Handbook

Handbook

PIPEPATROL

PIPEPATROL

PIPEPATROLPIPEPATROL

Leak detection and localisation system

HandbookHandbook

© KROHNE 02/2013 - 4002275001 - MA PipePatrol R01 en

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2013 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 02/2013 - 4002275001 - MA PipePatrol R01 en

PIPEPATROL

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Safety instructions from the manufacturer ..................................................................... 5

1.2.1 Copyright and data protection ................................................................................................ 5

1.2.2 Disclaimer ............................................................................................................................... 5

1.2.3 Product liability and warranty ................................................................................................ 6

1.2.4 Information concerning the documentation........................................................................... 6

1.2.5 Warnings and symbols used................................................................................................... 7

1.3 Safety instructions for the operator................................................................................. 7

2 Device description 8

2.1 Functionality ..................................................................................................................... 8

2.2 Hardware installation....................................................................................................... 8

2.3 Principle of Extended Real Time Transient Model (E-RTTM).......................................... 9

2.4 Leak localisation method ............................................................................................... 10

3 Operation 12

3.1 General safety notes.......................................................................................................12

3.2 Start-up........................................................................................................................... 13

3.3 Layout of user interface ................................................................................................. 13

3.3.1 Status window ....................................................................................................................... 14

3.3.2 Controls................................................................................................................................. 17

3.3.3 Operator windows ................................................................................................................. 17

3.3.4 Main Overview ....................................................................................................................... 18

3.3.5 Pipeline Overview.................................................................................................................. 20

3.3.6 Trend ..................................................................................................................................... 21

3.4 Detailed description of leak detection screens ............................................................. 24

3.4.1 Leak information................................................................................................................... 24

3.4.2 Events.................................................................................................................................... 26

3.4.3 Alarm history......................................................................................................................... 29

3.4.4 Explanation (Legend) ............................................................................................................ 30

3.5 Leak alarm handling ...................................................................................................... 31

3.6 LDS system commands.................................................................................................. 36

3.6.1 Stop and start the LDS.......................................................................................................... 36

3.6.2 Application alarm.................................................................................................................. 37

3.7 Messages and error handling ........................................................................................ 38

3.7.1 List of event messages ......................................................................................................... 38

3.7.2 List of alarm messages ........................................................................................................ 41

3.7.3 Troubleshooting .................................................................................................................... 42

3.8 Expert functions on Operator Station ............................................................................ 43

3.8.1 User settings......................................................................................................................... 43

3.8.2 Default passwords ................................................................................................................ 43

www.krohne.com02/2013 - 4002275001 - MA PipePatrol R01 en

3

CONTENTS

PIPEPATROL

4 Service 44

4.1 Maintenance on the hardware ....................................................................................... 44

4.1.1 Filters .................................................................................................................................... 44

4.1.2 Mechanical damages ............................................................................................................ 44

4.2 Availability of services .................................................................................................... 44

5 Notes 45

4

www.krohne.com 02/2013 - 4002275001 - MA PipePatrol R01 en

PIPEPATROL

1.1 Intended use

PipePatrol is a leak detection and localisation system for liquid and gas pipelines which operates

in the stand-alone mode without any human interaction. It can be used during pumping, rampup, ramp-down, shut in and standstill conditions and allows continuous montitoring during all

operating conditions. Additionally functionalities are the batch tracking and the instrument error

analysis.

1.2 Safety instructions from the manufacturer

1.2.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

SAFETY INSTRUCTIONS 1

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.2.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

www.krohne.com02/2013 - 4002275001 - MA PipePatrol R01 en

5

1 SAFETY INSTRUCTIONS

1.2.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.2.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

PIPEPATROL

6

www.krohne.com 02/2013 - 4002275001 - MA PipePatrol R01 en

PIPEPATROL

1.2.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

SAFETY INSTRUCTIONS 1

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.3 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com02/2013 - 4002275001 - MA PipePatrol R01 en

7

2 DEVICE DESCRIPTION

2.1 Functionality

INFORMATION!

For detailed overview about the system architecture please refer to the "Functional Design

Specification (FDS)" of the project.

