Page 1

© KROHNE 06/2001

Addendum to

Operating and

Instruction Manual

For Modis Converters

MFC 081/085i

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 1 of 18

Page 2

Addendum to Operating and Instruction Manual for “Modis” Converters

Contents

Ex Versions

1. Description………………………………………………………………………….3

2. Output Options …………………………………………………………………….3

3. Power Supplies…………………………………………………………………….4

4. Output Wiring……………………………………………………………………… 5

Non-Ex Modis Converters

5. Description…………………………………………………………………………5

6. Available Versions…………………………………………………………………5

7. Terminal Connections……………………………………………………………..6

Communication Options

8. Supplementary Instructions for PROFIBUS PA ………………………………..7

9. Foundation Fieldbus (Pending)

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 2 of 18

Page 3

Addendum to Operating and Instruction Manual for “Modis” Converters

Ex Versions

1. Description

These versions of the converter are suitable for installation in a hazardous area where

intrinsically safe outputs are required.

This converter has passive outputs, which also has the benefit of utilizing the multi-drop

feature of HART®. The outputs are galvanically separated from each other.

Please ensure that you know which converter options you have, to use the correct wiring

diagram.

2. Output Options

The following output options are available:

G. 1 x 4 -20mA and 1 x Pulse output

H. 1 x 4 -20mA and 1 x Status output

K. 1 x 4 -20mA and 1 x Control input

L. 2 x 4-20 mA

M. 1 x 4-20mA and PROFIBUS PA

N. 1 x 4-20mA and Foundation Fieldbus (pending)

Note: HART® is available on the first current output in all cases except options M and N.

