Page 1

● Easy to install

● Low-cost signal converter,

measuring error < 0.5% of the measured value

● Easy user-friendly operation

● Self-monitoring feature to rule out errors in operation

● Low power consumption

IFC 010

Signal Converter

for electromagnetic flowmeters

GR

©

KROHNE 04/2003 7.02347.22.00

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Page 2

IFC 010

Signal Converter

for electromagnetic flowmeters

Standard-setting technology

● µP-controlled signal converter with digital signal processing

ensures reliability and long-time stability

● High-speed signal conversion system (patented) allows flowmeter

application even in difficult cases

● Modular signal converter, low-cost basic version without display or

control panel, easy to set and document with every DOS-PC (notebook) and KROHNE software, error-free

● can be optionally fitted with local display and control panel

● terminals and all signal converter modules pluggable, easily

replaceable without recalibration or resetting

● plus all the numerous functions:

- current, pulse and status indication outputs

- flow measurement in both directions

- low-flow cutoff

- limit signalling or direction identification

- volume flow counting via passive, galvanically

- isolated pulse output

● available for AC or DC voltage operation

2

The modular KROHNE system will have the

right electromagnetic flowmeter for your

specific application – right from both the

flowmetering and the economic viewpoint.

Available versions

● IFC 010 _/B

signal converter without local display

and control elements

( B = basic version). All operating data

factory-set to your specifications.

For control and settings via DOS-PC, RS

232 adapter including PC software is

available as option.

● IFC 010 _/D

signal converter with local display and

control elements (D). All operating data

factory-set to your specifications.

Calibrated on EN 17 025

accredited calibration rigs,

accuracy of calibration better

than 99.97% of the measured value

Page 3

IFC 010 3

IFC 010

The modular KROHNE system with the IFC 010 IMoCom signal converter

The IFC 010 signal converter is compatible with all KROHNE primary heads.

Integral systems (K): Primary head and signal converter form a single unit and are solidly

connected.

Remote systems (F): Primary head and signal converter are remote units and electrically

connected by signal and field current cables.

Full data of the primary heads (IFS .... .) are specified in the relevant Data Sheets:

ALTOFLUX ..... / AQUAFLUX ..... / ECOFLUX ..... / PROFIFLUX ..... / VARIFLUX .....

Teflon® is a registered trademark of Du Pont.

Integral systems Remote systems Characterization of primary heads

with regedly mounted IFC 010 K Primary heads System with IFC 010 F Meter size Flowtube / Connection

ECOFLUX IFM 1010 K ECOFLUX IFS 1000 F ECOFLUX IFM 1010 F DN 10-150 Teflon®-PFA liner,

3

/8”-6” flangeless design

AQUAFLUX 010 K AQUAFLUX F AQUAFLUX 010 F DN 10-1000 Hard rubber liner

3

/8”-40” (≥ DN 25 / ≥ 1”),

flanged design

ALTOFLUX IFM 4010 K ALTOFLUX IFS 4000 F ALTOFLUX IFM 4010 F DN 10-1000 e.g. Teflon®-PFA liner,

3

/8”-40” flanged design

PROFIFLUX IFM 5010 K PROFIFLUX IFS 5000 F PROFIFLUX IFM 5010 F DN 2.5-100 fused aluminium oxide tube,

