Page 1

Technical Datasheet

Technical Datasheet

OPTIWAVE 6500 C

OPTIWAVE 6500 C

OPTIWAVE 6500 COPTIWAVE 6500 C

Technical DatasheetTechnical Datasheet

80 GHz Radar (FMCW) Level Transmitter for powders

and dusty atmosphere

•

Flush-mounted PEEK Lens antenna hence no intrusion into tank

•

Extremely high dynamics for reliable measurement despite dusty conditions

•

Easy installation due to small beam angles

© KROHNE 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 2

CONTENTS

OPTIWAVE 6500 C

1 Product features 3

1.1 The FMCW radar level transmitter for powders and dusty atmosphere ........................ 3

1.2 Applications ...................................................................................................................... 4

1.3 Product family .................................................................................................................. 5

1.4 Measuring principle.......................................................................................................... 9

2 Technical data 10

2.1 Technical data................................................................................................................. 10

2.2 Minimum power supply voltage ..................................................................................... 15

2.3 Measuring accuracy ....................................................................................................... 15

2.4 Guidelines for maximum operating pressure................................................................ 18

2.5 Dimensions and weights ................................................................................................ 20

3 Installation 25

3.1 Intended use ................................................................................................................... 25

3.2 Pre-installation requirements ....................................................................................... 25

3.3 Installation...................................................................................................................... 26

3.3.1 Pressure and temperature ranges....................................................................................... 26

3.3.2 Recommended mounting position........................................................................................ 27

3.3.3 Mounting restrictions............................................................................................................ 28

3.3.4 Process connections............................................................................................................. 29

4 Electrical connections 31

4.1 Electrical installation: 2-wire, loop-powered ................................................................ 31

4.2 Non-Ex devices............................................................................................................... 31

4.3 Devices for hazardous locations .................................................................................... 31

4.4 Networks ........................................................................................................................ 32

4.4.1 General information.............................................................................................................. 32

4.4.2 Point-to-point connection..................................................................................................... 32

4.4.3 Multi-drop networks ............................................................................................................. 33

5 Order information 34

5.1 Order code ...................................................................................................................... 34

6 Notes 39

2

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 3

OPTIWAVE 6500 C

PRODUCT FEATURES

1.1 The FMCW radar level transmitter for powders and dusty atmosphere

This device is a non-contact radar level transmitter that uses FMCW technology. It measures

distance, level and volume of powders, granulates and other solids. It is ideal for measuring the

level of solids in applications with very dusty atmospheres.

1

1 Aluminium or stainless steel housing

2 Large, backlit LCD screen with 4-button keypad can be used with a bar magnet without opening the housing cover. The

software has a quick setup assistant for easy commissioning. 12 languages are available.

3 2-wire 80 GHz FMCW radar level transmitter

4 PEEK Lens antenna design

Highlights

• KROHNE is the pioneer of FMCW radar level measurement and has more than 28 years of

experience with this technology

• 2-wire loop-powered 80 GHz transmitter – HART® 7

• Accuracy: ±2mm/ ±0.08¨

• PEEK Lens antenna options include:

- DN70 / 2¾¨ antenna with 4° beam angle suitable for long nozzles and distances up to

100 m / 328 ft

- DN40 / 1½¨ antenna with 8° beam angle, available with 1½¨ thread connections, measures

up to 30 m / 98 ft

- 112 mm / 4.4¨ antenna extension for long nozzles

• Antenna purging system for flange connection without antenna extension

• Extensive choice of process connections (threaded ≥1½¨ and flange ≥DN50 / 2¨)

• One user interface for all applications

• Empty tank spectrum function eliminates false reflections caused by tank internals

• Extensive choice of process connections (threaded ≥1½¨ and flange ≥DN50 / 2¨)

• Extremely high dynamics with considerable signal-to-noise ratio for clear vision in dusty

atmospheres

• 4 GHz sweep for high resolution

• Low-cost low-pressure disc flange

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

3

Page 4

1

PRODUCT FEATURES

• No need for antenna aiming kits. A slanted flange can be installed if necessary.

Industries

• Metals, Minerals & Mining

• Chemical market

• Power

• Agri-food

• Wastewater

• Pulp & Paper

Applications

• High and narrow silos

• Buffer silos

• Bulk storage containers or hoppers

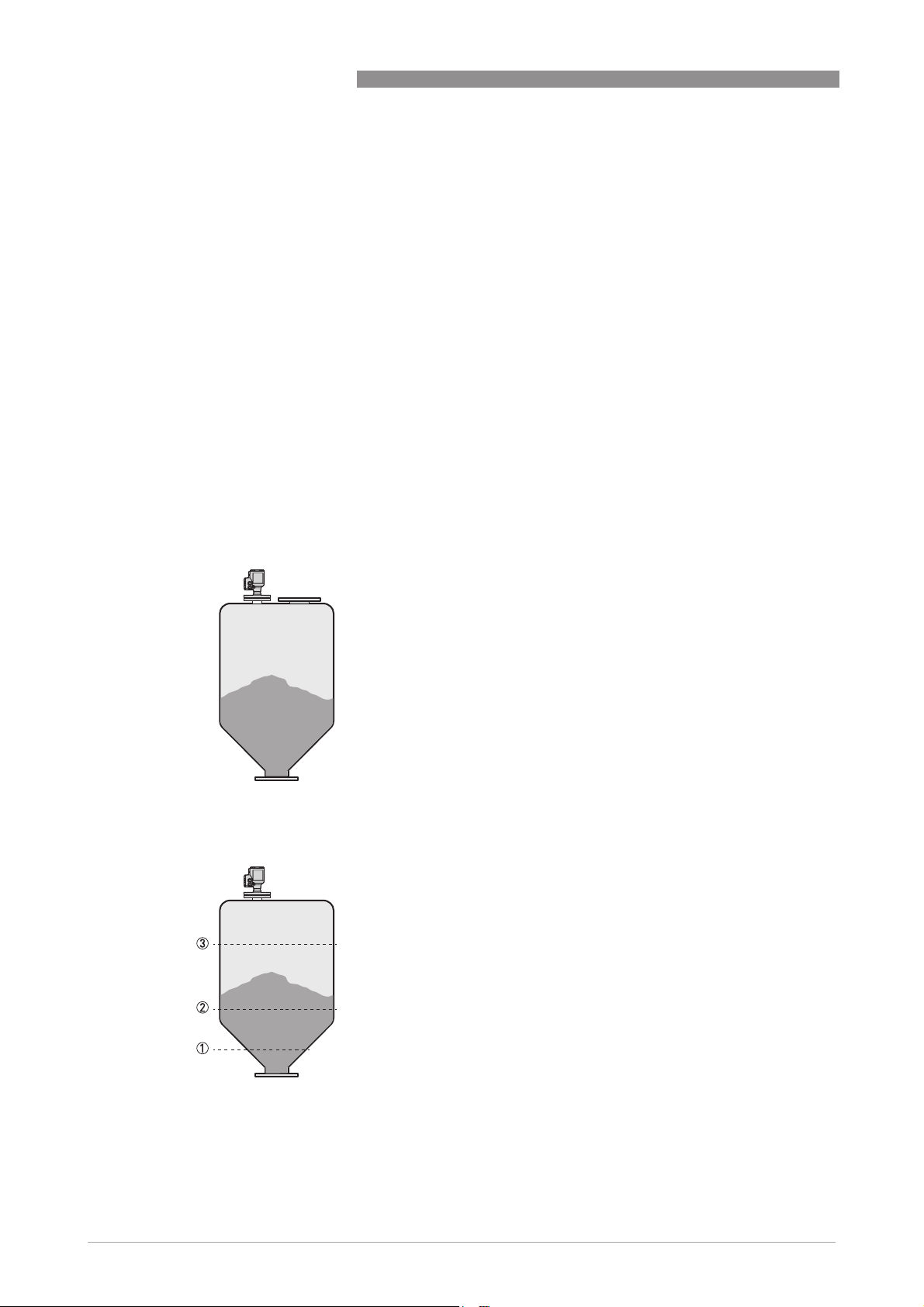

1.2 Applications

OPTIWAVE 6500 C

1. Level measurement of solids

2. Mass (volume) measurement

The level transmitter can measure the level of a

wide range of solid products on a large variety of

installations within the stated pressure and

temperature range. It does not require any

calibration: it is only necessary to do a short

configuration procedure.

A strapping table function is available in the

configuration menu for volume or mass

measurement. Up to 50 mass (volume) values can be

related to level values. For example:

Level 1= 2 m / Mass 1= e.g. 100 kg

Level 2= 10 m / Mass 2= e.g. 500 kg

Level 3= 20 m / Mass 3= e.g. 1000 kg

This data permits the device to calculate (by linear

interpolation) volume or mass between strapping

table entries.

PACTware™ software and a DTM (Device Type

Manager) is supplied free of charge with the device.

This software permits the user to easily configure

the device with a computer. It has a conversion table

function with a large number of tank shapes.

4

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 5

OPTIWAVE 6500 C

1.3 Product family

OPTIWAVE 1010 (6 GHz)

for liquids in bypass chambers

PRODUCT FEATURES

The OPTIWAVE 1010 is a non-contact FMCW radar

welded to a bypass chamber with an optional IP68

level indicator (BM 26 Advanced). It continuously

measures the distance and level of clean liquids.