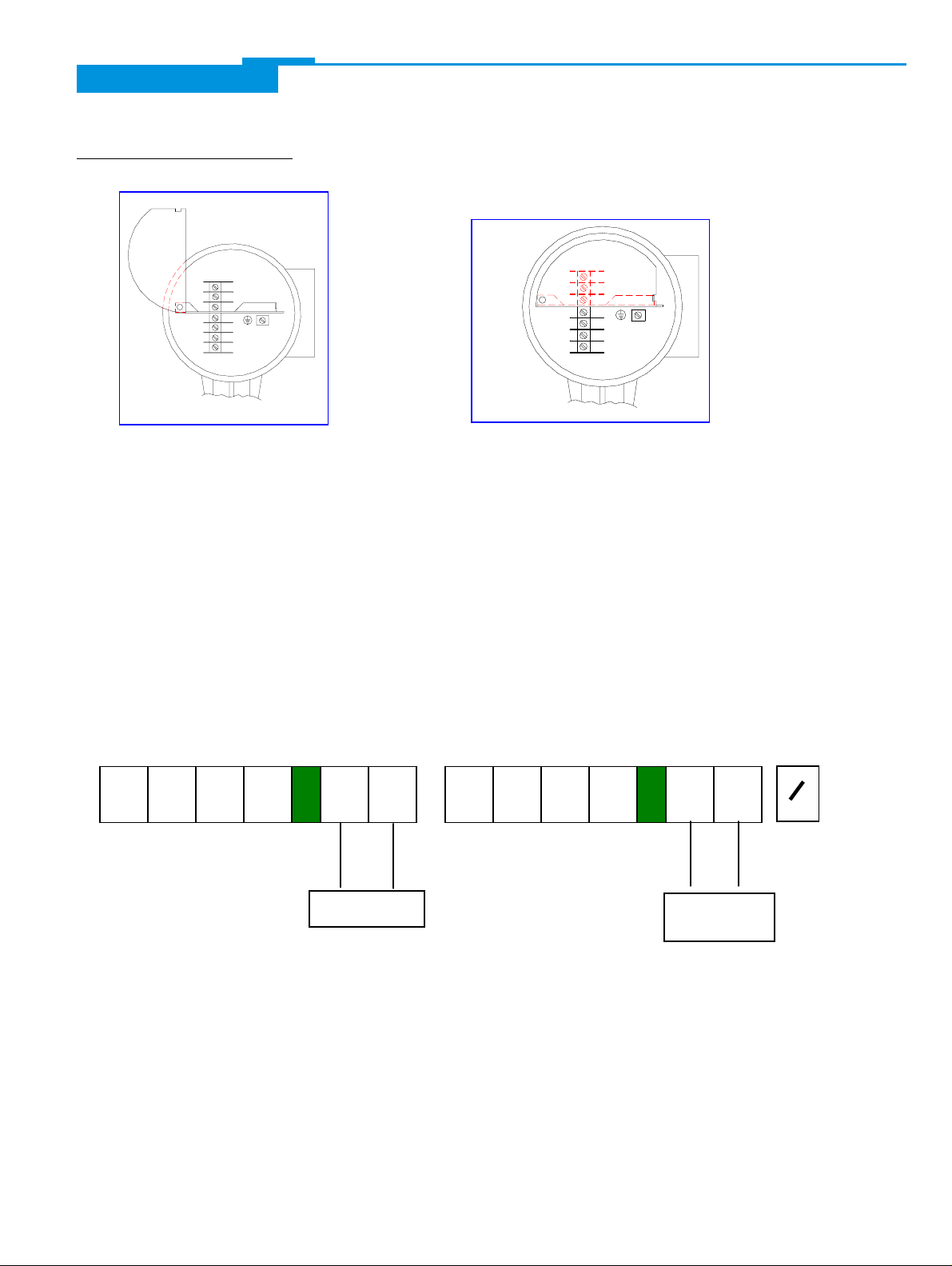

Wiring the Converter:

Note:

Supply compartment is

separated from output

terminals

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 3 of 18

Page 4

Addendum to Operating and Instruction Manual for “Modis” Converters

Wiring the Power Supply:

Slide the cover to the left to Power supply terminals

Expose the power terminals. covered.

3. Power Supplies:

The converter is available in two options:

A. 24 V AC/DC Switched mode supply

B. 100/230 V AC

24V AC/DC Version 100 – 230V AC Version

11 12 11 12

24V AC/DC

N L

100-230 V

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 4 of 18

Page 5

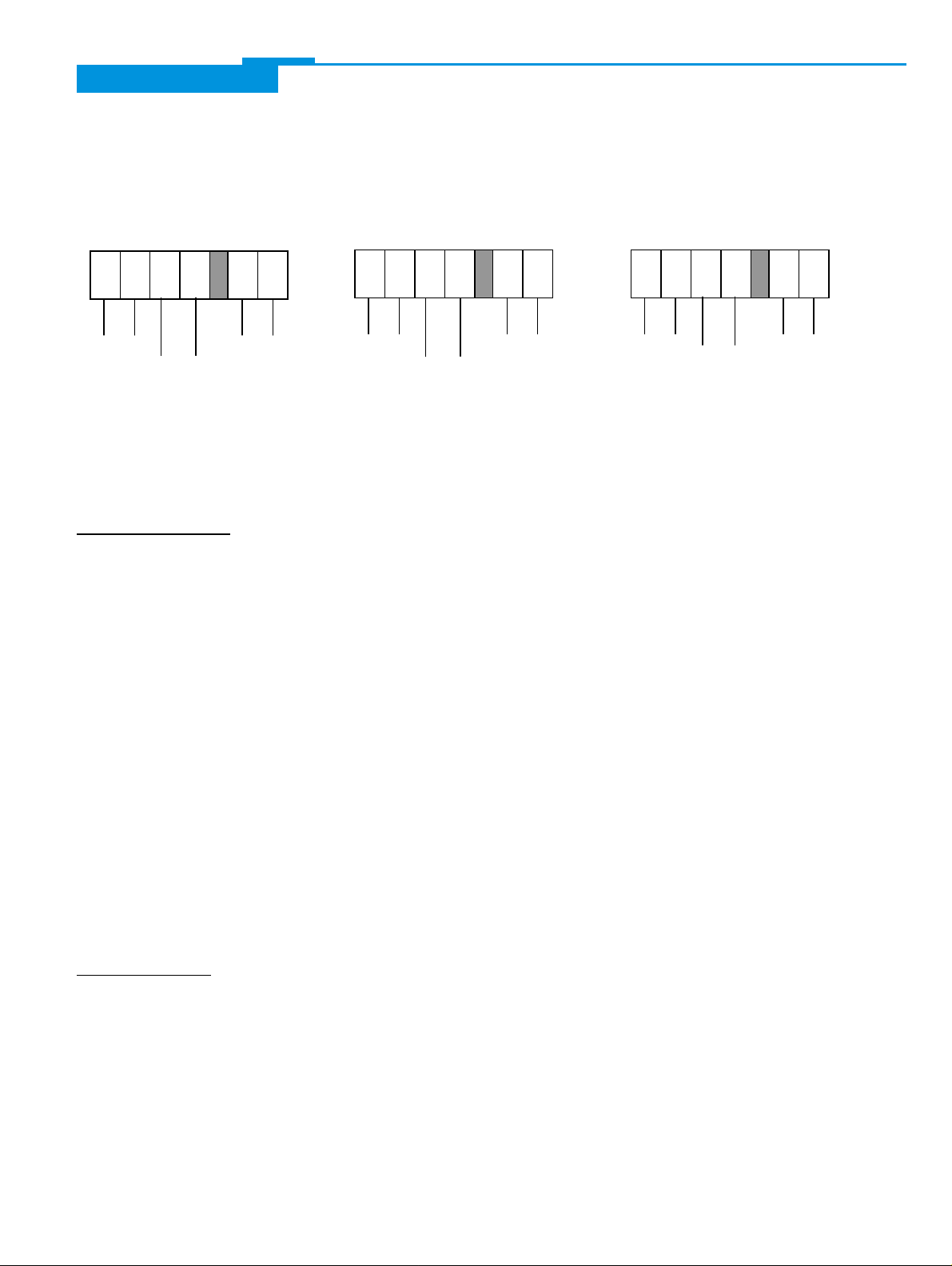

4. Output Wiring:

Option G, H, K Option L Option M, N

I

I

1

⊥

B B 11 12

1

⊥

+

Addendum to Operating and Instruction Manual for “Modis” Converters

I

1

⊥

+

I1I2I

⊥

11 12

2

+

I

I

1

⊥

D D 11 12

1

⊥

+

+

4 - 20 mA 24 V AC/DC

P- P+

or

S- S+

or

C- C+

Depending on function

programmed

or

100-230 VAC

4 - 20 mA

#1

4 - 20 mA

#2

24 V AC/DC

or 100-230 VAC

4 - 20 mA

Fieldbus Foundation

Profibus PA

or

24 V AC/DC

or

100-230 VAC

Non-Ex Versions

5. Description:

This version of converter is similar to the existing Modis converter range but has no Ex

approvals.

It has been introduced to provide the options of Profibus PA, Foundation Fieldbus (planned)

and galvanically isolated outputs for non-Ex environments such as food and pharmaceutical

applications.

6. Available Versions:

L 2 x 4-20mA passive output (freely programmable). HART protocol on first output. Both

outputs galvanically separated from each other and the power supply.

M 1 x 4-20mA passive output (freely programmable) and 1 x Profibus PA passive output

(HART protocol not available). Both outputs galvanically separated from each other

and the power supply.

N Like M, but 1x Fieldbus Foundation passive output (pending)

Supply Voltage:

These converters are available with the same two voltage options:

24V AC/DC

100 – 230 V AC

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 5 of 18

Page 6

Addendum to Operating and Instruction Manual for “Modis” Converters

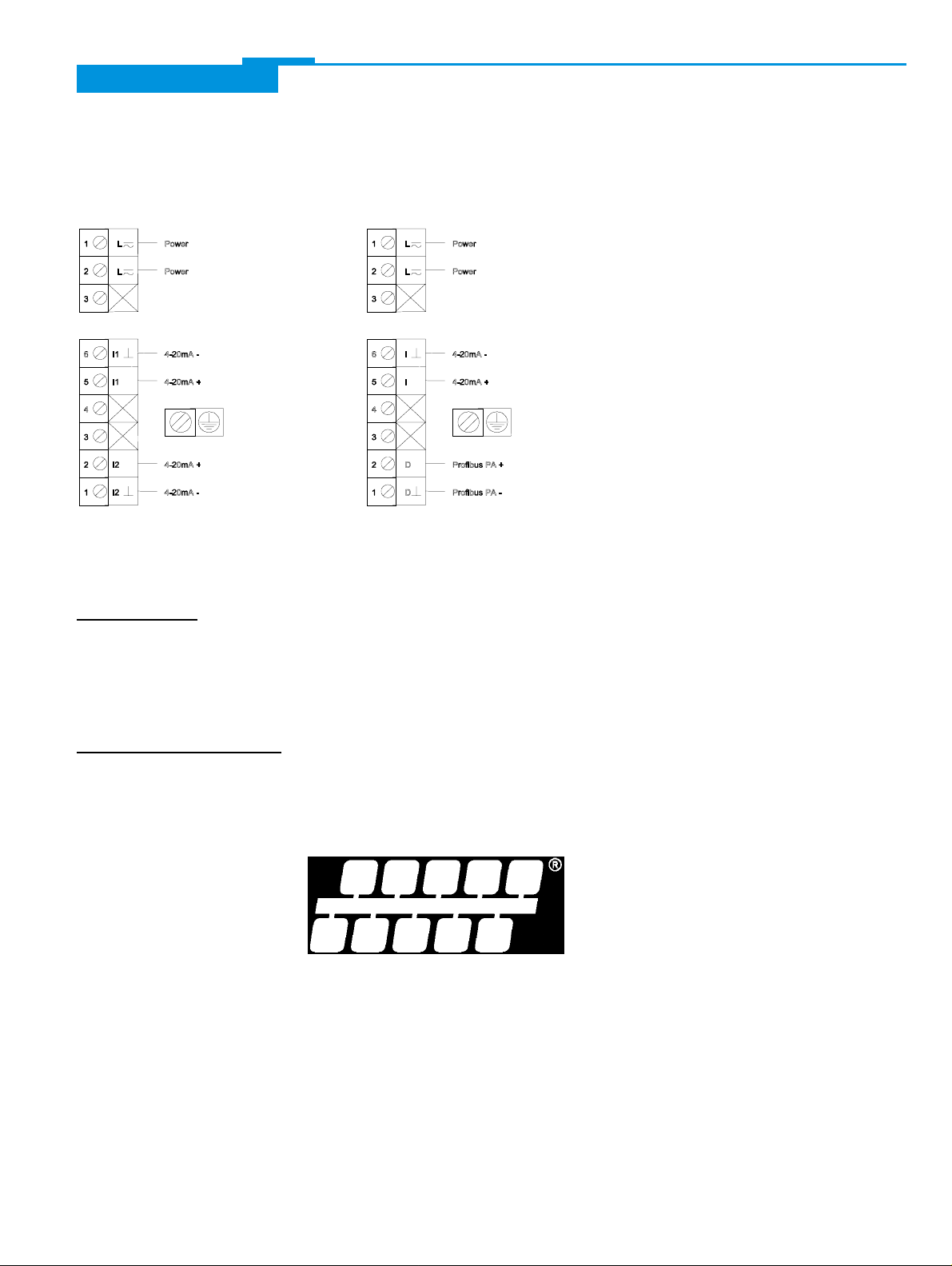

7. Terminal Connections:

Option L Option M, N

Programming:

All programming and functions remain as for standard converters as described in the main

instruction manual.

Communication Options

Two options are planned for this converter. PROFIBUS PA is available with Foundation

Fieldbus to follow.

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 6 of 18

Page 7

Addendum to Operating and Instruction Manual for “Modis” Converters

8. Supplementary Instructions for PROFIBUS PA

Ex Versions......................................................................................................................................................... 2

Non-Ex Versions................................................................................................................................................. 2

Communications Options.................................................................................................................................... 2

Ex Approval Versions ......................................................................................................................................... 3

Wiring the Converter:

Non-Ex Modis Converters................................................................................................................................... 5

1. General

Items included with supply.................................................................................................................................. 8

Software history.................................................................................................................................................. 8

........................................................................................................................................................... 8

2. Technical Specifications

2.1 GSD File....................................................................................................................................................... 9

2.2 PROFIBUS-PA Profile................................................................................................................................ 11

2.3 Meaning of the Measuring- and Status Messages...................................................................................... 12

3. Connection of Instruments on the PROFIBUS-PA system

3.1 Interconnection of devices in hazardous locations ..................................................................................... 14

3.2 Bus cable.................................................................................................................................................... 14

3.3 Shielding and grounding............................................................................................................................. 14

3.4 PROFIBUS-PA connection......................................................................................................................... 14

4. Menu Settings for PROFIBUS-PA

5. Technical Data

....................................................................................................................................... 3

............................................................................................................................ 8

............................................................ 14

........................................................................................................ 15

............................................................................................................................................ 16

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 7 of 18

Page 8

Addendum to Operating and Instruction Manual for “Modis” Converters

1. General

These Instructions are supplementary to the “Installation and Operating Instructions MFM

4085 K / F or MFM2081/3081 K/F“. The details given there, in particular the Safety

Information, are valid and should be observed. These Supplementary Instructions provide

only additional information for device Operation and connection to a PROFIBUS-PA Fieldbus.

Items included with supply

In addition to the standard scope of supply, these Supplementary Instructions for the MFM

4085 K / F i and MFM 2081/3081 K / F i with PROFIBUS-PA interface, plus a diskette with all

available GSD files for KROHNE devices.

Software history

,VVXHG Signal converter Instructions

month/

Hardware Firmware Device User

year

05/99 352),%863$

4.10/PRE990528

Module

06/99 PROFIBUS-

4.15/PRE990618

PA Module

11/99 PROFIBUS-

4.12/991126

PA Module

2. Technical Specifications

Control system (PLC)

Class 1 master

Analog I/O module

program

Engineering or operation

control tool

Class 2 master

PROFIBUS-DP, up to 12 Mbit/s

Power

Supply

Segment

coupler/link

Segment

coupler/link

PROFIBUS-PA

,30)/&

1 2 3 4 5 6

kg/h

1000

kg

2

03687

900

800

H250

,30)/&

700

SN 586 677/01-03

MC H250/RR/M9/K2/ESK-Z

600

C K25.2 1.4571

F CIV 25 1.4571

500

MD 1997

400

C2H50H

D 0.93 kg/l

V 2.5 mPa.s

300

T 23.5 C

P 0.4 MPa

200

100

FIA 1025

RP

PROFIBUS-PA

,30)/&

1 2 3 4 5 6

4-20 mA

HART device

The above diagram shows a typical instrumentation with PROFIBUS-PA devices in hazardous

and non-hazardous locations, including connection of conventional devices (e.g. with 4-20mA

signals) to the PROFIBUS-PA.

