Page 1

Supplementary Installation and

Operating Instructions

Variable-area flowmeters H250/H54

Signal converter M10

of hazardous-duty

design EEx d

PTB 01 ATEX 1154

©

KROHNE 11/2002 7.02247.22.00

GR

Stand: 08/2000

ANL. A.1 EG-Baumusterprüfbescheinigung PTB 00 ATEX 2063

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications engineering

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Page 2

Contents

1

General safety information .................................................................................................. 3

2 Safety-relevant type code .................................................................................................... 4

3 Main safety-relevant characteristics ................................................................................... 4

3.1 Process products .................................................................................................................... 4

3.2 Category / Zone allocation ......................................................................................................4

3.3 Type of protection ................................................................................................................... 4

3.4 Special lock............................................................................................................................. 4

3.5 Cable entries / sealing plugs...................................................................................................5

3.6 Power supply .......................................................................................................................... 5

3.7 I/O functions............................................................................................................................ 5

3.8 Ambient temperatures / temperature classes ......................................................................... 5

4 Marking.................................................................................................................................. 6

5 Mounting and installation .................................................................................................... 6

5.1 Electrical connection............................................................................................................... 7

5.1.1 General................................................................................................................................... 7

5.1.2 Terminal compartment............................................................................................................7

5.1.3 Connecting cables .................................................................................................................. 7

5.1.4 Connection of power and I/O function..................................................................................... 7

6 Initial startup ......................................................................................................................... 9

7 Operation............................................................................................................................... 9

8 Preventive maintenance....................................................................................................... 9

8.1 Maintenance ........................................................................................................................... 9

8.2 Dismantling ........................................................................................................................... 10

8.2.1 General................................................................................................................................. 10

8.2.2 Replacement of signal converter / display ............................................................................ 10

8.2.3 Replacement of complete device .......................................................................................... 10

Attachment A.1 EC Type Test Certificate PTB 01 ATEX 1154................................................. 11

Attachment A.2 Declaration of Conformity ............................................................................... 19

If you need to return a device for testing or repair to KROHNE.............................................. 20

2

Signal converter M10-EEx d – Supplementary instructions 11/2002

Page 3

1 General safety information

These additional “Ex“ Instructions apply to the hazardous-duty versions of H..../..../M10-EEx

variable-area flowmeters. They are supplementary to the Installation and Operating Instructions for

the non-hazardous-duty versions.

The information given in these Instructions contains only the data relevant to explosion protection.

The technical details given in the Installation and Operating Instructions for the non-hazardousduty version apply unchanged unless excluded or superseded by these Instructions.

In compliance with European Directive 94/9 EG (ATEX 100a), variable-area flowmeters of the

H..../..../M10-EEx series are certified in conformity with European Standards EN 50xxx for use in

hazardous areas under

PTB 01 ATEX 1154

by the Physikalisch-Technische Bundesanstalt (PTB).

This certification together with its boundary conditions is required to be observed without fail (see

Attachment A.1 ”EC type test certificate“).

IMPORTANT!

Mounting, installation, (initial) startup and maintenance work may only be carried out

by personnel who have received "training in explosion protection"!

Maintenance work of a safety-relevant nature within the meaning of explosion protection

may only be carried out by the manufacturer, his authorized representative or under the

supervision of authorized inspectors.

Note!

For processes involving combustible and highly flammable products, easily removable

threaded connections to DIN 11851; SMS; TriClamp (e.g. DIN 32676; ISO 2852 Clamp);

are not allowed.

11/2002

Signal converter M10-EEx d – Supplementary instructions 3

Page 4

2 Safety-relevant type code

The safety-relevant type code is made up of the following elements:

(1)

H .... / .... / M10 - E Ex

1 2 3 4 5

1 : Model series : measuring section

H54

H250

H250C

2 : Material of wetted parts

RR

HC

Ti

PTFE

3 : Model series : indicator section

M10

4 : Territorial application of the approval

E:

5 : Safety function

Ex:

(1)

places for items not needed may be omitted from the type code

: measuring section, Series H54

: measuring section, Series H250

: measuring section, Series H250C

: stainless steel

: Hastelloy

: titanium

: PTFE, ceramics

: signal converter M10

Europe (EC, CENELEC area of validity)

explosion-protected electrical equipment

3 Main safety-relevant characteristics

The H..../..../M10-EEx variable-area flowmeter consists of a combination of signal converter and

measuring tube. The main characteristics of the explosion-protected version are described below.

