Page 1

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

User Guide

Optiwave

(FMCW)

Device

Asset Management

Solutions (AMS)

HART Communicator 375

Version 1.1

January 2008

© 2006 KROHNE SAS 26103 Romans (France) Page 1 of 34

Page 2

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

Table of Contents

1 HART® Transmitter Revisions and Instrument Firmware ............................................................................................................ 3

1.1 Device Revision ....................................................................................................................................................................... 3

1.2 DD Revision ............................................................................................................................................................................ 3

2 Installation of DLL in AMS ........................................................................................................................................................... 3

3 Menu .............................................................................................................................................................................................. 3

3.1 Access Rights .......................................................................................................................................................................... 3

3.1.1 Password protection implementation ............................................................................................................................. 3

3.1.2 Supervisor Password ...................................................................................................................................................... 4

3.1.3 Service Password ........................................................................................................................................................... 5

3.2 Save Device Parameters .......................................................................................................................................................... 6

3.3 Diagnostic and Test ................................................................................................................................................................. 7

3.3.1 Internal Test ................................................................................................................................................................... 7

3.3.2 Set Output1 .................................................................................................................................................................... 9

3.3.3 Set Output2 .................................................................................................................................................................. 10

3.4 Calibration ............................................................................................................................................................................. 10

3.4.1 Output1 Lower ............................................................................................................................................................. 10

3.4.2 Output1 Upper.............................................................................................................................................................. 12

3.5 Tables .................................................................................................................................................................................... 14

3.5.1 Volume/Mass Table ..................................................................................................................................................... 14

3.5.2 Linearisation Table ...................................................................................................................................................... 16

3.5.3 Delete Tables ............................................................................................................................................................... 17

3.6 Empty Spectrum Recording ................................................................................................................................................... 18

3.7 Reset ...................................................................................................................................................................................... 20

3.7.1 Factory Reset ............................................................................................................................................................... 20

3.7.2 Customer Reset ............................................................................................................................................................ 21

3.7.3 Device Reset ................................................................................................................................................................ 22

3.8 Configuration Variables ........................................................................................................................................................ 23

3.8.1 Installation Parameters1 ............................................................................................................................................... 23

3.8.2 Installation Parameters2 ............................................................................................................................................... 24

3.8.3 Output Selection ........................................................................................................................................................... 25

3.8.4 Primary Output Setting ................................................................................................................................................ 26

3.8.5 Secondary Output Setting ............................................................................................................................................ 27

3.8.6 Service.......................................................................................................................................................................... 28

3.8.7 HART ........................................................................................................................................................................... 29

3.8.8 Device .......................................................................................................................................................................... 30

3.9 Process Variable .................................................................................................................................................................... 31

3.10 Device Diagnostic .................................................................................................................................................................. 32

4 Status Meaning............................................................................................................................................................................. 33

5 HART® Communicator 375 (HC375) ......................................................................................................................................... 34

5.1 Offline Restriction ................................................................................................................................................................. 34

5.2 Save Device Parameters ........................................................................................................................................................ 34

© 2006 KROHNE SAS 26103 Romans (France) Page 2 of 34

Page 3

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

1 HART® Transmitter Revisions and Instrument Firmware

1.1 Device Revision

The Optiwave HART® transmitter has only one revision: Device revision 1.

1.2 DD Revision

Optiwave 7300C has the DD revision 2.

DD is tested with AMS 9.0.

2 Installation of DLL in AMS

Refer to the AMS help to install the device (Optiwave 7300C) into an AMS System.

3 Menu

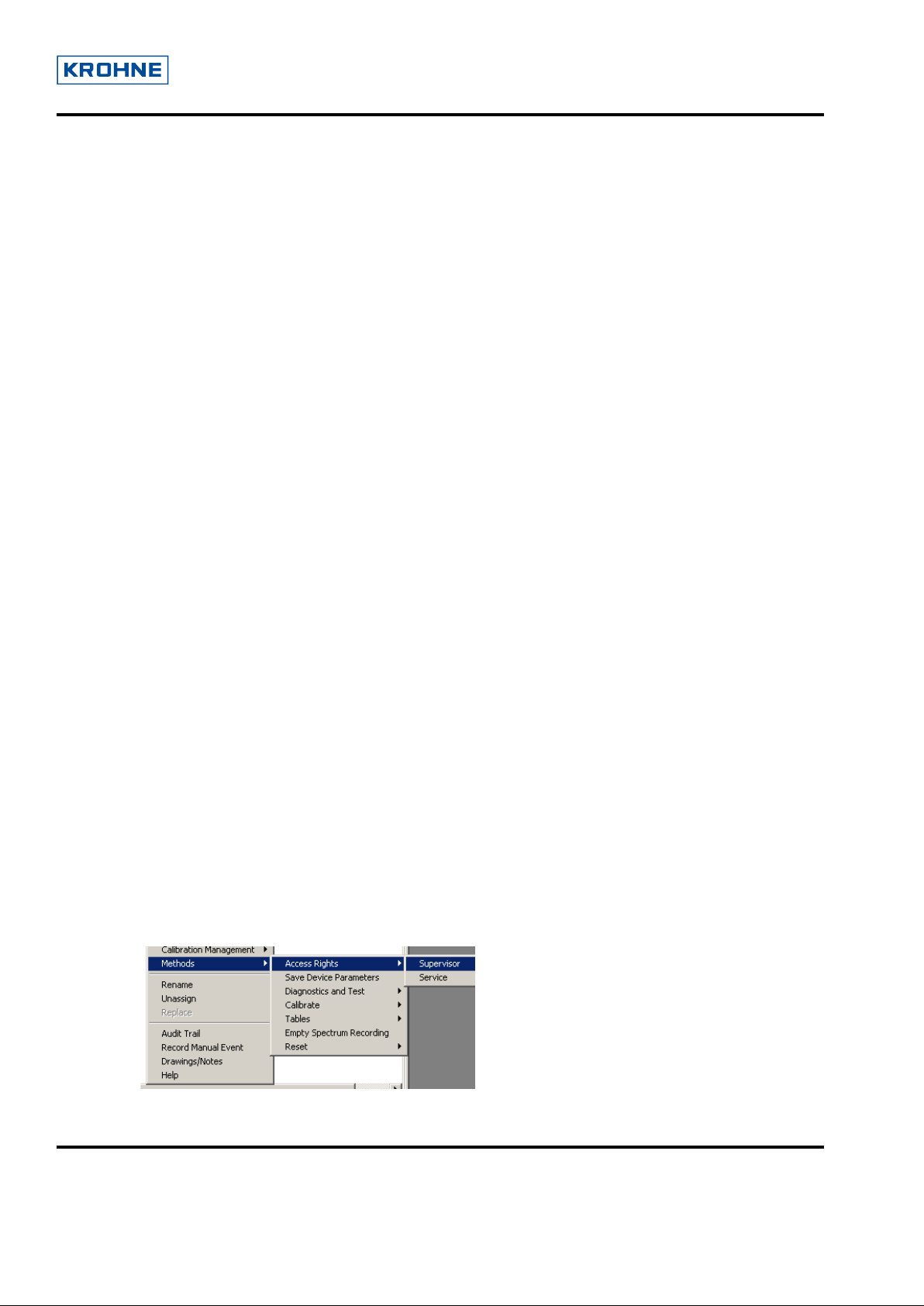

3.1 Access Rights

3.1.1 Password protection implementation

There will be two user login, Supervisor & Service which is implemented in <Access Rights>

menu. By default, Supervisor can see & edit all parameters except service parameter. After service

person is logged in he can see & edit all the parameters including the service parameters and

tables.

