KROHNE OPTIFLUX 7300 Specifications

Technical Datasheet

Technical Datasheet

OPTIFLUX 7300

OPTIFLUX 7300

OPTIFLUX 7300OPTIFLUX 7300

Technical DatasheetTechnical Datasheet

Electromagnetic flowmeter with non wetted electrodes

and ceramic liner

• No insulation of electrodes

• Stable measurement in noisy applications

• Improved safety and hygiene with absolute leak tight design

© KROHNE 01/2011 - 4000962501 - TD OPTIFLUX 7300 R01 en

CONTENTS

OPTIFLUX 7300

1 Product features 3

1.1 Non wetted electrodes with high tech ceramic liner....................................................... 3

1.2 Features............................................................................................................................ 5

1.3 Measuring principle.......................................................................................................... 7

2 Technical data 8

2.1 Technical data................................................................................................................... 8

2.2 Dimensions and weights ................................................................................................ 19

3 Installation 23

3.1 Notes on installation ......................................................................................................23

3.2 Installation conditions ....................................................................................................23

3.2.1 Inlet and outlet...................................................................................................................... 23

3.2.2 Mounting position.................................................................................................................. 23

3.2.3 Flange deviation.................................................................................................................... 24

3.2.4 T-section ............................................................................................................................... 24

3.2.5 Vibration ................................................................................................................................ 24

3.2.6 Magnetic field........................................................................................................................ 25

3.2.7 Bends .................................................................................................................................... 25

3.2.8 Open discharge .....................................................................................................................26

3.2.9 Control valve ......................................................................................................................... 26

3.2.10 Air venting ........................................................................................................................... 26

3.2.11 Pump ................................................................................................................................... 27

3.2.12 Temperatures ..................................................................................................................... 27

4 Electrical connections 28

4.1 Safety instructions.......................................................................................................... 28

4.2 Grounding ....................................................................................................................... 28

4.3 Connection diagrams ..................................................................................................... 29