3.1 Process products

Flammable products are allowed provided they are not present in potentially explosive form.

3.2 Category / Zone allocation

The H..../..../M10-EEx variable-area flowmeter is basically designed in Category 2 for use in

Zone 1.

3.3 Type of protection

The H..../. .../M10-EEx variable-area flowmeters bear the following marking: EEx d IIC T6

3.4 Special lock

The sealing covers of the electronics compartment are secured by a special lock. The locking

screw requires use of an Allen key (3 mm size).

4

Signal converter M10-EEx d – Supplementary instructions 11/2002

Page 5

3.5 Cable entries / sealing plugs

Cable entries and sealing plugs must, in ready-to-operate condition, satisfy the IP Class of

Protection IP67 and each be separately certified in conformity with EN 50 018. Any requirements

specified in the test certificates of the components shall be observed.

3.6 Power supply

Type H..../..../M10-EEx variable-area flowmeters do not require any separate power source. The

necessary supply is obtained via the current output.

3.7 I/O functions

When connecting the I/O interfaces of the H..../..../M10-EEx variable-area flowmeters, the

following values need to be taken into account.

I/O function

(1)

Nominal values of the non- Added restriction

certified receiver instrument

See Standard Installation See Standard Installation Supply power for receiver

and Operating Instructions and Operating Instructions instruments max. 253V

(1)

Only for connection to circuits with “functional extra-low voltage with protective separation

(PELV)”

Peak values U

≤ 25V ; UDC ≤ 60V

AC

3.8 Ambient temperatures / temperature classes

The permissible ambient temperature for the variable-area flowmeters is limited to a value

≤ 60 °C.

of T

amb

With regard to maximum surface temperatures, variable-area flowmeters are exposed to three

heat sources:

Ambient temperature T

•

Electric power loss Pv

•

Process temperature Tm

•

Accordingly, at a given maximum ambient temperature (T

loss (P

≤ 3 W), we obtain maximum surface temperatures as a factor of the process temperature.

v

For that reason, the devices are not allocated to any specific temperature class; rather, the

temperature class of the devices is a function of the actual process temperature and ambient

temperature, see table below.