Password can be numeric digits from 0-9. There may be maximum six digits password. As we

can’t store the password directly in AMS, we are validating the password in AMS by reading the

password from device. Password setting facility is not given from AMS to avoid conflicts to know

the password to login from HMI. After validation it will give following messages “Supervisor

Password OK” or “Service Password OK” as per the login. On clicking the Access Rights on the

main menu, two submenus appear as Supervisor and Service.

© 2006 KROHNE SAS 26103 Romans (France) Page 3 of 34

Page 4

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

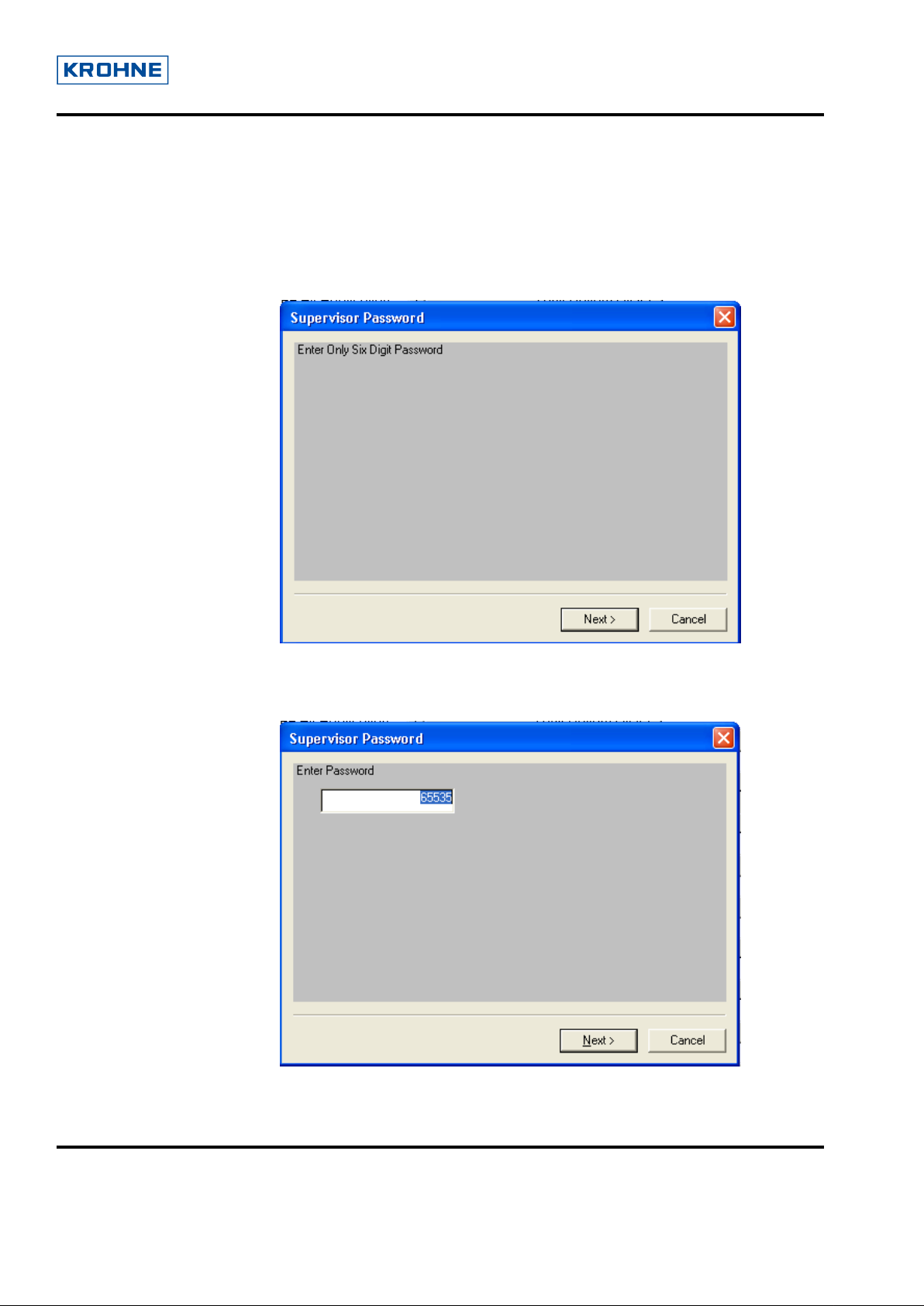

3.1.2 Supervisor Password

On clicking Supervisor it shows the following screen.

Note: Before accessing this menu user needs to select the “configuration variables” for

synchronization of all device parameters and for proper validation of the device parameters.

On clicking next, it shows the following window, which asks user to enter the Supervisor

Password with the default value as 65535.