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 8 of 18

Page 9

Addendum to Operating and Instruction Manual for “Modis” Converters

The PROFIBUS-PA is normally connected to a segment coupler, which, among other things,

carries out conversion to the PROFIBUS-DP. Here, it needs to be noted in particular that the

segment coupler is normally set to a fixed baud rate on the DP side.

Further information on the planning and Operation of PROFIBUS-PA networks is to be found

in the KROHNE brochure “PROFIBUS-PA networks”.

2.1 GSD File

All available GSD files of KROHNE devices – including those of the MFC 081 i or 085 i, of

course - are supplied together with each device. The GSD contains information that is needed

for project planning of the PROFIBUS-DP/PA communication network. The relevant data files

must be loaded into the project planning system/master system before start-up of the bus

system.

For example, the following applies to COMET 200 or COM PROFIBUS from Siemens:

• all GSD files (*.GSD) into the directory of the GSD files, e.g. *\GSD

• all BMP files (*.BMP) into the directory of the bit maps, e.g. *\BITMAPS

In STEP7, the GSD file is automatically copied into the respective directory with “install new

GSD” (in the HW-Config Menu: EXTRAS). After that, the bit map must be copied into the

directory *\SIEMENS\STEP7\S7data\Nsbmp. Following “catalogue updating” the device can

be placed in the project. This will then enable the cyclic communication (measured values and

status).

The MFC 081/085 i are supporting the entire PROFIBUS-PA profile V 3.0. All devices have

two ident-no. and two GSD files. Ident-no. “F701” belongs to the GSD file KROHF701.GSD

and includes the complete functionality of the mass flow meter. The use of the manufacturer

independent Ident-no. “9742” (GSD file “PA_9742.GSD”) allows the user an interchange with

other mass flow devices from other manufacturers.

PA_9742.GSD

The limited functionality of the GSD file includes four function blocks:

Mass flow rate, density, temperature and mass flow totalizer.

You need the PA_9742 to use this functionality. Before this, the communication has to be

projected and it has to be switched from “full functionality” to “interchangeable basic

configuration” by using a Master Class 2 Tool (IDENT_NUMBER_SELECTOR: Slot 0, Index

40 change byte value from 1 to 0). After this has been done, the device has to be projected by

using PA _9742.

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 9 of 18

Page 10

Addendum to Operating and Instruction Manual for “Modis” Converters

KROHF701.GSD

KROHNE delivers the GSD with the entire device functionality, which is listed below:

Block Number Standard-Configuration KROHF701.GSD

Ident-No. F701

1 Mass Flow AI-FB ØxØ115

2 Density AI-FB ØxØ119

3 Temperature AI-FB ØxØ11D

4 Mass Totalizer Totalizer-FB ØxØ115

5 Volume Flow AI-FB ØxØ111

6 Percentage Mass or ° Brix AI-FB ØxØ139

7 Solid Flow AI-FB ØxØ141

8 Volume Totalizer Totalizer-FB ØxØ111

AI = Analog Input Function Block

FB = Function Block

Address of the

“channel

parameter”

Important Notes:

1. To project the PROFIBUS communication network, you have to allocate each of the

blocks to a function. On the PC-S7 from Siemens, this will be done with the Tool HWConfig. It offers the functions which are described as follows:

2. It is possible to program an “empty block” on each block number. This means, that for this

block no data are transmitted in the cyclic data telegram.

3. There is NO Al block allowed on block position 4 and 8! Only totalizer block is here

allowed! That means the function “Analog Input (AI) is not possible. Beside the totalizer

functions is only the “empty block” allowed.

4. There is a choice between 4 different totalizer functions, which can be allocated to the

blocks 4 and/or 8. The meaning of the cyclic data transfer (Totalizer and Status) does

always correspond the meaning in section Meaning of the Measuring- and Status

Messages. The four functions are defined as follows:

Function “Totalizer” cyclic transfer of the totalizer with status to the master

Function “TOT_SetTot” cyclic transfer of the totalizer with status to the master +

cyclic control data from master to the device via the Bytes

SetTot

Function “TOT_Mode_Tot” cyclic transfer of the totalizer with status to the master +

cyclic control data from master to the device via the Bytes

ModeTot

Function “TOT_SetTot_ModeTot” cyclic transfer of the totalizer with status to the master +

cyclic control data from master to the device via the Bytes

SetTot and after that ModeTot

Both, the Byte SetTot and ModeTot are beeing sent cyclicly from Master to the device, by

inserting these bytes as output datas to the PLC configurator. The meaning of the control

bytes are as follows:

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 10 of 18

Page 11

Addendum to Operating and Instruction Manual for “Modis” Converters

SetTot

SetTot =0: Totalizer is totalizing. If the value of SetTot changes from “1” or “2” to “0”

the totalizer starts from the actual (0 or Preset value).

