Page 1

Handbook

Handbook

OPTIBAR PC 5060 C

OPTIBAR PC 5060 C

OPTIBAR PC 5060 COPTIBAR PC 5060 C

HandbookHandbook

Pressure transmitter for the measurement of process

pressure and level

SW.REV. 1.0.x

© KROHNE 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2014 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 3

OPTIBAR PC 5060 C

CONTENTS

1 Safety instructions 6

1.1 Intended use ..................................................................................................................... 6

1.2 Technical limits ................................................................................................................ 7

1.3 Permissible mediums ...................................................................................................... 7

1.4 Certification ...................................................................................................................... 7

1.5 Safety instructions from the manufacturer ..................................................................... 8

1.5.1 Copyright and data protection ................................................................................................ 8

1.5.2 Disclaimer ............................................................................................................................... 8

1.5.3 Product liability and warranty ................................................................................................ 9

1.5.4 Information concerning the documentation........................................................................... 9

1.5.5 Warnings and symbols used................................................................................................. 10

1.6 Safety instructions for the operator............................................................................... 10

2 Device description 11

2.1 Scope of delivery............................................................................................................. 11

2.2 Device description .......................................................................................................... 12

2.2.1 Device design ........................................................................................................................ 12

2.3 Nameplates .................................................................................................................... 13

2.4 Terms and abbreviations................................................................................................ 14

2.5 Sealing concept .............................................................................................................. 15

2.5.1 Sealing concept for recessed installation ............................................................................ 15

2.5.2 Sealing concept for flush mounted installation with single seal......................................... 15

2.5.3 Sealing concept for flush mounted installation with double seal........................................ 16

2.5.4 Sealing concept for hygienic installation ............................................................................. 16

3 Installation 17

3.1 General notes on installation ......................................................................................... 17

3.2 Protection category of the housing ................................................................................ 17

3.3 Packaging ....................................................................................................................... 17

3.4 Storage ........................................................................................................................... 18

3.5 Transport ........................................................................................................................ 18

3.6 Installation specifications .............................................................................................. 18

3.7 Mounting......................................................................................................................... 19

3.7.1 Rotating the housing............................................................................................................. 19

3.7.2 Mounting the display and adjustment module .....................................................................19

3.7.3 Temperature limits ............................................................................................................... 20

3.8 Instructions for oxygen applications.............................................................................. 20

3.9 Venting ............................................................................................................................ 21

3.10 Measurement setup for process pressure measurement .......................................... 23

3.11 Measurement setup for steam measurement............................................................. 24

3.12 Measurement setup for liquid measurement.............................................................. 25

3.13 Measurement setup for level measurement ............................................................... 25

3.14 External housing........................................................................................................... 26

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

3

Page 4

CONTENTS

OPTIBAR PC 5060 C

4 Electrical connections 28

4.1 Safety instructions.......................................................................................................... 28

4.2 Notes for electrical cables ............................................................................................. 28

4.2.1 Requirements for signal cables provided by the customer ................................................. 29

4.2.2 Laying electrical cables correctly......................................................................................... 29

4.2.3 Cable preparation ................................................................................................................. 30

4.2.4 Cable entry 1/2-14 NPT (female) ..........................................................................................31

4.2.5 Connector pin assignment.................................................................................................... 31

4.2.6 Connection to the power supply ...........................................................................................32

4.2.7 Cable shield and grounding .................................................................................................. 33

4.3 Electrical connection......................................................................................................34

4.3.1 Connection in the terminal compartment ............................................................................ 34

4.3.2 Connection in the housing base (external housing)............................................................. 35

4.3.3 Single chamber housing .......................................................................................................36

4.3.4 Double chamber housing...................................................................................................... 37

4.3.5 Double chamber housing Ex d ia .......................................................................................... 38

4.4 Grounding the measuring device ................................................................................... 39

4.5 Description of the current output................................................................................... 39

5 Start-up 40

5.1 Start-up........................................................................................................................... 40

5.2 Keypad functions ............................................................................................................ 41

5.3 Quick setup ..................................................................................................................... 42

5.4 Extended adjustment...................................................................................................... 43

5.4.1 Start-up ................................................................................................................................. 43

5.4.2 Display................................................................................................................................... 45

5.4.3 Diagnosis............................................................................................................................... 45

5.4.4 Additional adjustments ......................................................................................................... 46

5.4.5 Info......................................................................................................................................... 46

5.5 Reset............................................................................................................................... 47

5.6 Saving the device settings .............................................................................................. 48

5.7 Diagnosis memory.......................................................................................................... 48

5.8 Failures and diagnostics ................................................................................................ 49

5.8.1 Error codes ........................................................................................................................... 50

5.8.2 Check 4...20 mA signal.......................................................................................................... 52

5.8.3 Error messages via the display and operating module ....................................................... 52

5.8.4 Change electronic insert....................................................................................................... 52

5.8.5 Software update .................................................................................................................... 53

5.9 Adjustment ..................................................................................................................... 53

4

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 5

OPTIBAR PC 5060 C

CONTENTS

6 Service 54

6.1 Replacement................................................................................................................... 54

6.2 Maintenance ................................................................................................................... 54

6.3 Spare parts availability...................................................................................................55

6.4 Availability of services .................................................................................................... 55

6.5 Repairs............................................................................................................................ 55

6.6 Returning the device to the manufacturer..................................................................... 55

6.6.1 General information.............................................................................................................. 55

6.6.2 Form (for copying) to accompany a returned device............................................................ 56

6.7 Disposal .......................................................................................................................... 56

6.8 Exchange process assembly for IP 68 (25 bar) version ................................................. 57

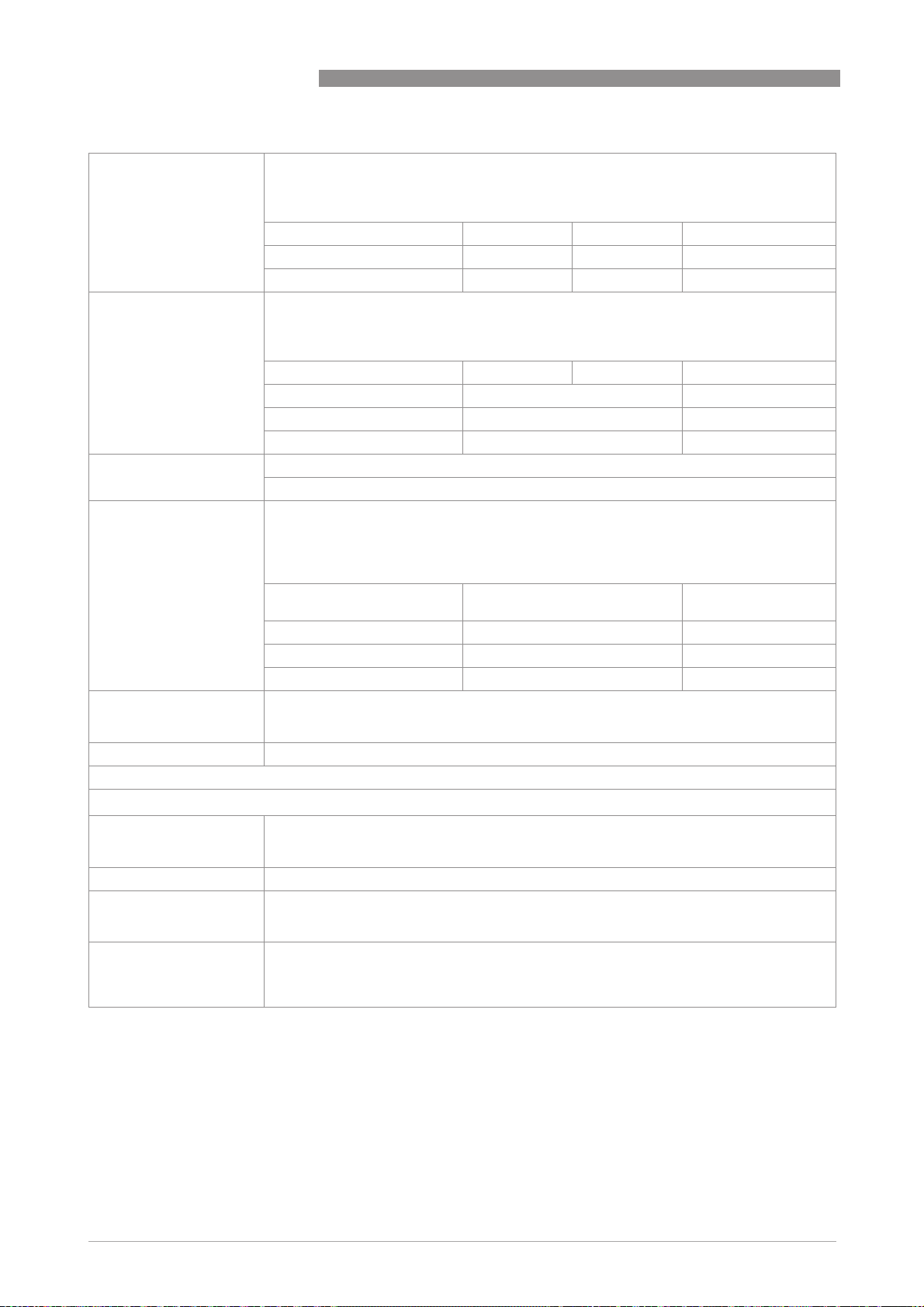

7 Technical data 58

7.1 Measuring principle........................................................................................................58

7.2 Technical data................................................................................................................. 59

7.3 Pressure ranges............................................................................................................. 66

7.4 Ambient temperature effect on current output............................................................. 68

7.5 Dynamic output behaviour.............................................................................................. 69

7.6 Dimensions and weights ................................................................................................ 70

8 Description of HART interface 85

8.1 General description ........................................................................................................85

8.2 Software history ............................................................................................................. 85

8.3 Connection variants........................................................................................................86

8.3.1 Point-to-Point connection - analogue / digital mode........................................................... 87

8.4 Inputs/outputs and HART® dynamic variables and device variables............................ 87

8.5 Field Communicator 475 (FC 475).................................................................................. 88

8.5.1 Installation ............................................................................................................................ 88

8.5.2 Operation............................................................................................................................... 88

8.6 Field Device Tool / Device Type Manager (FDT / DTM).................................................. 88

8.6.1 Installation ............................................................................................................................ 88

9 Notes 89

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

5

Page 6

1 SAFETY INSTRUCTIONS

1.1 Intended use

DANGER!

For devices used in hazardous areas, additional safety instructions apply.

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

The OPTIBAR PC 5060 C process pressure transmitter is suitable for measuring the process

pressure and level of gases, vapours and liquids. The available measuring ranges and permitted

maximum working pressures for each are indicated on the nameplate and described in the refer

Technical data

to

points:

on page 59 section. To observe the intended use, adhere to the following

OPTIBAR PC 5060 C

• Observe the instructions in this document.

• Comply with the technical specifications (for further information refer to

page 59).

• Only suitably qualified personnel may install and operate the device.

• Observe the generally accepted standards of good practice.

Technical data

CAUTION!

•

Any modification to the device, including drilling, sawing, trimming, welding and soldering of

parts, or partially painting over or coating, is prohibited.

•

Neither is it permitted to use the device as a climbing aid e.g. for installation purposes, as a

holder for cables, pipes or other loads.

•

The mounting or installation of parts is only permitted as described in this document, or

insofar as it has been authorised by the manufacturer or a certified service partner.

on

6

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 7

OPTIBAR PC 5060 C

1.2 Technical limits

The device was constructed solely for use within the technical limits indicated on the nameplate

and in the technical data. Applications outside of these limits are not permitted and could lead to

significant risk of accident. For this reason, observe the following limits:

• Do not exceed the maximum working pressure (MWP).

• Do not exceed the indicated permissible operating temperature range.

• The permissible ambient temperatures given may not be exceeded or undershot.

• Observe the ingress protection of the housing during use.

1.3 Permissible mediums

The device is designed to measure the pressure of vaporous, gaseous and liquid media. Prior to

using any corrosive or abrasive products, the operator must check the resistance of all materials

which are in contact with the product.

1.4 Certification

SAFETY INSTRUCTIONS 1

CE marking

The device fulfils the statutory requirements of the following EC directives:

• EMC Directive 2004/108/EC

• EMC specification acc. to EN 61326/A1

The manufacturer certifies successful testing of the product by applying the CE marking.

Pressure equipment directive (PED)

Pressure equipment directive (PED)

Pressure equipment directive (PED)Pressure equipment directive (PED)

Devices with a permissible pressure PS ≤ 200 bar (20 MPa) comply with Article 3 Section (3) and

are not subject to a conformity assessment. These devices were designed and manufactured in

accordance with sound engineering practice (SEP).

The CE marking on the device does not apply to the pressure equipment directive.