Temperature

Ambient temperature

class

T6 -40 … +60 85 85 85

T5 -40 … +50 100 100 100

-40 … +60

T4 -40 … +50 135 135 135

-40 … +60

T3 ... T1 -40 … +40

-40 … +50

-40 … +60

Table 1

Max. permissible process temperatures

The cable glands and line entries must have the same degree of thermal

stability as the connecting cable

amb

in °C

≤ 60°C) and a given maximum power

amb

Max. permissible process

permanent temperature

Wiring Wiring Wiring

70°C 80°C 90°C

85 100 100

85 135 135

180 200 200

135 190 200

85 145 200

11/2002

Signal converter M10-EEx d – Supplementary instructions 5

Page 6

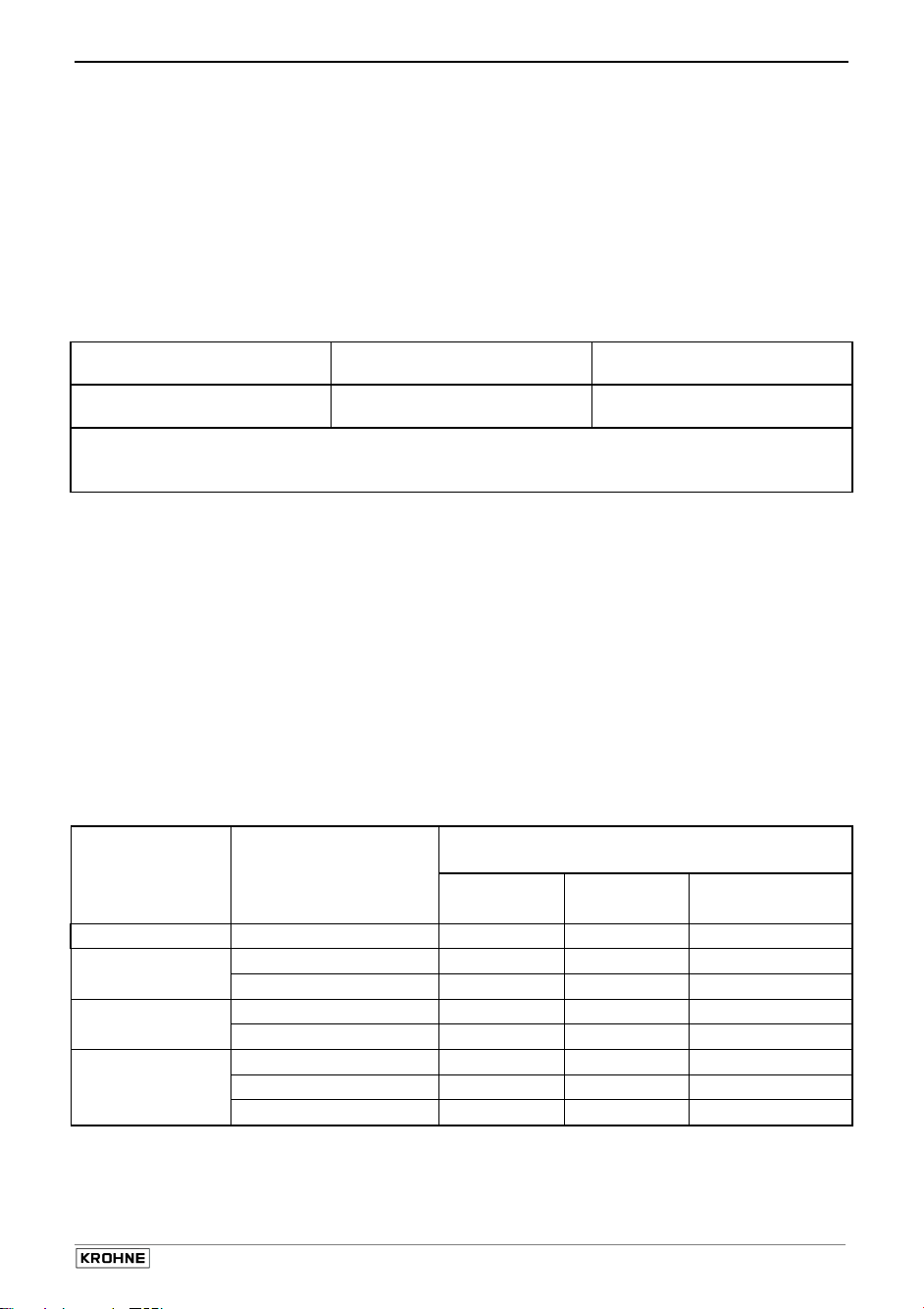

4 Marking

The variable-area flowmeters are identified by an adhesive label or metal plate attached to the

signal converter. The type code is explained in Section 2.

H..../..../M10- EEx, Category 2G

Manufacturer Year of manufacture

Type

Approval

information

Technical

data of

circuits

Safety

info

5 Mounting and installation

Mounting and installation to be carried out in conformity with the valid installation standards for

hazardous areas (e.g. EN 60079-14 / VDE 0165) by specialist personnel trained in explosion

protection.

The information given in the standard Installation and Operating Instructions, the Supplementary

Installation and Operating Instructions (Ex) and also in the EC type test certificate (see Attachment

A.1) must be observed without fail.

Verify that the variable-area flowmeter is suitable for the application in question by comparing

the details on the nameplate with those in Section 3.2 (Categories / Zone allocation), Section 2

(Type code) and Section 4 (Marking).

When installing, please pay special attention to the following points.

