Page 1

Operating Instructions

SU 501 Ex

Signal conditioning instrument

Page 2

Contents

Contents

1 About this document

1.1 Function .............................

1.2 Target group ..........................

1.3 Symbolism used .......................

2 For your safety

2.1 Authorised personnel ....................

2.2 Appropriate use........................

2.3 Warning about misuse ...................

2.4 General safety instructions ................

2.5 CE conformity .........................

2.6 Safety information for Ex areas.............

3 Product description

3.1 Configuration..........................

3.2 Principle of operation ....................

3.3 Adjustment ...........................

3.4 Storage and transport ...................

4 Mounting

4.1 General instructions .....................

4.2 Mounting information ....................

4

4

4

5

5

5

5

5

6

7

7

8

8

9

9

5 Connecting to power supply

5.1 Preparing the connection .................

5.2 Connection procedure ...................

5.3 Wiring plan ...........................

6 Set up

6.1 Adjustment system .....................

6.2 Adjustment elements ....................

7 Maintenance and fault rectification

7.1 Maintenance ..........................

7.2 Fault rectification .......................

7.3 Instrument repair .......................

8 Dismounting

8.1 Dismounting procedure ..................

8.2 Disposal .............................

9 Functional safety

9.1 General..............................

2 SU 501 Ex - Signal conditioning instrument

12

12

14

15

16

20

20

23

24

24

25

27953-EN-050616

Page 3

Contents

9.2 Planning .............................

9.3 Setup ...............................

9.4 Reaction during operation and in case of failure.

9.5 Recurring function test ...................

9.6 Safety-related characteristics ..............

10 Supplement

10.1 Technical data.........................

10.2 Dimensions ...........................

10.3 Certificate ............................

26

28

28

28

29

31

33

34

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 3

Page 4

About this document

1 About this document

1.1 Function

This operating instructions manual has all the information you

need for quick setup and safe operation of SU 501 Ex. Please

read this manual before you start setup.

1.2 Target group

This operating instructions manual is directed to trained

personnel. The contents of this manual should be made

available to these personnel and put into practice by them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution, warning, danger

This symbol informs you of a dangerous situation that could

occur. Ignoring this cautionary note can impair the person and/

or the instrument.

Ex applications

This symbol indicates special instructions for Ex applications.

l List

The dot set in front indicates a list with no implied sequence.

à Action

This arrow indicates a single action.

1 Sequence

Numbers set in front indicate successive steps in a procedure.

4 SU 501 Ex - Signal conditioning instrument

27953-EN-050616

Page 5

For your safety

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual

must be carried out only by trained specialist personnel

authorised by the operator. For safety and warranty reasons,

any internal work on the instruments must be carried out only

by personnel authorised by the manufacturer.

2.2 Appropriate use

SU 501 Ex is a universal signal conditioning instrument for

connection of a level switch.

2.3 Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to

application-specific hazards, e.g. vessel overfill or damage to

system components through incorrect mounting or adjustment.

2.4 General safety instructions

SU 501 Ex is a high-tech instrument requiring the strict

observance of standard regulations and guidelines. The user

must take note of the safety instructions in this operating

instructions manual, the country-specific installation standards

(e.g. the VDE regulations in Germany) as well as all prevailing

safety regulations and accident prevention rules.

2.5 CE conformity

SU 501 ExisinCE conformity with EMC (89/336/EWG) and

NSR (73/23/EWG).

Conformity has been judged acc. to the following standards:

l EMC:

- Emission EN 50081-1: 1993

- Susceptibility EN 50082-2: 1995

l NSR: EN 61010-1: 1993

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 5

Page 6

For your safety

2.6 Safety information for Ex areas

Please note the Ex-specific safety information for installation

and operation in Ex areas. These safety instructions are part of

the operating instructions manual and come with the Exapproved instruments.

6 SU 501 Ex - Signal conditioning instrument

27953-EN-050616

Page 7

3 Product description

3.1 Configuration

Product description

Scope of delivery

Components

The scope of delivery encompasses:

l SU 501 Ex signal conditioning instrument

l Documentation

- this operating instructions manual

SU 501 Ex consists of the following components:

l SU 501 Ex signal conditioning instrument

3

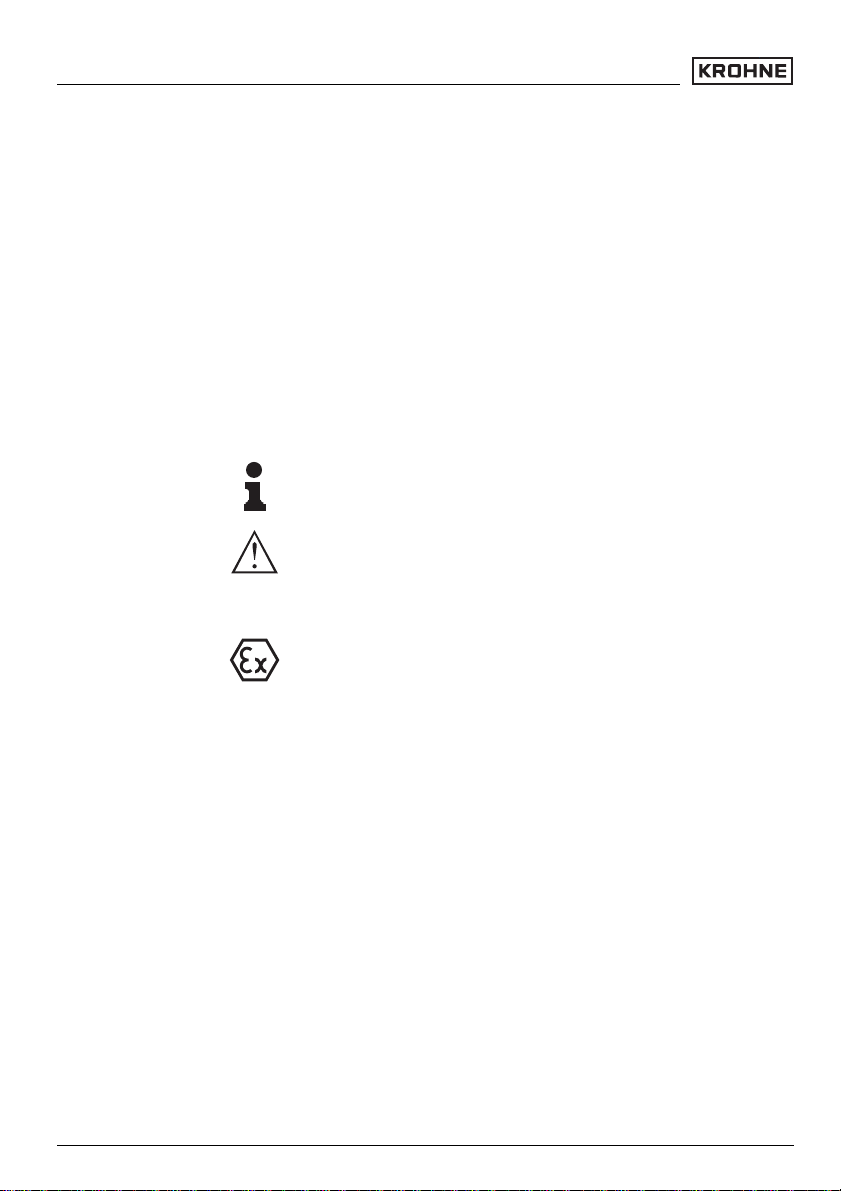

Fig. 1: SU 501 Ex

1 Ex separating chamber with Ex version

2 Socket

3 Transparent cover

1

2

TEST

on

56 78

910 121314

3.2 Principle of operation

Area of application

Physical principle

Power supply

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 7

SU 501 Ex is a single signal conditioning instrument for

processing of vibrating level switches.

SU 501 Ex signal conditioning instrument can power connected instruments and process their measuring signals.

You can find detailed information on the power supply in the

"Technical data" in the "Supplement".

Page 8

Product description

3.3 Adjustment

The integration time and the mode (A/B) can be preset on the

signal conditioning instrument via a DIL switch block.

A test key is lowered on the front plate of SU 501 Ex. When

pushing the key, the measuring system is checked on correct

function.

3.4 Storage and transport

Packaging

Storage and transport tempe-

rature

Your instrument was protected by packaging during transport.

Its capacity to handle normal loads during transport is assured

by a test acc. to DIN EN 24180.

The packaging of standard instruments consists of environ-

ment-friendly, recyclable cardboard. For special versions PE

foam or PE foil is also used. Dispose of the packaging material

via specialised recycling companies.

l Storage and transport temperature see "Supplement –

Technical data – Ambient conditions"

l Relative humidity 20 … 85 %

8 SU 501 Ex - Signal conditioning instrument

27953-EN-050616

Page 9

4 Mounting

4.1 General instructions

Mounting

Installation location

Transparent cover

SU 501 Ex signal conditioning instrument with plug-in socket

for mounting on carrier rail acc. to EN 50022.

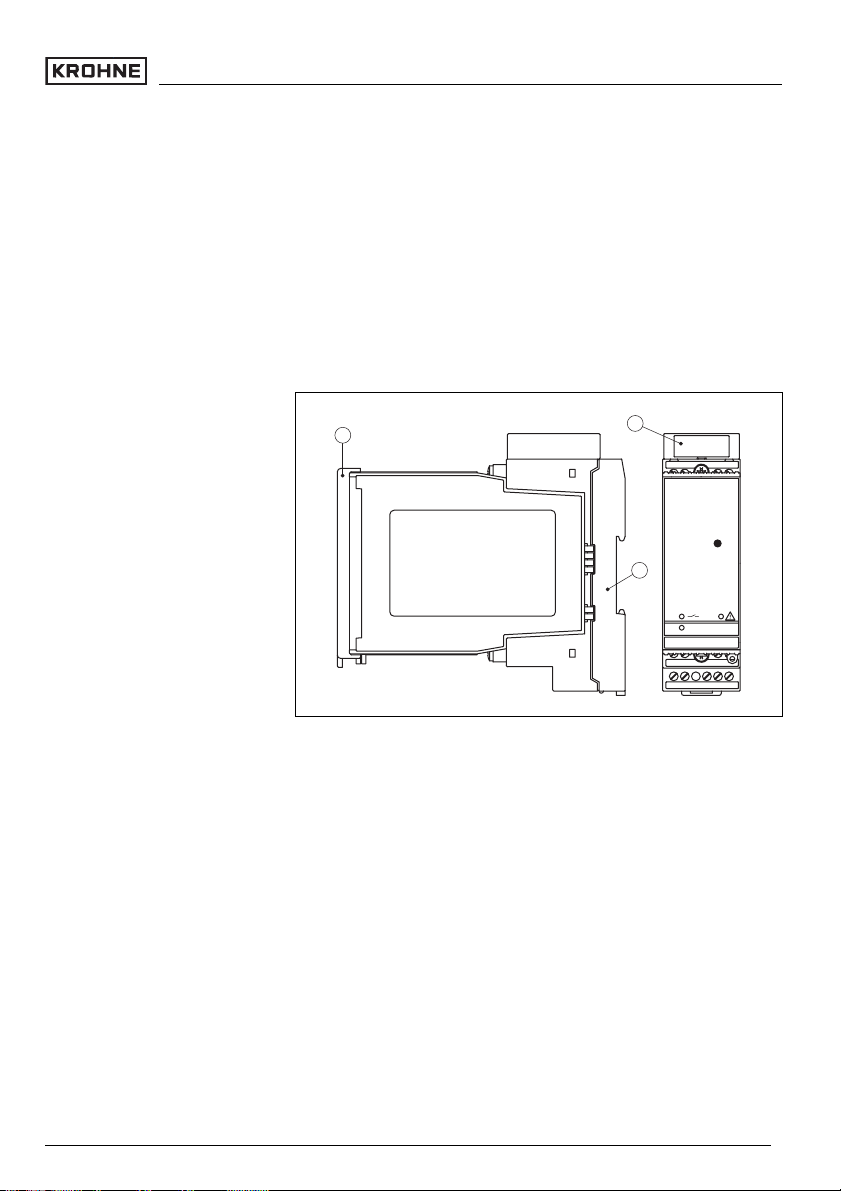

The front plate of SU 501 Ex can be provided with a lockable

transparent cover to protect the instrument against unauthorised adjustment. See the following figure for how to remove

the transparent cover.

