Page 1

Supplementary instructions

Supplementary instructions

OPTIWAVE 5200 C/F

OPTIWAVE 5200 C/F

OPTIWAVE 5200 C/FOPTIWAVE 5200 C/F

Supplementary instructions Supplementary instructions

2-wire / 10 GHz Radar (FMCW) Level Meter

Supplementary Instructions for IECEx applications

Supplementary Instructions for IECEx applications

Supplementary Instructions for IECEx applicationsSupplementary Instructions for IECEx applications

© KROHNE 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 2

CONTENTS

OPTIWAVE 5200 C/F

1 General safety information 4

1.1 Scope of the document..................................................................................................... 4

1.2 Device description ............................................................................................................ 4

1.3 Standards and approvals.................................................................................................. 4

1.4 Equipment protection levels (EPL)................................................................................... 5

1.4.1 Ex ia-approved devices ........................................................................................................... 5

1.4.2 Ex dia / Ex ia tb-approved devices .......................................................................................... 5

1.4.3 Ex ic-approved devices ........................................................................................................... 5

1.5 IECEx nameplates ............................................................................................................ 6

2 Installation 11

2.1 Precautions..................................................................................................................... 11

2.1.1 General notes........................................................................................................................ 11

2.1.2 Electrostatic discharge......................................................................................................... 11

2.2 Operating conditions ...................................................................................................... 12

2.2.1 Ambient and flange temperature ......................................................................................... 12

2.2.2 Maximum surface temperature of the housing for dust applications ................................. 19

2.2.3 Process pressure.................................................................................................................. 19

3 Electrical connections 20

3.1 General notes ................................................................................................................. 20

3.2 Terminal compartment .................................................................................................. 20

3.2.1 How to open the terminal compartment .............................................................................. 20

3.2.2 How to close the terminal compartment ............................................................................. 21

3.3 Terminal tightening capacity.......................................................................................... 22

3.4 Equipotential bonding system........................................................................................ 22

3.5 Ex ia equipment .............................................................................................................. 23

3.5.1 How to connect the electrical cables ................................................................................... 23

3.5.2 Maximum intrinsically-safe values for the electrical circuit............................................... 23

3.5.3 Supply voltage....................................................................................................................... 23

3.5.4 Electrical schematic ............................................................................................................. 24

3.6 Ex d ia / Ex ia tb equipment ............................................................................................ 25

3.6.1 General notes........................................................................................................................ 25

3.6.2 How to connect the electrical cables ................................................................................... 26

3.6.3 Supply voltage....................................................................................................................... 26

3.6.4 Electrical schematic ............................................................................................................. 27

3.7 Ex ic equipment .............................................................................................................. 28

3.7.1 How to connect the electrical cables ................................................................................... 28

3.7.2 Maximum intrinsically-safe values for the electrical circuit............................................... 28

3.7.3 Supply voltage....................................................................................................................... 29

3.7.4 Electrical schematic ............................................................................................................. 29

4 Start-up 31

2

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 3

OPTIWAVE 5200 C/F

CONTENTS

5 Service 32

5.1 Periodic maintenance..................................................................................................... 32

5.2 Keep the device clean..................................................................................................... 32

5.3 Returning the device to the manufacturer..................................................................... 32

5.3.1 General information.............................................................................................................. 32

5.3.2 Form (for copying) to accompany a returned device............................................................ 33

6 Notes 34

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

3

Page 4

1 GENERAL SAFETY INFORMATION

1.1 Scope of the document

These instructions are applicable only to the explosion-protection version of the radar level

transmitter. For all other data, use the Quick Start and Handbook. If you do not have these

documents, please contact the nearest office or download them from the manufacturer's

internet site.

INFORMATION!

The information in these supplementary instructions only contains the data applicable to

explosion protection. The technical data for the non-Ex version in the Handbook shall be valid in

its current version, provided that it is not rendered invalid or replaced by these supplementary

instructions.

WARNING!

Installation, commissioning and maintenance may only be carried out by "Personnel trained in

explosion protection".

1.2 Device description

OPTIWAVE 5200 C/F

This device is a 2-wire level transmitter that uses FMCW (Frequency-Modulated Continuous

Wave) radar technology. It measures the level, distance, volume, mass and flow rate of liquids,

liquid gases, pastes and slurries. It is suitable for installation on storage tanks, process tanks

and stilling wells. Measurements are displayed via a DTM (device type manager) for remote

communication or an optional integrated display screen with wizard-driven setup and online

help functions.

The level transmitter is approved for use in potentially explosive atmospheres when equipped

with the appropriate options.

1.3 Standards and approvals

DANGER!

In compliance with the IECEx scheme rules, the IECEx version of the device described in these

Supplementary Instructions agrees with International Standards IEC 60079-0:2007, IEC 600791:2007, IEC 60079-11:2011, IEC 60079-26:2006, IEC 61241-11:2005 and IEC 60079-31:2008. The

Ex ia, Ex d ia / Ex ia tb and Ex ic versions are certified for use in hazardous areas by the DEKRA

Certification B.V. under DEK 11.0060X.

WARNING!

Carefully read the IECEx approval certificate. Obey the boundary conditions.

4

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 5

OPTIWAVE 5200 C/F

GENERAL SAFETY INFORMATION 1

1.4 Equipment protection levels (EPL)

1.4.1 Ex ia-approved devices

The Ex ia-approved device is suitable for use in potentially explosive atmospheres of all

flammable substances in Gas Groups IIA, IIB and IIC when fitted with appropriate options. It is

certified for applications for which an EPL of Ga/Gb or Gb is necessary.

The Ex ia-approved device is also suitable for use in potentially explosive atmospheres of all

flammable substances in Dust Group IIIA, IIIB and IIIC when fitted with appropriate options. It is

certified for applications for which an EPL of Da/Db or Db is necessary.

1.4.2 Ex dia / Ex ia tb-approved devices

The Ex dia-approved device is suitable for use in potentially explosive atmospheres of all

flammable substances in Gas Groups IIA, IIB and IIC when fitted with the appropriate options. It

is certified for applications for which an EPL of Ga/Gb or Gb is necessary.

The Ex ia tb-approved device is suitable for use in potentially explosive atmospheres of all

flammable substances in Dust Group IIIA, IIIB and IIIC when fitted with the appropriate options. It

is certified for applications for which an EPL of Da/Db or Db is necessary.

1.4.3 Ex ic-approved devices

The Ex ic-approved device is suitable for use in potentially explosive atmospheres of all

flammable substances in Gas Groups IIA, IIB and IIC when fitted with appropriate options. It is

certified for applications for which an EPL of Gc is necessary.

The Ex ic-approved device is also suitable for use in potentially explosive atmospheres of all

flammable substances in Dust Group IIIA, IIIB and IIIC when fitted with appropriate options. It is

certified for applications for which an EPL of Dc is necessary.

The Ex ic approval is available only for devices with the FOUNDATION fieldbus or PROFIBUS PA

option.

