Page 1

OPTISYS SLM 2100

OPTISYS SLM 2100

OPTISYS SLM 2100OPTISYS SLM 2100

Sludge level meter

Software Revision:

01.00.01

Original handbook

Handbook

Handbook

HandbookHandbook

© KROHNE 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2014 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 3

OPTISYS SLM 2100

CONTENTS

1 Safety instructions 5

1.1 Software history ............................................................................................................... 5

1.2 Intended use ..................................................................................................................... 5

1.3 Certifications .................................................................................................................... 6

1.4 Safety instructions from the manufacturer ..................................................................... 7

1.4.1 Copyright and data protection ................................................................................................ 7

1.4.2 Disclaimer ............................................................................................................................... 7

1.4.3 Product liability and warranty ................................................................................................ 8

1.4.4 Information concerning the documentation........................................................................... 8

1.4.5 Warnings and symbols used................................................................................................... 9

1.5 Safety instructions for the operator................................................................................. 9

2 Device description 10

2.1 Scope of delivery............................................................................................................. 10

2.2 Device description .......................................................................................................... 11

2.3 Nameplate ...................................................................................................................... 13

3 Installation 14

3.1 General notes on installation ......................................................................................... 14

3.2 Storage and transport .................................................................................................... 14

3.3 Installation order............................................................................................................ 15

3.3.1 Mounting of the sludge level meter...................................................................................... 16

3.4 Typical measuring point ................................................................................................. 18

3.5 Installing the cleaning unit (optional) ............................................................................ 19

3.5.1 Installation of the water hose ............................................................................................... 20

4 Electrical connections 21

4.1 Safety instructions.......................................................................................................... 21

4.2 Used abbreviations .........................................................................................................21

4.3 Description of electrical symbols................................................................................... 22

4.4 Important device-specific notes on electrical connection............................................. 23

4.5 Overview cable connections ........................................................................................... 24

4.6 Overview of the terminal compartment ......................................................................... 25

4.7 Connecting the power supply......................................................................................... 26

4.8 Description and properties of the outputs and the input............................................... 27

4.8.1 Current output ...................................................................................................................... 27

4.8.2 Control input (active)............................................................................................................. 28

4.9 Connection of the outputs and the input........................................................................ 29

4.9.1 Important notes..................................................................................................................... 29

4.9.2 Current output (active).......................................................................................................... 30

4.9.3 Electrical connection of control inputs................................................................................. 31

4.10 Description and properties of the relays ..................................................................... 33

4.10.1 Connection of the relays ..................................................................................................... 33

4.11 Electrical connection of the external pump................................................................. 35

4.12 Protection category ...................................................................................................... 35

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

3

Page 4

CONTENTS

OPTISYS SLM 2100

5 Operation 36

5.1 Start-up and general remarks for configuration........................................................... 36

5.2 Switching on the power .................................................................................................. 37

5.3 Operating elements........................................................................................................ 38

5.4 Measuring page .............................................................................................................. 39

5.4.1 Navigating through the menus .............................................................................................40

5.5 Menu mode structure..................................................................................................... 44

5.6 Function tables ............................................................................................................... 45

5.6.1 Menu A, quick setup.............................................................................................................. 45

5.6.2 Menu B, test .......................................................................................................................... 45

5.6.3 Menu C, setup ....................................................................................................................... 46

5.7 Functions in detail .......................................................................................................... 51

5.7.1 Definition of positions and zones.......................................................................................... 51

5.7.2 Measuring function ............................................................................................................... 52

5.7.3 Measuring mode ................................................................................................................... 52

5.7.4 Definition of fluff and blanket concentration........................................................................ 53

5.7.5 Definition in zone tracking mode.......................................................................................... 53

5.7.6 Rake guard / external trigger ............................................................................................... 53

5.7.7 Timer / start signal ............................................................................................................... 54

5.7.8 Extended settings.................................................................................................................. 54

5.7.9 Calibration............................................................................................................................. 55

5.7.10 Passwords........................................................................................................................... 58

5.7.11 Timeout function ................................................................................................................. 58

5.8 Status messages and diagnostic information................................................................ 59

5.8.1 Error category "Device failure" (bold "F")............................................................................ 60

5.8.2 Error category "Application error" ( "F", not bold) .............................................................. 61

5.8.3 Error category "Information" (I) ........................................................................................... 61

5.8.4 Error category "Out of specification" (S) .............................................................................. 61

6 Service 62

6.1 Manual initiation of a measurement .............................................................................. 62

6.2 Maintenance ................................................................................................................... 62

6.2.1 Cleaning unit (optional)......................................................................................................... 64

6.3 Spare parts availability...................................................................................................65

6.4 Availability of services .................................................................................................... 65

6.5 Returning the device to the manufacturer..................................................................... 65

6.5.1 General information.............................................................................................................. 65

6.5.2 Form (for copying) to accompany a returned device............................................................ 66

6.6 Disposal .......................................................................................................................... 66

7 Technical data 67

7.1 Measuring principle........................................................................................................67

7.2 Technical data................................................................................................................. 68

7.3 Dimensions ..................................................................................................................... 72

8 Notes 73

4

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 5

OPTISYS SLM 2100

1.1 Software history

INFORMATION!

This documentation explains the installation and operation of the OPTISYS SLM 2100 sludge

level meter.

Release date Software version Documentation

04/2013 01.00.01 MA OPTISYS SLM 2100 R02 en

1.2 Intended use

The OPTISYS SLM 2100 sludge level meter is primarily designed for use in water and waste

water treatment plants. There it determines the sedimentation profile in clarifiers and sludge

thickeners and detects sludge blanket or fluff level. For this it measures the suspended solids

concentration and height of the sensor above ground as the sensor is lowered into the basin or

tank.

However, the design of the OPTISYS SLM 2100 makes it possible to use it in other applications

where reliable monitoring of interface or stratification in suspensions is necessary.

SAFETY INSTRUCTIONS 1

The OPTISYS SLM 2100 shall not be used in hazardous areas, which e.g. require Ex approvals. It

could ignite gases. Additionally, due to the sensors material, the meter shall not be used in

applications with a high concentration of salt (e.g. seawater). The device has been constructed

for indoor and outdoor use below the maximum altitude of 2000 m / 6562 ft.

By observing the operation instructions, national standards, safety requirements and accident

prevention regulations the residual risk is reduced to an acceptable level.

