Page 1

Technical Datasheet

Technical Datasheet

MFC 400

MFC 400

MFC 400MFC 400

Technical DatasheetTechnical Datasheet

Signal converter for mass flowmeters

•

High performance signal converter for all applications, developed acc. to

IEC 61508, SIL 2/3

•

Stable in multi-phase applications due to Entrained Gas Management (EGM™)

•

Smart diagnostics acc. to NAMUR NE 107

The documentation is only complete when used in combination with the relevant

documentation for the flow sensor.

© KROHNE 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 2

CONTENTS

MFC 400

1 Product features 3

1.1 The high performance signal converter for all applications ........................................... 3

1.2 Options and variants......................................................................................................... 5

1.3 Signal converter/flow sensor combination possibilities ................................................. 8

1.4 Measuring principle.......................................................................................................... 8

2 Technical data 9

2.1 Technical data................................................................................................................... 9

2.2 Dimensions and weight .................................................................................................. 20

2.2.1 Housing ................................................................................................................................. 20

2.2.2 Mounting plate of field housing ............................................................................................ 20

3 Installation 21

3.1 Intended use ................................................................................................................... 21

3.2 Installation specifications .............................................................................................. 21

3.3 Mounting of the compact version................................................................................... 21

3.4 Mounting the field housing, remote version .................................................................. 22

3.4.1 Pipe mounting ....................................................................................................................... 22

3.4.2 Wall mounting....................................................................................................................... 23

4 Electrical connections 24

4.1 Safety instructions.......................................................................................................... 24

4.2 Connection diagram ....................................................................................................... 24

4.3 Grounding the flow sensor ............................................................................................. 25

4.4 Connecting power - all housing variants ....................................................................... 26

4.5 Inputs and outputs, overview ......................................................................................... 27

4.5.1 Combinations of the inputs/outputs (I/Os) ........................................................................... 27

4.5.2 Description of the CG number .............................................................................................. 28

4.5.3 Fixed, non-alterable input/output versions.......................................................................... 29

4.5.4 Alterable input/output versions............................................................................................ 30

5 Notes 31

2

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 3

MFC 400

PRODUCT FEATURES

1.1 The high performance signal converter for all applications

The MFC 400

MFC 400 Coriolis mass flow signal converter will provide the highest performance possible

MFC 400MFC 400

across a wide range of applications. For the measurement of liquids or gases, cryogenic to high

temperature fluids, single or multi-phase fluids and advanced digital signal processing

techniques is used to give stable and accurate measurements of mass flow, density and

temperature.

It is developed according to IEC 61508 and depending on the I/O and flow sensor variant suited

for use in safety applications SIL 2/3.

Conforming to the NAMUR standard NE 107 for status and error handling, the MFC 400 features

enhanced meter diagnostics. This provides extensive self-checking of internal circuits and

information regarding the health of the flow sensor, but just as importantly, vital information

about the process and process conditions.

Measuring values and diagnostic information can be transmitted via field bus interfaces

including HART

®

, RS485 Modbus, FOUNDATION™ Fieldbus, PROFIBUS

®

and PROFINET IO.

1

(signal converter in field housing)

1 Supply voltage: 100...230 VAC (standard) and 24 VDC

2 Communication with any third party system possible via HART

PROFINET IO

3 Intuitive navigation and a wide variety of languages integrated as standard for ease of operation

EGM

EGM™ Entrained Gas Management

Entrained Gas Management

EGMEGM

Entrained Gas Management Entrained Gas Management

EGM™ was developed for the OPTIMASS Coriolis mass flowmeters to

overcome problems caused by air or gas entrainments in a liquid.

Powerful control algorithms maintain measurement, even during a complete

transition from a pure liquid phase to a gas phase and back.

Mass flow and density measurements remain stable and continuous, which

has been demonstrated in batch / loading / empty-full-empty applications.

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

®

, Modbus, FOUNDATION™ Fieldbus, PROFIBUS

®

and

3

Page 4

1

PRODUCT FEATURES

Highlights

• High performance signal converter with multiple output options

• Developed according to IEC 61508

• Safe configuration via local display or HART

• Partial proof test capable

• Smart diagnostics, covering entire devices in less than a minute

• NE 107 status indicated by display background light

• Entrained Gas Management (EGM

• Excellent long-term stability

• Optical and mechanical keys for ease of use

• Redundant data storage in signal converter housing

• Real time clock for logging events

• Overall, flexible lock concept

®

• HART

• Communication interfaces for integration into third party systems via HART

Modbus, FOUNDATION™ Fieldbus, PROFIBUS

7

®

TM

) – the new standard for entrained gas immunity

®

(as standard),

®

and PROFINET IO

MFC 400

Industries

• Water & Wastewater

• Chemicals

• Power plants

• Food & Beverage

• Machinery

• Oil & Gas

• Petrochemical

• Pulp & Paper

• Pharmaceutical

• Marine

Applications

• Liquids and gases

• Liquids with gas entrainment

• Slurries and viscous products

• Concentration measurement for quality control

• Measurement of volume flow

• Measurement of density and reference density

• Custody transfer loading/unloading

• Custody transfer measurements

4

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 5

MFC 400

1.2 Options and variants

Compact design for standard applications

(Example: OPTIMASS 6400 – compact)

PRODUCT FEATURES

The MFC 400 mass flow signal converter is available

in different variants and offers superior

performance in any conceivable application. From

process control in chemistry, to density and

concentration measurements in the food and

beverage industry, to custody transfer filling and

transport measurements for oil and gas right down

to conveyor systems in the pulp and paper industry.

Coriolis mass flow measuring systems measure the

mass and volume flow, the density and the

temperature of liquids and gases. In addition, the

concentration in mixtures and slurries can also be

determined.

Thanks to Entrained Gas Management (EGM

MFC 400 systems offer high performance with air

entrainment, delivering continuous measurement

even with 0...100% gas entrainment.

TM

1

) the

(Example: OPTIMASS 2400 – compact)

Remote field housing version

For standard applications the compact housing is

mounted directly on the measuring sensor. In the

unlikely event of a failure, the electronics can be

easily exchanged and reconfigured using a backup

data set that is stored in the housing.

The signal converter in the robust field housing is

generally used when it is difficult to access the

measuring point or when ambient conditions do not

allow the use of the compact version.