It measures in bypass chambers up to 8 m / 26.2 ft

high with a maximum accuracy of ±5mm/ ±0.2¨. It

can measure in process conditions with

temperatures up to +150°C / +302°F and pressures

up to 40 barg / 580 psig.

1

OPTIWAVE 5200 C/F (10 GHz)

for liquids in storage and process applications

This 10 GHz 2-wire FMCW radar level transmitter

measures distance, level, volume, mass and flow

rate of liquids and pastes. It is ideal for corrosive

products with its PP or PTFE antenna options. It

features unique PP and PTFE antennas for

aggressive products. The device is able to measure

distances up 30 m / 98.4 ft in process conditions up

to +250°C / +482°F and 40 barg / 580psig.

The device agrees with SIL2 requirements for

safety-related systems (as per IEC 61508). Output

options include HART®, FOUNDATION™ fieldbus

and PROFIBUS PA industrial communication

protocols.

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

5

Page 6

1

PRODUCT FEATURES

OPTIWAVE 5400 C (24 GHz)

for liquids in basic process applications

OPTIWAVE 6500 C

Designed for basic liquid applications, this market

entry 24 GHz 2-wire FMCW radar transmitter

provides accurate readings even in fast moving

processes, in closed tanks or in the open air like

rivers or dams. Its proven PP Drop antenna is

insensitive to condensation.

The OPTIWAVE 5400 can measure in process

conditions with temperatures up to +130°C / +266°F

and pressures up to 16 barg / 232 psig. The antenna

options permit to measure distances up to 100 m /

328 ft. The device can be installed in high nozzles

(≤1 m / 3.28 ft) when it is fitted with antenna

extensions.

OPTIWAVE 7400 C (24GHz)

for agitated and corrosive liquids

This 24 GHz FMCW radar level transmitter is

designed for liquids in harsh environment like tanks

with agitators containing corrosives or in non-Ex

applications with extremely high process

temperatures, like molten salt in solar plants

(+700°C / +1292°F). For toxic and dangerous

products, the use of a Metaglas® second sealing

barrier is recommended.

The PTFE and PEEK Drop antennas have optional

flange plate protection for corrosive media. Heating

and cooling systems prevent from crystallization

inside the Metallic Horn antennas. The device

measures distances up to 100 m / 328 ft and can be

installed in high nozzles (≤1 m / 3.28 ft) when fitted

with antenna extensions. Standard process

conditions up to +200°C / 392°F; 100 barg / 1450 psig

(higher on request).

6

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 7

OPTIWAVE 6500 C

OPTIWAVE 7500 C (80 GHz)

for liquids in narrow tanks with internal obstructions

The small beam angle and negligible dead zone of

this 80 GHz FMCW radar level transmitter makes it

the premium choice for liquids in small and narrow

tanks with internal obstructions like agitators or

heating coils, as well as tanks with long nozzles. It

can even measure through tank roofs made of nonconductive material (e.g. plastic, fiberglass or

glass). The flush-mounted PEEK Lens antenna (no

tank intrusion) is insensitive to deposit.

There is an extensive choice of process connections

starting

plate protection for corrosive tank contents. The

OPTIWAVE 7500 operates in process conditions with

temperatures up to +150°C / +302°F and pressures

up to 40 barg / 580 psig. It measures distances up to

100 m / 328 ft and a 112 mm / 4.4¨ extension is

available for high nozzles.

PRODUCT FEATURES

from ¾¨. Flanges have an optional PEEK

1

OPTIWAVE 3500 C (80 GHz)

for liquids with hygienic requirements

This 80 GHz FMCW radar transmitter for hygienic

liquid applications in the pharmaceutical, food and

beverage industries is CIP-SIP suitable and offers a

large choice of hygienic process connections:

Tri-Clamp®, Tuchenhagen VARIVENT®, SMS,

DIN 11851, DIN 11864-1 Form A, NEUMO

BioControl®.

The small dead zone and beam angle of its

flush-mounted Lens antenna enables precise

measurement even in small and narrow tanks with

agitators. The OPTIWAVE 3500 measures up to

50 m / 164 ft in process conditions up to +150°C/

+302°F and 25 barg / 363 psig.

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

7

Page 8

1

PRODUCT FEATURES

OPTIWAVE 6400 C (24 GHz)

for solids from granulates to rocks

OPTIWAVE 6500 C

By combining high signal dynamics and FMCW radar

technology, this market-entry 24 GHz radar device

measures accurately and reliably the level of solids

like stone, plastic granulates or coffee beans. No

need for expensive antenna aiming kits or purging

systems; the proven Drop antenna design minimizes

scaling and is not affected by the angle of repose.

It operates in process conditions with temperatures

up to +130°C / +266°F and pressures up to 16 barg /

232 psig. The antenna options permit the device to

measure distances up to 100 m / 328 ft.

OPTIWAVE 6500 C (80 GHz)

for powders and dusty atmosphere

Accurate continuous level measurement of fine

powders has to deal with a series of issues like dust,

low-reflective media, build-up and uneven surfaces.

The specific algorithms and high signal dynamics of

this 80 GHz FMCW radar transmitter are the key to

provide reliable and accurate readings despite these

difficult conditions. Thanks to the small beam angle

of the flush-mounted Lens antenna, this powerful

device handles high and narrow silos even in the

presence of internal obstructions.

The OPTIWAVE 6500 operates in process conditions

with temperatures up to +200°C / +392°F and

pressures up to 40 barg / 580 psig. It offers an

extensive choice of threaded (≥1½¨) and flanged

(≥DN50 / 2¨) process connections. The antenna

options permit the device to measure distances up to

100 m / 328 ft. A 112 mm / 4.4¨ extension is available

for high nozzles.

8

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 9

OPTIWAVE 6500 C

1.4 Measuring principle

A radar signal is emitted via an antenna, reflected from the product surface and received after a

time t. The radar principle used is FMCW (Frequency Modulated Continuous Wave).

The FMCW-radar transmits a high frequency signal whose frequency increases linearly during

the measurement phase (called the frequency sweep). The signal is emitted, reflected on the

measuring surface and received with a time delay, t. Delay time, t=2d/c, where d is the distance

to the product surface and c is the speed of light in the gas above the product.

For further signal processing the difference Δf is calculated from the actual transmitted

frequency and the received frequency. The difference is directly proportional to the distance. A

large frequency difference corresponds to a large distance and vice versa. The frequency

difference Δf is transformed via a Fast Fourier Transform (FFT) into a frequency spectrum and

then the distance is calculated from the spectrum. The level results from the difference between

the tank height and the measured distance.

PRODUCT FEATURES

1

Figure 1-1: Measuring principle of FMCW radar

1 Transmitter

2 Mixer

3 Antenna

4 Distance to product surface, where change in frequency is proportional to distance

5 Differential time delay, Δt

6 Differential frequency, Δf

7 Frequency transmitted

8 Frequency received

9 Frequency

10 Time

Measurement modes

"Direct" mode

"Direct" mode

"Direct" mode"Direct" mode

The device uses the largest radar signal to monitor level.

"Direct Plus" mode

"Direct Plus" mode

"Direct Plus" mode"Direct Plus" mode

If it is possible there will be an interference signal in the measurement zone that is larger than

the level signal, select "Direct Plus" mode. If you select "Direct Plus" mode, the device locks on

the level signal and monitors changes in level. If the device then finds larger reflections in the

silo, it will only monitor the largest signal in a small search zone around the first reflection found

and ignore all other reflections. The interference signal must not be near to the level signal.