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

7

Page 8

1 SAFETY INSTRUCTIONS

1.5 Safety instructions from the manufacturer

1.5.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

OPTIBAR PC 5060 C

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.5.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

8

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 9

OPTIBAR PC 5060 C

1.5.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.5.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

9

Page 10

1 SAFETY INSTRUCTIONS

1.5.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

OPTIBAR PC 5060 C

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.6 Safety instructions for the operator

10

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 11

OPTIBAR PC 5060 C

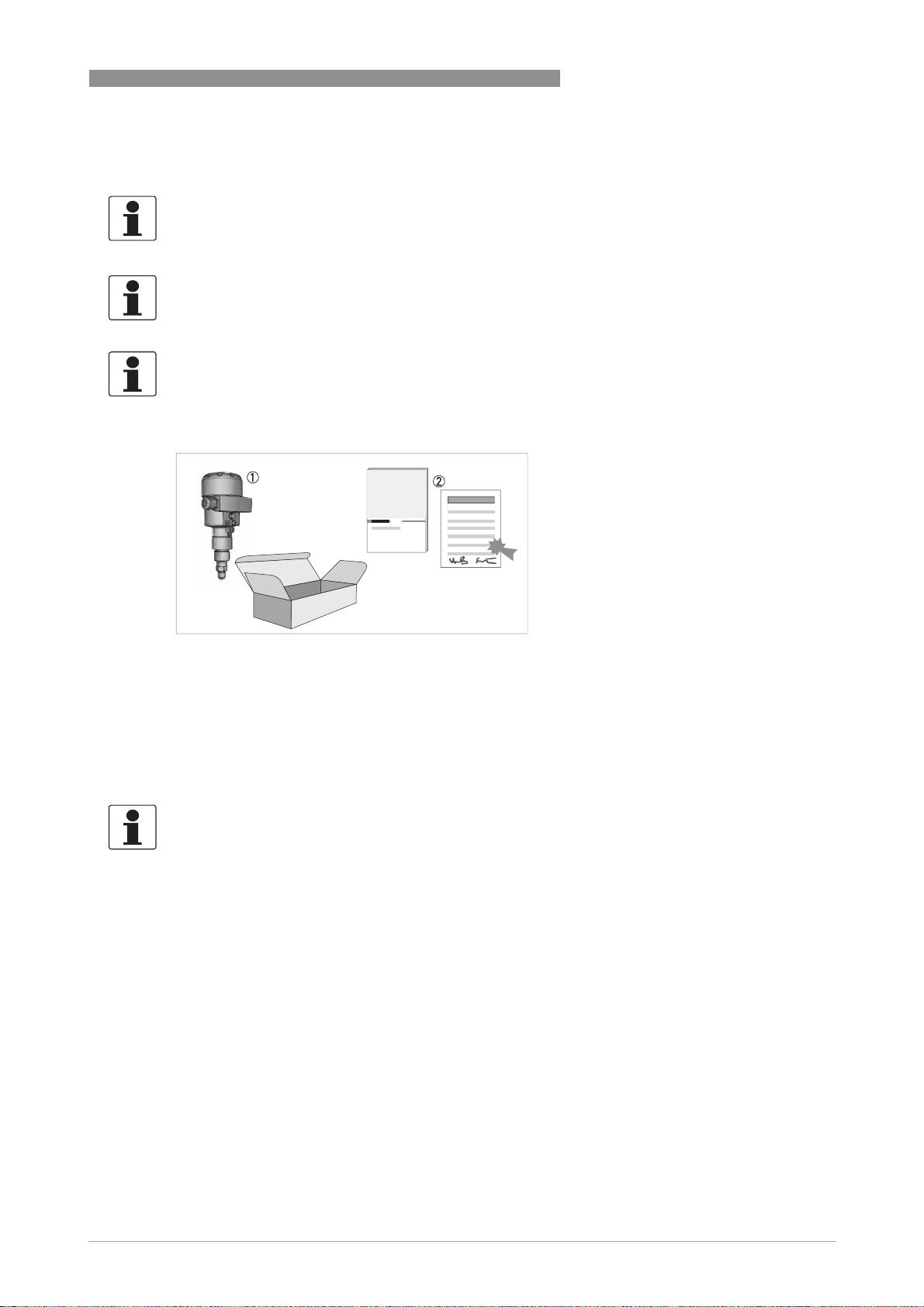

2.1 Scope of delivery

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

Figure 2-1: Scope of delivery

1 Device in the version as ordered

2 Mounting bracket

3 Documentation (test reports, factory and material certification (if ordered) and product documentation)

Optional accessories

• Gaskets

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

11

Page 12

2 DEVICE DESCRIPTION

2.2 Device description

The OPTIBAR PC 5060 C is suited to applications in virtually all areas of industry. It is used to

measure the following types of pressure:

• Gauge pressure

• Absolute pressure

• Vacuum

The setup of the device is carried out via the display and adjustment unit. For further information

refer to

Keypad functions

A capacitive ceramic sensor element is used in the measuring cell.

The measuring device is supplied ready for operation. The factory settings for the process data

correspond to your order specifications.

For safety reasons do not exceed the measuring range or permissible process pressure. This

also applies when, based on the order, a measuring cell is installed with a higher measuring

range than the permissible pressure range of the process connection.

on page 41.

OPTIBAR PC 5060 C

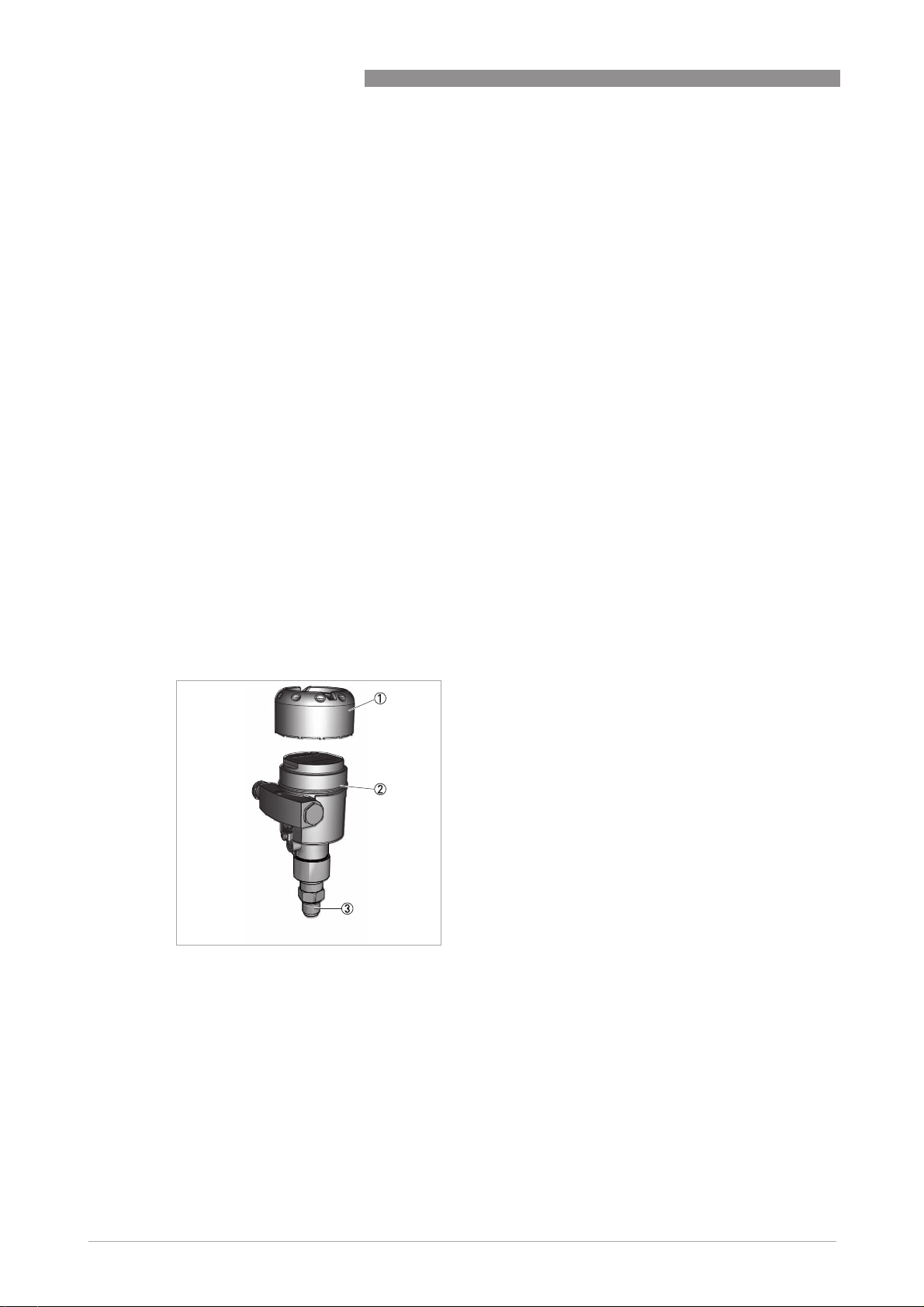

2.2.1 Device design

The following drawing shows the basic components of the pressure transmitter.

Figure 2-2: Basic components of single chamber pressure transmitter

1 Housing cover, optional with display and adjustment module below

2 Housing with electronics

3 Process assembly with measuring cell

12

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 13

OPTIBAR PC 5060 C

Figure 2-3: Basic components of double chamber pressure transmitter

1 Housing cover

2 Housing with electronics

3 Process assembly with measuring cell

4 Housing cover, optional with display and adjustment module below

5 Operating and display module

DEVICE DESCRIPTION 2

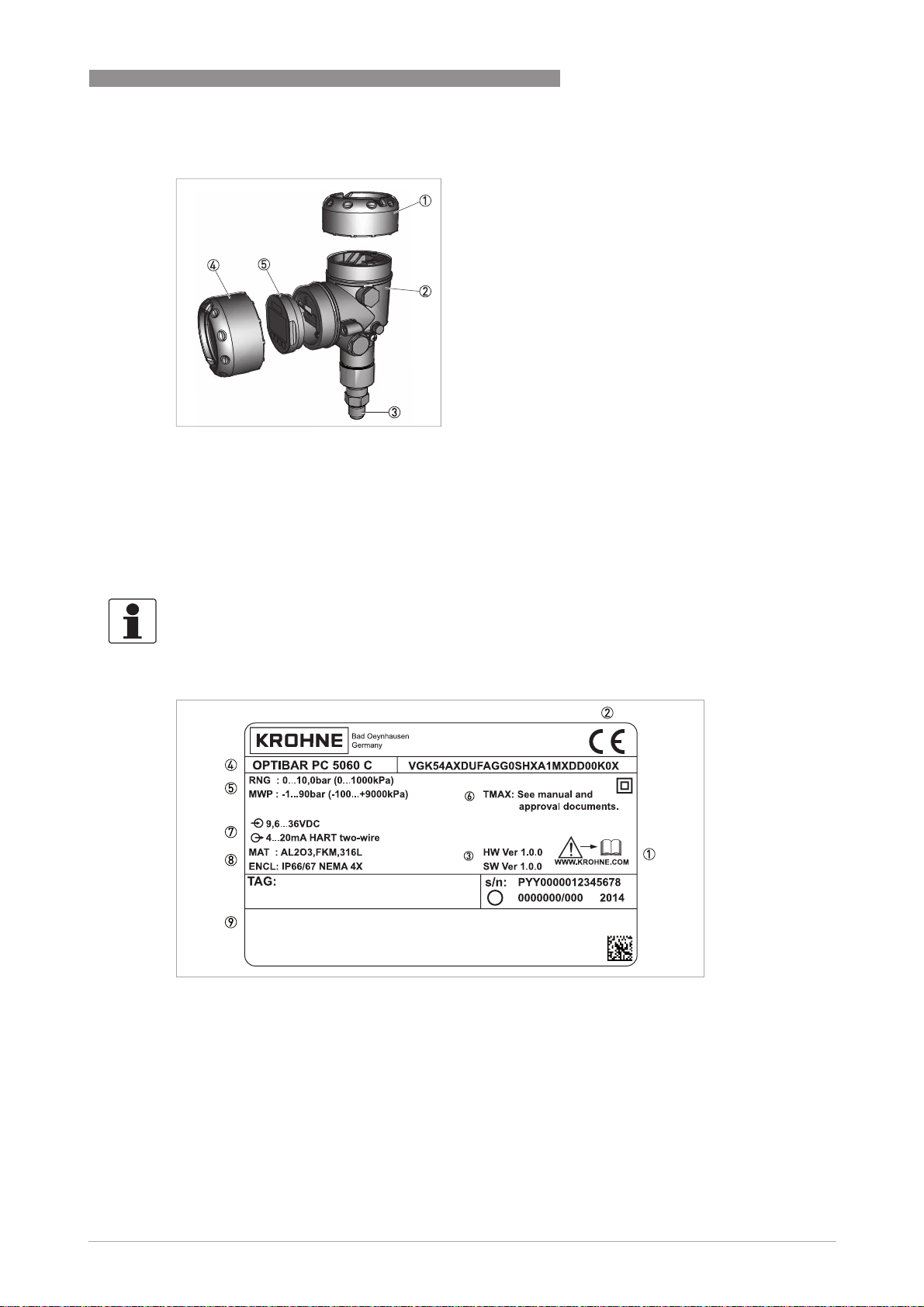

2.3 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

Figure 2-4: Example for nameplate for a OPTIBAR * 5060

1 Observe the installation and operating instructions

2 CE marking and marking of notified body

3 Hardware and Software version

4 Product name and type code

5 Nominal range

Permissible process pressure

6 Permissible temperature range

7 Electronics power supply and signal output

8 Ingress protection and material of wetted parts

(Diaphragm, process connections, gasket and fill fluid)

9 Approvals and approval guidelines

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

13

Page 14

2 DEVICE DESCRIPTION

2.4 Terms and abbreviations

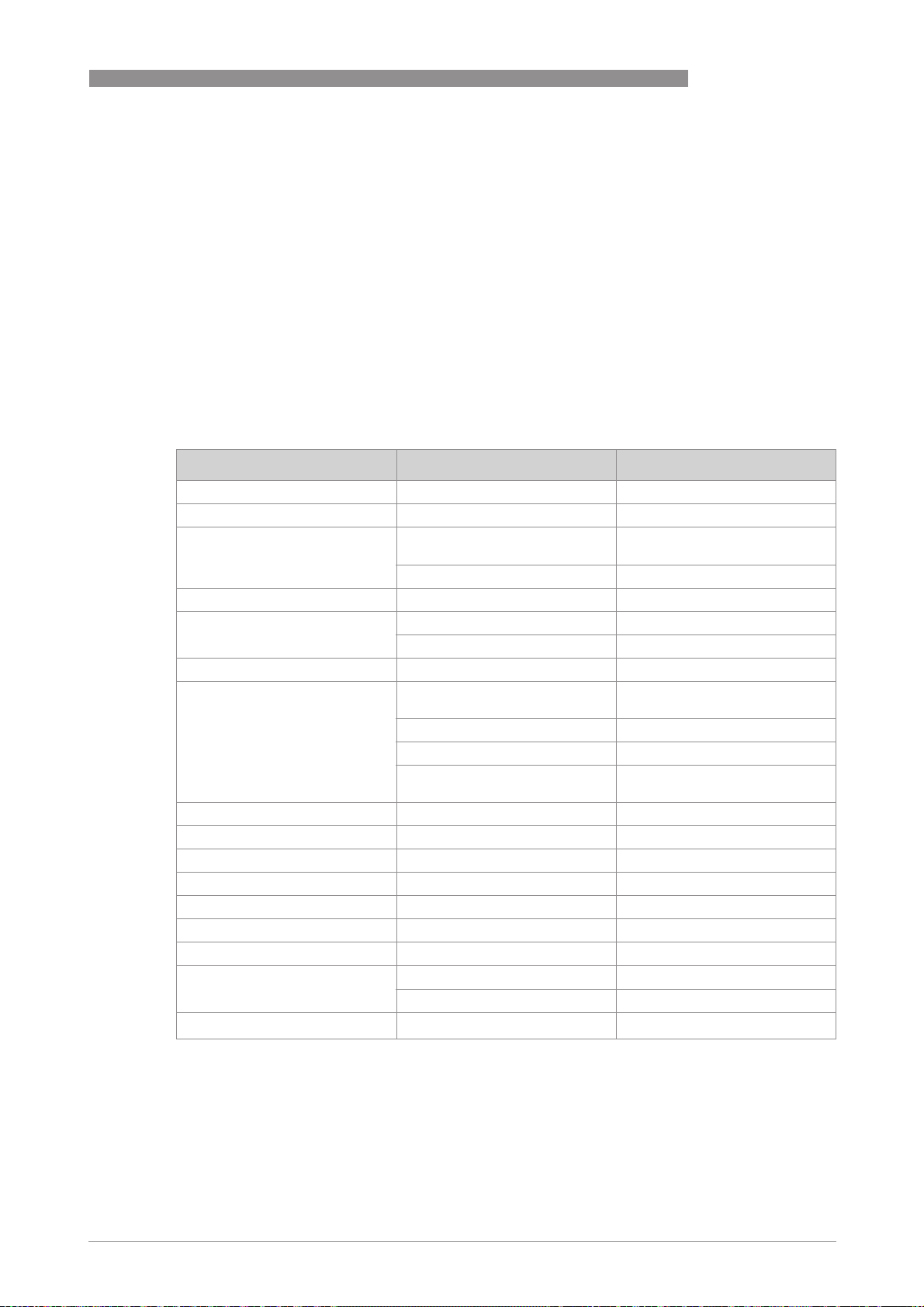

The following terms and abbreviations are used in this document.

