

6.10.1 Base density ......................................................................................................................... 110

6.10.2 Relative density / Specific gravity ........................................................................................ 112

6.10.3 Base sediment and water .................................................................................................... 113

6.11 Heating Value................................................................................................................. 114

6.11.1 GPA 2145 ...............................................................................................................................115

6.11.2 TAB Normal and extended ...................................................................................................115

6.11.3 TAB Select standard ............................................................................................................. 116

6.12 Enthalpy ......................................................................................................................... 116

6.13 Gas Data ........................................................................................................................ 118

6.13.1 TAB Normal and extended ...................................................................................................119

6.14 General Calculations ..................................................................................................... 120

6.14.1 Pipe constants ...................................................................................................................... 121

6.15 Constants ....................................................................................................................... 121

6.16 Options ........................................................................................................................... 122

6.17 Preset counters ............................................................................................................. 123

7 Run switching 125

7.1 Introduction ..................................................................................................................... 125

7.2 General configuration...................................................................................................... 125

7.3 Stream configuration ...................................................................................................... 126

7.3.1 General ................................................................................................................................... 126

7.3.2 Valve control ........................................................................................................................... 127

7.3.3 Flow control valve ................................................................................................................... 127

7.4 Run switching I/O selections ........................................................................................... 128

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

5

Page 6

SUMMIT 8800CONTENTS

8 Watchdog 131

9 Station 132

9.1 Station totals ................................................................................................................... 132

9.2 Station units .................................................................................................................... 133

9.3 Preset counters ............................................................................................................... 133

9.4 Pressure .......................................................................................................................... 133

9.5 Temperature .................................................................................................................... 133

10 Prover 134

10.1 Prover configuration ......................................................................................................134

10.1.1 Prover pressure .................................................................................................................... 135

10.1.2 Prover temperature .............................................................................................................. 136

10.1.3 Alarm settings ...................................................................................................................... 137

10.1.4 Prover options ......................................................................................................................139

10.1.5 Calculations .......................................................................................................................... 144

10.1.6 Valve control .........................................................................................................................146

10.1.7 Line and base density ........................................................................................................... 147

10.2 Modbus link to stream flow computers ........................................................................ 148

11 Valves 150

11.1 Analog ............................................................................................................................ 151

11.2 Digital............................................................................................................................. 152

11.3 PID ................................................................................................................................ 153

11.4 Feedback ....................................................................................................................... 155

11.5 Four way ........................................................................................................................ 157

11.6 Digital valve alarm .........................................................................................................159

12 Sampler 160

12.1 Sampler method ............................................................................................................ 160

13 Batching 168

13.1 General .......................................................................................................................... 168

6 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 7

SUMMIT 8800

CONTENTS

14 Redundancy 174

14.1 Introduction ................................................................................................................... 174

14.2 Global redundancy ........................................................................................................ 174

14.3 Redundancy Parameters ............................................................................................... 175

14.4 Redundancy ID’s ............................................................................................................ 176

15 Appendix 1: Software versions 177

15.1 Versions/ Revisions ....................................................................................................... 177

15.2 Current versions ............................................................................................................ 177

15.2.1 Latest version 0.35.0.0 .........................................................................................................177

15.2.2 Approved version MID2.4.0.0 ................................................................................................ 177

16 Appendix 2: Liquid calculations 179

16.1 Perform meter curve linearisation ............................................................................... 179

16.2 Linear corrected volume flow [m3/h] ...........................................................................179

16.3 Perform meter body correction ................................................................................... 180

16.4 Low flow cut-off control ................................................................................................ 181

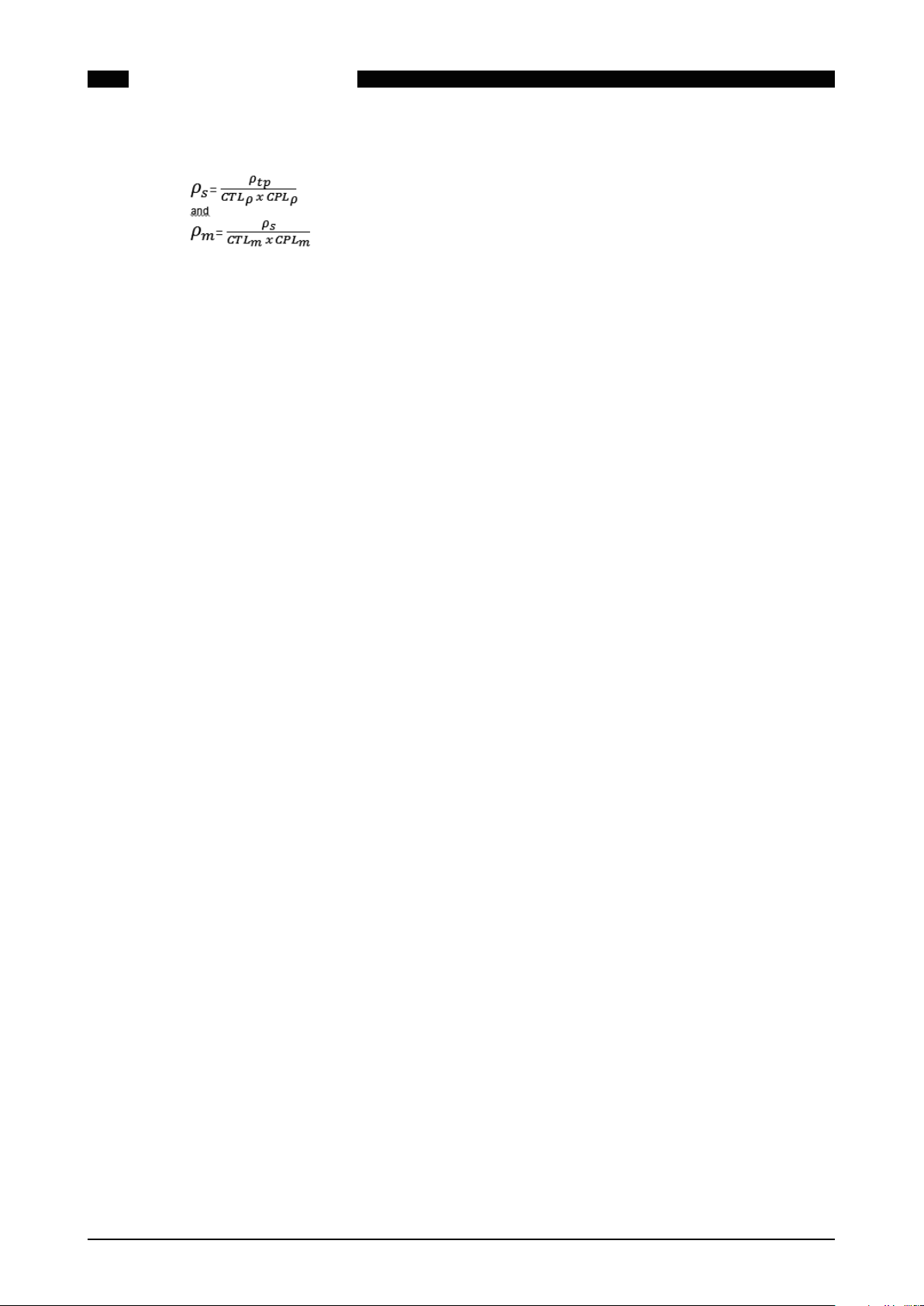

16.5 Retrieve base density .................................................................................................... 181

16.6 Temperature correction factor to base ......................................................................... 181

16.7 Pressure correction factor to base ...............................................................................182

16.8 Line density ................................................................................................................... 182

16.9 Mass flow [t/h] ............................................................................................................... 182

17 Appendix 3: Gas calculations 184

17.1 Perform meter body correction .................................................................................... 184

17.2 Low flow cut-off control ................................................................................................ 185

17.3 Perform meter curve linearisation ............................................................................... 185

17.4 Calculation for normal volume flow rate ...................................................................... 185

17.5 Calculate base and line density .................................................................................... 186

17.6 Calculation for mass flow rate ...................................................................................... 186

17.7 Calculation for energy flow rate .................................................................................... 186

17.8 Calculate heating value ................................................................................................. 186

17.9 Integrate flow rates for totalisation .............................................................................. 186

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

7

Page 8

SUMMIT 8800TABLE OF FIGURES

Figure 1 Example ID Tree ..................................................... 18

Figure 2 Turbine and rotary meter .............................................. 21

Figure 3 Ultrasonic measurement principle ..................................... 22

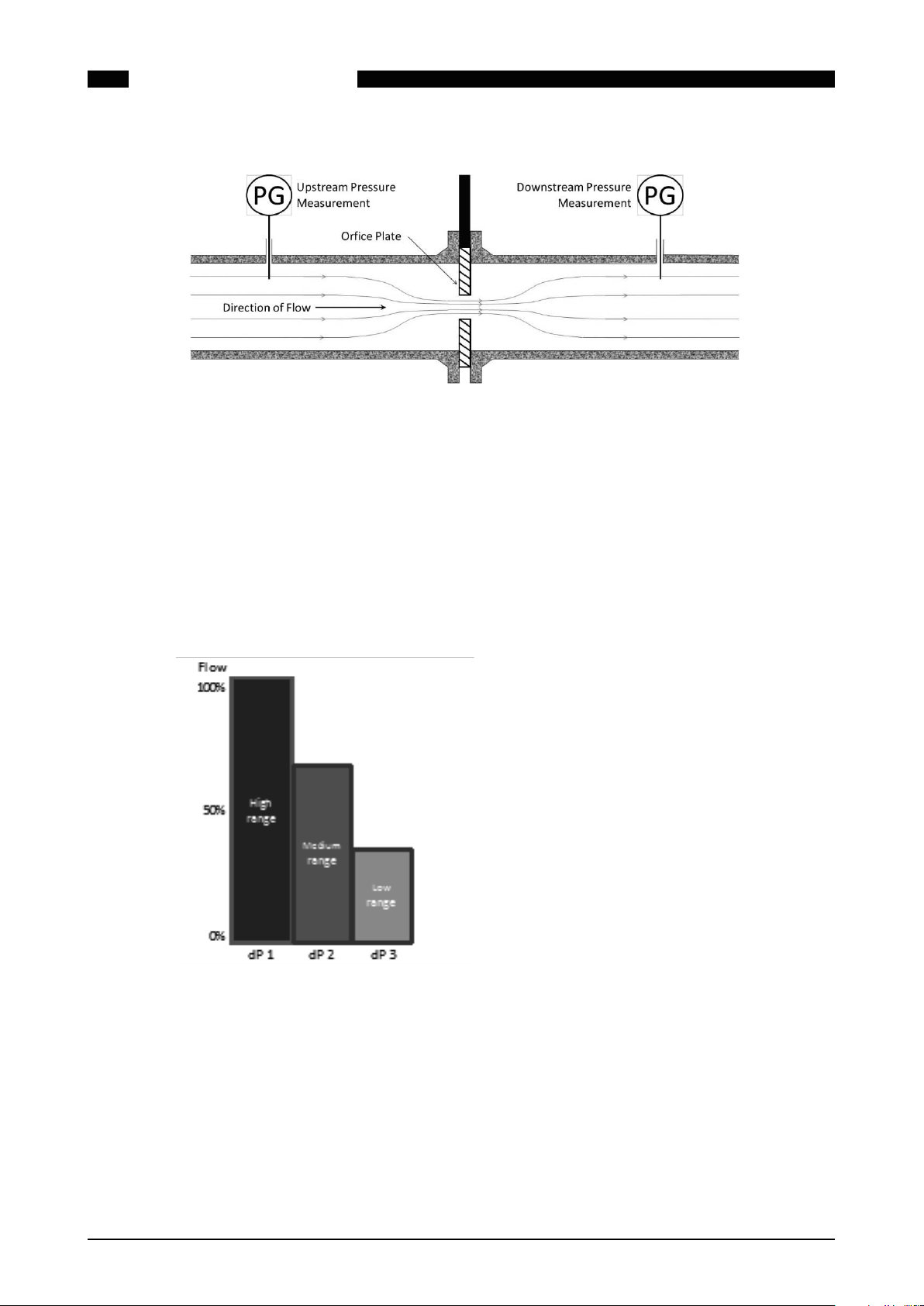

Figure 4 DP measurement principles .......................................... 24

Figure 5 Up to 3 dP ranges .................................................... 24