The PipePatrol leak detection system (LDS) station will be configured to provide the following

main features:

Monitoring Station (LDS server)

• Leak detection and localisation in pumping and standstill conditions

• Calculation of the leak rate

• Calculation of the leak location

• Remote maintenance via a remote access gateway (if connection is available)

• Alarming

• Data logging and event reporting

• Storing of reports and other data

PIPEPATROL

Operator Station (LDS client)

• Visualisation of the running leak detection system

• Alarming (visual and acoustic)

• Trending

• Event logging

• Controlling & operating functions

2.2 Hardware installation

The Monitoring Station (MS) is completely installed before the start-up. No further installation is

required.

8

www.krohne.com 02/2013 - 4002275001 - MA PipePatrol R01 en

PIPEPATROL

DEVICE DESCRIPTION 2

2.3 Principle of Extended Real Time Transient Model (E-RTTM)

According to API 1130, leak detection systems can be categorised into external and internal

systems. External systems include acoustic sensors and sensing cables that are placed

alongside the pipeline. Due to the extremely high installation costs the use of external systems is

usually restricted to high risk areas such as nature protection areas and near rivers. Internal

systems are systems that perform leak detection based on measured parameters such as flow,

pressure and temperature.

PipePatrol is an internal system based on E-RTTM (Extended Real Time Transient Model) and

SMB (Statistical Mass Balance).

E-RTTM

E-RTTM

E-RTTME-RTTM

E-RTTM is a combination of RTTM and leak pattern recognition by means of statistical analysis.

The fundamental principle is that RTTM is a series of algorithms that allow calculation of the

flow, based solely on pressure and temperature readings at the inlet and outlet of the pipeline.

To do this RTTM uses the conservation laws for mass, momentum and energy and the

thermodynamic state equations for pressure and enthalpy.

When applying RTTM algorithms, the flow is not only measured by flowmeters but also

calculated from pressure and temperature readings at the inlet and outlet. Subtracting the

calculated flow from the measured flow gives the flow residual. Combining the two flow

residuals gives the true flow residual (inlet minus outlet). The RTTM algorithms compensate for

medium compressibility and line expansion.

Leak pattern recognition

Leak pattern recognition

Leak pattern recognitionLeak pattern recognition

Basically the leak pattern recognition algorithm constantly monitors whether the residual

(difference between inlet and outlet flow after the transient effects have been compensated for

by RTTM) exceed a predefined threshold. If this threshold is exceeded statistical analysis will be

used to determine whether this is caused by a true leak or by a sensor drift.

SMB

SMB

SMBSMB

SMB is a combination of compensated mass balance and leak pattern recognition by means of

statistical analysis.

Compensated mass balance method is based on the equation of conservation of mass. The

result of this equation is permanently passed to the leak pattern recognition, which analyses it

statistical to avoid false alarms.

www.krohne.com02/2013 - 4002275001 - MA PipePatrol R01 en

9

2 DEVICE DESCRIPTION

2.4 Leak localisation method

To idendify the source of the leak accuratley the following 3 localisation methods are combined

in PipePatrol.