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

9

Page 10

2

TECHNICAL DATA

OPTIWAVE 6500 C

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

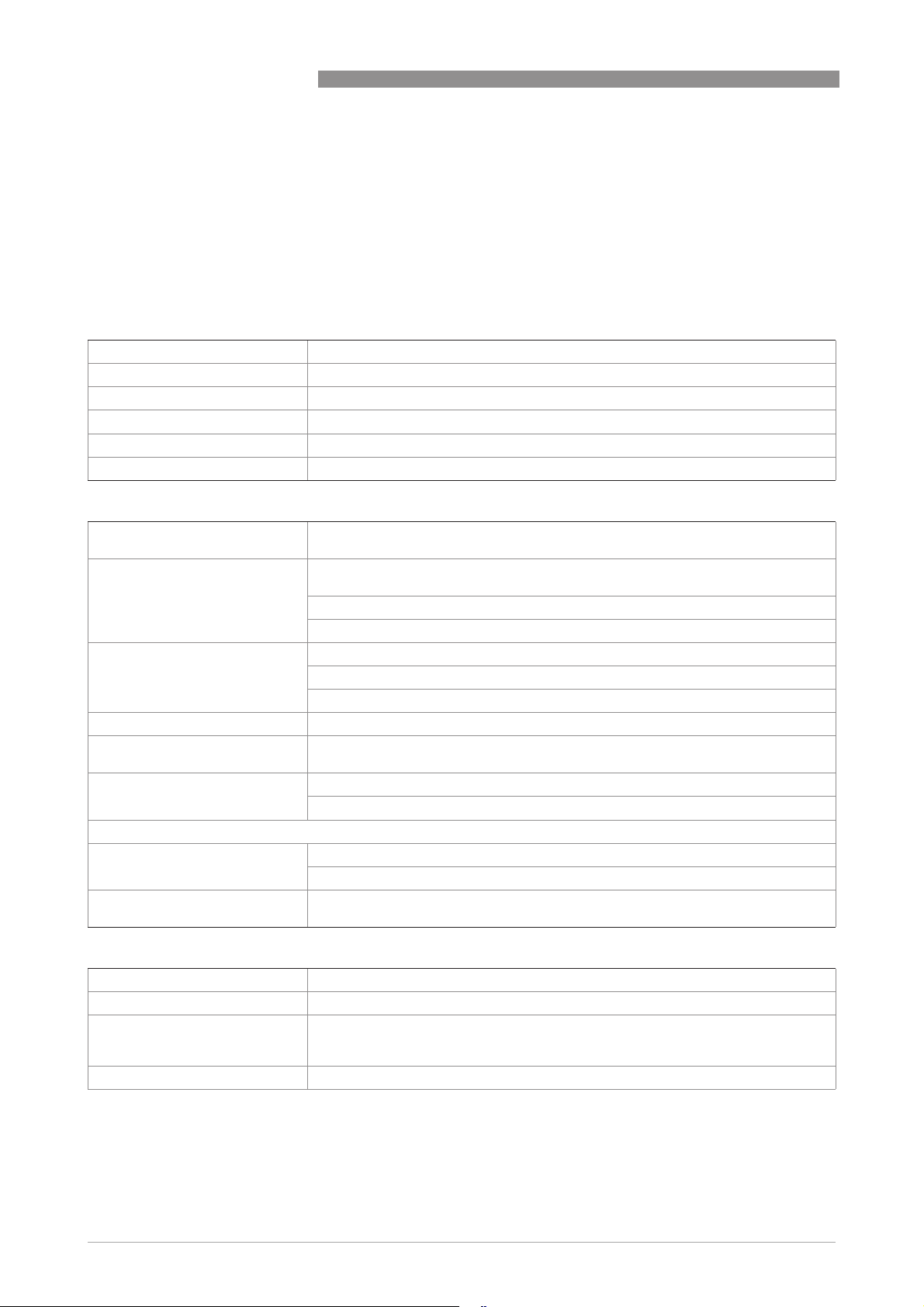

Measuring system

Measuring principle 2-wire loop-powered level transmitter; FMCW radar

Frequency range W-band (78...82 GHz)

Max. radiated power (EIRP) < -41.3 dBm according to ETSI EN 307 372 (TLPR) and ETSI EN 302 729 (LPR)

Application range Level measurement of powders and granulates

Primary measured value Distance and reflection

Secondary measured value Level, volume and mass

Design

Construction The measurement system consists of a measuring sensor (antenna) and a signal

Options Integrated LCD display (-20..+70°C/ -4…+158°F); if the ambient temperature is not

Max. measuring range Lens, DN40 (1½¨): 50 m / 164 ft

Min. tank height 1m/ 40¨

Recommended minimum

blocking distance

Beam angle

(antenna)

Display and user interface

Display and user interface

Display and user interfaceDisplay and user interface

Display Backlit LCD display

Interface languages English, French, German, Italian, Spanish, Portuguese, Chinese (simplified),

converter

in these limits, then this condition can stop the display

Distance piece (for process temperature: +150...+200°C / +302...+392°F)

Weather protection

Lens, DN70 (2¾¨): 100 m / 328.1 ft

Refer also to "Measuring accuracy" on page 15

0.3 m / 12¨ (add 112 mm / 4.4¨ if the DN40 Lens antenna has antenna extension)

Lens, DN40 (1½¨): 8°

Lens, DN70 (2¾¨): 4°

128 × 64 pixels in 64-step greyscale with 4-button keypad

Japanese, Russian, Czech, Polish and Turkish

Measuring accuracy

Resolution 1mm/ 0.04¨

Repeatability ±1mm/ ±0.04¨

Accuracy Standard: ±2mm/ ±0.8¨, when distance ≤ 10 m / 33 ft;

Digital temperature drift Max. ±10 mm / ±0.39¨ for the full temperature range

10

±0.02% of measured distance, when distance > 10 m / 33 ft. For more data, refer to

Measuring accuracy

on page 15.

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 11

OPTIWAVE 6500 C

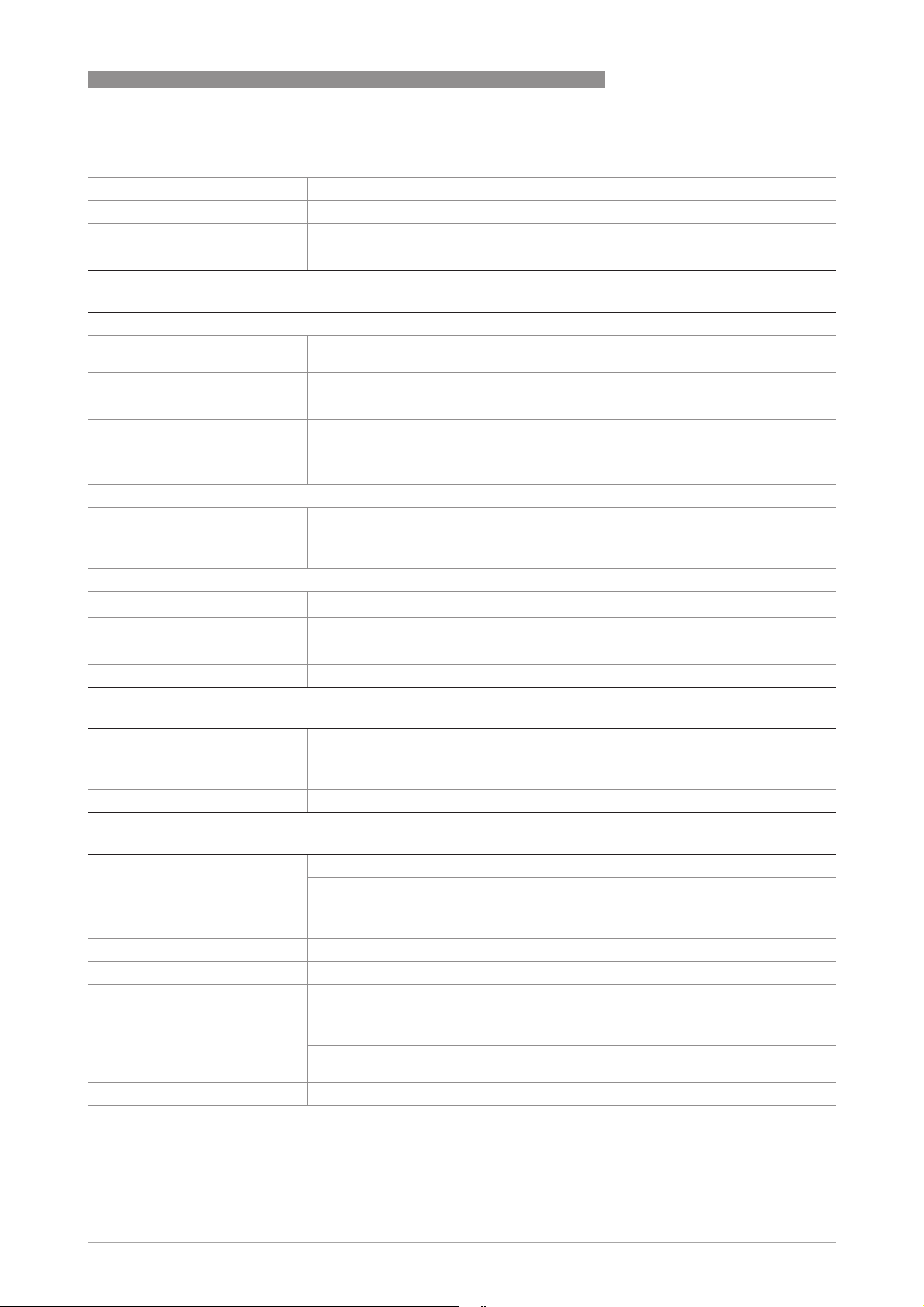

Reference conditions acc. to EN 61298-1

Reference conditions acc. to EN 61298-1

Reference conditions acc. to EN 61298-1Reference conditions acc. to EN 61298-1

Temperature +15...+25°C / +59...+77°F

Pressure 1013 mbara ±50 mbar / 14.69 psia ±0.73 psi

Relative air humidity 60% ±15%

Target Metal plate in an anechoic chamber. The device has specified settings.

TECHNICAL DATA

Operating conditions

Temperature

Temperature

TemperatureTemperature

Ambient temperature -40…+80°C/ -40…+176°F

Relative humidity 0...99%

Storage temperature -40…+85°C/ -40…+185°F

Process connection temperature

(higher temperature on request)

Pressure

Pressure

PressurePressure

Process pressure -1…40 barg / -14.5…580 psig

Other conditions

Other conditions

Other conditionsOther conditions

Dielectric constant (εr) ≥1.4

Ingress protection IEC 60529: IP66 / IP68 (0.1 barg / 1.45 psig)

Maximum rate of change 60 m/min / 196 ft/min

Ex: see supplementary operating instructions or approval certificates

-50…+150°C/ -58…+302°F

The process connection temperature must agree with the temperature limits of the

gasket material. Refer to "Materials" in this table.)

Ex: see supplementary operating instructions or approval certificates

Subject to the process connection used and the process connection temperature.