5 Notes 30

2

www.krohne.com 01/2011 - 4000962501 - TD OPTIFLUX 7300 R01 en

OPTIFLUX 7300

PRODUCT FEATURES 1

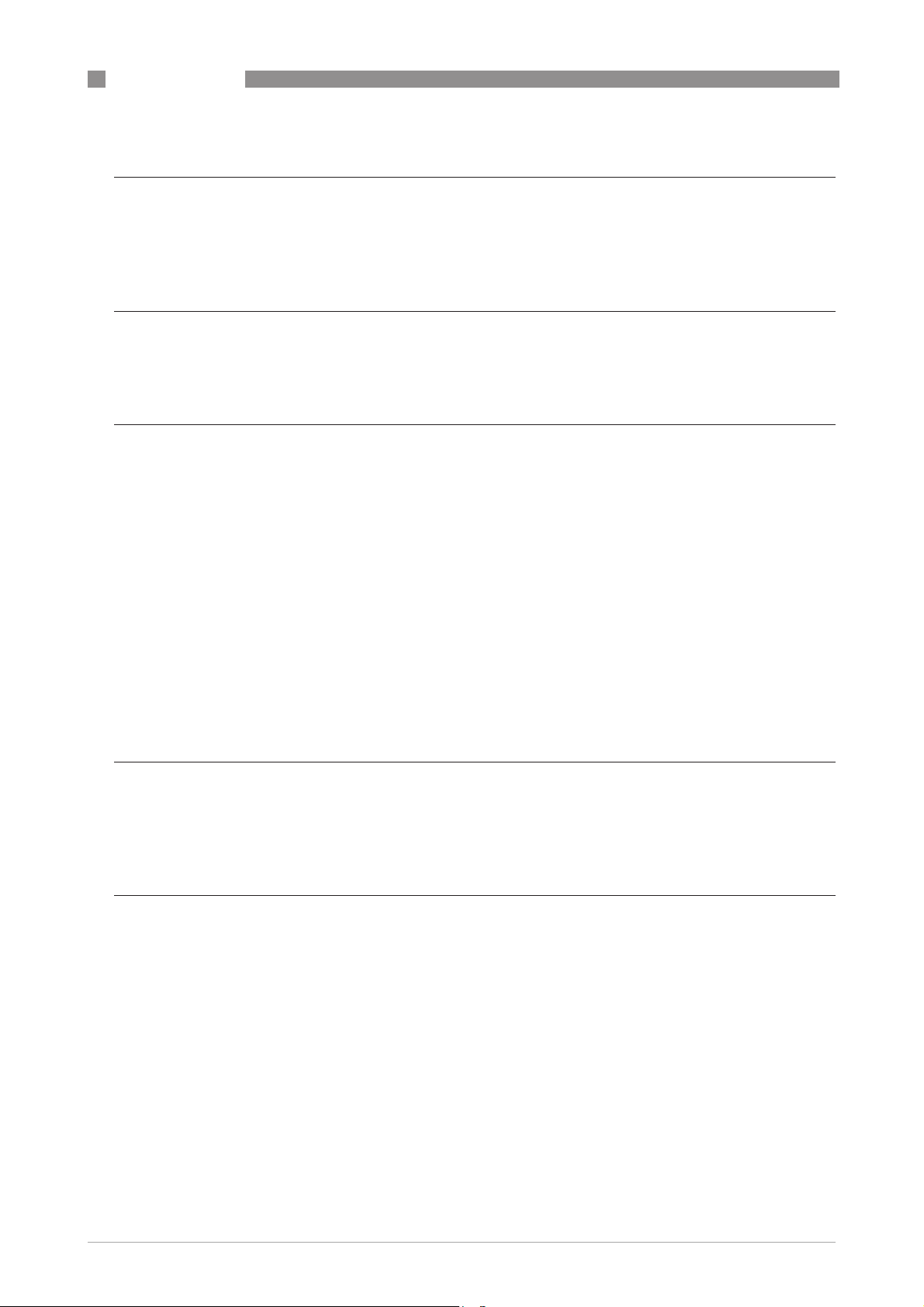

1.1 Non wetted electrodes with high tech ceramic liner

The OPTIFLUX 7300 combines the advantages of non wetted capacitive electrodes, a ceramic

liner and the IFC 300 converter. This electromagnetic flowmeter can be used for noisy

applications, low conductivities, mediums tending to form an insulating film, applications with

high vibrations, and oxidizing, abrasive and toxic mediums.

Instead of conventional electrodes that have a direct contact with the process liquid,

OPTIFLUX 7300 has a non-contacting capacitive signal pick-up. The electrodes are designed as

large-area capacitor plates, mounted behind the ceramic liner.

Because the electrodes have no contact with the medium, unwanted catalytic action with

metallic parts is eliminated. A second benefit is that the insulation of electrodes no longer forms

a risk. In case of a medium that tends to form a non conductive surface coating on the tube wall,

the signal pick up between medium and electrodes will not be interrupted.

The smooth and pore free ceramic tube construction does not leak and is CIP / SIP resistant,

making it highly suitable for hygienic applications in for example the food & beverage and

pharmaceutical industry. It is very hard, non permeable and has an extreme and broad chemical

resistance, fulfilling requirements of the chemical industry.

The construction of the OPTIFLUX 7300 offers an absolute leak tight solution, because leakage

through the liner and leakage along the electrodes is not possible.

The IFC 300 converter standardly includes extensive diagnostics of the process and meter and

powerful filter settings for stable flow measurements.

1 Stainless steel sensor housing

2 Ceramic liner

3 Capacitor plates for signal pick up behind the liner

www.krohne.com01/2011 - 4000962501 - TD OPTIFLUX 7300 R01 en

3

1 PRODUCT FEATURES

Highlights

• Ceramic liner with non wetted electrodes

• Excellent chemical and abrasion resistance

• Increased safety and hygiene with absolutely leak tight design

• No metals in contact with the medium

• No insulation of the electrodes

• No wear or corrosion of the electrodes

• Stable flow measurement

• Low conductivities to 0.05 μS/cm

• Fully vacuum resistant

• Insensitive for temperature shocks

• Sterile and hygienic; conformity to FDA requirements

• Excellent long term stability and accuracy

• Alternative for mass flowmeter (for the price of an electromagnetic flowmeter)