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

5

Page 6

1 SAFETY INSTRUCTIONS

1.3 Certifications

CE marking

The device fulfils the statutory requirements of the following EC directives:

• Electromagnetic compatibility (EMC) in accordance with directive 2004/108/EC:

EN 61000-6-4 2007 Electromagnetic compatibility (EMC) - Part 6-4: Generic standards -

Emission standard for industrial environments

EN 61000-6-3:2007 Electromagnetic compatibility (EMC) - Part 6-3: Generic standards Emission standard for residential, commercial and light-industrial environments

EN 61000-6-2:2005 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards Immunity for industrial environments

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use - EMC

requirements - Part 1: General requirements

• Low voltage directive according to directive 2006/95/EC:

EN 61010-1:2011 Safety requirements for electrical equipment for measurement, control,

and laboratory use (Part 1: General requirements)

• Directive for machinery 2006/42/EC in accordance with:

EN 60204-1:2006 Safety of machinery - Electrical equipment of machines (Part 1: General

requirements)

EN 953:1997+A1:2009 Safety of machinery - Guards - General requirements for the design

and construction of fixed and movable guards

• Directive on the restriction of the use of certain hazardous substances in electrical and

electronic equipment in accordance with directive 2011/65/EU

OPTISYS SLM 2100

The manufacturer certifies successful testing of the product by applying the CE marking.

6

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 7

OPTISYS SLM 2100

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

SAFETY INSTRUCTIONS 1

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

7

Page 8

1 SAFETY INSTRUCTIONS

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

OPTISYS SLM 2100

8

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 9

OPTISYS SLM 2100

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

SAFETY INSTRUCTIONS 1

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.5 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

9

Page 10

2 DEVICE DESCRIPTION

2.1 Scope of delivery

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

OPTISYS SLM 2100

Figure 2-1: Scope of delivery

1 Sludge level meter

2 Brackets for round / rectangular handrail

3 Handrail mounting frame

4 Mounting accessories

5 Documentation

6 Key for cable drum lock and key for electronic compartment lock

7 Cleaning unit (optional)

10

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 11

OPTISYS SLM 2100

2.2 Device description

DEVICE DESCRIPTION 2

Figure 2-2: Device description of OPTISYS SLM 2100

1 Fan

2 Electronic compartment door with display

3 Cable drum compartment door

4 Guide roller

5 Sensor

6 4 x cable feedthrough M20

7 Cable drum

8 Pickup and axle board with optical interface

9 Safety switch

10 Main electronics and connectors

Main electronics unit

The main electronics unit is located in a separate compartment above the cable drum, which can

be accessed via a separate door with a key lock. It contains the main board and fan assembly.

The main board bears the main processor and all electrical connectors. It also controls all

mechanical and electrical events in the device and communicates with sensor, display and

keyboard. It additionally contains the current outputs and control inputs.

Fan assembly

The position of the fan is on the top right side of the enclosure. Together with the heater it

maintains a stable temperature inside the enclosure of the meter.

DANGER!

The rotating fan blades can be accessed, when the electronic compartment door is open and

there is a risk of injury when rotating fan is touched.

Display and keyboard

Display and keyboard are located in the front door of the electronics compartment. Display and

keyboard are based on the GDC (general device concept), which means a common HMI to all

KROHNE GDC instruments is provided. The keyboard consists of four membrane keys and the

display is a LCD graphic display with a resolution of 128 x 64 Pixel.

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

11

Page 12

2 DEVICE DESCRIPTION

Cable drum assembly and heater unit

The cable drum helps to move the sensor up and down in the basin. It is mounted directly on the

motor shaft of a synchronous motor, hidden behind the drum mounting plate. The cable drum

always moves with a very constant speed. Since the diameter of the cable roll in the drum varies,

the speed of the sensor varies. That is why the sensor moves slower during the end of the

sampling.

The heater unit is located behind the drum mounting plate. In conjunction with the fan it

maintains a stable temperature inside the enclosure of the meter.

Guide roller

The guide roller helps to keep the cable in place during the measuring process.

Sensor

The sensor contains a near-infrared light source and a receiver. Both are positioned in such a

way that the emitted near-infrared light has to pass through the liquid before reaching the

receiver.

Pickup board & axle board

The pickup board is mounted on a spring loaded lever arm and transfers power and

communication signals to the cable drum.

OPTISYS SLM 2100

The axle board on the cable drum is powered contactless ("inductively") from the pickup board. It

communicates with the main electronics unit via the pickup board and with the sensor via an

optical interface.

Cable feedthroughs

The four M20 cable feedthroughs are for the connection of power, signal and control cables.

Safety switch

The safety switch located on the top left corner of the cable drum compartment is a protective

device, which de-energizes the motor when the front door is opened in order to avoid danger due

to moving parts inside the meter.

Cleaning unit (optional)

The cleaning unit, mounted under the device, consist of a valve and a spraying system to keep

the sensor and cable free of deposits ensuring low maintenance efforts of OPTISYS SLM 2100.

12

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 13

OPTISYS SLM 2100

2.3 Nameplate

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

Figure 2-3: Example of a nameplate

1 Manufacturer

2 CE marking

3 Manufacturing date

4 Power supply data

5 Observe the operation and installation instruction

6 Protection category

7 Order code / TAG no.

8 Production order / Serial number

9 Device name

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

13

Page 14

3 INSTALLATION

3.1 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

INFORMATION!

The display should be mounted in a height of 1.5...1.8 m / 4.9...5.9 ft to prevent ergonomic

hazards.

INFORMATION!

During work on the device above the basin the personnel have to be protected by personal safety

equipment.

OPTISYS SLM 2100

3.2 Storage and transport

• Store and transport the device in a dry, dust-free environment.

• Store and transport the device in an environment with a temperature between 0...+60°C/

+32...+140°F.

• The original packing is designed to protect the equipment. It has to be used if the device is

transported or sent back to the manufacturer including the sensor transportation packing, to

prevent damage of the sensor.

INFORMATION!

Due to the weight above 20 kg / 44.1 lbs please lift and carry the device only with two persons or

use approbiate lifting equipment and if the surfaces of the device are wet, please use gloves for

lifting.

14

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 15

OPTISYS SLM 2100

3.3 Installation order

DANGER!

Do not install the sludge level meter in hazardous areas, it can ignite explosive gases!

DANGER!

Do not cover or obstruct the ventilation. It can lead to overheating of the device.

INFORMATION!

Protect the device against strong weather (lightning protection / overvoltage protection) and

sunlight to prevent damages.

INFORMATION!

The operator is responsible for providing, securing and the possibility for switching off the supply

voltage.

INFORMATION!

The external electrical main switch (red / yellow) of the device have to be located close to the

device and easily accessible. An internal main switch is not available.

INSTALLATION 3

INFORMATION!

