Page 1

Supplementary instructions

Supplementary instructions

MFC 400

MFC 400

MFC 400MFC 400

Supplementary instructions Supplementary instructions

Signal converter for mass flowmeters

Description of PROFIBUS interface

Description of PROFIBUS interface

Description of PROFIBUS interfaceDescription of PROFIBUS interface

PROFIBUS PA:

PROFIBUS PA:

PROFIBUS PA:PROFIBUS PA:

PROFIBUS device with MBP Physical Interface and PA Profile 3.02 (V1.0.3_ / 130603)

PROFIBUS DP:

PROFIBUS DP:

PROFIBUS DP:PROFIBUS DP:

PROFIBUS device with RS485 Physical Interface and PA Profile 3.02 (V1.0.3_ / 130603)

The documentation is only complete when used in combination with the relevant

documentation for the .

© KROHNE 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 2

CONTENTS

MFC 400

1 Safety instructions 4

1.1 Scope of the document..................................................................................................... 4

1.2 Scope of delivery............................................................................................................... 4

1.3 Special notes .................................................................................................................... 4

2 PROFIBUS DP 5

2.1 Software history ............................................................................................................... 5

2.2 System configuration of PROFIBUS DP network............................................................. 5

2.3 Electrical connection for DP signal converter................................................................. 6

2.4 Technical data................................................................................................................... 8

2.5 PROFIBUS PA Profile implementation ............................................................................ 9

2.6 GSD files ........................................................................................................................... 9

2.7 Ident. Number selector .................................................................................................. 10

2.8 Summary ........................................................................................................................ 13

2.9 Baud rate ........................................................................................................................ 14

3 PROFIBUS PA 15

3.1 Software history ............................................................................................................. 15

3.2 System configuration of PROFIBUS PA network ........................................................... 16

3.3 Electrical connection for PA signal converter ............................................................... 17

3.4 Technical data................................................................................................................. 18

3.5 PROFIBUS PA Profile implementation .......................................................................... 19

3.6 GSD files ......................................................................................................................... 19

3.7 Ident. Number selector .................................................................................................. 20

3.8 Summary ........................................................................................................................ 23

4 Commissioning / Operation 24

4.1 Configuration of cyclic data transfer.............................................................................. 24

4.2 Cyclic data....................................................................................................................... 24

4.2.1 Input data .............................................................................................................................. 24

4.2.2 Output data............................................................................................................................ 30

4.3 Diagnosis ........................................................................................................................ 31

4.3.1 Mapping of DIAGNOSIS_EXTENSION bits into DIAGNOSIS bits if "Condensed Status and Di-

agnosis" handling selected ............................................................................................................ 37

4.3.2 Mapping of DIAGNOSIS_EXTENSION bits into DIAGNOSIS bits if "Classic Status and Diagno-

sis" handling selected .................................................................................................................... 40

4.3.3 Variable "Event groups"........................................................................................................ 42

4.3.4 Filtering of "Single events"................................................................................................... 45

2

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 3

MFC 400

CONTENTS

5 Profibus settings 46

5.1 Menu A, Quick Setup ...................................................................................................... 46

5.2 Menu B, Test................................................................................................................... 46

5.3 Menu C, Setup................................................................................................................. 47

5.4 Menu D, Service.............................................................................................................. 51

5.5 Status messages and diagnostic information................................................................ 52

6 Notes 54

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

3

Page 4

1 SAFETY INSTRUCTIONS

1.1 Scope of the document

These instructions are supplementary to the signal converter Handbook. For all other data, use

the relevant chapters of the Handbook. If you do not have this document, please contact the

nearest office or download them from the manufacturer's internet site.

INFORMATION!

The information in this chapter only contains the data applicable to PROFIBUS communication.

The technical data in the Handbook shall be valid in its current version, provided that it is not

rendered invalid or replaced by this supplement.

1.2 Scope of delivery

The information in this chapter only contains the data applicable to PROFIBUS communication.

The technical data in the Handbook shall be valid in its current version, provided that it is not

rendered invalid or replaced by this supplement.

A device for PROFIBUS communication is supplied with:

MFC 400

• Supplementary instructions for PROFIBUS communication

• PROFIBUS device data files (GSD) which can be also downloaded from the manufacturer's

internet site

1.3 Special notes

Don't switch off (power off) the signal converter immediately after manual change of parameter

values:

• Please wait approx. 10 seconds before you switch off the signal converter after you have done

both a parameter download via PROFIBUS or a manual change of a parameter value via the

local display.

CAUTION!

Please wait approx. 15 seconds before you switch off the signal converter after you have carried

out a "Factory Reset" (PROFIBUS "Coldstart") via PROFIBUS or local display.

"Deactivation of the Service Parameter Lock" of the signal converter via PROFIBUS:

• After writing down the service password (via PROFIBUS) the "Deactivation of the Service

Parameter Lock" will last at least 20 minutes if the internal password timer of the signal

converter won't be retriggered by writing this password again. The "Deactivation of the

Service Parameter Lock" will be terminated at once by a PROFIBUS Coldstart / Warmstart or

if the internal password timer of the signal converter elapsed.

4

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 5

MFC 400

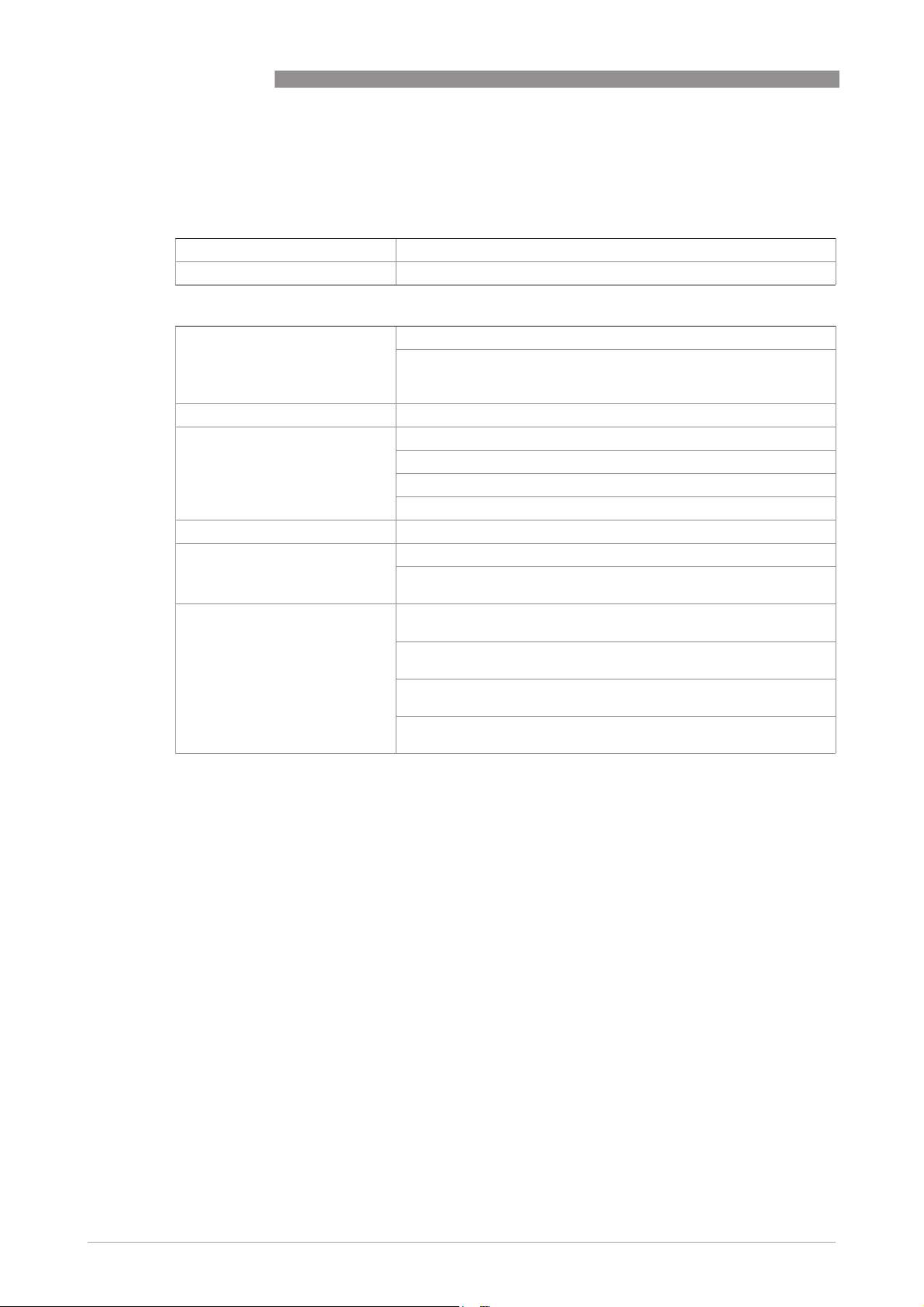

2.1 Software history

Issued Signal converter Application program System integration

PROFIBUS DP 2

Mth./

Hardware Firmware Hardware Software Driver Version Model name

year

06/13 Signal

converter

with

RS485

interface +

PA Profile

3.02

V1.0.3_ /

130603

Simatic

PCS7

other SPS

of other

manufact.

Laptop / PC PDM

HW Config

other

Software of

other SPS

manufact.

(≥ 6.0 SP5)DD(Ident.-No.)

Pactware DTM ≥ - -

GSD

manuf.

specific

GSD

profile

specific

The PROFIBUS DP device has a RS485 interface to connect the device to a PROFIBUS DP

network.

The software supports the PROFIBUS PA Profile 3.02. Both, cyclic services towards a control

system (e.g. PLC) as well as acyclic services for operating with engineering tools (e.g. DD/DTM

based tools) are supported.

The PROFIBUS station address can be set via PROFIBUS services or via the device display.

2.2 System configuration of PROFIBUS DP network

KR014512.GSD MFC400

(RS485)

Rev.1

PA039742.GSD Flow, dens,

temp with

3AI, 1TOT

(PhyL 0)