URL

URL

URLURL

Upper Range Limit

LRL

LRL

LRLLRL

Lower Range Limit

URV

URV

URVURV

Upper Range Value

LRV

LRV

LRVLRV

Lower Range Value

SPAN

SPAN

SPANSPAN

Span

CAL SPAN

CAL SPAN

CAL SPANCAL SPAN

calibrated Span

TD

TD

TDTD

Turn Down

The following applies: URV ≤ URL, CAL SPAN ≤ SPAN, TD ≥ 1

Example: URL

Upper measuring range limit. Also called nominal range. The highest value that

can be measured by a particular device.

Lower measuring range limit. The lowest value that can be measured by a

particular device.

The calibrated measuring range or the highest adjusted measured value. This

value corresponds to the 20 mA signal.

The calibrated measuring range or the lowest adjusted measured value. This

value corresponds to the 4 mA signal.

Span or measuring range. SPAN = URL – LRL

Calibrated or adjusted measuring span. CAL SPAN = URV – LRV. Also called

"cSPAN".

This is the span set to the 4…20 mA output.

The ratio from the measuring span to the adjusted measuring span.

TD= SPAN/(CAL SPAN)= (+URL)/(CAL SPAN)

URL= 3 bar

URLURL

LRL

LRL= 0 bar

LRLLRL

URV

URV= 2 bar

URVURV

LRV

LRV= 0.5 bar

LRVLRV

OPTIBAR PC 5060 C

SPAN

SPAN= 3 bar

SPANSPAN

CAL SPAN

CAL SPAN= 1.5 bar TD

CAL SPANCAL SPAN

TD= 2:1

TDTD

14

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 15

OPTIBAR PC 5060 C

2.5 Sealing concept

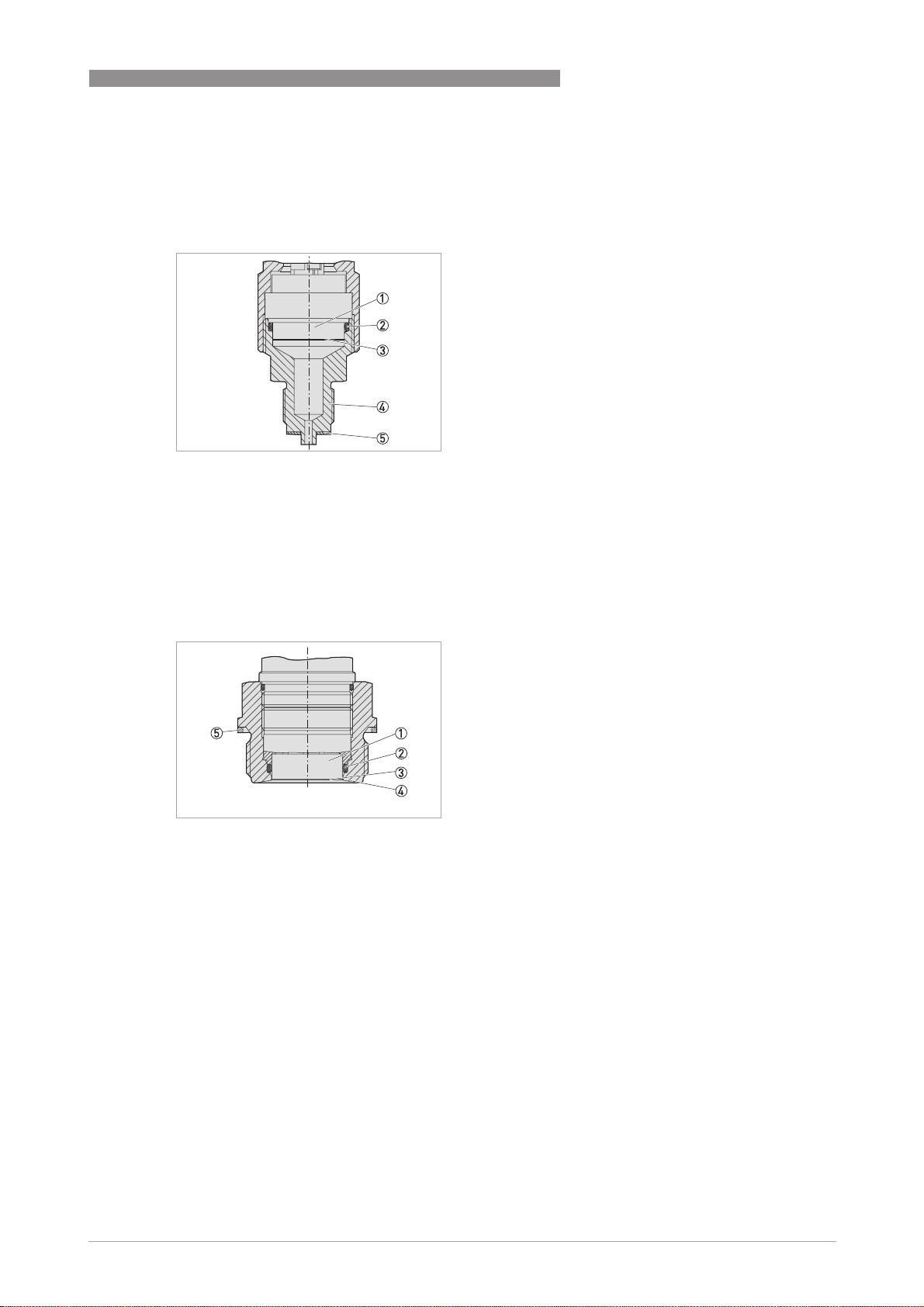

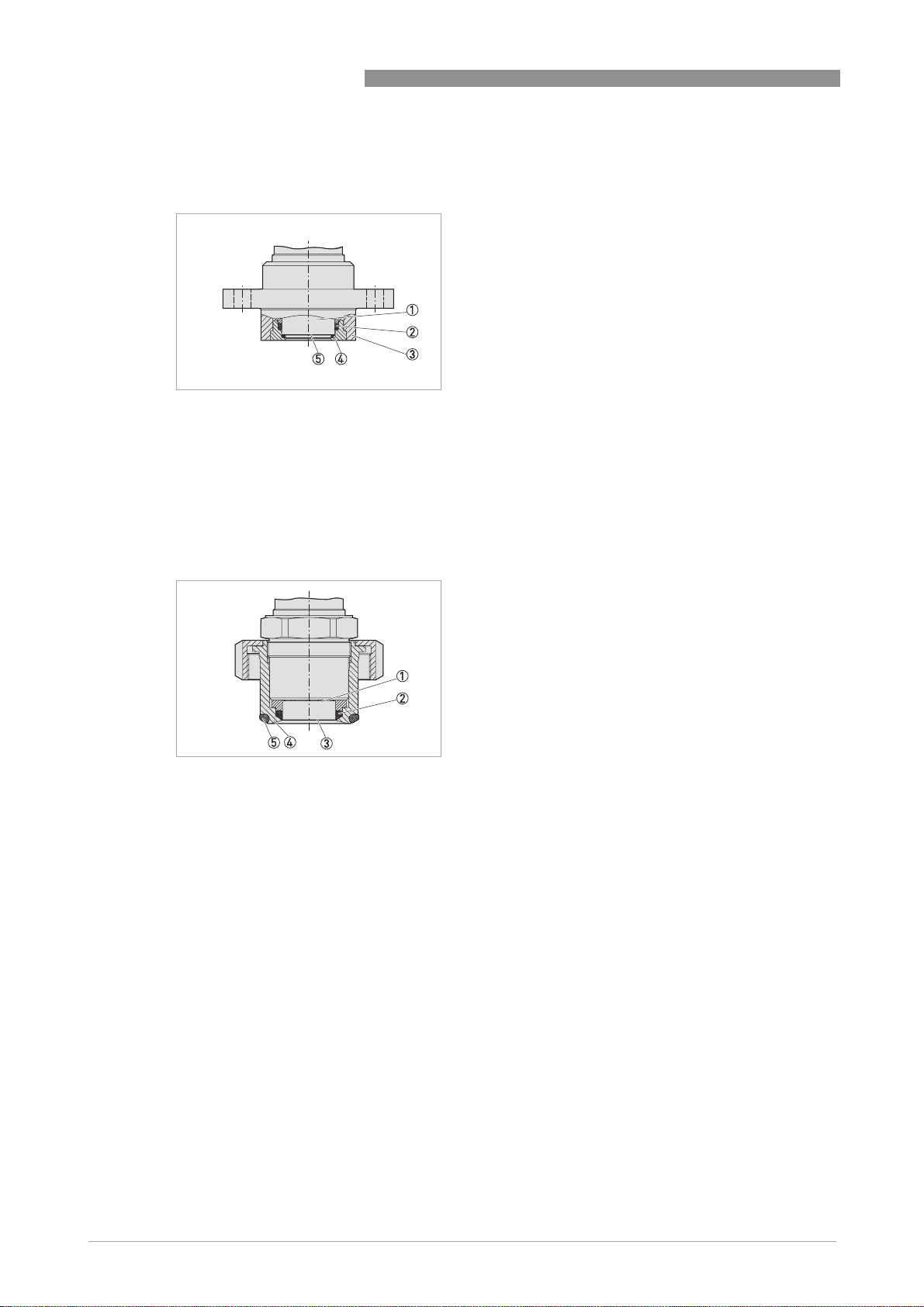

2.5.1 Sealing concept for recessed installation

Figure 2-5: Recessed installation of the CERTEC® measuring cell

1 Measuring cell

2 Measuring cell seal

3 Process diaphragm

4 Process connection

5 Seal for the process connection (optional)

DEVICE DESCRIPTION 2

2.5.2 Sealing concept for flush mounted installation with single seal

Figure 2-6: Flush mounted installation of the CERTEC® measuring cell

1 Measuring cell

2 Measuring cell seal

3 Process diaphragm

4 Process connection

5 Seal for the process connection (optional)

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

15

Page 16

2 DEVICE DESCRIPTION

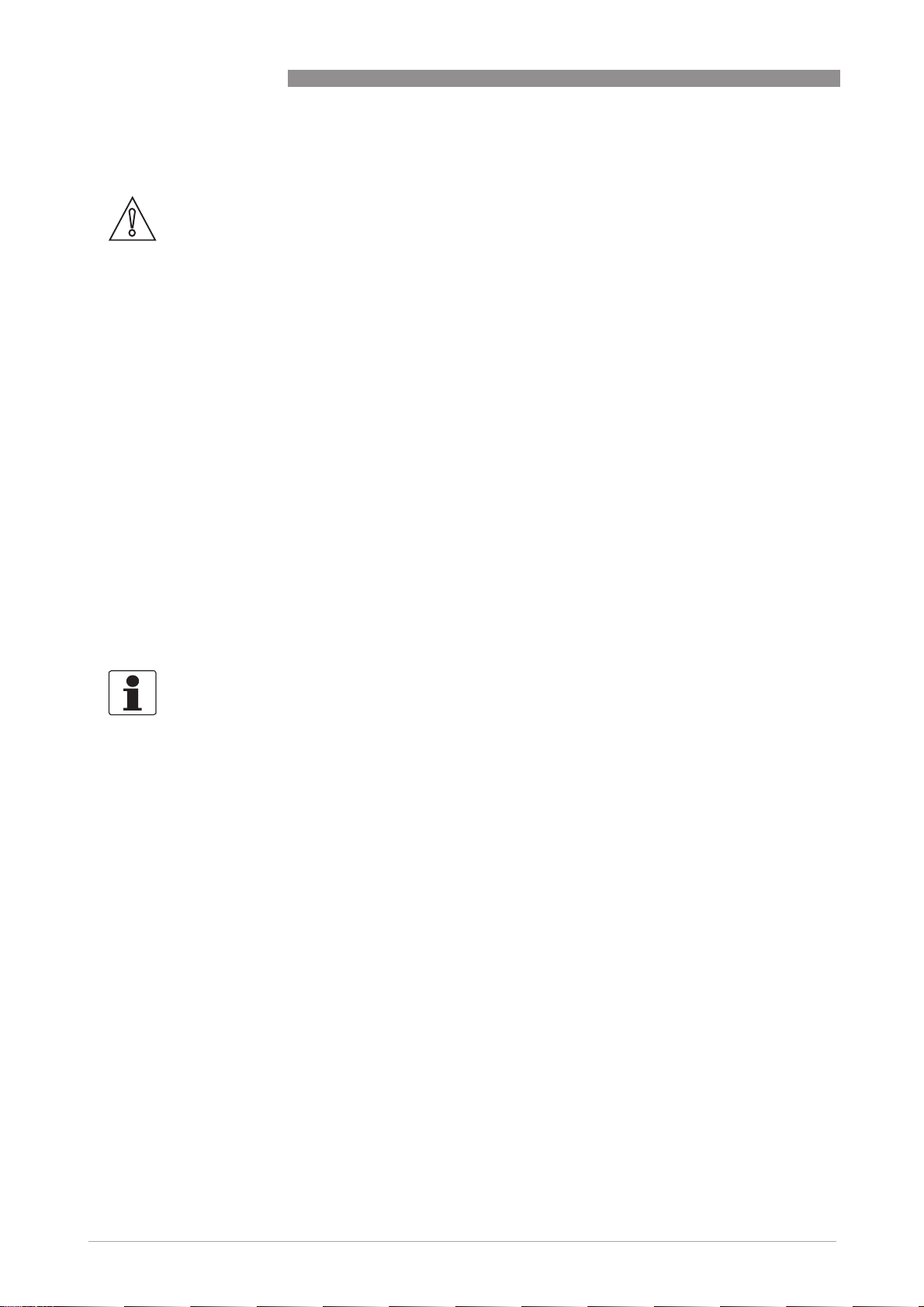

2.5.3 Sealing concept for flush mounted installation with double seal

Figure 2-7: Flush mounted installation of the CERTEC® measuring cell with double seal

1 Measuring cell

2 Measuring cell seal

3 Process diaphragm

4 Process connection

5 Additional front measuring cell seal

2.5.4 Sealing concept for hygienic installation

OPTIBAR PC 5060 C

Figure 2-8: Hygienic installation of the CERTEC® measuring cell

1 Measuring cell

2 Measuring cell moulded seal

3 Process diaphragm

4 Process connection

5 Gap-free seal for process connection

16

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 17

OPTIBAR PC 5060 C

3.1 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Protection category of the housing

The housing of the differential pressure transmitter fulfills the requirements for ingress

protection in accordance with IEC 60529. Housing for protection category IP69K in accordance

with ISO 20653 is also available. For further information refer to

INSTALLATION 3

Technical data

on page 59.