The device should be located at save installation site in order to prevent the danger of falling in

the water basin. Furthermore in front of the device should be space to access the device easily.

INFORMATION!

For the security of access to the device is the operator responsible.

To install the measuring system in the best way, follow the steps described below.

Steps to install the meter

1 Mounting of the sludge level meter

(for detailed information refer to

2 Installing the cleaning unit (optional)

(for detailed information refer to

3 Connecting the power supply

(for detailed information refer to

4 Connection of the current outputs

(for detailed information refer to

5 Connecting the rake guard switch / external trigger or maintenance switch - if required

(for detailed information refer to

6 Configuration of the sludge level meter

(for detailed information refer to

7 Calibration of the sludge level meter

(for detailed information refer to

Mounting of the sludge level meter

Cleaning unit (optional)

on page 64)

Connecting the power supply

Current output (active)

on page 30).

Electrical connection of control inputs

Functions in detail

Calibration

on page 55).

on page 51).

on page 16).

on page 26).

on page 31).

INFORMATION!

For decommissioning of the device please repeat the steps above in reverse order.

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

15

Page 16

3 INSTALLATION

3.3.1 Mounting of the sludge level meter

INFORMATION!

All needed bolts, nuts and washers belong to the standard scope of delivery. To ensure proper

assembly, please use only the mounting material provided with the meter.

INFORMATION!

All blots, nuts and washers should be greased to prevent cold welding and ensure simple

disassemble after use.

INFORMATION!

Please ask a second person to help with this procedure.

The mounting frame, which is part of the scope of delivery, can be used to mount the meter on

round or square handrails, as well as on vertical mounting posts or walls.

The first step of the installation procedure is to build the frame as shown in the picture below.

OPTISYS SLM 2100

Step 1: Assembling of the mounting frame

• Assemble the two brackets and two crossbar braces with the help of bolts, nuts and washers

according to the following drawing.

16

Figure 3-1: Mounting frame

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 17

OPTISYS SLM 2100

Step 2a: Mounting on round handrail

• Mount the frame with help of the brackets in a position that the horizontal bar of the frame is

above the handrail.

Figure 3-2: Mounting on handrail

INSTALLATION 3

Step 2b: Mounting on square handrail

• Mount the frame with help of the brackets in a position that the horizontal bar of the frame is

above the handrail.

Step 2c: Mounting on vertical post

• Mount the frame with help of the brackets in a position that the horizontal bar of the frame is

above the handrail.

Step 3: Fixing of meter

• Fix the meter to the upper part of the brackets with the help of bolts and washers according to

the following drawing.

• Please make sure that the meter is mounted in such a height that display and keyboard are at

eye level.

• Remove the sensor transportation protection to prevent blocking of the sensor.

Figure 3-3: Mounting device on handrail

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

17

Page 18

3 INSTALLATION

Step 4: Adjusting

• Open the door of the meter for 45°.

• Adjust the meter horizontally using the last two screws that you screw in the lower part of the

frame.

• Turn the screws until the door does not move (open and close) any more from the 45° position.

OPTISYS SLM 2100

Figure 3-4: Adjusting frame

3.4 Typical measuring point

18

Figure 3-5: Typical measuring points

1 OPTISYS SLM 2100 with brackets for round handrail on vertical post

2 OPTISYS SLM 2100 with brackets for rectangular handrail

3 OPTISYS SLM 2100 with brackets for round handrail

4 Handrail

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 19

OPTISYS SLM 2100

3.5 Installing the cleaning unit (optional)

The cleaning unit consist of a water connection, an OPTISYS SLM 2100 controlled valve and the

spraying unit to clean the cable and the sensor.

If installing a device containing a cleaning unit, keep a safety area around the sensor garage free

from electrical device or water sensitive parts, as outlined in the following drawing.

INSTALLATION 3

Figure 3-6: Safety area

1 Radius: 2 m / 78.74"

Keep this area around the device free from electrical installations or water sensitive devices.

When the cleaning system is active, water might be sprayed in this area.

The cleaning unit can be supplied with water by 2 options:

• External water supply by hose

• Pump controller (for more information refer to

page 35)

Electrical connection of the external pump

on

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

19

Page 20

3 INSTALLATION

3.5.1 Installation of the water hose

WARNING!

The maximum allowed water pressure should not exceed 6 bar / 87 psi.

INFORMATION!

An external separation switch of the water supply have to be located close to the device and

easily accessible.

A 3/4" connector wit metric thread provides the mounting point for the water hose adapter.

When installing the water hose adapter on the connector, carefully fix the nut of the fitting. The

electric valve inside the cleaning system housing maybe twisted, which may cause water

leakage. If it is not possible to tighten the nut of the hose fitting adequately, remove the lower

cover of the cleaning unit and lock the nut mounted in the electric value.

When installing the device, make sure the water hose is adequately fixed as outlined. Mount the

water hose in such a way that the weight of it is not carried by the hose adaptor. When fixing the

hose also take into account that it must be avoided that it moves when the system is switched

on/off.

OPTISYS SLM 2100

20

Figure 3-7: Fixing points water hose

1 Water hose

2 Fixing points

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 21

OPTISYS SLM 2100

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

WARNING!

Before performing any work on the device switch off the power and make sure that it cannot be

switched on accidently.