For more data, refer to

NEMA 250: NEMA type 6 - 6P (housing) and type 6P (antenna)

Guidelines for maximum operating pressure

2

on page 18.

Installation conditions

Process connection size The nominal diameter (DN) should be equal to or larger than the antenna diameter.

Process connection position Make sure that there are not any obstructions directly below the process

Dimensions and weights For dimensions and weights data, refer to

connection for the device. For more data, refer to

Dimensions and weights

Installation

on page 25.

on page 20.

Materials

Housing Standard: Polyester-coated aluminium

Option: Stainless steel (1.4404 / 316L) – non-Ex devices only. Ex approvals will be

available in the second quarter of 2018.

Wetted parts, including antenna PEEK – this material agrees with FDA regulations

Process connection Stainless steel (1.4404 / 316L)

Slanted flange (option) PTFE (≤ +150°C / +302°F); PEEK (> +150°C / +302°F)

Gaskets (and o-rings for the

sealed antenna extension option)

Cable gland Standard: none

Weather protection (Option) Stainless steel (1.4404 / 316L)

FKM/FPM (-20…+150°C/ -4…+302°F); EPDM (-20°C…+200°C/ -4…+392°F)

Options: Plastic (Non-Ex: black, Ex i-approved: blue); nickel-plated brass; stainless

steel; M12 (4-pin connector)

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

11

Page 12

2

TECHNICAL DATA

Process connections

DN70 (2

DN70 (2¾¨) Lens antenna

DN70 (2DN70 (2

Thread G1½ A (ISO 228); 1½ NPT (ASME B1.20.1)

Flange, EN 1092-1 Low-pressure flanges: DN50...200 in PN01;

Flange, ASME B16.5 Low-pressure flanges: 2¨...8¨ in 150 lb (max. 15 psig);

DN70 (2

DN70 (2¾¨) Lens antenna

DN70 (2DN70 (2

Thread G3 A (ISO 228); 3 NPT (ASME B1.20.1)

Flange, EN 1092-1 Low-pressure flanges: DN80...200 in PN01;

Flange, ASME B16.5 Low-pressure flanges: 3¨...8¨ in 150 lb (max. 15 psig);

) Lens antenna

) Lens antenna) Lens antenna

) Lens antenna

) Lens antenna) Lens antenna

Standard flanges: DN50 in PN40; DN80...200 in PN10, PN16 and PN40 (Type B1);

others on request

Optional flange facing: Type A

Standard flanges: 2¨…8¨ in 150 lb RF and 300 lb RF; others on request

Optional flange facing: FF (Flat Face)

Standard flanges: DN80...200 in PN10, PN16 and PN40 (Type B1); others on request

Optional flange facing for standard flanges: Type A

Standard flanges: 3¨…8¨ in 150 lb RF and 300 lb RF; others on request

Optional flange facing for standard flanges: FF (Flat Face)

OPTIWAVE 6500 C

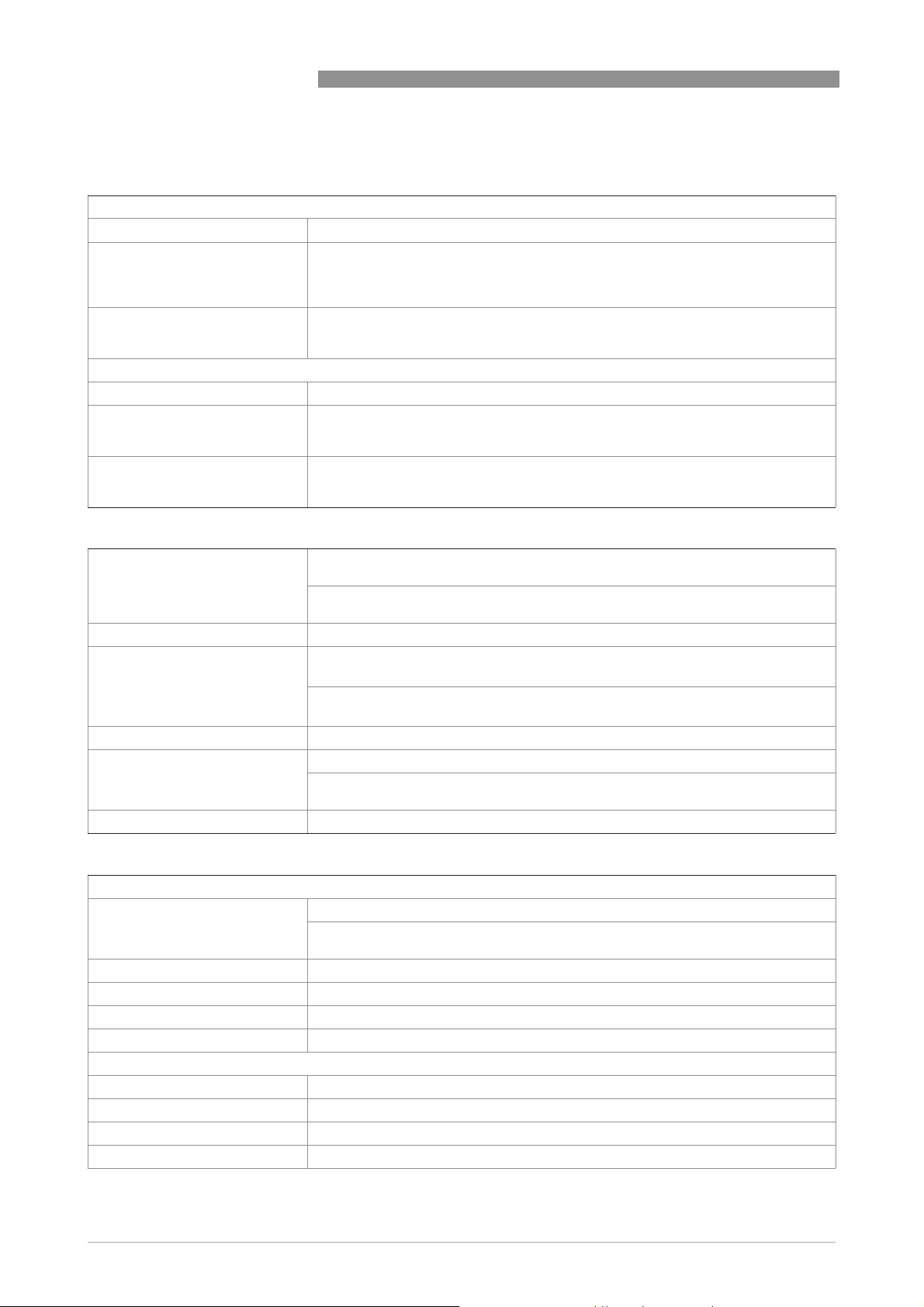

Electrical connections

Power supply Terminals output

Maximum current 21.5 mA

Current output load Non-Ex / Ex i:

Cable entry Standard: M20×1.5; Option: ½ NPT

Cable gland Standard: none

Cable entry capacity (terminal) 0.5…3.31 mm² (AWG 20...12)

Terminals output – Non-Ex / Ex i:

Terminals output Terminals output

12…30 VDC; min./max. value for an output of 21.5 mA at the terminals

Terminals output

Terminals output – Ex d:

Terminals output Terminals output

16…36 VDC; min./max. value for an output of 21.5 mA at the terminals

Non-Ex / Ex i: RL [Ω] ≤ ((U

Non-Ex / Ex i:Non-Ex / Ex i:

power supply voltage

Ex d:

Ex d: RL [Ω] ≤ ((U

Ex d:Ex d:

on page 15.

voltage

Options: M20×1.5 (cable diameter: 7…12 mm / 0.28…0.47¨); others are available on

request

Non-Ex / Ex i:

Non-Ex / Ex i: Non-Ex / Ex i:

Ex d:

Ex d: Ex d:

-12V)/21.5mA). For more data, refer to

ext

on page 15.

-16 V)/21.5 mA). For more data, refer to

ext

Minimum

Minimum power supply

Input and output

Current output

Current output

Current outputCurrent output

Output signal Standard: 4…20 mA

Options: 3.8…20.5 mA acc. to NAMUR NE 43; 4…20 mA (reversed); 3.8…20.5 mA

(reversed) acc. to NAMUR NE 43

Output type Passive

Resolution ±5 µA

Temperature drift Typically 50 ppm/K

Error signal High: 21.5 mA; Low: 3.5 mA acc. to NAMUR NE 43

HART

HART®

HARTHART

Description Digital signal transmitted with the current output signal (HART® protocol)

Version 7.4

Load ≥ 250 Ω

Digital temperature drift Max. ±15 mm / 0.6¨ for the full temperature range

1

12

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 13

OPTIWAVE 6500 C

TECHNICAL DATA

2

Multi-drop operation Yes. Current output = 4 mA. Enter Program mode to change the polling address

(1...63).

Available drivers FC475, AMS, PDM, FDT/DTM

Approvals and certification

CE The device meets the essential requirements of the EU Directives. The

Vibration resistance EN 60068-2-6 and EN 60721-3-4 (1...9 Hz: 3 mm / 10...200 Hz:1g, 10g shock ½

Explosion protection

Explosion protection

Explosion protectionExplosion protection

ATEX (EU Type Approval) II 1/2 G Ex ia IIC T6...T3 Ga/Gb;

ATEX (Type Approval) II 3 G Ex nA IIC T6...T3 Gc;

IECEx Ex ia IIC T6...T3 Ga/Gb;

cQPSus Division ratings

manufacturer certifies successful testing of the product by applying the CE

marking.

