Page 1

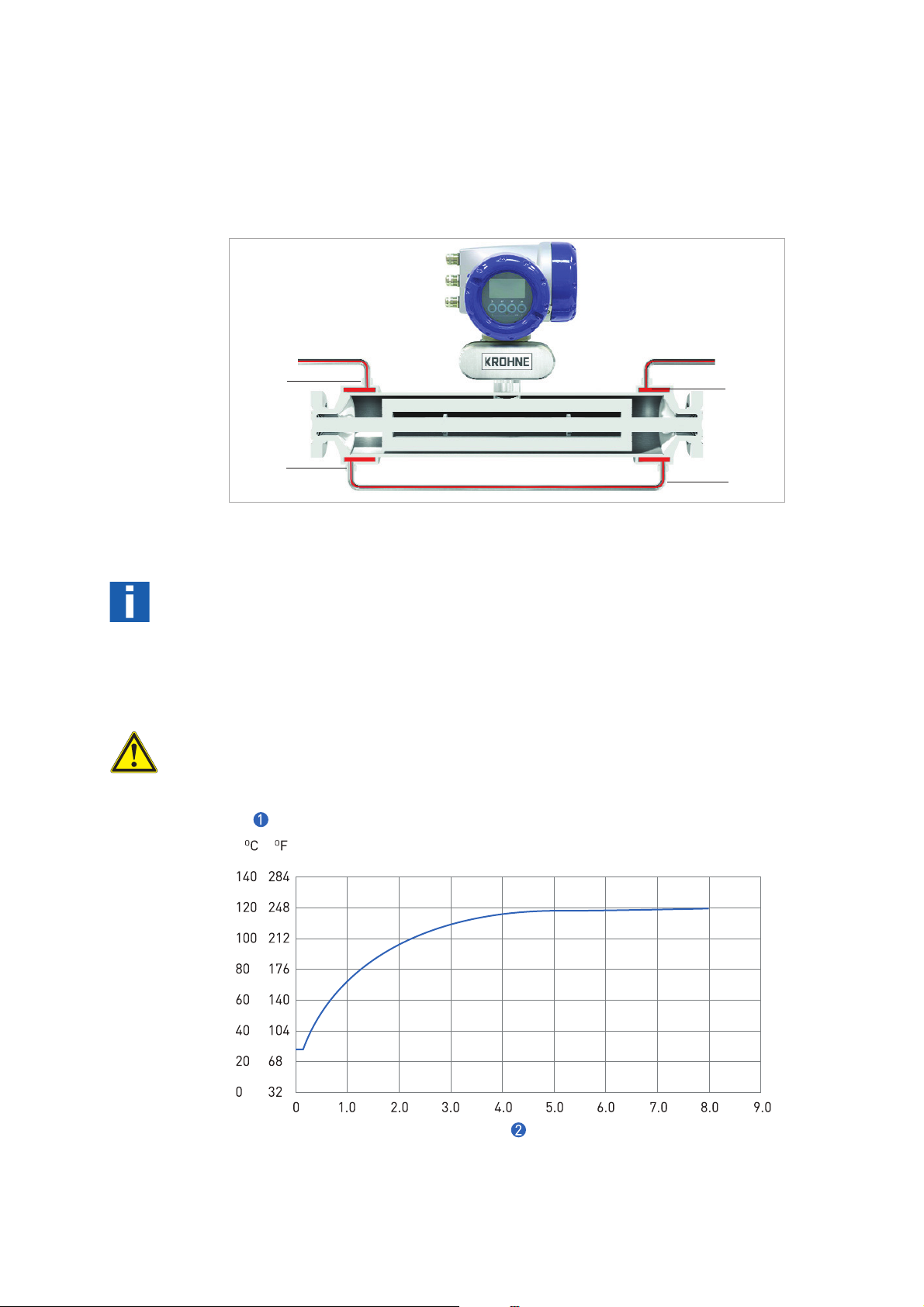

• 1000 Series Twin Straight Tube Coriolis Mass Flowmeter

• 2000 Series Twin Straight Tube Coriolis Ma

ss Flowmeter

• 3000 Series Single Z Tube Coriolis Mass Flowmeter

• 7000 Series Single Straight Tube Co

riolis Mass Flowmeter

• 8000/9000 Series Twin U Tube Coriolis Mass Flowmeter

OPTIMASS

Handbook

r

s

Page 2

2

Page 3

3

CONTENTS

1. Safety Instructions

1.1 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.2 CE/EMC Standards/Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.3 PED Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4 Secondary Containment & Burst Discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.5 Explanation of Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2. Instrument Description

2.1. Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.1 Flanged Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.2 Hygienic Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.3 Remote Field/Wall Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3. Installation Guidance

3.1 General Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2 General Installation Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

OPTIMASS

3.4 Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.5 CSA Dual Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4. OPTIMASS 1000 (Twin Straight Tube Meter)

4.1 Specific Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.2 Ambient/Prcocess Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.3 Pressure Equipment Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.4 Secondary Pressure Containment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.5 Hygienic Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.6 Pressure Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.7 Heating and Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.8 Purge Ports & Burst Discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.9 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5. OPTIMASS 2000 (Twin Straight Tube Meter)

5.1 Specific Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.2 Ambient/Process Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.3 Pressure Equipment Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.4 Secondary Pressure Containment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.5 Hygienic Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.6 Pressure Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5.7 Heating and Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.8 Purge Ports & Burst Discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

5.9 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6. OPTIMASS 3000 (Single Z Shaped Tube Meter)

6.1 Specific Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.2 Ambient/Process Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Page 4

4

6.3 Pressure Equipment Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.4 Secondary Pressure Containment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.5 Pressure Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.6 Heating & Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.7 Purge Port Meters & Burst Discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.8 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7. OPTIMASS 7000 (Single Straight Tube Meter)

7.1 Specific Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

7.2 Ambient/Process Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

7.3 Pressure Equipment Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

7.4 Secondary Pressure Containment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7.5 Hygienic Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7.6 Pressure Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

7.7 Heating and Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

7.8 Purge Port and Burst Discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

7.9 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

8. OPTIMASS 8000/9000 (Twin U Tube Meter)

8.1 Specific Installation Guidlines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

8.2 Ambient/Process Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

8.3 Pressure Equipment Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

8.4 Secondary Pressure Containment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

8.5 Pressure De-rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

8.6 Hygienic and Sanitary Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

8.7 Heating and Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

8.8 Purge Ports and Burst Discs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

8.9 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

9. MFC 300 Converter

9.1 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

9.2 Mounting MFC 300W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

9.3 Mounting MFC 300F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

9.4 Changing Display Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

9.5 Mains Power Connection versions C, F and W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

9.6 Connection of Remote Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

9.6.1 MFC 300F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

9.6.2 MFC 300W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

9.6.3 MFC 300R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

9.7 I/O Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

9.7.1 Basic I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

9.7.2 Fixed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

9.7.3 Modular I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

9.8 Operating Data I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

9.8.1 Current Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Page 5

5

9.8.2 Pulse & Frequency Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

9.8.3 Status Output and Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

9.8.4 Control Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

9.9 Connection Diagrams (Outputs/Inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

9.9.1 MFC300 W Connection Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

9.9.2 Basic I/O Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

9.9.3 Modular I/O & BUS I/O Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . .89

9.9.4 HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

9.10 Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

9.11 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

10. Start Up

10.1 Operator Control of the Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

10.2 Time Out Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

10.3 Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

10.4 Table of Settable Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

10.5 Description of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

11. Service and Troubleshooting

11.1 Diagnostic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

11.2 Functional Tests and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

11.3 Driver or Sensor Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

11.4 Replacing the Sensor or Converter Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

11.5 Status Messages and Diagnostics Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

12. Additional Information

12.1 External Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

12.2 Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

12.3 Krohne Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

12.4 Declaration of Cleanliness Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

12.5 Specimin Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

Page 6

6

1

SAFETY INSTRUCTIONS

Congratulations on purchasing this high quality product. To get the best out of your mass

flowmeter, please take some time to read through this handbook which describes the many

features and options available. Please refer to the index for a list of detailed topics.

If applicable, a separate document is supplied that describes hazardous area information.

1.1 Intended Use

The OPTIMASS mass flowmeter family is designed for the direct measurement of mass flow

rate, product density and product temperature. Indirectly, it also enables measurement of

parameters such as: total mass; concentration of dissolved substances and the volume flow.

For use in hazardous areas, special codes and regulations are applicable which are specified in

a separate handbook.

Responsibility as to the suitability and intended use of our instruments rests solely with the

purchaser. The supplier does not accept any liability resulting from misuse by the customer.

Improper installation and operation of the flow meters may lead to loss of warranty. Warranty

is also null and void if the instrument is damaged or interfered with in any way.

In addition, the “general conditions of sale” which forms the basis of the purchase agreement

are applicable.

If you need to return your OPTIMASS flow meters to KROHNE, please complete the form on the

last page of this handbook and return it with the meter to be repaired. KROHNE regrets that it

cannot repair or check your flow meter unless accompanied by a completed form.

OPTIMASS

1.2 CE/EMC Standards/Approvals

The OPTIMASS family with the MFC 300/010 signal converter meets all the requirements of the

EU-EMC and PED Directives and bears the CE Symbol.

The OPTIMASS system is approved for hazardous duty installations to the harmonised

European Standards (ATEX) to Factory Mutual (FM) and CSA (Canadian Standards).

Technical data subject to change without notice

It should be noted that this handbook MUST be read in conjunction with the following additional

documentation:

• Hazardous Areas Handbook.

• Communications Handbook.

• Concentration Handbook.

• Corrosion Guidelines.

1.3 PED Integrity

To ensure the PED integrity of the meter, you MUST ensure that the serial numbers on both the

conveter (or remote terminal box) data label and the sensor match.

1.4 Secondary Containment & Burst Discs

Where the meter is being used to measure:

• high pressure gases

• gases kept as liquids by high pressure

and/or where there is a risk of tube failure because of:

• the use of corrosive and/or errosive process fluids

• frequent pressure and/or temperature shocking

• seismic or other shock loading

Krohne strongly recommends that a secondary containment option is purchased. Where the

above situation applies and the process pressure exceeds the secondary pressure containment, Krohne recommends that the burst disc option is also purchased. For more information,

please contact Krohne Ltd

Page 7

7

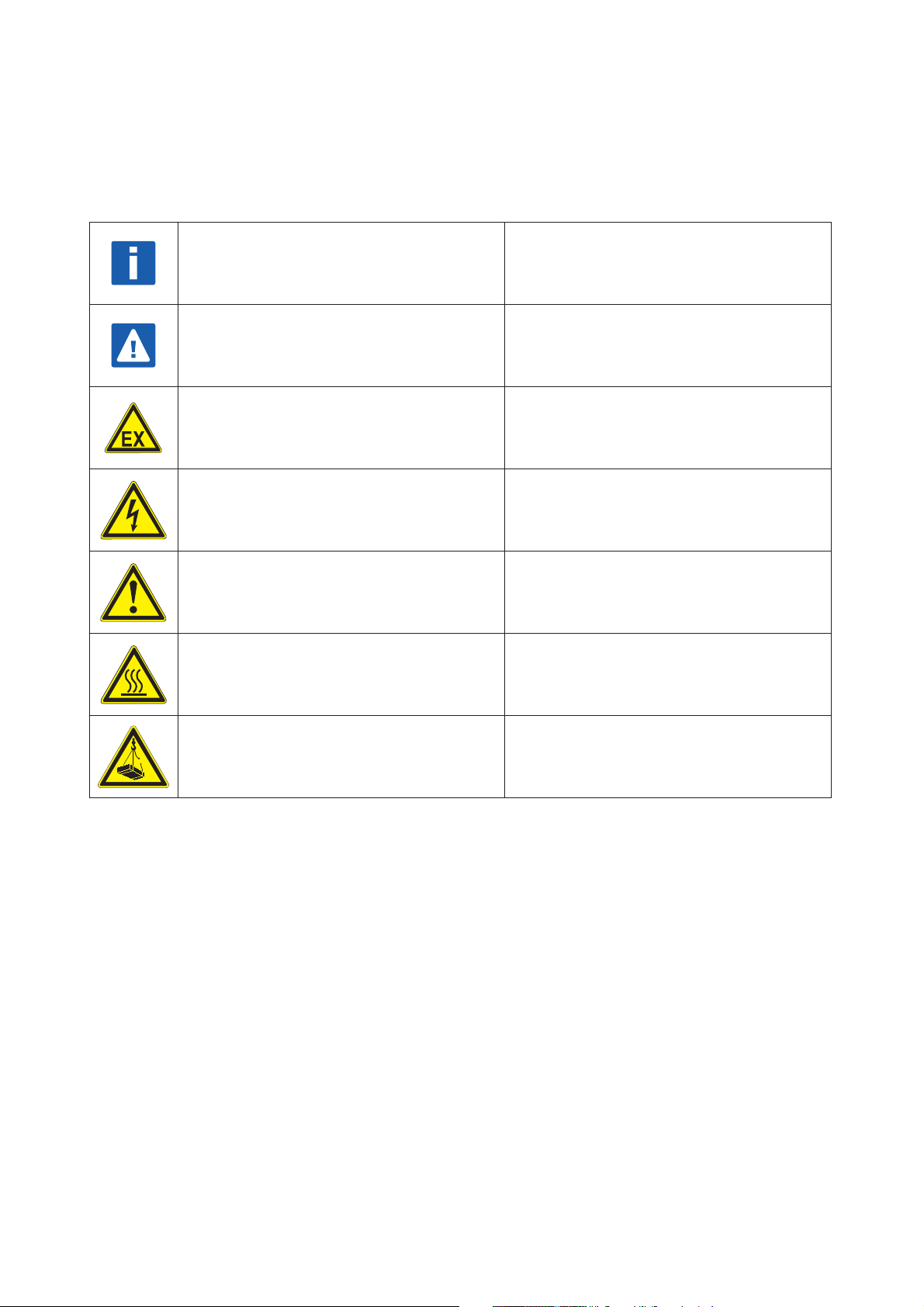

1.5 Explanation of Symbols Used

General Information

General Warning

EX - Hazardous Area Warning

High Voltage

General Hazard

Hot Surface or High Temperature

Heavy Item

The following is a guide to the meaning of the symbols used in this handbook.The symbols fall

into two types. The rectangular symbols with blue background draws the reader’s attention to

general points of information. The triangular symbols with yellow background draw the reader’s attention to hazards or hazardous situations.

Information is important to the

installation/operation of the meter.

Risk of damage to the meter or installation.

Instruction MUST be observed in order to

comply with Hazardous Areas Certification.

Risk of electric shock.

Non specific hazard that could result in injury.

Risk of burning.

Risk of injury.

Page 8

8

2

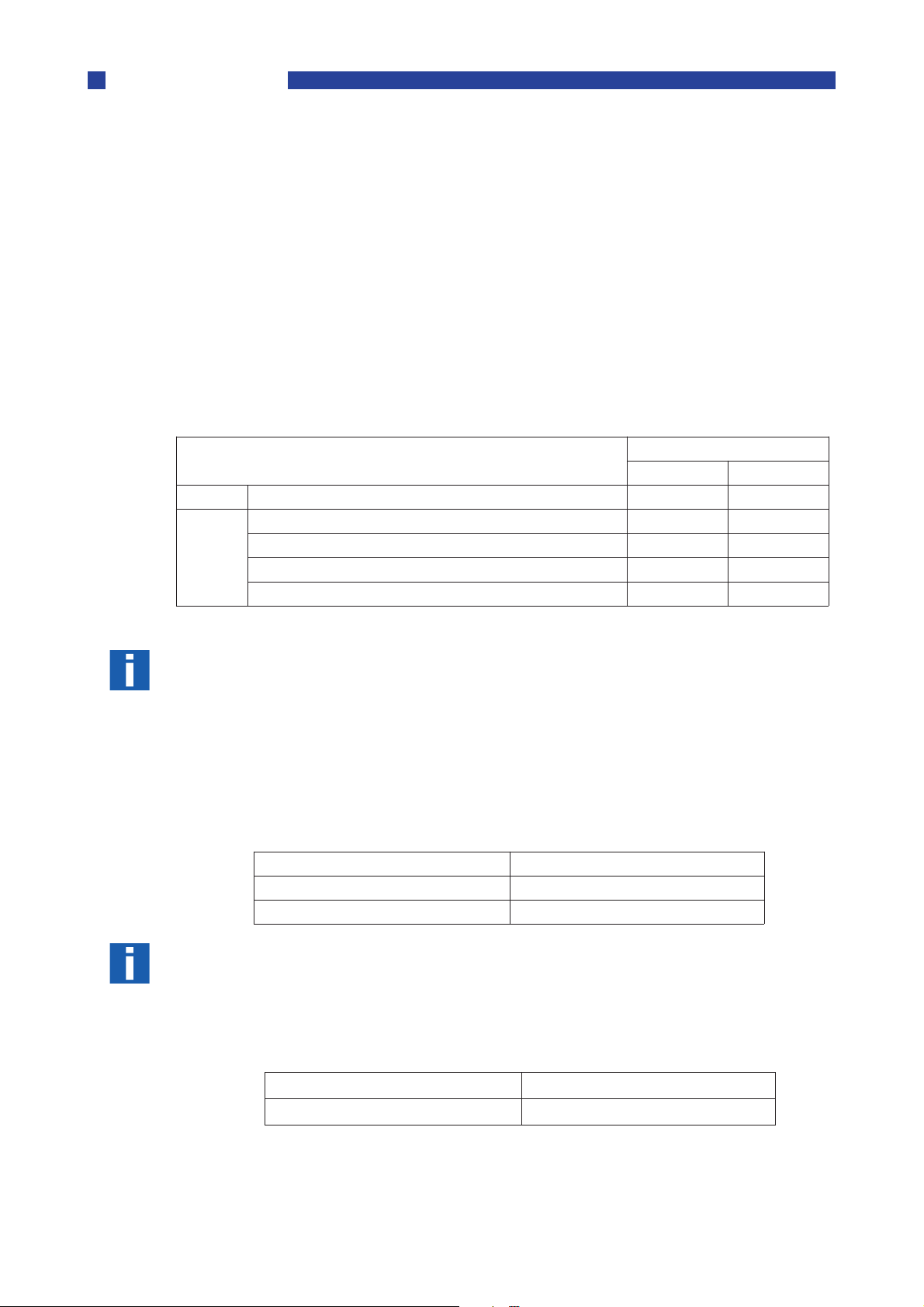

2.1.1 Flange Versions

2.1.2 Hygienic Versions

2.1.3 Remote Field/Wall/Rack Conveter

Wall Converter

19” Rack Mount Converter

INSTRUMENT DESCRIPTION

2.1 Scope of Delivery

When unpacking your meter, please ensure that no visible damage has occurred during transportation. If damage has occurred, please contact the carrier for claims.