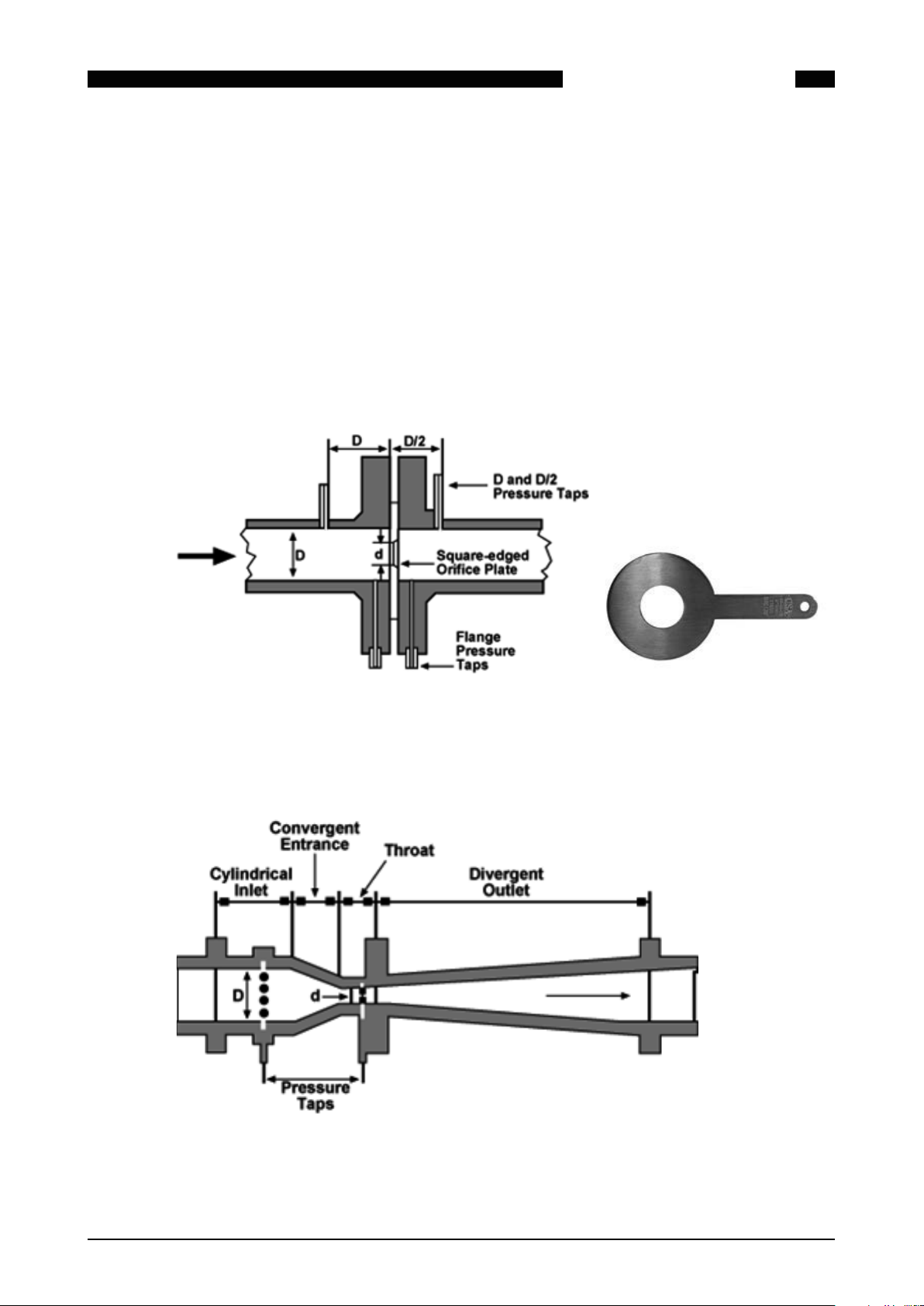

Figure 6 Orifice meter and plate .............................................. 25

Figure 7 Venturi tube layout .................................................. 25

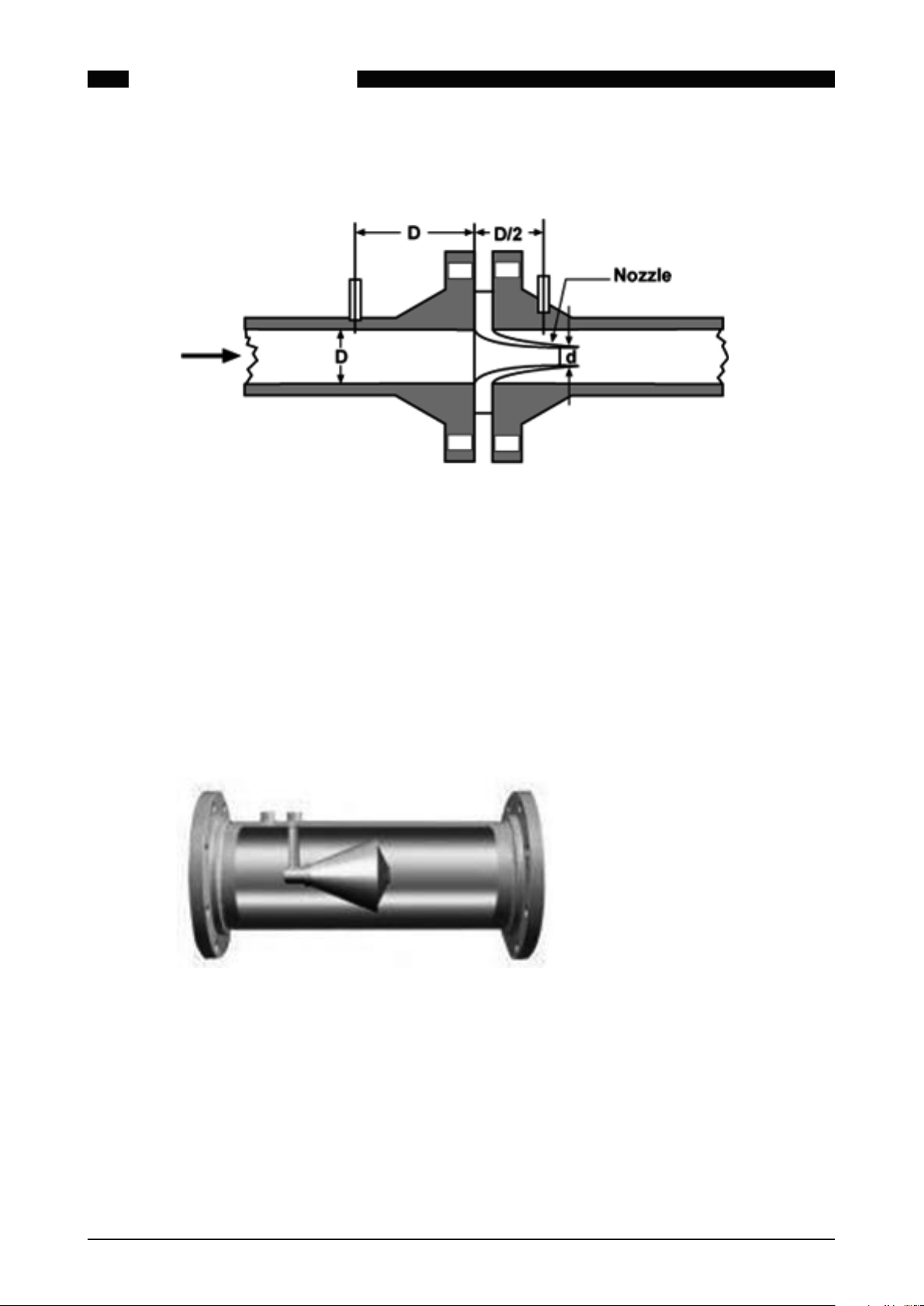

Figure 8 Venturi Nozzle ....................................................... 26

