Page 1

Handbook

Handbook

MFC 300

MFC 300

MFC 300MFC 300

HandbookHandbook

Signal converter for mass flowmeters

Electronic revision:

ER 3.3.xx

(SW.REV. 3.4x)

The documentation is only complete when used in combination with the relevant

documentation for the measuring sensor.

© KROHNE 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2012 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 3

MFC 300

CONTENTS

1 Safety instructions 7

1.1 Software History ............................................................................................................... 7

1.2 Intended Use..................................................................................................................... 9

1.3 Certifications .................................................................................................................... 9

1.4 Safety instructions from the manufacturer ................................................................... 10

1.4.1 Copyright and data protection .............................................................................................. 10

1.4.2 Disclaimer ............................................................................................................................. 10

1.4.3 Product liability and warranty .............................................................................................. 11

1.4.4 Information concerning the documentation......................................................................... 11

1.4.5 Warnings and symbols used................................................................................................. 12

1.5 Safety instructions for the operator............................................................................... 12

2 Device description 13

2.1 Scope of delivery............................................................................................................. 13

2.2 Device description .......................................................................................................... 14

2.2.1 Field housing......................................................................................................................... 15

2.2.2 Wall-mounted housing ......................................................................................................... 16

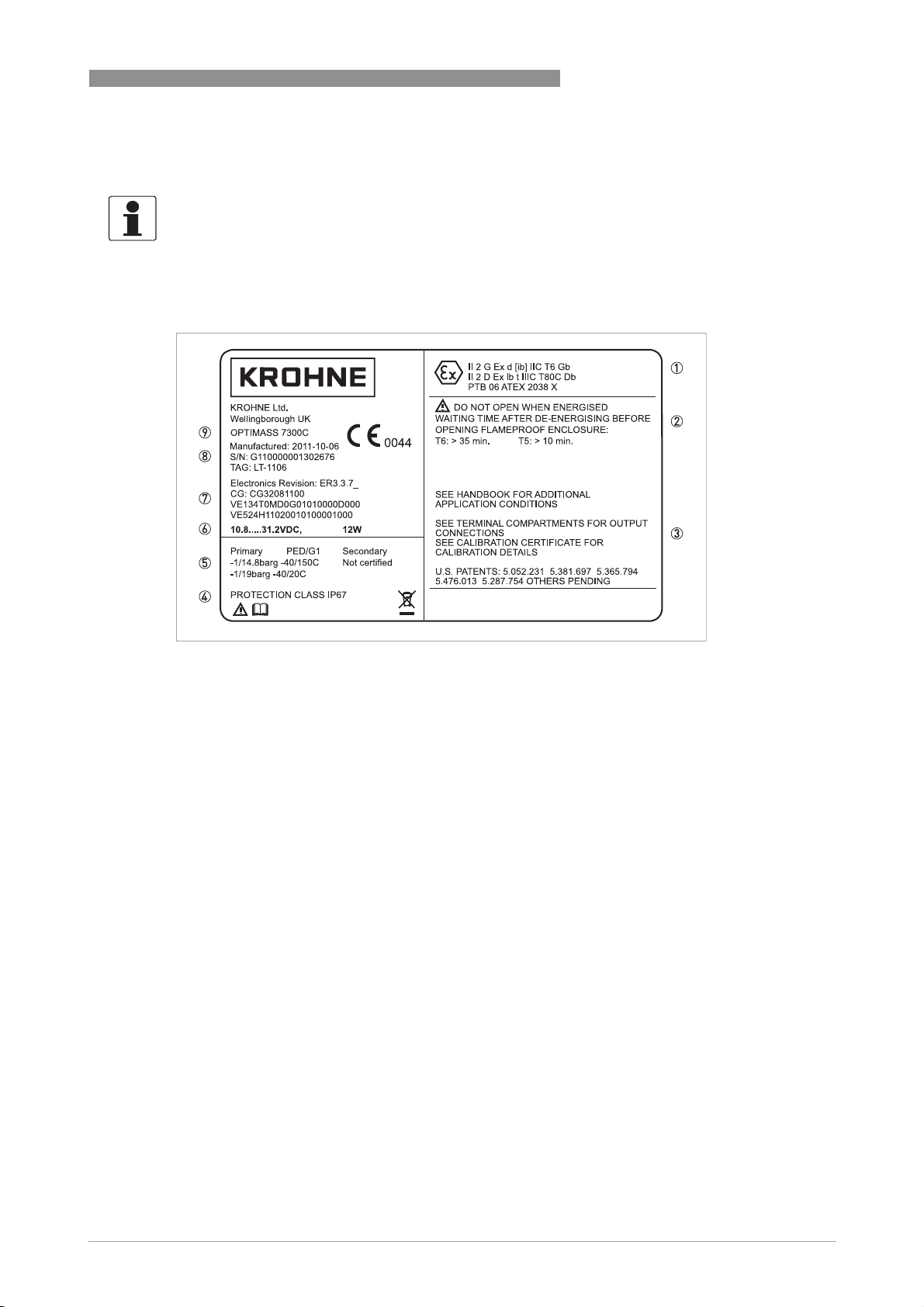

2.3 Nameplates .................................................................................................................... 17

2.3.1 Compact version (example) .................................................................................................. 17

2.3.2 Remote version (example) .................................................................................................... 18

2.3.3 Electrical connection data of inputs/outputs (example of basic version)............................ 19

3 Installation 20

3.1 Notes on installation ......................................................................................................20

3.2 Storage ........................................................................................................................... 20

3.3 Transport ........................................................................................................................ 20

3.4 Installation specifications .............................................................................................. 20

3.5 Mounting of the compact version................................................................................... 21

3.6 Mounting the field housing, remote version .................................................................. 21

3.6.1 Pipe mounting ....................................................................................................................... 21

3.6.2 Wall mounting....................................................................................................................... 22

3.6.3 Turning the display of the field housing version .................................................................. 23

3.7 Mounting the wall-mounted housing, remote version .................................................. 24

3.7.1 Pipe mounting ....................................................................................................................... 24

3.7.2 Wall mounting....................................................................................................................... 25

4 Electrical connections 26

4.1 Safety instructions.......................................................................................................... 26

4.2 Important notes on electrical connection...................................................................... 26

4.3 Requirements for signal cables provided by the customer........................................... 27

4.4 Connecting the signal cables ......................................................................................... 28

4.4.1 Connection of signal cable, field housing............................................................................. 29

4.4.2 Connection of signal cable, wall-mounted housing............................................................. 30

4.4.3 Connection of signal cable, 19" rack-mounted housing ...................................................... 31

4.4.4 Connection box of measuring sensor................................................................................... 32

4.4.5 Connection diagram.............................................................................................................. 33

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

3

Page 4

CONTENTS

4.5 Grounding the measuring sensor .................................................................................. 34

4.6 Connecting power, all housing variants......................................................................... 35

4.7 Inputs and outputs, overview ......................................................................................... 37

4.7.1 Combinations of the inputs/outputs (I/Os) ........................................................................... 37

4.7.2 Description of the CG number .............................................................................................. 38

4.7.3 Fixed, non-alterable input/output versions.......................................................................... 39

4.7.4 Alterable input/output versions............................................................................................ 41

4.8 Description of the inputs and outputs............................................................................ 42

4.8.1 Current output ...................................................................................................................... 42

4.8.2 Pulse and frequency output.................................................................................................. 43

4.8.3 Status output and limit switch .............................................................................................. 44

4.8.4 Control input ......................................................................................................................... 45

4.9 Electrical connection of the inputs and outputs ............................................................ 46

4.9.1 Field housing, electrical connection of the inputs and outputs........................................... 46

4.9.2 Wall-mounted housing, electrical connection of the inputs and outputs............................ 47

4.9.3 19" rack-mounted housing (28 TE), electrical connection of the inputs and outputs ......... 48

4.9.4 Laying electrical cables correctly......................................................................................... 48

4.10 Connection diagrams of inputs and outputs................................................................ 49

4.10.1 Important notes................................................................................................................... 49

4.10.2 Description of the electrical symbols................................................................................. 50

4.10.3 Basic inputs/outputs ........................................................................................................... 51

4.10.4 Modular inputs/outputs and bus systems.......................................................................... 54

4.10.5 Ex i inputs/outputs .............................................................................................................. 62

4.10.6 HART

MFC 300

®

connection .............................................................................................................. 66

5 Start-up 68

5.1 Switching on the power .................................................................................................. 68

5.2 Starting the signal converter ......................................................................................... 68

6 Operation 69

6.1 Display and operating elements .................................................................................... 69

6.1.1 Display in measuring mode with 2 or 3 measured values ................................................... 71

6.1.2 Display for selection of sub-menu and functions, 3 lines.................................................... 71

6.1.3 Display when setting parameters, 4 lines ............................................................................ 72

6.1.4 Display when changing parameters, 4 lines ........................................................................ 72

6.1.5 Using an IR interface (option) ............................................................................................... 73

6.2 Zero calibration (menu C1.1.1)....................................................................................... 74

6.3 Menu structure............................................................................................................... 76

6.4 Function tables ............................................................................................................... 79

6.4.1 Menu A, Quick Setup............................................................................................................. 79

6.4.2 Menu B, Test ......................................................................................................................... 81

6.4.3 Menu C, Setup ....................................................................................................................... 82

6.4.4 Set free units......................................................................................................................... 96

6.5 Description of functions ................................................................................................. 97

6.5.1 Reset counter in the menu "quick setup" ............................................................................ 97

6.5.2 Deleting error messages in the menu "quick setup"........................................................... 97

6.5.3 Mode (menu A8) .................................................................................................................... 98

6.5.4 Density calibration (menu C1.2.1)......................................................................................... 99

6.5.5 Temperature/density tables ............................................................................................... 102

6.5.6 Density mode (menu C1.2.2)............................................................................................... 105

4

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 5

MFC 300

CONTENTS

6.5.7 Pipe diameter (menu C1.1.3) .............................................................................................. 106

6.5.8 Concentration measurement (menu C2)............................................................................ 106

6.5.9 Flow direction (menu C1.3.1).............................................................................................. 106

6.5.10 Pressure suppression....................................................................................................... 106

6.5.11 Process control ................................................................................................................. 108

6.5.12 2 phase threshold (Menu C1.5.3) ...................................................................................... 109

6.5.13 Diagnosis values (menu C1.5.4...C1.5.6)........................................................................... 110

6.5.14 Graphic page (menu C6.5)................................................................................................. 110

6.5.15 Save settings (menu C6.6.2).............................................................................................. 110

6.5.16 Load settings (menu C6.6.3) ............................................................................................. 110

6.5.17 Passwords (Menu 6.6.4 Quick Set; Menu 6.6.5 Setup) ..................................................... 111

6.5.18 Low flow cutoff .................................................................................................................. 111

6.5.19 Time constant.................................................................................................................... 112

6.5.20 Dual phase pulse output ................................................................................................... 112

6.5.21 Timeouts in programming mode ...................................................................................... 112

6.5.22 Output hardware ............................................................................................................... 113

6.6 Status messages and diagnostic information.............................................................. 113

6.7 Function tests and troubleshooting ............................................................................. 118

6.8 Diagnostic functions..................................................................................................... 120

6.8.1 Temperature (menu B2.6) .................................................................................................. 120

6.8.2 Strain (menu B2.7 strain MT / B2.8 strain IC) .................................................................... 120

6.8.3 Frequency (menu B2.9)....................................................................................................... 120

6.8.4 Drive level (menu B2.10)..................................................................................................... 120

6.8.5 Sensor levels A and B (menu B2.11, B2.12) ....................................................................... 121

6.8.6 2 phase signal (menu B2.13)............................................................................................... 121

6.8.7 SE board or BE board temperature (menu B2.14 or B2.15) .............................................. 121

7 Service 122

7.1 Replacing the sensor or converter electronics ........................................................... 122

7.1.1 Replacing the sensor electronics (SE) ............................................................................... 122

7.1.2 Replacing the signal converter electronics (BE)................................................................ 123

7.2 Driver or sensor coil fault ............................................................................................ 125

7.2.1 OPTIMASS 1000................................................................................................................... 125

7.2.2 OPTIMASS 2000................................................................................................................... 126

7.2.3 OPTIMASS 3000................................................................................................................... 127

7.2.4 OPTIMASS 7000................................................................................................................... 128

7.2.5 OPTIMASS 8000k................................................................................................................. 129

7.3 Spare parts availability................................................................................................. 130

7.4 Availability of services .................................................................................................. 130

7.5 Returning the device to the manufacturer................................................................... 130

7.5.1 General information............................................................................................................ 130

7.5.2 Form (for copying) to accompany a returned device.......................................................... 131

7.6 Disposal ........................................................................................................................ 131