- -

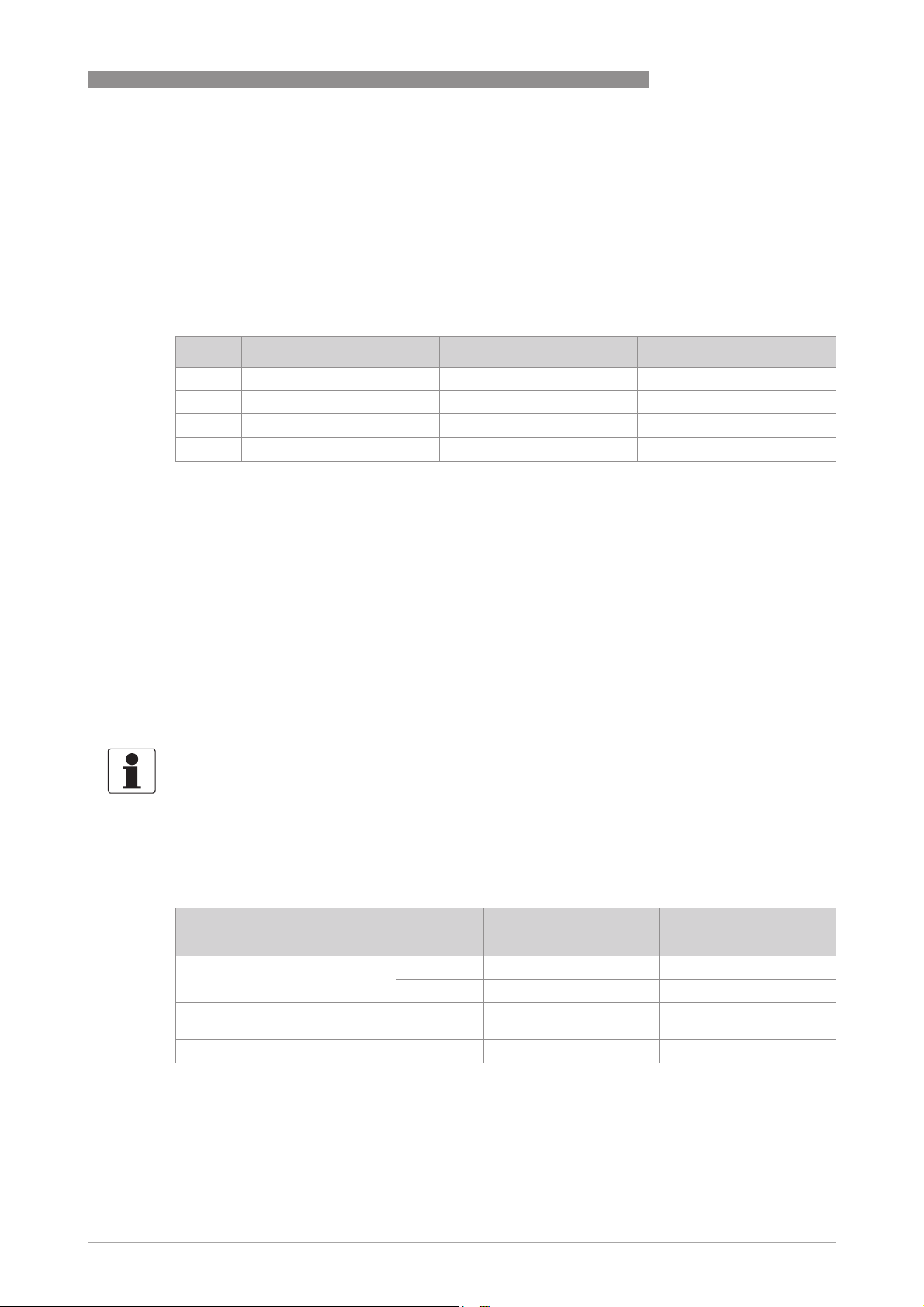

The following diagram shows a typical network configuration with PROFIBUS devices with RS485

interface in a non-hazardous environment. The PROFIBUS devices with RS485 interface do not

need any segment coupler. They are connected directly to the PROFIBUS DP network.

Figure 2-1: PROFIBUS DP network

1 SPS

2 PROFIBUS DP with max. 12 Mbit/s

3 Signal converter

4 Other devices with PROFIBUS RS485 interface

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

5

Page 6

2 PROFIBUS DP

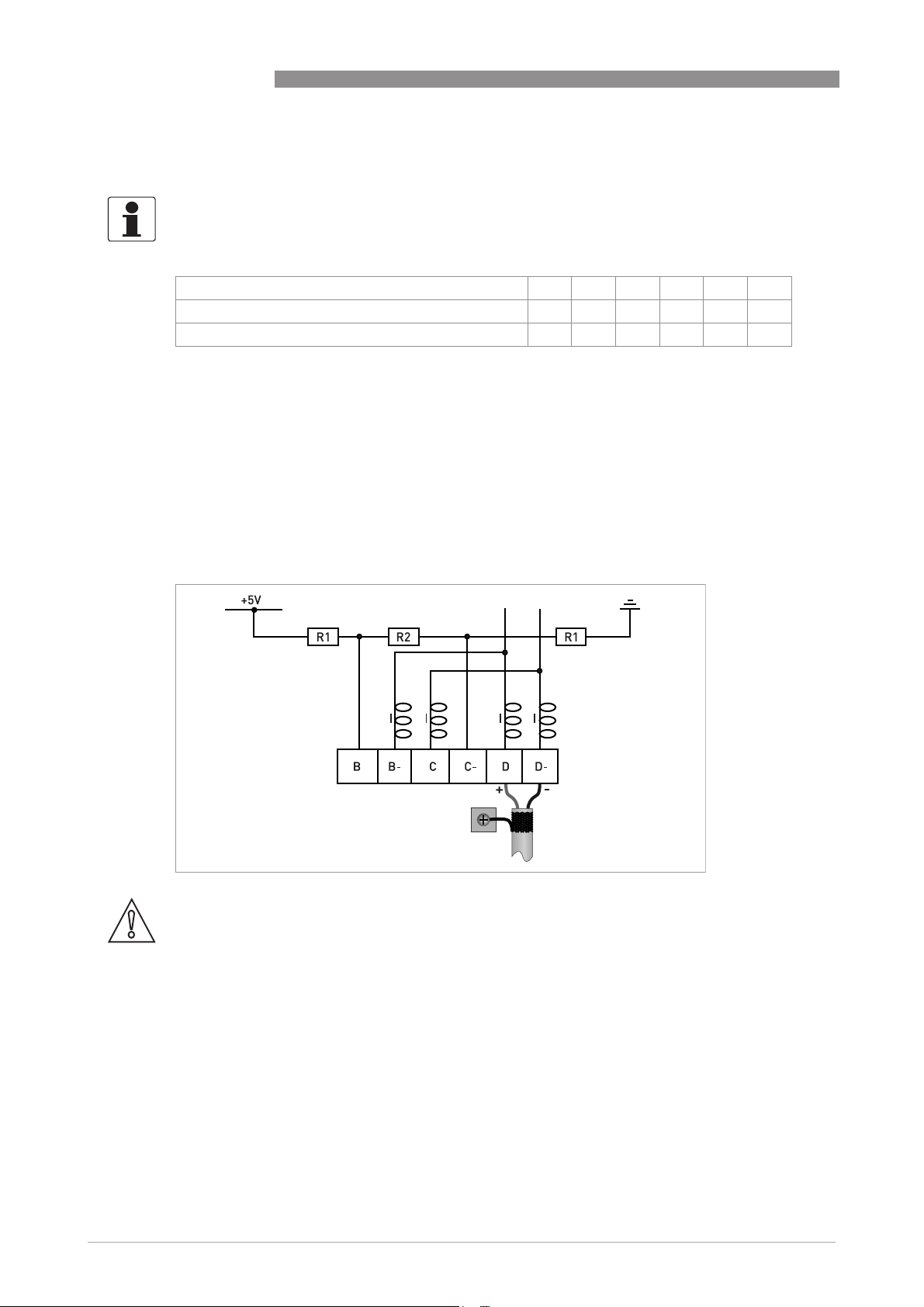

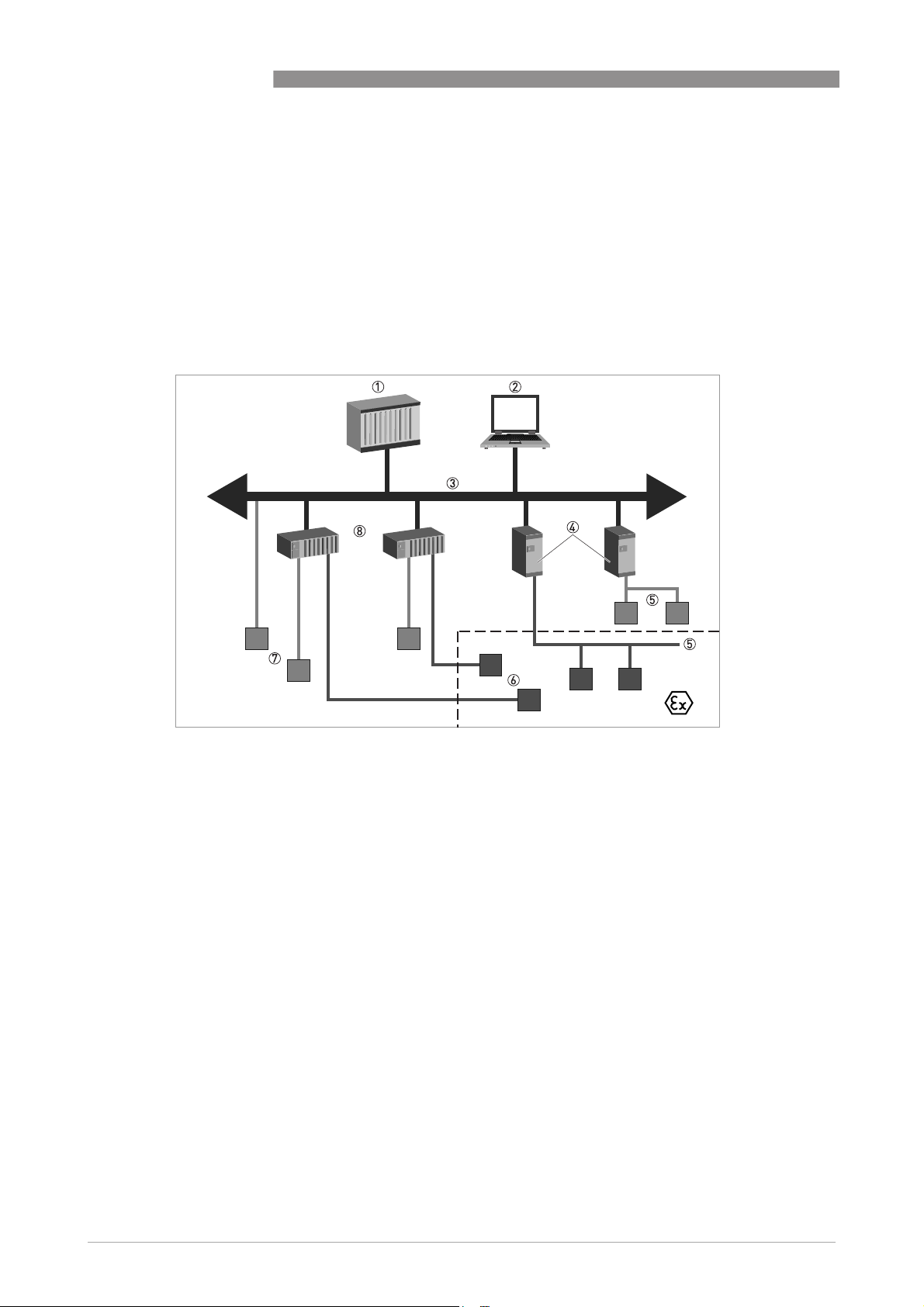

2.3 Electrical connection for DP signal converter

INFORMATION!

For a detailed description of the electrical connections please refer to the standard signal

converter handbook.

Signal converter terminals B B- C C- D D-

PROFIBUS designation T +B -A -T +B -A

1 2 3 4 5 6

1 Termination positive

2 TxD+/RxD+ second connection

3 TxD-/RxD- second connection

4 Termination negative

5 TxD+/RxD+ first connection

6 TxD-/RxD- first connection

MFC 400

External connection with spur

CAUTION!

Spurs are not allowed at high data rates!