SetTot =1: Totalizer will be reset to 0 and stays there until SetTot is switched to 0.

SetTot =2: Totalizer is set to the value of PresetTot. PresetTot can be written via a

acyclic master (totalizer in block 4 = Slot 4 Index 32; totalizer in block 8

Index 32).

SetTot > 2: Is not allowed

ModeTot

ModeTot = 0 totalizer totalizes positive and negative values.

ModeTot = 1 totalizes only positive values.

ModeTot = 2 totalizes only negative values.

ModeTot = 3 totalizer is stopped, no totalization happens.

ModeTot >3 is not allowed

5. The standard block configuration can be changed, e.g. that density will be transferred in

block 1 instead of block 2. To do this, customer has to use a user tool, which can change

the “channel parameter” under the relative index 14, for totalizer function blocks under

index 12. In the above listed table, we have listed in the column “ Address of the “channel

parameter” the value, which you have to program in the channel parameter of the function

blocks.

6. Does the device include the options “volume concentration” or “° Baumé”, ° Brix and

NaOH, these values can be programmed via the channel parameters on a Al function

block. The value of the corresponding function block (relative Index 14) has to be

programmed 0x0135 for volume concentration or 0x013D for ° Baumé.

2.2 PROFIBUS-PA Profile

The MFC 081/085 i supports the PROFIBUS-PA Profile Version 3.0. Additionally, all relevant

parameters in the device are offered via the PROFIBUS-PA interface. The MFC 081/ 085

i

defines the following blocks:

• Six blocks Analog Input (AI): mass flow, density, temperature, volume flow, percentage

mass and solid flow. Optional volume concentration and ° Baumé can be provided.

• Two totalizer function blocks (TOT): totalized mass and totalized volume. As an option, the

solids can be totalized.

• One transducer block for Coriolis mass flow devices.

This block provides the parameters and functions defined in Profile 3.0, as well attached

are the values, which are not defined by the profile.

• One physical block.

This block contains the parameters defined in Profile 3.0.

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 11 of 18

Page 12

Addendum to Operating and Instruction Manual for “Modis” Converters

2.3 Meaning of the Measuring- and Status Messages

By implementing devices in the PROFIBUS-Master by using the GSD, it is possible to

indicate, which measuring and totalizer messages will be transferred over the PROFIBUS. To

each values a status will be added. First, the 4 value byte (Float Format to IEEE Standard 754

Short Real Number) and then 1 status Byte will be transferred. That means that each

measuring or totalizing value is described with 5 byte and transmitted one after the other

according to the sequence which was projected over the GSD. If 4 function blocks have been

projected, 20 byte will be transmitted.

First an example of the float format:

Byte n Byte n+1 Byte n+2 Byte n+3

Bit7Bit6 Bi

Bit6 Bit7 Bit7

t7

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

VZ27262524232221202

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

2

19

20

21

-

2

2

22

23

Exponent Mantisse Mantisse Mantisse

Example: 40 F0 00 00 (hex) = 0100 0000 1111 0000 0000 0000 0000 0000 (binary)

Formula: Value = (-1)

Value = (-1)

VZ

0

(Exponent - 127)

* 2

(129 - 127)

* 2

* (1 + Mantisse)

* (1 + 2-1 + 2-2 + 2-3)

Value = 1 * 4 * (1 + 0,5 + 0,25 + 0,125)

Value = 7,5

The meaning of the status (unsigned integer) you will find in following table:

Qualit

y

Gr Gr QSQSQSQSQuQ

272625242322212

0 0 = bad

0 1 = uncertain

1 0 = good (Non Cascade)

1 1 = good (Cascade) - not supported

Status = bad

0 0 0 0 0 0 = non-specific

0 0 0 0 0 1 = configuration error

0 0 0 0 1 0 = not connected

0 0 0 0 1 1 = device failure

0 0 0 1 0 0 = sensor failure

0 0 0 1 0 1 = no communication (last usable value)

0 0 0 1 1 0 = no communication (no usable value)

0 0 0 1 1 1 = out of service

Status = uncertain

Quality-

Substatus

Limits

u

0

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 12 of 18

Page 13

Addendum to Operating and Instruction Manual for “Modis” Converters

0 1 0 0 0 0 = non-specific

0 1 0 0 0 1 = last usable value

0 1 0 0 1 0 = substitute-set

0 1 0 0 1 1 = initial value

0 1 0 1 0 0 = sensor conversion not accurate

0 1 0 1 0 1 = engineering unit violation (unit not in the

valid set)