Your high quality instrument has been fully tested and checked before shipping. The following

items should be included with your instrument unless otherwise requested:

1. OPTIMASS Mass Flow Meter

2. Separate Converter with remote converter wall mount (not for compact version)

3. CD-ROM & Quick Start Guides

4. Screw driver for terminal connections

5. Calibration certificate

6. Factory and Material certification, if ordered.

If any of these items are missing, please contact your nearest KROHNE Office or representative

(see back page).

If your meter has been ordered with a flange connection, this will be supplied as per your order

and the flange specification is stamped on the outer edge of the flange.

OPTIMASS

Please check this specification against your original order and refer to the appropriate section

in this handbook.

If your meter was ordered with a hygienic connector, it should be noted that the ‘O’ ring seals

between the meter and process pipework are NOT normally supplied.

If the hygienic connection is via an adaptor, then ‘O’ rings (material EPDM) are supplied in

order to make the connection between the meter and the adaptor. Please note that other

materials are available on request.

‘O’ rings are not normally supplied for the seal between the adaptor connection and process

pipework.

Adaptor connections may also be supplied loose, dependng upon type supplied.

For DIN11864-2 connections, ‘O’ rings and counter flanges are not supplied as standard but

are available on request.

The OPTIMASS range of massflow meters are normally supplied with the converter integrally

fitted. If you have specified a remote converter, the meter will be supplied with the converter

as a separate unit, together with a wall/pipe mounting bracket and a connection box mounted

to the meter.

In order to comply with 3A approval, all unused holes MUST be plugged and unused threads

MUST be covered or removed!

If ordered with the meter, cabling is supplied loose and IS NOT pre-prepared!

If specified at the time of ordering, the meter will be supplied with a plastic wall mounted converter that can be mounted on a wall or a pipe The housing material is Polyamide - polycarbonate.

Please note that the wall converter has not been 3A approved for hygienic applications.

If specified at the time of ordering, the meter will be supplied with a 19” rack mounted converter

Page 9

9

3

INSTALLATION GUIDANCE

3.1 General Installation Information

The OPTIMASS mass flow meters provide high accuracy and excellent repeatability. Narrow

band pass digital filtering, and the mathematically modelled internal primary head design with

AST (Adaptive Sensor Technology) for the OPTIMASS sensor family provide exceptional immunity to external disturbances caused by vibrations from nearby process equipment.

The accuracy of the flow meter is not affected by velocity profile.

The following installation guidelines are practical to implement, particularly if planned before

the OPTIMASS meter is first installed. For further dimensions or connections, please refer to

the relevant section.

For the OPTIMASS, in general, no special mounting requirements are necessary. However,

good general engineering practice for the installation of flow meters should still be observed.

The general guidelines described in this section are valid for the complete OPTIMASS family of

mass flow meters

• The mass flow meters do not require any straight inlet or outlet runs.

• Due to the weight of the meters we recommend the use of supports.

• It is permissible to support the body of the meter.

• The meter can be installed horizontally, in an upward sloping pipeline or vertically. For best

results, a vertical installation with flow in an upward direction is recommended.

OPTIMASS

This label on the meter shows the flow direction programmed into the converter in function

C.1.3.1

As default this is always in the direction of the ‘+’ arrow, i.e. left-to right as the label is viewed.

3.2 General Installation Principles

1

456

2

3

Page 10

10

1 Horizontal intalation with flow from left to right

Notes:

NOTE:

OPTIMASS

Liquids

Pressure/Temperature data:

2 Vertcial installation with flow uphill

3 Angled installation with flow uphill

4 Horizontal installation with long vertical drops after the meter ARE NOT recommended

5 6 Vertical installations with isolation valves fitted for setting the zero calibration. It is rec-

ommended that a valve is fitted below the meter to prevent a reverse flow when the

pump is switched off.

Avoid long vertical runs after the meter (4). They can cause siphoning and therefore measurement errors. If long vertical runs are unavoidable, then you should use a valve or orifice plate

downstream of the mter in order to the restrict flow.

Avoid mounting the meter at the highest point in the pipeline. Air or gas can accumulate here

and cause faulty measurements.

3.3 Storage

If the meter is to be stored prior to installation, it is recomended that the meter is stored in its

original packaging and that the ambient temperature range does not exceed -50°C or 85°C

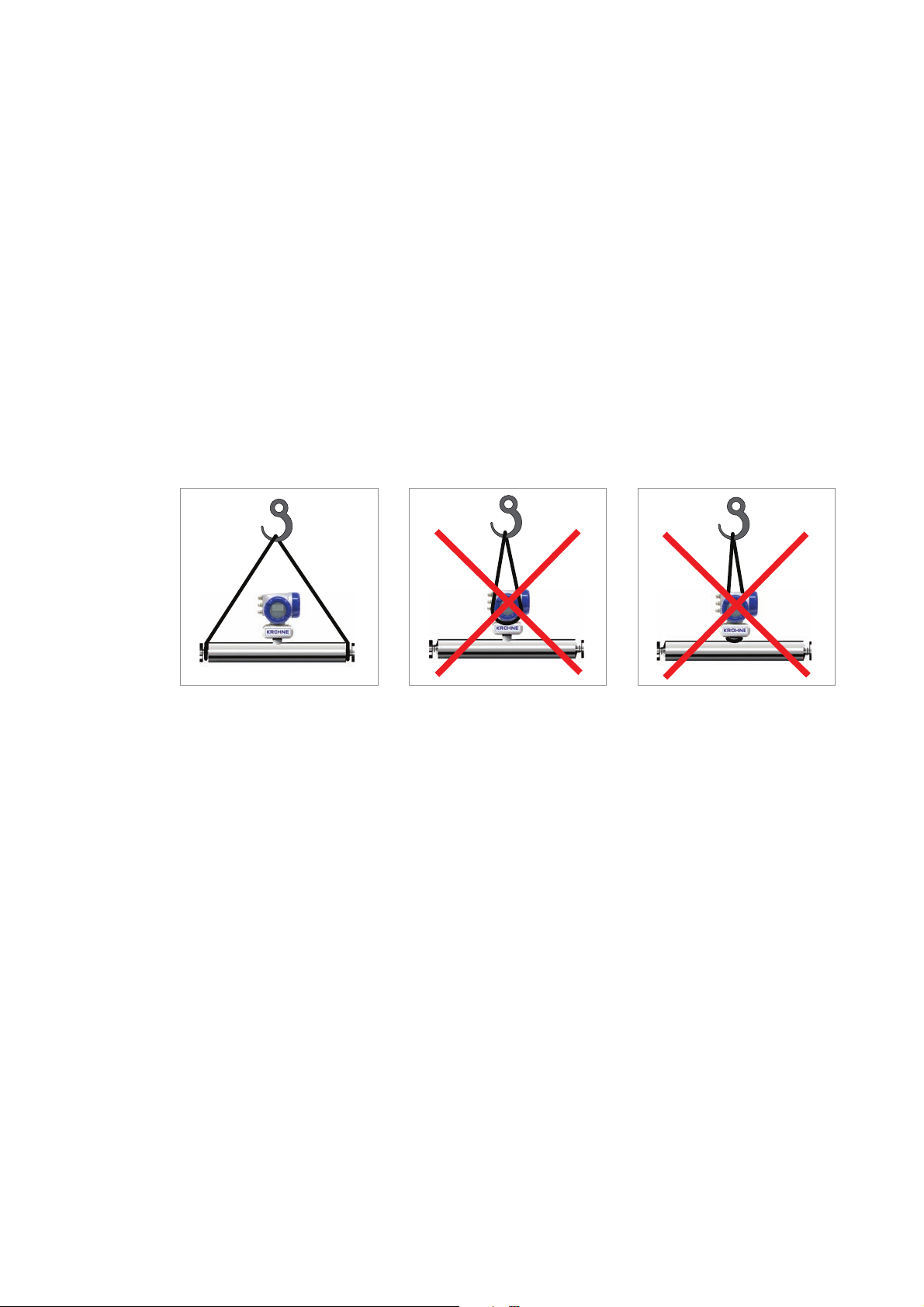

3.4 Lifting

1

1 Use a well maintained sling to lift the meter by the spigots

2 DO NOT lift the meter by the electronics housing.

3 DO NOT lift the meter by the electronics stem.

The 1000 and 2000 meters have 4 eye holes on the outer tube, 2 each end. These can be used

to lift the meter into place on vertical installations, where the meter is supplied with hygienic

connections. Please be aware, that they ARE NOT suitable for lifting the meter where is has

been supplied with [heavier] flange connections. It is the user’s responsibility to use suitable

lifting equipment.

2

3

3.5 CSA Dual Seal

To cover the requirements of ANSI/ISA -12.27.01-2003 “Requirements for Process Sealing

Between Electrical Systems and Flammable or Combustible Process Fluids” a secondary seal

is incorporated into all Optimass/gas products. If the primary seal fails, the secondary seal will

prevent escaping fluid reaching the electronic compartment.

OPTIMASS 1000 / 1300 / 1010 -40°C...130°C and 100...10,000 kPa

OPTIMASS 2000 / 2300 / 2010 -45°C...130°C and 100...14,000 kPa

OPTIMASS 3000 / 3300 / 3010 -40°C...150°C and 100...15,000 kPa

OPTIMASS 7000 / 7300 / 7010 -40°C...150°C and 100...10,000 kPa

1000, 2000, 3000, 7000, 8000, 9000

(Example model code: OPTIMASS 1000C S25 – LIQUID)

Page 11

11

OPTIMASS 8000 / 8300 / 8010 -180°C...230°C and 100 to 26,000 kPa

Meter Status:

Gases

Regular Maintenance of Burst Disc:

OPTIMASS 9000 / 9300 / 9010 0°C...350°C and 100 to 26,000 kPa

If the primary seal fails, the casing of the meter will fill with liquid and the meter will stop

working. The meter will notify the operator by going into <start up> mode and a diagnostic

error will be shown on the MFC300 or PLC display. This is an indication that the primary seal

(tube/s) has failed and the status of the meter should be checked.

The meter will also go into <Start up> mode if the primary seal (tube/s) fail, or are not completely filled with fluid. For example, if the meter is drained or re/filled. To check the status of

the meter, drain and re/fill with fluid and note the MFC300 or PLC display. See section11.5 for a

list of status messages and diagnistics information.

If the meter remains in <Start Up> mode you MUST assume that the primary seal (tube/s) has

failed and the appropriate action MUST be taken.

(Example model code: OPTIMASS 1000C S25 – GAS)

Pressure/Temperature data:

OPTIMASS 1000 / 1300 / 1010 -40°C...130°C and +500 to +10,000 kPa

OPTIMASS 2000 / 2300 / 2010 -45°C...130°C and +500 to +15,000 kPa

OPTIMASS 3000 / 3300 / 3010 -40°C...150°C and +500 to +15,000 kPa

OPTIMASS 7000 / 7300 / 7010 -40°C...150°C and +500 to +10,000 kPa

OPTIMASS 8000 / 8300 / 8010 -180°C...30°Cand +2000 to +26,000 kPa

OPTIMASS 9000 / 9300 / 9010 0°C...350°C and +2000 to +26,000 kPa

Pressures and/or temperatures may be further limited by tube, temperature, connection and

Ex limits. Consult the meter data plates and relevant documentation for full details.

On all meters operating on gas measurement the casing of the meter is fitted with a burst disc.

If the the primary seal (tube/s) fails leakage will occur from the burst disc.

Install the meter so that the burst disc is pointing away from personnel.

Carry out regular maintenance checks on burst discs for leakage and/or blockages.

On all OPTIMASS meters, the primary seal is considered to be the measuring tube of the

meter. The materials of construction of the measuring tube/s are described within the relevant

sections of this handbook and the customer’s product and any other fluid flowing through the

tube must be compatible with the material of construction.

If failure of the primary seal is suspected then the process line should be de-pressurised and

the meter removed as soon as it is safe to do so. Please then contact Krohne customer service

for servicing or replacement of the meter.

Page 12

12

4

Meter Max. Temperature Shift

Measuring tube: Sealing Faces:

Process

Ambient

OPTIMASS 1000

4.1 Specific Installation Guidelines

• Tighten flange bolts evenly.

• Observe the pipe end loads as shown in s. 4.6

• It is permissible to support the weight of the meter on the body.

• Use of standard pipework reducers at the flange is allowed. Avoid extreme changes in pipe

• The use of flexible hoses directly at the meter is permitted.

• The meter can be installed so that the converter is on the side of the meter, resulting in the

• The 1000 series has exceptional immunity to cross-talk, therefore allowing meters to be

4.2 Ambient / Process temperatures

The specified and approved ambient and process temperatures must be observed.

OPTIMASS

size (step changes).

measuring tubes on top of each other, unless gases or solids are being measured.

used in series.

SS318L

°C °F

All meters -45...+130 -49...266

Compact Al. -40...+60 40...+140

Compact Al. with certain I/O options (consult Krohne) -40...+65 -40...+149

Compact SS -40...+55 -40...+131

Remote -40...+65 -40...+149

Note:

For additional temperature limits in hazardous area applications, reference should be made to

the publication “

Where meters are mounted in direct sunlight, it is recommended to install a sunshade. This is

particularly important in countries with high ambient temperatures.

The maximum differential temperature between the process and ambient temperature without

insulation is 110°C or 200°F.

To avoid thermal shock, the meter MUST not be subject to rapid changes in process tempratures and reference should be made to the following table

Operation outside these limits may result in shifts in density and mass flow calibration.

Repeated shocking may also lead to premature failure of the meter!

Guidelines for the use of Coriolis Meters in Hazardous Areas”.

S15 & S25 80°C

S40 & S50 110°C

4.3 Pressure Equipment Directive (PED) requirements

To comply with the requirements of the PED in Europe, the following information is provided to

assist the plant engineer in installing the meter:

Stainless Steel UNS 31803 Stainless Steel 316L

The outer cylinder 304 / 304L is dual certified (Optional outer cylinder of 316/316L). This also

applies to PED certified housings.

Wiring feedthrough is made of Epoxy (or PEEK) with 2 ‘O’ ring seals in FPM / FKM &

Hydrogenated Nitrile.

Page 13

13

Flanges all 316 / 316 L dual certified.

Note:

Hygienic Connections are 316L

Optional heating jacket 316 / 316L

Note: Outer cylinder is in contact with heating medium

4.4 Secondary Pressure containment

The OPTIMASS 1000 meters are supplied (as standard) without certified housings that have a

typical burst pressure

Options are available with PED certified housings, with the following pressure ratings:

304/304L and 316/316L: 63 bar @20°C 580 psi @ 68°F

316/316L: 100 bar @20°C 1450 psi @ 68°F

If the user suspects that the primary tube has failed, the unit must be depressurised and

removed from service as soon as it is safe to do so.

In the 1000 series there is a high pressure wire feed through with ‘O’ rings that might not be

compatible with the process fluid for an extended period if a primary tube fails.

It is the user’s responsibility to ensure that the materials used are compatible with this product.

Other ‘O’ ring materials are available on request.

>100 barg.

4.5 Hygienic Applications

The OPTIMASS 1000 series is available with a variety of hygienic process connectors.

When installing / using meters with hygienic process connectors, support /clamp the meter

properly. The meters are heavy and could injure when disconnected from the adjacent pipe

work.

The recommended method of installation is to mount the meter against a support / wall with

the body of the meter supported / clamped. The process pipe work can then be supported off

the meter. The meter is too heavy to be supported from the thin walled piping usually associated with the hygienic industry

1

1 2 Meter Supports

2

Page 14

14

The 3A approval for the 1000 series requires that it is “self draining”. Install the meter vertical-

Installation lengths

whichever is the lower.

Maximum pipe work forces

ly with the flow running uphill.

For installation lengths, please see section 4.9

Please check with KROHNE if you are unsure of the installation length. Many meters are built

to customer requirements / specifications especially where special hygienic process nectors

have been adapted to the meter. As these are normally non-standard, the installation length

will not be given in the technical data

It is also recommended that the seals be replaced regularly to maintain the hygienic integrity

of the connection.

Unless specifically requested, internal surfaces are not polished and no warranty is made as to

the surface finish.

If polishing option and /or EHEDG, ASME Bio-Processing or 3A approvals was selected at time

of order, all product contact surfaces are polished 0.5 micrometer Ra (20CLa) finish or better.