For more data about the EU Directives and European Standards related to this

device, refer to the EU Declaration of Conformity. You can find this documentation

on the DVD-ROM supplied with the device or it can be downloaded free of charge

from the website.

sinus: 11 ms)

II 1/2 D Ex ia IIIC T85°C...T*°C Da/Db;

2

II 1/2 G Ex db ia IIC T6...T3 Ga/Gb;

II 1/2 D Ex ia tb IIIC T85°C...T*°C Da/Db

2

II 3 G Ex ic IIC T6...T3 Gc;

II 3 D Ex ic IIIC T85°C...T*°C Dc

Ex ia IIIC T85°C...T*°C Da/Db;

2

2

Ex db ia IIC T6...T3 Ga/Gb;

Ex ia tb IIIC T85°C...T*°C Da/Db;

2

Ex ic IIC T6...T3 Gc;

Ex ic IIIC T85°C...T*°C Gc

Division ratings

Division ratingsDivision ratings

2

XP-IS, Class I, Div 1, GPS ABCD, T6...T3 – available in September 2017;

DIP, Class II, III, Div 1, GPS EFG, T85°C...T*°C – available in September 2017;

IS, Class I, Div 1, GPS ABCD, T6...T3;

IS, Class II, III, Div 1, GPS EFG, T85°C...T*°C;

2

NI, Class I, Div 2, GPS ABCD, T6...T3 – available in September 2017;

NI, Class II, III, Div 2, GPS EFG, T85°C...T*°C – available in September 2017

Zone ratings

Zone ratings

Zone ratingsZone ratings

2

Class I, Zone 1, AEx db ia [ia Ga] IIC T6...T3 Gb (US) – antenna suitable for Zone 0

– available in September 2017;

Ex db ia [Ex ia Ga] IIC T6...T3 Gb (Canada) – antenna suitable for Zone 0

– available in September 2017;

Class I, Zone 0, AEx ia IIC T6...T3 Ga (US);

Ex ia IIC T6...T3 Ga (Canada);

Class I, Zone 2, AEx nA IIC T6...T3 Gc (US);

Ex nA IIC T6...T3 Gc (Canada);

Zone 20, AEx ia IIIC T85°C...T*°C Da (US);

Ex ia IIIC T85°C...T*°C Da (Canada);

2

Zone 21, AEx ia tb [ia Da] IIIC T85°C...T*°C Db (US) – antenna suitable for zone 20

– available in September 2017

Ex ia tb [Ex ia Da] IIIC T85°C...T*°C Db (Canada) – antenna suitable for zone 20

– available in September 2017

2

2

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

13

Page 14

2

TECHNICAL DATA

OPTIWAVE 6500 C

NEPSI

(available in September 2017)

EAC-EX

(available in November 2017)

Other standards and approvals

Other standards and approvals

Other standards and approvalsOther standards and approvals

Electromagnetic compatibility EU

Radio approvals EU

Electrical safety EU

NAMUR NAMUR NE 21 Electromagnetic Compatibility (EMC) of Industrial Process and

CRN Option available in September 2017. This certification is applicable for all Canadian

Construction code Option: ASME B31.3

1 HART® is a registered trademark of the HART Communication Foundation

2 T*°C = 150°C or 200°C. For more data, refer to the related Ex approval certificate.

Ex ia IIC T3~T6 Ga/Gb;

Ex d ia IIC T3~T6 Ga/Gb;

Ex iaD 20/21 T85°C...T*°C IP6X;

Ex iaD tD A20/A21 T85°C...T*°C IP6X

Ga/Gb Ex ia IIC T6...T3;

Ex ia IIIC T85°C...T*°C Da/Db;

Ga/Gb Ex d ia IIC T6...T3;

Ex ia tb IIIC T85°C...T*°C Da/Db;

EU: Electromagnetic Compatibility directive (EMC)

EUEU

EU: Radio Equipment directive (RED)

EUEU

FCC Rules

FCC Rules: Part 15

FCC RulesFCC Rules

Industry Canada

Industry Canada: RSS-211

Industry CanadaIndustry Canada

EU: Agrees with the safety part of the Low Voltage directive (LVD)

EUEU

USA and Canada

USA and Canada: Agrees with NEC and CEC requirements for installation in

USA and CanadaUSA and Canada

ordinary locations

Laboratory Control Equipment

NAMUR NE 43 Standardization of the Signal Level for the Failure Information of

Digital Transmitters

NAMUR NE 53 Software and Hardware of Field Devices and Signal Processing

Devices with Digital Electronics

NAMUR NE 107 Self-Monitoring and Diagnosis of Field Devices

provinces and territories. For more data, refer to the website.

2

2

2

2

14

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 15

OPTIWAVE 6500 C

2.2 Minimum power supply voltage

Use these graphs to find the minimum power supply voltage for a given current output load.

TECHNICAL DATA

2

Figure 2-1: Minimum power supply voltage for an output of 21.5 mA at the terminal (Non-Ex and Hazardous Location

approval (Ex i / IS))

X: Power supply U [VDC]

Y: Current output load R

L

[Ω]

Hazardous Location (Ex d / XP/NI) approved devices

Figure 2-2: Minimum power supply voltage for an output of 21.5 mA at the terminal (Hazardous Location approval

(Ex d / XP/NI))

X: Power supply U [VDC]

Y: Current output load R

L

[Ω]

2.3 Measuring accuracy

Use these graphs to find the measuring accuracy for a given distance from the transmitter.

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

15

Page 16

2

TECHNICAL DATA

DN40 (1½¨) Lens antenna

Figure 2-3: DN40 (1½¨) Lens antenna: measuring accuracy (graph of measuring accuracy in mm against measuring

distance in m)

X: Measuring distance from the thread stop or flange facing of the process connection [m]

Y: Measuring accuracy [+yy mm / -yy mm]

1 50 mm

2 200 mm

OPTIWAVE 6500 C

16

Figure 2-4: DN40 (1½¨) Lens antenna: measuring accuracy (graph of measuring accuracy in inches against measuring

distance in ft)

X: Measuring distance from the thread stop or flange facing of the process connection [ft]

Y: Measuring accuracy [+yy inches / -yy inches]

1 1.97¨

2 7.87¨

To calculate the accuracy at a given distance from the antenna, refer to Technical data on page

(measuring accuracy).

10

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 17

OPTIWAVE 6500 C

DN70 (2¾¨) Lens antenna

Figure 2-5: DN70 (2¾¨) Lens antenna: measuring accuracy (graph of measuring accuracy in mm against measuring

distance in m)

X: Measuring distance from the thread stop or flange facing of the process connection [m]

Y: Measuring accuracy [+yy mm / -yy mm]

1 100 mm

TECHNICAL DATA

2

Figure 2-6: DN70 (1½¨) Lens antenna: measuring accuracy (graph of measuring accuracy in inches against measuring

distance in ft)

X: Measuring distance from the thread stop or flange facing of the process connection [ft]

Y: Measuring accuracy [+yy inches / -yy inches]

1 3.94¨

To calculate the accuracy at a given distance from the antenna, refer to Technical data on page

(measuring accuracy).

10

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

17

Page 18

2

TECHNICAL DATA

2.4 Guidelines for maximum operating pressure

Make sure that the devices are used within their operating limits.

40

30

20

10

OPTIWAVE 6500 C

0

-50 0 50 100 150 200

Figure 2-7: Pressure / temperature de-rating (EN 1092-1), flange and threaded connection, in °C and barg

600

550

500

450

400

350

300

250

200

150

100

50

0

-60

Figure 2-8: Pressure / temperature de-rating (EN 1092-1), flange and threaded connections, in °F and psig

1 Process pressure, p [barg]

2 Process connection temperature, T [°C]

3 Process pressure, p [psig]

4 Process connection temperature, T [°F]

5 Threaded connection, G (ISO 228-1)

6 Flange connection, PN40

7 Flange connection, PN16

068

20

160 210 300

380

400

18

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 19

OPTIWAVE 6500 C

CRN certification (available in September 2017)

CRN certification (available in September 2017)

CRN certification (available in September 2017)CRN certification (available in September 2017)

There is a CRN certification option for devices with process connections that agree with ASME

standards. This certification is necessary for all devices that are installed on a pressure vessel

and used in Canada.

40

30

20

10

TECHNICAL DATA

2

0

-50

Figure 2-9: Pressure / temperature de-rating (ASME B16.5), flange and threaded connections, in °C and barg

600

550

500

450

400

350

300

250

200

150

100

50

0

-60

Figure 2-10: Pressure / temperature de-rating (ASME B16.5), flange and threaded connections, in °F and psig

1 Process pressure, p [barg]

2 Process connection temperature, T [°C]

3 Process pressure, p [psig]

4 Process connection temperature, T [°F]

5 Threaded connection, NPT (ASME B1.20.1)

6 Flange connection, Class 300

7 Flange connection, Class 150

0

0

50 100 150 200

100 120 210 300 320 380 400

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

19

Page 20

2

TECHNICAL DATA

2.5 Dimensions and weights

DN40 / 1½¨ Lens antenna versions

Figure 2-11: DN40 / 1½¨ Lens antenna versions

1 DN40 / 1½¨ Lens antenna with a G 1½A or 1½ NPT threaded connection

2 DN40 / 1½¨ Lens antenna with a low-pressure flange attached to a threaded connection

3 DN40 / 1½¨ Lens antenna with a flange connection

4 DN40 / 1½¨ Lens antenna with a flange connection and the 2° slanted flange option

•

The diameter of the outer sheath of the cable must be 7…12 mm or 0.28…0.47¨.