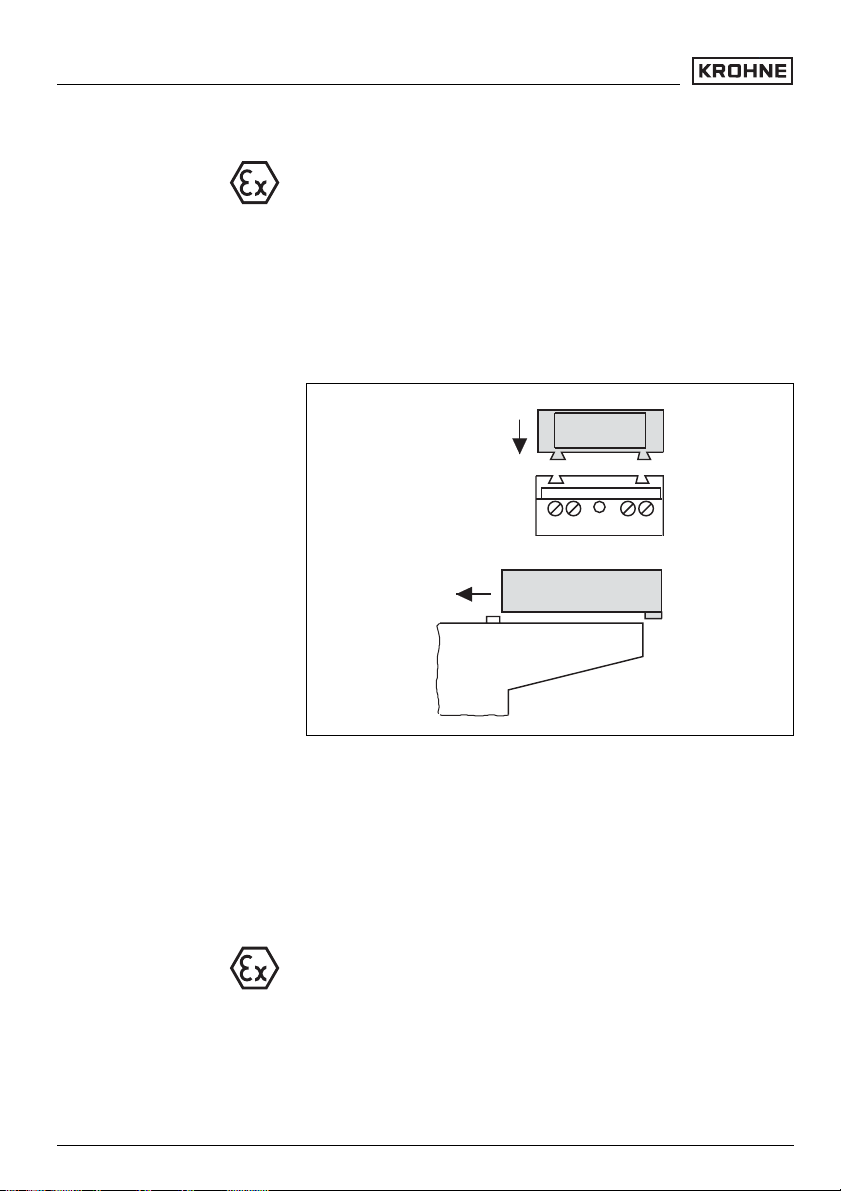

Fig. 2: Removing the transparent cover

4.2 Mounting information

Mounting

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 9

The plug-in socket is constructed for carrier rail mounting acc.

to EN 50022. Power supply is connected to terminals 9 and 10.

For neighbouring signal conditioning instruments, it is possible

to continue connection L1 and N directly via the supplied

bridges.

Danger:

The bridges must never be used with single instruments or at

the end of a row of instruments. If this rule is not heeded, there

is a danger of coming into contact with the operating voltage or

causing a short circuit.

Page 10

Mounting

ASU501 ExinEx version is an auxiliary, intrinsically safe

instrument and must not be installed in hazardous areas.

Ex separating chamber

Instrument coding

Before setup, the Ex separating chamber must be attached (as

shown below) with Ex versions. Safe operation can be only

ensured if the operating instructions manual and the EU type

approval certificate are observed. SU 501 Ex must not be

opened.

Close the upper terminals acc. to the following illustration.

12 43

Fig. 3: Mounting the separating chamber

All signal conditioning instruments are provided with different

gaps dependent on type and version (mechanical coding).

The plug-in socket is provided with coded pins that can be

inserted to prevent accidental interchanging of the various

instrument types.

With a SU 501 ExinEx version, the supplied coded pins (type

coded pin and Ex coded pin) must be inserted by the user acc.

to the below chart.