4.6 Pressure ratings

Tubes and secondary

pressure containment 100 barg

De-rated to 80 bar at 130°C (1160 psi at 266°F)

Heating Jacket 10 bar at 130°C (145 psi at 266°F)

Secondary pressure containment 63 barg 63 bar at 20°C (914 psi at 68°F)

De-rated to 50 bar at 130°C (725 psi at 266°F)

Meter data plates are stamped with maximum pressure rating at both 20°C (68°F) and max.

operating temperature of connection, primary tube or secondary pressure containment

20°C 130°C

40 bar 100 bar 32 bar 80 bar

Size Max Load Max Load Max Load Max Load

15 25 kN 17 kN 18 kN 12 kN

25 38 kN 19 kN 28 kN 12 kN

40 48 kN 15 kN 35 kN 7 kN

100 bar at 20°C (1450 psi at 68°F)

50 99 kN 20 kN 72 kN 8 kN

Flange Connections

These loads are roughly equivalent to the max axial loading allowed in an un-radiographed butt

weld in a 316L schedule 40 pipe.

Loads given are maximum static loads. If loads are cycling, particularly between tension and

compression, these loads should be reduced.

Please consult KROHNE for more information.

Page 15

15

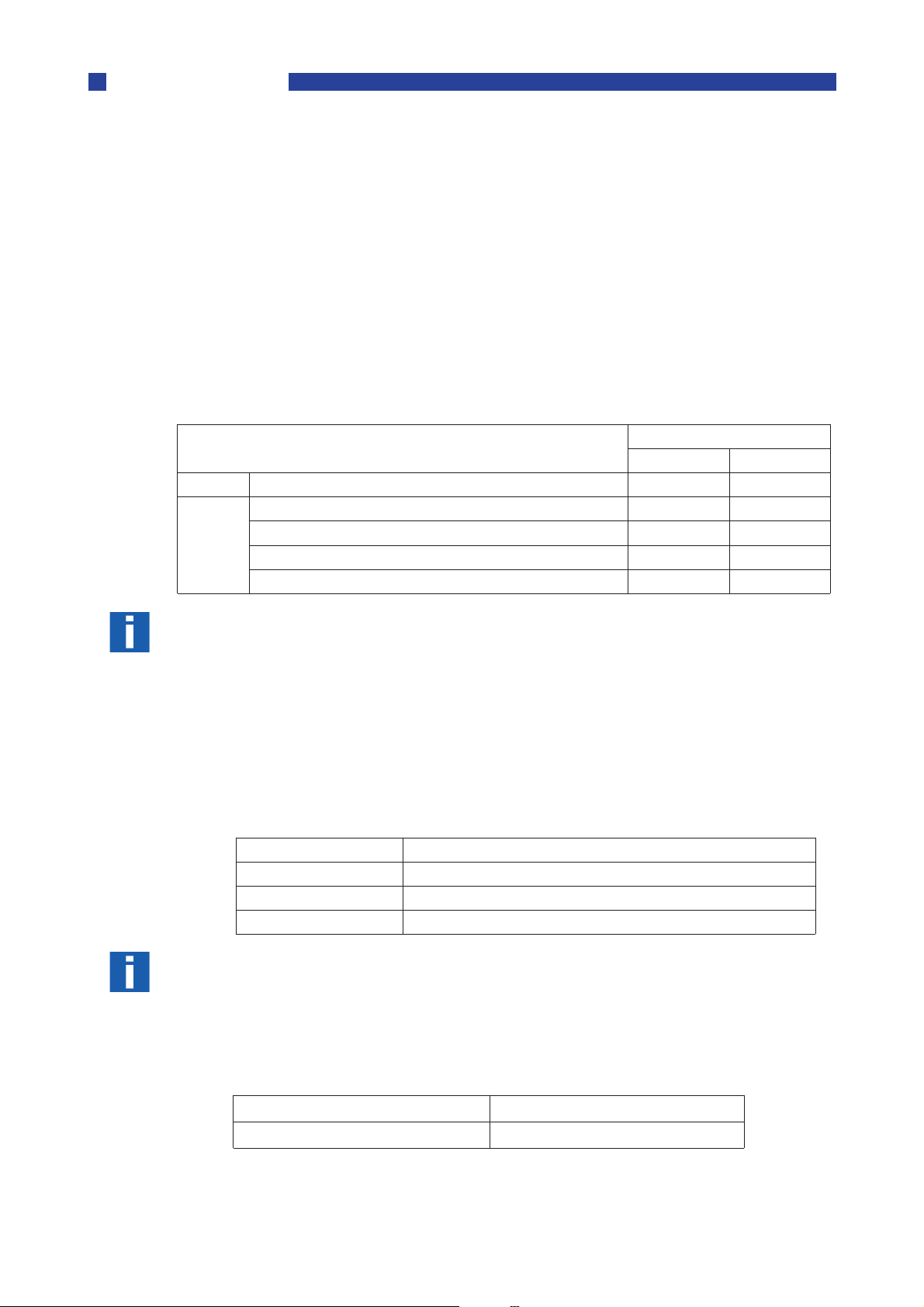

Pressure de-rating (barg)

-40 -20 0 20 40 60 80 100 120 130

T

O

C

100

90

80

70

60

50

40

30

20

10

0

7

4

5

6

8

1

P (barg)

2

3

-40 -20 0 20 40 60 80 100 120 130

T

O

F

1450

1305

1160

1015

870

725

580

435

290

145

0

7

4

5

6

8

1

P (psig)

2

3

Pressure de-rating (psig)

1 Measuring tubes (PED & CRN 15/25) and outer cyclinder 316 (100 barg PED option) PN100,

DIN2637, PN100

2 CRN S40 measuring tube

3 CRN S30 measuring tube

4 Outer cylinder 304 & 316 (63 barg PED option), DIN 2636, PN 63

5 DIN 2635 PN 40

6 JIS 20K

7 JIS 10K

8 Hygienic connection

1 Measuring tubes (PED & CRN 15/25) and outer cyclinder 316 (1450 psig PED option)

2 CRN S40 measuring tube

3 CRN S30 measuring tube

4 ASME 600 lbs

5 Outer cyclinder 304 & 316 (914 psig PED option)

6 ASME 300 lbs

7 ASME 150 lbs

8 Hygienic connection

Page 16

16

Insulation

Electrical Heating

Size

DIM

DIN flange ratings based on EN 1092-1: 2001 table 18, 1% proof stress material group 14EO

ASME flange ratings based on ASME B16.5: 2003 table 2 material group 2.2

JIS flange rating based on JIS 2220: 2001 table 1 division 1 material group 022a

4.7 Heating and insulation

There are several ways to heat the meter. In most cases heating is unnecessary as the meter

is designed as such that very little heat is lost or gained through the outer cylinder.

Where insulation is required a variety of materials may be used to insulate the meter. Care

must be taken not to insulate the meter above the halfway mark of the electronics support post

as shown.

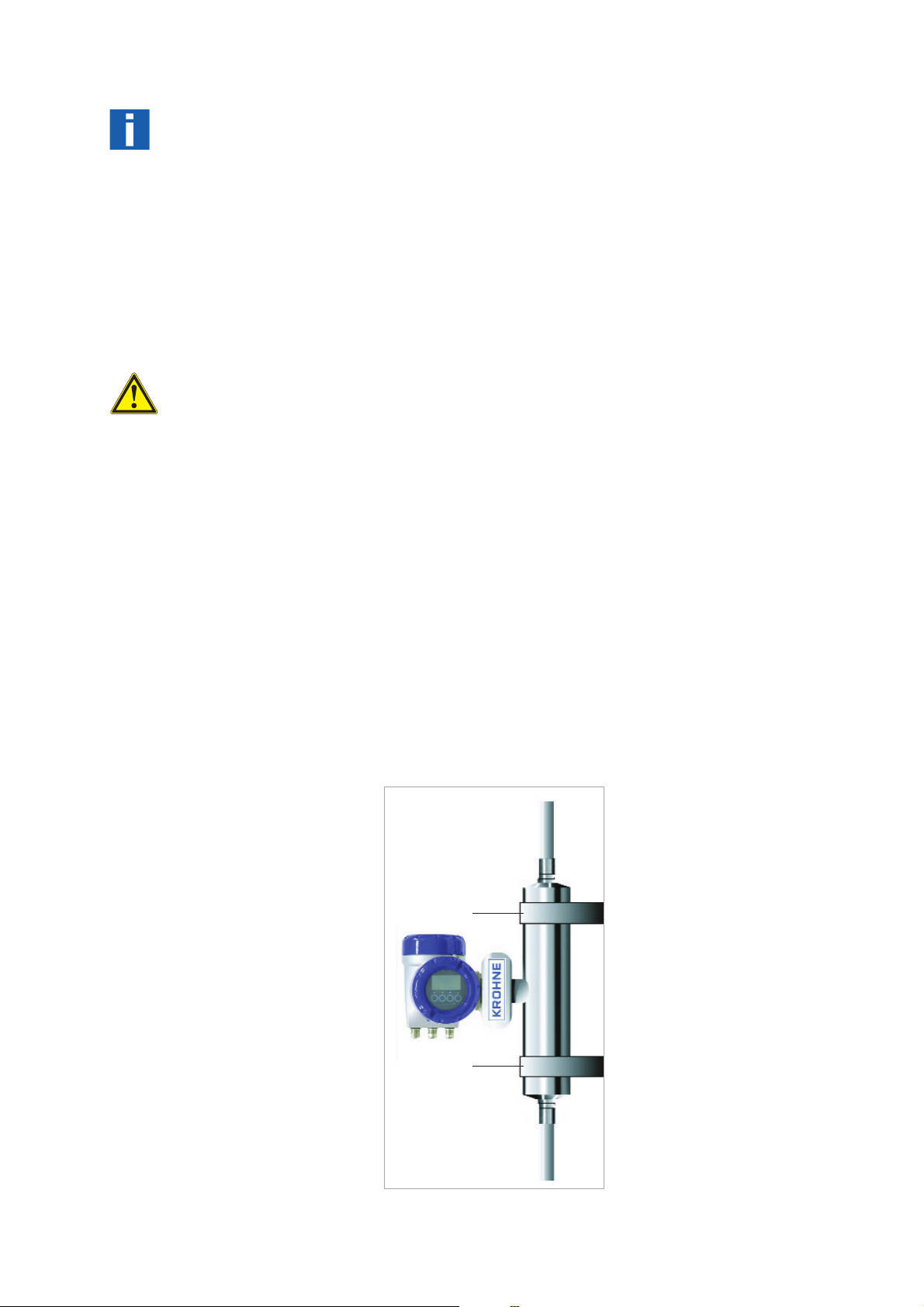

Electrical tape heating may be used. Care should be taken to only heat the sections where the

best effect will be achieved. Do not heat above the converter mount centre line See illustration.

1

2

3

2

1 Max insulation depth

2 Heated Areas

3 Do NOT heat this area

When insulating please observe guidelines as per insulation section.

2

15 65 mm

25 75 mm

40 110 mm

50 125 mm

Page 17

17

Cooling:

Important:

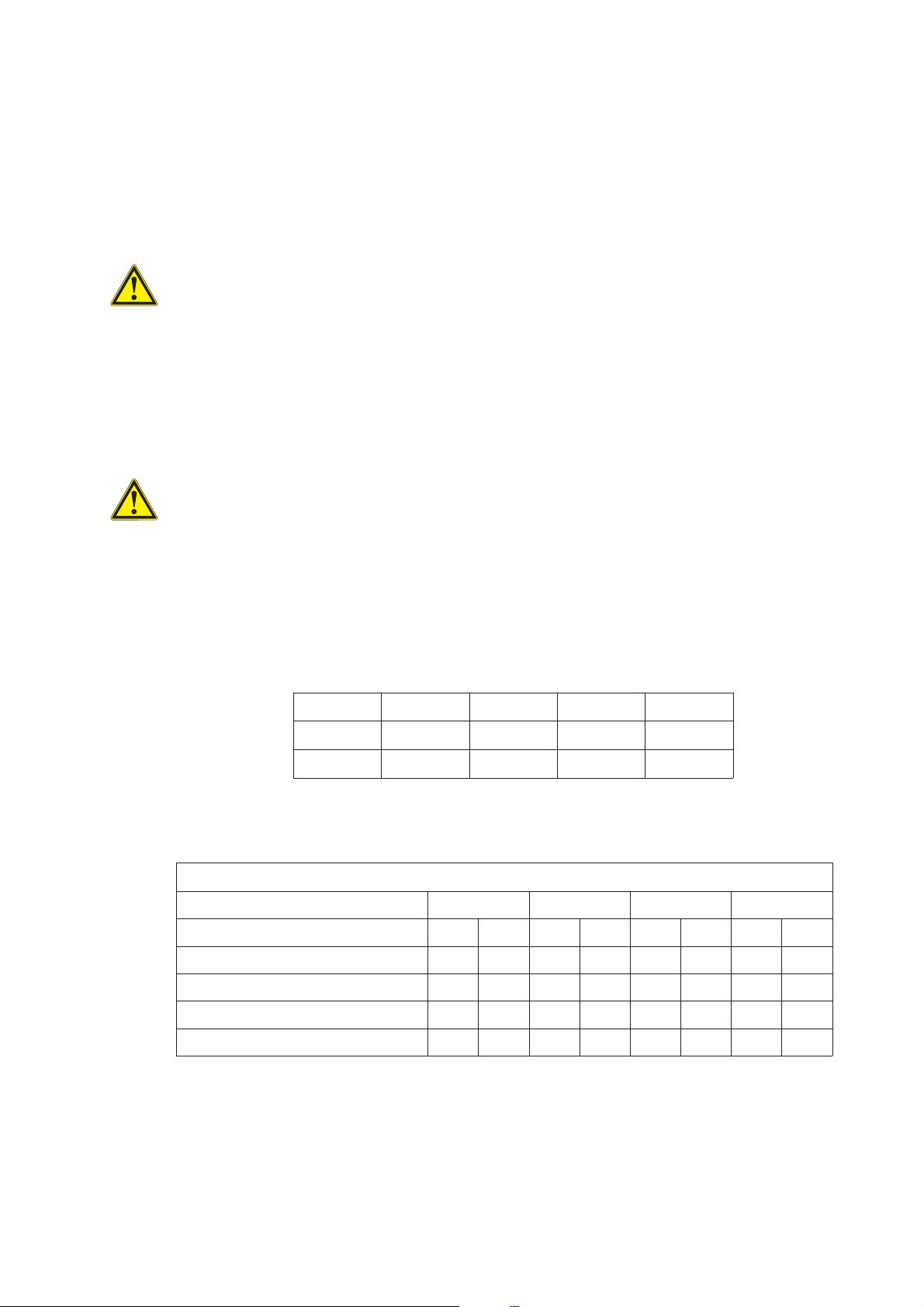

Heating Times (based on heating jacket operating at maximum temperature)

Liquid / S

team heating jacket

t

The meter can be supplied with a heating jacket. This jacket is designed to minimise the differential stress across the meter where differences in temperature between outer cylinder and

measuring tube exist.

The connections to the heating jacket are NPT or Ermeto sockets.

It is recommended that reinforced flexible hoses be used to connect the heating jacket to the

heat source.

1

3

2

4

1 2 3 4 Connection Points

Always heat the jacket to working temperature before flowing product in measuring tube.

Avoid the use of fluids that can cause crevice corrosion.

Although all the jacket materials are 316L, the outer cylinders are 304L (Optional 316L).

Connections should be made to ensure all air can be vented on liquid systems and all condensate can be drained on steam systems.

Note :

The maximum heating medium pressure and temperature for heating jackets is 10 bar at

130°C or 145 psig at 266°F.

1 Temperature at centre of measuring tube

2 Time (hours)

please consult KROHNE if cooling medium is to be used in the heating jacket.

Page 18

18

Minimum flow rate

4.8 Purge Port Meters and Burst Disc Meters

Weights (PN40 flanges)

15 25 40 50

kg lbs kg lbs kg lbs kg lbs

Kg/h

Lbs/min

Purge Port Options

If the purge port option was selected at time of order, then your meter will be fitted with ½”

NPT female connections – these will be clearly identified. These connections are sealed with

NPT plugs and PTFE tape.

Important:

Do not remove these plugs.

The meter is factory sealed with a dry nitrogen gas fill and any ingress of moisture will damage

the meter. The plugs should only be removed to purge the inside of the meter case of any

product if it is suspected that the primary measuring tube has failed. If it is suspected that the

primary tube has failed, depressurise and remove the meter from service, as soon as it is safe

to do so.

Burst Disc meters (Meters up to size 25 only)

OPTIMASS 1000 meters that have been ordered with a burst (rupture) disc will be suppled with

the disc fitted. The disc is fitted when the operating pressure of the measuring tube exceeds

the design pressure of the secondary containment. The disc failure pressure is 20bar @ 20°C.

Important:

The burst disc is suitable for the designed application according to the process conditions and

flow rates as per original order. If conditions alter, consult KROHNE for further advice regarding suitability of disc fitted.

If the product is in any way hazardous, it is strongly recommended that an exhaust tube is connected to the NPT male thread of the burst disc so that the discharge can be piped to a safe

area. This tube should be large enough that pressure cannot build up in the meter case.

Ensure arrow on burst disc is pointing away from meter

4.9 Technical Data

Maximum Flow Rates

15 25 40 50

Depending on measuring error required.