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

5

Page 6

CONTENTS

MFC 300

8 Technical data 132

8.1 Measuring principle (single tube) ................................................................................ 132

8.2 Technical data............................................................................................................... 134

8.3 Dimensions and weights .............................................................................................. 145

8.3.1 Housing ............................................................................................................................... 145

8.3.2 Mounting plate, field housing ............................................................................................. 146

8.3.3 Mounting plate, wall-mounted housing ............................................................................. 146

9 Description of HART interface 147

9.1 General description ...................................................................................................... 147

9.2 Software history ...........................................................................................................147

9.3 Connection variants...................................................................................................... 148

9.3.1 Point-to-Point connection - analogue / digital mode......................................................... 149

9.3.2 Multi-Drop connection (2-wire connection) ....................................................................... 150

9.3.3 Multi-Drop connection (3-wire connection) ....................................................................... 151

9.4 Inputs/outputs and HART® dynamic variables and device variables.......................... 152

9.5 Parameter for the basic configuration......................................................................... 153

9.6 Field Communicator 375/475 (FC 375/475) ................................................................. 154

9.6.1 Installation .......................................................................................................................... 154

9.6.2 Operation............................................................................................................................. 154

9.6.3 Parameter for the basic configuration ............................................................................... 154

9.7 Asset Management Solutions (AMS)............................................................................ 155

9.7.1 Installation .......................................................................................................................... 155

9.7.2 Operation............................................................................................................................. 155

9.7.3 Parameter for the basic configuration ............................................................................... 155

9.8 Field Device Manager (FDM) ........................................................................................ 156

9.8.1 Installation .......................................................................................................................... 156

9.8.2 Operation............................................................................................................................. 156

9.9 Process Device Manager (PDM)................................................................................... 156

9.9.1 Installation .......................................................................................................................... 156

9.9.2 Operation............................................................................................................................. 157

9.9.3 Parameter for the basic configuration ............................................................................... 157

9.10 Field Device Tool / Device Type Manager (FDT / DTM) .............................................. 158

9.10.1 Installation ........................................................................................................................ 158

9.10.2 Operation........................................................................................................................... 158

9.11 Appendix A: HART® menu tree for Basic-DD ............................................................ 158

9.11.1 Overview Basic-DD menu tree (positions in menu tree).................................................. 159

9.11.2 Basic-DD menu tree (details for settings)........................................................................ 160

9.12 Appendix B: HART® menu tree for AMS .................................................................... 164

9.12.1 Overview AMS menu tree (positions in menu tree) .......................................................... 165

9.12.2 AMS menu tree (details for settings)................................................................................ 166

9.13 Appendix C: HART® menu tree for PDM.................................................................... 171

9.13.1 Overview PDM menu tree (positions in menu tree).......................................................... 171

9.13.2 PDM menu tree (details for settings) ............................................................................... 174

6

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 7

MFC 300

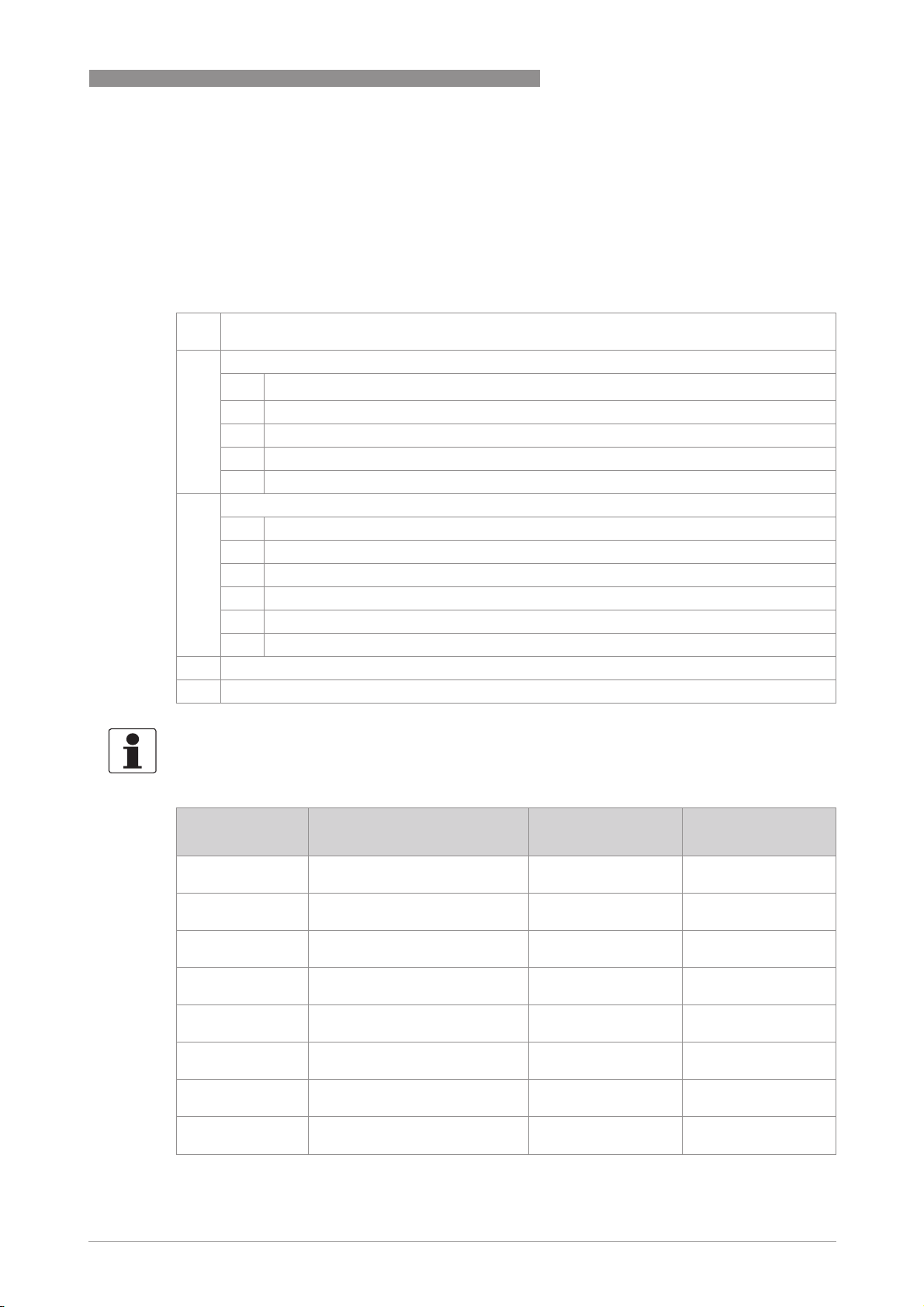

1.1 Software History

The "Electronic Revision" (ER) is consulted to document the revision status of electronic

equipment according to NE 53 for all GDC devices. It is easy to see from the ER whether

troubleshooting or larger changes in the electronic equipment have taken place and how that

has affected the compatibility.

Changes and effect on compatibility

1 Downwards compatible changes and fault repair with no effect on operation (e.g. spelling

mistakes on display)

2-_ Downwards compatible hardware and/or software change of interfaces:

H

HART

P PROFIBUS

F Foundation Fieldbus

M Modbus

X all interfaces

3-_ Downwards compatible hardware and/or software change of inputs and outputs:

I Current output

F, P Frequency / pulse output

S Status output

C control input

CI Current input

X all inputs and outputs

4 Downwards compatible changes with new functions

5 Incompatible changes, i.e. electronic equipment must be changed.

SAFETY INSTRUCTIONS 1

®

INFORMATION!

In the table below, "x" is a placeholder for possible multi-digit alphanumeric combinations,

depending on the available version.

Release date Electronic Revision Changes and

Documentation

compatibility

2006-11-06 ER 3.1.0x

(SW.REV. 3.10 (2.21))

2006-12-12 ER 3.1.1x

(SW.REV. 3.11 (2.21))

2007-02-07 ER 3.1.2x

(SW.REV. 3.11 (2.21))

2007-03-12 ER 3.1.3x

(SW.REV. 3.11 (2.21))

2007-06-27 ER 3.1.4x

(SW.REV. 3.11 (2.22))

2007-04-02 ER 3.2.0x

(SW.REV. 3.20 (2.22))

2007-05-04 ER 3.2.1x

(SW.REV. 3.20 (2.22))

2007-05-25 ER 3.2.2x

(SW.REV. 3.20 (2.22))

- -

1; 2-P; 2-M MA MFC 300 R02

1; 2-M MA MFC 300 R02

1; 2-H MA MFC 300 R02

1 MA MFC 300 R02

1; 2-X; 2-P; 2-F MA MFC 300 R02

1 MA MFC 300 R02

1; 3-I MA MFC 300 R02

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

7

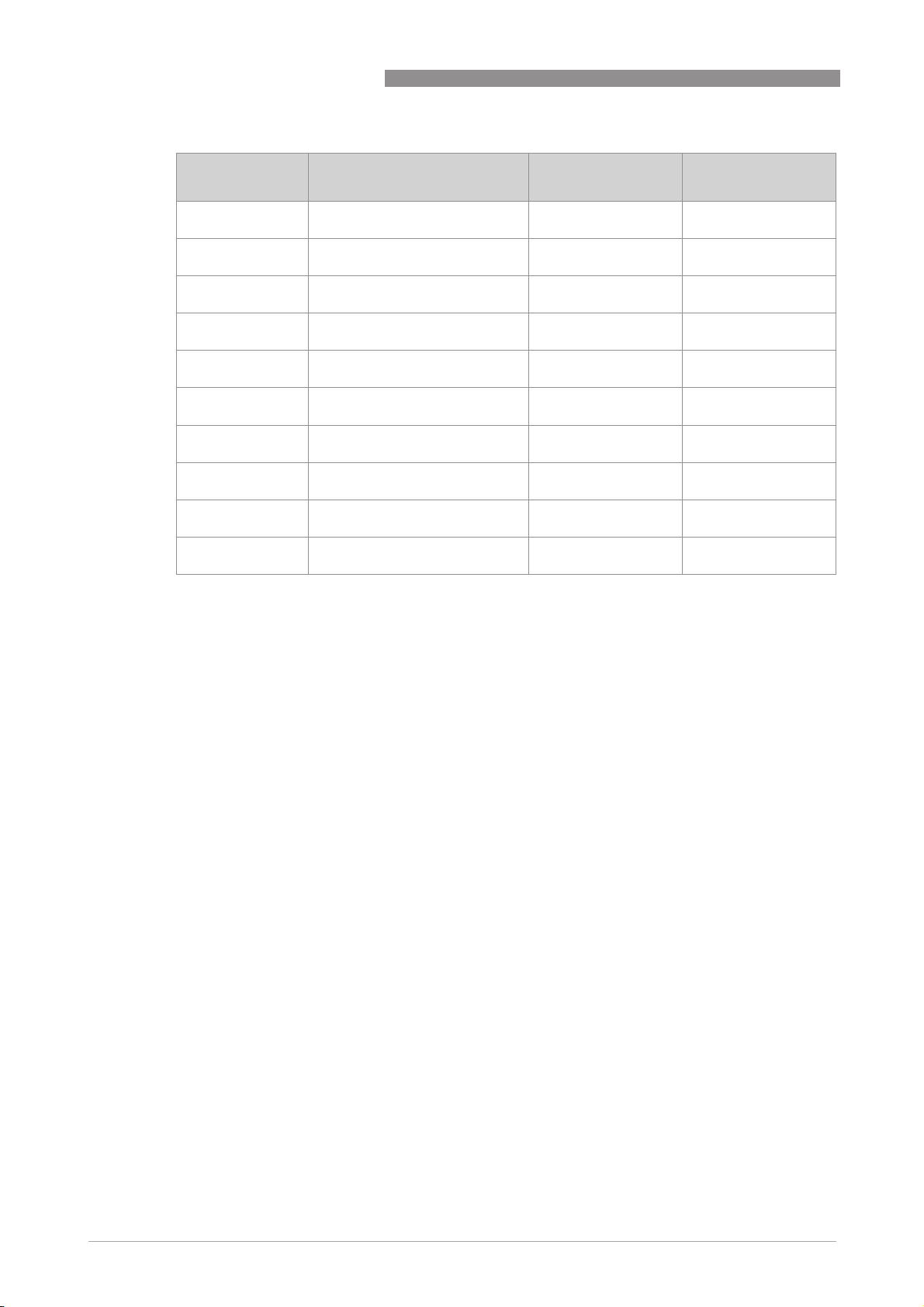

Page 8

1 SAFETY INSTRUCTIONS

MFC 300

Release date Electronic Revision Changes and

compatibility

2007-06-27 ER 3.2.3x

(SW.REV. 3.20 (2.22))

2007-07-16 ER 3.2.4x

(SW.REV. 3.20 (2.22))

2008-08-01 ER 3.3.0x

(SW.REV. 3.30 (3.02))

2008-08-25 ER 3.3.1x

(SW.REV. 3.30 (3.03))

2008-10-23 ER 3.3.2x

(SW.REV. 3.30 (3.03))

2009-05-13 ER 3.3.3x

(SW.REV. 3.30 (3.03))

2009-10-29 ER 3.3.4x

(SW.REV. 3.30 (3.03))

2009-12-07 ER 3.3.5x

(SW.REV. 3.30 (3.03))

2011-03 ER 3.3.6x

(SW.REV. 3.40 (3.04))

2011-06 ER 3.3.7x

(SW.REV. 3.40 (3.04))

1 MA MFC 300 R02

1; 2-F MA MFC 300 R02

1; 2-X; 4 MA MFC 300 R02

1 MA MFC 300 R02

2-M MA MFC 300 R02

2-F MA MFC 300 R02

1 MA MFC 300 R02

2-F; 2-X MA MFC 300 R02

1; 2-F MA MFC 300 R02

1 MA MFC 300 R03

Documentation

8

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 9

MFC 300

1.2 Intended Use

The mass flowmeters are designed exclusively to directly measure mass flow rates, product

density and temperature as well to indirectly measure parameters such as the total volume and

concentration of dissolved substances as well as the volume flow rate.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

If the device is not used according to the operating conditions (refer to chapter "Technical data"),

the intended protection could be affected.