CAUTION!

The first digit stands for the protection of the inner electronic components against the ingress of

foreign bodies including dust. The first digit "6" means that the housing is dust-proof. The

second digit designates the protection of the inner electronic components against the ingress of

water. The second digit "6" means that the housing is waterproof and also resistant against a

strong jet of water resists. The number "7" means that the case is waterproof even under water

for a given pressure and time. The number "8" means that the housing is permanently

waterproof even under water.

3.3 Packaging

CAUTION!

Devices for oxygen applications are sealed in PE foil and provided with a label "Oxygen! Use no

Oil". Remove this foil just before mounting the device! After removing the protection for the

process connection the label OOOO

grease and dirt should be avoided. Danger of explosion!

Your device was protected by packaging during transport. Its capacity to handle normal loads

during transport is assured by a test following ISO 22248. The packaging of standard devices

consists of environmentally friendly, recyclable cardboard and PE foil. For special versions, PE

foam or PE foil is also used. Dispose of the packaging material via specialised recycling

companies.

will be visible on the process connection. Penetration of oil,

2222

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

17

Page 18

3 INSTALLATION

3.4 Storage

CAUTION!

Observe the storage information found on the packaging. Labels on the original packaging must

always remain legible and may not be damaged.

• Store the device in a dry and dust-free location.

• Avoid lasting direct exposure to the sun.

• Store the device in the original packaging supplied.

• Do not expose to aggressive media.

• Avoid mechanical shocks.

• Storage temperature of -40 to +80°C / -40 to +176°F.

• Relative air humidity of 20 to 85%.

3.5 Transport

• Use original packaging for transport and ensure that the packaging does not get crushed or

damaged by sharp objects or other boxes.

• Do not throw or drop the device.

• Avoid temperatures below -40°C / -40°F and above +80°C / +176°F.

• When transporting by ship, use seaworthy outer packing.

OPTIBAR PC 5060 C

3.6 Installation specifications

INFORMATION!

Observe the relevant directives, ordinances, standards and accident prevention regulations (e.g.

VDE/VDI 3512, DIN 19210, VBG, Elex V, etc.).

Ensure that all of the parts in the process are suitable for the current process conditions. This

includes in particular:

• Parts active in the measurement

• Process connection

• Process seal

Process conditions include in particular:

• Process pressure

• Process temperature

• Chemical properties of the media

• Abrasion and mechanical impact

18

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 19

OPTIBAR PC 5060 C

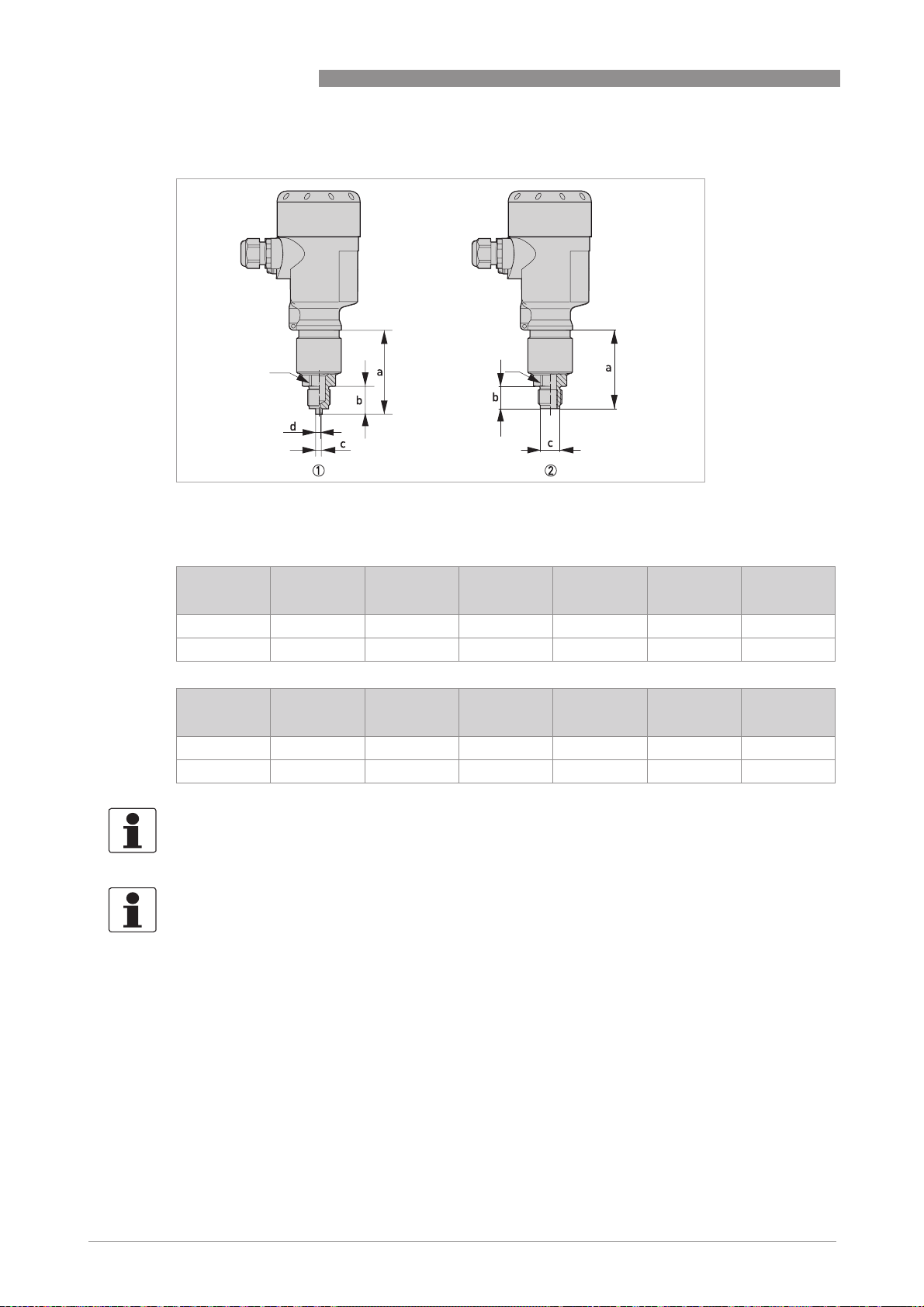

3.7 Mounting

CAUTION!

•

Prior to installing the pressure transmitter, it is essential to verify whether the version of the

device on hand completely fulfils the technical and safety requirements of the measuring

point. This applies in particular to the measuring range, overpressure resistance,

temperature, explosion protection and operating voltage.

•

Check the materials used for the wetted parts (e.g. gasket, process connection, separating

diaphragm etc.) for suitability as regards process compatibility.

3.7.1 Rotating the housing

The transmitter housing can be rotated 350° for better readability of the display or access to the

wiring. A stop prevents the housing from being rotated too far.

• On all 2 chamber housings, the locking screw must first be loosened at the neck of the

housing.

i The housing can then be rotated to the desired position.

• Once the desired position is reached, the locking screw is tightened again.

INSTALLATION 3

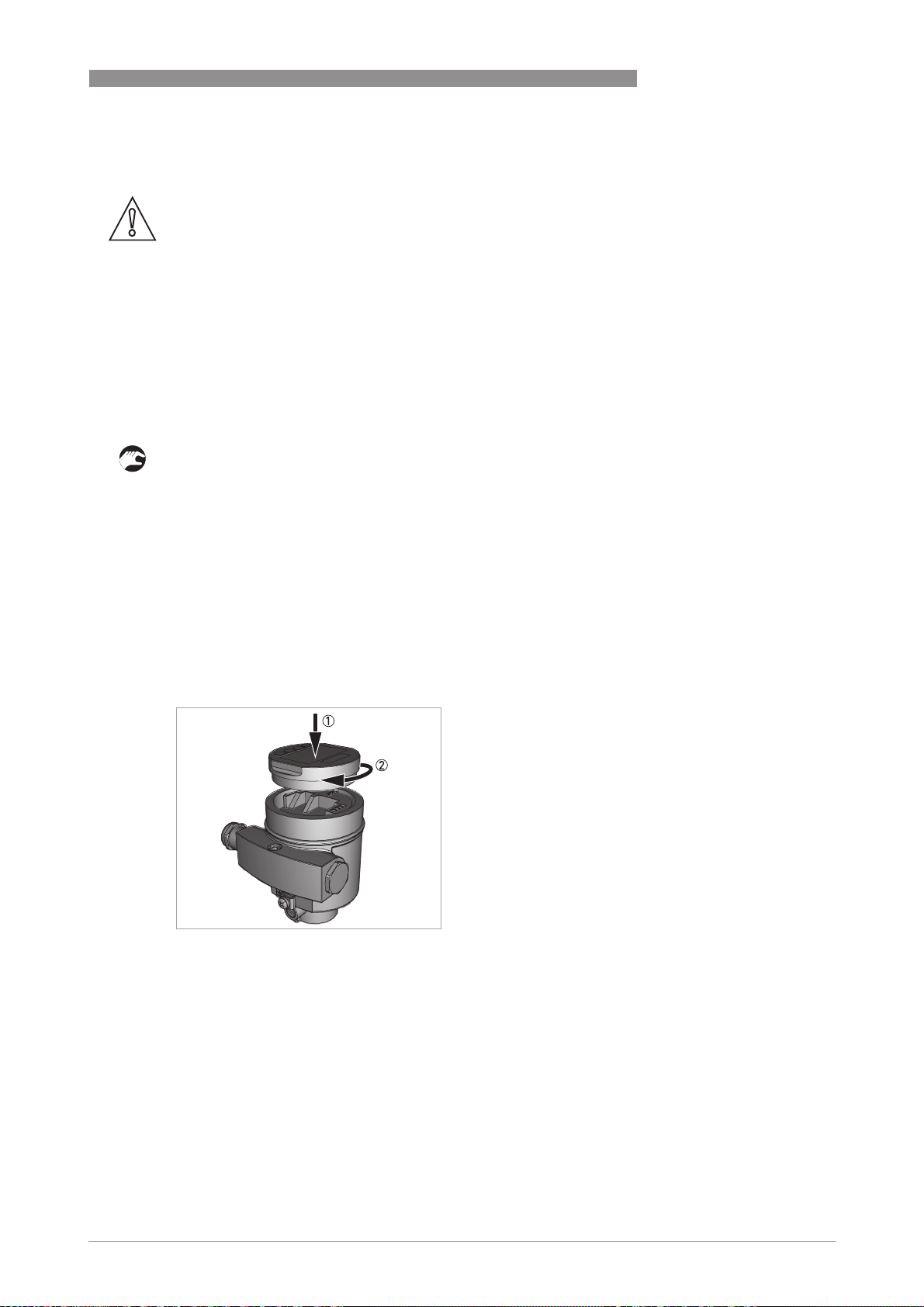

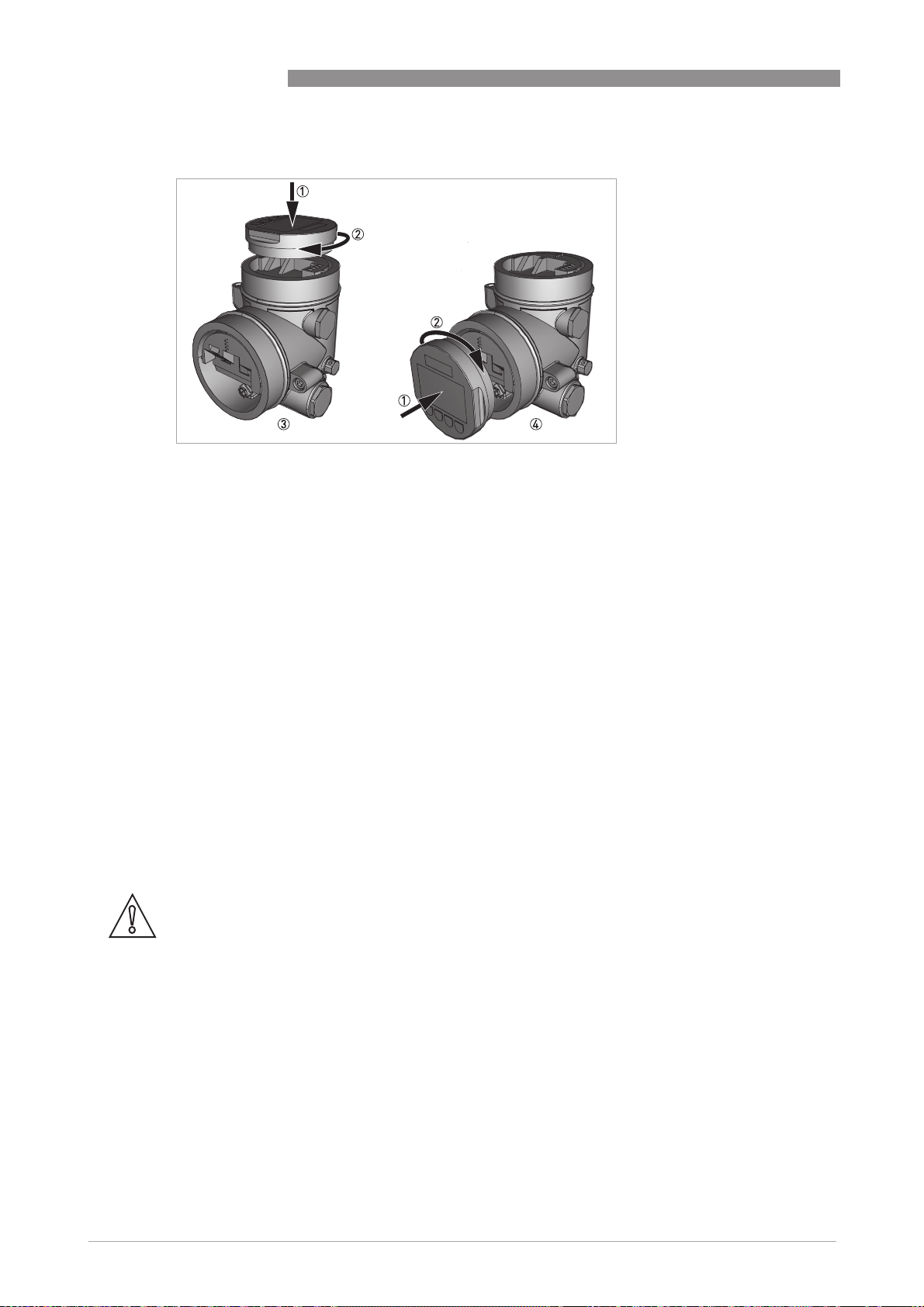

3.7.2 Mounting the display and adjustment module

The optional display and adjustment module can be set in any one of four different positions at

90° intervals. The installation of the adjustment module is carried out as per the illustrations

below. To do so, unscrew the housing cover and insert the adjustment module clockwise. The

display can be installed rotated at 90°. It is not necessary to interrupt the power supply.