Industries

• Chemical

• Food & beverage

• Pharmaceutical

• Paper & pulp

• Wastewater

• Machine building

• Primaries

OPTIFLUX 7300

Applications

• Toxic, aggressive and abrasive mediums

• Emulsions: latex, emulsion paints

• Adhesives

• Organic mass production

• Low conductive mediums: (bio-) alcohols, spirits, glycols, glycerine

• Abrasive slurries

• Water mixed with oil or metallic particles

• Fibrous products

• Oil-based products: vegetable oils

• Dairy products: fat creams, milk, cheese, yoghurt with fruit particles

• Cement

4

www.krohne.com 01/2011 - 4000962501 - TD OPTIFLUX 7300 R01 en

OPTIFLUX 7300

1.2 Features

Non wetted, capacitive electrodes

PRODUCT FEATURES 1

The electrodes are designed as large-area

capacitor plates, fitted onto the outside of

the ceramic tube. The non-wetted signal

pick-up offers major benefits over a classic

wetted electrode design:

• No metals in contact with the medium

• No risk of insulation of electrodes

• No leakage

• No wear or corrosion of electrodes

• Minimum conductivity of the medium

down to 0.05 μS/cm

• More stable flow indication with

inhomogeneous media.

With non wetted capacitive electrodes

noise is significantly reduced because

there is no electromechanical interaction

or particles hitting electrodes.

Ceramic liner with conical design

The ceramic liner of the OPTIFLUX 7300

has an excellent abrasion resistance, is

extremely hard, dimensionally stable and

has a low thermal expansion coefficient.

The chemical resistance is excellent and

broad. It is also smooth, pore-free and

non-permeable.

These features result in the following

advantages:

• High wear resistance, and therefore very

suitable for abrasive fluids

• Absolute vacuum resistance

• Very suitable for aggressive media

• Exceptional long term stability

• High measurement accuracy also under

unfavorable measurement conditions

• No crevices, no gaps, no bacteria growth

• No leaching of the ceramic into the

medium

• Suitable for CIP /SIP

www.krohne.com01/2011 - 4000962501 - TD OPTIFLUX 7300 R01 en

5

1 PRODUCT FEATURES

All electronic parts rigidly fixed to the ceramic tube

OPTIFLUX 7300

With OPTIFLUX 7300 noise is not only

reduced by capacitive electrodes but also

by the rigid construction of the electronic

parts.

All electronic parts are fully integrated

with the ceramic tube using LTCC (Low

Temperature Co-fired Ceramic)

technology. The capacitive electrodes,

shielding and pre-amplifiers are sintered

in three layers of LTCC tape on the ceramic

tube. This results in a very rigid and fixed

construction, eliminating relative

movements of these parts. This is also

known as microphonic effects. The use of

non-piezo electric materials avoids piezoelectric noise that can be induced when

using plastic insulation materials.

The benefits of the highly rigid design are a

high noise and vibration immunity.