1.3 Certifications

CE marking

SAFETY INSTRUCTIONS 1

The device fulfils the statutory requirements of the following EC directives:

• Low Voltage Directive 2006/95/EC

• EMC Directive 2004/108/EC

as well as

• EN 61010

• EMC specification acc. to EN 61326/A1

• NAMUR recommendations NE 21 and NE 43

The manufacturer certifies successful testing of the product by applying the CE marking.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

9

Page 10

1 SAFETY INSTRUCTIONS

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

MFC 300

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

10

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 11

MFC 300

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

11

Page 12

1 SAFETY INSTRUCTIONS

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

MFC 300

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.5 Safety instructions for the operator

12

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 13

MFC 300

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

Figure 2-1: Scope of delivery

1 Device in the version as ordered

2 Documentation (calibration report, factory and material certification if ordered, CD-Rom with product documentation

for measuring sensor and signal converter)

3 Signal cable (only for remote version)

Signal converter / measuring sensor combination possibilities

Measuring sensor Signal converter MFC 300

Compact Remote field

housing

OPTIMASS 1000 OPTIMASS 1300 C OPTIMASS 1300 F OPTIMASS 1300 W OPTIMASS 1300 R

OPTIMASS 2000 OPTIMASS 2300 C OPTIMASS 2300 F OPTIMASS 2300 W OPTIMASS 2300 R

OPTIMASS 3000 OPTIMASS 3300 C OPTIMASS 3300 F OPTIMASS 3300 W OPTIMASS 3300 R

OPTIMASS 7000 OPTIMASS 7300 C OPTIMASS 7300 F OPTIMASS 7300 W OPTIMASS 7300 R

OPTIMASS 8000 OPTIMASS 8300 C OPTIMASS 8300 F OPTIMASS 8300 W OPTIMASS 8300 R

Remote wallmounted housing

Remote rackmounted housing

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

13

Page 14

2 DEVICE DESCRIPTION

2.2 Device description

The mass flowmeters are designed exclusively to directly measure mass flow rates, product

density and temperature as well to indirectly measure parameters such as the total volume and

concentration of dissolved substances as well as the volume flow rate.

Your measuring device is supplied ready for operation. The factory settings for the operating

data have been made in accordance with your order specifications.

The following versions are available:

• Compact version (the signal converter is mounted directly on the measuring sensor)

• Remote version (electrical connection to the measuring sensor via field current and signal

cable)