ELECTRICAL CONNECTIONS 4

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

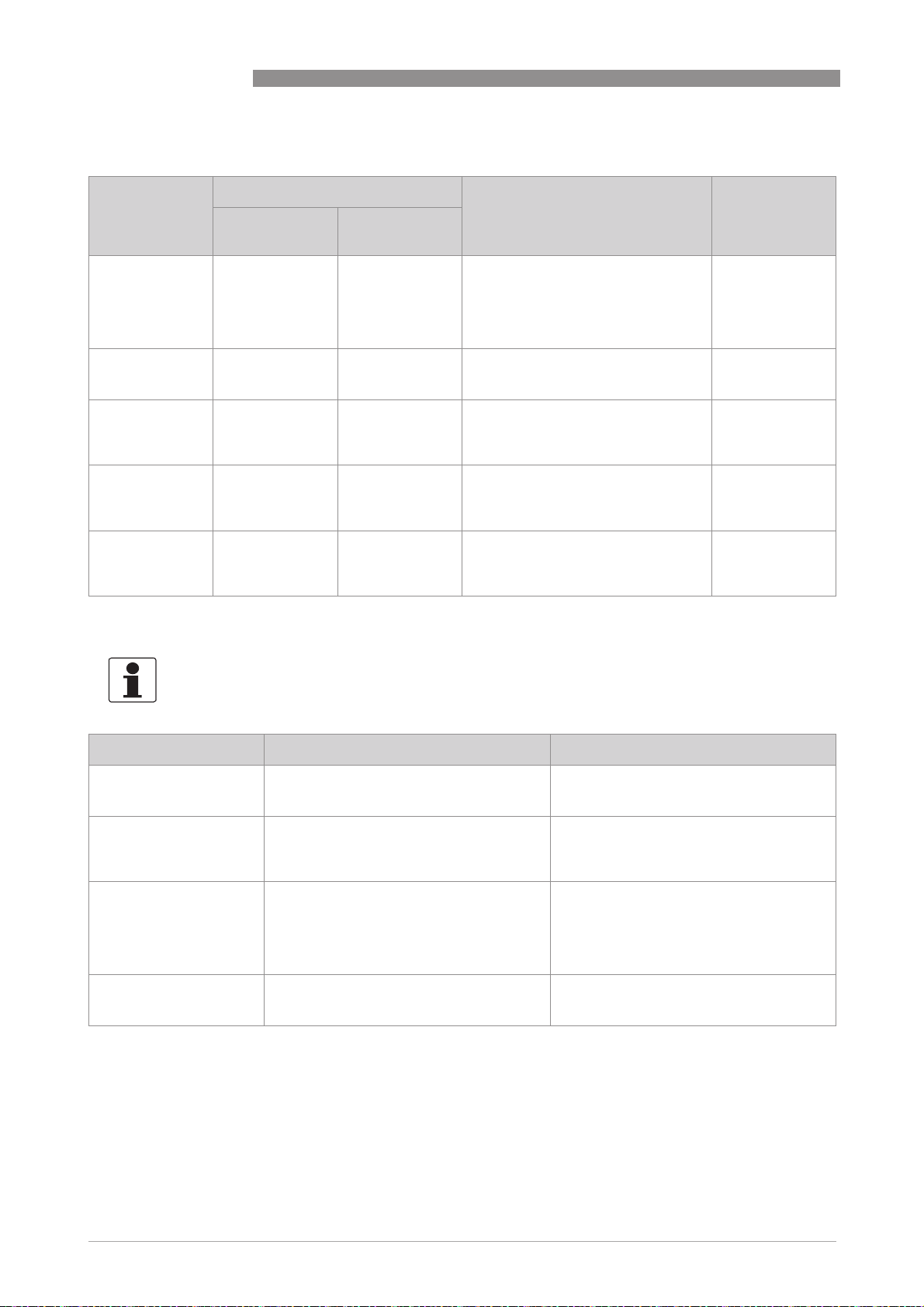

4.2 Used abbreviations

Abbreviation Description

CI

a

I

a

I

max

I

nom

R

L

P Power

U

int, nom

U

ext

U

o

VAC Volt alternated current

CI Control input

PCS Process control system

NO Switch (normally open)

NC Switch (normally closed)

LED Light-emitting diode

K Relay

Control input active

Current output active

Maximum current

Nominal current

Load resistance

Nominal internal voltage

External voltage

Terminal voltage

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

21

Page 22

4 ELECTRICAL CONNECTIONS

4.3 Description of electrical symbols

Symbol Description

mA meter, 0...20 mA or 4...20 mA and other, RL is the internal resistance of the

measuring point including the cable resistance

Internal DC voltage source

Controlled internal current source in the device

Switch, NO contact or similar

Input, galvanically insulated

OPTISYS SLM 2100

PTC resistance

Symbol for LED

Symbol for the protection switch

22

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 23

OPTISYS SLM 2100

ELECTRICAL CONNECTIONS 4

4.4 Important device-specific notes on electrical connection

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries!

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

DANGER!

When installing and wiring the device, note the safety regulations of the current state of the art.

Also note the following items to avoid fatal injuries, destruction or damage of the device or

measuring errors:

•

De-energise the cables of the power supply before you start any installation works!

•

All used cables must have a corresponding dielectric strenght of min. 2 kV.

•

It is recommended to use shielded signal cables which are only connected on one side (e.g. to

the protective earth on the mainboard next to the relays).

•

When using relays, note that with inductive loads the interference must be suppressed (spark

quenching).

•

Assure that all electrical connection works are compliant with the VDE 0100 directive

"Regulations for electrical power installations with line voltages up to 1000 V" or equivalent

national regulations.

•

Use suitable cable glands for the various electrical cables and suitable connecting cables for

the field of application. The outer diameter of the connecting cables has to fit to the cable

glands.

•

The nominal voltage of the connecting cable has to fit to the operating voltage of the device.

•

If the handrail is not adequately grounded, ground the device with a wire of 6 mm2 / 0.009

square inch.

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

23

Page 24

4 ELECTRICAL CONNECTIONS

4.5 Overview cable connections

DANGER!

When installing and wiring the device, note the safety regulations of the current state of the art.

Also note the following items to avoid fatal injuries, destruction or damage of the device or

measuring errors:

•

Do not run cables on pathways. Regularly check the cable runs that no loose cables are

hanging into footpaths.

•

Before connecting mains power, all connectors at the connecting terminal need to be

plugged.

•

Please pay attention to the front doors. Make sure that the doors don't shut if hands or tools

are inside the meter. Otherwise the sharp edges of the doors can cause fatal injuries or

damage to the equipment.

In the bottom lower left corner of the enclosure there are 4 cable feedthrough connections as

cable feedthroughs to the electronics compartment. All cables fixed to the meter go outside the

enclosure via these connections.

OPTISYS SLM 2100

INFORMATION!

In order to assure proper sealing of the cable feedthrough only cables with a minimum and

maximum diameter of 6-12 mm / 0.24-0.47 inch.

After feeding the cables through the feedthroughs they are run in the cable guide to the bottom

of the electronics compartment where they need to be fed into another cable guide in order to be

routed further to the connectors at the main board.

24

Figure 4-1: Overview cable connections

1 4 x M20 cable feedthroughs

2 Cable guides

3 Main board with connector blocks

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 25

OPTISYS SLM 2100

ELECTRICAL CONNECTIONS 4

4.6 Overview of the terminal compartment

The terminal compartment is located in the electronic compartment at the lower part of the

main board.

Figure 4-2: Overview of the electrical connections

1 Power connections

2 Motor, heater and fan connection block

3 Cleaning connection block

4 Relais connection block

5 External connection block

6 Output connection block

7 Control inputs connection block

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

25

Page 26

4 ELECTRICAL CONNECTIONS

4.7 Connecting the power supply

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries!

CAUTION!