Figure 9 V-cone meter ....................................................... 26

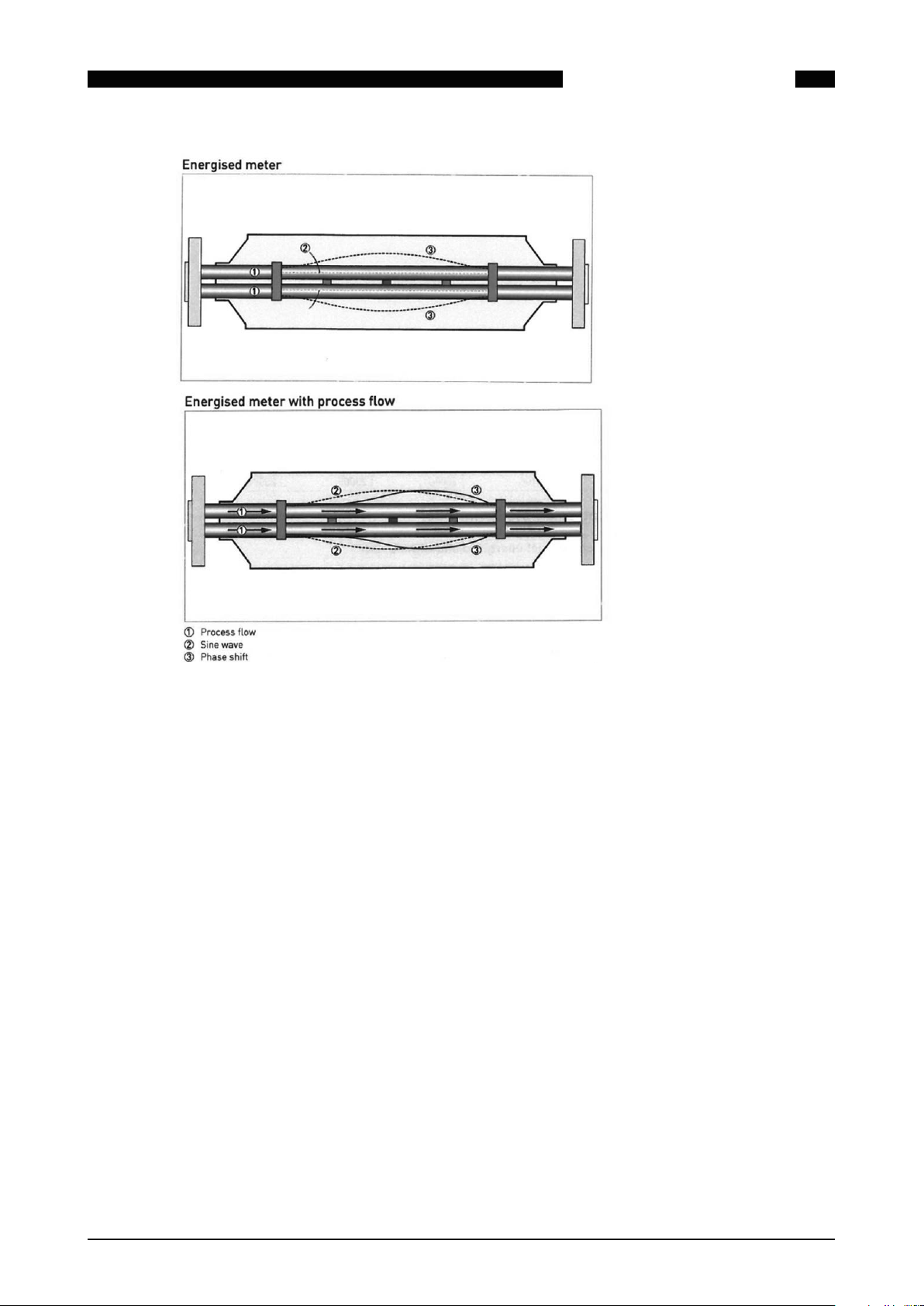

Figure 10 Coriolis meter flow principle ......................................... 27

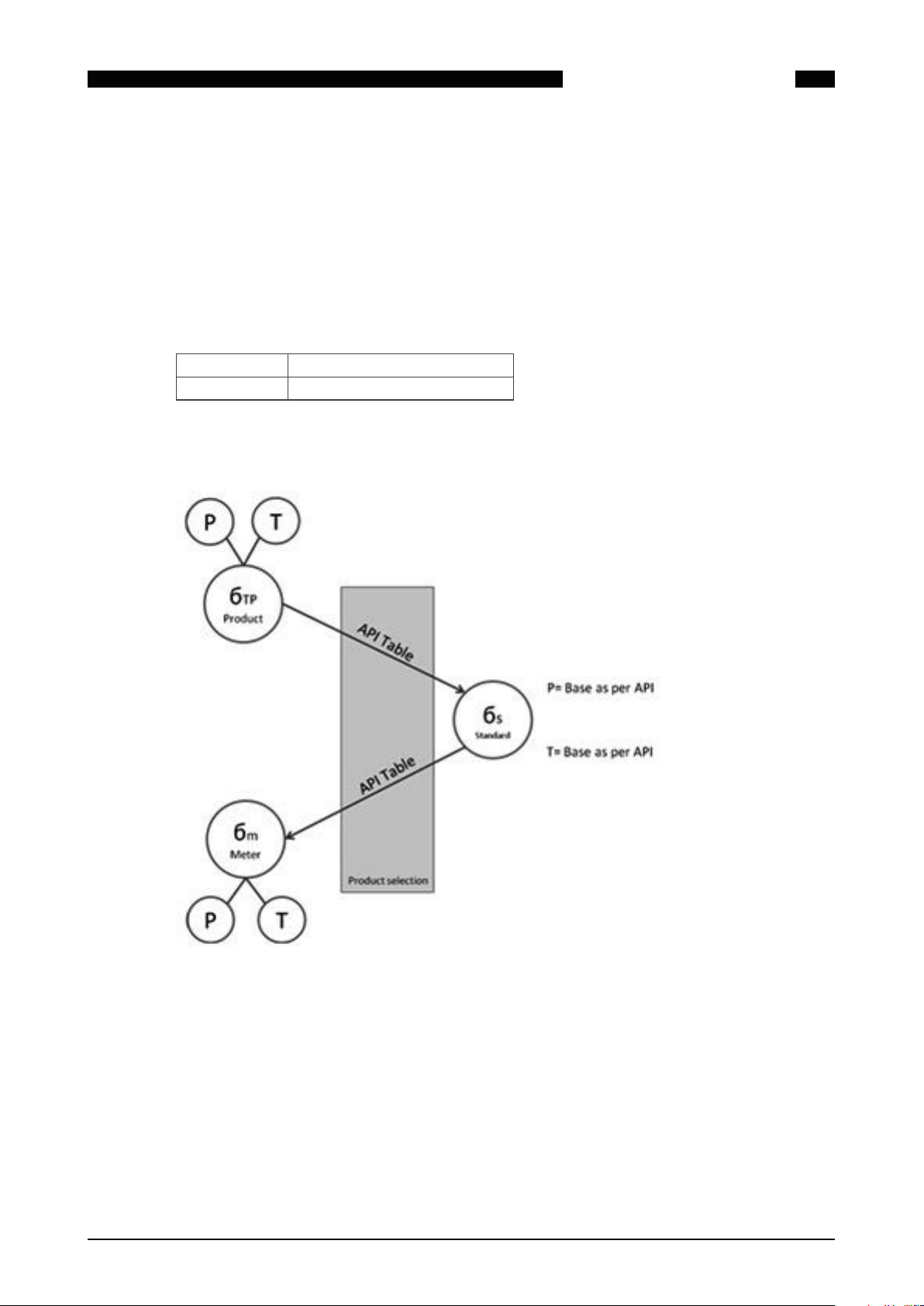

Figure 11 Density calculations for oil ............................................ 29

Figure 12 Uni-directional prover ............................................... 36

Figure 13 Bi-directional prover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 14 Small compact prover ................................................ 37

Figure 15 Master meter loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 16 Proving flowchart ................................................... 38

Figure 17 Proving sequence flowchart ........................................... 42

Figure 18 Proving run flowchart ................................................ 45

Figure 19 Configurator main menu ............................................. 48

Figure 20 Configuration version ................................................ 49

Figure 21 Configuration machine type ........................................... 49

Figure 22 Main Configurator screen ............................................ 50

Figure 23 Configurator I/O board setup .......................................... 51

Figure 24 I/O and communication board selected ................................. 51

Figure 25 Board configuration window .......................................... 52

Figure 26 Signal selection from a tree ........................................... 53

Figure 27 Error for a duplicated variable ........................................ 53

Figure 28 Configure HART inputs ............................................... 54

Figure 29 Configure analog input ............................................... 54

Figure 30 Configure PRT input ................................................. 55

Figure 31 Configure digital inputs .............................................. 56

Figure 32 Configure analog output .............................................. 56

Figure 33 Configure digital output .............................................. 57

Figure 34 Configure pulse outputs .............................................. 57

Figure 35 Configure alarm output .............................................. 58

Figure 36 Configure State output ............................................... 58

Figure 37 Configure corrected pulse output ...................................... 59

Figure 38 Setup of a meter pulse in Hardware selection ............................ 60

Figure 39 Setup of a monitor pulse in Hardware selection .......................... 60

Figure 40 Setup of a Level A dual pulse in Hardware selection ...................... 60

Figure 41 Setup of a serial meter in Hardware selection ........................... 61

Figure 42 Setup of an Instromet ultrasonic meter in Hardware selection .............. 61

Figure 43 Setup of an Elster gas turbine encoder in Hardware selection .............. 62

Figure 44 Setup of a analog meter in Hardware selection ........................... 62

Figure 45 Setup of a meter with Hart in Hardware selection ........................ 63

Figure 46 DP transmitter selection in Hardware input ............................. 63

Figure 47 Hart DP transmitter selection in Hardware input ......................... 64

Figure 48 Analog DP transmitter selection in Hardware input ....................... 64

Figure 49 Stream and station temperature selection in Hardware input .............. 65

Figure 50 Temperature input selection .......................................... 65

Figure 51 Temperature serial input selection ..................................... 66

Figure 52 Stream and station pressure selection in Hardware input .................. 66

Figure 53 Pressure input selection ............................................. 67

Figure 54 Pressure serial input selection ........................................ 67

Figure 55 Densitometer input selection ......................................... 68

Figure 56 Density input selection ............................................... 68

Figure 57 Density serial input selection ......................................... 69

8 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 9

SUMMIT 8800

Figure 58 Density temperature and pressure input selection ........................ 69

Figure 59 Stream and station ouput selection .................................... 70

Figure 60 Analog and digital pulse output ....................................... 70

Figure 61 Density serial input selection ......................................... 71

Figure 62 Alarm output ....................................................... 71

Figure 63 Define input engineering units ........................................ 72

Figure 64 Define output engineering units ....................................... 73

Figure 65 Define pulse based meter input API level B to E .......................... 74

Figure 66 Figure 65 define pulse based meter input API level A .................... 74

Figure 67 Define meter information ............................................. 75

Figure 68 Example ultrasonic meter input section ................................ 76

Figure 69 Ultrasonic pulse input section for liquid and gas API 5.5 Level B to E ........ 77

Figure 70 Ultrasonic pulse input section for liquid API 5.5 level A .................... 78

Figure 71 Examples ultrasonic meter correction section ........................... 79

Figure 72 Define meter information ............................................. 80

Figure 73 Differential pressure General section .................................. 81

Figure 74 Define meter information ............................................. 83

Figure 75 Define the differential pressure transmitter selection ..................... 84

Figure 76 Define the differential pressure transmitter calibration constants .......... 85

Figure 77 Define the differential pressure transmitter advanced settings ............. 86

Figure 78 Example Coriolis meter input section .................................. 87

Figure 79 Coriolis pulse input section for liquid and gas API 5.5 Level B to E .......... 88

Figure 80 Coriolis pulse input section for API 5.5 level A ........................... 89

Figure 81 Coriolis density deviation ............................................. 90

Figure 82 Define meter information ............................................. 90

Figure 83 Product information ................................................. 91

Figure 84 Flow rate limits & scaling ............................................ 93

Figure 85 Liquid Meter and K-factor ............................................ 94

Figure 86 Liquid K-factor Curve ................................................ 95

Figure 87 Gas or steam flow rate correction for a 6 point calibration ................. 95

Figure 88 Gas or steam flow rate calculations .................................... 96

Figure 89 Tariff selection ..................................................... 97

Figure 90 Tariff flow rate output ............................................... 97

Figure 91 Stream pressure selection ............................................ 98

Figure 92 Stream pressure calibration constants ................................. 99

Figure 93 Stream pressure advanced options ..................................... 99

Figure 94 Stream temperature selection ........................................ 101

Figure 95 Stream temperature calibration constants .............................. 101

Figure 96 Stream temperature advanced options ................................. 102

Figure 97 Stream Liquid, gas and steam line density selection ...................... 104

Figure 98 Stream ratio of specific heats ......................................... 104

Figure 99 Viscosity ........................................................... 105

Figure 100 Density transducer parameters ...................................... 105

Figure 101 Liquid and gas measurement selection ................................ 106

Figure 102 Liquid serial selection .............................................. 106

Figure 103 Line density table .................................................. 107

Figure 104 Liquid line density calculation method ................................. 107

Figure 105 Gas Line density Z-equation method .................................. 108

