Page 1

Handbook

Handbook

MFC 400

MFC 400

MFC 400MFC 400

HandbookHandbook

Signal converter for mass flowmeters

Electronic revision:

ER 2.1.x

The documentation is only complete when used in combination with the relevant

documentation for the flow sensor.

© KROHNE 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 2

:

IMPRINT

:::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2020 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 3

MFC 400

CONTENTS

1 Safety instructions 7

1.1 Software history ............................................................................................................... 7

1.2 Intended use ..................................................................................................................... 8

1.3 CE certification ................................................................................................................. 9

1.4 Safety instructions from the manufacturer................................................................... 10

1.4.1 Copyright and data protection .............................................................................................. 10

1.4.2 Disclaimer ............................................................................................................................. 10

1.4.3 Product liability and warranty .............................................................................................. 11

1.4.4 Information concerning the documentation......................................................................... 11

1.4.5 Warnings and symbols used................................................................................................. 12

1.5 Safety instructions for the operator............................................................................... 12

2 Device description 13

2.1 Scope of delivery............................................................................................................. 13

2.2 Device description .......................................................................................................... 14

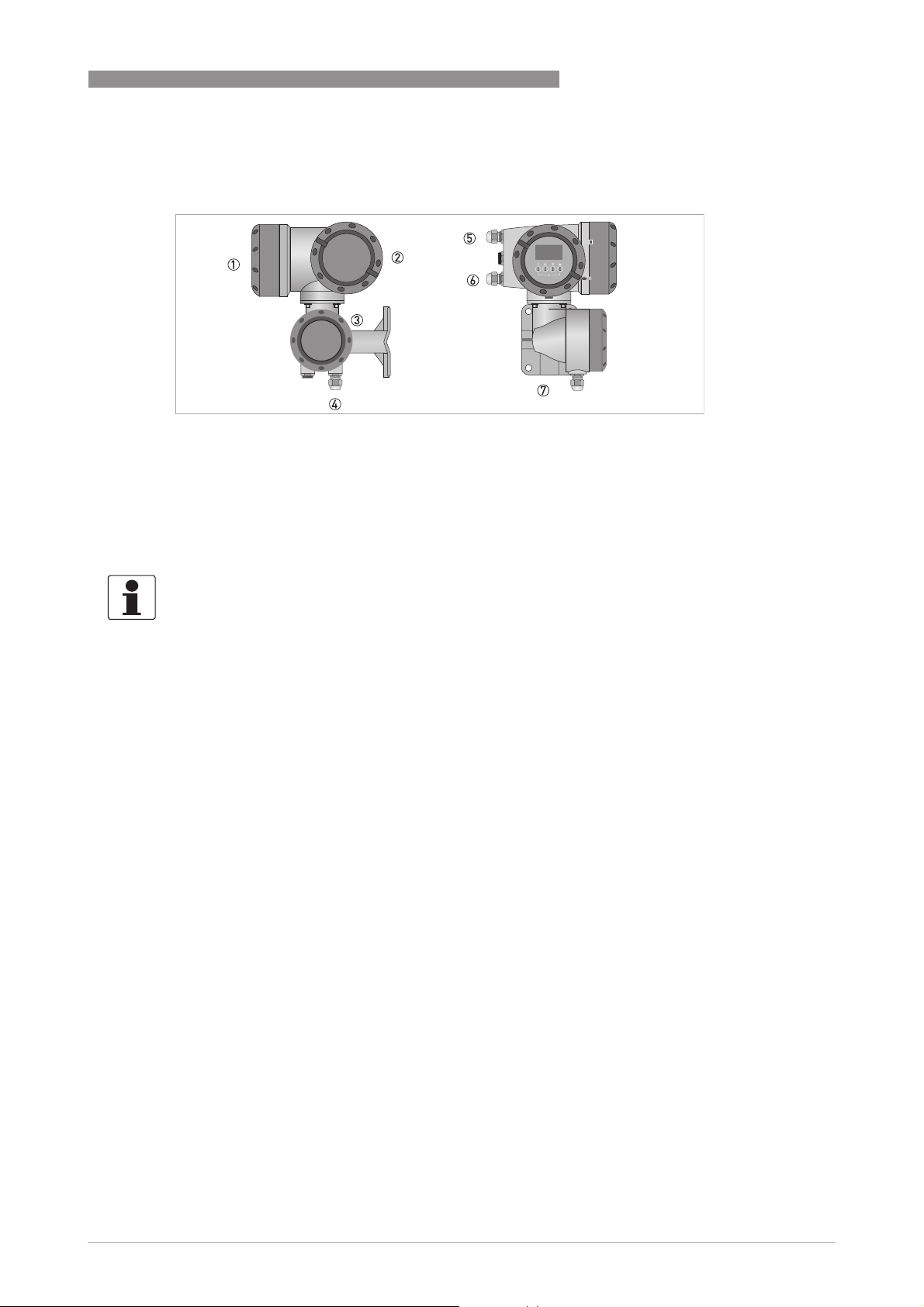

2.2.1 Field housing......................................................................................................................... 15

2.3 Nameplates .................................................................................................................... 16

2.3.1 Example of a nameplate ....................................................................................................... 16

2.3.2 Electrical connection data of inputs/outputs (example of basic version)............................ 17

3 Installation 18

3.1 General notes on installation ......................................................................................... 18

3.2 Storage ........................................................................................................................... 18

3.3 Transport ........................................................................................................................ 18

3.4 Installation specifications .............................................................................................. 18

3.5 Mounting of the compact version................................................................................... 19

3.6 Mounting the field housing, remote version .................................................................. 19

3.6.1 Pipe mounting ....................................................................................................................... 19

3.6.2 Wall mounting....................................................................................................................... 20

3.6.3 Turning the display of the field housing version ..................................................................21

4 Electrical connections 22

4.1 Safety instructions.......................................................................................................... 22

4.2 Important notes on electrical connection...................................................................... 22

4.3 Signal cable requirements............................................................................................. 23

4.4 Connecting the signal cables ......................................................................................... 24

4.4.1 Connection of signal cable - field housing and connection box for flow sensor ................. 25

4.4.2 Connection diagram.............................................................................................................. 26

4.5 Grounding the flow sensor ............................................................................................. 26

4.6 Connecting power - all housing variants ....................................................................... 27

4.7 Inputs and outputs, overview ......................................................................................... 28

4.7.1 Combinations of the inputs/outputs (I/Os) ........................................................................... 28

4.7.2 Description of the CG number .............................................................................................. 29

4.7.3 Fixed, non-alterable input/output versions.......................................................................... 30

4.7.4 Alterable input/output versions............................................................................................ 31

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

3

Page 4

CONTENTS

MFC 400

4.8 Description of the inputs and outputs............................................................................ 32

4.8.1 Current output ...................................................................................................................... 32

4.8.2 Pulse output and frequency output ...................................................................................... 33

4.8.3 Status output and limit switch .............................................................................................. 34

4.8.4 Control input ......................................................................................................................... 35

4.9 Electrical connection of the inputs and outputs ............................................................ 36

4.9.1 Field housing, electrical connection of the inputs and outputs ........................................... 36

4.9.2 Laying electrical cables correctly......................................................................................... 37

4.10 Description of the inputs and outputs.......................................................................... 38

4.10.1 Important notes................................................................................................................... 38

4.10.2 Description of the electrical symbols................................................................................. 39

4.10.3 Modular inputs/outputs and bus systems .......................................................................... 40

4.10.4 Ex i inputs/outputs .............................................................................................................. 48

4.10.5 HART connection................................................................................................................. 51

5 Start-up 53

5.1 Switching on the power .................................................................................................. 53

5.2 Starting the signal converter ......................................................................................... 53

6 Operation 54

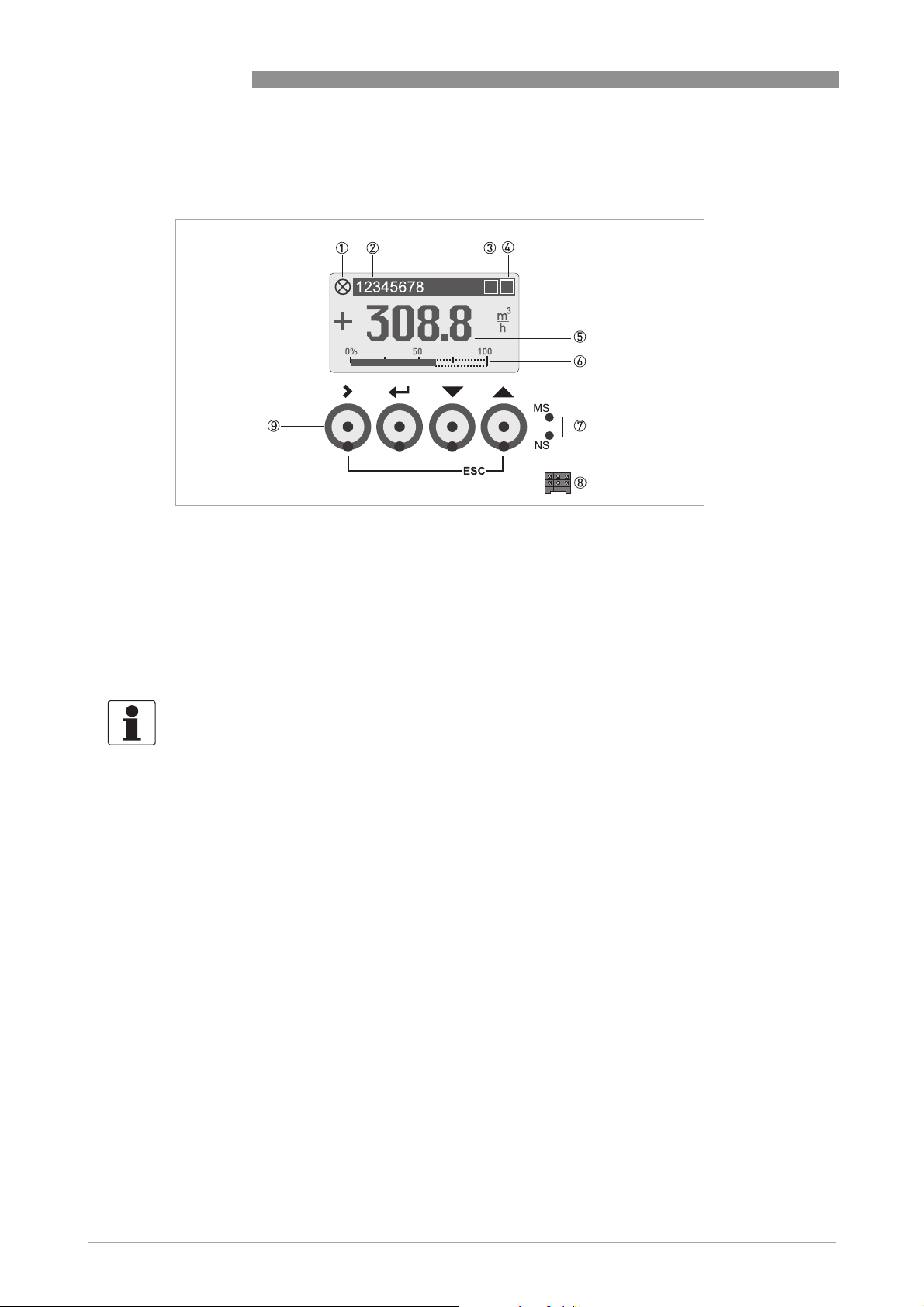

6.1 Display and operating elements .................................................................................... 54

6.1.1 Display in measuring mode with 2 or 3 measured values ................................................... 57

6.1.2 Display for selection of submenu and functions, 3 lines ..................................................... 57

6.1.3 Display when setting parameters, 4 lines ............................................................................ 58

6.1.4 Display when previewing parameters, 4 lines...................................................................... 58

6.2 Menu structure............................................................................................................... 59

6.3 Function tables ............................................................................................................... 63

6.3.1 Menu "Quick Setup" .............................................................................................................. 63

6.3.2 Menu "Test"........................................................................................................................... 65

6.3.3 Menu "Setup" ........................................................................................................................ 68

6.3.4 Set free units......................................................................................................................... 83

6.4 Calibration functions ......................................................................................................84

6.4.1 Zero calibration (C1.1.1 Calibrate Zero) ............................................................................... 84

6.4.2 Density calibration (C1.2.1 Calibrate Density)...................................................................... 86

6.4.3 Temperature/density tables ................................................................................................. 88

6.5 Measurement functions ................................................................................................. 91

6.5.1 Flow (C1.1.0 Flow)................................................................................................................. 91

6.5.2 Density (C1.2.0 Density) ........................................................................................................93

6.5.3 System control (C1.4.0 System Control)............................................................................... 94

6.5.4 Detection of 2 phase flow...................................................................................................... 95

6.6 I/O configuration............................................................................................................. 96

6.6.1 Damp output signals............................................................................................................. 96

6.6.2 Suppress small flow rates.................................................................................................... 96

6.6.3 Polarity of measurement ...................................................................................................... 97

6.6.4 Current output ...................................................................................................................... 97

6.6.5 Alarm signalling via current outputs.................................................................................... 98

6.6.6 Pulse output and batching applications ...............................................................................98

6.7 Display configuration......................................................................................................99

6.7.1 Optical keys (C5.3.0 Optical Keys)......................................................................................... 99

6.7.2 Backlight (C5.4.0 Backlight) ................................................................................................. 99

4

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 5

MFC 400

CONTENTS

6.8 Configuration management (C6.3.0 Config. Management) ........................................... 99

6.8.1 Load and save configuration (C6.3.1 Save Settings & C6.3.2 Load Settings) ...................... 99

6.8.2 Factory reset (C6.3.3 Factory Reset) .................................................................................. 100

6.8.3 Change log (B1.2.0 Change Log)......................................................................................... 100

6.8.4 Locking of configuration ..................................................................................................... 100

6.9 Special functions ..........................................................................................................102

6.10 SIL configuration (only for SIL capable devices)........................................................ 102

6.11 Testing of device installation (B3.0.0 Simulation)...................................................... 102

6.12 Diagnostic information and status messages ........................................................... 103

6.12.1 Status groups (C6.6.0 Status Groups)............................................................................... 104

6.12.2 Status log (B1.1.0 Status Log)........................................................................................... 105

6.12.3 Reset errors (A2.1.0 Reset Errors)................................................................................... 105

6.13 Bluetooth interface..................................................................................................... 105

7 Service 106

7.1 Replacing the signal converter electronics ................................................................. 106

7.2 Driver or sensor coil fault ............................................................................................ 107

7.2.1 OPTIMASS 1000................................................................................................................... 107

7.2.2 OPTIMASS 2000................................................................................................................... 108

7.2.3 OPTIMASS 3000................................................................................................................... 109

7.2.4 OPTIMASS 6000................................................................................................................... 110

7.2.5 OPTIMASS 7000................................................................................................................... 111

7.3 Spare parts availability................................................................................................. 112

7.4 Availability of services .................................................................................................. 112

7.5 Returning the device to the manufacturer................................................................... 112

7.5.1 General information............................................................................................................ 112

7.5.2 Form (for copying) to accompany a returned device.......................................................... 113

7.6 Disposal ........................................................................................................................ 113

7.7 Disassembly and recycling........................................................................................... 114

7.7.1 Disassembly of aluminum or stainless steel field housing ............................................... 115

7.7.2 Disassembly of aluminum or stainless steel compact housing ........................................ 116

7.7.3 Location of battery .............................................................................................................. 117

7.7.4 Overview of the materials and components....................................................................... 117

8 Technical data 119

8.1 Measuring principle...................................................................................................... 119

8.2 Technical data............................................................................................................... 119

8.3 Dimensions and weight ................................................................................................ 131

8.3.1 Housing ............................................................................................................................... 131

8.3.2 Mounting plate of field housing .......................................................................................... 132

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

5

Page 6

CONTENTS

MFC 400

9 Description of HART interface 133

9.1 General description ...................................................................................................... 133

9.2 Software history ...........................................................................................................133

9.3 Connection variants...................................................................................................... 134

9.3.1 Point-to-Point connection - analogue / digital mode......................................................... 135

9.3.2 Multi-Drop connection (2-wire connection) ....................................................................... 136

9.3.3 Multi-Drop connection (3-wire connection) ....................................................................... 137

9.4 Inputs/outputs and HART dynamic variables and device variables ............................ 138

10 Description of Bluetooth interface 140

10.1 Introduction ................................................................................................................ 140

10.1.1 Functionality...................................................................................................................... 140

10.1.2 Quick start guide ............................................................................................................... 140

10.2 Security considerations.............................................................................................. 141

10.2.1 Wireless security concept................................................................................................. 141

10.2.2 Bluetooth interface and SIL mode .................................................................................... 141

10.3 Field device setup....................................................................................................... 142

10.3.1 Bluetooth access level ...................................................................................................... 142

10.3.2 Bluetooth access level setting via mechanical switch ..................................................... 143

10.3.3 Bluetooth access level setting via software (C8.1.0 Access Level).................................. 144

10.3.4 Password for the Bluetooth interface (C8.2.0 Password) ................................................ 144

10.3.5 LED Signalling (C8.3.0) ..................................................................................................... 145

10.3.6 Reset Bluetooth lockout (A2.7.0, C8.4.0) .......................................................................... 145

10.3.7 Check Bluetooth connection status (B1.7.1) .................................................................... 146

10.3.8 Login history (B1.7.2, B1.7.3) ............................................................................................ 146

10.4 Installation of the OPTICHECK Flow Mobile app ....................................................... 146

10.5 FCC and ISED statements .......................................................................................... 147

11 Notes 149

6

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 7

MFC 400

SAFETY INSTRUCTIONS

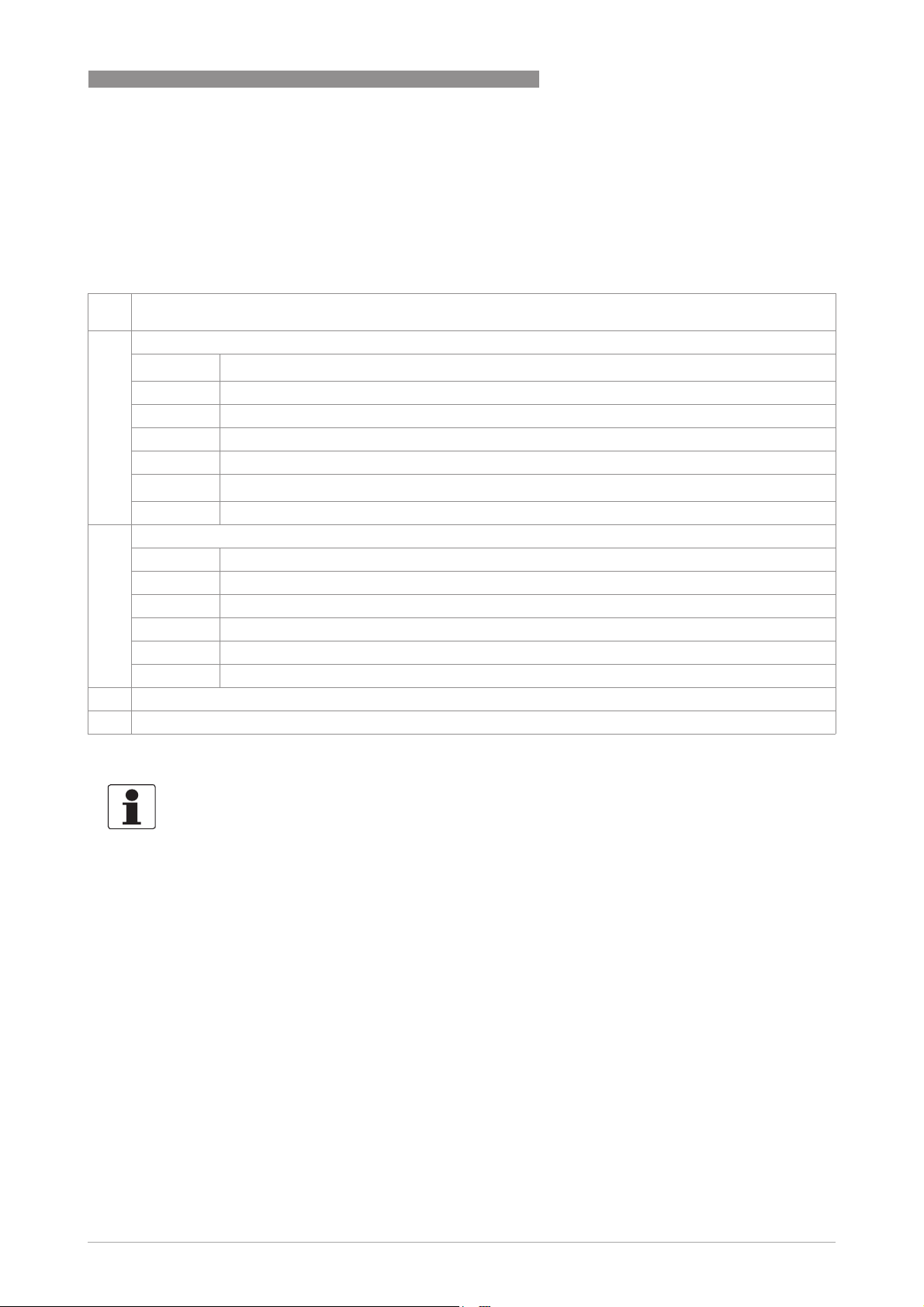

1.1 Software history

The "Electronic Revision" (ER) is consulted to document the revision status of electronic

equipment according to NE 53 for all devices. It is easy to see from the ER whether

troubleshooting or larger changes in the electronic equipment have taken place and how that

has affected the compatibility.