•

Cable glands for cQPSus-approved devices must be supplied by the customer.

•

A weather protection cover is available as an accessory with all devices.

OPTIWAVE 6500 C

20

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 21

OPTIWAVE 6500 C

DN40 / 1½¨ Lens antenna: Dimensions in mm

TECHNICAL DATA

2

Type of process

Dimensions [mm]

connection

a b c d e f

Thread connection 151 160 203.5

Low-pressure flange

151 160 206.5

connection

Flange connection 151 160 209.5

Flange connection with

151 160 209.6

slanted flange option

1 If the process temperature is more than +150°C, add 112 mm to this value

2 If the process temperature is more than +150°C, add 112 mm to this value. If the device has the antenna extension option, add 112 mm

to this value.

3 If the device has the antenna extension option, add 112 mm to this value

1

1

1

1

228

228

214

219.6

1

1

2

1

29.5

32.2

49.2

49.2

1

1

1

1

4.2

24.2

21.2

3

10

DN40 / 1½¨ Lens antenna: Dimensions in inches

Type of process

connection

a b c d e f

Thread connection 5.94 6.30 8.01

Low-pressure flange

connection

Flange connection 5.94 6.30 8.25

Flange connection with

slanted flange option

1 If the process temperature is more than +302°F, add 4.41¨ to this value

2 If the process temperature is more than +302°F, add 4.41¨ to this value. If the device has the antenna extension option, add 4.41¨ to this

value.

3 If the device has the antenna extension option, add 4.41¨ to this value

5.94 6.30 8.13

5.94 6.30 8.25

Dimensions [inches]

1

1

1

1

8.98

8.98

8.42

8.65

1

1

2

1

1.16

1.27

1.94

1.94

1

1

1

1

0.17

0.95

0.83

3

0.39

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

21

Page 22

2

TECHNICAL DATA

DN70 / 2¾¨ Lens antenna versions

Figure 2-12: DN70 / 2¾¨ Lens antenna versions

1 DN70 / 2¾¨ Lens antenna with a G 3A or 3 NPT threaded connection

2 DN70 / 2¾¨ Lens antenna with a low-pressure flange attached to a threaded connection

3 DN70 / 2¾¨ Lens antenna with a flange connection

4 DN70 / 2¾¨ Lens antenna with a flange connection and the 2° slanted flange option

•

The diameter of the outer sheath of the cable must be 7…12 mm or 0.28…0.47¨.

•

Cable glands for cQPSus-approved devices must be supplied by the customer.

•

A weather protection cover is available as an accessory with all devices.

OPTIWAVE 6500 C

DN70 / 2¾¨ Lens antenna: Dimensions in mm

Type of process

connection

a b c d e f

Thread connection 151 160 209.8

Low-pressure flange

connection

Flange connection 151 160 233.2

Flange connection with

slanted flange option

1 If the process temperature is more than +150°C, add 112 mm to this value

151 160 212.8

151 160 233.2

Dimensions [mm]

DN70 / 2¾¨ Lens antenna: Dimensions in inches

Type of process

connection

a b c d e f

Thread connection 5.94 6.30 8.25

Low-pressure flange

connection

Flange connection 5.94 6.30 9.18

Flange connection with

slanted flange option

1 If the process temperature is more than +302°F, add 4.41¨ to this value

5.94 6.30 8.38

5.94 6.30 9.18

Dimensions [inches]

1

1

1

1

1

1

1

1

233.2

1

233.2

1

— 72.8

243.2

1

9.18

1

9.18

1

— 2.87

9.57

1

49.5

52.5

72.8

1.95

2.07

2.87

1

1

1

1

1

1

1

1

24.2

21.2

—

10

0.95

0.83

—

0.39

22

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 23

OPTIWAVE 6500 C

Weather protection option

Figure 2-13: Weather protection option

1 Front view (with weather protection closed)

2 Left side (with weather protection closed)

3 Rear view (with weather protection closed)

Weather protection: Dimensions and weights

Dimensions Weights [kg]

TECHNICAL DATA

2

Weather

protection

a b c

[mm] [inch] [mm] [inch] [mm] [inch] [kg] [lb]

177 6.97 153 6.02 216 8.50 1.3 2.9

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

23

Page 24

2

TECHNICAL DATA

OPTIWAVE 6500 C

Converter weight

Type of housing Weights

[kg] [lb]

Compact aluminium housing 2.1 4.6

Compact aluminium housing with distance piece

Compact stainless steel housing 4.5 9.9

Compact stainless steel housing with distance piece

1 The housing has a distance piece, if the process temperature is more than +150°C / +302°F

1

1

3.0 6.6

5.4 11.9

Antenna option weights

Antenna options Min./Max. weights

[kg] [lb]

Standard options, with converter

Standard options, with converter

Standard options, with converterStandard options, with converter

DN40 (1½¨) Lens antenna with G 1½ or 1½ NPT threaded connection 2.5 5.5

DN70 (2¾¨) Lens antenna with G 3 or 3 NPT threaded connection 4.3 9.5

DN40 (1½¨) Lens antenna with G 1½ or 1½ NPT threaded connection and low-pressure

flange (type A)

DN70 (2¾¨) Lens antenna with G 3 or 3 NPT threaded connection and low-pressure

flange (type A)

DN40 (1½¨) Lens antenna with DN80 PN16 / B1 or 3¨ 150 lb / RF flange 6.7 14.8

DN70 (2¾¨) Lens antenna with DN80 PN16 / B1 or 3¨ 150 lb / RF flange 7.0 15.4

DN40 (1½¨) Lens antenna with DN80 PN16 / B1 or 3¨ 150 lb / RF flange and 2° PP

slanted flange

DN70 (2¾¨) Lens antenna with DN80 PN16 / B1 or 3¨ 150 lb / RF flange and 2° PP

slanted flange

3.1 6.8

4.8 10.6

6.9 15.2

7.1 15.7

24

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 25

OPTIWAVE 6500 C

3.1 Intended use

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

This radar level transmitter measures distance, level, mass, volume and reflectivity of

granulates and powders.

It can be installed on silos, hoppers and bunkers.

3.2 Pre-installation requirements

Obey the precautions that follow to make sure that the device is correctly installed.

• Make sure that there is sufficient space on all sides.

• Protect the signal converter from direct sunlight. If necessary, install the weather protection

accessory.

• Do not subject the signal converter to heavy vibrations. The devices are tested for vibration

and agree with EN 50178 and IEC 60068-2-6.

INSTALLATION

3

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

25

Page 26

3

INSTALLATION

3.3 Installation

3.3.1 Pressure and temperature ranges

OPTIWAVE 6500 C

2

1

Figure 3-1: Pressure and temperature ranges

1 Temperature at the process connection

Non-Ex devices: The temperature range depends on the type of antenna, process connection and the seal material.

Refer to the table that follows.

Devices with Hazardous Location approvals: see supplementary instructions

2 Ambient temperature for operation of the display

-20...+70°C / -4...+158°F

If the ambient temperature is not between these limits, then it is possible that the display screen will not operate temporarily. The device continues to measure level and send an output signal.

3 Ambient temperature

Non-Ex devices: -40...+80°C / -40...+176°F

Devices with Hazardous Location approvals: see supplementary instructions

4 Process pressure

Depends on the type of antenna and process connection. Refer to the table that follows.

3

4

The process connection temperature range must agree with the temperature limits of the

gasket material. The operating pressure range is subject to the process connection used and the

flange temperature.

Maximum process connection temperature and operating pressure

Antenna type Maximum process connection

[°C] [°F] [barg] [psig]

Lens DN40, PEEK +150

Lens DN70, PEEK +150

1 Pending: +200°C / +392°F

For more data on pressure ratings, refer to

18.

temperature

1

1

+302

+302

Guidelines for maximum operating pressure

Maximum operating pressure

1

1

40 580

40 580

on page

26

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 27

OPTIWAVE 6500 C

3.3.2 Recommended mounting position

Follow these recommendations to make sure that the device measures correctly. They have an

effect on the performance of the device.

We recommend that you prepare the installation when the tank is empty.

Recommended nozzle position for solids

INSTALLATION

3

Figure 3-2: Recommended nozzle position for solids

1 Position of the process fitting from the silo wall, r/2 (for the DN40 or DN70 Lens antenna)

2 Radius of the silo, r

3 The minimum measured level for a device without a 2° slanted PP flange option

4 The minimum measured level for a device with a 2° slanted PP flange option

If there is a nozzle on the tank before installation, the nozzle must be a minimum of 200 mm /

¨

from the tank wall. The tank wall must be flat and there must not be obstacles adjacent to

7.9

the nozzle or on the tank wall.

Number of devices that can be operated in a silo

Figure 3-3: There is no maximum limit to the number of devices that can be operated in the same silo

There is no maximum limit to the number of devices that can be operated in the same silo. They

can be installed adjacent to other radar level transmitters.