MFC 300

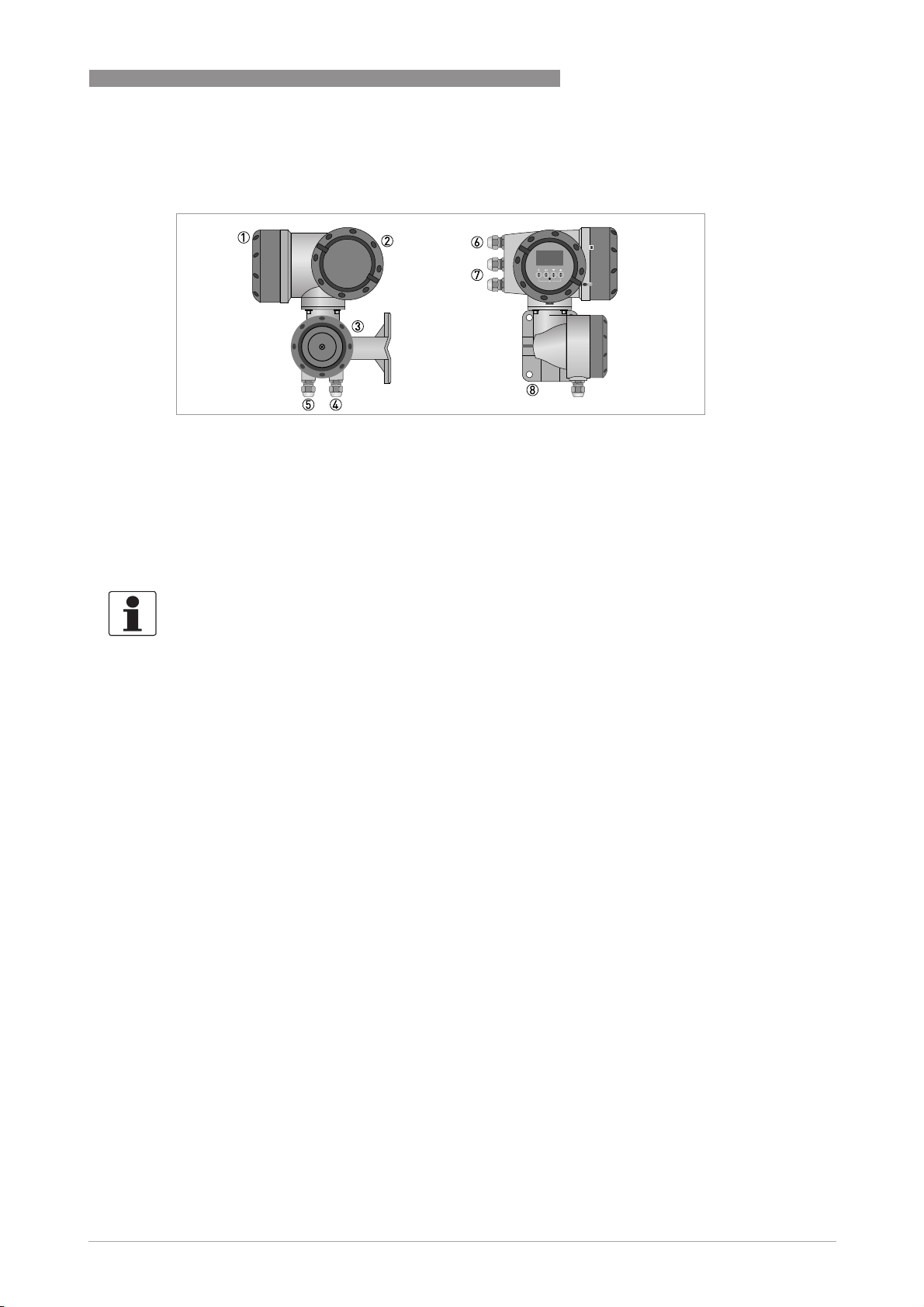

Figure 2-2: Device versions

1 Compact version

2 Measuring sensor with connection box

3 Field housing

4 Wall-mounted housing

5 19" rack-mounted housing

14

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 15

MFC 300

2.2.1 Field housing

Figure 2-3: Construction of the field housing

1 Cover for electronics and display

2 Cover for power supply and inputs/outputs terminal compartment

3 Cover for measuring sensor terminal compartment with locking screw

4 Cable entry for measuring sensor signal cable

5 Cable entry for measuring sensor field current cable

6 Cable entry for power supply

7 Cable entry for inputs and outputs

8 Mounting plate for pipe and wall mounting

DEVICE DESCRIPTION 2

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

15

Page 16

2 DEVICE DESCRIPTION

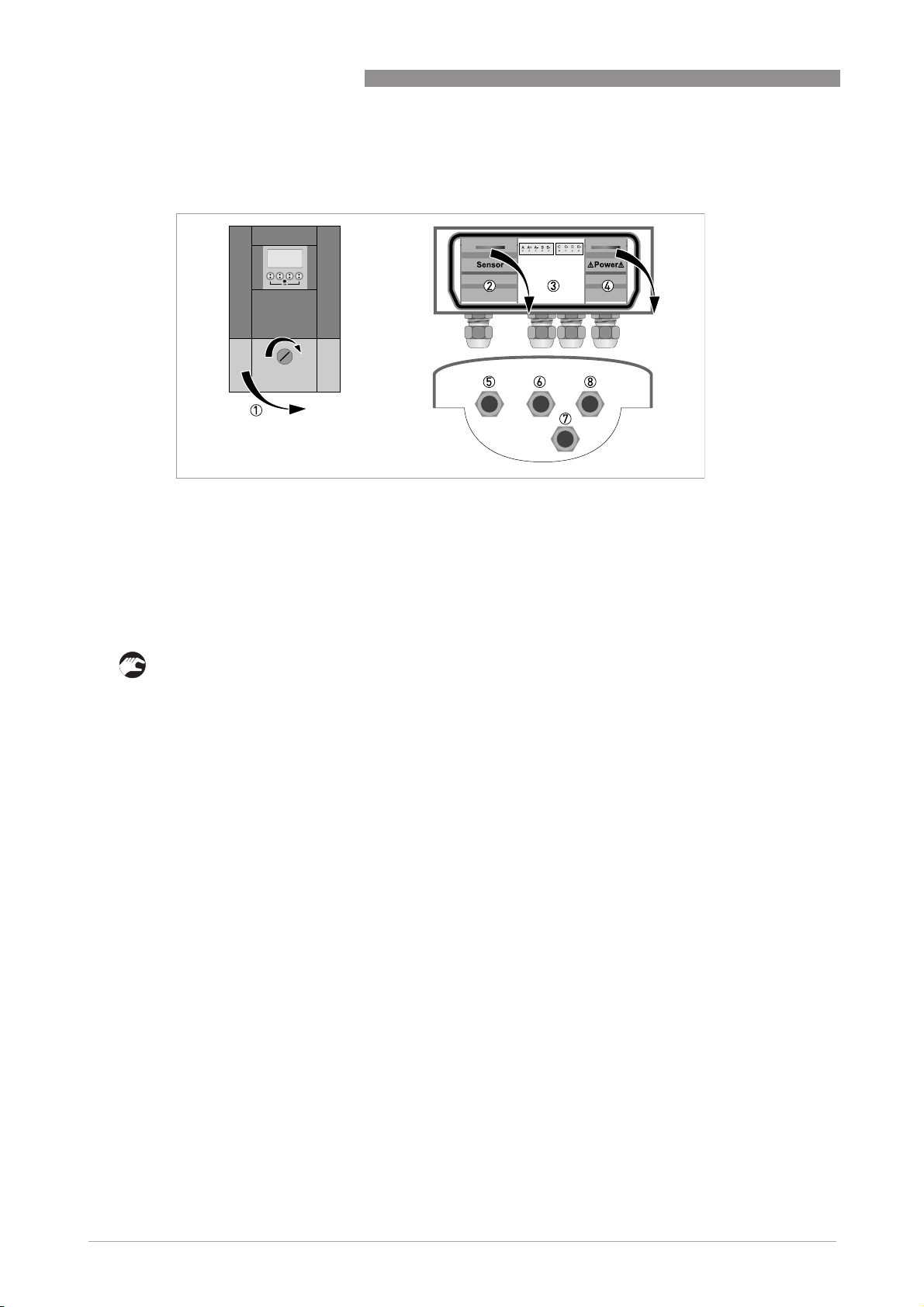

2.2.2 Wall-mounted housing

Figure 2-4: Construction of wall-mounted housing

1 Cover for terminal compartments

2 Terminal compartment for measuring sensor

3 Terminal compartment for inputs and outputs

4 Terminal compartment for power supply with safety cover (shock-hazard protection)

5 Cable entry for measuring sensor cable

6 Cable entry for inputs and outputs

7 Cable entry for inputs and outputs

8 Cable entry for power supply

MFC 300

1 Turn lock to the right and open the cover.

16

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 17

MFC 300

2.3 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

2.3.1 Compact version (example)

DEVICE DESCRIPTION 2

Figure 2-5: Example of nameplate for the compact version

1 Approvals-related information: Ex approval, EC type test certificate, hygienic approvals, etc.

2 Approvals-related thresholds

3 Additional information on documentation, calibration and patents

4 Protection category

5 Approvals-related pressure and temperature thresholds

6 Electrical connection data

7 Software and hardware revision (Electronics Revision), CG number, order number for signal converter and measuring

sensor

8 Manufacturing date, serial number and TAG number

9 Product description

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

17

Page 18

2 DEVICE DESCRIPTION

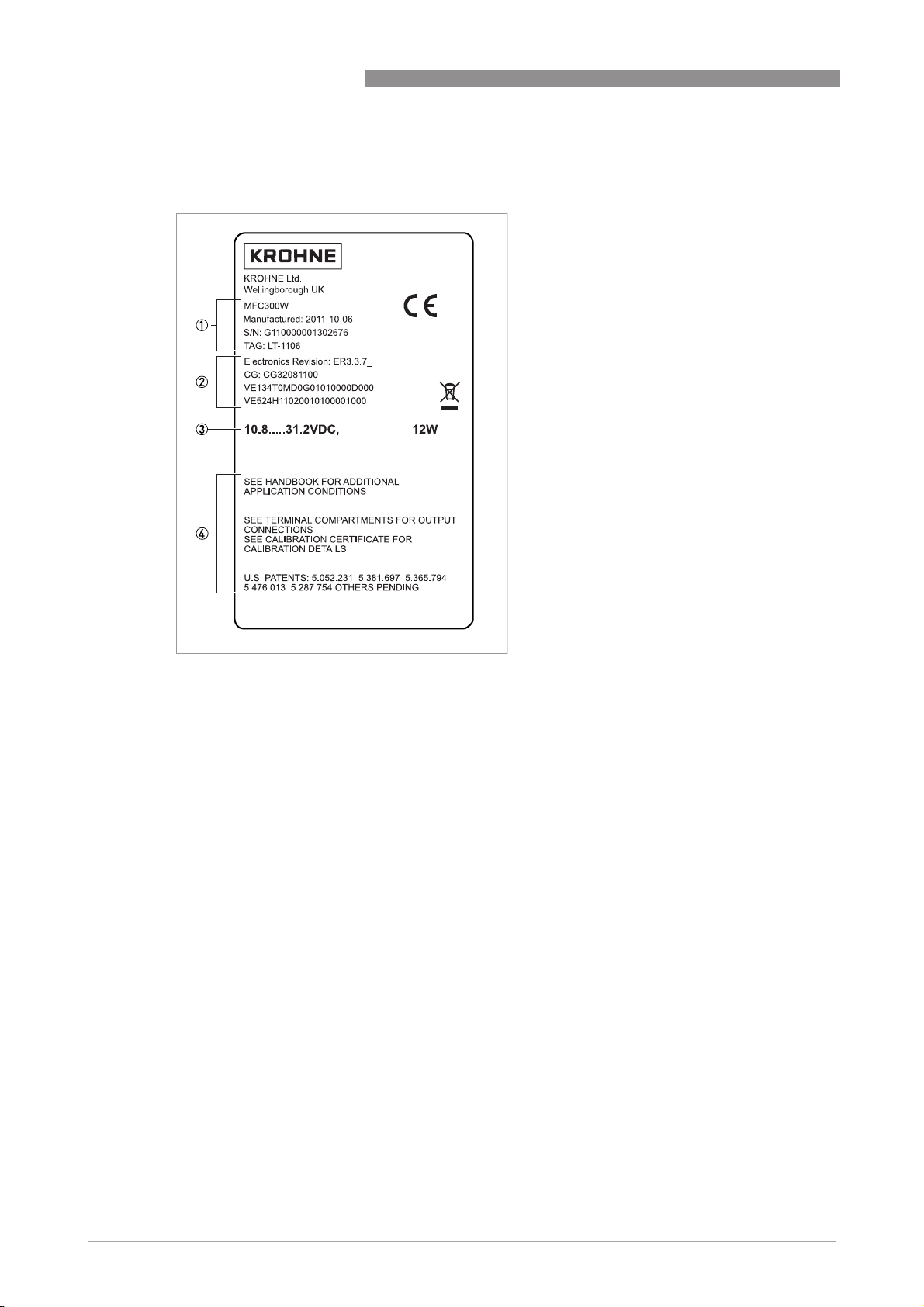

2.3.2 Remote version (example)

MFC 300

Figure 2-6: Example of a nameplate for the remote version

1 Product designation, manufacturing date, serial number and TAG number

2 Software and hardware revision (Electronics Revision), CG number, order number for signal converter and measuring

sensor

3 Electrical connection data

4 Additional information on documentation, calibration and patents

18

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 19

MFC 300

DEVICE DESCRIPTION 2

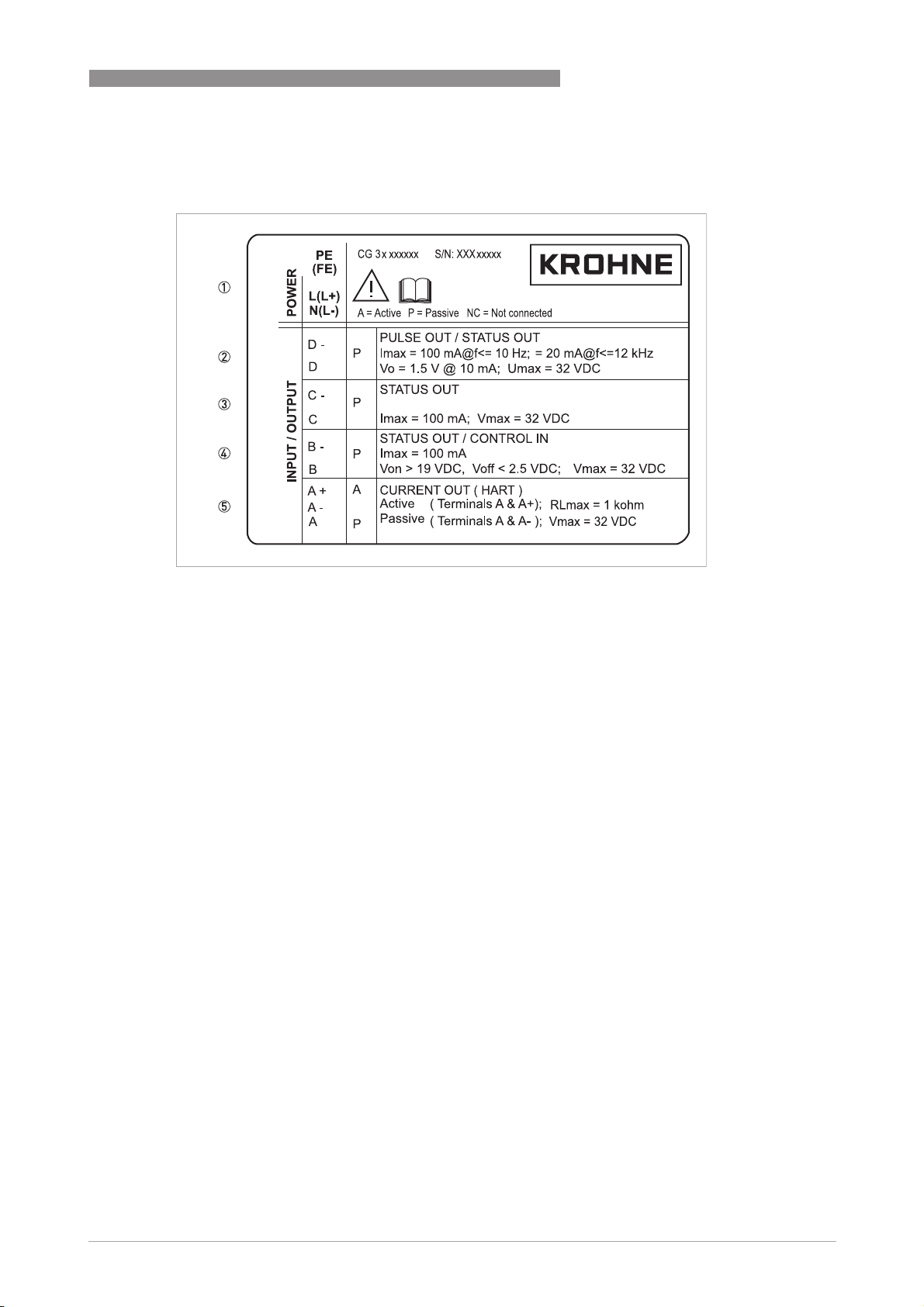

2.3.3 Electrical connection data of inputs/outputs (example of basic version)

Figure 2-7: Example of a nameplate for electrical connection data of inputs and outputs

1 Power supply (AC: L and N; DC: L+ and L-; PE for ≥ 24 VAC; FE for ≤ 24 VAC and DC)

2 Connection data of connection terminal D/D-

3 Connection data of connection terminal C/C-

4 Connection data of connection terminal B/B-

5 Connection data of connection terminal A/A-; A+ only operable in the basic version

• A = active mode; the signal converter supplies the power for connection of the subsequent

devices

• P = passive mode; external power supply required for operation of the subsequent devices

• N/C = connection terminals not connected

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

19

Page 20

3 INSTALLATION

3.1 Notes on installation

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

• Store the device in a dry, dust-free location.

• Avoid continuous direct sunlight.

• Store the device in its original packing.

• Storage temperature: -50...+70°C / -58...+158°F

MFC 300

3.3 Transport

Signal converter

• No special requirements.

Compact version

• Do not lift the device by the signal converter housing.

• Do not use lifting chains.

• To transport flange devices, use lifting straps. Wrap these around both process connections.

3.4 Installation specifications

INFORMATION!

The following precautions must be taken to ensure reliable installation.

•

Make sure that there is adequate space to the sides.

•

Protect the signal converter from direct sunlight and install a sun shade if necessary.

•

Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat

exchanger.

•

Do not expose the signal converter to intense vibration. The flowmeters are tested for a

vibration level in accordance with IEC 68-2-3.

20

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 21

MFC 300

3.5 Mounting of the compact version

INFORMATION!

The signal converter is mounted directly on the measuring sensor. For installation of the

flowmeter, please observe the instructions in the supplied product documentation for the

measuring sensor.