Compact with aluminium MFC 300 13.5 30 16.5 36 29.5 65 57.5 127

Compact with SS MFC 300 18.8 41 21.8 48 34.8 77 62.8 138

6,500 27,000 80,000 170,000

239 992 2,940 6,247

Remote with aluminium J box 11.5 25 14.5 32 25.5 56 51.5 113

Remote with SS J box 12.4 27 15.4 34 26.4 58 52.4 115

Page 19

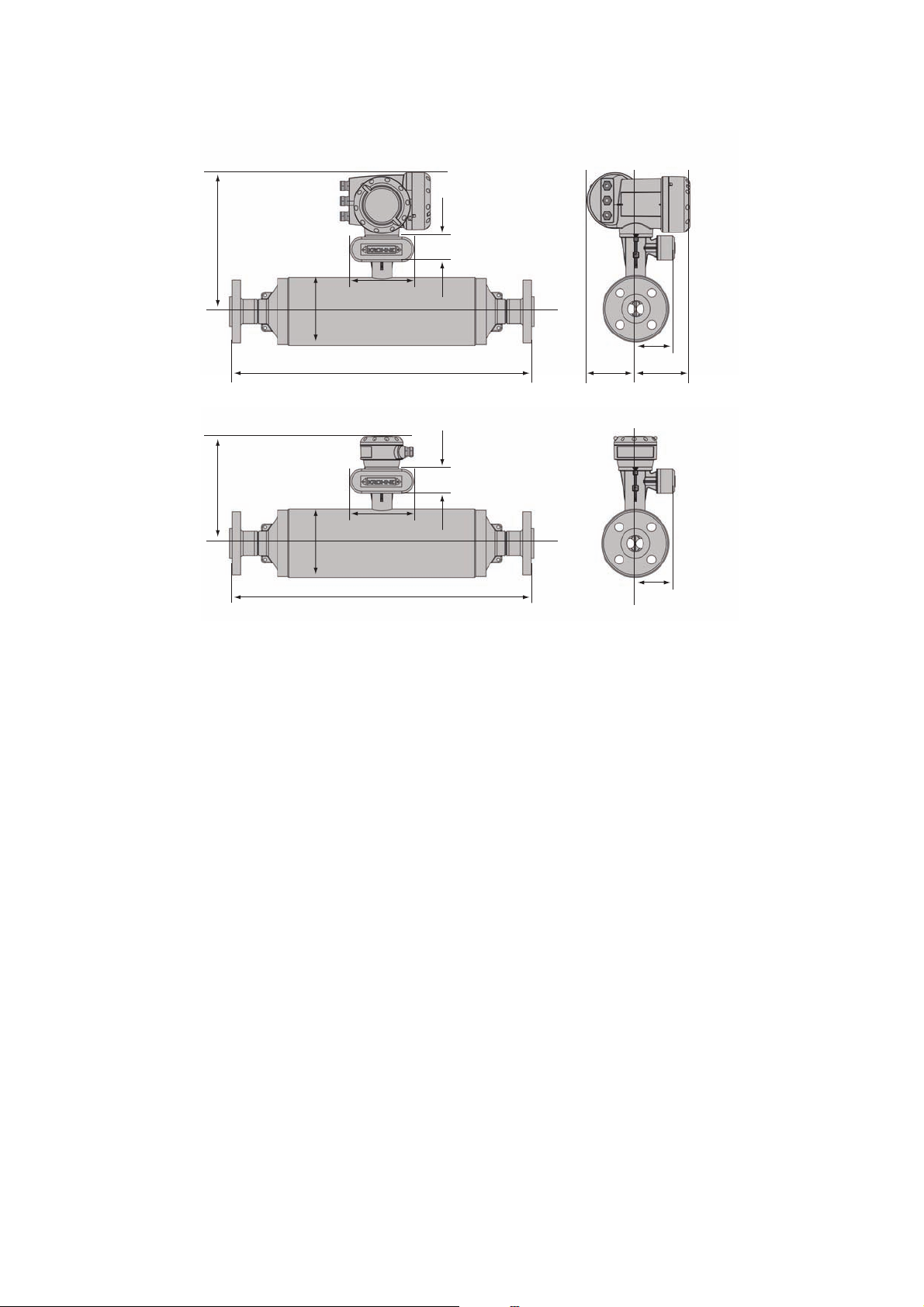

19

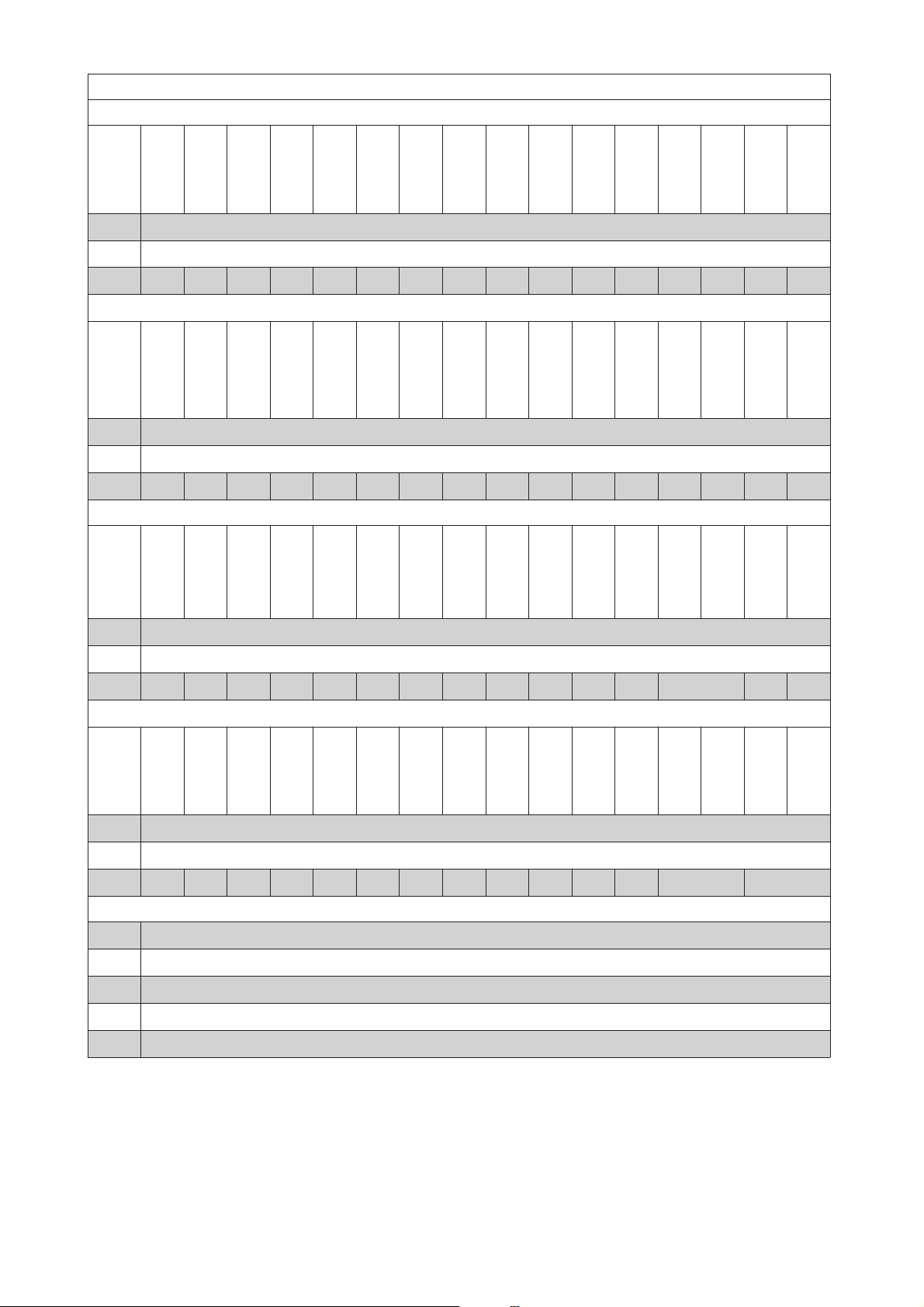

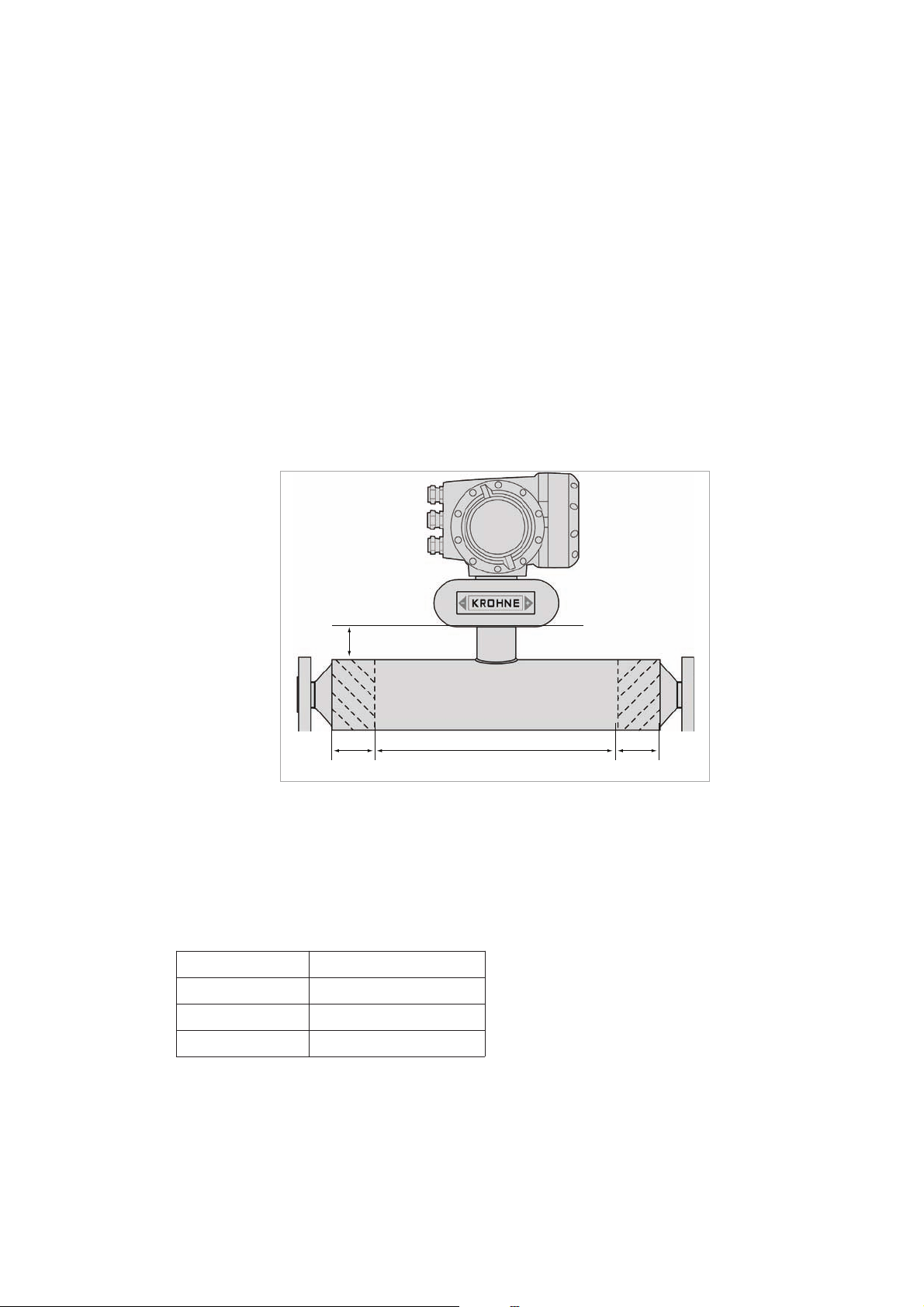

Dimensions

Flanged versions

1

B1

2

B2

F

E

A

G

D

H

I

1 Compact version

2 Remote Version

A

D

G

Page 20

20

Metric (mm)

DN15

DN 15 PN40

DN 25 PN40

DN 15 PN100

DN 25 PN100

½" ASME 150

½" ASME 300

½" ASME 600

¾" ASME 150

¾" ASME 300

¾" ASME 600

1” ASME 150

1” ASME 300

1” ASME 600

15A JIS 20K

A 101.6

B1 / B2 311 / 231

D 498 503 513 538 518 528 541 528 538 550 534 546 558 498 503

DN25

25A JIS 20K

DN 25 PN40

DN 40 P N40

DN 25 PN100

DN 40 PN100

1” ASME 150

1” ASME 300

1” ASME 600

1½” ASME 150

1½” ASME 300

1½” ASME 600

25A JIS 20K

40A JIS 20K

A 114.3

B1 / B2 317 / 237

D 531 541 567 575 563 575 589 575 589 603 531 541

DN40

DN 40 PN40

DN 40 PN100

DN 50 PN40

DN 50 PN63

DN 50 PN100

1½” ASME 150

1½” ASME 300

1½” ASME 600

2” ASME 150

2” ASME 300

2” ASME 600

40A JIS 20K

50A JIS 20K

A 168.3

B1 / B2 344 / 264

D 706 740 712 740 752 740 754 770 744 756 774 706 712

DN50

DN 50 PN40

DN 50 PN63

DN 50 PN100

DN 80 PN40

DN 80 PN63

DN 80 PN100

2” ASME 150

2” ASME 300

2” ASME 600

3” ASME 150

3” ASME 300

3” ASME 600

50A JIS 10K

A 219.1

50A JIS 10K

50A JIS 20K

80A JIS 10K

80A JIS 20K

B1 / B2 370 / 290

D 862 890 902 882 910 922 894 906 926 906 926 944 862 882

All sizes

E 160

F60

G 98.5

H 123.5

I 137

Page 21

21

Imperial (Inches)

DN15

DN 15 PN40

DN 25 PN40

DN 15 PN100

DN 25 PN100

½" ASME 150

½" ASME 300

½" ASME 600

¾" ASME 150

¾" ASME 300

¾" ASME 600

1” ASME 150

1” ASME 300

1” ASME 600

15A JIS 20K

A 4

B1 / B2 12.2 / 9.09

D 19 19.8 20.2 21.2 20.4 20.8 21.3 20.8 21.2 21.6 21 21.5 22 19.6 19.8

DN25

25A JIS 20K

DN 25 PN40

DN 40 P N40

DN 25 PN100

DN 40 PN100

1” ASME 150

1” ASME 300

1” ASME 600

1½” ASME 150

1½” ASME 300

1½” ASME 600

25A JIS 20K

40A JIS 20K

A 4.5

B1 / B2 12.5 / 9.3

D 20.9 21.3 22.3 22.6 22.2 22.6 23.8 22.6 23.2 23.7 20.9 22.8

DN40

DN 40 PN40

DN 40 PN100

DN 50 PN40

DN 50 PN63

DN 50 PN100

1½” ASME 150

1½” ASME 300

1½” ASME 600

2” ASME 150

2” ASME 300

2” ASME 600

40A JIS 20K

50A JIS 20K

A 6.6

B1 / B2 14.6 / 11.4

D 27.8 29.1 28 29.1 29.6 29.1 29.7 30.3 29.3 29.8 30.5 27.8 28

DN50

DN 50 PN40

DN 50 PN63

DN 50 PN100

DN 80 PN40

DN 80 PN63

DN 80 PN100

2” ASME 150

2” ASME 300

2” ASME 600

3” ASME 150

3” ASME 300

3” ASME 600

50A JIS 10K

A 8.6

50A JIS 10K

50A JIS 20K

80A JIS 10K

80A JIS 20K

B1 / B2 14.6 / 11.4

D 33.9 35 35.5 34.7 35.8 36.3 35.2 35.7 36.4 35.7 36.5 37.2 39.9 34.7

All sizes

E 6.3

F 2.4

G 3.9

H 4.9

I 5.4

Page 22

22

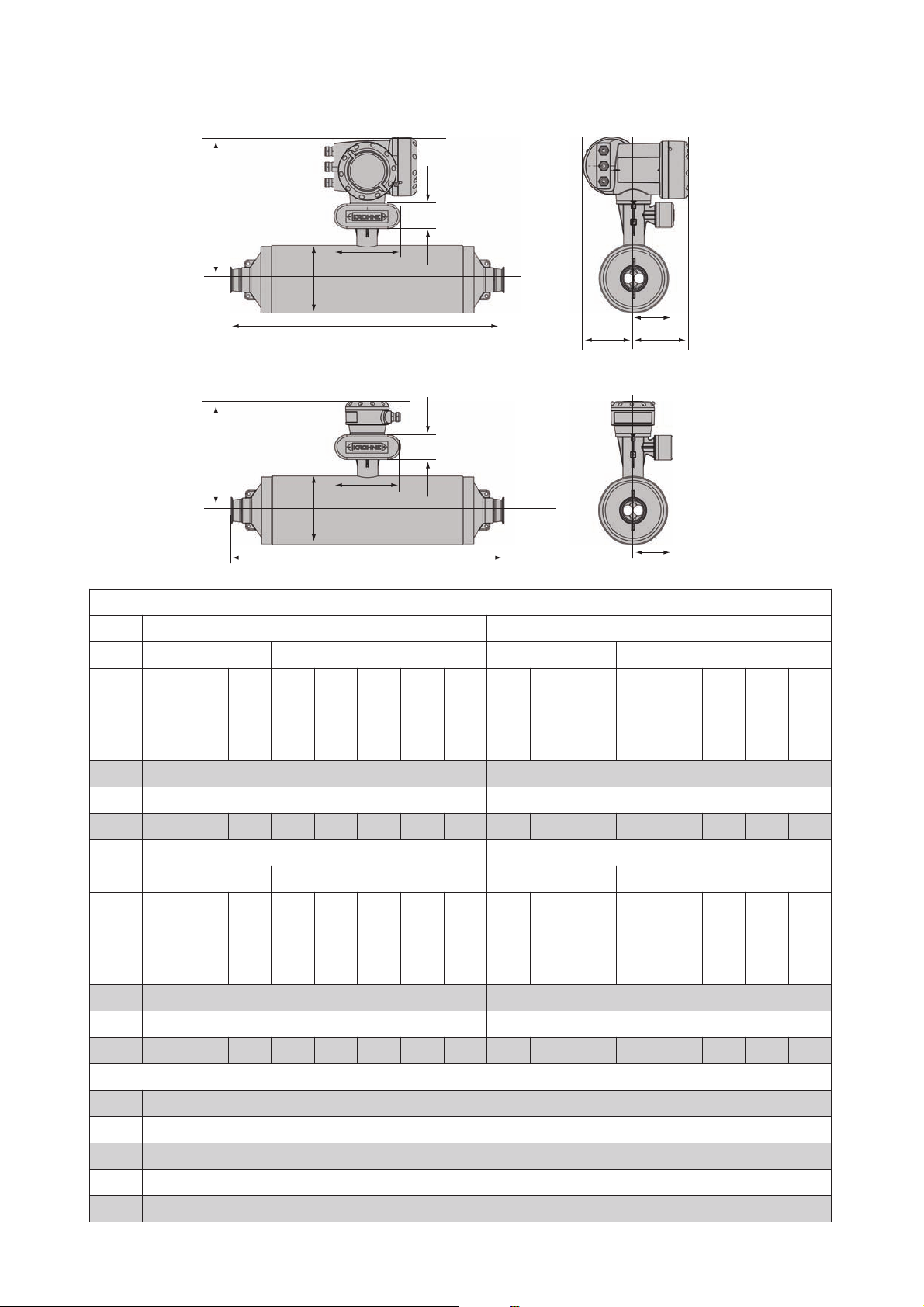

Hygienic versions

Metric (mm)