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

27

Page 28

3

INSTALLATION

3.3.3 Mounting restrictions

LPR and TLPR devices

LPR (Level Probing Radar)

LPR (Level Probing Radar) devices measure level in the open air or in a closed space (a metallic

LPR (Level Probing Radar)LPR (Level Probing Radar)

tank etc.). TLPR (Tank Level Probing Radar)

can use LPR devices for TLPR applications. For more data, refer to Order code on page 34

antenna options.

Causes of interference signals

• Objects in the tank or silo.

• Sharp corners that are perpendicular to the path of the radar beam.

• Sudden changes in tank diameter in the path of the radar beam.

Do not install the device above objects in the silo (ladder, supports etc.) or pit. Objects in the silo

or pit can cause interference signals. If there are interference signals, the device will not

measure correctly.

If it is not possible to install the device on another part of the silo or pit, do an empty spectrum

scan. For more data, refer to the handbook.

TLPR (Tank Level Probing Radar) devices measure level in a closed space only. You

TLPR (Tank Level Probing Radar)TLPR (Tank Level Probing Radar)

OPTIWAVE 6500 C

,

Equipment and obstacles: how to prevent measurement of interference signals

Do not put the device immediately above equipment and obstacles in a silo or pit. This can have

an effect on the performance of the device.

If possible, do not install a nozzle on the silo centerline.

28

Figure 3-4: Equipment and obstacles: how to prevent measurement of interference signals

1 Do not tilt the device more than 2°

2 We recommend that you do an empty spectrum recording if there are too many obstacles in the radar beam (refer to

the handbook).

3 Beam radius of the antenna: refer to the table below. The beam radius increases by increments of "x" mm for each

metre of distance from the antenna.

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 29

OPTIWAVE 6500 C

Beam radius of the antenna

Product inlets

Figure 3-5: Product inlets

1 The device is in the correct position.

2 The device is too near to the product inlet.

INSTALLATION

Antenna type Beam angle Beam radius, x

[mm/m] [in/ft]

Lens, DN40 (1½¨) 8° 70 0.8

Lens, DN70 (2¾¨) 4° 35 0.4

3

Do not put the device near to the product inlet. If the product that enters the silo touches the

antenna, the device will measure incorrectly. If the product fills the silo directly below the

antenna, the device will also measure incorrectly.

For more data about the measuring range of each type of antenna, refer to Measuring accuracy

on page 15

.

3.3.4 Process connections

Flange connections

Figure 3-6: Flange connections

Ød = nozzle diameter

h = nozzle height

Recommended nozzle size for flange connections

The nozzle must be as short as possible. Refer to the table below for the maximum height of the

nozzle:

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

29

Page 30

3

INSTALLATION

OPTIWAVE 6500 C

Nozzle and antenna diameter,

Maximum nozzle height, h

Ød

Lens, DN40 Lens, DN70

[mm] [inch] [mm] [inch] [mm] [inch]

40 1½ 50

50 2 50

80 3 150

100 4 200

150 6 250

200 8 300

1 If the device has an antenna extension, this option extends the maximum nozzle height. Add 112 mm / 4.4¨ to this value.

1

1

1

1

1

1

1.97

1.97

5.91

7.87

9.84

11.81

1

1

1

1

1

1

— —

— —

200 7.87

300 11.81

500 19.69

500 19.69

Threaded connections

Figure 3-7: Threaded connections

a = 6 mm / 0.24¨, if the device has an threaded connection and DN40 Lens antenna

Recommended socket size for threaded connections

The socket must be as short as possible. If the socket is in a recess, then use the maximum

limits for nozzle dimensions (flange connections) in this section.

If the device has antenna extensions, this option extends the maximum socket height. Add the

length of the antenna extensions attached to the device to this value.

30

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 31

OPTIWAVE 6500 C

ELECTRICAL CONNECTIONS

4.1 Electrical installation: 2-wire, loop-powered

Terminals for electrical installation

Figure 4-1: Terminals for electrical installation

1 Grounding terminal in the housing (if the electrical cable is shielded)

2 Current output -

3 Current output +

4 Location of the external grounding terminal (at the bottom of the converter)

4

Electrical power to the output terminal energizes the device. The output terminal is also used for

®

HART

communication.

4.2 Non-Ex devices

Figure 4-2: Electrical connections for non-Ex devices

1 Power supply

2 Resistor for HART® communication (typically 250 ohms)

3 Optional connection to the grounding terminal

4 Output: 12...30 VDC for an output of 21.5 mA at the terminal

5 Device

4.3 Devices for hazardous locations

For electrical data for device operation in hazardous locations, refer to the related certificates of

compliance and supplementary instructions (ATEX, IECEx etc.). You can find this documentation

on the DVD-ROM delivered with the device or it can be downloaded free of charge from the

website (Download Center).

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

31

Page 32

4

ELECTRICAL CONNECTIONS

4.4 Networks

4.4.1 General information

The device uses the HART® communication protocol. This protocol agrees with the HART®

Communication Foundation standard. The device can be connected point-to-point. It can also

have a polling address of 1 to 63 in a multi-drop network.

The device output is factory-set to communicate point-to-point. To change the communication

mode from point-to-point

4.4.2 Point-to-point connection

point-to-point to multi-drop

point-to-pointpoint-to-point

multi-drop, refer to "Network configuration" in the handbook.

multi-dropmulti-drop

OPTIWAVE 6500 C

Figure 4-3: Point-to-point connection (non-Ex)

1 Address of the device (0 for point-to-point connection)

2 4...20 mA + HART®

3 Resistor for HART® communication (typically 250 ohms)

4 Power supply

5 HART® converter

6 HART® communication software

32

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 33

OPTIWAVE 6500 C

4.4.3 Multi-drop networks

ELECTRICAL CONNECTIONS

4

Figure 4-4: Multi-drop network (non-Ex)

1 Address of the device (each device must have a different address in multidrop networks)

2 4mA + HART®

3 Resistor for HART® communication (typically 250 ohms)

4 Power supply

5 HART® converter

6 HART® communication software

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

33

Page 34

5

ORDER INFORMATION

5.1 Order code

Make a selection from each column to get the full order code.

OPTIWAVE 6500 C

VFDD 4 0 OPTIWAVE 6500 C 80 GHz Radar (FMCW) level transmitter for powders and dusty atmosphere (up to

VFDD

VFDD 4 0 0

VFDDVFDD

OPTIWAVE 6500 C 80 GHz Radar (FMCW) level transmitter for powders and dusty atmosphere (up to

OPTIWAVE 6500 C 80 GHz Radar (FMCW) level transmitter for powders and dusty atmosphere (up to OPTIWAVE 6500 C 80 GHz Radar (FMCW) level transmitter for powders and dusty atmosphere (up to

40 barg (580 psig) and 150

40 barg (580 psig) and 150°C (302

40 barg (580 psig) and 15040 barg (580 psig) and 150

Regional directives

Regional directives

Regional directivesRegional directives

1 Europe

2 China

3 USA

4 Canada

5 Brazil

6 Australia

A Russia

B Kazakhstan

C Belarus

W Worldwide

Ex approvals

Ex approvals

Ex approvalsEx approvals

0 Without

1 ATEX II 1/2 G Ex ia IIC T6…T3 Ga/Gb + II 1/2 D Ex ia IIIC T85°C…T150°C or T85°C…T200°C Da/Db

2 ATEX II 1/2 GD Ex db ia IIC T6…T3 Ga/Gb + II 1/2 D Ex ia tb IIIC T85°C…T150°C or T85°C…T200°C

Da/Db

3 ATEX II 3 G Ex ic IIC T6…T3 Gc + II 3 D Ex ic IIIC T85°C…T150°C or T85°C…T200°C Dc

4 ATEX II 3 G Ex nA T6…T3 Gc

5 NEPSI Ex ia IIC T6…T3 Ga/Gb + Ex iaD 20/21 T85°C…T150°C or T85°C…T200°C IP6X

6 NEPSI Ex d ia IIC T6…T3 Ga/Gb + Ex iaD tD A20/A21 T85°C…T150°C or T85°C…T200°C IP6X

A cQPSus IS CL I/II/III DIV 1 GP A-G + CL I Z0 AEx ia/Ex ia IIC T6…T3 Ga + Z20 AEx ia/Ex ia IIIC

T85°C…T150°C or T85°C…T200°C Da

B cQPSus XP-IS/DIP CL I DIV 1 GP A-G + CL I Z1 AEx db ia/Ex db ia IIC T6…T3 Gb + Z21

AEx ia tb/Ex ia tb IIIC T85°C…T150°C or T85°C…T200°C Db

C cQPSus NI CL I/II/III DIV 2 GP A-G + CL I Z2 AEx nA/Ex nA IIC T6…T3 Gc

K IECEx Ex ia IIC T6…T3 Ga/Gb + Ex ia IIIC T85°C…T150°C or T85°C…T200°C Da/Db

L IECEx Ex d ia IIC T6…T3 Ga/Gb + Ex ia tb IIIC T85°C…T150°C or T85°C…T200°C Da/Db