1

/10”-4” flangeless design

VARIFLUX IFM 6010 K VARIFLUX IFS 6000 F VARIFLUX IFM 6010 F DN 10-80 Teflon®-PFA liner,

3

/8”-3” food-grade and sterile

connections

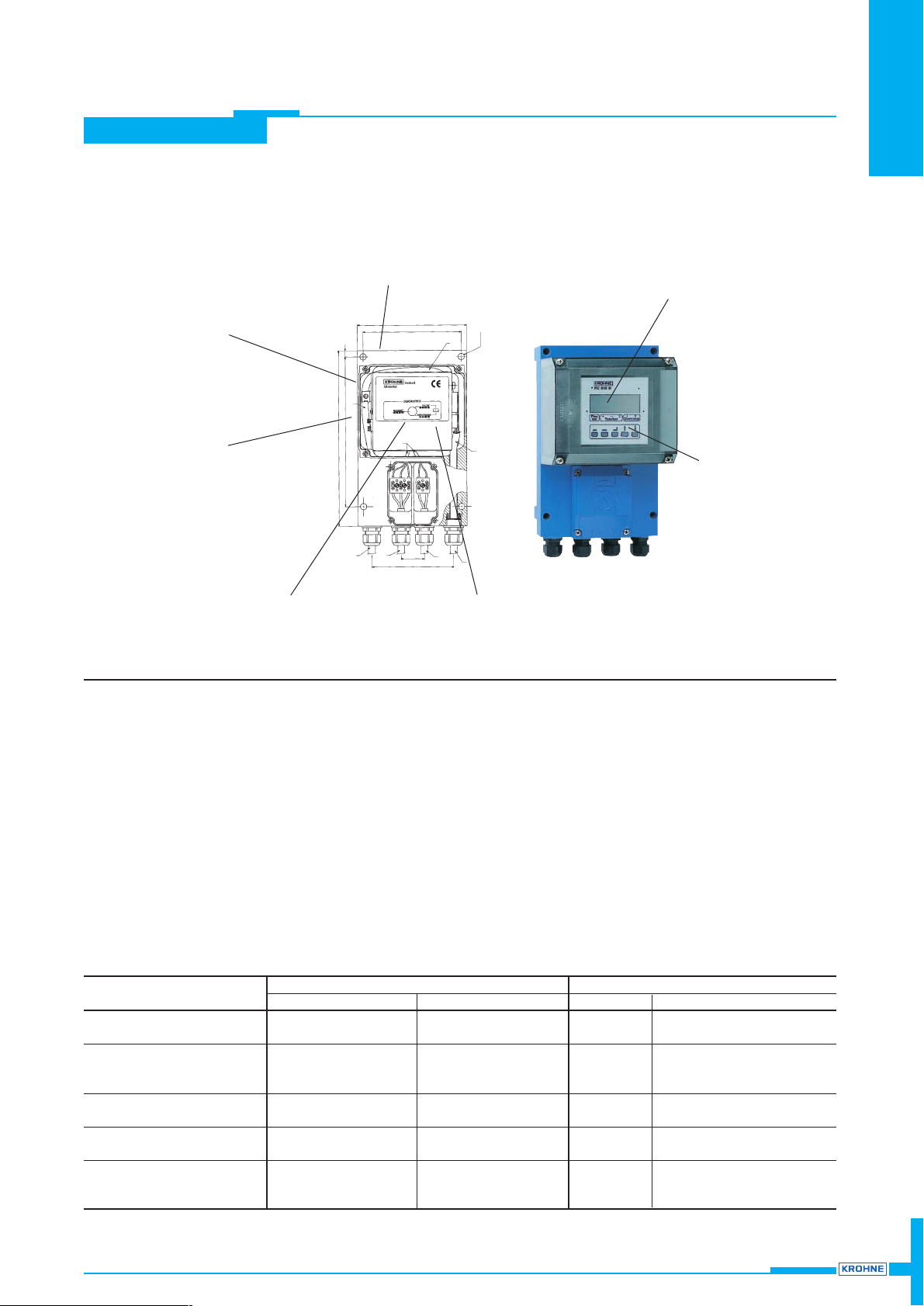

Low maintenance requirement, electronics unit easy and quick to replace,

no recalibration needed

Large, high-contrast LC display (option)

5-key keypad, easy

user-friendly operation (option)

Many different (scaled)

outputs available

IMoCom plug connectors for operating,

saving, documenting and downloading

all setting data

Portable operating data EEPROM

Low-cost signal converter, measuring

error < 0.5% of the measured value

Highlights

Page 4

IFC 010

IFC 010

4

Flowrate for Q = 100 % adjustable 6 liters/h to 33000 m3/h or 0.4 to 156000 US gallons/min, corresponding to flow velocity

v = 0.3 to 12 m/s or 1 to 40 ft/s

Unit adjustable m

3

/h, liters/s or US-gallons/min, and 1 user-defined unit e. g. m3/min or US million gallons per day

Full-scale range Q

100%

Reference conditions

Product Water, 10 to 30°C/50 to 86 °F

Electrical conductivity > 300 µS/cm (µmho/cm)

Power supply (line voltage) U

N

(± 2 %)