1

2

B2

D

D

E

E

A

A

F

F

G

G

H

I

B1

Meter 15 25

Conn DN25 1” DN40 1½”

DIN 11851

DIN 32676

DIN 11864-2

Tr-Clamp (ISO)

Tri-Clover

SMS

IDF

RJT

DIN 11851

DIN 32676

DIN 11864-2

Tr-Clamp (ISO)

Tri-Clover

SMS

IDF

RJT

A 101.6 114.3

B1 / B2 311 / 231 317 / 237

D 483 468 505 473 487 474 487 498 538 515 562 502 534 537 534 545

40 50

DN50 2” DN80 3”

DIN 11851

DIN 32676

DIN 11864-2

Tr-Clamp (ISO)

Tri-Clover

SMS

IDF

RJT

DIN 11851

DIN 32676

DIN 11864-2

Tr-Clamp (ISO)

Tri-Clover

SMS

IDF

A 168.3 219.1

B1 / B2 344 / 264 370 / 290

D 704 677 724 667 691 694 691 702 870 836 896 817 832 837 832 843

All sizes

E 160

F60

RJT

G 98.5

H 123.5

I 137

Page 23

23

Imperial (inches)

Meter 15 25

Conn DN25 1” DN40 1½”

DIN 11851

DIN 32676

DIN 11864-2

Tr-Clamp (ISO)

Tri-Clover

SMS

IDF

RJT

DIN 11851

DIN 32676

DIN 11864-2

Tr-Clamp (ISO)

Tri-Clover

SMS

IDF

A 4 4.5

B1 / B2 12.2 / 9.0 12.5 / 9.3

D 19 18.4 19.9 18.6 19.2 18.7 19.2 19.6 21.2 20.3 22.1 19.8 21 21.1 21 21.4

40 50

DN50 2” DN80 3”

DIN 11851

DIN 32676

DIN 11864-2

Tr-Clamp (ISO)

Tri-Clover

SMS

IDF

RJT

DIN 11851

DIN 32676

DIN 11864-2

Tr-Clamp (ISO)

Tri-Clover

SMS

IDF

A 6.6 8.6

B1 / B2 13.5 / 10.4 14.6 / 11.4

D 27.7 26.6 28.5 26.2 27.2 27.3 27.2 27.6 34.2 32.9 35.3 32.2 32.7 32.9 32.7 33.2

RJT

RJT

All sizes

E 6.3

F 2.4

G 3.9

H 4.9

I 5.4

Page 24

24

Purge Port

Heating Jacket

Meter size DN15 DN25 DN40 DN50

Connection size ½” (12mm) 1” (25mm)

Metric (mm)

A 115 ±1.0 142 ±1.0 206 ±1.0 254 ±1.0

B 515590105

C 20 26

Imperial (inches)

A 4.5 ±0.04 5.6 ±0.04 8.1 ±0.04 10.0 ±0.04

B 2.0 2.2 3.5 4.1

C 0.8 1.0

P

B

A

Meter size DN15 DN25 DN40 DN50

Metric (mm)

A 30 ±1.0 65 ±1.0

B 30 ±1.0 65 ±1.0

Imperial (inches)

A 1.2 ±0.04 2.5 ±0.04

B 1.2 ±0.04 2.5 ±0.04

Page 25

25

5

Measuring tube: Spigots

Meter Max. Temperature Shift

Process

Ambient

OPTIMASS 2000

5.1 Specific Installation Guidelines

• Tighten flange bolts evenly.

• Observe the pipe end loads as shown in S.5.6

• It is permissible to support the weight of the meter on the body.

• Use of standard pipework reducers at the flange is allowed. Avoid extreme changes in pipe

• The use of flexible hoses for connection to the process pipework is NOT recommended.

• The meter can be installed so that the converter is on the side of the meter, resulting in the

• The 2000 series has exceptional immunity to cross-talk, therefore allowing meters to be

5.2 Ambient / Process temperatures

The specified and approved ambient and process temperatures must be observed.

OPTIMASS

size (step changes).

measuring tubes on top of each other, unless gases or solids are being measured.

used in series or parallel

SS318L

°C °F

All meters -45...+130 -49...266

Compact Al. -40...+60 40...+140

Compact Al. with certain I/O options (consult Krohne) -40...+65 -40...+149

Compact SS -40...+55 -40...+131

Remote -40...+65 -40...+149

Note:

For additional temperature limits in hazardous area applications, reference should be made to

the publication “

Where meters are mounted in direct sunlight, it is recommended to install a sunshade that

covers the converter and front end. This is particularly important in countries with high ambient temperatures.

The maximum differential temperature between the process and ambient temperature without

insulation is 110°C or 200°F.

To avoid thermal shock, the meter MUST NOT be subject to rapid changes in process tempratures and reference should be made to the following table

Operation outside these limits may result in shifts in density and mass flow calibration.

Repeated shocking may also lead to premature failure of the meter! However, higher thermal

shocks are possible at lower working presures. Please consult Krohne for more information.

Guidelines for the use of Coriolis Meters in Hazardous Areas”.

S100 90°C (110°C with a max operating pressure of 40 barg)

S150 80°C

S250 50°C

5.3 Pressure Equipment Directive (PED) requirements

To comply with the requirements of the PED in Europe, the following information is provided to

assist the plant engineer in installing the meter:

Stainless Steel UNS 531803 Stainless Steel UNS J902205

The outer cylinder 304 / 304L is dual certified (Optional outer cylinder of 316 / 316L).

Wiring feedthrough is made of Epoxy (or PEEK) with 2 ‘O’ ring seals in Fpm / fkm &

Hydrogenated Nitrile.

Page 26

26

Flanges:

PN160/250 and ASME 900/1500 are duplex stainless steel (UNS 531803). All other flanges are

316 / 316 L dual certified (optional UNS 531803).

NOTE: if the NACE option has been selected at the time of order, the flanges will be duplex

stainless steel (UNS 31803).

Hygienic Connections are 316L (S100 only)

Optional heating jacket 316 / 316L

Note: Outer cylinder is in contact with heating medium

5.4 Secondary Pressure containment

The OPTIMASS 2000 meters are supplied (as standard) without certified housings that have a

typical burst pressure

If the user suspects that the primary tube has failed, the unit must be depressurised and

removed from service as soon as it is safe to do so.

Note:

In the 2000 Series there is a high pressure wire feed through with ‘O’ rings that might not be

compatible with the process fluid for an extended period if a primary tube fails.

It is the user’s responsibility to ensure that the materials used are compatible with this product.

>100 barg.

Other ‘O’ ring materials are available on request.

5.5 Hygienic Applications

The OPTIMASS 2000 (S100) is available with a variety of hygienic process connectors.

When installing / using meters with hygienic process connectors, support /clamp the meter

properly. The meters are heavy and could injure when disconnected from the adjacent pipe

work.

The recommended method of installation is to mount the meter against a support / wall with

the body of the meter supported / clamped. The process pipe work can then be supported off

the meter. The meter is too heavy to be supported from the thin walled piping usually associated with the hygienic industry. For information regarding lifting the meter, please refer to section 3.4.

1

2

1 2 Meter Supports

Page 27

27

whichever is the lower

Maximum pipe work forces

The 3A approval for the 2000 series requires that it is “self draining”. Therefore, the meter

MUST be installed vertically with the flow running uphill.

Installation lengths

For installation lengths, please see section 5.9

Please check with KROHNE if you are unsure of the installation length. Many meters are built

to customer requirements / specifications especially where special hygienic process nectors

have been adapted to the meter. As these are normally non-standard, the installation length

will not be given in the technical data.

5.6 Pressure Ratings

Measuring Tube PED certification

See pressure de-rating graphsMeasuring Tube FM certification

Measuring Tube CRN & CSA certification

Meter data plates are stamped with maximum pressure rating at both 20°C (68°F) and maximum operating temperature of connection or primary tube,

size 20°C 130°C

.

40 barg 100 barg 150 barg 32 bar 80 barg 115 barg

100 150 kN 100 kN 150 kN 60 kN

150 650 kN 120 kN 280 kN 50 kN

250 550 kN 60 kN 400 kN 50 kN

Flange Connections

These loads are roughly equivalent to the max axial loading allowed in an un-radiographed butt

weld in a 316L schedule 80 pipe.

Loads given maximum static loads. If loads are cycling, particularly between tension and compression then these loads should be reduced.

Please consult KROHNE for more information.

Page 28

28

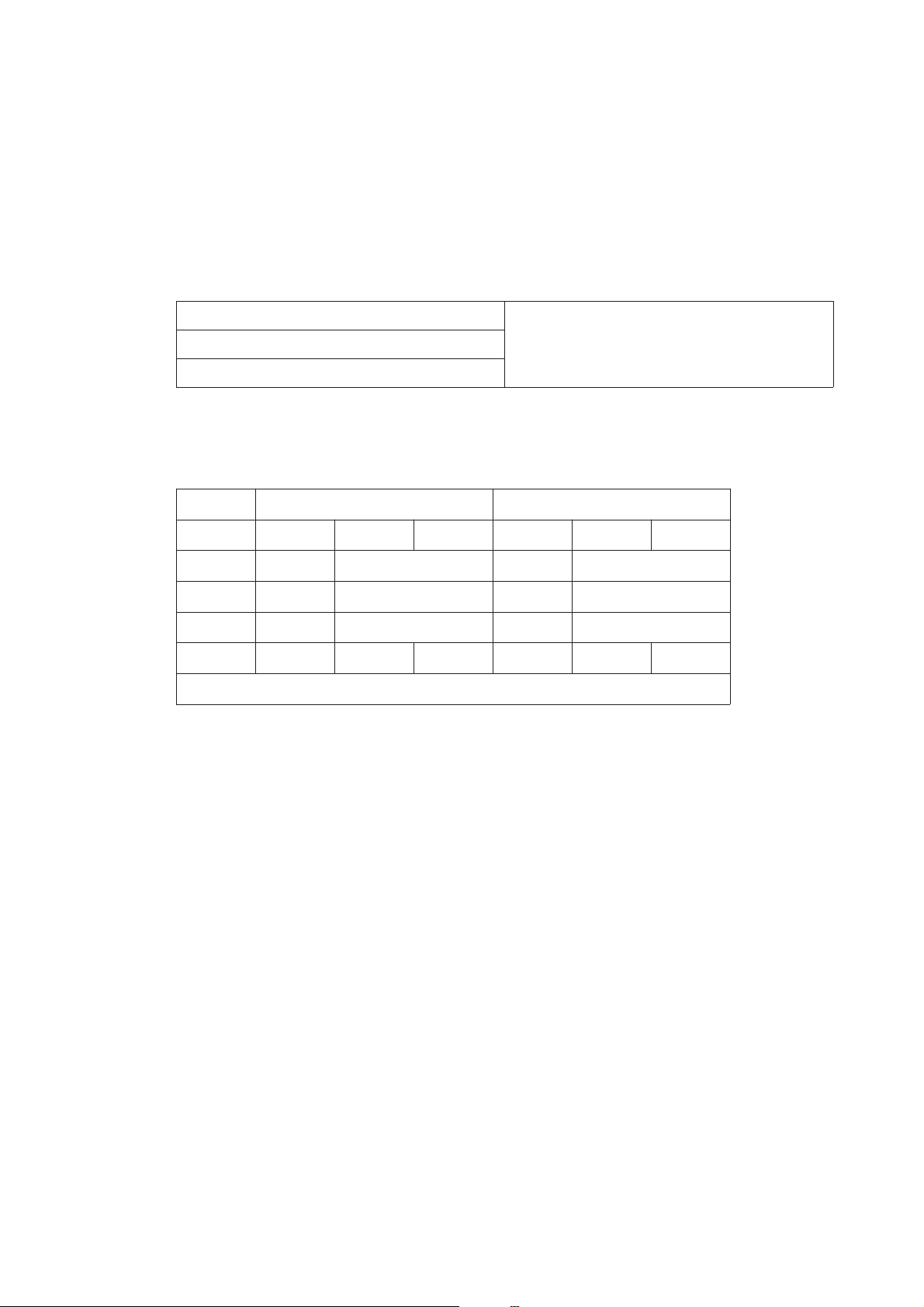

Flanges

Note:

WHICHEVER IS THE LOWER!

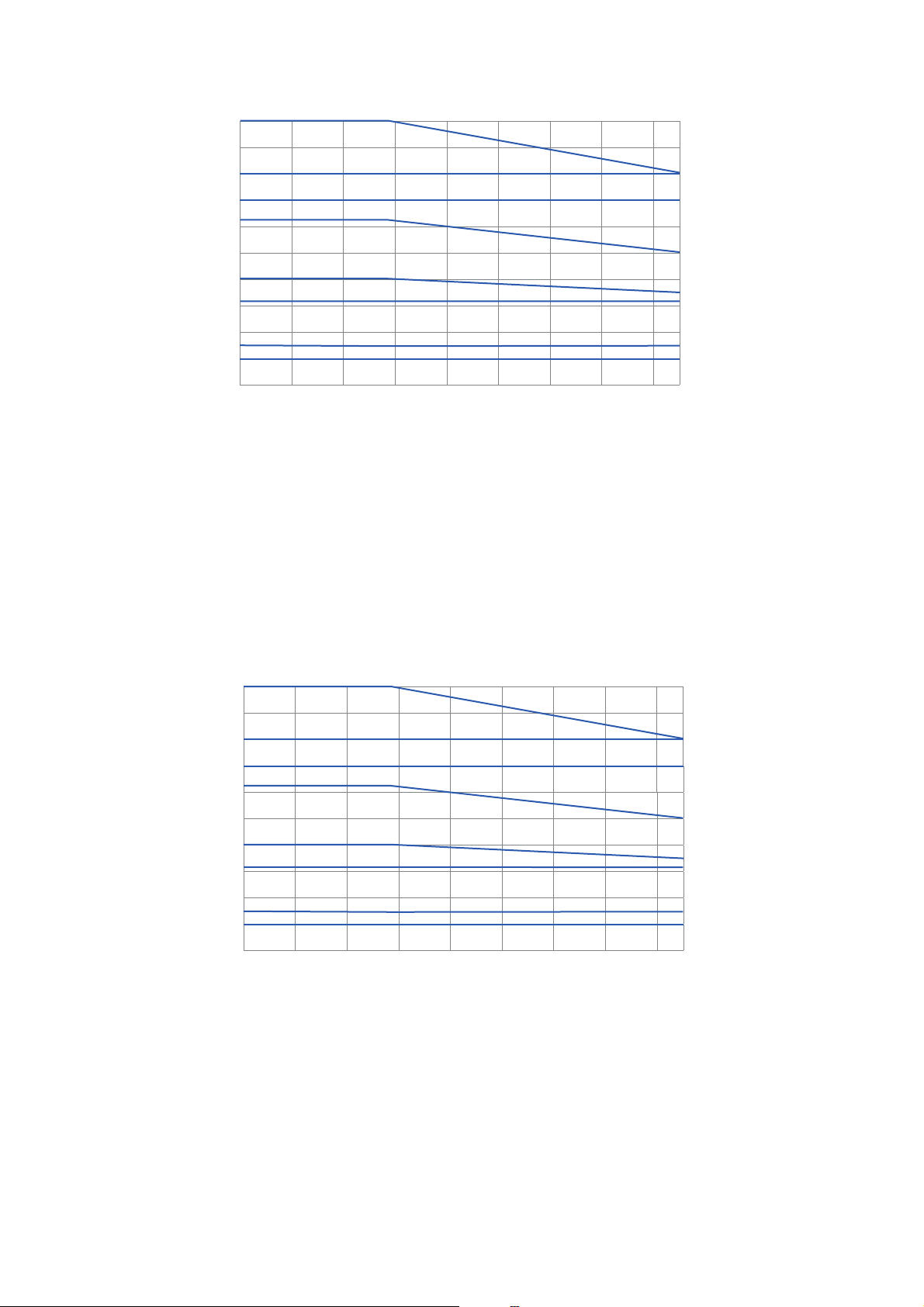

-40 -20 0 20 40 60 80 100 120 130

P (bar)150

145

140

135

130

125

120

115

110

105

100

0

2

3

1

P

Pressure de-rating

P (psi) 2176

2103

2030

1958

1885

1813

1740

1668

1595

1523

1450

0

-40 -4 32 68 104 140 176 212 248 266

O

F

T

1 Measuring Tube PED certification

2 Measuring Tube FM certification

3 Measuring Tube CRN & CSA certification

DIN flange ratings based on EN 1092-1 2007 table G.4.1 material group 14E0

1

2

3

ASME flange ratings based on ASME B16.5 2003 table 2 material group 2.2

JIS flange ratings based on JIS 2220: 2001 table 1 division 1 material group 022a

The maximum operating pressure will be either the flange rating or measuring tube rating

It is recommended that the seals be replaced regularly to maintain the hygienic integrity of the

connection.