Figure 106 Z-table ........................................................... 109

Figure 107 Meter line density, keypad ........................................... 109

Figure 108 Meter line density, calculated ........................................ 110

Figure 109 Base density selection .............................................. 111

Figure 110 Compressibility options ............................................. 111

Figure 111 Relative density options ............................................. 112

Figure 112 Basic sediment & water ............................................. 113

Figure 113 Heating value selection ............................................. 114

Figure 114 GPA 2145 normal Gas data .......................................... 115

TABLE OF FIGURES

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

9

Page 10

SUMMIT 8800TABLE OF FIGURES

Figure 115 Enthalpy settings .................................................. 116

Figure 116 Gas data selection .................................................. 118

Figure 117 Normal Gas data .................................................. 119

Figure 118 Base density of air ................................................. 120

Figure 119 Molecular weight of gas ............................................ 120

Figure 120 Emission factors ................................................... 120

Figure 121 AGA 10 speed of sound .............................................. 121

Figure 122 Constants ......................................................... 122

Figure 123 Stream options selection ............................................ 122

Figure 124 Preset counters .................................................... 124

Figure 125 Turn run switching on ............................................... 125

Figure 126 Stream configuration run switching ................................... 126

Figure 127 Stream run switching switch conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 128 Stream run switching valve control ................................... 127

Figure 129 Stream run switching valve control ................................... 128

Figure 130 Run switching digital input selection .................................. 128

Figure 131 Run switch digital output selection .................................... 129

Figure 132 Flow control valve analogue output ................................... 129

Figure 133 Run switching alarms ............................................... 130

Figure 134 Stream run switching alarm selections ................................ 130

Figure 135 Watchdog settings .................................................. 131

Figure 136 Define station totals ................................................ 132

Figure 137 Flow computer machine type ......................................... 135

Figure 138 Prover section for liquid and gas ...................................... 135

Figure 139 Prover pressure ................................................... 136

Figure 140 Prover temperature ................................................ 137

Figure 141 Prover alarm settings, re-prove ...................................... 138

Figure 142 Prover options: general ............................................. 139

Figure 143 Prover options: general, proving points ................................ 140

Figure 144 Prover options: general settings, uni-directional prover .................. 140

Figure 145 Prover options: general settings, bi-directional prover ................... 140

Figure 146 Prover options: general settings, small volume prover ................... 140

Figure 147 Prover options: general settings, master meter ......................... 141

Figure 148 Prover options: stability ............................................. 142

Figure 149 Prover options: meter correction ..................................... 143

Figure 150 Prover options: meter information .................................... 143

Figure 151 Prover calculations, k-factor for liquid and gas ......................... 144

Figure 152 Prover calculations, pipe correction ................................... 145

Figure 153 Prover valve control, bi-directional .................................... 146

Figure 154 Prover valve control, uni-directional or small volume .................... 146

Figure 155 Prover valve control, master metering 3 streams ........................ 147

Figure 156 Prover line and base density ......................................... 148

Figure 157 Prover modbus slave configuration ................................... 149

Figure 158 Valve options ...................................................... 150

Figure 159 Analog valve ....................................................... 151

Figure 160 Analog valve setpoint ............................................... 151

Figure 161 Select the analog valve output ID ..................................... 152

Figure 162 Digital valve ....................................................... 152

Figure 163 Select the digital valve ID ............................................ 153

Figure 164 PID control loop .................................................... 153

Figure 165 PID valve .......................................................... 154

Figure 166 Select the PID valve ID and the Preset keypad setpoint ID ................. 155

Figure 167 Feedback valve .................................................... 155

Figure 168 Open & close feedback action command ............................... 156

Figure 169 Open & close feedback valve signals: command and feedback ............. 156

Figure 170 Four way valve configuration for different leak sensors types ............. 157

Figure 171 Four way valve action command ...................................... 158

10 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 11

SUMMIT 8800

Figure 172 Four way valve digital output and input selection ........................ 158

Figure 173 Four way valve leak sensor input ..................................... 159

Figure 174 Digital alarm valve output ........................................... 159

Figure 175 Sampler timed based configuration ................................... 160

Figure 176 Flow based sampler counter selection ................................. 161

Figure 177 Sampler can weighing .............................................. 161

Figure 178 Sampler can flow limits ............................................. 162

Figure 179 Sampler can calculated can level parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 180 Sampler can calculated volume % full parameters ...................... 162

Figure 181 Sampler status information .......................................... 163

Figure 182 Sampler digital grab output .......................................... 164

Figure 183 Sampler can measured can level ..................................... 164

Figure 184 Sampler analogue output selection ................................... 165

Figure 185 Sampler can weight inputs .......................................... 165

Figure 186 Sampler digital input selection ....................................... 166

Figure 187 Sample accountable alarm selection .................................. 167

Figure 188 Batching general selection .......................................... 168

Figure 189 Fixed batching trigger .............................................. 169

Figure 190 Batching fixed batching selection ..................................... 169

Figure 191 Station batching stream selection ..................................... 170

Figure 192 Batching information ............................................... 170

Figure 193 Batching parameters to be recalculated ............................... 171

Figure 194 Batching digital input selection ....................................... 172

Figure 195 Batching analogue output selection ................................... 172

Figure 196 Batching digital output selection ...................................... 173

Figure 197 Batching alarm status .............................................. 173

Figure 198 Global redundancy ................................................. 175

Figure 199 Redundancy ID’s ................................................... 176

TABLES

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

11

Page 12

SUMMIT 8800ABOUT THIS HANDBOOK01

IMPORTANT INFORMATION

KROHNE Oil & Gas pursues a policy of continuous development and product improvement. The

Information contained in this document is, therefore subject to change without notice. Some

display descriptions and menus may not be exactly as described in this handbook. However, due

the straight forward nature of the display this should not cause any problem in use.

To the best of our knowledge, the information contained in this document is deemed accurate

at time of publication. KROHNE Oil & Gas cannot be held responsible for any errors, omissions,

inaccuracies or any losses incurred as a result.

In the design and construction of this equipment and instructions contained in this handbook,

due consideration has been given to safety requirements in respect of statutory industrial regulations.

Users are reminded that these regulations similarly apply to installation, operation and maintenance, safety being mainly dependent upon the skill of the operator and strict supervisory

control.

12 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 13

SUMMIT 8800

1. About this book

1.1 Volumes

This is Volume 2 of 3 of the SUMMIT 8800 Handbook:

Volume 1

Volume 1 is targeted to the electrical, instrumentation and maintenance engineer

This is an introduction to the SUMMIT 8800 flow computer, explaining its architect and layout providing the user with familiarity and the basic principles of build. The volume describes the

Installation and hardware details, its connection to field devices and the calibration.

The manual describes the operation via its display, its web site and the configuration software.

Also the operational functional of the Windows software tools are described, including the configurator, the Firmware wizard and the display monitor.

Volume 2

Volume 2 is targeted to the metering software configuration by a metering engineer.

The aim of this volume is to provide information on how to configure a stream and the associated hardware.

The handbook explains the configuration for the different metering technologies, including meters, provers, samplers, valves, redundancy etc.. A step by step handbook using the Configurator

software, on the general and basic setup to successfully implement flow measurement based on

all the applications and meters selections within the flow computer.

ABOUT THIS HANDBOOK

01

Volume 3

Volume 3 is targeted to the software configuration of the communication.

The manual covers all advance functionality of the SUMMIT 8800 including display configuration,

reports, communication protocols, remote access and many more advance options.

1.2 Content Volume 1

Volume 1 concentrates on the daily use of the flow computer

• Chapter 2: Basic functions of the flow computer

• Chapter 3: General information on the flow computer

• Chapter 4: Installation and replacement of the flow computer

• Chapter 5: Hardware details on the computer, its components and boards

• Chapter 6: Connecting to Field Devices

• Chapter 7: Normal operation via the touch screen

• Chapter 8: How to calibration the unit

• Chapter 9: Operation via the optional web site

• Chapter 10: Operational functions of the configuration software, more details in volume 2

• Chapter 11: How to update the firmware

• Chapter 12: Display monitor software to replicate the SUMMIT 8800 screen on a PC and make

screen shots

1.3 Content Volume 2

Volume 2 concentrates on the software for the flow computer.

• Chapter 2: General information on the software aspects of the flow computer

• Chapter 3: Details on metering principles

• Chapter 4: Basic functions of configurator

• Chapter 5: Configuration of the hardware of the boards

• Chapter 6: Stream configuration

• Chapter 7: Run switching

• Chapter 8: Watchdog

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

13

Page 14

• Chapter 9: Configure a station

• Chapter 10: Configure a prover or master meter

• Chapter 11: Configure valves

• Chapter 12: Configure a sampler

• Chapter 13: Set-up batching

• Chapter 14: Set two flow computers in redundant configuration

1.4 Content Volume 3

Volume 3 concentrates on the configuration of the SUMMIT 8800

• Chapter 3; Configurator software

• Chapter 4: Date & Time

• Chapter 5: Data Logging

• Chapter 6: Display and web access

• Chapter 7: Reporting

• Chapter 8: Communication

• Chapter 9: General Information

1.5 Information in this handbook

SUMMIT 8800ABOUT THIS HANDBOOK01

The information in this handbook is intended for the integrator who is responsible to setup and

configure the SUMMIT 8800 flow computer for Liquid and or Gas and or Steam application:

Integrators (hereafter designated user) with information of how to install, configure, operate and

undertake more complicated service tasks.

This handbook does not cover any devices or peripheral components that are to be installed and

connected to the SUMMIT 8800 it is assumed that such devices are installed in accordance with

the operating instructions supplied with them.

Disclaimer

KROHNE Oil & Gas take no responsibility for any loss or damages and disclaims all liability for

any instructions provided in this handbook. All installations including hazardous area installations are the responsibility of the user, or integrator for all field instrumentation connected to

and from the SUMMIT 8800 Flow computer.

Trademarks

SUMMIT 8800 is a trade mark of KROHNE Oil & Gas.

Notifications

KROHNE Oil & Gas reserve the right to modify parts and/or all of the handbook and any other

documentation and/ or material without any notification and will not be held liable for any damages or loss that may result in making any such amendments.

Copyright

This document is copyright protected.

KROHNE Oil & Gas does not permit any use of parts, or this entire document in the creation of

any documentation, material or any other production. Prior written permission must be obtained

directly from KROHNE Oil & Gas for usage of contents. All rights reserved.

Who should use this handbook?

This handbook is intended for the integrator or engineer who is required to configure the flow

computer for a stream including devices connected to it.