© 2006 KROHNE SAS 26103 Romans (France) Page 4 of 34

Page 5

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

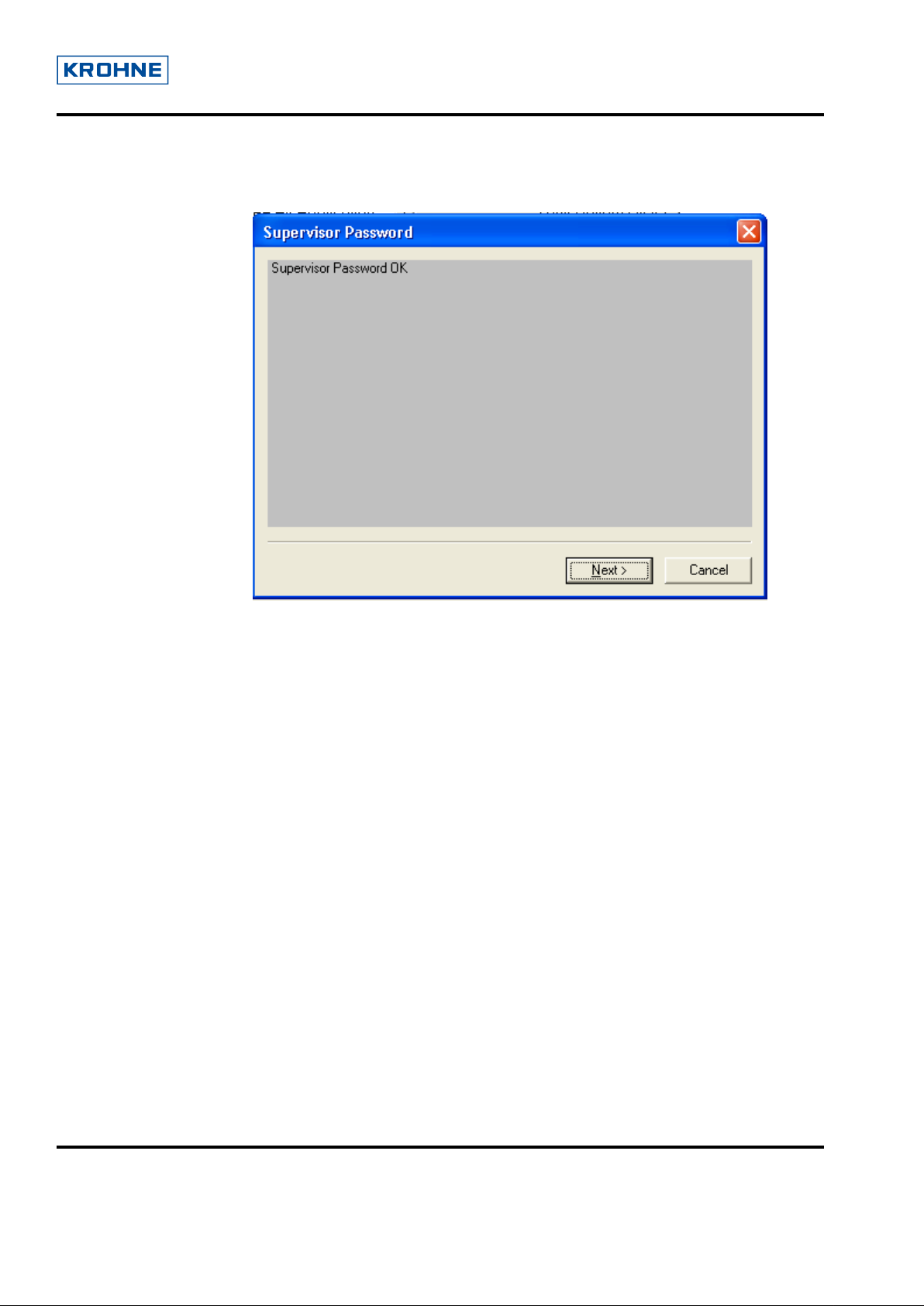

After entering the valid password and clicking next, it shows the following screen:

For success: “Supervisor Password OK”

For invalid password: “Supervisor Password Invalid”

3.1.3 Service Password

See “Supervisor Password” method

© 2006 KROHNE SAS 26103 Romans (France) Page 5 of 34

Page 6

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

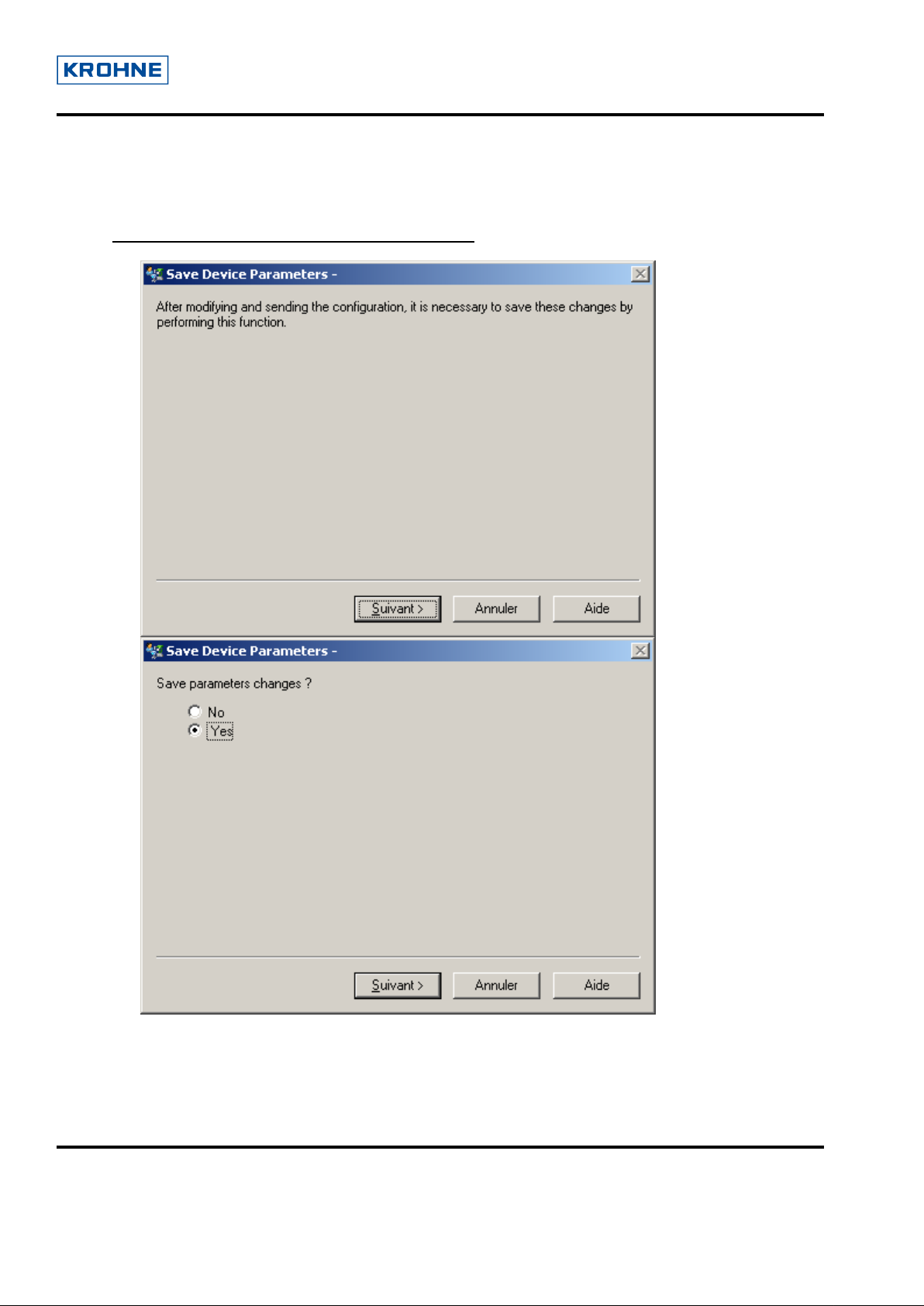

3.2 Save Device Parameters

ATTENTION: This is a very important method.