10 SU 501 Ex - Signal conditioning instrument

27953-EN-050616

Page 11

Mounting

4

3

2

1

EEx ia

A

B

Plug-in socket

C

Typ 600-1

1

2

3

0...10V

DISBUS

7

8

9

12

56 78

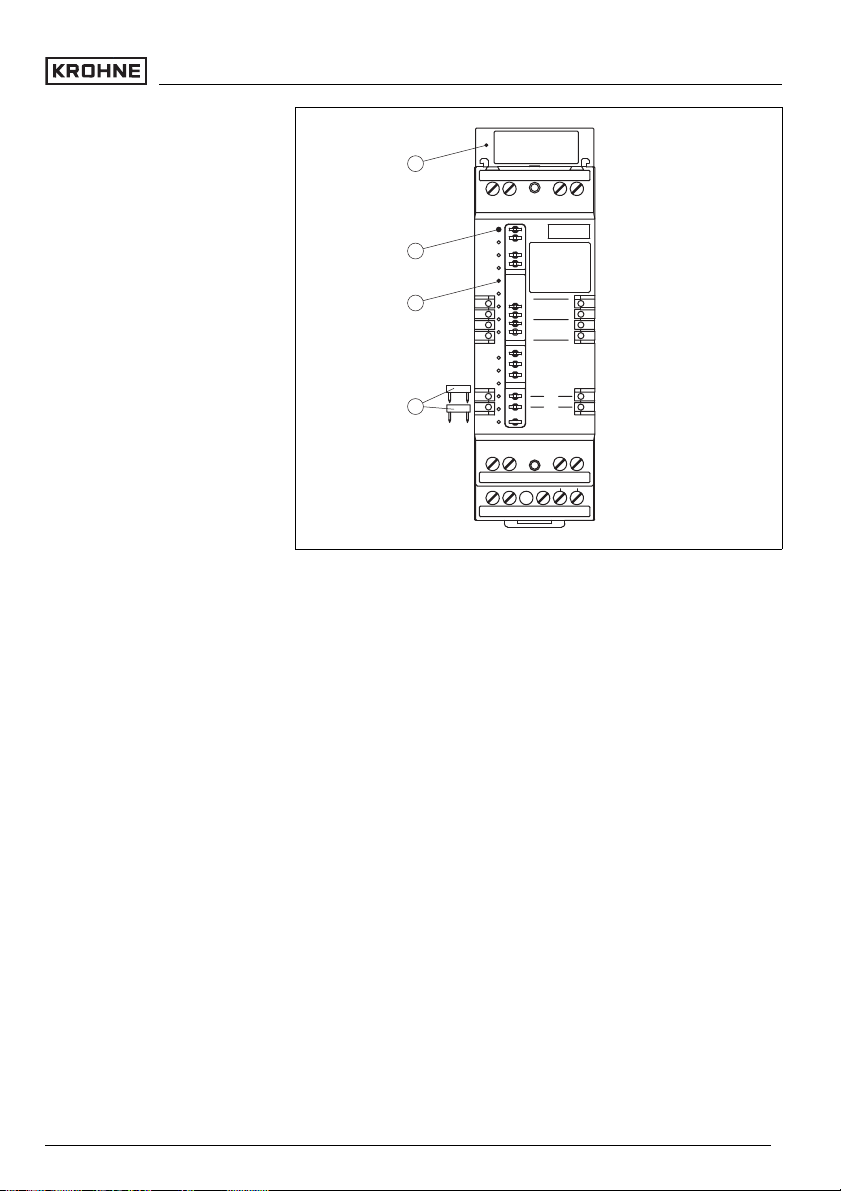

Fig. 4: Plug-in socket SU 501 Ex

1 Bridges for looping the power supply

2 Type coding for SU 501 Ex

3 Ex coding with Ex version

4 Ex separating chamber

4321

-

+

N

L

1

141312109

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 11

Page 12

Connecting to power supply

5 Connecting to power supply

5.1 Preparing the connection

Note safety instructions

Take note of safety

instructions for Ex

applications

Select power supply

Select connection cable

Cable screening and groun-

ding

Always observe the following safety instructions:

l Connect only in the complete absence of line voltage

l If overvoltages are expected, overvoltage arresters should

be installed.

In hazardous areas you should take note of the appropriate

regulations, conformity and type approval certificates of the

sensors and power supply units.

The power supply can be 20 … 250 VAC, 50/60 Hzor

20 … 72 VDC.

Power supply of SU 501 Ex is connected with standard cable

acc. to the national installation standards.

Standard two-wire cable without screening can be used to

connect sensors. If electromagnetic interference is expected,

screened cable must be used.

Connect the cable screen on both ends to ground potential. In

the sensor, the screen must be connected directly to the

internal ground terminal. The ground terminal outside on the

sensor housing must be connected to the potential equalisation.

If potential equalisation currents are expected, the screen

connection on SU 501 Ex must be made via a ceramic

capacitor (e.g. 1 nF, 1500 V). The low frequency potential

equalisation currents are thus suppressed, but the protective

effect against high frequency interference signals remains.

Select connection

cable for Ex applications

Take note of the corresponding installation regulations for Ex

applications. In particular, make sure that no potential

equalisation currents flow over the cable screen. In case of

grounding on both sides this can be achieved by the use of a

capacitor or a separate potential equalisation.

5.2 Connection procedure

Move to electrical connection and proceed as follows:

1 Snap the socket without SU 501 Ex onto the carrier rail

12 SU 501 Ex - Signal conditioning instrument

27953-EN-050616

Page 13

Connecting to power supply

2 Connect sensor cable to terminal 1 and 2, and where

applicable, connect the screen

3 Connect power supply (switched off) to terminal 9 and 10

4 Insert SU 501 Ex into the plug-in socket and screw it down

tightly

The electrical connection is finished.

Before setting up Ex versions, make sure the Ex separating

chamber is plugged (above the sensor terminals). The pins for

type and Ex coding must also be inserted correctly.