(signal converter in field housing)

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

5

Page 6

1

PRODUCT FEATURES

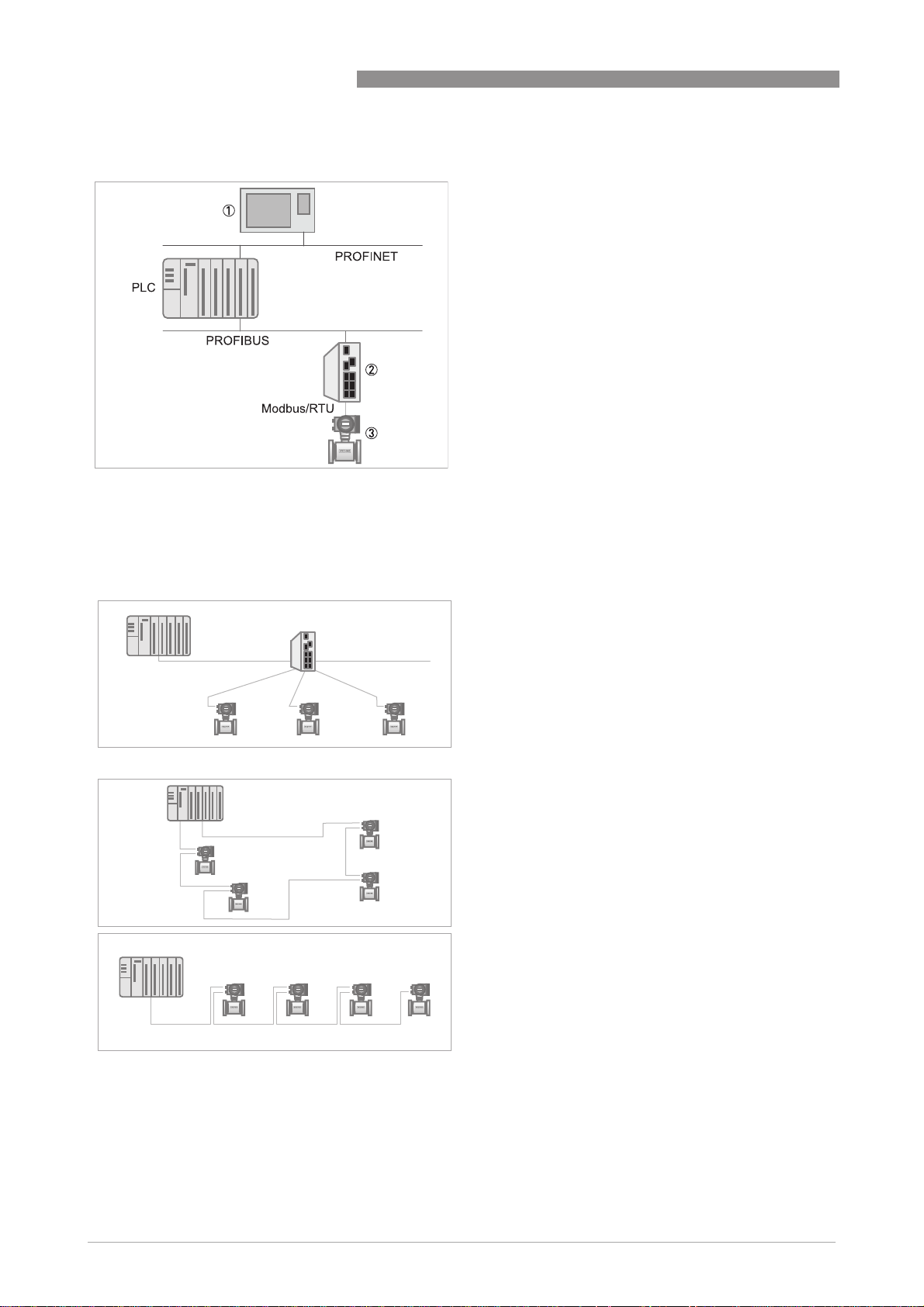

Communication options

1 Monitoring system

2 Gateway

3 Flowmeter

MFC 400

The basic signal converter variant covers a current

®

output including HART

status output, control input and a current input.

The modular input/output variant allows for any

combination of up to four inputs and outputs. All

inputs and outputs are galvanically isolated from

each other and from the rest of the electronic

equipment. Inputs and outputs can be passive or

active.

In addition, the electronics can be equipped with

fieldbus functionality including Foundation Fieldbus,

Profibus PA/DP, Modbus or PROFINET IO to enable

communication to any third party system.

, pulse/ frequency output,

New: PROFINET IO option

(1. point-to-point or star communication)

With PROFINET IO, real time Ethernet can be

connected to IoT scenarios.

The use of existing, legacy, industry-grade devices

(e.g. PROFINET flow sensors, actuators and

Programmable Logic Controllers (PLC’s)) enables a

new architecture to be used across the Internet.

An unique network topology:

1. Working with point-to-point or star

communication using a single Ethernet port and an

external switch.

2. Using ring or line communication there are two

Ethernet ports available controlled by an internal

switch.

(2. ring or line communication)

6

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 7

MFC 400

Extensive diagnostics of the device and application

PRODUCT FEATURES

The primary focus of a user for a flowmeter is that it

delivers reliable and robust measurements.

To achieve this all Coriolis mass flowmeters are

calibrated before leaving the factory.

In addition, KROHNE was one of the first to introduce

extensive diagnostic features.

The MFC 400 provides a wide range diagnostic

functions on the flow sensor, signal converter and

process integrated in the signal converter.

1

(Measuring principle (Twin tube))

1 Measuring tubes

2 Drive coil

3 Sensor 1

4 Sensor 2

OPTICHECK tool for on-site verification

(Suitcase with OPTICHECK and all cables and

accessories)

Potential problems that may occur in the process

including gas bubbles, solids, corrosion, deposits,

empty pipe and partial filling of the flow sensor.

Diagnostic info available via local display, status

outputs, Fieldbuses, PACTware, xFC toolbox or the

OPTICHECK.

The OPTICHECK provides an inline health check of

the device under test by an external tool.

A hard copy of the verification report can be printed

for every flowmeter. The verification data are

digitally stored.

Contact us for more information or for an on-site

service visit.

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

7

Page 8

1

PRODUCT FEATURES

1.3 Signal converter/flow sensor combination possibilities

Flow sensor Flow sensor + signal converter MFC 400

Compact Remote field housing

OPTIMASS 1000 OPTIMASS 1400 C OPTIMASS 1400 F

OPTIMASS 2000 OPTIMASS 2400 C OPTIMASS 2400 F

OPTIMASS 3000 OPTIMASS 3400 C OPTIMASS 3400 F

OPTIMASS 6000 OPTIMASS 6400 C OPTIMASS 6400 F

OPTIMASS 7000 OPTIMASS 7400 C OPTIMASS 7400 F

1.4 Measuring principle

The signal converter has been designed to work with all the measuring tube designs used in the

mass flowmeters. For information regarding the measuring principle for a specific measuring

tube design, please refer to the technical documentation of the relevant flow sensor.

MFC 400

8

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 9

MFC 400

TECHNICAL DATA

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

Measuring system

Measuring principle Coriolis principle

Application range Measurement of mass flow, density, temperature, volume flow, flow velocity,

Design

Modular construction The measuring system consists of a flow sensor and a signal converter.