Each time the device configuration is modified

method. Otherwise the modifications will not be taking into account.

(after applying changes) it is necessary to execute this

© 2006 KROHNE SAS 26103 Romans (France) Page 6 of 34

Page 7

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.3 Diagnostic and Test

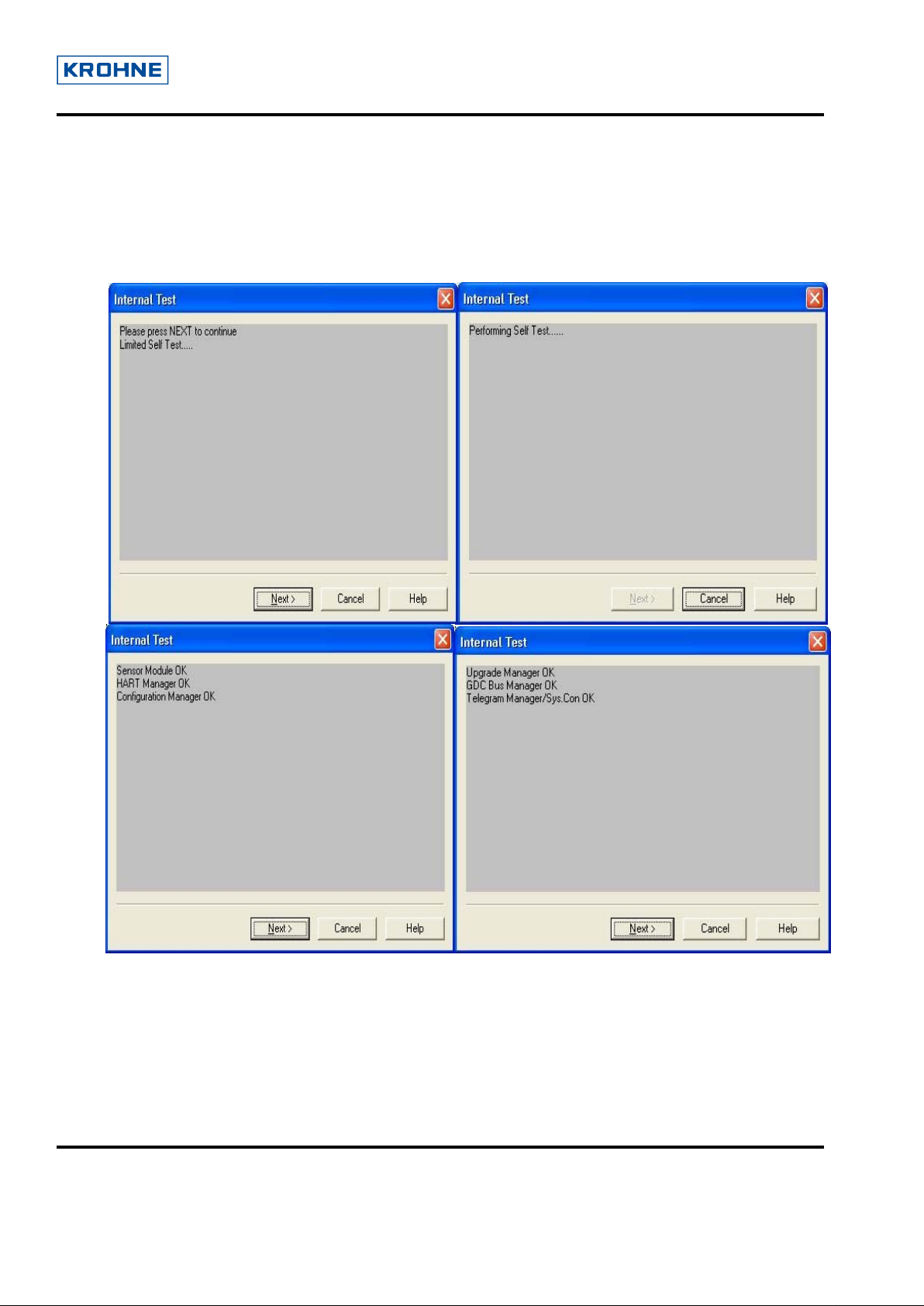

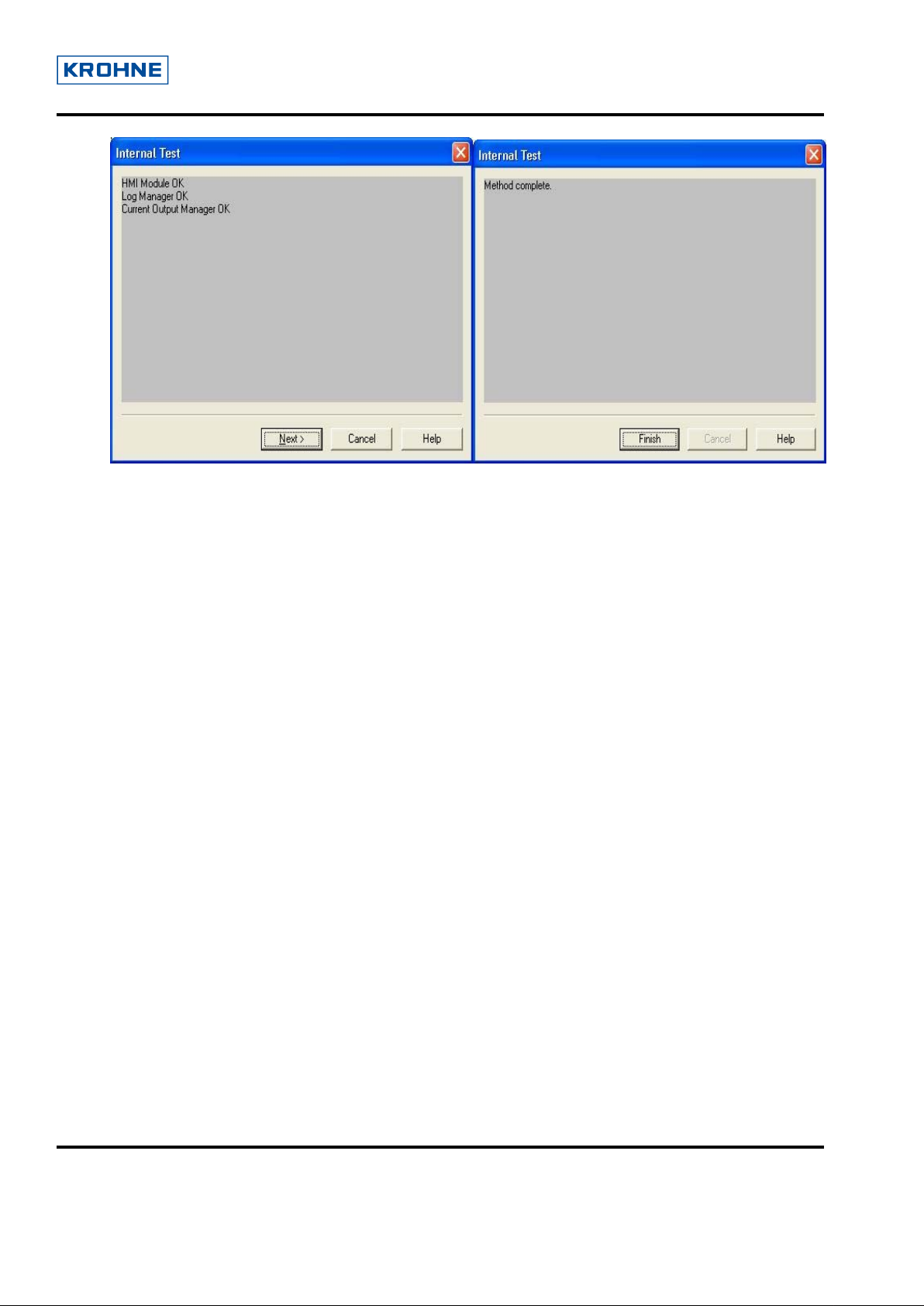

3.3.1 Internal Test

On selecting “Internal Test” from the main menu, device performs self test and displays results as

following:

© 2006 KROHNE SAS 26103 Romans (France) Page 7 of 34

Page 8

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

© 2006 KROHNE SAS 26103 Romans (France) Page 8 of 34

Page 9

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

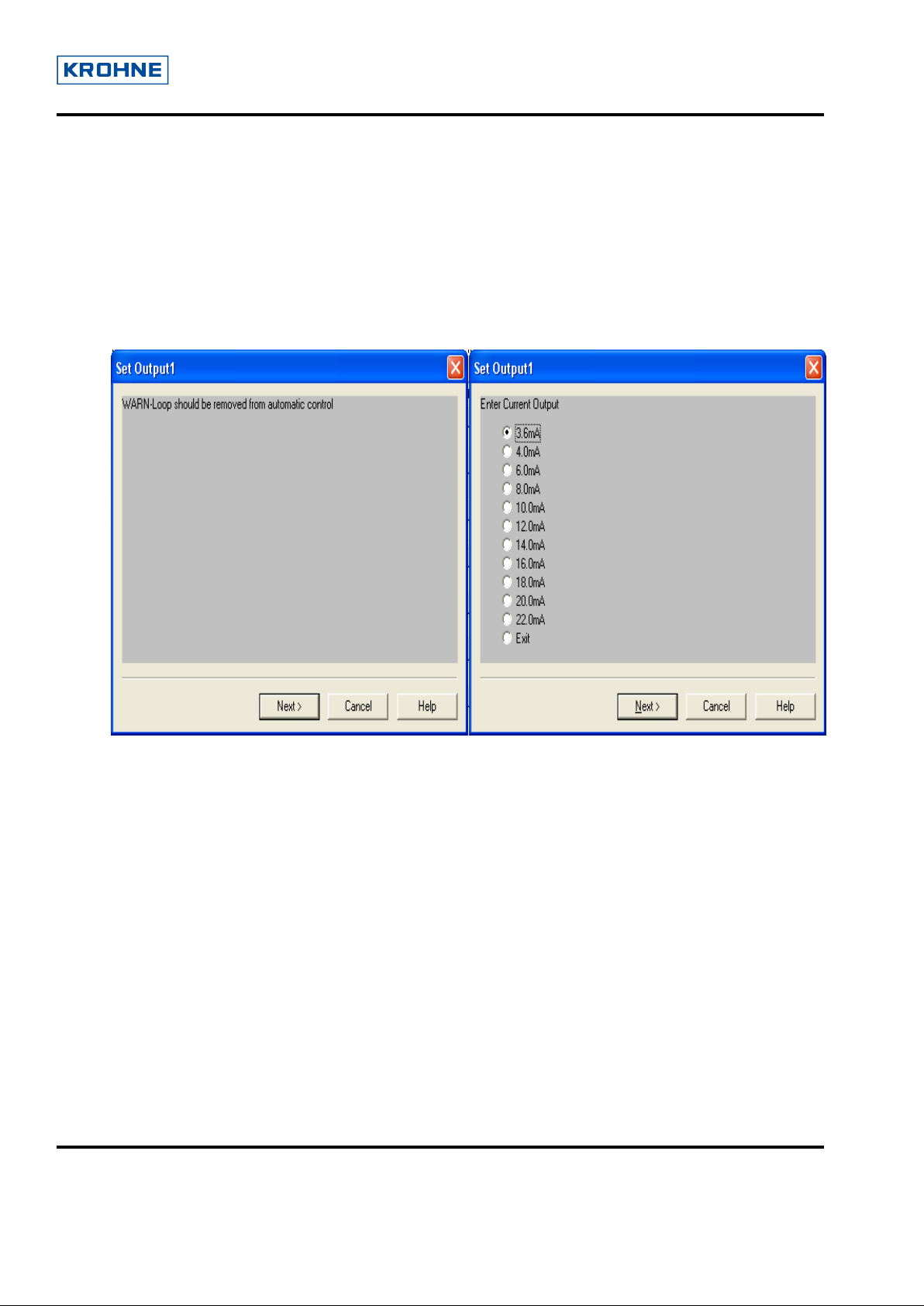

3.3.2 Set Output1

It allows fixing different values to the current output1 . It is a test mode. User can check the loop

currents in output1 and output2. The list of currents are displayed in the list box.

Once the appropriate current is selected the loop current is fixed to that current value. Check the loop

current by ammeter and validates the current as selected from the device. The loop current exits from

the current mode after clicking on 'Exit' or 'Cancel' from the method.

© 2006 KROHNE SAS 26103 Romans (France) Page 9 of 34

Page 10

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.3.3 Set Output2

See “Set Output1”

3.4 Calibration

The Calibration can be done for the output1 and output2. Here the following sections will be

describes the detailed about the calibration screen options for the output1 lower and upper.