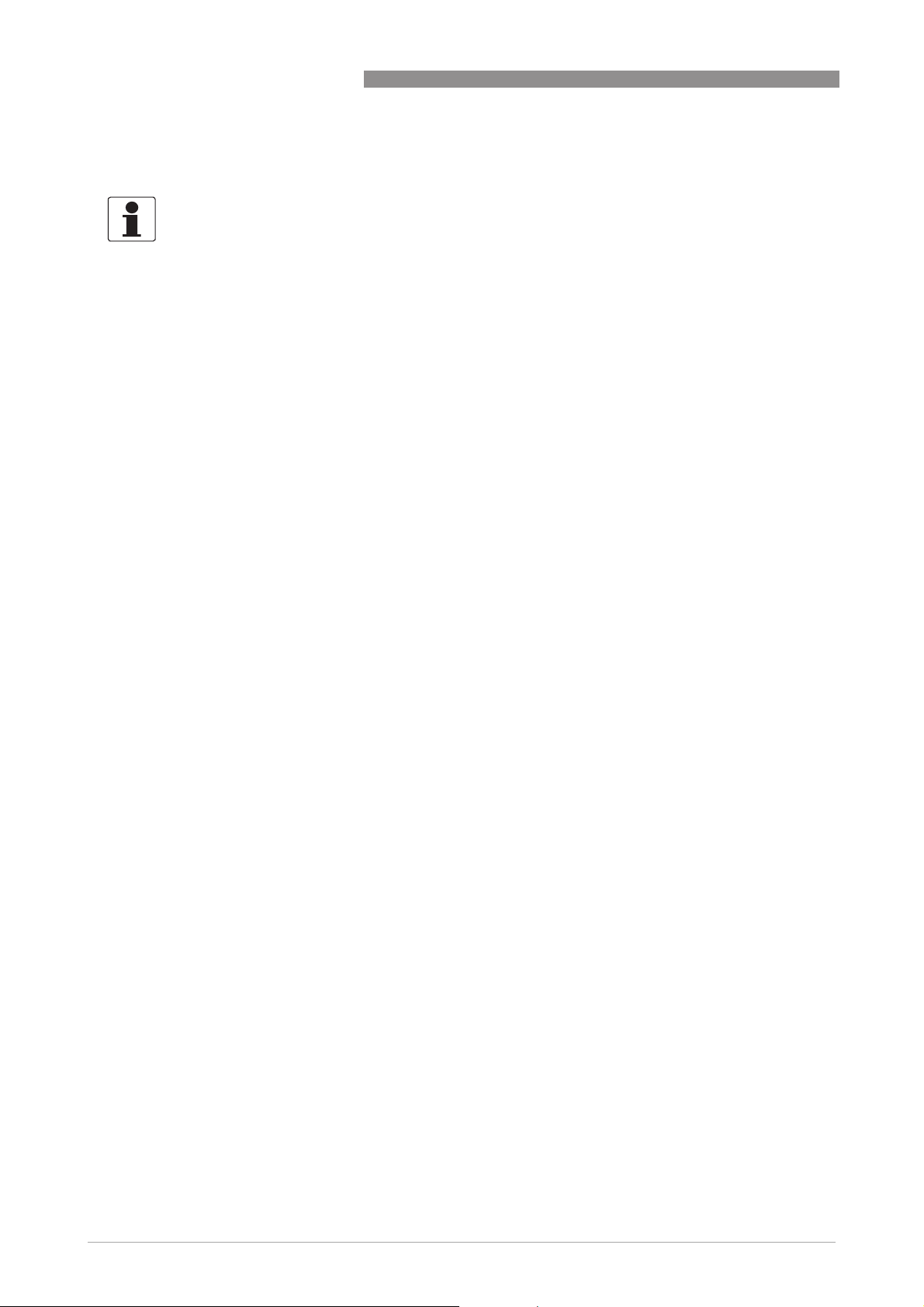

Gradient Intersection Method

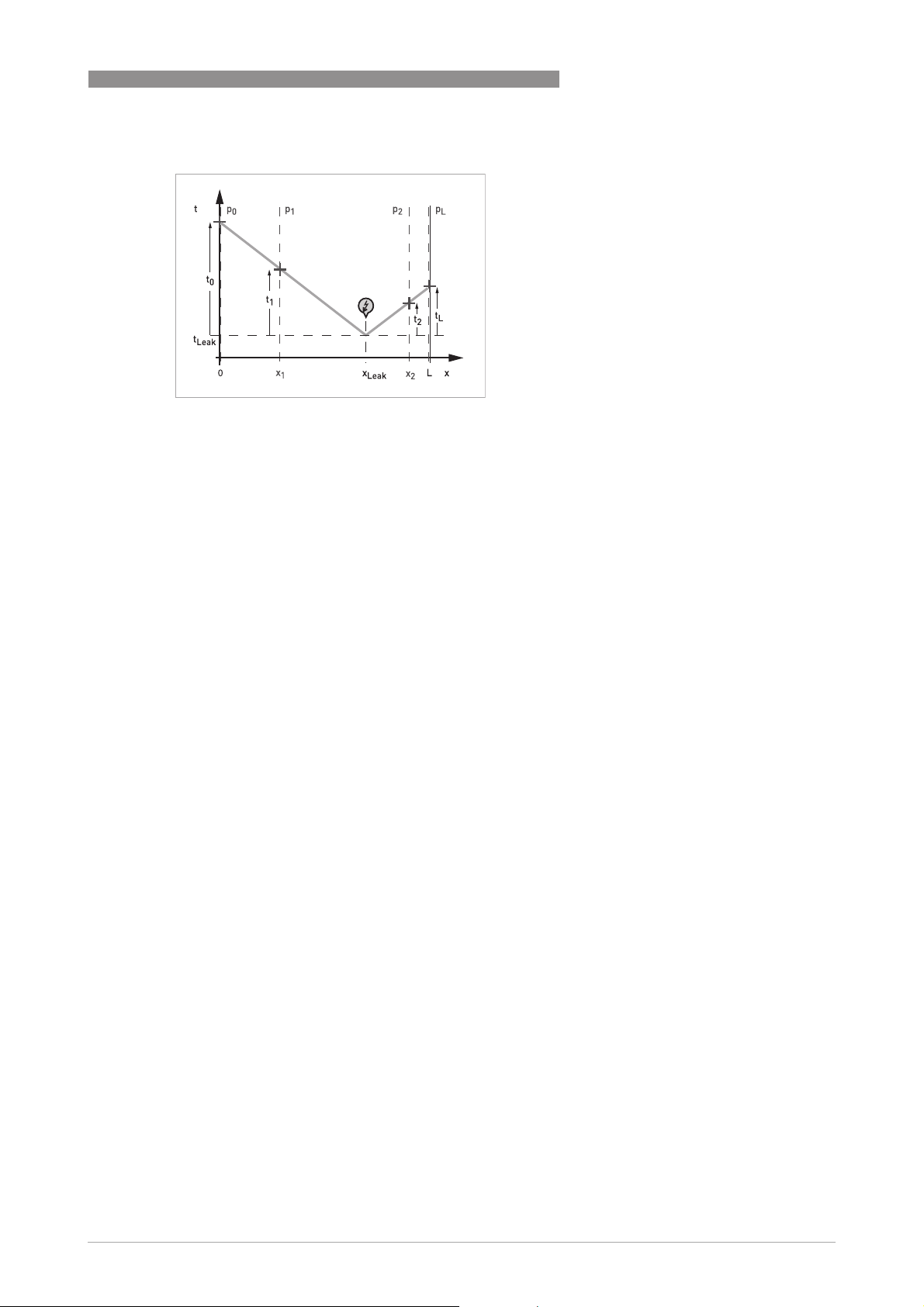

Figure 2-1: Gradient Intersection Method

PIPEPATROL

Under zero leak conditions, pressure drops uniformly along the pipeline. When a leak occurs,

more liquid or gas flows through the pipeline before the leak than after it.

The pressure gradient along the pipeline therefore changes at the leak. The leak localisation can

thus be identified at the point where the gradient changes.