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

5

Page 6

1 GENERAL SAFETY INFORMATION

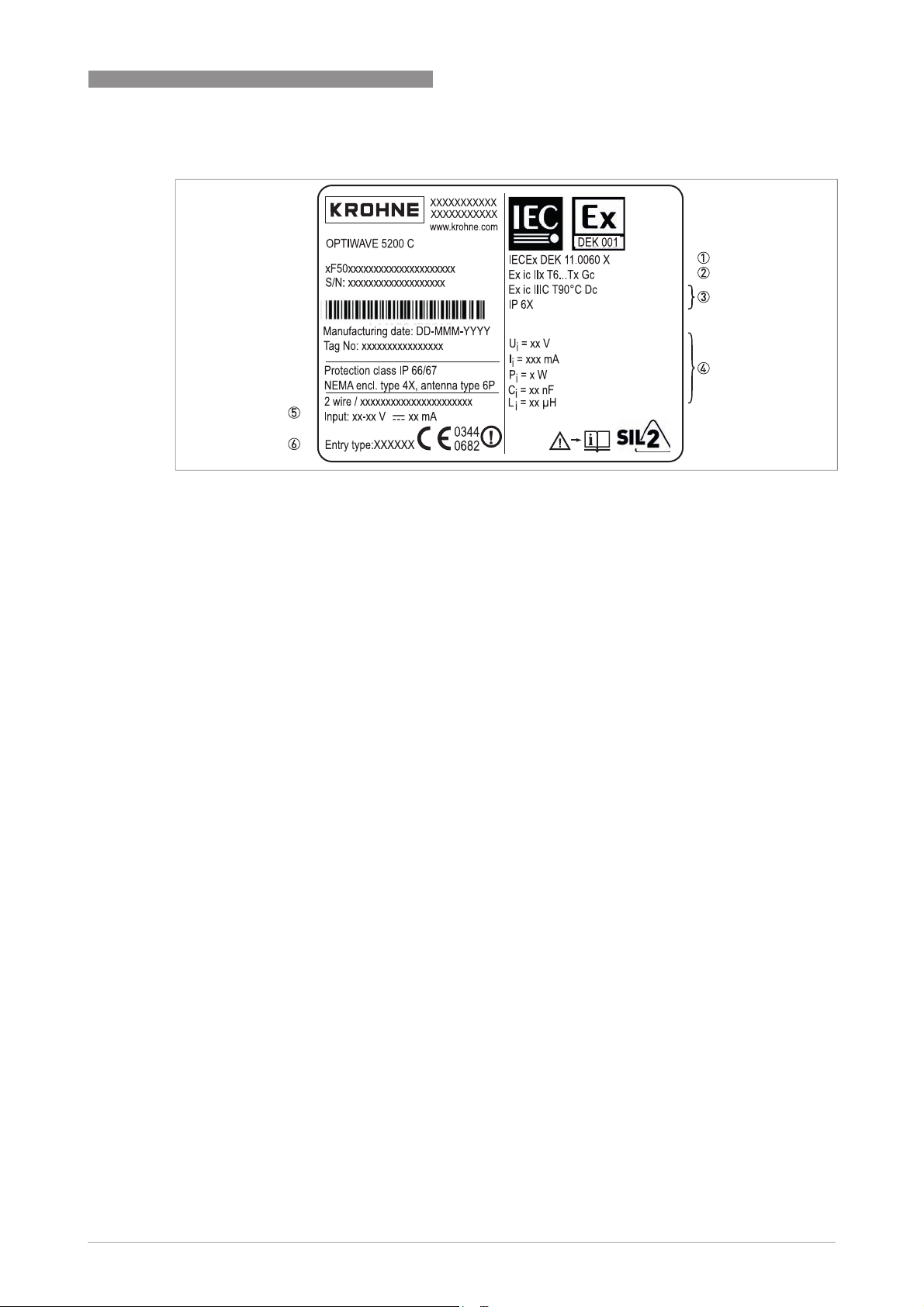

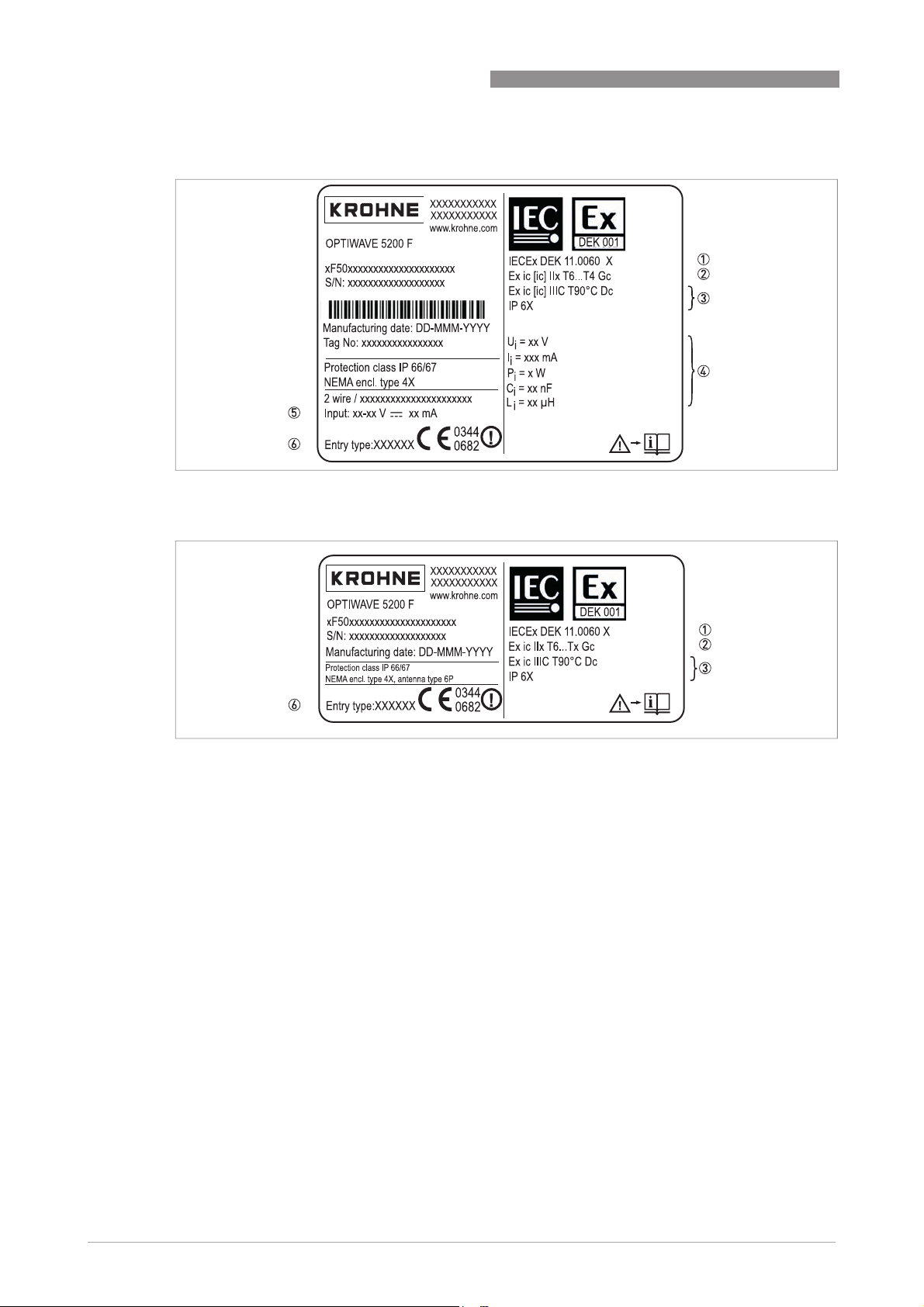

1.5 IECEx nameplates

Compact version

Figure 1-1: Compact version, Ex ia nameplate

OPTIWAVE 5200 C/F

Figure 1-2: Compact version, Ex d ia / Ex ia tb nameplate

1 IECEx certification agency code

2 Types of device protection including approved Gas Groups and temperature classes (T6...T4 or T3 or T2 - depends on

the antenna type) and equipment protection level

3 Types of device protection including approved Dust Groups, maximum surface temperature degree of ingress protec-

tion (if fitted with the appropriate cable glands) and equipment protection level

4 4...20 mA passive - HART output option:

4...20 mA passive - HART output option: Intrinsically-safe circuit data

4...20 mA passive - HART output option:4...20 mA passive - HART output option:

Fieldbus (FF or PROFIBUS PA) options:

Fieldbus (FF or PROFIBUS PA) options: Entity or FISCO power supply parameters

Fieldbus (FF or PROFIBUS PA) options:Fieldbus (FF or PROFIBUS PA) options:

5 4...20 mA passive - HART output option:

4...20 mA passive - HART output option: Maximum voltage in accordance with IEC 60079-0. Refer to 7 for the input