1 Downwards compatible changes and fault repair with no effect on operation

(e.g. spelling mistakes on display)

2-_ Downwards compatible hardware and/or software change of interfaces:

H

P Profibus

F Foundation Fieldbus

M Modbus

N PROFINET IO

BT

X all interfaces

3-_ Downwards compatible hardware and/or software change of inputs and outputs:

I Current output

F, P Frequency / pulse output

S Status output

C Control input

LS Limit switch

X all inputs and outputs

4 Downwards compatible changes with new functions.

5 Incompatible changes, i.e. electronic equipment must be changed.

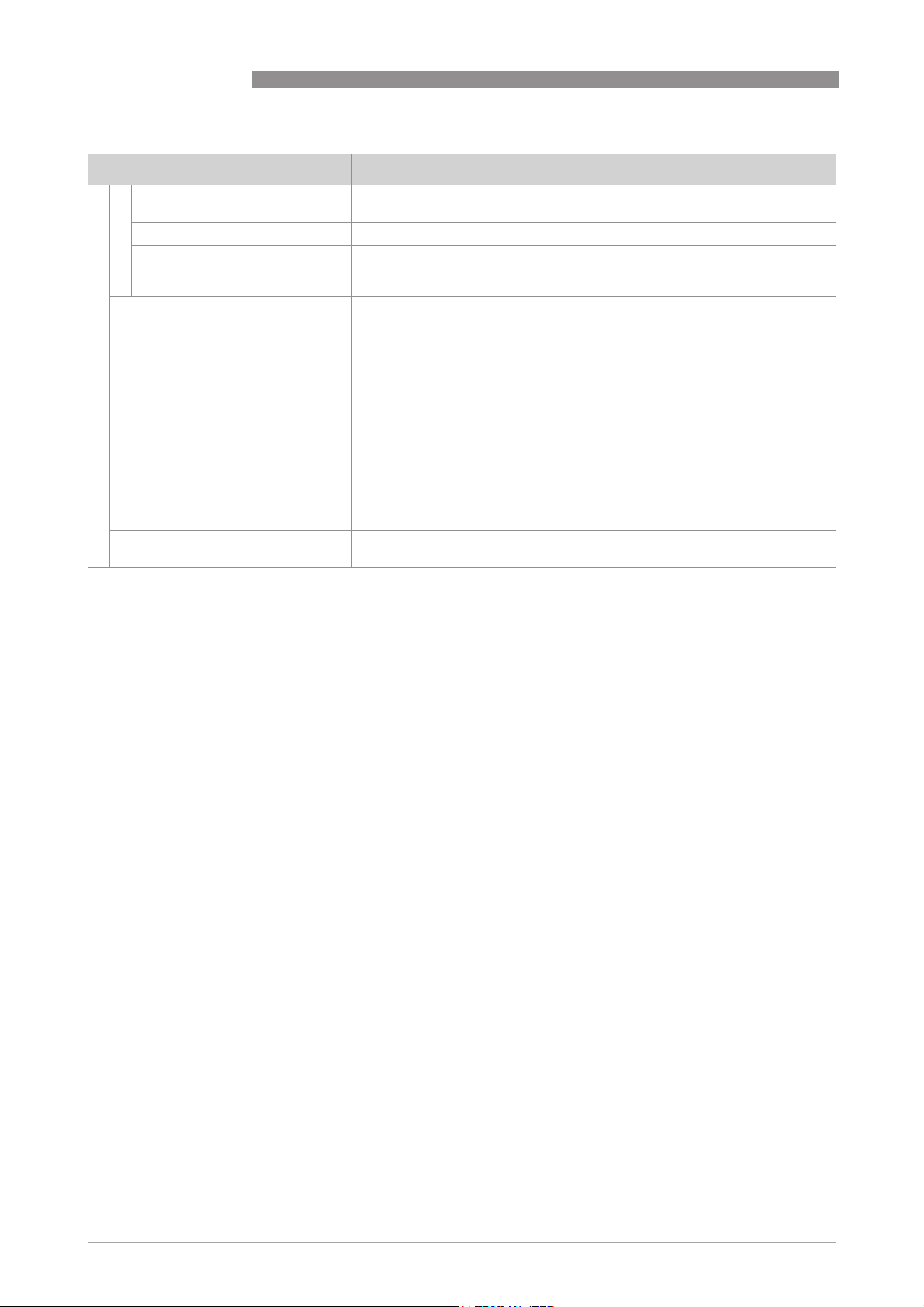

Table 1-1: Description of changes

®

HART

Bluetooth

®

1

INFORMATION!

In the table below, "_" is a placeholder for possible multi-digit alphanumeric combinations,

depending on the available version.

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

7

Page 8

1

SAFETY INSTRUCTIONS

MFC 400

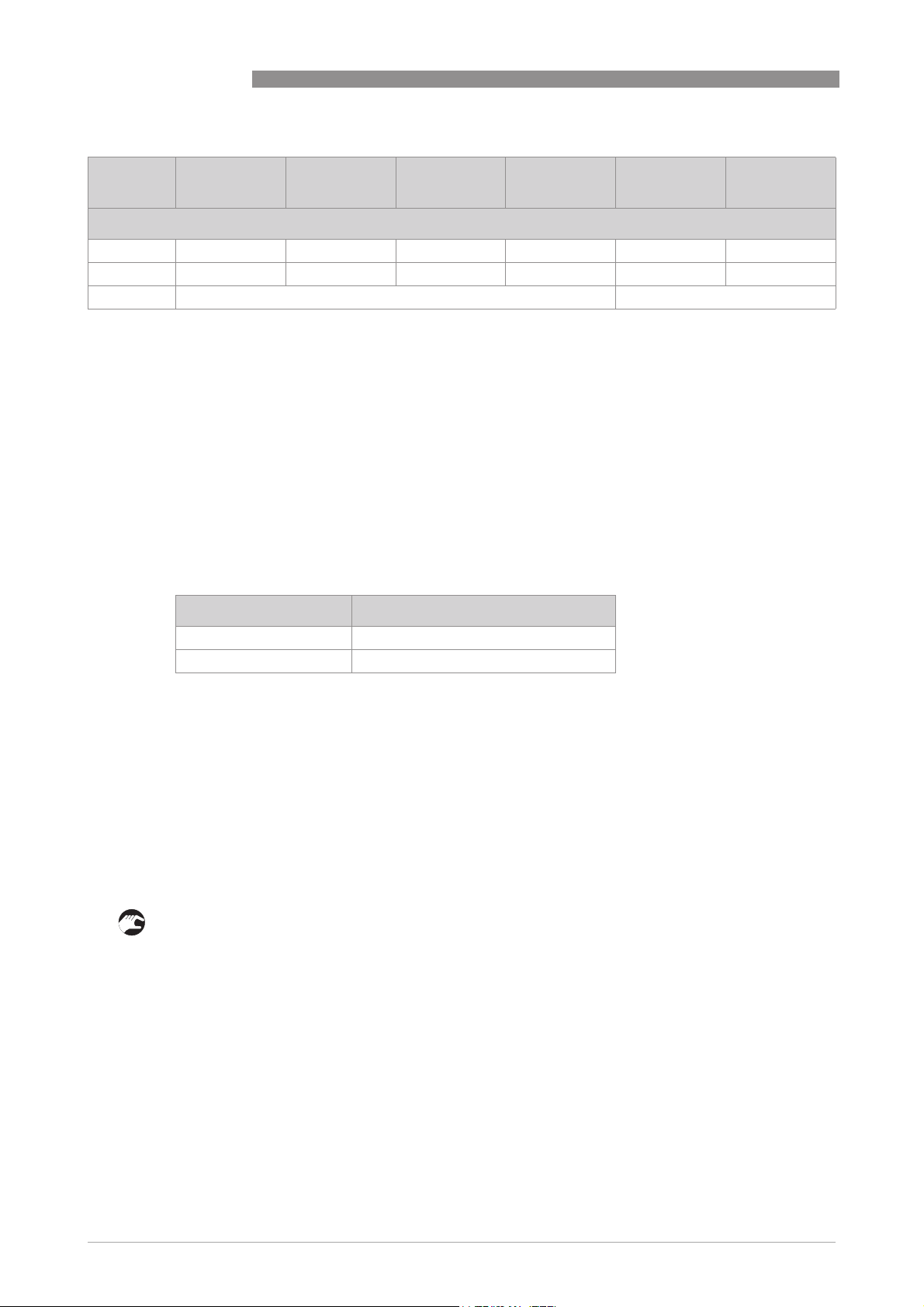

Release date Electronic revision (ER) Changes and compatibility Documentation

09/2012 ER 1.0.0_ - MA MFC400 R01

03/2013 ER 1.0.1_ 1 MA MFC400 R02

06/2013 ER 1.0.2_ 1; 2-M; 2-H MA MFC400 R02

ER 1.0.3_ 1; 2-F; 2-P; 2-X MA MFC400 R02

11/2013 ER 1.0.4_ 2-H; 3-P; 3-F MA MFC400 R03

05/2014 ER 1.0.5_ 1 MA MFC400 R03

08/2014 ER 1.0.6_ 1; 3-P; 3-I; 2-H MA MFC400 R03

08/2017 ER 1.0.7_ 1; 2-F; 3-F MA MFC400 R03

07/2016 ER 2.0.0_ 5 1 MA MFC400 ER2.0 R04

07/2017 ER 2.0.1_ 1 MA MFC400 ER2.0 R05

08/2017 ER 2.0.2_ 1; 2-P; 2-F; 2-N MA MFC400 ER2.0 R05

11/2018 ER 2.0.3_ 1 MA MFC400 ER2.0 R05

08/2019 ER 2.0.4_ 1; 2-M MA MFC400 ER2.0 R06

01/2020 ER 2.1.0_ 1; 2-BT 2 MA MFC400 ER2.1 R07, R08

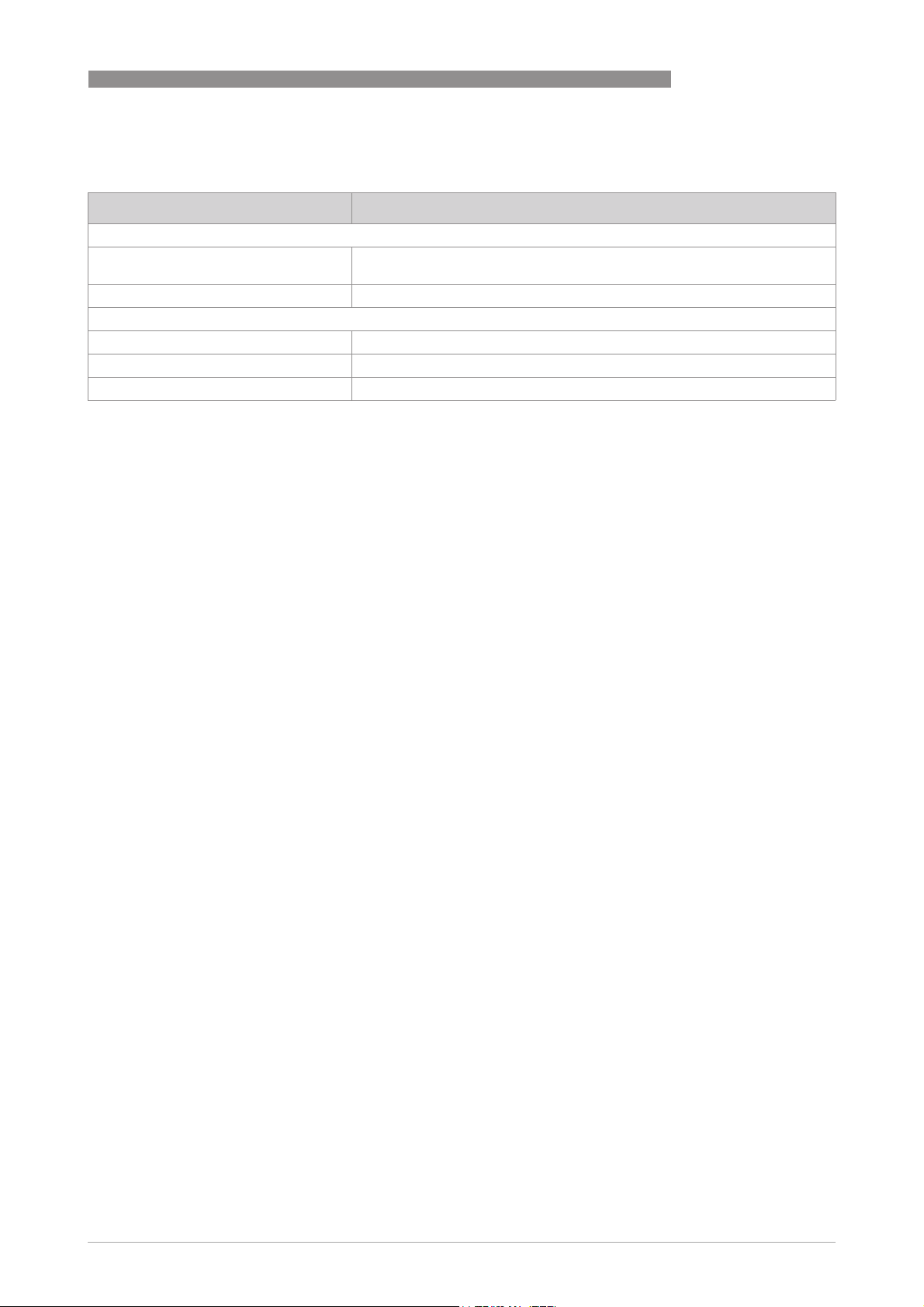

Table 1-2: Software changes and effect on compatibility

1 Incompatible change: hardware and software change; SIL mode capability

2 Incompatible change: hardware and software change; Bluetooth

®

functionality added

1.2 Intended use

The mass flowmeters are designed exclusively to directly measure mass flow rates, product

density and temperature as well to indirectly measure parameters such as the total volume and

concentration of dissolved substances as well as the volume flow rate.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

CAUTION!

For devices used in SIL applications, additional safety notes apply. For detailed information refer

to the "Safety manual".

WARNING!

If the device is not used according to the operating conditions (refer to chapter "Technical data"),

the intended protection could be affected.

INFORMATION!

This device is a Group 1, Class A device as specified within CISPR11:2009. It is intended for use in

industrial environment. There may be potential difficulties in ensuring electromagnetic

compatibility in other environments, due to conducted as well as radiated disturbances.

8

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 9

MFC 400

1.3 CE certification

CE marking

This device conforms with the most recent and up to date versions of the following:

• EMC Directive

• ATEX Directive

• Low Voltage Directive

• Pressure Equipment Directive (PED)

• RoHS

• Measuring Instrument Directive

• Radio Equipment Directive (RED)

SAFETY INSTRUCTIONS

1

The manufacturer declares conformity and the device carries the CE mark.

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

9

Page 10

1

SAFETY INSTRUCTIONS

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

MFC 400

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

10

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 11

MFC 400

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation or operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of icons as shown below.

SAFETY INSTRUCTIONS

1

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

11

Page 12

1

SAFETY INSTRUCTIONS

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

MFC 400

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.5 Safety instructions for the operator

12

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 13

MFC 400

2.1 Scope of delivery

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION

2

Figure 2-1: Scope of delivery

1 Device in the version as ordered

2 Product documentation

3 Signal cable (only for remote version)

Flow sensor Flow sensor + signal converter MFC 400

Compact version Remote field housing

OPTIMASS 1000 OPTIMASS 1400 C OPTIMASS 1400 F

OPTIMASS 2000 OPTIMASS 2400 C OPTIMASS 2400 F

OPTIMASS 3000 OPTIMASS 3400 C OPTIMASS 3400 F

OPTIMASS 6000 OPTIMASS 6400 C OPTIMASS 6400 F

OPTIMASS 7000 OPTIMASS 7400 C OPTIMASS 7400 F

Table 2-1: Signal converter / flow sensor combination possibilities

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

13

Page 14

2

DEVICE DESCRIPTION

2.2 Device description

The mass flowmeters are designed exclusively to directly measure mass flow rates, product

density and temperature as well to indirectly measure parameters such as the total volume,

concentration of dissolved substances and the volume flow rate.

Your measuring device is supplied ready for operation. The factory settings for the operating

data have been made in accordance with your order specifications.