I = 110 nH

R1 = 390 Ω

R2 = 220 Ω

6

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 7

MFC 400

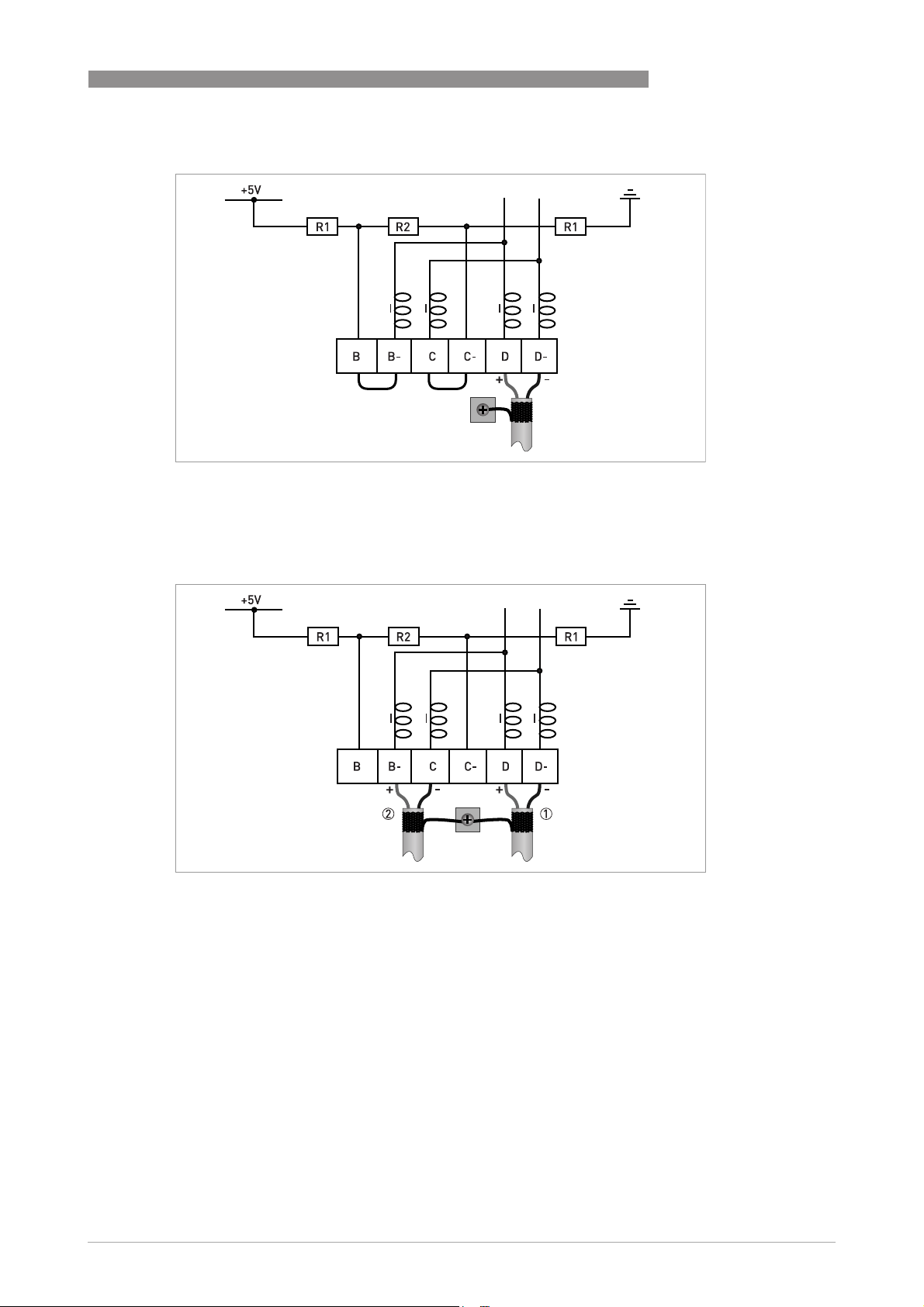

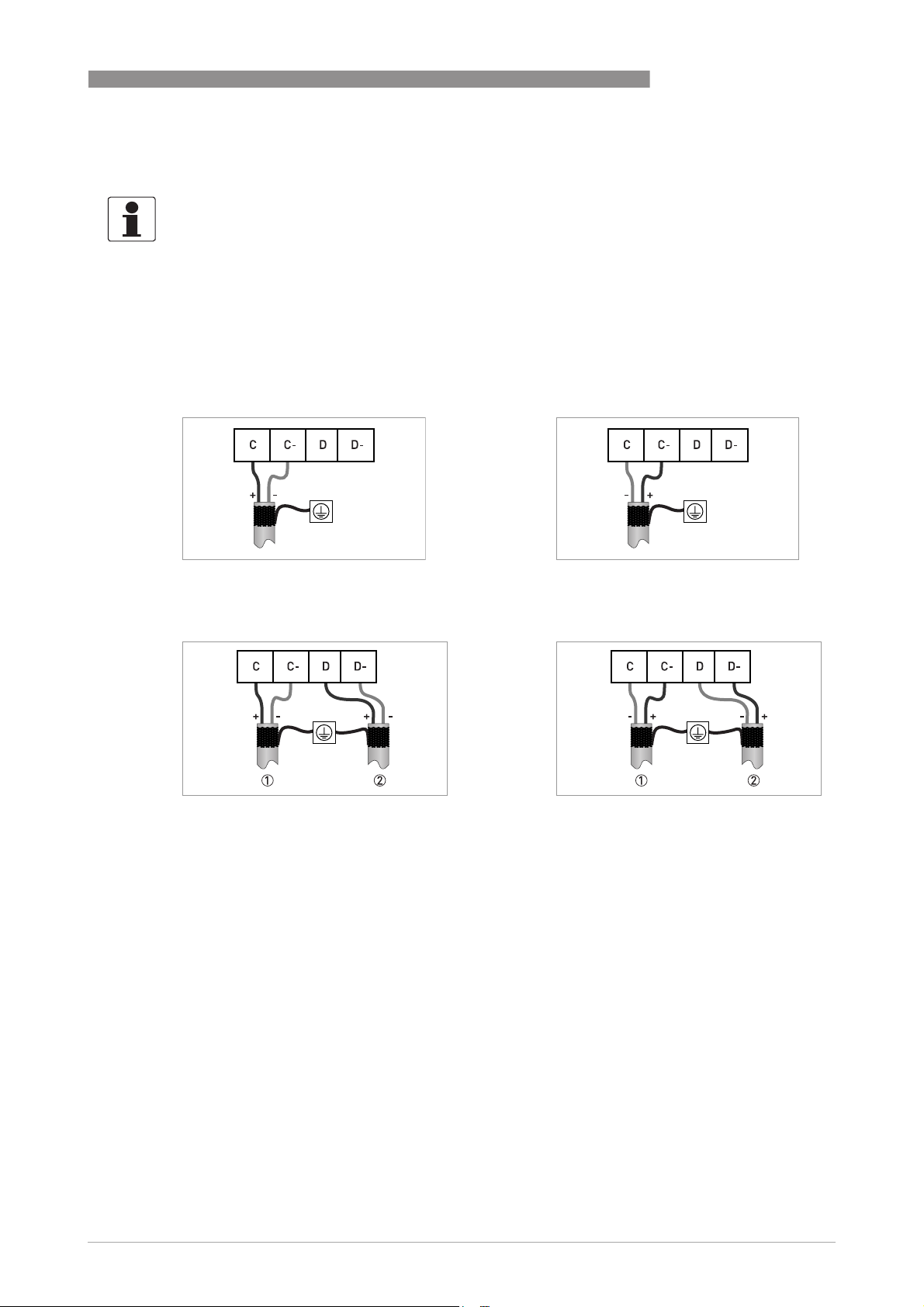

PROFIBUS DP 2

External connection at last device with active internal bus termination

I = 110 nH

R1 = 390 Ω

R2 = 220 Ω

External connection to a trunk

1 e.g. incoming data lines

2 e.g. outgoing data lines

I = 110 nH

R1 = 390 Ω

R2 = 220 Ω

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

7

Page 8

2 PROFIBUS DP

2.4 Technical data

Hardware

Type PROFIBUS RS485 interface according to IEC 61158-2

Connection Dependent of polarity; please note at electrical connection!

Software

GSD GSD file on CD-ROM or from internet site

Device profile PROFIBUS PA Profile 3.02; conformance class B, compact

Address range 0…126 (default 126)

Local control Local display and operator interface at device

SAPs 2 x MS1 SAPs – acyclic interface to PLC

Function blocks 1 x TB = Transducer Block: contains the parameters and functions

MFC 400

Supported GSD:

• KRO14512.GSD

• PA039742.GSD

0…125 via PROFIBUS service set_slave_add

0…126 via local display

126 via factory_reset = 2712

3 x MS2 SAPs – the number of MS2 Service Access Points is typically

equal to the maximum number of master class 2 tools

defined in PA Profile 3.02

1 x PB = Physical Block: contains the parameters defined in PA

Profile 3.02

8 x AI = Analog Input Blocks: contains the parameters defined in PA

Profile 3.02

3 x TOT = Totalizer Function Blocks: contains the parameters defined

in PA Profile 3.02

8

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 9

MFC 400

2.5 PROFIBUS PA Profile implementation

The PROFIBUS PA Profile 3.02 defines standardized parameters and functions for PROFIBUS

devices used for process control. It describes a PROFIBUS device as a function block application,

i.e. parameters and functions are grouped into different blocks. In the MFC 400 PROFIBUS

device the following blocks are implemented:

Block Usage

1 Physical Block (PB) contains identification and diagnosis parameters of the device

1 Flow Transducer Block

(TB)

8 Analog Input Function Block

(AI-FB)

3 Totalizer Function Blocks

(TOT-FB)

The Analog Input Function Block and the Totalizer Function Blocks provide the data interface

towards a process control system (e.g. a PLC); i.e. their input/output data can be read/written by

the control system. In a PROFIBUS network this is done via cyclic communication services.

contains parameters and functions to control the flow measurement

contains parameters and functions to control the measuring output;

provides the measuring value(s)

contains parameters and functions to control/provide the counter

value(s)

PROFIBUS DP 2

From the PROFIBUS point of view the MFC 400 device is designed as a compact device with 11

slots. While the Analog Input function blocks are assigned to slot 1, 2, 3, 7, 8, 9, 10 and 11 the

Totalizer Function Blocks are assigned to slot 4, 5 and 6. This assignment is fixed and cannot be

modified by the user. Nevertheless during network configuration the user can choose which

function block data shall be transferred between the PROFIBUS master and the PROFIBUS

device.

2.6 GSD files

The GSD file contains information that will be needed for configuration of the PROFIBUS DP

communication network. Supplementary files (e.g. ___.bmp and ___.dib) contain icons which will

represent the PROFIBUS devices in the view of the bus configuration system/master system. The

files must be loaded into the configuration program before. Follow the instructions in the

manual of the host supplier when installing GSD file and supplementary files.

A PROFIBUS GSD ZIP file (e.g. GSD-4002171502.zip) including both all GSD files of all KROHNE

devices with PROFIBUS PA interface and all additional data files mentioned above are available

at the KROHNE download page (e.g. http://www.krohne.com/html/dlc/GSD-4002171502.zip).

INFORMATION!

If it is supported by the host configuration tool the device entry for the MFC400 PROFIBUS device

will be located within the slave family "PROFIBUS PA".

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

9

Page 10

2 PROFIBUS DP

2.7 Ident. Number selector

Within a PROFIBUS network the type of a PROFIBUS slave is identified by its Ident. Number

which is unique for this slave type. The PROFIBUS DP device supports two different Ident.

Numbers. Therefore it can be installed for different use cases. When the Ident. Number is

changed the behaviour of the device concerning the cyclic data transfer is changed; i.e. the

maximum number of transferred measuring values and/or the length and content of the

diagnosis information will be different. The user can select the required Ident. Number by an

engineering tool (e.g. DD/DTM - parameter IDENT_NUMBER_SELECTOR slot 0; index 40) or via

the MFC 400 device display menu (menu item "Identification No.", C6.8.7).

The following settings are supported:

• Automatic adaptation mode (factory setting)

• Manufacturer specific Ident. Number (4512 hex)

• Profile specific Ident. Number (9742 hex)

Automatic adaptation mode (factory setting)

If the parameter IDENT_NUMBER_SELECTOR is set to this mode the device will select its

operation mode during start-up of the cyclic data transfer according to the used GSD file. The

active Ident. Number is set to one of the settings described below. If the

IDENT_NUMBER_SELECTOR is changed to this mode the current Ident. Number is not changed

until the cyclic data transfer is (re-)started.