Ambient temperature 20 to 22°C/68 to 71.6°F

Warm-up time 30 minutes

Straight inlet run > 10 x DN DN =

Straight outlet run > 03 x DN

}

meter size

Primary heads properly grounded and centered

Error limits for complete system at reference conditions

Pulse output

± F Error in % of flowrate (actual value): Curve A: DN 10 – 600 /

3

/8” – 24”

v ≥ 0.4 m/s or ≥ 1.3 ft/s: ± 0.5 % of measured value

v < 0.4 m/s or < 1.3 ft/s: ± 0.002 m/s or 0.0066 ft/s

Curve B: DN 2.5 – 6 /

1

/10”– 1/4” (PROFIFLUX) and DN 700 – 1000 / 28” – 40”

v ≥ 0.25 m/s or ≥ 0.8 ft/s: ± 0.8 % of measured value

v < 0.25 m/s or < 0.8 ft/s: ± 0.002 m/s or 0.0066 ft/s

Q Actual flowrate

Q

F

Flow for error limit vF = 0.25 m/s or 0.8 ft/s

v Flow velocity in m/s and ft/s

v

F

Flow velocity in m/s and ft/s at QF

Current output same as above error limit for pulse output plus...

0 to 20 mA:

± 0.05 %

4 to 20 mA:

± 0.062 %

}

of full-scale range in each case

All KROHNE signal converters undergo burn-in tests, duration minimum 20 hours at varying ambient temepratures –20 to +60°C / –4 to +140°F.

Function and accuracy are controlled by computers.

3

2

1

0.8

0.5

v

m/s

(ft / sec)

0.25

(0.8)

0.4

(1.3)

0.5

(1.6)

0.75

(2.4)1 (3.2)

10

(33)

11

(36)

12

(40)

B

A

Q

F

Q

F

e F

%

Flow tables

v = flow velocity in m/s

Meter size Full-scale range Q

100% in m

3

/h

DN v = 0.3 m/s v = 1 m/s v = 12 m/s

mm inch (minimum) (maximum)

2.5

1

/10 0.0053 0.0177 0.2121

4

1

/8 0.0136 0.4520 0.5429

6

1

/4 0.0306 0.1018 1.222

10

3

/8

0.0849 0.2827 3.392

15

1

/2 0.1909 0.6362 7.634

20

3

/4 0.3393 1.131 13.57

25 1 0.5302 1.767 21.20

32 – 0.8686 2.895 34.74

40 11/2 1.358 4.524 54.28

50 2 2.121 7.069 84.82

65 – 3.584 11.95 143.3

80 3 5.429 18.10 217.1

100 4 8.483 28.27 339.2

125 – 13.26 44.18 530.1

150 6 19.09 63.62 763.4

200 8 33.93 113.1 1357

250 10 53.02 176.7 2120

300 12 76.35 254.5 3053

400 16 135.8 452.4 5428

500 20 212.1 706.9 8482

600 24 305.4 1018 12215

700 28 415.6 1385 16625

800 32 542.9 1810 21714

900 36 662.8 2290 26510

1000 40 848.2 2827 33929

v = flow velocity in ft/s

Meter size Full-scale range Q

100% in US gallons/min

DN v = 1 ft/s v = 40 ft/s

mm inch (minimum) (maximum)

2.5

1

/10 0.0245 0.979

4

1

/8 0.0383 1.530

6

1

/4 0.1530 6.120

10

3

/8

0.3735 14.93

15

1

/2 0.8405 33.61

20

3

/4 1.494 59.75

25 1 2.334 93.34

32 – 3.824 153.0

40 11/2 5.979 239.0

50 2 9.339 373.5

65 – 15.78 630.9

80 3 23.90 955.6

100 4 37.35 1493

125 – 58.38 2334

150 6 84.05 3361

200 8 149.43 5975

250 10 233.4 9334

300 12 336.2 13442

400 16 597.9 23899

500 20 933.9 37345

600 24 1345 53781

700 28 1919 76760

800 32 2507 100272

900 36 3173 126904

1000 40 3917 156672

Page 5

IFC 010 5

IFC 010

Technical data

1000

P

100%

[Hz]

Versions

B - version without display / control unit (basic version)