6

Signal converter M10-EEx d – Supplementary instructions 11/2002

Page 7

5.1 Electrical connection

5.1.1 General

Insulation rating

The insulation of variable-area flowmeters H..../..../M10 - EEx is rated in conformity with

VDE 0110-1/04.97, equivalent to IEC 60 664-1, and takes into account the following ratings:

• Overvoltage category for signalling and measurement circuits: II

• Insulation contamination level: 2

HAZARDOUS-DUTY Systems

• The signal converter to be incorporated in the equipotential bonding system via the external

PA (equipotential bonding) connection.

• The electrical connection of the variable-area flowmeters to be made as a fixed installation.

5.1.2 Terminal compartment

The electrical connection of the power supply and I/O functions is made in the integrated terminal

compartment of the signal converter. The terminal compartment is designed in EEx d type of

protection. Unassigned openings to be sealed in conformity with EN 50 018.

The cables can basically be routed into the flameproof terminal compartment in one of two ways.

Direct entry of the connecting cables by way of certified flameproof cable glands into the

•

flameproof terminal compartment (V ≤ 2000 cm³). The cable glands must possess a separate

test certificate to EN 50 018. The requirements specified in the test certificate for the cable

gland need to be observed.

Direct entry of the power cables by way of conduits into the flameproof terminal compartment

•

of the device. After the conduit has been screwed in, this must together with the housing form

a flameproof joint with a minimum of 8mm depth of engagement. A suitable stopping box shall

be provided in accordance with the regulations for electrical installations. Installation of the

conduit must be carried out in compliance with its separate test certificate.

5.1.3 Connecting cables

The connecting cables shall be selected in keeping with the valid installation standards

(e.g. EN 60079-14 / VDE 0165). The outside diameter of the cables must match the cable

clamping area for the cable entries.

5.1.4 Connection of power and I/O function

Before connecting or disconnecting the electrical interconnecting cables of the device, make

•

sure that all cables leading to the signal converter are isolated from the ground (reference

potential) of the hazardous area. This also applies to safety conductors (PE) and equipotential

bonding conductors (PA).

All cores and shields of the connecting cables not safety-connected to the equipotential

•

bonding system for the hazardous area should be carefully insulated from each other and

from ground (test voltage 1500V

for conductors of non-intrinsically safe cables).

rms

11/2002

Signal converter M10-EEx d – Supplementary instructions 7

Page 8

Connect the shields by the shortest possible route to the press-fitted U-clamp terminal (PE) in

•

the terminal compartment. If shields are to be grounded at both ends (e.g. for EMC reasons),

adequate equipotential bonding is required between the two shield ends to avoid

unacceptable equalizing currents.

The signal converter must be incorporated in the equipotential bonding system of the

•

hazardous area. The cable is to be connected to the outer press-fitted U-clamp terminal in the

converter housing.

The measuring tube can be incorporated in the equipotential bonding system of the

•

hazardous area by means of the U-clamp terminal (if provided) in the flange or by means of

conductive connections (gaskets, etc.).