MFC 400

INFORMATION!

Depending on the components in the PROFIBUS network the automatic adaptation might fail. In

this case the active Ident. Number has to be selected by the user via an engineering tool or via

the device display menu. The parameter IDENT_NUMBER_SELECTOR has to be set to a fixed

Ident. Number.

10

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 11

MFC 400

PROFIBUS DP 2

Manufacturer specific Ident. Number (4512 hex)

This setting provides complete functionality of the PROFIBUS DP device. All function Blocks are

available for cyclic data transfer. Device specific diagnosis information is transferred in addition

to the Profile diagnosis.

Cyclic layout:

Slot Description Function Block types Default unit

1 Mass Flow AI-FB kg/s

2 Density AI-FB kg/l

3 Temperature AI-FB K

4 Mass Totaliser Totaliser-FB kg

5 Volume Totaliser Totaliser-FB

6 Mass Totaliser Totaliser-FB kg

7 Volume Flow AI-FB

8 Concentration 1 AI-FB %

9 Concentration 2 AI-FB %

10 Concentration Mass Flow 1 AI-FB kg/s

11 Concentration Mass Flow 2 AI-FB kg/s

3

m

m3/h

• AI: Analog Input Function Block

• FB: Function Block

There are separate settings to select the units for local display and PROFIBUS. Modifications of

the units of the display will have no effect on the data transferred via PROFIBUS.

A master class 2 tool is required to modify the units for PROFIBUS transfer.

Valid GSD Modules:

AI-FB Empty Module

Totaliser-FB Empty Module

AI: Out

TOT (Id.F.): Total

TOT (Id.F.): SetTot + Total

TOT (Id.F.): ModeTot + Total

TOT (Id.F.): SetTot+ModeTot+Total

TOT (Id.F.): SetTot

TOT (Id.F.): ModeTot

TOT (Id.F.): SetTot + ModeTot

GSD File required:

GSD file KRO14512.GSD

the PROFIBUS DP device. All function blocks are available for cyclic data transfer.

KRO14512.GSD is required in this mode. This GSD file provides complete functionality of

KRO14512.GSDKRO14512.GSD

INFORMATION!

If another GSD file is used in the PROFIBUS master system the cyclic data transfer cannot be

established in this setting.

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

11

Page 12

2 PROFIBUS DP

INFORMATION!

During network configuration the user has to define which function block outputs of the signal

converter should be transferred cyclically to the master. This is performed by a bus

configuration tool (e.g. "HW- Config" for PC-S7 from Siemens). This tool offers specific functions

as follows:

1. It is possible to configure an "Empty" block (the code of an "Empty" block is defined as 0x00) on

each block number. This implies: no data are transmitted in the cyclic data telegram for this

block.

2. There is NO "Totaliser (TOT)" function block allowed on block position 1, 2, 3, 7, 8, 9, 10 and 11!

On these positions, only an "Analog Input (AI)" function block or an "Empty" block is allowed!

(Note: All codes supported by "Analog Input (AI)" - and "Totaliser (TOT)"

be found in the corresponding GSD files.)

3. There is NO "Analog Input (AI)" function block allowed on block position 4, 5 and 6! On these

positions, only a "Totaliser (TOT)" function block or an "Empty" block is allowed!

4. There is a choice of 7 different totaliser functions, which can be allocated to the blocks 4, 5

and/or 6.

MFC 400

–

function blocks will

12

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 13

MFC 400

PROFIBUS DP 2

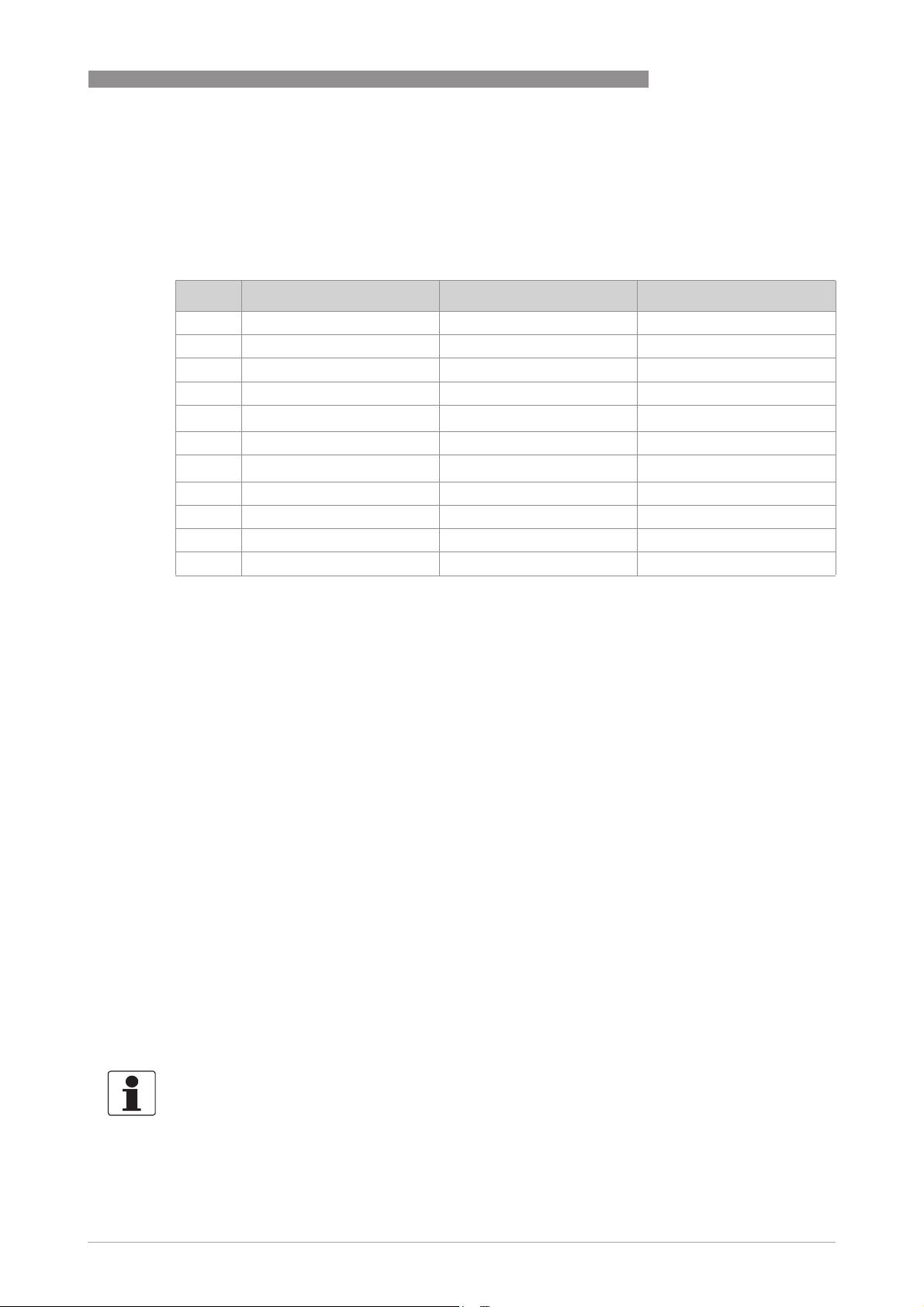

Profile specific Ident. Number (9742 hex)

Functionality is reduced to the requirements which are mandatory in the PA Profile; e.g. 3 x AIFB and 1 x TOT-FB are available for cyclic data transfer only. Device specific diagnosis

information is not available via cyclic PROFIBUS services. Nevertheless this behaviour will

improve interchangeability between devices of different vendors because only functions are

available which are provided by all PROFIBUS PA variable area flowmeters. Exchange is possible

without modifying the configuration of the control system.

Cyclic layout:

Slot Description Function Block type Default unit

1 Mass Flow AI-FB kg/s

2 Density AI-FB kg/l

3 Temperature AI-FB K

4 Mass Totaliser Totaliser-FB kg

Valid GSD Modules:

AI-FB EMPTY_MODULE

AI

Totaliser-FB EMPTY_MODULE

TOTAL

SETTOT_TOTAL

SETTOT_MODETOT_TOTAL

GSD File required:

GSD file PA039742.GSD

Take care that "Condensed Status and Diagnosis" is not supported by this file.

INFORMATION!

If another GSD file is used in the PROFIBUS master system the cyclic data transfer cannot be

established in this setting.

2.8 Summary

The following table shows a summary of the supported combinations of the PROFIBUS

device with RS485 Physical Interface and PA Profile 3.02:

Ident. Number Selector Ident.

Automatic adaptation mode 4512 KR014512.GSD Classic / Condensed

Manufacturer specific Ident.

Number

Profile specific Ident. Number 9742 PA039742.GSD 1 Classic

1 This file is p rovided by P ROFIBUS Interna tional (www .profibus.com) . Take care t hat "Condense d Status and Diagnosis"

is not supported by this file.

PA039742.GSD is required in this mode. This file is provided by PROFIBUS International.

PA039742.GSDPA039742.GSD

GSD File Status

Number

9742 PA039742.GSD 1 Classic

4512 KR014512.GSD Classic / Condensed

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

13

Page 14

2 PROFIBUS DP

2.9 Baud rate

Supported baud rates are listed in the GSD file (see below). After power-on or PROFIBUS

timeout a baud rate search is active to detect the current transfer speed on the bus. It is not

necessary to set the baud rate manually.

If the data transmission rate is changed during operation the baud rate search will not be started

by the device. A new power-up or a manual interruption of the PROFIBUS communication is

required to activate the baud rate search in this case.

MFC 400

14

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 15

MFC 400

3.1 Software history

Issued Signal converter Application program System integration

PROFIBUS PA 3

Mth./

Hardware Firmware Hardware Software Driver Version Model name

year

06/13 Signal

converter

with MBP

interface +

PA Profile

3.02

V1.0.3_ /

130603

Simatic

PCS7

other SPS

of other

manufact.

Laptop / PC PDM

HW Config

other

Software of

other SPS

manufact.

(≥ 6.0 SP5)DD(Ident.-No.)

Pactware DTM ≥ - -

GSD

manuf.

specific for

stand.