Versions covered in this handbook

All Versions

14 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 15

SUMMIT 8800

2. General Information

2.1 Software versions used for this guide

This handbook is based on the software versions as mentioned in Appendix 1: software versions

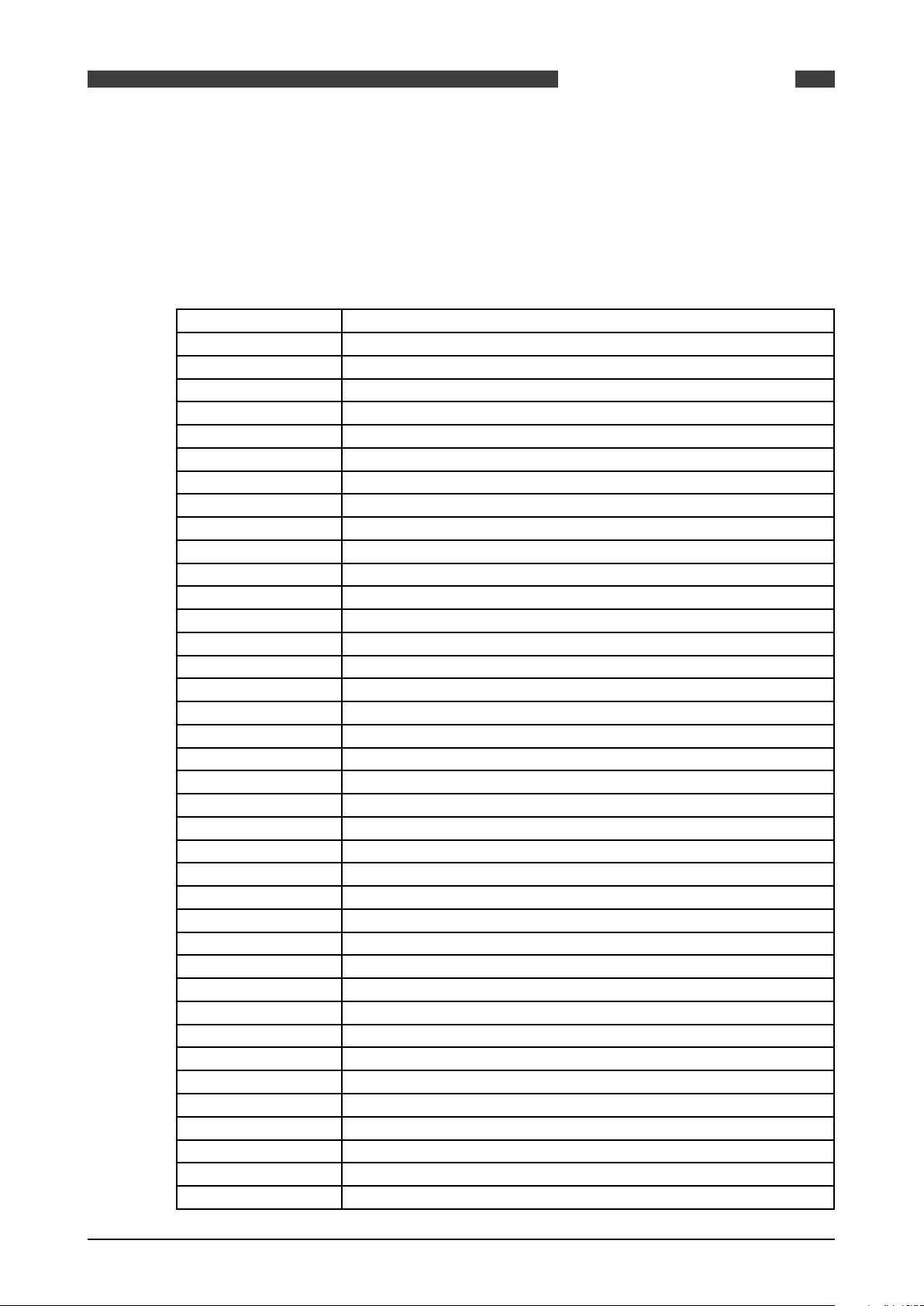

2.2 Terminology and Abbreviations

AGA American Gas Association

API American Petroleum Institute

Communication board Single or dual Ethernet network board

Configurator Windows software tool to configure and communicate to the SUMMIT 8800

CP Control Panel

CPU Central Processing Unit

CRC32 Cyclic Redundancy Check 32 bits. Checksum to ensure validity of information

FAT Factory Acceptance Test

FDS Functional Design Specification

HMI Human-Machine Interface

HOV Hand Operated Valve

I/O Input / Output

ISO International Standards Organization

KOG KROHNE Oil and Gas

KVM Keyboard / Video / Mouse

MOV Motor Operated Valve

MSC Metering Supervisory Computer

MUT Meter Under Test

Navigator 360 optical rotary dial

PC Personal Computer

PRT Platinum Resistance Thermometers

PSU Power Supply Unit

PT Pressure Transmitter

Re-try Method to repeat communication a number of times before giving an alarm

RTD: Resistance Temperature Device

Run: Stream/Meter Run

SAT Site Acceptance Test

SUMMIT 8800 Flow computer

Timestamp Time and date at which data is logged

Time-out Count-down timer to generate an alarm if software stopped running

TT Temperature Transmitter

UFC Ultrasonic Flow Converter

UFM Ultrasonic Flow Meter

UFP Ultrasonic Flow Processor (KROHNE flow computer )

UFS Ultrasonic Flow Sensor

VOS Velocity of Sound

ZS Ball detector switch

XS Position 4-way valve

XV Control 4-way valve

GENERAL INFORMATION

02

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

15

Page 16

2.3 General Controls and Conventions

In the configurator software several conventions are being used:

Numeric Data Entry Box

Clear background, black text, used for entering Numeric Data, a value must be entered here

Optional: Coloured background, black text used for entering optional Numeric Data. If no value

is entered then right click mouse key and select Invalidate, box will show and no number will be

entered.

An invalid Number will be shown on the SUMMIT 8800 display as “---------“ and is read serially

as 1E+38

Pull-Down Menu

Select a function or option from a list functions or options

SUMMIT 8800GENERAL INFORMATION02

Icon

Selects a function or a page.

Tabs

Allows an individual page, sub-page or function to be selected from a series of pages, sub-pages or functions.

Expanded item Fewer items shown.

Non Expanded item +

More items shown.

Option Buttons

Red cross means OFF or No

Green tick means ON or Yes

Data Tree

Items from the Data Tree can be either selected or can be “Dragged and dropped” from the Tree

into a selection box; for example when setting up a logging system or a Modbus list, etc.

Yellow Data circle means Read Only. Red data circle means Read and Write.

Hover over

Hold the cursor arrow over any item, button or menu, etc. Do not click any mouse button, the

item will be lightly highlighted and information relating to the selection will be illustrated.

Grey Text

Indicates that this item has no function or cannot be entered in this particular mode of the system. The data is shown for information purposes only.

Help Index

Display information that assists the user in configuration.

Naming convention of Variables

In the KROHNE SUMMIT 8800 there are variables used with specific naming.

This naming is chosen to identify a variable and relate it to the correct stream.

16 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 17

SUMMIT 8800

The most complex variable is explained below and this explanation can be used to interpret all

the other variable names.

Example: + ph uVN . 1

+ Positive (+) or negative (-)

Ph Previous (P) or Current (C) period

u Type of totals

VN Type of flow

1 Stream/ Run number

GENERAL INFORMATION

Pqh – previous 15 minutes

Ph – previous hour

Pd – previous Day

Pm – previous month

Pq – previous quarter of a year

Cqh – current 15 minutes

Ch – current hour

Cd – current Day

Cm – current month

Cq – current quarter of a year

u – Unhaltable, counts always

m – Maintenance, counts when maintenance is active (optional)

n – Normal, fiscal counters during normal operation

e – Error, fiscal counters with an accountable error

t1 –> t4 – Tarif , fiscal counters based on fiscal thresholds

VPulses, pulses counted

Vline, gross volume flow

Vmon, monitored grass volume flow

Vbc (p/t) pressure and temperature corrected gross volume flow

Vbc, linearization corrected (Vbc(p/t))gross volume flow

VN, Normalized volume flow

VN(net), Nett normalized flow

VM, Mass flow

VE, Energy flow

VCO2, carbon dioxide flow

02

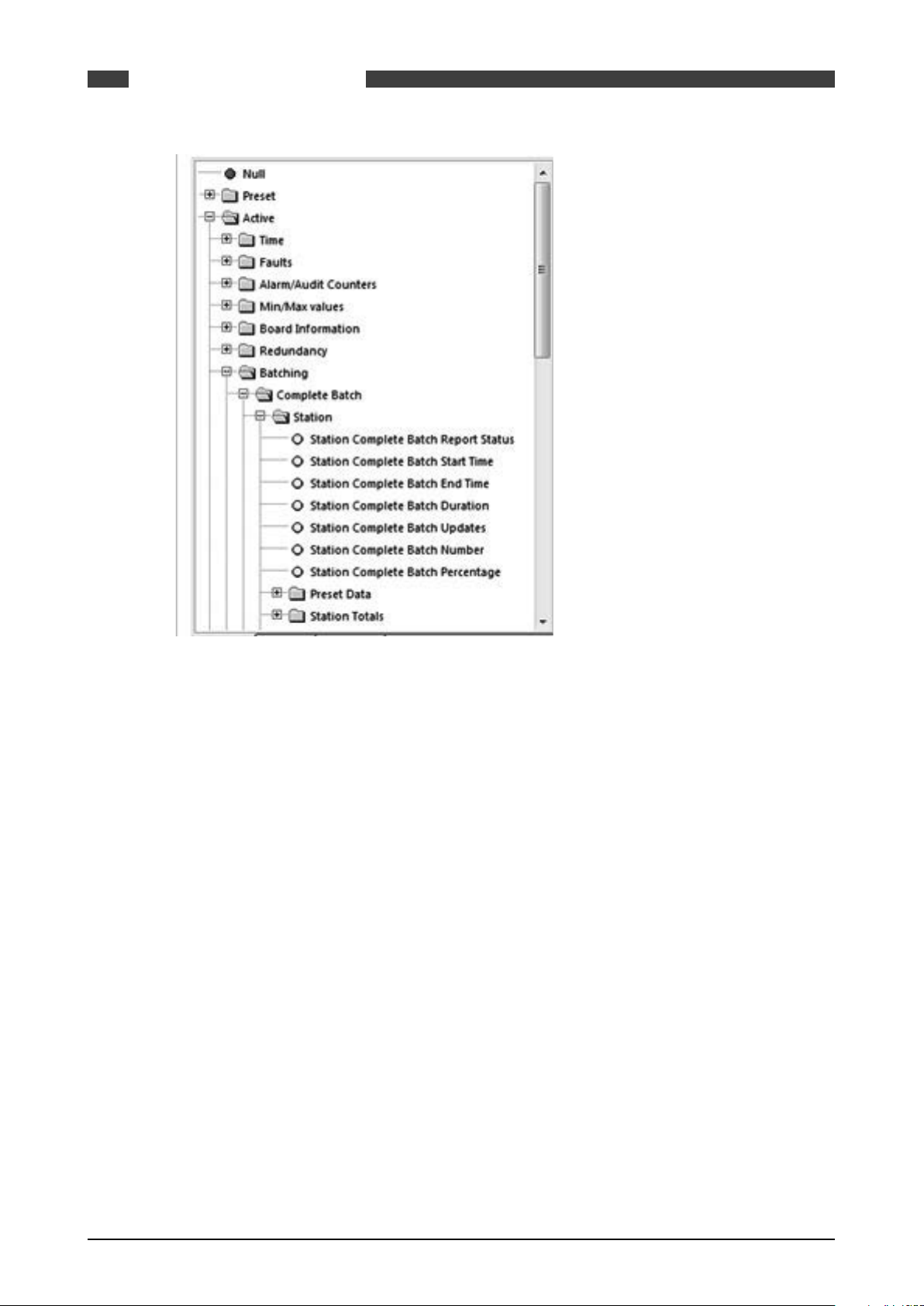

2.4 ID Data Tree

When selecting parameters and options in the Configurator software, the user will be presented

with a tree structure for instance:

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

17

Page 18

SUMMIT 8800GENERAL INFORMATION02

Figure 1 Example ID Tree

This is referred to as the ID tree which, depending on its context, includes folders and several

parameters:

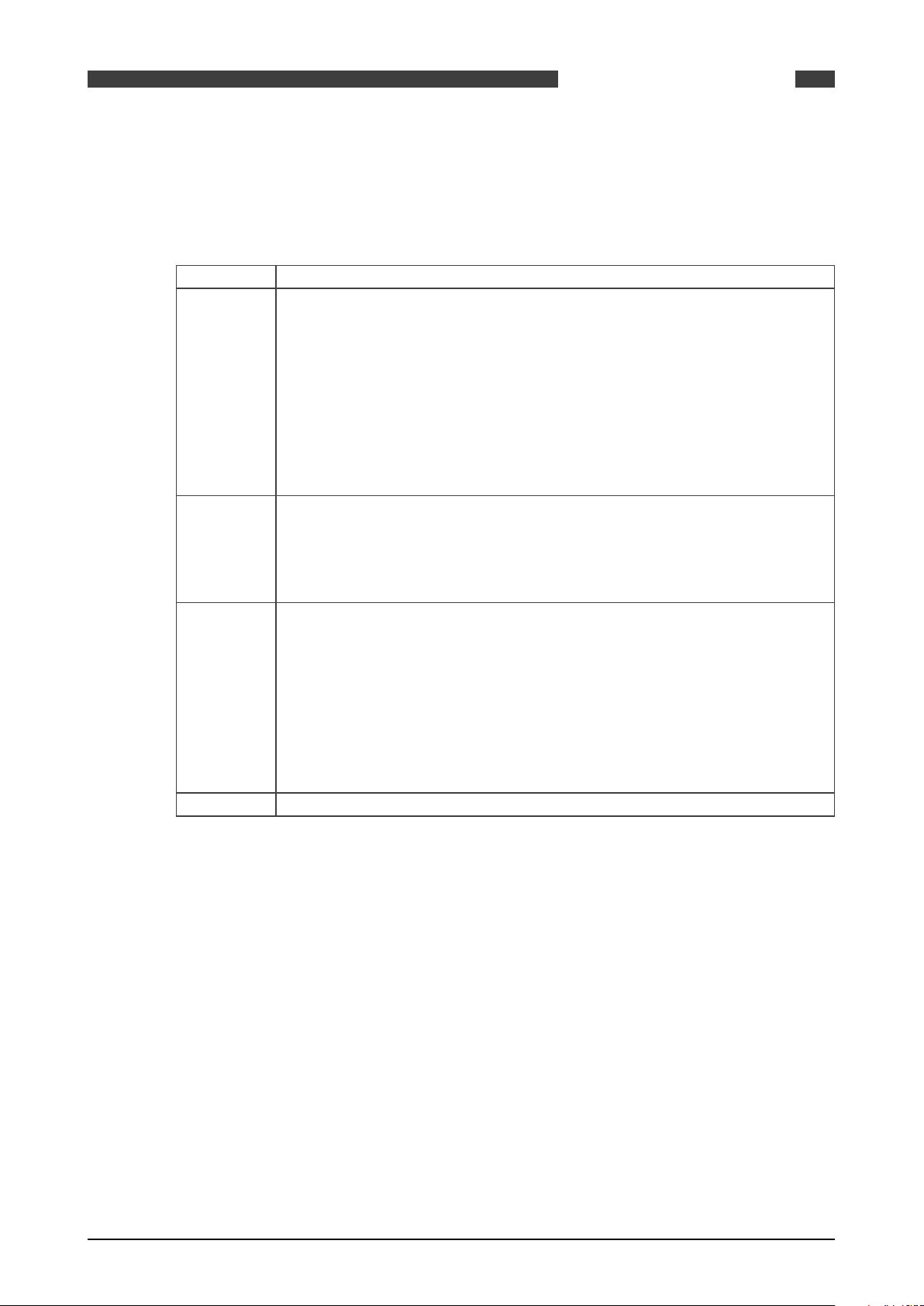

2.4.1 Type of data

The rest of this chapter will explain the folders available, the type of selection within the folder

and any other corresponding data.

Preset Data

Essential to the configuration of the flow computer. Typical data would be keypad values, operating limits, equation selection, calibration data for Turbines and Densitometers and Orifice

plates.

This data would be present in a configuration report, and enables you to see what the flow computer is configured to do.

Used for validation and will form the Data Checksum (visible on the System Information Page).

E.g., if a data checksum changes, the setup of the flow computer has changed and potentially

calculating different results to what is expected.

Typically configured and left alone, only updated after validation e.g. every 6 month / 1 year.

Active Data

These values cover inputs to the flow computer. E.g., from GC, pressure & temperature transmitters, meters etc..

Also Values calculated in the flow computer. E.g., Flow rates, Z, Averages, Density etc..

Local Data

Data that an operator can change locally to perform maintenance tasks. E.g., turn individual

transmitters off without generating alarms. Setting Maintenance mode or Proving Mode.

18 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 19

SUMMIT 8800

Totals

Totals for the streams and station.

Contents of this folder are stored in the non-volatile RAM and are protected using the battery.

Custom

User defined variables.

Allows calculations, made in a LUA script, to be used in a configuration.

For details, see volume 3.

2.4.2 Colour codes

With each parameter and option, there are corresponding coloured dots that represent the access and status of the particular selection.

General ID tree

Please note that it might be possible to change the values via the screen

GENERAL INFORMATION

Red Dot Data is Read/Write and can be changed over Modbus.

Yellow Dot Data is Read-Only and cannot be changed over Modbus

02

90% of the data will be Read Only, but items such as Serial Gas Compositions, Time/Date, MF

are commonly written over Modbus.

NOTE: Although the ID may be read/write, the security setting determines whether the ID indeed

can be written.

Alarm Tree

The alarm tree is built of all the registers that hold alarm data. Alarm registers are 32-bit integers, where each bit represents a different alarm.

Red Dot Represents an accountable alarm visible on the alarm list.

Dark Blue Dot Represents a non-accountable alarm visible on the alarm list.

Orange Dot Represents a warning visible on the alarm list.

Light Blue Dot Represents a status alarm, not visible on the alarm list.

Black/Grey Dot Represents a hard- or software fault alarm visible on the alarm list.

An example of typical usage would be the General Alarm Register. This is a 32 bit register that

indicates up to 32 different alarms in the flow computer. This will contain Status Alarms, for example, 1 bit will indicate if there is a Pressure alarm or not. If the Pressure Status bit is set the

user will know that there is a problem with the Pressure.

This should be sufficient information, however if it is not satisfactory, the user can look at the

Pressure alarm, this contains 32 different alarms relating to the Pressure measurement, these

would be Red Dots as they each can create an entry in the alarm list. By reading this register

the user can view exactly what is wrong with the Pressure measurement.

The Light Blue Dots are generally an OR of several other dots. By reading the General register

you can quickly see if the unit is healthy, more information can be provided by reading several

more registers associated with that parameter.

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

19

Page 20

2.5 Specific Requirements for Meters and Volume Convertors

2.5.1 Numbering formats

The number formats used internally in the unit are generally IEEE Double Precision floating

point numbers of 64 bit resolution.

It is accepted that such numbers will yield a resolution of better than 14 significant digits.

In the case of Totalisation of Gas, Volumes, Mass and Energy such numbers are always shown to

a resolution of 8 digits before the decimal point and 4 after, i.e. 12 significant digits.

Depending upon the required significance of the lowest digit, these values can be scaled by a

further multiplier.

2.5.2 Alarms

Each of the various modules that comprise the total operating software, are continuously monitored for correct operation. Depending upon the configuration, the flow computer will complete

its allocated tasks within the configured cycle time, 250mS, 500mS or 1 second. Failure to

complete the tasks within the time will force the module to complete, and where appropriate, a

substitute value issued together with an alarm indication.

For example, if a Calculation fails to complete correctly then a result of 1 or similar will be

returned, which allows the unit to continue functioning whilst an accountable alarm is raised,

indicating an internal problem.

SUMMIT 8800GENERAL INFORMATION02

2.5.3 Accountable alarm

When the value of any measurement item or communication to an associated device that is providing measurement item to the SUMMIT 8800 goes out of range, the flow computer will issue

an Accountable Alarm.

When any calculation module or other item that in some way affects the ultimate calculation result goes outside its operating band, i.e. above Pressure Maximum or below Pressure minimum,

then the SUMMIT 8800 will issue an Accountable Alarm.

When the SUMMIT 8800 issues an Accountable alarm a number of consequences will occur as

follows:

Front panel accountable alarm will turn on and Flash.

Nature of accountable alarm will be shown on the top line of the alarm log.

Alarm log will wait for user acknowledgement of alarm.

During the period of the alarm, main totalisation will occur on the alarm counters.

2.5.4 Optional consequences

Depending upon the configuration of the SUMMIT 8800 the following optional Consequences will

also occur:

An Entry will be made in the Audit Log, with Time and Date of occurrence.

The “Used” value of the Parameter in Alarm will be substituted by an alternative value, either

from an alternative measurement source that is in range, or from a pre-set value.

A digital Alarm output will indicate an Alarm condition.

20 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 21

SUMMIT 8800

METERING PRINCIPLES

3. Metering principles

In this Chapter the different meter technologies supported by the SUMMIT 8800 and the need for

correction and normalization is described. Each of these technologies has its own particularities

which are important to know when configuring the flow computer.