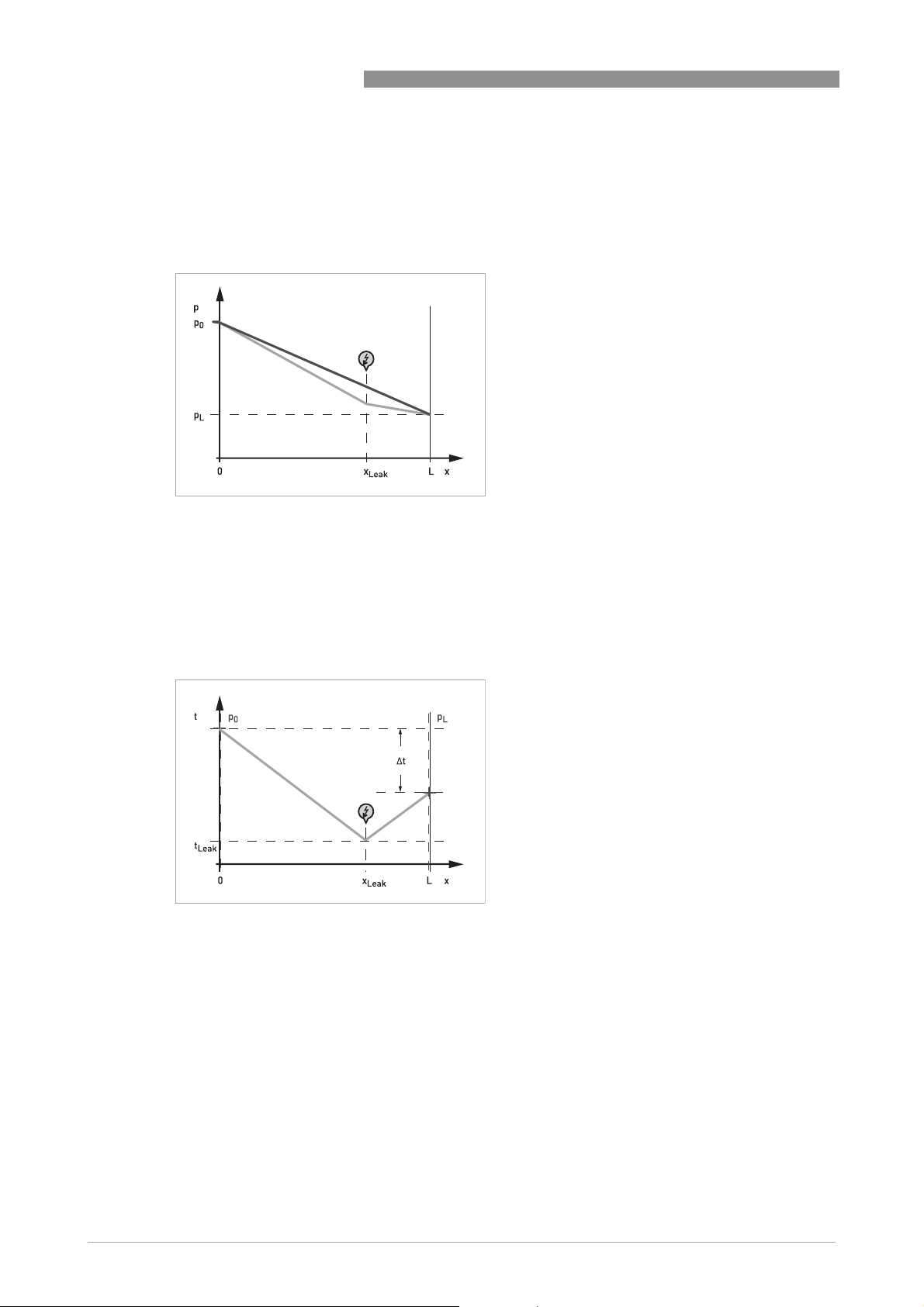

Wave Propagation Method

Figure 2-2: Wave Propagation Method

A sudden leak will cause a negative pressure wave in the pipeline, simply because gas or liquid is

leaking out. This pressure wave will travel through the pipeline at the sound velocity of gas or

liquid.

10

Depending on the localisation of the leak, the pressure wave will arrive at one end of the pipeline

before it arrives at the other. The leak position can be calculated from the difference in the

arrival times at the inlet and outlet.

www.krohne.com 02/2013 - 4002275001 - MA PipePatrol R01 en

PIPEPATROL

DEVICE DESCRIPTION 2

Extended Wave Propagation Method

Figure 2-3: Extended Wave Propagation Method

Using the same physical principle as the wave propagation method, the extended method takes

into account intermediate station measurements. Using the information from intermediate

stations and E-RTTM's knowledge about the velocity of sound profile in the pipeline, jitter error

introduced by slow sensor scan rates can be eliminated.

www.krohne.com02/2013 - 4002275001 - MA PipePatrol R01 en

11

3 OPERATION

3.1 General safety notes

DANGER!

This system operates on 230 VAC, 50/60 Hz. This current can cause serious injuries or death.

WARNING!

•

None of the system components should be opened, unless by trained and certified electrical

engineers.

•

Damaged or interrupted electrical cables between the PC and the rest of the system, as well

as terminated or damaged software, can lead to a failure in the leak detection system.