D - version with display / control unit

Add-on equipment (option) - CONFIG-software and RS 232-adapter for control via MS-DOS-PC,

connection to IMoCom interface

- Hand-Held-Terminal for control of blind versions

Current output

Function – all operating data configurable, galvanically isolated

Current 0 – 20 mA or 4 – 20 mA

Active output load max. 500 ohms

Passive output external voltage: 15 ... 20 V DC 20 ... 32 V DC

load: min. ... max. 0 ... 500 Ω 250 ... 750 Ω

Error identification 0 / 3.6 / 22 mA

Forward/reverse measurement direction identified via status output

Pulse output

Function – all operating data settable

– galvanically isolated

– digital pulse division, interpulse period non-uniform, therefore if

– frequency meters connected allow for minimum counting interval:

gate time, totalizer ≥

Pulse rate for Q = 100 %

Standard 10, 100 or 1000 pulses per second (= Hz), fixed or optionally adjustable in pulses

per liter, m3or US gallons

Special version (option) up to 10 kHz scaling

Active output: connection: electronic totalizer (EC)

internal voltage: approx. 15 V DC, from current output

load rating: I

max

< 23 mA when operated without current output

I

max

< 3 mA when operated with current output

Passive output: connection electromechanical (EMC) or electronic (EC) totalizers

external voltage: U

ext

≤ 30 V DC / ≤ 24 V AC

load current: I

max

≤ 150 mA / special version 10 kHz: f ≤ 1 kHz I

max

≤ 150 mA

f > 1 kHz I

max

≤ 30 mA

Pulse width 50, 100, 200, 500 ms or 1 s, choice with frequencies below 10 Hz

Forward/reverse measurement direction identified via status indication output

Status output (passive)

Function configurable as indicator for flow direction, errors or trip point

Connection external voltage: extern, U

ext.

≤ 30 V DC / ≤ 24 V AC

load current: I

max

≤ 150 mA

Time constant 0.2 to 99.9 seconds, settable in increments of 0.1 second

Low-flow cutoff

cutoff ”on“ value: 1 to 19 %

cutoff ”off” value: 2 to 20 %

}

of Q100%, adjustable in 1 % increments

Local display (D versions only) 3-line LCD

Display functions actual flowrate, forward, reverse and sum totalizers (7-digit)

or 25-character bar graph with percent display and status messages

Display units:actual flowrate configurable in liter/s, m3/h, US gallons/min or user-defined unit,

e. g. hectoliter/day or US million gallons/day

totalizers liter, m3or US gallons and 1 user-defined unit

(e.g. hectoliter), choice of overflow time

Language of plain texts English, German, French, others on request

Display: 1st (top) line 8-character, 7-segment numeral and sign display,

symbols for key acknowledgement

2nd (middle) line 10-character, 14-segment text display

3rd (bottom) line 6 markers ▼ to identify display

Power supply 1. AC-Version 2. AC-Version 3. AC-Version DC-Version

Standard Option Option Option

1. Rated voltage 230 / 240 V 200 V 48 V 24 V

tolerance band 200 - 260 V 170 - 220 V 41 - 53 V 11 - 32 V

2. Rated voltage 115 / 120 V 100 V 24 V tolerance band 100 - 130 V 85 - 110 V 20 - 26 V -

Frequency 48 - 63 Hz - - Power consumption (incl. primary head) approx. 5 VA approx. 4.5 W

When connected to a functional extra-low voltage, 11 - 32 V DC,

protective separation (PELV) must be ensured

(VDE 0100 / VDE 0106 and IEC 364 / IEC 536)

Housing

Material polyamide (PA) and die-cast aluminium

Protection category

(IEC 529/EN 60529) IP 67 equivalent to NEMA 6

The responsibility as to the suitability, intended use and corrosion-resistance of the materials used in their

construction rests solely with the purchaser.

Full primary head (flowmeter) data are specified in the relevant Data Sheets.