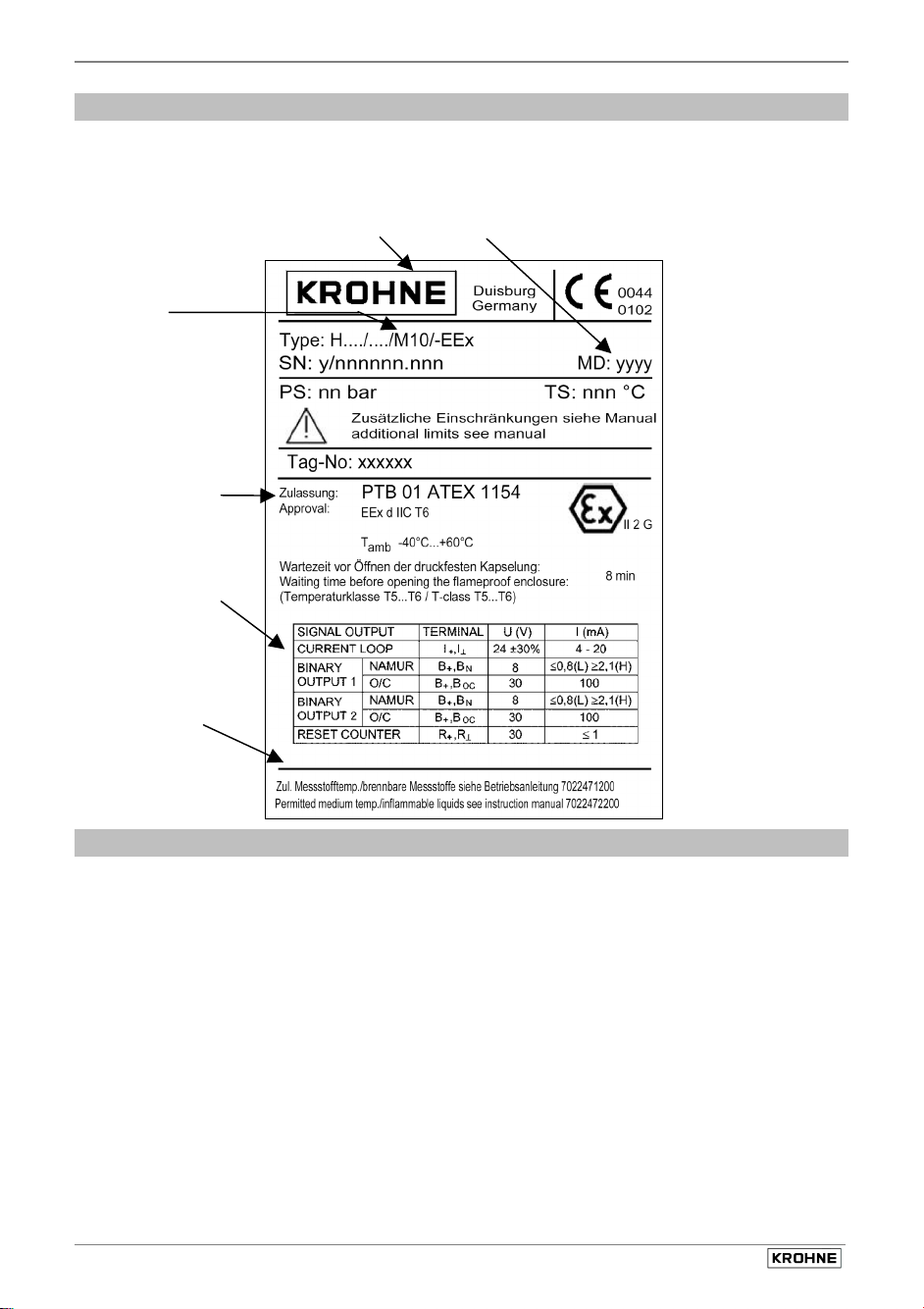

The terminal assignment is listed in the following table:

Function Terminal designation

Signal output (see sketch)

Current output HART (current loop) I+

Status output (1) NAMUR B+ B

(binary output 1) O/C-PNP B+ B

Status output (2) NAMUR B+ B

(binary output 2) O/C-PNP B+ B

Status input (reset counter) R+

I

⊥

N

OC

N

OC

R

⊥

Note the electrical data of the circuits given in Section 3.7! Even when operated in the nonhazardous area, the requirements pertaining to the signal output circuits need to be met.

R

+

R

Reset

counter

B

+

B

N

Binary

output 2

B

OC

Achtung!

CAUTION!

Rohrleit ungsadapter v erwenden.

APPLY C ERTIFIED C ABLE ENTRI ES OR

Nur bescheinigte Leitungseinführungen bzw.

B

+

B

N

Binary

output 1

B

CONDUIT ADAPTORS ONLY.

OC

I

+

loop

I

Current

8

Signal converter M10-EEx d – Supplementary instructions 11/2002

Page 9

6 Initial startup

Check the following points before initial startup:

Suitability of the materials used for the measuring tube and gaskets for adequate resistance

•

to corrosion through the process product.

Compare the data on the nameplate on the signal converter with the existing operating data.