Figure 3-1: Installation in single chamber housing

1 Insert the display and adjustment module into the housing

2 Turn the display and adjustment module clockwise

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

19

Page 20

3 INSTALLATION

Figure 3-2: Installation in double chamber housing

1 Insert the display and adjustment module into the housing

2 Turn the display and adjustment module clockwise

3 Mounting on top

4 Mounting at side

OPTIBAR PC 5060 C

3.7.3 Temperature limits

Higher process temperatures often mean also higher ambient temperatures for electronics and

connection cables. Make sure that the upper temperature limits for the environment of the

electronics housing and connection cable are not exceeded. For further information refer to

Technical data

on page 59.

3.8 Instructions for oxygen applications

Oxygen and other gases can be explosive when brought into contact with oils, grease and

plastics, so the following measures must also be taken:

• All components of the plant, such as e.g. measuring devices must be cleaned according to the

requirements of BAM (DIN 19247).

• Depending on the seal material, certain temperatures and pressures must not be exceeded

in oxygen applications, refer to

CAUTION!

Devices for oxygen applications are sealed in PE foil and provided with a label "Oxygen! Use no

Oil". Remove this foil just before mounting the device! After removing the protection for the

process connection the label OOOO

grease and dirt should be avoided. Danger of explosion!

Technical data

will be visible on the process connection. Penetration of oil,

2222

on page 59.

20

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 21

OPTIBAR PC 5060 C

3.9 Venting

CAUTION!

The filter element causes a delayed pressure equalisation when the housing cover is opened or

closed quickly. During the process the measurement can change by up to 15 mbar for up to 5

seconds.

CAUTION!

In order to ensure effective ventilation, the filter element must be always free of deposits.

CAUTION!

Do not use a high-pressure cleaner to clean the housing. The filter element may become

damaged and as a result moisture can penetrate into the housing. The exception to this is the

IP69K single chamber housing.

The ventilation for the electronics housing is assured via a filter element in the vicinity of the

cable glands, which is permeable to air but water-absorbent.

INSTALLATION 3

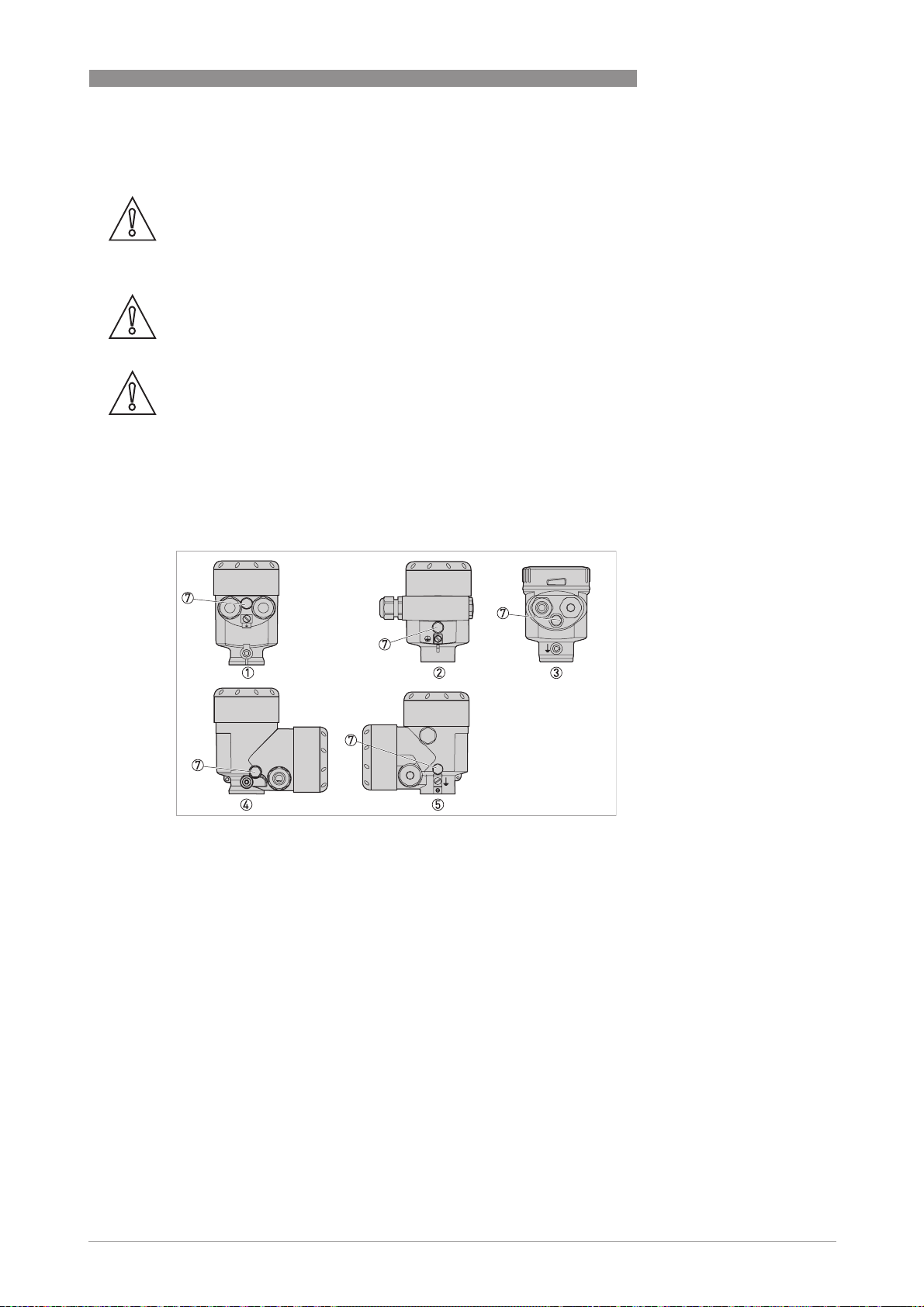

Figure 3-3: Venting in non-Ex, Ex ia and Ex d ia versions

1 Single chamber housing, plastic, stainless steel precision casting

2 Single chamber housing, aluminium

3 Single chamber housing, electro-polished stainless steel

4 Double chamber housing, plastic

5 Double chamber housing, aluminium

6 Filter element

The following devices feature a dummy plug instead of a filter element:

• Devices in the IP 66 / IP 68 (1bar) protection category - venting via capillary tube in

permanently connected cable

• Devices with absolute pressure

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

21

Page 22

3 INSTALLATION

Devices in Ex d version

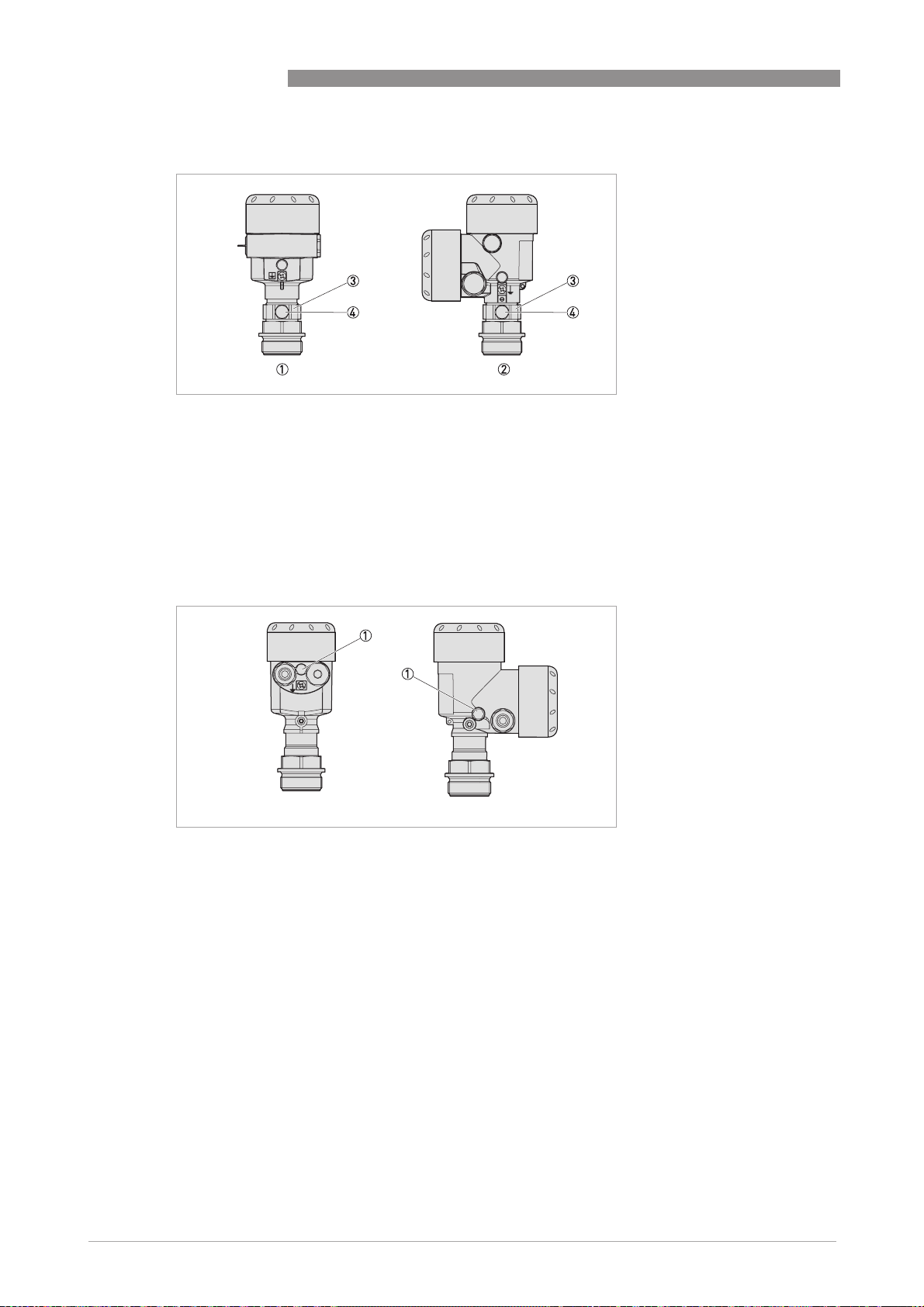

Figure 3-4: Ventilation Ex-housing

1 Single chamber housing, aluminium and stainless steel precision casting

2 Double chamber housing, aluminium and stainless steel precision casting

3 Rotating metal ring

4 Filter element

The filter element is integrated into the sensor assembly via a rotating metal ring. Align the

metal ring towards the bottom to better protect the filter element from deposits. Devices with

absolute pressure feature a dummy plug instead of a filter element.

OPTIBAR PC 5060 C

Devices with second process barrier

Figure 3-5: Ventilation gas-proof feedthrough

1 Filter element

For devices with a second process barrier, the sensor assembly is completely encased by an

additional, gas-proof feedthrough. Additional venting is not required for absolute pressure

sensors. With relative pressure sensors, the ambient pressure is measured and compensated by

an additional sensor in the electronics.

22

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 23

OPTIBAR PC 5060 C

INSTALLATION 3

Devices in IP69K version

Figure 3-6: Ventilation IP69K

Filter element

Devices with absolute pressure feature a dummy plug instead of a filter element.

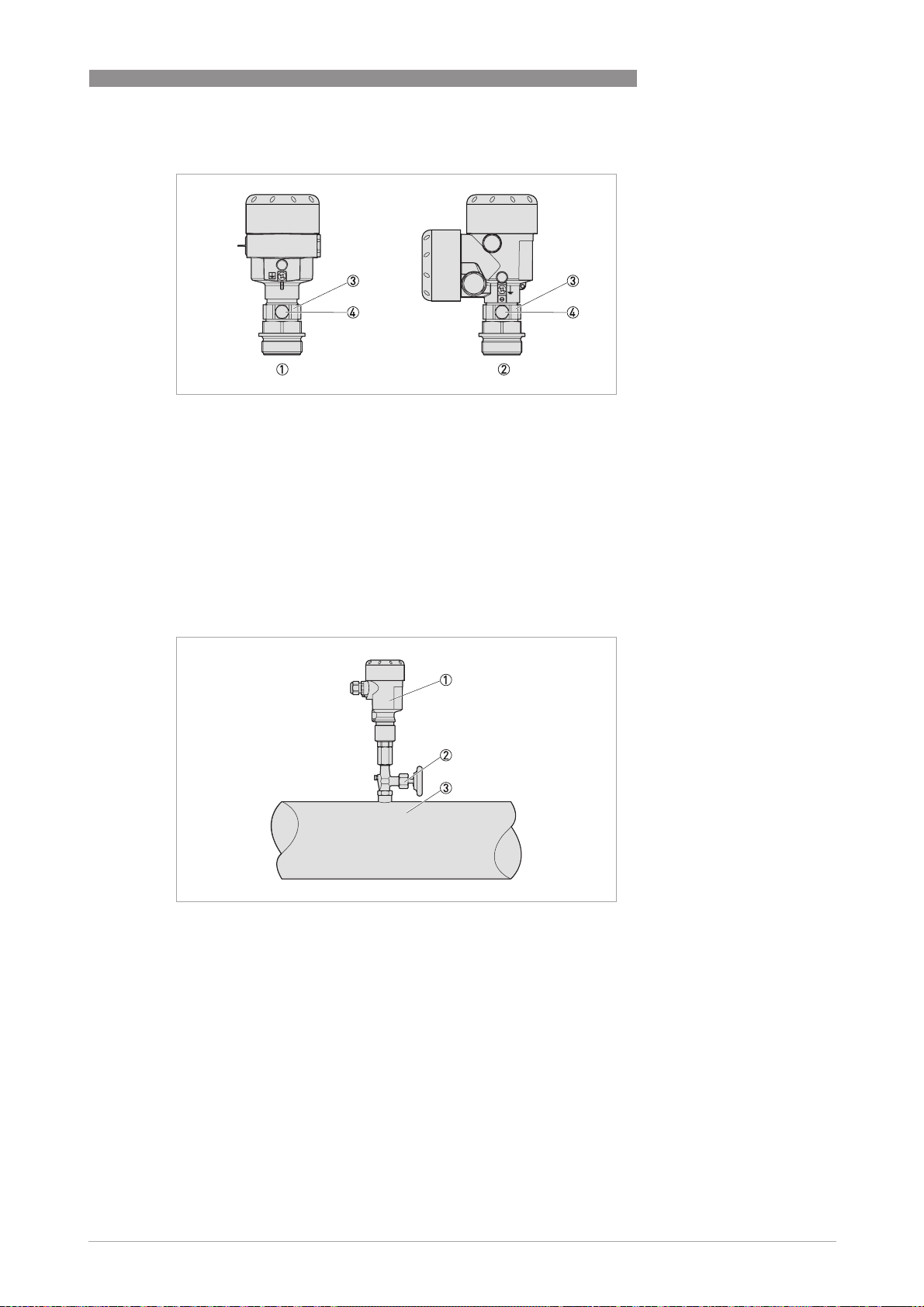

3.10 Measurement setup for process pressure measurement

The following points should be observed in this application:

• The signal converter must be mounted above the measuring point.