3.6 Mounting the field housing, remote version

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

3.6.1 Pipe mounting

INSTALLATION 3

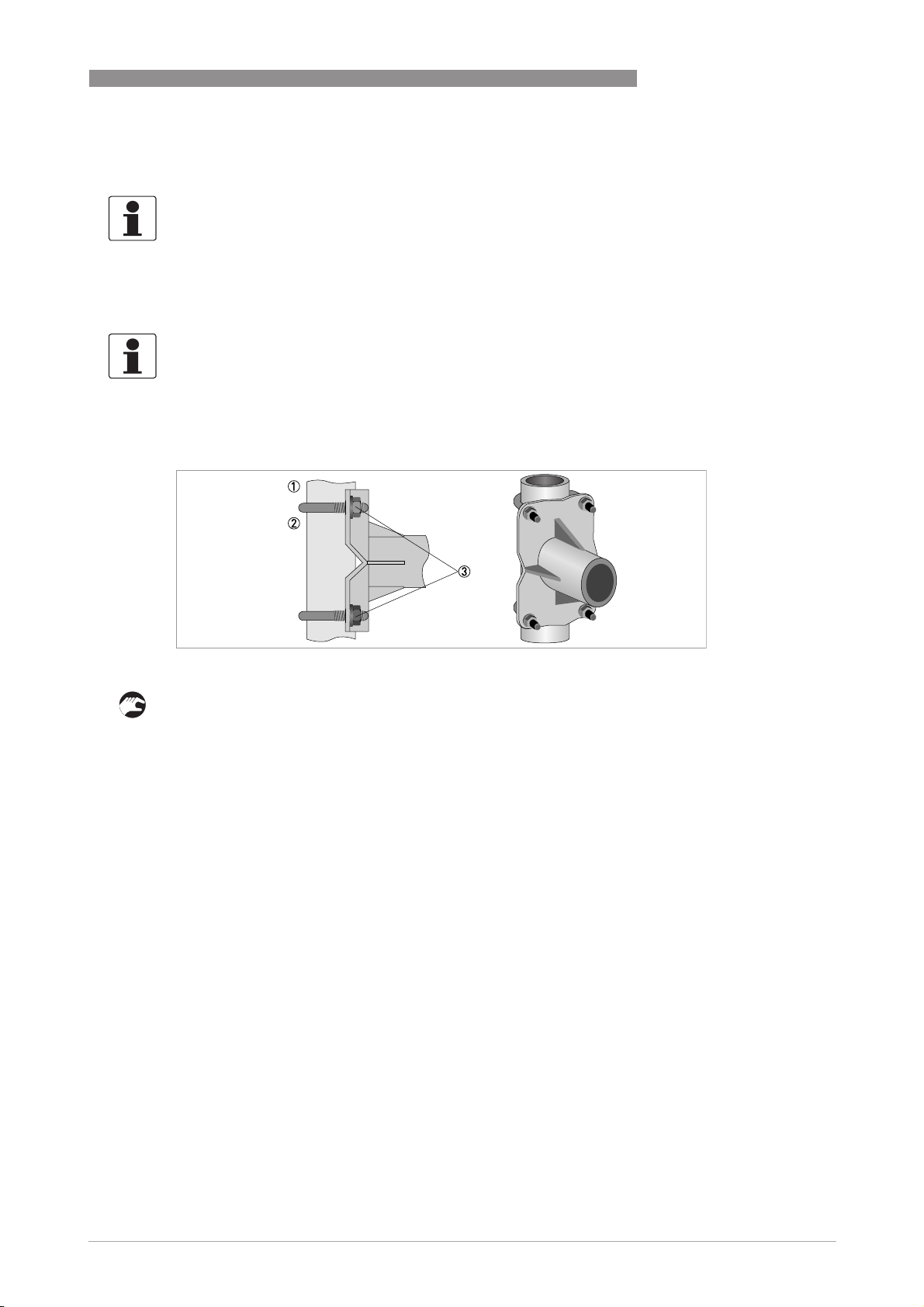

Figure 3-1: Pipe mounting of the field housing

1 Fix the signal converter to the pipe.

2 Fasten the signal converter using standard U-bolts and washers.

3 Tighten the nuts.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

21

Page 22

3 INSTALLATION

3.6.2 Wall mounting

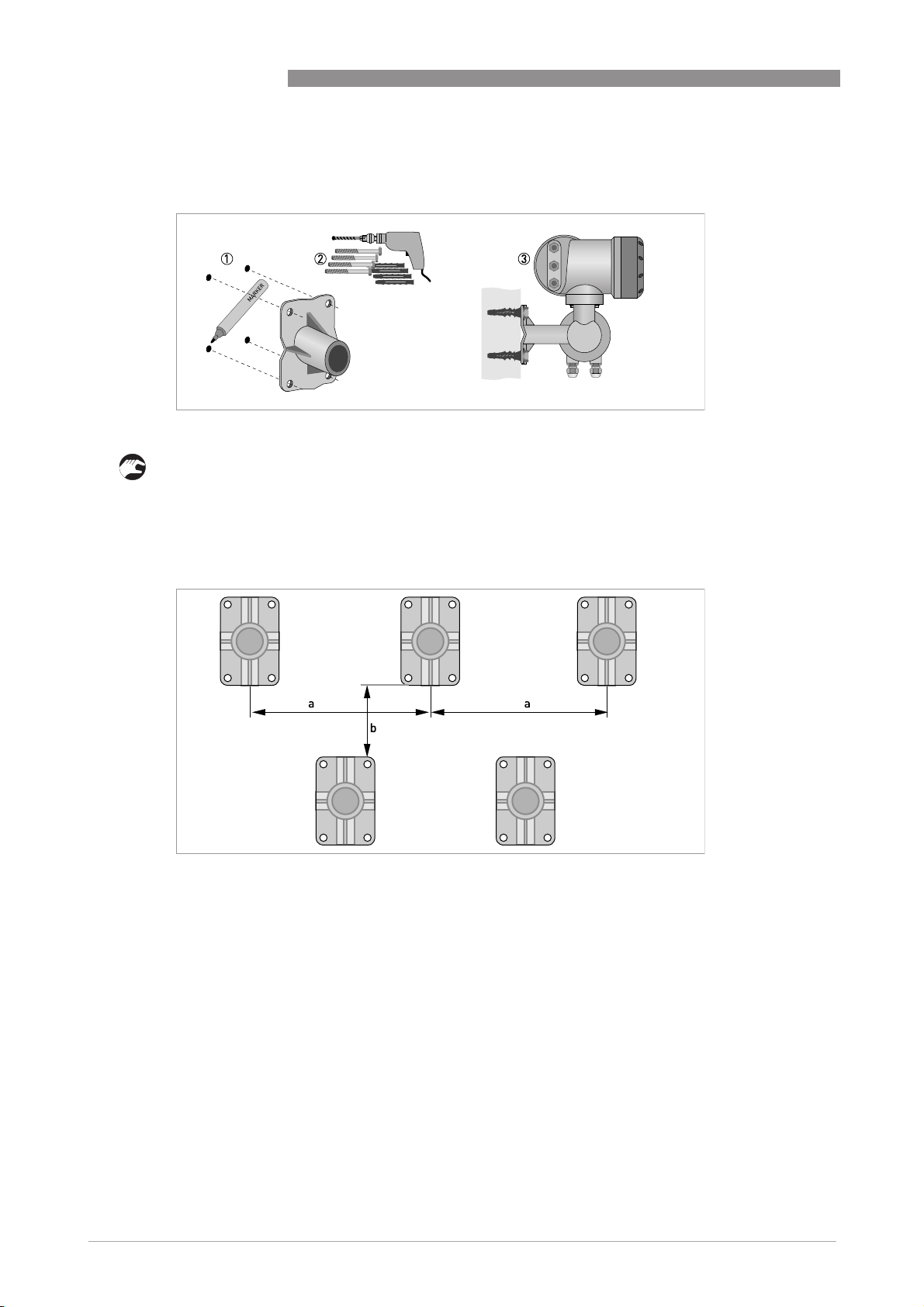

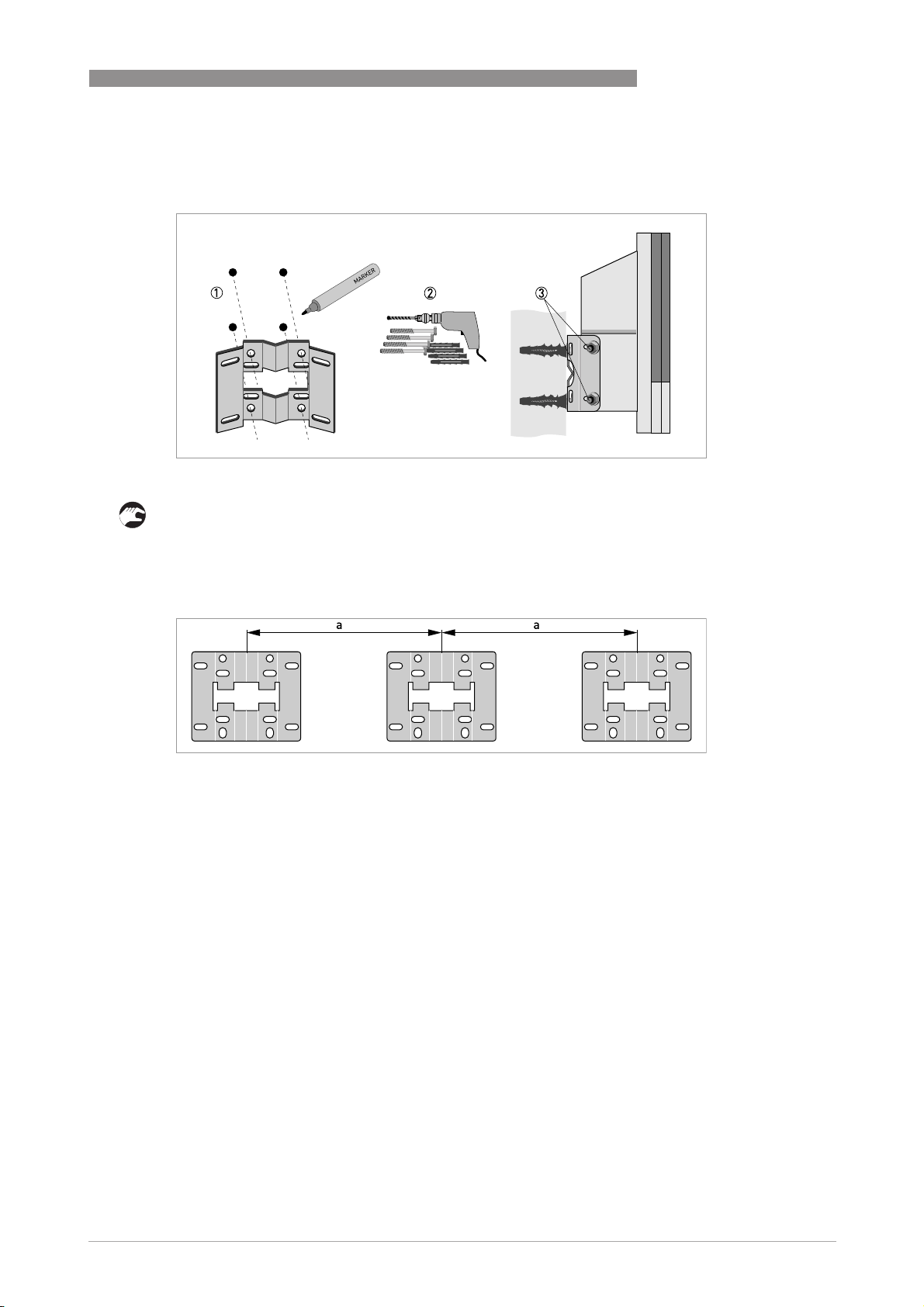

Figure 3-2: Wall mounting of the field housing

MFC 300

1 Prepare the holes with the aid of the mounting plate. For further information refer to

plate, field housing

on page 146.

Mounting

2 Use the mounting material and tools in compliance with the applicable occupational health

and safety directives.

3 Fasten the housing securely to the wall.

Mounting multiple devices next to each other

a ≥ 600 mm / 23.6"

b ≥ 250 mm / 9.8"

22

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 23

MFC 300

3.6.3 Turning the display of the field housing version

INSTALLATION 3

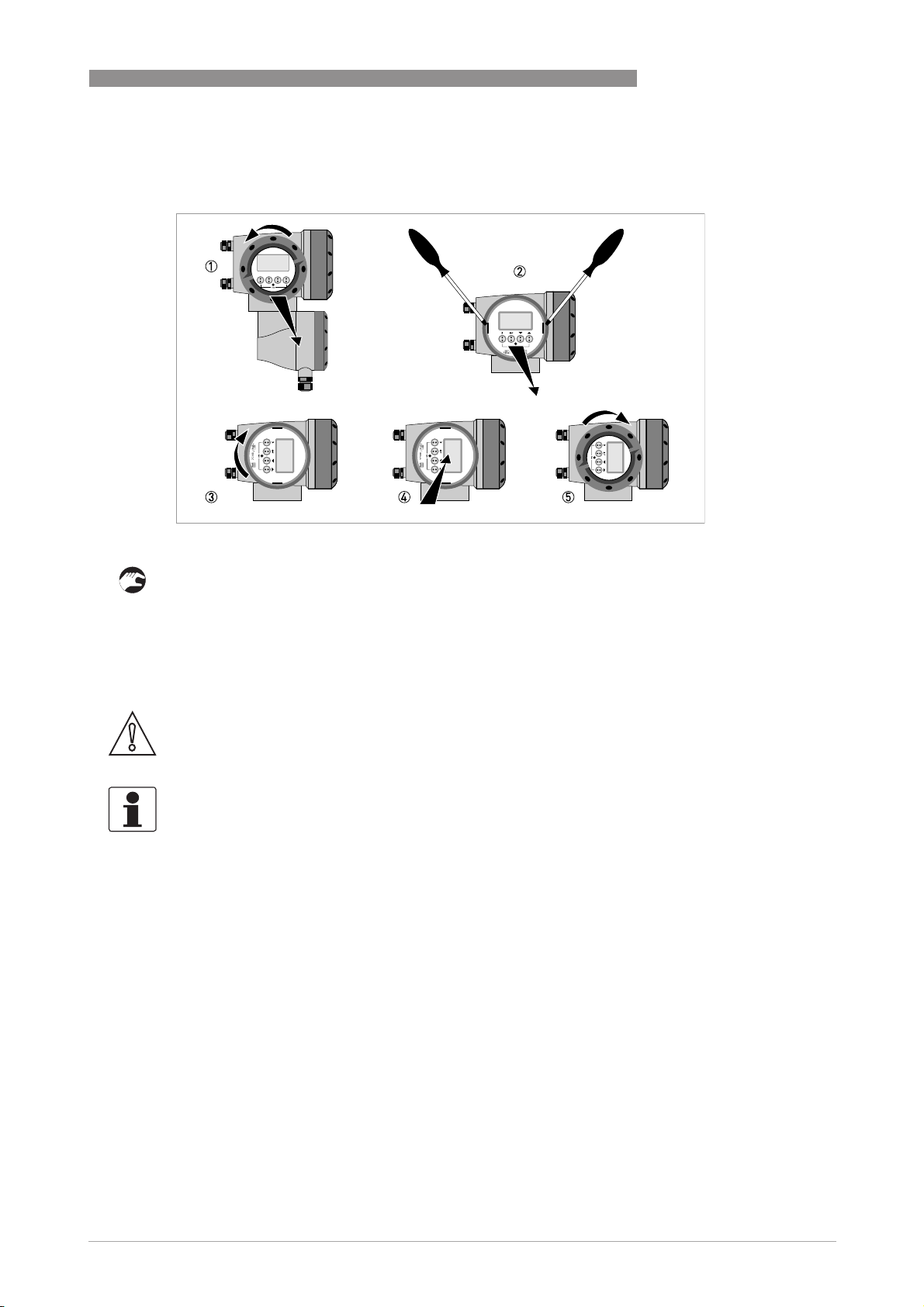

Figure 3-3: Turning the display of the field housing version

The display of the field housing version can be turned in 90° increments.