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 13

Page 14

Connecting to power supply

5.3 Wiring plan

Fig. 5: Wiring plan SU 501 Ex

1 Sensor

2 Sensor input

3 Transistor output

4 Relay output

5 Power supply

12 34

2

3

+-

56 78

910 121314

+

-

L1 N

5 4

1

14 SU 501 Ex - Signal conditioning instrument

27953-EN-050616

Page 15

6 Set up

6.1 Adjustment system

TEST

1

2

3

on

56 78

910 121314

4

EEx ia

A

B

Plug-in socket

C

Typ 600-1

1

2

3

7

8

9

12

56 78

0...10V

DISBUS

N

L

1

-

+

Set up

5

4321

6

7

7

8

9

141312109

10

Fig. 6: Indicating and adjustment elements

1 Test key

2 Control lamp level relay (LED)

3 Control lamp fail safe relay (LED)

4 Control lamp power supply (LED)

5 Ex separating chamber

6 Terminal for probe

7 Sockets for bridges

8 Transistor output

9 Relay output

10 Power supply

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 15

Page 16

Set up

12

6

t sec

2

off

ze

za

123456

A

B

1

Control lamps

PTB-Nr.: Ex-95/xxxx X

Sensorstromkreis EEx ia IIC

Uo < xx V Lo < xx mH

< xx nF

Io < xx mA

Co

Po < xx mW

Sensor

Terminal

+

-

12

out

max: 36V

60mA

+

56

-

IP 30

nsp. I

max.250VAC/DC

500VA/54W

3AAC/1ADC

1312

: -20...+60°C

a

power supply

14

20...250 VAC

20...72VDC

L

N

+

-

910

2 W

23

Fig. 7: Indicating and adjustment elements

1 DIL switch block

2 Type label

3 Transparent cover

6.2 Adjustment elements

Control lamps (LED) in the front plate indicate operation,

switching status and fault signal.

l Green

- Operation control lamp

- Mains voltage on, instrument operates

l Red

- Failure lamp

- Fault on the sensor circuit by sensor failure or line

break

27953-EN-050616

16 SU 501 Ex - Signal conditioning instrument

Page 17

DIL switch block

Set up

- If the fail safe relay is deenergized, the red failure lamp

will light

l Yellow

- Relay control lamp

- The yellow relay control lamp reacts depending on the

set mode (A/B)

- In general, the relay control lamp indicates the

activated (energised) condition of the relay

- A dark relay control lamp means that the relay is

deenergised (transistor blocks)

Laterally on top (covered when mounted) there is a DIL switch

block with six switches. The individual switches are assigned

as follows:

l 1 – A/B mode

- A – Max. detection or overfill protection

- B – Min. detection or dry run detection

l 2 – Switch off delay (za)

l 3 – Switch on delay (ze)

l 4 – Integration time 2 s

l 5 – Integration time 6 s

l 6 – Integration time 12 s

With switch 1 you can adjust the mode (A – overfill protection

or B – dry run protection).

With switch 2 and 3 you can adjust the switch off and/or switch

on delay independently.

In the example (see previous illustration), mode A (max.

detection of overfill protection) is selected (switch 1). The

switch on delay is activated (switch 3 ) and the integration time

is set to 8 seconds (switch 4, 5 and 6).

With switches 4, 5 and 6 you can adjust the integration time.

The times of the activated time switches accumulate. If the

switch on (ze) and switch off delay (za) are switched on

together, the adjusted time applies to both delay modes.

Information:

Keep in mind that the integration time of the sensor and signal

conditioning instrument accumulate.

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 17

Page 18

Set up

Switch 12345 6

Time za ze 2 s 6 s 12 s

0.2 s A/B off off off off off

0.5 s A/B

2 s A/B on off off

6 s A/B off on off

8 s A/B on on off

12 s A/B off off on

14 s A/B on off on

18 s A/B off on on

20 s A/B on on on

1)

off off off

Fault monitoring

Test key

The measuring system is continuously monitored. The

following criteria are checked:

l Two-wire cable on line break and shortcircuit

l Interruption of the connection cable to the piezo elements

l Corrosion or damage of the tuning fork (vibrating rod)

l Break of the tuning fork (vibrating rod)

l no vibration

l Too low vibrating frequency

l Medium penetrating from the vessel side into the sensor

In systems with OPTISWITCH level switches in conjunction

with a two-wire oscillator, a function test can be carried out. SU

501 Ex has an integrated test key. The test key is lowered in

the front plate of the signal conditioning instrument. Push the

test key with a suitable object (e.g. screwdriver, pen etc.).

By pushing the key, the system is checked on the following

criteria:

l Switching function of the switching outputs

l Potential separation of the outputs

l The signal processing of the signal conditioning instrument

After pushing the test key, the complete measuring system is

checked on correct function. The following operating conditions are simulated during the test:

l Fault signal

l Empty signal

27953-EN-050616

1)

Set alternately switch 2 and/or 3 to "on". The times apply to the adjusted

delay mode.

18 SU 501 Ex - Signal conditioning instrument

Page 19

Set up

l Full signal

Check if all three switching conditions occur in the correct

sequence and the stated duration. If not, there is a fault in the

measuring system (see chapter "Fault rectification").

Note:

Keep in mind that the connected instruments are activated

during the function test. By doing this, you can check the

correct function of the measuring system.

Test procedure A-mode B-mode

1 Simulation of a fault signal (approx. 3 s)

Level relay deenergised Relay control

lamp off

1 Simulation of a fault signal

Failure lamp Failure lamp

lights

2 Simulation an empty signal (approx. 1.5 s)

Level relay energised Relay control

lamp lights

2 Simulation of an empty signal

Failure lamp Failure lamp off Failure lamp off

3 Simulation of a full signal (approx. 1.5 s)

Level relay deenergised Relay control

lamp off

3 Simulation of a full signal

Failure lamp Failure lamp off Failure lamp off

4 Return to the current operating condition (covered/uncovered)

Relay control

lamp off

Failure lamp

lights

Relay control

lamp off

Relay control

lamp lights

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 19

Page 20

Maintenance and fault rectification

7 Maintenance and fault rectification

7.1 Maintenance

When used as directed in normal operation, SU 501 Exis

completely maintenance-free.