Flow sensor

Flow sensor

Flow sensorFlow sensor

OPTIMASS 1000 DN15…50 / 1/2…2"

OPTIMASS 2000 DN100…400 / 4...12"

OPTIMASS 3000 DN01…04 / 1/25...4/25"

OPTIMASS 6000 DN08…250 / 3/8...10"

OPTIMASS 7000 DN06…80 / 1/4…3"

Signal converter

Signal converter

Signal converterSignal converter

Compact version (C) OPTIMASS x400 C (x = 1, 2, 3, 6 or 7)

Field housing (F) remote version

Options

Options

OptionsOptions

Outputs / inputs

Totaliser 2 (optional 3) internal totalisers with a max. of 8 counter places (e.g. for counting

Verification Integrated verification, diagnostic functions: measuring device, process, measured

Concentration measurement Universal concentration measurement, °Brix, °Baume, °Plato, alcohol

Communication interfaces

concentration

All flow sensors are also available in an Ex version.

MFC 400 F

Compact and field housing versions are also available in an Ex version.

Current output (including HART®), pulse output, frequency output, and/or status

output, limit switch and/or control input (depending on the I/O version)

volume and/or mass units)

value, stabilisation

concentration, NaOH and API density

HART®, Foundation Fieldbus, Profibus PA and DP, PROFINET IO, Modbus

2

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

9

Page 10

2

TECHNICAL DATA

Display and user interface

Display and user interface

Display and user interfaceDisplay and user interface

Graphic display LC display, backlit white.

Size: 256 x 128 pixels, corresponds to 59 x 31 mm = 2.32" x 1.22"

Display turnable in 90° steps.

Ambient temperatures below -25°C/ -13°F may affect the readability of the display.

Operating elements 4 push buttons/optical keys for operator control of the signal converter without

Remote operation

Display functions

Display functions

Display functionsDisplay functions

Operating menu Setting the parameters using 2 measuring pages, 1 status page, 1 graphic page

Language display texts Available languages: English, German, French, Danish, Spanish, Italian, Dutch,

Measurement functions Units:

Diagnostic functions Standards:

opening the housing.

Infrared interface for reading and writing all parameters with IR interface (option)

without opening the housing.

PACTwareTM (including Device Type Manager (DTM))

HART® Hand Held Communicator from Emerson Process

AMS® from Emerson Process

PDM® from Siemens

All DTMs and drivers are available free of charge from the manufacturer's website.

(measured values and graphics are freely adjustable)

Polish, Portuguese, Swedish, Turkish

Units: Metric, British and US units selectable as desired from lists for volume/mass

Units:Units:

flow and counting, velocity, temperature, pressure

Measured values:

Measured values: Mass flow, total mass, temperature, density, volume flow, total

Measured values:Measured values:

volume, velocity, flow direction (not displayed unit – but available via outputs), Brix,

Baume, NaOH, Plato, API, mass concentration, volume concentration

Standards: VDI / NAMUR / WIB 2650 and NE 107

Standards:Standards:

Status messages:

Status messages: Output of status messages optional via display, current and/or

Status messages:Status messages:

status output, HART

Sensor and sensor electronics diagnosis:

Sensor and sensor electronics diagnosis: Sensor signal integrity, sensor and drive

Sensor and sensor electronics diagnosis:Sensor and sensor electronics diagnosis:

coils diagnostics, measurement channels check, comparison of internal signals

with references, drive circuit integrity, process temperature, CPU diagnostics,

process temperature circuit monitoring, internal data integrity check, redundant

calibration

Signal converter and inputs/outputs:

Signal converter and inputs/outputs: Data bus monitoring, current output

Signal converter and inputs/outputs:Signal converter and inputs/outputs:

connections, current readback with redundant calibration, factory calibration

integrity, electronics temperature, CPU diagnostics, voltage monitoring

®

or bus interface

MFC 400

10

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 11

MFC 400

TECHNICAL DATA

Measuring accuracy

Reference conditions Medium: water

Temperature: +20°C / +68°F

Pressure: 1 bar / 14.5 psi

Maximum measuring error Refer to technical data for the flow sensor.

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process temperature Refer to technical data for the flow sensor.

Ambient temperature Depending on the version and combination of outputs.

It is a good idea to protect the signal converter from external heat sources such as

direct sunlight as higher temperatures reduce the life cycle of all electronic

components.

Die-cast aluminium housing:

Die-cast aluminium housing:

Die-cast aluminium housing:Die-cast aluminium housing:

SIL device: -40…+55°C/ -40…+131°F

Non-SIL device: -40...+60°C / -40...+140°F

Stainless steel housing:

Stainless steel housing:

Stainless steel housing:Stainless steel housing:

SIL device: -40…+55°C/ -40…+131°F

Non-SIL device: -40...+60°C / -40...+140°F

Ambient temperatures below -25°C/ -13°F may affect the readability of the display.

Storage temperature -40…+70°C/ -40…+158°F

Pressure

Pressure

PressurePressure

Medium Refer to technical data for the flow sensor.

Ambient pressure Atmospheric

Chemical properties

Chemical properties

Chemical propertiesChemical properties

State of aggregation Liquids, gases and slurries

Flow rate Refer to technical data for the flow sensor.

Other conditions

Other conditions

Other conditionsOther conditions

Ingress protection according to

IEC 60529

IP66/67 (according to NEMA 4/4X)

2

Installation conditions

Installation For detailed information, refer to chapter "Installation".

Dimensions and weight For detailed information refer to chapter "Dimensions and weight".

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

11

Page 12

2

TECHNICAL DATA

MFC 400

Materials

Signal converter housing Standard: die-cast aluminium (polyurethane coated)

Option: stainless steel 316 / 1.4408

Flow sensor For housing material, process connections, measuring tubes, accessories and

gaskets, refer to technical data for the flow sensor.

Electrical connection

General Electrical connection is carried out in conformity with the VDE 0100 directive

Power supply Standard: 100…230 VAC (-15% / +10%), 50/60 Hz

Power consumption AC: 22 VA

Signal cable Only for remote versions.

Cable entries Standard: M20 x 1.5 (8...12 mm)

"Regulations for electrical power installations with line voltages up to 1000 V" or

equivalent national specifications.

Option: 24 VDC (-55% / +30%)

DC: 12 W

10 core shielded cable. Detailed specifications are available on request.

Length: max. 20 m / 65.6 ft

Option: 1/2 NPT, PF 1/2

12

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 13

MFC 400

TECHNICAL DATA

Inputs and outputs

General All outputs are electrically isolated from each other and from all other circuits.

All operating data and output values can be adjusted.

Description of abbreviations U

Current output

Current output

Current outputCurrent output

Output data Volume flow, mass flow, temperature, density, flow velocity, diagnostic values, 2-

Resolution <1 µA

Uncertainty ±5 µA

Temperature coefficient Typically ±30 ppm/K

Settings

Operating data Modular I/Os

Active U

= external voltage; RL = load + resistance;

ext

= terminal voltage; I

U

0

= nominal current

nom

Safety limit values (Ex i):

Ui = max. input voltage; Ii = max. input current;

= max. input power rating;

P

i

Ci = max. input capacity; Li = max. input inductivity

phase signal

Concentration and concentration flow are also possible with available concentration

measurement (optional).