•

Check that the measuring tube has been correctly installed in the pipeline.

•

Check that the equipotential bonding system is properly connected.

•

Check correct connection of the power cables.

•

Check that the cover(s) of the electronics compartment is firmly in place, that the special lock

•

is tightened down.

7 Operation

It is not permitted to open the cover of the electronics compartment during operation and in the

presence of an explosive atmosphere.

Should parameterization of the device become necessary in the presence of an explosive

atmosphere, this can be done by applying the supplied programming bar magnet to the glass

window of the electronics compartment, without opening the housing, or digitally by way of the

signal output (HART interface).

In the case of flammable products, the measuring sections shall be included in the periodic

pressure testing of the plant.

8 Preventive maintenance

8.1 Maintenance

The signal converter does not require any maintenance under normal operating conditions and

when used for the intended purpose. Within the scope of checks required to be carried out in

hazardous areas to maintain systems in proper working order, the following visual inspections

should be carried out at regular intervals:

Inspection of the housing, cable entries and incoming cables for signs of corrosion and

•

damage,

Check of pipe connections for leakages.

•

11/2002

Signal converter M10-EEx d – Supplementary instructions 9

Page 10

8.2 Dismantling

8.2.1 General

Should it prove necessary to open the Flameproof Enclosure of the electronics compartment in the

presence of an explosive atmosphere, the device must first be disconnected from supply. Be sure

to allow the waiting time printed on the nameplate of the signal converter of:

8 minutes for temperature classes T6 and T5

•

to elapse before opening the Flameproof Enclosure. There is no waiting time for any of the other

temperature classes.

Before connecting or disconnecting the device interconnecting cables, make sure that all cables

leading into the signal converter are isolated from the ground (reference potential) of the

hazardous area. This also applies to safety conductors (PE), functional ground (FE) and the

equipotential bonding conductor (PA).

After any maintenance work has been carried out, be sure to regrease the thread of the

flameproof cover of the signal converter, including cover gaskets, with a resin-free and acid-free

all-purpose grease.

8.2.2 Replacement of signal converter / display

Disconnect the device from supply before opening the Flameproof Enclosure. Be sure to follow the

procedure described in Section 8.2.1.

Note :

The display can be replaced after opening the Flameproof Enclosure of the electronics

compartment. To replace a complete display, take note of the information given in Section 5.1.4.

The measuring tube of the variable-area flowmeter can in both cases remain in the pipeline, also

when product is flowing.

Note :

Only same-type displays and complete converter housings may be replaced.

Individual device inserts may not be replaced! Compare nameplates when

replacing the signal converter. Only same-type signal converters to be replaced.

Always renew defective fastening clips (prisms) between measuring tube and

display housing.

8.2.3 Replacement of complete device

Please refer to Sections 8.2.1 and 8.2.2. In addition, make sure that all process connections and

the pipeline are non-pressurized and free of product. In the case of environmentally critical

substances, carefully decontaminate the wetted parts of the flange system after dismantling.

10

Signal converter M10-EEx d – Supplementary instructions 11/2002

Page 11

Attachment A.1

EC Type Test Certificate PTB 01 ATEX 1154

11/2002

Signal converter M10-EEx d – Supplementary instructions 11

Page 12

Attachement A.1

EC Type Test Certificate PTB 01 ATEX 1154

Physikalisch-Technische Bundesanstalt

PTB

Brunswick and Berlin

(1)

(2) Devices and protective systems for use as prescribed

in hazardous areas - Directive 94/9/EC

(3) EC Type Test Certificate Number

PTB 01 ATEX 1154

(4) Device: Variable-area flowmeter H…./…./M10-EEx

(5) Manufacturer: KROHNE Messtechnik GmbH & Co. KG

(6) Address: Ludwig-Krohne-Str. 5, 47058 Duisburg, Germany

(7) The design of this device as well as the variously approved versions are defined in the

Schedule to this Type Test Certificate and in the documents listed in the Schedule.