0 1 0 1 1 0 = sub-normal

010111 = configuration error

011000 = simulated value

011001 = sensor calibration

Status = good (Non-Cascade)

1 0 0 0 0 0 = ok

1 0 0 0 0 1 = update event

1 0 0 0 1 0 = active advisory alarm (priority < 8)

1 0 0 0 1 1 = active critical alarm (priority > 8)

1 0 0 1 0 0 = unacknowledged update event

1 0 0 1 0 1 = unacknowledged advisory alarm

1 0 0 1 1 0 = unacknowledged critical alarm

101000 = initiate fail safe

101001 = maintenance required

Status = Limits

0 0 = ok

0 1 = low limited

1 0 = high limited

1 1 = constant

Please test the first two (Quality) to check the quality of the measuring value:

Good (non Cascade) measuring value is ok and can be used

Uncertain the measuring value can be used, although the accuracy is not

confirmed (e. g. measuring value is frozen or A/D-value is outside

of the valid range)

Bad the measuring value is not acceptable and cannot be used for

further processing.

Good (Cascade) will not be supported, because it is not applicable for the device

Diagnosis

If the internal diagnostic detects a error, additional information will be transmitted in the

Master. The meaning of this information are described in the GSD-file under

UNIT_DIAG_BIT(i).

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 13 of 18

Page 14

Addendum to Operating and Instruction Manual for “Modis” Converters

3. Connection of Instruments on the PROFIBUS-PA system

3.1 Interconnection of devices in hazardous locations

We recommend that a PROFIBUS-PA network in the hazardous location be projected in

accordance with PTB’s FISCO model (see KROHNE brochure “PROFIBUS-PA networks”). In

that case, all connected electrical components (including the bus termination) must be

approved in conformity with the FISCO model.

3.2 Bus cable

The statements given in the FISCO model apply only provided the bus cable used meets the

following specifications: R´=15...150 Ohm/km; L´=0.4...1 mH/km; C´=80...200 nF/km.

3.3 Shielding and grounding

For optimum electromagnetic compatibility of systems it is extremely important that the

system components, and particularly the bus cables connecting the components, be shielded

and that such shields - if possible - form an unbroken cover, electrically speaking.

Hence it follows that, for use in non-hazardous duty systems , the cable shield should be

grounded as often as possible.

In “Ex“ systems with adequate equipotential bonding in the hazardous and non-hazardous

location along the entire Fieldbus installation, multiple grounding of the shield is also of

advantage.

Note: The use of twisted and shielded cables is strongly recommended, otherwise EMC

protection of the mass flow meter cannot be assured.

3.4 PROFIBUS-PA connection

Connect the bus cable as shown in

the figure.

• Connect the cable cores to

terminals D and D• .

• Polarity reversal will not have

any effect.

• The cable shield should be

connected with minimum length

to the FE functional ground.

• The equipotential bonding

conductor must be connected to

the device by connecting it to FE

functional ground

PROFIBUS-PA with current output:

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 14 of 18

Page 15

Addendum to Operating and Instruction Manual for “Modis” Converters

Non-Ex-Version Ex-Version

Fieldbus

DI

D I

Shield

PROFIBUS-

PA

Current

Output

-+

4-20mA

U=8-30V

Power

Supply

4-20mA

U=8-30V

Current

Output

1

+-

PROFIBUS-

Fieldbus

1

PA

DDII

Power

Supply

Shield

4. Menu Settings for PROFIBUS-PA

The following settings need to be made for Operation of the MFC 081/ 85 i on a PROFIBUSPA network. Note, that the address can be set over the communication service “Set slave

address” from the master.

Function (Fct.) Description

3.8.4

LOCATION

3.11.0 Text, measuring-point tag (max. 10 characters)

3.11.1

PROTOCOL

3.11.2

ADDRESS

3.11.3

BAUD RATE

Tag name setting

Characters assignable to each place:

A-Z 0-9 or "_" (blank character)

Characters assignable to each place:

A-Z 0-9 or "_" (blank character)

•

PROFI PA

Set address

Range: 00-126 for PROFIBUS-PA (default 126)

BLOCKED

(measuring point no.) max. 10 characters

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 15 of 18

Page 16

5. Technical Data

y

g

g

g

g

Addendum to Operating and Instruction Manual for “Modis” Converters

Hardware Software

Physical to IEC 61158-2 and the FISCO

model

Bus characteristic 9... 30 V; 0.3 A max.; 4.2 W max. Device profile complete implementation of

Base current 10 mA. Function blocks Function blocks (listed

FDE yes: separate fault disconnection

electronics provided.

Fault current 6 mA; (fault current = max.

continuous current – base

current).