Page 6

IFC 010

IFC 010

6

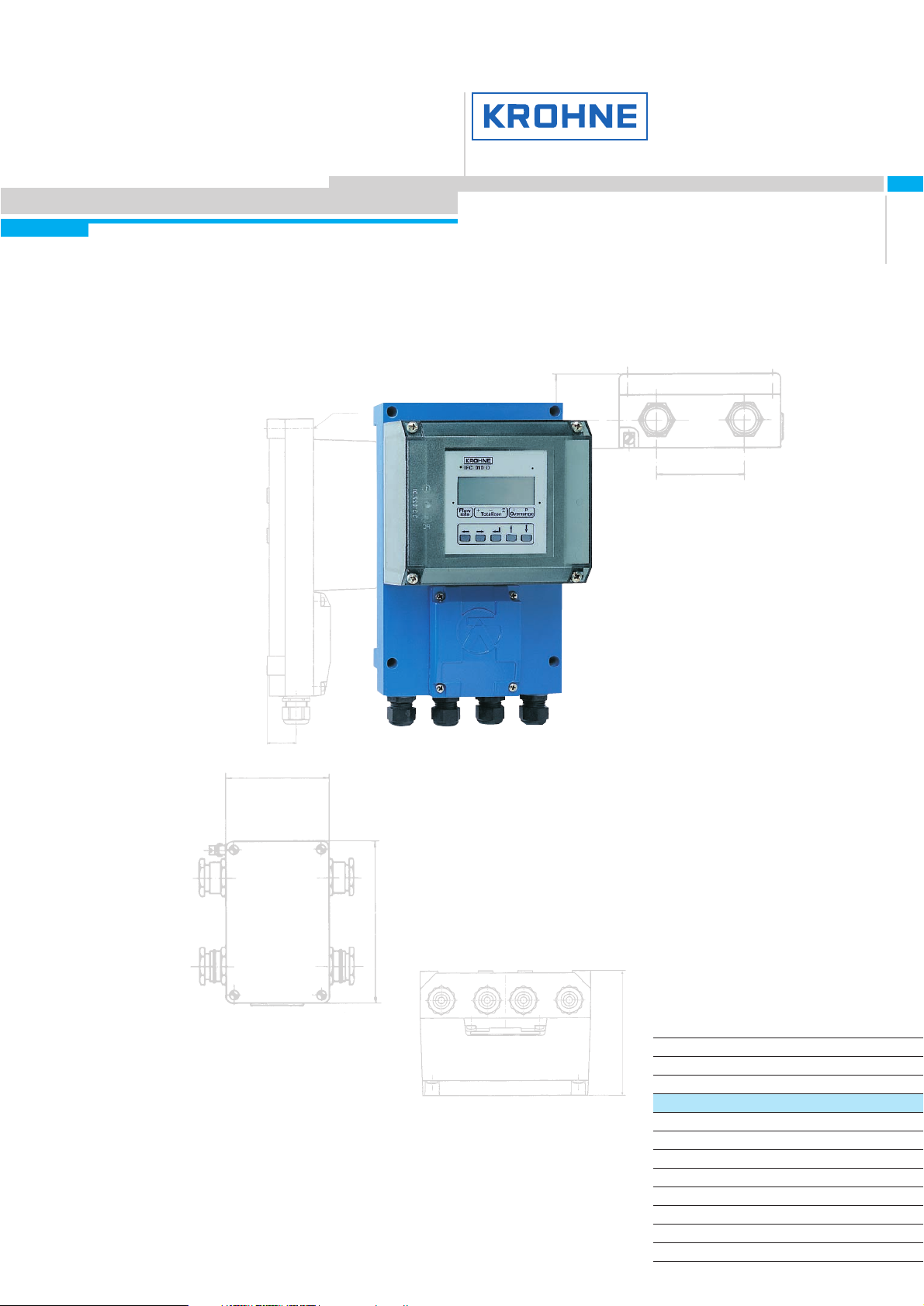

Dimensions and weights

Housing for intermediate connection box ZD

for product temperature > 150 °C or 302 °F

Dimensions in mm and (inches)

Weight approx. 0.5 kg or 1.1 lbs

IFC 010 F signal converter

Dimensions in mm and (inches)

Weight approx. 3.8 kg (8.4 lb)

120 (4.72”)

34 (1.34”)

220 (8.66”)

258 (10.16”)

160 (6.30”)

80 (3.15”)

dia. 9 (3x)

(dia. 0.38”)

27.5

(1.08”)

116 (4.57”)

80 (3.15”)

57 (2.24”)

125 (4.92”)

68 (2.68”)

22

(0.87”)

Page 7

IFC 010 7

IFC 010

IFC 010 Electrical connection

Power supply and outputs

protective conductor

functional ground

}

Current output

passiv

e

active

Pulse and status output

passiv

e active

Electrical connection in conformity with

VDE 0100 ”Regulations governing heavycurrent installations with mains voltages

up to 1000 V” or equivalent national

standard.