•

The PCs must be properly grounded and cannot be used in an Ex area.

INFORMATION!

•

Before shutting down (one of the) PCs all running software application should be closed in a

normal way.

•

The instructions mentioned in manuals from subsuppliers should be followed.

•

Each operator must know the functionality of all functions that are accessible for this

operator.

PIPEPATROL

12

www.krohne.com 02/2013 - 4002275001 - MA PipePatrol R01 en

PIPEPATROL

3.2 Start-up

The LDS software is automatically loaded after the monitoring station has been switched on. The

software automatically starts to record measurement data and reaches its operational state

shortly after start-up.

For the correct operation of the system, the following items should be considered:

• An uninterrupted power supply is required. Power supply variations can lead to re-starting of

the computer and in the worst case cause the PC to crash.

• The data communication between monitoring station and the metering system must be

running in order for the system to receive measurement data.

3.3 Layout of user interface

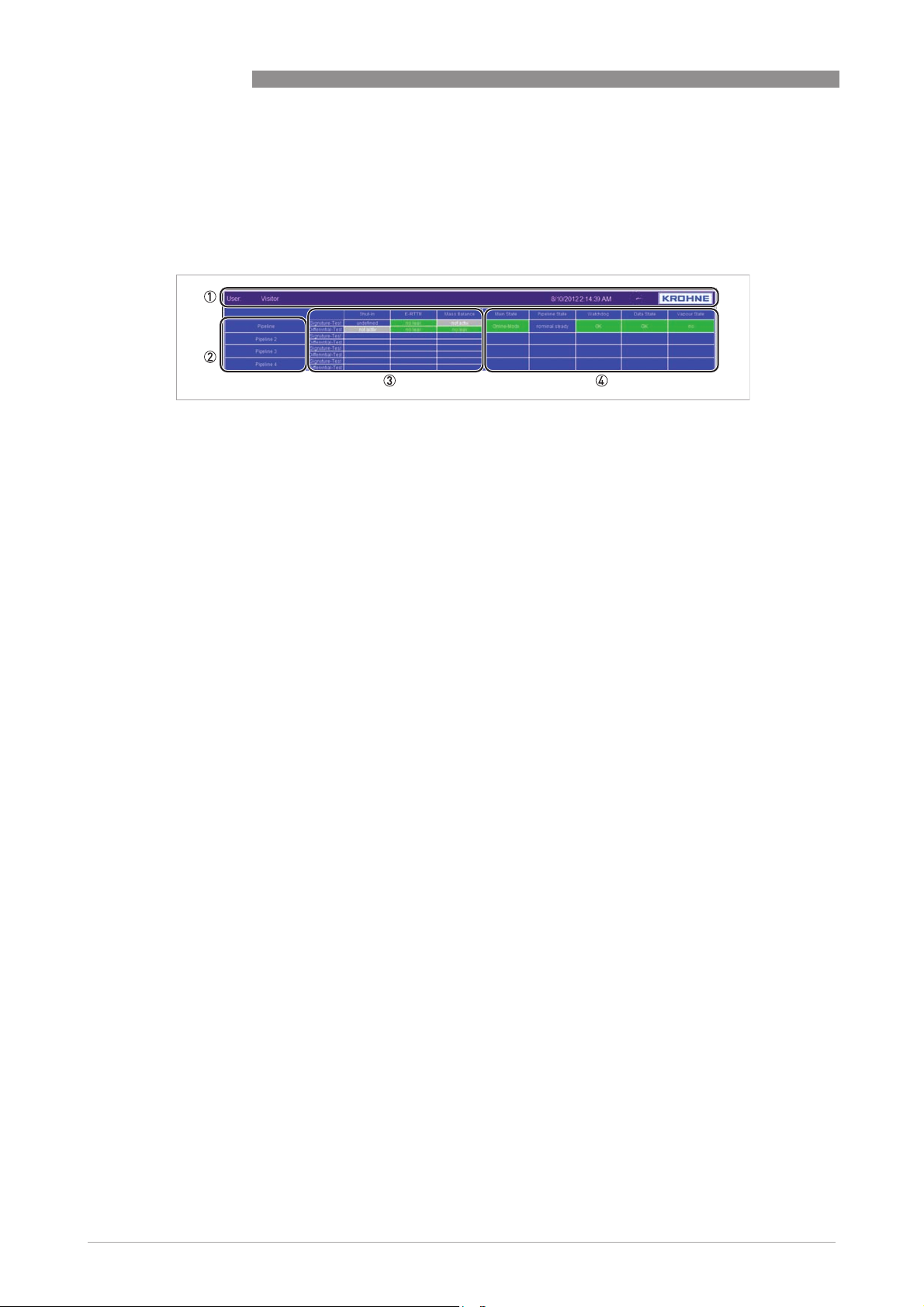

The main screen is the interface between the user and the leak detection system. The menu

layout and the different windows are shown in the following drawing.

OPERATION 3

Figure 3-1: Layout of user interface

1 Status window

2 Operator window

3 Controls

www.krohne.com02/2013 - 4002275001 - MA PipePatrol R01 en

13

3 OPERATION

3.3.1 Status window

The status window shows main information of each applicable system, which is available on each

screen of the PipePatrol HMI. The functionality of each information is explained in the following

part.

1 General error information from the operator station

General error information from the operator station

General error information from the operator stationGeneral error information from the operator station

The operator station is the PC where the actual HMI is running.

The following information can be shown:

• Name of the user who is logged in

• Date and time of the operator station machine

• Error OPC Connection (red/flashing)

The connection to the OPC server of the leak detection software is lost.

2 Name of the leak detection system

Name of the leak detection system

Name of the leak detection systemName of the leak detection system

The operator station HMI is designed to be able to monitor several running leak detection systems

which are designated by a unique system name. A click on one of the systems, switches the operator

screen to the leak information of the selected leak detection system.