Without HART

Without HART

Without HARTWithout HART

®

Q = 0%: 0…20 mA; Q = 100%: 10…20 mA

Alarm signal: selectable 0…22 mA

With HART

With HART

With HARTWith HART

®

Q = 0%: 4…20 mA; Q = 100%: 10…20 mA

Alarm signal: selectable 3…22 mA

Modular I/Os Ex i

Modular I/OsModular I/Os

=24VDC

int, nom

Ex i

Ex iEx i

U

int, nom

=21VDC

2

Passive U

I ≤ 22 mA

RL≤ 1kΩ

≤ 30 VDC

ext

I ≤ 22 mA

U

≥ 1.8 V

0

≤ (U

R

L

ext-U0

)/I

max

I ≤ 22 mA

RL≤ 400 Ω

I0=90mA

=0.5W

P

0

C0= 90 nF / L0 = 2 mH

= 110 nF / L0=0.5mH

C

0

U

≤ 30 VDC

ext

I ≤ 22 mA

U

≥ 4V

0

≤ (U

R

L

ext-U0

)/I

max

Ui=30V

Ii= 100 mA

=1W

P

i

Ci=10nF

~0mH

L

i

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

13

Page 14

2

TECHNICAL DATA

®

HART

HART

HARTHART

Description

HART® protocol via active and passive current output

HART® version: V7

Universal HART® parameter: completely integrated

Load

≥ 230 Ω at HART® test point;

Note maximum load for current output!

Multi-Drop operation Disabled loop current mode, output current = 0%, e.g. 4 mA

Multi-Drop address adjustable in operation menu 0...63

Device drivers Available for FC 375/475, AMS, PDM, FDT/DTM

Registration (HART

Yes

Communication Foundation)

Pulse output or frequency output

Pulse output or frequency output

Pulse output or frequency outputPulse output or frequency output

Output data Pulse output: volume flow, mass flow, mass or volume of dissolved substance

during activated concentration measurement

Frequency output: flow velocity, mass flow, temperature, density, diagnostic value

Optional: concentration, flow of the dissolved substance

Function Can be set as a pulse output or frequency output

Pulse rate/frequency 0.01...10000 pulses/s or Hz

Settings Mass or volume per pulse or max. frequency for 100% flow

Pulse width: adjustable as automatic, symmetric or fixed (0.05...2000 ms)

Operating data Modular I/Os

Active U

Modular I/Os Ex i

Modular I/OsModular I/Os

=24VDC -

nom

f

in operating menu set to

max

f

≤ 100 Hz:

max

Ex i

Ex iEx i

I ≤ 20 mA

MFC 400

open:

I ≤ 0.05 mA

closed:

=24V at I=20mA

U

0, nom

f

in operating menu set to 100 Hz <

max

f

≤ 10 kHz:

max

I ≤ 20 mA

open:

I ≤ 0.05 mA

closed:

= 22.5 V at I = 1 mA

U

0, nom

U

= 21.5 V at I = 10 mA

0, nom

=19V at I=20mA

U

0, nom

14

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 15

MFC 400

TECHNICAL DATA

2

Passive U

≤ 32 VDC -

ext

f

in operating menu set to

max

≤ 100 Hz:

f

max

I ≤ 100 mA

open:

I ≤ 0.05 mA at U

=32VDC

ext

closed:

= 0.2 V at I ≤ 10 mA

U

0, max

U

= 2 V at I ≤ 100 mA

0, max

f

in operating menu set to 100 Hz <

max

≤ 10 kHz:

f

max

I ≤ 20 mA

open:

I ≤ 0.05 mA at U

=32VDC

ext

closed:

= 1.5 V at I ≤ 1mA

U

0, max

U

= 2.5 V at I ≤ 10 mA

0, max

= 5.0 V at I ≤ 20 mA

U

0, max

NAMUR Passive to EN 60947-5-6

U

=8.2V ± 0.1 VDC

ext

R = 1 kΩ ± 10 Ω

open:

I

=0.6mA

nom

closed:

=3.8mA

I

nom

Passive to EN 60947-5-6

open:

I

=0.43mA

nom

closed:

I

=4.5mA

nom

Ui=30V

= 100 mA

I

i

Pi=1W

=10nF

C

i

Li~0mH

Low flow cut off

Low flow cut off

Low flow cut offLow flow cut off

Function Switching point and hysteresis separately adjustable for each output, counter and

the display

Switching point Set in increments of 0.1%.

0…20% (current output, frequency output)

Hysteresis Set in increments of 0.1%.

0…20% (current output, frequency output)

Damping

Damping

DampingDamping

Function The time constant corresponds to the elapsed time until 63% of the end value has

been reached according to a step function.

Settings Set in increments of 0.1 seconds.

0…100 seconds

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

15

Page 16

2

TECHNICAL DATA

Status output / limit switch

Status output / limit switch

Status output / limit switchStatus output / limit switch

MFC 400

Function and settings Adjustable as automatic measuring range conversion, display of flow direction,

overflow, error or switching point.

Valve control with activated dosing function

Status and/or control: ON or OFF

Operating data Modular I/Os

Active U

Modular I/Os Ex i

Modular I/OsModular I/Os

=24VDC

int

Ex i

Ex iEx i

-

I ≤ 20 mA

open:

I ≤ 0.05 mA

closed:

=24V at I=20mA

U

0, nom

Passive U

≤ 32 VDC

ext

-

I ≤ 100 mA

R

=47kΩ

L, max

R

L, min

=(U

ext-U0

)/I

max

open:

I ≤ 0.05 mA at U

=32VDC

ext

closed:

= 0.2 V at I ≤ 10 mA

U

0, max

U

= 2 V at I ≤ 100 mA

0, max

NAMUR Passive to EN 60947-5-6

U

=8.2V ± 0.1 VDC

ext

R = 1 kΩ ± 10 Ω

open:

=0.6mA

I

nom

closed:

I

=3.8mA

nom

Passive to EN 60947-5-6

open:

I

=0.43mA

nom

closed:

=4.5mA

I

nom

Ui=30V

= 100 mA

I

i

=1W

P

i

Ci=10nF

=0mH

L

i

16

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 17

MFC 400

Control input

Control input

Control inputControl input

TECHNICAL DATA

Function Hold value of the outputs (e.g. for cleaning work), set value of the outputs to "zero",

counter and error reset, stop counter, range conversion, zero calibration

Start of dosing when dosing function is activated.