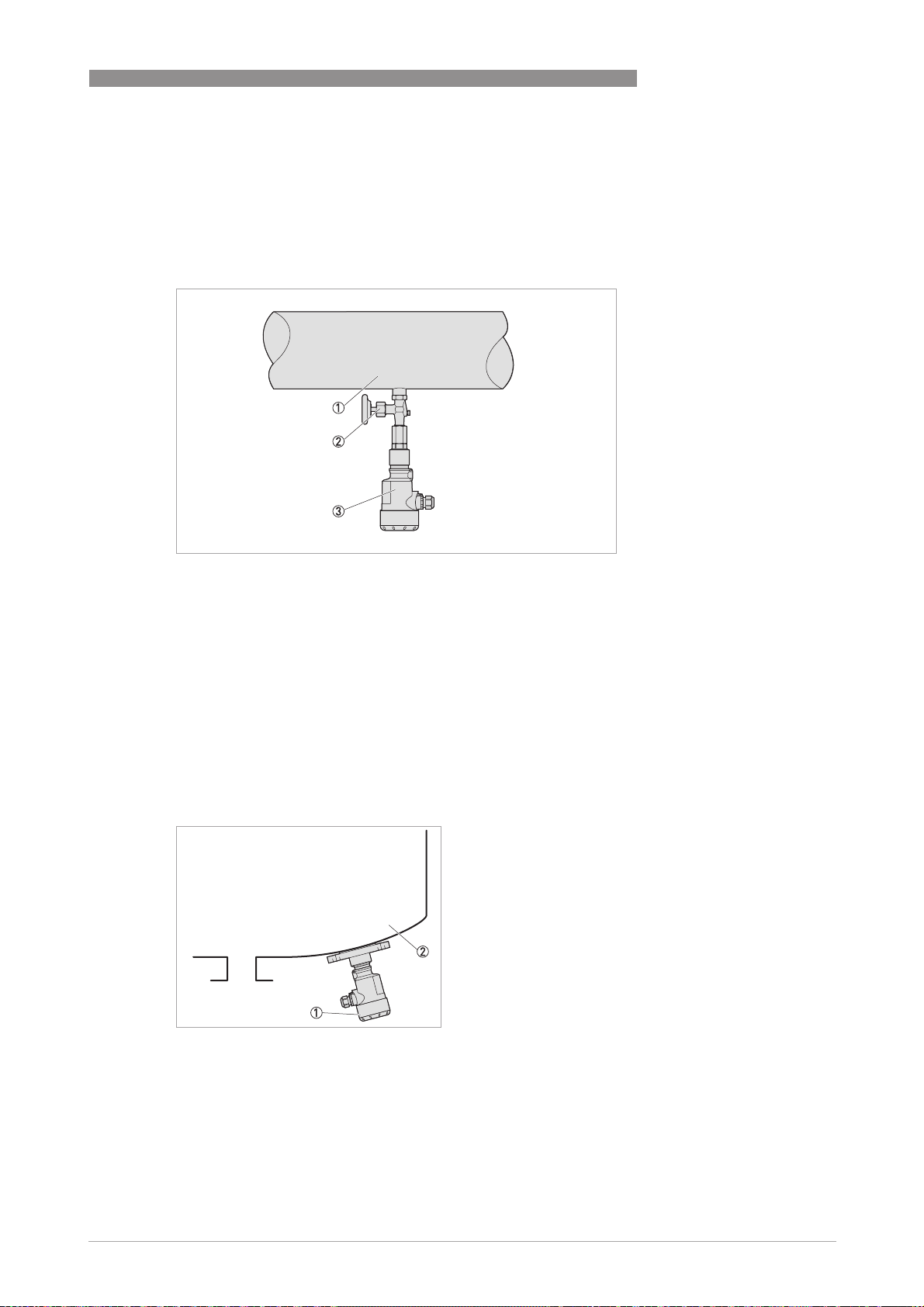

Figure 3-7: Measurement setup for measuring the process pressure of gases

1 Pressure transmitter

2 Shut-off valve

3 Tapping point

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

23

Page 24

3 INSTALLATION

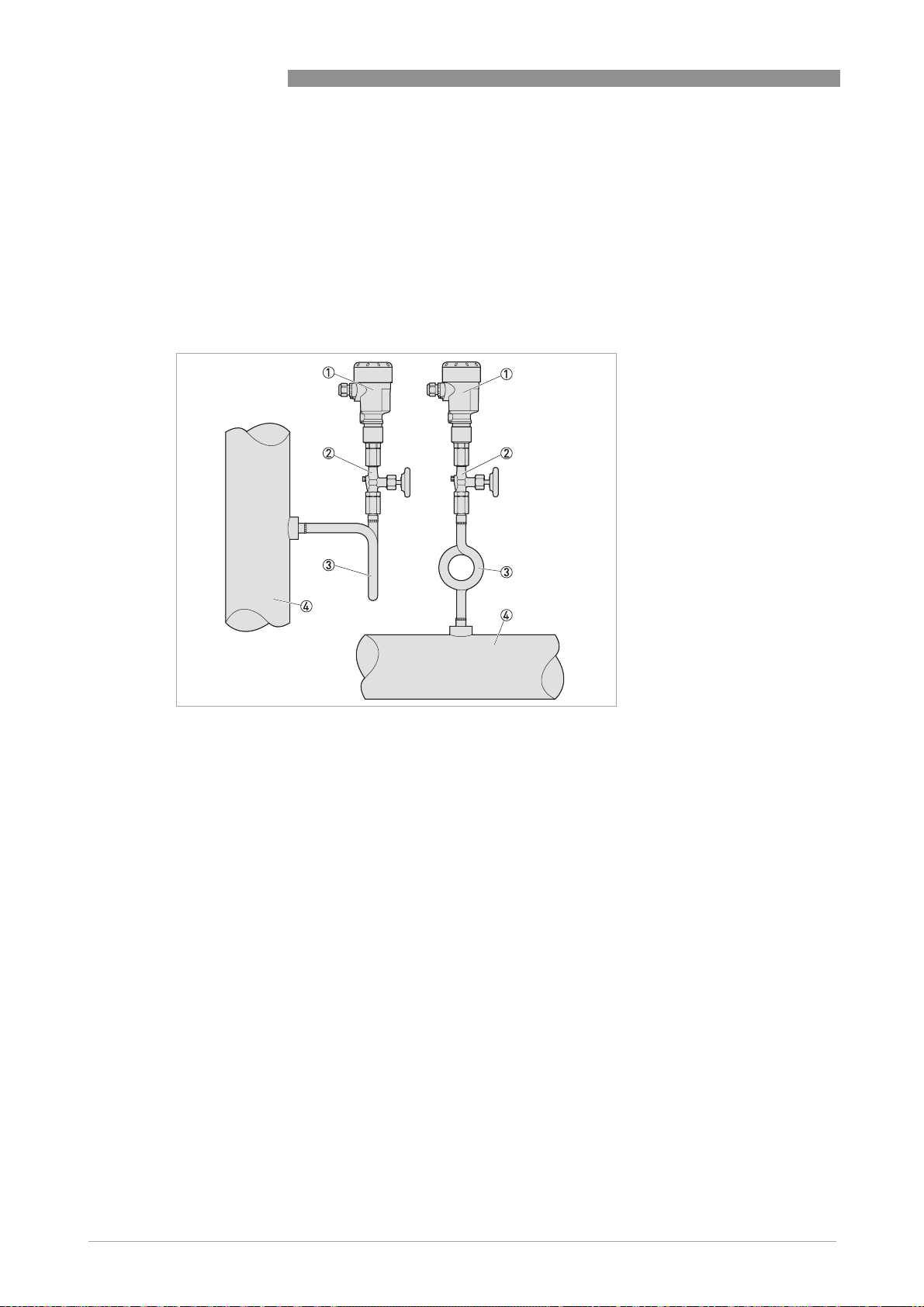

3.11 Measurement setup for steam measurement

The following points should be observed in this application:

• The pressure transmitter should be connected via a siphon to protect the measuring cell

from non-permitted high temperatures.

• Siphon to be kept free of insulation.

• When using superheated steam, the siphon must be filled with water prior to start-up.

OPTIBAR PC 5060 C

Figure 3-8: Measurement setup for steam measurement

1 Pressure transmitter

2 Shut-off valve

3 Siphon

4 Tapping point

24

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 25

OPTIBAR PC 5060 C

3.12 Measurement setup for liquid measurement

The following points should be observed in this application:

• The signal converter must be mounted below the measuring point.

INSTALLATION 3

Figure 3-9: Measurement setup for liquid measurement

1 Tapping point

2 Shut-off valve

3 Pressure transmitter

3.13 Measurement setup for level measurement

The following points should be observed in this application:

• The pressure transmitter should be mounted below the lowest level.

• The pressure transmitter should be protected from filling/emptying current and agitator

surges when mounted.

Figure 3-10: Measurement setup for level measurement

1 Pressure transmitter

2 Tank

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

25

Page 26

3 INSTALLATION

3.14 External housing

A mounting plate is available as an option to facilitate the mounting of the external housing. For

further information refer to

Technical data

OPTIBAR PC 5060 C

on page 59.

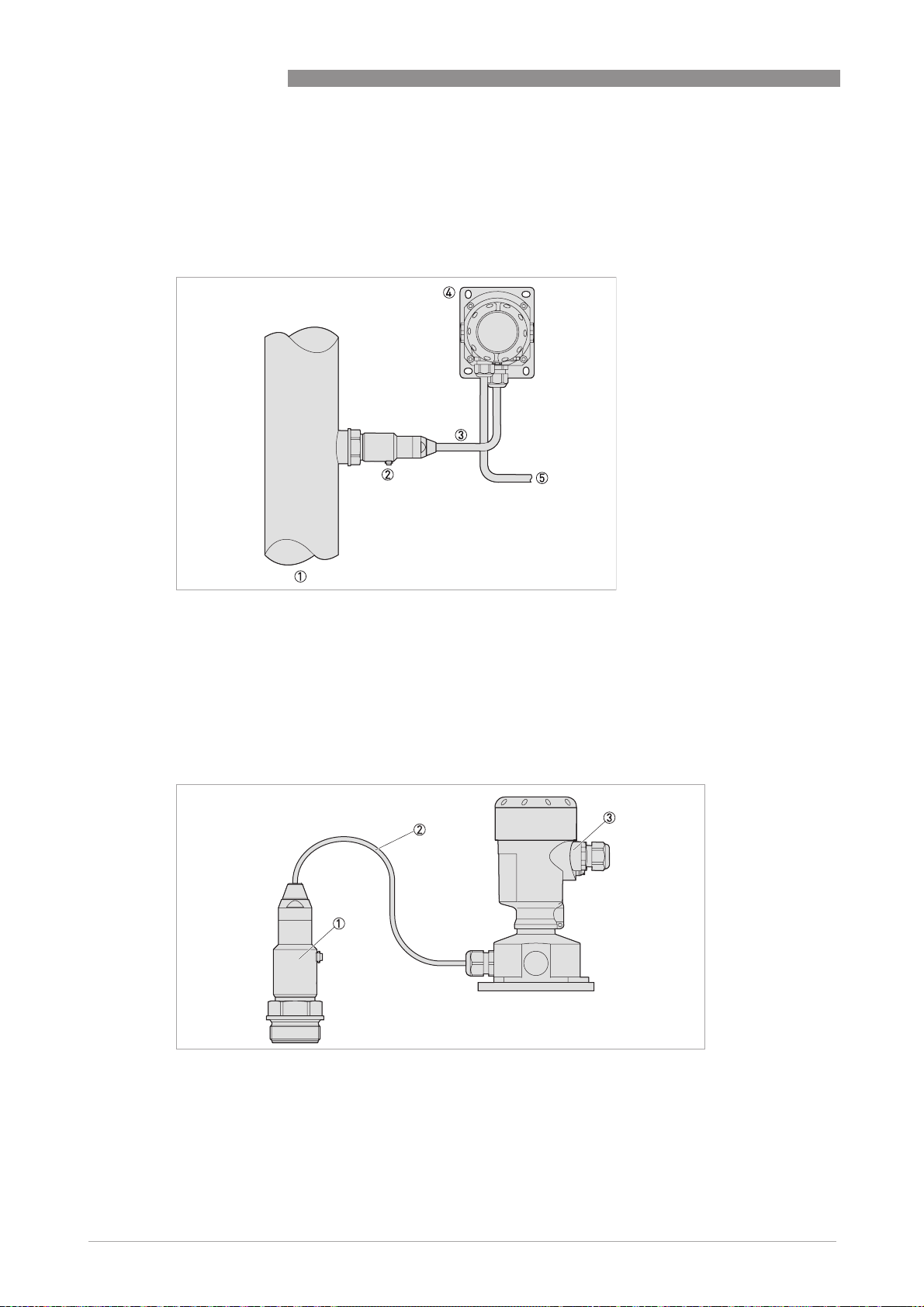

Figure 3-11: Measurement setup with an external housing

1 Tapping point

2 Sensor assembly

3 Connecting cable

4 External housing

5 Signal cable

IP 68 version (25 bar)