7.2 Fault rectification

Causes of malfunction

Fault rectification

Failure

SU 501 Exoffers maximum reliability. Nevertheless faults can

occur during operation. These may be caused by the following,

e.g.:

l Measured value of the sensor not correct

l Power supply

l Interference on the cables

The first measures are checking the input and output signal.

The procedure is described as follows. In many cases the

causes can be determined and faults can be rectified.

? The red failure LED of the signal conditioning instrument

lights

l Sensor not connected correctly

à Measure the current value on the signal cable to the

sensor

In Ex systems, make sure that the Ex protection is not

influenced by the measuring instruments used.

à Faults on the sensor causing a current change below

2 mA or above 23 mA, cause a fault signal on

measuring instruments.

20 SU 501 Ex - Signal conditioning instrument

27953-EN-050616

Page 21

Maintenance and fault rectification

12... 20V4... 20mA

VmA

+

-

2

Fig. 8: Connection of a multimeter

1 SU 501 Ex signal conditioning instrument

2 Sensor

1

12 34

l Sensor not connected correctly

à Measure the voltage on the connection cable

In Ex systems, make sure that the Ex protection is not

influenced by the measuring instruments used.

à The terminal voltage of the sensor is at least 12 V in

normal condition

? The red failure LED of the signal conditioning instrument

lights

l Current value <2 mA

à Measure the current value on the signal cable to the

sensor

1 Check all connections and connection cables to the sensor

The voltage should be approx. 17 … 20 V

If the value is below 17 V, probably the signal conditioning

instrument is defective.

Exchange signal conditioning instrument or return it for

repair

2 If the red failure lamp continues to light, separate the

sensor from the connection cable and connect a resistor of

1 kOhm instead on the signal conditioning instrument

The signal conditioning instrument is defective if the failure

lamp continues to light

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 21

Page 22

Maintenance and fault rectification

Exchange signal conditioning instrument or return it for

repair

3 Should the failure lamp extinguish, you can connect the

sensor again. Separate the signal conditioning instrument

from the connection cable and connect a resistor of 1

kOhm to the sensor input

4 If the failure lamp continues to light, the connection cable is

probably interrupted

Check the connection cable to the sensor

5 Should the failure lamp extinguish, the sensor will be

defective

Exchange sensor or return it for repair

? The red failure LED of the signal conditioning instrument

lights

l Current value >22 mA

à Measure the current value on the signal cable to the

sensor

1 Check all connections and connection cables to the sensor

2 If the red failure lamp continues to light, separate the

sensor from the connection cable and connect a resistor of

1 kOhm instead on the signal conditioning instrument

If the failure lamp extinguishes, the sensor is defective.

Check the connected sensor

3 If the failure lamp continues to light, connect the sensor

again. Separate signal conditioning instrument from the

connection cable and connect a resistor of 1 kOhm to the

sensor input.

4 If the failure lamp extinguishes, this is probably due to a

shortcircuit in the connection cable

Check the connection cable to the sensor

5 If the failure lamp continues to light, the signal conditioning

instrument is defective

Exchange signal conditioning instrument or return it for

repair

27953-EN-050616

22 SU 501 Ex - Signal conditioning instrument

Page 23

Maintenance and fault rectification

? Malfunction during function test

l After pushing the test key, the switching conditions do

not occur in the correct sequence or correct duration, e.

g. no full signal is outputted.

à Measure the line resistance

à If the cable is highly resistive, bring it to a normal

resistance, e.g. check terminals and cable connections

on corrosion

7.3 Instrument repair

If a repair is necessary, please proceed as follows:

You can download a return form from our Internet homepage

http://www.krohne-mar.com/fileadmin/media-lounge/PDF-

Download/Specimen_e.pdf.

By doing this you help us carry out the repair quickly and

without having to call back for needed information.

l Print and fill out one form per instrument

l Clean the instrument and pack it damage-proof

l Attach the completed form and possibly also a safety data

sheet to the instrument.

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 23

Page 24

Dismounting

8 Dismounting

8.1 Dismounting procedure

Warning:

Before dismounting, be aware of dangerous process conditions such as e.g. pressure in the vessel, high temperatures,

corrosive or toxic products etc.

Take note of chapters "Mounting" and "Connecting to power

supply" and carry out the listed steps in reverse order.

8.2 Disposal

SU 501 Ex consists of materials which can be recycled by

specialised recycling companies. We have purposely designed the electronic modules to be easily separable. Mark the

instrument as scrap and dispose of it according to government

regulations (electronic scrap ordinance,…).

Materials: see "Technical data"

If you cannot dispose of the instrument properly, please

contact us about disposal methods or return.

24 SU 501 Ex - Signal conditioning instrument

27953-EN-050616

Page 25

9 Functional safety

9.1 General

Functional safety

Validity

Area of application

Safety function

Relevant standards

Safety requirements

This safety manual applies to the SU 501 Ex signal

conditioning instrument. The instrument corresponds to a part

system of type A.