6

www.krohne.com 01/2011 - 4000962501 - TD OPTIFLUX 7300 R01 en

OPTIFLUX 7300

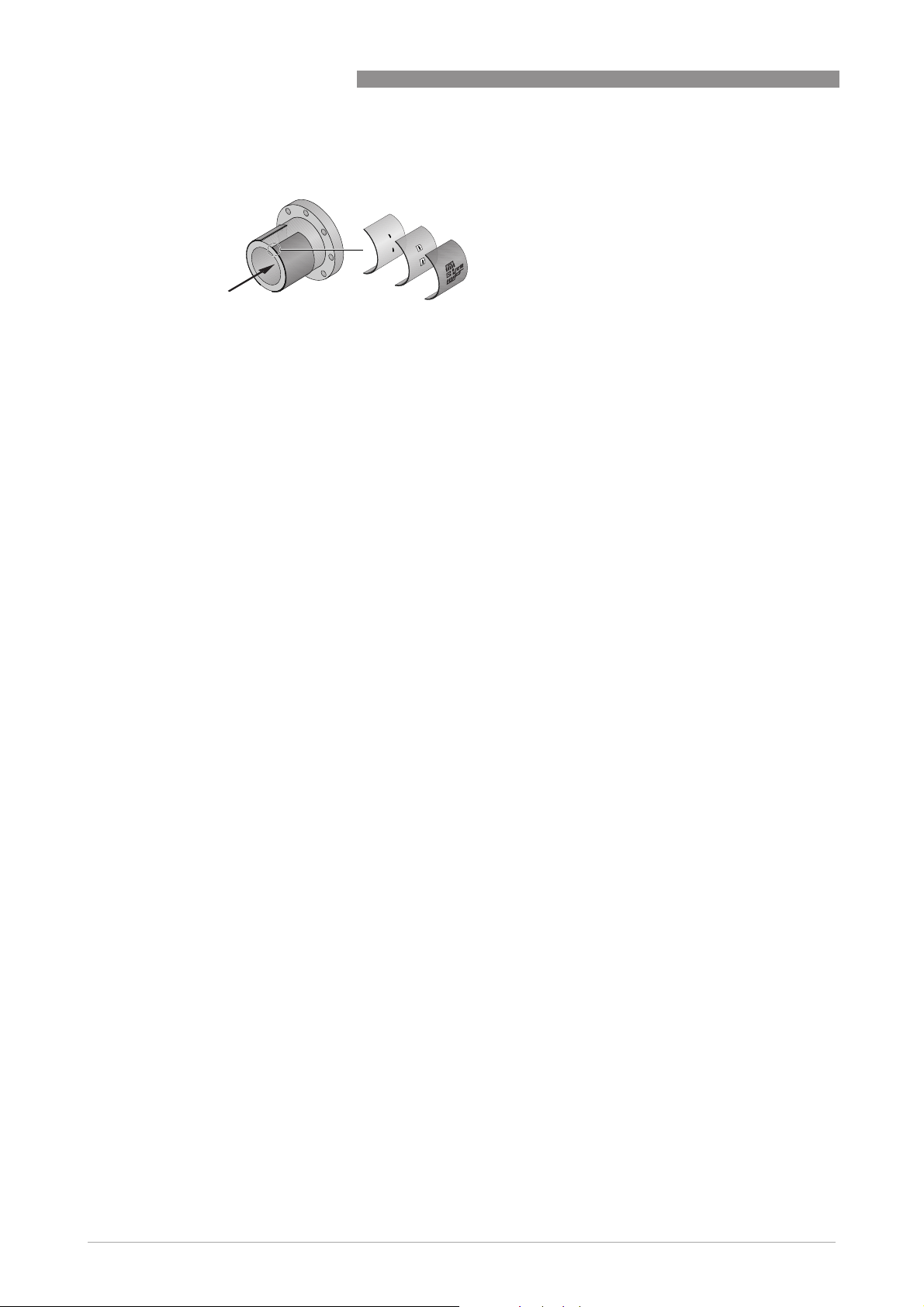

1.3 Measuring principle

An electrically conductive fluid flows inside an electrically insulated pipe through a magnetic

field. This magnetic field is generated by a current, flowing through a pair of field coils. Inside of

the fluid, a voltage U is generated:

U = v * k * B * D

U = v * k * B * D

U = v * k * B * DU = v * k * B * D

in which:

v = mean flow velocity

k = factor correcting for geometry

B = magnetic field strength

D = inner diameter of flow meter

The signal voltage U is picked off by electrodes and is proportional to the mean flow velocity v

and thus the flow rate q. A signal converter is used to amplify the signal voltage, filter it and

convert it into signals for totalising, recording and output processing.