Operating data Modular I/Os

Active U

Modular I/Os Ex i

Modular I/OsModular I/Os

=24VDC

int

Ex i

Ex iEx i

-

External contact open:

U

=22V

0, nom

External contact closed:

=4mA

I

nom

Contact open (off):

≥ 12 V with I

U

0

nom

=1.9mA

Contact closed (on):

≤ 10 V with I

U

0

Passive 3V≤ U

I

=9.5mA at U

max

=9.5mA at U

I

max

≤ 32 VDC

ext

nom

ext

ext

=1.9mA

≤ 24 V

≤ 32 V

U

≤ 32 VDC

ext

I ≤ 6mA at U

I ≤ 6.5 mA at U

ext

=24V

=32V

ext

2

Contact closed (on):

U0≥ 3V with I

nom

=1.9mA

Contact open (off):

≤ 2.5 V with I

U

0

nom

=1.9mA

NAMUR Active to EN 60947-5-6

Terminals open:

U

=8.7V

0, nom

Contact closed (on):

=6.3V with I

U

0, nom

nom

Contact open (off):

=6.3V with I

U

0, nom

nom

Detection of cable break:

U0≥ 8.1 V with I ≤ 0.1 mA

Detection of cable short circuit:

≤ 1.2 V with I ≥ 6.7 mA

U

0

>1.9mA

<1.9mA

On:

U0≥ 5.5 V with I ≥ 4mA

Off:

≤ 3.5 V with I ≤ 0.5 mA

U

0

Ui=30V

Ii= 100 mA

=1W

P

i

Ci=10nF

=0mH

L

i

-

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

17

Page 18

2

TECHNICAL DATA

PROFIBUS DP

PROFIBUS DP

PROFIBUS DPPROFIBUS DP

Description Galvanically isolated according to IEC 61158

Profile version: 3.02

Automatic data transmission rate recognition (max. 12 MBaud)

Bus address adjustable via local display at the measuring device

Function blocks 8 x analogue input (AI), 3 x totaliser

Output data Mass flow, volume flow, mass counter 1 + 2, volume counter, product temperature,

PROFIBUS PA

PROFIBUS PA

PROFIBUS PAPROFIBUS PA

Description Galvanically isolated according to IEC 61158

Function blocks 8 x analogue input (AI), 3 x totaliser

Output data Mass flow, volume flow, mass counter 1 + 2, volume counter, product temperature,

FOUNDATION Fieldbus

FOUNDATION Fieldbus

FOUNDATION FieldbusFOUNDATION Fieldbus

Description Galvanically isolated according to IEC 61158

Function blocks 6 x analogue input (AI), 2 x integrator, 1 x PID

Output data Mass flow, volume flow, density, temperature of tube, several concentration

Modbus

Modbus

ModbusModbus

Description Modbus RTU, Master/Slave, RS485

Address range 1…247

Supported function codes 01, 03, 04, 05, 08, 16, 43

Supported Baud rate 1200, 2400, 3600, 4800, 9600, 19200, 38400, 57600, 115200 Baud

PROFINET IO

PROFINET IO

PROFINET IOPROFINET IO

Description PROFINET IO is an Ethernet based communications protocol.

Output data Mass flow, volume flow, flow speed, density, mass or volume counter 1 + 2, product

several concentration measurements and diagnostic data

Profile version: 3.02

Current consumption: 10.5 mA

Permissible bus voltage: 9…32 V; in Ex application: 9...24 V

Bus interface with integrated reverse polarity protection

Typical error current FDE (Fault Disconnection Electronic): 4.3 mA

Bus address adjustable via local display at the measuring device

several concentration measurements and diagnostic data

Current consumption: 10.5 mA

Permissible bus voltage: 9…32 V; in Ex application: 9...24 V

Bus interface with integrated reverse polarity protection

Link Master function (LM) supported

Tested with Interoperable Test Kit (ITK) version 6.01

measurements and diagnostic data

The device features two Ethernet ports with an integrated industrial Ethernet

switch.

The Ethernet standard 100BASE-TX is supported.

Additionally, the PHYs support the following features:

- Auto negotiation

- Auto crossover

- Auto polarity

temperature, several concentration measurements and diagnostic data

MFC 400

18

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 19

MFC 400

TECHNICAL DATA

Approvals and certificates

CE This device fulfils the statutory requirements of the relevant EU directives.

Non-Ex Standard

Functional safety according to

EN 61508

Hazardous areas

Hazardous areas

Hazardous areasHazardous areas

Option (C version only)

Option (C version only)

Option (C version only)Option (C version only)

ATEX II 1/2 (1) G - Ex d ia [ia Ga] IIC T6 Ga/Gb

Option (F version only)

Option (F version only)

Option (F version only)Option (F version only)

ATEX II 2 (1) G - Ex d [ia Ga] IIC T6 Gb

NEPSI Ex d ia [ia Ga] IIC T6…T1 Ga/Gb; Ex de ia [ia Ga] IIC T6…T1 Ga/Gb

Option

Option

OptionOption

FM / CSA FM: Class I, Div 1 groups A, B, C, D

IECEx Ex zone 1 + 2

Custody transfer

Custody transfer

Custody transferCustody transfer

Without Standard

Option (in preparation) Liquids other than water 2004/22/EC (MID MI005) according to OIML R117-1

Other standards and approvals

Other standards and approvals

Other standards and approvalsOther standards and approvals

Vibration resistance IEC 60068-2-6

NAMUR NE 21, NE 43, NE 53, NE 107

The manufacturer certifies successful testing of the product by applying the CE

mark.

For full information of the EU directives & standards and the approved

certifications, please refer to the CE declaration or the manufacturer website.

Depends on I/O variant and flow sensor. For detailed information refer to the

"Safety manual".

