Page 1

Handbook

Handbook

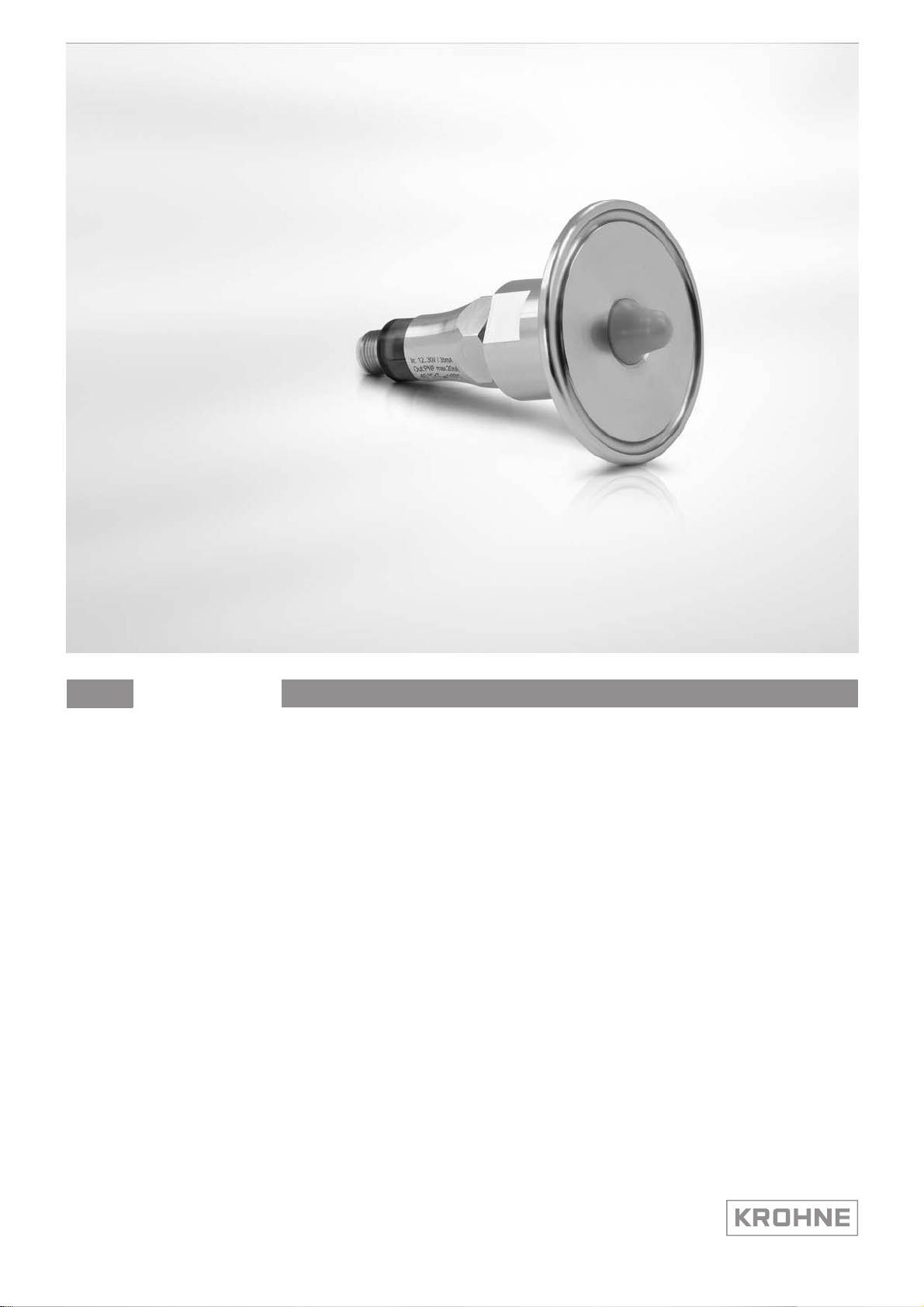

LS 6600

LS 6600

LS 6600LS 6600

Switch for level detection and dry-run protection

HandbookHandbook

© KROHNE 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2013 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 3

LS 6600

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Certifications .................................................................................................................... 5

1.3 ATEX approval................................................................................................................... 5

1.4 Safety instructions from the manufacturer ..................................................................... 6

1.4.1 Copyright and data protection ................................................................................................ 6

1.4.2 Disclaimer ............................................................................................................................... 6