PRODUCT FEATURES 1

1 Induced voltage (proportional to flow velocity)

2 Electrodes (capacitive)

3 Magnetic field

4 Field coils

www.krohne.com01/2011 - 4000962501 - TD OPTIFLUX 7300 R01 en

7

2 TECHNICAL DATA

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

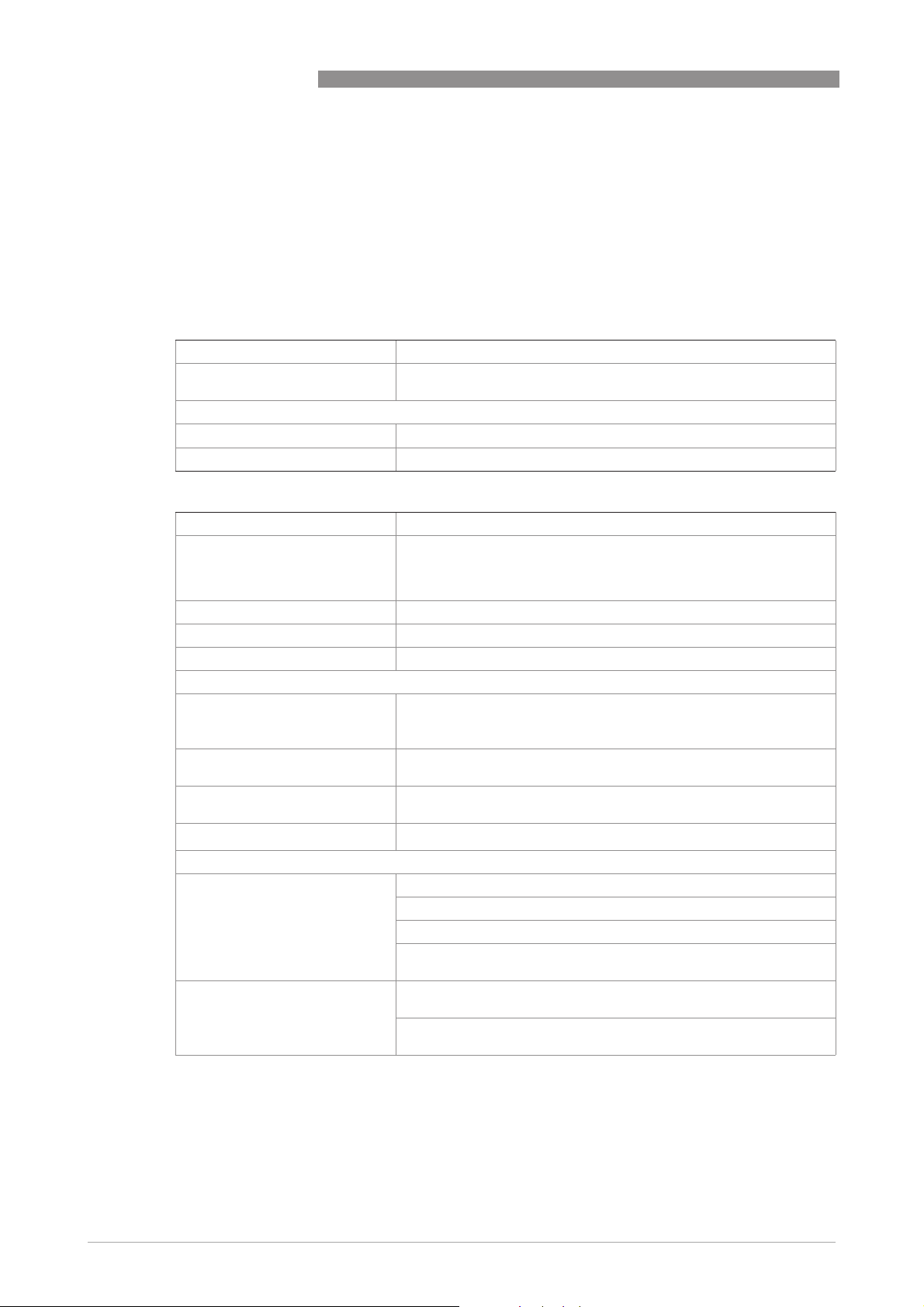

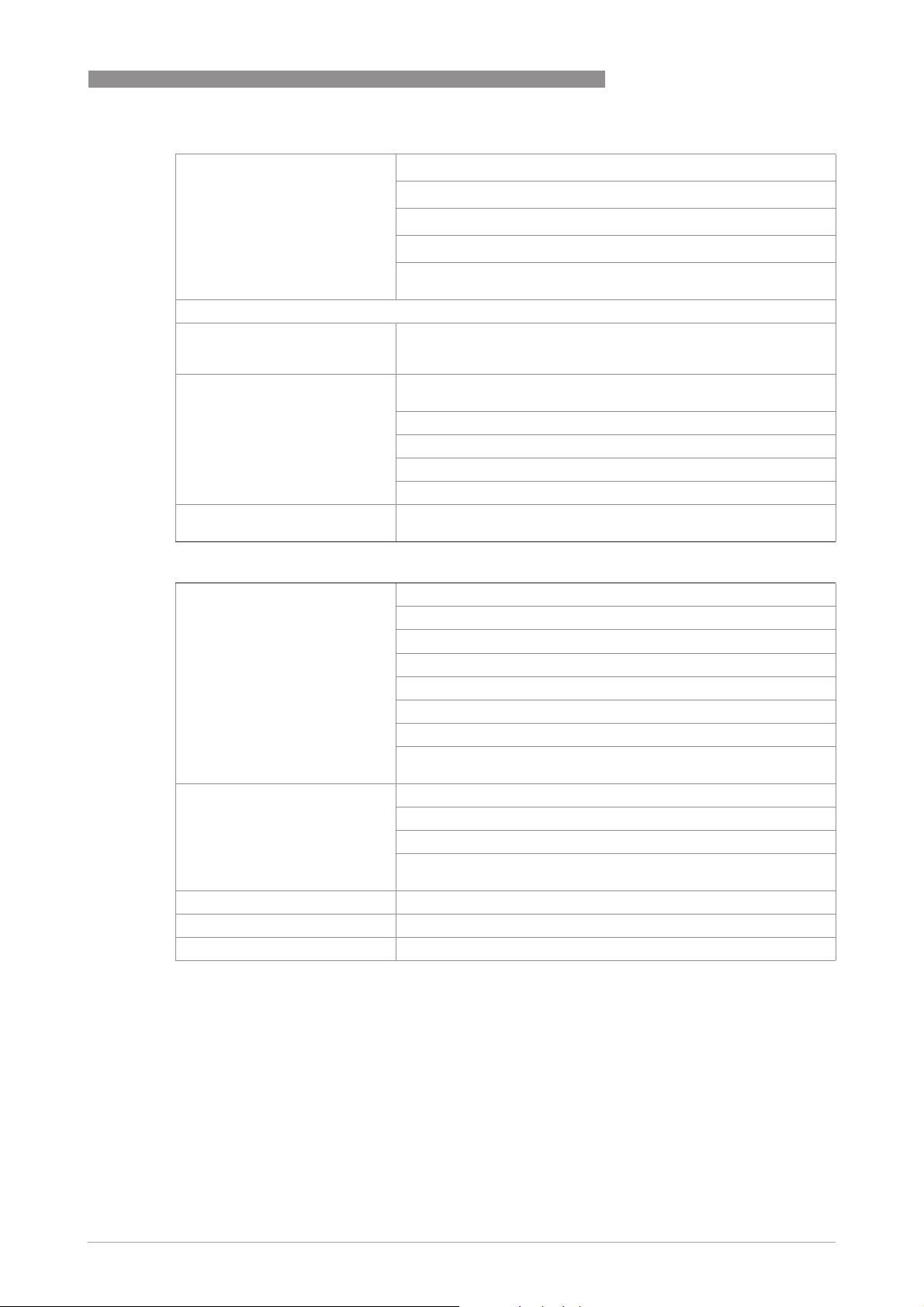

Measuring system

Measuring principle Farady's law of induction

Application range Continuous measurement of the volumetric flow rate of electrically

Measured value

Measured value

Measured valueMeasured value

Primary measured value Flow velocity

Secondary measured value Volume flow, mass flow

Design

Features Sandwich / flanged version with optimized flow tube

Modular construction The measurement system consists of a flow sensor and a signal

Compact version With IFC 300 C / CAP converter: OPTIFLUX 7300 C

Nominal diameter DN25, 40, 50, 80, 100 / 1", 1½", 2", 3" and 4".

Measurement range -12...+12 m/s / -40...+40 ft/s

Signal converter

Signal converter

Signal converterSignal converter

Outputs / inputs

Counters 2 (optional 3) internal counters with a max. of 8 counter places

Verification Intergrated verification, diagnostic functions: measuring device,

Communication interfaces

User interface

User interface

User interfaceUser interface

Display LC Display, backlit white

Operating elements 4 optical keys for operator control of the signal converter without

OPTIFLUX 7300

conductive liquids.

converter. It is available as compact version only. More information

about the signal converter can be found in the documentation of the

signal converter.

Current- (incl. HART®), pulse, frequency and/or status output, limit

switch and/or control input, current input (depends on the I/O

version)

(e.g. for counting volume and/or mass units)

process, measured value, empty pipe detection, stabilization.

Foundation Fieldbus, Profibus PA and DP, Modbus, HART

Size: 128 x 64 pixel, corresponds to 59 x 31 mm / 2.32" x 1.22"

Display can be turned in steps of 90°

Ambient temperature below -25°C / -13°F, may effect the readability

of the display.

opening the housing.

Infrared interface for reading and writing all parameters with IR

interface (option) without opening the housing.

®

8

www.krohne.com 01/2011 - 4000962501 - TD OPTIFLUX 7300 R01 en

OPTIFLUX 7300

TECHNICAL DATA 2

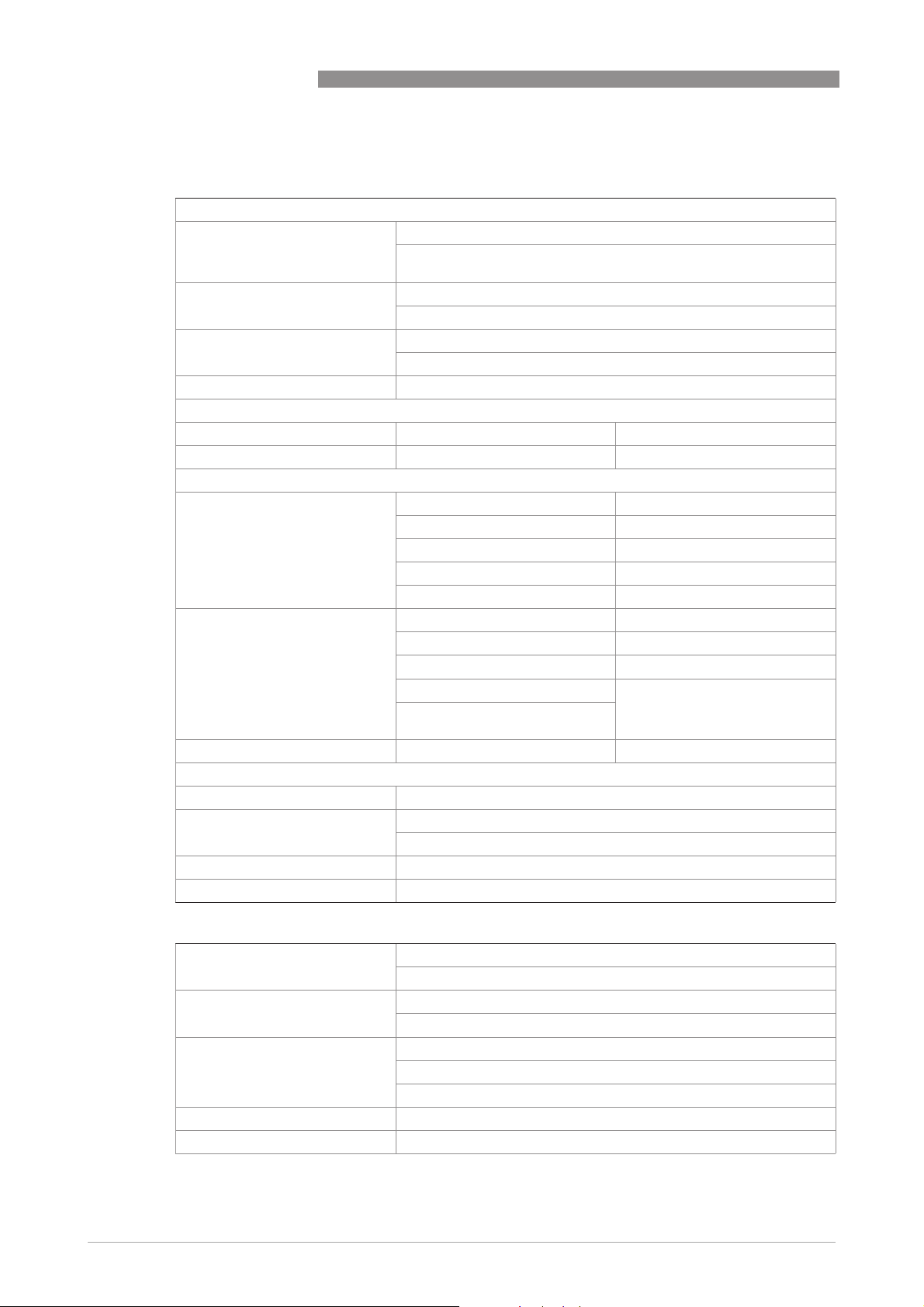

Remote control

Display functions

Display functions

Display functionsDisplay functions

Operating menu Setting the parameters using 2 measured value pages, 1 status page,

Language display texts

(as language package)

Units Metric, British and US units selectable as required from lists for

PACTware® (incl. Device Type Manager (DTM))

HART® Hand Held Communicator from Emerson Process

AMS® from Emerson Process

PDM® from Siemens

All DTMs and drivers are available free of charge from the

manufacturer's website.

1 graphics page (measured values and graphics are freely

adjustable).

Standard: English, French, German, Dutch, Portuguese, Swedish,

Spanish, Italian

Eastern Europe: English, Slovenian, Czech, Hungarian

Northern Europe: English, Danish, Polish

China: English, Chinese

Russia: English, Russian

volume / mass flow and counting, flow velocity, temperature.

Measuring accuracy

Reference conditions Flow conditions: similar to EN 29104

Medium: water

Temperature: 20°C / 68°F

In-/outlet section: 10 DN / 5 DN

Flow velocity: > 1 m/s / > 3 ft/s

Operating pressure: 1 bar / 14.5 psig

Valve closing time variation: < 1 ms

Wet calibrated on EN 17025 accredited calibration rig by direct

volume comparison.

Maximum measuring error ±0.5% of measured value ±5 mm/s

Related to volume flow.

These values are related to the pulse / frequency output.

The additional typical measuring deviation for the current output

is ±10 μA.

Repeatability ±0.1% of MV, minimum 1 mm/s

Long term stability ±0.1% of MV

Special calibration On request

www.krohne.com01/2011 - 4000962501 - TD OPTIFLUX 7300 R01 en

9

2 TECHNICAL DATA

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process temperature -40...100°C / -40...+212°F (up to 120°C / 248°F for up to 30 min.)

Maximum temperature change

(shock)

Ambient temperature Non-Ex: -40..+65°C / -40...+149°F

Storage temperature -50...+70°C / -58...+158°F

Pressure

Pressure

PressurePressure

Ambient pressure Atmospheric Atmospheric

Nominal flange pressure

EN 1092-1 Standard:

ASME B16.5 Standard:

Vacuum load 0 mbar / 0 psig 0 mbar / 0 psig

Chemical properties

Chemical properties

Chemical propertiesChemical properties

Physical condition Liquids

Electrical conductivity 0.05 μS/cm

Permissible gas content (volume) ≤ 5%

Permissible solid content ≤ 70%

OPTIFLUX 7300

For Ex versions different temperature ranges are applicable.

Please see the relevant Ex documentation for details.

Rising: 125°C / 257°F (in 10 min.); 120°C / 248°F (sudden change)

Falling: 100°C / 212°F (in 10 min.); 80°C / 176°F (sudden change)

Ex: -40...+60°C / -40...+140°F

OPTIFLUX 7300 C - SW

OPTIFLUX 7300 C - SW OPTIFLUX 7300 C - FL

OPTIFLUX 7300 C - SWOPTIFLUX 7300 C - SW

Standard: Standard:

Standard:Standard:

DN100: PN 16 DN100: PN 16

DN25...80: PN 40 DN25...80: PN 40

Option:

Option: Option:

Option:Option:

DN100: PN 25 -

Standard: Standard:

Standard:Standard:

1...4": 150 lb 1...4": 150 lb

Option:

Option: Option:

Option:Option:

1...3": 300 lb 1...3": 300 lb

4": 300 lb

Max. pressure is 30 bar / 435 psig

Demineralised cold water: ≥ 1 μS/cm

OPTIFLUX 7300 C - FL

OPTIFLUX 7300 C - FLOPTIFLUX 7300 C - FL

Standard:

Standard:Standard:

Option:

Option:Option:

Standard:

Standard:Standard:

Option:

Option:Option:

10

Installation conditions

Installation Take care that the flow sensor is always fully filled.

For detailed information see chapter "Installation".

Flow direction Forward and reverse

Arrow on flow sensor indicates positive flow direction.

Inlet run ≥ 5 DN (without disturbing flow, after a single 90° bend)

≥ 10 DN (after a double bend 2x90°)

≥ 10 DN (behind a control valve)

Outlet run ≥ 2 DN

Dimensions and weights For detailed information see chapter "Dimensions and weights".

www.krohne.com 01/2011 - 4000962501 - TD OPTIFLUX 7300 R01 en

Loading...

Loading...