26

Figure 3-12: Process assembly

1 Sensor assembly

2 Connection cable

3 External housing

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 27

OPTIBAR PC 5060 C

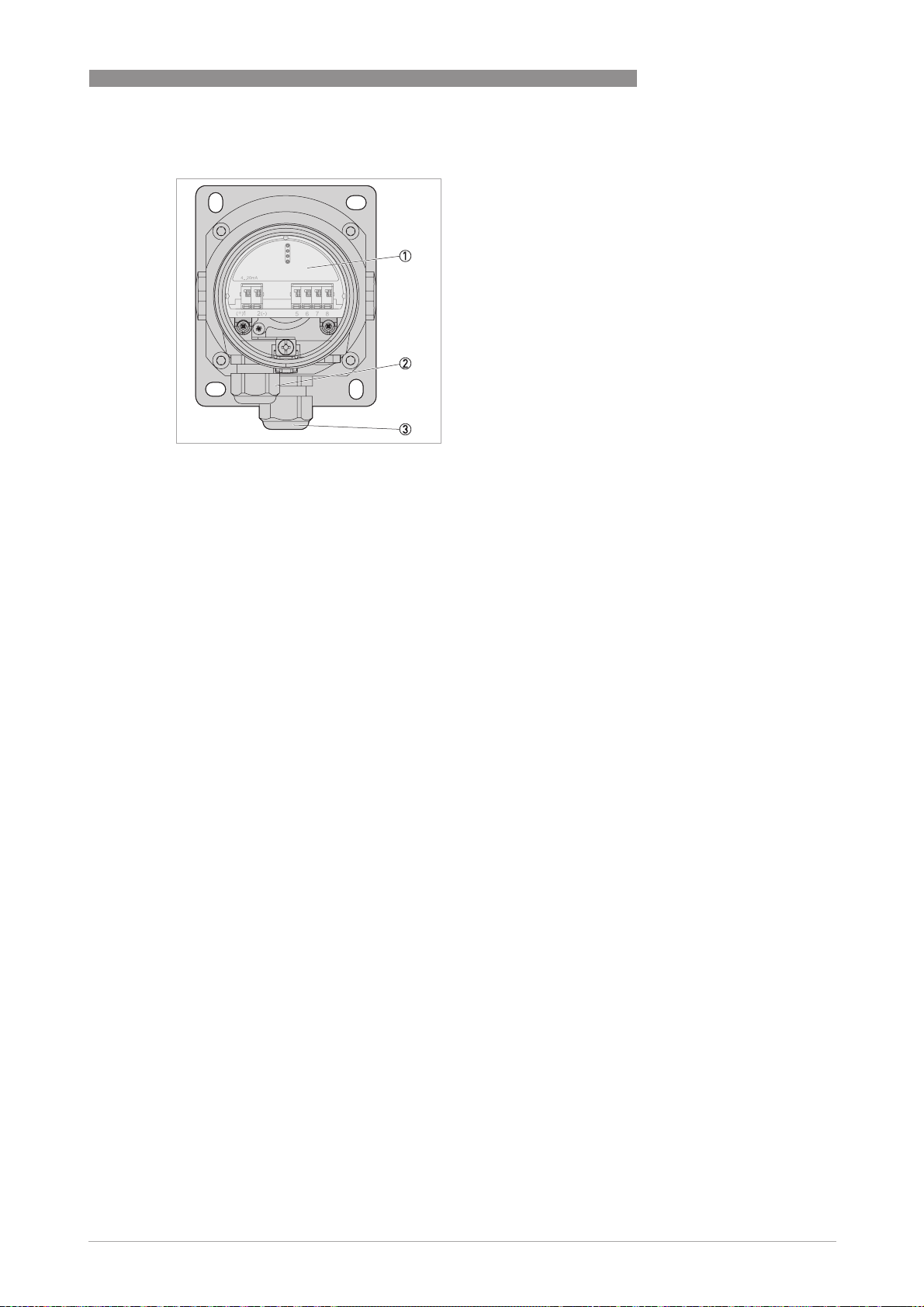

Figure 3-13: External housing (IP 68)

Electronic insert

Cable gland for the power supply

Cable gland for the sensor connection cable

INSTALLATION 3

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

27

Page 28

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

OPTIBAR PC 5060 C

4.2 Notes for electrical cables

DANGER!

The device must be grounded to a spot in accordance with regulations in order to protect

personnel against electric shocks.

DANGER!

Cables may only be connected when the power is switched off! Since the transmitter has no

switch-off elements, overcurrent protection devices, lightning protection and/or energy isolating

devices must be provided by the customer.

28

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 29

OPTIBAR PC 5060 C

ELECTRICAL CONNECTIONS 4

4.2.1 Requirements for signal cables provided by the customer

If the signal cable was not ordered, it is to be provided by the customer. The following

requirements regarding the electrical specifications of the signal cable must be observed:

Specifications for standard signal cables

• Test voltage: ≥ 500 VAC RMS (750 VDC)

• Temperature range: -40...+105°C / -40...+221°F

• Capacity: ≤ 200 pF/m / 61 pF/ft

• Inductance: ≤ 0.7 µH/m / 0.2 µH/ft

• Use cable with round cross section.

• A cable outer diameter of 5…9 mm / 0.2 … 0.35" ensures the seal effect of the cable gland. If

you are using cable with a different diameter or cross-section, exchange the seal or use a

suitable cable gland.

• We generally recommend the use of a shielded cable for HART

4.2.2 Laying electrical cables correctly

®

multidrop mode.

Figure 4-1: Protect housing from dust and water

1 Lay the cable in a loop just before the housing.

2 Tighten the screw connection of the cable entry securely.

3 Never mount the housing with the cable entries facing upwards.

4 Seal cable entries that are not needed with a plug.

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

29

Page 30

4 ELECTRICAL CONNECTIONS

4.2.3 Cable preparation

The device is connected with standard two-wire cable without shielding. If electromagnetic

interference is expected which is above the test values of EN 61326-1 for industrial areas, a

shielded cable should be used.

Check which outer diameter is suitable for the cable gland in order to ensure the sealing effect

according to the specified IP protection class.

• 5...9 mm / 0.20...0.35" (standard)

• 6...12 mm / 0.24...0.47" (optional)

• 10...14 mm / 0.40...0.55" (optional)

The terminals in the terminal compartment are designed for wire cross-sections of up to

1.5 mm². To ensure a proper connection, you should strip the cable 40…50 mm / 1.6...2".

OPTIBAR PC 5060 C

Figure 4-2: Stripping the cable

1 40...50 mm / 1.6...2"

2 5mm/ 0.2"

30

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 31

OPTIBAR PC 5060 C

4.2.4 Cable entry 1/2-14 NPT (female)

With plastic housings, the NPT cable gland or the conduit steel tube must be screwed without

grease into the thread. For further information about max. torque for all housings refer to

Technical data

on page 59.

4.2.5 Connector pin assignment

Figure 4-3: Connector M12 x 1, 4-pin

1 VS+

2 Not connected

3 Not connected

4 VS-

ELECTRICAL CONNECTIONS 4

Contact pin Colour of cable Electronic insert for terminal

Pin 1 Brown 1

Pin 4 Blue 2

Figure 4-4: 7/8 connector, Foundation Fieldbus (FF)

1 VS-

2 VS+

3 Not connected

4 Cable shield

Contact pin Colour of cable Electronic insert for terminal

Pin 1 Blue 1

Pin 2 Brown 2

Pin 4 Green / yellow Grounding

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

31

Page 32

4 ELECTRICAL CONNECTIONS

Figure 4-5: Connector, Harting HAN 8D (left) and Harting HAN 7D (right)

1 VS-

2 VS+

Contact pin Colour of cable Electronic insert for terminal

Pin 1 Black 1

Pin 2 Blue 2

Pin 8 Green / yellow Grounding

OPTIBAR PC 5060 C

4.2.6 Connection to the power supply

Figure 4-6: Connection to the power supply

1 Red

2 Black

3 Power supply with load

32

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 33

OPTIBAR PC 5060 C

4.2.7 Cable shield and grounding

If a shielded cable is necessary, connect the cable shield on both ends to the grounding potential.

In the device, the cable shield must be connected directly to the internal ground terminal.

The ground terminal outside on the housing must be connected to the grounding potential with

low impedance.

DANGER!

In hazardous areas, the grounding is carried out according to the installation instructions.

CAUTION!

Significant potential differences exist inside galvanization plants as well as on vessels with

cathodic corrosion protection. A two-sided shield grounding can cause unacceptably high shield

currents as a result.

CAUTION!

The metallic and wetted parts (process connection, cap flange, measuring cell and separating

diaphragm etc.) are conductive connected with the inner and outer ground terminal on the

housing.

ELECTRICAL CONNECTIONS 4

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

33

Page 34

4 ELECTRICAL CONNECTIONS

4.3 Electrical connection

The connection of the power supply and the signal output is carried out via spring-loaded

terminals in the housing. The display and adjustment module is connected via contact pins with

the interface adapter.

4.3.1 Connection in the terminal compartment

OPTIBAR PC 5060 C

Figure 4-7: Terminal compartment from above

Procedure

• Unscrew the housing cover.

• If present, remove the display and adjustment module by turning it to the left.

• Loosen union nut of the cable gland.

• For preparation of connection cable refer to

• Push the cable through the cable gland into the terminal compartment.

• Insert the wire ends into the open terminals according to the wiring plan. Flexible cores with

cable end sleeves as well as solid cores can be inserted directly into the terminal openings. In

case of flexible cores, press the spring terminal with a small screwdriver to open the terminal

opening.

• Check the proper hold of the wires in the terminals by lightly pulling on them.

• Connect the cable shield to the internal ground terminal, connect the outer ground terminal to

the customer/plant equipotential bonding.

• Tighten the union nut of the cable gland. The sealing ring must completely enclose the cable.

• Screw the housing cover back on.

Cable preparation

on page 30.

34

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 35

OPTIBAR PC 5060 C

ELECTRICAL CONNECTIONS 4

4.3.2 Connection in the housing base (external housing)

Figure 4-8: Terminal box from front

1 Brown

2 Blue

3 Yellow

4 White

5 Shielding

6 Pressure equalisation capillary

Procedure

• Unscrew the housing cover

• If present, remove the display and adjustment module by turning it to the left

• Loosen union nut of the cable gland

• For preparation of connection cable refer to

Cable preparation

• Push the cable through the cable gland into the terminal compartment

• Insert the wire ends into the open terminals according to the wiring plan. Solid cores as well

as flexible cores with cable end sleeves can be inserted directly into the terminal openings. In

case of flexible cores, press the spring terminal with a small screwdriver to open the terminal

opening.

• Check the hold of the wires in the terminals by lightly pulling on them

• Connect the cable shield to the internal ground terminal, connect the outer ground terminal to

the equipotential bonding

• Tighten the union nut of the cable gland. The sealing ring must completely enclose the cable

• Screw the housing cover back on

on page 30

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

35

Page 36

4 ELECTRICAL CONNECTIONS

4.3.3 Single chamber housing

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

The following illustration applies to both the non-Ex as well as the Ex ia, the Ex d and the Ex d ia

version.

Electronics compartment

OPTIBAR PC 5060 C

1 Power supply / signal output

2 Interface adapter for the display and adjustment module

3 Digital interface

4 Ground terminal for connection of the cable shield

36

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 37

OPTIBAR PC 5060 C

4.3.4 Double chamber housing

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

The following illustration applies to both the non-Ex as well as the the Ex ia, and the Ex d version.

Electronics compartment

ELECTRICAL CONNECTIONS 4

1 Internal connection to terminal compartment

2 Interface adapter for the display and adjustment module

Terminal compartment

1 Power supply / signal output

2 Interface adapter for the display and adjustment module

3 Ground terminal for connection of the cable shield

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

37

Page 38

4 ELECTRICAL CONNECTIONS

4.3.5 Double chamber housing Ex d ia

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

Electronics compartment

1 Power supply / signal output

2 Interface adapter for the display and adjustment module

3 Digital interface

OPTIBAR PC 5060 C

Terminal compartment

1 Power supply / signal output

2 Ground terminal for connection of the cable shield

38

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 39

OPTIBAR PC 5060 C

4.4 Grounding the measuring device

WARNING!

Within galvanic plants as well as vessels with cathodic corrosion protection there are

considerable potential differences. Considerably equipotential bonding currents can be caused

via the cable shield when the shield is grounded on both ends. To avoid this, the cable shield

must only be connected to the grounding potential on one side of the control cabinet in such

applications. The cable shield must not be connected to the internal ground terminal in the

device and the outer ground terminal on the housing not to the equipotential bonding!

CAUTION!

The metallic and wetted parts (process connection, cap flange, measuring cell and separating

diaphragm etc) are conductive connected with the inner and outer ground terminal on the

housing.

If a shielded cable is necessary, connect the cable shield on both ends to the grounding potential.

In the signal converter, the cable shield must be connected directly to the internal ground

terminal. The ground terminal outside on the housing must be connected to the equipotential

bonding with low impedance. If equipotential bonding currents are expected, the evaluation side

must be connected with a ceramic capacitor (e.g. 1 nF, 1500 V). The low frequency equipotential

bonding currents are thus suppressed, but the protective effect against high frequency

interference signals remains.

ELECTRICAL CONNECTIONS 4

4.5 Description of the current output

The current output is a 2-wire 4…20 mA output with a low alarm of 3.6 mA and high alarm of

21 mA set by default. A high frequency HART

information on the current output, refer to

®

signal superimposes this signal. For further

Technical data

on page 59.

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

39

Page 40

5 START-UP

5.1 Start-up

The pressure transmitter may only be started up after it has been completely installed and

checked by appropriately qualified personnel. Switch on the operating voltage for start-up. Prior

to applying the operating voltage, it is essential to check the correctness of the process

connection and the electrical connection and ensure that the impulse line has been completely

filled with the process medium. Then proceed with start-up.

Prior to applying the operating voltage check that

1. the process connection fits properly

2. the signal and, if necessary, supply lines are properly connected

3. the impulse lines are completely filled with the process medium

After connecting the differential pressure transmitter to the power supply or after voltage

recovery, the device performs a self test for approximately 10 seconds.

Self test routine

1. Internal check of the electronics.

2. Indication of the device type, hardware and software version as well as the measurement loop

name on the display or PC.