(8) The Physikalisch-Technische Bundesanstalt, being the notified body No. 0102 in

accordance with Article 9 of the Council Directive of European Communities dated

23rd March 1994 (94/9/EC), certifies that the basic health and safety requirements

have been satisfied for the conception and construction of devices and protective

systems for use as prescribed in hazardous areas in accordance with Appendix II of

said Directive.

The results of the test are specified in the confidential test report PTB Ex 01-11294.

(9) The basic health and safety requirements are satisfied by conformity with

EN 50014:1997 + A1 + A2 EN 50018:2000

(10) If the character “X“ is appended to the certificate number, this refers to special

conditions for the safe application of the device as given in the Schedule to this

Certificate.

(11) This EC Type Test Certificate applies only to the conception and construction of the

defined device in accordance with Directive 94/9/EC. Further requirements of said

Directive apply to the manufacture of that device and to putting it on the market. Such

requirements are not covered by this Certificate.

(12) The marking of the device must include the following details:

EC Type Test Certificate

Certification Agency for Explosion Protection Brunswick, 30st September 2002

on behalf of Official stamp

(signed) of the PTB

Dr.-Ing. U. Klausmeyer

Regierungsdirektor

Page 1/4

12

Signal converter M10-EEx d – Supplementary instructions 11/2002

II 2 G EEx d IIC T6 … T1

Page 13

11/2002

Signal converter M10-EEx d – Supplementary instructions 13

Page 14

Physikalisch-Technische Bundesanstalt

PTB

Brunswick and Berlin

(13)

(14)

(15) Device description

The H…./…./M10-EEx variable-area flowmeter is designed to measure the volume rate of flow

of flammable and non-flammable gases and liquids in vertical pipe runs. The flow through the

measuring tube is from bottom to top, and the guided float adjusts so that lifting force, form

resistance and float weight are in equilibrium. Every vertical position of the float thus

corresponds to a specific flow rate. Electromagnetic position sensors in the display section

convert the position of the float into an appropriate electrical output signal.

Technical data

Supply (functional extra-low voltage PELV, U

Signal output 4 – 20 mA U

(terminal I

Signal output 1 & 2 NAMUR circuit

Output 1 (terminal B

Output 2 (terminal B

or

Output 1 (terminal B

Output 2 (terminal B

U

Status input U

(terminal R

Protection against ingress of

foreign bodies and water IP 67 in conformity with EN 60529

(16) Test report

Page 2/4

EC Type Test Certificate PTB 01 ATEX 1154

, I⊥) HART communication

+

, BN) UN = 8 V DC, depending on switch position ≤ 0.8 mA or

+

, BN)

+

, BOC ) open collector (pnp output)

+

, BOC ) UN = 8 ... 30 V DC; Ii ≤ 100 mA;

+

, R⊥)

+

PTB Ex 01-11294

S c h e d u l e

= 24 V DC + 30%, 2-wire connection with

N

≥

2.1 mA; Ri = 1 kΩ

with effectively conducting output ≤ 3 V

I

= 8 … 30 V DC; Ii ≤ 1 mA

N

≤ 60 V)

DC

14

Signal converter M10-EEx d – Supplementary instructions 11/2002

Page 15

11/2002

Signal converter M10-EEx d – Supplementary instructions 15

Page 16

Physikalisch-Technische Bundesanstalt

PTB

Brunswick and Berlin

Schedule to EC Type Test Certificate PTB 01 ATEX 1154

(17) Special conditions

none.

Additional directions for safe operation

Connection conditions

1. The H…./…./M10-EEx variable-area flowmeter shall be connected up via suitable

cable glands and/or conduit systems that satisfy the requirements of EN 50018

Sections 13.1 and 13.2 and for which a separate test certificate is to hand.

2. Cable glands and entry fittings (screwed conduit entries) as well as blanking plugs

of simple design may not be used. On connection of the H…./…./M10-EEx

variable-area flowmeter using a conduit entry approved for the purpose, the

associated sealing facility must be arranged directly on the housing.

3. Unused openings shall be closed off as defined in EN 50018 Section 11.9.

4. The connecting cable of the variable-area flowmeter shall be permanently installed

and in such as manner as to be adequately protected against damage.