When connecting the power supply, always note the safety regulations of the current state of the

art. To avoid fatal injuries, destruction or damage of the device or measuring errors, also note

the following items:

•

De-energise the cables of the power supply before you start any installation works!

•

Ground the device (cross section of the wire is 6 mm2 / 0.009 square inch).

•

The device must be led over a ground fault circuit interrupter (GFCI) 0.03 A which has to be

tested every 6 months.

•

Inspect the continuous PE conductor connection to all contactable metal parts by carrying out

a standardised procedure (The maximum allowed resistance is 0.5 Ohm).

•

Assure that there is a fuse protection for the infeed power circuit (I

•

Check the nameplate and assure that the power supply meets the voltage and frequency of

the device. The device can be operated with 230 VAC (-15/+10%) at 50 Hz (

VA. A power supply outside these specifications may destroy the device!

•

Assure that the protective earth conductor (PE) is approx. 5 mm / 0.20" longer than the L- and

N-conductor.

nom

OPTISYS SLM 2100

≤ 6A).

±

10%) and max. 150

INFORMATION!

The operator is responsible for providing, securing and the possibility for switching off the supply

voltage.

Before you start to connect the power supply cables, note the following drawing with the function

of the terminals:

Figure 4-3: Connecting power supply

1 L1...L3 (live)

2 Neutral

3 Protective earth (PE)

26

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 27

OPTISYS SLM 2100

ELECTRICAL CONNECTIONS 4

INFORMATION!

All cables must have a test voltage of min. 2 kV and an appropriate outer insulation (additional to

the insulation of the individual wire). The outer insulation should be removed 40 mm / 1.57". The

2

minimum cross section of the wires is 1.5 mm

2

2.5 mm

/ 0.0039 square inch.

/ 0.0023 square inch and the maximum is

INFORMATION!

In order to assure proper sealing of the cable feedthrough only cables with a minimum and

maximum diameter of 6-12 mm / 0.24-0.47 inch.

4.8 Description and properties of the outputs and the input

4.8.1 Current output

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries.

INFORMATION!

For further information refer to the connection diagrams and the technical data table.

All outputs are electrically isolated from the power supply.

Active mode: output range 0(4)...20 mA, load resistance R

U

int, nom

Error signalling possible via current output (error current adjustable via software). For more

information refer to

The functions of the current output can be adjusted via the menu:

=15VDC.

Menu C, setup

on page 46.

≤ 550 Ω at I

L

max

≤ 22 mA,

Level mode

• Current output A: height

• Current output B: height

height/depth

heightheight

height/depth

heightheight

depth of concentration 1 (fluff)

depthdepth

depth of concentration 2 (sludge blanket)

depthdepth

Profile mode

• Current output A: The output range is calculated automatically by the OPTISYS SLM 2100

according to the parameters filled in the extended setup (dimensions).

• Current output B: The output range of current channel B must be define in the I/O menu of

the device.

Zone tracking mode

• Current output A: The output range is calculated automatically by the OPTISYS SLM 2100

according to the parameters filled in the extended setup (dimensions).

• Current output B: The output range of current channel B must be define in the I/O menu of

the device.

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

27

Page 28

4 ELECTRICAL CONNECTIONS

4.8.2 Control input (active)

INFORMATION!

The factory default is a disabled control input!

The electrical properties of the control inputs in detail are the following:

• Active

max

≤ 32 VDC

• U

Function of the control inputs

Function of the control inputs

Function of the control inputsFunction of the control inputs

The three active control inputs can trigger different events in the meter from outside. They are

engaged via simple contact closure of an external contact.

The three control inputs have the following functions:

• Control input 1: Rake guard switch or external trigger (switchable via software)

• Control input 2: Rake guard switch or external trigger (switchable via software)

• Control input 3: Maintenance mode

OPTISYS SLM 2100

Rake guard switch

Rake guard switch

Rake guard switch Rake guard switch

CAUTION!

To avoid damages or destructions, use a limit rake guard switch in all applications where a rake

or other moving devices may come in contact with the sensor or cable! The manufacturer does

not assume any responsibility for damages caused by the absence or malfunction of the rake

guard limit switch.

To protect the sensor and cable from being damaged or destructed by rakes or other moving

parts, the control input 1 and 2 can be used. For this purpose a NO switch has to be connected to

CI 1 / 2 (Note the switch is not part of the scope of delivery. You have to buy this switch with

another manufacturer). In case CI 1 / 2 is set to rake guard switch, the sampling will be

interrupted and the sensor hauled back as soon as the external contact is closed.

External trigger

External trigger

External triggerExternal trigger

The function of the external trigger is to trigger the sampling process. For this purpose a NO

switch has to be connected to CI 1 / 2 (Note the switch is not part of the scope of delivery. You

have to buy this switch with another manufacturer). In case CI 1 / 2 is set to external trigger

mode the sampling cycle will start as soon as the external contact is closed.

28

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 29

OPTISYS SLM 2100

Maintenance mode

Maintenance mode

Maintenance modeMaintenance mode

The function of the maintenance mode is to set the device to maintenance mode in order to

enable easy cleaning of sensor, cable and meter. For this purpose a NO switch has to be

connected to CI 3 (Note the switch is not part of the scope of delivery. You have to buy this switch

with another manufacturer). In case CI 3 is activated the sampling cycle will be interrupted and

the sensor is moving back to the home position as soon as the external contact is closed. After

that, the current outputs are frozen and the sensor can be moved by the simple push of the

arrow buttons on the keypad.

ELECTRICAL CONNECTIONS 4

4.9 Connection of the outputs and the input

4.9.1 Important notes

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries.

INFORMATION!

•

Depending on the version, the inputs/outputs must be connected passively or actively or acc.

to EN 60947-5-6.

•

Active operating mode: the signal converter supplies the power for operation (activation) of

the subsequent devices, observe max. operating data.

•

Terminals that are not used must not have any conductive connection to other electrically

conductive parts.

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

29

Page 30

4 ELECTRICAL CONNECTIONS

4.9.2 Current output (active)

DANGER!

All work on the electrical connections may only be carried out with the power disconnected.

CAUTION!

To avoid damage or destruction of the device always note the following items:

•

Observe the connection polarity!

•

Note the properties of the current output; for further information refer to Technical data on

page 68

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

Connection diagram of current output (active)

.

OPTISYS SLM 2100

Figure 4-4: Current output (active)

The terminals for the connection of the two current outputs are located on the main board.

Please refer to the following diagram for proper connection of the cables.

Figure 4-5: Connection current output

1 Current output A

2 Current output B

INFORMATION!

The correct connection of the current outputs takes place with the help of shielded signal cables

which are approved for the rated current and voltage.