II 1/2 (1) G - Ex de ia [ia Ga] IIC T6…T1 Ga/Gb

II 2 (1) G - Ex d ia [ia Ga] IIC T6…T1 Gb

II 2 (1) G - Ex de ia [ia Ga] IIC T6…T1 Gb

II 2 (1) D - Ex t [ia Da] IIIC Txxx Db

II 1/2 G - Ex d ia IIC T6…T1 Ga/Gb; II 1/2 G - Ex de ia IIC T6…T1 Ga/Gb

II 2 G - Ex d ia IIC T6…T1 Gb; II 2 G - Ex de ia IIC T6…T1 Gb

II 2 D - Ex t IIIC Txxx°C Db

II 2 (1) G - Ex de [ia Ga] IIC T6 Gb

II 2 (1) D - Ex t [ia Da] IIIC T75°C Db

II 2 G - Ex d [ia] IIC T6 Gb; II 2 G - Ex de [ia] IIC T6 Gb

II 2 D - Ex t IIIC T75 Db

CSA: Class I, Div 1 groups C, D

Class II, Div 1 groups E, F, G

Class III, Div 1 hazardous areas

FM: Class I, Div 2 groups A, B, C, D

CSA: Class I, Div 2 groups C, D

Class II, Div 2 groups E, F, G

Class III, Div 2 hazardous areas

Gases 2004/22/EC (MID MI002) according to OIML R137

Compliance with API and AGA

10 cycles 10-150-10 Hz with: 0.15 mm for 10-60 Hz and 20 m/s² for 60-150 Hz

2

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

19

Page 20

2

TECHNICAL DATA

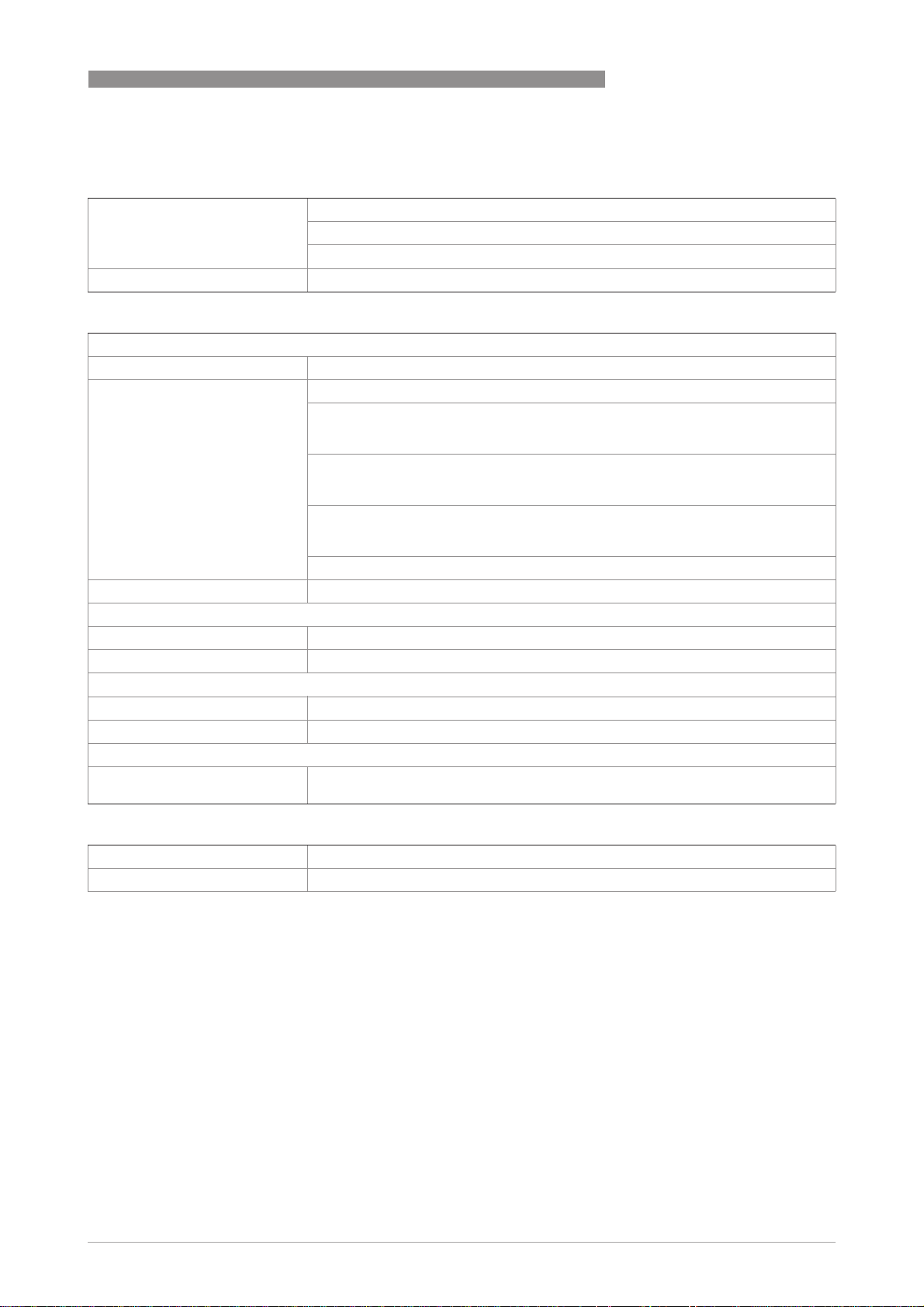

2.2 Dimensions and weight

2.2.1 Housing

Figure 2-1: Dimensions for field housing (F) - remote version

MFC 400

Dimensions [mm / inch] Weight [kg /

a b c g h

202 / 7.75 120 / 4.75 155 / 6.10 295.8 / 11.60 277 / 10.90 5.7 / 12.60

Table 2-1: Dimensions and weight

2.2.2 Mounting plate of field housing

Figure 2-2: Dimensions for mounting plate of field housing

a 72 2.8

b 72 2.8

c Ø9 Ø0.4

Table 2-2: Dimensions in mm and inch

lb]

[mm] [inch]

20

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 21

MFC 400

3.1 Intended use

The mass flowmeters are designed exclusively to directly measure mass flow rates, product

density and temperature as well to indirectly measure parameters such as the total volume and

concentration of dissolved substances as well as the volume flow rate.

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

For devices used in SIL applications, additional safety notes apply. For detailed information refer

to the "Safety manual".

If the device is not used according to the operating conditions (refer to chapter "Technical data"),

the intended protection could be affected.

This device is a Group 1, Class A device as specified within CISPR11:2009. It is intended for use in

industrial environment. There may be potential difficulties in ensuring electromagnetic

compatibility in other environments, due to conducted as well as radiated disturbances.

INSTALLATION

3

3.2 Installation specifications

The following precautions must be taken to ensure reliable installation.

•

Make sure that there is adequate space to the sides.

•

The device must not be heated by radiated heat (e.g. exposure to the sun) to an electronics

housing surface temperature above the maximum permissible ambient temperature. If it is

necessary to prevent damage from heat sources, a heat protection (e.g. sun shade) has to be

installed.

•

Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat

exchanger.

•

Do not expose the signal converter to intense vibrations. The measuring devices are tested

for a vibration level as described in the chapter "Technical data".

3.3 Mounting of the compact version

Turning the housing of the compact version is not permitted.

The signal converter is mounted directly on the flow sensor. For installation of the flowmeter,

please observe the instructions in the supplied product documentation for the flow sensor.

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

21

Page 22

3

INSTALLATION

3.4 Mounting the field housing, remote version

Remarks for sanitary applications

•

To prevent contamination and dirt deposits behind the mounting plate, a cover plug must be

installed between the wall and the mounting plate.

•

Pipe mounting is not suitable for sanitary applications!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

3.4.1 Pipe mounting

MFC 400

Figure 3-1: Pipe mounting of the field housing

1 Fix the signal converter to the pipe.

2 Fasten the signal converter using standard U-bolts and washers.

3 Tighten the nuts.

22

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 23

MFC 400

3.4.2 Wall mounting

Figure 3-2: Wall mounting of the field housing

INSTALLATION

3

1 Prepare the holes with the aid of the mounting plate. For further information refer to

plate of field housing

on page 20.