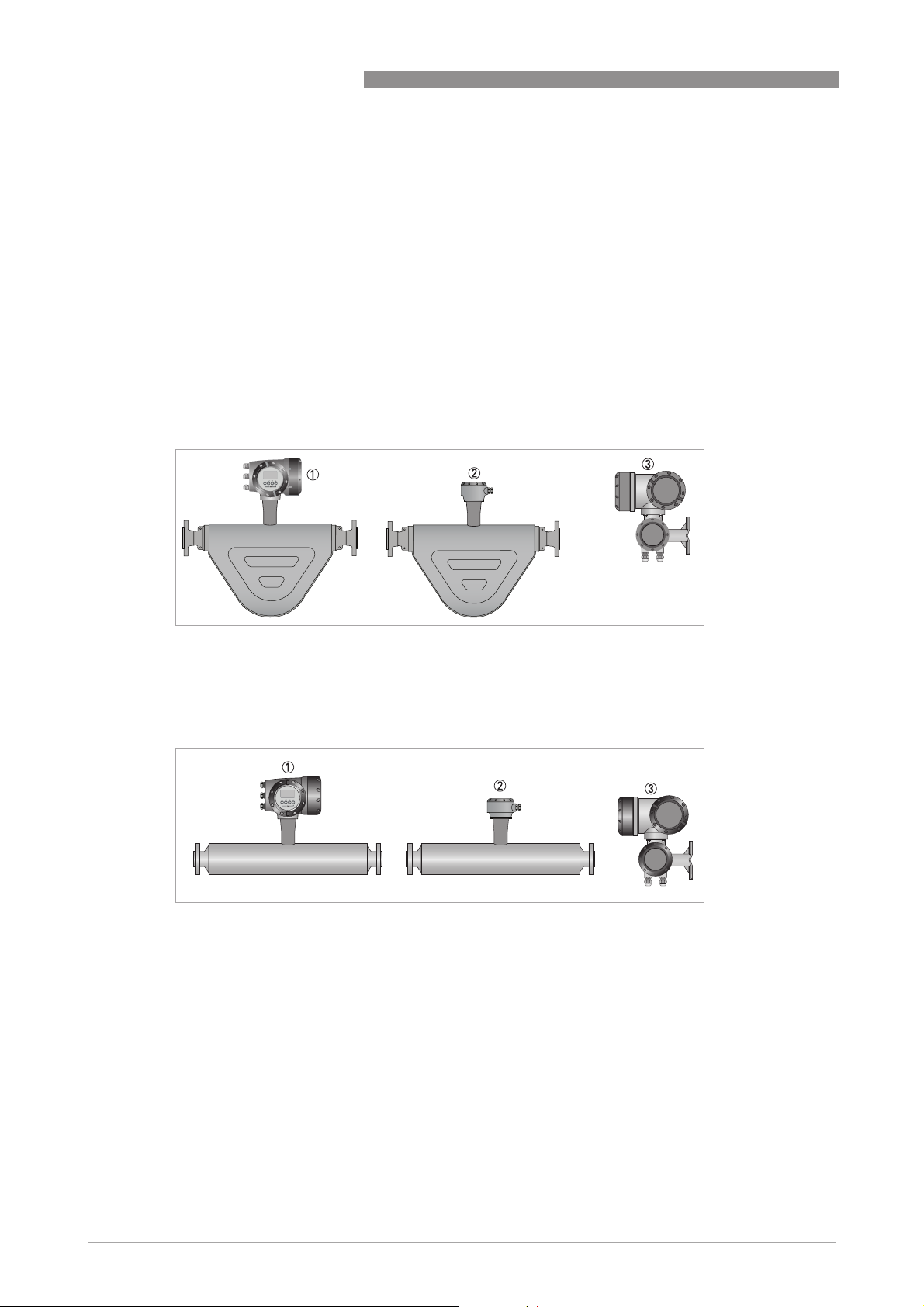

The following versions are available:

• Compact version (the signal converter is mounted directly on the flow sensor)

• Remote version (electrical connection to the flow sensor via field current and signal cable)

MFC 400

Figure 2-2: Versions with bent tube

1 Compact version

2 Flow sensor with connection box

3 Field housing

Figure 2-3: Versions with straight tube

1 Compact version

2 Flow sensor with connection box

3 Field housing

14

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 15

MFC 400

2.2.1 Field housing

Figure 2-4: Construction of the field housing

1 Cover for electronics and display

2 Cover for power supply and inputs/outputs terminal compartment

3 Cover for flow sensor terminal compartment

4 Cable entry for flow sensor signal cable

5 Cable entry for power supply

6 Cable entry for inputs and outputs

7 Mounting plate for pipe and wall mounting

DEVICE DESCRIPTION

2

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

15

Page 16

2

DEVICE DESCRIPTION

2.3 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

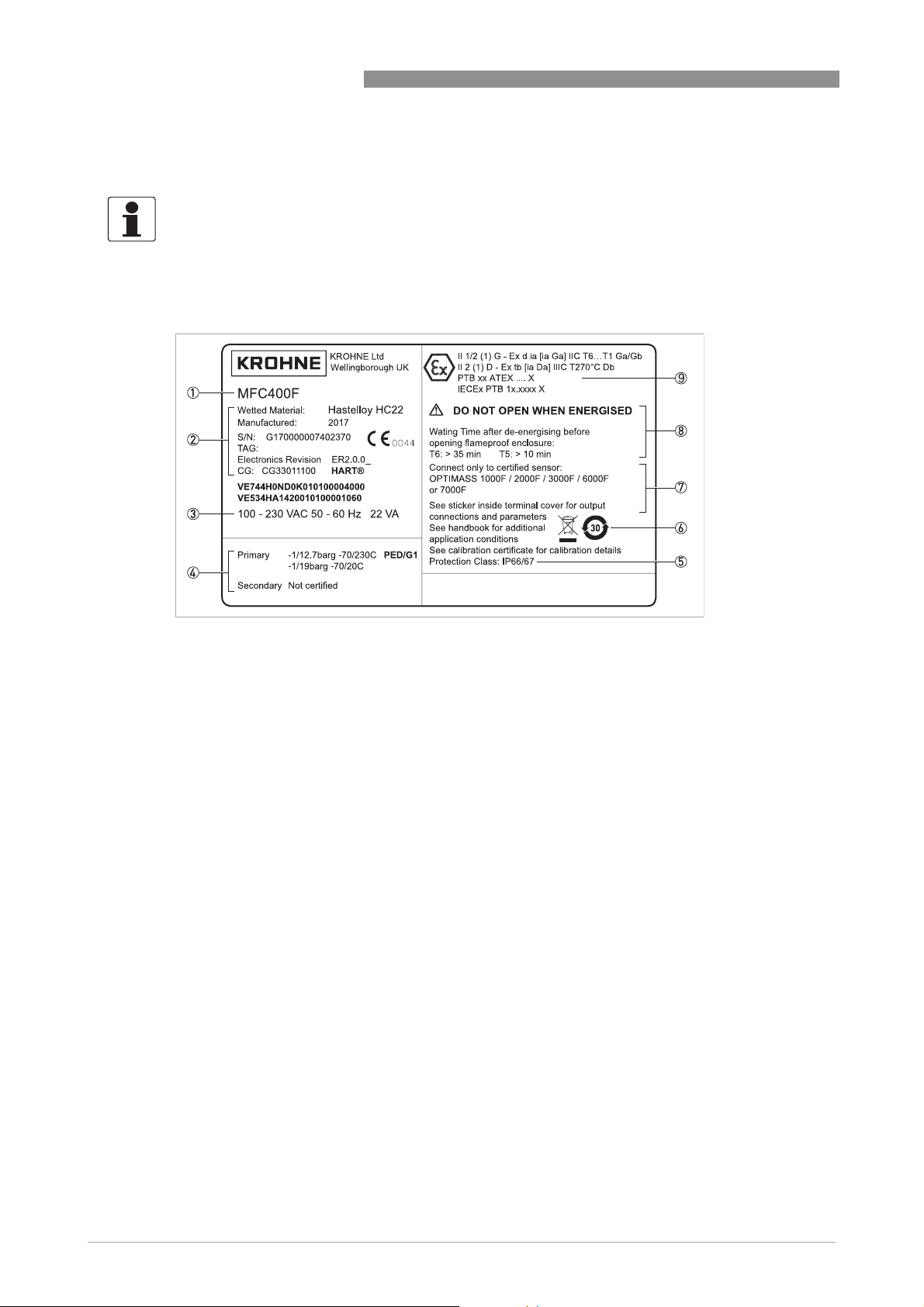

2.3.1 Example of a nameplate

MFC 400

Figure 2-5: Example of a nameplate

1 Product designation

2 Data about wetted material, manufacturing date, serial number, electronic revision and CG number

3 Electrical connection data

4 PED data

5 Protection category

6 Marking for WEEE disposal and China RoHS

7 Reference to additional information: flow sensor combination, sticker in terminal cover for output connections,

documentation, calibration certificates, etc.

8 Approvals-related thresholds

9 Approvals-related information: Ex approval, type test certificate, hygienic approvals, etc.

16

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 17

MFC 400

DEVICE DESCRIPTION

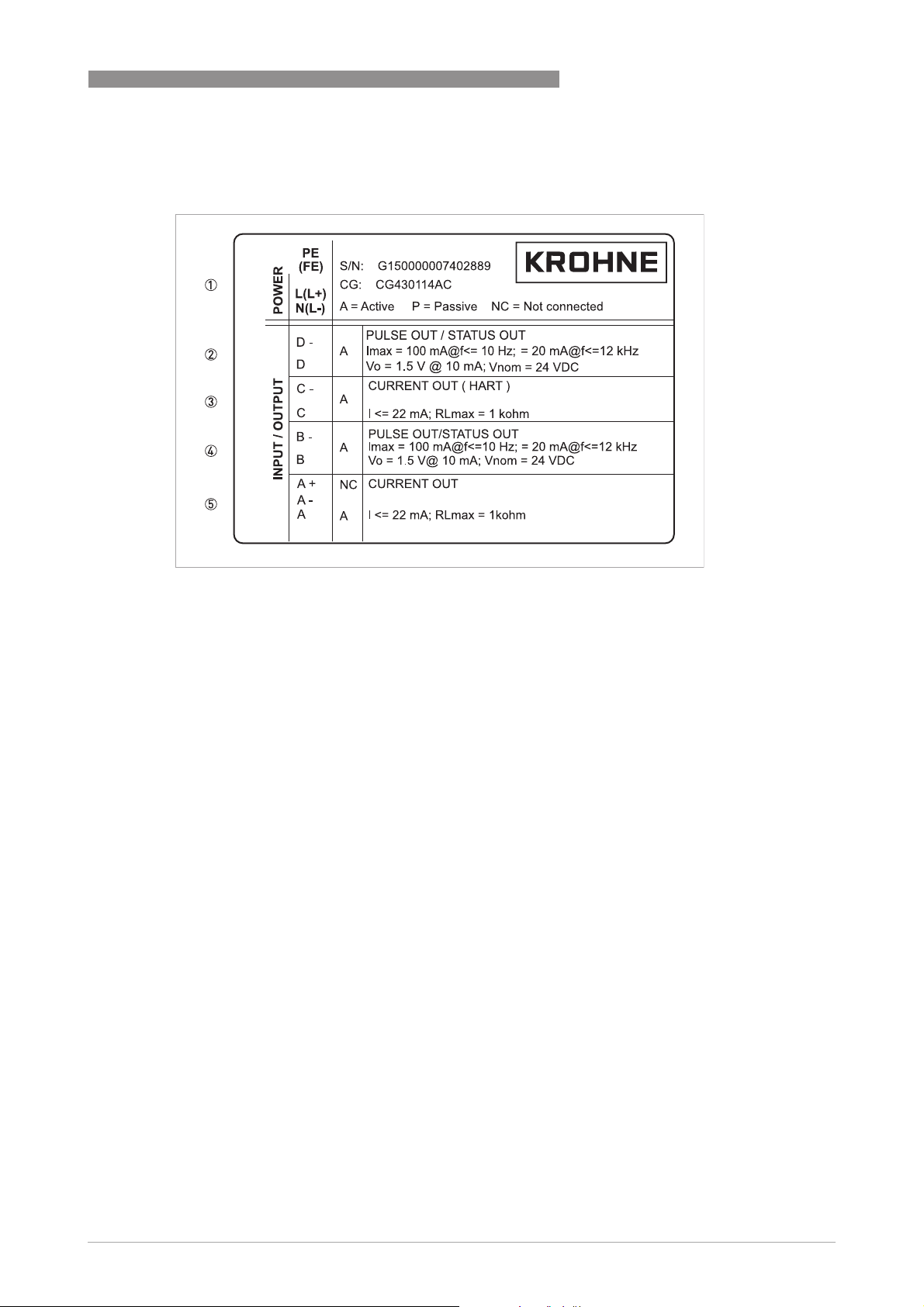

2.3.2 Electrical connection data of inputs/outputs (example of basic version)

2

Figure 2-6: Example of a nameplate for electrical connection data of inputs and outputs

1 Power supply (AC: L and N; DC: L+ and L-; PE for ≥ 24 VAC; FE for ≤ 24 VAC and DC)

2 Connection data of connection terminal D/D-

3 Connection data of connection terminal C/C-

4 Connection data of connection terminal B/B-

5 Connection data of connection terminal A/A-; A+ only operable in the basic version

• A = active mode; the signal converter supplies the power for connection of the subsequent

devices

• P = passive mode; external power supply required for operation of the subsequent devices

• N/C = connection terminals not connected

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

17

Page 18

3

INSTALLATION

3.1 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

• Store the device in a dry, dust-free location.

• Avoid continuous direct sunlight.

• Store the device in its original packing.

• Storage temperature: -40...+70°C / -40...+158°F

MFC 400

3.3 Transport

Signal converter

• No special requirements.

Compact version

• Do not lift the device by the signal converter housing.

• Do not use lifting chains.

• To transport flange devices, use lifting straps. Wrap these around both process connections.

3.4 Installation specifications

INFORMATION!

The following precautions must be taken to ensure reliable installation.

•

Make sure that there is adequate space to the sides.

•

The device must not be heated by radiated heat (e.g. exposure to the sun) to an electronics

housing surface temperature above the maximum permissible ambient temperature. If it is

necessary to prevent damage from heat sources, a heat protection (e.g. sun shade) has to be

installed.

•

Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat

exchanger.

•

Do not expose the signal converter to intense vibrations. The measuring devices are tested

for a vibration level as described in the chapter "Technical data".

18

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 19

MFC 400

3.5 Mounting of the compact version

CAUTION!

Turning the housing of the compact version is not permitted.

INFORMATION!

The signal converter is mounted directly on the flow sensor. For installation of the flowmeter,

please observe the instructions in the supplied product documentation for the flow sensor.

3.6 Mounting the field housing, remote version

CAUTION!

Remarks for sanitary applications

•

To prevent contamination and dirt deposits behind the mounting plate, a cover plug must be

installed between the wall and the mounting plate.

•

Pipe mounting is not suitable for sanitary applications!