Page 29

29

Unless specifically requested, internal surfaces are not polished and no warranty is made as to

Insulation

Electrical Heating

Size

DIM

the surface finish.

If polishing option and /or EHEDG, ASME Bio-Processing or 3A approvals was selected at time

of order, all product contact surfaces are polished 0.5 micrometer Ra (20CLa) finish or better.

5.7 Heating and insulation

There are several ways to heat the meter. In most cases heating is unnecessary as the meter

is designed so that very little heat is lost or gained through the outer cylinder.

Where insulation is required, a variety of materials may be used to insulate the meter. Care

must be taken not to insulate the meter above the halfway mark of the electronics support post

as shown.

Electrical tape heating may be used. Care should be taken to only heat the sections where the

best effect will be achieved. Do not heat above the converter mount centre line as shown

above.

The following guidelines must be observed.

1

2

1 Max insulation depth

2 Heated Areas

3 Do NOT heat this area

When insulating please observe guidelines as per insulation section.

100 200 mm

150 250 mm

250 250 mm

1

3

2

Page 30

30

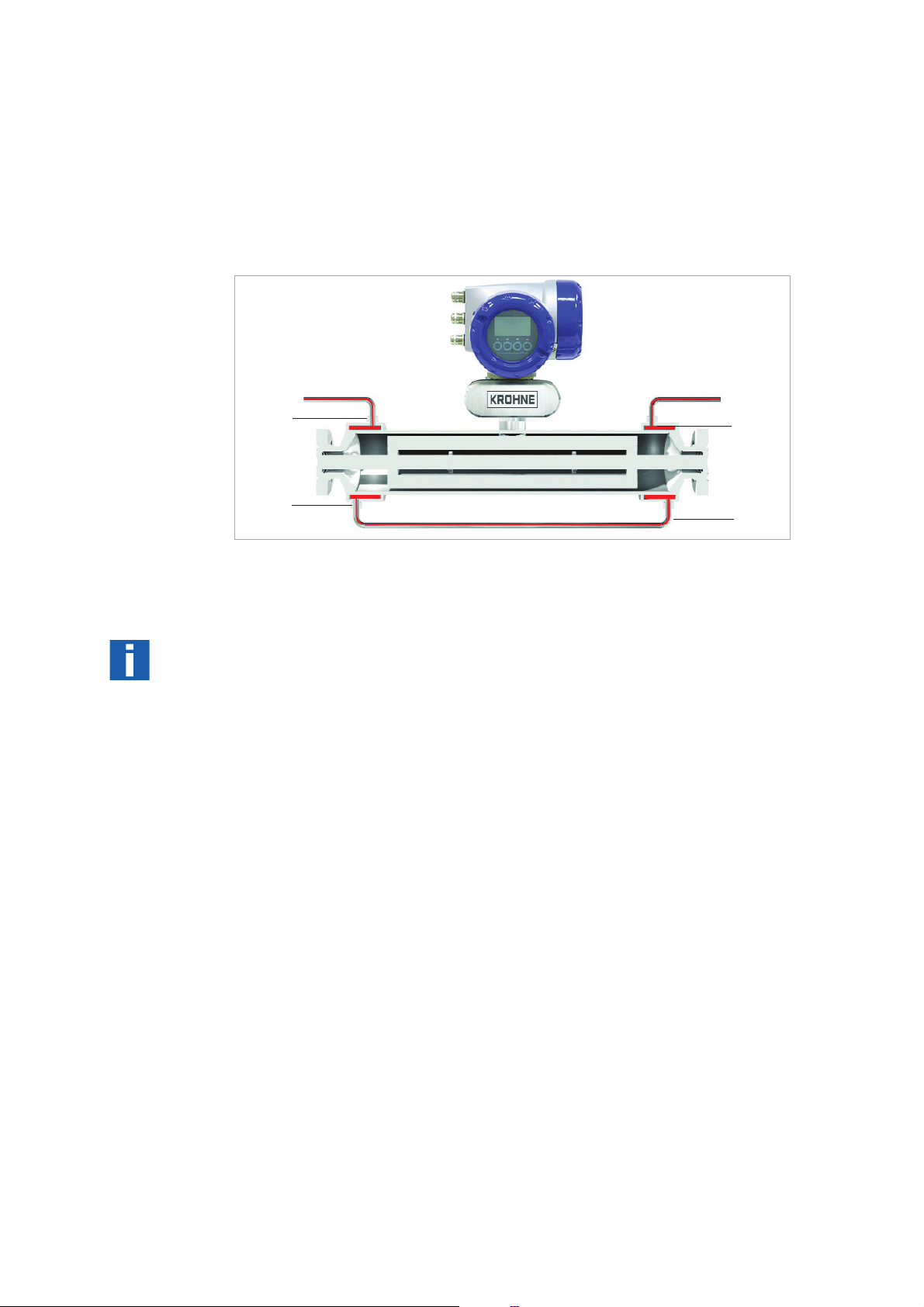

Liquid / Steam heating jacket

Important:

Heating Times

The meter can be supplied with a heating jacket. This jacket is designed to minimise the differential stress across the meter where differences in temperature between outer cylinder and

measuring tube exist.

The connections to the heating jacket are NPT or Ermeto sockets.

It is recommended that reinforced flexible hoses be used to connect the heating jacket to the

heat source.

1

3

2

4

1 2 3 4 Connection Points

Always heat the jacket to working temperature before flowing product in measuring tube.

Avoid the use of fluids that can cause crevice corrosion.

Although all the jacket materials are 316L, the outer cylinders are 304L (Optional 316L).

Connections should be made to ensure all air can be vented on liquid systems and all condensate can be drained on steam systems.

Note :

Max heating medium pressure and temperature for heating jackets is 10 bar at 130°C or 145

psig at 266°F.

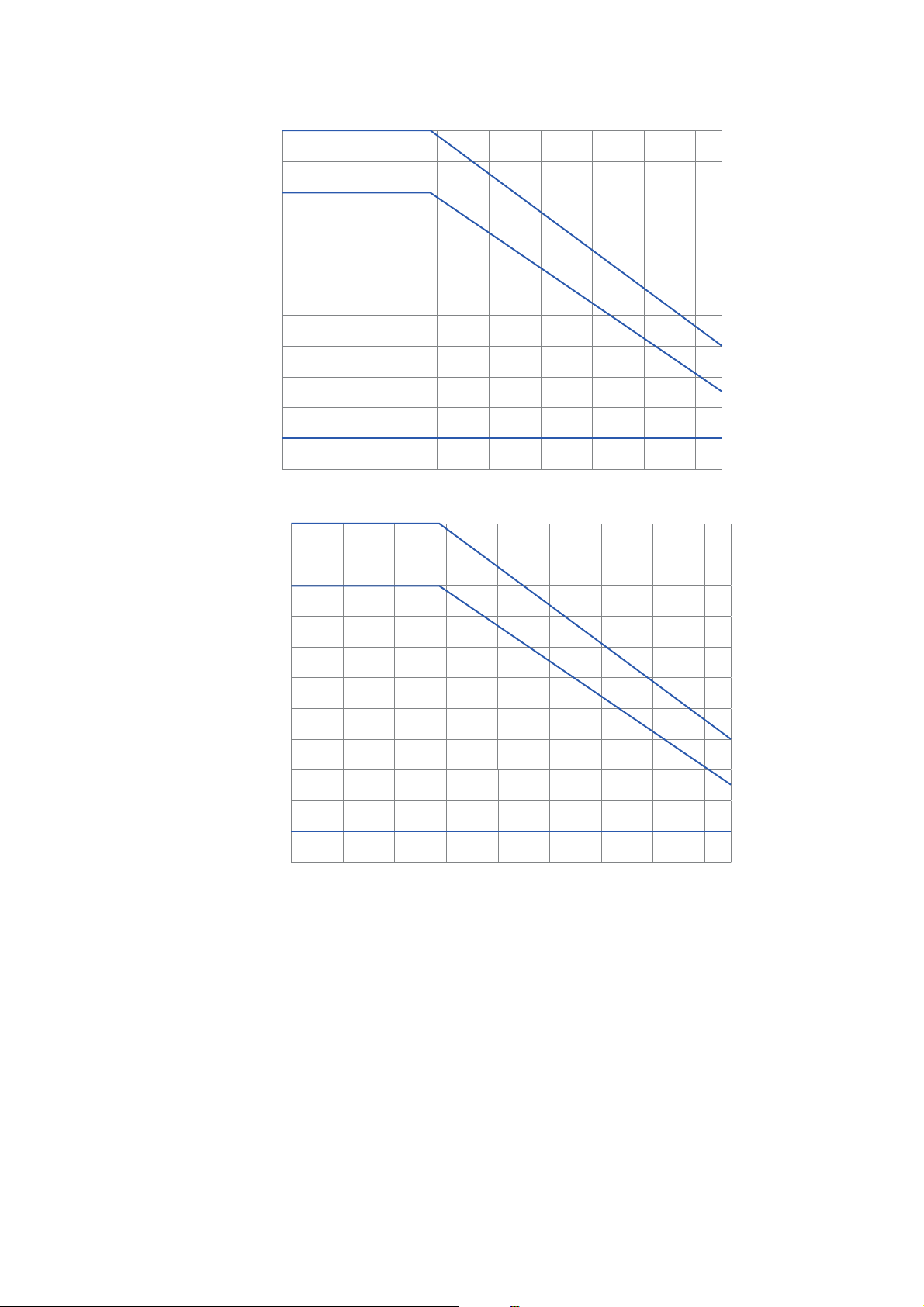

The heating times shown in the following illustrations are based on the heating jacket operating at maximum temperature and show the measured temperatures at the spigot end of the

measuring tubes. If a desired temperature is required in the centre of the measuring tubes,

then the heating times MUST be extended.

Page 31

31

O

OPTIMASS 2000 S100

OPTIMASS 2000 S150

OPTIMASS 2000 S250

1

OCO

F

140 284

120 248

100 212

80 176

60 140

40 104

20 68

032

0 0.5 1 1.5 2 2.5

1

OCO

F

140 284

120 248

100 212

80 176

60 140

40 104

20 68

032

0 0.5 1 1.5 2 2.5 3 3.5 4

1

OCO

F

2

2

140 284

120 248

100 212

80 176

60 140

40 104

20 68

032

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

2

1 Temperature at spigot end of measuring tubes

2 Time (hours)

Page 32

32

Purge Port Options

Burst Disc meters

Maximum Flow Rates

Kg/h

Lbs/min

Minimum Flow Rates

Kg/h

Lbs/min

Weights (PN40 Flanges)

100 150 250

kg lbs kg lbs kg lbs

Cooling

Please consult KROHNE if cooling medium is to be used in the heating jacket.

5.8 Purge Port Meters and Burst Disc Meters

If the purge port option was selected at time of order, then your meter will be fitted with ½”

NPT female connections – these will be clearly identified. These connections are sealed with

NPT plugs and PTFE tape.

Important:

Do not remove these plugs.

The meter is factory sealed with a dry nitrogen gas fill and any ingress of moisture will damage

the meter. The plugs should only be removed to purge the inside of the meter case of any

product if it is suspected that the primary measuring tube has failed. If it is suspected that the

primary tube has failed, depressurise and remove the meter from service, as soon as it is safe

to do so.

OPTIMASS 2000 meters that have been ordered with a burst (rupture) disc will be suppled with

the disc fitted. The disc failure pressure is 20barg @ 20°C.

Meters fitted with connection ratings in excess of 100 barg,(1450 psig) will be supplied with a

burst disc fitted.

Important:

The burst disc is suitable for the designed application according to the process conditions and

flow rates as per original order. If conditions alter, consult KROHNE for further advice regarding suitability of disc fitted.

If the product is in any way hazardous, it is strongly recommended that an exhaust tube is connected to the NPT male thread of the burst disc so that the discharge can be piped to a safe

area. This tube should be large enough that pressure cannot build up in the meter case.