1 Unscrew the cover from the display and operation control unit.

2 Using a suitable tool, pull out the two metal puller devices to the left and right of the display.

3 Pull out the display between the two metal puller devices and rotate it to the required position.

4 Slide the display and then the metal puller devices back into the housing.

5 Re-fit the cover and tighten it by hand.

CAUTION!

The ribbon cable of the display must not be folded or twisted repeatedly.

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

23

Page 24

3 INSTALLATION

3.7 Mounting the wall-mounted housing, remote version

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

3.7.1 Pipe mounting

MFC 300

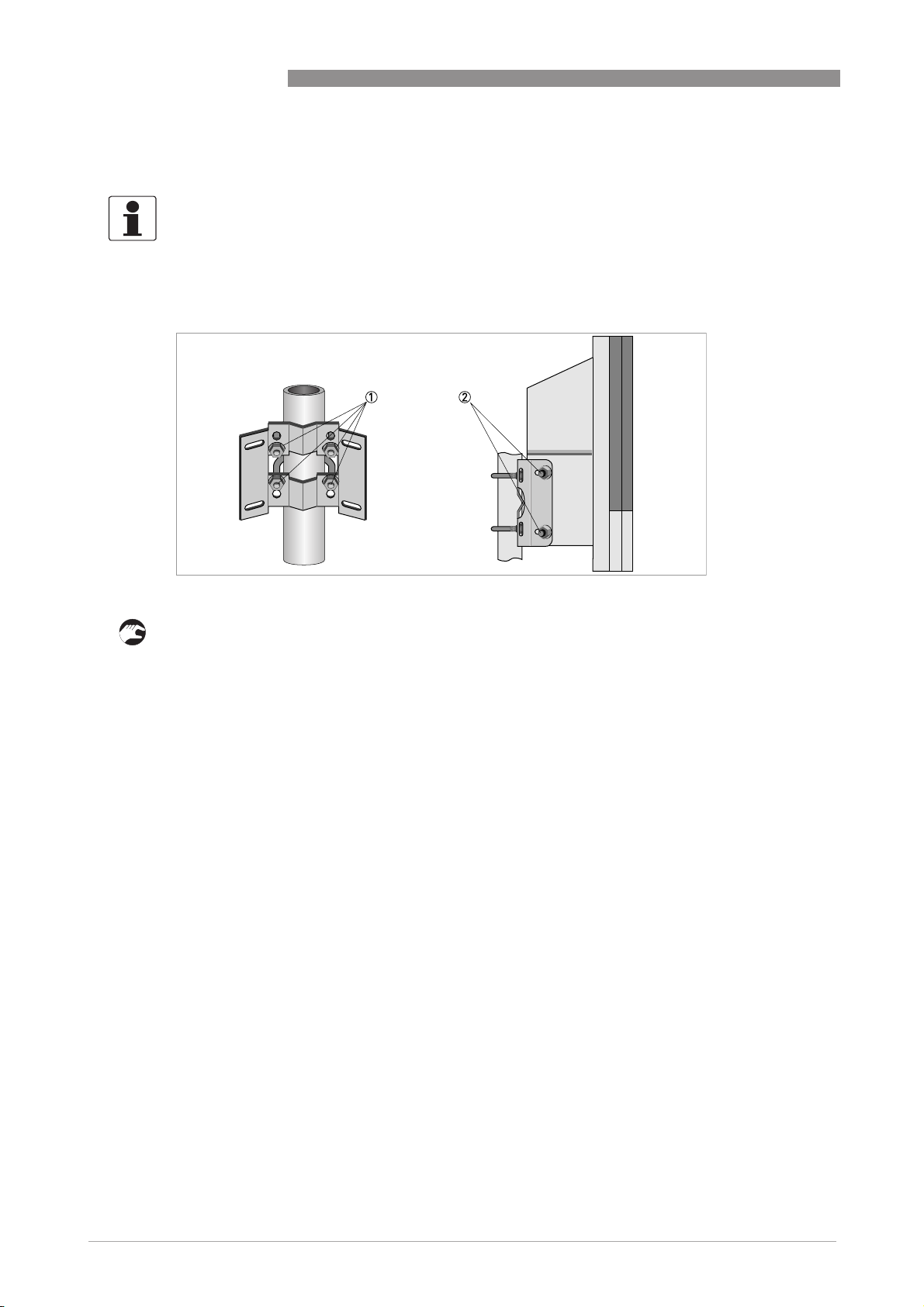

Figure 3-4: Pipe mounting of the wall-mounted housing

1 Fasten the mounting plate to the pipe with standard U-bolts, washers and fastening nuts.

2 Screw the signal converter to the mounting plate with the nuts and washers.

24

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 25

MFC 300

3.7.2 Wall mounting

Figure 3-5: Wall mounting of the wall-mounted housing

INSTALLATION 3

1 Prepare the holes with the aid of the mounting plate. For further information refer to

plate, wall-mounted housing

2 Fasten the mounting plate securely to the wall.

3 Screw the signal converter to the mounting plate with the nuts and washers.

on page 146.

Mounting multiple devices next to each other

a ≥ 240 mm / 9.4"

Mounting

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

25

Page 26

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

MFC 300

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Important notes on electrical connection

DANGER!

Electrical connection is carried out in conformity with the VDE 0100 directive "Regulations for

electrical power installations with line voltages up to 1000 V" or equivalent national regulations.

CAUTION!

•

Use suitable cable entries for the various electrical cables.

•

The measuring sensor and signal converter have been configured together at the factory. For

this reason, please connect the devices in pairs.

26

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 27

MFC 300

ELECTRICAL CONNECTIONS 4

4.3 Requirements for signal cables provided by the customer

INFORMATION!

If the signal cable was not ordered, it is to be provided by the customer. The following

requirements regarding the electrical values of the signal cable must be observed:

Specifications for standard signal cables

• 2 twisted double wire circuits

• 20 AWG twisted, tinned copper conductors (19 mm / 0.2")

• Completely tinned copper shielding

• Casing colour: grey

• Colour of wires:

Pair 1: black / red

Pair 2 : green / white

• Test voltage: ≥ 500 VAC RMS (750 VDC)

• Temperature range: -20...+105°C / -4...+221°F

• Capacity: ≤ 200 pF/m / 61 pF/ft

• Inductance: ≤ 0.7 µH/m / 0.2 µH/ft

Specifications for cables in hazardous areas

• 2 shielded twisted double wire circuits

• 20 AWG twisted, tinned copper conductors (19 mm / 0.2")

• Casing colour: blue

• Colour of wires:

Pair 1: black / red

Pair 2 : green / white

• Test voltage: ≥ 500 VAC RMS (750 VDC)

• Temperature range: -20...+105°C / -4...+221°F

• Capacity: ≤ 200 pF/m / 61 pF/ft

• Inductance: ≤ 0.7 µH/m / 0.2 µH/ft

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

27

Page 28

4 ELECTRICAL CONNECTIONS

4.4 Connecting the signal cables

DANGER!

Cables may only be connected when the power is switched off.