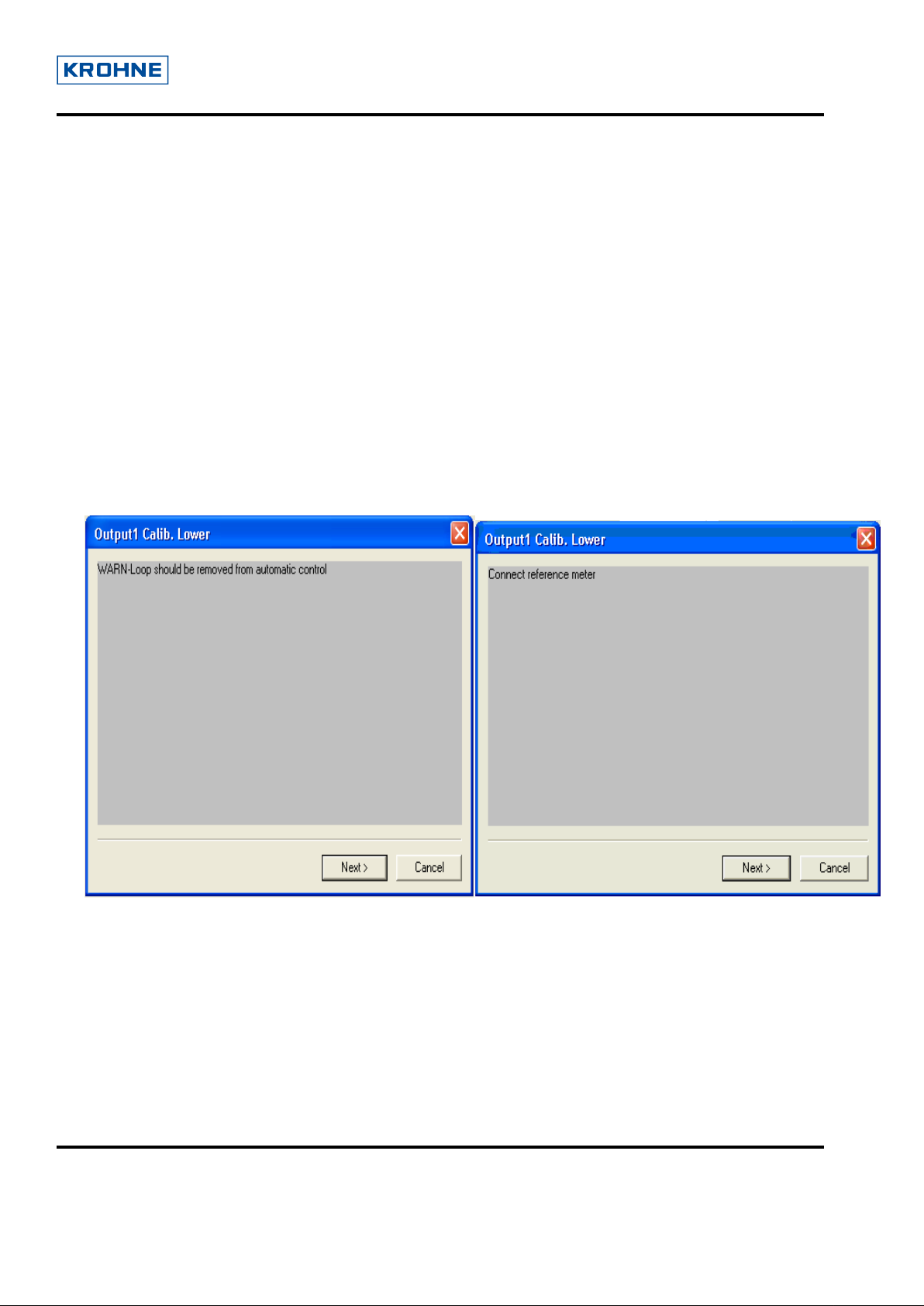

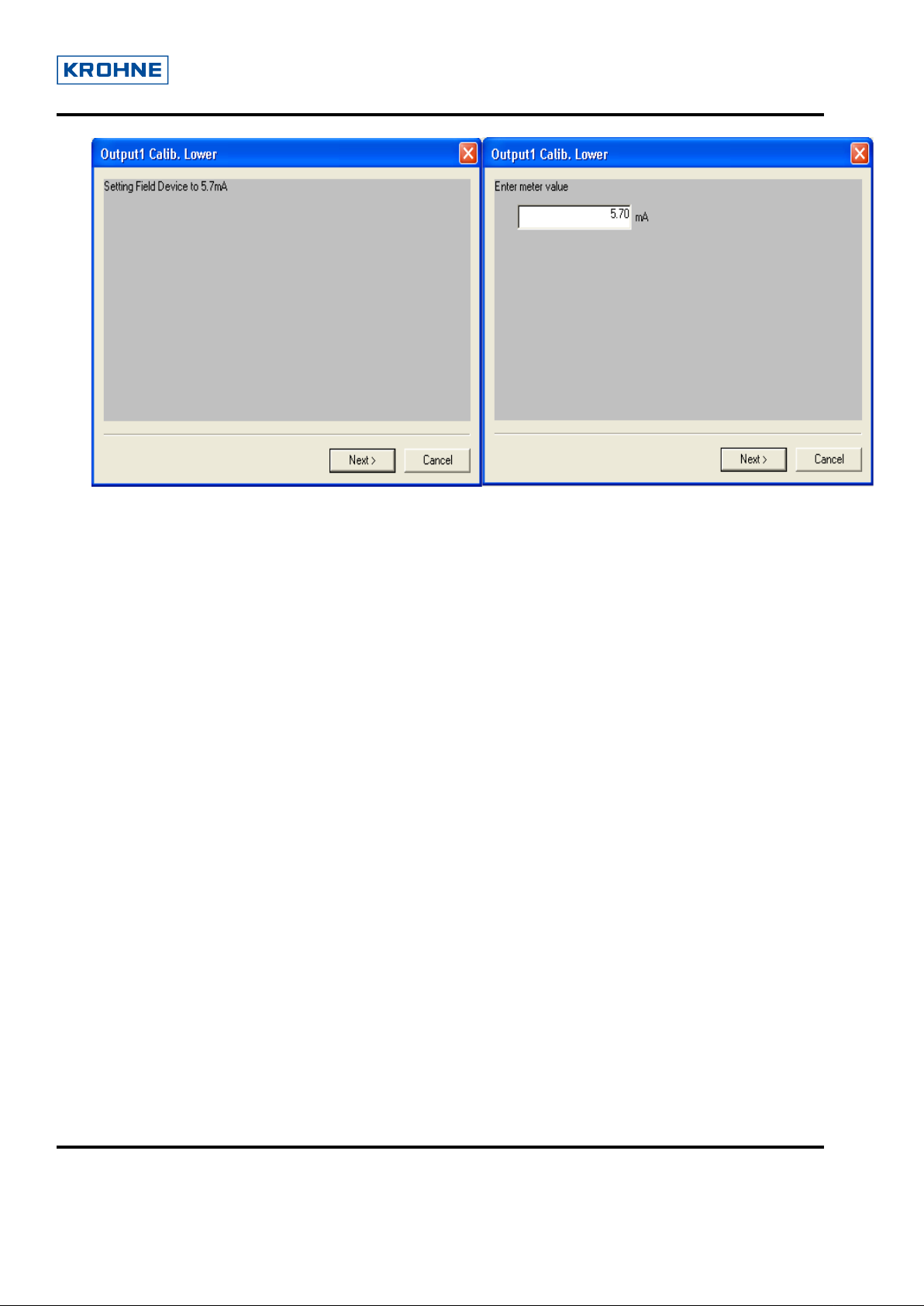

3.4.1 Output1 Lower

In Output1 Lower, it allows user to trim current output1.