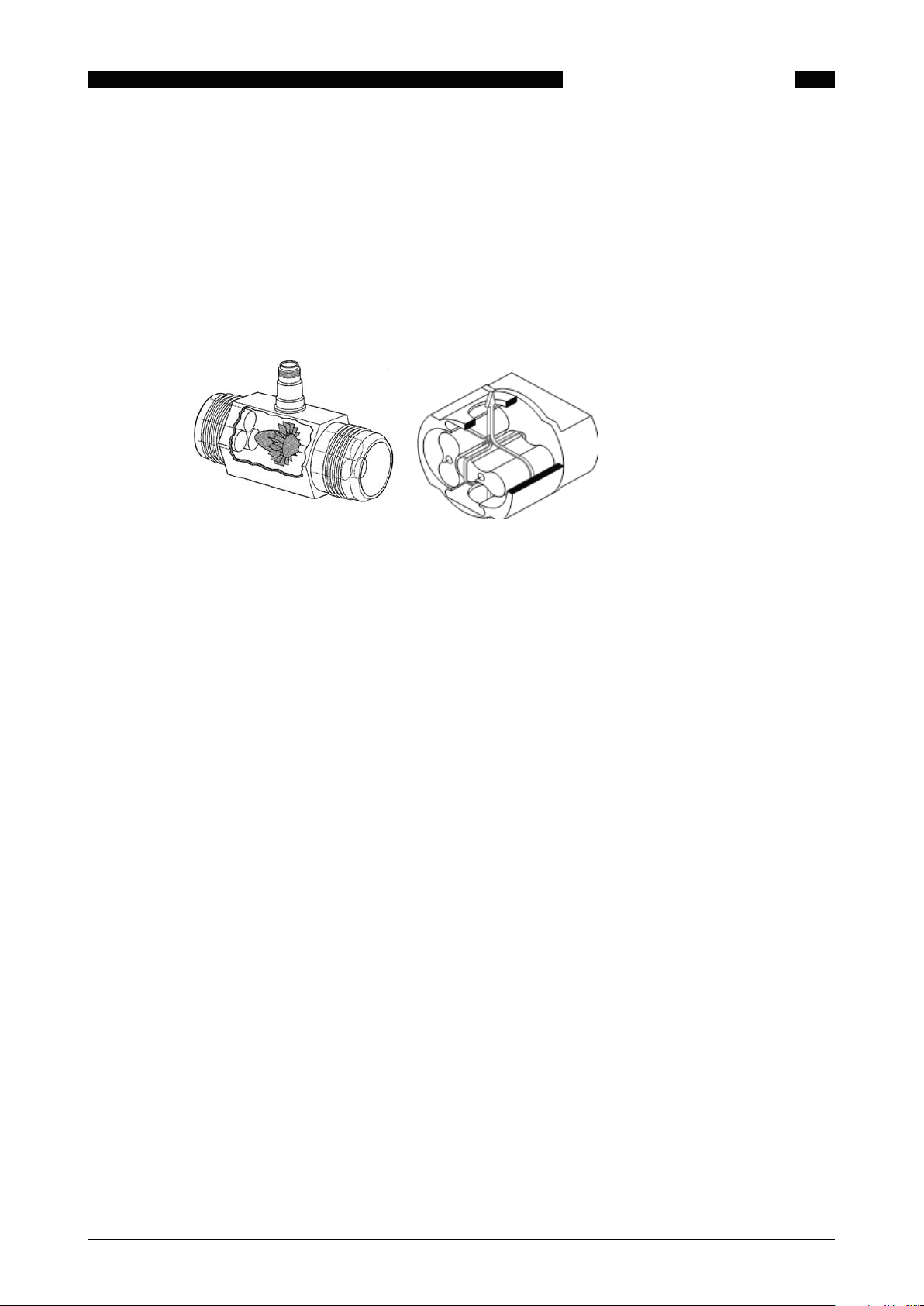

3.1 Pulse based meters: e.g. turbine/ positive displacement / rotary meter

This method stems from the time when rotating meters where used, such as turbine meters and

rotary (Positive displacement) meters.

Figure 2 Turbine and rotary meter

03

A turbine meter is basically a fan in a tube. The gas makes the fan rotate and the rotations are

recorded in an index on top of the meter. A positive displacement or rotary meter consists of

two tighly coupled impellers which together create a moving chamber of gas. The rotation of the

impellers drive an index.

A contact switch is operated by the rotating meter. The result is that the periodic closure of the

switch is directly related to the amount of gas going through the meter. Depending on the location of the switch there are:

HF pulses or high frequency pulses

• The switch can be mounted just above the turbine blades. This switch is closing at the higher

rate than the meter rotates (typically up to 5000 Hz). The ratio between the two is called

“blade ratio”.

MF pulses or medium frequency pulses

• The switch mounted on the primary axes, so this switch is closing every turn of the meter.

This results in a medium frequency pulse (typically up to 500 Hz)

LF pulses or low frequency pulses

• For low cost meters the switch can be mounted in the index after a gear resulting in slow

pulsing switches and in a low accuracy measurement (typically below 50 Hz)

A problem with this method is that the switches do not always close 100% reliable. This is particularly true for the HF pulses as non-contact switches are used. This means that we can have

missing pulses. Also too many pulses can occur, e.g. when interference occurs with the high

frequency wires or due to thunder storms. The solution is to have dual pulses and check the

relation between the two.

It may also be that a turbine blade may break off resulting in the wrong measurement. There is

therefore a need for diagnostics. Several solutions have been implemented:

• The dual pulse method with a 90° angle between the two. This allows for diagnostics and even

corrections for missing pulses. An API classification level A to E is available (see below) for

this.

• A second pulse from a turbine wheel with different blade angle.

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

21

Page 22

SUMMIT 8800METERING PRINCIPLES03

• A second lower frequency pulse, so a combination of HF with MF or LF. Off course the frequency ratio or blade ratio between the two pulses must be given.

API has a classification on the quality actions taken on the pulses:

API level E is achieved solely by correctly applied

transmission systems, criteria and recommended

installed apparatus of good quality.

API level D system consists of manual error

monitoring at methods of comparison, as used in

Levels A through D.

API level C consists of automatic error monitoring

for number, frequency, phase, and sequence and

error indication at specified intervals.

API level B consists of continuous monitoring, with

an error indication under all circumstances when

impaired pulses occur.

API level A: consists of continuous verification and

correction given by the comparator.

Basically a non-issue for flow computers

This means: Only 1 pulse is needed on the flow

computer.

This means: two pulses must be installed: the

meter pulse and monitor pulse, which may be of

different frequency (see frequency ratio)

This means two pulses of the same frequency

must be installed: the meter and monitor pulse.

The major issue here is; the flow computer has

to correct when a wrong pulse occurs. This is

quite advanced and is fully implemented in the

SUMMIT.

Nowadays more and more electronics is incorporated into the meters, such as in ultrasonic

and Coriolis meters. These meters normally emulate two high frequency pulses, to make them

look the same as rotating meters from the installation standpoint. The flow is calculated and a

special pulse output is driven by the processor. Although the need for a second output pulse is

diminished, most meters still carry them. API Level A is not really required.

There are also meters with smart indexes. Here the indexes values itself can be read by the

flow computer. The advantage is that the totals on the meters index are identical to the flow

computer totals. Also, if the flow computer is replaced, the total will be automatically read. The

communication is then digital and can be read via the serial port.

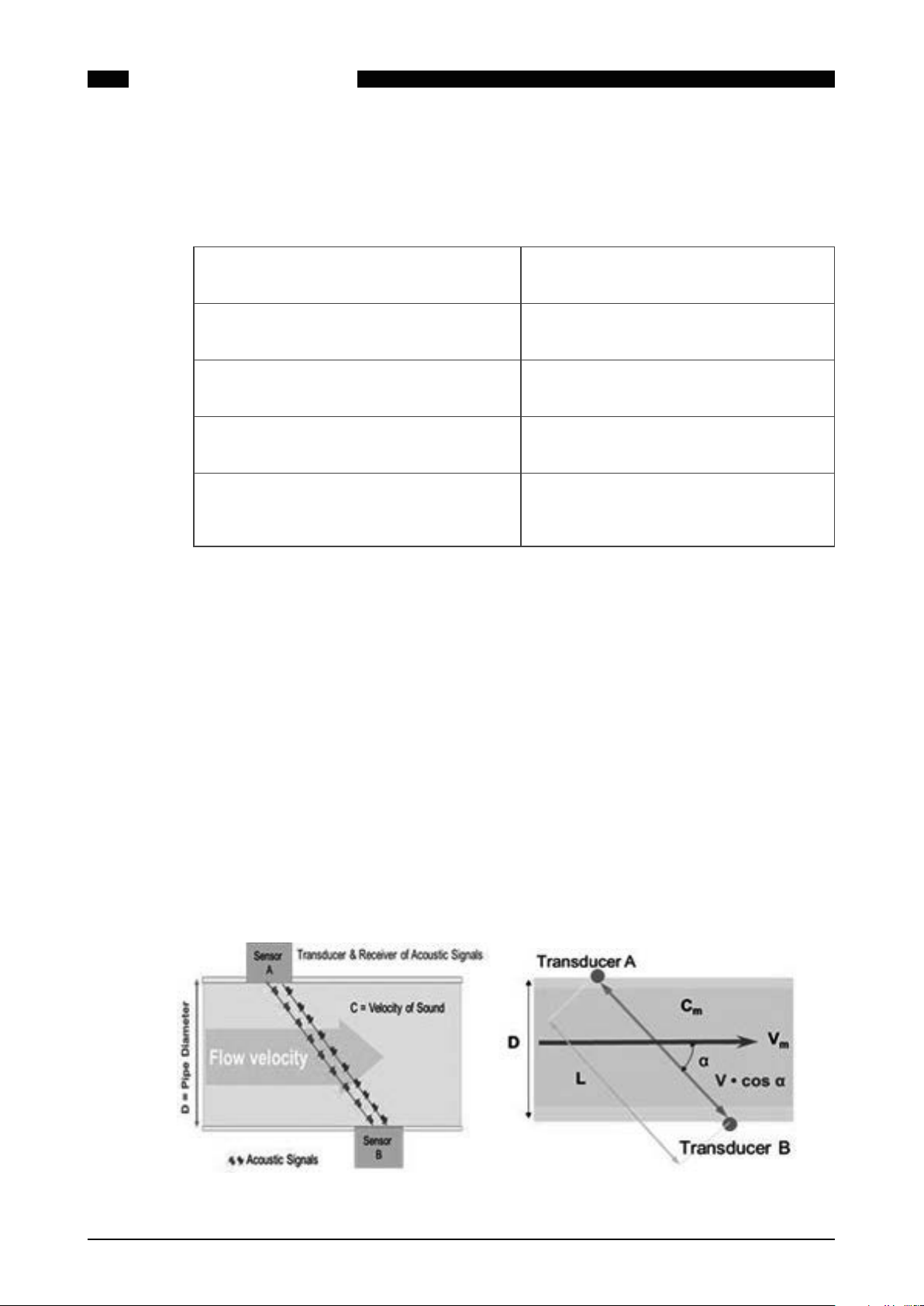

3.2 Ultrasonic meters

Ultrasonic meters are based on Transit Time Measurement of high frequency acoustic signals.

These signals are transmitted and received along a diagonal measuring path.

A sound wave going downstream with the flow travels faster than a sound wave going upstream

against the flow. The difference in transit time is directly proportional to the flow velocity of

the liquid or gas. This can be compared with the speed a canoe travels upstream compared to

downstream.