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

MFC 300

28

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 29

MFC 300

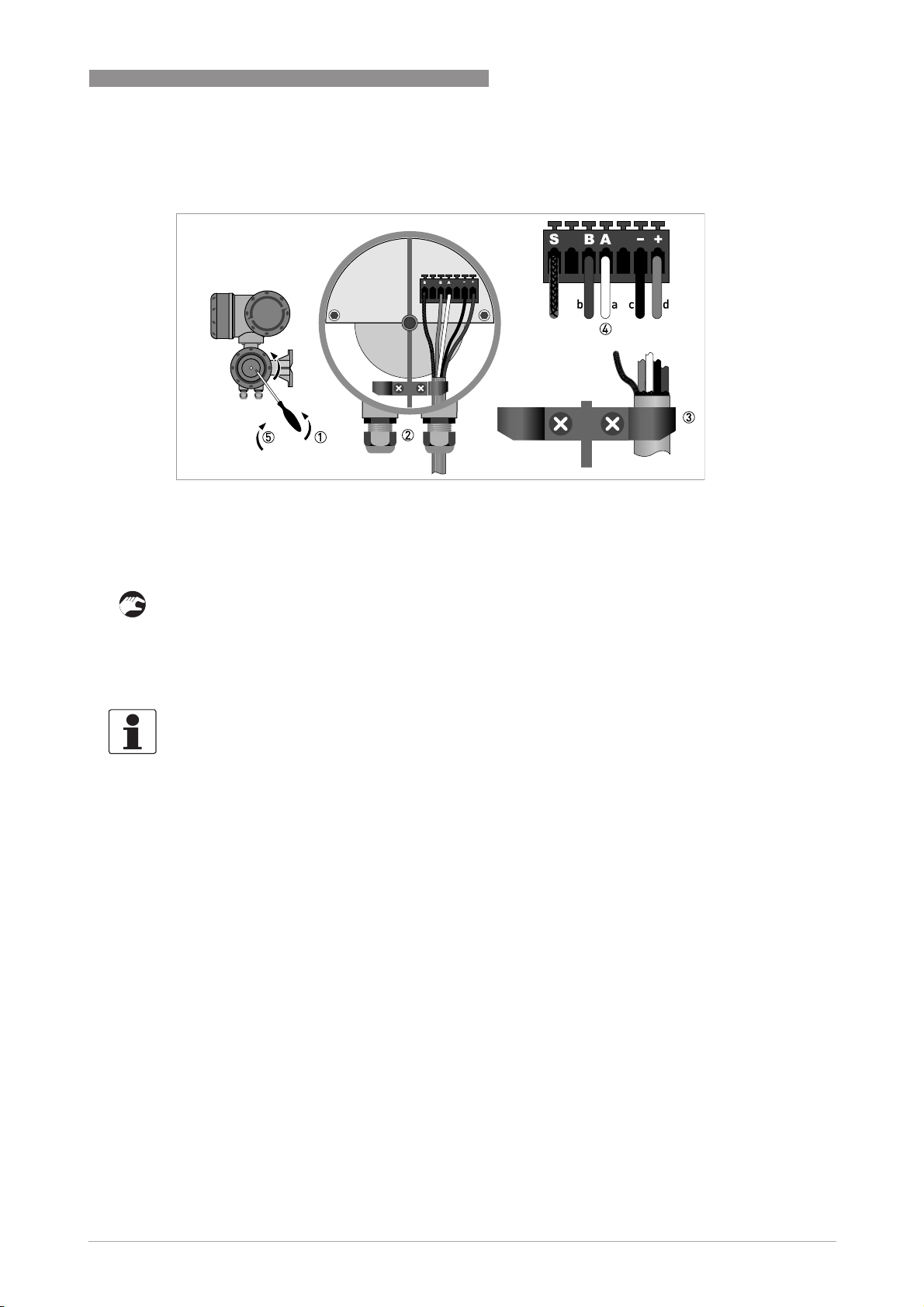

4.4.1 Connection of signal cable, field housing

Figure 4-1: Electrical connection of the signal cables, field housing

a = white

b = green

c = black

d = red

ELECTRICAL CONNECTIONS 4

1 Remove the locking screw and open the housing cover.

2 Pass the prepared signal cable through the cable entry.

3 Secure the signal cable using the clip.

4 Connect the electrical conductors as shown. The shielding is connected to terminal S.

5 Close the housing cover and secure it with the locking screw.

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

29

Page 30

4 ELECTRICAL CONNECTIONS

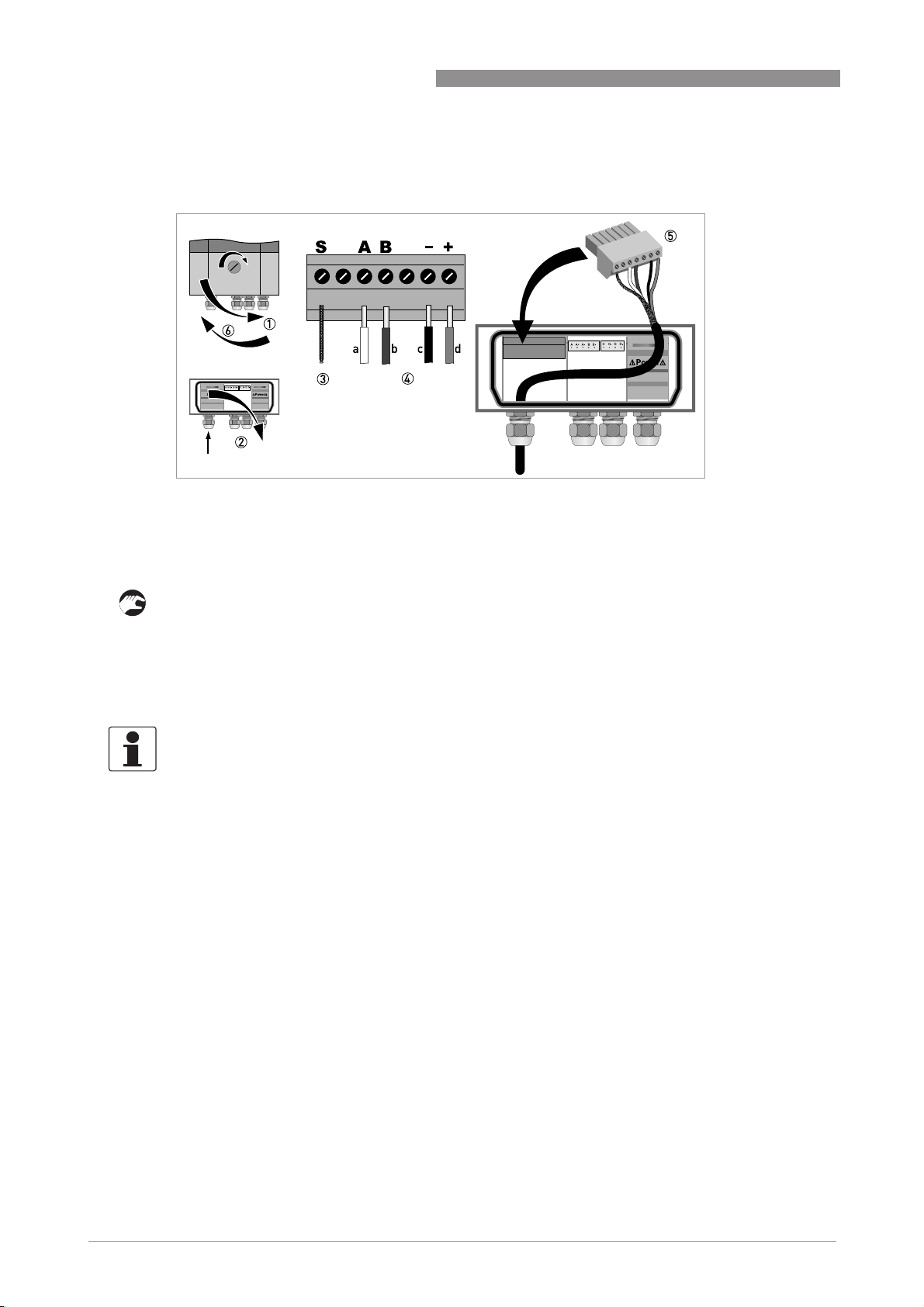

4.4.2 Connection of signal cable, wall-mounted housing

Figure 4-2: Electrical connection of signal cable, wall-mounted housing

a = white

b = green

c = black

d = red

MFC 300

1 Open the housing cover.

2 Open the cover and guide the prepared signal cable through the cable entry.

3 Connect the twisted shielding to terminal S.

4 Connect the electrical conductors to terminals +, -, A, B.

5 Press the plug into the connector.

6 Close the cover and the housing cover.

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

30

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 31

MFC 300

ELECTRICAL CONNECTIONS 4

4.4.3 Connection of signal cable, 19" rack-mounted housing

Figure 4-3: Electrical connection of signal cable, 19" rack-mounted housing

• Connect the conductor to the multipolar plug according to the illustration.

• The shielding of the signal cable can be connected to 22z, 22d, 24z or 24d.

• Press the plug into the connector.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

31

Page 32

4 ELECTRICAL CONNECTIONS

4.4.4 Connection box of measuring sensor

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

MFC 300

Figure 4-4: Electrical connection to connection box of the sensor

a = white

b = green

c = black

d = red

1 Remove the locking screw and open the housing cover.

2 Pass the prepared signal cable through the cable entry.

3 Secure the signal cable using the spring terminal. The shielding MUST

MUST also be connected to

MUSTMUST

the spring terminal.

4 Connect the electrical conductors as shown.

5 Close the housing cover and secure it with the locking screw.

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

32

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 33

MFC 300

4.4.5 Connection diagram

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

Wall housing

ELECTRICAL CONNECTIONS 4

Figure 4-5: Connection diagram for remote versions, wall housing

1 Terminal compartment for signal converter

2 Terminal compartment for measuring sensor

3 Connect shielding to spring terminal

4 Connect shielding to terminal S

5 Functional ground

Field housing

Figure 4-6: Connection diagram for remote versions, field housing

1 Terminal compartment for signal converter

2 Terminal compartment for measuring sensor

3 Connect shielding to spring terminal

4 Connect shielding to terminal S

5 Functional ground

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

33

Page 34

4 ELECTRICAL CONNECTIONS

19" rack-mounted housing

Figure 4-7: Connection diagram for remote versions, 19" rack-mounted housing

1 Terminal compartment for signal converter

2 Terminal compartment for measuring sensor

3 Connect shielding to spring terminal

4 Connect shielding to terminal S

(The shielding can be connected to 22z, 22d, 24z or 24d)

5 Functional ground

MFC 300

4.5 Grounding the measuring sensor

DANGER!

There should be no difference in potential between the measuring sensor and the housing or

protective earth of the signal converter!

• The measuring sensor must be properly grounded.

• The grounding cable should not transmit any interference voltages.

• Do not use the grounding cable to connect more than one device to ground.

• The measuring sensors are connected to ground by means of a functional grounding

conductor FE.

• In hazardous areas, grounding is used at the same time for equipotential bonding. Additional

grounding instructions are provided in the separate "Ex documentation", which are only

supplied together with hazardous area equipment.

34

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 35

MFC 300

ELECTRICAL CONNECTIONS 4

4.6 Connecting power, all housing variants

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

• The protection category depends on the housing versions (IP65...67 to IEC 529 / EN 60529 or

NEMA4/4X/6).

• The housings of the devices, which are designed to protect the electronic equipment from

dust and moisture, should be kept well closed at all times. Creepage distances and

clearances are dimensioned to VDE 0110 and IEC 664 for pollution severity 2. Supply circuits

are designed for overvoltage category III and the output circuits for overvoltage category II.

• Fuse protection (I

breaker) to isolate the signal converter must be provided close to the device. The separator

must be marked as the separator for this device.

≤ 16 A) for the infeed power circuit, as well as a separator (switch, circuit

N

100...230 VAC (tolerance range: -15% / +10%)

• Note the power supply voltage and frequency (50...60 Hz) on the nameplate.

• The protective ground terminal PE

clamp terminal in the terminal compartment of the signal converter

For the 19" rack-mounted housing please refer to the connection diagrams.

PE of the power supply must be connected to the separate U-

PEPE

INFORMATION!

240 VAC+5% is included in the tolerance range.

24 VDC (tolerance range: -55% / +30%)

24 VAC/DC (tolerance ranges: AC: -15% / +10%; DC: -25% / +30%)

• Note the data on the nameplate!

• For measurement process reasons, a functional ground FE

separate U-clamp terminal in the terminal compartment of the signal converter.

• When connecting to functional extra-low voltages, provide a facility for protective separation

(PELV) (acc. to VDE 0100 / VDE 0106 and/or IEC 364 / IEC 536 or relevant national

regulations).

FE must be connected to the

FEFE

INFORMATION!

For 24 VDC, 12 VDC-10% is included in the tolerance range.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

35

Page 36

4 ELECTRICAL CONNECTIONS

Power supply connection (excluding 19" rack-mounted housing)

1 100...230 VAC (-15% / +10%), 22 VA

2 24 VDC (-55% / +30%), 12 W

3 24 VAC/DC (AC: -15% / +10%; DC: -25% / +30%), 22 VA or 12 W

Power supply connection for 19" rack-mounted housing (28 TE)

MFC 300

36

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 37

MFC 300

4.7 Inputs and outputs, overview

4.7.1 Combinations of the inputs/outputs (I/Os)

This signal converter is available with various input/output combinations.

Basic version

• Has 1 current output, 1 pulse output and 2 status outputs / limit switches.

• The pulse output can be set as status output/limit switch and one of the status outputs as a

control input.

Ex i version

• Depending on the task, the device can be configured with various output modules.

• Current outputs can be active or passive.

• Optionally available also with Foundation Fieldbus and Profibus PA

Modular version

• Depending on the task, the device can be configured with various output modules.

ELECTRICAL CONNECTIONS 4

Bus systems

• The device allows intrinsically safe and non intrinsically safe bus interfaces in combination

with additional modules.

• For connection and operation of bus systems, please note the separate documentation.

Ex option

• For hazardous areas, all of the input/output variants for the housing designs C and F with

terminal compartment in the Ex d (pressure-resistant casing) or Ex e (increased safety)

versions can be delivered.

• Please refer to the separate instructions for connection and operation of the Ex-devices.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

37

Page 38

4 ELECTRICAL CONNECTIONS

4.7.2 Description of the CG number

Figure 4-8: Marking (CG number) of the electronics module and input/output variants

1 ID number: 2

2 ID number: 0 = standard; 9 = special

3 Power supply option

4 Display (language versions)

5 Input/output version (I/O)

6 1st optional module for connection terminal A

7 2nd optional module for connection terminal B

The last 3 digits of the CG number (5, 6 and 7) indicate the assignment of the terminal

connections. Please refer to the following examples.

Examples for CG number

MFC 300

CG 320 11 100 100...230 VAC & standard display; basic I/O: Ia or Ip & Sp/Cp & Sp & Pp/S

p

CG 320 11 7FK 100...230 VAC & standard display; modular I/O: Ia & PN/SN and optional module PN/SN & C

CG 320 81 4EB 24 VDC & standard display; modular I/O: Ia & Pa/Sa and optional module Pp/Sp & I

p

Description of abbreviations and CG identifier for possible optional modules

on terminals A and B

Abbreviation Identifier for CG No. Description

I

a

I

p

Pa / S

a

Pp / S

p

PN / S

N

C

a

C

p

C

N

IIn

a

IIn

p

- 8 No additional module installed

- 0 No further module possible

A Active current output

B Passive current output

C Active pulse output, frequency output, status output or limit switch

(changeable)

E Passive pulse output, frequency output, status output or limit switch

(changeable)

F Passive pulse output, frequency output, status output or limit switch acc.

to NAMUR (changeable)

G Active control input

K Passive control input

H Active control input to NAMUR

Signal converter monitors cable breaks and short circuits acc. to

EN 60947-5-6. Errors indicated on LC display. Error messages possible

via status output.

P Active current input

R Passive current input

N

38

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 39

MFC 300

4.7.3 Fixed, non-alterable input/output versions

This signal converter is available with various input/output combinations.

• The grey boxes in the tables denote unassigned or unused connection terminals.

• In the table, only the final digits of the CG no. are depicted.

• Connection terminal A+ is only operable in the basic input/output version.