3. Indication of a status message on the display or PC.

4. Output signal jumps to the set alarm current.

5. After that the current measuring value is outputted to the signal cable.

OPTIBAR PC 5060 C

40

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 41

OPTIBAR PC 5060 C

5.2 Keypad functions

INFORMATION!

The device can be configured either via the relevant fieldbus or the adjustment module.

The display and adjustment module is used for indication of measuring values, adjustment and

diagnosis.

START-UP 5

1 LCD display

2 Function buttons

The device is operated via the four keys of the display and adjustment module 2. The LC display

1 indicates the individual menu items. Approx. 60 minutes after the last pressing of a key, an

automatic reset in the indication of measuring values is triggered. Any values not confirmed with

[OK] will not be saved.

[OK]

• Move back to the menu overview

• Confirm selected menu

• Editing the parameters

• Store value

[Z]

• Change measured value

• Select list entry

• Select editing position

[+]

• Change value of the parameter

[ESC]

• Cancel entry

• Jump to next higher menu

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

41

Page 42

5 START-UP

5.3 Quick setup

To quickly and easily adapt the device to the application, select the menu item "Quick setup".

This parameter adjustment essentially involves the selection of the application, position

correction and adjustment of the span.

In this chapter, not all settings are displayed graphically but all settings are described.

OPTIBAR PC 5060 C

1 Measurement loop name

Measurement loop name

Measurement loop nameMeasurement loop name

Assign a suitable measurement loop name

2 Adjustment units

Adjustment units

Adjustment unitsAdjustment units

Determine the adjustment and temperature units of the device.

3 Application

Application

ApplicationApplication

The selection includes process pressure and level.

Adjustment process pressure

1 Sensor mounting correction

Sensor mounting correction

Sensor mounting correctionSensor mounting correction

In this menu item you compensate the influence of the installation position of the device (offset) on the

measured value.

2 Zero

Zero

ZeroZero

In this menu item you determine the zero point of your measurement (LRV)

This value corresponds to the output signal of 4 mA.

3 Span

Span

SpanSpan

This value corresponds 100%, or rather an output signal of 20 mA (URV)

If the zero point is actually 0, this value corresponds to the measuring span.

42

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 43

OPTIBAR PC 5060 C

Adjustment level

1 Sensor mounting correction

Sensor mounting correction

Sensor mounting correctionSensor mounting correction

In this menu item you compensate the influence of the installation position of the device (offset) on the

measured value.

2 Min.-adjustment

Min.-adjustment

Min.-adjustmentMin.-adjustment

Enter the (pressure) value for the min. level.

At 0% this corresponds to the output signal of 4 mA.

3 Max.-adjustment

Max.-adjustment

Max.-adjustmentMax.-adjustment

Enter the (pressure) value for the max. level.

At 100% this corresponds to the output signal of 20 mA.

5.4 Extended adjustment

The main menu is divided into five sections:

• Start-up

• Display

• Diagnosis

• Additional adjustments

• Info

START-UP 5

5.4.1 Start-up

Measurement

loop name

Application In this menu item you select the application: process pressure and level are available. The default

Units In this menu item the adjustment units, as well as the temperature unit are determined. The selection

Assign a unique device ID. This is useful or even necessary in digital systems and for monitoring large

systems.

setting is process pressure.

of the adjustment unit determines the unit displayed in the "Min-adjustment" and "Max-adjustment"

items. In "Level" mode, it is possible to carry out the adjustment in a height unit (e.g. meters). To do

so, the density of the medium must also be specified.

Adjustment units Process pressure

Temperature unit °C, °F and K

Process pressure

Process pressureProcess pressure

mbar, bar, Pa, kPa, MPa, psi, mmH2O,

mmHg, inH2O, inHg and user-defined

Level

Level

LevelLevel

Density input required:

mm, cm, m, in and ft

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

43

Page 44

5 START-UP

OPTIBAR PC 5060 C

Sensor

mounting

correction

Adjustment Adjustment refers to setting the zero point (zero) and maximum measured value (span). These values

Damping For the damping of process-dependent measured value fluctuations, you can choose a suitable

Linearization A linearization is necessary for all vessels in which the vessel volume does not increase linearly with

The mounting position of the device has a great impact on the measured value (offset), especially with

small measuring ranges and isolating systems. The position correction compensates for this offset.

The position correction can automatically take on the current measured value as correction value

(auto correct). Alternatively, this correction value can also be entered manually using the "Edit"

function. Once the position has been corrected, the measured value is corrected to 0. Position

correction can compensate for a maximum of 20% of the nominal measuring range.

Offset Input in adjustment unit, automatic transfer

correspond to the values of 4 and 20 mA. If the adjustment ranges are exceeded, the message

"Outside parameter limits" is displayed.

Min.-adjustment / Zero Process pressure

Max.-adjustment / Span Process pressure

integration time. The values which can be entered are from 0 … 999 seconds with an increment of 0.1

seconds.

Integration time In 0.1 second increments

the level, e.g. in a horizontal cylindrical or spherical tank, and the indication or output of the volume is

required. Corresponding linearization curves are preprogrammed for these vessels. They represent

the correlation between the level percentage and vessel volume. By activating the appropriate curve,

the volume percentage of the vessel is displayed correctly. Enter the desired parameters using the

function buttons and save the entries. Note the following if the pressure transmitter with

corresponding approval is used as part of an overfill protection system according to WHG (Water

Resources Act): If a linearization curve is selected, the measuring signal is no longer linearly

proportional to the level. This must be taken into consideration by the user, particularly when setting

the switching point on the limit signal indicator.

of the current measured value

Process pressure

Process pressureProcess pressure

Zero in %, pressure

Level (standard 0%)

Level (standard 0%)

Level (standard 0%)Level (standard 0%)

Min. in X %, pressure or filling height

Process pressure

Process pressureProcess pressure

Span in %, pressure

Level (standard 100%)

Level (standard 100%)

Level (standard 100%)Level (standard 100%)

Min. in X %, pressure or filling height

Type of linearization Level

Current output In the current output menu, the saturation region for above or below a threshold is set. Under

Lock

adjustment /

Unlock

adjustment

"Current output min./max." these limit values can be set. The factory setting is 3.8 mA and 20.5 mA.

This corresponds to the NAMUR recommendation NE 43.

Mode Output characteristic 0...100% = 4...20 mA or

Failure mode ≤ 3.6 mA, ≥ 21 mA, last valid measured value

Min. and

Max.

In this menu item, a 4-digit PIN can be activated, which protects against undesirable or unintended

changes of the settings. With a PIN active, remote access via software or other systems is also no

longer possible.

Run now

Min. current 3.8 mA, 4 mA

Max. current 20.5 mA, 20 mA

Level

LevelLevel

Linear, Horiz.cylinder, Sphere and User

programmable

0...100% = 20...4 mA

44

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 45

OPTIBAR PC 5060 C

5.4.2 Display

START-UP 5

Menu language In this menu item you can set the desired language.

Displayed value

1 and 2

Backlight A backlight on the display is available, which can be turned on or off in this menu. By default, this

Factory settings: English

German, English, French, Spanish, Portuguese, Italian, Dutch, Russian, Turkish, Polish and Czech

In this menu item you can define how the measured value should be presented on the display.

The factory setting is "Linear percent".

"Level" Filling height or Process pressure (Adjustment

units), Percent, Scaled, Current output, Linear

percent, Meas. cell temp. and Electronics

temperature

"Process pressure" Process pressure, Percent, Scaled, Current

output, Linear percent, Meas. cell temp. and

Electronics temperature

function is disabled.

Off, On

5.4.3 Diagnosis

Device status Status signals Check function, Out of Specification, Maintenance required, Failure

Peak value The respective minimum and maximum pressure values are stored in the device. Under "Peak

Simulation In menu item "Simulation", measured values can be simulated via the current output. These are

values", these values can be viewed or reset. In addition to the pressure, the minimum and maximum

values of the sensor cell and the electronics temperature is stored. These can be viewed or reset

here.

Peak value

"Process pressure"

Peak value

"Meas. cell temp."

Peak value

"Electronics temperature"

issued as both analogue and digital (via HART

minutes after the last key stroke.

For applications

"Process pressure"

For applications

"Level"

Reset peak value

Reset peak value

Reset peak value

®

). The simulation is automatically cancelled 60

Process pressure, Percent, Current output, Linear percent, Meas.

cell temp. and Electronics temperature

Filling height or Process pressure (Adjustment units), Percent,

Current output, Linear percent, Meas. cell temp. and Electronics

temperature

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

45

Page 46

5 START-UP

5.4.4 Additional adjustments

OPTIBAR PC 5060 C

PIN In this menu item the PIN can be changed. This option is only available if it has been enabled under

Date / Time Internal clock setting

Reset For further information refer to

Copy instrument

settings

Special

parameters

Scaling In menu item "Scaling variable" you define the scaling variables and the scaling unit for the level

Current output In this menu item it is determined which measured variable relates to which current output. Under

"Setup - Lock adjustment". The PIN is "0000" by default factory conditions.

0000 Change PIN

Write date, time, data in device

Reset

on page 47.

Delivery status and Basic settings

For further information refer to

Copy instrument settings

Changing these settings is possible only after consultation with a service employee.

mode.

In menu item "Scaling format" you define the scaling format on the display and the scaling of the

level measurement for 0% and 100%.

Scaling variable Scaling variable

Scaling format Scaling format

"Current output - Adjustment", the current output can be assigned a corresponding measured

value.

Current output

variable

Current output,

adjustment

Saving the device settings

Scaling unit

100% corresponds - user-defined value

0% corresponds - user-defined value

For applications "Level"

Filling height or Process pressure (Adjustment units), Percent, Scaled,

Linear percent, Meas. cell temp. and Electronics temperature

For applications "Process pressure"

Process pressure, Percent, Linear percent, Meas. cell temp. and

Electronics temperature

0% = 0% or 100% = 100%

on page 48.

HART® mode The pressure transmitter offers the HART® modes "Analogue current output" and "Fix current (4

mA). Under "Fix current (4 mA)", up to 64 sensors can be operated on a two-wire multidrop mode.

Each device must be assigned a HART

mA. Under "Analogue current output", however, a 4…20 mA signal can also be issued for the

assigned HART

HART® address

Output mode

®

address in multidrop mode.

0...63

Analogue current output with HART® or Fix current (4 mA) with HART

®

address between 0 und 63. The analogue signal is fixed at 4

5.4.5 Info

Device name Device name

Serial number

Instrument version Software version

Hardware version

Factory calibration Factory calibration date

Date of last change

Sensor characteristics Order-related device characteristics

46

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

®

Page 47

OPTIBAR PC 5060 C

5.5 Reset

The reset function resets specific user entries. There are two reset functions available:

Delivery status

Delivery status

Delivery statusDelivery status

Restore the default values at the time of delivery, including the order-specific settings. A false

signal suppression, user programmable linearization curve as well as the measured value

memory will be deleted.

Basic settings

Basic settings

Basic settingsBasic settings

Reset the set data, including special parameters to the default values of the manufacturer. A

false signal suppression, user programmable linearization curve as well as the measured value

memory will be deleted.

The following menu items are affected during a reset

Menu item Parameter Default

Measurement loop name Sensor

Application No reset

Unit Adjustment units mbar (cell ≤ 400 mbar)

Sensor mounting correction 0.00 bar

Adjustment Zero / Min.-adjustment 0.00 bar - 0.00%

Damping Integration time 0.0 seconds

Current output Current output mode Output characteristic 4...20 mA

Lock adjustment Unlock

Language English

Displayed value 1 Current output in %

Displayed value 2 Meas. cell temp. in °C

Backlight Off

Simulation Process pressure

PIN 0000

Scaling Scaling variable Volume in L

HART® mode

START-UP 5

bar (cell ≥ 1 bar)

Temperature unit C°

Span / Max.-adjustment +URL in bar - 100%

Failure mode ≤ 3.6 mA

Current output variable Linear percent - Level

Current output, adjustment 0...100% = 4...20 mA

Current output min./max. Min. 3.8 mA

Max. 20.5 mA

Scaling format 0% = 0 L / 100% = 0 L

Address 0

www.krohne.com04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

47

Page 48

5 START-UP

5.6 Saving the device settings

We recommended noting the parameters and archiving them afterwards. They are thus available

for multiple use or service purposes. If the pressure transmitter is equipped with a display and

adjustment module, the most important data can be read out of the sensor into the display and

adjustment module. The data remain there permanently even if the sensor power supply fails. If

it is necessary to exchange the signal converter, the display and adjustment module is inserted

into the replacement device and the data are written into the signal converter under the menu

item "Copy device data".

5.7 Diagnosis memory

The device has several internal memories which are available for diagnosis purposes. The data

remain even with voltage interruption.

Measured value memory

Measured value memory

Measured value memoryMeasured value memory

Up to 60,000 measured values can be stored in a ring memory. Each entry contains a time stamp

as well as the respective measured value. Storable values are for example:

• Process pressure

• Level

• Percent value

• Linear percent

• Scaled values

• Meas. cell temp.

• Electronic temperature

OPTIBAR PC 5060 C

With the default factory settings, the measured value memory is active and stores distance,

measurement reliability and electronics temperature every minute. The requested values and

TM

recording conditions are set via a PC with PACTware

/DTM or the control system with EDD.

48

www.krohne.com 04/2014 - 4003437201 - MA OPTIBAR PC 5060 C R01 en

Page 49

OPTIBAR PC 5060 C

Event memory

Event memory

Event memoryEvent memory

Up to 500 events are automatically stored with a time stamp in the event memory (nondeletable). Each entry contains the date/time, event type, event description and value. Event

types are for example:

• Modification of a parameter

• Switch on and shut off times

• Status message acc. to NE 107

• Error message acc. to NE 107

The data are read out via a PC with PACTware

5.8 Failures and diagnostics

The operator of the system is responsible for taking suitable measures to remove interferences.

The differential pressure transmitter offers maximum reliability. Nevertheless, faults can occur

during operation. The first measures are to evaluate the error messages, check the output

signals as well as the verification of measurement errors.

START-UP 5

TM

/DTM or the control system with EDD.

Asset Management and diagnostics acc. to NE 107

Asset Management and diagnostics acc. to NE 107

Asset Management and diagnostics acc. to NE 107Asset Management and diagnostics acc. to NE 107

The device features self-monitoring and diagnostics according to NE 107 and VDI/VDE 2650. In

addition to the status messages in the following tables there are more detailed error messages

available under the menu item "Diagnostics" via the display and adjustment module,

TM

PACTware

Status messages

Status messages

Status messagesStatus messages

/DTM and EDD.

The status messages are divided into the following categories in accordance with NE 107:

• Failure

Failure

FailureFailure

Due to a malfunction in the device, a failure message is outputted. This status message is

always active. It cannot be deactivated by the user.