Ensure arrow on burst disc is pointing away from meter

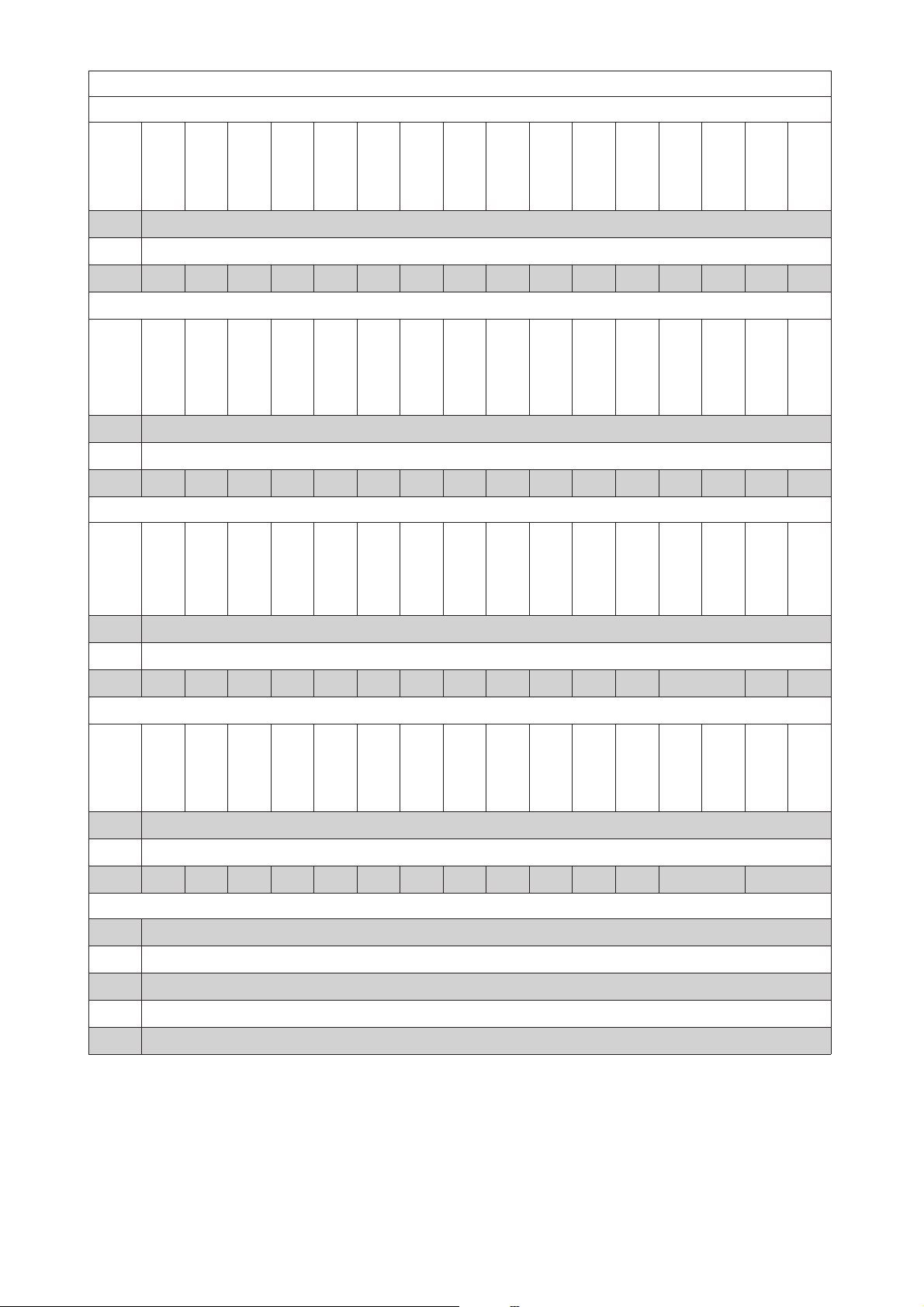

5.9 Technical Data

100 150 250

420,000 900,000 2,300,000

14,698 33,804 84,510

Dependant on measuring error required

Dependant on measuring error required

Compact with aluminium MFC 300 84.8 187 211.5 466 444.5 980

Compact with SS MFC 300 90.1 198 216.8 478 449.8 991

Remote with aluminium J box 80.8 178 207.8 457 440.5 971

Remote with SS J box 81.7 180 208.4 459 441.4 973

Page 33

33

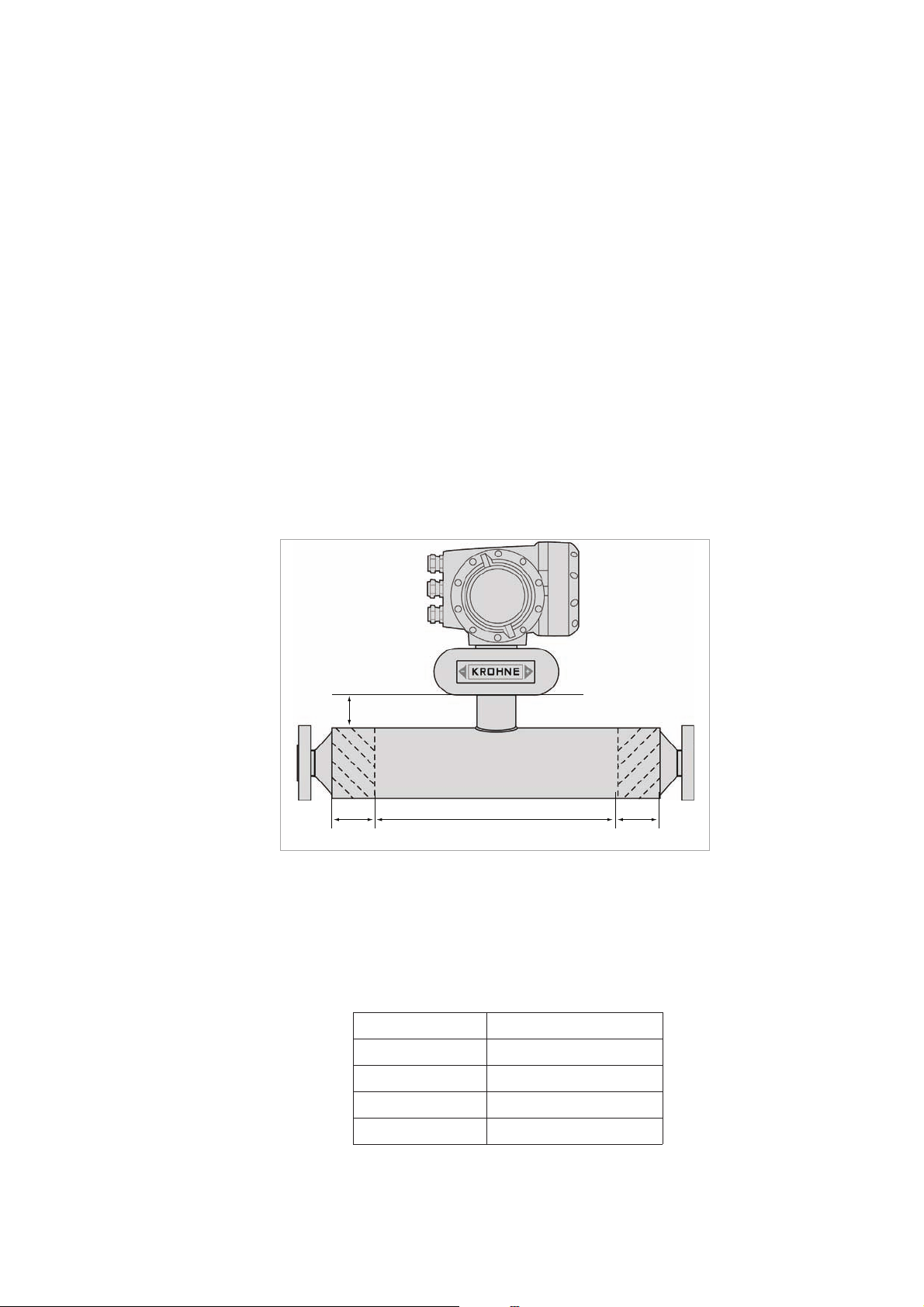

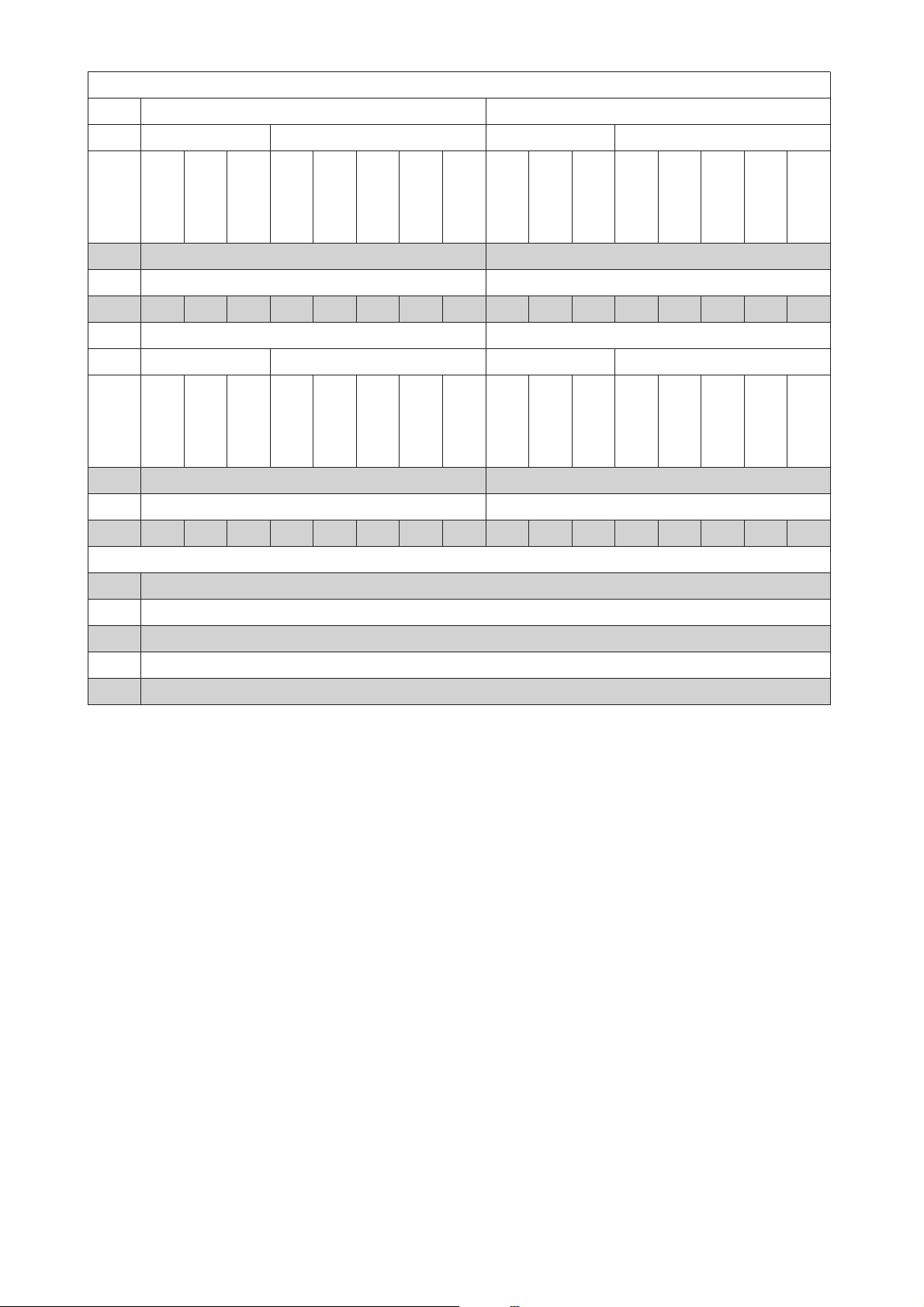

Dimensions (Flanged versions)

1

C1

2

D

E

A

B

D

E

FHG

C2

1 Compact version

2 Remote Version

A

B

H

Page 34

34

Metric (mm)

DN100

DN 100 PN40

DN 150 PN40

DN 100 PN63

DN 150 PN63

DN 100 PN100

DN 150 PN100

4” ASME 150

4” ASME 300

4” ASME 600

4” ASME 900

6” ASME 150

6” ASME 300

6” ASME 600

6” ASME 900

JIS 10K

A 219

B 1310 1330 1336 1370 1360 1410 1334 1352 1398 1422 1358 1378 1428 1474 1332

C1 / C2 370 ±5 / 293±5

DN150

DN 150 PN40

DN 200 PN40

DN 150 PN63

DN 200 PN63

DN 150 PN100

DN 200 PN100

6” ASME 150

6” ASME 300

6” ASME 600

6” ASME 900

8” ASME 150

8” ASME 300

8” ASME 600

8” ASME 900

JIS 10K

A 323

B 1621 1647 1661 1691 1701 1731 1649 1669 1719 1765 1675 1695 1751 1809 N/A

C1 / C2 422 ±5 / 345 ±5

DN250

JIS 20K

JIS 20K

DN 250 PN40

DN 300 PN40

DN 250 PN63

DN 300 PN63

DN 250 PN100

DN 300 PN100

10” ASME 150

10” ASME 300

10” ASME 600

10” ASME 900

12” ASME 150

12” ASME 300

12” ASME 600

12” ASME 900

JIS 10K

JIS 20K

A 406

B 2030 2050 2070 2100 1977 2160 2024 2056 2138 2202 2050 2082 2146 2234 N/A

C1 / C2 463 ±5 / 386 ±5

All sizes

D 160

E60

F 123.5

G 137

H 98.5

Page 35

35

Imperial (inches)

Hygienic connections (S100 only)

DN100

DN 100 PN40

DN 150 PN40

DN 100 PN63

DN 150 PN63

DN 100 PN100

DN 150 PN100

4” ASME 150

4” ASME 300

4” ASME 600

4” ASME 900

6” ASME 150

6” ASME 300

6” ASME 600

6” ASME 900

JIS 10K

A 8.6

B 51.6 52.4 52.6 53.9 53.5 55.5 52.5 53.2 55 56 53.5 54.2 56.2 58 52.4

C1 / C2 14.6 ±0.2 / 11.5 ±0.2

DN150

DN 150 PN40

DN 200 PN40

DN 150 PN63

DN 200 PN63

DN 150 PN100

DN 200 PN100

6” ASME 150

6” ASME 300

6” ASME 600

6” ASME 900

8” ASME 150

8” ASME 300

8” ASME 600

8” ASME 900

JIS 10K

A 12.7

B 63.8 64.8 65.4 66.6 67 68.1 65 65.7 67.7 69.5 65.5 66.7 69 71.2 N/A

C1 / C2 16.6 ±0.2 / 13.6 ±0.2

DN250

JIS 20K

JIS 20K

DN 250 PN40

DN 300 PN40

DN 250 PN63

DN 300 PN63

DN 250 PN100

DN 300 PN100

10” ASME 150

10” ASME 300

10” ASME 600

10” ASME 900

12” ASME 150

12” ASME 300

12” ASME 600

12” ASME 900

JIS 10K

A 16

B 80 80.7 81.5 82.7 77.8 85 79.7 81 84.2 86.7 80.7 82 84.5 88 N/A

C1 / C2 18.2 ±0.2 / 15.2 ±0.2

All sizes

D 6.3

E 2.4

F 4.9

G 5.4

H 3.9

DN100 4”

DIN 11864-2

DIN 11851

DIN 32676

Tri-Clover

Tri-clamp

(ISO)

SMS

IDF

RJT

Metric (mm)

B 1296 1288 1236 1223 1223 1236 1223 1234

Imperial (inches)

B 51 50.1 48.7 48 48 48.7 48 48.6

JIS 20K

Page 36

36

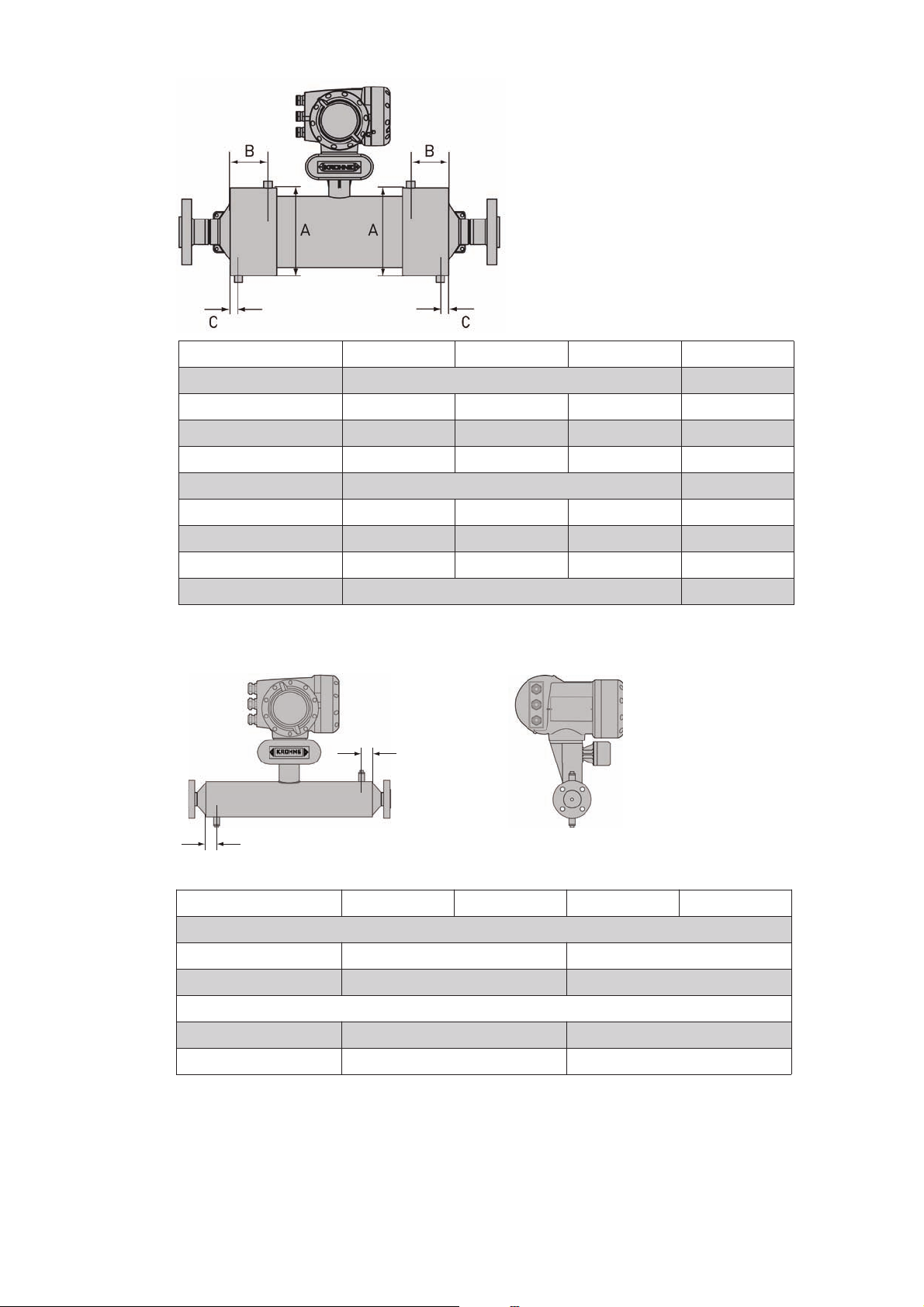

Purge Port

Heating Jacket

S100 S150 S250

S100 S150 S250

BB

A

CC

All flanges All flanges All flanges

mm

A 254 ±2.5 355 ±2.5 444 ±2.5

B 178 ±2.0 228 ±2.0 208 ±2.0

C 28 ±2.0 28 ±2.0 6.5 ±2.0

inches

A 10 ±0.1 14 ±0.1 17.5 ±0.06

B 7 ±0.08 9 ±0.08 8.2 ±0.08

C 1.1 ±0.08 1.1 ±0.08 0.25 ±0.08

A

All flanges All flanges All flanges

mm

A 70 ±1.0 100 ±1.0

B 70 ±1.0 100 ±1.0

inches

A 2.75 ±0.04 4.0 ±0.04

B 2.75 0.04± 4.0 ±0.04

B

Page 37

37

6

Orientation:

Meter Size Angle of Rotation (Clockwise)

OPTIMASS 3000

6.1 Specific Installation Guidelines

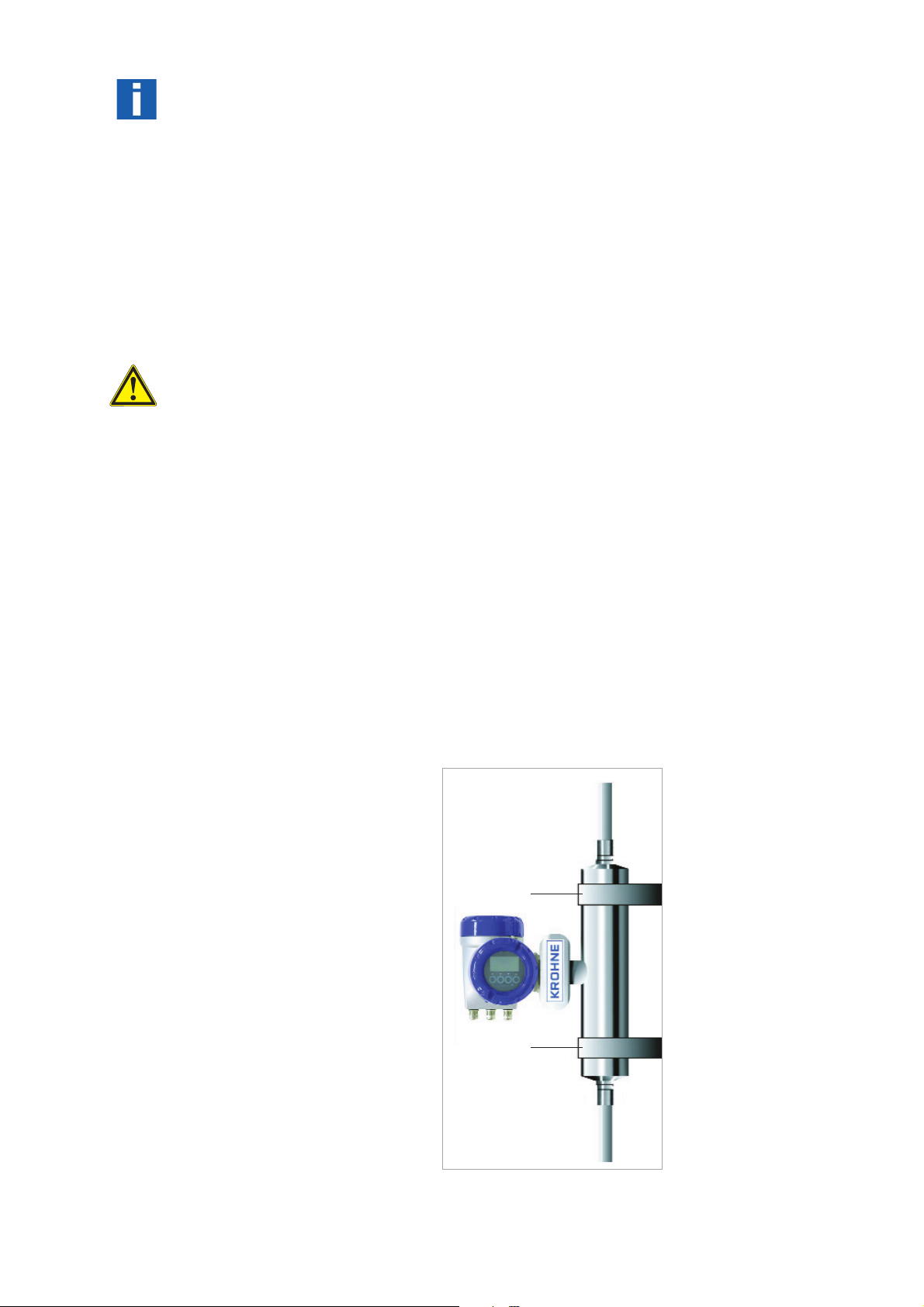

The OPTIMASS 3000 is a single Z Shaped Tube Meter. During installation, the following general

guidelines MUST be followed:

• The base plate has four holes to enable the meter to be mounted and all four mounting

• The plastic inserts in the base plate mounting holes are important to ensure a rigid and sta-

• It is important to mount on a firm and rigid structure to obtain a stable zero condition.