1.4.3 Product liability and warranty ................................................................................................ 7

1.4.4 Information concerning the documentation........................................................................... 7

1.4.5 Warnings and symbols used................................................................................................... 8

1.5 Safety instructions for the operator................................................................................. 8

2 Device description 9

2.1 Scope of delivery............................................................................................................... 9

2.2 System description........................................................................................................... 9

2.3 Nameplate ........................................................................................................................ 9

3 Installation 10

3.1 General notes on installation ......................................................................................... 10

3.2 Installation requirements .............................................................................................. 10

3.3 Process connection ........................................................................................................ 10

3.4 Mounting of 3A marked products................................................................................... 11

4 Electrical connections 12

4.1 Safety instructions.......................................................................................................... 12

4.2 Description of electrical connection .............................................................................. 12

4.3 Electrical connection diagramms .................................................................................. 13

4.4 Electrical connection data for use in hazadous areas................................................... 14

4.5 Configuration tool........................................................................................................... 15

5 Operation 16

5.1 Start-up........................................................................................................................... 16

5.2 Fault diagnosis and corrective action ............................................................................ 16

6 Service 17

6.1 Availability of services .................................................................................................... 17

6.2 Spare parts and accessories.......................................................................................... 17

6.3 Returning the device to the manufacturer..................................................................... 18

6.3.1 General information.............................................................................................................. 18

6.3.2 Form (for copying) to accompany a returned device............................................................ 19

6.4 Disposal .......................................................................................................................... 19

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

3

Page 4

CONTENTS

LS 6600

7 Technical data 20

7.1 Measuring principle........................................................................................................20

7.2 Technical data................................................................................................................. 21

7.3 Dimensions and weights ................................................................................................ 23

7.4 Temperature limits.........................................................................................................24

8 Notes 25

4

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 5

LS 6600

1.1 Intended use

The LS 6600 is a level switch for level detection and dry-run protection for liquids and solids. The

device measures liquids such as water and beer and well as viscous and sticky products such as

honey or toothpaste. Even dry medias can be measured such as sugar or flour.

The measurement is precise and not affected by the mounting position.

Coating of the sensor or condensate are not detected.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

1.2 Certifications

CE marking

SAFETY INSTRUCTIONS 1

The device fulfils the statutory requirements of the following EC directives:

• EMC specification acc. to EN 61326

• Vibration specification acc. to IEC 68-2-6, GL test 2

The manufacturer certifies successful testing of the product by applying the CE marking.

1.3 ATEX approval

The LS 6600 is approved for the use in hazardous areas in accordance with the current EC

directives with the following classifications:

• Ex ia IIC T5, ATEX II 1G (in preparation)

• Ex nA II T5, ATEX II 3G (in preparation)

• Ex ta IIIC T100 Da, ATEX II 1D (in preparation)

INFORMATION!

For further information refer to Electrical connection data for use in hazadous areas on page 14

.

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

5

Page 6

1 SAFETY INSTRUCTIONS

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

LS 6600

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

6

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 7

LS 6600

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

7

Page 8

1 SAFETY INSTRUCTIONS

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

LS 6600

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.5 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

8

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 9

LS 6600

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

The following items are supplied with the device:

• Measuring device

• Hygienic adapter

• Product documentation

DEVICE DESCRIPTION 2

2.2 System description

Inputting physical quantities into an SPC or PLC or other computer and control systems requires

accurate and reliably working sensors. The sensor is a detecting element that converts physical

quantities, such as temperature, level, pressure, conductivity, turbidity and flow, into an

electrical signal. Locally further processed, usually by an integrated microcontroller, the

measuring signal can be transmitted by analogue (e.g. 4...20 mA loop). The LS 6600 is designed

to detect the level of liquids or for pump protecting purposes.