4...20 mA passive - HART output option:4...20 mA passive - HART output option:

voltage range.

6 4...20 mA passive - HART output option:

4...20 mA passive - HART output option: Minimum waiting time after power-off before it is safe to open the terminal

4...20 mA passive - HART output option:4...20 mA passive - HART output option:

compartment

Fieldbus (FF or PROFIBUS PA) options:

Fieldbus (FF or PROFIBUS PA) options: Entity or FISCO power supply parameters

Fieldbus (FF or PROFIBUS PA) options:Fieldbus (FF or PROFIBUS PA) options:

7 Input voltage range and maximum current (4...20 mA passive - HART) / basic current (FF or PROFIBUS PA)

8 Cable entry type and size (M20×1.5 or ½ NPT)

6

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 7

OPTIWAVE 5200 C/F

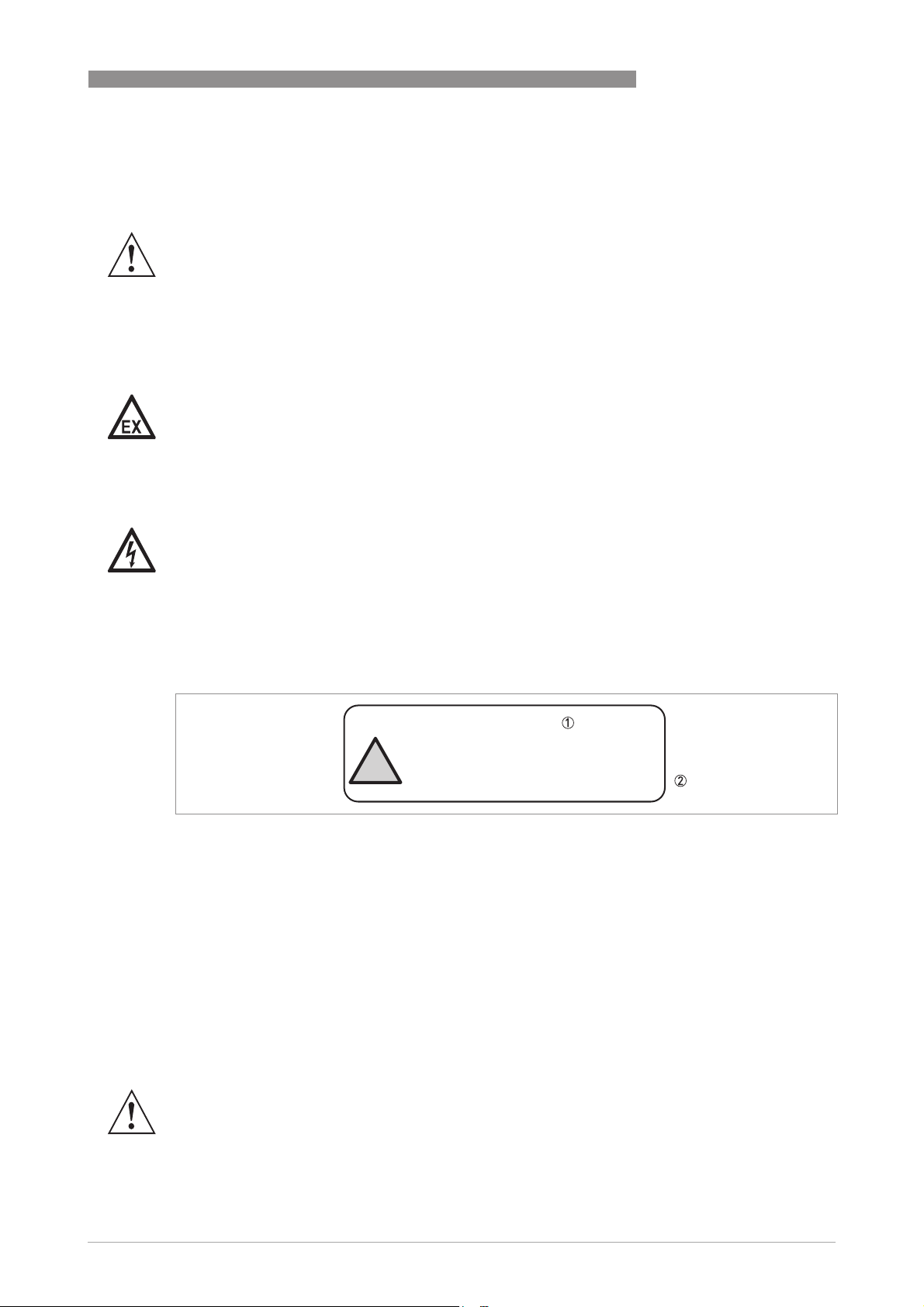

Figure 1-3: Compact version, Ex ic nameplate

1 IECEx certification agency code

2 Types of device protection including approved Gas Groups and temperature classes (T6...T4 or T3 or T2 - depends on

the antenna type) and equipment protection level

3 Types of device protection including approved Dust Groups, maximum surface temperature degree of ingress protec-

tion (if fitted with the appropriate cable glands) and equipment protection level