In combination with a vibrating level switch, the signal

conditioning instrument can be used as measuring system for

level detection meeting the special requirements of the safety

technology, e.g.

l Mode "max."=A-mode for overfill protection

l Mode "min."=B-mode for dry run protection

The measuring system is qualified in both modes to meet the

following requirement degree acc. to IEC 61508-2/IEC 61511:

l SIL2 with architecture 1oo1D (single channel)

l SIL3 with architecture 1oo2D (double-channel/redundant)

The safety function of the signal conditioning instrument is the

recognition of the meas. currents stated below and the

conversion into a respective switching signal on the relay

contact or the transistor output. The safe condition depends on

the mode:

l In mode "max.": 16 ±1 mA for condition "covered"

l In mode "min.": 8 ±1 mA for condition "uncovered"

l IEC 61508-1,-2,-4

- Functional safety of electrical/electronic/programmable

electronic systems

l IEC 61511-1

- Functional safety – safety instrumented systems for the

process industry sector – Part 1: Framework, definitions, system, hardware and software requirements

The failure limit values for a safety function, depending on the

SIL class (of IEC 61508-1, 7.6.2)

Safety integrity level Low demand mode High demand mode

SIL PFD

4 >=10

3 >=10-4up to <10

2 >=10-3up to <10

1 >=10-2up to <10

avg

-5

up to <10

-4

-3

-2

-1

PFH

>=10-9up to <10

>=10-8up to <10

>=10-7up to <10

>=10-6up to <10

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 25

-8

-7

-6

-5

Page 26

Functional safety

Safety integrity of the hardware for safety-relating subsystems

of type A (IEC 61508-2, 7.4.3)

General instructions and

restrictions

Assumptions

Low demand mode

Safe failure fraction Hardware

fault tolerance

SFF HFT = 0 HFT = 1 HFT = 2

<60 % SIL1 SIL1 SIL2

60 % up to <90 % SIL2 SIL3 (SIL4)

90 % up to <99 % SIL3 (SIL4)(SIL4)

>=99 % SIL3 (SIL4)(SIL4)

9.2 Planning

l The measuring system must be used acc. to the

application

l The application-specific limits must be maintained and the

specifications must not be exceeded.

l Acc. to the specifications in the operating instructions

manual, the current load of the output circuits must be

within the limits.

For the implementation of FMEDA (Failure Mode, Effects and

Diagnostics Analysis) the following assumptions form the

basis:

l Failure rates are constant, wear of the mechanical parts is

not taken into account

l Failure rates of external power supplies are not included

l Multiple errors are not taken into account

l The average ambient temperature during the operating

time is +40°C (104°F)

l The environmental conditions correspond to an average

industrial environment

l The lifetime of the components is around 8 to 12 years

(IEC 61508-2, 7.4.7.4, remark 3)

l The condition of the output circuit is further processed acc.

to the quiescent current principle

l The repair time (exchange of the meas. system) after a fail-

safe error is eight hours (MTTR = 8 h)

If the demand rate is only once a year, then the measuring

system can be used as safety-relevant subsystem in "low

demand mode" (IEC 61508-4, 3.5.12).

27953-EN-050616

26 SU 501 Ex - Signal conditioning instrument

Page 27

Functional safety

If the ratio of the internal diagnostics test rate of the measuring

system to the demand rate exceeds the value 100, the

measuring system can be treated in the way it is executing a

safety function in the mode with low demand rate (IEC 61508-2,

7.4.3.2.5).

Corresponding characteristics is the value PFD

(average

avg

Probability of dangerous Failure on Demand). It is dependent

on the test interval T

between the function tests of the

Proof

protective function.

Numbers see paragraph "Safety-technical characteristics".

High demand mode

Safe condition and fault

description

Configuration of the proces-

sing unit

If the "low demand mode" does not apply, the measuring

system must be used as safety-relevant subsystem in "high

demand" (IEC 61508-4, 3.5.12).

The fault tolerance time of the complete system must be higher

than the sum of the reaction times or the diagnostics test

periods of all components in the safety chain.

Corresponding characteristics is the value PFH (failure rate).

Numbers see paragraph "Safety-technical characteristics".

The safe condition of the measuring system is the switched off

status (quiescent current principle):

l Relay output – relay deenergised

l Transistor output – transistor blocks

A fail-safe failure (safe failure) exists if the measuring system

changes to the defined safe condition without demand of the

process.

If the signal conditioning instrument detects currents <3.6 mA

or >21.6 mA, the signal conditioning instrument takes on the

safe condition.

A dangerous undetected failure exists if the measuring system

does not go to the defined safe condition when required by the

process.

The processing unit must evaluate the output circuit of the

measuring system by taking the quiescent current principle

into account.

The processing unit must correspond to the SIL level of the

measuring chain.

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 27

Page 28

Functional safety

9.3 Setup

Mounting and installation

The prevailing plant conditions influence the safety of the

measuring system. Therefore note the mounting and installation instructions of the appropriate operating instructions

manual. Mainly important is the correct setting of the mode

(min./max.).

9.4 Reaction during operation and in case of

failure

l The adjustment elements must not be modified during

operation.

l In case of modifications during operation, you have to take

note of the safety functions.

l Occurring fault signals are described in the appropriate

operating instructions manual.

l In case of detected failures or fault signals, the entire

measuring system must be switched out of service and the

process held in a safe condition by means of other

measures.

l The manufacturer must be informed if due to a determined

fault, the instrument will be exchanged (incl. a fault

description)

9.5 Recurring function test

The recurring function test serves to reveal potential dangerous errors that are otherwise not discernible. The function of

the measuring system must be checked at adequate intervals.

The operator is responsible for choosing the type of test and

the intervals in the stated time frame. The time frame depends

on the PFD

"Safety-related characteristics".

With high demand rate, a recurring function test is not

requested in IEC 61508. The function of the measuring system

is proven by the frequent use of the system. In double channel

architectures it is useful to proof the redundancy by recurring

function tests in appropriate intervals.

The test must be carried out in a way that verifies the flawless

operation of the safety functions in conjunction with all system

components.

value acc. to the chart and diagram in section

avg

27953-EN-050616

28 SU 501 Ex - Signal conditioning instrument

Page 29

Functional safety

The methods and procedures used during the tests must be

stated and their suitability must be specified. The tests must be

documented.

If the function test proves negative, the entire measuring

system must be switched out of service and the process held

in a safe condition by means of other measures.

In the double channel architecture 1oo2D this applies

separately to both channels.