2 Fasten the mounting plate securely to the wall.

3 Screw the signal converter to the mounting plate with the nuts and washers.

Figure 3-3: Mounting multiple devices next to each other

a ≥ 600 mm / 23.6"

b ≥ 250 mm / 9.8"

Mounting

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

23

Page 24

4

ELECTRICAL CONNECTIONS

4.1 Safety instructions

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

Observe the national regulations for electrical installations!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Connection diagram

MFC 400

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

Figure 4-1: Connection diagram

1 Terminal compartment for signal converter

2 Terminal compartment for flow sensor

3 Connect shielding to spring terminal (drain wire and overall shield)

24

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 25

MFC 400

Cable Connection terminal

Cable pair Colour

1 yellow X1 SA+

1 black X1 SA-

2 green X1 SB+

2 black X1 SB-

3 blue X2 T1

3 black X2 T2

4 red X2 T3

4 black X2 T4

5 white X3 DR+

5 black X3 DR-

Table 4-1: Colour coding of cables

4.3 Grounding the flow sensor

ELECTRICAL CONNECTIONS

4

There should be no difference in potential between the flow sensor and the housing or protective

earth of the signal converter!

• The flow sensor must be properly grounded.

• The grounding cable should not transmit any interference voltages.

• Do not use the grounding cable to connect more than one device to ground.

• The flow sensors are connected to ground by means of a functional grounding conductor FE.

• In hazardous areas, grounding is used at the same time for equipotential bonding. Additional

grounding instructions are provided in the supplementary "Ex documentation", which are

only supplied together with hazardous area equipment.

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

25

Page 26

4

ELECTRICAL CONNECTIONS

4.4 Connecting power - all housing variants

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

• The protection category depends on the housing versions (IP65...67 or NEMA4/4X/6).

• The housings of the devices, which are designed to protect the electronic equipment from

dust and moisture, should be kept well closed at all times. Creepage distances and

clearances are dimensioned to VDE 0110 and IEC 60664 for pollution severity 2. Supply

circuits are designed for overvoltage category III and the output circuits for overvoltage

category II.

• Fuse protection (I

breaker) to isolate the signal converter must be provided close to the device. The separator

must be marked as the separator for this device.

100...230 VAC (tolerance range: -15% / +10%)

• Note the power supply voltage and frequency (50...60 Hz) on the nameplate.

• The protective ground terminal PE

clamp terminal in the terminal compartment of the signal converter

≤ 16 A) for the infeed power circuit, as well as a separator (switch, circuit

N

PE of the power supply must be connected to the separate U-

PEPE

MFC 400

240 VAC + 5% is included in the tolerance range.

24 VDC (tolerance range: -55% / +30%)

• Note the data on the nameplate!

• For measurement process reasons, a functional ground FE

separate U-clamp terminal in the terminal compartment of the signal converter.

• When connecting to functional extra-low voltages, provide a facility for protective separation

(PELV) (acc. to VDE 0100 / VDE 0106 and/or IEC 60364 / IEC 61140 or relevant national

regulations).

FE must be connected to the

FEFE

For 24 VDC, 12 VDC - 10% is included in the tolerance range.

Figure 4-2: Power supply connection

1 100...230 VAC (-15% / +10%), 22 VA

2 24 VDC (-55% / +30%), 12 W

26

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 27

MFC 400

4.5 Inputs and outputs, overview

4.5.1 Combinations of the inputs/outputs (I/Os)

This signal converter is available with various input/output combinations.

Modular version

• Depending on the task, the device can be configured with various output modules.

Ex i version

• Depending on the task, the device can be configured with various output modules.

• Current outputs can be active or passive.

• Optionally available also with Foundation Fieldbus and Profibus PA.

Bus systems

• The device allows intrinsically safe and non intrinsically safe bus interfaces in combination

with additional modules.

• For connection and operation of bus systems, note the supplementary instructions.

ELECTRICAL CONNECTIONS

4

Ex option

• For hazardous areas, all of the input/output variants for the housing designs C and F can be

delivered with terminal compartment in Ex d (pressure-resistant casing) or Ex e (increased

safety).

• For connection and operation of Ex devices, note the supplementary instructions.