3 Alarm information of the running leak detection

Alarm information of the running leak detection

Alarm information of the running leak detectionAlarm information of the running leak detection

The system performs leak detection by using different modules. Each module provides alarm

information by Signature-Test and Differential-Test. The usage of these modules depends on the

actual running conditions of the pipeline.

• Shut-In:

Shut-In: This module is performing an analysis of the pressure reading inside the closed pipe

Shut-In:Shut-In:

section. As long one of the reading is available it will perform leak detection for standstill

conditions.

• E-RTTM:

E-RTTM: This module indicates the model based leak detection. It will be activated as long flow,

E-RTTM:E-RTTM:

pressure and temperature readings are available.

• Mass Balance:

Mass Balance: This module offers a statistical analysis of the inlet and outlet flow. As long both

Mass Balance:Mass Balance:

readings are available it will provide leak detection in pumping conditions.

• Following additional modules, following the same operating philosophy, may be available:

- Virtual Flow

- Substation Monitoring

The following information can be shown:

• Undefined (blue):

Undefined (blue): LDS is not running; no leak information is available.

Undefined (blue):Undefined (blue):

• Unknown (blue):

Unknown (blue): LDS is starting-up; leak information will be available soon.

Unknown (blue):Unknown (blue):

• No leak (green):

No leak (green): The system is running; no leak is detected.

No leak (green):No leak (green):

• Leak Alarm (red flushing):

Leak Alarm (red flushing): The system is up and running and a leak has been detected.

Leak Alarm (red flushing):Leak Alarm (red flushing):

• Acknowledge alarm (blue):

Acknowledge alarm (blue): An alarm has been detected and confirmed by a logged operator.

Acknowledge alarm (blue):Acknowledge alarm (blue):

4 States information of the running leak detection

States information of the running leak detection

States information of the running leak detectionStates information of the running leak detection

The following state information are available:

• Main State:

Main State: Indication of the main systems states.

Main State:Main State:

• Pipeline State:

Pipeline State: Indication of the actual pipeline conditions.

Pipeline State:Pipeline State:

• Watchdog:

Watchdog: Indication of the actual status of the watchdog monitoring.

Watchdog:Watchdog:

• Data State:

Data State: Indication of the actual status of data gathering.

Data State:Data State:

• Indication of the status of vapour monitoring along the line.