If to be connected to a functional extralow voltage source (24 V DC / AC and 48

V AC) protective separation in conformity

with VDE 0100, Part 410, or equivalent

national standard, must be ensured.

AC: 100–240 V

AC: 24/48 V

DC: 24 V

Power

for

internal

use only

I current outputs

P pulse output

S status indication output

Outputs

U-clamp terminal

PE

FE

FE

e. g.

indicator

A

Technical Data of the pulse output see page 8.

Length (L) of signal cable A

dependent on electrical conductivity k

IFC 010 F signal converter

↔

primary head

Connection diagram

The figures in brackets refer to the stranded drain wires for the shields,

see sectional drawings of signal cable on page 8.

IFC 010 F

Primary head

FE

Field power supply cable C (not supplied)

A

A

Length Cable type, single shielding

0 - 150 m / 5 to 500 ft 2 x 0.75 mm2Cu / 2 x 18 AWG

150 - 300 m / 1000 to 1600 ft 2 x 1.50 mm2Cu / 2 x 14 AWG

L N

1L~ 0L~

L+ L–

Primary head Meter size Signal cable

DN mm inches

ECOFLUX IFS 1000 F 10 - 153/8-1/

2

A4

25 - 150 1 - 6 A3

AQUAFLUX F 10 - 10003/8-40 A1

ALTOFLUX IFS 4000 F 10 - 1503/8-6 A2

200 - 1000 8 - 40 A1

PROFIFLUX IFS 5000 F 2.5 - 151/10-1/

2

A4

25 - 100 1 - 4 A2

VARIFLUX IFS 6000 F 10 - 151/8-1/

2

A4

25 - 80 1 - 3 A2

Page 8

IFC 010

IFC 010

8

IFC 010 Description

The standard

● outstanding accuracy

● full set of standard equipment

● current and pulse outputs (galvanically isolated)

● status output, easy to set for numerous tasks: as

● trip point, to indicate flow direction, error messages

● IMoCom bus can be used for numerous internal and external tasks

● simplified, standard KROHNE operator control concept

● very low power consumption

1 Input amplifier

● overdrive-proof signal processing, rapidly and accurately

● digital signal processing and sequence control

● patented, high-resolution A/D converter, digitally controlled

and monitored

● high signal-to-noise ratio through low-loss field power supply

2 Field power supply

● the low-loss field power supply generates the pulsed, elec-

tronically controlled DC current for the magnetic coils of the

primary head

3 Current output

● galvanically isolated from all other groups

● converts the digital output signal from the µP 3 micro-

processor into a proportional current

4 Binary outputs

● galvanically isolated from other groups

● selectable input/output combinations

● pulse output (B1), passive FET optocouplers allow connec-

tion of electronic and electromechanical totalizers

● status output (B2) for limit value, error identification, or flow

direction in forward/reverse flow mode (F/R)

5 Display/operator control unit

(option, D Version)

● large-size illuminated LC display

● 3 keys for operator control of the signal converter

● connection to the internal IMoCom bus

● unit can be retrofitted to basic devices (B Version)

6 IMoCom bus plug connector

for connection of external control and test devices such as:

● HHT handheld terminal (option), display/operator control

unit for operation of basic versions

● adapter and CONFIG software for operation via MS-DOS PC

6

1 Stranded drain wire, 1st shield, 1.5 mm2or AWG 14

2 Insulation

3 Stranded wire 0.5 mm

2

or AWG 20

4 Special foil, 1st shield

5 Insulation

6 Mu-metal foil, 2nd shield

7 Stranded drain wire, 2nd shield, 0.5 mm

2

or AWG 20

8 Outer sheath

Signal cable A (type DS), with double shielding

Page 9

9

IFC 010

IFC 010

Ordering Code

IFC 010 Signal converter for primary heads (flowmeter)

AQUAFLUX / ECOFLUX 1000 / ALTOFLUX 4000 / PROFIFLUX 5000 / VARIFLUX 6000

Loading...

Loading...