Figure 3 Ultrasonic measurement principle

22 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 23

SUMMIT 8800

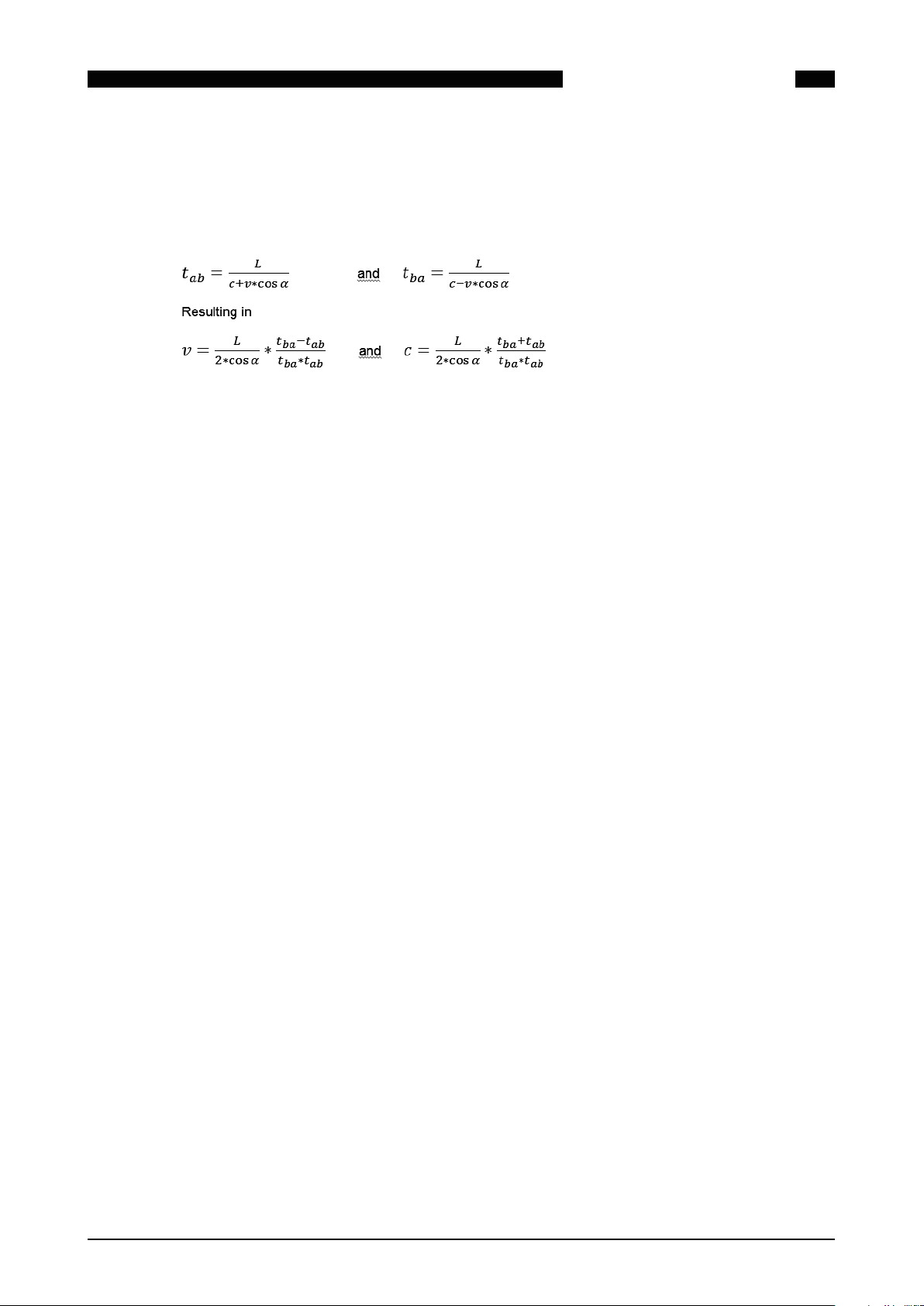

Mathematically, the time to transmit from a to b and back depends on the distance (L) between

the two transducers, the speeds of the medium (v) and sound (c) plus the angle of the path (α) as

follows:

Equation 1 Ultrasonic measurement formulae

With the velocity of the gas and the area of the pipe, the volume flow rate can be calculated.

The problem is however that the oil or gas is not always equally distributed through the pipe.

The flow normally is faster in the centre than in at the pipe and has a certain profile depending

on turbulent or laminar flow. So you do need the proper average velocity over the complete pipe.

With single beam meters, such as clamp-on meters, the accuracy is therefore very limited.

That is why the medium must be measured at different locations in the pipe. The trick is to best

estimate the profile/ the average flow. All manufacturers come up with different arrangements

in multi-path meters.

METERING PRINCIPLES

03

The output of ultrasonic meters is normally a combination of a dual pulse and a serial link.

• The dual pulse is generated by the electronics to emulate a turbine meter but does not provide its diagnostics.

• The serial link has typically a modbus protocol specific to the manufacturer, but for Instromet

there is also the proprietary “Instromet protocol”. This serial protocol carries the flow rate,

but also meter diagnostics. For that reason in many cases both links are used at the same

time.

Each manufacturer has its own set of diagnostics. Typical diagnostics are:

• The amplification needed to send a signal between the transducers, both up- and downstream

• The signal to noise ratio at each transmitter

• The speed of sound measured by each path or ratio’s between them

• An indication of the type of flow profile

For gas there is an interesting additional diagnostics which is the calculated against the measured speed of sound based on AGA 10. The meter calculates besides the speed of the gas also

the speed of sound. AGA 10 gives the formula from which the speed of sound can be calculated

from the composition, the temperature and the pressure. Off course the measured and calculated speed of sound should be equal. If not one of the variables (meter, chromatograph or P or

T) must be wrong or badly calibrated. This is therefore a perfect over all metering system check.

3.3 Differential pressure (dP) meters: e.g. orifice, venturi and cone meter

Differential pressure flowmeters use the Bernoulli’s rule to measure the volume flow of gas

or liquid in a pipe. They use a restriction in a pipe to measure the volume as it creates a difference in pressure before and after the restriction. The pressure difference (∆p) increases as flow

increases.

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

23

Page 24

SUMMIT 8800METERING PRINCIPLES03

Figure 4 DP measurement principles

The shape of the restriction is determines the type of meter: orifice, V-cone venture or nozzle

(see later paragraphs). For each type there are several parameters that will be required to successfully calculate the flow rate.

A single dP transmitter can used, but the problem is that a transmitter typically only has a 1:3

turndown ratio, so the accuracy for low flow is very limited. For that reason in custody transfer

applications multiple dP transmitters with different ranges are used for one meter and the flow

computer switches between them over depending on the flow.

The SUMMIT can handle 1 to 3 ranges:

Figure 5 Up to 3 dP ranges

dP 1 will always measure the high range. In case of multiple ranges, an automatic switch-over

to dP 2 will occur to medium range if the flow decreases to the dP measurement range, optimizing the accuracy. If 3 ranges are available, dP 3 will kick in when the flow gets within its measurement range.

In the SUMMIT the switch-up and switch-down values for the dP may be given. They will be

normally be different to have some hysteresis to prevent continues switch-up and –down when

at the threshold.

In high end applications, where the accuracy is crucial, multiple dP transmitters per range can

be used for the following reasons:

24 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 25

SUMMIT 8800

• Accuracy: By averaging the transmitter values.

• Redundancy: If one transmitter fails, the other value may be used.

• Diagnostics: A warning can be given if there is a deviation between the transmitters.

For diagnostics 2 transmitters can be used, but it is not possible to determine which one is correct. For that reason 3 dP transmitters may be used.

The SUMMIT also can have 1 to 3 dP transmitters for 1 to 3 ranges, so 1 to 9 dP transmitters in

total.

3.3.1 Orifice Plate

A flat circular plate with a hole, mounted inside the pipe that causes the fluid to push through a

smaller diameter.

METERING PRINCIPLES

03

Figure 6 Orifice meter and plate

This is the most commonly used type of meter.

Classical venture or Herschel venturi

Consists of a tapering in the pipe.

Figure 7 Venturi tube layout

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

25

Page 26

3.3.2 Venturi nozzle

The venturi nozzle has a trumpet shape restriction ending up in the pipe..

Figure 8 Venturi Nozzle

SUMMIT 8800METERING PRINCIPLES03

The main advantage of the venturi nozzle is pressure recovery.

ISA 1932 nozzle

Typically used for high velocity, set by ISO 5167 to determine the flow of fluid.

Long radius nozzle

A variation of the ISA 1932 nozzle, with a convergent section as the ISA 1932 nozzle and divergent section as a classical venturi

Cone or V-cone meter

The shape of the cone is to stable the flow profile in order to accurately measure the fluid regardless of flow properties.

Figure 9 V-cone meter

3.4 Coriolis meters

The Coriolis effect is the deflection of a fluid by a rotating effect. If the rotation is clockwise, the

deflection is to the left, if counter-clockwise, the deflection is to the right.

Coriolis meters use a vibrating meter tube to generate the rotating effect and measure the deflection to calculate the mass passing through the meter.

26 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 27

SUMMIT 8800

METERING PRINCIPLES

03

Figure 10 Coriolis meter flow principle

A tube with a fluid is brought into a sine waveform vibration. The eigen frequency with which this

occurs is directly dependent on the density of the fluid. If the fluid is flowing, a phase shift of the

vibration will occur between the inlet and outlet of the tube. This phase shift is a measure of the

velocity with which the fluid passes through the pipe.

Traditional Coriolis meters have a bent tube to maximize the Coriolis effect. With more advanced

electronics nowadays there is also straight tube Coriolis meters (see drawing).

Coriolis meters determine the mass flow, but can also determine the density. Most Coriolis

meters will also calculate the volume flow using internal temperature and pressure, but it is

recommended to use external measurements because of accuracy.

Coriolis meters typically have a dual pulse output mostly with the choice to have mass or volume

flow rate, where mass flow rate is more accurate. Because of the fact that also density, pressure

and temperature are available, most meters have also the option for a serial (modus) output, or

a (multi-variable) Hart output.

08/2013 - MA SUMMIT 8800 Vol2 R02 en

www.krohne.com

27

Page 28

3.5 Meter corrections

3.5.1 Gas & steam

The meter provides a number of pulses/s. We would like to know the Volume flow rate e.g. m3/s.

For this need:

Pulse factor or impulse factor or meter factor

The factor provided by the manufacturer of the meter giving the number of pulses per volume of

gas e.g. Pulses/m3. This assumes a linear meter. This is configured in the meter section.

Linearisation/ error Curve

The errors in % obtained during calibration of a meter which are the corrections needed to linearise the meter. So for each flow rate a different error is used. In between the given flow rates

a linear interpolation is used. For flow outside the operating range, extrapolation is used, except

when MID is chosen, then the error is fixed, and low and high flow is used.

Volume flow rate= Pulses per period*(1-Error)

Gross Volume= Pulses*(1-Error)

SUMMIT 8800METERING PRINCIPLES03

3.5.2 Liquid

The meter provides a number of pulses/s. We would like to know the Volume flow rate e.g.

gallons/s. For this there are three important corrections for the meter possible:

K-factor

The factor provided by the manufacturer of the meter or as a result of proving which is the number of pulses per volume of fluid e.g. Pulses/gallon.

For a linear meter only one factor can be given.

In case that the meter is not linear then a K-factor curve can be used. In this These factors are

obtained during calibration or prove of a meter which are the corrections needed to linearise the

meter. This is expressed by a variation of the K-factor over the specified flow range. So for each

flow rate a different K-factor is used. In between the given flow rates a linear interpolation is

used. For flow above maximum extrapolation is used.

Meter factor

The factor determined during proving to correct a fluid flowmeter for the ambient conditions by

shifting its curve. The factor is used to compensate for such conditions as liquid temperature

change and pressure shrinkage and is meter and product dependent. The meter factor should

be close to1.

Equation 2 Volume calculation with MF

Equation 3 Gross volume calculation with MF

28 www.krohne.com 08/2013 - MA SUMMIT 8800 Vol2 R02 en

Page 29

SUMMIT 8800

3.6 Liquid normalisation

As with gas also oil flow is measured by meters using a variety of different measurement principles, most based on volume flow, some based on mass flow. Examples are turbine meters,