DP/PA

segment

coupler

GSD

profile

specific

KR014513.GSD MFC400 (MBP)

Rev.1

PA139742.GSD Flow, dens,

temp with

3AI, 1TOT

(PhyL 1)

- -

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

15

Page 16

3 PROFIBUS PA

3.2 System configuration of PROFIBUS PA network

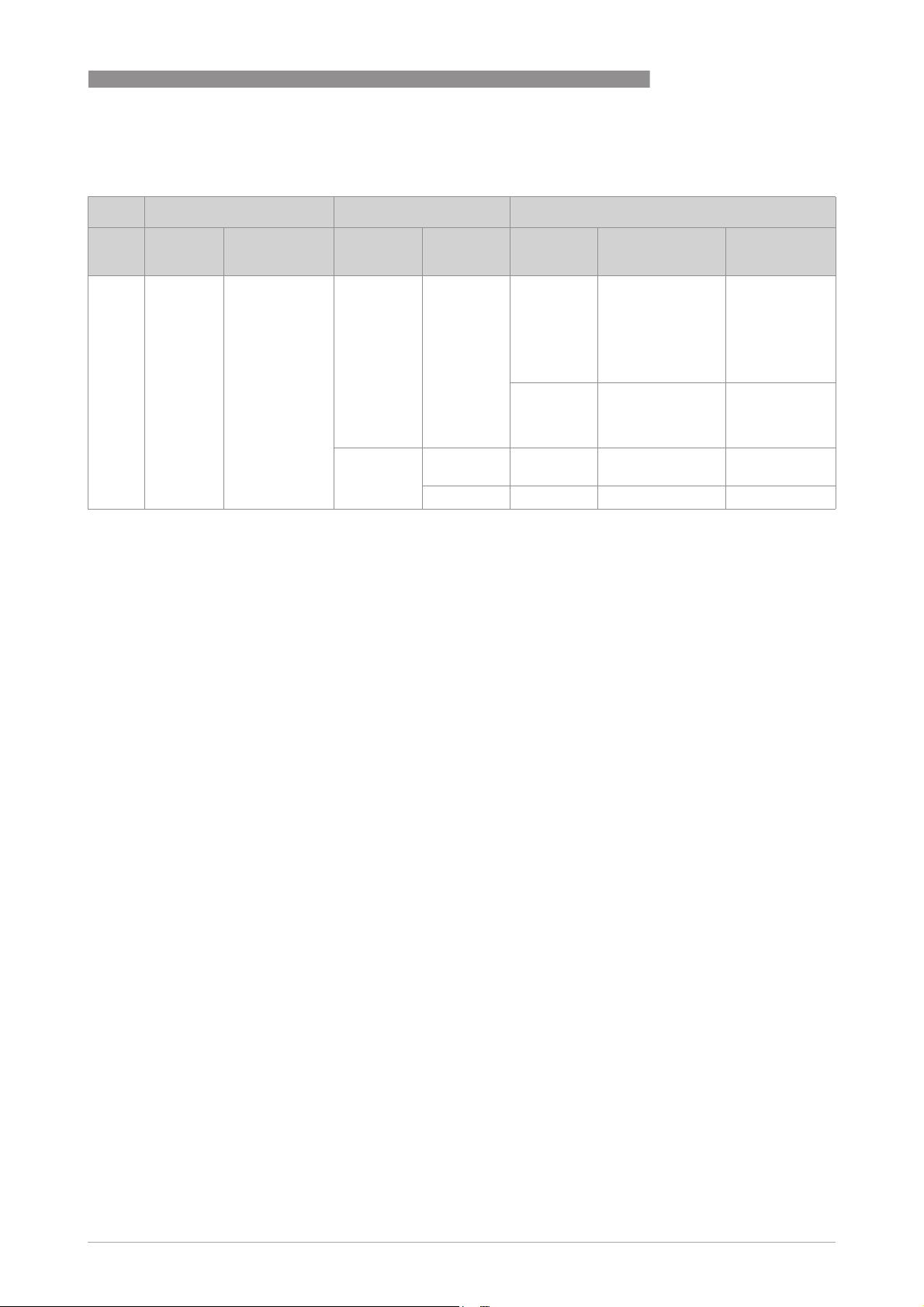

The following diagram shows a typical instrumentation with PROFIBUS PA devices with MBP

interface in hazardous and non-hazardous locations, including connections of conventional

devices (e.g. with 4...20 mA signals) in a PROFIBUS network.

As a rule, the PROFIBUS PA segment is connected to a segment coupler which, among other

things, carries out the conversion to the PROFIBUS DP bus line. It should be mentioned that the

segment coupler is normally set to a fixed baud rate on the DP side.

MFC 400

Figure 3-1: PROFIBUS PA network

1 Control system (PLC); class 1 master

2 Engineering or operation control tool; class 2 master

3 PROFIBUS DP network with max. 12 Mbit/s

4 PROFIBUS PA segment coupler DP / PA

5 Device with PROFIBUS PA interface, 31.25 kbit/s

6 HART

7 More devices with 4…20 mA

8 Analogue I/O module

®

device

16

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 17

MFC 400

3.3 Electrical connection for PA signal converter

INFORMATION!

The wiring between the device and the PROFIBUS PA bus cable is independant of polarity.

The signal converter PROFIBUS PA interface will operate only if the additional power supply for

the device is connected/available.

For a detailed description of the electrical connections please refer to the standard signal

converter handbook. Refer also to the PROFIBUS PA user and installation guideline (Version 2.2,

February 2003 PNO order no. 2.092).

Connection to a spur

or

PROFIBUS PA 3

Connection to a trunk

1 e.g. incoming data lines

2 e.g. outgoing data lines

or

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

17

Page 18

3 PROFIBUS PA

3.4 Technical data

Hardware

Type PROFIBUS MBP interface according to IEC 61158-2 with

Connection Independent of polarity at electrical connection

Base current 10.5 mA

FDE Yes, separate fault disconnection electronics provided (FDE = Fault

Fault current 6 mA (fault current = max. continuous current – base current)

Starting current <12 mA

Ex approval Ex ia IIC or Ex ib IIC/IIB, FISCO Device

Software

GSD GSD file on CD-ROM or from internet site

Device profile PROFIBUS PA Profile 3.02; conformance class B, compact

Address range 0…126 (default 126)

Local control Local display and operator interface at device

SAPs 2 x MS1 SAPs – acyclic interface to PLC

Function blocks 1 x TB = Transducer Block: contains the parameters and functions

MFC 400

31.25 kbits/s; voltage mode

[MBP = Manchester Coded Bus Powered]

Disconnection Electronics)

For detailed information refer to standard product documentation.

Supported GSD:

• KRO14513.GSD

• PA139742.GSD

0…125 via PROFIBUS service set_slave_add

0…126 via local display

126 via factory_reset = 2712

3 x MS2 SAPs – the number of MS2 Service Access Points is typically

equal to the maximum number of master class 2 tools

defined in PA Profile 3.02

1 x PB = Physical Block: contains the parameters defined in PA

Profile 3.02

8 x AI = Analog Input Blocks: contains the parameters defined in PA

Profile 3.02

3 x TOT = Totalizer Function Blocks: contains the parameters defined

in PA Profile 3.02

18

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 19

MFC 400

3.5 PROFIBUS PA Profile implementation

The PROFIBUS PA Profile 3.02 defines standardized parameters and functions for PROFIBUS

devices used for process control. It describes a PROFIBUS device as a function block application,

i.e. parameters and functions are grouped into different blocks. In the MFC 400 PROFIBUS

device the following blocks are implemented:

Block Usage

1 Physical Block (PB) contains identification and diagnosis parameters of the device

1 Flow Transducer Block

(TB)

8 Analog Input Function Block

(AI-FB)

3 Totalizer Function Blocks

(TOT-FB)

The Analog Input Function Block and the Totalizer Function Blocks provide the data interface

towards a process control system (e.g. a PLC); i.e. their input/output data can be read/written by

the control system. In a PROFIBUS network this is done via cyclic communication services.

contains parameters and functions to control the flow measurement

contains parameters and functions to control the measuring output;

provides the measuring value(s)

contains parameters and functions to control/provide the counter

value(s)

PROFIBUS PA 3

From the PROFIBUS point of view the MFC 400 device is designed as a compact device with 11

slots. While the Analog Input function blocks are assigned to slot 1, 2, 3, 7, 8, 9, 10 and 11 the

Totalizer Function Blocks are assigned to slot 4, 5 and 6. This assignment is fixed and cannot be

modified by the user. Nevertheless during network configuration the user can choose which

function block data shall be transferred between the PROFIBUS master and the PROFIBUS

device.

3.6 GSD files

The GSD file contains information that will be needed for configuration of the PROFIBUS DP

communication network. Supplementary files (e.g. ___.bmp and ___.dib) contain icons which will

represent the PROFIBUS devices in the view of the bus configuration system/master system. The

files must be loaded into the configuration program before. Follow the instructions in the

manual of the host supplier when installing GSD file and supplementary files.

A PROFIBUS GSD ZIP file (e.g. GSD-4002171502.zip) including both all GSD files of all KROHNE

devices with PROFIBUS PA interface and all additional data files mentioned above are available

at the KROHNE download page (e.g. http://www.krohne.com/html/dlc/GSD-4002171502.zip).

INFORMATION!

If it is supported by the host configuration tool the device entry for the MFC400 PROFIBUS device

will be located within the slave family "PROFIBUS PA".

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

19

Page 20

3 PROFIBUS PA

3.7 Ident. Number selector

Within a PROFIBUS network the type of a PROFIBUS slave is identified by its Ident. Number

which is unique for this slave type. The PROFIBUS PA device supports two different Ident.

Numbers. Therefore it can be installed for different use cases. When the Ident. Number is

changed the behaviour of the device concerning the cyclic data transfer is changed; i.e. the

maximum number of transferred measuring values and/or the length and content of the

diagnosis information will be different. The user can select the required Ident. Number by an

engineering tool (e.g. DD/DTM - parameter IDENT_NUMBER_SELECTOR slot 0; index 40) or via

the MFC 400 device display menu (menu item "Identification No.", C6.8.7).

The following settings are supported:

• Automatic adaptation mode (factory setting)

• Manufacturer specific Ident. Number (4513 hex)

• Profile specific Ident. Number (9742 hex)

Automatic adaptation mode (factory setting)

If the parameter IDENT_NUMBER_SELECTOR is set to this mode the device will select its

operation mode during start-up of the cyclic data transfer according to the used GSD file. The

active Ident. Number is set to one of the settings described below. If the

IDENT_NUMBER_SELECTOR is changed to this mode the current Ident. Number is not changed

until the cyclic data transfer is (re-)started.

MFC 400

INFORMATION!

Depending on the components in the PROFIBUS network the automatic adaptation might fail. In

this case the active Ident. Number has to be selected by the user via an engineering tool or via

the device display menu. The parameter IDENT_NUMBER_SELECTOR has to be set to a fixed

Ident. Number.

20

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 21

MFC 400

PROFIBUS PA 3

Manufacturer specific Ident. Number (4513 hex)

This setting provides complete functionality of the PROFIBUS PA device. All function Blocks are

available for cyclic data transfer. Device specific diagnosis information is transferred in addition

to the Profile diagnosis.

Cyclic layout:

Slot Description Function Block types Default unit

1 Mass Flow AI-FB kg/s

2 Density AI-FB kg/l

3 Temperature AI-FB K

4 Mass Totaliser Totaliser-FB kg

5 Volume Totaliser Totaliser-FB

6 Mass Totaliser Totaliser-FB kg

7 Volume Flow AI-FB

8 Concentration 1 AI-FB %

9 Concentration 2 AI-FB %

10 Concentration Mass Flow 1 AI-FB kg/s

11 Concentration Mass Flow 2 AI-FB kg/s

3

m

m3/h

• AI: Analog Input Function Block

• FB: Function Block

There are separate settings to select the units for local display and PROFIBUS. Modifications of

the units of the display will have no effect on the data transferred via PROFIBUS.

A master class 2 tool is required to modify the units for PROFIBUS transfer.

Valid GSD Modules:

AI-FB Empty Module

Totaliser-FB Empty Module

AI: Out

TOT (Id.F.): Total

TOT (Id.F.): SetTot + Total

TOT (Id.F.): ModeTot + Total

TOT (Id.F.): SetTot+ModeTot+Total

TOT (Id.F.): SetTot

TOT (Id.F.): ModeTot

TOT (Id.F.): SetTot + ModeTot

GSD File required:

GSD file KRO14513.GSD

the PROFIBUS PA device. All function blocks are available for cyclic data transfer.

KRO14513.GSD is required in this mode. This GSD file provides complete functionality of

KRO14513.GSDKRO14513.GSD

INFORMATION!

If another GSD file is used in the PROFIBUS master system the cyclic data transfer cannot be

established in this setting.

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

21

Page 22

3 PROFIBUS PA

INFORMATION!