9.6 Safety-related characteristics

The failure rates of the electronics are determined by an

FMEDA acc. to IEC 61508. These calculations are based on

component failure rates acc. to SN 29500. All numerical values

refer to an average ambient temperature during the operating

time of +40°C (104°F). The calculations are also based on the

specifications stated in chapter "Planning".

The data are also valid for overfill protection (A-mode) as well

as dry run protection (B-mode).

λ

sd

λ

su

λ

dd

λ

du

SFF >84 % Safe Failure Fraction

0 FIT safe detected failure (1 FIT = failure/109h)

516 FIT safe undetected failure

0 FIT dangerous detected failure

100 FIT dangerous undetected failure

General data

Failure reaction time 0.5 sec

T

Reaction

MTBF = MTTF + MTTR 1.52x10

max. useful life of the measuring system for the safety

function

approx. 10 years

Single channel architecture

The following characteristics are derived from the above

mentioned data:

SIL2 (Safety Integrity Level)

HFT = 0 (Hardware Fault Tolerance)

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 29

6

h

Page 30

Functional safety

Architecture 1oo1D

PFD

avg

T

= 1 year

Proof

T

= 5 years

Proof

T

= 10 years

Proof

PFH <0.1x10-6/h

<0.044x10

<0.218x10

<0.436x10

-2

-2

-2

Double channel architecture

If the measuring instrument is used in a double channel

architecture, the safety-relevant characteristics of the selected

structure of the measuring chain must be calculated acc. to the

above failure rates (especially for the selected application). A

Common Cause Factor must be taken into account which is in

the worst case 10 %.

The following is applicable:

SIL3 (Safety Integrity Level)

HFT = 1 (Hardware Fault Tolerance)

Time-dependent process of

PFD

avg

The time-dependent process of PFD

reacts in the time

avg

period up to 10 years virtually linear to the operating time. The

above values only apply to the T

interval, after which a

Proof

recurring function test must be carried out.

PFD

avg

4

3

2

1

1510

Fig. 9: Time-dependent process of PFD

1 PFD

2 PFD

3 PFD

4 PFD

2)

= 0

avg

after 1 year

avg

after 5 years

avg

after 10 years

avg

Numbers see in the above charts.

2)

avg

T

Proof

27953-EN-050616

30 SU 501 Ex - Signal conditioning instrument

Page 31

Supplement

10 Supplement

10.1 Technical data

General data

Series module unit with plug-in socket for mounting on

carrier rail 35x7.5 or 35x5 acc. to EN 50022

Dimensions W = 36 mm (1.42 in), H = 118.5 mm (4.66 in), D

= 134 mm (5.28 in)

Weight approx. 170 g (6 oz)

Housing material Noryl SE100, Lexan 920A

Socket material Noryl SE100, Noryl SE1 GFN3

Screw terminals max. 1x1.5 mm²

Power supply

Power supply 20 … 250 VAC, 50/60 Hz, 20 … 72 VDC

Power consumption max. 3 W (3 … 18 VA)

Sensor input

Quantity 1

Data transmission Analogue

Hysteresis 100 µA

Switching threshold 12 mA

Current limitation 24 mA (permanently short-circuit proof)

Sensor power supply 15 … 18 VDC

Detection line break <=3.6 mA

Detection shortcircuit >=21 mA

Connection cable 2-wire

Resistance per conductor max. 35 Ohm

Relay output

Number, function 1x switching relay (spdt)

Integration time 0.2 … 20 s, directional switching

Mode A/B switch (A - max. detection or overfill

protection; B - min. detection or dry run

protection)

Contact 1x spdt

Contact material AgNi, hard gold-plated

Turn-on voltage min. 10 mVDC, max. 250 VAC, 250 VDC

Switching current min. 10 µADC, max. 3 AAC, 1 ADC

Breaking capacitance max. 500 VA, max. 54 WDC

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 31

Page 32

Supplement

Transistor output

Number, function 1 output, synchronously switching with the

relay

Galvanic separation floating

Max. values

- U

B

- I

B

Transistor voltage loss U

max. 36 VDC

max. 60 mA (short-circuit proof)

min.-1.5 V at IB60 mA

CE

Blocking current <10 µA

Adjustment elements

DIL switch block for preadjustment of the integration time and

mode

Test key for function test

Control lamps in the front plate

- status indication operating voltage LED green

- Status indication fault signal LED red

- Status indication switching point

LED yellow

control

Ambient conditions

Ambient temperature -20 … +60°C (-4 … +140°F), with an operating

voltage of 60 … 72 VDCthe permissible

ambient temperature reduces linear from

+60°C (+140°F) to +40°C (+104°F)

Storage and transport temperature -40 … +70°C (-40 … +158°F)

Electrical protective measures

Protection

- Signal conditioning instrument IP 30

- Socket IP 20

Overvoltage category II

Protection class II

Electrical separating measures reliable separation (VDE 0106, part 1) between

power supply, meas. data input, level relay and

transistor output

Approvals

3)

ATEX ATEX II (1) GD [EExia] IIC

Others WHG

3)

Deviating data with Ex applications: see separate safety instructions.

32 SU 501 Ex - Signal conditioning instrument

27953-EN-050616

Page 33

10.2 Dimensions

1

Supplement

134mm (5

9

/

")

32

Fig. 10: Dimensions SU 501 Ex

1 Transparent cover

2 Carrier rail 35x7.5 or 35x15 acc. to EN 50022

2

")

64

/

9

54,5mm (2

on

56 78

910 121314

27

/

36mm (1

")

64

")

64

/

43

118,5mm (4

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 33

Page 34

10.3 Certificate

CE declaration of conformity

Fig. 11: CE declaration of conformity

34 SU 501 Ex - Signal conditioning instrument

27953-EN-050616

Page 35

27953-EN-050616

SU 501 Ex - Signal conditioning instrument 35

Page 36

Subject to change without notice

27953-EN-050616

Loading...

Loading...