The user starts to fix the current to 4mA, after entering the current value he reads on a voltmeter,

this value is sent to the device. This method allows adjusting to have exactly the good current

value of output1 loop.

© 2006 KROHNE SAS 26103 Romans (France) Page 10 of 34

Page 11

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

© 2006 KROHNE SAS 26103 Romans (France) Page 11 of 34

Page 12

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.4.2 Output1 Upper

In Output1 Upper, user allows to trim current output1.

The user start to fix the current to 20mA, after entering the current value he read on a voltmeter,

this value is sent to the device. This method allows adjusting to have exactly the good current

value of output1 loop.

© 2006 KROHNE SAS 26103 Romans (France) Page 12 of 34

Page 13

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

© 2006 KROHNE SAS 26103 Romans (France) Page 13 of 34

Page 14

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.5 Tables

3.5.1 Volume/Mass Table

Select “Conversion Table” will display all the entries of conversion table in ‘2 x 2’ Format.

Display will be in following steps

1. After Displaying all entries:

If yes is selected, it permits user to edit or add new entries.

© 2006 KROHNE SAS 26103 Romans (France) Page 14 of 34

Page 15

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

2. Selection of Next Entry will show next entry Level to edit, after clicking Enter, Volume/Mass is

displayed for next Entry to edit. After editing Level & Volume/Mass for current entry, above shown

menu is displayed again.

3. Selection of Previous Entry will show previous entry Level to edit, after clicking next, Volume/Mass

is displayed for previous Entry to edit. After editing Level & Volume/Mass for current entry, above

shown menu is displayed again.

4. Selection of Entry Number will take Entry Number from user and will display that entry Level to edit,

after clicking next, Volume is displayed for given Entry number to edit. After editing Level & Volume

for entry, above shown menu is displayed again.

If Entered Entry Number is greater than Entries+1, Entry Number is made equal to Number of Entries

+ 1.

If Yes is entered, table with edited values is stored in to the Device (If table entered is monotonous).

Note: All values entered for Level and Volume should be in increasing order with Entry numbers

(Corresponding warnings are displayed). Level value entered can not exceed Tank Height.

© 2006 KROHNE SAS 26103 Romans (France) Page 15 of 34

Page 16

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.5.2 Linearisation Table

Above explained steps for volume/mass Table are to be followed, with Distance Real, Distance Device

instead of Level and Volume respectively.

The editing and displaying wizard is the same as that of volume/mass table .The display of the

Linearisation table is shown below

Note : The length and volume/mass unit can be changed from installation plate2

© 2006 KROHNE SAS 26103 Romans (France) Page 16 of 34

Page 17

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.5.3 Delete Tables

Delete tables allow user to delete the volume/mass and Linearisation tables entirely.

© 2006 KROHNE SAS 26103 Romans (France) Page 17 of 34

Page 18

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.6 Empty Spectrum Recording

The following figure in order illustrates the steps for Empty Spectrum Recording.

© 2006 KROHNE SAS 26103 Romans (France) Page 18 of 34

Page 19

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

After validating all the depending parameters required for the empty spectrum process, It starts the recording,

displaying the current status of it.

© 2006 KROHNE SAS 26103 Romans (France) Page 19 of 34

2

Page 20

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.7 Reset

There are three types of reset. For the security reasons it re-ensures for the reset.

3.7.1 Factory Reset

In the Factory Reset, the device or configurations are set to the factory default values.

© 2006 KROHNE SAS 26103 Romans (France) Page 20 of 34

Page 21

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.7.2 Customer Reset

This makes the parameter values to user default values.

© 2006 KROHNE SAS 26103 Romans (France) Page 21 of 34

Page 22

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.7.3 Device Reset

It is used to restart the device.

© 2006 KROHNE SAS 26103 Romans (France) Page 22 of 34

Page 23

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.8 Configuration Variables

To view Help for each configuration parameter, first click on Help button on toolbar & then click on

the parameter for which help is to be viewed.

3.8.1 Installation Parameters1

This plate consists of the editable parameters of the device like Tank Type, Tank Height etc. In this

plate some of the parameters are dependent on other parameters like Measuring Range, Tank Height,

etc is dependent on Tank Type, Stillwell Height, Stillwell Diameter depends upon the Application

Type which gets disabled.

On editing particular parameter it gets yellow in color and Apply button get

activated. On clicking, Apply Button the new value gets stored in the parameter.

© 2006 KROHNE SAS 26103 Romans (France) Page 23 of 34

Page 24

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.8.2 Installation Parameters2

It allows user to change the unit of configuration parameters.

© 2006 KROHNE SAS 26103 Romans (France) Page 24 of 34

Page 25

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.8.3 Output Selection

It allows user to change the Primary Output Function, Secondary Output Function, Tertiary Output

Function and Fourth Output function. Beside this it provides detail’s of primary and secondary output

as differentiated by the group box namely output1 and output2.

© 2006 KROHNE SAS 26103 Romans (France) Page 25 of 34

Page 26

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.8.4 Primary Output Setting

It allows user to change the upper and lower limit of the parameters set in the output selection plate for

the primary output function. The units of all these parameters are shown as set in the installation

plate2. Since only one pair of parameters can be set to the primary output function, hence the rest of

the parameters are disabled.

© 2006 KROHNE SAS 26103 Romans (France) Page 26 of 34

Page 27

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.8.5 Secondary Output Setting

It allows user to change the upper and lower limit of the parameter set in the output selection plate for

the secondary output function.

© 2006 KROHNE SAS 26103 Romans (France) Page 27 of 34

Page 28

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.8.6 Service

It allows user to view all the service parameters, calibration parameters and the service information.

The service parameters are only activated by the service password.