CG no. Connection terminals

A+ A A- B B- C C- D D-

Basic I/Os (standard)

1 0 0

Ia + HART® active 1

Ip + HART® passive 1

Ex i IOs (option)

2 0 0

3 0 0

2 1 0 Ia active PN / SNNAMUR

3 1 0 Ia active PN / SNNAMUR

2 2 0 Ip passive PN / SNNAMUR

3 2 0 Ip passive PN / SNNAMUR

Sp / Cp passive 2 Sp passive Pp / Sp passive 2

passive 2

C

p

Cp passive 2

passive 2

C

p

Cp passive 2

ELECTRICAL CONNECTIONS 4

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

PN / SN NAMUR 2

PN / SN NAMUR 2

PN / SN NAMUR 2

PN / SN NAMUR 2

PN / SNNAMUR 2

PN / SNNAMUR 2

PROFIBUS PA (Ex i) (option)

D 0 0 PA+ PA- PA+ PA-

FISCO Device FISCO Device

D 1 0 Ia active PN / SNNAMUR

passive 2

C

p

D 2 0 Ip passive PN / SNNAMUR

passive 2

C

p

PA+ PA- PA+ PA-

FISCO Device FISCO Device

PA+ PA- PA+ PA-

FISCO Device FISCO Device

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

39

Page 40

4 ELECTRICAL CONNECTIONS

FOUNDATION Fieldbus (Ex i) (option)

E 0 0 V/D+ V/D- V/D+ V/D-

FISCO Device FISCO Device

E 1 0 Ia active PN / SNNAMUR

Cp passive 2

E 2 0 Ip passive PN / SNNAMUR

Cp passive 2

1 function changed by reconnecting

2 changeable

V/D+ V/D- V/D+ V/D-

FISCO Device FISCO Device

V/D+ V/D- V/D+ V/D-

FISCO Device FISCO Device

MFC 300

40

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 41

MFC 300

4.7.4 Alterable input/output versions

This signal converter is available with various input/output combinations.

• The grey boxes in the tables denote unassigned or unused connection terminals.

• In the table, only the final digits of the CG no. are depicted.

• Term. = (connection) terminal

CG no. Connection terminals

A+ A A- B B- C C- D D-

Modular IOs (option)

4 _ _ max. 2 optional modules for term. A + B

8 _ _ max. 2 optional modules for term. A + B

6 _ _ max. 2 optional modules for term. A + B

B _ _ max. 2 optional modules for term. A + B

7 _ _ max. 2 optional modules for term. A + B

C _ _ max. 2 optional modules for term. A + B

ELECTRICAL CONNECTIONS 4

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

Ia + HART® active

Ip + HART® passive

Pa / Sa active 1

Pa / Sa active 1

Pp / Sp passive 1

Pp / Sp passive 1

PN / SN NAMUR 1

PN / SN NAMUR 1

PROFIBUS PA (option)

D _ _ max. 2 optional modules for term. A + B PA+ (2) PA- (2) PA+ (1) PA- (1)

FOUNDATION Fieldbus (option)

E _ _ max. 2 optional modules for term. A + B V/D+ (2) V/D- (2) V/D+ (1) V/D- (1)

PROFIBUS DP (option)

F _ 0 1 optional module for

term. A

Terminati

on P

RxD/TxDP(2)

RxD/TxDN(2)

Terminati

on N

RxD/TxDP(1)

RxD/TxDN(1)

Modbus (option)

G _ _ 2 max. 2 optional modules for term. A + B Common Sign. B

(D1)

H _ _ 3 max. 2 optional modules for term. A + B Common Sign. B

(D1)

1 changeable

2 not activated bus terminator

3 activated bus terminator

Sign. A

(D0)

Sign. A

(D0)

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

41

Page 42

4 ELECTRICAL CONNECTIONS

4.8 Description of the inputs and outputs

4.8.1 Current output

INFORMATION!

The current outputs must be connected depending on the version! Which I/O versions and

inputs/outputs are installed in your signal converter are indicated on the sticker in the cover of

the terminal compartment.

• All outputs are electrically isolated from each other and from all other circuits.

• All operating data and functions can be adjusted.

• Passive mode: external power U

• Active mode: load impedance R

R

≤ 450 Ω at I ≤ 22 mA for Ex i outputs

L

• Self-monitoring: interruption or load impedance too high in the current output loop

• Error message possible via status output, error indication on LC display.

• Current value error detection can be adjusted.

• Automatic range conversion via threshold or control input. The setting range for the

threshold is between 5 and 80% of Q

smaller to larger range of 1:20 to 1:1.25).

Signaling of the active range possible via a status output (adjustable).

• Forward / reverse flow measurement (F/R mode) is possible.

≤ 32 VDC at I ≤ 22 mA

ext

≤ 1kΩ at I ≤ 22 mA;

L

100%

MFC 300

, ± 0...5% hysteresis (corresponding ratio from

INFORMATION!

For further information refer to Connection diagrams of inputs and outputs on page 49

Technical data on page 134

to

.

and refer

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

42

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 43

MFC 300

4.8.2 Pulse and frequency output

INFORMATION!

Depending on the version, the pulse and frequency outputs must be connected passively or

actively or according to NAMUR EN 60947-5-6! Which I/O version and inputs/outputs are

installed in your signal converter are indicated on the sticker in the cover of the terminal

compartment.

• All outputs are electrically isolated from each other and from all other circuits.

• All operating data and functions can be adjusted.

• Passive mode:

External power supply required: U

I ≤ 20 mA at f ≤ 10 kHz (override up to f

I ≤ 100 mA at f ≤ 100 Hz

• Active mode:

Use of the internal power supply: U

I ≤ 20 mA at f ≤ 10 kHz (over range up to f

I ≤ 20 mA at f ≤ 100 Hz

• NAMUR mode: passive in accordance with EN 60947-5-6, f ≤ 10 kHz,

over range up to f

• Scaling:

Frequency output: in pulses per time unit (e.g. 1000 pulses/s at Q

Pulse output: quantity per pulse.

• Pulse width:

symmetric (pulse duty factor 1:1, independent of output frequency)

automatic (with fixed pulse width, duty factor approx. 1:1 at Q

fixed (pulse width adjustable as required from 0.05 ms...2 s)

• Forward / reverse flow measurement (F/R mode) is possible.

• All pulse and frequency outputs can also be used as a status output / limit switch.

max

≤ 12 kHz

≤ 32 VDC

ext

max

=24VDC

nom

ELECTRICAL CONNECTIONS 4

≤ 12 kHz)

≤ 12 kHz)

max

);

100%

) or

100%

CAUTION!

At frequencies above 100 Hz, shielded cables must be used to prevent radio interference.

INFORMATION!

For further information refer to Connection diagrams of inputs and outputs on page 49

Technical data on page 134

to

.

and refer

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

43

Page 44

4 ELECTRICAL CONNECTIONS

4.8.3 Status output and limit switch

INFORMATION!

Depending on the version, the status outputs and limit switches must be connected passively or

actively or according to NAMUR EN 60947-5-6! Which I/O version and inputs/outputs are

installed in your signal converter are indicated on the sticker in the cover of the terminal

compartment.

• The status outputs / limit switches are electrically isolated from each other and from all

other circuits.

• The output stages of the status outputs/limit switches during simple active or passive

operation behave like relay contacts and can be connected with any polarity.

• All operating data and functions can be adjusted.

• Passive mode: external power supply required:

≤ 32 VDC; I ≤ 100 mA

U

ext

• Active mode: use of the internal power supply:

=24VDC; I ≤ 20 mA

U

nom

• NAMUR mode: passive in accordance with EN 60947-5-6

• For information on the adjustable operating states refer to

Function tables

MFC 300

on page 79.

INFORMATION!

For further information refer to Connection diagrams of inputs and outputs on page 49

Technical data on page 134

to

.

and refer

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

44

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 45

MFC 300

4.8.4 Control input

INFORMATION!

Depending on the version, the control inputs must be connected passively or actively or

according to NAMUR EN 60947-5-6! Which I/O version and inputs/outputs are installed in your

signal converter are indicated on the sticker in the cover of the terminal compartment.

• All control inputs are electrically isolated from each other and from all other circuits.

• All operating data and functions can be adjusted.

• Passive mode: external power supply required:

≤ 32 VDC

U

ext

• Active mode: use of the internal power supply:

U

nom

• NAMUR mode: in accordance with EN 60947-5-6

(Active control input to NAMUR EN 60947-5-6: signal converter monitors cable breaks and

short circuits acc. to EN 60947-5-6. Errors indicated on LC display. Error messages possible

via status output.

• For information on the adjustable operating states refer to

=24VDC

ELECTRICAL CONNECTIONS 4

Function tables

on page 79.

INFORMATION!

For further information refer to Connection diagrams of inputs and outputs on page 49

Technical data on page 134

to

.

and refer

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

45

Page 46

4 ELECTRICAL CONNECTIONS

4.9 Electrical connection of the inputs and outputs

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

4.9.1 Field housing, electrical connection of the inputs and outputs

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

INFORMATION!

For frequencies above 100 Hz, shielded cables are to be used in order to reduce effects from

electrical interferences (EMC).

MFC 300

Figure 4-9: Terminal compartment for inputs and outputs in field housing

1 Open the housing cover.

2 Push the prepared cable through the cable entry and connect the necessary conductors.

3 Connect the shield if necessary.

4 Close the touch guard.

5 Close the housing cover.

INFORMATION!

Each time a housing cover is opened, the thread should be cleaned and greased. Use only resinfree and acid-free grease.

Ensure that the housing gasket is properly fitted, clean and undamaged.

46

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 47

MFC 300

ELECTRICAL CONNECTIONS 4

4.9.2 Wall-mounted housing, electrical connection of the inputs and outputs

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

INFORMATION!

Use shielded cables for frequencies above 100 Hz. The electrical connection of the shielding

must take place using 6.3 mm / 0.25" blade receptacles (insulation as per DIN 46 245) in the I/O

terminal compartment.

Figure 4-10: Terminal compartment for inputs and outputs in wall-mounted housing

1 Open the housing cover.

2 Push the cables through the cable entry and connect them to the supplied connector plugs 3.

3 Connect the shield if necessary.

4 Route the connector plugs with the clamped conductors into the sockets provided for that pur-

pose.

5 Close the housing cover.

INFORMATION!

Ensure that the housing gasket is properly fitted, clean and undamaged.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

47

Page 48

4 ELECTRICAL CONNECTIONS

MFC 300

4.9.3 19" rack-mounted housing (28 TE), electrical connection of the inputs and outputs

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

• For frequencies above 100 Hz, shielded cables are to be used in order to reduce effects from

electrical interferences (EMC).

• Terminal A+ is only operable in the basic version.

Figure 4-11: Terminal compartment for inputs and outputs in rack-mounted housing

1 Shielding

• Connect the conductor to the multipolar plug according to the illustration.

• The signal cable shield is connected to the Pin S.

• Press the plug into the connector.

4.9.4 Laying electrical cables correctly

Figure 4-12: Protect housing from dust and water

1 Lay the cable in a loop just before the housing.

2 Tighten the screw connection of the cable entry securely.

3 Never mount the housing with the cable entries facing upwards.

4 Seal cable entries that are not needed with a plug.

48

www.krohne.com 02/2012 - 4000498602 - MA MFC 300 R03 en

Page 49

MFC 300

ELECTRICAL CONNECTIONS 4

4.10 Connection diagrams of inputs and outputs

4.10.1 Important notes

INFORMATION!

Depending on the version, the inputs/outputs must be connected passively or actively or acc. to

NAMUR EN 60947-5-6! Which I/O version and inputs/outputs are installed in your signal

converter are indicated on the sticker in the cover of the terminal compartment.

• All groups are electrically isolated from each other and from all other input and output

circuits.

• Passive mode: An external power supply is necessary to operate (activation) the subsequent

devices (U

• Active mode: The signal converter supplies the power for operation (activation) of the

subsequent devices, observe max. operating data.

• Terminals that are not used should not have any conductive connection to other electrically

conductive parts.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

ext

).

Description of the used abbreviations

I

I

a

P

a

P

N

S

a

S

N

C

a

C

N

IInaIInpCurrent input active or passive

Current output active or passive

p

P

Pulse/frequency output active or passive

p

Pulse/frequency output passive acc. to NAMUR EN 60947-5-6

S

Status output/limit switch active or passive

p

Status output/limit switch passive acc. to NAMUR EN 60947-5-6

C

Control input active or passive

p

Control input active acc. to NAMUR EN 60947-5-6:

Signal converter monitors cable breaks and short circuits acc. to EN 60947-5-6. Errors

indicated on LC display. Error messages possible via status output.

www.krohne.com02/2012 - 4000498602 - MA MFC 300 R03 en

49

Page 50

4 ELECTRICAL CONNECTIONS

4.10.2 Description of the electrical symbols

mA meter

0...20 mA or 4...20 mA and other

RL is the internal resistance of the measuring point including the cable

resistance

DC voltage source (U

), external power supply, any connection polarity

ext

MFC 300

Table 4-1: Description of symbols

DC voltage source (U

connection diagrams

Internal DC voltage source

Controlled internal power source in the device

Electronic or electromagnetic counter

At frequencies above 100 Hz, shielded cables must be used to connect the

counters.

Ri Internal resistance of the counter