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

INSTALLATION

3

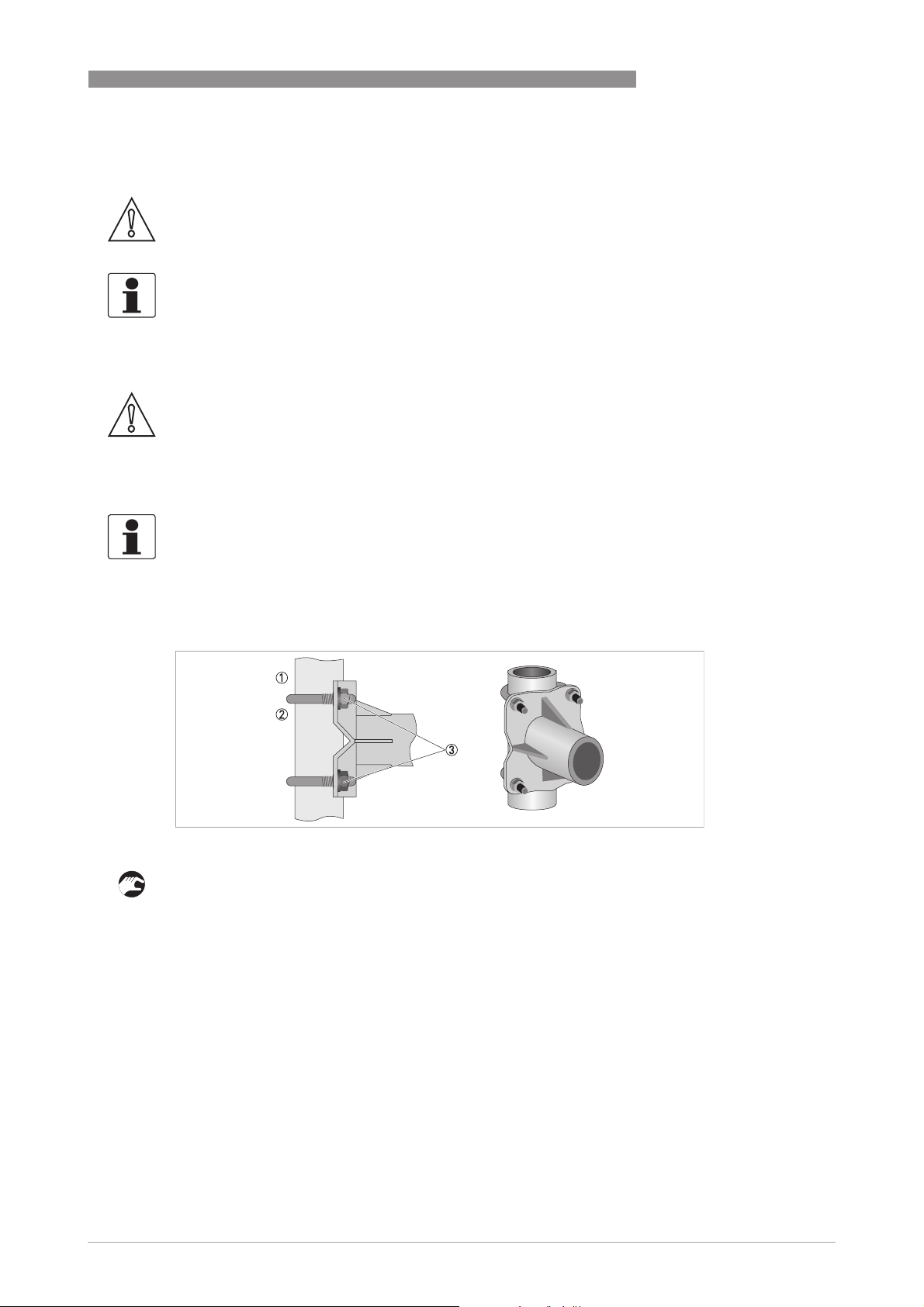

3.6.1 Pipe mounting

Figure 3-1: Pipe mounting of the field housing

1 Fix the mounting bracket of the signal converter to the pipe.

2 Fasten the mounting bracket of the signal converter using standard U-bolts and washers.

3 Tighten the nuts.

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

19

Page 20

3

INSTALLATION

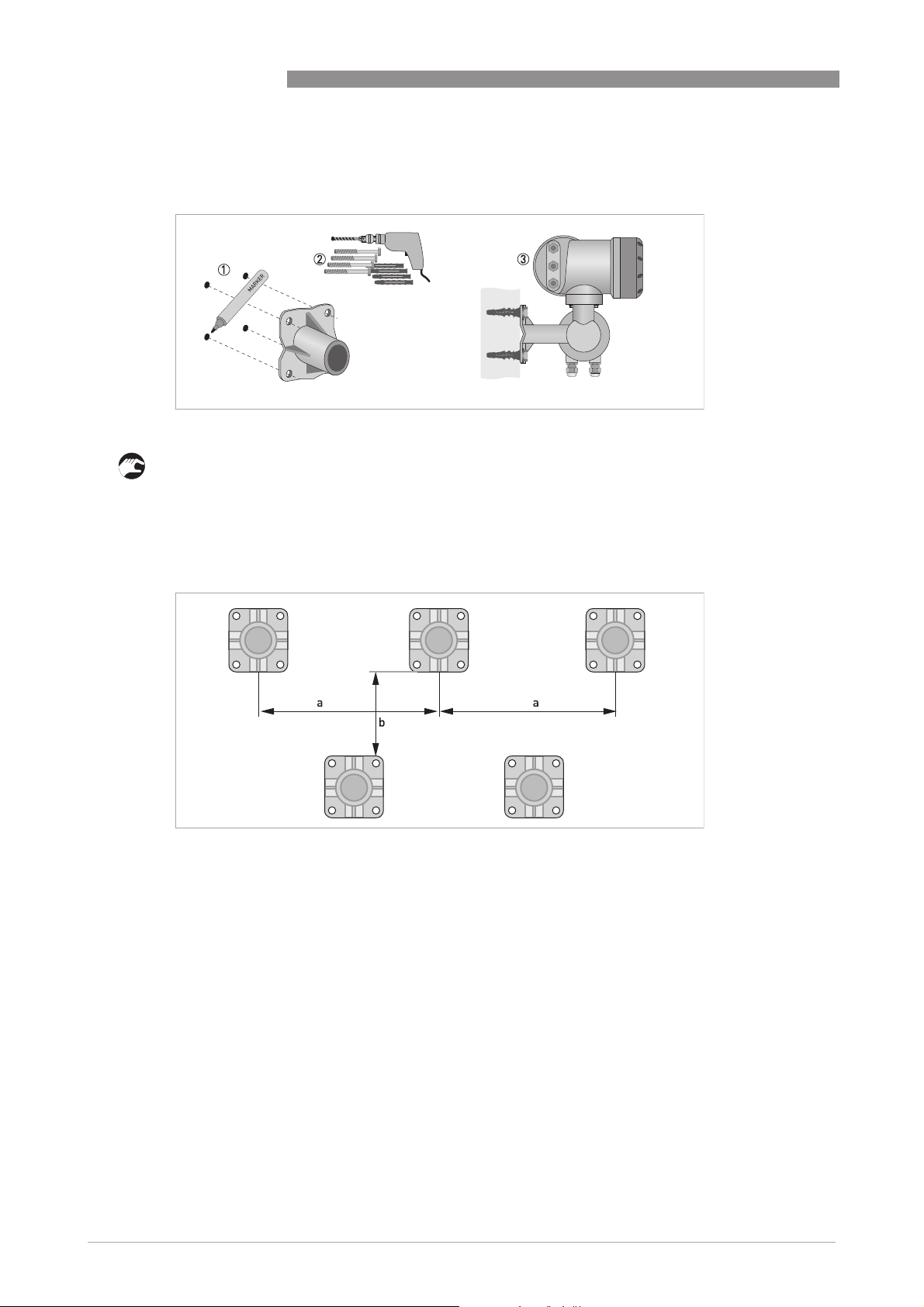

3.6.2 Wall mounting

Figure 3-2: Wall mounting of the field housing

MFC 400

1 Prepare the holes with the aid of the mounting plate. For further information refer to

plate of field housing

on page 132.

Mounting

2 Fasten the mounting plate securely to the wall.

3 Screw the mounting bracket of the signal converter to the mounting plate with the nuts and

washers.

Figure 3-3: Mounting multiple devices next to each other

a ≥ 600 mm / 23.6"

b ≥ 250 mm / 9.8"

20

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 21

MFC 400

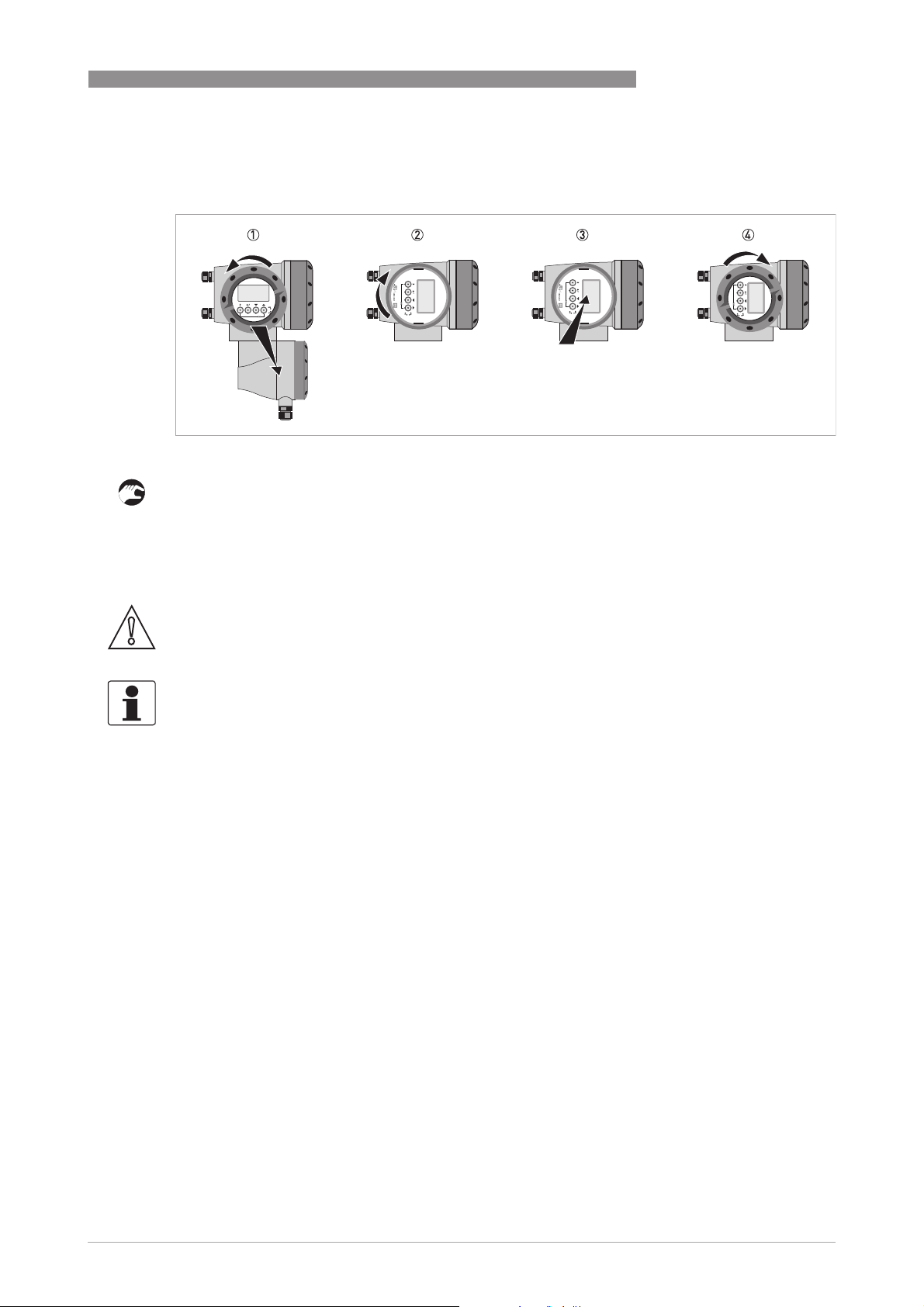

3.6.3 Turning the display of the field housing version

Figure 3-4: Turning the display of the field housing version

The display of the field housing version can be turned in 90° increments

1 Unscrew the cover from the display and operation control unit.

2 Pull out the display and rotate it to the required position.

3 Slide the display back into the housing.

4 Re-fit the cover and tighten it by hand.

INSTALLATION

3

CAUTION!

The ribbon cable of the display must not be folded or twisted repeatedly.

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

21

Page 22

4

ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected.

Take note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations.

Any work done on the electrical components of the measuring device may only be carried out by

properly trained specialists.

MFC 400

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Important notes on electrical connection

DANGER!

Electrical connection is carried out in conformity with the VDE 0100 directive "Regulations for

electrical power installations with line voltages up to 1000 V" or equivalent national regulations.

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

CAUTION!

•

Use suitable cable entries for the various electrical cables.

•

The flow sensor and signal converter have been configured together at the factory. For this

reason, please connect the devices in pairs.

22

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 23

MFC 400

4.3 Signal cable requirements

CAUTION!

It is strongly recommended that the signal cable for remote flowmeters is provided by the

manufacturer.

Specifications for standard signal cables

• 5 twisted pair circuits (24 AWG)

• Insulation thickness of cables: ≥ 0.2 mm / 0.008"

• Each cable pair shielded with foil and drain wire

• Overall foil/braid shield

• Casing colour: grey

• Colour of wires:

Pair 1: yellow/black

Pair 2: green/black

Pair 3: blue/black

Pair 4: red/black

Pair 5: white/black

• Test voltage: ≥ 100 VAC

• Temperature range: -40...+85°C / -40...+185°F

• Capacity between cables: ≤ 41 pF/m

• Capacity compared to shielding: ≤ 73 pF/m

• Inductance: ≤ 0.8 µH/m

ELECTRICAL CONNECTIONS

4

Specifications for cables in hazardous areas

• 5 twisted pair circuits (24 AWG)

• Insulation thickness of cables: ≥ 0.2 mm / 0.008"

• Each cable pair shielded with foil and drain wire

• Overall foil/braid shield

• Casing colour: blue

• Colour of wires:

Pair 1: yellow/black

Pair 2: green/black

Pair 3: blue/black

Pair 4: red/black

Pair 5: white/black

• Test voltage: ≥ 100 VAC

• Temperature range: -40...+85°C / -40...+185°F

• Capacity between cables: ≤ 41 pF/m

• Capacity compared to shielding: ≤ 73 pF/m

• Inductance: ≤ 0.8 µH/m

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

23

Page 24

4

ELECTRICAL CONNECTIONS

4.4 Connecting the signal cables

DANGER!

Cables may only be connected when the power is switched off.

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations.

Any work done on the electrical components of the measuring device may only be carried out by

properly trained specialists.

MFC 400

24

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 25

MFC 400

ELECTRICAL CONNECTIONS

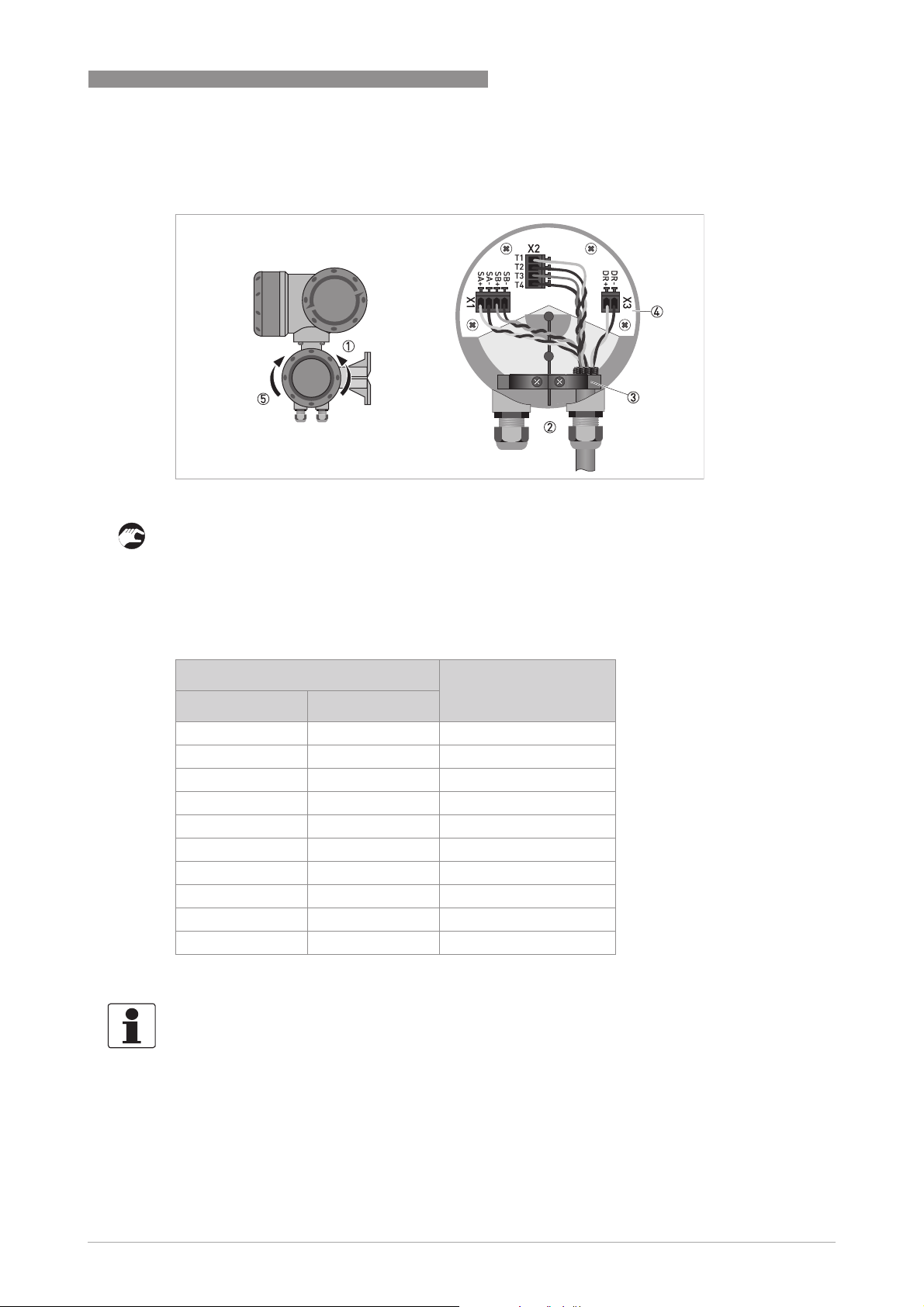

4.4.1 Connection of signal cable - field housing and connection box for flow sensor

Figure 4-1: Connection of signal cable - field housing and connection box for flow sensor

1 Unscrew the terminal compartment cover.

2 Pass the prepared signal cable through the cable entry.

3 Secure the signal cable using the clip.

4 Connect the electrical conductors as shown. The shielding must also be connected to the

spring terminal.

5 Re-fit the cover and tighten it by hand.

4

Cable Connection terminal

Cable pair Colour

1 yellow X1 SA+

1 black X1 SA-

2 green X1 SB+

2 black X1 SB-

3 blue X2 T1

3 black X2 T2

4 red X2 T3

4 black X2 T4

5 white X3 DR+

5 black X3 DR-

Table 4-1: Colour coding of cables

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

25

Page 26

4

ELECTRICAL CONNECTIONS

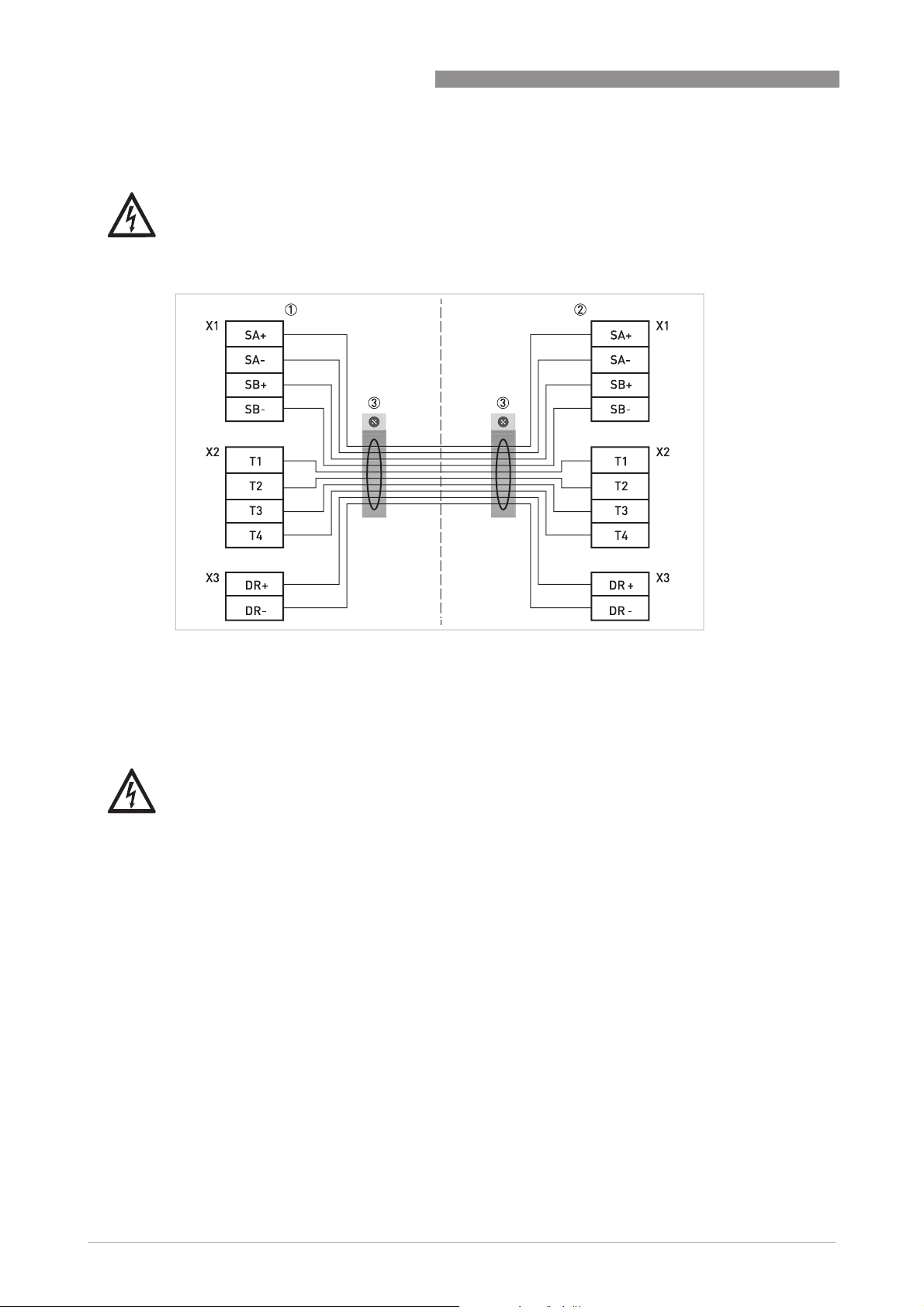

4.4.2 Connection diagram

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

MFC 400

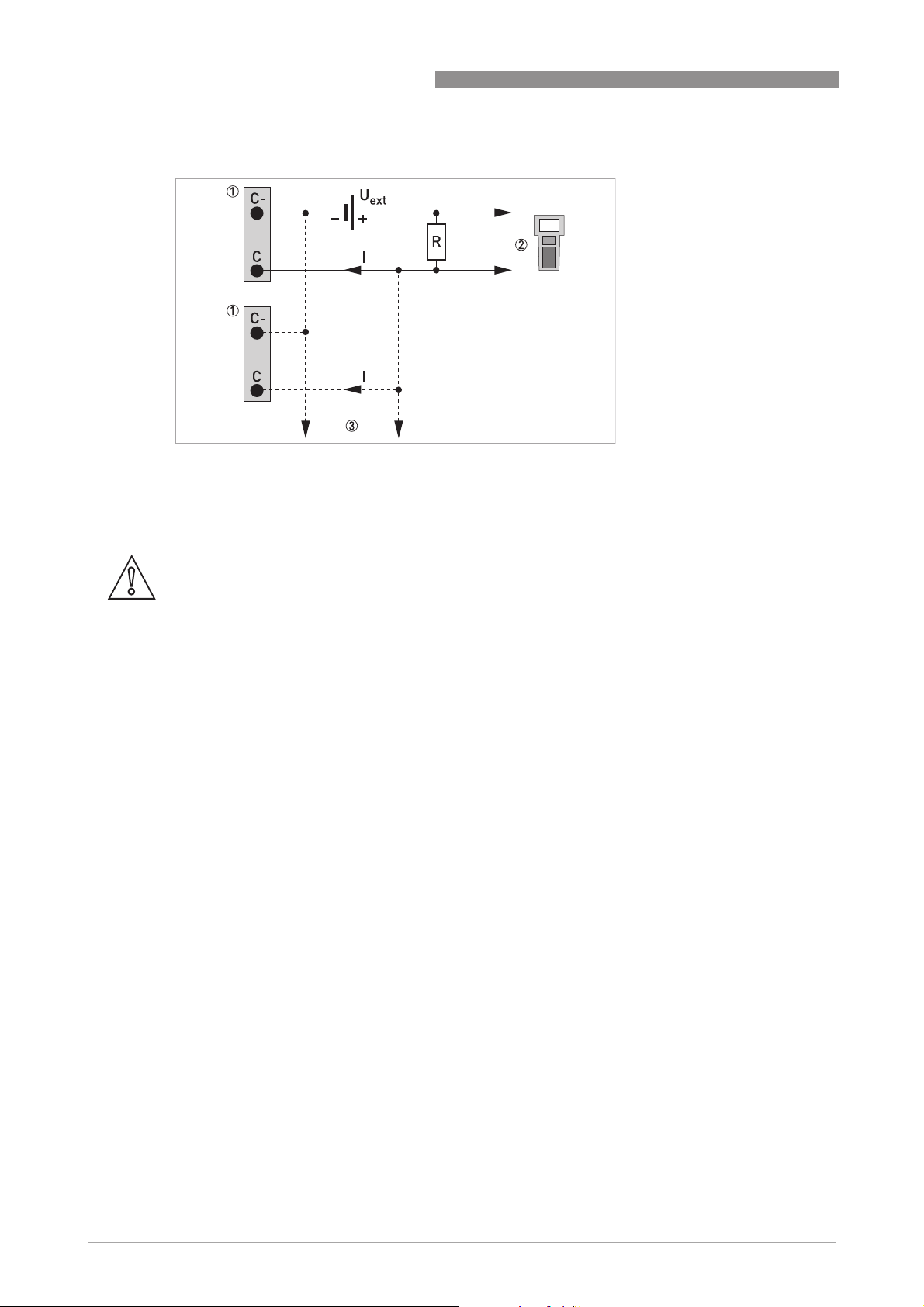

Figure 4-2: Connection diagram

1 Terminal compartment for signal converter

2 Terminal compartment for flow sensor

3 Connect shielding to spring terminal (drain wire and overall shield)

4.5 Grounding the flow sensor

DANGER!

There should be no difference in potential between the flow sensor and the housing or protective

earth of the signal converter!

• The flow sensor must be properly grounded.

• The grounding cable should not transmit any interference voltages.

• Do not use the grounding cable to connect more than one device to ground.

• The flow sensors are connected to ground by means of a functional grounding conductor FE.

• In hazardous areas, grounding is used at the same time for equipotential bonding. Additional

grounding instructions are provided in the supplementary "Ex documentation", which are

only supplied together with hazardous area equipment.

26

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 27

MFC 400

ELECTRICAL CONNECTIONS

4.6 Connecting power - all housing variants

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

• The protection category depends on the housing versions (IP66/67 or NEMA4/4X).

• The housings of the devices, which are designed to protect the electronic equipment from

dust and moisture, should be kept well closed at all times. Creepage distances and

clearances are dimensioned to VDE 0110 and IEC 60664 for pollution severity 2. Supply

circuits are designed for overvoltage category III and the output circuits for overvoltage

category II.

• Fuse protection (I

breaker) to isolate the signal converter must be provided close to the device. The separator

must be marked as the separator for this device.

≤ 16 A) for the infeed power circuit, as well as a separator (switch, circuit

N

4

100...230 VAC (tolerance range: -15% / +10%)

• Note the power supply voltage and frequency (50...60 Hz) on the nameplate.

• The protective ground terminal PE

clamp terminal in the terminal compartment of the signal converter.

PE of the power supply must be connected to the separate U-

PEPE

INFORMATION!

240 VAC + 5% is included in the tolerance range.

24 VDC (tolerance range: -55% / +30%)

• Note the data on the nameplate!

• For measurement process reasons, a functional ground FE

separate U-clamp terminal in the terminal compartment of the signal converter.

• When connecting to functional extra-low voltages, provide a facility for protective separation

(PELV) (according to VDE 0100 / VDE 0106 and/or IEC 60364 / IEC 61140 or relevant national

regulations).

FE must be connected to the

FEFE

INFORMATION!

For 24 VDC, 12 VDC - 10% is included in the tolerance range.

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

27

Page 28

4

ELECTRICAL CONNECTIONS

Figure 4-3: Power supply connection

1 100...230 VAC (-15% / +10%), 22 VA

2 24 VDC (-55% / +30%), 12 W

4.7 Inputs and outputs, overview

4.7.1 Combinations of the inputs/outputs (I/Os)

This signal converter is available with various input/output combinations.

Modular version

• Depending on the task, the device can be configured with various output modules.

MFC 400

Ex i version

• Depending on the task, the device can be configured with various output modules.

• Current outputs can be active or passive.

• Optionally available also with Foundation Fieldbus and Profibus PA.

Bus systems

• The device allows intrinsically safe and non intrinsically safe bus interfaces in combination

with additional modules.

• For connection and operation of bus systems, note the supplementary instructions.

Ex option

• For hazardous areas, all of the input/output variants for the housing designs C and F can be

delivered with terminal compartment in Ex d (pressure-resistant casing) or Ex e (increased

safety).

• For connection and operation of Ex devices, note the supplementary instructions.

28

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 29

MFC 400

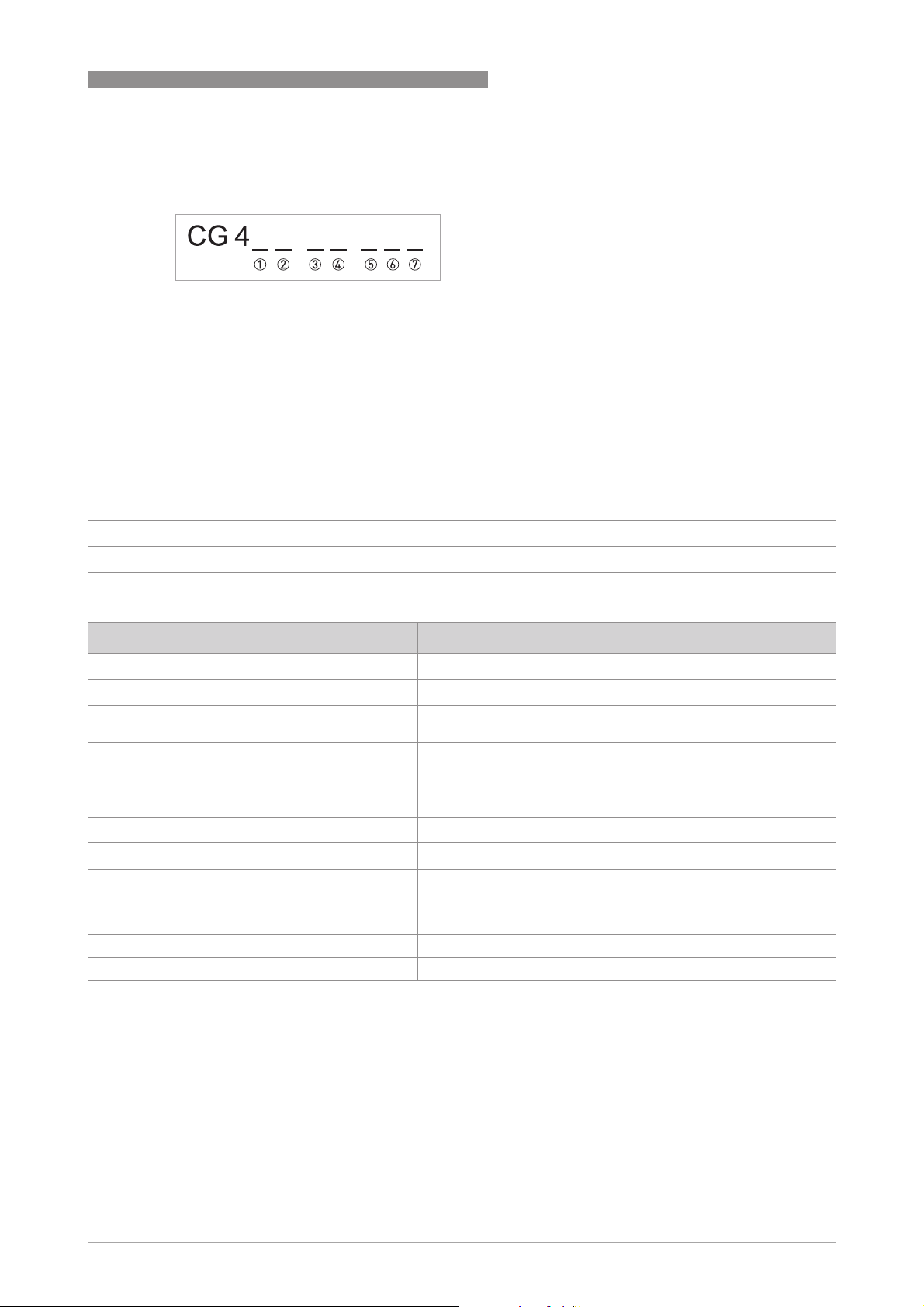

4.7.2 Description of the CG number

Figure 4-4: Marking (CG number) of the electronics module and input/output variants

1 ID number: 3

2 ID number: 0 = standard

3 Power supply option

4 Display

5 Input/output version (I/O)

6 1st optional module for connection terminal A

7 2nd optional module for connection terminal B

The last 3 digits of the CG number (5, 6 and 7) indicate the assignment of the terminal

connections.

Please refer to the following examples.

ELECTRICAL CONNECTIONS

4

CG430114AC 100...230 VAC & standard display; modular I/O: Ia & PN/SN and optional module Ia/SN & Pa/S

CG43081200 24 VDC & standard display; Ex i I/O: Ia & Pa/Sa and optional module Ia & PN/SN/C

Table 4-2: Examples for CG number

N

Abbreviation Identifier for CG number Description

I

a

I

p

Pa / S

a

Pp / S

p

PN / S

N

C

a

C

p

C

N

- 8 No additional module installed

- 0 No further module possible

Table 4-3: Description of abbreviations and CG identifier for possible optional modules on terminals A and B

A Active current output

B Passive current output

C Active pulse output, frequency output, status output or limit

switch (changeable)

E Passive pulse output, frequency output, status output or limit

switch (changeable)

F Passive pulse output, frequency output, status output or limit

switch according to NAMUR (changeable)

G Active control input

K Passive control input

H Active control input according to NAMUR

Signal converter monitors cable breaks and short circuits

according to EN 60947-5-6. Errors indicated on LC display.

Error messages possible via status output.

a

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

29

Page 30

4

ELECTRICAL CONNECTIONS

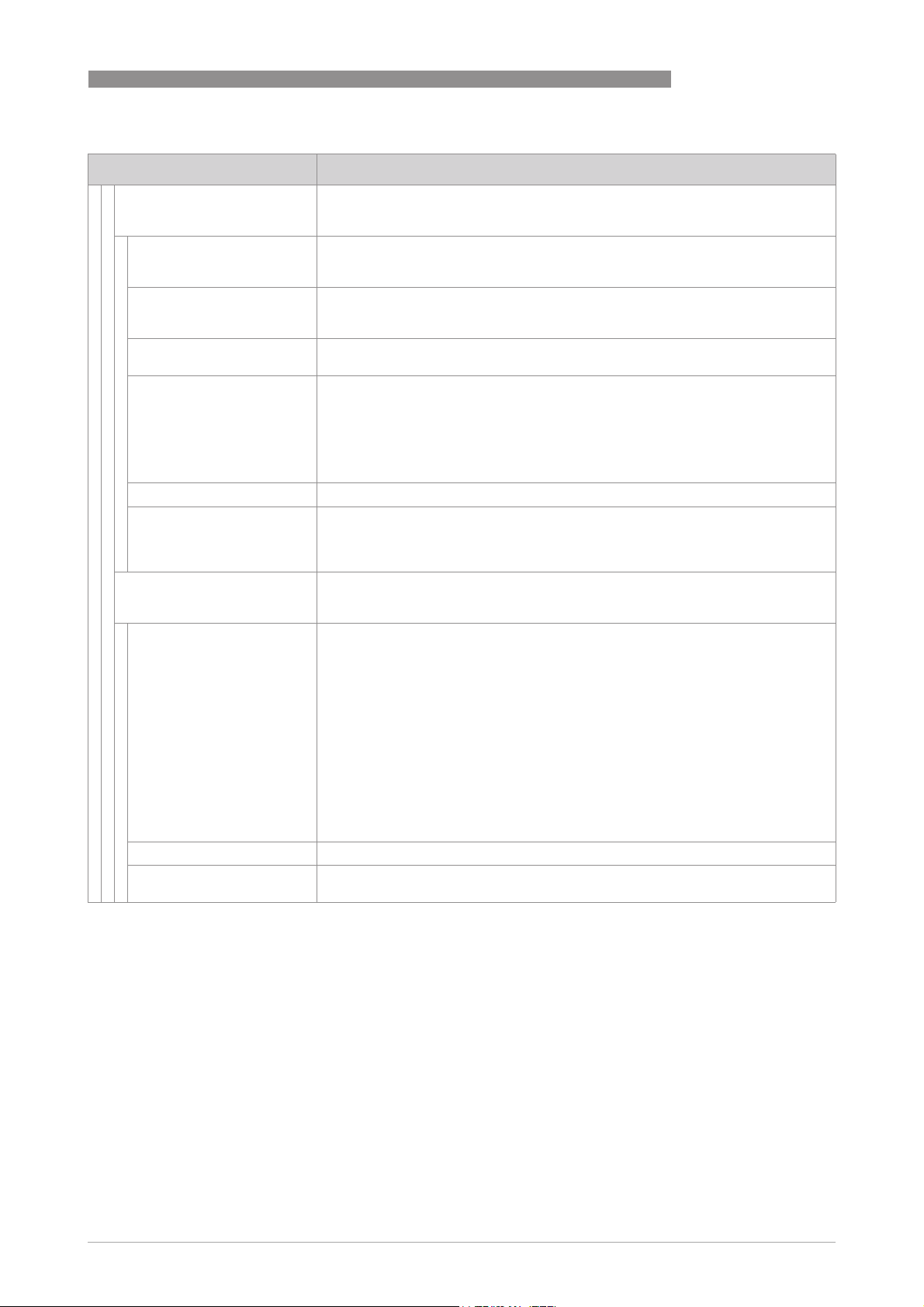

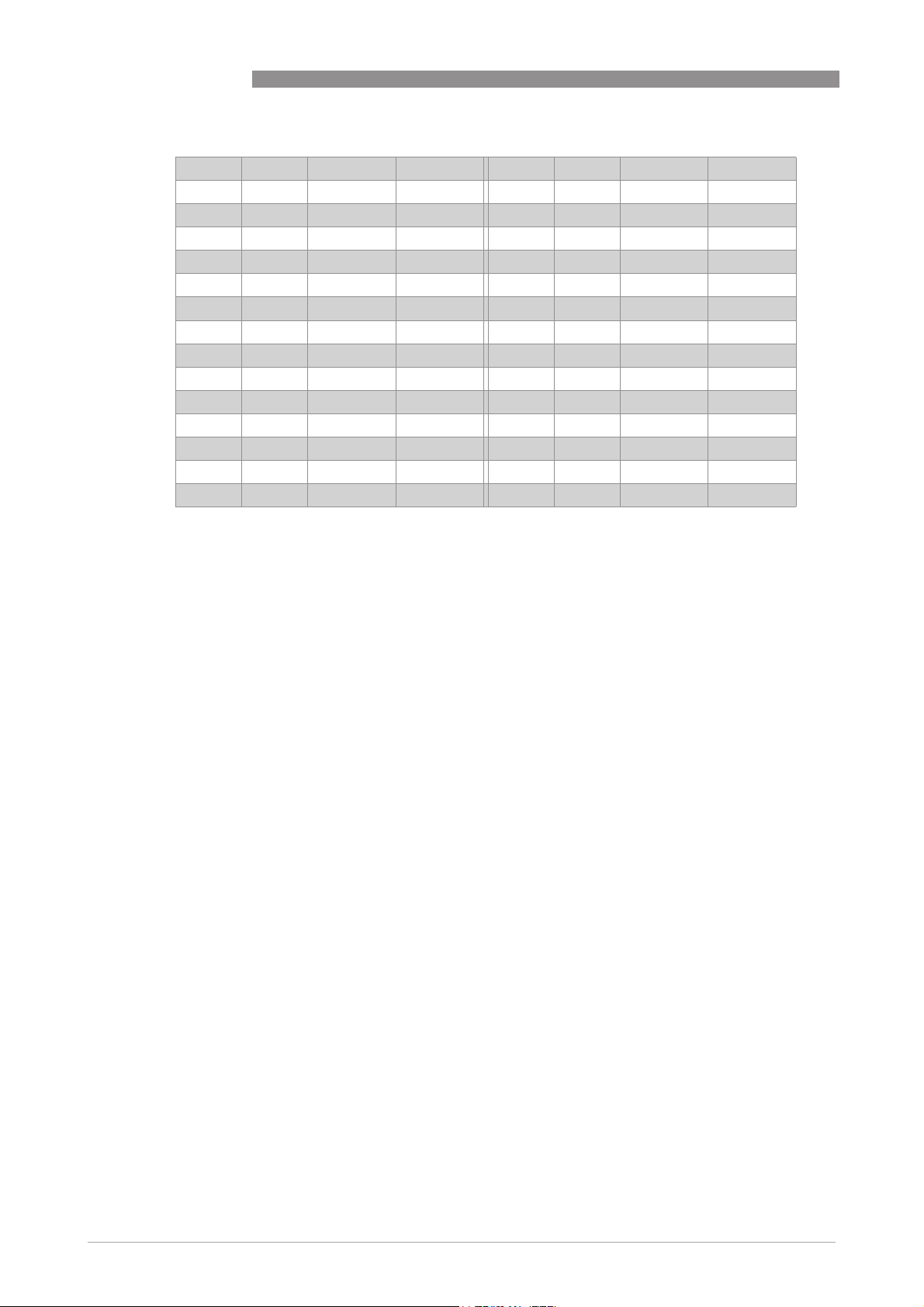

4.7.3 Fixed, non-alterable input/output versions

This signal converter is available with various input/output combinations.

• The grey boxes in the tables denote unassigned or unused connection terminals.

• In the table, only the final digits of the CG no. are depicted.

CG no. Connection terminals

A+ A A- B B- C C- D D-

Ex i I/Os (option)

2 0 0

3 0 0

2 1 0 Ia active PN / SNNAMUR

Cp passive 1

3 1 0 Ia active PN / SNNAMUR

passive 1

C

p

2 2 0 Ip passive PN / SNNAMUR

Cp passive 1

3 2 0 Ip passive PN / SNNAMUR

passive 1

C

p

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

MFC 400

PN / SN NAMUR 1

PN / SN NAMUR 1

PN / SN NAMUR 1

PN / SN NAMUR 1

PN / SNNAMUR 1

PN / SNNAMUR 1

PROFIBUS PA (Ex i) (option)

D 0 0 PA+ PA- PA+ PA-

FISCO Device FISCO Device

D 1 0 Ia active PN / SNNAMUR

passive 1

C

p

D 2 0 Ip passive PN / SNNAMUR

passive 1

C

p

PA+ PA- PA+ PA-

FISCO Device FISCO Device

PA+ PA- PA+ PA-

FISCO Device FISCO Device

FOUNDATION Fieldbus (Ex i) (option)

E 0 0 V/D+ V/D- V/D+ V/D-

FISCO Device FISCO Device

E 1 0 Ia active PN / SNNAMUR

passive 1

C

p

E 2 0 Ip passive PN / SNNAMUR

Cp passive 1

V/D+ V/D- V/D+ V/D-

FISCO Device FISCO Device

V/D+ V/D- V/D+ V/D-

FISCO Device FISCO Device

PROFINET IO (option)

N 0 0 RX+ RX- TX+ TX- TX+ TX- RX+ RX-

Port 2 Port 1

Table 4-4: Electrical connection of fixed, non-alterable input/output versions

1 Changeable

30

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 31

MFC 400

ELECTRICAL CONNECTIONS

4.7.4 Alterable input/output versions

This signal converter is available with various input/output combinations.

• The grey boxes in the tables denote unassigned or unused connection terminals.

• In the table, only the final digits of the CG no. are depicted.

• Term. = (connection) terminal

CG no. Connection terminals

A+ A A- B B- C C- D D-

Modular I/Os (option)

4 _ _ max. 2 optional modules for term. A + B

I + HART®

active/passive 1

PROFIBUS PA (option)

D _ _ max. 2 optional modules for term. A + B PA+ (2) PA- (2) PA+ (1) PA- (1)

P/S active/passive/

NAMUR 1

4

FOUNDATION Fieldbus (option)

E _ _ max. 2 optional modules for term. A + B V/D+ (2) V/D- (2) V/D+ (1) V/D- (1)

PROFIBUS DP (option)

F _ 0 1 optional module for

term. A

Termination P

RxD/TxDP(2)

RxD/TxDN(2)

Termination N

RxD/TxDP(1)

RxD/TxDN(1)

Modbus (option)

G _ _ 2 max. 2 optional modules for term. A + B Common Sign. B

(D1)

Table 4-5: Electrical connection of alterable input/output versions

1 Software configurable

2 Bus termination and bus polarisation can be enabled/disabled by DIP switches

Sign. A

(D0)

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

31

Page 32

4

ELECTRICAL CONNECTIONS

4.8 Description of the inputs and outputs

4.8.1 Current output

INFORMATION!

The current outputs must be connected depending on the version! Which I/O versions and

inputs/outputs are installed in your signal converter are indicated on the sticker in the cover of

the terminal compartment.

For Modular I/Os, the current output at terminal C must be configured to active/passive before

connecting it.

• All outputs are electrically isolated from each other and from all other circuits.

• All operating data and functions can be adjusted.

• Passive mode:

External power supply required: U

• Active mode:

Load impedance R

≤ 400 Ω at I ≤ 22 mA for Ex i outputs

R

L

• Self-monitoring: interruption or load impedance too high in the current output loop

• Error message possible via status output, error indication on LC display.

• Alarm signal can be adjusted. Default setting: 3.5 mA

• Automatic range conversion via threshold or control input is available for current output at

terminal A or B. The range for the threshold is between 5 and 80% of Q

hysteresis (corresponding ratio from smaller to larger range of 1:20 to 1:1.25).

Signalling of the active range possible via a status output (adjustable).

• Forward/reverse flow measurement (F/R mode) is possible.

≤ 1kΩ at I ≤ 22 mA;

L

≤ 30 VDC at I ≤ 22 mA

ext

100%

MFC 400

, ± 0...5%

INFORMATION!

For further information refer to Description of the inputs and outputs on page 38

Technical data on page 119

.

and refer to

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

32

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 33

MFC 400

4.8.2 Pulse output and frequency output

INFORMATION!

Depending on the version, the pulse and frequency outputs must be connected passively or

actively or according to NAMUR EN 60947-5-6! Which I/O version and inputs/outputs are

installed in your signal converter are indicated on the sticker in the cover of the terminal

compartment.

For Modular I/Os, the pulse output or frequency output at terminal D must be configured to

active/passive/NAMUR before connecting it.

• All outputs are electrically isolated from each other and from all other circuits.

• All operating data and functions can be adjusted.

• Passive mode:

External power supply required: U

I ≤ 20 mA at f ≤ 10 kHz (over range up to f

I ≤ 100 mA at f ≤ 100 Hz

• Active mode:

Use of the internal power supply: U

I ≤ 20 mA at f ≤ 10 kHz (over range up to f

I ≤ 20 mA at f ≤ 100 Hz

• NAMUR mode:

Passive in accordance with EN 60947-5-6;

f ≤ 10 kHz (over range up to f

• Scaling:

Frequency output: in pulses per time unit (e.g. 1000 pulses/s at Q

Pulse output: quantity per pulse

• Pulse width:

symmetric (pulse duty factor 1:1, independent of output frequency),

automatic (with fixed pulse width, duty factor approx. 1:1 at Q

fixed (pulse width adjustable as required from 0.05 ms...2 s)

• When pulse shape is set to fixed, then the maximum pulse rate/frequency is limited to

1/(1.5 * pulse width).

• If output pulse rate is limited, pulses are cached and will continue to be transmitted even

when the flow rate falls to zero.

• Forward/reverse flow measurement (F/R mode) is possible.

• All pulse and frequency outputs can also be used as a status output / limit switch.

max

≤ 32 VDC;

ext

=24VDC;

nom

≤ 12 kHz)

ELECTRICAL CONNECTIONS

≤ 12 kHz);

max

≤ 12 kHz);

max

);

100%

) or

100%

4

INFORMATION!

For further information refer to Description of the inputs and outputs on page 38

Technical data on page 119

.

and refer to

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

33

Page 34

4

ELECTRICAL CONNECTIONS

4.8.3 Status output and limit switch

INFORMATION!

Depending on the version, the status outputs and limit switches must be connected passively or

actively or according to NAMUR EN 60947-5-6! Which I/O version and inputs/outputs are

installed in your signal converter are indicated on the sticker in the cover of the terminal

compartment.

For Modular I/Os, the status output at terminal D must be configured to active/passive/NAMUR

before connecting it.

• The status outputs / limit switches are electrically isolated from each other and from all

other circuits.

• The output stages of the status outputs / limit switches during simple active or passive

operation behave like relay contacts and can be connected with any polarity.

• All operating data and functions can be adjusted.

• Passive mode:

External power supply required: U

• Active mode:

Use of the internal power supply: U

• NAMUR mode:

Passive in accordance with EN 60947-5-6

≤ 32 VDC at I ≤ 100 mA

ext

=24VDC at I≤ 20 mA

nom

MFC 400

INFORMATION!

For further information refer to Description of the inputs and outputs on page 38

Technical data on page 119

.

and refer to

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

34

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 35

MFC 400

4.8.4 Control input

INFORMATION!

Depending on the version, the control inputs must be connected passively or actively or

according to NAMUR EN 60947-5-6! Which I/O version and inputs/outputs are installed in your

signal converter are indicated on the sticker in the cover of the terminal compartment.

• All control inputs are electrically isolated from each other and from all other circuits.

• All operating data and functions can be adjusted.

• Passive mode:

External power supply required: U

• Active mode:

Use of the internal power supply: U

• NAMUR mode:

In accordance with EN 60947-5-6

Active control input to NAMUR EN 60947-5-6: signal converter monitors cable breaks and

short circuits according to EN 60947-5-6. Errors indicated on LC display. Error messages

possible via status output.

≤ 32 VDC

ext

nom

ELECTRICAL CONNECTIONS

=24VDC

4

INFORMATION!

For further information refer to Description of the inputs and outputs on page 38

Technical data on page 119

.

and refer to

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

35

Page 36

4

ELECTRICAL CONNECTIONS

4.9 Electrical connection of the inputs and outputs

CAUTION!

I/O connections must not be connected to DC power supply networks.

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

4.9.1 Field housing, electrical connection of the inputs and outputs

DANGER!

All work on the electrical connections may only be carried out with the power disconnected.

Take note of the voltage data on the nameplate!

INFORMATION!

For frequencies above 100 Hz, shielded cables are to be used in order to reduce effects from

electrical interferences (EMC).

MFC 400

36

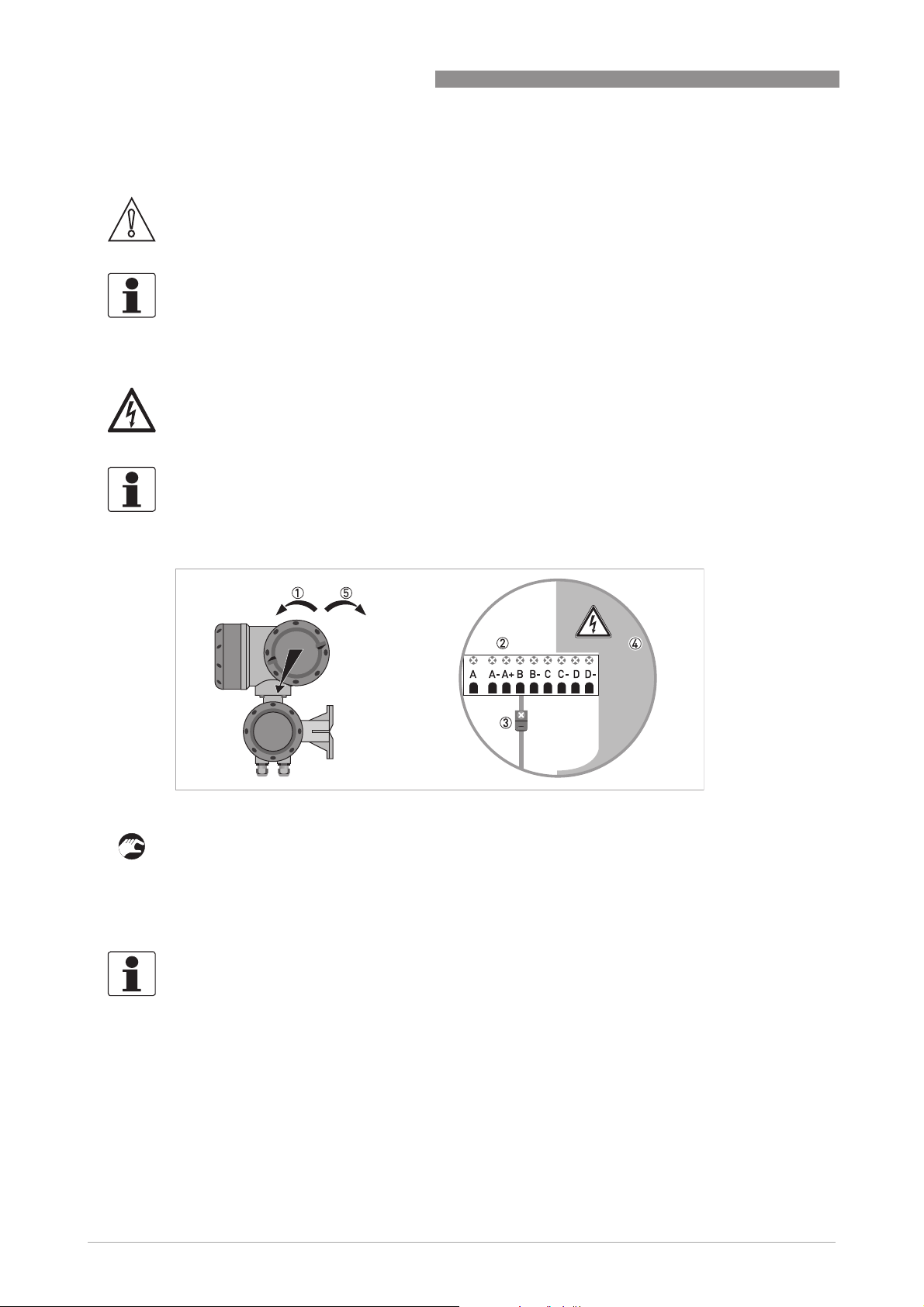

Figure 4-5: Terminal compartment for inputs and outputs in field housing

1 Open the housing cover.

2 Push the prepared cable through the cable entry and connect the necessary conductors.

3 Connect the shield if necessary.

4 Close the touch guard.

5 Close the housing cover.

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 37

MFC 400

4.9.2 Laying electrical cables correctly

Figure 4-6: Protect housing from dust and water

1 Lay the cable in a loop just before the housing.

2 Tighten the screw connection of the cable entry securely.

3 Never mount the housing with the cable entries facing upwards.

4 Seal cable entries that are not needed with a plug.

ELECTRICAL CONNECTIONS

4

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

37

Page 38

4

ELECTRICAL CONNECTIONS

4.10 Description of the inputs and outputs

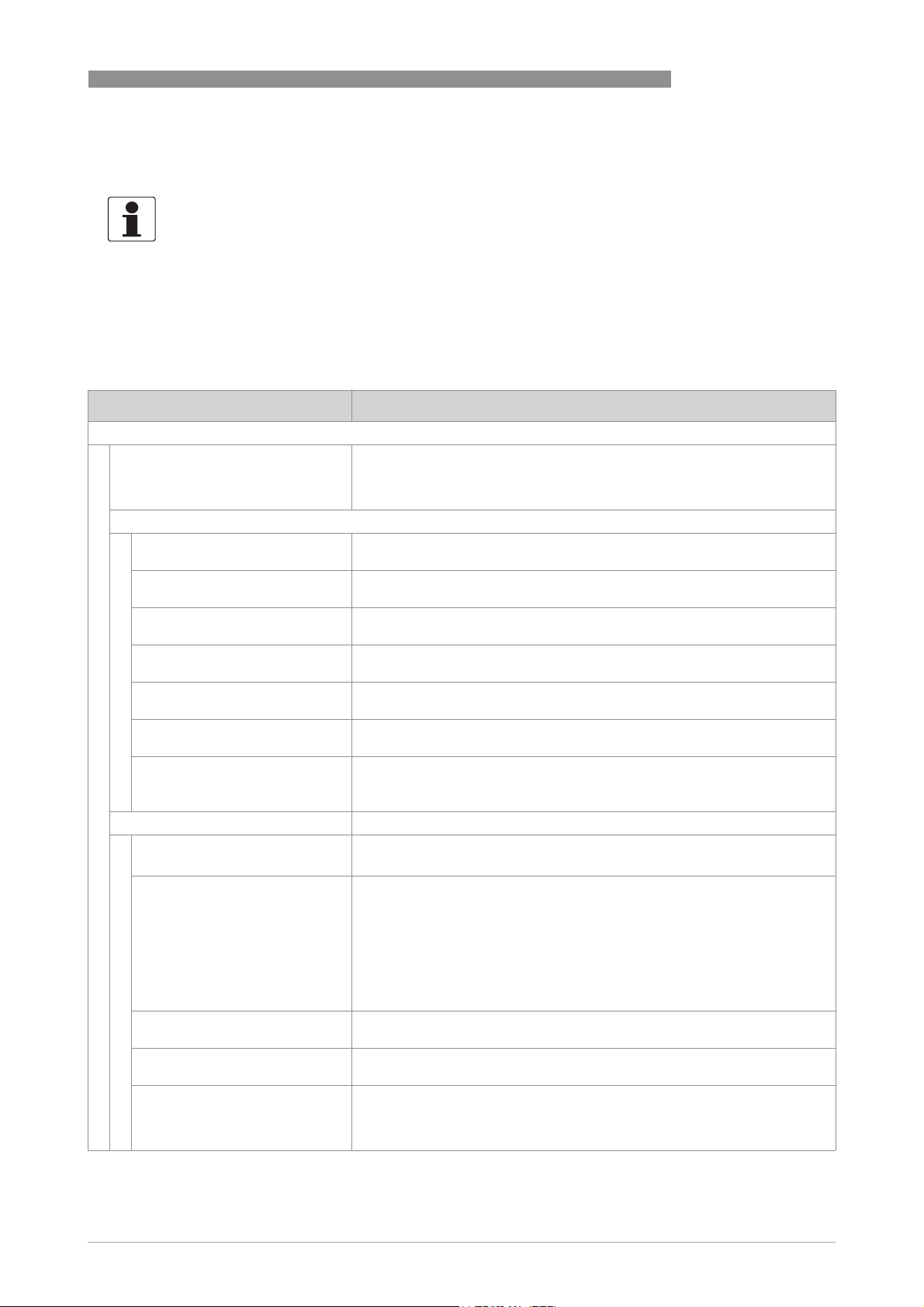

4.10.1 Important notes

INFORMATION!

Depending on the version, the inputs/outputs must be connected passively or actively or

according to NAMUR EN 60947-5-6! Which I/O version and inputs/outputs are installed in your

signal converter are indicated on the sticker in the cover of the terminal compartment.

• All groups are electrically isolated from each other and from all other input and output

circuits.

• Passive mode: An external power supply is necessary to operate (activation) the subsequent

devices (U

• Active mode: The signal converter supplies the power for operation (activation) of the

subsequent devices, observe max. operating data.

• Terminals that are not used should not have any conductive connection to other electrically

conductive parts.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

ext

).

MFC 400

I

I

a

P

a

P

N

S

a

S

N

C

a

C

N

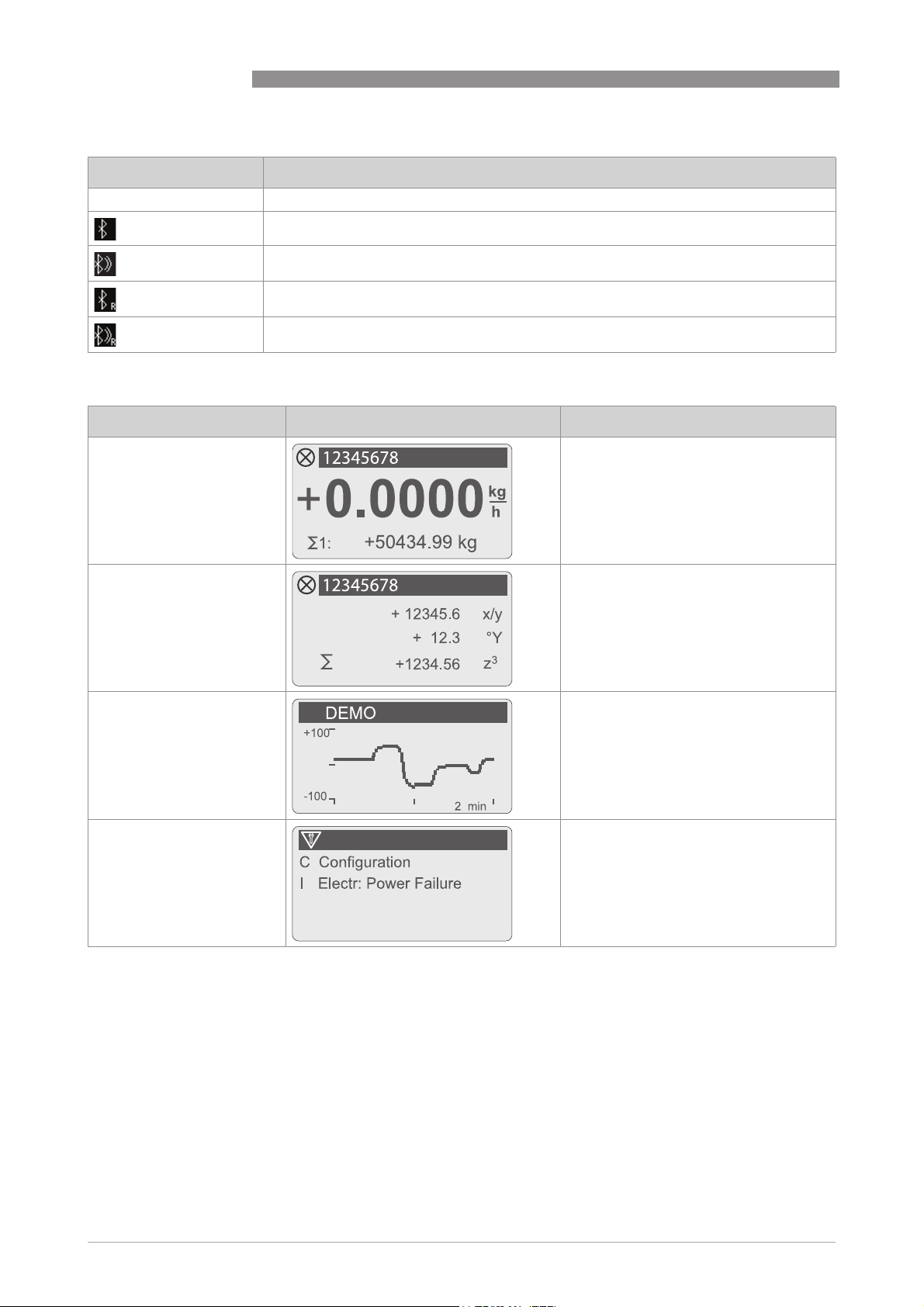

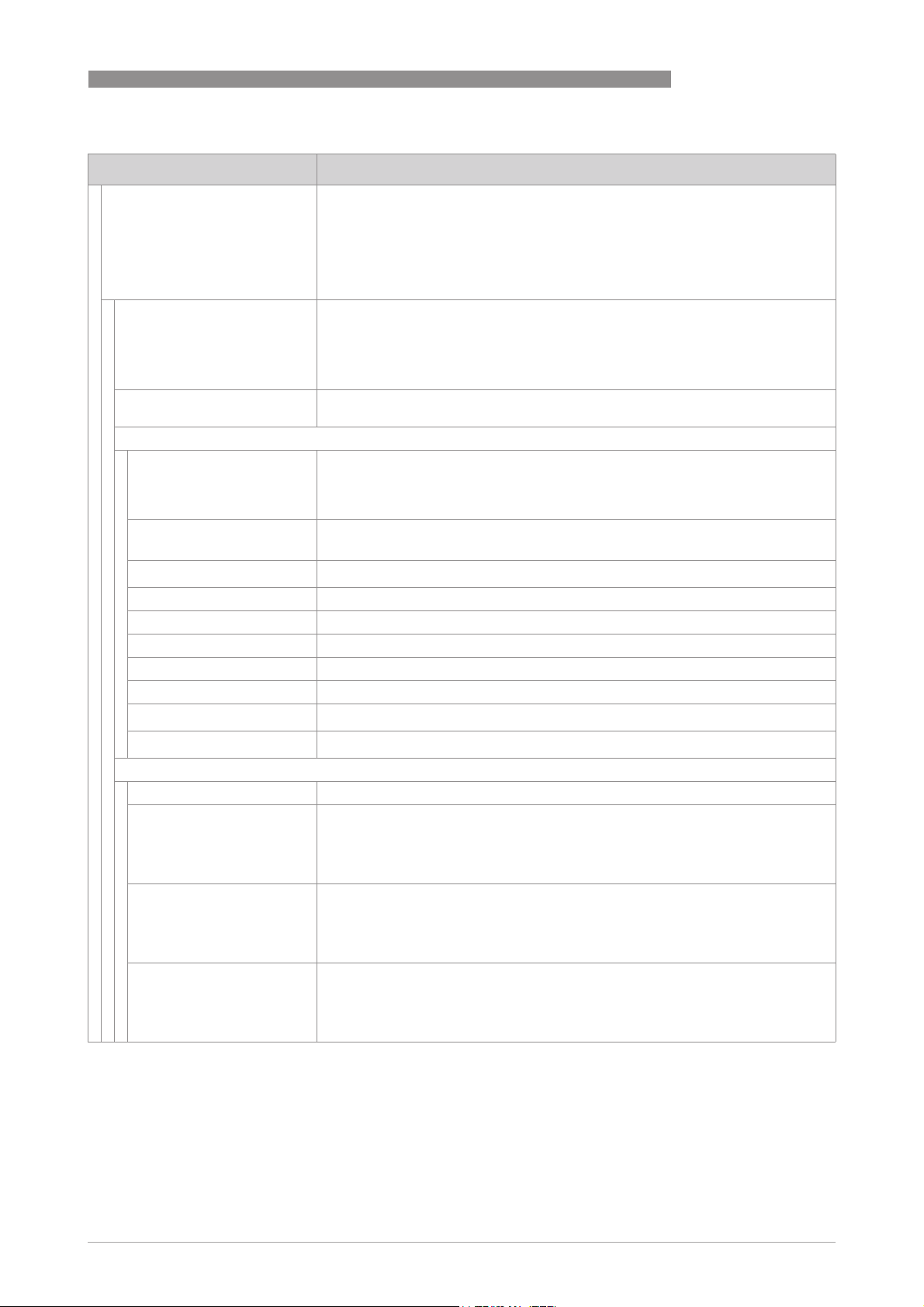

Table 4-6: Description of used abbreviations

Current output active or passive

p

P

Pulse/frequency output active or passive

p

Pulse/frequency output passive according to NAMUR EN 60947-5-6

S

Status output/limit switch active or passive

p

Status output/limit switch passive according to NAMUR EN 60947-5-6

C

Control input active or passive

p

Control input active according to NAMUR EN 60947-5-6:

Signal converter monitors cable breaks and short circuits according to EN 60947-5-6.

Errors indicated on LC display. Error messages possible via status output.

38

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 39

MFC 400

4.10.2 Description of the electrical symbols

mA meter

0...20 mA or 4...20 mA and other

RL is the internal resistance of the measuring point including the cable

resistance

DC voltage source (U

ELECTRICAL CONNECTIONS

), external power supply, any connection polarity

ext

4

DC voltage source (U

connection diagrams

Internal DC voltage source

Controlled internal power source in the device

Electronic or electromagnetic counter

At frequencies above 100 Hz, shielded cables must be used to connect the

counters.

Ri Internal resistance of the counter

Button, N/O contact or similar

Table 4-7: Description of the electrical symbols

), observe connection polarity according to

ext

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

39

Page 40

4

ELECTRICAL CONNECTIONS

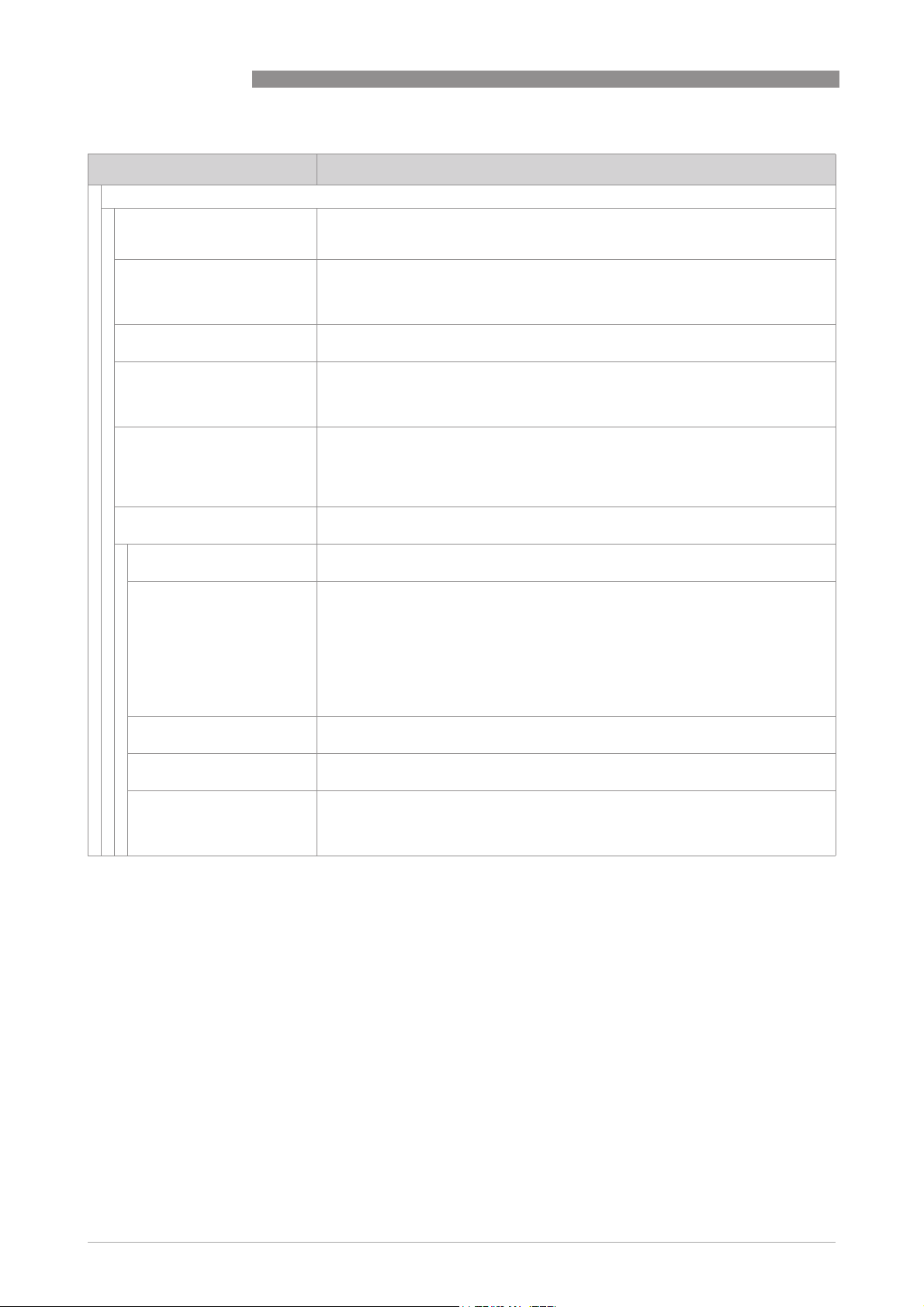

4.10.3 Modular inputs/outputs and bus systems

CAUTION!

•

Observe connection polarity.

•

Configure the outputs at terminal C and D before connecting them.

INFORMATION!

•

For further information refer to Description of the inputs and outputs on page 32

The electrical connection of the bus systems are described in the supplementary instructions

•

of the respective bus system.

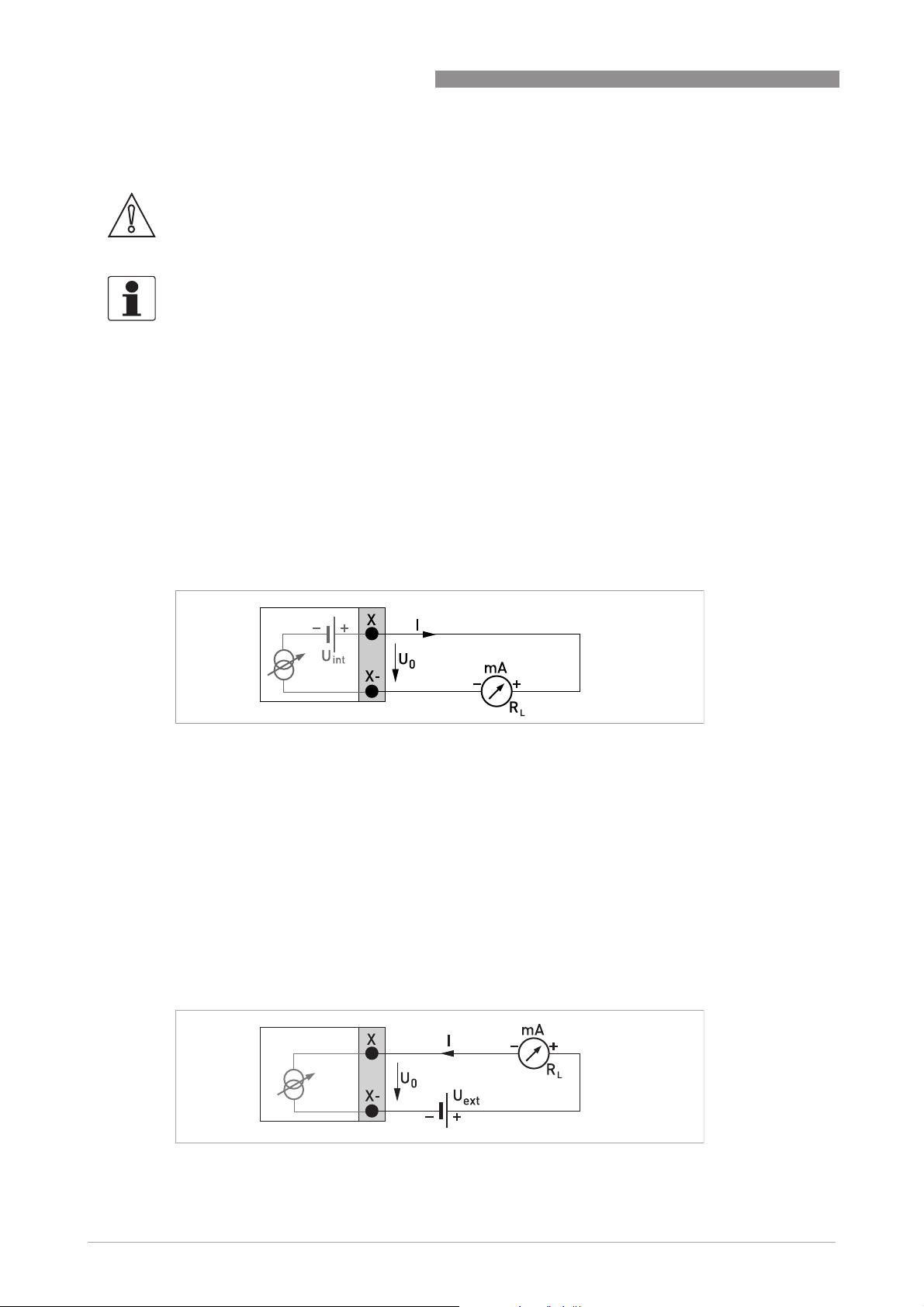

Current output active (only current output terminals C/C- have HART® capability),

modular I/Os

• U

int, nom

• I ≤ 22 mA

• R

L

• X designates the connection terminals A, B or C, depending on the version of the signal

converter.

=24VDC

≤ 1kΩ

MFC 400

.

Figure 4-7: Current output active I

a

Current output passive (only current output terminals C/C- have HART® capability),

modular I/Os

• U

• I ≤ 22 mA

• U

• R

• X designates the connection terminals A, B or C, depending on the version of the signal

Figure 4-8: Current output passive I

≤ 30 VDC

ext

≥ 1.8 V

0

≤ (U

L

ext-U0

converter.

)/I

max

p

40

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 41

MFC 400

ELECTRICAL CONNECTIONS

INFORMATION!

•

Compact and field housing versions:

Compact and field housing versions: Shield connected via the cable terminals in the terminal

Compact and field housing versions:Compact and field housing versions:

compartment.

•

Any connection polarity.

Pulse/frequency output active, modular I/Os

• U

• f

• f

• If the following maximum load impedance R

• The minimum load impedance R

• X designates the connection terminals A, B or D, depending on the version of the signal

=24VDC

nom

in the operating menu set to f

max

max

≤ 100 Hz:

I ≤ 20 mA

open:

I ≤ 0.05 mA

closed:

U

max

=24V at I=20mA

0, nom

in operating menu set to 100 Hz < f

max

≤ 10 kHz:

I ≤ 20 mA

open:

I ≤ 0.05 mA

closed:

U

U

U

= 22.5 V at I = 1 mA

0, nom

= 21.5 V at I = 10 mA

0, nom

=19V at I=20mA

0, nom

L, max

be reduced accordingly by parallel connection of R:

f ≤ 100 Hz: R

f ≤ 1kHz: R

L, max

f ≤ 10 kHz: R

R

L, min=U0/Imax

L, max

L, max

=47kΩ

=10kΩ

=1kΩ

is calculated as follows:

L, min

converter.

is exceeded, the load impedance RL must

4

Figure 4-9: Pulse/frequency output active P

a

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

41

Page 42

4

ELECTRICAL CONNECTIONS

Pulse/frequency output passive, modular I/Os

• U

• f

• f

• If the following maximum load impedance R

• The minimum load impedance R

• Can also be set as status output. For the electrical connection refer to status output

• X designates the connection terminals A, B or D, depending on the version of the signal

≤ 32 VDC

ext

in the operating menu set to f

max

I ≤ 100 mA

open:

I ≤ 0.05 mA at U

=32VDC

ext

closed:

U

U

=0.2V at I≤ 10 mA

0, max

=2V at I≤ 100 mA

0, max

in operating menu set to 100 Hz < f

max

open:

I ≤ 0.05 mA at U

=32VDC

ext

closed:

U

U

U

=1.5V at I≤ 1mA

0, max

=2.5V at I≤ 10 mA

0, max

=5V at I≤ 20 mA

0, max

be reduced accordingly by parallel connection of R:

f ≤ 100 Hz: R

f ≤ 1kHz: R

f ≤ 10 kHz: R

R

L, min

=(U

L, max

ext-U0

L, max

L, max

=47kΩ

=10kΩ

=1kΩ

)/I

max

connection diagram.

converter.

≤ 100 Hz:

max

≤ 10 kHz:

max

is exceeded, the load impedance RL must

L, max

is calculated as follows:

L, min

MFC 400

42

Figure 4-10: Pulse/frequency output passive P

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

p

Page 43

MFC 400

ELECTRICAL CONNECTIONS

INFORMATION!

•

Compact and field housing versions:

Compact and field housing versions: Shield connected via the cable terminals in the terminal

Compact and field housing versions:Compact and field housing versions:

compartment.

•

Any connection polarity.

Pulse/frequency output passive PN NAMUR, modular I/O

• Connection acc. to EN 60947-5-6.

=8.2V ± 0.1 VDC

U

ext

R = 1 kΩ ± 10 Ω

• open:

=0.6mA

I

nom

closed:

=3.8mA

I

nom

• X designates the connection terminals A, B or D, depending on the version of the signal

converter.

4

Figure 4-11: Pulse/frequency output passive PN according to NAMUR EN 60947-5-6

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

43

Page 44

4

ELECTRICAL CONNECTIONS

Status output / limit switch active, modular I/Os

• Observe connection polarity.

• U

• I ≤ 20 mA

• R

• open:

• X designates the connection terminals A, B or D, depending on the version of the signal

=24VDC

int

≤ 47 kΩ

L

I ≤ 0.05 mA

closed:

U

=24V at I=20mA

0, nom

converter.

MFC 400

Figure 4-12: Status output / limit switch active S

a

Status output / limit switch passive, modular I/Os

• Any connection polarity.

• U

• I ≤ 100 mA

• R

• open:

• The output is open when the device is de-energised.

• X designates the connection terminals A, B or D, depending on the version of the signal

=32VDC

ext

=47kΩ

L, max

L, min

=(U

ext-U0

R

I ≤ 0.05 mA at U

closed:

U

U

=0.2V at I≤ 10 mA

0, max

=2V at I≤ 100 mA

0, max

converter.

)/I

=32VDC

ext

max

44

Figure 4-13: Status output / limit switch passive S

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

p

Page 45

MFC 400

ELECTRICAL CONNECTIONS

Status output / limit switch SN NAMUR, modular I/Os

• Any connection polarity.

• Connection acc. to EN 60947-5-6.

=8.2V ± 0.1 VDC

U

ext

R = 1 kΩ ± 10 Ω

• open:

=0.6mA

I

nom

closed:

=3.8mA

I

nom

• The output is open when the device is de-energised.

• X designates the connection terminals A, B or D, depending on the version of the signal

converter.

4

Figure 4-14: Status output / limit switch SN according to NAMUR EN 60947-5-6

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

45

Page 46

4

ELECTRICAL CONNECTIONS

CAUTION!

Observe connection polarity.

Control input active, modular I/Os

• U

• External contact open:

• Switching point for identifying "contact open or closed":

• X designates the connection terminals A or B, depending on the version of the signal

=24VDC

int

0, nom

=22V

U

External contact closed:

=4mA

I

nom

Contact closed (on): U

Contact open (off): U

0

≥ 12 V at I

0

converter.

≤ 10 V at I

nom

nom

MFC 400

=1.9mA

=1.9mA

Figure 4-15: Control input active C

1 Signal

a

Control input passive, modular I/Os

• 3V≤ U

• I

max

I

max

• Switching point for identifying "contact open or closed":

Contact open (off): U

Contact closed (on): U

• X designates the connection terminals A or B, depending on the version of the signal

converter.

≤ 32 VDC

ext

=9.5mA at U

=9.5mA at U

≤ 24 V

ext

≤ 32 V

ext

≤ 2.5 V at I

0

0

≥ 3V at I

nom

nom

=1.9mA

=1.9mA

46

Figure 4-16: Control input passive C

1 Signal

p

www.krohne.com 01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

Page 47

MFC 400

ELECTRICAL CONNECTIONS

CAUTION!

Observe connection polarity.

Control input active CN NAMUR, modular I/Os

• Connection acc. to EN 60947-5-6:

• Switching point for identifying "contact open or closed":

Contact open (off): U

Contact closed (on): U

0, nom

0, nom

=6.3V at I

=6.3V at I

• Detection of cable break:

≥ 8.1 V at I ≤ 0.1 mA

U

0

• Detection of cable short circuit:

≤ 1.2 V at I ≥ 6.7 mA

U

0

• X designates the connection terminals A or B, depending on the version of the signal

converter.

nom

nom

<1.9mA

>1.9mA

4

Figure 4-17: Control input active CN according to NAMUR EN 60947-5-6

www.krohne.com01/2021 - 4002075808 - MA MFC400 ER2.1 R08 en

47

Page 48

4

ELECTRICAL CONNECTIONS

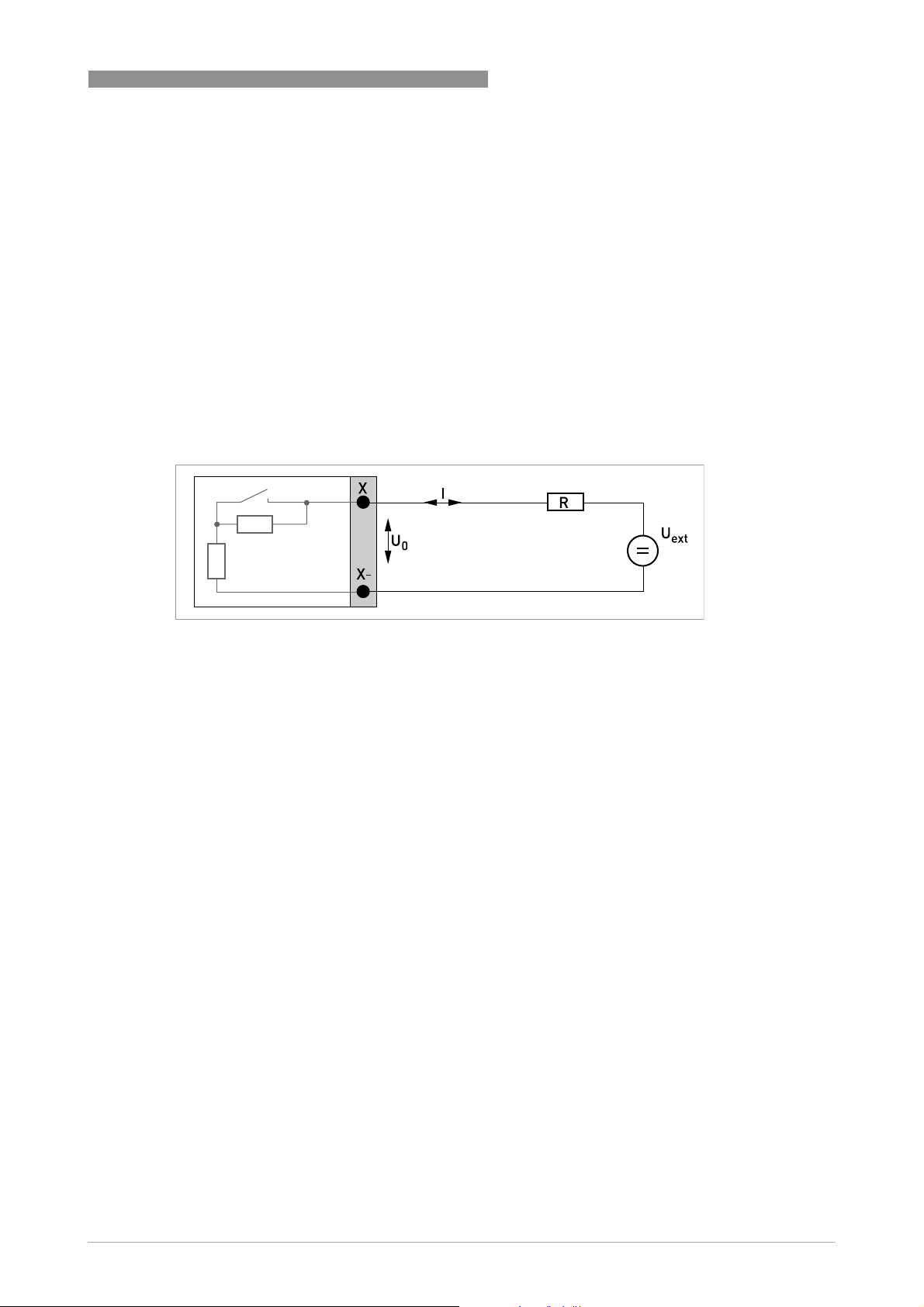

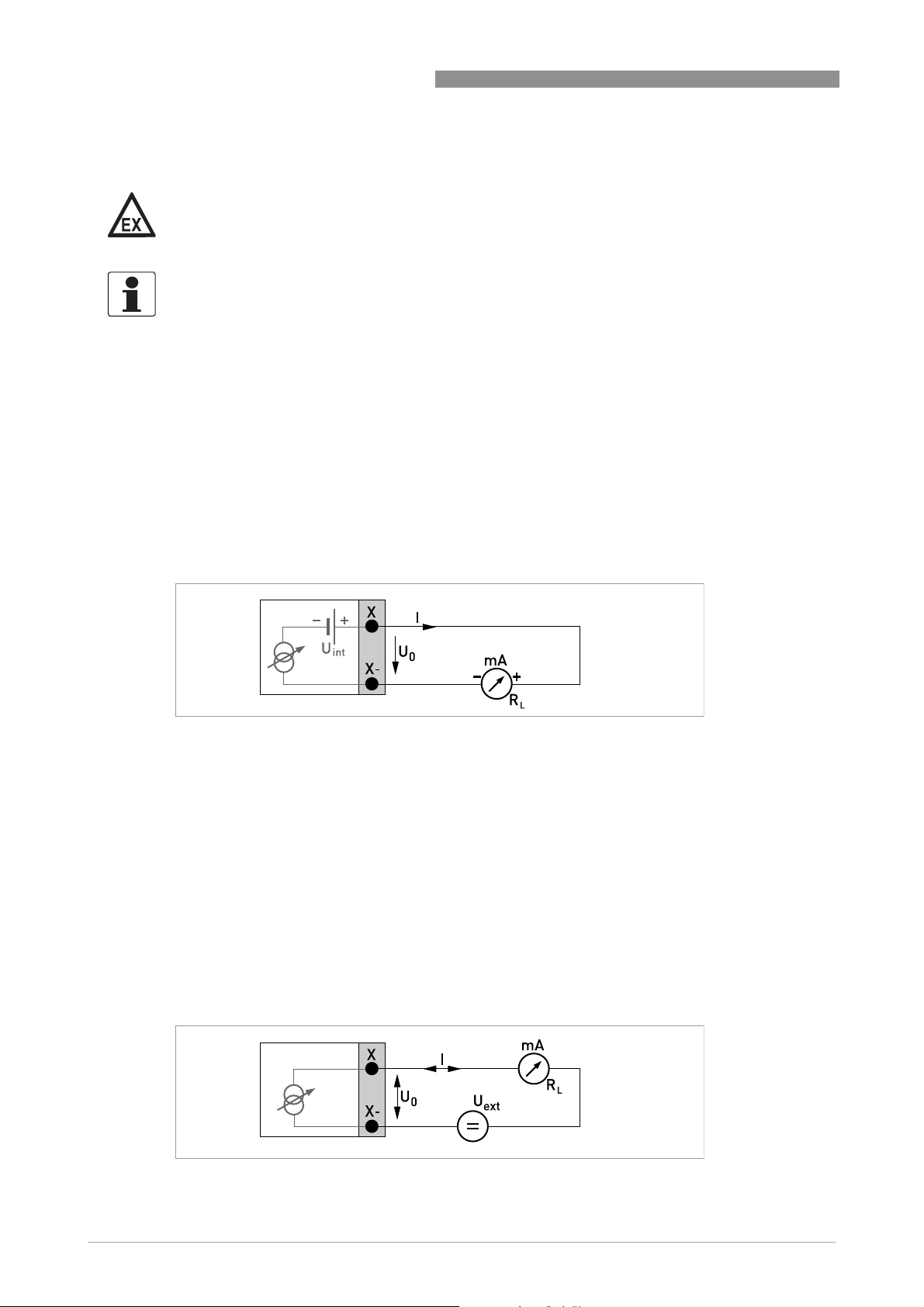

4.10.4 Ex i inputs/outputs

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

INFORMATION!

For further information refer to Description of the inputs and outputs on page 32

Current output active (only current output terminals C/C- have HART® capability), Ex i

I/Os

• Observe connection polarity.

• U

int, nom

• I ≤ 22 mA

• R

L

• X designates the connection terminals A or C, depending on the version of the signal

converter.

=21VDC

≤ 400 Ω

MFC 400

.

Figure 4-18: Current output active Ia Ex i

Current output passive (only current output terminals C/C- have HART® capability),

Ex i I/Os

• Any connection polarity.

• U

• I ≤ 22 mA

• U

• R

• X designates the connection terminals A or C, depending on the version of the signal

Figure 4-19: Current output passive Ip Ex i

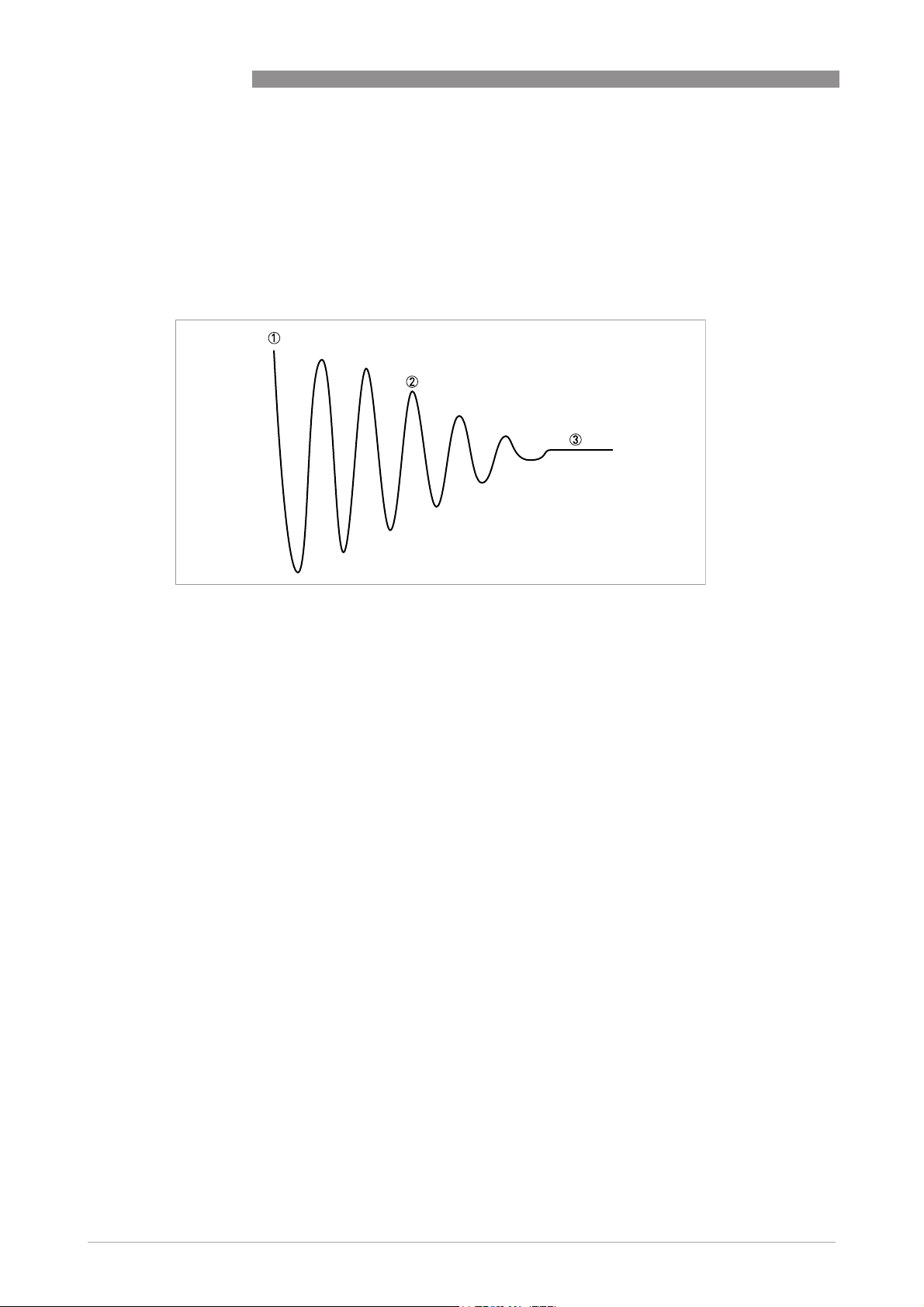

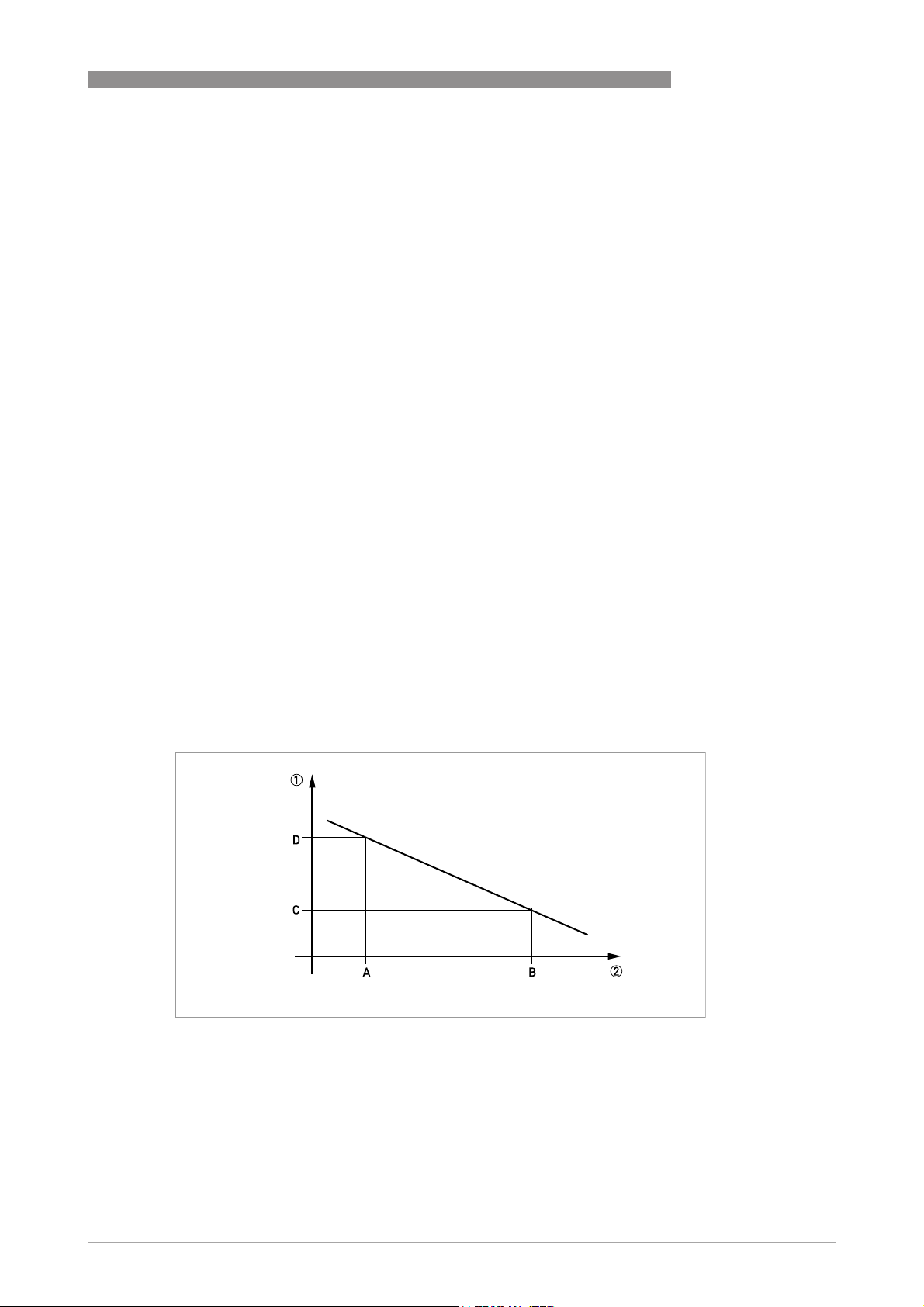

≤ 30 VDC