M IECEx Ex ic IIC T6…T3 Gc + Ex ic IIIC T85°C…T150°C or T85°C…T200°C Dc

P EAC Ex Ga/Gb Ex ia T6…T3 + Ex ia IIIC T85°C…T150°C or T85°C…T200°C Da/Db

R EAC Ex Ga/Gb Ex d ia T6…T3 + Ex ia tb IIIC T85°C…T150°C or T85°C…T200°C Da/Db

0 Construction

Construction

ConstructionConstruction

0 Without

1 CRN / ASME B31.3

4 ASME B31.3

Converter version (Housing material / IP class)

Converter version (Housing material / IP class)

Converter version (Housing material / IP class)Converter version (Housing material / IP class)

2 C / Compact version (aluminium housing – IP66/68 0.1 barg)

3 C / Compact version (stainless steel housing – IP66/68 0.1 barg)

C (302°F))

F))

C (302C (302

F))F))

1

1

1

2

3

3

4

34

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 35

OPTIWAVE 6500 C

Outputs

Outputs

OutputsOutputs

1 2-wire / 4...20mA passive HART®

Cable entry / cable gland

Cable entry / cable gland

Cable entry / cable glandCable entry / cable gland

1 M20×1.5 / without

2 M20×1.5 / 1 × plastic + plug

3 M20×1.5 / 1 × nickel-plated brass + plug

4 M20×1.5 / 1 × stainless steel + plug

5 M20×1.5 / 1 × M12 (4-pin connector) + plug

6 M20×1.5 / 2 × plastic

7 M20×1.5 / 2 × nickel-plated brass

8 M20×1.5 / 2 × stainless steel

A M20×1.5 / 2 × M12 (4-pin connector)

C ½ NPT / without

D ½ NPT / 1 × nickel-plated brass + plug

E ½ NPT / 1 × stainless steel + plug

F ½ NPT / 2 × nickel-plated brass

G ½ NPT / 2 × stainless steel

Display

Display

DisplayDisplay

0 Without (no display, cover without window)

4 Plug-in display (cover with window)

Display

Display – Documentation language

Display Display

1 English

2 German

3 French

4 Italian

5 Spanish

6 Portuguese

7 Japanese

8 Chinese (simplified)

A Russian

B Czech

C Turkish

D Polish

VFDD

VFDD 4 0 0 1 0 Order code (complete this code on the pages that follow)

VFDDVFDD

Documentation language

Documentation language Documentation language

0 Process conditions (Pressure, temperature, material and remarks) /

Process conditions (Pressure, temperature, material and remarks) /

Process conditions (Pressure, temperature, material and remarks) / Process conditions (Pressure, temperature, material and remarks) /

Process seal

Process seal

Process sealProcess seal

1 -1…40 barg (-14.5…580 psig) / -40°C...+150°C (-40°F…+302°F) /

FKM/FPM

2 -1…40 barg (-14.5…580 psig) / -50°C...+150°C (-58°F…+302°F) /

EPDM

4 -1…40 barg (-14.5…580 psig) / -40°C...+200°C (-40°F…+392°F) /

FKM/FPM

Order code (complete this code on the pages that follow)

Order code (complete this code on the pages that follow)Order code (complete this code on the pages that follow)

5

5

5

ORDER INFORMATION

5

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

35

Page 36

5

ORDER INFORMATION

Antennas (antenna type, material, radio approval)

Antennas (antenna type, material, radio approval)

Antennas (antenna type, material, radio approval)Antennas (antenna type, material, radio approval)

3 Lens, DN40 (1½¨)/ PEEK/ LPR

4 Lens, DN70 (2¾¨)/ PEEK/ LPR

Antenna extension

Antenna extension

Antenna extensionAntenna extension

0 Without

1 316 L / 112 mm (4.4¨)

Process connection: Size / Pressure class / Flange face

Process connection: Size / Pressure class / Flange face

Process connection: Size / Pressure class / Flange face Process connection: Size / Pressure class / Flange face

finish

finish

finishfinish

ISO 228 (threaded connection)

G P 0 G1½ A

L P 0 G3A

ASME B1.20.1 (threaded connection)

G A 0 1½ NPT

L A 0 3NPT

Low-pressure EN flange (screwed to G 1½A connection)

H C 7 DN50 PN01

L C 7 DN80 PN01

M C 7 DN100 PN01

P C 7 DN150 PN01

R C 7 DN200 PN01

Low-pressure ASME flange (screwed to 1½ NPT

connection)

H 1 B 2¨ 150 lb 15 psig max.

L 1 B 3¨ 150 lb 15 psig max.

M 1 B 4¨ 150 lb 15 psig max.

P 1 B 6¨ 150 lb 15 psig max.

R 1 B 8¨ 150 lb 15 psig max.

EN 1092-1 flange

H G 1 DN50 PN40 – Type B1

L D 1 DN80 PN10 – Type B1

L E 1 DN80 PN16 – Type B1

L G 1 DN80 PN40 – Type B1

M D 1 DN100 PN10 – Type B1

M E 1 DN100 PN16 – Type B1

M G 1 DN100 PN40 – Type B1

P D 1 DN150 PN10 – Type B1

P E 1 DN150 PN16 – Type B1

P G 1 DN150 PN40 – Type B1

R D 1 DN200 PN10 – Type B1

R E 1 DN200 PN16 – Type B1

R G 1 DN200 PN40 – Type B1

VFDD

VFDD 4 0 0 1 0 Order code (complete this code on the pages

VFDDVFDD

Order code (complete this code on the pages

Order code (complete this code on the pages Order code (complete this code on the pages

that follow)

that follow)

that follow)that follow)

6

6

7

OPTIWAVE 6500 C

36

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 37

OPTIWAVE 6500 C

ASME B16.5 flange

H 1 A 2¨ 150 lb RF

H 2 A 2¨ 300 lb RF

L 1 A 3¨ 150 lb RF

L 2 A 3¨ 300 lb RF

M 1 A 4¨ 150 lb RF

M 2 A 4¨ 300 lb RF

P 1 A 6¨ 150 lb RF

P 2 A 6¨ 300 lb RF

R 1 A 8¨ 150 lb RF

R 2 A 8¨ 300 lb RF

JIS B2220 flange

H U P 50A JIS 10K RF

L U P 80A JIS 10K RF

M U P 100A JIS 10K RF

P U P 150A JIS 10K RF

R U P 200A JIS 10K RF

VFDD

VFDD 4 0 0 1 0 Order code (complete this code on the

VFDDVFDD

ORDER INFORMATION

Alternative flange facing

Alternative flange facing

Alternative flange facingAlternative flange facing

EN 1092-1 flange

7 Type A (Flat Face)

ASME B16.5 flange

B FF (Flat Face)

Calibration certificate

Calibration certificate

Calibration certificateCalibration certificate

0 Without: Accuracy ±2 mm (±0.08¨)

1 Calibration certificate ±2mm (±0.08¨) up to

10 m (32.81 ft), 2 points

2 Calibration certificate ±2mm (±0.08¨) up to

10 m (32.81 ft), 5 points

3 Calibration certificate ±2mm (±0.08¨) up to

10 m (32.81 ft), 5 points specified by the

customer min. ≥ 400 mm (16¨)

Options

Options

OptionsOptions

0 Without

2 Purging system

Order code (complete this code on the

Order code (complete this code on the Order code (complete this code on the

pages that follow)

pages that follow)

pages that follow)pages that follow)

5

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

37

Page 38

5

ORDER INFORMATION

Accessories / Tag plate

Accessories / Tag plate

Accessories / Tag plateAccessories / Tag plate

OPTIWAVE 6500 C

0 Without

1 Weather protection

3 Stainless steel Tag plate

(18 characters max.)

4 2° slanted flange

8

6 Weather protection + Stainless steel

Tag plate (18 characters max.)

A Weather protection + 2° slanted

flange

B Weather protection + stainless steel

tag plate (18 characters) + 2°

slanted flange

8

C Stainless steel tag plate

(18 characters max.) + 2° slanted

flange

8

VFDD

VFDD 4 0 0 1 0 Order code

VFDDVFDD

1 Available in September 2017

2 Available in September 2017. DIP = Dust Ignition Proof.

3 Available in November 2017

4 For non-Ex devices only. Ex approvals will be available in the second quarter of 2018.

5 For DN40 (1½¨) and DN70 (2¾¨) Lens antennas with a threaded or flange connection

6 LPR = You can install the antenna in a closed tank or outdoors (but the antenna must point down and not be near sensitive installations

(e.g. a radio astronomy station)). TLPR = You must install the antenna in a closed tank.

7 For the DN40 (1½¨) Lens antenna only. This option is not available if the process temperature is more than +150°C (+302°F).

8 If the process connection temperature is less than +150°C / +302°F, then the 2° slanted flange is made of PTFE. If the process connec-

tion temperature is more than +150°C / +302°F, then the 2° slanted flange is made of PEEK.

Order code

Order codeOrder code

38

www.krohne.com 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

Page 39

OPTIWAVE 6500 C

NOTES

6

www.krohne.com04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en

39

Page 40

K

K

K

KROHNE – Process instrumentation and measurement solutions

•

Flow

•

Level

•

Temperature

•

Pressure

•

Process Analysis

•

Services

© KROHNE 04/2017 - 4005813001 - TD OPTIWAVE 6500 R01 en - Subject to change without notice.

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.: +49 203 301 0

Fax: +49 203 301 10389

info@krohne.com

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...