• The following guidelines are provided to assist the installer to select the best option:

The meter can be mounted horizontally or vertically

If mounting vertically the meter MUST be mounted with the flow uphill and with a set angle

from the vertical that allows the meter to self drain The set angles are:

OPTIMASS

holes MUST be used

ble connection to the mounting structure.

01 7°

03 13°

04 13°

1 2 3

1 Horizontal Mount

2 7° clockwise rotation from the vertical. (See angle markings on base plate).

3 13° clockwise rotation from the vertical. (See angle markings on base plate).

DO NOT allow the pipework to carry the weight of the meter This

will cause severe damage!

DO NOT mount the meter upside down!

Page 38

38

Flanged and Tri-clamp Meters

Measuring tube:

SS316L or HC22

Process

Ambient

When installing these meters ensure that the pipework is supported behind the process , so

that no unnecessary stress is applied to the meter flanges.

443

1 Fix meter to a firm support

2 Carefully align the process flanges and connect

3 Support the process pipe close to the flanges. Do not pull pipe with clamps!

4 Make the final process connections. If there are no connections in this area, try to have

some flexibility in the process pipe

Note:

Please note that gas bubbles can also accumulate between flange and measuring tube due to

the step change, mount vertically to avoid this.

2

1

2

3

6.2 Ambient / Process temperatures

The specified and approved ambient and process temperatures must be observed.

°C °F

Note:

For additional temperature limits in hazardous area applications, reference should be made to

the publication “

Where meters are mounted in direct sunlight, it is recommended to install a sunshade. This is

particularly important in countries with high ambient temperatures.

Compact Aluminium -40 ... +60 -40 ... +140

Compact Stainless -40 ... +55 -40 ... +130

Remote -40 ... +60 -40 ... +140

Guidelines for the use of Coriolis Meters in Hazardous Areas”.

-40 ... +150 -40 ... +300

6.3 Pressure Equipment Directive (PED) requirements.

To comply with the requirements of the PED in Europe, the following information is provided to

assist the plant engineer in installing the meter.

The outer casing (Secondary Pressure containment) is 316L

S Stainless SS 316 L

H Hastelloy C22

Wiring feedthrough is made of epoxy with ‘0’ ring seals in FPM / FKM and hydrogenated nitrile.

Connections are all 316 / 316 L dual certified or Hastelloy C22

The optional heating jacket is 316 or 316L.

Page 39

39

Note :

Pressure De-rating:

Stainless Steel tubes:

Hastelloy C22 tubes:

The outer casing is in contact with the heating medium.

6.4 Secondary Pressure containment

The OPTIMASS 3000 meters are supplied with secondary pressure containment as standard.

20 °C 50°C 100°C 150°C

30 bar 28.5 bar 26.1 bar 24 bar

The maximum secondary containment pressure (as certified) is 30 barg at 20°C (435 psig at

70°F), de-rated as follows :

The de-rating is based on the reduction of material strength with temperature for 316L (W No.

1.4404) material from DIN 17456.

Heating jacket is rated to 10 barg at 150°C (145 psig at 300°F).

If a heating jacket fitted, secondary containment is limited to 10 barg at 150°C (145 psig at

300°F). This is because the jacket is fitted inside of the secondary containment dome.

If the meter operating pressure is higher than the secondary containment allowable pressure

then a relief or bursting disc option (fitted in the dome) MUST be ordered. In this case the

meter data plate is stamped with maximum pressure rating (at 20°C and maximum operating

temperature) of the connection or the primary tube (whichever is the lower).

If the user suspects that the primary tube has failed, the unit must be depressurised and

removed from service as soon as it is safe to do so.

Notes:

• In the 3000 series there is a high pressure wire feed through with ‘O’ rings that might not be

compatible with the process fluid for an extended period if a primary tube fails.

• It is the user’s responsibility to ensure that the materials used are compatible with this

product.

• Other ‘O’ ring materials are available on request.

• Burst disc options ARE NOT available in combination with a heating jacket.

6.5 Pressure Ratings

Meter data plates are stamped with maximum pressure rating (at 20°C and max. operating

temperature) of connection, primary tube or secondary pressure containment (whichever is the

lower).

150 bar at 80°C or 2175 psi at 175°F

50 bar at 150°C or 725 psi at 300°F

150 bar at 150°C or 2175 psi at 300°F

(no de-rating required)

Page 40

40

Flanged connections as per DIN 2501 (metric)

Notes:

Flanged connections as per DIN 2501 (Imperial)

1 ASME 6000 lbs with HC22 measuring tube

2 ASME 600 lbs with 316L measuring tube

3 DIN 2636 PN63

4 ASME 300 lbs

5 JIS 20K

6 DIN 2635 PN40

7 ASME 150 lbs

8 Hygienic connection

•All hygienic type process connections rated to 10 barg @20°C (145psig @68°F)

•If operating pressure is above 30 barg (435 psig) the burst disc option MUST be purchased.

•Ensure that the meters are used within their operating limits.

Page 41

41

NPT connections (metric)

NPT connections (Imperial)

Notes:

1 Hastelloy C22 measuring tube with ¼” NPT connections

2 SS 316L measuring tube with ¼” NPT connections

3 30 barg secondary containment

1 Hastelloy C22 measuring tube with ¼” NPT connections

2 SS 316L measuring tube with ¼” NPT connections

3 435 psig secondary containment

•If operating pressure is above 30 barg (435 psig) the burst disc option MUST be purchased.

•Ensure that the meters are used within their operating limits.

6.6 Heating and insulation

All secondary containment and heated jacket parts are 316L, except the ¼" NPT Female connections, which are 316.

Max heating medium pressure and temperature is 10 bar at 150°C or 145 psig at 300°F.

The max secondary containment pressure on the OPTIMASS 3000 when fitted with a heating

jacket is 10 bar at 150°C or 145 psig at 300°F.

Page 42

42

Important:

Burst Disc meters:

Make sure that the arrow on the burst disc is pointing aw

ay from the meter.

Heating Jacket & Purge Port dimensions

01 03 04

A

BC

All flanges All flanges All flanges

mm

A 129 ±5.0

B 45° ±6.0

C 45° ±6.0

D

D 45° (approx)

inches

A 5.01 ±0.2

6.7 Purge Port Meters and Burst Disc Meters

Purge Port Options

If the purge port option was selected at the time of order, then your meter will be fitted with ¼"

NPT female connections and will be clearly identified. These connections are sealed with NPT

plugs and PTFE tape.

Do not remove these plugs.

The meter is factory sealed with a dry nitrogen gas fill and any ingress of moisture will damage

the meter. The plugs should only be removed to purge the inside of the meter case of any

product if it is suspected that the primary measuring tube has failed. If it is suspected that the

primary tube has failed, depressurise and remove the meter from service, as soon as it is safe

to do so.

OPTIMASS 3000 meters that have been ordered with a burst (rupture) disc will have the disc

fitted during manufacture. The burst disc option MUST be ordered for applictions where the

operating pressure of the measuring tube, exceeds the design pressure of the secondary containment. The disc failure pressure is 20bar @ 20°C.

Important:

The burst disc is suitable for the designed application according to the process conditions and

flow rates as per original order. If conditions alter, consult KROHNE for further advice regarding suitability of the fitted disc.

If the product is in any way hazardous, it is strongly recommended that an exhaust tube is connected to the NPT male thread of the burst disc so that the discharge can be piped to a safe

area. This tube should be large enough that pressure cannot build up in the meter case.

a

Page 43

43

Weights

6.8 Technical Data

Maximum flow rate

Secondary pressure containment

Size

Kg

lbs

Kg/h

Lbs/min

Nominal Flow Rates

01 03 04

Typically 130 % of the nominal flow rate for the sensor size depending on application.

Minimum flow rate

Depending on measuring error required.

Tube materials:

15 100 350

0.5 3.5 12.5

• S 316L

• Hastelloy C22

The meter size has a prefix S or H indicating the tube material.

• All OPTIMASS 3000 Series meters have secondary containment rated to 30 bar or 435 psi.

Materials of construction

• Connections: SS 316 L or HC22

• Secondary Containment: SS 316 L

• Front end housing and post: SS 316 L

• Converter housing/remote junction box: Epoxy coated aluminium or stainless steel

Weight of OPTIMASS 3000 sensor fitted with a typical standard connection in kg (lbs)

01 03 04

12 12 12

26.4 26.4 26.4

Page 44

44

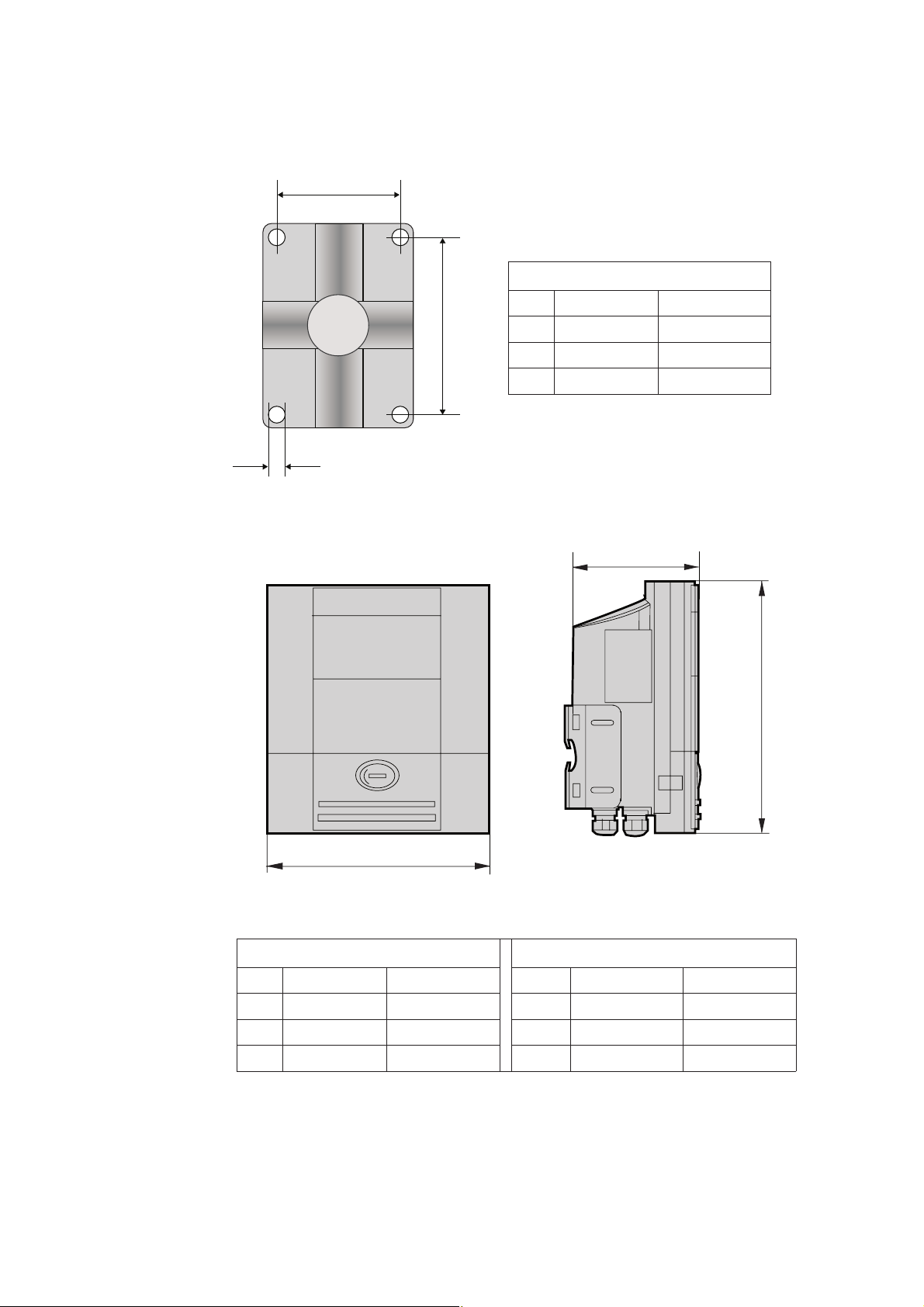

Dimensions

1

D1

2

D2

E

C

B

3

A

G

H

F

K

C

B

A

G

1 Compact version

2 Remote Version

All dimensions (mm)

S/H 01 S/H 03 S/H 04

A

1 1 1

B 160

C 60

D1 348

D2 269

E 123.5

F 137

G 98.5

I

H 156

I 180

K 132

Measuring tube inner diameter 1.2 2.6 4.0

1 depending on process connection. See table for dimensions

Page 45

45

All dimensions (inches)

S/H 01 S/H 03 S/H 04

A

1 1 1

B6.3

C 2.4

D1 13.7

D2 10.6

E4.9

F 5.4

G3.9

H 6.1

I7.1

K 5.2

Measuring tube inner diameter 0.05 0.1 0.2

1 depending on process connection. See table for dimensions

Dimension of A in mm & inches for all available process connector lengths

A

Connection type mm inches

¼” NPT 256 ±3 10.1 ±0.1

ASME 150 286 ±3 11.3 ±0.1

ASME 300 286 ±3 11.3 ±0.1

ASME 600 295 ±3 11.6 ±0.1

DIN15 PN40 286 ±3 11.3 ±0.1

DIN15 PN63 295 ±3 11.6 ±0.1

15A JIS20K 286 ±3 11.3 ±0.1

DIN10 DIN32676 260 ±3 10.2 ±0.1

½” Tri-Clover clamp 262 ±3 10.3 ±0.1

www.krohne.com

Page 46

46

7

Note:

Measuring tube: Sealing Faces:

Note:

OPTIMASS 7000

7.1 Specific Installation Guidelines

• Tighten flange bolts evenly.

• Observe min and max pipe end loads at the end of this section.

The use of reducers at the flanges is allowed but extreme pipe size reductions should be avoided. This is to prevent the possibility of cavitation and degassing.

There are no additional installation requirements for the OPTIMASS 7000 sensors. Fixing of

flexible hoses directly on the meter is allowed.

7.2 Ambient/Process Temperatures

The specified and approved ambient and process temperatures MUST be observed.

Titanium

°C -40...+150 -20...+150 -40...+60

°F -40...+300 4...+300 -40...+140 -40...+130 -40...+140

Process Ambient

Hygienic/aseptic

connections

1

Compact Al Compact S.S Remote

-40...+55 -40...+60

3

OPTIMASS

HC22 /

Tantalum

SS318L

°C 0...+100 -40...+60

°F 0...212 -40...+140 -40...+130 -40...+140

°C 0...+100 0...+130

°F 0...212 0...266 -40...+140 -40...+130 -40...+140

1 Available across the whole range (½”ASME on the T15)

2 Option available on 25, 40, 50 & 80 meters

3 Temp range: -40...+65°C (-40...+149°F) on certain I/O options. Pleae call Krohne for details

For additional temperature limits in hazardous area applications, reference should be made to

the publication “

Where meters are mounted in direct sunlight, it is recommended that a sunshade is installed.

This is particularly important in countries with high ambient temperatures!

The maximum differential temperature between the process and ambient temperature without

insulation is 130°C or 266°F for Titanium and 80°C or 1 76°F for Hastelloy, Stainless Steel and

Tantalum meters.

Guidelines for the use of Coriolis Meters in Hazardous Areas”.

-40...+60

2

3

3

-40...+55 -40...+60

-40...+55 -40...+60

7.3 Pressure Equipment Directive (PED) Requirements.

To comply with the requirements of the PED in Europe, the following information is provided to

assist the plant engineer in installing the meter.

Titanium Grade 9 Titanium Grade 2

Hastelloy C22 Hastelloy C22

Stainless UNS 31803 Stainless UNS 31803

Tantalum grade RO5255 Tantalum grade RO5255

The outer cylinder 304 / 304L is dual certified (Optional outer cylinder of 316 / 316L). This also

applies to PED certified housings.