PIPEPATROL

14

For detailed information refer to the following details.

www.krohne.com 02/2013 - 4002275001 - MA PipePatrol R01 en

PIPEPATROL

OPERATION 3

Main State

Main State

Main StateMain State

A click on the "Main State" box of a system enables the change of the actual state.

The following information can be shown:

• Undefined (blue):

Undefined (blue): The system is not running; no system information is available.

Undefined (blue):Undefined (blue):

• Stopped (red):

Stopped (red): The system is stopped. The recording of data is still running.

Stopped (red):Stopped (red):

• Online-Mode (green):

Online-Mode (green): The system is running by using the current measured pipeline data.

Online-Mode (green):Online-Mode (green):

• Self Test-Mode (yellow):

Self Test-Mode (yellow): The system is running by using the recorded pipeline data.

Self Test-Mode (yellow):Self Test-Mode (yellow):

• Tuning-Mode (blue):

Tuning-Mode (blue): Maintenance activities are carried out on the monitoring station.

Tuning-Mode (blue):Tuning-Mode (blue):

Therefore the leak detection is stopped at the moment.

• Application alarm (red):

Application alarm (red): An internal error of the leak detection software has been detected.

Application alarm (red):Application alarm (red):

System stopped working. A logged operator has to reset the alarm and to restart the system.

If the failure occurs several times please contact our support.

• Error (red):

Error (red): The application is not running correctly.

Error (red):Error (red):

Pipeline State

Pipeline State

Pipeline StatePipeline State

The following information can be shown:

• Undefined (blue):

Undefined (blue): The system is not running; no information is available.

Undefined (blue):Undefined (blue):

• Unknown (blue):

Unknown (blue): The system is filling up the internal FIFOs. There is not enough information

Unknown (blue):Unknown (blue):

available to estimate the pipeline conditions (possible after a restart of the system). The

information will be available soon.

• Shut-In (blue):

Shut-In (blue): The pipeline is running in shut-in conditions. Valves at the inlet and at the

Shut-In (blue):Shut-In (blue):

outlet are closed.

• Multi Shut-in (blue):

Multi Shut-in (blue): All valves are closed.

Multi Shut-in (blue):Multi Shut-in (blue):

• Partial Shut-in (blue):

Partial Shut-in (blue): At least one section is closed.

Partial Shut-in (blue):Partial Shut-in (blue):

• Blocked Line (blue):

Blocked Line (blue): Minimum one valve is closed, either at the inlet or at the outlet.

Blocked Line (blue):Blocked Line (blue):

• Standstill (blue):

Standstill (blue): No flow conditions along the line. The flow readings are below a predefined

Standstill (blue):Standstill (blue):

value. Valves at the inlet and at the outlet are opened.

• Start-Up (blue):

Start-Up (blue): The pipeline start-up with pumping operations. The flow readings are above a

Start-Up (blue):Start-Up (blue):

predefined value.

• Shutdown (blue):

Shutdown (blue): The pumping operations stopped.

Shutdown (blue):Shutdown (blue):

• Nominal unknown (blue):

Nominal unknown (blue): The pipeline is running in pumping conditions at nominal flow level.

Nominal unknown (blue):Nominal unknown (blue):

The system is filling the internal FIFOs. There is not enough information available to estimate

further exact pipeline conditions (possible after a restart of the system). Further pipeline

information about pipeline conditions will be available soon.

• Nominal high transient (blue):

Nominal high transient (blue): The pipeline is running in pumping conditions at nominal flow

Nominal high transient (blue):Nominal high transient (blue):

level. High transient conditions detected by high variation of flow readings.

Watchdog

Watchdog

WatchdogWatchdog

A click on the "Watchdog" box of one of the systems opens a dialogue windows which is showing

all available counters, monitored by the HMI.

The following information can be shown:

• OK:

OK: The watchdog counter of the system is updated within the timeout range.

OK:OK:

• Alarm (red/flashing):

Alarm (red/flashing): The watchdog counter of the system is not updated and exceeds the

Alarm (red/flashing):Alarm (red/flashing):

timeout range. The system might be not working correctly.

www.krohne.com02/2013 - 4002275001 - MA PipePatrol R01 en

15