During network configuration the user has to define which function block outputs of the signal

converter should be transferred cyclically to the master. This is performed by a bus

configuration tool (e.g. "HW- Config" for PC-S7 from Siemens). This tool offers specific functions

as follows:

1. It is possible to configure an "Empty" block (the code of an "Empty" block is defined as 0x00) on

each block number. This implies: no data are transmitted in the cyclic data telegram for this

block.

2. There is NO "Totaliser (TOT)" function block allowed on block position 1, 2, 3, 7, 8, 9, 10 and 11!

On these positions, only an "Analog Input (AI)" function block or an "Empty" block is allowed!

(Note: All codes supported by "Analog Input (AI)" - and "Totaliser (TOT)"

be found in the corresponding GSD files.)

3. There is NO "Analog Input (AI)" function block allowed on block position 4, 5 and 6! On these

positions, only a "Totaliser (TOT)" function block or an "Empty" block is allowed!

4. There is a choice of 7 different totaliser functions, which can be allocated to the blocks 4, 5

and/or 6.

Profile specific Ident. Number (9742 hex)

Functionality is reduced to the requirements which are mandatory in the PA Profile; e.g. 3 x AIFB and 1 x TOT-FB are available for cyclic data transfer only. Device specific diagnosis

information is not available via cyclic PROFIBUS services. Nevertheless this behaviour will

improve interchangeability between devices of different vendors because only functions are

available which are provided by all PROFIBUS PA variable area flowmeters. Exchange is possible

without modifying the configuration of the control system.

MFC 400

–

function blocks will

Cyclic layout:

Slot Description Function Block type Default unit

1 Mass Flow AI-FB kg/s

2 Density AI-FB kg/l

3 Temperature AI-FB K

4 Mass Totaliser Totaliser-FB kg

Valid GSD Modules:

AI-FB EMPTY_MODULE

AI

Totaliser-FB EMPTY_MODULE

TOTAL

SETTOT_TOTAL

SETTOT_MODETOT_TOTAL

GSD File required:

GSD file PA139742.GSD

Take care that "Condensed Status and Diagnosis" is not supported by this file.

PA139742.GSD is required in this mode. This file is provided by PROFIBUS International.

PA139742.GSDPA139742.GSD

INFORMATION!

If another GSD file is used in the PROFIBUS master system the cyclic data transfer cannot be

established in this setting.

22

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 23

MFC 400

3.8 Summary

The following table shows a summary of the supported combinations of the PROFIBUS

device with MBP Physical Interface and PA Profile 3.02:

PROFIBUS PA 3

Ident. Number Selector Ident.

GSD File Status

Number

Automatic adaptation mode 4513 KR014513.GSD Classic / Condensed

9742 PA139742.GSD 1 Classic

Manufacturer specific Ident.

Number

Profile specific Ident. Number 9742 PA139742.GSD 1 Classic

1 This file is p rovided by P ROFIBUS Interna tional (www .profibus.com) . Take care t hat "Condense d Status and Diagnosis"

is not supported by this file.

4513 KR014513.GSD Classic / Condensed

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

23

Page 24

4 COMMISSIONING / OPERATION

4.1 Configuration of cyclic data transfer

During network configuration the user has to select which function block input/output data shall

be transferred between the PROFIBUS master and the PROFIBUS slave. Network configuration

will be done using one of the GSD files described before. During configuration a functional

module - describing a valid configuration of a single function block and defined in the GSD file

selected - has to be assigned to each slot of the device in order to select which data has to be

transferred for the corresponding function blocks.

The cyclic layout (have a look at chapter "Ident. Number selector") shows which type of

functional module is valid for each slot.

The order of transmission of the data always remains the same. If an "Empty Module" is

assigned to a slot no data will be sent for the corresponding function block and all function block

data following this empty module will move up one position.

4.2 Cyclic data

In a PROFIBUS network cyclic data is described from the point of view of the master. Therefore

input data is transferred from the slave to the master while output data is transferred from the

master to the slave.

MFC 400

4.2.1 Input data

Input data is transferred from the PROFIBUS device to the master for the measuring value and

the totalizer values. The format is the same for both. If input data transfer is configured 5 bytes

are transferred for the corresponding slot:

• 4 byte float value (Float Format according to IEEE Standard 754 Short Real Number)

• 1 byte status value

Float value

Float value

Float valueFloat value

The following example describes the format of the float value according to IEEE Standard 754

Short Real Number:

Float format

Byte n Byte n+1

Bit7 Bit6 Bit7 Bit6

VZ

Byte n+2 Byte n+3

Bit7 Bit7

-82-9

2

Mantissa Mantissa

7

6

5

4

3

2

1

0

2

2

2

2

2

2

2

2

Exponent Mantissa

-102-112-122-132-142-152-162-172-182-192-202-212-222-23

2

-12-22-32-4

2

-52-62-7

2

24

Example (binary): 40 F0 00 00 (hex) = 0100 0000 1111 0000 0000 0000 0000 0000

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 25

MFC 400

COMMISSIONING / OPERATION 4

Formula:

Formula:

Formula:Formula:

VZ

(Exponent – 127)

0

* 2

* 2

(129 – 127)

value = (-1)

value = (-1)

value = 1 * 4 * (1 + 0.5 + 0.25 + 0.125)

value = 7.5

Status value

Status value

Status valueStatus value

The PROFIBUS device supports the PROFIBUS-PA Profile Version 3.02. In this Profile the

Condensed Status and Diagnosis has replaced by default the Classic Status and Diagnosis of the

PROFIBUS-PA Profile Version 3.0. The Condensed Status and Diagnosis has been created to

make diagnostic events more obvious and to allow predictive and preventive maintenance.

Nevertheless Classic Status and Diagnosis is still available for this device. It is implemented for

backwards compatibility to "older" devices or PLC systems which do not support Condensed

Status and Diagnosis.

The device may be switched between "Condensed Status and Diagnosis" and "Classic Status and

Diagnosis"

• automatically during start-up of the cyclic data transfer by setting the parameter PRM_COND

within the Set_Prm service data.

• using an engineering tool (e.g. DD/DTM) to write the parameter COND_STATUS_DIAG (slot 0,

index 43).

• using the device display menu (menu item "Condensed Status", C6.8.8)

* (1 + Mantissa)

* (1 + 2-1 + 2-2 + 2-3)

Coding for the first two parameters is:

• 0: Classic Status

• 1: Condensed Status (factory setting)

Coding for the third selection is:

• OFF: Classic Status

• ON: Condensed Status (factory setting)

INFORMATION!

The parameter COND_STATUS_DIAG cannot be modified directly if cyclic data transfer is active.

Nevertheless it is reset to the factory setting if a reset to default data is requested by an

engineering tool.

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

25

Page 26

4 COMMISSIONING / OPERATION

The coding of the status value depends on the active status and diagnosis mode. It is described in

the following tables.

Condensed Status

Condensed Status

Condensed StatusCondensed Status

The Condensed Status codes have been defined to allow easier decoding of the information

provided by the PROFIBUS devices. The coding is shown in the following table:

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

2

2

2

2

2

0 0 = bad

0 1 = uncertain

1 0 = good (Non Cascade)

1 1 = good (Cascade) - not supported

Status = bad

1

2

2

MFC 400

0

2

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

1

2

2

2

2

2

2

0

2

2

0 0 0 0 0 0 0 0 = non-specific (not provided by the device)

0 0 1 0 0 0 1 1 = passivated (diagnostic alerts inhibited)

0 0 1 0 0 1 x x = maintenance alarm, more diagnosis available

0 0 1 0 1 0 x x = process related, no maintenance

0 0 1 1 1 1 x x = function check / local override; value not usable

Status = uncertain

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

1

2

2

2

2

2

2

0 1 0 0 1 0 x x = substitute set

0 1 0 0 1 1 1 1 = initial value

0 1 1 0 1 0 x x = maintenance demanded

0 1 1 1 0 0 1 1 = simulated value, start

0 1 1 1 0 1 1 1 = simulated value, end

0 1 1 1 1 0 x x = process related, no maintenance

0

2

2

26

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 27

MFC 400

COMMISSIONING / OPERATION 4

Status = good (Non Cascade)

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

1

2

2

2

2

2

2

1 0 0 0 0 0 x x = ok

1 0 0 0 0 1 x x = update event

1 0 0 0 1 0 x x = advisory alarm

1 0 0 0 1 1 x x = critcal alarm

1 0 1 0 0 0 x x = initiate fail safe (not provided by ESK4-PA)

1 0 1 0 0 1 x x = maintenance required

1 0 1 0 1 0 x x = maintenance demanded

1 0 1 1 1 1 x x = function check

Status = Limits

Quality Quality substatus Limits

0

2

2

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

1

2

2

2

2

2

2

0

2

2

0 0 = ok

0 1 = low limited

1 0 = high limited

1 1 = constant

Check the first two quality bits in order to get the quality information of the measurement value:

• Good (Non Cascade):

Good (Non Cascade): function block output value is ok and can be used without restrictions

Good (Non Cascade):Good (Non Cascade):

• Good (Cascade):

Good (Cascade): will not be supported, because it is not applicable for the device

Good (Cascade):Good (Cascade):

• Uncertain:

Uncertain: function block output value can be used but the accuracy can not be guaranteed

Uncertain:Uncertain:

(e.g. function block outputs value has been frozen or A/D converter is saturated or out of

range)

• Bad:

Bad: function block output value is bad - don’t use it for process control!

Bad:Bad:

The "Quality-Substatus" and "Limit" bits will be used for further diagnostics or limit checking.

INFORMATION!

The status should be monitored because a number will be transmitted even if the status of the

measurement value is bad or uncertain. This is the only way to check the quality of the

transmitted measurement values.

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

27

Page 28

4 COMMISSIONING / OPERATION

Classic Status

Classic Status

Classic StatusClassic Status

The Classic Status is implemented to provide compatibility to systems which are not configured

for Condensed Status. The coding is shown in the following table:

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

2

2

2

2

2

0 0 = bad

0 1 = uncertain

1 0 = good (Non Cascade)

1 1 = good (Cascade) - not supported

Status = bad

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

2

2

2

0 0 0 0 0 0 = non-specific

0 0 0 0 0 1 = configuration error

0 0 0 0 1 0 = not connected

0 0 0 0 1 1 = device failure

0 0 0 1 0 0 = sensor failure

0 0 0 1 0 1 = no communication (last usable value)

0 0 0 1 1 0 = no communication (no usable value)

0 0 0 1 1 1 = out of service

3

2

2

1

2

2

2

1

2

2

MFC 400

0

2

0

2

Status = uncertain

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

1

2

2

2

2

2

2

0 1 0 0 0 0 = non-specific

0 1 0 0 0 1 = last usable value

0 1 0 0 1 0 = substitute-set

0 1 0 0 1 1 = initial value

0 1 0 1 0 0 = sensor conversion not accurate

0 1 0 1 0 1 = engineering unit violation (unit not in the valid set)

0 1 0 1 1 0 = sub-normal

0 1 0 1 1 1 = configuration error

0 1 1 0 0 0 = simulated value

0

2

2

28

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 29

MFC 400

COMMISSIONING / OPERATION 4

Status = good (Non Cascade)

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

1

2

2

2

2

2

2

1 0 0 0 0 0 = ok

1 0 0 0 0 1 = update event

1 0 0 0 1 0 = active advisory alarm

1 0 0 0 1 1 = active critcal alarm

1 0 0 1 0 0 = unacknowledged update event

1 0 0 1 0 1 = unacknowledged advisory alarm

1 0 0 1 1 0 = unacknowledged critical alarm

1 0 1 0 0 0 = initiate fail safe

1 0 1 0 0 1 = maintenance required

Status = Limits

0

2

2

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

1

2

2

2

2

2

2

0

2

2

0 0 = ok

0 1 = low limited

1 0 = high limited

1 1 = constant

Check the first two quality bits in order to get the quality information of the measurement value:

• Good (Non Cascade):

Good (Non Cascade): function block output value is ok and can be used without restrictions

Good (Non Cascade):Good (Non Cascade):

• Good (Cascade):

Good (Cascade): will not be supported, because it is not applicable for the device

Good (Cascade):Good (Cascade):

• Uncertain:

Uncertain: function block output value can be used but the accuracy can not be guaranteed

Uncertain:Uncertain:

(e.g. function block outputs value has been frozen or A/D converter is saturated or out of

range)

• Bad:

Bad: function block output value is bad - don’t use it for process control!