30

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 31

OPTISYS SLM 2100

INFORMATION!

All cables must have a test voltage of min. 2 kV and an appropriate outer insulation (additional to

the insulation of the individual wire) . The outer insulation should be removed 30-50 mm / 1.18"-

1.97". The minimum cross section of the wires is 0.5 mm

maximum is 1.5 mm

INFORMATION!

In order to assure proper sealing of the cable feedthrough only cables with a minimum and

maximum diameter of 6-12 mm / 0.24-0.47 inch.

Connecting the current output

• Open the cable drum and electronic compartment door.

• Push the prepared cables through the cable feedthrough and route them to the electronic

compartment (for more information refer to

• Connect the positive and negative lead according to the connection diagrams above.

• Connect the shield to one side only (e.g. to the protective earth on the mainborad next to the

relay) side.

• Tighten the screw connection of the cable feedthrough securely.

• Seal all cable feedthrough that are not needed with a plug.

• Close both compartment doors.

2

/ 0.0023 square inch.

ELECTRICAL CONNECTIONS 4

2

/ 0.00077 square inch and the

Overview cable connections

on page 24).

4.9.3 Electrical connection of control inputs

DANGER!

All work on the electrical connections may only be carried out with the power disconnected.

CAUTION!

To avoid damage or destruction of the device always note the properties of the control input; for

further information refer to Technical data on page 68

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

INFORMATION!

All cables must have a test voltage of min. 2 kV and an appropriate outer insulation (additional to

the insulation of the individual wire) . The outer insulation should be removed 30-50 mm / 1.18"-

1.97". The minimum cross section of the wires is 0.5 mm

2

maximum is 1.5 mm

/ 0.0023 square inch.

.

2

/ 0.00077 square inch and the

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

31

Page 32

4 ELECTRICAL CONNECTIONS

Figure 4-6: Control input

1 Signal

The terminals for the connection of the three control inputs are located on the main board.

Please refer to the following diagram for proper connection of the cables.

OPTISYS SLM 2100

Figure 4-7: Connection control input

1 Control input (CI1)

2 Control input (CI2)

3 Control input (CI3)

Connecting the control inputs

• Open the cable drum and electronic compartment door.

• Push the prepared cables through the cable feedthrough and route them to the electronic

compartment (for more information refer to

Overview cable connections

on page 24).

• Connect the positive and negative lead according to the connection diagrams above.

• Connect the shield to one side only e.g on PCS (process control system) side.

• Tighten the screw connection of the cable feedthrough securely.

• Seal all cable feedthroughs that are not needed with a plug.

• Close both compartment doors.

INFORMATION!

In order to assure proper sealing of the cable feedthrough only cables with a minimum and

maximum diameter of 6-12 mm / 0.24-0.47 inch.

32

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 33

OPTISYS SLM 2100

ELECTRICAL CONNECTIONS 4

4.10 Description and properties of the relays

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries.

The two relays can be either configured as limit switch or as status output.

In status output mode:

If an error of the selected class occurs the relays remains active, until the error is cleared by the

user or the device is leaving the error state automatically.

In limit switch mode:

When the relay is configured as limit switch the limit parameter used is the sensor position

(height / depth). The relays can work as limit switch only in level and zone tracking mode. The

parameter "direction" defines the trigger for the relay, which means the relay is switched either

when the sensor position about limit value or the sensor position below limit. The hysteresis

defines the sensor position, where the limit switch (relay) is reset, relatively to the selected

threshold. Combining the parameters threshold and hysteresis a range can be defines, were the

limit switch is active. The relay configuration menus can be found in the setup I/O menu. For

more information refer to

Menu C, setup

on page 46.

4.10.1 Connection of the relays

DANGER!

All work on the electrical connections may only be carried out with the power disconnected.

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

INFORMATION!

The correct connection of the relays takes place with the signal cables which are approved for

the rated current and voltage.

INFORMATION!

All cables must have a test voltage of min. 2 kV and an appropriate outer insulation (additional to

the insulation of the individual wire). The outer insulation should be removed 40 mm / 1.57". The

minimum cross section of the wires is 1.5 mm

2

2.5 mm

INFORMATION!

In order to assure proper sealing of the cable feedthrough only cables with a minimum and

maximum diameter of 6-12 mm / 0.24-0.47 inch.

/ 0.0039 square inch.

2

/ 0.0023 square inch and the maximum is

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

33

Page 34

4 ELECTRICAL CONNECTIONS

OPTISYS SLM 2100

Note the electrical properties of the relays. For more information refer to

Technical data

on page

68.

The terminals for the connection of the two current relays are located on the main board. Please

refer to the following diagram for proper connection of the cables.

Figure 4-8: Connection diagram of relays K1 and K2

1 LED

2 Voltage source

The electrical specifications of the relays (K1 and K2) are as follows:

≤ 24 VDC/250 VAC (K2)

U

ext

I ≤ 0.3 A (K3)

For installation of the relays follow the steps below:

• Move the sensor by using the manual operation in the home position and turn off the power of

the instrument.

• Open the cable drum and electronics compartment doors.

• Push the prepared cables through the cable feed through and route them to the electronic

compartment.

• Connect the positive and negative lead according to the connection diagrams above.

• Connect the shield to one side only e.g. on PCS (process control system) side.

• Tighten the screw connection of the cable entries securely.

• Seal all cable entries that are not needed with a plug.

• Close both compartment doors.

34

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 35

OPTISYS SLM 2100

ELECTRICAL CONNECTIONS 4

4.11 Electrical connection of the external pump

DANGER!

Never install or operate the device in potentially explosive areas, it might cause an explosion that

can result in fatal injuries.

DANGER!

Never connect an external water pump directly to the OPTISYS SLM 2100 connector K3, the

output connector is only specified as a control output for a motor protection.

An external pump can be controlled by connecting K3 to a motor protection.

Figure 4-9: Connection diagram pump (K3)

1 External voltage

2 PTC resistance (I

The electrical specification for pump control connector K3 is specified as follows:

• U

• I ≤ 0.3 A

≤ 24 VDC / 230 VAC

ext

max

= 0.3 A)

4.12 Protection category

DANGER!

Do not install the sludge blanket meter in hazardous areas, it can ignite explosive gases!

IP 68 (sensor), IP 54 (electronic compartment), IP 44 (cable drum compartment).

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

35

Page 36

5 OPERATION

5.1 Start-up and general remarks for configuration

DANGER!

In order to avoid injuries or damage of the device or plant equipment the device shall only be

operated with both doors properly closed and locked. The device also has to be properly

mounted and all cable feedthrough has to be properly tightened or plugged, if unused.