These directions shall in suitable form accompany each apparatus.

Equipotential bonding

The H…./…./M10-EEx variable-area flowmeter shall be incorporated in the local

equipotential bonding system.

Permissible ambient and process temperatures as a factor of the temperature

class

Temperature

class

T6 -40 … +60 85 85 85

T5 -40 … +50 100 100 100

T4 -40 … +50 135 135 135

T3 ... T1 -40 … +40

Ambient temperature in

°C

-40 … +60

-40 … +60

-40 … +50

-40 … +60

Max. permissible process

permanent temperature

Wiring Wiring Wiring

70°C 80°C 90°C

85 100 100

85 135 135

180 200 200

135 190 200

85 145 200

The cable glands and line entries must have the same degree of thermal stability as the

connecting cable.

Page 3/4

16

Signal converter M10-EEx d – Supplementary instructions 11/2002

Page 17

11/2002

Signal converter M10-EEx d – Supplementary instructions 17

Page 18

Physikalisch-Technische Bundesanstalt

PTB

Brunswick and Berlin

Schedule to EC Type Test Certificate PTB 01 ATEX 1154

General directions

Flammable products are allowed provided they do not form any potentially explosive

gas mixture inside the plant. When operated with flammable products, the measuring

sections shall be included in the routine plant pressure tests.

Before the Flameproof Enclosure of the electronics compartment is opened, a waiting

time of at least 8 minutes shall be allowed to elapse in respect of temperature classes

T5 and T6.

(18) Basic health and safety requirements

are satisfied by conformity with the afore-mentioned standards.

Certification Agency Brunswick, 30st September 2002

for Explosion Protection

On behalf of Official stamp

(signed) of the PTB

Dr.-Ing. U. Klausmeyer

Regierungsdirektor

Page 4/4

18

Signal converter M10-EEx d – Supplementary instructions 11/2002

Page 19

Attachment A.2 Declaration of Conformity

11/2002

Signal converter M10-EEx d – Supplementary instructions 19

Page 20

If you need to return a device for testing or repair to KROHNE

Your instrument has been carefully

manufactured and tested. If installed and

operated in accordance with these operating

instructions, your instrument will rarely present

any problems. Should you nevertheless need

to return an instrument for checkout or repair,

please pay strict attention to the following

points:

Due to statutory regulations concerning

protection of the environment and

safeguarding the health and safety of our

personnel, KROHNE may only handle, test and

repair returned instruments that have been in

contact with liquids if it is possible to do so

without risk to personnel and environment.

This means that KROHNE can only service

your instrument if it is accompanied by a

certificate in line with the following model

confirming that the instrument is safe to

handle.

Specimen certificate

Company:........................................................... Address:.................................................................

Department: ....................................................... Name: ....................................................................

Tel. No.: ............................................................. Fax No.: .................................................................

The enclosed instrument

Type: .................................................................. .: .............................................................................

KROHNE Order No. or Series No ...................... ...............................................................................

has been operated with the following process liquid

Because this process liquid is

water-endangering * / toxic * / caustic * / flammable*

we have

- checked that all cavities in the instrument are free from such substances *

- flushed out and neutralised all cavities in the instrument *

(* delete where not applicable)

We confirm that there is no risk to man or environment through any residual liquid contained in the

instrument.

Date: .................................................................... Signature..............................................................

.............................................................................

Company stamp:

If the instrument has been operated with toxic,

caustic, flammable or water-endangering liquids,

you are kindly requested

•

to check and ensure, if necessary by rinsing

or neutralising, that all cavities in the

instrument are free from such dangerous

substances.

(Directions on how you can find out whether

the primary head has to be opened and

flushed out or neutralised are obtainable

from KROHNE on request.)

•

to enclose a certificate with the instrument

confirming that the instrument is safe to

handle and stating the liquid used.

KROHNE regret that they cannot service your

instrument unless it is accompanied by such a

certificate.

...............................................................................

20

Signal converter M10-EEx d – Supplementary instructions 11/2002

Loading...

Loading...