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

27

Page 28

4

ELECTRICAL CONNECTIONS

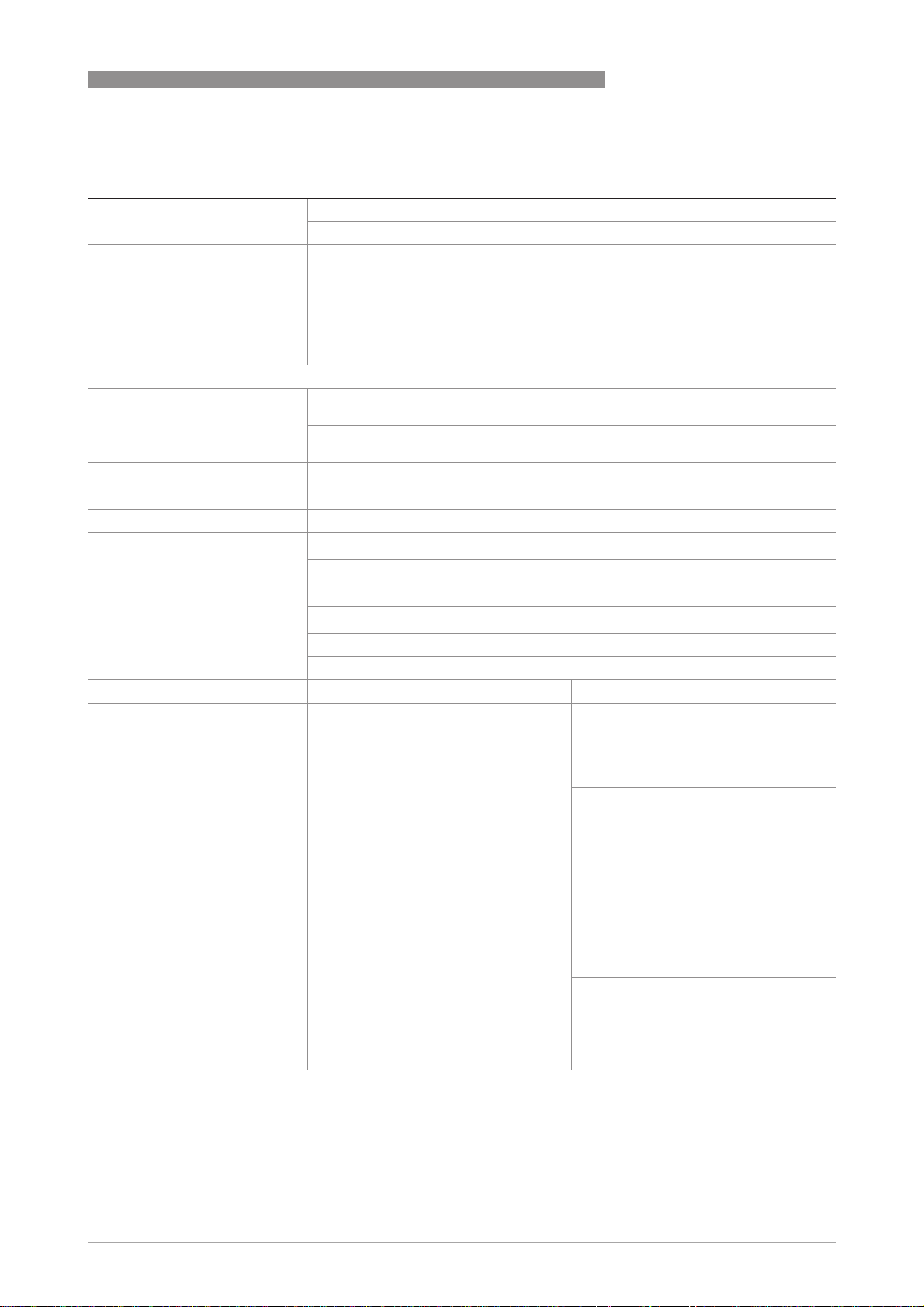

4.5.2 Description of the CG number

Figure 4-3: Marking (CG number) of the electronics module and input/output variants

1 ID number: 3

2 ID number: 0 = standard

3 Power supply option

4 Display

5 Input/output version (I/O)

6 1st optional module for connection terminal A

7 2nd optional module for connection terminal B

The last 3 digits of the CG number (5, 6 and 7) indicate the assignment of the terminal

connections. Please refer to the following examples.

MFC 400

CG430114AC 100...230 VAC & standard display; modular I/O: Ia & PN/SN and optional module Ia/SN & Pa/S

CG43081200 24 VDC & standard display; Ex i I/O: Ia & Pa/Sa and optional module Ia & PN/SN/C

Table 4-2: Examples for CG number

N

Abbreviation Identifier for CG number Description

I

a

I

p

Pa / S

a

Pp / S

p

PN / S

N

C

a

C

p

C

N

- 8 No additional module installed

- 0 No further module possible

Table 4-3: Description of abbreviations and CG identifier for possible optional modules on terminals A and B

A Active current output

B Passive current output

C Active pulse output, frequency output, status output or limit

switch (changeable)

E Passive pulse output, frequency output, status output or limit

switch (changeable)

F Passive pulse output, frequency output, status output or limit

switch according to NAMUR (changeable)

G Active control input

K Passive control input

H Active control input acc. to NAMUR

Signal converter monitors cable breaks and short circuits

according to EN 60947-5-6. Errors indicated on LC display.

Error messages possible via status output.

a

28

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 29

MFC 400

4.5.3 Fixed, non-alterable input/output versions

This signal converter is available with various input/output combinations.

• The grey boxes in the tables denote unassigned or unused connection terminals.

• In the table, only the final digits of the CG no. are depicted.

CG no. Connection terminals

A+ A A- B B- C C- D D-

Ex i I/Os (option)

2 0 0

3 0 0

2 1 0 Ia active PN / SNNAMUR

Cp passive 1

3 1 0 Ia active PN / SNNAMUR

passive 1

C

p

2 2 0 Ip passive PN / SNNAMUR

Cp passive 1

3 2 0 Ip passive PN / SNNAMUR

passive 1

C

p

ELECTRICAL CONNECTIONS

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

PN / SN NAMUR 1

PN / SN NAMUR 1

PN / SN NAMUR 1

PN / SN NAMUR 1

PN / SNNAMUR 1

PN / SNNAMUR 1

4

PROFIBUS PA (Ex i) (option)

D 0 0 PA+ PA- PA+ PA-

FISCO Device FISCO Device

D 1 0 Ia active PN / SNNAMUR

passive 1

C

p

D 2 0 Ip passive PN / SNNAMUR

passive 1

C

p

PA+ PA- PA+ PA-

FISCO Device FISCO Device

PA+ PA- PA+ PA-

FISCO Device FISCO Device

FOUNDATION Fieldbus (Ex i) (option)

E 0 0 V/D+ V/D- V/D+ V/D-

FISCO Device FISCO Device

E 1 0 Ia active PN / SNNAMUR

passive 1

C

p

E 2 0 Ip passive PN / SNNAMUR

Cp passive 1

V/D+ V/D- V/D+ V/D-

FISCO Device FISCO Device

V/D+ V/D- V/D+ V/D-

FISCO Device FISCO Device

PROFINET IO (option)

N 0 0 RX+ RX- TX+ TX- TX+ TX- RX+ RX-

Port 2 Port 1

Table 4-4: Electrical connection of fixed, non-alterable input/output versions

1 Changeable

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

29

Page 30

4

ELECTRICAL CONNECTIONS

MFC 400

4.5.4 Alterable input/output versions

This signal converter is available with various input/output combinations.

• The grey boxes in the tables denote unassigned or unused connection terminals.

• In the table, only the final digits of the CG no. are depicted.

• Term. = (connection) terminal

CG no. Connection terminals

A+ A A- B B- C C- D D-

Modular I/Os (option)

4 _ _ max. 2 optional modules for term. A + B

I + HART®

active/passive 1

PROFIBUS PA (option)

D _ _ max. 2 optional modules for term. A + B PA+ (2) PA- (2) PA+ (1) PA- (1)

P/S active/passive/

NAMUR 1

FOUNDATION Fieldbus (option)

E _ _ max. 2 optional modules for term. A + B V/D+ (2) V/D- (2) V/D+ (1) V/D- (1)

PROFIBUS DP (option)

F _ 0 1 optional module for

term. A

Termination P

RxD/TxDP(2)

RxD/TxDN(2)

Termination N

RxD/TxDP(1)

RxD/TxDN(1)

Modbus (option)

G _ _ 2 max. 2 optional modules for term. A + B Common Sign. B

(D1)

H _ _ 3 max. 2 optional modules for term. A + B Common Sign. B

(D1)

Table 4-5: Electrical connection of alterable input/output versions

1 Software configurable

2 Not activated bus terminator

3 Activated bus terminator

Sign. A

(D0)

Sign. A

(D0)

30

www.krohne.com 11/2017 - 4002075706 - TD MFC 400 R06 en

Page 31

MFC 400

NOTES

5

www.krohne.com11/2017 - 4002075706 - TD MFC 400 R06 en

31

Page 32

K

K

K

KROHNE – Process instrumentation and measurement solutions

•

Flow

•

Level

•

Temperature

•

Pressure

•

Process Analysis

•

Services

© KROHNE 11/2017 - 4002075706 - TD MFC 400 R06 en - Subject to change without notice.

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.: +49 203 301 0

Fax: +49 203 301 10389

info@krohne.com

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...