WARNING!

In general, the device may only be installed, commissioned, operated and maintained by properly

trained and authorised personnel.

WARNING!

To avoid damages to the equipment please make sure that power up of the meter takes place

°

above 0

from freezing.

WARNING!

The device starts up / restarts automatically as soon the power is switched on.

C / +32°F. Once power is connected, the internal heater will than keep the electronics

OPTISYS SLM 2100

INFORMATION!

Ensure that the sensor transportation protection is removed before starting-up the system.

INFORMATION!

To install the meter in the best way, follow the steps described below.

Steps for starting up the device:

• Power up

• Selection of the measuring function

• Selection of the measuring mode

• Definition of fluff and blanket concentration

• Setting of start signal / rake guard switch

• Input of extended settings

• Calibration of concentration measurement (if necessary)

36

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 37

OPTISYS SLM 2100

5.2 Switching on the power

DANGER!

To avoid fatal injuries as well as destruction or damage of the device assure a correct installation

before switching on the power. This includes:

•

The device is mechanically safe, mounting and power connection comply with the regulations.

•

Both doors need to be closed and locked.

•

The electrical operating data of the power supply comply with the requirements of the device.

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

INFORMATION!

The manufacturer delivers the device preconfigured and ready for operation. Due to the physics

of the measurement, the operator has to perform an onsite calibration or an adjustment to the

environmental conditions at the initial start-up.

OPERATION 5

Switch on the power

Switch on the power

Switch on the powerSwitch on the power

The device performs a self test and calibrates the home position of the sensor. For this the

sensor is moved inside the meter until it finds the home position. Afterwards the meter is ready

for measurement. The display shows 000 as values. If this is the first time the device is switched

on, it needs to be configured as described in the following chapters.

Figure 5-1: The previous drawing shows the measured value after successful start-up

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

37

Page 38

5 OPERATION

5.3 Operating elements

The operation elements consist of the four operation keys below the display. In the texts of this

documentation each operation key has a specific symbol:

Operating key Symbol in text

OPTISYS SLM 2100

The function of a key depends on the mode of the device and on the menu level:

Key Measuring mode Menu mode

Main menu

level

> Switch from measuring mode to

menu mode; press key for

2.5 seconds (display shows "keep

key pressed" and countdown) and

release it after further

2.5 seconds (display shows

"release key now" and

countdown)

^ Reset of the display controller Return to

↑ or ↓ Switch between measuring pages Select menu,

Esc: > + ↑ No function No function Return to main

↓ Starting measurement cycle

manually and press key for 2.5

seconds (display shows "keep

key pressed" and countdown) and

release it after further 2.5

seconds (display shows "release

key now" and countdown)

Access to

displayed menu,

then 1st

submenu is

displayed

measuring mode

(prompt appears

whether the data

should be saved)

moving up or

down

No function No function No function

Sub-menu or

function level

Access to

displayed submenu or function

Return to next

higher level or

sublevel, data

are saved

Select sub-menu

or function,

moving up or

down

menu level, data

not saved

Parameter and

data level

Numerical

values: move

cursor one

position to the

right

Return to submenu or

function, data

are saved

Change

parameter/data

marked by the

cursor, move the

decimal point

Return to next

higher level, data

not saved

38

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 39

OPTISYS SLM 2100

INFORMATION!

•

Always push the keys at right angles to the front. Touching them from the side can cause

incorrect operation!

•

After 5 minutes of inactivity in the menu mode, there is an automatic return to the measuring

mode. In this case the device does not save previously changed data!

5.4 Measuring page

After switching on the power, the display always shows the measuring page. Right beside all

measuring results you see the corresponding unit at the end of the line. Only if there is no unit

available it is left out (this is only the case with the diagnosis values).

The following drawing shows an example of the measuring page in the measuring mode "Level":

OPERATION 5

Figure 5-2: Example of the measuring page

Pressing ↑ will bring you to the status page.

If profile mode is applied, a second measuring page can be choosen, presenting the profile of the

measurement as bar plot.

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

39

Page 40

5 OPERATION

5.4.1 Navigating through the menus

To switch from the measuring mode to the menu mode you have to execute the following steps:

• Press > for at least 2.5 seconds (meanwhile the display shows the text "keep key pressed" and

a time counting back).

• After 2.5 seconds release the pressed key (you have to do this within the next 2.5 seconds

during which the display shows the text "release key now" and a time counting back).

i You are in the main menu level of the menu mode. The display always looks as follows:

Display in main menu level

OPTISYS SLM 2100

Figure 5-3: Example for selection in main menu level

1 Indicates a possible status message in the status list (only if there are one or more messages)

2 Menu code of selected menu item (see table of menu structure or function tables)

3 Indicates position within the current item list

4 Next menu item, reachable by pressing ↑ (if "- - -" appears in this line, this signalises the end of the list)

5 Selected menu item in bold characters

6 Previous menu item, reachable by pressing ↓ (if "- - -" appears in this line, this signalises the beginning of the list)

The main menu mode consists of the main menus "quick setup", "test", "setup" and "service".

You can either leave the main menu level and return to the measuring mode or choose and enter

a main menu:

• Press ^ to return to the measuring mode (in this case a prompt appears and asks if you want

to save the changed data; choose "Yes" or "No" with the help of ↓ or ↑ and confirm by

pressing ^).

• If you do not want to leave the main menu level, press > to enter the first main menu

("quick setup") or choose another main menu with the help of ↑ or ↓ and enter it by

pressing >.

i You are in the submenu level. The display always looks as follows:

40

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 41

OPTISYS SLM 2100

Display in submenu level

Figure 5-4: Example for selection in submenu menu level

1 Indicates a possible status message in the status list (only if there are one or more messages)

2 Superior main menu

3 Menu code of selected menu item (see table of menu structure or function tables); up to two figures can appear right

beside the character indicating the main menu (one if you are on the first submenu level and two on the second submenu level)

4 Indicates position within the current item list

5 Previous menu item, reachable by pressing ↓ (if "- - -" appears in this line, this signalises the beginning of the list)

6 Currently setting of the chosen menu item in bold character (here 7)

7 Selected menu item, in bold characters

8 Next menu item, reachable by pressing ↑ (if "- - -" appears in this line, this signalises the end of the list)

OPERATION 5

The submenu level consists of the first and second submenu level. The principle of choosing a

menu item is always the same:

• Press > to enter the first menu item or choose another menu item with the help of ↑ or ↓ and

enter it by pressing >.

i You navigate through the tree structure of the submenu level, finally you always reach the

parameter or data level.

• If you want to return to the main menu level without saving the input, press > and ↑ at the

same time.

• If you want to return to the main menu level and save your input, press ^ one or more times

depending on the level you are (pressing ^ results in moving one level upwards until you

reach the main menu level).

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

41

Page 42

5 OPERATION

INFORMATION!

Like the lowest menu level (i.e. the parameter or data level) some submenus also offer the

possibility to make adjustments. The procedure is similar to the procedure on the parameter

level.

On the parameter level you see a list with one or more parameters or data. You can scroll

through this list using ↑ or ↓:

INFORMATION!

In this list all parameters or data which have been changed (i.e. they deviate from the default

setting) have a hook at the right end of their line (see position number 4 in the following

drawing).

Display with list of parameters or data

OPTISYS SLM 2100

Figure 5-5: Example of a list with parameters and data

1 Indicates a possible status message in the status list (only if there are one or more messages)

2 Superior submenu or subsequent submenu

3 Menu code of selected parameter (see table of menu structure or function tables)

4 Denotes the change of a parameter (this marking allows to simply and quickly identify all data which differ from the

default setting when browsing through the list); instead of the check mark there can also appear a lock symbol at this

position, it indicates a parameter that cannot be changed because of the parameter lock on the front.

5 Indicates position within the current item list

6 Previous menu item, reachable by pressing ↓ (if "- - -" appears in this line, this signalises the beginning of the list)

7 Currently setting of the chosen menu item, also in bold character (here 7)

8 Selected menu item, in bold characters

9 Next menu item, reachable by pressing ↑ (if "- - -" appears in this line, this signalises the end of the list)

On the parameter or data level you have the possibility to change the decimal point, numbers,

units or settings. Before that you have to choose the desired parameter or data and open to edit

it as follows:

• Press > to open and edit the first list item or choose another item with the help of ↑ or ↓ and

press >.

i You are in the parameter edit mode now. All changeable values are highlighted and shown

reverse (if nothing is shown reverse, you are in the read-only view and you cannot change

the setting).

• Use ↑ or ↓ to change the highlighted area; if there are numerical values or a decimal point to

be changed, you can move the cursor with > to the desired position and change its value with

the help of ↑ or ↓.

• If you want to return to the parameter or data list and save your input, press ^; afterward you

can press ^ one or more times to return to the main menu.

• If you want to return to the next higher level without saving the input, press > and ↑ to the

same time.

42

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 43

OPTISYS SLM 2100

Display with parameter or data ready to edit

Figure 5-6: Example of parameter or data ready to edit

1 Indicates a possible status message in the status list (only if there are one or more messages)

2 Superior submenu or subsequent submenu

3 Menu code of selected parameter (see table of menu structure or function tables)

4 Symbol denotes that there is a factory setting

5 Symbol denotes that there is a permissible value range

6 Permissible value range (for numerical values)

7 Currently set value, unit or function that you can change (always appears with highlighted background)

8 Current selected parameter

9 Factory setting of parameter (non-alterable)

OPERATION 5

www.krohne.com03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

43

Page 44

5 OPERATION

5.5 Menu mode structure

INFORMATION!

The following table just presents an overview. When programming the device, always consult the

function tables additionally as they contain further information!

OPTISYS SLM 2100

Measuring

mode

3 or 4

pages,

scrolling

with ↓ or ↑

3 or 4

pages,

scrolling

with ↓ or ↑

Main menu Submenu Parameter

>2.5s^A quick setup

>2.5s^B test

>2.5s^C setup

A quick setup >^A1 language

A quick setupA quick setup

↓↑ ↓↑ ↓↑ ↓↑

B test >^B1 simulation >^B1.1 current out A

B testB test

↓↑ ↓↑ ↓↑ ↓↑

C setup >^C1 measuring >^C1.1 measuring function

C setupC setup

D service:

D service: This menu is password protected and contains functions to be used by service

D service:D service:

personnel only.

A2 set clock

A3 reset errors

B1.2 current out B

B1.3 relay 1

B1.4 relay 2

B1.5 cleaning

B2 actual values B2.1 operating hours

B.3 logbooks B3.1 status log

B4 information B4.1 device serial number

C2 maintenance C2.1 calibration

C3 I/O C3.1 current out A

C4 extended

setup

C5 device C5.1 device info

B2.2 ADC value

B2.3 act. sensor temperature

B2.4 electr. temperature

B4.2 mainboard

B4.3 sensor electronic

C1.2 measuring mode

C1.3 definition fluff

C1.4 def. sludge blanket

C1.5 hysteresis

C1.6 tracking time

C1.7 tracking position

C1.8 start signal

C1.9 timer interval

C1.10 units

C3.2 current out B

C3.3 control input 1

C3.4 control input 2

C3.5 control input 3

C3.6 relay 1

C3.7 relay 2

C4.1 maximum depth

C4.2 start position

C4.3 blind zone

C4.4 rake height

C4.5 cleaning

C5.2 display

C5.3 special functions

>^For further

information

see function

tables.

>^For further

information

see function

tables.

>^For further

information

see function

tables.

44

www.krohne.com 03/2014 - 4002737302 - MA OPTISYS SLM 2100 R02 en

Page 45

OPTISYS SLM 2100

OPERATION 5

5.6 Function tables

5.6.1 Menu A, quick setup

A1, language

Language selection (depends on the region for which the device has been ordered). Available languages: German,

English.

A2, set clock

Manual setting of date and time.

A3, reset errors

This functions allows to reset all errors that are not reset automatically (e.g. power fail or counter overflow). You can

answer the question "reset?" with the following options: no (exit without reset) / yes (reset and exit the function).

5.6.2 Menu B, test

The procedure to start the simulation process is the same for all functions:

• Choose the function with the help of ↓ or ↑ and press ^.

i You see the two options set value

(exit the menu without simulation).

• Choose the desired option with the help of ↑ or ↓ and press ^.

i If you choose break

device asks start simulation

yes

yes (starts the simulation finally).

yesyes

• Choose the desired option with the help of ↑ or ↓ and press ^.

i If you choose yes

simulation.

break you will exit the menu without simulation. If you chose set value

breakbreak

start simulation and offers the options no

start simulationstart simulation

yes, the simulation starts. If you choose no

yesyes

set value (opens the editor to enter the simulation value) and break

set valueset value

set value, the

set valueset value

no (exit the menu without simulation) or

nono

no, you will exit the menu without

nono

break

breakbreak

B1, Simulation

Level Designation / function Settings / descriptions

This menu groups several functions to simulate the input and output values. The procedure to start the simulation