© 2006 KROHNE SAS 26103 Romans (France) Page 28 of 34

Page 29

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

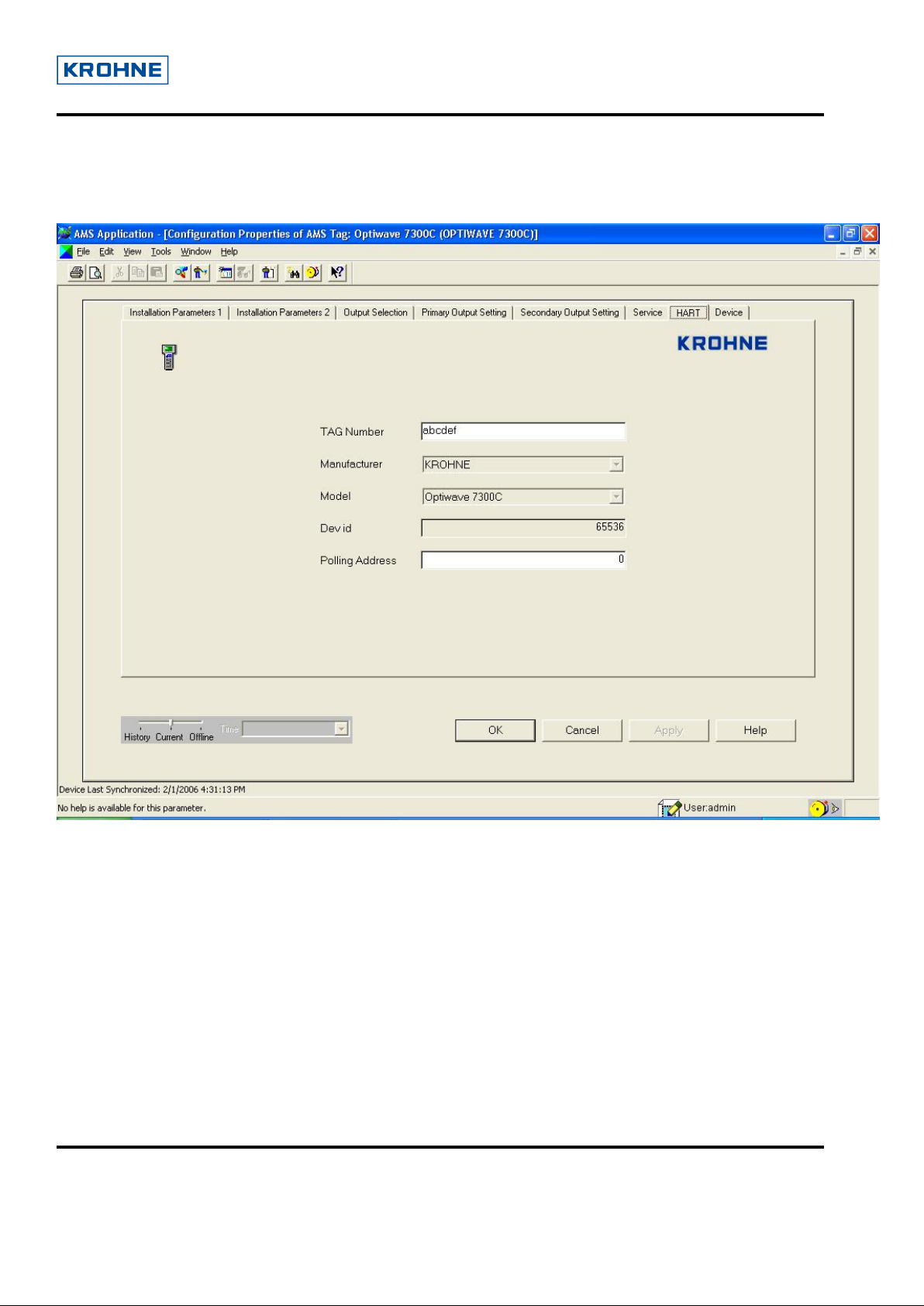

3.8.7 HART

It shows all the hart related parameters viz: manufacturer name, model name etc.

© 2006 KROHNE SAS 26103 Romans (France) Page 29 of 34

Page 30

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.8.8 Device

It shows the device specific information. This plate doesn’t require any authentication. All the

parameters can be viewed with no password.

© 2006 KROHNE SAS 26103 Romans (France) Page 30 of 34

Page 31

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.9 Process Variable

The Process Variables are displayed with magnitude and its corresponding unit along with upper & lower

limits. Four process variables are active on a single screen depending on the Output function setting.

Primary Output Function, Secondary Output Function, Tertiary Output Function, and Fourth Output Function

are used to set Primary Process Variable, Secondary Process Variable, Tertiary Process Variable, & Fourth

Process Variable respectively.

If “Level” is set as Primary Output Function, then “Level” is displayed as a Primary Process Variable &

respective current, percentage value for level is also displayed in below process variable face plate.

© 2006 KROHNE SAS 26103 Romans (France) Page 31 of 34

Page 32

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

3.10 Device Diagnostic

It contains the status of the device.

© 2006 KROHNE SAS 26103 Romans (France) Page 32 of 34

Page 33

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

4 Status Meaning

Status Message

Supervisor Password OK Entered password for Supervisor rights is

correct.

Supervisor Password Invalid Entered password for Supervisor rights is

incorrect.

Simulation Service Password OK Entered password for Service rights in

Simulation mode is correct.

Service Password Invalid

Entered password for Service rights is

incorrect.

Service Password OK Entered password for Service rights is

correct.

Simulation Supervisor Password OK

Dependency failure

Update not possible

Reading data from device

Dependency Warning Message

Entered password for Supervisor rights in

Simulation mode is correct.

It appears if the dependency of the

parameter being modified is failed.

It appears if read only parameter is

modified.

It appears when the entries of table being

read by the device.

It appears if the variable is modified and is

dependent on other variables. Such

scenario could violate its normal operation.

Max range failure When the entered value is more than its

maximum allowed value.

Min range failure When the entered value is less than its

minimum allowed value.

Table entered is not monotonous

Device busy

If the entered value is less than the next

entry.

Appears when the device is busy. Normally

it appears when the device is in search

mode or if it is executing a function.

Access Restricted

This message appears if we try to modify a

read only parameter.

Invalid Section You have selected a non valid item.

Too Few Bytes Received There are not enough bytes received.

Invalid Command Request Requested command is invalid.

Value out of range

Exceed precision

This occurs if the entered value is out of

range for that parameter.

If the decimal value entered exceeds its

range.

Meaning

© 2006 KROHNE SAS 26103 Romans (France) Page 33 of 34

Page 34

User Guide for Optiwave (FMCW) DD of AMS

Dev Rev-01, DD Rev-02

Illegal character If any invalid character is entered.

Max range failure occurred writing level

20mA.Restore device value

It appears if entered Value for 20mA is

out of range.

Method is currently invalid It appears if access right is not

5 HART® Communicator 375 (HC375)

5.1 Offline Restriction

In order to transfer an Offline configuration to the device the Service parameter “Supervisor

Password Enable” (C.5.2.0)

In case this parameter has got the value “YES” the configuration is not transferred successfully to the

device even if we don’t see any error messages!

must be set to “NO”.

5.2 Save Device Parameters

ATTENTION: This is a very important method.

Each time the device configuration is modified

method. Otherwise the modifications will not be taking into account.

This method is only accessible in case the supervisor or service password method has been executed.

(after sending new values) it is necessary to execute this

© 2006 KROHNE SAS 26103 Romans (France) Page 34 of 34

Loading...

Loading...