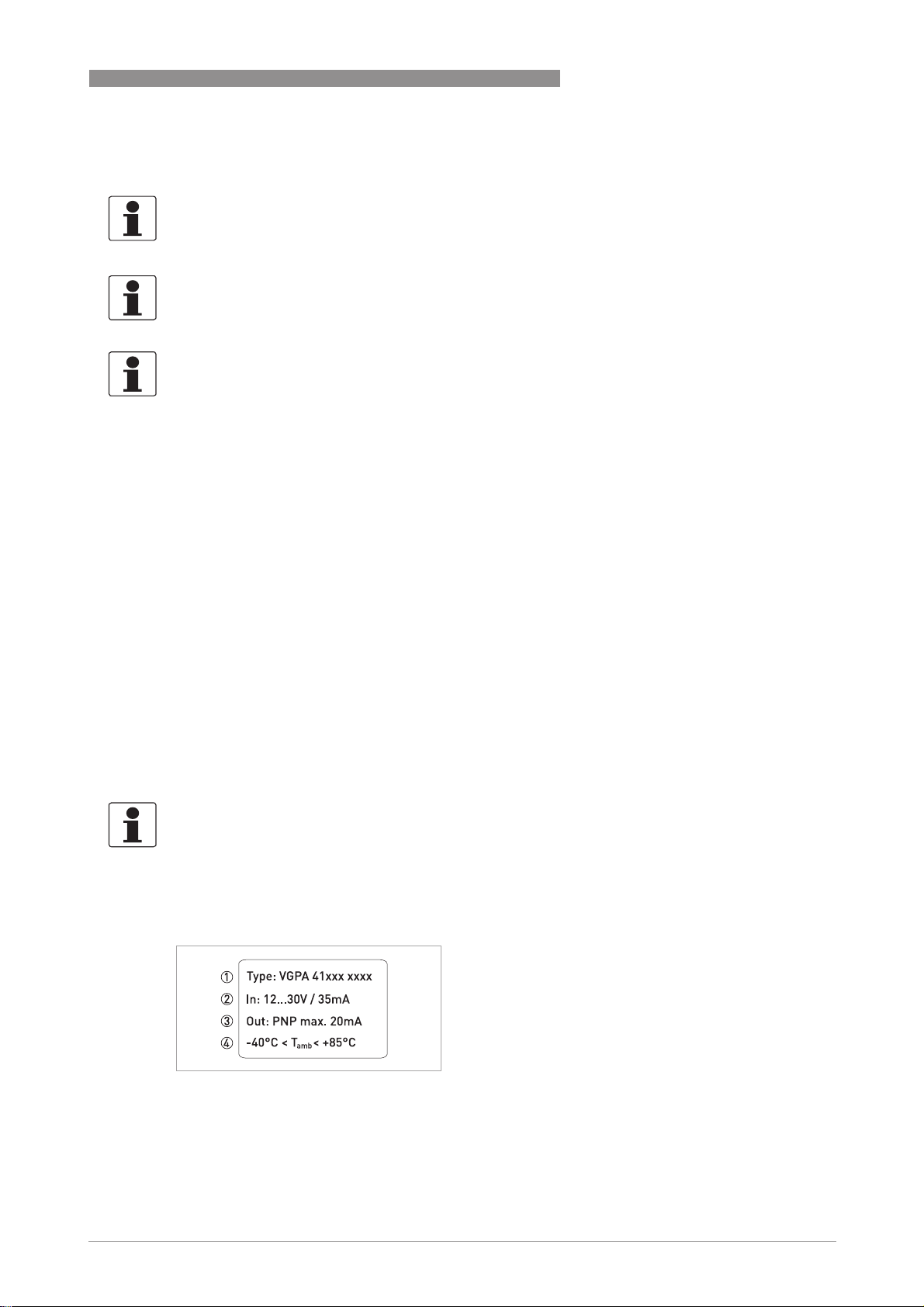

2.3 Nameplate

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

The important technical values are engraved on the device body.

Figure 2-1: Example of engraved technical values

1 Device type

2 Electrical data for input

3 Electrical data for output

4 Operating temperture limits

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

9

Page 10

3 INSTALLATION

3.1 General notes on installation

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Installation requirements

• For the hygienic version, use only the recommended sleeves or adapters. If other systems are

used, no guarantee can be given for proper functionality or leak-tightness.

• The connection thread must have direct electrical contact with the threaded sleeve and the

metal tank or pipe.

• At the hygienic connection G½ do not use Teflon or paper gaskets between switch and

hygienic adapter. The PEEK sensor together with the Stainless Steel adapter will perform a

hygienic tightening. Assumed that the requirements have been followed.

• The tightening torque for the sleeve should be 25...30 Nm.

LS 6600

3.3 Process connection

The hygienic ½" process sleeve is easy to weld into tanks or pipes. This kind of assembly allows

installation in conformity with standards of hygiene (to EHEDG, FDA). The G½ and G1

connections can be mounted in any counter thread acc. to ISO 228.

Various hygienic adapter sleeves (refer to chapter "Accessories") are available for fitting to other

process connections. For more information refer to data sheet "Accessories".

The sensor can be installed in any desired position.

10

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 11

LS 6600

3.4 Mounting of 3A marked products

The 3A mark is valid only when the product is mounted in a 3A marked counterpart and installed

acc. to the installation manual. Use also a 3A marked O-ring or gasket if relevant.

The 3A marked products conforms to the 3A sanitary standards criteria. Materials and surfaces

fulfil the FDA demands and are certified by EHEDG.

EPDM O-rings supplied with 3A marked products are conform to sanitary standards class II (8%

milk fat).

1 Use only 3A approved counterparts.

2 The inspection hole should be visible and drained. Face it downwards that leaking can be

observed.

3 Mount the device in a self-drained position.

4 Level the inner surface of the pipe with the counterpart.

5 Weld from the inside of the tank, if possible. Welds shall be free from cracks, crevices and

grooves. Weldings should be grinded to R

=0.8

a

INSTALLATION 3

Figure 3-1: Mounting of 3A products in pipe installations (A) or tank installations (B)

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

11

Page 12

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

LS 6600

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Description of electrical connection

Pin 1 and 3 are used for supplying a DC voltage of 12...30 V. According to polarity, the output will

switch to active or inactive when the sensor is immersed (refer to connection diagram). The

terminal wired to the negative pole is connected via an internal protective diode to the housing.

The maximum power consumption is 35 mA (excluding load switched). This value should be

taken into account in connection with the recommended use of a fuse. An active switching output

(Pin 4) is available. The switching voltage is a minimum of 1 V below the supply voltage. The

maximum output current is 20 mA. At higher loads, the current is limited accordingly. Damage

through shorting cannot occur.

12

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 13

LS 6600

4.3 Electrical connection diagramms

Description of normally open (NO) and normally closed (NC)

Normally open Normally closed

ELECTRICAL CONNECTIONS 4

1 0mA

2 20 mA

3 LED

1 20 mA

2 0mA

3 LED

PNP

Normally open Normally closed

NPN

Normally open Normally closed

M12 plug

1: brown; 2: white; 3: blue; 4: black

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

13

Page 14

4 ELECTRICAL CONNECTIONS

4.4 Electrical connection data for use in hazadous areas

Ex ta IIIC T100 Da, ATEX II 1D (in preparation)

Ex ta IIIC T100 Da, ATEX II 1D (in preparation)

Ex ta IIIC T100 Da, ATEX II 1D (in preparation)Ex ta IIIC T100 Da, ATEX II 1D (in preparation)

The LS 6600 must be installed in accordance with prevailing guidelines for zone 20 without

barrier.

Supply range: 12...30 VDC; max. 100 mA

Temperature class: T100; -40°C < T

Ex nA II T5, ATEX II 3G (in preparation)

Ex nA II T5, ATEX II 3G (in preparation)

Ex nA II T5, ATEX II 3G (in preparation)Ex nA II T5, ATEX II 3G (in preparation)

< 85°C/ -40°F < T

amb

The LS 6600 must be installed in accordance with prevailing guidelines for zone 2 without

barrier.

Supply range: 12...30 VDC; max. 100 mA

Temperature class: T1...T5; -40°C < T

< 85°C/ -40°F < T

amb

amb

amb

< 185°F

< 185°F

LS 6600

without a

withoutwithout

without a

withoutwithout

Ex ia IIC T5, ATEX II 1G (in preparation)

Ex ia IIC T5, ATEX II 1G (in preparation)

Ex ia IIC T5, ATEX II 1G (in preparation)Ex ia IIC T5, ATEX II 1G (in preparation)

The LS 6600 must be installed in accordance with prevailing guidelines for zone 0 with

with a barrier.

withwith

A certified Ex ia or isolation barrier with the max. values

≤ 10 µH;

L

i

C

≤ 43 nF;

i

U ≤ 30 VDC;

I ≤ 0.1 A;

P ≤ 0.75 W

must be used.

Supply range: 24...30 VDC

Temperature class:

T1...T4: -40°C < T

T1...T5: -40°C < T

< 85°C/ -40°F < T

amb

< 74°C/ -40°F < T

amb

< 185°F;

amb

< 165.2°F

amb

14

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 15

LS 6600

4.5 Configuration tool

The configuration tool can be ordered optionally to configure the LS 6600 switches.

Scope of delivery:

• Interface unit

• CD with software and product drivers (DTM)

• USB cable

• Cable with M12 connector

The configuration tool connects the LS 6600 with a computer. With the corresponding software,

it is possible to get an online communication with the LS 6600.

By using this tool, device information like serial number, switching point range and tag numbers

are displayed on the computer. Settings as switching point and damping can be changed.

Self-learning function for the contact output is possible as well as reset function to the default

values of the switching point.

ELECTRICAL CONNECTIONS 4

By fine-tuning of the switching point settings, LS 6600 could differentiate between various

products which are covering the sensor. In other words, the device could be set to trigger on a

specific product and ignore a second product. Basis for this would be a different ε

two products.

value of the

r

DANGER!

Disconnect the power supply before connecting the configuration tool to the switch!

Figure 4-1: Electrical connection of configuration tool

1 M12 plug

INFORMATION!

°

Ambient temperature range is 0...+50

C / +32...+122°F.

DANGER!

The configuration tool cannot be connected to the LS 6600 within the hazardous area. For

programming, remove the device out of this area.

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

15

Page 16

5 OPERATION

5.1 Start-up

Before connecting to power, please check that the system has been correctly installed.

This includes:

• The device must be mechanically safe and mounted in compliance with the regulations.

• Check the leak-tightness at the sleeve.

• Make sure that the M12 plug is properly connected.

• The power connections must have been made in compliance with the regulations.

• Check that the electrical operating data of the power supply are correct.

• Switching on the power.

i Check for correct switching function.

5.2 Fault diagnosis and corrective action

LS 6600

Fault Cause Action / elimination

LED not "on" Sensor cap not in contact with

liquid product

Supply voltage < 12 V, permittivity

too low

No switching output Cable break Check continuity of cables

Incorrect polarity of supply Reverse terminal 1 and 3

Short-circuit Check wiring

-

Measure voltage at pin 1 and 3

16

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 17

LS 6600

6.1 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local sales office.

6.2 Spare parts and accessories

This device contains no replaceable parts. In case of malfunction the device must be returned to

the manufacturer. Refer also to chapter "Returning the device to the manufacturer".

Accessories

Designation Type

Weld-in sleeve HWN 200

Liquiphant adapter sleeve G1", shape "G" HLM 200

Liquiphant assembly kit Rd 52, shape "F" HLS 210

Varivent flange version N HVF 250

Sanitary pipe assembly kit DN25 HMT 225

Sanitary pipe assembly kit DN50 HMT 250

Tri-Clamp flange 2", DN50 DIN 32676, ISO 40/51 mm HTC 250

SERVICE 6

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

17

Page 18

6 SERVICE

6.3 Returning the device to the manufacturer

6.3.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralising, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

LS 6600

18

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 19

LS 6600

6.3.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

SERVICE 6

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

6.4 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

19

Page 20

7 TECHNICAL DATA

7.1 Measuring principle

A high frequency signal sweep is radiated from the sensor tip into the tank / pipe. The medium

will act as a virtual capacitor, which together with a coil in the sensor head, will form a circuit

creating the switching point signal. This virtual capacity will depend of the dielectric value of the

medium and it is well defined for most media.

The measurement is precise and unaffected by the mounting position.

LS 6600

1 Tank wall / pipe wall

2 Medium

3 Line of electric flux

20

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 21

LS 6600

TECHNICAL DATA 7

7.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Measuring principle Electromagnetic wave, 100..180 MHz

Application range Level detection, dry-run protection and media separation of liquids and

Design

Construction The measurement system consists of a measuring sensor and the electronic

Options Teach-In function for applications where the medium is hard to detect.

Accessories Comprehensive range of adapters and process connections for hygienic

solids.

unit which is available in a compact version. The switching point is signalled

by a blue LED indication at the neck of the M12 connector.

installation. Please refer to the specific data sheet "Accessories".

Measuring accuracy

Resolution ±1 mm / ±0.04"

Hysteresis ±1 mm / ±0.04"

Reference conditions acc. to EN 60770

Reference conditions acc. to EN 60770

Reference conditions acc. to EN 60770Reference conditions acc. to EN 60770

Temperature +20°C ±5°C / +70°F ±10°F

Pressure 1013 mbar abs. ±20 mbar / 14.69 psig ±0.29 psig

Relative air humidity 60% ±15%

Operating conditions

Temperature

Temperature

TemperatureTemperature

Ambient temperature (T

Process temperature -40…+115°C / -40…+239°F (refer to separate diagram)

Pressure

Pressure

PressurePressure

Ambient pressure Atmosphere

Process pressure Max. 100 bar / 1450 psi

Other conditions

Other conditions

Other conditionsOther conditions

Ingress protection

(acc. to EN 60529)

) -40…+85°C / -40…+185°F

amb

130°C / 266°F < 1 hour, T

IP67 equivalent to NEMA 4X

< 40°C / 104°F

amb

Installation conditions

Installation In any position. For detailed information refer to chapter "Installation".

Dimensions and weights For detailed information refer to chapter "Dimensions and weights".

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

21

Page 22

7 TECHNICAL DATA

LS 6600

Materials

Sensor housing Stainless Steel 1.4404 / 316L

Process connection

Sensor insulation Virgin PEEK, FDA conform

Electrical connection Plug M12

Process connections

Standard Hygienic G½; standard G½; G1 and reverse G½

Other For other hygienic process connections, e. g. Tri-clamp, 11851, Varivent see

data sheet "Accessories".

Electrical connections

Power supply Non-Ex / Ex nA / Ex ta: 12…30 VDC, 35 mA max.

Ex ia: 24…30 VDC

Power consumption 1.1 W

Power-up time <2s

Reaction time Max. 0.2 s

Damping 0...10 s

Cable entry M12 (4 pole Lumberg)

Output

Output (active) Max. 20 mA, short-circuit and high-temperature protected

Output type PNP or NPN

Output polarity See drawing in chapter "Electrical connection".

Active "Low" NPN; (-VDC + 1.5 V) ± 0.5 V; R

Active "High" PNP; (VDC - 1.5 V) ± 0.5 V; R

Factory settings Measure: εr>2; damping: 0.1s

Off leak current ±100 μA max.

load

=10kOhm

load

=10kOhm

Approvals and certifications

CE This device fulfils the statutory requirements of the EC directives.

ATEX Ex ia IIC T5, ATEX II 1G (in preparation)

Other standards and approvals

Other standards and approvals

Other standards and approvalsOther standards and approvals

Electromagnetic compatibility (EMC) EN 61326

Vibration resistance IEC 60068-2-6, GL test 2

Hygiene 3A for hygienic G½, FDA conform materials

The manufacturer certifies successful testing of the product by applying the

CE marking.

Ex nA II T5, ATEX II 3G (in preparation)

Ex ta IIIC T100 Da, ATEX II 1D (in preparation)

22

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 23

LS 6600

7.3 Dimensions and weights

1 Standard G½ version

2 G1 version

3 Hygienic G½ version

4 Reverse G½ version

TECHNICAL DATA 7

Dimensions Approx. weight without adapter

[mm] [inch] [kg] [lb]

Standard G

Standard G½ version

Standard GStandard G

a 97 3.82 0.1 0.22

b 41 1.61

c G½ ISO 228/1

d WS 22 WS 0.87

G1 version

G1 version

G1 versionG1 version

a 97 3.82 0.15 0.33

b 38 1.50

c G1 ISO 228/1

d WS 36 WS 1.41

Hygienic G

Hygienic G½ version

Hygienic GHygienic G

a 97 3.82 0.1 0.22

b 48 1.89

c G½ ISO 228/1

d WS 22 WS 0.87

Reverse G

Reverse G½ version

Reverse GReverse G

a 97 3.82 0.1 0.22

b 68 2.68

c Ø27 Ø1.06

d WS 24 WS 0.94

e G½ A ISO 228/1

version

version version

version

version version

version

version version

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

23

Page 24

7 TECHNICAL DATA

7.4 Temperature limits

LS 6600

Figure 7-1: Media temperature versus ambient temperature

a: media temperature in [°C] or [°F]

b: ambient temperature in [°C] or [°F]

CIP: 130°C / 266°F < 1 hour (T

< 40°C / 104°F)

amb

24

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 25

LS 6600

NOTES 8

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

25

Page 26

8 NOTES

LS 6600

26

www.krohne.com 03/2013 - 4001367702 - MA LS 6600 R02 en

Page 27

LS 6600

NOTES 8

www.krohne.com03/2013 - 4001367702 - MA LS 6600 R02 en

27

Page 28

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Products and systems for the oil & gas industry

• Measuring systems for the marine industry

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

The current list of all KROHNE contacts and addresses can be found at:

© KROHNE 03/2013 - 4001367702 - MA LS 6600 R02 en - Subject to change without notice.

www.krohne.com

Loading...

Loading...