Bad:Bad:

The "Quality-Substatus" and "Limit" bits will be used for further diagnostics or limit checking.

INFORMATION!

The status should be monitored because a number will be transmitted even if the status of the

measurement value is bad or uncertain. This is the only way to check the quality of the

transmitted measurement values.

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

29

Page 30

4 COMMISSIONING / OPERATION

4.2.2 Output data

Output data is transferred from the master to the PROFIBUS device to control the totalizers.

Behaviour and coding is described by the following tables.

Module types (defined in GSD):

MFC 400

Total cyclic transfer of the totalizer value with status to the master (no output data)

SetTot + Total cyclic transfer of the totalizer value with status to the master +

ModeTot + Total cyclic transfer of the totalizer value with status to the master +

SetTot +

ModeTot + Total

SetTot cyclic control data from master to the slave via the parameter SetTot

ModeTot cyclic control data from master to the slave via the parameter ModeTot

SetTot + ModeTot cyclic control data from master to the slave via the parameters SetTot and ModeTot

cyclic control data from master to the slave via the parameter SetTot

cyclic control data from master to the slave via the parameter ModeTot

cyclic transfer of the totalizer value with status to the master +

cyclic control data from master to the slave via the parameters SetTot and ModeTot

(in this order)

(in this order)

(no output data)

(no output data)(no output data)

Coding of SetTot

SetTot = 0 Totalizer is totalizing

SetTot = 1 Totalizer is reset to 0.0 and remains at this value until SetTot is reset to 0. If the

SetTot = 2 Totalizer is set to the value defined by PresetTot. PresetTot can be written via an

Other values are not accepted for SetTot. Values are ignored; totalizer remains in its last valid setting.

value of SetTot changes from "1" to "0" the totalizer starts counting from 0.0.

acyclic service (totalizer in slot 4: Slot 4, Index 32; totalizer in slot 5: Slot 5, Index 32;

totalizer in slot 6: Slot 6, Index 32). If the value of SetTot changes from "2" to "0" the

totalizer starts counting from the current value defined by PresetTot.

Coding of ModeTot

ModeTot = 0 True arithmetic integration of the incoming rate values.

ModeTot = 1 Totalization of positive incoming rate values only.

ModeTot = 2 Totalization of negative incoming rate values only.

ModeTot = 3 Totalizer is stopped, no totalization is done.

ModeTot = 248 All incoming rates will be handled as positive values; i.e. negative input values will

ModeTot = 249 All incoming rates will be handled as negative values; i.e. positive input values will

Other values are not accepted for ModeTot. Values are ignored; totalizer remains in its last valid setting.

be multiplied with "-1.0".

be multiplied with "-1.0".

INFORMATION!

Take care that SetTot and ModeTot are level sensitive parameters; e.g. if SetTot is changed from

"0" to "1" the totalizer is reset and stopped. It will not start counting before SetTot is reset to "0"

via the control system or an engineering tool. It is not reset by the PROFIBUS device.

30

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 31

MFC 400

4.3 Diagnosis

The PROFIBUS device performs internal self-tests. The results are provided as detailed

diagnosis information according to PA Profile 3.02. This diagnosis information is available via

several parameters and can be read by an engineering tool (e.g. DD/DTM). In addition the

diagnosis information is transferred via cyclic services towards the control system (e.g. PLC).

Diagnosis is bitwise coded. Therefore it is possible to report more than one indication

simultaneously. The GSD file contains a text for each diagnosis bit in order to provide a text

message in the control system. The references are defined by the UNIT_DIAG_BIT(i) entries.

They show which bit is set to indicate a special diagnosis event.

The amount and content of the diagnosis information depends on the device configuration. The

active Ident. Number and the selected status and diagnosis mode will influence diagnosis

propagation. The following tables show the diagnosis events which are reported for different

settings. The bit number is equal to the counting within the GSD file. It represents the position in

the device-related diagnostic field of the Slave_Diag service.

INFORMATION!

Diagnosis to control system in case of

•

Manufacturer specific Ident. Number (4512 hex)

•

Manufacturer specific Ident. Number (4513 hex)

•

Profile specific Ident. Number (9742 hex)

COMMISSIONING / OPERATION 4

(these diagnosis events are contained in PROFIBUS parameter "DIAGNOSIS")

Bit Number

supported

Description

16 yes Error appears -

17 yes Error disappears 24 1 Hardware failure electronics The device or measurement is defective and cannot measure.

29 1 Measurement failure The device or application condition is in a way that the

35 yes Restart Device is restarted because of power-up or warmstart request. In

36 yes Coldstart Device is reset to its Factory/Default settings because of a user

Remedy

Related output values are invalid. Typically a repair or

replacement of the device is required.

Check detailed diagnosis. Restart the device. If the error occurs

again: send the device back to the manufacturer with an

indication of the error.

measurement accuracy may be reduced. But still the

measurement value follows the source. E.g. the device may be

operated outside its specified operating range.

Check detailed diagnosis. Restart the device. If the error occurs

again: send the device back to the manufacturer with an

indication of the error.

case of unexpected restart: send the device back to the

manufacturer with an indication of the error.

request or exchange of the basic module (serial number is

changed). Recover user specific parameter settings.

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

31

Page 32

4 COMMISSIONING / OPERATION

Bit Number

supported

Description

37 yes Maintenance required The device detects problem(s), which are less severe compared to

39 yes Ident_Number violation Ident. Number Selector was modified while cyclic data transfer

Remedy

the diagnosis "Measurement failure". But still the measurement

values are accurate. The output values are still valid, but this may

change in the near future. Check detailed diagnosis to solve the

problem.

was active. To clear this message perform one of the following

actions:

MFC 400

• Reset Ident. Number Selector to its former setting

• Stop cyclic data transfer

• Restart the device

40 2 Maintenance alarm The device or measurement is defective and cannot measure.

41 2 Maintenance demanded The device or application condition is in a way that the

42 2 Function check Simulation is active. Disable simulation to clear this message.

55 yes Extension available Refer to detailed diagnosis in bits 56 to 103.

56 3 C – Process

(classification fixed - not changeable)

57 3 C – Configuration

(classification fixed - not changeable)

58 3 C – Electronics

(classification fixed - not changeable)

59 3 C – Sensor

(classification fixed - not changeable)

60 3 F – Process

(classification fixed - not changeable)

61 3 F – Configuration

(classification fixed - not changeable)

62 3 F – Electronics

(classification fixed - not changeable)

Related output values are invalid. Typically a repair or

replacement of the device is required.

Check detailed diagnosis. Restart the device. If the error occurs

again: send the device back to the manufacturer with an

indication of the error.

measurement accuracy may be reduced. But still the

measurement value follows the source. E.g. the device may be

operated outside its specified operating range.

Check detailed diagnosis. Restart the device. If the error occurs

again: send the device back to the manufacturer with an

indication of the error.

Process related "Function check" running. E.g. the measurement

values may be simulated values for a currently performed check.

The related output values are temporarily invalid. Turn off

"Function check" to change back into measurement mode / 6.

Configuration related "Function check" running. E.g. the

measurement values may be simulated values for a currently

performed check. The related output values are temporarily

invalid. Turn off "Function check" to change back into

measurement mode / 6.

Converter Electronics related "Function check" running. E.g. the

measurement values may be simulated values for a currently

performed check. The related output values are temporarily

invalid. Turn off "Function check" to change back into

measurement mode / 6.

Sensor related "Function check" running. E.g. the measurement

values may be simulated values for a currently performed check.

The related output values are temporarily invalid. Turn off

"Function check" to change back into measurement mode / 6.

Process related settings are defective. Related output values are

invalid. A repair or replacement of the device can be necessary.

Check process parameters / 4 - restart the device – if the error

still occur contact the service department of the manufacturer.

Configuration is defective. Related output values are invalid. A

repair or replacement of the device can be necessary. Check

configuration / 4 - restart the device – if the error still occur

contact the service department of the manufacturer.

Converter Electronic is defective and not able to measure.

Related output values are invalid. Typically a repair or

replacement of the device is required. Check converter / 4 restart the device – if the error still occur send back the device to

the manufacturer with an indication of the error.

32

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 33

MFC 400

Bit Number

supported

Description

63 3 F – Sensor

64 3 M – Process

65 3 M – Configuration

66 3 M – Electronics

67 3 F – Sensor

68 3 S – Process

69 3 S – Configuration

70 3 S – Electronics

71 3 S – Sensor

72 3 ("I-") Electr: Power Failure

73 3 ("I-") Proc: System Control

(classification fixed - not changeable)

(classification fixed - not changeable)

(classification fixed - not changeable)

(classification fixed - not changeable)

(classification fixed - not changeable)

(classification fixed - not changeable)

(classification fixed - not changeable)

(classification fixed - not changeable)

(classification fixed - not changeable)

(default classification / 9)

(default classification / 9)

COMMISSIONING / OPERATION 4

Remedy

Sensor is defective and not able to measure. Related output

values are invalid. Typically a repair or replacement of the device

is required. Check sensor / cabling / 4 - restart the device – if the

error still occur send back the device to the manufacturer with an

indication of the error.

Process related problem(s) detected. But still the measurement

values are accurate. The output values are still valid, but this may

change in the near future. Check problem(s) / 5 - if the

problem(s) cannot be fixed contact the service department of the

manufacturer with an indication of the problem(s).

Configuration related problem(s) detected. But still the

measurement values are accurate. The output values are still

valid, but this may change in the near future. Check problem(s) /

5 - if the problem(s) cannot be fixed contact the service

department of the manufacturer with an indication of the

problem(s).

Converter Electronic related problem(s) detected. But still the

measurement values are accurate. The output values are still

valid, but this may change in the near future. Check problem(s) /

5 - if the problem(s) cannot be fixed contact the service

department of the manufacturer with an indication of the

problem(s).

Sensor related problem(s) detected. But still the measurement

values are accurate. The output values are still valid, but this may

change in the near future. Check problem(s) / 5 - if the

problem(s) cannot be fixed contact the service department of the

manufacturer with an indication of the problem(s).

Process related fault(s) detected. E.g. the device may be operated

outside its specified operating range. The measurement accuracy

may be reduced. But still the measurement value follows the

source. Check fault(s) detected / 4 - if the fault(s) cannot be

cleared contact the service department of the manufacturer with

an indication of the problem(s).

Configuration related fault(s) detected. E.g. the device may be

operated outside its specified operating range. The measurement

accuracy may be reduced. But still the measurement value

follows the source. Check fault(s) detected / 4 - if the fault(s)

cannot be cleared contact the service department of the

manufacturer with an indication of the problem(s).

Converter Electronic related fault(s) detected. E.g. the device may

be operated outside its specified operating range. The

measurement accuracy may be reduced. But still the

measurement value follows the source. Check fault(s) detected /

4 - if the fault(s) cannot be cleared contact the service

department of the manufacturer with an indication of the

problem(s).