4 4...20 mA passive - HART output option:

4...20 mA passive - HART output option: Intrinsically-safe circuit data

4...20 mA passive - HART output option:4...20 mA passive - HART output option:

Fieldbus (FF or PROFIBUS PA) options:

Fieldbus (FF or PROFIBUS PA) options: Entity or FISCO power supply parameters

Fieldbus (FF or PROFIBUS PA) options:Fieldbus (FF or PROFIBUS PA) options:

5 Input voltage range and maximum current (4...20 mA passive - HART) / basic current (FF or PROFIBUS PA)

6 Cable entry type and size (M20×1.5 or ½ NPT)

GENERAL SAFETY INFORMATION 1

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

7

Page 8

1 GENERAL SAFETY INFORMATION

Remote (Field) version

Figure 1-4: Remote version, Ex ia nameplate on the converter housing

OPTIWAVE 5200 C/F

Figure 1-5: Remote version, Ex ia nameplate on the antenna housing

1 IECEx certification agency code

2 Types of device protection including approved Gas Groups, temperature classes (T6...T4 or T3 or T2 - depends on the

antenna type) and equipment protection level

3 Types of device protection (explosive atmosphere - dust), zones, maximum surface temperature, equipment protection

level and degree of ingress protection (if fitted with the appropriate cable glands)

4 4...20 mA passive - HART output option:

4...20 mA passive - HART output option: Intrinsically-safe circuit data for the device

4...20 mA passive - HART output option:4...20 mA passive - HART output option:

Fieldbus (FF or PROFIBUS PA) options:

Fieldbus (FF or PROFIBUS PA) options: Entity or FISCO power supply parameters

Fieldbus (FF or PROFIBUS PA) options:Fieldbus (FF or PROFIBUS PA) options:

5 Input voltage range and maximum current (4...20 mA passive - HART) / basic current (FF or PROFIBUS PA)

6 Cable entry type and size (M20×1.5 or ½NPT)

8

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 9

OPTIWAVE 5200 C/F

Figure 1-6: Remote version, Ex d / Ex ia tb nameplate on the converter housing

GENERAL SAFETY INFORMATION 1

Figure 1-7: Remote version, Ex ia nameplate on the probe housing

1 IECEx certification agency code

2 Types of device protection including approved Gas Groups, temperature classes (T6...T4 or T3 or T2 - depends on the

antenna type), equipment protection level

3 Types of device protection (explosive atmosphere - dust), zones, maximum surface temperature and degree of ingress

protection (if fitted with the appropriate cable glands)

4 4...20 mA passive - HART output option:

4...20 mA passive - HART output option: Maximum voltage in accordance with IEC 60079-0. Refer to 7 for the input

4...20 mA passive - HART output option:4...20 mA passive - HART output option:

voltage range.

5 4...20 mA passive - HART output option:

4...20 mA passive - HART output option: Minimum waiting time after power-off before it is safe to open the terminal

4...20 mA passive - HART output option:4...20 mA passive - HART output option:

compartment

Fieldbus (FF or PROFIBUS PA) options:

Fieldbus (FF or PROFIBUS PA) options: Entity or FISCO power supply parameters

Fieldbus (FF or PROFIBUS PA) options:Fieldbus (FF or PROFIBUS PA) options:

6 Input voltage range and maximum current (4...20 mA passive - HART) / basic current (FF or PROFIBUS PA)

7 Cable entry type and size (M20×1.5 or ½ NPT)

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

9

Page 10

1 GENERAL SAFETY INFORMATION

Figure 1-8: Remote version, Ex ic nameplate on the converter housing

OPTIWAVE 5200 C/F

Figure 1-9: Remote version, Ex ic nameplate on the antenna housing (fieldbus options only)

1 IECEx certification agency code

2 Types of device protection including approved Gas Groups, temperature classes (T6...T4 or T3 or T2 - depends on the

antenna type), equipment protection level

3 Types of device protection (explosive atmosphere - dust), zones, maximum surface temperature and degree of ingress

protection (if fitted with the appropriate cable glands)

4 4...20 mA passive - HART output option:

4...20 mA passive - HART output option: Intrinsically-safe circuit data

4...20 mA passive - HART output option:4...20 mA passive - HART output option:

Fieldbus (FF or PROFIBUS PA) options:

Fieldbus (FF or PROFIBUS PA) options: Entity or FISCO power supply parameters

Fieldbus (FF or PROFIBUS PA) options:Fieldbus (FF or PROFIBUS PA) options:

5 Input voltage range and maximum current (4...20 mA passive - HART) / basic current (FF or PROFIBUS PA)

6 Cable entry type and size (M20×1.5 or ½ NPT)

10

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 11

OPTIWAVE 5200 C/F

2.1 Precautions

2.1.1 General notes

WARNING!

When you install the device, obey the conditions in the IECEx approval certificate. These

conditions include:

•

The special conditions for safe use.

•

The Essential Health and Safety Requirements.

The certificate is given on the CD-ROM supplied with the device. You can also download the

certificate from our internet site.

DANGER!

This installation must agree with IEC 60079-14: Explosive atmospheres - Part 14: Electrical

installations design, selection and erection and IEC 61241-14: Electrical apparatus for use in the

presence of combustible dust - Part 14: Selection and installation.

2.1.2 Electrostatic discharge

INSTALLATION 2

DANGER!

•

The apparatus shall be installed in such a way that the risk from electrostatic discharges and

propagating brush discharges caused by rapid flow of dust is avoided.

•

Risk of electrostatic discharge from Wave Horn and Wave-Stick antennas made of PP or

PTFE.

•

Make sure that all equipment is correctly grounded.

PLASTIC PARTS

WARNING:

POTENTIAL ELECTROSTATIC HAZARD

!

SEE INSTRUCTIONS

Figure 2-1: ESD warning sticker (below the device nameplate)

1 Text: Plastic Parts

2 Text: Warning! Potential electrostatic hazard - see instructions

Take the necessary antistatic precautions if you:

• handle,

• install or

• use

the device in potentially explosive atmospheres. Do not install in a location (near ventilation

systems, for example) where the electrostatic charge can increase.

WARNING!

If there is a risk of electrostatic discharge, Wave Horn and Wave-Stick antennas (made of PP or

PTFE) cannot be used with Gas group IIC or in Zone 0.

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

11

Page 12

2 INSTALLATION

OPTIWAVE 5200 C/F

2.2 Operating conditions

The allowable ambient temperature and corresponding flange temperature range for the device

depends on the IEC equipment protection level (EPL) and temperature classes marked on the

nameplate.

2.2.1 Ambient and flange temperature

The IEC equipment protection level and temperature class give the ambient temperature and

related flange temperature ranges for the device.

WARNING!

The gasket temperature must be in the approved limits. The minimum gasket temperature is:

The gasket temperature must be in the approved limits. The minimum gasket temperature is:

The gasket temperature must be in the approved limits. The minimum gasket temperature is:The gasket temperature must be in the approved limits. The minimum gasket temperature is:

Gasket material Antenna type Minimum process connection temperature

[°C] [°F]

PFA Metallic Horn

EPDM -50 -58

FKM/FPM -40 -40

Kalrez® 6375

- PTFE Wave Horn -50 -58

- PP Wave Horn

Wave-Guide

Wave-Stick

-60 -76

-20 -4

-20 -4

For more data, refer to "Pressure and temperature ranges" in the Installation chapter of the

handbook.

Definitions

12

Figure 2-2: Definitions

1 Compact version: Signal converter, process connection and antenna

2 Remote (Field) version: remote converter

3 Remote (Field) version: antenna housing, process connection and antenna

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 13

OPTIWAVE 5200 C/F

WARNING!

Compact version only: If the device is used in a potentially explosive atmosphere that contains

dust, do not install the device on the side of the tank.

If the device must operate at a high process temperature, make sure that the maximum flange

temperature and maximum ambient temperature are not more than the values given in the

table.

The temperature data that follows is applicable to devices that have the 4...20 mA passive -

HART, PROFIBUS PA or FOUNDATION™ fieldbus output options.

Compact versions

EPL Ga/Gb: Ex ia and Ex d ia devices

INSTALLATION 2

Temperature

class

PP Wave Horn PTFE Wave Horn

[°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F]

T6 +46 +115 +46 +115 +46 +115 +46 +115 +45 +113

T5 +41 +106 +42 +108 +41 +106 +44 +111 +55 +131

T4 +38 +100 +40 +104 +39 +102 +43 +109 +60 +140

Temperature

class

PP Wave Horn

Wave-Stick

[°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F]

T6...T2 -40 -40 -40 -40 -40 -40 -40 -40 -20 -4

Maximum ambient temperature Max. flange

Metallic Horn

Wave-Stick

Minimum ambient temperature Min. flange

PTFE Wave Horn Metallic Horn

(standard

temperature)

Wave-Guide

(standard

temperature)

Wave-Guide

Metallic Horn

(high-

temperature)

Metallic Horn

(high-

temperature)

temperature

temperature

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

13

Page 14

2 INSTALLATION

Compact version

EPL Gb: Ex ia and Ex d ia devices

EPL Gc: Ex ic devices

OPTIWAVE 5200 C/F

Temperature

class

PP Wave Horn PTFE Wave Horn

Maximum ambient temperature Max. flange

temperature

Wave-Stick

Metallic Horn

(standard

temperature)

Metallic Horn

(high-

temperature)

Wave-Guide

[°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F]

T6 +46 +115 +46 +115 +46 +115 +46 +115 +45 +113

+41 +106 +42 +108 +41 +106 +44 +111 +55 +131

+38 +100 +40 +104 +39 +102 +43 +109 +60 +140

T5 +53 +127 +55 +131 +54 +129 +58 +136 +75 +167

+40 +104 +44 +111 +43 +109 +54 +129 +100 +212

T4 +77 +171 +77 +171 +77 +171 +79 +174 +85 +185

+69 +156 +71 +160 +70 +158 +76 +169 +110 +230

- - +57 +135 +54 +129 +71 +160 +135 1 +275 1

T3 - - +50 +122 +48 +118 +68 +154 +150 1 +302 1

- - - - - - +64 +147 +180 1 +356 1

- - - - - - +61 +142 +200 1 +392 1

T2 - - - - - - +53 +127 +250 1 +482 1

1 Make sure that gasket temperature is in the specified limits. For more data, refer to the handbook.

Temperature

class

PP Wave Horn

Wave-Stick

Minimum ambient temperature Min. flange

temperature

PTFE Wave Horn Metallic Horn

(standard

temperature)

Metallic Horn

(high-

temperature)

Wave-Guide

[°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F]

T6...T2 -40 -40 -40 -40 -40 -40 -40 -40 -40 1 -40 1

- - -36 -32 -35 -31 -37 -34 -50 1 -58 1

- - - - - - -37 -34 -60 1 -76

1 Make sure that gasket temperature is in the specified limits. For more data, refer to the handbook.

14

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 15

OPTIWAVE 5200 C/F

Remote (Field) versions (antenna housing only)

EPL Ga/Gb: Ex ia and Ex d ia devices

INSTALLATION 2

Temperature

class

PP Wave Horn PTFE Wave Horn

[°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F]

T6 +46 +115 +46 +115 +46 +115 +46 +115 +45 +113

T5 +41 +106 +41 +106 +41 +106 +44 +111 +55 +131

T4 +39 +102 +39 +102 +39 +102 +43 +109 +60 +140

Temperature

class

PP Wave Horn

Wave-Stick

[°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F]

T6...T2 -40 -40 -40 -40 -40 -40 -40 -40 -20 -4

Maximum ambient temperature Max. flange

Metallic Horn

Wave-Stick

Minimum ambient temperature Min. flange

PTFE Wave Horn Metallic Horn

(standard

temperature)

Wave-Guide

(standard

temperature)

Wave-Guide

Metallic Horn

(high-

temperature)

Metallic Horn

(high-

temperature)

temperature

temperature

INFORMATION!

Remote converter

Remote converter

Remote converterRemote converter

The maximum ambient temperature, T

•

Ta= +60°C for class T6

•

Ta= +70°C for class T5

•

Ta= +80°C for class T4

, permitted depends on the temperature class:

a

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

15

Page 16

2 INSTALLATION

Remote (Field) version (antenna housing only)

EPL Gb: Ex ia and Ex d ia devices

EPL Gc: Ex ic devices

OPTIWAVE 5200 C/F

Temperature

class

PP Wave Horn PTFE Wave Horn

Maximum ambient temperature Max. flange

temperature

Wave-Stick

Metallic Horn

(standard

temperature)

Metallic Horn

(high-

temperature)

Wave Guide

[°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F]

T6 +46 +115 +46 +115 +46 +115 +46 +115 +45 +113

+41 +106 +41 +106 +41 +106 +44 +111 +55 +131

+39 +102 +39 +102 +39 +102 +43 +109 +60 +140

T5 +54 +129 +54 +129 +54 +129 +59 +138 +75 +167

+43 +109 +43 +109 +41 +106 +55 +131 +100 +212

T4 +77 +171 +77 +171 +77 +171 +79 174 +85 +185

+70 +158 +71 +160 +70 +158 +77 +171 +110 +230

- - +55 +131 +53 +127 +72 +162 +135 1 +275 1

T3 - - +48 +118 +45 +113 +66 +151 +150 1 +302 1

- - - - - - +63 +145 +180 1 +356 1

- - - - - - +57 +135 +200 1 +392 1

T2 - - - - - - +53 +127 +250 1 +482 1

1 Make sure that gasket temperature is in the specified limits. For more data, refer to the handbook.

Temperature

class

PP Wave Horn

Wave-Stick

Minimum ambient temperature Min. flange

temperature

PTFE Wave Horn Metallic Horn

(standard

temperature)

Metallic Horn

(high-

temperature)

Wave Guide

[°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F]

T6...T2 -40 -40 -40 -40 -40 -40 -40 -40 -40 1 -40 1

- - -36 -33 -35 -31 -39 -38 -50 1 -58 1

- - - - - - -37 -34 -60 1 -76 1

1 Make sure that gasket temperature is in the specified limits. For more data, refer to the handbook.

INFORMATION!

Remote converter

Remote converter

Remote converterRemote converter

The maximum ambient temperature, T

•

Ta= +60°C for class T6

•

Ta= +70°C for class T5

•

Ta= +80°C for class T4

, permitted depends on the temperature class:

a

16

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 17

OPTIWAVE 5200 C/F

INSTALLATION 2

Compact and Remote (Field) versions - PP and PFTE Wave Horn antennas

EPL Da/Db, Db: Ex ia and Ex ia tb devices

EPL Dc: Ex ic devices

Flange

Ambient temperature

temperature

PP Wave Horn PTFE Wave Horn and Wave-Stick

Compact version Remote (Field)

version

Compact version Remote (Field)

version

[°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F]

+80 +176 +80 +176 +80 +176 +80 +176 +80 +176

+90 +194 +75 +167 +75 +167 +76 +169 +76 +169

+100 +212 +70 +158 +71 +160 +72 +162 +71 +160

+110 +230 - - - - +68 +154 +67 +153

+120 +248 - - - - +63 +145 +62 +144

+130 +266 - - - - +59 +138 +58 +136

+140 +284 - - - - +55 +131 +54 +129

+150 +302 - - - - +51 +124 +49 +120

+160 +320 - - - - - - - -

+170 +338 - - - - - - - -

+180 +356 - - - - - - - -

+190 +374 - - - - - - - -

+200 +392 - - - - - - - -

+210 +410 - - - - - - - -

+220 +428 - - - - - - - -

+230 +446 - - - - - - - -

+240 +464 - - - - - - - -

+250 +482 - - - - - - - -

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

17

Page 18

2 INSTALLATION

Compact and Remote (Field) versions - Metallic Horn and Wave Guide antennas

EPL Da/Db, Db: Ex ia and Ex ia tb devices

EPL Dc: Ex ic devices

OPTIWAVE 5200 C/F

Flange

Ambient temperature

temperature

Metallic Horn (standard temperature)

Metallic Horn (high-temperature)

Wave Guide

Compact version Remote (Field)

version

Compact version Remote (Field)

version

[°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F] [°C] [°F]

+80 +176 +80 +176 +80 +176 +80 +176 +80 +176

+90 +194 +75 +167 +75 +167 +78 +172 +79 +174

+100 +212 +71 +160 +70 +158 +77 +171 +77 +171

+110 +230 +66 +151 +65 +149 +75 +167 +76 +169

+120 +248 +62 +144 +60 +140 +74 +165 +75 +167

+130 +266 +57 +135 +55 +131 +72 +162 +73 +163

+140 +284 +53 +127 +51 +124 +71 +160 +72 +162

+150 +302 +48 +118 +46 +115 +69 +156 +71 +160

+160 +320 - - - - +67 +153 +69 +156

+170 +338 - - - - +66 +151 +68 +154

+180 +356 - - - - +64 +147 +67 +153

+190 +374 - - - - +63 +145 +65 +149

+200 +392 - - - - +61 +142 +64 +147

+210 +410 - - - - +60 +140 +63 +145

+220 +428 - - - - +58 +136 +61 +142

+230 +446 - - - - +56 +133 +60 +140

+240 +464 - - - - +55 +131 +59 +138

+250 +482 - - - - +53 +127 +57 +135

18

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 19

OPTIWAVE 5200 C/F

INSTALLATION 2

2.2.2 Maximum surface temperature of the housing for dust applications

WARNING!

Equipment category 1/2D, 2D, 3D or EPL Da/Db, Db, Dc: Ex ia, Ex ia tb and Ex ic devices only

Equipment category 1/2D, 2D, 3D or EPL Da/Db, Db, Dc: Ex ia, Ex ia tb and Ex ic devices only

Equipment category 1/2D, 2D, 3D or EPL Da/Db, Db, Dc: Ex ia, Ex ia tb and Ex ic devices onlyEquipment category 1/2D, 2D, 3D or EPL Da/Db, Db, Dc: Ex ia, Ex ia tb and Ex ic devices only

If the ambient and flange temperatures of the device are not more than values given in the table

for Ex ia, Ex ia tb and Ex ic devices, the surface temperature of the housing will not be more than

°

C / +194°F.

+90

For more data, refer to the table for Ex ia, Ex ia tb and Ex ic devices in the "Ambient and flange

temperature" section.

2.2.3 Process pressure

Equipment protection level (EPL) Allowable process pressure

[kPa] [psi]

Ga/Gb 80…110 1 11.6…16 1

Others As per non-Ex device As per non-Ex device

1 Atmospheric pressure

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

19

Page 20

3 ELECTRICAL CONNECTIONS

3.1 General notes

WARNING!

•

De-energize the circuit.

•

Use the applicable cable glands for the cable entry openings in the housing (M20×1.5 or

½

NPT). For the cable entry size, refer to the device nameplate.

•

If ambient temperature >65°C / >149°F, use heat-resistant cables, cable glands and cable

entry plugs certified for continuous operation above +80

3.2 Terminal compartment

3.2.1 How to open the terminal compartment

WARNING!

If dirt collects on the housing, clean the device before you remove the terminal compartment

cover.

How to open the Ex i terminal compartment

°

C / +176°F.

OPTIWAVE 5200 C/F

Figure 3-1: How to open the Ex i terminal compartment

How to open the Ex d / Ex t terminal compartment

Figure 3-2: How to open the Ex d / Ex t terminal compartment

1 Cover stop

2 Terminal compartment cover

20

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 21

OPTIWAVE 5200 C/F

Equipment needed (not supplied)

• 2.5 mm Allen wrench.

INFORMATION!

Ex i applications

Ex i applications

Ex i applicationsEx i applications

If you remove the terminal compartment cover, the device has a degree of ingress protection

IP 20.

WARNING!

Ex d / Ex t applications

Ex d / Ex t applications

Ex d / Ex t applicationsEx d / Ex t applications

Do not remove the terminal compartment cover while the electrical power is connected.

• De-energize the circuit.

• After the time given in the table that follows, remove the cover stop 1.

i Use a 2.5 mm allen wrench.

• Remove the terminal compartment cover 2.

Ex d ia- or Ex ia tb-approved devices:

Time for the internal temperature of the housing to decrease to a safe level

ELECTRICAL CONNECTIONS 3

Temperature class Time for the internal temperature of the housing to

T6, T5 10

T4, T3, T2 Not necessary

3.2.2 How to close the terminal compartment

Ex i applications

• Attach the terminal compartment cover 2. Turn the terminal compartment cover carefully to

prevent damage to the thread and the gasket.

• Make sure that the terminal compartment cover is tight.

DANGER!

Ex d / Ex t applications

Ex d / Ex t applications

Ex d / Ex t applicationsEx d / Ex t applications

Make sure that the terminal compartment is correctly sealed. An explosion can cause death or

injury to personnel and/or damage to equipment. Obey the instructions that follow:

Ex d / Ex t applications

• Attach the terminal compartment cover 2. Turn the terminal compartment cover carefully to

prevent damage to the thread and the gasket.

• Make sure that the terminal compartment cover is tight.

• Use a 2.5 mm Allen wrench to attach the cover stop 1.

• Make sure that the cover stop 1 screw is tight.

decrease to a safe level

[minutes]

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

21

Page 22

3 ELECTRICAL CONNECTIONS

3.3 Terminal tightening capacity

The terminal tightening capacity for the current output terminal and the communication cable is:

Type of wire Terminal tightening capacity

Rigid 4 11

Flexible 2.5 13

3.4 Equipotential bonding system

Compact version

There is a terminal at the bottom of the converter that can be used as an equipotential bonding

conductor. Connect the device to the equipotential bonding system for the hazardous location.

Remote (Field) version

There is a terminal on the wall support and a terminal at the bottom of the antenna housing that

can be used as equipotential bonding conductors. Connect the device to the equipotential

bonding system for the hazardous location.

OPTIWAVE 5200 C/F

[mm²] [AWG]

22

Figure 3-3: Ex i applications: Terminals for the equipotential bonding system

Figure 3-4: Ex d / Ex t applications: Terminals for the equipotential bonding system

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 23

OPTIWAVE 5200 C/F

ELECTRICAL CONNECTIONS 3

3.5 Ex ia equipment

3.5.1 How to connect the electrical cables

Cable entries are supplied on customer demand. If you supply the cable entries, this part must

have a degree of ingress protection IP≥6x (IEC 60529).

• Use the electrical connection procedure in the Handbook.

• If possible, use galvanically-isolated equipment.

• Supply the Ex i equipment connected to the device. Use only certified intrinsically-safe

equipment.

• Connect only to separate certified, intrinsically-safe circuits. Make sure that the electrical

circuit characteristics are not more than the values that follow.

• Do not remove more than 6 mm / 0.2¨ of insulation from the wire.

3.5.2 Maximum intrinsically-safe values for the electrical circuit

Output option Intrinsically-safe values for the electrical circuit

4...20 mA passive - HART ≤30 ≤300 ≤1 =30 =30

PROFIBUS PA

FOUNDATION™ fieldbus

3.5.3 Supply voltage

Level transmitter with the 4...20 mA output option

Current output terminal 12 1 30 1

1 For a current output of 22 mA

Level transmitter with the PROFIBUS PA or FOUNDATION fieldbus output options

Output terminal Entity 9 24

U

i

I

i

P

i

C

i

L

i

[V] [mA] [W] [nF] [µH]

Entity ≤24 ≤300 ≤1.2 =1 =0

FISCO ≤17.5 ≤380 ≤5.32 =1 =0

Minimum voltage at

output terminal [VDC]

Minimum voltage at

output terminal [VDC]

FISCO 9 17.5

Maximum voltage at

output terminal [VDC]

Maximum voltage at

output terminal [VDC]

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

23

Page 24

3 ELECTRICAL CONNECTIONS

3.5.4 Electrical schematic

Level transmitter with the 4...20 mA passive - HART output option

Figure 3-5: Electrical schematic for Ex ia-approved equipment with the 4...20 mA passive - HART output option

Level transmitter with the FOUNDATION™ fieldbus or PROFIBUS PA output option

OPTIWAVE 5200 C/F

Figure 3-6: Electrical schematic for Ex ia-approved equipment with the FOUNDATION™ fieldbus or PROFIBUS PA

output option

1 Intrinsically-safe power supply

2 Approved barrier with entity parameters or FISCO power supply

3 Non-Ex zone

4 Ex zone

5 Resistor for HART

6 Grounding wire - if the electrical cable is shielded (braided wire etc.). NOTE: Shielded electrical cable is mandatory

for fieldbus output options.

Remote (Field) version

Remote (Field) version

Remote (Field) versionRemote (Field) version

®

communication

The communication cable (between the converter electronics and the probe end electronics) is

supplied by the manufacturer for IECEx applications. The communication cable cannot be

changed by the user. For more data, speak to the supplier.

24

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 25

OPTIWAVE 5200 C/F

3.6 Ex d ia / Ex ia tb equipment

3.6.1 General notes

Ex d ia- and Ex ia tb-approved equipment have two separate compartments. The electronics in

the electronics block compartment are Ex ia-approved and the terminals compartment is Ex d /

Ex t-approved.

ELECTRICAL CONNECTIONS 3

Figure 3-7: Compact version: Compartments in Ex d ia- and Ex ia tb-approved equipment

Figure 3-8: Remote (Field) version: Compartments in Ex d ia- and Ex ia tb-approved equipment

1 Electronics block (Ex ia) compartment

2 Terminal (Ex d / Ex t) compartment

INFORMATION!

The flamepath dimensions are better than the values specified in the International Standard

µ

IEC 60079-1 (minimum length 13.9 mm and maximum gap 118

m).

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

25

Page 26

3 ELECTRICAL CONNECTIONS

3.6.2 How to connect the electrical cables

Cable entries are supplied on customer demand. If you supply the cable entries, this part must

have a degree of ingress protection IP≥6x (IEC 60529).

WARNING!

Use only Ex d-approved cable entries and plugs for Ex d applications. Use only Ex t-approved

cable entries and plugs for Ex t applications.

Do not remove more than 6 mm / 0.2

• Do not remove more than 6 mm / 0.2¨ of insulation from the wire.

• Connect the load resistor to the positive terminal of the power supply

• Ground the negative connection.

• If the load resistor has to be connected to the negative terminal, the loop resistance must not

be more than 350 ohms.

CAUTION!

4...20 mA passive - HART output option:

4...20 mA passive - HART output option: Do not ground the positive connection.

4...20 mA passive - HART output option:4...20 mA passive - HART output option:

¨

of insulation from the wire.

OPTIWAVE 5200 C/F

3.6.3 Supply voltage

INFORMATION!

For maximum intrinisically-safe values, refer to Maximum intrinsically-safe values for the

electrical circuit on page 23

Level transmitter with the 4...20 mA output option

Current output terminal 16 1 36 1

1 For a current output of 22 mA

Level transmitter with the PROFIBUS PA or FOUNDATION fieldbus output options

Output terminal Entity 9 24

For more data, refer to

.

Minimum voltage at

output terminal [VDC]

Minimum voltage at

output terminal [VDC]

FISCO 9 17.5

Maximum intrinsically-safe values for the electrical circuit

Maximum voltage at

output terminal [VDC]

Maximum voltage at

output terminal [VDC]

on page 23.

26

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 27

OPTIWAVE 5200 C/F

3.6.4 Electrical schematic

DANGER!

Keep the grounding wire a minimum distance of 2 mm / 0.83

CAUTION!

Make sure that you connect the load resistor to the positive side.

Level transmitter with the 4...20 mA passive - HART output option

ELECTRICAL CONNECTIONS 3

¨

away from the output terminal.

Figure 3-9: Electrical schematic for Ex d ia / Ex ia tb-approved equipment (with galvanic isolation)

Figure 3-10: Electrical schematic for Ex d ia / Ex ia tb-approved equipment (without galvanic isolation)

1 Galvanically-isolated power supply

2 Power supply

3 Resistor for HART

4 Non-Ex zone

5 Ex zone

6 |U| < 13 V

7 Grounding wire - if the electrical cable is shielded (braided wire etc.)

®

communication

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

27

Page 28

3 ELECTRICAL CONNECTIONS

Level transmitter with the FOUNDATION™ fieldbus or PROFIBUS PA output option

Figure 3-11: Electrical schematic for Ex d ia / Ex ia tb-approved equipment with the FOUNDATION™ fieldbus or

PROFIBUS PA output option

1 Approved barrier with entity parameters or FISCO power supply. For more data, refer to

values for the electrical circuit

2 Non-Ex zone

3 Ex zone

4 Grounding wire. NOTE: Shielded electrical cable is mandatory for fieldbus output options.

Remote (Field) version

Remote (Field) version

Remote (Field) versionRemote (Field) version

The communication cable (between the converter electronics and the probe end electronics) is

supplied by the manufacturer for IECEx applications. The communication cable cannot be

changed by the user. For more data, speak to the supplier.

on page 23.

OPTIWAVE 5200 C/F

Maximum intrinsically-safe

3.7 Ex ic equipment

3.7.1 How to connect the electrical cables

Cable entries are supplied on customer demand. If you supply the cable entries, this part must

have a degree of ingress protection IP≥6x (IEC 60529).

• Use the electrical connection procedure in the Handbook.

• If possible, use galvanically-isolated equipment.

• Supply the Ex i equipment connected to the device. Use only certified intrinsically-safe

equipment.

• Connect only to separate certified, intrinsically-safe circuits. Make sure that the electrical

circuit characteristics are not more than the values that follow.

• Do not remove more than 6 mm / 0.2¨ of insulation from the wire.

3.7.2 Maximum intrinsically-safe values for the electrical circuit

Output option Intrinsically-safe values for the electrical circuit

4...20 mA passive - HART ≤30 ≤300 ≤1 =30 =30

PROFIBUS PA

FOUNDATION™ fieldbus

1 Ii and Pi values are not applicable.

U

i

[V] [mA] [W] [nF] [µH]

Entity ≤32

FISCO ≤17.5

I

i

1 1

1 1

P

i

C

i

=1 =0

=1 =0

L

i

28

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 29

OPTIWAVE 5200 C/F

3.7.3 Supply voltage

Level transmitter with the 4...20 mA output option

ELECTRICAL CONNECTIONS 3

Current output terminal 12 1 30 1

1 For a current output of 22 mA

Level transmitter with the PROFIBUS PA or FOUNDATION fieldbus output options

Output terminal Entity 9 32

3.7.4 Electrical schematic

Level transmitter with the 4...20 mA passive - HART output option

Minimum voltage at

output terminal [VDC]

Minimum voltage at

output terminal [VDC]

FISCO 9 17.5

Maximum voltage at

output terminal [VDC]

Maximum voltage at

output terminal [VDC]

Figure 3-12: Electrical schematic for Ex ic-approved equipment with the 4...20 mA passive - HART output option

Level transmitter with the FOUNDATION™ fieldbus or PROFIBUS PA output option

Figure 3-13: Electrical schematic for Ex ic-approved equipment with the FOUNDATION™ fieldbus or PROFIBUS PA

output option

1 Approved barrier with entity parameters or FISCO power supply

2 Non-Ex zone

3 Ex zone

4 Grounding wire - if the electrical cable is shielded (braided wire etc.). NOTE: Shielded electrical cable is mandatory

for fieldbus output options.

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

29

Page 30

3 ELECTRICAL CONNECTIONS

Remote (Field) version

Remote (Field) version

Remote (Field) versionRemote (Field) version

The communication cable (between the converter electronics and the probe end electronics) is

supplied by the manufacturer for IECEx applications. The communication cable cannot be

changed by the user. For more data, speak to the supplier.

OPTIWAVE 5200 C/F

30

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 31

OPTIWAVE 5200 C/F

WARNING!

Make sure that it is safe to supply electrical power. Do a start-up check:

• Are the wetted components (gasket, flange and antenna) resistant to corrosion by the tank

product?

• Does the information given on the nameplate agree with the application?

• Did you connect the equipotential bonding system correctly?

• Ex d applications:

Ex d applications: Are the cable entries, plugs and adaptors Ex d-approved?

Ex d applications:Ex d applications:

• Ex t applications:

Ex t applications: Are the cable entries, plugs and adaptors Ex t-approved?

Ex t applications:Ex t applications:

• Ex ia applications:

Ex ia applications: Are you using an intrinsically-safe barrier within the correct parameters?

Ex ia applications: Ex ia applications:

For more data, refer to

not be more than the maximum intrinsically-safe values.

• Ex ic applications:

Ex ic applications: Are you using an intrinsically-safe barrier within the correct parameters?

Ex ic applications: Ex ic applications:

For more data, refer to

not be more than the maximum intrinsically-safe values.

• Did you install the correct cable entries? Is the terminal compartment correctly sealed?

• Does the optional purging system agree with Ex requirements?

Ex ia equipment

Ex ic equipment

START-UP 4

on page 23. The electrical circuit characteristics must

on page 28. The electrical circuit characteristics must

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

31

Page 32

5 SERVICE

5.1 Periodic maintenance

No maintenance is necessary.

5.2 Keep the device clean

Obey these instructions:

• Keep the thread of the terminal compartment cover clean.

• If dirt collects on the device, clean it.

5.3 Returning the device to the manufacturer

5.3.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

OPTIWAVE 5200 C/F

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralising, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

32

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 33

OPTIWAVE 5200 C/F

5.3.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

SERVICE 5

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

33

Page 34

6 NOTES

OPTIWAVE 5200 C/F

34

www.krohne.com 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

Page 35

OPTIWAVE 5200 C/F

NOTES 6

www.krohne.com04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en

35

Page 36

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Products and systems for the oil & gas industry

• Measuring systems for the marine industry

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

© KROHNE 04/2013 - 4001906102 - AD IECEX OPTIWAVE 5200 R02 en - Subject to change without notice.

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...