Starting current lower than the base current Operator control local display and operator

“Ex“ approval EEx ia IIC T6 or EEx ib IIC/IIB T6

in conformity with the FISCO

model

Connection independent of polarity

GSD GSD file supplied on diskette

Profile B, V3.0

units=default units)

mass flow [kg/s]

densit

temperature [°K]

mass totalizer [k

volume flow [m3/h]

percenta

°Brix [de

solid flow [k

volume totalizer [m3]

Optional Percentage volume [%vol]

° Baumé [degBaum hv]

Address range 0-126, default 126,

interface at device.

SAP’s 1; the number of Service

Access Points is typically equal

of the number of master class

2 tools

[kg/l]

]

e mass [%sol/wt] or

Brix]

/s]

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 16 of 18

Page 17

Addendum to Operating and Instruction Manual for “Modis” Converters

Ex

Supply voltage 24 V AC/DC (Switch mode power supply)

U

= 24 V DC +30% / -25%, 5W

N

= 24 V AC +10% / -15%, 5W

U

N

100 V AC...230 V AC + 10% / 15%, 10 V A

24 V AC/DC (Switch mode power supply)

U

= 24 V DC +30% / -25%, 5W

N

= 24 V AC +10% / -15%, 5W

U

N

100 V AC...230 V AC + 10% / 15%, 10 V A

Non-Ex

Fuse rating IN <= 1.25 A IN <= 1.25 A

Outputs / inputs Module dependant Module dependant

Current output (IS)

Function All operating data programmable galvanically

isolated from supply, CPU and other outputs.

i

Passive (Current sink, EX

)

All operating data programmable

galvanically isolated from supply, CPU and

other outputs. Passive.

Current 4 – 20 mA 4 – 20 mA

Linearity 0.05% (reference 20 mA at 25°C) 0.05% (reference 20 mA at 25°C)

Temperature drift <= 100 ppm/°K (Typical 30ppm/°K) <= 100 ppm/°K (Typical 30ppm/°K)

Load US – 8V

<= 22 mA (US = external supply voltage)

U

– 8V

S

<= 22 mA (US = external supply voltage)

Supply 8 – 30 V 8 – 30 V

Connect ONLY to certified IS circuits with the

maximum values:

Ui = 30V, Ii = 250mA, Pi = 1W

Pulse output (IS) Not available

Function All operating data programmable galvanically

isolated from supply, CPU and other outputs.

Operation Passive, loop-powered

External supply

6 – 30V DC

voltage

Current Maximum 110 mA / 6 – 30 V DC

I high <= 900 µA (30 V)

I high <= 200 µA (8 V)

Saturation

≤

2V @ I = 110mA

voltage

Frequency

≤

1300Hz

Connect ONLY to certified IS circuits with the

maximum values:

Ui = 30V, Ii = 250mA, Pi = 1W

Status output Not available

Function All operating data programmable galvanically

isolated from supply, CPU and other outputs.

Operation Passive, loop-powered

External supply

6 – 30V DC

voltage

Current

≤

110 mA

I high <= 900 µA (30 V)

I high <= 200 µA (8 V)

Connect ONLY to certified IS circuits with the

maximum values:

Ui = 30V, Ii = 250mA, Pi = 1W

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 17 of 18

Page 18

Addendum to Operating and Instruction Manual for “Modis” Converters

Ex

Control input (IS) Not available

Function All operating data programmable galvanically

isolated from supply, CPU and other outputs.

Operation Passive, loop-powered

External supply

voltage

Current

Control signals 7-30V DC for HIGH

PROFIBUS PA

Hardware See table above See table above

Software See table above See table above

Fieldbus

Foundation (IS)

Hardware Designed to ISA and IEC 1158-2 physical

Ambient

Temperature

7 – 30V DC

≤

4.5 mA

0-2V or open terminals for LOW

Connect ONLY to certified IS circuits with the

maximum values:

Ui = 30V, Ii = 250mA, Pi = 1W

Pending Pending

Designed to ISA and IEC 1158-2 physical

layer. Standards applicable to type 121

device profile.

Connection: polarity independent

Connect ONLY to certified IS circuits

according to the FISCO model with the

maximum values:

Ui = 30V, Ii = 250mA, Pi = 1W

-20 to 65°C -20 to 65°C

layer. Standards applicable to type 121

device profile.

Connection: polarity independent

Bus data: 9V – 32V; 11mA typical

Non-Ex

KROHNE Ltd • Rutherford Drive • Park Farm Industrial Estate • Wellingborough • Northamptonshire • NN8 6AE • UK

Tel. +44 1933 408 500 • Fax +44 1933 408 501• WWW.KROHNE.com

Page 18 of 18

Loading...

Loading...