Sensor related fault(s) detected. E.g. the device may be operated

outside its specified operating range. The measurement accuracy

may be reduced. But still the measurement value follows the

source. Check fault(s) detected / 4 - if the fault(s) cannot be

cleared contact the service department of the manufacturer with

an indication of the problem(s).

Information only; e.g. power-down detected / 7. Just information.

No impact on measurement expected.

Information only; e.g. system-control messages present / 7. Just

information. No impact on measurement expected.

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

33

Page 34

4 COMMISSIONING / OPERATION

Bit Number

supported

Description

74 3 ("S-") Config_ Totalizer

(default classification / 9)

75 3 ("S-") Proc: Signal Low

(default classification / 9)

76 3 ("S-") Proc: 2 Phase Flow

(default classification / 9)

77 3 ("F-") Proc: Signal Search

(default classification / 9)

78 3 ("S-") Electr: IO Connection

(default classification / 9)

79 3 ("F-") Proc: Current Input

(default classification / 9)

81 3 ("I-") Electr: Info. Operation

(classification fixed - not changeable)

82 3 ("I-") Config: No Meas. Value

(classification fixed - not changeable)

97 3 I - Parameter Update in Progress

(classification fixed - not changeable)

99 3 F - No Meas. Value

(classification fixed - not changeable)

100 3 F - Parameter Update Error

(classification fixed - not changeable)

101 3 F - No Device Communication

(classification fixed - not changeable)

Remedy

Configuration related fault(s) detected concerning totalizer. E.g.

"Overflow" of a totalizer – counting starts with "zero". The

measurement accuracy may be reduced. But still the

measurement value follows the source. Check fault(s) detected /

4 - if the fault(s) cannot be cleared contact the service

department of the manufacturer with an indication of the

problem(s).

Process related fault(s) detected concerning the "sensor". E.g.

not reached accuracy. The measurement accuracy may be

reduced. But still the measurement value follows the source.

Check fault(s) detected / 4 - if the fault(s) cannot be cleared

contact the service department of the manufacturer with an

indication of the problem(s).

Process related fault(s) detected concerning the "2 Phase Flow".

E.g. an unknown accuracy. The measurement accuracy may be

reduced. But still the measurement value follows the source.

Check fault(s) detected / 4 - if the fault(s) cannot be cleared

contact the service department of the manufacturer with an

indication of the problem(s).

Process related error(s) detected concerning the "sensor". E.g. a

very high damping in the sensor. Related output values are

invalid. A repair or replacement of the device can be necessary.

Check error(s) detected / 4 - restart the device – if the error still

occur contact the service department of the manufacturer.

Converter related fault(s) detected concerning interconnection of

modules and terminals. E.g. an open or short circuit at the related

terminal. The measurement accuracy may be reduced. But still

the measurement value follows the source. Check fault(s)

detected / 4 - if the fault(s) cannot be cleared contact the service

department of the manufacturer with an indication of the

problem(s).

Process related error(s) detected concerning "current input

modules". Related output values are invalid. A repair or

replacement of the device can be necessary. Check error(s)

detected / 4 - restart the device – if the error still occur contact

the service department of the manufacturer.

Converter Electronic related information. Just information. No

impact on measurement expected. Check information just

present / 7.

Configuration / measurement value related information. Just

information. No impact on measurement expected. Check

information just present / 7.

GDC warm start in progress / 8

Measurement value not available (or no more available) / 8.

(status bit "F – Electronics" will be set too)

Error occurred during parameter update of PROFIBUS

parameters / 8.

(status bit "F – Configuration" will be set too)

No communication between basic device and PROFIBUS module /

8.

(status bit "F – Electronics" will be set too)

MFC 400

34

www.krohne.com 06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

Page 35

MFC 400

COMMISSIONING / OPERATION 4

1 Indication is supported if Classic Diagnosis is active only.

2 Indication is supported if Condensed Diagnosis is active only.

3 Indication is supported in cyclic diagnosis only if Ident. Number 4512 hex or 4513 is active.

Nevertheless this information is always available via acyclic access (e.g. by using DD / DTM) for

all Ident. Numbers supported.

yes Indication is supported for all Ident. Numbers mentioned on top.

4 If available readout more detailed diagnosis information using the device display ("Test →

Information → Status Details → …" / menu B3.2) or the PROFIBUS parameter "Device Status

Complete (Slot 0, Index 94)" via "DD"/ "DTM" and try to clear faults displayed.

5 If available readout more detailed diagnosis information using the device display ("Test →

Information → Status Details → …" / menu B3.2) or the PROFIBUS parameter "Device Status

Complete (Slot 0, Index 94)" via "DD"/ "DTM" and try to fix the problem(s) occurred.

6 If available readout more detailed diagnosis information using the device display ("Test →

Information → Status Details → …" / menu B3.2) or the PROFIBUS parameter "Device Status

Complete (Slot 0, Index 94)" via "DD"/ "DTM" and checkout which sort of "Function check" is

running.

7 If available readout more detailed diagnosis information using the device display ("Test →

Information → Status Details → …" / menu B3.2) or the PROFIBUS parameter "Device Status

Complete (Slot 0, Index 94)" via "DD"/ "DTM" to get a more detailed overview about all additional

information just present

8 Detailed information of the PROFIBUS module itself – no more detailed information available.

9 Classification is changeable by the user itself – have a look at chapter "Variable Event Groups".

INFORMATION!

A rough classification of status values according "NE107" is done by using the first character of

the description of a status event:

•

F- / ("F-"): Failure (No measurement possible)

•

S- / ("S-"): Out of specification (Measurements are available but no longer sufficiently

accurate and should be checked)

•

M- / ("M-"): Maintenance required: (Measurements are still accurate but this could change

soon)

•

M- / ("M-"): Maintenance required: (Measurements are still accurate but this could change

soon)

•

C- / ("C-"): Function check: (A test function is active; the displayed or transferred measured

value does not correspond to the actual measured value)

•

I- / ("I-"): Information (not defined by NE107 / device specific): (No direct influence on the

measurements)

INFORMATION!

Each diagnosis event defined by UNIT_DIAG_BIT (56) up to UNIT_DIAG_BIT (82) (being contained

Each diagnosis event defined by UNIT_DIAG_BIT (56) up to UNIT_DIAG_BIT (82) (being contained

Each diagnosis event defined by UNIT_DIAG_BIT (56) up to UNIT_DIAG_BIT (82) (being contained Each diagnosis event defined by UNIT_DIAG_BIT (56) up to UNIT_DIAG_BIT (82) (being contained

in PROFIBUS parameter "DIAGNOSIS_EXTENSION") will be defined as a so called "Event group"

in PROFIBUS parameter "DIAGNOSIS_EXTENSION") will be defined as a so called "Event group"

in PROFIBUS parameter "DIAGNOSIS_EXTENSION") will be defined as a so called "Event group" in PROFIBUS parameter "DIAGNOSIS_EXTENSION") will be defined as a so called "Event group"

(for detailed information refer to chapter 6.6 "Status messages and diagnostic information" of

(for detailed information refer to chapter 6.6 "Status messages and diagnostic information" of

(for detailed information refer to chapter 6.6 "Status messages and diagnostic information" of (for detailed information refer to chapter 6.6 "Status messages and diagnostic information" of

the MFC 400 Handbook). Each "Event group" will consist of up to 32 so called "Single events".

the MFC 400 Handbook). Each "Event group" will consist of up to 32 so called "Single events".

the MFC 400 Handbook). Each "Event group" will consist of up to 32 so called "Single events". the MFC 400 Handbook). Each "Event group" will consist of up to 32 so called "Single events".

The diagnosis event bit of an "Event group" will be set if at least one "Single event" belonging to

The diagnosis event bit of an "Event group" will be set if at least one "Single event" belonging to

The diagnosis event bit of an "Event group" will be set if at least one "Single event" belonging to The diagnosis event bit of an "Event group" will be set if at least one "Single event" belonging to

this "Event group" will occur. "Single events" occurred can be displayed by using the MFC 400

this "Event group" will occur. "Single events" occurred can be displayed by using the MFC 400

this "Event group" will occur. "Single events" occurred can be displayed by using the MFC 400 this "Event group" will occur. "Single events" occurred can be displayed by using the MFC 400

display menu and/or by using the MFC 400 PROFIBUS DTM or the MFC 400 PROFIBUS EDD in

display menu and/or by using the MFC 400 PROFIBUS DTM or the MFC 400 PROFIBUS EDD in

display menu and/or by using the MFC 400 PROFIBUS DTM or the MFC 400 PROFIBUS EDD in display menu and/or by using the MFC 400 PROFIBUS DTM or the MFC 400 PROFIBUS EDD in

conjunction with the appropriate control software (MFC 400 PROFIBUS DTM in conjunction with

conjunction with the appropriate control software (MFC 400 PROFIBUS DTM in conjunction with

conjunction with the appropriate control software (MFC 400 PROFIBUS DTM in conjunction with conjunction with the appropriate control software (MFC 400 PROFIBUS DTM in conjunction with

PACTware; the MFC 400 PROFIBUS EDD in conjunction with SIMATIC PDM). An overview of all

PACTware; the MFC 400 PROFIBUS EDD in conjuncti

PACTware; the MFC 400 PROFIBUS EDD in conjunction with SIMATIC PDM). An overview of all PACTware; the MFC 400 PROFIBUS EDD in conjunction with SIMATIC PDM). An overview of all

"Single events" supported by MFC 400 can be found in the MFC 400 Handbook.

"Single events" supported by MFC 400 can be found in the MFC 400 Handbook.

"Single events" supported by MFC 400 can be found in the MFC 400 Handbook."Single events" supported by MFC 400 can be found in the MFC 400 Handbook.

on with SIMATIC PDM). An overview of all

www.krohne.com06/2013 - 4002835301 - AD MFC 400 PROFIBUS R01 en

35

Page 36

4 COMMISSIONING / OPERATION

Displaying "Single events" currently existing using the MFC 400 PROFIBUS DTM:

Displaying "Single events" currently existing using the MFC 400 PROFIBUS DTM:

Displaying "Single events" currently existing using the MFC 400 PROFIBUS DTM:Displaying "Single events" currently existing using the MFC 400 PROFIBUS DTM:

Enter Menu "Device → Diagnosis → Current status messages" to get a detailed view of all "Event

groups" with at least one "Single event" currently existing:

• Have a look at section "Current status display (click for details)"

• All "Event groups" with at least one "Single event" currently existing will be displayed

• A "double-click" on an "Event group" displayed will display all "Single events" (belonging to

this "Event group") currently existing.

Note: A "single-click" on both an "Event group" or an "Single event" will display additional

information within section "Detailed information for selected status"

Displaying "Single events" currently existing using the MFC 400 PROFIBUS EDD:

Displaying "Single events" currently existing using the MFC 400 PROFIBUS EDD:

Displaying "Single events" currently existing using the MFC 400 PROFIBUS EDD:Displaying "Single events" currently existing using the MFC 400 PROFIBUS EDD:

Enter Menu "Diagnostics → General (Online)" to get a rough general view of all "Event groups"

with at least one "Single event" currently existing:

MFC 400

• Have a look at section "Diagnosis (Profile)"

• All "Event groups" with at least one "Single event" currently existing will be marked (see

check box in front of the name of the "Event group")

Enter Menu "Diagnostics → Details (Online)" to get a more detailed view of all "Event groups"

with at least one "Single event" currently existing:

• Have a look at section "Detailed Status Information"

• All "Event groups" with at least one "Single event" currently existing will be displayed

• All "Single events" (belonging to a "Event group" displayed) currently existing will be marked

(see check box in front of the name of the "Single event")

Displaying "Single events" currently existing using the MFC 400 display menu:

Displaying "Single events" currently existing using the MFC 400 display menu: